Page 1

Great Plains Mfg., Inc.

Assembly Instructions

24- and 30-Foot, No-Till

Flat Fold Marker Option

Used with:

2N-2410 and 2N-3010 Drills

•

2N-2420 and 2N-3020 Drills

•

When you see this symbol, the subsequent instructions

and warnings are serious - follow without exception. Your

!

!

life and the lives of others depend on it!

General Information

These instructions explain how to assemble, install and setup the

optional hydraulic markers for your two-section, folding no-till

drill. The units are operated hydraulically and hav e a cast hub, tapered roller bearings and a bolt-on notched blade to cut though

heavy residue, leaving a line to f ollo w on the next field pass.

Markers are sold as single or dual units. Dual markers are

equipped with a sequence valve f or easy oper ation.

These instructions apply to:

113-498A 24-Foot No-Till Left-Hand Flat-Fold Marker

113-499A 24-Foot No-Till Dual Flat-Fold Markers

113-500A 30-Foot No-Till Left-Hand Flat-Fold Marker

113-501A 30-Foot No-Till Dual Flat-Fold Markers

Manual Update

Refer to the drill operator’ s manual for detailed information on

safely operating, adjusting, troubleshooting and maintaining the

markers. Refer to the drill parts manual for part identification.

• 2N-2410 and 2N-3010 Operator’s Manual . . . . . . . . . . . . . . . . . . . . 196-126M

• 2N-2420 and 2N-3020 Operator’s Manual . . . . . . . . . . . . . . . . . . . . 196-164M

• 2N-2410 and 2N-3010 Parts Manual . . . . . . . . . . . . . . . . . . . . . . . . 196-126P

• 2N-2420 and 2N-3020 Parts Manual . . . . . . . . . . . . . . . . . . . . . . . . 196-164P

Definitions

Right and left as used in this manual are determined by facing

the direction the machine will travel while in use unless otherwise

stated.

IMPORTANT: A crucial point of information related to the

preceding topic. For safe and correct operation, read and

follow the directions provided before continuing.

NOTE: Useful information related to the

preceding topic.

Before You Start

Pages 8 through 11 are detailed listings of parts included in the

marker kit. Use these lists to inventory parts received.

Assembly and Setup Instructions

Marker Assembly

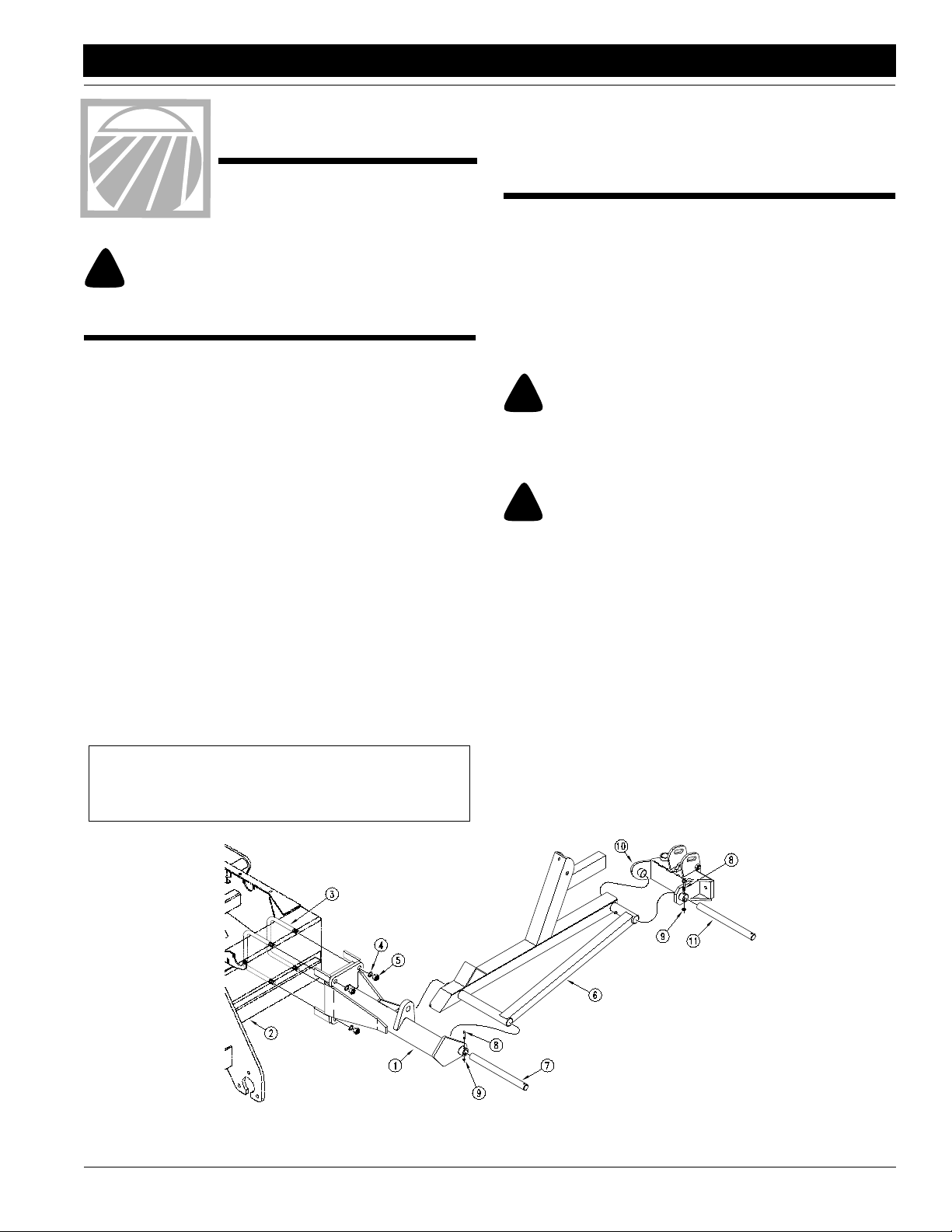

Refer to Figure 1.

1. Park the drill in an area large enough for folding and unfolding the assembled markers. A single marker will increase

the width of the drill by 15 feet.

1. Unfold and lower the drill. P ark and shut off the tractor.

2. The marker sections are pre-assembled and banded together for shipment. Unpack the shipment and group the assemblies according to right-hand or left-hand.

!

Do not lift the assemblies unassisted. Lifting the assemblies without

mechanical aid could cause severe injury. Use a forklift or hoist to

move the assemblies during installation, or disassemble the assemblies

into smaller pieces before installation.

You could be severely injur ed by a failing assembly. Obey all safety instructions from lifting-equipment manufacturer. Do not walk or place

any body part under the raised sections. Be sure lifting equipment has

enough capacity.

NOTE: These instructions explain how to assemble the marker

if the sections are completely disassembled. If you do not have

adequate lifting equipment, disassemble the sections before

proceeding. If you do have a forklift or hoist large enough to lift

the pre-assembled sections, you can skip many of the following

steps.

3. Install the left-hand marker mount (1) on the left wing (2) of

CAUTION!

!

WARNING!

the drill. Install the mount as close to the outside of the drill

as possible. F asten the mount to the 6-by-8-inch frame tube

using two u-bolts (3), lock washers (4) and nuts (5). Install

the first section of the marker (6) on the mount (1) by pushing the pivot shaft (7) through the pivot holes on the mount

and the first section. Use the bolt (8) and lock nut (9) to secure the shaft.

Mount the left-hand breakaway hinge (10) onto the first section (6) by pushing the pivot shaft (11) through the pivot

holes in each

part. Use the

bolt (8) and lock

nut (9) to secure

the shaft.

© Copyright 1997 Printed 2/19/01

■

Figure 1

Marker Assembly

113-502M

1

Page 2

Assembly Instructions

Great Plains Mfg., Inc.

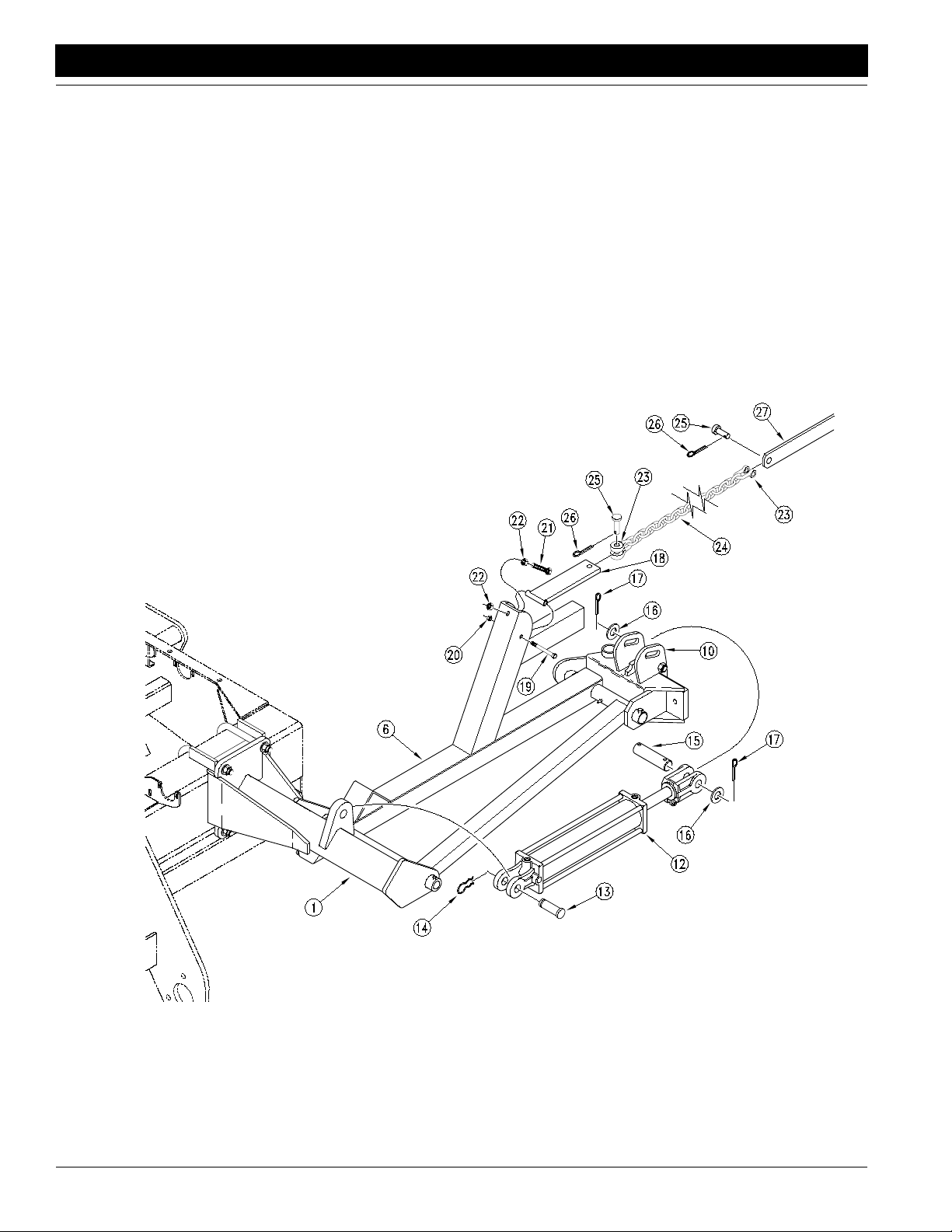

Refer to Figure 2.

4. Pin the base end of the hydraulic cylinder (12) to the marker

mount (1) using the pin and clip (13 and 14). Remove the

plastic plugs from the cylinder ports. Pull the rod end of the

cylinder out to its maximum length. Pin the rod end of the

cylinder to the breakaway hinge using the cylinder pin, flat

washers and cotter pins provided.

5. Install the chain bar (18) on the first section (6) with the bolt

(19) and lock nut (20). The chain bar should pivot freely

around the bolt (19).

6. Install the full-threaded adjustment bolt (21) in the hole directly above the pivot bolt (19). To install, first thread one

lock nut (22) up the entire length of the adjustment bolt.

Next, push the bolt with nut through the hole. Complete the

assembly by threading a second lock nut (22) up the entire

remaining length of the adjustment bolt.

After marker assembly, use the adjustment bolt to control

folding slack. F or no w, turn the adjustment bolt so its head

extends as little as possible to pre vent damage the first time

the marker is folded.

7. Thread a utility clevis (23) through one end of the chain (24).

Pin this clevis to the chain bar (18) using the pin and cotter

pin (25 and 26) provided. Do not fully bend the cotter pin at

this time. Thread a second utility clevis (23) through the last

link at the opposite end of the chain (24). Pin this clevis to

the rounded end of the chain bar (27) using the pin and cotter pin (25 and 26) provided.

Figure 2

Marker Assembly

24- and 30-Foot, No-Till Flat Fold Marker Option 113-502M 4/9/04

2

■

Page 3

Great Plains Mfg., Inc.

Assembly Instructions

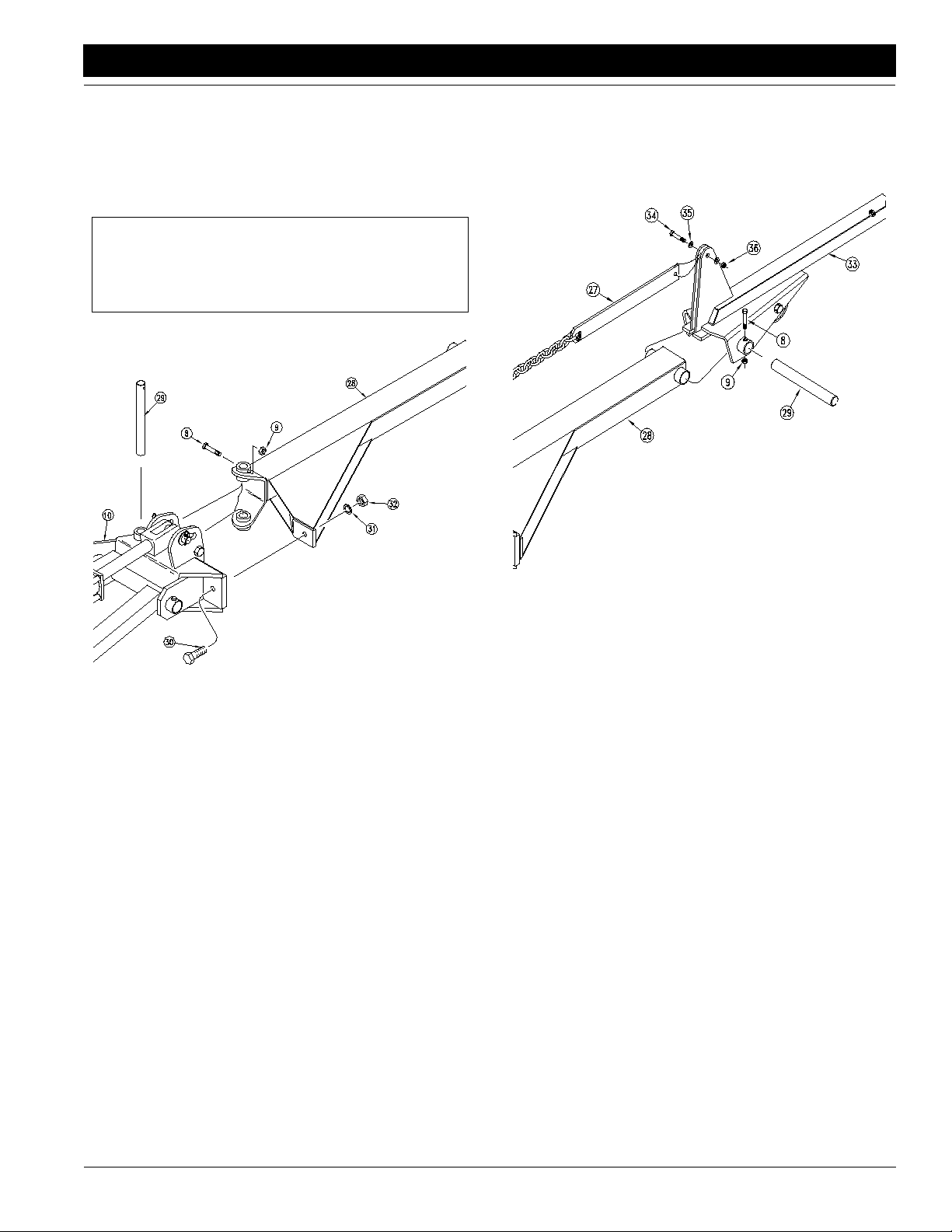

Refer to Figure 1.

8. Attach the second section (28) to the breakaway hinge (10)

with the pivot pin (29). Secure the pivot pin (29) with the bolt

and lock nut (8 and 9). Complete this joint by passing the

grade 5 breakawa y bolt (30) through the holes in the hinge

and second section. Install the lock washer (31) and nut (32)

on the breakaway bolt.

IMPORTANT: The breakaway bolt (30) is a 7/16 x

2 1/4-inch, grade 5 (G.P. # 802-234C). It is identified as a

grade 5 by having three marks on the head. If it breaks, replace it with an equivalent grade 5 bolt to prevent marker

damage.

third section (33) by using the bolt (34) flat washers (35) and

lock nut (36). Do not over tighten this pivot, which would

cause the ears to bend in. The chain bar must pivot freely

around the bolt.

11102

11101

Figure 1

Attaching Second Section

Refer to Figure 1.

9. Attach the third section (33) to the second section (28) by using the pivot pin (29). Secure the pivot pin with the bolt (8) and

lock nut (9).

Fasten the loose end of chain bar (27) to the ears on the

Figure 1

Attaching Third Section

Refer to Figure 1.

10. Slide the fourth-section tube (37) inside the third section

(33). The holes in the fourth section must be to the outside of

the drill and on the top and bottom side as shown. Thread

the jam nuts (38) on the square-headed set screws (39).

Thread the set screws into the nuts welded to the outer end

of the third section (33). Tighten the set screws and jam nuts.

11. Slide the blade and spindle (40) over the f ourth-section tube

(37). Secure the spindle to the tube with bolts (41), flat

washers (42), lock washers (43) and nuts (44). Tighten the

two nuts.

4/9/04

■

24- and 30-Foot, No-Till Flat Fold Marker Option 113-502M

3

Page 4

Assembly Instructions

Great Plains Mfg., Inc.

11103

Attaching Fourth Section

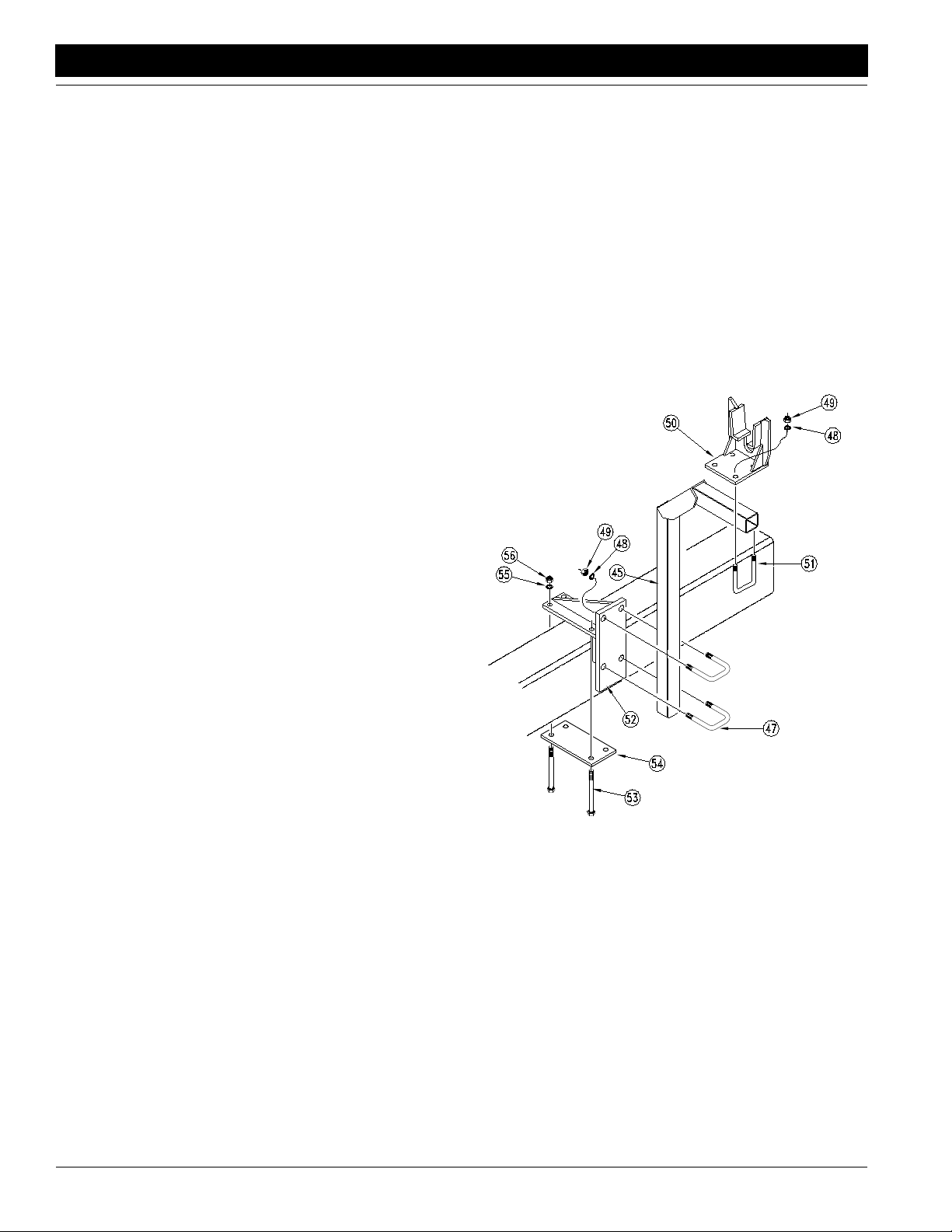

Refer to Figure 1.

12. Mount the transport carrier (45) to the box frame on the inside of the gauge-wheel mount. Use the mounting bracket

(52) and secure it with the four 1/2 x 9 1/2-inch bolts (53), the

plate (54), lock washers (55) and nuts (56).

NOTE: On 30-foot drills, y ou may need to reposition the optional

weight brackets to mak e room for the transport carrier.

13. Fasten the carrier to the mount using the two u-bolts

(47).Tighten the u-bolts with the lock washers (48) and nuts

(49) so that the top of the carrier is about 29 3/8 inches

above the top of the frame tube. You may need to re-adjust

carrier height after assembly. Refer to Transport Carrier,

"Setup Adjustments," page 7.

14. Mount the transport saddle (50) on the top of the carrier arm

(45) using the u-bolts (51), lock washers (48) and nuts (49).

On 24-foot drills, position the offset in the saddle to the outside of the drill as shown.

15. To complete assembly for dual markers, repeat steps three

through nine.

Figure 1

Figure 1

11701

Transport Carrier Mounting

16. After all parts are in place, tighten all bolts and u-bolts. Refer

to the torque chart in your drill operator’s manual. Torque ubolts to grade 5 values.

24- and 30-Foot, No-Till Flat Fold Marker Option 113-502M 4/9/04

4

■

Page 5

Great Plains Mfg., Inc.

Assembly Instructions

Single-Marker Hydraulics

IMPORTANT: JIC fittings do not require high torque. JIC and O-ring fittings do not require sealant. To

avoid cracking fittings or castings

from overtightening, do not use

plastic sealant tape.

Refer to Figure 1.

1. Attach the 90-degree swivel elbo w (1)

to the rod end of the marker cylinder

(2). Insert the orfice (3) in the base

end of the marker cylinder (2). Attach

the 90-degree swivel elbo w (1) to the

base end of the marker cylinder (2).

2. Uncoil and attach hose (4) to the swivel elbow at the rod end of the marker

cylinder (2). Uncoil and attach hose

(5) to the swivel elbow (1) at the base

end of the marker cylinder (2).

3. Install the two adapters (9) and two elbow fittings (7) in the top ports (A2 and

B2) of the manifold valv e (8). The

manifold valv e is located in rear-center of the main frame.

4. Route and connect the two marker

hoses (4 and 5) to the elbow fittings (7).

Route hoses through the frame member cut-outs and hose clamps. Route

the hoses parallel to the hoses feeding

the outer gauge-wheel cylinder. See

Figure 1.

Figure 1

Hydraulic Hose Routing

Refer to Figure 1.

5. Fine tune the hose placement. Make a generous loop in

both hoses near the folding hinge. This loop should be large

enough to allow the outer wing to flex without the hoses pulling tight. Maintain the loops by clamping the hoses in the

center hole of the existing hose clamps. Use the split rubber

sleeves as b ushings between the clamps and the mark er

hose. Use the cable ties (6) supplied with the kit to hold the

hoses away from an y pinch point.

Figure 1

Transport Carrier Mounting

IMPORTANT: Read and complete Setup Adjustments,

page 7 before folding the markers.

13005

4/9/04

■

24- and 30-Foot, No-Till Flat Fold Marker Option 113-502M

5

Page 6

Assembly Instructions

Great Plains Mfg., Inc.

Dual Marker Hydraulics

NOTE: JIC fittings do not require high torque. JIC and Oring fittings do not require sealant. To avoid cracking fittings or castings from overtightening, do not use plastic

sealant tape.

Refer to Figure 1.

1. Attach the 90˚ swivel elbows (1) to the rod end of both marker cylinders (2). Insert the orifices (7) in the base end of the

marker cylinders (2). Attach the 90˚ swivel elbo ws (1) to the

base end of the marker cylinders (2).

2. Uncoil and attach hoses (3 and 4) to the swivel elbows (1).

Notice that the longer hoses go to the rod end of the cylinders.

3. Attach the two adapters (9) and the 90-degree elbows (6) in

the manifold valv e (8) at ports A2 and B2. The manifold

valve is located in the rear-center of the main frame.

4. Attach the sequence valve (10) on the mounting brac ket using the lock washers (11) and 3/8 x 7/8-inch bolts (12).

5. Install hydraulic hoses (13) on the sequence valve (10).

Connect port A2 on the manifold valve (8) to port 2 on the

sequence valve (10). Connect port B2 on the manifold valv e

to port 1 on the sequence valve.

6. Connect the four hoses coming from the marker cylinders to

the sequence valve. Connect the base-end hoses (4) to

ports R1 and R2 (10) and the rod hoses (3) to ports C1 and

C2 as shown.

7. Route the hoses coming from the marker cylinders through

the frame member cut-outs and hose clamps. Run the hoses parallel to the hoses feeding the outer gauge-wheel cylinder as shown in Figure 1 on page 5.

8. Fine tune the hose placement. Make a generous loop in

both hoses near the box flex hinge. This loop should be

large enough to allow the outer wing to flex without the hoses pulling tight. Maintain the loops by clamping the hoses in

the center hole of the existing hose clamps. Use the split

rubber sleeves as bushings betw een the clamps and the

marker hose. Use the cable ties (6) supplied with the kit to

hold the hoses away from an y pinch point.

IMPORTANT: Read and complete Setup Adjustments,

page 7 before folding the markers.

Figure 1

Dual Marker Hydraulic Schematic

24- and 30-Foot, No-Till Flat Fold Marker Option 113-502M 4/9/04

6

14683

■

Page 7

Great Plains Mfg., Inc.

Assembly Instructions

Setup Adjustments

1. Storage Saddle. When folding the marker for the first time,

you may need to move the storage saddle into alignment

with the second section of the marker arm. Slowly fold the

marker and stop when the marker is just above the storage

saddle. Adjust the bracket in or out as needed.

2. T ransport Carrier. After centering the storage saddle and

folding the marker , visually check the height of the transport

carrier. The second section of the marker should appear

parallel with the top of the drill box. If not, loosen the transport carrier u-bolts and adjust the carrier up or down.

3. Marker Chain. There are two basic adjustments needed on

the marker chain, especially in new installations. They are

interrelated and should be done in the following order.

a. Lifting Slack. Start with the marker in the unfolded po-

sition. Back the adjustment bolt (Figure 2, page 2, 21)

down until the head extends as little as possible . Slowly

fold the marker , observing the motion of the disk. If the

marker disk slides across the ground more than about

one foot before the chain and linkage lifts it up , the chain

is too slack. Tighten the chain by moving the cle vis one

or two links at the inboard end of the chain. Recheck by

repeating this process.

If the chain does not have enough slack when the mark-

er is in the unfolded field position, the chain will prev ent

the end of the marker from dropping down to follow a depression in the field. Correct this condition by moving

the utility clevis one or two links, giving the chain more

slack.

b. Folding Slack. Fold the marker . Extend the adjustment

bolt until the slack is out of the chain. Lock the bolt in

this position by tightening the nuts on either side of the

upright channel.

!

CAUTION!

Never allow anyone near the drill when cycling the markers!

!

WARNING!

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin causing serious injury. Avoid the hazard by

relieving pressure before disconnecting hydraulic lines. Use a

piece of paper or cardboard, NOT BODY PARTS, to check for

leaks. Wear protective gloves and safety glasses or goggles

when working with hydraulic systems. If an accident occurs, see

a doctor immediately. Any fluid injected into the skin must be

surgically removed within a few hours or gangrene will result.

1. Be sure tractor hydraulic reservoir is full.

2. With the drill unfolded and lowered, set the switch on the

control console to the left-marker position.

3. With the marker unfolded, crack the hose fitting at the base

end of the left-marker cylinder. With y our tractor at an idle

speed, activate your hydr aulic valve until oil seeps out

around the hose ends. Tighten the hose-end fittings.

4. Repeat step three with the hose-end fitting at the rod end of

the cylinder.

5. If dual markers are used, repeat steps three and four for the

right marker cylinder.

NOTE: For dual markers, both are controlled by the left-marker

switch.

6. Fold and unfold the marker(s) slo wly to work all the air out of

your marker hydraulics .

Bleeding Marker Hydraulics

To operate correctly, the marker h ydraulics must be free of air. If

not properly bled, the markers will fold in jerky, uneven motions.

Follow these instructions to bleed the marker h ydr aulics .

IMPORTANT: JIC fittings do not require high torque. JIC

and O-Ring fittings do not require sealant. Always use liquid pipe sealant when adding or replacing pipe thread fittings. To avoid possible danger of cracking hydraulic

fittings from over tightening, do not use plastic sealant

tape.

4/9/04

■

24- and 30-Foot, No-Till Flat Fold Marker Option 113-502M

7

Page 8

Listing of Parts

113-498A 24-Foot No-Till Left-Hand Flat-Fold Marker

Your Kit Includes:

Qty. Part No. Part Description

1 113-180H LH FIRST SECTION

1 113-197H MARKER CARRIER

1 113-248D MARKER CYLINDER PIN BODY

1 113-311D HINGE PIN

1 113-312D FIRST PIVOT SHAFT

1 113-313D SECOND PIVOT SHAFT

1 113-324D CYLINDER STOP

2 113-325D STOP BUSHING

1 113-342H NO-TILL MARKER 24' 2ND SECTION

1 113-344H NO-TILL MARKER 24' 3RD SECTION

1 113-350H NO-TILL BREAKAWAY JOINT LH

1 113-360S NOTILL MRKR DSK & 4BLT HUB ASY

1 113-379D NO-TILL 24' 4TH SECT TUBE

1 113-381H 2SNT L.H. MARKER MOUNT WMNT

4 800-001C GREASE ZERK STRAIGHT 1/4-28

2 801-013C SCREW SER SQ HD 1/2-12x1 1/2 +

2 802-042C HHCS 1/2-13X3 3/4 GR5

3 802-115C HHCS 5/16-18X2 GR5

1 802-201C HHCS 1/2-13X4 3/4 GR5

1 802-234C HHCS 7/16-14X2 1/4 GR5

1 802-260C HHCS 1/2-13X7 GR5

3 803-011C NUT LOCK 5/16-18 PLT

1 803-015C NUT HEX 7/16-14 PLT

2 803-019C NUT LOCK 1/2-13 PLT

2 803-020C NUT HEX 1/2-13 PLT

2 803-036C NUT HEX JAM 1/2-13 PLT

1 804-014C WASHER LOCK 7/16 PLT

2 804-015C WASHER LOCK SPRING 1/2 PLT

4 804-017C WASHER FLAT 1/2 USS PLT

2 804-029C WASHER FLAT 1 SAE

2 805-058C PIN COTTER 3/16 X 2

1 810-118C CYL 2.5X20X1.12 ROD (TIE)1 PIN

1 113-200H CHAIN BAR WELDMENT

1 113-311D HINGE PIN

1 113-316H MARKER TRNSPT ARM MOUNT WLDMT

1 113-323D CHAIN BAR

1 113-328D 24' MARKER CHAIN

1 113-365H NO-TILL SADDLE REST WELDMENT

1 113-398D RUBBER TUBE RD 3 OD X 5 LONG

1 113-502M MANUAL 24 & 30 2SNT FF MARKER

1 113-555D MARKER MOUNT PLATE

6 800-082C CABLE TIE .31X21.5 6DIA 120LB

1 802-022C HHCS 3/8-16X1 1/2 GR5

4 802-048C HHCS 1/2-13X9 1/2 GR5

1 802-115C HHCS 5/16-18X2 GR5

1 802-168C HHCS 3/8-16X3 1/4 GR5

1 802-261C HHCS 3/8-16X2 1/2 GR5 FTHD

1 803-011C NUT LOCK 5/16-18 PLT

4 803-013C NUT LOCK 3/8-16 PLT

12 803-020C NUT HEX 1/2-13 PLT

4 803-027C NUT HEX 3/4-10 PLT

2 804-011C WASHER FLAT 3/8 USS PLT

12 804-015C WASHER LOCK SPRING 1/2 PLT

4 804-023C WASHER LOCK SPRING 3/4 PLT

2 806-005C U-BOLT 1/2-13 X 2 X 3 GR 5

2 806-023C U-BOLT 1/2-13 X 2 1/32 X 3 1/4

2 806-037C U-BOLT 3/4-10 X 8 1/16 X 9 1/2

1 811-044C AD 3/8MNPT

2 811-133C AD 9/16MJIC 3/4MORB

2 811-169C EL 9/16MJIC 9/16FJIC

2 811-281C EL 3/8FNPT 9/16MORB

1 811-347C ORPL 1/16 9/16MORB

2 890-018C UTILITY CLEVIS 5/16

1 811-035C HH1/4R1 252 9/16FJIC 3/8MNPT

1 811-333C HH1/4R1 032 9/16FJIC

1 811-451C HH1/4R1 212 3/8MNPT 9/16FJIC

Great Plains Mfg., Inc.

24- and 30-Foot, No-Till Flat Fold Marker Option 113-502M 4/9/04

8

■

Page 9

Great Plains Mfg., Inc.

Listing of Parts

113-499A 24-Foot No-Till Dual Flat-Fold Markers

Your Kit Includes:

Qty. Part No. Part Description

1 113-180H LH FIRST SECTION

1 113-188H RH FIRST SECTION

2 113-197H MARKER CARRIER

2 113-248D MARKER CYLINDER PIN BODY

2 113-312D FIRST PIVOT SHAFT

2 113-313D SECOND PIVOT SHAFT

2 113-316H MARKER TRNSPT ARM MOUNT WLDMT

2 113-324D CYLINDER STOP

4 113-325D STOP BUSHING

2 113-342H NO-TILL MARKER 24' 2ND SECTION

2 113-344H NO-TILL MARKER 24' 3RD SECTION

1 113-350H NO-TILL BREAKAWAY JOINT LH

1 113-351H NO-TILL BREAKAWAY JOINT RH

2 113-360S NOTILL MRKR DSK & 4BLT HUB ASY

2 113-365H NO-TILL SADDLE REST WELDMENT

2 113-379D NO-TILL 24' 4TH SECT TUBE

1 113-381H 2SNT L.H. MARKER MOUNT WMNT

1 113-382H 2SNT R.H. MARKER MOUNT WMNT

2 113-398D RUBBER TUBE RD 3 OD X 5 LONG

8 800-001C GREASE ZERK STRAIGHT 1/4-28

4 801-013C SCREW SET SQ HD 1/2-13X1 1/2G5

2 802-042C HHCS 1/2-13X3 3/4 GR5

4 802-115C HHCS 5/16-18X2 GR5

2 802-201C HHCS 1/2-13X4 3/4 GR5

2 802-234C HHCS 7/16-14X2 1/4 GR5

2 802-260C HHCS 1/2-13X7 GR5

4 803-011C NUT LOCK 5/16-18 PLT

2 803-015C NUT HEX 7/16-14 PLT

4 803-019C NUT LOCK 1/2-13 PLT

6 803-020C NUT HEX 1/2-13 PLT

4 803-036C NUT HEX JAM 1/2-13 PLT

2 804-014C WASHER LOCK 7/16 PLT

4 804-015C WASHER LOCK SPRING 1/2 PLT

8 804-017C WASHER FLAT 1/2 USS PLT

4 804-029C WASHER FLAT 1 SAE

4 805-058C PIN COTTER 3/16 X 2

2 810-118C CYL 2.5X20X1.12 ROD (TIE)1 PIN

2 113-200H CHAIN BAR WELDMENT

4 113-311D HINGE PIN

2 113-323D CHAIN BAR

2 113-328D 24' MARKER CHAIN

1 113-502M MANUAL 24 & 30 2SNT FF MARKER

2 113-555D MARKER MOUNT PLATE

12 800-082C CABLE TIE .31X21.5 6DIA 120LB

2 802-022C HHCS 3/8-16X1 1/2 GR5

8 802-048C HHCS 1/2-13X9 1/2 GR5

4 802-115C HHCS 5/16-18X2 GR5

2 802-168C HHCS 3/8-16X3 1/4 GR5

2 802-261C HHCS 3/8-16X2 1/2 GR5 FTHD

2 802-417C HHCS 3/8-16X7/8 GR5

4 803-011C NUT LOCK 5/16-18 PLT

8 803-013C NUT LOCK 3/8-16 PLT

24 803-020C NUT HEX 1/2-13 PLT

8 803-027C NUT HEX 3/4-10 PLT

4 804-011C WASHER FLAT 3/8 USS PLT

2 804-013C WASHER LOCK SPRING 3/8 PLT

24 804-015C WASHER LOCK SPRING 1/2 PLT

8 804-023C WASHER LOCK SPRING 3/4 PLT

4 806-005C U-BOLT 1/2-13 X 2 X 3 GR 5

4 806-023C U-BOLT 1/2-13 X 2 1/32 X 3 1/4

4 806-037C U-BOLT 3/4-10 X 8 1/16 X 9 1/2

1 810-197C VALVE,SEQUENCE SHOEMAKER

2 811-133C AD 9/16MJIC 3/4MORB

2 811-169C EL 9/16MJIC 9/16FJIC

4 811-281C EL 3/8FNPT 9/16MORB

4 890-018C UTILITY CLEVIS 5/16

2 811-035C HH1/4R1 252 9/16FJIC 3/8MNPT

2 811-333C HH1/4R1 032 9/16FJIC

2 811-451C HH1/4R1 212 3/8MNPT 9/16FJIC

4/9/04

■

24- and 30-Foot, No-Till Flat Fold Marker Option 113-502M

9

Page 10

Listing of Parts

113-500A 30-Foot No-Till Left-Hand Flat-Fold Marker

Your Kit Includes:

Qty. Part No. Part Description

1 113-180H LH FIRST SECTION

1 113-197H MARKER CARRIER

1 113-248D MARKER CYLINDER PIN BODY

1 113-311D HINGE PIN

1 113-312D FIRST PIVOT SHAFT

1 113-313D SECOND PIVOT SHAFT

1 113-324D CYLINDER STOP

2 113-325D STOP BUSHING

1 113-350H NO-TILL BREAKAWAY JOINT LH

1 113-360S NOTILL MRKR DSK & 4BLT HUB ASY

1 113-381H 2SNT L.H. MARKER MOUNT WMNT

4 800-001C GREASE ZERK STRAIGHT 1/4-28

2 801-013C SCREW SER SQ HD 1/2-12x1 1/2 +

2 802-042C HHCS 1/2-13X3 3/4 GR5

3 802-115C HHCS 5/16-18X2 GR5

1 802-201C HHCS 1/2-13X4 3/4 GR5

1 802-234C HHCS 7/16-14X2 1/4 GR5

1 802-260C HHCS 1/2-13X7 GR5

3 803-011C NUT LOCK 5/16-18 PLT

1 803-015C NUT HEX 7/16-14 PLT

2 803-019C NUT LOCK 1/2-13 PLT

2 803-020C NUT HEX 1/2-13 PLT

2 803-036C NUT HEX JAM 1/2-13 PLT

1 804-014C WASHER LOCK 7/16 PLT

2 804-015C WASHER LOCK SPRING 1/2 PLT

4 804-017C WASHER FLAT 1/2 USS PLT

2 804-029C WASHER FLAT 1 SAE

2 805-058C PIN COTTER 3/16 X 2

1 810-118C CYL 2.5X20X1.12 ROD (TIE)1 PIN

1 113-200H CHAIN BAR WELDMENT

1 113-311D HINGE PIN

1 113-316H MARKER TRNSPT ARM MOUNT WLDMT

1 113-323D CHAIN BAR

1 113-365H NO-TILL SADDLE REST WELDMENT

1 113-398D RUBBER TUBE RD 3 OD X 5 LONG

1 113-502M MANUAL 24 & 30 2SNT FF MARKER

1 113-555D MARKER MOUNT PLATE

6 800-082C CABLE TIE .31X21.5 6DIA 120LB

1 802-022C HHCS 3/8-16X1 1/2 GR5

4 802-048C HHCS 1/2-13X9 1/2 GR5

1 802-115C HHCS 5/16-18X2 GR5

1 802-168C HHCS 3/8-16X3 1/4 GR5

1 802-261C HHCS 3/8-16X2 1/2 GR5 FTHD

1 803-011C NUT LOCK 5/16-18 PLT

4 803-013C NUT LOCK 3/8-16 PLT

12 803-020C NUT HEX 1/2-13 PLT

4 803-027C NUT HEX 3/4-10 PLT

2 804-011C WASHER FLAT 3/8 USS PLT

12 804-015C WASHER LOCK SPRING 1/2 PLT

4 804-023C WASHER LOCK SPRING 3/4 PLT

2 806-005C U-BOLT 1/2-13 X 2 X 3 GR 5

2 806-023C U-BOLT 1/2-13 X 2 1/32 X 3 1/4

2 806-037C U-BOLT 3/4-10 X 8 1/16 X 9 1/2

1 811-044C AD 3/8MNPT

2 811-133C AD 9/16MJIC 3/4MORB

2 811-169C EL 9/16MJIC 9/16FJIC

2 811-281C EL 3/8FNPT 9/16MORB

1 811-347C ORPL 1/16 9/16MORB

2 890-018C UTILITY CLEVIS 5/16

1 811-035C HH1/4R1 252 9/16FJIC 3/8MNPT

1 811-333C HH1/4R1 032 9/16FJIC

1 113-341H NO-TILL MARKER 30' 2ND SECTION

1 113-343H NO-TILL MARKER 30' 3RD SECTION

1 113-378D NO-TILL 30' 4TH SECT TUBE

1 113-319D MARKER CHAIN 30'

4 804-017C WASHER FLAT 1/2 USS PLT

1 811-014C HH1/4R1 288 9/16FJIC 3/8MNPT

Great Plains Mfg., Inc.

24- and 30-Foot, No-Till Flat Fold Marker Option 113-502M 4/9/04

10

■

Page 11

Great Plains Mfg., Inc.

Listing of Parts

113-501A 30-Foot No-Till Dual Flat-Fold Marker

Your Kit Includes:

Qty. Part No. Part Description

1 113-180H LH FIRST SECTION

1 113-188H RH FIRST SECTION

2 113-197H MARKER CARRIER

2 113-248D MARKER CYLINDER PIN BODY

2 113-312D FIRST PIVOT SHAFT

2 113-313D SECOND PIVOT SHAFT

2 113-316H MARKER TRNSPT ARM MOUNT WLDMT

2 113-324D CYLINDER STOP

4 113-325D STOP BUSHING

1 113-350H NO-TILL BREAKAWAY JOINT LH

1 113-351H NO-TILL BREAKAWAY JOINT RH

2 113-360S NOTILL MRKR DSK & 4BLT HUB ASY

2 113-365H NO-TILL SADDLE REST WELDMENT

1 113-381H 2SNT L.H. MARKER MOUNT WMNT

1 113-382H 2SNT R.H. MARKER MOUNT WMNT

2 113-398D RUBBER TUBE RD 3 OD X 5 LONG

8 800-001C GREASE ZERK STRAIGHT 1/4-28

4 801-013C SCREW SET SQ HD 1/2-13X1 1/2G5

2 802-042C HHCS 1/2-13X3 3/4 GR5

4 802-115C HHCS 5/16-18X2 GR5

2 802-201C HHCS 1/2-13X4 3/4 GR5

2 802-234C HHCS 7/16-14X2 1/4 GR5

2 802-260C HHCS 1/2-13X7 GR5

4 803-011C NUT LOCK 5/16-18 PLT

2 803-015C NUT HEX 7/16-14 PLT

4 803-019C NUT LOCK 1/2-13 PLT

2 803-020C NUT HEX 1/2-13 PLT

4 803-036C NUT HEX JAM 1/2-13 PLT

2 804-014C WASHER LOCK 7/16 PLT

4 804-015C WASHER LOCK SPRING 1/2 PLT

8 804-017C WASHER FLAT 1/2 USS PLT

4 804-029C WASHER FLAT 1 SAE

4 805-058C PIN COTTER 3/16 X 2

2 810-118C CYL 2.5X20X1.12 ROD (TIE)1 PIN

2 113-200H CHAIN BAR WELDMENT

4 113-311D HINGE PIN

2 113-323D CHAIN BAR

1 113-502M MANUAL 24 & 30 2SNT FF MARKER

2 113-555D MARKER MOUNT PLATE

12 800-082C CABLE TIE .31X21.5 6DIA 120LB

2 802-022C HHCS 3/8-16X1 1/2 GR5

8 802-048C HHCS 1/2-13X9 1/2 GR5

4 802-115C HHCS 5/16-18X2 GR5

2 802-168C HHCS 3/8-16X3 1/4 GR5

2 802-261C HHCS 3/8-16X2 1/2 GR5 FTHD

2 802-417C HHCS 3/8-16X7/8 GR5

4 803-011C NUT LOCK 5/16-18 PLT

8 803-013C NUT LOCK 3/8-16 PLT

24 803-020C NUT HEX 1/2-13 PLT

8 803-027C NUT HEX 3/4-10 PLT

4 804-011C WASHER FLAT 3/8 USS PLT

2 804-013C WASHER LOCK SPRING 3/8 PLT

24 804-015C WASHER LOCK SPRING 1/2 PLT

8 804-023C WASHER LOCK SPRING 3/4 PLT

4 806-005C U-BOLT 1/2-13 X 2 X 3 GR 5

4 806-023C U-BOLT 1/2-13 X 2 1/32 X 3 1/4

4 806-037C U-BOLT 3/4-10 X 8 1/16 X 9 1/2

1 810-197C VALVE,SEQUENCE SHOEMAKER

2 811-133C AD 9/16MJIC 3/4MORB

2 811-169C EL 9/16MJIC 9/16FJIC

4 811-281C EL 3/8FNPT 9/16MORB

4 890-018C UTILITY CLEVIS 5/16

2 811-035C HH1/4R1 252 9/16FJIC 3/8MNPT

2 811-333C HH1/4R1 032 9/16FJIC

2 113-341H NO-TILL MARKER 30' 2ND SECTION

2 113-343H NO-TILL MARKER 30' 3RD SECTION

2 113-378D NO-TILL 30' 4TH SECT TUBE

2 113-319D MARKER CHAIN 30'

8 804-017C WASHER FLAT 1/2 USS PLT

2 811-014C HH1/4R1 288 9/16FJIC 3/8MNPT

4/9/04

■

24- and 30-Foot, No-Till Flat Fold Marker Option 113-502M

11

Loading...

Loading...