Page 1

Operator’s Manual

2700 and 3000

Three-Point Drill

Model Serial No.

3PD27 and 2700 1316E+

3PD30 and 3000 1171S+

Manufacturing, Inc.

www.greatplainsmfg.com

Read the operator’s manual entirely. When you see this symbol, the subsequent in-

!

structions and warnings are serious - follow without exception. Your life and the lives of

others depend on it!

© Copyright 2010 Printed

9/9/2010

17883

Illustrations may show optional equipment not supplied with standard unit.

118-365M-A

Page 2

Table of Contents

Table of Contents

Great Plains Mfg., Inc.

Important Safety Information . . . . . . . . . . . . . . . . . 1

Safety Decals. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Description of Unit . . . . . . . . . . . . . . . . . . . . . . . . 7

Intended Usage . . . . . . . . . . . . . . . . . . . . . . . 7

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . 7

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . 7

Section 1 Preparation and Setup . . . . . . . . . . . . . . 8

Prestart Checklist. . . . . . . . . . . . . . . . . . . . . . . . . 8

Tractor Requirements . . . . . . . . . . . . . . . . . . . . . 8

Hitching Tractor to the Drill. . . . . . . . . . . . . . . . . . 8

Gauge-Wheel Adjustment . . . . . . . . . . . . . . . . . . 8

Bleeding Marker Hydraulics. . . . . . . . . . . . . . . . . 8

Section 2 Operating Instructions . . . . . . . . . . . . . . 9

Prestart Checklist. . . . . . . . . . . . . . . . . . . . . . . . . 9

Field Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Shaft Monitor Operation . . . . . . . . . . . . . . . . 9

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Transporting with Markers . . . . . . . . . . . . . . . 9

Parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Section 3 Adjustments . . . . . . . . . . . . . . . . . . . . . 11

Gauge-Wheel Adjustment . . . . . . . . . . . . . . . . . 11

Adjusting Seeding Depth . . . . . . . . . . . . . . . . . . 12

Press Wheels . . . . . . . . . . . . . . . . . . . . . . . 12

Down-Pressure Springs . . . . . . . . . . . . . . . 12

Bedded Irrigation . . . . . . . . . . . . . . . . . . . . . 12

Seeding Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Small Seeds Attachment . . . . . . . . . . . . . . . 14

Seed Rate Charts (pounds per acre). . . . . . . . . 15

Small Seeds Attachment Seed Rate Chart . . . . 17

Marker Adjustments. . . . . . . . . . . . . . . . . . . . . . 18

Chain Adjustment. . . . . . . . . . . . . . . . . . . . . 18

Disk Adjustment . . . . . . . . . . . . . . . . . . . . . . 18

Speed Adjustment . . . . . . . . . . . . . . . . . . . . 19

Disk Scraper Adjustment . . . . . . . . . . . . . . . . . . 19

Seed-Lok™. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Section 4 Troubleshooting . . . . . . . . . . . . . . . . . . . 20

Section 5 Maintenance and Lubrication . . . . . . . . 22

General Maintenance . . . . . . . . . . . . . . . . . . . . . 22

Marker Maintenance . . . . . . . . . . . . . . . . . . 22

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Seed-Cup-Drive Sprocket . . . . . . . . . . . . . . 22

Drive Chains. . . . . . . . . . . . . . . . . . . . . . . . . 23

Drive Chains. . . . . . . . . . . . . . . . . . . . . . . . . 23

Jackshaft Bearings. . . . . . . . . . . . . . . . . . . . 23

Wheel Axles . . . . . . . . . . . . . . . . . . . . . . . . . 23

Marker Hinges . . . . . . . . . . . . . . . . . . . . . . . 24

Marker-Disk Bearings. . . . . . . . . . . . . . . . . . 24

Section 6 Options . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Seed-Cup Plugs . . . . . . . . . . . . . . . . . . . . . . . . . 25

Markers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Seed-Lok™ Firming Wheels. . . . . . . . . . . . . . . . 25

Small Seeds Attachment . . . . . . . . . . . . . . . . . . 26

Steel Depth Bands . . . . . . . . . . . . . . . . . . . . . . . 26

Shaft Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Section 7 Specifications and Capacities . . . . . . . 27

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Tire Inflation Chart . . . . . . . . . . . . . . . . . . . . . . . 29

Torque Values Chart for Common Bolt Sizes . . . 29

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

© Copyright 2010 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the preparation

of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at the

time of its publication, and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains, Seed-Lok

All other brands and product names are trademarks or registered trademarks of their respective holders.

2700 and 3000 Three-Point Drill 118-365M-A 9/9/10

Great Plains Manufacturing, Incorporated Trademarks

Printed in the United States of America.

Page 3

Great Plains Mfg., Inc.

Important Safety Information

Important Safety Information

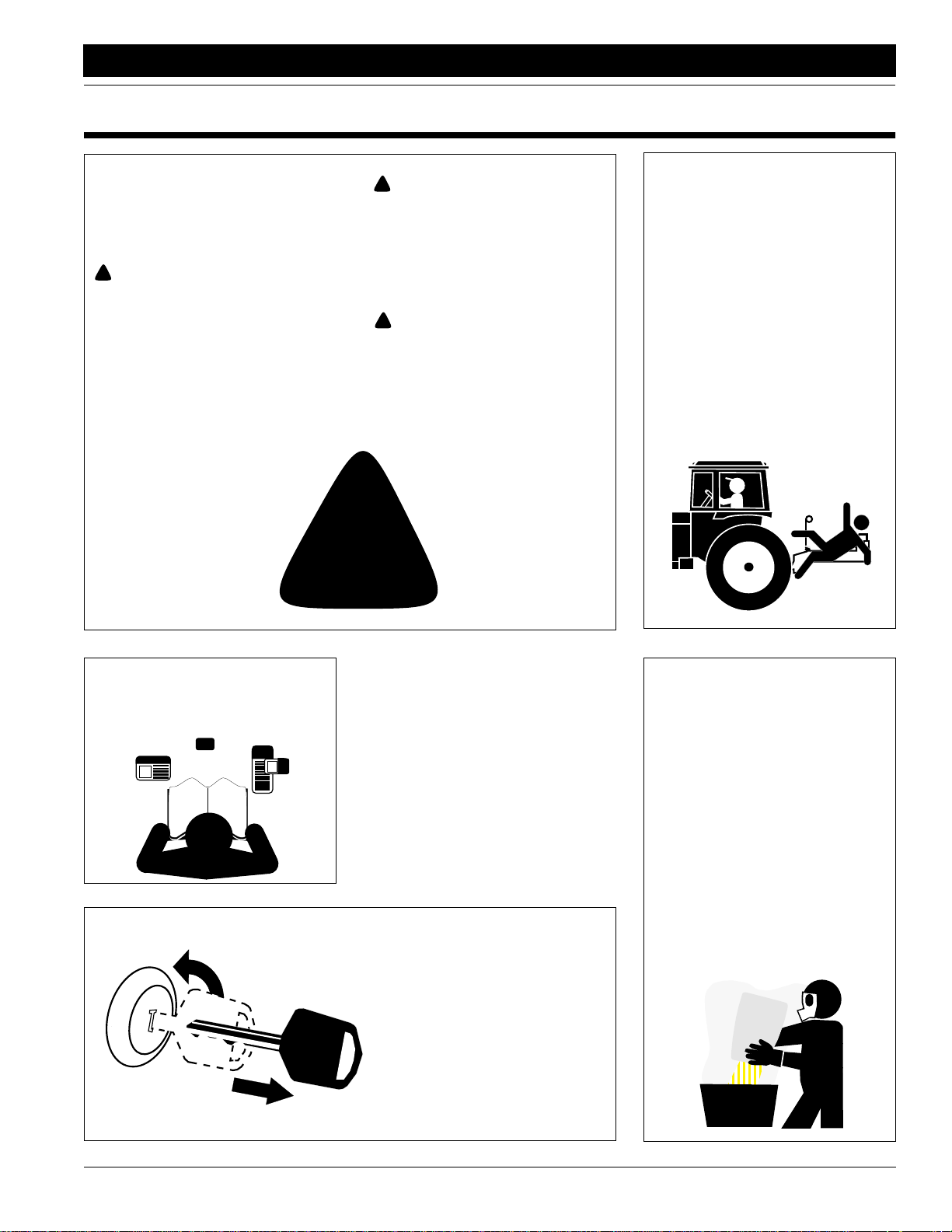

Be Aware of Signal Words

Signal words designate a degree or

level of hazard seriousness. The signal words are:

!

DANGER!

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury. This

signal word is limited to the most

extreme situations, typically for

machine components that, for functional purposes, cannot be guarded.

!

WARNING!

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury, and

includes hazards that are exposed

when guards are removed. It may

also be used to alert against unsafe

practices.

!

CAUTION!

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

!

Keep Riders

Off Machinery

▲ Riders obstruct the operator’s

view. Riders could be struck by

foreign objects or thrown from the

machine.

▲ Never allow children to operate

equipment.

For Your Protection

▲ Thoroughly read and understand

Safety Decals, page 4. Read all

instructions noted on the decals.

OFF

Shutdown and Storage

▲ Lower machine to ground, put

tractor in park, turn off engine,

and remove the key.

▲ Detach and store implements in a

area where children normally do

not play. Secure implement by

using blocks and supports.

Handle

Chemicals Properly

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Follow instructions on container

label.

▲ Agricultural chemicals can be

dangerous. Improper use can

seriously injure persons, animals,

plants, soil, and property.

▲ Inhaling smoke from any type of

chemical fire is a serious health

hazard.

▲ Store or dispose of unused chem-

icals as specified by the chemical

manufacturer.

9/9/10

2700 and 3000 Three-Point Drill 118-365M-A

1

Page 4

Important Safety Information

Great Plains Mfg., Inc.

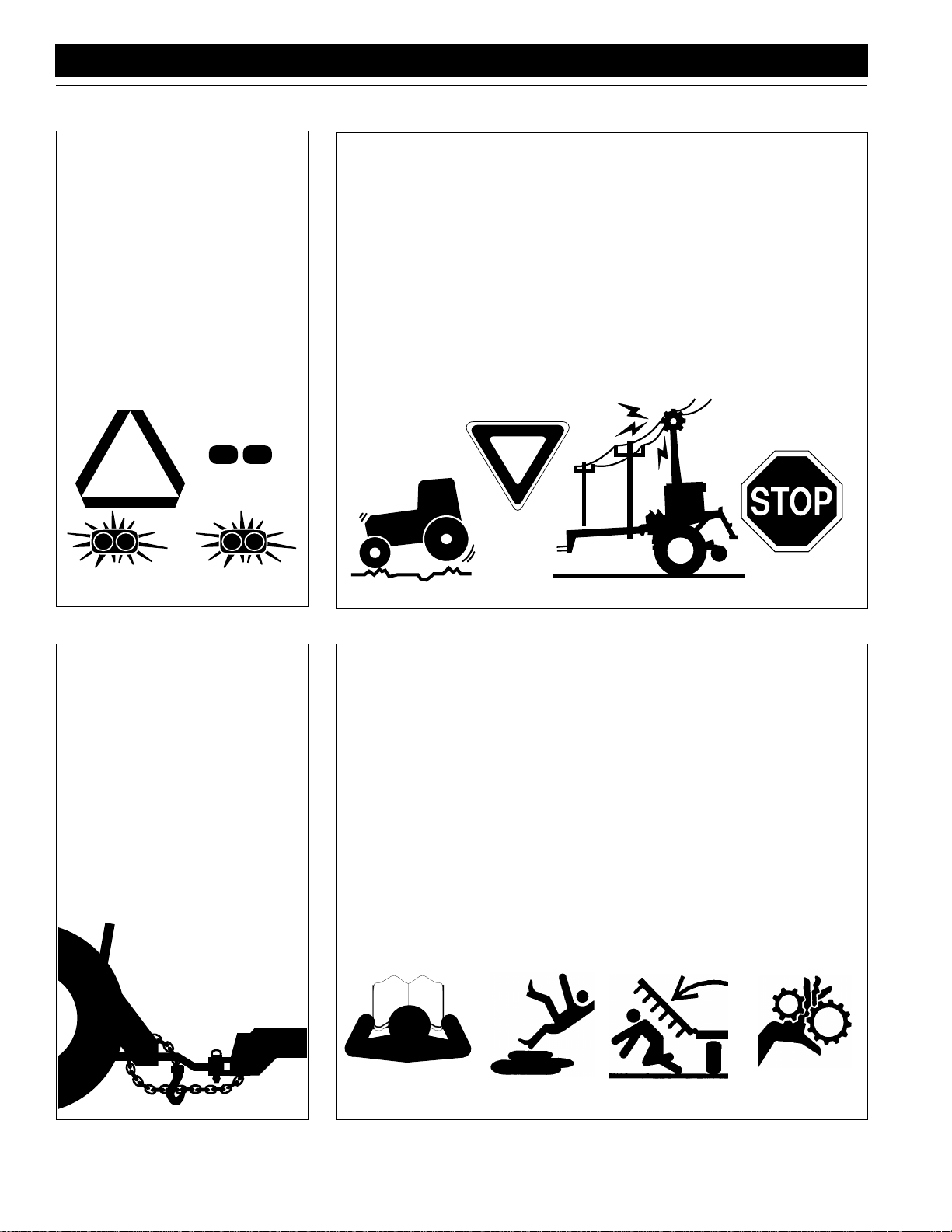

Use Safety

Lights and Devices

▲ Slow moving tractors, self-pro-

pelled equipment, and towed

implements can create a hazard

when driven on public roads. They

are difficult to see, especially at

night.

▲ Flashing warning lights and turn

signals are recommended whenever driving on public roads. Use

tractor lights and devices provided

with implement.

Transport

Machinery Safely

▲ Comply with state and local laws.

▲ Maximum transport speed for

implement is 20 mph. DO NOT

EXCEED. Never travel at a speed

which does not allow adequate

control of steering and stopping.

Some rough terrains require a

slower speed.

▲ Sudden braking can cause a

towed load to swerve and upset.

Reduce speed if towed load is not

equipped with brakes.

▲ Follow these weight ratios as a

guideline.

20 mph maximum when weight is

less than or equal to the weight of

tractor.

10 mph maximum when weight is

double the weight of tractor.

▲ IMPORTANT: Do not tow a load

that is more than double the

weight of tractor.

Use A Safety Chain

▲ A safety chain will help control

drawn machinery should it separate from the tractor drawbar.

▲ Use a chain with the strength

rating equal to or greater than

the gross weight of the towed

machinery.

▲ Attach the chain to the tractor

drawbar support or other specified anchor location. Allow only

enough slack in the chain to permit turning.

▲ Do not use safety chain for tow-

ing.

Practice Safe Maintenance

▲ Understand procedure before

doing work. Use proper tools and

equipment. Refer to “Mainte-

nance and Lubrication,” page

22, for additional information.

▲ Work in a clean, dry area.

▲ Lower the implement to the

ground, put tractor in park, turn off

engine, and remove key before

preforming maintenance.

▲ Allow implement to cool com-

pletely.

▲ Do not grease or oil implement

while it is in operation.

▲ Disk edges are sharp. Be careful

when working in this area.

▲ Disconnect battery ground cable

(-) before servicing or adjusting

electrical systems or before welding on implement.

▲ Inspect all parts. Make sure parts

are in good condition and installed

properly.

▲ Remove buildup of grease, oil or

debris.

▲ Remove all tools and unused

parts from implement before operation.

2700 and 3000 Three-Point Drill 118-365M-A 9/9/10

2

Page 5

Great Plains Mfg., Inc.

Important Safety Information

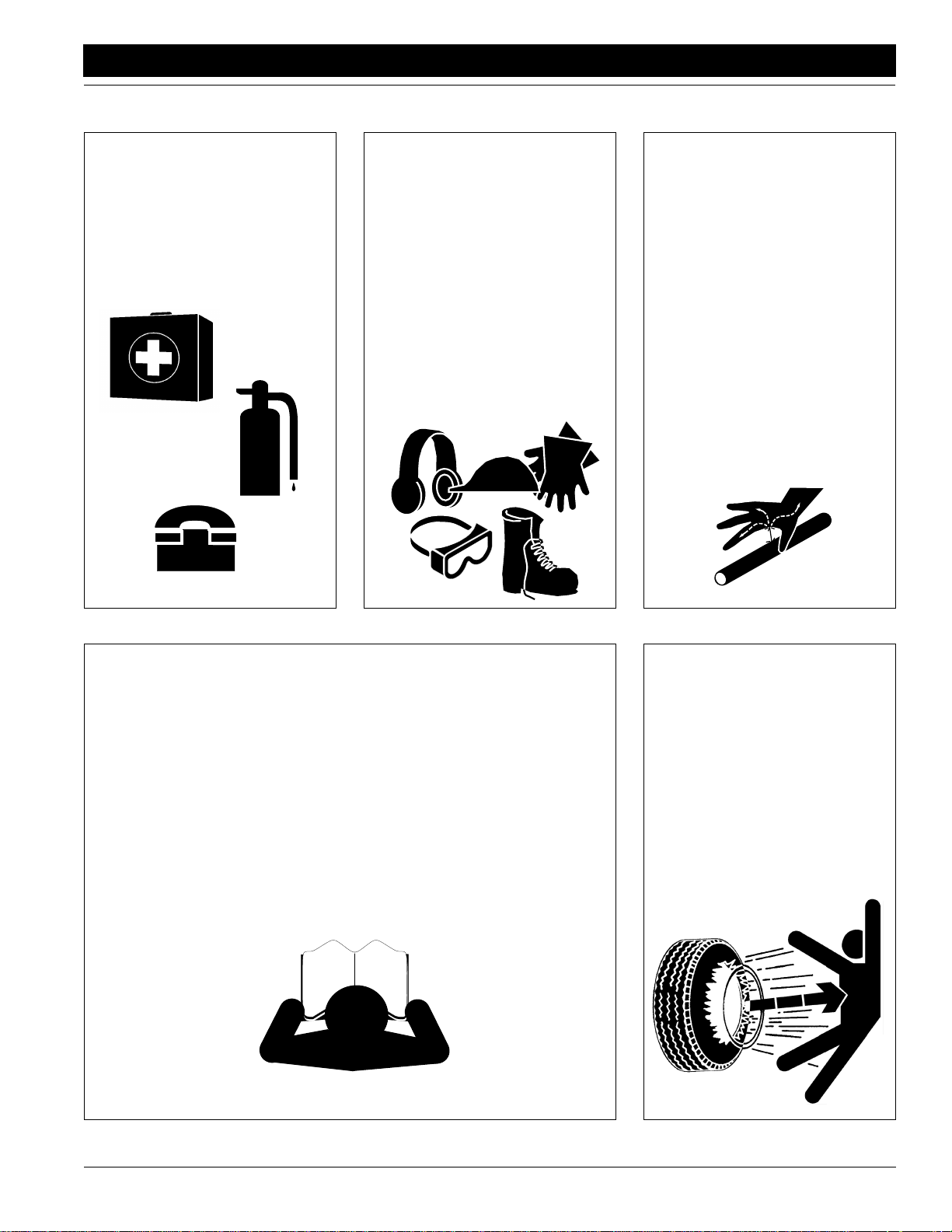

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extin-

guisher handy.

▲ Keep emergency numbers for

doctor, ambulance, hospital and

fire department near phone.

911

Wear

Protective Equipment

▲ Protective clothing and equipment

should be worn.

▲ Wear clothing and equipment

appropriate for the job. Avoid

loose-fitting clothing.

▲ Prolonged exposure to loud noise

can cause hearing impairment or

hearing loss. Wear suitable hearing protection such as earmuffs or

earplugs.

▲ Operating equipment safely

requires the full attention of the

operator. Avoid wearing radio

headphones while operating

machinery.

Avoid High

Pressure Fluids Hazard

▲ Escaping fluid under pressure can

penetrate the skin causing serious

injury.

▲ Avoid the hazard by relieving

pressure before disconnecting

hydraulic lines.

▲ Use a piece of paper or card-

board, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety

glasses or goggles when working

with hydraulic systems.

▲ If an accident occurs, see a doc-

tor immediately. Any fluid injected

into the skin must be surgically

removed within a few hours or

gangrene may result.

Safety at All Times

Thoroughly read and understand the

instructions given in this manual

before operation. Refer to Safety

Decals, page 4. Read all instructions

noted on the decals.

▲ Operator should be familiar with

all functions of the unit.

▲ Operate implement from the

driver’s seat only.

▲ Do not leave tractor or implement

unattended with engine running.

▲ Dismounting from a moving trac-

tor could cause serious injury or

death.

▲ Do not stand between the tractor

and implement during hitching.

▲ Keep hands, feet and clothing

away from power-driven parts.

▲ Wear snug fitting clothing to avoid

entanglement with moving parts.

▲ Watch out for wires, trees, etc.,

when raising implement. Make

sure all persons are clear of working area.

▲ Turning tractor too tight may

cause implement to ride up on

wheels. This could result in injury

or equipment damage.

Tire Safety

▲ Tire changing can be dangerous

and should be preformed by

trained personnel using the correct tools and equipment.

▲ When inflating tires, use a clip-on

chuck and extension hose long

enough to allow you to stand to

one side and NOT in front of or

over the tire assembly. Use a

safety cage if available.

▲ When removing and installing

wheels, use wheel-handling

equipment adequate for the

weight involved.

9/9/10

2700 and 3000 Three-Point Drill 118-365M-A

3

Page 6

Important Safety Information

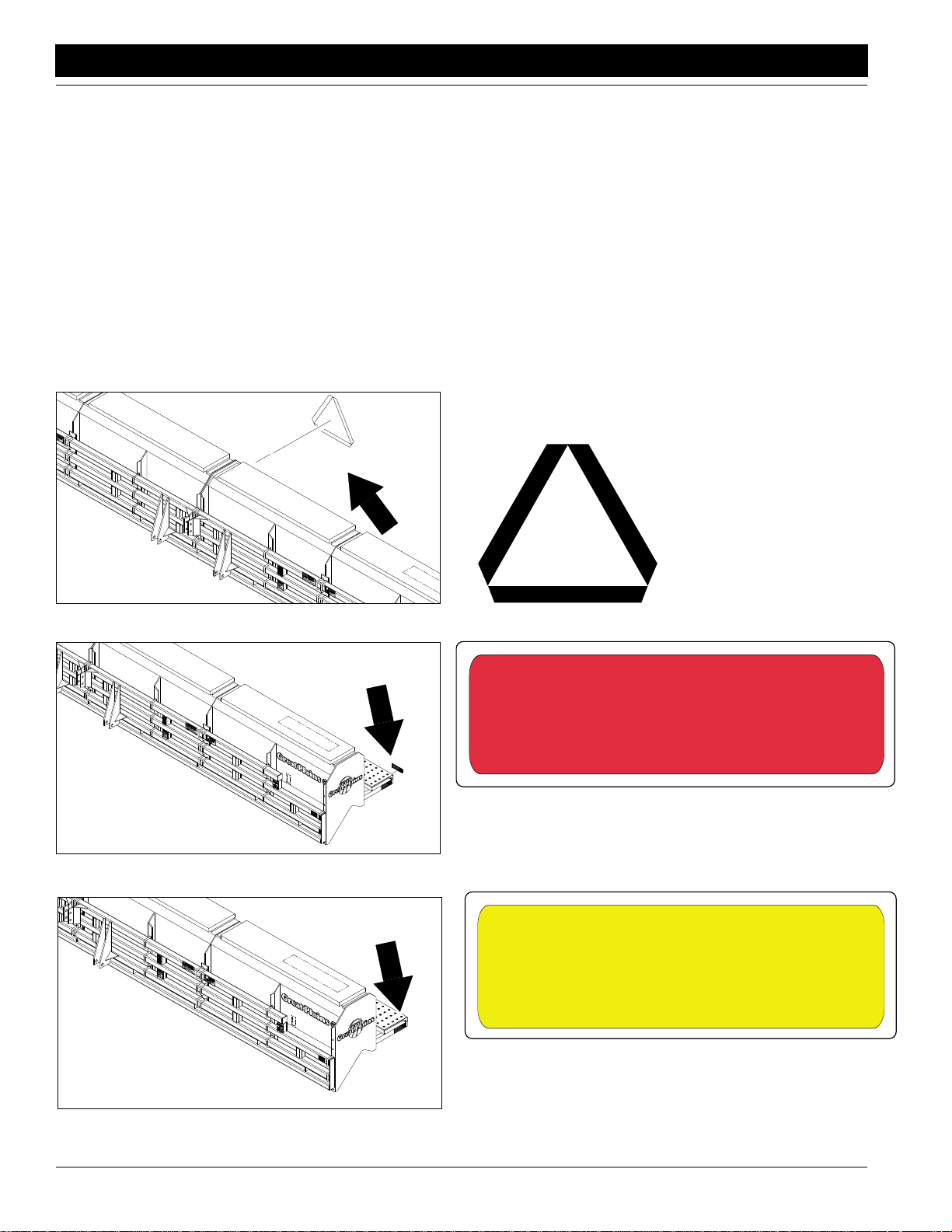

Safety Decals

Your implement comes equipped with all safety decals in place.

They were designed to help you safely operate your implement.

1. Read and follow decal directions.

2. Keep all safety decals clean and legible.

3. Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

Great Plains Mfg., Inc.

4. When ordering new parts or components, also request corresponding safety decals.

5. To install new decals:

a. Clean the area on which the decal is to be placed.

b. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

17882

17894

818-003C

Slow Moving Vehicle Decal

838-266C

Red Reflectors

One on each walkboard;

two decals total

838-265C

17882

2700 and 3000 Three-Point Drill 118-365M-A 9/9/10

4

Amber Reflectors

Outside ends of each

walkboard

Page 7

Great Plains Mfg., Inc.

Important Safety Information

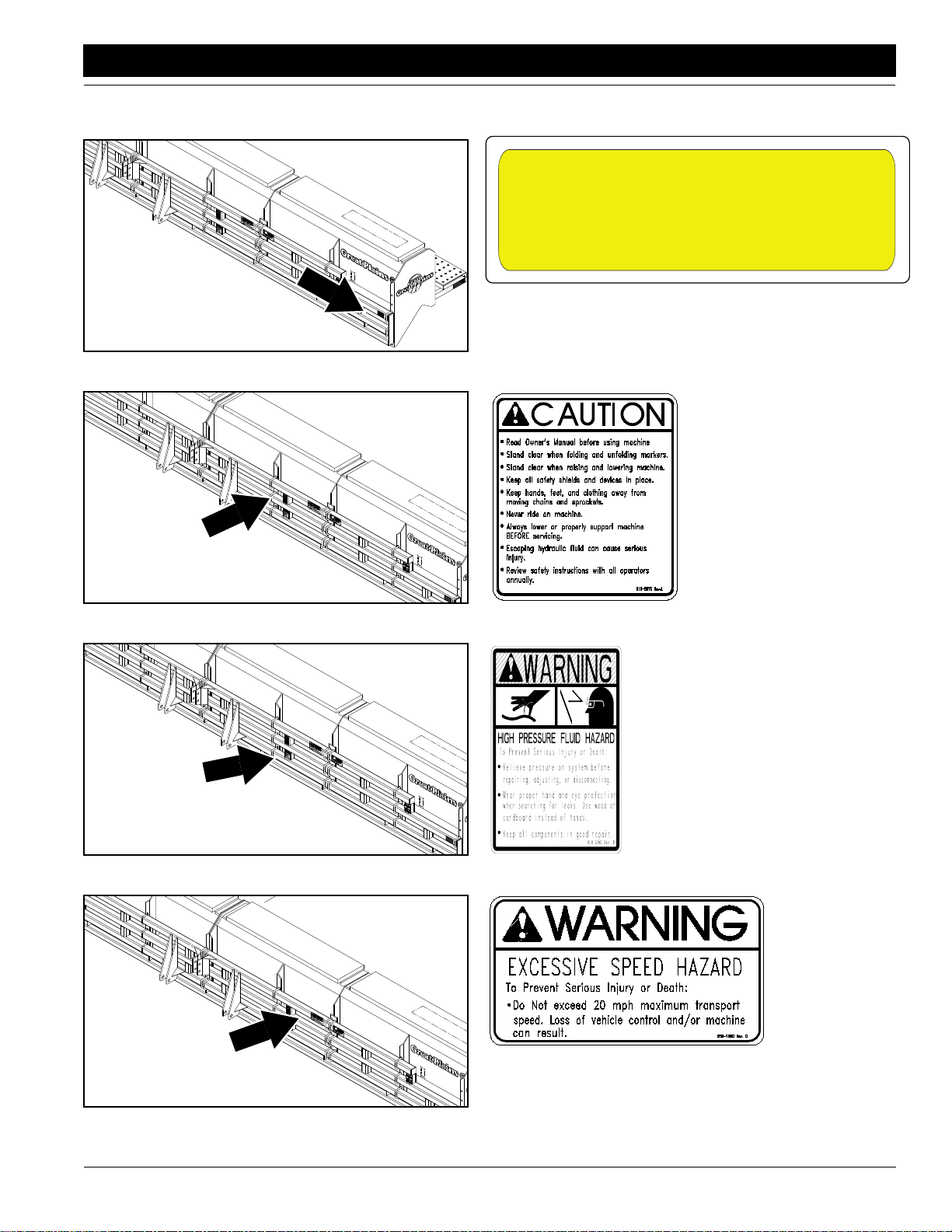

17882

838-265C

Amber Reflectors

Both ends of drill

17882

17882

818-587C

Caution Gen Safety 3-PT

818-339C

Warning High Pressure SML

17882

9/9/10

818-188C

Warning 20 MPH Transport

2700 and 3000 Three-Point Drill 118-365M-A

5

Page 8

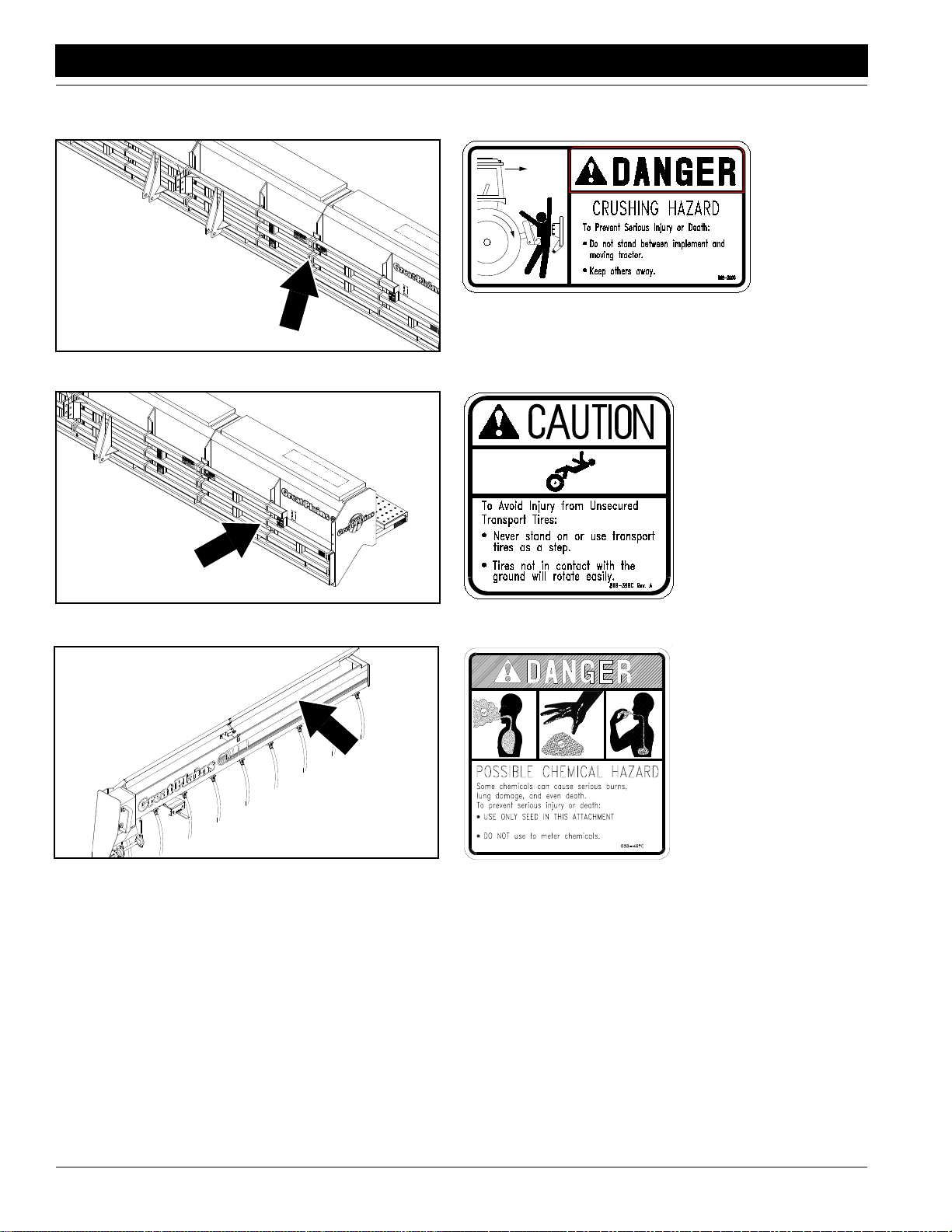

Important Safety Information

17882

Great Plains Mfg., Inc.

818-590C

Danger Crushing; both ends of drill, two decals total

17882

13734

818-389C

Caution Tires Not a Step

Both ends of drill, two decals total

838-467C

Possible Chemical Hazard

Small Seeds Box, Underside of Box Lid

2700 and 3000 Three-Point Drill 118-365M-A 9/9/10

6

Page 9

Great Plains Mfg., Inc.

Introduction

Introduction

Great Plains welcomes you to the growing family of new

product owners. This implement has been designed with

care and built by skilled workers using quality materials.

Proper assembly, maintenance and safe operating practices will help you get years of satisfactory use from this

machine.

Description of Unit

The 27- or 30-foot, 3-point drill is a seeding implement designed to be raised, lowered and towed with a three-point

tractor hitch. The drill is equipped with offset double-disk

openers mounted on the drill frame with straight arms. The

openers are staggered for easy residue flow. Down-pressure springs can be adjusted individually for each opener.

A T-handle adjustment on the depth-controlling press

wheels allows for easy depth adjustment. The seeding

rate can be adjusted from 2 to 240 pounds per acre.

When combined with the bedded irrigation option, the drill

can be used to seed in furrows and ridges simultaneously.

Intended Usage

This drill is intend for use in conventional- and some minimum-till applications.

Using This Manual

This manual is designed to help familiarize you with safety,

set-up, operation, adjustment, troubleshooting and maintenance. Read this manual and follow the recommendations to help ensure safe and efficient operation.

Fill out the warranty sheet with the dealer at the time of

purchase. Give the dealer the completed white copy and

send the pink copy to Great Plains. Keep your yellow copy

in the manual for use when corresponding with the dealer.

The information in this manual is current at printing. Some

parts may change to assure top performance.

Definitions

Right and left as used in this manual are determined by

facing the direction the machine will travel while in use unless otherwise stated.

IMPORTANT: A crucial point of information related to

the preceding topic. For safe and correct operation,

read and follow the directions provided before continuing.

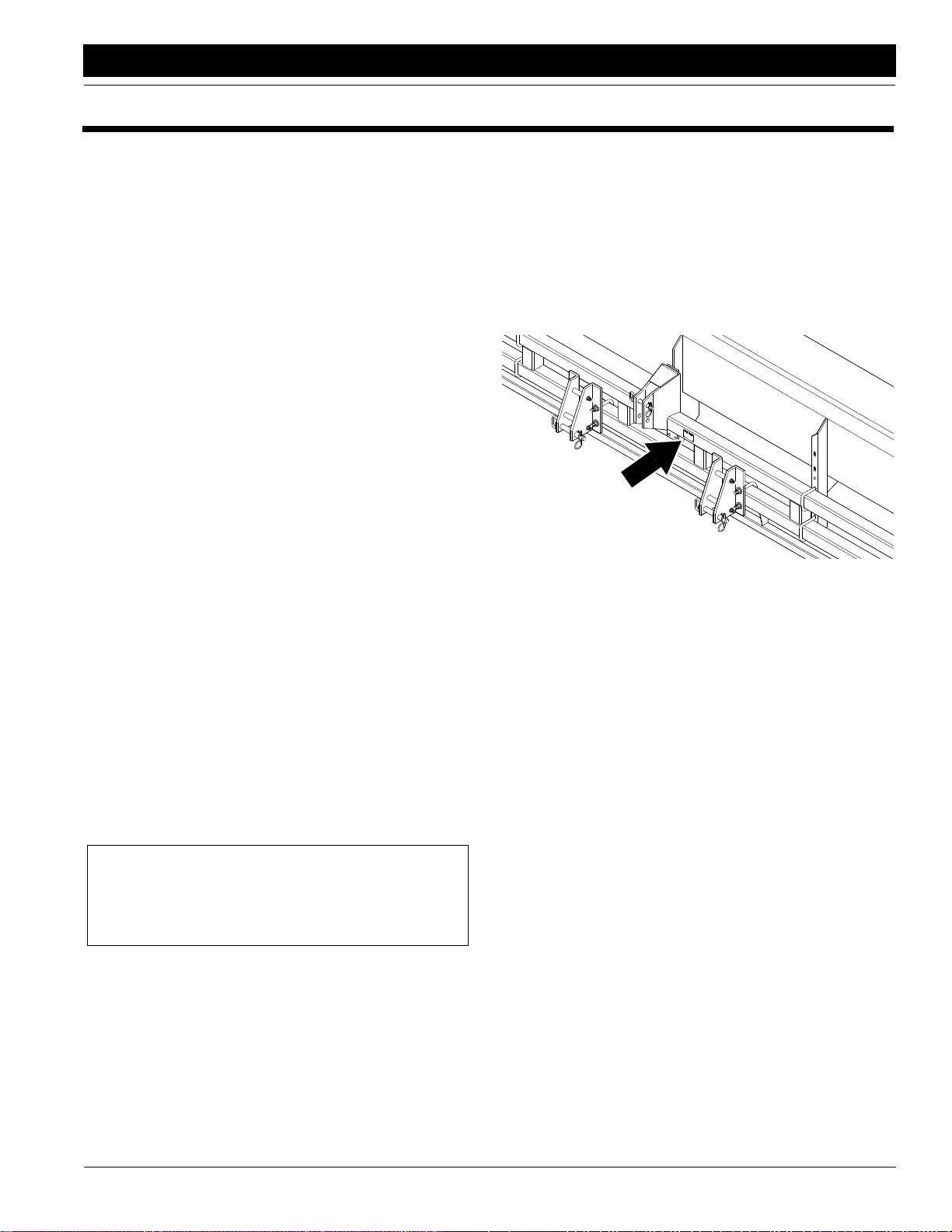

Owner Assistance

If customer service or repair parts are needed contact

your Great Plains dealer. They have trained personnel,

parts and service equipment specially designed for Great

Plains products.

Your machine’s parts were specially designed and should

be replaced with Great Plains parts only. Always use the

serial and model number when ordering parts from your

Great Plains dealer. The serial number plate is located as

shown in Figure A.

16404

Figure A

Serial Number Plate

Your Great Plains dealer wants you to be satisfied with

your new machine. If you do not understand any part of

this manual or are not satisfied with the service received,

please take the following actions:

1. Discuss the matter with your dealer service manager.

Make sure they are aware of any problems so they can

assist you.

2. If you are still not satisfied, seek out the dealership

owner or general manager.

3. For further assistance, write to:

Product Support

Great Plains Mfg. Inc.

Service Department

P.O. Box 5060

Salina, KS 64702-5060

NOTE: Useful information related to the preceding topic.

9/9/10

2700 and 3000 Three-Point Drill 118-365M-A

7

Page 10

Section 1 Preparation and Setup

!

!

Section 1 Preparation and Setup

Great Plains Mfg., Inc.

This section will help you prepare your tractor and drill for

use. This section also includes instructions for bleeding

the optional marker hydraulics.

Prestart Checklist

1. Read and understand “Important Safety Information,” page 1.

2. Check that all working parts are moving freely, bolts

are tight, and cotter pins are spread.

3. Check that all grease fittings are in place and lubricated. Refer to Lubrication,“Maintenance and Lubrica-

tion,” page 22.

4. Check that all safety decals and reflectors are correctly located and legible. Replace if damaged. Refer to

Safety Decals,“Important Safety Information,” page

4.

5. Inflate tires to recommended pressure as listed on

Tire Inflation Chart,“Appendix,” page 29. Tighten

wheel bolts as specified on Torque Values Chart,“Ap-

pendix,” page 29.

Tractor Requirements

Your drill is designed and factory set for category III tractors.

Hitching Tractor to the Drill

Gauge-Wheel Adjustment

Gauge-wheel adjustments affect the operating height of

your drill, and drill height directly affects the working range

of the openers.The drill must be adjusted so your openers

can travel up and down and follow the ground contour.

Before using in the field, adjust your drill so the opener

mount tube runs 18 1/4 inches above ground. You likely

will need to make further adjustments later to compensate

for field conditions. Refer to Gauge-Wheel Adjustments,

“Adjustments,” page 11 for how to make gauge-wheel

adjustments.

Bleeding Marker Hydraulics

If you install or replace part of optional markers, you must

bleed air from the marker hydraulics. Your markers will not

fold properly with air in the hydraulic circuit.

WARNING!

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin causing serious injury. Avoid the hazard by

relieving pressure before disconnecting hydraulic lines. Use a

piece of paper or cardboard, NOT BODY PARTS, to check for

leaks. Wear protective gloves and safety glasses or goggles

when working with hydraulic systems. If an accident occurs, see

a doctor immediately. Any fluid injected into the skin must be

surgically removed within a few hours or gangrene will result.

DANGER!

Do not place any body part between the tractor and drill during

hitching.

1. Raise or lower the 3-point links as needed.

2. Install the lower hitch pins.

3. Pin the top link to the drill and adjust so it remains

loose in normal field conditions.

4. Check that all three-point links are securely pinned,

then slowly raise the drill. Watch for cab interference.

5. Unpin the parking stands as shown in Figure 1-1. Rotate the stands up into field position and repin.

12151

1. Be sure tractor hydraulic reservoir if full.

2. With the markers unfolded, crack the hydraulic hose

fittings at the base end of the cylinders. With your tractor at an idle speed, activate your tractor hydraulic

valve until oil seeps out around the hose ends. Retighten the fittings.

3. Repeat step 2 for the hose-end fittings at the rod end

of the cylinders.

4. Fold and unfold the markers slowly to work all the air

out of your marker hydraulics. Use caution when folding and unfolding the marker for the first time and

check for pinching and kinking of hoses.

Figure 1-1

Parking Stand

2700 and 3000 Three-Point Drill 118-365M-A 9/9/10

8

Page 11

Great Plains Mfg., Inc.

!

!

Section 2 Operating Instructions

Section 2 Operating Instructions

The following section will give you general operating procedures. Experience, machine familiarity and thefollowing

information will lead to efficient operation and good working habits. Always operate farm machinery with safety in

mind.

Prestart Checklist

1. Carefully read “Important Safety Information,” page

1.

2. Lubricate the drill as indicated under Lubrication,

“Maintenance and Lubrication,” page 22.

3. Check all tires for proper inflation as indicated on Tire

Inflation Chart,“Appendix,” page 29.

4. Check all bolts, pins and fasteners. Torque as specified on Torque Values Chart,“Appendix,” page 29.

5. Check the drill for worn or damaged parts. Repair or

replace them before going to the field.

6. Check hydraulic hoses, fittings and cylinders for leaks.

Repair or replace them before going to the field.

7. Check disk scrapers for proper adjustment. Refer to

Disk Scraper Adjustment,“Adjustments,” page 19.

8. Rotate both gauge wheels to see that seed cups and

drive are working properly and free from foreign material.

Field Operation

CAUTION!

Do not allow anyone to ride on the drill.

1. Hitch the drill to a suitable tractor before filling the drill.

Refer to Tractor Requirements and Hitching Tractor to

Drill,“Preparation and Setup,” page 8. Adjust the top

link so it remains loose in normal drilling conditions.

2. Set and calibrate the seeding rate as explained under

Seeding Rate,“Adjustments,” page 12.

3. Load box with clean seed.

4. Record the acremeter readout. Subtract the initial

reading from later readings to determine acres drilled.

5. Check that the seed-cup-door handles are set the

same across the drill. Refer to Seeding Rate,“Adjust-

ments,” page 12.

NOTE: If you notice excessive cracking on large seeds,

adjust all seed-cup doors to a wider setting. Use the widest setting for seed-cup clean out only.

6. Lift the drill out of the ground when turning at end of

the field and for other short turns. Do not back up with

openers in ground. If you do, check all openers for

clogging.

Shaft Monitor Operation

To operate the optional shaft monitor, turn system on by

activating on-off switch on monitor head. If the seed-cup

shaft stops for 20 seconds or more, an alarm will sound

and the light on the monitor will flash.

The 20-second delay is to prevent nuisance alarms when

turning at the end of the field. If a failure does occur and

the alarm sounds, remember you have traveled for 30

seconds without planting.

Transporting

WARNING!

Never tow the drill faster than 20 mph.

You can transport the drill with a full box of grain, but it is

not recommended. The increased weight will make steering more difficult and increase the risk of road accidents.

To maintain steering control, you may need to add ballast

to your tractor front end. Refer to your tractor operator’s

manual for the amount of ballast required.

Before transporting the drill, check the following.

1. Check that all 3-point hitch links are securely pinned

to the tractor.

2. Comply with all federal, state and local laws when

traveling on public roads.

3. Remember that the drill is wider than the tractor. Always allow for drill clearance.

Transporting with Markers

Always transport the drill with the markers folded. Check

that the second marker section rests securely on the

transport carrier. If it does not, refer to Marker Adjust-

ments,“Adjustments,” page 19 for transport carrier ad-

justments.

9/9/10

2700 and 3000 Three-Point Drill 118-365M-A

9

Page 12

Section 2 Operating Instructions

Parking

Unhitching the drill while the box is loaded is not recommended. Empty the box if possible. See Storage,“Mainte-

nance and Lubrication,” page 22 for additional

information on the long-term storage.

1. Park on a level, solid area.

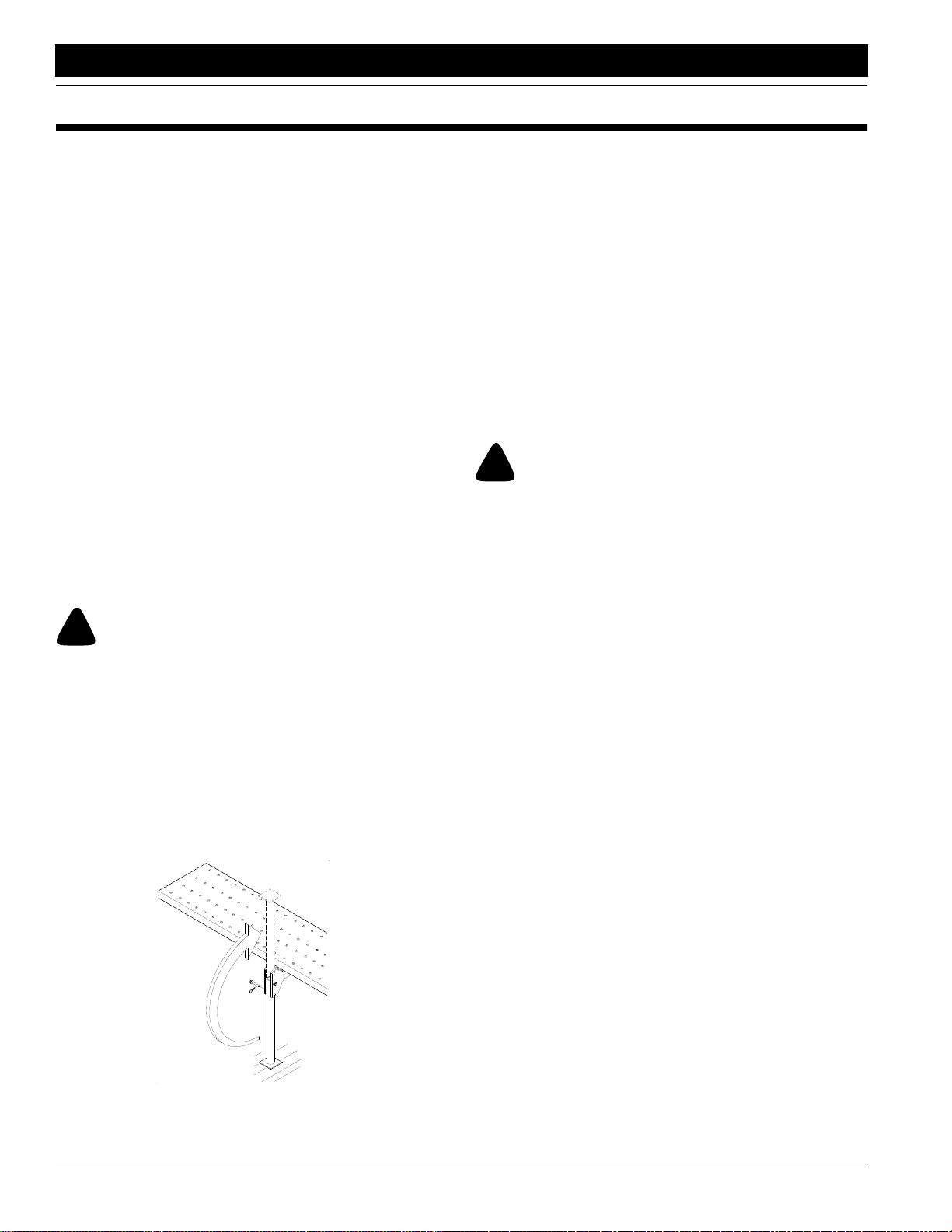

2. Unpin and rotate the parking stands down into the

parking position. Replace pins as shown in Figure 2. If

the ground is soft, place a board under the parking

stand to increase ground contact area.

Great Plains Mfg., Inc.

3. Lower the drill to the ground.

4. Extend or retract the top link until the top 3-point pin is

free. Remove the pin.

5. Remove pins from the lower links.

16504

Figure 2

Parking Stand

2700 and 3000 Three-Point Drill 118-365M-A 9/9/10

10

Page 13

Great Plains Mfg., Inc.

Section 3 Adjustments

Section 3 Adjustments

Gauge-Wheel Adjustment

Gauge-wheel adjustments affect the operating height of

your drill, and drill height directly affects the working range

of the openers. The drill must be adjusted so your openers

can travel up and down and follow the ground contour. Initially adjust the gauge wheels so the bottom of the opener

mounting tube runs 18 1/4 inches above ground.

To adjust drill height:

1. Loosen the jam nut near the bottom clevis of each

gauge-wheel turnbuckle. Refer to Figure 3-1.

10548

Figure 3-2

Normal Spring Rod Setting, Drill Level

IMPORTANT: Do not use the links to adjust opener

depth. To achieve desired seeding depth, refer to Seed-

ing Depth, “Adjustments,” page 12.

10546

Figure 3-1

Gauge Wheel Turnbuckle

2. Bolt the upper clevis in the upper mounting hole.

3. Set the turnbuckle length. Turn the turnbuckle to

shorten or lengthen as necessary. Initially set the

length to 20 3/8 inches between pin centers to

achieve the 18 1/4-inch dimension mentioned above.

When adjusting the turnbuckle, remember:

•Lengthening the turnbuckle raises the drill and allows

less downward float of the openers.

•Shortening the turnbuckle lowers the drill and allows

less upward float of the openers.

NOTE: Remember that lowering the drillincreases the risk

of opener damage on rocks or obstructions.

4. After adjusting both turnbuckles, be certain they are

the same length, then tighten the jam nuts.

5. After setting the turnbuckles, level the drill with the top

hitch link. When the drill is level, the gap between the

spring-rod casting and the cross bolt will be about 2

inches. See Figure 3-2. This is a general dimension

that will vary with the amount of down pressure required for your planting conditions.

For some drill applications, you may want to equip your

drill with two spring-loaded links (part number 120-106A)

or a slotted link (part number 120-171A). Mount the links

in the top hole of the gauge wheel bracket as shown in Figure 3-3. You do not need to adjust the spring-loaded or

slotted links.

10547

Figure 3-3

Spring-Loaded Links For No-Till Drilling

9/9/10

2700 and 3000 Three-Point Drill 118-365M-A

11

Page 14

Section 3 Adjustments

Great Plains Mfg., Inc.

Adjusting Seeding Depth

Your drill is designed to run level to the ground when lowered into seeding position. You may need to make minor

adjustments to achieve desired seeding depth.

Press Wheels

Opener depth is controlled by the height of its press wheel.

Changing the height of the press wheel automatically

changes the seeding depth of the opener.

To adjust press-wheel height, lift up on the T-handle and

slide it forward or back. Refer to Figure 3-4.

12100

Figure 3-4

Press Wheel Adjustment

Down-Pressure Springs

Each opener can be adjusted individually for increased or

decreased down pressure. Increased down pressure aids

opener penetration in hard soils and tire tracks. Decreased down pressure may prevent openers from plugging in wet soil.

To adjust opener down pressure, remove the W clip at the

bottom of the spring shown in Figure 3-5. Place the clip in

a higher spring-rod hole for increased pressure. Place the

clip in a lower hole for decreased pressure. If an opener is

running too deep at the lowest pressure setting, the W clip

can be removed completely.

Bedded Irrigation

If your drill is outfitted with the bedded irrigation option,

you can adjust the height of openers that run in irrigation

furrows.

When running the drill in a level field, mount the openers in

the top hole (1).

To lower the openers for irrigation furrows, move the opener pivot bolt (2) to a lower hole in the opener mount. Lowering the pivot bolt one hole lowers the opener body 2 1/2

inches.

1

2

16766

Figure 3-6

Bedded Irrigation

Seeding Rate

Calibrating the seeding rate requires four steps: arranging

the drive sprockets, setting the seed-rate adjustment handle, positioning the seed-cup door, and checking the seeding rate.

Refer to the seed-rate charts starting on page 15. These

charts list the proper sprocket sizes and seed-rate-handle

settings for various seeds and seeding rates.

The seed-rate charts are based on cleaned, untreated

seed of average size and test weight. The rates are based

on 9.5L x 15 rib implement tires. Many factors will affect

seeding rates including foreign material, seed treatment,

seed size, field conditions, tire pressure and test weight.

Minor adjustments likely will be needed. Set and check the

seeding rate using the procedures below, then re-adjust

the rate as necessary.

Before setting the seeding rate, rotate the drive gauge

wheel to see that seed cups and drive are working properly and free from foreign material.

Minimum Pressure

12102

Figure 3-5

Individual Opener Spring Adjustment

2700 and 3000 Three-Point Drill 118-365M-A 9/9/10

12

Maximum Pressure

12103

Page 15

Great Plains Mfg., Inc.

Section 3 Adjustments

1. Change Drive Sprockets

Refer to the seed-rate charts for the correct drive

type–1, 1A, 2 or 2A. Figure 3-7 shows the sprocket arrangement for each drive type.

c. To change the jackshaft sprocket shown in Figure

3-9, remove the set screws and slide the sprockets so the correct-sized sprockets are aligned.

Reinsert set screws.

16412

Figure 3-9

Jackshaft Sprocket

d. Shorten or lengthen chains as necessary and re-

install chains. Be sure chain is installed with the

chain connector link retainer towards the centerline and the clip opening (split end) is facing the

opposite way of the chain travel. Move the idler

arms into chains. See Figure 3-10 for correct

chain slack.

16400

Figure 3-7

Drive Types

To change the drive type:

a. Loosen the idler-arm bolts and remove chains.

b. To change the double speed-change sprocket

shown in Figure 3-8, remove nut and turn sprocket

over.

Idler

Spr

oc

ket

1/2

In.

3/4

In.

Figure 3-10

Chain Slack

2. Set Seed-Rate Handle

The position the handle for each drill box to the setting

indicated on the chart. One handle is shown in Figure

3-11. To adjust the handles, loosen the wing nut under

the handles and slide until the indicator lines up with

the correct setting.

9/9/10

Idler

16409

Figure 3-8

Double Speed-Change Sprocket

Figure 3-11

Seed-Rate Handle

2700 and 3000 Three-Point Drill 118-365M-A

12927

13

Page 16

Section 3 Adjustments

Great Plains Mfg., Inc.

3. Position Seed-Cup Doors

For wheat and other small seeds. move the seed-cupdoor handles to the highest position. For soybeans

and other large seeds, lower the handles to the second position. If excessive seed cracking occurs, lower

the handles to the third position. Move the handles to

the fourth, wide-open position for seed-cup clean out.

Make sure all handles are in the same position before

drilling.

Figure 3-12

Seed-Cup-Door Handle

4. Check Seeding Rate

a. Record the weight of an empty container large

enough to hold the seed metered for one acre.

b. Place several pounds of seed over three seed

cups on an outside end of the drill box. Pull the

seed tubes off these three openers.

c. Raise the drill off the ground.

d. Turn the gauge wheel a few turns to fill the cups

with seed. Turn wheel until seed drops to the

ground from all three cups.

e. Place a container under the three seed tubes to

gather the seed as it is metered.

13867

f. Turn the drive gauge wheel until one acre has

been tallied on the acremeter (200 rotations on

a 27-foot drill or 182 rotations on a 30-foot drill).

Check that the three seed cups have plenty of

seed coming into them.

g. Weigh the metered seed. Subtract the initial

weight of the empty container. Divide by three

for the amount metered by each seed cup, then

multiply by the number of drill openers for the

pounds-per-acre seeding rate. If this figure is

different than desired, adjust the seed-rate handle and recheck the rate.

NOTE: If your results vary greatly from the charts, you

may want to repeat the calibration procedure.

When satisfied with the rate, set the same seeding rate

on the opposite drill box by repeating steps 1 through 3.

Small Seeds Attachment

To calibrate the seeding rate on the optional small seeds

attachment, follow these steps.

1. Refer to Figure 3-13 for the proper small-seeds

sprocket arrangement given different drive types on

the main drill box. Arrange the sprockets on the

small-seeds attachment according to which drive

type you will use on the main drill box.

NOTE: For accurate metering on the small seeds attachment, the main drill box sprockets must be set to

drive type 1, 2 or 2A.

2. Set the seed-rate adjustment handle on the small

seeds attachment as indicated by the chart on

Small Seeds Attachment Seed Rate Chart, page

17.

3. Calibrate the small seeds attachment to your material by following the steps under Check Seeding

Rate, page 14.

16399

Figure 3-13

Small Seeds Sprocket Arrangements

2700 and 3000 Three-Point Drill 118-365M-A 9/9/10

14

Page 17

Great Plains Mfg., Inc.

Section 3 Adjustments

Seed Rate Charts (pounds per acre)

Setting number

Wheat

Drive Type

1

Based on

60 lb/bu

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

6" 0 11 20 28 37 47 55 65 75 85 96 106 116 129 140 153 161 170 175 184 189

7" 0 10 17 24 32 40 48 56 65 73 83 92 100 111 121 132 140 147 152 159 164

7.5" 0 9 16 23 29 37 44 52 60 68 77 85 93 103 112 122 129 136 140 147 152

8" 0 8 15 21 27 34 40 48 55 62 70 78 85 94 103 112 118 124 129 135 139

Row Spacing

10" 0 7 12 17 22 28 33 39 45 51 58 64 70 77 84 92 97 102 105 110 114

Wheat

Drive Type

2A

Based on

60 lb/bu

Rice,

Short

Grain

Drive Type

1

Rice,

Short

Grain

Drive Type

1A

Rice, Long

Grain

Drive Type

1

Rice, Long

Grain

Drive Type

1A

6" 0 8 13 19 25 31 37 44 50 57 64 71 78 86 94 102 108 114 117 123 127

7" 0 7 11 16 21 27 32 38 44 46 56 62 67 75 81 89 94 99 102 107 110

7.5" 0 6 11 15 20 25 30 35 40 45 52 57 62 69 75 82 86 91 94 99 102

8" 0 6 10 14 18 23 27 32 37 42 47 52 57 63 69 75 79 83 86 90 93

Row Spacing

10"0 5 8 111519222630343943475256616568707476

6" 0 7 13 18 23 30 35 42 46 51 57 62 66 74 83 90 98 103 107 112 115

7" 0 6 11 16 20 26 31 36 39 44 49 54 57 64 72 78 85 90 93 97 100

7.5" 0 6 10 14 19 24 28 33 36 41 45 50 53 59 66 72 78 83 85 90 92

8" 0 5 9 131722263133374146495561667276788285

Row Spacing

10"0 4 8 111418212527313437404550545962646769

6" 0 15 26 37 48 61 73 85 93 104 116 128 136 153 169 185 201 212 219 230 237

7" 0 13 23 32 42 53 63 74 81 91 101 111 118 132 147 160 175 184 190 199 205

7.5" 0 12 21 30 39 49 58 68 75 84 93 103 109 122 136 148 161 170 175 184 189

8" 0 11 19 27 35 45 53 63 69 77 85 94 100 112 124 136 148 156 161 169 174

Row Spacing

10" 0 9 16 22 29 37 44 51 56 63 70 77 81 92 102 111 121 127 132 138 142

6" 0 6 10 15 20 25 29 34 39 44 49 54 58 64 73 79 85 91 93 97 100

7" 0 5 9 131721253034384247505663697478818487

7.5" 0 5 8 12 16 20 23 28 31 35 39 43 46 51 59 63 98 72 74 78 80

8" 0 4 8 111418212529323640424754586366687174

Row Spacing

10" 0 4 6 9 12 15 17 21 23 26 29 32 35 39 44 47 51 54 56 58 60

6" 0 12 21 31 40 50 60 71 80 91 100 110 119 132 150 162 175 185 191 200 206

7" 0 11 19 27 35 44 52 61 69 78 87 96 103 114 130 141 152 160 165 173 179

7.5" 0 10 17 25 32 40 48 57 64 72 80 89 95 105 120 130 140 148 153 160 165

8" 0 9 16 23 29 37 44 52 59 66 74 81 87 97 110 119 129 135 140 146 151

Row Spacing

10’ 0 7 13 18 24 30 36 42 48 54 60 66 71 79 90 97 105 111 115 120 124

Barley

Drive Type

1

Based on

46.4 lb/bu

Oats or

Safflower

Drive Type

1

Based on

39 lb/bu

Rye

Drive Type

2

Millet

Drive Type

2

9/9/10

6" 0 0 7 142027333944505562687582889399102105107

7’ 0 0 6 121823283438444854596571768186889193

7.5" 0 0 6 11 16 21 26 31 36 40 44 50 55 60 66 70 75 79 81 84 86

8" 0 0 5 101520242833374046505560646873757779

Row Spacing

10" 0 0 4 8 12 16 20 23 27 30 33 37 41 45 49 53 56 59 61 63 64

6" 0 4 8 1419253137445157647176839096102107112116

7" 0 4 7 1216222732384449556166727883889397100

7.5" 0 3 7 11 15 20 25 29 35 41 45 51 57 61 67 72 77 81 85 89 93

8" 0 3 6 101419232732374147525661667075788285

Row Spacing

10" 0 3 5 8 11 15 19 22 26 31 34 38 42 46 50 54 58 61 64 67 70

6" 0 3 6 8 11 14 16 18 20 23 25 28 30 33 36 38 40 42 43 46 47

7" 0 3 5 7 9 12131618202224262931333536384041

7.5" 0 3 5 7 9 11 12 14 16 18 20 22 24 27 29 31 32 34 35 36 38

8" 0 2 4 6 8 10111315171920222426282931323334

Row Spacing

10"0 2 4 5 7 8 9 1112141517182021232425262728

6" 0 3 5 7 10 12 15 18 21 24 26 30 32 36 39 43 47 50 52 53 53

7" 0 2 4 6 8 11131618212326283134374043454646

7.5" 0 2 4 6 8 10 12 14 17 19 21 24 26 29 31 34 37 40 42 42 42

8" 0 2 3 5 7 9 11 13 15 17 19 22 24 26 29 31 34 36 38 39 39

Row Spacing

10"0 2 3 4 6 7 9 1113141618192123262830313232

2700 and 3000 Three-Point Drill 118-365M-A

15

Page 18

Section 3 Adjustments

Great Plains Mfg., Inc.

Setting number

Buckwheat

Drive Type

1

Flax or

Sudan

Drive Type

2

Sunflow-

ers

Drive Type

2

Based on

28.9 lb/bu

Soybeans

Drive Type

1

Based on

59.1 lb/bu

Soybeans

Drive Type

2

Based on

59.1 lb/bu

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

6" 0 8 14 20 26 33 40 47 55 62 70 77 85 94 102 111 118 124 128 134 138

7" 0 7 12 17 22 29 34 40 47 54 61 67 73 81 88 97 102 107 111 116 120

7.5" 0 6 11 16 21 26 32 37 44 50 56 62 68 75 82 89 94 99 102 107 111

8" 0 6 10 15 19 24 29 34 40 45 51 57 62 69 75 82 86 91 94 98 101

Row Spacing

10"0 5 8 121520242833374246515661677174778083

6" 0 2 4 6 9 12141619212426293235384245474748

7" 0 2 3 5 8 10121416182123252830333639414141

7.5" 0 2 3 5 7 9 11 13 15 17 19 21 23 26 28 30 33 36 37 38 38

8" 0 1 3 5 7 9 10 12 14 16 17 19 21 23 26 28 31 33 34 35 35

Row Spacing

10" 0 1 2 4 5 7 8 10 11 13 14 16 18 19 21 23 25 27 28 28 29

6" 0 0 0 2 3 4 6 8 9 111415171920232426272829

7" 0 0 0 2 3 3 5 7 8 101213151618202122232425

7.5" 0 0 0 1 3 3 5 6 8 9 11 12 14 15 16 18 19 21 21 22 23

8" 0 0 0 1 2 3 5 6 7 8 10 11 12 14 15 17 18 19 20 20 21

10" 0 0 0 1 2 3 4 5 6 7 8 9 10 11 12 14 14 15 16 17 17

Row Spacing

6" 0 0 0 0 30 40 55 70 84 98 113 127 140 154 166 176 188 200 204 207 209

7" 0 0 0 0 26 35 48 61 72 85 98 110 122 133 144 153 163 173 177 180 181

7.5" 0 0 0 0 24 32 44 56 67 79 91 101 112 123 132 141 150 160 164 166 167

8" 0 0 0 0 22 30 40 51 61 72 83 93 103 113 121 129 138 147 150 152 153

Row Spacing

10" 0 0 0 0 18 24 33 42 50 59 68 76 84 92 99 106 113 120 123 124 125

6" 0 0 0 0 10 13 18 23 27 32 37 41 46 50 54 57 61 65 67 68 68

7" 0 0 0 0 8 11162024283236404347505357585959

7.5" 0 0 0 0 8 11 14 18 22 26 30 33 37 40 43 46 49 52 53 54 55

8" 0 0 0 0 7 10131720242730343740424548495050

Row Spacing

10" 0 0 0 0 6 8 11 14 16 19 22 25 27 30 32 34 37 39 40 41 41

Soybeans

Drive Type

2A

Based on

59.1 lb/bu

Peas

Drive Type

1

Pinto

Beans

Drive Type

2

Based on

60 lb/bu

Alfalfa or

Rape

Drive Type

2

Milo

Drive Type

2

Based on

62.4 lb/bu

6" 0 0 0 0 20 27 37 47 56 66 76 85 94 103 111 118 126 134 137 139 140

7" 0 0 0 0 17 23 32 41 49 57 66 73 81 89 96 103 110 116 119 121 122

7.5" 0 0 0 0 16 22 30 37 45 53 61 68 75 82 89 95 101 107 110 111 112

8" 0 0 0 0 15 20 27 34 41 48 56 62 69 75 82 87 93 98 101 102 103

Row Spacing

10" 0 0 0 0 12 16 22 28 34 40 45 51 56 62 67 71 76 80 82 84 84

6" 0 0 10 26 41 55 70 82 95 110 123 135 150 163 176 189 204 215 227 235 241

7" 0 0 8 23 35 48 61 71 82 96 107 117 130 141 152 164 177 186 197 204 209

7.5" 0 0 8 21 33 44 56 66 76 88 99 108 120 130 140 151 163 172 182 188 193

8" 0 0 7 19 30 40 51 60 69 81 90 99 110 120 129 139 149 158 167 172 177

Row Spacing

10" 0 0 6 16 24 33 42 49 57 66 74 81 90 98 105 113 122 129 136 141 145

6" 0 0 0 4 7 12162024283236414448535660636465

7" 0 0 0 3 6 10141821242731353842464952555556

7.5" 0 0 0 3 6 9 13 16 19 22 25 29 32 35 39 42 45 48 50 51 52

8" 0 0 0 3 5 9 12 15 18 20 23 27 30 32 35 39 41 44 46 47 47

10" 0 0 0 2 4 7 10 12 14 17 19 22 24 27 29 32 34 36 38 38 39

Row Spacing

6" 0 4 6 8 11 14 17 20 23 26 29 32 35 37 40 42 45 47 50 52 54

7" 0 3 5 7 10 13 15 18 20 23 25 28 30 32 34 37 39 41 43 45 46

7.5" 0 3 5 7 9 12 14 16 18 21 23 26 28 30 32 34 36 38 40 41 43

8" 0 3 4 6 8 11131517192224262729313335363839

Row Spacing

10" 0 2 3 5 7 9 10 12 14 16 18 19 21 22 24 25 27 28 30 31 32

6" 0 3 5 8 12 15 18 21 24 27 30 34 37 41 45 49 54 57 60 60 61

7" 0 2 4 7 10 12 15 18 21 24 26 29 32 36 39 42 46 50 52 52 53

7.5" 0 2 4 6 9 11 14 16 19 22 24 27 30 33 36 39 43 46 48 48 49

8" 0 2 3 6 8 10131518202225273033363942444445

Row Spacing

10" 0 2 3 5 7 9 11 12 14 16 18 20 22 25 27 29 32 34 36 36 37

2700 and 3000 Three-Point Drill 118-365M-A 9/9/10

16

Page 19

Great Plains Mfg., Inc.

Section 3 Adjustments

Setting number

Wheat

Grass

Drive Type

2

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

6" 0 1 2 2 3 4 4 5 6 7 8 9 9 1011121314141515

7" 0 1 1 2 3 3 4 5 5 6 7 8 8 9 10 11 11 12 12 13 13

7.5" 0 1 1 2 2 3 4 4 5 6 6 7889101011111212

8"01122334456678891010101111

Row Spacing

10"011122334455667788999

Small Seeds Attachment Seed Rate Chart (pounds per acre)

Setting number 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Kentucky Blue

Grass, Fescue, Annual

Rye Grass

Ladino Clover, Canary

Grass, Timo-

thy, Canola

Bermuda, Red

Top, Unhulled

Lespedeza,

Sercia, Sand

& Weeping

Love Grass

6" 0 .2 1.2 1.9 2.7 3.3 4.1 4.6 5.2 5.8 6.3 6.8 7.3 7.8 8.3 8.8 9.2 9.7 10.0 10.5

7" 0 .2 1.0 1.6 2.3 2.8 3.5 4.0 4.5 5.0 5.4 5.9 6.3 6.7 7.1 7.5 7.9 8.0 8.6 9.0

7.5" 0 .2 .9 1.5 2.2 2.7 3.3 3.7 4.2 4.6 5.1 5.5 5.9 6.3 6.7 7.0 7.4 7.7 8.1 8.4

8" 0 .2 .9 1.4 2.0 2.5 3.0 3.5 3.9 4.3 4.8 5.1 5.5 5.9 6.2 6.6 6.9 7.5 7.5 7.9

Row Space

10" 0 .1 .7 1.1 1.6 2.0 2.4 2.7 3.1 3.4 3.7 4.0 4.3 4.6 4.9 5.2 5.4 5.7 5.9 6.2

6" 0 1.1 2.1 3.3 4.7 6.1 7.6 9.2 10.7 12.2 13.8 15.5 17.0 18.5 20.3 21.7 23.4 25.4 27.3 29.2

7" 0 .9 1.7 2.8 4.1 5.2 6.6 7.9 9.2 10.5 11.8 13.3 14.6 15.9 17.4 18.7 20.0 22.0 23.4 25.1

7.5" 0 .9 1.6 2.6 3.9 4.9 6.1 7.4 8.6 9.8 11.1 12.5 13.7 14.9 16.3 17.6 18.8 20.4 21.9 23.5

8" 0 .8 1.5 2.5 3.6 4.6 5.7 6.9 8.0 9.2 10.3 11.6 12.8 13.9 15.2 16.4 17.5 19.0 20.5 21.9

Row Space

10" 0 .6 1.5 1.9 2.5 3.6 4.5 5.4 6.3 7.2 8.1 9.1 10.0 10.9 12.0 12.9 13.8 14.9 16.1 17.2

6" 0 .7 1.1 1.7 2.6 3.3 4.1 5.0 5.9 6.6 7.2 7.8 8.4 9.0 9.5 10.2 10.9 11.6 12.2 12.9

7" 0 .6 .9 1.5 2.2 2.8 3.6 4.3 5.1 5.6 6.2 6.7 7.1 7.7 8.1 8.7 9.4 10.0 10.5 11.0

7.5" 0 .5 .9 1.4 2.1 2.6 3.3 4.0 4.7 5.3 5.8 6.3 6.7 7.2 7.6 8.2 8.8 9.3 9.8 10.4

8" 0 .5 .8 1.3 2.0 2.5 3.1 3.8 4.4 4.9 5.4 5.9 6.5 6.7 7.1 7.6 8.2 8.7 9.2 9.7

Row Space

10" 0 .4 .6 1.0 1.5 1.9 2.4 3.0 3.5 3.9 4.2 4.6 4.9 5.3 5.6 6.0 6.4 6.8 7.2 7.6

Red & Sweet

Clover, Lespe-

deza Hulled

Bird’s-foot Tre-

foil, Sudan

Orchard Grass

Millet, Reed

Canary

Alfalfa, Red

Alsike, Crim-

son Clover

6" 0 1.5 3.4 5.2 7.1 9.0 11.3 13.2 15.3 17.0 19.0 20.8 22.5 24.5 26.4 28.3 30.1 32.1 33.8 35.6

7" 0 1.3 2.9 4.5 6.1 7.7 9.7 11.3 13.1 14.6 16.3 17.8 19.3 21.0 22.7 24.6 25.8 27.5 29.0 30.5

7.5" 0 1.2 2.7 4.2 5.7 7.2 9.1 10.6 12.3 13.7 15.3 16.7 18.1 19.7 21.2 22.7 24.2 25.8 27.2 28.6

8" 0 1.1 2.5 3.9 5.3 6.7 8.5 9.9 11.5 12.8 14.3 15.6 16.9 18.3 19.8 21.2 22.6 24.1 25.4 26.7

Row Space

10" 0 .9 2.0 3.1 4.2 5.3 6.7 7.8 9.0 10.0 11.2 12.2 13.3 14.4 15.6 16.6 17.8 18.9 19.9 20.9

6" 0 1.7 3.3 5.2 6.8 8.7 10.7 12.7 14.7 16.8 19.2 21.2 23.4 25.6 28.0 29.9 32.1 34.2 36.3 38.4

7" 0 1.5 2.8 4.5 5.8 7.5 9.2 10.9 12.5 14.4 16.5 18.2 20.0 21.9 24.0 25.6 27.5 29.0 31.1 32.9

7.5" 0 1.4 2.6 4.2 5.4 7.0 8.6 10.2 11.9 13.5 15.4 17.0 18.8 20.5 22.5 24.0 25.8 27.6 29.1 30.9

8" 0 1.3 2.5 3.9 5.1 6.6 8.1 9.5 11.0 12.6 14.4 15.9 17.5 19.2 21.0 22.4 24.1 25.7 27.2 28.8

Row Space

10" 0 1.0 1.9 3.1 4.0 5.1 6.3 7.5 8.6 9.9 11.3 12.5 13.8 15.1 16.5 17.6 18.9 20.2 21.4 22.7

6" 0 0 .3 .7 .9 1.3 1.5 2.0 2.4 2.8 3.3 3.5 3.9 4.4 4.8 5.0 5.5 5.7 6.1 6.3

7" 0 0 .2 .6 .7 1.1 1.3 1.7 2.1 2.4 2.8 3.0 3.4 3.7 4.1 4.3 4.7 5.0 5.2 5.4

7.5" 0 0 .2 .5 .7 1.1 1.2 1.6 1.9 2.3 2.6 2.8 3.2 3.5 3.9 4.0 4.4 4.6 4.9 5.1

8" 0 0 .2 .5 .7 1.0 1.1 1.5 1.8 2.1 2.5 2.6 2.9 3.3 3.6 3.8 4.1 4.3 4.6 4.8

Row Space

10" 0 0 .1 .4 .5 .8 .9 1.2 1.4 1.7 1.9 2.1 2.3 2.6 2.8 3.0 3.2 3.3 3.6 3.7

6" .4 1.4 2.4 3.5 4.4 5.5 6.5 7.5 8.5 9.5 10.5 11.5 12.5 13.6 14.6 15.6 16.6 17.6 18.5 19.0

7" .4 1.2 2.1 3.0 3.8 4.7 5.6 6.4 7.3 8.1 9.0 9.9 10.7 11.6 12.5 13.3 14.2 15.1 15.9 16.1

7.5" .3 1.2 2.0 2.8 3.6 4.4 5.2 6.0 6.8 7.6 8.4 9.3 10.1 10.9 11.7 12.5 13.3 14.1 14.9 15.1

8" .3 1.1 1.8 2.6 3.3 4.1 4.9 5.6 6.4 7.1 7.9 8.6 9.4 10.2 10.9 11.7 12.4 13.2 13.9 14.1

Row Space

10" .3 .8 1.4 2.0 2.6 3.2 3.8 4.4 5.0 5.6 6.2 6.8 7.4 8.0 8.6 9.2 9.8 10.4 10.9 11.5

6" 0 2..2 3.5 4.8 6.0 7.5 8.7 9.8 11.2 12.5 13.8 15.1 16.4 17.5 18.6 20.2 21.4 22.9 24.0 25.2

7" 0 1.9 3.0 4.1 5.1 6.4 7.5 8.4 9.5 10.8 11.8 12.9 14.0 15.0 16.3 17.3 18.3 20.0 20.6 21.6

7.5" 0 1.8 2.8 3.9 4.8 6.0 7.0 7.9 9.0 10.0 11.1 12.1 13.2 14.0 15.3 16.2 17.2 18.3 19.3 20.3

8" 0 1.6 2.6 3.6 4.5 5.6 6.6 7.4 8.4 9.4 10.3 11.3 12.3 13.0 13.1 15.2 16.1 17.1 18.0 18.9

Row Space

10" 0 1.3 2.1 2.8 3.5 4.4 5.1 5.8 6.6 7.4 8.1 8.9 9.7 10.3 11.2 11.9 12.6 13.4 14.2 14.9

9/9/10

2700 and 3000 Three-Point Drill 118-365M-A

17

Page 20

Section 3 Adjustments

Great Plains Mfg., Inc.

Marker Adjustments

Chain Adjustment

There are two chain adjustments. These adjustments are

interrelated and should be done in the following order. Refer to Figure 3-14.

1. Lifting Slack. Start with the marker unfolded. Back the

full-threaded adjustment bolt (1) down until the head

extends as little as possible. Slowly fold the marker, observing the motion of the disk. If the disk slides across

the ground more than about a foot before the chain and

linkage lifts it up, the chain is too long. Shorten the

chain by moving the clevis (2) in one or two links. Check

the adjustment by repeating the folding process.

If the chain is too short when the marker is unfolded, it

will prevent the end of the marker from dropping into

field depressions. Correctthis condition by moving the

clevis (2) one or two links toward the end of the chain

to make it longer.

2. Folding Slack. After completing the adjustment in step

one, fold the marker. Extend the full-threaded adjustment bolt (1) until the slack is out of the chain. Lock the

bolt in this position by tightening the nuts (3) on either

side of upright channel (4).

Disk Adjustment

The field mark left by the marker disk may be changed by

adjusting disk angle or direction of cut.

Disk Angle. Refer to Figure 3-15. To change the angle of

cut loosen the two 1/2-inch bolts holding the disk assembly. Rotate the disk assembly as desired.

11757

Figure 3-15

Disk Angle

Direction of Cut. The disk may be mounted to throw dirt in

or out for different marks in different soil conditions. Refer

to Figure 3-16. To change the direction of cut:

1. Reverse the disk by removing the four lug bolts on the

disk hub. Remount the depth band and lug bolts.

2. Turn the entire disk assembly by removing the two 1/2inch bolts and turning the assembly one-half turn. Reinstall the 1/2-inch bolts and set the disk angle as desired.

15669

Figure 3-14

Marker Chain Adjustment

2700 and 3000 Three-Point Drill 118-365M-A 9/9/10

18

16403

Figure 3-16

Direction of Cut Reversed

Page 21

Great Plains Mfg., Inc.

Section 3 Adjustments

Speed Adjustment

The markers are equipped with hex-head screws for adjusting folding speed. The screws are on the sequencevalve body as shown in Figure 3-17. There are two

screws–one for folding speed (1), the other for unfolding

speed (2). Turn the adjustment screws clockwise for slower folding or counterclockwise for faster folding. Adjust to a

safe speed. Excessive speed could damage the markers

and void the warranty.

14048

Figure 3-17

Folding Speed Adjustment

tions vary, you may need to adjust the scrapers. In damp

conditions, the scrapers may need to be lowered. If openers are not turning freely, the scrapers may need to be

raised. To adjust scrapers, loosen the 3/8-inch bolt and

move scraper as needed.

16411

Figure 3-18

Disk Scraper

Seed-Lok™

The optional Seed-Lok™ firming wheels provide additional

seed-to-soil contact. The wheels are spring loaded and do

not require adjusting. In some wet and sticky conditions

the wheels may accumulate soil. Remove or install the

wheels as field conditions warrant.

Disk Scraper Adjustment

To keep the double-disk openers turning freely, dirt scrapers are mounted between the disks to clean as the disks

rotate. A scraper is shown in Figure 3-18. As field condi-

9/9/10

2700 and 3000 Three-Point Drill 118-365M-A

19

Page 22

Great Plains Mfg., Inc.

Section 4 Troubleshooting

Section 4 Troubleshooting

Problem Solution

Uneven seed spacing or uneven stand Check for plugging in seed cups.

Check for plugging in seed tubes.

Reduce ground speed.

Check if opener disks are turning freely.

Use faster drive type and position seed-rate handle to a lower setting.

Increase opener spring pressure to penetrate low spots. Refer to Down-Pressure

Springs, “Adjustments,” page 12.

Check for trash or mud build-up on Seed-Lok wheels.

Opener disks not turning freely Check for trash or mud build-up on disk scraper. Readjust scraper. Refer to Disk

Actual seeding rate is different than desired Check tire pressure. Proper inflation is listed on Tire Inflation Chart, “Appendix,” page

Excessive seed cracking Use slower drive type and position seed-rate handle to a higher setting.

Acremeter doesn’t measure accurately Check tire pressure. Proper inflation is listed on Tire Inflation Chart, “Appendix,” page

Uneven seeding depth Refer to Seeding Depth, “Adjustments,” page 12.

Press wheels not compacting the soil as desired Reset press-wheel depth. Refer to Press Wheels, “Adjustments,” page 12.

Grain box not emptying evenly Certain models do not have the same number of seed cups between each divider of

Scraper Adjustment, “Adjustments,” page 19.

Check if scraper is adjusted too tight, restricting disk movement. Refer to Disk

Scraper Adjustment, “Adjustments,” page 19.

Check disk bearings.

Check opener frame for damage.

If opener disks turn freely by hand but not in field, reduce down pressure on disk

opener. Down-Pressure Springs, “Adjustments,” page 12.

Check press wheel adjustment. Refer to Press Wheels, “Adjustments,” page 12.

29.

Check tire size. Proper size is 9.5L x 15".

Regularly clean seed treatment from seed cups.

Check drill box setting.

Refer to Seeding Rate, “Adjustments,” page 14, for instructions on calculating seeding rate.

Position seed-cup handles to a lower notch.

29.

Check tire size. Proper size is 9.5L x 15".

Check planting operation for excessive overlap or gaps between passes.

Consider soil conditions. Loose soil and slippage will cause variations in acres registered.

Check that your acremeter is for your width of drill. Refer to the parts manual.

Increase down pressure on disk openers. Down-Pressure Springs, “Adjustments,”

page 12.

bulkhead. The section with more cups will empty sooner.

2700 and 3000 Three-Point Drill 118-365M-A 9/9/10

20

Page 23

Great Plains Mfg., Inc.

Section 4 Troubleshooting

Problem Solution

Press wheel or openers plugging

Seed-cup sprockets locked up or twisted feeder

drive shaft

Hydraulic marker functioning improperly Check all hose fittings and connections for air or oil leaks.

Drill is not pulling level (parallel to ground, front to

rear)

Gauge wheel leans to left or right Realign brackets where gauge wheel is attached to main frame by adjusting u-bolts.

Marker blade does not mark Check that the marker folding linkage has enough slack to allow the marker disk to

Chain

Consider soil conditions–may be too damp or wet.

Reduce down pressure on openers. Down-Pressure Springs, “Adjustments,” page 12.

Do not back up or allow drill to roll backward with openers in the ground.

Check Seed-Lok wheel. If conditions are too wet, you may need to remove the wheels.

Check for foreign material stuck in the seed-cup sprockets.

Check for dried liquid insecticide in seed cups. Remove the build up by disassembling each seed cup and scraping the foreign substance from the turning surfaces.

The chain on the folding three-section marker should be slack when the marker is

both fully extended and fully raised. Refer to Marker Adjustments, “Adjustments,”

page 19.

Check tractor hydraulic oil level.

Check all bolts and fasteners.

Open needle valve, cycle markers slowly and reset needle valve if plugged.

Readjust top hitch link to level drill.

Check if axle bearings are securely attached to gauge-wheel arm.

drop into field depressions. Maximum down float should be limited by the slot at the

rod end of the marker cylinder–not by the chain. Refer to Marker Adjustments,

“Adjustments,” page 25.

Reverse the blade to pull or throw dirt. Refer to Marker Adjustments, “Adjustments,”

page 25.

Try the optional notched blade available through your Great Plains dealer.

Be sure retainer clip is facing opposite way of chain travel

9/9/10

2700 and 3000 Three-Point Drill 118-365M-A

21

Page 24

Section 5 Maintenance and Lubrication

Section 5 Maintenance and Lubrication

Great Plains Mfg., Inc.

General Maintenance

Proper servicing and adjustment is the key to long implement life. With careful and systematic inspection, you can

avoid costly maintenance, downtime and repair.

Always turn off and remove the tractor key before making

any adjustments or performing maintenance. Securely

block raised drill before working under or around it.

1. After using your drill for several hours, check all bolts

to be sure they are tight. Periodically check and secure all bolts, pins and fasteners. Tighten as specified

on Torque Values Chart,“Appendix,” page 29.

2. Clean or replace any fittings that will not take grease.

Lubricate the drill as noted under Lubrication, this

page.

3. Adjust idlers to remove excess slack from chains.

Clean and use chain lube on all roller chains as needed.

4. Always maintain correct tire pressure. Refer to Tire In-

flation Chart,“Appendix,” page 29.

5. Check disk scrapers for proper adjustment. Refer to

Disk Scraper Adjustment,“Adjustments,” page 19.

6. Replace any worn, damaged or illegible safety decals

at once. Refer to Safety Decals,“Important Safety In-

formation,” page 4, for correct decal placement. Obtain new decals from your Great Plains dealer.

Marker Maintenance

Under normal conditions, the disk hub bearings need to be

repacked every 2 or 3 years. If the grease seal cap is damaged or missing, disassemble and clean the hub. Repack

with grease and install a new seal or grease cap.

Storage

Store the drill where children do not play. If possible, store

the drill inside for longer life.

1. Clean the drill as necessary. Be sure the seed boxes

are cleaned completely before storing.

2. Adjust and oil all roller chains. Lubricate the drill at all

points indicated under Lubrication, this page.

IMPORTANT: Be sure the seed-cup drive sprocket is

oiled before the drill is stored. Squirt oil onto the

square seed-cup shaft and move adjustment handle

to get the oil into the square.

3. Check all bolts, pins, fitting and hoses. Tighten, repair

or replace parts as needed.

4. Check all moving and soil-contact parts for wear or

damage. Make notes of any parts needing repair.

5. Use Great Plains touch-up paint to cover scratches,

chips and worn areas to prevent rust.

Lubrication

Lubrication

Legend

12126

2700 and 3000 Three-Point Drill 118-365M-A 9/9/10

22

Multipurpose

spray lube

Multipurpose

grease lube

Seed-Cup-Drive Sprocket

Squirt oil onto the square seed-cup shaft and move adjustment handle to get the oil into the square.

Type of Lubrication: Oil

Quantity: Coat thoroughly

Multipurpose

oil lube

50

Intervals at which

lubrication is required

50

Page 25

Great Plains Mfg., Inc.

Section 5 Maintenance and Lubrication

20

Jackshaft Bearings

Two sets of bearings on each end of drill; four zerks total.

16412

16409

Type of Lubrication: Grease

Quantity = Until resistance is felt

As

Required

Drive Chains

Both gauge wheels

Type of Lubrication: Chain Lube

Quantity = Coat generously

As

Required

Drive Chains

Both ends of drill

12116

9/9/10

16408

Type of Lubrication: Chain Lube

Quantity = Coat generously

Wheel Axles

Type of Lubrication: Grease

Quantity = Full Pack

2700 and 3000 Three-Point Drill 118-365M-A

Seasonally

23

Page 26

Section 5 Maintenance and Lubrication

12237

Great Plains Mfg., Inc.

20

Marker Hinges

Type of Lubrication: Grease

Quantity: Until resistance is felt

2-3 Years

15545

Marker-Disk Bearings

Type of Lubrication: Grease

Quantity = Repack

2700 and 3000 Three-Point Drill 118-365M-A 9/9/10

24

Page 27

Great Plains Mfg., Inc.

Section 6 Options

Section 6 Options

16407

Markers

Hydraulic markers are available. Markers come complete

with double-acting cylinders, hoses and fittings.

For information on how to adjust the markers, refer to Marker

Adjustments,“Adjustments,” page 18. For marker mainte-

nance and lubrication, refer to Marker Maintenance and Lu-

brication,“Maintenance and Lubrication,” page 22.

To order markers, contact your Great Plains dealer. Refer to

the table below for the correct marker package for your drill

Marker Package Part Number

27-ft. Dual Flat-Fold Hydraulic Markers 113-199A

30-ft. Dual Flat-Fold Hydraulic Markers 113-195A

.

15642

Seed-Cup Plugs

Seed-cup plugs are available to block off individual rows

when you want wider row spacings. Install the plugs by

pushing them into the seed-cup openings on the desired

rows.

To order seed-cup plugs, contact your Great Plains dealer.

Seed Cup Plugs Package Part Number

Seed-Cup Plugs 817-200C

Seed-Lok™ Firming Wheels

The optional, spring-loaded Seed-Lok™ firming wheel

presses the seed directly into the bottom of the seed bed.

The Seed-Lok™ option provides more even seed emergence since seeds are planted and firmed at the same

depth.

For adjustment, refer to Seed-Lok,“Adjustments,” page

19.

To order Seed-Lok™ firming wheels, contact your Great

Plains dealer.

9/9/10

12677

See-Lok Bundle Part Number

Solid Stand Removable 5-in. Seed-Lok Assembly 122-193K

2700 and 3000 Three-Point Drill 118-365M-A

25

Page 28

Section 6 Options

Great Plains Mfg., Inc.

Shaft Monitor

The optional shaft monitor detects when the seed-cup shaft

stops turning. If the shaft stops for more than 20 seconds, an

alarm sounds and a warning light flashes.

For information on how to operate the shaft monitor, refer to

Shaft Monitor Operation,“Operating Instructions,” page 9.

To order shaft monitors, contact your Great Plains dealer.

Monitor Bundle Part Number

Vansco 2-Channel Shaft Monitor 116-120A

13178

Small Seeds Attachment

The small-seeds attachment delivers small seeds evenly

and gently. With a Y-tube, small seeds are placed through

the opener seed tube. Otherwise, seeds are placed directly

in front of the press wheel. For setting the seeding rate on

the attachment, refer to Small Seeds Attachment,“Adjust-

ments,” page 14.

To order the small seeds attachment, contact your Great

Plains dealer. Refer to the table below for the correct part

number for your drill.

13734

Attachment Package Part Number

Drill Size Press Wheel Hose

Mount

27-ft., 6-in. Rows 133-042A 133-043A

27-ft., 7-in Rows 133-044A 133-045A

27-ft., 7 1/2-in. Rows 133-046A 133-047A

27-ft., 8-in. Rows 133-048A 133-049A

27-ft., 10-in. Rows 133-050A 133-052A

30-ft, 6-in Rows 133-053A 133-054A

30-ft, 7-in. Rows Not Available Not Available

30-ft., 7 1/2-in. Rows 133-055A 133-056A

30-ft., 8-in. Rows 133-057A 133-058A

30-ft., 10-in. Rows 133-059A 133-060A

Y-Tube Mount

Steel Depth Bands

Optional steel depth bands help to maintain even seeding

depth. When bolted around the center of the opener disks,

the bands keep the opener from running deeper than 1 1/2

inches.

Bundle Part Number

Steel Depth Band 121-705A

2700 and 3000 Three-Point Drill 118-365M-A 9/9/10

26

Page 29

Great Plains Mfg., Inc.

Section 7 Specifications and Capacities

Section 7 Specifications and Capacities

27-ft Drill

Rows Per Drill

Row Spacing: 6-in/15.2-cm 54

7 in/17.8 cm 46

7 1/2 in/19.1 cm 44

8 in/20.3 cm 40

10 in/25.4 cm 32

Base Unit Weight

Row Spacing: 6-in/15.2-cm 4455 lb/2025.75 kg

7 in/17.8 cm 4620 lb/2095.60 kg

7 1/2 in/19.1 cm 4128 lb/1872.43 kg

8 in/20.3 cm 4093 lb/1856.55 kg

10 in/25.4 cm 3658 lb/1659.24 kg

Box Capacity

Small Seeds Attachment Capacity

55 bu./1938.14 L

6.5 bu/229.05 L

30-ft Drill

Rows Per Drill

Row Spacing: 6-in/15.2-cm 60

7 in/17.8 cm --

7 1/2 in/19.1 cm 48

8 in/20.3 cm 44

10 in/25.4 cm 36

Drill Weight

Row Spacing: 6-in/15.2-cm 4862 lb/2205.37 kg

7 in/17.8 cm -----------------

7 1/2 in/19.1 cm 4596 lb/2084.71 kg

8 in/20.3 cm 4348 lb/1972.22 kg

10 in/25.4 cm 3996 lb/1812.55 kg

Box Capacity

Small Seeds Attachment Capacity

60 bu/2114.34 L

7.20 bu./253.72 L

NOTE: All tires are warranted by the original manufacturer of the tire. Tire warranty infomation can be found in the brochures included with your Operator’s and Parts Manuals or online at the manufacturer’s websites. For service assistance

or information, contact your nearest Authorized Farm Tire Retailer.

Manufacturer Website

Titan www.titan-intl.com

Goodyear www.goodyearag.com

Firestone www.firestoneag.com

9/9/10

2700 and 3000 Three-Point Drill 118-365M-A

27

Page 30

Section 7 Specifications and Capacities

Great Plains Mfg., Inc.

Specification Drawing

10584

2700 and 3000 Three-Point Drill 118-365M-A 9/9/10

28

Page 31

Great Plains Mfg., Inc.

Appendix

Appendix

Torque Values Chart for Common Bolt Sizes

Bolt Head Identification

Bolt Size

(Inches)

1

in-tpi

1/4" - 20 7.4 5.6 11 8 16 12 M 5 X 0.8 436597

1/4" - 28 8.5 6 13 10 18 14 M 6 X 1 7 5 11 8 15 11

5/16 - 18 15 11 24 17 33 25 M 8 X 1.25 17 12 26 19 36 27

5/16" - 24 17 13 26 19 37 27 M 8 X 1 18 13 28 21 39 29

3/8" - 16 27 20 42 31 59 44 M10 X 1.5 33 24 52 39 72 53

3/8" - 24 31 22 47 35 67 49 M10 X 0.75 39 29 61 45 85 62

7/16" - 14 43 32 67 49 95 70 M12 X 1.75 58 42 91 67 125 93

7/16" - 20 49 36 75 55 105 78 M12 X 1.5 60 44 95 70 130 97

1/2" - 13 66 49 105 76 145 105 M12 X 1 90 66 105 77 145 105

1/2" - 20 75 55 115 85 165 120 M14 X 2 92 68 145 105 200 150

9/16" - 12 95 70 150 110 210 155 M14 X 1.5 99 73 155 115 215 160

9/16" - 18 105 79 165 120 235 170 M16 X 2 145 105 225 165 315 230

5/8" - 11 130 97 205 150 285 210 M16 X 1.5 155 115 240 180 335 245

5/8" - 18 150 110 230 170 325 240 M18 X 2.5 195 145 310 230 405 300

3/4" - 10 235 170 360 265 510 375 M18 X 1.5 220 165 350 260 485 355

3/4" - 16 260 190 405 295 570 420 M20 X 2.5 280 205 440 325 610 450

7/8" - 9 225 165 585 430 820 605 M20 X 1.5 310 230 650 480 900 665

7/8" - 14 250 185 640 475 905 670 M24 X 3 480 355 760 560 1050 780

1" - 8 340 250 875 645 1230 910 M24 X 2 525 390 830 610 1150 845

1" - 12 370 275 955 705 1350 995 M30 X 3.5 960 705 1510 1120 2100 1550

1-1/8" - 7 480 355 1080 795 1750 1290 M30 X 2 1060 785 1680 1240 2320 1710

1 1/8" - 12 540 395 1210 890 1960 1440 M36 X 3.5 1730 1270 2650 1950 3660 2700

1 1/4" - 7 680 500 1520 1120 2460 1820 M36 X 2 1880 1380 2960 2190 4100 3220

1 1/4" - 12 750 555 1680 1240 2730 2010

1 3/8" - 6 890 655 1990 1470 3230 2380

1 3/8" - 12 1010 745 2270 1670 3680 2710

1 1/2" - 6 1180 870 2640 1950 4290 3160

1 1/2" - 12 1330 980 2970 2190 4820 3560

Grade 2 Grade 5

N · m2ft-lb3N · m ft-lb N · m ft-lb mm x pitch4N · m ft-lb N · m ft-lb N · m ft-lb

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

Grade 8

Bolt Size

(Metric)

1

in-tpi = nominal thread dia.in inches-threads per inch

4

mm x pitch = nominal thread dia. in millimeters x thread pitch

Bolt Head Identification

5.8 8.8 10.9

Class 5.8 Class 8.8 Class 10.9

2

N· m = newton-meters

3

ft-lb= foot pounds

Tire Inflation Chart

Tire Size Inflation PSI Tire Size Inflation PSI

7.50 x 20" 4-Ply Drill Rib 28 11L x 15" 6-Ply Rib Implement 28

9.0 x 22.5 10-Ply Highway Service 70 70 11L x 15" 12-Ply Rib Implement 52

9.0 x 24" 8-Ply Rib Implement 40 12.5L x 15" 8-Ply Rib Implement 36

9.5L x 15" 6-Ply Rib Implement 32 12.5L x 15" 10-Ply Rib Implement 44

9.5L x 15" 8-Ply Rib Implement 44 16.5L x 16.1" 10-Ply Rib Implement 36

9.5L x 15" 12-Ply Rib Implement 60 41 x 15" x 18 - 22-Ply Rib Implement 44

9/9/10

2700 and 3000 Three-Point Drill 118-365M-A

29

Page 32

Appendix

Great Plains Mfg., Inc.

Warranty

Great Plains Manufacturing, Incorporated warrants to the original purchaser that this seeding equipment will be free from defects in material

and workmanship for a period of one year from the date of original purchase when used as intended and under normal service and conditions

for personal use; 90 days for commercial or rental purposes. This Warranty is limited to the replacement of any defective part by Great Plains

Manufacturing, Incorporated and the installation by the dealer of any

such replacement part. Great Plains reserves the right to inspect any

equipment or part which are claimed to have been defective in material

or workmanship.

This Warranty does not apply to any part or product which in Great

Plains’ judgement shall have been misused or damaged by accident or

lack of normal maintenance or care, or which has been repaired or altered in a way which adversely affects its performance or reliability, or

which has been used for a purpose for which the product is not designed. This Warranty shall not apply if the product is towed at a speed

in excess of 20 miles per hour.

Claims under this Warranty must be made to the dealer which originally

sold the product and all warranty adjustments must by made through

such dealer. Great Plains reserves the right to make changes in materials or design of the product at any time without notice.

This Warranty shall not be interpreted to render Great Plains liable for

damages of any kind, direct, consequential, or contingent, to property.

Furthermore, Great Plains shall not be liable for damages resulting from

any cause beyond its reasonable control. This Warranty does not extend to loss of crops, losses caused by harvest delays or any expense

or loss for labor, supplies, rental machinery or for any other reason.

No other warranty of any kind whatsoever, express or implied, is

made with respect to this sale; and all implied warranties of merchantability and fitness for a particular purpose which exceed

the obligations set forth in this written warranty are hereby disclaimed and excluded from this sale.

This Warranty is not valid unless registered with Great Plains Manufacturing, Incorporated within 10 days from the date of original purchase.

2700 and 3000 Three-Point Drill 118-365M-A 9/9/10

30

Page 33

Great Plains Manufacturing, Inc.

Corporate Office: PO. Box 5060

Salina, Kansas 67402-5060 USA

Loading...

Loading...