Page 1

Great Plains Mfg., Inc.

Installation Instructions

2S-2600 2 Section Folding Drill

Point Row Option

Used with:

• 2S-2600

General Information

When you see this symbol, the subsequent instructions and

warnings areserious- follow without exception. Your life and

!

!

the lives of others depend on it!

These instructions explain how to install the Point

Row option. The Point Row option allows you to

raise and lower openers on each drill section

independently.

These instructions apply to:

195-299A 2S-2600PointRowACC2004 CBV

Manual Update

Referto the 2S-2600 operator’smanual for detailed

information on safely operating, adjusting, troubleshooting and maintaining the Point Row option.

Refer to the parts manual for part identification.

195-200M-A Operator’sManual

195-200P Parts Manual

Before You Start

Page 8 is a detailed listing of parts included in the

PointRowoption package. Use thislist to inventory

parts received.

Tools Required

• Basic hand tools

Definitions

Right-hand (RH) and left-hand (LH) as used in this

manual are determined by facing the direction the

machine will travel while in use unless otherwise

stated.

Overview of Installation

Thepointrowvalve blockwill be plumbed directly after the filter on the drill. Oil from the valve block is

directed to both the LH and RH wing reducing

valves all the time. With no power to a solenoid, oil

flows to the P port on the reducing valve, and the

openers are pushed down. Whenpower is supplied

to a solenoid, oilis routed to theTank port on the reducing valve and the openers will raise.

The point row valve block will be bolted toa plate

on the drill just ahead of the base end of the fold

cylinders. Two bulk head hydraulic T fittings pass

through this plate from the original plumbing.

These fittings will be removed to make room for

the valve.

The Counterbalance valve (CBV) supplied with

the point row kit will hang under the LH pressure

reducing valve.

TheCounterbalance valvewith thepoint row kit is

thicker than the reducing valveit is plumbed to.

Because of this, the pressure LH reducing valve

willneedto be shimmed outwithwashersto make

room for the new valve.

Center and Wings Vs.LH andRH wings.The drill

is originally plumbed so the two cylinders at the

center of the drillshared a reducing valve and the

outercylinderssharedanother. Withthepointrow

option, the drill plumbing is altered so the LH reducing valve controls the LH wing and the RH

valve controls the RH wing.

A solenoid valve will be installed in the bypass

valveblocklocated on the drill. The solenoid valve

blocksflow throughthe bypassvalve everytime a

point row switch is activated. This stops the bypass oil and lets the tractor pressure increase

enough to raise the openers off the ground when

a section is shut off.

OncethePointRowkit has been installed,thedrill

needs to be raised and loweredso the complete

installation can be checked AND the new Counterbalance valve can be checkedand adjusted if

needed. Refer to "Adjusting the valve" at the end

of these instructions.

© Copyright 2004 Printed

2/22/2005

195-300M

Page 2

Point Row Option

2

Great Plains Mfg., Inc.

Assembly Instructions

Hook the drill to a tractor. Move the opener lock

handles to "Field", unfold the drill and lower the

openers to the ground. Place the remote lever in

float position to relieve any residual hydraulic

pressure. Clean the area around the pressure reducing valves bywashing or using compressed

air.

Disassembly

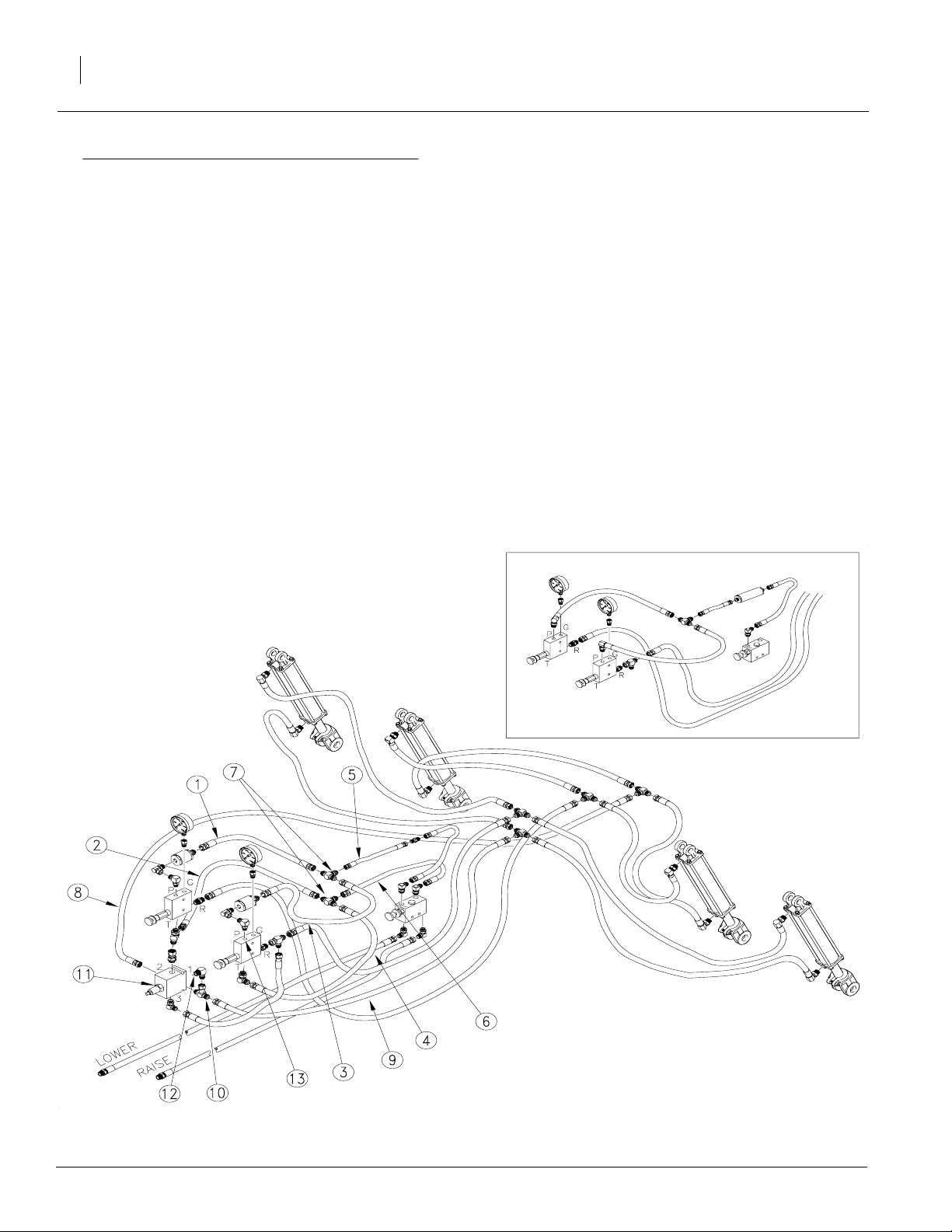

Refer to Figure 1

1. Removehoses(1),(2),(3),(4),(5) and (6) from

bulkhead tee fittings (7).

2. Removethebulkhead tee fittings (7)from the

drill, and discard.

3. Removehoses (8) and(9) from the tee fitting

(10) on counter balance valve (11).

4. Removethe teefitting(10)from CBV (10) and

discard.

5. Reinstall hose (8) on elbow fitting (12).

S/N DD1215- December 2004-

S/N 1216+ January 2005+

22624

Figure 1

Original Plumbing

195-300M 2/22/2005

Page 3

Great Plains Mfg., Inc.

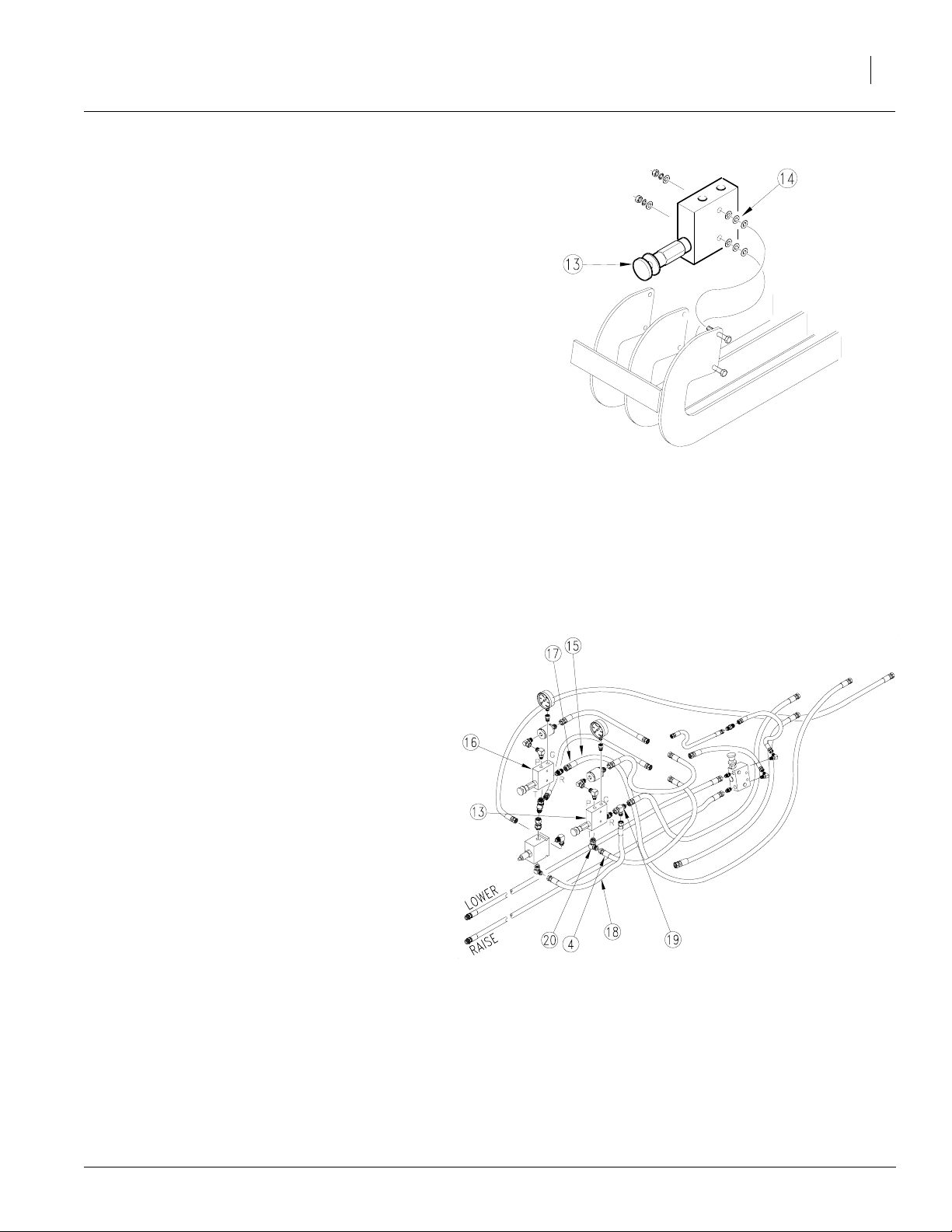

Refer to Figure 2

6. Removethe mountingbolts for the LH Reducing Valve(13). Reinstall the bolts, placing six

flat washers (14) against the valve's body to

shim it away from the mounting bracket.

Installation Instructions

Figure 2

Shimming the Valve

3

22625

Refer to Figure 3

7. Removehose (15) from the back of the RH reducing valve (16). Install tee fitting (17) supplied with the kit.

8. Removehose (18) from the tee fitting (19)on

backof LHreducingvalve(13)and re-attachit

to tee fitting (17)on the backof theRH reducing valve (16).

9. Disconnect Hose (4) from elbow (20). Save

this hose for re-use. Remove and save elbow

(20) from the bottom ofthe LHreducing valve

(13).

22626

Figure 3

Removing Fittings

2/22/2005

195-300M

Page 4

Point Row Option

4

Refer to Figure 4

10. Assemble 9/16" x 3/4"elbows (21), from thekit,

to the ports V1, V2 of the block (22). Assemble

9/16" x 9/16" elbows(23), from the kit, to ports

A1, B1, A3 and B3. Install plugs (24), from the

kit, in ports A2, B2, V1 and V2.

Great Plains Mfg., Inc.

22627

Refer to Figure 5

11. Mount valve block (22) to the bracket as shown

using 3/8" x 3 3/4" bolts (25) as shown.

12. Place new decals (26) over the existing decals

to distinguish valves for the LH and RH wings.

Figure 4

Sub Assembly Solenoid Valve

22628

Figure 5

Installing Solenoid Valve

195-300M 2/22/2005

Page 5

Great Plains Mfg., Inc.

Refer to Figure 6

13. Install the LH Counterbalance valve (27) under the

LHreducingvalve(13)using fitting (28) andtee(29)

fromthekit.Besureto connect port2 on the CBV to

the T port on the reducing valve.

14. Connect supply hose (5)from the filterto the elbow

in port V1.Connectthe return hose(6) totheelbow

in port V2.

15. Connecthose(1)from the RH reducing valve(16) P

port to theelbow on portA1. Connect hose (3) from

the LH reducing valve (13) P port to the elbow in

port A3.

16. Connect returnhose (2) from the Tee in thebottom

of the RH reducing valve (16) to elbow in port B1.

Re-installreturn hose (4) from the Teeinthebottom

of the LH reducing valve (13) to the elbow on port

B3.

17. Install elbow (20), removed earlier and elbow

(30),from the kit, to ports 1 and 3 on

the LH CBV (27).

Installation Instructions

20. Isolate the LH and the RH wing opener lift cylinders

on the drill by switching hoses at the T fittings (34),

(35), (36) and (37) at therear ofthe mainframe. Connect rod-end hoses to rod-end hosesand base end

hoses to base end hoses.Keep the LH wing andRH

wing separate. Connect hoses going forward from

the T's as follows:

• RH cylinders, base end Tee (34) to RH reducing

valve R port Tee (32).

• LH cylinders, base end Tee (35) to LH reducing

valve R port Tee (33).

• RH cylinders, rod end Tee (36) to RH CBV port 1

elbow (38).

• LH cylinders, rod end Tee (37) to LH CBV port 1

elbow (30).

21. This finishes the hoserouting, tighten all fittingsand

hardware.

5

18. Connect the LH pilot line hose (31)

supplied with the kit, from elbow

(20) to Tee (19).

19. Connectelbows(32)and (33) from the

kit to Tees(17) and(19) on the backof

the reducing valves (13) and

(16).

2/22/2005

Figure 6

Final Plumbing

22629

195-300M

Page 6

Point Row Option

6

Refer to Figure 7

22. Remove the plug (39) on the bypass valve

block (40) and discard. Install the solenoid

valve(41) from the kit into this open port. Refer to the next step for special handling and

tightening instructions.

23. Thesolenoidvalve(41)needstobe tightened

into the valve block (40) to seat the oring. A

special thin wrench is required forthis. If a

special thin wrench is notavailable,do the following.

24. Carefully loosen the coil nut (42) ontop ofthe

solenoid(41). Removethe coilassembly(43).

The hex (44) on the lower part of the valve is

now exposed and a regular wrench may be

used to tighten the valve into the block.

Great Plains Mfg., Inc.

25. Reinstall the coil (43) and coil nut (42). Use

great care tonot over tighten this nut. Torque

to 4-6 lb-ft.

26. Route the wire harness through the tongue.

Connect the 3 weatherpak ends without dust

caps to the 3 solenoid valves on the large

valve block (22).

Note that the center solenoid is not used on this

drill, butcan be connected to keepdirt and water

out of the ends.

27. Remove the dust cap from the remaining

weatherpak end and connect it to the single

solenoid valve (41) in the bypass valve block

(40).

22637

Figure 7

Bypass Valve Solenoid Installation

195-300M 2/22/2005

Page 7

Great Plains Mfg., Inc.

ADJUSTING THE COUNTERBALANCE

VALVE(S).

On the stemof the valve (item 27,Figure 6) there

is a rubber cap that protects the threads of an adjustment stem. This stemislockedin place with a

hex nut. To adjust the valve, loosen the nutand

turn the stem using an Allen wrench.

Screwing the stem in (clockwise) pushes on a

spring which supplementsthe pilot line's forceon

an internal piston. More spring force will let the

valve open with a low pilot pressure. Less spring

forcewillrequire higher pilot pressure toopenthe

valve.

Note: With the screw turned infully,the springwill

developenough force on the pistonthat the valve

will unlock even with no pilot pressure. Theopeners will settle.

Raise and lower the drill several times then hold

hydraulicdown pressure on theopeners to purge

air from the system and to warm the oil. Repeat.

Installation Instructions

7

Raise the openers andreturn the lever to neutral.

Observe the openers closely to detect settling. If

the openers remain up, no valve adjustment is

needed.

If the openers settle,the stem is screwedin too

far. Gently back the stem out until it stops, then

screw it in one turn. Generallythis is agood starting point. Check for settling.

Backing the stem outwill lock the valve, screwing

it in too far can cause it to unlock.

A small increase in lowering speed can be

achievedby screwing the stem in.

2/22/2005

195-300M

Page 8

Great Plains Mfg., Inc.

195-299A 2S-2600 Point Ro w ACC 2004 CBV

Your kit includes:

Qty. Part No. Part Description

1 195-300M MANUAL 2600 PNTROW INSTALL

6 800-082C CABLE TIE .31X21.5 6DIA 120LB

2 802-026C HHCS 3/8-16X3 3/4 GR5

2 803-014C NUT HEX 3/8-16 PLT

2 804-013C WASHER LOCK SPRING 3/8 PLT

6 804-007C WASHER FLAT 1/4 SAE PLT

1 810-371C MANIFOLD ASY 3S-3000 POINT ROW

1 810-408C BYPASS CARTRIDGE AND SOLENOID

1 810-523C VALVE COUNTER BAL 10:1 9/16FOB

1 811-061C TEE 9/16MJIC 9/16MJIC 9/16MORB

2 811-069C EL 9/16MJIC 9/16FJIC

1 811-064C TEE 9/16MJIC 9/16MJIC 9/16MORB

5 811-065C EL 9/16MJIC 9/16MORB

2 811-171C EL 3/4MORB 9/16MJIC

2 811-203C PL 3/4MORB HOLLOW HEX

1 811-627C AD 9/16MORB 9/16FJIC

1 811-631C HH3/8R1 018 9/16FJIC

2 811-757C PL 9/16MORB HOLLOW HEX

1 818-662C DECAL RIGHT SECTION

1 818-663C DECAL LEFT SECTION

1 823-175C 3 SECT POINT ROW WIRE HARNESS

1 823-185C POINT ROW CONTROL BOX

1 823-190C POINT ROW CABLE W/ POWER LEAD

Installation Instructions

8

195-300M2/22/2005

Loading...

Loading...