Page 1

Great Plains Mfg., Inc.

Manufacturing, Inc.

Seed and Small Seeds Rate

Charts

The following pages are to assist in the proper setting of seeding rates

for the 2700 and 3000 Three-Point drill. The rates indicated in the

charts are approximate values. To assure the most accurate seeding

rate it is recommended that the drill be calibrated for the desired seed

at the time of planting.

© Copyright 2010 Printed

9/9/2010

118-365B

Page 2

2

Table of Contents

Seeding Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Change Drive Sprockets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

To change the drive type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Set Seed-Rate Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Position Seed-Cup Doors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Check Seeding Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Small Seeds Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Seed Rate Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Small Seeds Attachment Seed Rate Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Great Plains Mfg., Inc.

118-365B 9/9/2010

Page 3

Great Plains Mfg., Inc.

Seeding Rate

Calibrating the seeding rate requires four steps: arranging

the drive sprockets, setting the seed-rate adjustment handle, positioning the seed-cup door, and checking the

seeding rate.

Refer to the seed-rate charts starting on page 6. These

charts list the proper sprocket sizes and seed-rate-handle

settings for various seeds and seeding rates.

The seed-rate charts are based on cleaned, untreated

seed of average size and test weight. The rates are based

on 9.5L x 15 rib implement tires. Many factors will affect

seeding rates including foreign material, seed treatment,

seed size, field conditions, tire pressure and test weight.

Minor adjustments likely will be needed. Set and check

the seeding rate using the procedures below, then re-adjust the rate as necessary.

Before setting the seeding rate, rotate the drive gauge

wheel to see that seed cups and drive are working properly and free from foreign material.

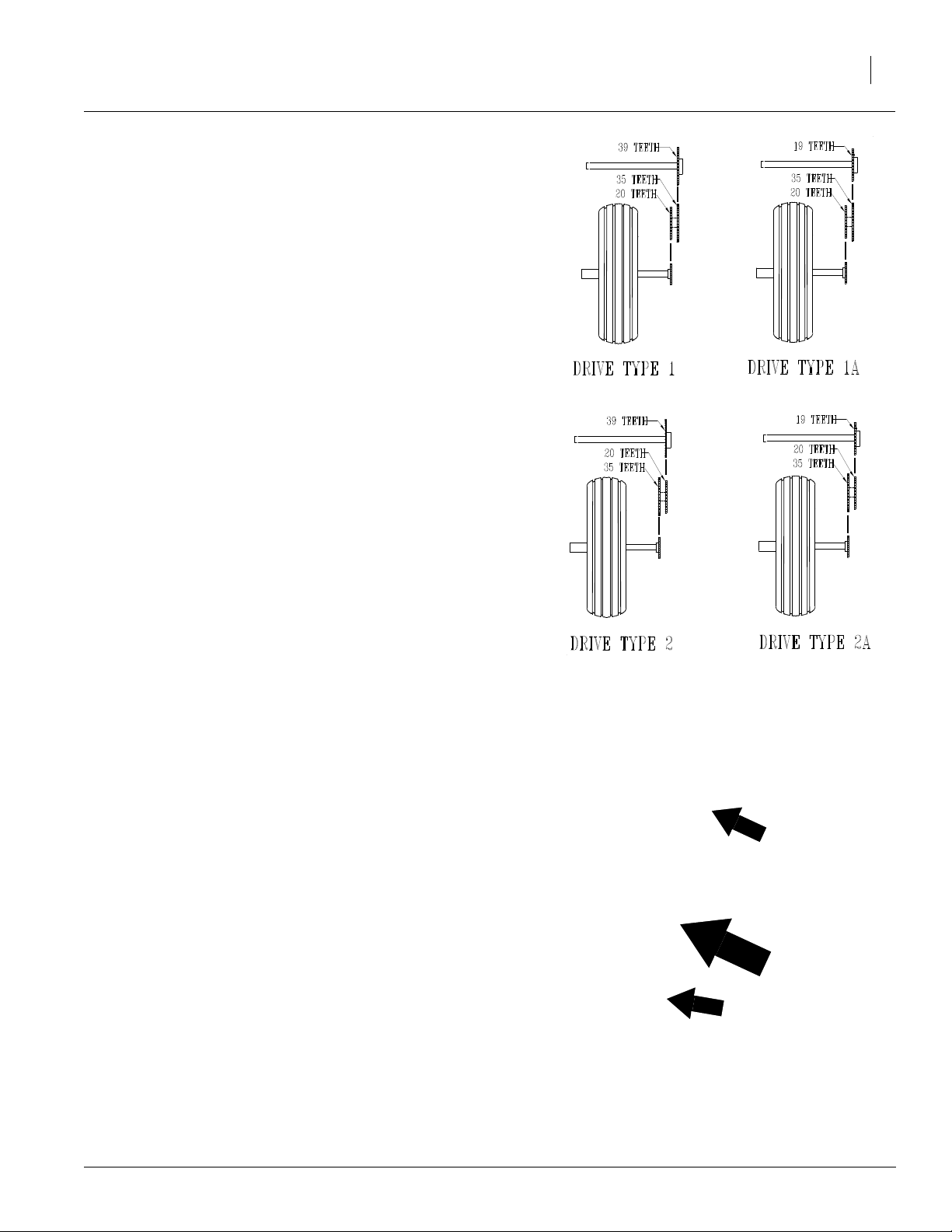

Change Drive Sprockets

Refer to Figure 1

3

Refer to the seed-rate charts for the correct drive

type–1, 1A, 2 or 2A.

To change the drive type

Refer to Figure 2

1. Loosen the idler-arm bolts and remove chains.

2. To change the double speed-change sprocket, remove nut and turn sprocket over.

16400

Figure 1

Drive Types

Idler

Spr

oc

ket

Idler

16409

9/9/2010

Figure 2

Double Speed-Change Sprocket

118-365B

Page 4

4

Refer to Figure 3

3. To change the jackshaft sprocket, remove the set

screws and slide the sprockets so the correct-sized

sprockets are aligned. Reinsert set screws.

Great Plains Mfg., Inc.

16412

Refer to Figure 4

4. Shorten orlengthen chainsas necessary and reinstall

chains. Be sure chain is installed with the chain connector link retainer towards the centerline and the clip

opening (split end) is facing the opposite way of the

chain travel. Move the idler arms into chains. See Figure 4 for correct chain slack.

Set Seed-Rate Handle

Refer to Figure 5

5. The position the handle for each drill box to the setting

indicated on the chart. One handle is shown. To adjust

the handles, loosen the wing nut under the handles

and slide until the indicator lines up with the correct

setting.

Figure 3

Jackshaft Sprocket

1/2

3/4

Figure 4

Chain Slack

In.

In.

16409

12927

Figure 5

Seed-Rate Handle

118-365B 9/9/2010

Page 5

Great Plains Mfg., Inc.

5

Position Seed-Cup Doors

Refer to Figure 6

For wheat and other small seeds. move the seed-cupdoor handles to the highest position. For soybeans

and other large seeds, lower the handles to the second position. If excessive seed cracking occurs, lower

the handles to the third position. Move the handles to

the fourth, wide-open position for seed-cup clean out.

Make sure all handles are in the same position before

drilling.

13867

Figure 6

Seed-Cup-Door Handle

Check Seeding Rate

1. Record the weight of an empty container large enough

to hold the seed metered for one acre.

2. Place several pounds of seed over three seed cups on

an outside end of the drill box. Pull the seed tubes off

these three openers.

3. Raise the drill off the ground.

4. Turn the gauge wheel a few turns to fill the cups with

seed. Turn wheel until seed drops to the ground from

all three cups.

5. Place a container under the three seed tubes to gather the seed as it is metered.

6. Turn the drive gauge wheel until one acre has been

tallied on the acremeter (200 rotations on a 27-foot

drill or 182 rotations on a 30-foot drill). Check that

the three seed cups have plenty of seed coming into

them.

7. Weigh the metered seed. Subtract the initial weight

of the empty container. Divide by three for the

amount metered by each seed cup, then multiply by

the number of drill openers for the pounds-per-acre

seeding rate. If this figure is different than desired,

adjust the seed-rate handle and recheck the rate.

Note: If your results vary greatly from the charts, you

may want to repeat the calibration procedure.

When satisfied with the rate, set the same seeding rate

on the opposite drill box by repeating steps 1 through 3.

Small Seeds Attachment

To calibrate the seeding rate on the optional small seeds

attachment, follow these steps.

Refer to Figure 7

1. The proper small-seeds sprocket arrangement given different drive types on the main drill box. Arrange the sprockets on the small-seeds attachment

according to which drive type you will use on the

main drill box.

Note: For accurate metering on the small seeds attachment, the main drill box sprockets must be set to drive

type 1, 2 or 2A.

2. Set the seed-rate adjustment handle on the small

seeds attachment as indicated by the chart on

Small Seeds Attachment Seed Rate Chart, page 9.

3. Calibrate the small seeds attachment to your material by following the steps under Check Seeding

Rate, page 5.

Figure 7

Small Seeds Sprocket Arrangements

16399

118-365B9/9/2010

Page 6

6

Seed Rate Charts (pounds per acre)

Great Plains Mfg., Inc.

Setting number

Wheat

Drive

Type 1

Based on

60 lb/bu

Wheat

Drive

Type 2A

Based on

60 lb/bu

Rice,

Short

Grain

Drive

Type 1

Rice,

Short

Grain

Drive

Type 1A

Rice,

Long

Grain

Drive

Type 1

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

6" 0 11 20 28 37 47 55 65 75 85 96 106 116 129 140 153 161 170 175 184 189

7" 0 10 17 24 32 40 48 56 65 73 83 92 100 111 121 132 140 147 152 159 164

7.5" 0 9 16 23 29 37 44 52 60 68 77 85 93 103 112 122 129 136 140 147 152

8" 0 8 15 21 27 34 40 48 55 62 70 78 85 94 103 112 118 124 129 135 139

10" 0 7 12 17 22 28 33 39 45 51 58 64 70 77 84 92 97 102 105 110 114

Row Spacing

6" 0 8 13 19 25 31 37 44 50 57 64 71 78 86 94 102 108 114 117 123 127

7" 0 7 11 16 21 27 32 38 44 46 56 62 67 75 81 89 94 99 102 107 110

7.5" 0 6 11 15 20 25 30 35 40 45 52 57 62 69 75 82 86 91 94 99 102

8" 0 6 10 14 18 23 27 32 37 42 47 52 57 63 69 75 79 83 86 90 93

10"0 5 8 111519222630343943475256616568707476

Row Spacing

6" 0 7 13 18 23 30 35 42 46 51 57 62 66 74 83 90 98 103 107 112 115

7" 0 6 11 16 20 26 31 36 39 44 49 54 57 64 72 78 85 90 93 97 100

7.5" 0 6 10 14 19 24 28 33 36 41 45 50 53 59 66 72 78 83 85 90 92

8" 0 5 9 13 17 22 26 31 33 37 41 46 49 55 61 66 72 76 78 82 85

10"0 4 8 111418212527313437404550545962646769

Row Spacing

6" 0 15 26 37 48 61 73 85 93 104 116 128 136 153 169 185 201 212 219 230 237

7" 0 13 23 32 42 53 63 74 81 91 101 111 118 132 147 160 175 184 190 199 205

7.5" 0 12 21 30 39 49 58 68 75 84 93 103 109 122 136 148 161 170 175 184 189

8" 0 11 19 27 35 45 53 63 69 77 85 94 100 112 124 136 148 156 161 169 174

10" 0 9 16 22 29 37 44 51 56 63 70 77 81 92 102 111 121 127 132 138 142

Row Spacing

6" 0 6 10 15 20 25 29 34 39 44 49 54 58 64 73 79 85 91 93 97 100

7" 0 5 9 13 17 21 25 30 34 38 42 47 50 56 63 69 74 78 81 84 87

7.5" 0 5 8 12 16 20 23 28 31 35 39 43 46 51 59 63 98 72 74 78 80

8" 0 4 8 11 14 18 21 25 29 32 36 40 42 47 54 58 63 66 68 71 74

10" 0 4 6 9 12 15 17 21 23 26 29 32 35 39 44 47 51 54 56 58 60

Row Spacing

Rice,

Long

Grain

Drive

Type 1A

Barley

Drive

Type 1

Based on

46.4 lb/bu

Oats or

Safflower

Drive

Type 1

Based on

39 lb/bu

Rye

Drive

Type 2

6" 0 12 21 31 40 50 60 71 80 91 100 110 119 132 150 162 175 185 191 200 206

7" 0 11 19 27 35 44 52 61 69 78 87 96 103 114 130 141 152 160 165 173 179

7.5" 0 10 17 25 32 40 48 57 64 72 80 89 95 105 120 130 140 148 153 160 165

8" 0 9 16 23 29 37 44 52 59 66 74 81 87 97 110 119 129 135 140 146 151

10’ 0 7 13 18 24 30 36 42 48 54 60 66 71 79 90 97 105 111 115 120 124

Row Spacing

6" 0 0 7 142027333944505562687582889399102105107

7’ 0 0 6 12 18 23 28 34 38 44 48 54 59 65 71 76 81 86 88 91 93

7.5" 0 0 6 11 16 21 26 31 36 40 44 50 55 60 66 70 75 79 81 84 86

8" 0 0 5 10 15 20 24 28 33 37 40 46 50 55 60 64 68 73 75 77 79

10" 0 0 4 8 12 16 20 23 27 30 33 37 41 45 49 53 56 59 61 63 64

Row Spacing

6" 0 4 8 1419253137445157647176839096102107112116

7" 0 4 7 12 16 22 27 32 38 44 49 55 61 66 72 78 83 88 93 97 100

7.5" 0 3 7 11 15 20 25 29 35 41 45 51 57 61 67 72 77 81 85 89 93

8" 0 3 6 10 14 19 23 27 32 37 41 47 52 56 61 66 70 75 78 82 85

10" 0 3 5 8 11 15 19 22 26 31 34 38 42 46 50 54 58 61 64 67 70

Row Spacing

6" 0 3 6 8 11 14 16 18 20 23 25 28 30 33 36 38 40 42 43 46 47

7" 0 3 5 7 9 12 13 16 18 20 22 24 26 29 31 33 35 36 38 40 41

7.5" 0 3 5 7 9 11 12 14 16 18 20 22 24 27 29 31 32 34 35 36 38

8" 0 2 4 6 8 10 11 13 15 17 19 20 22 24 26 28 29 31 32 33 34

10"0 2 4 5 7 8 9 1112141517182021232425262728

Row Spacing

9/9/2010

118-365B

Page 7

Great Plains Mfg., Inc.

7

Setting number

Millet

Drive

Type 2

Buckwheat

Drive

Type 1

Flax or

Sudan

Drive

Type 2

Sunflow-

ers

Drive

Type 2

Based on

28.9 lb/bu

Soybeans

Drive

Type 1

Based on

59.1 lb/bu

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

6" 0 3 5 7 10 12 15 18 21 24 26 30 32 36 39 43 47 50 52 53 53

7" 0 2 4 6 8 11 13 16 18 21 23 26 28 31 34 37 40 43 45 46 46

7.5" 0 2 4 6 8 10 12 14 17 19 21 24 26 29 31 34 37 40 42 42 42

8" 0 2 3 5 7 9 11 13 15 17 19 22 24 26 29 31 34 36 38 39 39

10"0 2 3 4 6 7 9 1113141618192123262830313232

Row Spacing

6" 0 8 14 20 26 33 40 47 55 62 70 77 85 94 102 111 118 124 128 134 138

7" 0 7 12 17 22 29 34 40 47 54 61 67 73 81 88 97 102 107 111 116 120

7.5" 0 6 11 16 21 26 32 37 44 50 56 62 68 75 82 89 94 99 102 107 111

8" 0 6 10 15 19 24 29 34 40 45 51 57 62 69 75 82 86 91 94 98 101

10"0 5 8 121520242833374246515661677174778083

Row Spacing

6" 0 2 4 6 9 12141619212426293235384245474748

7" 0 2 3 5 8 10 12 14 16 18 21 23 25 28 30 33 36 39 41 41 41

7.5" 0 2 3 5 7 9 11 13 15 17 19 21 23 26 28 30 33 36 37 38 38

8" 0 1 3 5 7 9 10 12 14 16 17 19 21 23 26 28 31 33 34 35 35

10" 0 1 2 4 5 7 8 10 11 13 14 16 18 19 21 23 25 27 28 28 29

Row Spacing

6" 0 0 0 2 3 4 6 8 9 11 14 15 17 19 20 23 24 26 27 28 29

7" 0 0 0 2 3 3 5 7 8 10 12 13 15 16 18 20 21 22 23 24 25

7.5" 0 0 0 1 3 3 56891112141516181921212223

8" 0 0 0 1 2 3 5 6 7 8 10 11 12 14 15 17 18 19 20 20 21

10"000123456789101112141415161717

Row Spacing

6" 0 0 0 0 30 40 55 70 84 98 113 127 140 154 166 176 188 200 204 207 209

7" 0 0 0 0 26 35 48 61 72 85 98 110 122 133 144 153 163 173 177 180 181

7.5" 0 0 0 0 24 32 44 56 67 79 91 101 112 123 132 141 150 160 164 166 167

8" 0 0 0 0 22 30 40 51 61 72 83 93 103 113 121 129 138 147 150 152 153

10" 0 0 0 0 18 24 33 42 50 59 68 76 84 92 99 106 113 120 123 124 125

Row Spacing

Soybeans

Drive

Type 2

Based on

59.1 lb/bu

Soybeans

Drive

Type 2A

Based on

59.1 lb/bu

Peas

Drive

Type 1

Pinto

Beans

Drive

Type 2

Based on

60 lb/bu

6" 0 0 0 0 10 13 18 23 27 32 37 41 46 50 54 57 61 65 67 68 68

7" 0 0 0 0 8 11 16 20 24 28 32 36 40 43 47 50 53 57 58 59 59

7.5" 0 0 0 0 8 11 14 18 22 26 30 33 37 40 43 46 49 52 53 54 55

8" 0 0 0 0 7 10 13 17 20 24 27 30 34 37 40 42 45 48 49 50 50

10" 0 0 0 0 6 8 11 14 16 19 22 25 27 30 32 34 37 39 40 41 41

Row Spacing

6" 0 0 0 0 20 27 37 47 56 66 76 85 94 103 111 118 126 134 137 139 140

7" 0 0 0 0 17 23 32 41 49 57 66 73 81 89 96 103 110 116 119 121 122

7.5" 0 0 0 0 16 22 30 37 45 53 61 68 75 82 89 95 101 107 110 111 112

8" 0 0 0 0 15 20 27 34 41 48 56 62 69 75 82 87 93 98 101 102 103

10" 0 0 0 0 12 16 22 28 34 40 45 51 56 62 67 71 76 80 82 84 84

Row Spacing

6" 0 0 10 26 41 55 70 82 95 110 123 135 150 163 176 189 204 215 227 235 241

7" 0 0 8 23 35 48 61 71 82 96 107 117 130 141 152 164 177 186 197 204 209

7.5" 0 0 8 21 33 44 56 66 76 88 99 108 120 130 140 151 163 172 182 188 193

8" 0 0 7 19 30 40 51 60 69 81 90 99 110 120 129 139 149 158 167 172 177

10" 0 0 6 16 24 33 42 49 57 66 74 81 90 98 105 113 122 129 136 141 145

Row Spacing

6" 0 0 0 4 7 12162024283236414448535660636465

7" 0 0 0 3 6 10 14 18 21 24 27 31 35 38 42 46 49 52 55 55 56

7.5" 0 0 0 3 6 9 13 16 19 22 25 29 32 35 39 42 45 48 50 51 52

8" 0 0 0 3 5 9 12 15 18 20 23 27 30 32 35 39 41 44 46 47 47

10" 0 0 0 2 4 7 10 12 14 17 19 22 24 27 29 32 34 36 38 38 39

Row Spacing

9/9/2010

118-365B

Page 8

8

Great Plains Mfg., Inc.

Setting number

Alfalfa or

Rape

Drive

Type 2

Milo

Drive

Type 2

Based on

62.4 lb/bu

Wheat

Grass

Drive

Type 2

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

6" 0 4 6 8 11 14 17 20 23 26 29 32 35 37 40 42 45 47 50 52 54

7" 0 3 5 7 10 13 15 18 20 23 25 28 30 32 34 37 39 41 43 45 46

7.5" 0 3 5 7 9 12 14 16 18 21 23 26 28 30 32 34 36 38 40 41 43

8" 0 3 4 6 8 11 13 15 17 19 22 24 26 27 29 31 33 35 36 38 39

10" 0 2 3 5 7 9 10 12 14 16 18 19 21 22 24 25 27 28 30 31 32

Row Spacing

6" 0 3 5 8 12 15 18 21 24 27 30 34 37 41 45 49 54 57 60 60 61

7" 0 2 4 7 10 12 15 18 21 24 26 29 32 36 39 42 46 50 52 52 53

7.5" 0 2 4 6 9 11 14 16 19 22 24 27 30 33 36 39 43 46 48 48 49

8" 0 2 3 6 8 10 13 15 18 20 22 25 27 30 33 36 39 42 44 44 45

10" 0 2 3 5 7 9 11 12 14 16 18 20 22 25 27 29 32 34 36 36 37

Row Spacing

6" 0 1 2 2 3 4 4 5 6 7 8 9 9 1011121314141515

7" 0 1 1 2 3 3 4 5 5 6 7 8 8 9 10 11 11 12 12 13 13

7.5" 0 1 1 2 2 3 4 4 5 6 6 7889101011111212

8" 0 1 1 2 2 3 3 4 4 5 6 6 7 8 8 9 10 10 10 11 11

10"011122334455667788999

Row Spacing

118-365B 9/9/2010

Page 9

Great Plains Mfg., Inc.

Small Seeds Attachment Seed Rate Chart (pounds per acre)

Setting number 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Kentucky Blue

Grass, Fes-

cue, Annual

Rye Grass

6" 0 .2 1.2 1.9 2.7 3.3 4.1 4.6 5.2 5.8 6.3 6.8 7.3 7.8 8.3 8.8 9.2 9.7 10.0 10.5

7" 0 .2 1.0 1.6 2.3 2.8 3.5 4.0 4.5 5.0 5.4 5.9 6.3 6.7 7.1 7.5 7.9 8.0 8.6 9.0

7.5" 0 .2 .9 1.5 2.2 2.7 3.3 3.7 4.2 4.6 5.1 5.5 5.9 6.3 6.7 7.0 7.4 7.7 8.1 8.4

8" 0 .2 .9 1.4 2.0 2.5 3.0 3.5 3.9 4.3 4.8 5.1 5.5 5.9 6.2 6.6 6.9 7.5 7.5 7.9

Row Space

10" 0 .1 .7 1.1 1.6 2.0 2.4 2.7 3.1 3.4 3.7 4.0 4.3 4.6 4.9 5.2 5.4 5.7 5.9 6.2

9

Ladino Clo-

ver, Canary

Grass, Timo-

thy, Canola

Bermuda, Red

Top, Unhulled

Lespedeza,

Sercia, Sand &

Weeping Love

Grass

Red & Sweet

Clover, Lespe-

deza Hulled

Bird’s-foot Tre-

foil, Sudan

Orchard Grass

6" 0 1.1 2.1 3.3 4.7 6.1 7.6 9.2 10.7 12.2 13.8 15.5 17.0 18.5 20.3 21.7 23.4 25.4 27.3 29.2

7" 0 .9 1.7 2.8 4.1 5.2 6.6 7.9 9.2 10.5 11.8 13.3 14.6 15.9 17.4 18.7 20.0 22.0 23.4 25.1

7.5" 0 .9 1.6 2.6 3.9 4.9 6.1 7.4 8.6 9.8 11.1 12.5 13.7 14.9 16.3 17.6 18.8 20.4 21.9 23.5

8" 0 .8 1.5 2.5 3.6 4.6 5.7 6.9 8.0 9.2 10.3 11.6 12.8 13.9 15.2 16.4 17.5 19.0 20.5 21.9

Row Space

10" 0 .6 1.5 1.9 2.5 3.6 4.5 5.4 6.3 7.2 8.1 9.1 10.0 10.9 12.0 12.9 13.8 14.9 16.1 17.2

6" 0 .7 1.1 1.7 2.6 3.3 4.1 5.0 5.9 6.6 7.2 7.8 8.4 9.0 9.5 10.2 10.9 11.6 12.2 12.9

7" 0 .6 .9 1.5 2.2 2.8 3.6 4.3 5.1 5.6 6.2 6.7 7.1 7.7 8.1 8.7 9.4 10.0 10.5 11.0

7.5" 0 .5 .9 1.4 2.1 2.6 3.3 4.0 4.7 5.3 5.8 6.3 6.7 7.2 7.6 8.2 8.8 9.3 9.8 10.4

8" 0 .5 .8 1.3 2.0 2.5 3.1 3.8 4.4 4.9 5.4 5.9 6.5 6.7 7.1 7.6 8.2 8.7 9.2 9.7

Row Space

10" 0 .4 .6 1.0 1.5 1.9 2.4 3.0 3.5 3.9 4.2 4.6 4.9 5.3 5.6 6.0 6.4 6.8 7.2 7.6

6" 0 1.5 3.4 5.2 7.1 9.0 11.3 13.2 15.3 17.0 19.0 20.8 22.5 24.5 26.4 28.3 30.1 32.1 33.8 35.6

7" 0 1.3 2.9 4.5 6.1 7.7 9.7 11.3 13.1 14.6 16.3 17.8 19.3 21.0 22.7 24.6 25.8 27.5 29.0 30.5

7.5" 0 1.2 2.7 4.2 5.7 7.2 9.1 10.6 12.3 13.7 15.3 16.7 18.1 19.7 21.2 22.7 24.2 25.8 27.2 28.6

8" 0 1.1 2.5 3.9 5.3 6.7 8.5 9.9 11.5 12.8 14.3 15.6 16.9 18.3 19.8 21.2 22.6 24.1 25.4 26.7

Row Space

10" 0 .9 2.0 3.1 4.2 5.3 6.7 7.8 9.0 10.0 11.2 12.2 13.3 14.4 15.6 16.6 17.8 18.9 19.9 20.9

6" 0 1.7 3.3 5.2 6.8 8.7 10.7 12.7 14.7 16.8 19.2 21.2 23.4 25.6 28.0 29.9 32.1 34.2 36.3 38.4

7" 0 1.5 2.8 4.5 5.8 7.5 9.2 10.9 12.5 14.4 16.5 18.2 20.0 21.9 24.0 25.6 27.5 29.0 31.1 32.9

7.5" 0 1.4 2.6 4.2 5.4 7.0 8.6 10.2 11.9 13.5 15.4 17.0 18.8 20.5 22.5 24.0 25.8 27.6 29.1 30.9

8" 0 1.3 2.5 3.9 5.1 6.6 8.1 9.5 11.0 12.6 14.4 15.9 17.5 19.2 21.0 22.4 24.1 25.7 27.2 28.8

Row Space

10" 0 1.0 1.9 3.1 4.0 5.1 6.3 7.5 8.6 9.9 11.3 12.5 13.8 15.1 16.5 17.6 18.9 20.2 21.4 22.7

6" 0 0 .3 .7 .9 1.3 1.5 2.0 2.4 2.8 3.3 3.5 3.9 4.4 4.8 5.0 5.5 5.7 6.1 6.3

7" 0 0 .2 .6 .7 1.1 1.3 1.7 2.1 2.4 2.8 3.0 3.4 3.7 4.1 4.3 4.7 5.0 5.2 5.4

7.5" 0 0 .2 .5 .7 1.1 1.2 1.6 1.9 2.3 2.6 2.8 3.2 3.5 3.9 4.0 4.4 4.6 4.9 5.1

8" 0 0 .2 .5 .7 1.0 1.1 1.5 1.8 2.1 2.5 2.6 2.9 3.3 3.6 3.8 4.1 4.3 4.6 4.8

Row Space

10" 0 0 .1 .4 .5 .8 .9 1.2 1.4 1.7 1.9 2.1 2.3 2.6 2.8 3.0 3.2 3.3 3.6 3.7

Millet, Reed

Canary

Alfalfa, Red

Alsike, Crim-

son Clover

9/9/2010

6" .4 1.4 2.4 3.5 4.4 5.5 6.5 7.5 8.5 9.5 10.5 11.5 12.5 13.6 14.6 15.6 16.6 17.6 18.5 19.0

7" .4 1.2 2.1 3.0 3.8 4.7 5.6 6.4 7.3 8.1 9.0 9.9 10.7 11.6 12.5 13.3 14.2 15.1 15.9 16.1

7.5" .3 1.2 2.0 2.8 3.6 4.4 5.2 6.0 6.8 7.6 8.4 9.3 10.1 10.9 11.7 12.5 13.3 14.1 14.9 15.1

8" .3 1.1 1.8 2.6 3.3 4.1 4.9 5.6 6.4 7.1 7.9 8.6 9.4 10.2 10.9 11.7 12.4 13.2 13.9 14.1

Row Space

10" .3 .8 1.4 2.0 2.6 3.2 3.8 4.4 5.0 5.6 6.2 6.8 7.4 8.0 8.6 9.2 9.8 10.4 10.9 11.5

6" 0 2.2 3.5 4.8 6.0 7.5 8.7 9.8 11.2 12.5 13.8 15.1 16.4 17.5 18.6 20.2 21.4 22.9 24.0 25.2

7" 0 1.9 3.0 4.1 5.1 6.4 7.5 8.4 9.5 10.8 11.8 12.9 14.0 15.0 16.3 17.3 18.3 20.0 20.6 21.6

7.5" 0 1.8 2.8 3.9 4.8 6.0 7.0 7.9 9.0 10.0 11.1 12.1 13.2 14.0 15.3 16.2 17.2 18.3 19.3 20.3

8" 0 1.6 2.6 3.6 4.5 5.6 6.6 7.4 8.4 9.4 10.3 11.3 12.3 13.0 13.1 15.2 16.1 17.1 18.0 18.9

Row Space

10" 0 1.3 2.1 2.8 3.5 4.4 5.1 5.8 6.6 7.4 8.1 8.9 9.7 10.3 11.2 11.9 12.6 13.4 14.2 14.9

118-365B

Loading...

Loading...