Page 1

Operator’ s Manual

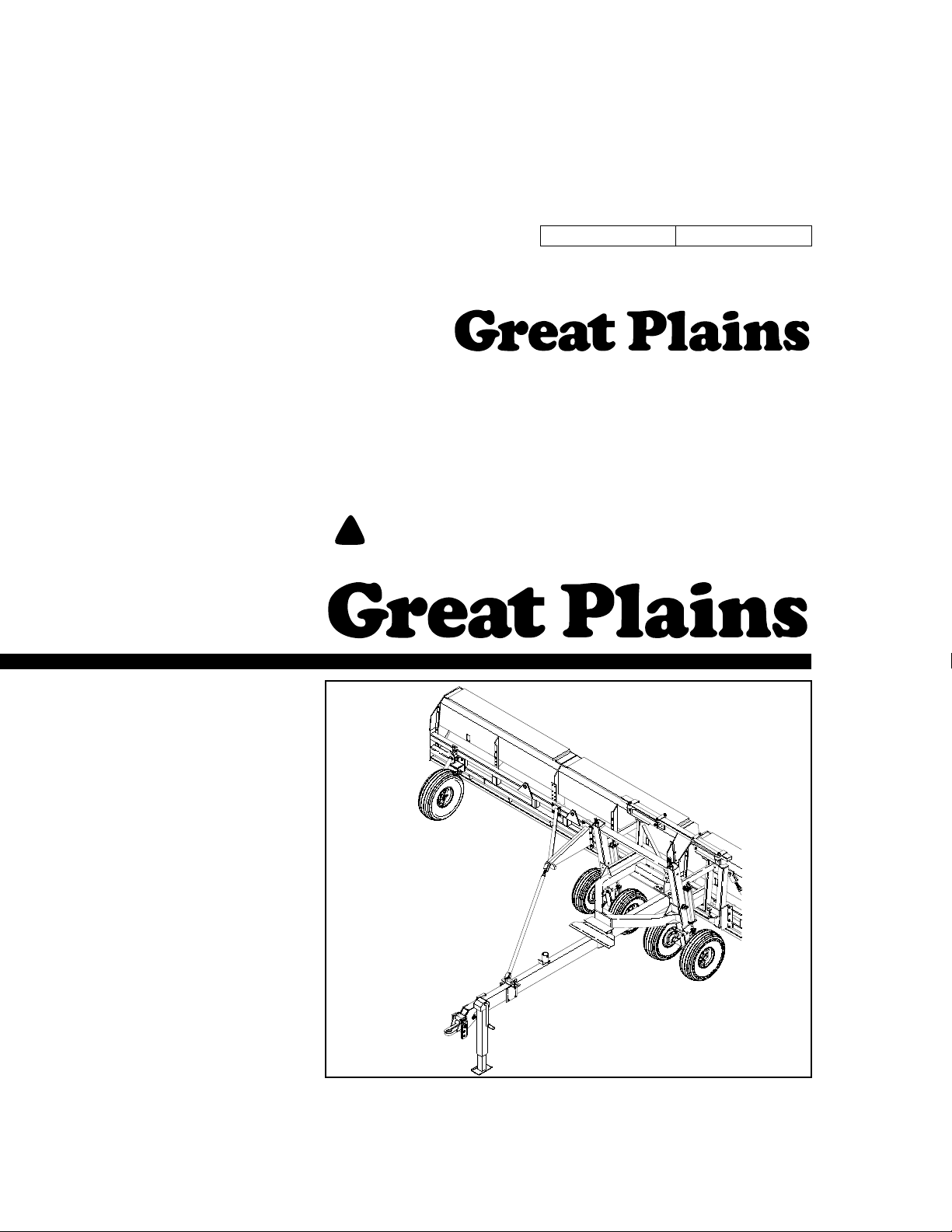

30-Foot, Folding, Soybean Machine

Model Serial No.

2SBD30 A1029+

Manufacturing, Inc.

www .g reatplainsmfg.com

Read the operator’s manual entirely. When you see this symbol, the subsequent in-

!

structions and warnings are serious -follow without exception. Your life and thelivesof

others depend on it!

2SBD30

© Copyright 1999 Printed 5/3/2005

12632

Cover illustration may show optional equipment not supplied with standard unit.

173-086M

Page 2

General Information

General Information

Important Notice

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either

expressed or implied, while every precaution has been

taken in the preparation of this manual, Great Plains

Manufacturing,Inc. assumes no responsibility for errors

oromissions.Neither is any liability assumed for damages resulting from the use of the information contained

herein. Great Plains Manufacturing, Inc. reserves the

righttoreviseand improveitsproductsasitseesfit.This

This Operators Manual applies to the 30’ 2-Section

Folding Soybean Machine:

Owner’s Information

publicationdescribesthe state of this product atthetime

of its publication, and may not reflect the product at all

times in the future.

Printed in the United States of America.

For your convenience, record your Serial Number,Mod-

el Number and the Date Purchased in the spaces

provided below. Have this information before you when

calling a Great Plains Authorized Dealer.

Name: _____________________________________

Address ____________________________________

City________________State ____ Zip

Phone_______________________

Name of Dealership ___________________________

Dealer’s Name _______________________________

Address ____________________________________

City________________State ____ Zip

Phone_______________________

Serial Number ________________

Model Number________________

Date Purchased_______________

2SBD30 30-Foot, Folding, Soybean Machine 173-086M 5/3/05Great Plains Mfg., Inc.

Page 3

Table of Contents

Table of Contents

General Information. . . . . . . . . . . . . . . . . . . . . . . . . 0

Owner’s Information. . . . . . . . . . . . . . . . . . . . . . . 0

Table of Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Using this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General Operation & Repair . . . . . . . . . . . . . . . . 3

Transporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Tire Handling & Repair . . . . . . . . . . . . . . . . . . . . 3

Safety Decals. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Section 1 Safety Rules. . . . . . . . . . . . . . . . . . . . . . . 3

Section 2 Assembly Instructions & Set-Up . . . . . . 7

Tire Inflation Chart. . . . . . . . . . . . . . . . . . . . . . . . 7

Torque Values Chart for UNC Threads . . . . . . . . 7

Assembly Instructions . . . . . . . . . . . . . . . . . . . . . 8

Tractor Hook-up. . . . . . . . . . . . . . . . . . . . . . . . . . 9

Tractor Hydraulic Hook-up. . . . . . . . . . . . . . . . . 10

Section 3 Hydraulics . . . . . . . . . . . . . . . . . . . . . . . 11

Bleeding The Lift Hydraulics . . . . . . . . . . . . . . . 11

Bleeding The Folding Hydraulics. . . . . . . . . . . . 11

Operating The Hydraulic System. . . . . . . . . . . . 12

Lifting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Unfolding. . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Folding . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Pull Bar Adjustment. . . . . . . . . . . . . . . . . . . . . . 14

Transporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Section 4 Seeding Adjustments . . . . . . . . . . . . . . 15

Seed Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Seed Rate Chart (Pounds per acre) . . . . . . . . . 15

Section 5 Basic Operation . . . . . . . . . . . . . . . . . . 17

Drill Preparation And Field Operations . . . . . . . 17

Transporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Preparing the Drill . . . . . . . . . . . . . . . . . . . . . . . 17

Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Opener Parallel Arms Adjustments . . . . . . . 17

Section 6 Drill & Gauge Wheel Adjustments . . . . 19

Transport Wheel Adjustments . . . . . . . . . . . . . . 19

Gauge Wheel Adjustments. . . . . . . . . . . . . . . . . 19

Down Force Row . . . . . . . . . . . . . . . . . . . . . . . . 19

Standard Spring Package . . . . . . . . . . . . . . 19

Row Unit Mounted Coulter. . . . . . . . . . . . . . . . . 20

Down Force Pressure Chart. . . . . . . . . . . . . . . . 20

Depth Adjustment. . . . . . . . . . . . . . . . . . . . . . . . 20

1 x 12 Closing Wheel Adjustments. . . . . . . . . . . 20

Closing Wheel Down Force Adjustment . . . 20

Closing Wheel Alignment. . . . . . . . . . . . . . . 21

Closing Wheel Offset. . . . . . . . . . . . . . . . . . 21

Closing Disk Adjustments. . . . . . . . . . . . . . . . . . 21

Seed Lok . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Section 7 Maintenance & Lubrication. . . . . . . . . . 23

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Upper Post Pivot. . . . . . . . . . . . . . . . . . . . . . . . . 23

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Lower Post Pivot. . . . . . . . . . . . . . . . . . . . . . . . . 23

Axle Bearings. . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Box Pivot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Feeder Cup Drive Shaft Sprocket Bearing . . . . . 24

Parallel Arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Flange Bearing. . . . . . . . . . . . . . . . . . . . . . . . . . 25

Section 8 Troubleshooting. . . . . . . . . . . . . . . . . . . 26

Section 9 Specifications . . . . . . . . . . . . . . . . . . . . 28

5/3/05 Great Plains Mfg., Inc.

2SBD30 30-Foot, Folding, Soybean Machine 173-086M

-1

Page 4

Using this Manual

Using this Manual

For your safety and to help in developinga better understanding of your equipment we highly recommend that

you read the operator sections of this manual. Reading

these sections not only provides valuable training but

also familiarizes you with helpful information and its lo-

Introduction

This manual has been prepared to instruct you in the

safeand efficient operationofyour30’ 2-Section Folding

Soybean Machine. Read and follow all instructions and

safety precautions carefully.

Read and follow all instructions and safety precautions

carefully.

The parts on your 30’ 2-Section Folding Soybean Machine have been specially designed and should only be

replaced with genuine Great Plains parts. Therefore,

should your 30’ 2-Section Folding Soybean Machine require replacement parts go to your Great Plains Dealer.

The right hand and left hand as used throughout this

manual is determined by facing in the direction the machine will travel when in use unless otherwise stated.

Serial Number

The serial number plate is located on the front of the left

hand transport axle post. It is suggested that the serial

number and purchase date also be recorded for your

convenience in the space provided.

Theserial number provides importantinformation about

your 30’ 2-Section Folding Bean Machine and may be

required to obtain the correct replacement part. Always

use the serial numberand model number when sending

correspondenceorwhenordering parts from your Great

Plains Dealer.

cation. The parts sections are for reference only and

don’trequire covertocoverreading.Afterreviewingyour

manual store it in a dry,easily accessible location for future reference.

safety precautions must be taken. When you see this

symbol, be alertand carefully read themessage that follows it. In addition to design and configuration of

equipment; hazard control and accident prevention are

dependentupon the awareness,concern,prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Watchforthe followingsafety notations through-out

your Operators Manual:

!

DANGER!

Indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury. This

signal word is limited to the most extreme situations.

!

WARNING!

Indicates a potentially hazardoussituation which, if not

avoided, could result in death or serious injury.

!

Indicates a potentially hazardoussituation which, if not

avoided, may result in minor or moderate injury.It may

also be used to alert against unsafe practices.

CAUTION!

!

The SAFETY ALERT SYMBOL indicates that there is a

potential hazard to personal safety involved and extra

2

2SBD30 30-Foot, Folding, Soybean Machine 173-086M 5/3/05

NOTE: Indicates a special point of information which

requires your attention.

Great Plains Mfg., Inc.

Page 5

Section 1 Safety Rules

Section 1 Safety Rules

Most accidents are the result of negligence and carelessness, usually caused by failure of the operator to

follow simple but necessary safety precautions. The followingsafetyprecautions are suggested to help prevent

such accidents. The safeoperation of any machinery is

a big concern to consumers and manufactures.Your 30’

2-SectionFoldingSoybeanMachinehasbeen designed

with many built-in safety features. However, no one

should operate this product beforecarefully reading this

Operators Manual.

!

General Operation & Repair

1. Never allow the 30’ 2-Section Folding Bean Machine to

be operated by anyone who is unfamiliar with the operation of all functions of the unit. All operators should read

and thoroughly understand the instructions given in this

manual prior to moving the unit.

2. Make sure safety rules are understood before operating

machinery or tractor.

3. Never permit any persons other than the operator to ride

on the tractor.

4. Never permit any persons to ride on or stand near the

drill while it is in operation.

5. Regulate your speed to the field conditions, maintaining

complete control at all times.

6. After repairing or adjusting, make sure all tools and

parts are removed from the implement before attempting

to operate it.

7. Do not grease or oil machine while it is in operation.

8. Loose fitting clothing should not be worn as it may catch

in moving parts.

9. Never dismount from a moving tractor.

10. Do not leave the tractor or the implement unattended

with the engine running.

11. Do not stand between the tractor and the implement during hitching.

12. Detach and store implements in an area where children

normally do not play. Stabilize implements by using suitable supports and block wheels.

13. If a hydraulic leak develops, correct it immediately. Escaping hydraulicoil can have extremely high pressure. A

stream of high pressure oil may easily penetrate the skin

as with modern needle-less vaccination equipment - but

with the exception that hydraulic fluid may cause blood

poisoning. It is imperative that the connections are tight

and that all lines and pipes are in good condition. If an

injury is caused by the escaping hydraulic fluid, see doctor at once!

14. Use a piece of cardboard or wood to detect leaks of hydraulic oil under pressure.

15. Be sure to relieve all hydraulic pressure before disconnection anylines or pipes between the implement and the tractor hydraulic system. Keep all guards and shields inplace.

Transporting

1. Use good judgement when transporting tractor and implements on the highway. Always maintain complete control of the machine.

2. Limit transport speed to 20 mph. Transport only with a

farm tractor of sufficient size and horse power.

3. Always make sure flashing safety lights, “Slow Moving

Vehicle” emblem, and reflectors are in place and visible

prior to transporting the machine on public roads.

4. Know your state and local laws concerning highway

safety and regulations. Comply with these laws when

transporting machinery.

5. Use warning flags or approved warning lights at night

and during other periods of poor visibility. Do your best

to prevent highway accidents.

6. Always make sure transport pins are in place to lock up

the drill in case a hydraulic hose ruptures during transport.

Tire Handling & Repair

1. Tire changing can be dangerous and should be preformed by trained personnel using the correct tools and

equipment.

2. Do not re-inflate a tire that has been run flat or seriously

under inflated. Have it checked by qualified personnel.

3. When removing and installing wheels, use wheel handling equipment adequate for the weight involved.

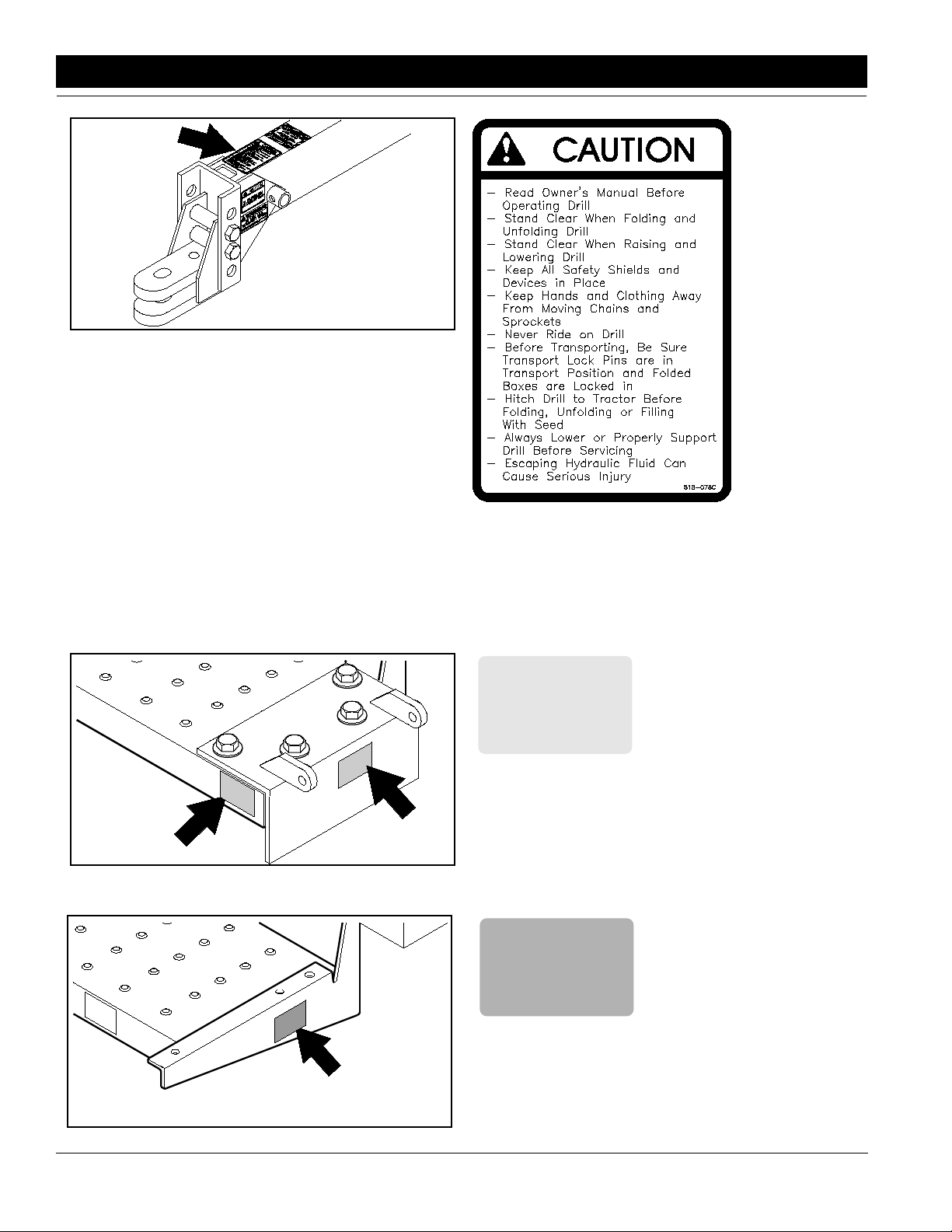

Safety Decals

1. Your 30’ 2-Section Folding Soybean Machine comes

equipped with all safety decals in place. They were designed to help you safely operate your 30’ 2-Section Folding Bean Machine. Read and follow their directions.

2. Keep safety decals clean and legible.

3. Replace all damaged or missing safety decals. To order

newsafety decals goto your Great Plains Dealerand refer

to the parts section for safety decal package part number.

4. Replace these decals whenever they become worn or unreadable. To instal new safety decals:

a. Clean the area the decal is to be placed

b. Peel backing from the decal. Press firmly on to sur-

face being careful not to cause air bubbles under the

decal.

5/3/05 Great Plains Mfg., Inc.

2SBD30 30-Foot, Folding, Soybean Machine 173-086M

-3

Page 6

Section 1 Safety Rules

12629

818-078C

General Caution

818-229C

Amber Reflectors

12476

818-230C

Red Reflector

12478

4

2SBD30 30-Foot, Folding, Soybean Machine 173-086M 5/3/05

Great Plains Mfg., Inc.

Page 7

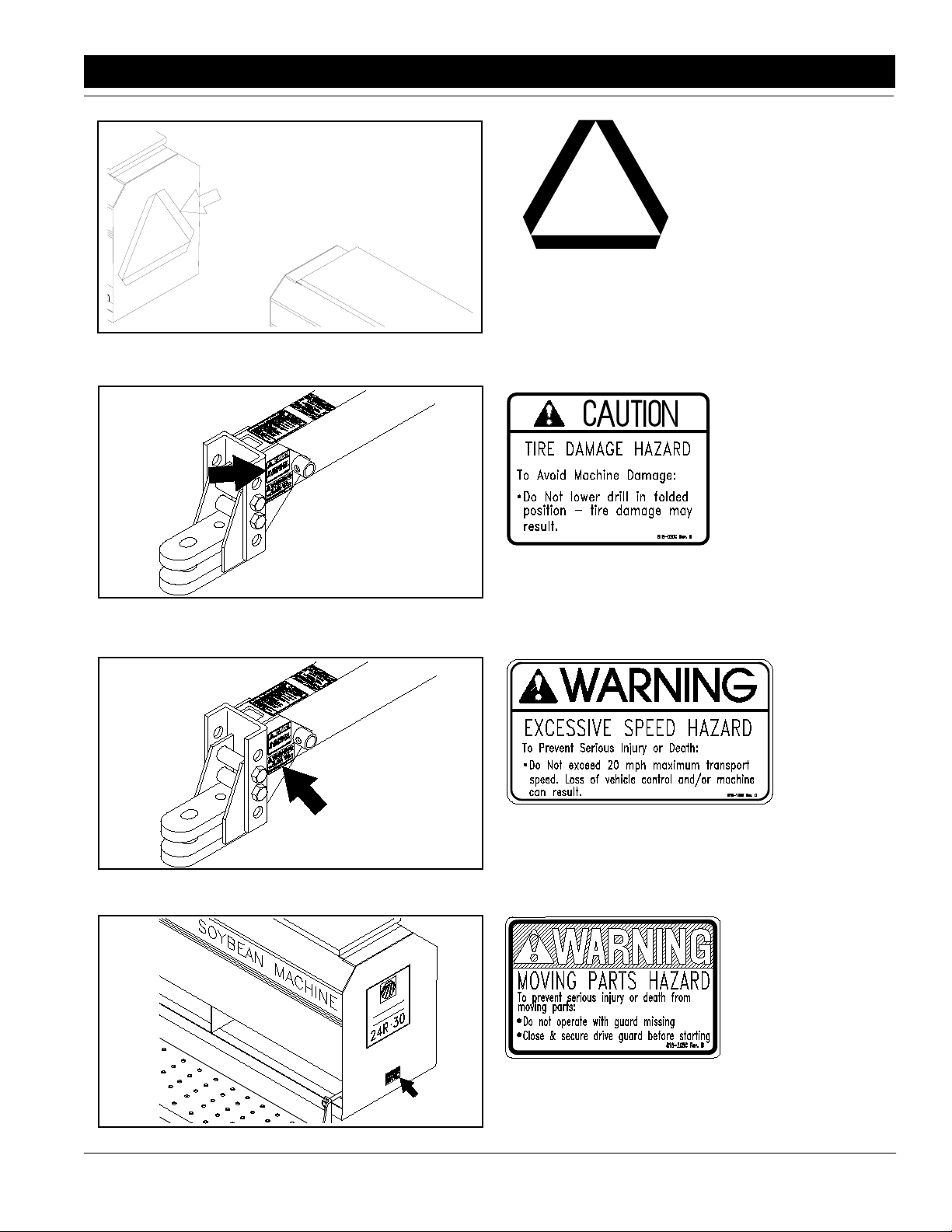

Section 1 Safety Rules

10222

818-003C

Slow Moving VehicleEmblem

12630

12631

818-020C

Caution Lowering Drill

818-188C

Transport Speed Warning

12475

5/3/05 Great Plains Mfg., Inc.

818-205C

Do Not Operate w/o Guard

in Place

2SBD30 30-Foot, Folding, Soybean Machine 173-086M

-5

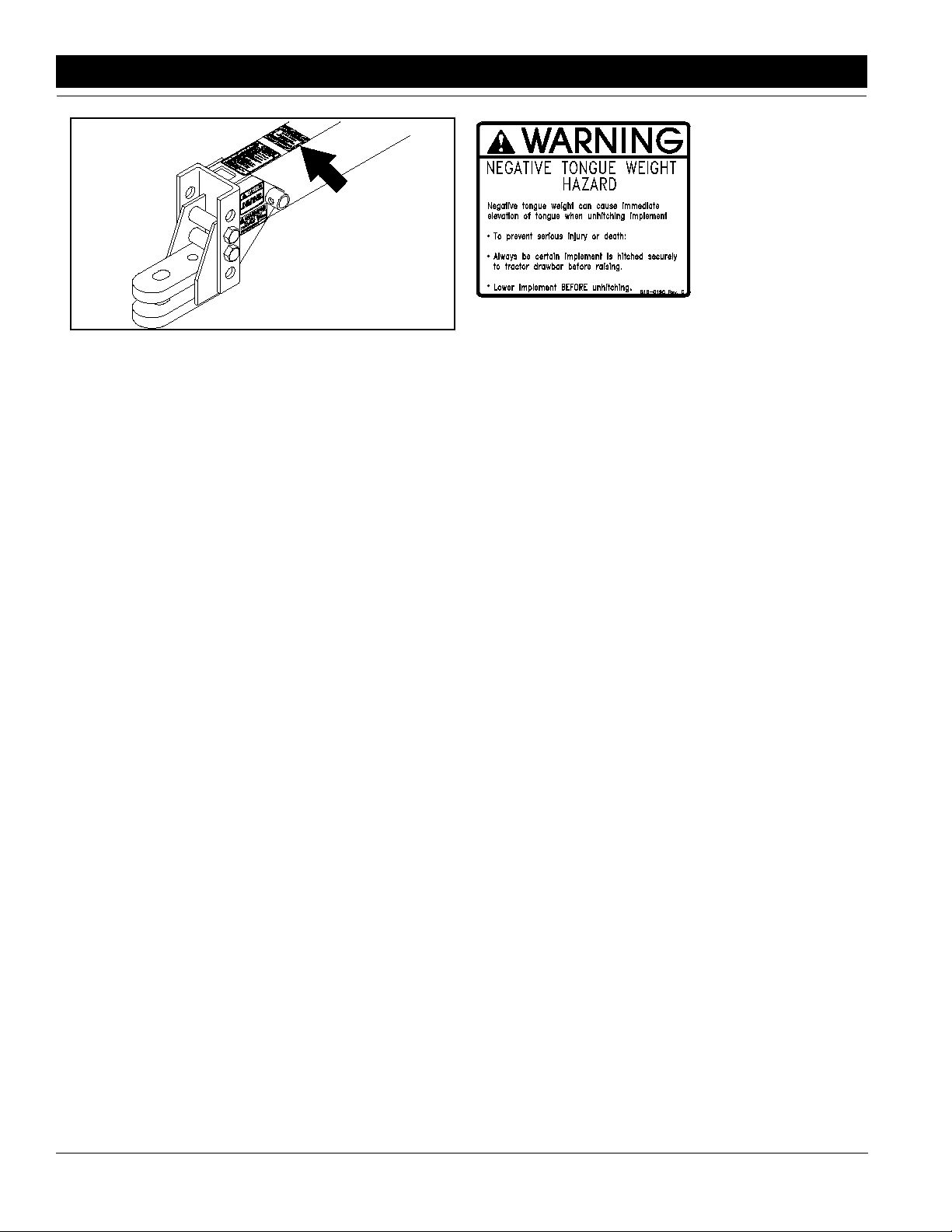

Page 8

Section 1 Safety Rules

12628

818-019C

Warning Negative Tongue Weight

6

2SBD30 30-Foot, Folding, Soybean Machine 173-086M 5/3/05

Great Plains Mfg., Inc.

Page 9

Section 2 Assembly Instructions & Set-Up

Section 2 Assembly Instructions & Set-Up

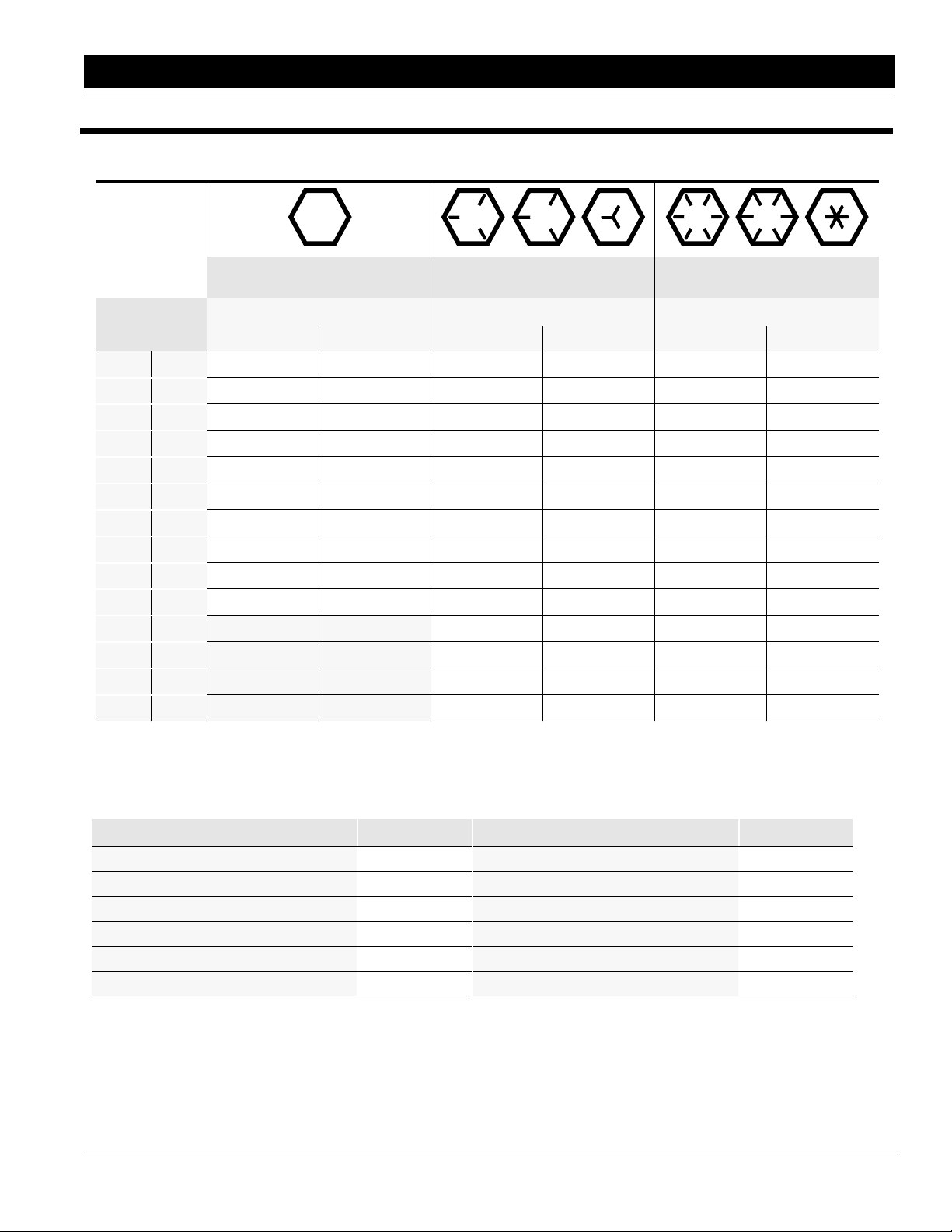

Torque Values Chart for UNC Threads

Bolt head

identification

marks are as per

grade.

NOTE: Manufacturing marks will vary.

Bolt Size

inches mm Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max.

1/4" 6.35

5/16" 7.94

3/8" 9.53

7/16" 11.11

1/2" 12.70

9/16" 14.29

5/8" 15.88

3/4" 19.05

7/8" 22.23

1" 25.40

1 1/8" 25.58

1 1/4" 31.75

1 3/8" 34.93

1 1/2" 38.10

Foot Pounds Newton-Meters Foot Pounds Newton-Meters Foot Pounds Newton-Meters

5 6 6.8 8.13 9 11 12.2 14.9 12 15 16.3 20.3

10 12 13.6 16.3 17 20.5 23.1 27.8 24 29 32.5 39.3

20 23 27.1 31.2 35 42 47.5 57.0 45 54 61.0 73.2

30 35 40.7 47.4 54 64 73.2 86.8 70 84 94.9 113.9

45 52 61.0 70.5 80 96 108.5 130.2 110 132 149.2 179.0

65 75 88.1 101.6 110 132 149.2 179.0 160 192 217.0 260.4

95 105 128.7 142.3 150 180 203.4 244.1 220 254 298.3 358.0

150 185 203.3 250.7 270 324 366.1 439.3 380 456 515.3 618.3

160 200 216.8 271.0 400 480 542.4 650.9 600 720 813.6 976.3

250 300 338.8 406.5 580 596 786.5 943.8 900 1080 1220.4 1464.5

Grade 2 Grade 5 Grade 8*

800 880 1084.8 1193.3 1280 1440 1735.7 1952.6

1120 1240 1518.7 1681.4 1820 2000 2467.9 2712.0

1460 1680 1979.8 2278.1 2380 2720 3227.3 3688.3

1940 2200 2630.6 2983.2 3160 3560 4285.0 4827.4

* Thick nuts must be used with Grade 8 bolts

NOTE: Torque requirements listed above do not apply to self-locking nuts. For self-locking nuts increase the torque requirements listed by 15%.

Tire Inflation Chart

Tire Size Inflation PSI

7.50 x 20" 4-Ply Drill Rib 28

9.0 x 22.5 10-Ply Highway Service 70 70

9.0 x 24" 8-Ply Rib Implement 40

9.5L x 15" 6-Ply Rib Implement 32

9.5L x 15" 8-Ply Rib Implement 44

9.5L x 15" 12-Ply Rib Implement 60

NOTE: All tires are warranted by the original manufacturer of the tire. Tire warranty information can be found in the

brochures included with your Operator’s and Parts Manuals or online at the manufacturer’s websites. For service assistance or information, contact your nearest Authorized Farm Tire Retailer.

Manufacturer Website

Titan www.titan-intl.com

Goodyear www.goodyearag.com

Firestone www.firestoneag.com

5/3/05 Great Plains Mfg., Inc.

Tire Size Inflation PSI

11L x 15" 6-Ply Rib Implement 28

11L x 15" 12-Ply Rib Implement 52

12.5L x 15" 8-Ply Rib Implement 36

12.5L x 15" 10-Ply Rib Implement 44

16.5L x 16.1" 10-Ply Rib Implement 36

41 x 15" x 18 - 22-Ply Rib Implement 44

2SBD30 30-Foot, Folding, Soybean Machine 173-086M

-7

Page 10

Section 2 Assembly Instructions & Set-Up

Assembly Instructions

1. Read “Section 1 Safety Rules” on page 3 before

assembling machine.

2. Setthe tongue approximately21"off the ground in a

horizontal position with stable blocking for support.

3. Raisethemain frame up,keepingthe side members

horizontal. Position the main frame over the tongue

and lower into position.

4. Secure tongue to main frame with 1"-6 x 2 1/2" long

bolts, lock washers and nuts.

5. Attach the tongue screw jack and remove blocking

so the unit is sitting on the ground.

6. Remove the safety wires from each hydraulic cylinder rod clevis between the tires and remove cylinders.See “Section 2BleedingLift Hydraulics” on

page 11.

7. Slide the hydraulic hoses from the mainframe

through the tongue and pull them out at the tractor

end. Attach tractor male couplers to the hydraulic

hoses.

8. Hook tractor up to the tongue and plug hydraulic

connectors into the tractor. With tractor running at

an idle speed, charge the machine hydraulic system. See “Section 2 Bleeding Lift Hydraulics” on

page 11. (Be sure your tractor has plenty of hydraulic fluid. This system requires approximately 3.3 gallons.)

9. Attach the gauge wheel turnbuckle to the gauge

wheel arm on each section and then mount the

wheel and tire.

10. Position the two drill boxes in line, end to end, with

the end chain drive sprockets outboard and approximately 3" between the machine boxes.

11. Using the tractor,back the machine’s main frame up

to the center of the two drill boxes. When getting

close, position the posts on each side of the main

framesothe faceofthe post mounting angles are towards the machine frames. Attach the post to the

machine frames using (16) 5/8"-11 x 1 3/4" long

bolts, (4) 5/8"-11 x 4" x 5 1/4" u-bolts, lock washers

and nuts. Tighten all the bolts and u-bolts.

12. Attach frame adjustment link from the machine

frame to the pivot post using the clevis pin with hair

pin cotters. Pin to pin centers should be adjusted to

approximately 38".

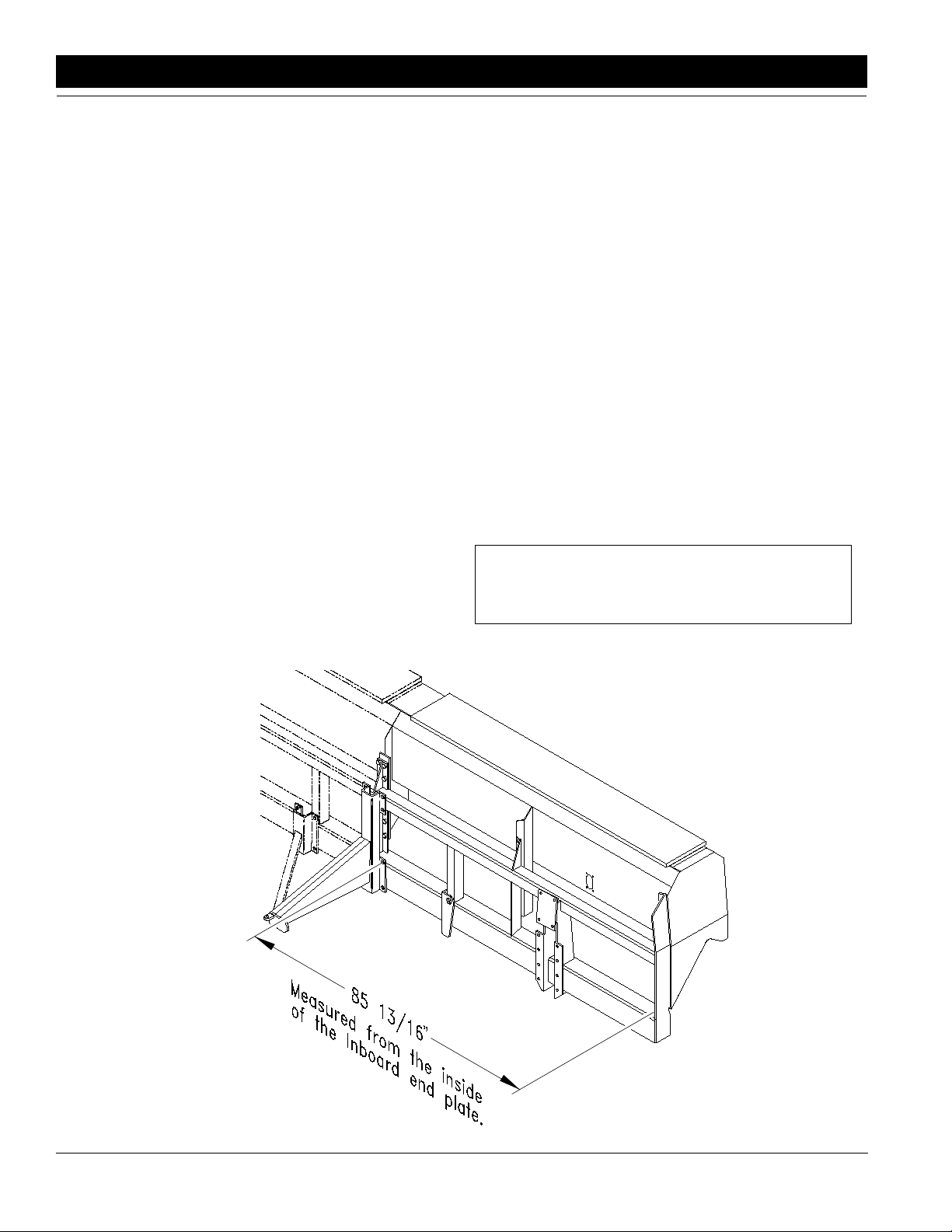

13. Locate the stabilizer frames inside mounting holes

85 13/16" from the inside of the inboard end of each

drill box frame,Figure 2-1. Using 5/8" u-bolts, 1/2" ubolts,5/8"-11 x 7" long bolts,lockwashersand nuts;

mount them to the box frame.

NOTE: One opener mounting u-bolt will be replaced

by 5/8"-11 x 7" long bolts.

10736

Stabilizer Frame

Figure 2-1

8

2SBD30 30-Foot, Folding, Soybean Machine 173-086M 5/3/05

Great Plains Mfg., Inc.

Page 11

Section 2 Assembly Instructions & Set-Up

14. Adjust clevis end of pull bars so that the distance

from the center of pull bar pin holes are approximately 134 1/4".

15. Mount pull bars to drill transport stabilizers and

tongue slide. With the tongue slide in the back position against its stop, adjust pull bar lengths so drills

are in line with one another and parallel to the back

edge of the main frame.

16. Raise the machine andplacethe transport lock pins

(2) in the transport position through the holes in the

main frame axle side tubes as shown in Figure 3-3.

17. Fold the machine, making sure that the tongue pull

bar slide moves smoothly up the tongue. When drill

boxesare almost foldedin, stop and adjust the postframe adjustment links on each box so that the tang

on each drill transport stabilizer frame lines up with

the nest on the front of the main frame. Fold machine completely closed. Refer to Figure 3-7 &

Figure 3-6.

18. With pull bar slide forward on the tongue and machine folded completely, position the pull bar lock

pin, across the top of the tongue slide as shown in

Figure 3-2. Adjust the transport lock bolt on top and

front of tongue up against lock pin with 1/16" clearance and lock the jam nut. This pin preventsthe machine from unfolding when in transport.

NOTE: Do not lower the Soybean Machine while it is

in the folding position.

11637

Clevis Hitch

Figure 2-3

Three sizes of hitches are available: The small hole clevis type hitch, Figure 2-3, (1 1/4" maximum pin diameter), the small hole strap hitch, and the large hole single

tang hitch, Figure 2-2, (up to 1 1/2" diameter pin). The

small hole clevis type hitch is sold as standard equipment. The mounting holes in the hitch have been offset

so the hitch can be turned over and bolted on in three

different positions giving you six different hitch heights

for both the single and clevis type

NOTE: Care should be taken when setting the hitch

so the tongue of the drill is parallel to the ground

when the drill is in the planting position.

Usetonguejacktolevel tongue, then find closest setting

of hitch to match your tractor drawbar height.

19. Checktoseethatall nuts andboltsaretight.See the

“Section 2 Torque Values Chart”, page 7, for

torque specifications.

Tractor Hook-up

The machine can be equipped with a single strap or clevis type hitch as shown in Figure 2-2 & Figure 2-3. Use

single strap when hooking up to a clevis type tractor

drawbar. Spacers between the drawbar and hitch may

be added to eliminate some of the movement of the

tongue caused from positive to negative tongue weight.

11638

Single Strap Hitch

Figure 2-2

Vertical Position

Figure 2-4

12624

5/3/05 Great Plains Mfg., Inc.

2SBD30 30-Foot, Folding, Soybean Machine 173-086M

-9

Page 12

Section 2 Assembly Instructions & Set-Up

The tongue jack makes it possible to raise or lower the

hitch for tractor unhooking and reconnecting. Always return jack to its horizontal storage position on top of the

tongue, Figure 2-5, and re-pinning before transporting

machine.

Storage Position

Figure 2-5

12625

!

This machine has both positive and negative tongue weight.

Never unhook from the tractor with the boxes unfolded and

raised off the ground.

CAUTION!

Tractor Hydraulic Hook-up

For easiest operation, your tractor should be equipped

withfourremote outlets (2 pair). One pair will be used for

lifting the machine. The second pair will be used for folding the machine.

!

Escaping fluidunder pressurecan have sufficient forceto penetrate the skin. Check all hydraulic lines and hoses before applying pressure. Fluid escaping from a very small hole can be

almost invisible. Use paper or cardboard, not body parts, to

check.

CAUTION!

10

2SBD30 30-Foot, Folding, Soybean Machine 173-086M 5/3/05

Great Plains Mfg., Inc.

Page 13

Section 3 Hydraulics

Section 3 Hydraulics

Bleeding The Lift Hydraulics

This folding machine is equipped with rephasing type

hydraulic lift cylinders that require a special procedure

for bleeding air from the hydraulic system. If your dealer

hasnotalreadypreparedthecylindersfortransportuse,

read the following information carefully. The rephasing

cylinders will not function properly if this bleeding procedure is not followed. Do not crack hose fittings in order

to bleed cylinders.

NOTE: Check the hydraulic fluid level in the tractor

reservoir and fill to the proper level before starting

this procedure. If the bleeding process is performed

with a low reservoirsupply,there is a chance of drawing air into the system. System capacity is approximately 3.3 gallons.

1. If required, raise your machine 1" in order to extend

yourlift cylinders a little. Loosen the jam nuts on top

of the transport vertical tubes and screw the adjustment screw in until it bottoms. Lower the machine a

small amount until the cylinders become loose.

2. Unpin the cylinders from the main frame and turn

the cylinders upside down to a position where the

rodend is higher than the base end. Supportthecylinders in a safe location. One transport tire may

haveto be removed in order to unpin the master cylinder.

3. Start the tractor and runthe engine at idle. With the

rod end of the cylinders higher than the base end,

hydraulically extend the cylinders and hold the tractorcontrol leverin position forsixtyseconds after the

cylinders haveextended to their maximum stroke.

4. Hydraulically retract the cylinders, then repeat the

extending procedure several more times until both

cylinders are free of air and operate together.

5. Repin the cylinders to the main frame, rod end

down. If air is trapped in either cylinder, the affected

cylinder will have a spongy, erratic movement and

the machine will not raise evenly. Refill the tractor

hydraulic fluid reservoir to its proper level.

NOTE: After machine is raised, a slight settling will

occur due to the action of the rephasing cylinders.

IMPORTANT: When using sealant on pipe threads, the

friction between the threads is reduced; therefore, be

certain not to over tighten causing damage to the cylinders, valves, or fittings.

Bleeding The Folding Hydraulics

NOTE: The Bean Machine liftsystem should be completely operational before attempting to set up the

folding hydraulic circuit.

1. Withthe machine unfolded & lowered to the ground.

Unpin the rod end of each fold cylinder and support

cylinders so it will not fall.

2. Make sure the tractor hydraulic fluid reservoir is

filled to the proper level.System capacity is approximately 1/2 gallon and requires 1 remote outlet.

3. Hook up the folding cylinder hydraulichoses to the

tractor remote outlets.

4. Loosenthe hose connection at thebaseendofeach

cylinder.

5. With the tractor at idle, slowly work the tractor remote lever to extend the cylinders.

6. When the cylinders are fully extended, tighten the

two base end connections.

7. Repeat the procedure with the hose connection at

the rod end ports.

8. Reconnect hydraulic cylinders.

NOTE: The JIC type hose connections do not require sealant or high torque fora good seal when reconnecting.

9. Refillthetractorhydraulic fluidreservoir to itsproper

level.

NOTE: The lift cylinders are rephasing type cylinders. This bleeding procedure will not work on

rephasing cylinders. See “Section 2 Bleeding Lift

Hydraulics” on page 11 for correct bleeding procedure.

5/3/05 Great Plains Mfg., Inc.

10. If the fold cylinders do not operate properly, clean

out small orifice hole in fittings circled on fold hydraulics illustration, Figure 3-1.

2SBD30 30-Foot, Folding, Soybean Machine 173-086M

-11

Page 14

Section 3 Hydraulics

Operating The Hydraulic System

Lifting

The lift cylinders may after a period of time get out of

time or phase. The effectsof this can be seen when one

cylinder is either overextended or over retracted comparedtothe other lift cylinders.Torephasethecylinders,

raise the machine completely up and hold the tractor hydraulic lever on for a few seconds to give the cylinders

time to rephase. This should be done each time the machine is raised out of the ground. Momentarily reversing

the hydrauliclever immediately after rephasing to allow

thecylinderstoretractabout1/2"willhelpinmaintaining

a level drill.

Unfolding

1. Removepin from pull-bar transportlock, Figure 3-2.

Pin must alwaysbe used when transporting the machine in the folded position.

2. Unfoldboxesusing hydrauliccylinders. Do this very

slowly and carefully. Serious damage could occur if

done fast and carelessly. Folding and unfolding is

best achieved on level ground. Install lock pin in bar

slide.

Fold Hydraulics

12

2SBD30 30-Foot, Folding, Soybean Machine 173-086M 5/3/05

Great Plains Mfg., Inc.

Page 15

Section 3 Hydraulics

Pull Bar Pin Transport Lock Location

Figure 3-2

10739

Pull Bar Pin In Field Location

Figure 3-5

10730

Transport Lock Pin Location

Figure 3-3

12608

3. Apply hydraulicpressureto the raising and lowering

system. Raising the machine may be required to

free up the transport lock pins in the vertical tubes

For removal, Figure 3-3.

4. Place pins into storage position, Figure 3-4

5/3/05 Great Plains Mfg., Inc.

Pins in Storage Location

Figure 3-4

10740

Folding

1. To fold the machine, reverse the order of the unfolding instructions. Be sure all transport devices are in

place before transporting, Figure 3-2 & Figure 3-3.

2SBD30 30-Foot, Folding, Soybean Machine 173-086M

-13

Page 16

Section 3 Hydraulics

2. When folding the machine, the machine transport

stabilizerframes should line up with the nests on the

front of the main frame, Figure 3-6.

Transport Stabilizer Frame

Figure 3-6

Iftheyscrapethe wing on the tongue, the boxes can

be raised or lowered by adjusting the wing adjustment clevis,Figure 3-7.

10673

10674

Wing Adjustment Clevis

Figure 3-7

Pull Bar Adjustment

With the machine completely unfolded, the drill boxes

should be in line with each other, and parallel to the

back of the main frame.

Should your drill boxes require alignment, simply disconnect the screw clevis end of the pull bar and screw it

in or out to move the box forward or backwards. Once

the boxes are aligned, be sure the pull bars are pinned

tothetongueslideand that the tongue slide is pinned for

field position.

Transporting

Before transporting the machine, you should always check the following items:

1. To preventpossibledamage in case of hydraulicfailure during transport, Always insert safety lock pins

when transporting, Figure 3-3.

2. Check to be sure the pull bar transport lock pin is in

position to insure boxes will not open during transport, Figure 3-2.

3. Checktoseeif you havethe requiredairpressure in

yourtires using the "Section 2 Tire Inflation Chart"

on page 7.

4. Whenin transport,useaccessorylightsanddevices

for adequate warning to other operators of other vehicles, and use safety hitch chain. Comply with all

14

2SBD30 30-Foot, Folding, Soybean Machine 173-086M 5/3/05

Great Plains Mfg., Inc.

Page 17

Section 4 Seeding Adjustments

Section 4 Seeding Adjustments

Seed Rates

NOTE: Seeding rates will vary greatly with variations

in sizes of the seeds. Although the seeding rates listedinthismanualarebasedonan averageseed size,

we recommend that you test and adjust your machine using the procedures listed below to help insure an accurate seeding rate.

1. Rotate each gauge wheel to see that feed cups and

drive are working properly and are free from foreign

matter.

2. To adjust your seeding rate, first you must decide

whichsprocketarrangement youneed(seeseeding

chart). In order to change sprockets, remove nut in

center of double speed change sprocket and turn it

over. Loosen the idler arm bolt, put chains on and

tighten both bolts. (The chains need to be reversed

to make this change.)

3. There are many factors which will affect seeding

rates: seed treatment, weight of seed, size of seed,

surface condition of seed, and tire configuration,

pressure and slippage. Minor adjustments will probablybe needed tocompensateforthe above factors.

4. The pounds-per-acre in the seed charts are based

onmachines having9.5L x 15" rib implement gauge

wheeltireswith proper air pressure."Section2Tire

Inflation Chart" on page 7.

5. The differences in seed size and treatment can

cause a wide variation in actual seeding rates. The

seed rate chart below is based on average size

seed. This may differ from the seed you are using.

Usetheseedratechartsas a guide. Set the poundsper-acredesired attheindicator numberforyourrow

spacing and complete the following procedure to

calibrate the machine for your specific seed.

a. Place several pounds of seed over three of the

feeder cups at the outboard end of one seed

box.

b. Pull the seed tubes out of these openers.

c. Raise the machine off the ground.

d. Place a container under the three seed tubes to

gather the seed as it is metered.

e. Rotatethe drive gauge wheel until one acre has

been tallied on the acremeter. This will be ap-

proximately 182 rotations on a 30’ machine. Be

sure to check the three feeder cups to make

sure each cup has plenty of seed coming into it.

f. Weigh the seed which has been metered. Di-

vide by three. This will give you the ounces/

poundsmeteredbyeach feeder cup.Multiply by

the number of openers on your machine to ar-

rive at the total pounds-per-acre you would

meter at that setting. If this figure is different

thandesired,set your feedcup adjustment lever

accordingly. Repeat procedures (a) through (f)

on both sections.

6. You may want to repeat the calibration procedure if

the results of your calibration vary greatly from the

suggested settings contained in this manual.

REMEMBER: Tire size and field conditions will also affect seeding rates. Be certain that your gauge wheel

tires are 9.5L x 15" and that they are inflated to the correct pressure. See "Section 2 Tire Inflation Chart" on

page 7. When planting check the amount of seed you

are using by noting acres planted, amount of seed added to machine and level of seed in box. If you suspect

that you are planting more or less seed than desired,

and you haveaccurately calibrated the machine to your

seed,youmayneed toadjustthe seeding rate slightly to

compensate for your field conditions.

Seed Rate Chart (Pounds per acre)

Setting number 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Soybeans

Wheat 1 0 6 10 14 19 24 29 34 39 44 50 59 60 67 73 79 87 88 91 92

Cotton 1 2 4 6 10 12 16 18 22 26 28 34 38 40 42 50 58 64 68 70 72

Milo 2 1 4 6 9 12 14 18 22 23 27 32 33 36 39 41 44 52 53 54 55

Seed sizes vary.These Charts were calculated with average size cleaned seed. We strongly recommend that you test and adjust your

machine for accurate planting of your seed variety.

5/3/05 Great Plains Mfg., Inc.

1 0 0 8 10 17 25 30 34 40 49 54 60 68 73 78 82 93 94 95 96

Drive Type

2SBD30 30-Foot, Folding, Soybean Machine 173-086M

-15

Page 18

Section 4 Seeding Adjustments

10732

Drive Types

Figure 4-1

16

2SBD30 30-Foot, Folding, Soybean Machine 173-086M 5/3/05

Great Plains Mfg., Inc.

Page 19

Section 5 Basic Operation

Section 5 Basic Operation

Drill Preparation

And Field Operations

1. Your machine is equipped with an acremeter and it

should be mounted to the left gauge wheel axle. It

will accumulate the total acres planted. In order to

findouttheacrescovered, write downthebeginning

reading and subtract it from the ending reading for

the total acres planted.

2. Make sure that the feed cup adjustment handle on

each cup is set the same across the machine.

3. With the drill hookedup tothe tractor,load seed box

with seed. You should use cleaned seed to get the

best results.

4. Neverback up with row units in ground. If you do,

check all rows to be sure none are plugged.

5. Neverallow anyone to ride on the machine.

6. Maximum seeding speed should vary according to

soil conditions.

7. This Bean Machine is not designed to be turned

sharply in the field. Always lift the machine out of

the ground when turning at ends of field rows

and other short-radius turns. If the machineisnot

completelyraised,the lift hydraulicswillbecomeout

of sequence. See “Section 2 Bleeding Lift Hy-

draulics” on page 11.

8. Neverunhook the Bean Machine from tractor with

boxesunfolded and raised off the ground. Negative

tongue weight is present in this position.

If you notice excessive cracking on large seeds, adjust

all feeder cup door handles to a more open position.

10672

Threaded Stud

Figure 5-1

Make sure both studs have approximately the same

length of threads extending above the jam nut (approximately 3" for most planting conditions). Adjustments

mayberequiredandis coveredin “Section 6 Transport

Wheel Adjustments” on page 19. Put the transport

pins in storage position, Figure 3-4. Slowly lower the

machine until it is on the ground and the top slide cylinder is fully extended, Figure 5-2. Pull the machine

forward a few feet to make sure that the transport and

gauge wheel tires have firm contact with the soil.

Transporting

• This machine can be transported with a full box of

seed. It is best not to do this unless necessary because the increased weight does increase the chances for problems on the road. Do not exceed 20 miles

per hour.

• Be sure your gauge wheel tires have proper inflation

as listed in the "Section 2 Tire Inflation Chart" on

page 7.

• Comply with all Federal, State and Local Safety Laws

when traveling on public roads.

• Remember, the drill is wider than the tractor and ex-

treme care must be taken to allow for safe clearance.

Preparing the Drill

Unfold the machine on a levelseedbed typical to your

planting soil conditions.

At the top of both vertical axletubeson transport frameis

a threaded adjustment stud and jam nut, Figure 5-1.

5/3/05 Great Plains Mfg., Inc.

Top Slide Cylinder

Figure 5-2

10671

Leveling

Opener Parallel Arms Adjustments

The row unit parallel arms are the indicators of the level

of the machine, because they show the amount of down

float left in the row unit.

Lowerthe Bean Machine on alevelseedbed and pull for-

2SBD30 30-Foot, Folding, Soybean Machine 173-086M

-17

Page 20

Section 5 Basic Operation

ward a few feet then check the planters parallel arms.

The parallel arms should be levelwith the ground,

Figure 5-3.

If all the parallel arms along the Bean Machine are the

same,the machine is leveland youshould tighten down

thethreadedadjustment studs and jam nut as described

in“Section6 TransportWheel Adjustments” on page

19 for leveling. If the parallel arms vary, the Bean Ma-

chine can be leveled with transport and gauge wheel

adjustments described in "Section 6 Gauge Wheel Ad-

justments" on page 19.

!

If the planter vertical travel is decreased, considerable damage could occur to the planter units.

CAUTION!

12675

Level Parallel Arms

Figure 5-3

18

2SBD30 30-Foot, Folding, Soybean Machine 173-086M 5/3/05

Great Plains Mfg., Inc.

Page 21

Section 6 Drill & Gauge Wheel Adjustments

Section 6 Drill & Gauge Wheel Adjustments

Transport Wheel Adjustments

Whenlevelingyour Bean Machine, planter parallel arms

nearthe center of the machine that arehigherabovelevel than desired can be adjusted by raising the transport

frame. This is done by slowly raising the machine until

levelwith the hydrauliclift cylinders. Planter parallel

arms near the center that are lower than desired are adjusted by lowering the transport frame by retracting the

cylinders. Once the parallel arms are at the desired setting, screw the threaded adjustment studs on top of the

vertical tubes down as far as possible and secure them

with the jam nuts, Figure 5-1. This adjustment will stop

the lift cylinder travel at the same point each time the

boxesare lowered for planting and assures accurate

seed depth control.

NOTE: If it is noticedthat one box row’sparallel arms

are different from the other box at the center of your

machine is a sign that your lift hydraulic master and

slavecylinders are out of sequence with one another.

In order to get them back in sequence simply raise

your machine all the way up and hold your tractor hydraulic control valveleveron for a few seconds. Now

lower your machine and both cylinders will be in sequence with one another and your two boxes should

be at the same level again.

low easy gauge wheel adjustment. By lengthening the

turnbuckle the gauge wheel is lowered, also lowering

parallel arms.By shortening the turnbuckle the gauge

wheel is raised, also raising parallel arms.After adjusting, be sure the turnbuckle on both gauge wheel arms

have the same pin center dimensions.

Down Force Row

Standard Spring Package

The standard down force spring package, consists of 2

non-adjustable springs applying approximately

90 lbs. of down force.

Optional Medium and Heavy Duty Spring Package

The medium and heavy duty spring packages consist of

2or 4 adjustablesprings,respectively. The mediumduty

packagecanbe adjusted from approximately 100 to 200

lbs. down force. The heavy duty package can be adjusted from approximately 200 to 400 lbs. of down force.

Spring Adjustments

• All spring adjustments must be made with the ma-

chine in the fully raised position.

NOTE: The maximum down force stated before is

reached when the parallel arms are all the way up.

Gauge Wheel Adjustments

Theplanterrowsneartheoutsideof the machine are adjusted by raising or lowering the gauge wheels.

Raise the machine out of the ground and loosen the jam

nut located near the bottom clevis of the gauge wheel

turnbuckle,Figure 6-1. This turnbuckle is threaded to al-

10546

Gauge Wheel Turnbuckle

Figure 6-1

• The spring package is adjustable from 90 lbs. to 325

lbs. of down force when the parallel arms are horizontal. Consult the Down Force Pressure Chart on

page 20 to obtain the desired down force.

NOTE: The maximum down force stated before is

reached when the parallel arms are all the way up. To

adjust the spring tension, lift the plunger by pulling up

onthe roll pin handleandsliding the handle adjustment

assembly into the appropriate hole, see Figure 6-2.

• Two springs can be purchased at your Great Plains

Dealerto make the mediumdutypackageinto a heavy

duty package or two springs can be removed fromthe

heavydutypackage to make a medium duty package.

Add or subtract springs by removing the snap ring at

the end of the spring pivot rod. Slide the rod inward to

addorremoveaspringfromeachside.Thenattachor

remove the other spring end on the hex bar support.

Reinstall the spring rod and snap ring on each side.

5/3/05 Great Plains Mfg., Inc.

2SBD30 30-Foot, Folding, Soybean Machine 173-086M

-19

Page 22

Section 6 Drill & Gauge Wheel Adjustments

Down Force Pressure Chart

To Obtain This

* Down Force

90 lbs. 2 A

105 lbs. 2 B

125 lbs. 2 C

140 lbs. 2 D

160 lbs. 2 E

185 lbs. 4 A

215 lbs. 4 B

245 lbs. 4 C

285 lbs. 4 D

325 lbs. 4 E

* Force when arms are parallel.

Use This # of

Springs

In This

Hole

12208

Row Unit Mounted Coulter

Figure 6-3

Depth Adjustment

Theplantingdepth of the row unit is controlled by 2 walking gauge tires located next to the disks.

Adjust the planting depth as follows:

1. Raisethe machine to removeweightfromthe gauge

tires.

2. RaisetheT-handleand move it forward to decrease

the planting depth, see Figure 6-4. Moving the handle rearward increases the planting depth. Small increments of depth adjustment can be made by

walking the T-handle from side to side.

3. After one row is set to the desired depth, move the

T-handle on the other rows to the same location.

12137

Adjustment Bar

Figure 6-2

Row Unit Mounted Coulter

The optional coulter allows the planter to penetrate

tough ground conditions. It is recommended that either

the medium duty or heavy duty spring package be used

in conduction with this coulter.

Coulter Adjustments

1. To adjust the coulter vertically, loosen the 3/4" jam

nut and the 3/4" x 3" long hex bolt, see Figure 6-3.

2. Byturning the cam hex, rotatethecamcasting to set

the desired height. Forwavy coulter blades, it is recommended that the coulter blade should be run

even to 1" below the disks on the row unit.

3. Tighten the bolt and jam nut to torque values in

"Section 2 Torque Value Chart" on page

Reference3.

20

2SBD30 30-Foot, Folding, Soybean Machine 173-086M 5/3/05

12345

T-Handle Adjustment

Figure 6-4

1 x 12 Closing Wheel Adjustments

The 1 X 12 closing wheel option can be adjusted for

down force, alignment, and offset.

Closing Wheel Down Force Adjustment

Adjust the closing wheel down force to permit proper

closingof the seedtrench.It is recommendedtostart with

Great Plains Mfg., Inc.

Page 23

Section 6 Drill & Gauge Wheel Adjustments

the T-handle in the first of 4 notches, see Figure 6-5.

If the seed trench is not closing move the handle to the

next notch back and try again. Keep moving the handle

back until the seed trench is closing, by doing this eliminates unnecessary down force and compaction. In

some field conditions, the T-handle can be left in the forward slot to minimize down force.

Closing Wheel Adjuster

Figure 6-5

12346

Closing Wheel Alignment (Refer to Figure 6-6)

If one closing wheel is running in the seed trench or the

wheelsarenotcenteredoverthe seed trench, adjust the

closing wheels as follows:

1. Raise the machine slightly to remove weight from

the closing wheels.

2. Loosen the two 1/2" bolts.

3. Turn the press wheel adjuster left or right to center

the wheels over the seed trench.

4. Tighten the 1/2" bolts to the correct torque value listed in "Section 2 Torque Values Chart" on page

Reference3.

are not offset, the wheels should be located in the front

holes of the press wheel arm.

To offset the wheels, do as follows:

1. Raise machine slightly to remove weight on the

closing wheels.

2. Remove the 3/4” bolt holding the wheel,

see Figure 6-7.

3. Move the wheel to therearhole and attach with the 3/

4"bolt.Tighten the bolt to the correct torquevaluelisted in "Section 2 Torque Values Chart" on page

Reference3.

12347

Closing Wheel & Offset

Figure 6-7

Closing Disk Adjustments

The closing disk options consists of two disks and a

6 1/2 x 12 press wheel. The disk down pressure can be

adjusted to provide closing of the seed trench.

To adjust the down pressure, ratchet the spring cam to

the next cam height by turning the head of the support

bolt clockwise. Refer to Figure 6-8.

12418

Closing Wheel Alignment

Figure 6-6

Closing Wheel Offset

The 1x12 wheels can be offset to help prevent trash

from plugging the closing wheels. If the closing wheels

5/3/05 Great Plains Mfg., Inc.

12348

Closing disk & Tube Holes

Figure 6-8

2SBD30 30-Foot, Folding, Soybean Machine 173-086M

-21

Page 24

Section 6 Drill & Gauge Wheel Adjustments

Seed Lok

The seed lok option provides additional seed to soil contact. The seed lok is spring loaded and does not require

adjusting. In some wet and sticky conditions the wheel

may accumulate soil and may require removal of the

seed lok until conditions improve.

The seed lok is attached to the shank with a 1/2" clevis

pin,see Figure 6-9. To remove the seedlok,remove the

clevis pin and pull down on the seed lok mount. Reattach in the reverse order.

12362

Seed Lok Assembly

Figure 6-9

22

2SBD30 30-Foot, Folding, Soybean Machine 173-086M 5/3/05

Great Plains Mfg., Inc.

Page 25

Section 7 Maintenance & Lubrication

Section 7 Maintenance & Lubrication

Maintenance

Proper servicing and adjustment is the key to the long

life of any farm implement. With careful and systematic

inspection, you can avoid costly maintenance, time and

repair.

1. After using your implement forseveralhours, check

all bolts to be sure they are tight.

2. Lubricate the marker-body hinges every 15 hours of

operation.

3. Adjust idlers to remove excess slack from chains.

Clean and use chain lube on all roller chains as

needed.

4. Oil the seed-cup-drive sprocket in its square bore.

Move seed-cup adjustment leveraway from the

sprocketas faras possible togettheoilback into the

square.

5. Always maintain the proper air pressure in the rib

implement tires.

Lubrication

6. Replace any worn, damaged or illegible safety decalsbyobtainingnewdecals from your Great Plains

Dealer.

Storage

1. Clean the implement as necessary. Besure that the

seed boxes are completely cleaned before storing.

2. Lubricate and adjust all roller chains.

3. Lubricate all pivots as indicated in the followingillustrations.

4. Be sure to oil the seed-cup-drive sprocket before

storing the implement. Squirt oil on to the square

seed-cup shaft and move seed-cup-adjustment leverback and forth to gettheoilbackintothesquare.

5. Disconnect seed hoses from parallel-linkage openers. Permanent elongation and premature cracking

of hoses may occur if stored connected

6. Store the implement inside if possibleforlonger machine life.

Lubrication

Legend

12703

Multipurpose

spray lube

Multipurpose

grease lube

Multipurpose

oil lube

Upper Post Pivot

Type of Lubrication: Grease

Lower Post Pivot

Type of Lubrication:

50

20

20

Intervals at which

lubrication is required

5/3/05 Great Plains Mfg., Inc.

12704

2SBD30 30-Foot, Folding, Soybean Machine 173-086M

-23

Page 26

Section 7 Maintenance & Lubrication

20

Box Pivot

12705

16639

Type of Lubrication: Grease

5

Parallel Arm

Type of Lubrication: Grease

Seasonally

Axle Bearings

13520

Type of Lubrication: Grease

20

Feeder Cup Drive Shaft Sprocket Bearing

12126

24

2SBD30 30-Foot, Folding, Soybean Machine 173-086M 5/3/05

Type of Lubrication: Grease

Great Plains Mfg., Inc.

Page 27

Section 7 Maintenance & Lubrication

As

Required

Chain

13522

13522

Type of Lubrication: Spray

As

Required

Chain

Type of Lubrication: Spray

As

Required

Chain

13522

13519

5/3/05 Great Plains Mfg., Inc.

Type of Lubrication: Spray

20

Flange Bearing

Type of Lubrication: Grease

2SBD30 30-Foot, Folding, Soybean Machine 173-086M

-25

Page 28

Section 8 Troubleshooting

Section 8 Troubleshooting

Problem Solution

Uneven seed spacing or uneven stand a. Check for trash in seed cup.

b. Check to see if seed tubes are plugged.

c. Reduce ground speed.

d. Check planter disks to see they turn freely.

e. Use faster drive type speed and close feed cup flutes to a more

narrow position.

Planter disks not turning freely a. Check for trash or mud buildup on disk.

b. Check row frame for possible damage.

Actual seeding rate is different than

desired.

Excessive seed cracking

Acremeter doesn’t measure accurately a. Check tire pressure. Proper inflation is listed in “Section 2 Tire In-

Uneven seeding depth

Press Wheel not compacting the soil

as desired

Grain box not emptying evenly a. Certain models do not have the same number of seed cups be-

Feeder cup sprockets locked up or

twisted

a. Check tire pressure. Proper inflation is listed on page 6 in “Tire In-

flation Chart”.

b. Check tire size. Proper size is 9.5L x 15".

c. Liquid seed treatment will affect seeding rateif the chemicals build

upin feedcup.Unless cleanedregularly, this buildup cancause in-

creased torque and breakage of the feed shaft.

d. Check drive type. See "Section 4 Seed Rate Chart" page 15.

e. See instructions on calculating seed rate.

Change drive type to a slower speed and open flutes in feed cup to a wider position.

flation Chart” on page 7.

b. Check tire size. Proper size is 9.5L x 15".

c. Check planting operation for excessive overlap or gaps between

passes.

d. Loose soil conditions and slippage will cause variations in acres

registered.

e. To check accuracy of acremeter. See "Section 4 Seed Rates"

page 15.

Check to see that all planter units are adjusted the same.

Check the spring tension bolt on the back of the press wheel arm. The spring

pressure can be adjusted heavier or lighter.

tweeneach divider ofbulkhead.The sectionwiththelarger number

of cups will empty sooner.

b. If your machine has multiple boxes, check adjustment levers on

each box to see that they are set on the same indicator number.

a. Check for foreign matter lodged in one or more feeder drive shaft

feeder cups.

b. Liquidinsecticidefromseedhasdriedwithinthefeedcup.Remove

thebuild upbydisassembling eachfeedcup andscrapethe foreign

substance from the turning surfaces. NOTE: Liquid inoculant

should be applied with caution and care should be taken to clean

the feeder system after planting treated seeds.

26

2SBD30 30-Foot, Folding, Soybean Machine 173-086M 5/3/05

Great Plains Mfg., Inc.

Page 29

Section 8 Troubleshooting

Press Wheels and planters plugging a. Drilling in damp or wet conditions may increase this problem.

b. DONOTback up machine in field, or stop and allow machine to roll

backwards with openers in the ground.

Gauge Wheel leans to left or right a. Realign brackets where gauge wheel is attached to main frame by

adjusting the mounting bolts.

b. Checkto see if gauge wheel axle bearing are securely attached to

gauge wheel arm.

Improper folding of drills a. Adjust post frame adjusting links Figure 3-7 in

"Section 3" on page 14.

b. Check hydraulic system for air and oil leaks.

c. Clean out small orifice fittings in wing cylinders.

d. Make sure that the wing boxesunfold and are aligned, see “Sec-

tion 3 Pull Bar Adjustments”, on page 14.

Hydraulic adaptors cracking a. JIC fittings do not require high torque.

b. Always use liquid pipe sealant when adding or replacing pipe

thread hydraulic fittings. Plastic sealant can crack fittings and plug

hydraulic lines. JIC and O-ring fittings do not require sealant. Oring fittings require a thin coat of oil on the O-ring. IMPORTANT:

When using sealant on pipe threads the friction between the

threadsis reduced; therefore,be certainnottoovertightencausing

damage to the cylinders, valves, or fittings.

Raising and lowering machine is rough a. Lubricate lower rollers of verticaltransporttubes andunevenlocat-

ed between the transport tires.

b. Check hydraulic fittings for leaks.

c. Rephasing cylinders not properly bled. See “Section 3 Hydrau-

lics” on page 11. When raising machine at end of field the lifting

cylinders should be fully extended to insure that they are always

rephased.

5/3/05 Great Plains Mfg., Inc.

2SBD30 30-Foot, Folding, Soybean Machine 173-086M

-27

Page 30

Section 9 Specifications

Section 9 Specifications

Row Spacing

Numbers of Rows

Machine Weight

Box Length

Unfolded Machine Width

Tire Size

Box Capacity

Transpor t Width

Weights are based on machines equipped with planter units without coulter attachments.

15"

24

10,800 Pounds

15’

30’ - 6"

9.5L x 15" 6-Ply

2 Bushels/Foot

15’ - 6"

16’ - 10" with coulters

28

2SBD30 30-Foot, Folding, Soybean Machine 173-086M 5/3/05

Great Plains Mfg., Inc.

12604

Page 31

Section 9 Specifications

Great Plains Manufacturing, Incorporated warrants to the original purchaser that this seeding equipment will be free from defects in material

and workmanship for a period of one year from the date of original purchasewhen used as intended and undernormal service and conditions

for personal use; 90 days for commercial or rental purposes. This Warranty is limited to the replacement of any defective part by Great Plains

Manufacturing, Incorporated and the installation by the dealer of any

such replacement part. Great Plains reserves the right to inspect any

equipment or part which are claimed to have been defective in material

or workmanship.

This Warranty does not apply to any part or product which in Great

Plains’ judgement shall have been misused or damaged by accident or

lack of normal maintenance or care, or which has been repaired or altered in a way which adversely affects its performance or reliability, or

which has been used for a purpose for which the product is not designed. ThisWarranty shall not apply if the product is towed at a speed

in excess of 20 miles per hour.

Claims under this Warranty must bemade to the dealer whichoriginally

sold the product and all warranty adjustments must by made through

such dealer. Great Plains reserves the right to make changes in materials or design of the product at any time without notice.

This Warranty shall not be interpreted to render Great Plains liable for

damages of any kind, direct, consequential, or contingent, to property.

Furthermore,GreatPlainsshallnot be liable for damages resulting from

any cause beyond its reasonable control. This Warranty does not extend to loss of crops, losses caused by harvest delays or any expense

or loss for labor, supplies, rental machinery or for any other reason.

No other warranty of any kind whatsoever, express or implied, is

made with respect to this sale; and all implied warranties of merchantability and fitness for a particular purpose which exceed

the obligations set forth in this written warranty are hereby disclaimed and excluded from this sale.

This Warranty is not valid unless registered with Great Plains Manufacturing, Incorporated within 10 days from the date of original purchase.

Warranty

5/3/05 Great Plains Mfg., Inc.

2SBD30 30-Foot, Folding, Soybean Machine 173-086M

-29

Page 32

Great Plains Manufacturing, Inc.

Corporate Office: PO. Box 5060

Salina, Kansas 67402-5060 USA

Loading...

Loading...