Page 1

Great Plains Mfg., Inc.

Manufacturing, Inc.

Seed and Small Seeds Rate

Charts

Thefollowingpagesare to assist in the proper setting of seeding rates

forthe 2N-2410,2N-2420, 2N-3010 and 2N-3020 FoldingNo-Till drill.

The rates indicated in the charts are approximate values. To assure

the most accurate seeding rate it is recommended that the drill be calibrated for the desired seed at the time of planting.

© Copyright 2003 Printed

12/17/2003

196-126B

Page 2

2

Table of Contents

Setting the Seeding Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Shift Speed-Change Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Adjust Seed-Rate Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Set Seed-Cup Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Check Seeding Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Small Seeds Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Seed Rate Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Small Seeds Attachment Seed Rate Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Great Plains Mfg., Inc.

196-126B 12/17/2003

Page 3

Great Plains Mfg., Inc.

Setting the Seeding Rate

Calibratingthe seeding raterequiresfour steps:shiftingthe

speed-change gearbox, adjusting the seed-rate handle,

setting the seed-cup doors, and checking the seeding rate.

Checktheseed-ratecharts startingonpage 5 or in the drill

boxes. These charts list the proper settings for the speedchange gearbox and seed-rate handle for various seeds

and seeding rates.

The seed-rate charts are based on cleaned, untreated

seed of average size and test weight. The rates are based

on 11L x 15 8-ply rib implement tires and 265/70B16 skid

steer tires. Many factors will affect seeding rates including

foreign material, seed treatment, seed size, field conditions, tire pressure and test weight. Minor adjustments

likelywill be needed. Set and check the seeding rate using

theprocedures below,thenre-adjustthe rateasnecessary.

Before setting the seeding rate, rotate both gauge wheels

to see that the seed cups and drive are working properly

and free from foreign material.

3

Note:Eachdrillboxhas its own metering mechanism. After

adjusting and checking the rate on one box, set the same

rate on the other box.

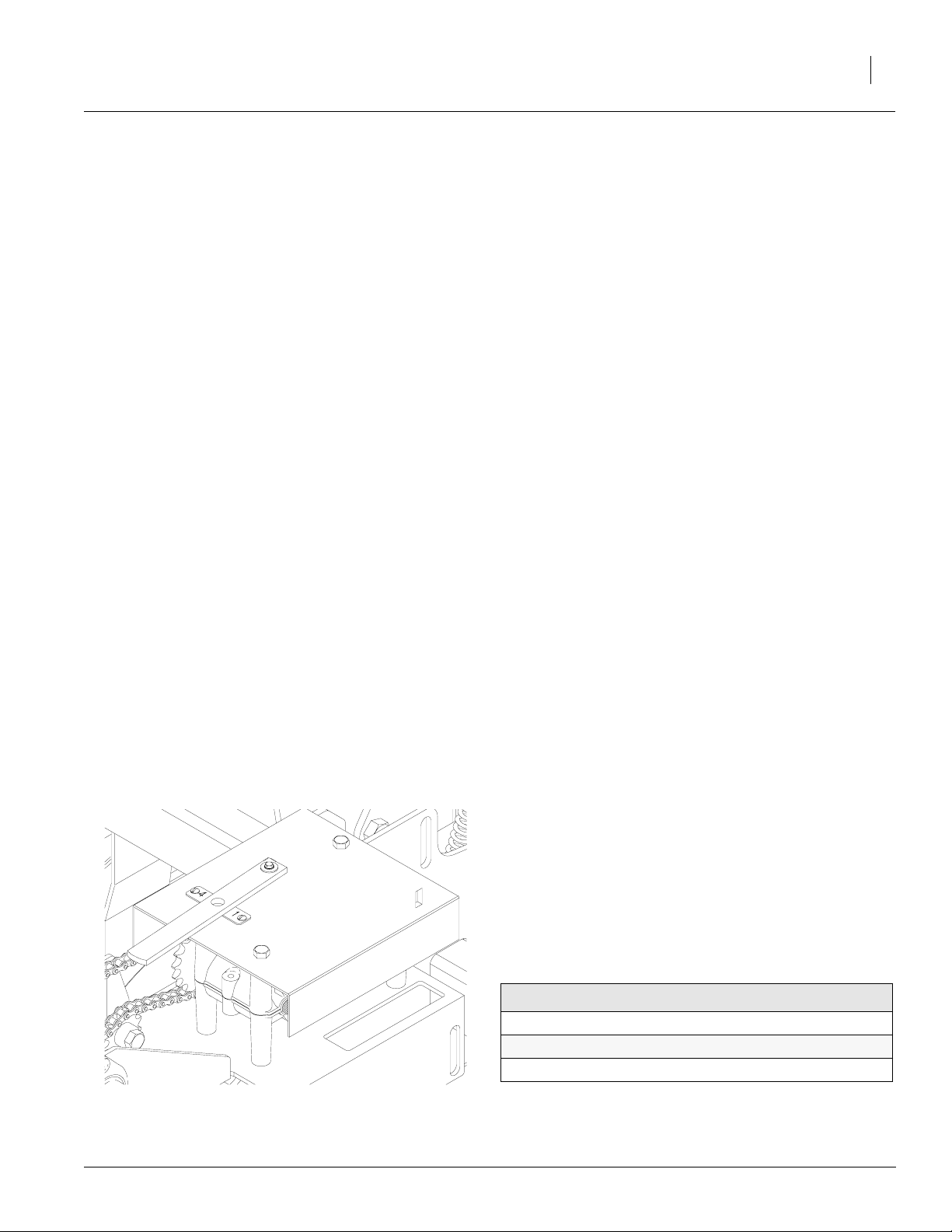

Refer to Figure 1

1. Shift Speed-Change Gearbox

The speed-change gearbox is designed to give you a

varietyof speeds for differentseeds and seeding rates.

You can shift between four different drive types.

Referto the seed-rate chartsfor the correct drive type–

1, 2, 3 or 4. Move the selector handle on the gearbox

untilthecorrectnumberappears in the handle window.

Rotate the tires a few turns to confirm the gearbox has

engaged.

12916

Gearbox Ratios:

Drive Type 2 is 2.06 Times Faster Than 1

Drive Type 3 is 3.08 Times Faster Than 1

Drive Type 4 is 5.03 Times Faster Than 1

9/22/2004

Figure 1

Speed-Change Gearbox

196-126B

Page 4

4

Great Plains Mfg., Inc.

Refer to Figure 2

2. Adjust Seed-Rate Handle

Position the handle to the setting indicated on the

seed-rate chart. To adjust, loosen the wing nut under

the handle and slide until indicator lines up with desired setting. Retighten nut.

12927

Figure 2

Seed-Rate Handle

Refer to Figure 3

3. Set Seed-Cup Doors

Forwheat and other small seeds, move the seed-cupdoor handles to the highest position. For soybeans

and other large seeds, lower the handles to the secondposition. If excessiveseedcrackingoccurs, lower

the handles to the third position. For seed-cup clean

out, move the handles to the fourth, wide-open position. Make sure all handles are in the same position

before drilling.

4. Check Seeding Rate

a. Place severalpounds ofseed overthe three seed

cups on the outside end of the drill box.

b. Disconnectthe seedtubesfrom thethreeopeners

fed by the covered cups.

c. Raise the drill off the ground.

d. Record the empty weight of a container large

enough to hold the seed metered for one acre.

e. Turn gauge wheels until seed drops to the ground

from each cup.

f. Place a container under the three seed tubes to

gather the seed as it is metered.

g. Rotate the gauge wheel until one acre has been

tallied on the acremeter. This will be about 225 ro-

tations on a 24-foot drill and about 181 rotations

on a 30-foot drill. Check that the seed cups have

plenty of seed coming into them.

h. Weigh the metered seed. Subtract the initial

weight of the container. Divide by three. Multiply

by the number of openers on your drill for the

pounds-per-acre seeding rate. If this figure is dif-

ferent than desired, re-adjust the seed-rate han-

dle and recheck the rate.

5. Whensatisfiedwiththeseedingrate,repeat steps 1

through3 fortheother drill box,settingit to the same

rate.

Small Seeds Attachment

To set the seeding rate, referto the small-seeds-rate chart

on page 9. Move the seed-rate handle on the attachment

to the setting indicated on the chart.

To calibrate the attachment to your material, follow the

steps listed under Check Seeding Rate, this page.

13867

Figure 3

Seed-Cup Door Handle

196-126B 12/17/2003

Page 5

Great Plains Mfg., Inc.

Seed Rate Charts (Pounds per acre)

Setting number 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Alfalfa

Drive Type 1

(Based on

60#/bu)

Row Space

1.8 4.6 7.0 10.0 12.8 16.0 19.1 22.7 26.3 30.7 34.3 37.5 41.5 45.3 49.3 52.9 57.5 61.8 66.3 68.3 70.2

7.5"

1.7 4.3 6.5 9.4 12.1 15.0 17.9 21.3 24.7 28.8 32.2 35.2 39.0 42.6 46.3 49.6 54.0 58.0 62.3 64.1 65.9

8"

1.4 3.5 5.2 7.5 9.7 12.0 14.4 17.1 19.8 23.1 25.8 28.2 31.2 34.1 37.1 39.8 43.2 46.5 49.9 51.4 52.8

10"

5

Barley

Drive Type 1

(Based on

51#/bu)

Barley

Drive Type 2

(Based on

51#/bu)

Buckwheat

Drive Type 2

(Based on

48#/bu)

Buckwheat

Drive Type 3

(Based on

48#/bu)

Buffalo Grass

Drive Type 1

(Based on

23#/bu)

Bermuda Grass

Drive Type 1

(Based on

60#/bu)

BermudaGrass

Drive Type 2

(Based on

60#/bu)

1.6 3.8 6.3 8.9 12.0 15.1 18.6 21.8 25.2 28.9 32.5 36.2 40.0 44.2 47.8 51.6 54.8 57.8 60.7 61.2 61.7

7.5"

1.5 3.5 6.0 8.4 11.3 14.2 17.4 20.5 23.7 27.1 30.6 34.0 37.6 41.5 44.8 48.5 51.5 54.2 57.0 57.4 57.9

8"

1.2 2.8 4.8 6.7 9.0 11.4 14.0 16.4 19.0 21.7 24.5 27.2 30.1 33.2 35.9 38.8 41.2 43.5 45.6 46.0 46.4

10"

Row Space

7.5" 2.9 7.2 13.3 18.0 24.9 30.9 37.7 44.9 51.7 59.4 66.4 72.8 80.2 87.1 95.0 102.6 111.1 119.1 126.8 128.8 130.8

8" 2.7 6.8 12.4 16.9 23.4 29.0 35.4 42.2 48.5 55.8 62.3 68.3 75.2 81.7 89.2 96.3 104.3 111.8 119.0 120.9 122.8

10" 2.2 5.4 10.0 13.6 18.7 23.2 28.4 33.8 38.9 44.7 49.9 54.7 60.3 65.5 71.4 77.2 83.5 89.6 95.3 96.8 98.4

Row Space

0.0 4.5 11.7 17.2 24.3 30.6 36.5 43.8 51.2 58.3 65.7 72.4 79.5 86.9 93.7 101.9 107.8 114.4 121.2 122.0 122.7

7.5"

0.0 4.2 10.9 16.2 22.9 28.7 34.3 41.1 48.1 54.7 61.7 68.0 74.6 81.6 87.9 95.6 101.2 107.4 113.8 114.5 115.2

8"

0.0 3.4 8.8 13.0 18.3 23.0 27.5 32.9 38.5 43.8 49.4 54.5 59.8 65.4 70.5 76.6 81.1 86.1 91.2 91.8 92.3

10"

Row Space

0.0 9.4 17.6 24.6 35.0 43.7 54.4 65.2 77.3 89.3 103.0 113.5 125.8 138.3 150.2 163.5 175.0 187.4 211.3 202.3 204.5

7.5"

0.0 8.8 16.5 23.1 32.9 41.0 51.0 61.2 72.5 83.9 96.7 106.5 118.1 129.9 141.0 153.5 164.3 175.9 198.3 189.9 191.9

8"

0.0 7.1 13.2 18.5 26.3 32.9 40.9 49.0 58.1 67.2 77.4 85.3 94.6 104.0 112.9 122.9 131.6 140.9 158.9 152.2 153.8

10"

Row Space

0.0 0.4 1.8 3.1 4.5 5.9 7.3 8.8 10.3 11.7 13.0 14.0 15.1 16.1 17.3 18.6 20.0 21.5 23.0 21.7 20.4

7.5"

0.0 0.4 1.7 2.9 4.2 5.5 6.9 8.2 9.6 11.0 12.2 13.2 14.2 15.1 16.2 17.5 18.8 20.1 21.6 20.4 19.1

8"

0.0 0.3 1.4 2.3 3.4 4.4 5.5 6.6 7.7 8.8 9.8 10.5 11.4 12.1 13.0 14.0 15.1 16.1 17.3 16.3 15.3

10"

Row Space

0.0 2.1 3.7 5.6 7.9 9.7 11.5 14.0 16.3 18.4 20.5 22.5 24.4 26.5 28.7 30.7 32.9 34.9 37.1 38.7 40.5

7.5"

0.0 2.0 3.4 5.3 7.4 9.1 10.8 13.2 15.3 17.3 19.2 21.1 22.9 24.9 26.9 28.9 30.9 32.8 34.8 36.3 38.0

8"

0.0 1.6 2.8 4.2 6.0 7.3 8.6 10.5 12.2 13.8 15.4 16.9 18.4 20.0 21.6 23.1 24.7 26.3 27.9 29.1 30.5

10"

Row Space

0.0 4.3 7.5 11.6 16.2 20.0 23.6 28.8 33.5 37.8 42.1 46.2 50.2 54.6 58.9 63.2 67.6 71.8 76.2 79.5 83.3

7.5"

0.0 4.1 7.1 10.9 15.3 18.7 22.2 27.0 31.4 35.5 39.5 43.4 47.1 51.2 55.3 59.3 63.5 67.4 71.5 74.6 78.2

8"

0.0 3.3 5.7 8.7 12.3 15.0 17.8 21.7 25.2 28.4 31.6 34.7 37.8 41.0 44.3 47.5 50.8 54.0 57.3 59.8 62.7

10"

Row Space

BermudaGrass

Drive Type 3

(Based on

60#/bu)

BermudaGrass

Drive Type 4

(Based on

60#/bu)

Fescue K-31

Drive Type 2

(Based on

21#/bu)

Fescue K-31

Drive Type 3

(Based on

21#/bu)

Fescue K-31

Drive Type 4

(Based on

21#/bu)

0.0 5.1 11.5 16.9 24.1 29.9 36.6 42.5 48.8 55.3 61.2 67.6 73.6 79.9 86.0 92.9 97.5 103.6 109.7 114.0 119.1

7.5"

0.0 4.8 10.8 15.9 22.7 28.1 34.4 39.9 45.8 51.9 57.5 63.5 69.1 75.0 80.7 87.2 91.6 97.2 103.0 107.0 111.8

8"

0.0 3.8 8.7 12.7 18.2 22.5 27.5 32.0 36.7 41.6 46.0 50.8 55.4 60.1 64.6 69.9 73.4 77.9 82.5 85.7 89.5

10"

Row Space

7.5" 0.0 8.3 18.8 27.6 39.4 48.8 59.7 69.3 79.5 90.1 99.8 110.2 120.1 130.3 140.1 151.5 159.0 168.9 178.9 185.8 194.1

8" 0.0 7.8 17.6 25.9 37.0 45.8 56.0 65.0 74.6 84.6 93.7 103.5 112.7 122.3 131.6 142.2 149.3 158.5 168.0 174.4 182.2

10" 0.0 6.2 14.1 20.7 29.7 36.7 44.9 52.1 59.8 67.8 75.1 82.9 90.3 98.0 105.4 114.0 119.6 127.0 134.6 139.7 146.0

Row Space

2.3 4.2 6.3 8.9 11.3 13.8 17.1 19.2 22.1 24.8 28.4 30.3 33.0 35.9 38.6 41.3 43.9 46.0 47.8 48.9 49.2

7.5"

2.1 3.9 5.9 8.3 10.6 13.0 16.0 18.0 20.7 23.3 26.6 28.4 31.0 33.7 36.3 38.8 41.3 43.2 44.9 45.9 46.2

8"

1.7 3.1 4.7 6.7 8.5 10.4 12.8 14.4 16.6 18.6 21.3 22.8 24.8 27.0 29.1 31.1 33.0 34.6 35.9 36.8 37.0

10"

Row Space

2.4 5.8 9.7 13.3 17.0 21.5 24.8 29.7 33.8 38.1 41.5 46.1 50.2 54.1 57.9 62.0 65.7 69.1 72.2 72.9 74.9

7.5"

2.3 5.4 9.1 12.5 15.9 20.2 23.3 27.9 31.7 35.8 39.0 43.3 47.1 50.8 54.4 58.2 61.6 64.8 67.8 68.4 70.3

8"

1.8 4.4 7.3 10.0 12.8 16.2 18.6 22.3 25.4 28.7 31.2 34.7 37.8 40.7 43.6 46.6 49.4 51.9 54.3 54.8 56.3

10"

Row Space

3.9 9.4 15.8 21.7 27.7 35.0 40.4 48.4 55.1 62.2 67.7 75.2 81.9 88.2 94.5 101.0 107.1 112.6 117.7 118.9 122.1

7.5"

3.7 8.9 14.8 20.3 26.0 32.9 37.9 45.5 51.7 58.4 63.5 70.6 76.9 82.8 88.7 94.9 100.5 105.7 110.5 111.6 114.7

8"

3.0 7.1 11.9 16.3 20.8 26.3 30.4 36.4 41.4 46.8 50.9 56.5 61.6 66.3 71.1 76.0 80.5 84.7 88.6 89.4 91.9

10"

Row Space

196-126B12/17/2003

Page 6

6

Great Plains Mfg., Inc.

Seed Rate Chart (Con’t.) (Pounds per acre)

Setting number 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Flax/Sudan

Drive Type 1

(Based on

55#/bu)

7.5" 0.0 3.1 6.9 9.8 13.5 16.8 20.2 23.6 27.4 30.9 35.0 38.2 41.7 45.5 49.4 54.1 58.3 63.3 68.5 69.6 71.0

8" 0.0 2.9 6.4 9.2 12.6 15.8 19.0 22.2 25.7 29.0 32.8 35.9 39.2 42.7 46.4 50.8 54.8 59.5 64.3 65.3 66.6

10" 0.0 2.4 5.2 7.4 10.1 12.7 15.2 17.8 20.6 23.3 26.3 28.7 31.4 34.2 37.2 40.7 43.9 47.6 51.5 52.4 53.4

Row Space

K.Bluegrass

Drive Type 3

(Based on

23#/bu)

K.Bluegrass

Drive Type 4

(Based on

23#/bu)

Millet

Drive Type 1

(Based on

60#/bu)

Milo

Drive Type 1

(Based on

60#/bu)

Oats

Drive Type 2

(Based on

37#/bu)

Oats

Drive Type 3

(Based on

37#/bu)

Orchard Grass

Drive Type 1

(Based on

18#/bu)

0.0 4.6 7.5 9.9 13.5 15.9 19.1 22.2 25.4 28.7 32.1 35.0 38.1 41.3 44.2 47.4 50.0 52.6 54.8 56.7 58.4

7.5"

0.0 4.3 7.1 9.3 12.7 15.0 17.9 20.9 23.8 27.0 30.2 32.9 35.8 38.8 41.5 44.5 46.9 49.4 51.4 53.3 54.8

8"

0.0 3.5 5.7 7.4 10.2 12.0 14.3 16.7 19.1 21.6 24.2 26.3 28.7 31.1 33.2 35.7 37.6 39.6 41.2 42.7 43.9

10"

Row Space

0.0 7.5 12.3 16.1 22.0 26.0 31.1 36.2 41.3 46.8 52.4 57.1 62.2 67.3 72.0 77.3 81.5 85.8 89.3 92.5 95.2

7.5"

0.0 7.0 11.5 15.2 20.7 24.4 29.2 34.0 38.8 44.0 49.2 53.6 58.4 63.2 67.6 72.6 76.5 80.6 83.8 86.8 89.4

8"

0.0 5.6 9.3 12.1 16.6 19.5 23.4 27.2 31.1 35.2 39.4 42.9 46.8 50.6 54.2 58.2 61.3 64.5 67.1 69.6 71.6

10"

Row Space

1.2 3.9 6.9 9.8 13.1 16.3 19.6 22.8 26.3 29.8 33.3 36.8 40.6 43.8 47.7 51.6 55.2 59.2 63.4 64.4 65.3

7.5"

1.1 3.7 6.4 9.2 12.3 15.3 18.4 21.4 24.7 28.0 31.2 34.5 38.1 41.2 44.8 48.5 51.8 55.6 59.5 60.4 61.3

8"

0.9 2.9 5.2 7.4 9.8 12.2 14.7 17.1 19.8 22.4 25.0 27.7 30.5 33.0 35.9 38.8 41.5 44.5 47.7 48.4 49.1

10"

Row Space

0.0 3.9 7.4 10.9 14.8 18.8 23.3 28.0 32.7 37.5 43.1 47.5 52.5 57.6 62.5 67.6 72.4 76.7 81.7 83.9 85.4

7.5"

0.0 3.7 6.9 10.2 13.9 17.6 21.8 26.3 30.7 35.2 40.4 44.5 49.3 54.0 58.7 63.4 68.0 72.0 76.7 78.7 80.1

8"

0.0 2.9 5.5 8.2 11.1 14.1 17.5 21.1 24.6 28.2 32.4 35.7 39.5 43.3 47.0 50.8 54.5 57.7 61.4 63.1 64.2

10"

Row Space

0.0 2.1 6.1 9.7 14.2 17.5 22.2 25.6 29.8 33.8 38.3 42.3 46.8 51.5 56.2 61.3 65.7 70.3 75.5 77.1 77.9

7.5"

0.0 2.0 5.7 9.1 13.3 16.5 20.9 24.0 28.0 31.7 36.0 39.7 44.0 48.4 52.7 57.6 61.6 66.0 70.9 72.4 73.1

8"

0.0 1.6 4.6 7.3 10.7 13.2 16.7 19.2 22.4 25.4 28.8 31.8 35.2 38.7 42.2 46.1 49.4 52.9 56.8 58.0 58.6

10"

Row Space

0.0 4.3 10.1 14.5 20.0 26.3 32.4 39.1 45.9 52.9 60.4 66.6 73.6 80.4 87.4 94.4 101.4 108.4 115.9 117.3 116.9

7.5"

0.0 4.1 9.5 13.6 18.8 24.7 30.4 36.7 43.1 49.6 56.7 62.6 69.1 75.5 82.0 88.6 95.2 101.8 108.8 110.2 109.7

8"

0.0 3.3 7.6 10.9 15.1 19.8 24.3 29.4 34.5 39.8 45.4 50.1 55.4 60.5 65.7 71.0 76.3 81.5 87.2 88.2 87.9

10"

Row Space

7.5" 0.0 0.7 1.5 2.2 3.0 3.7 4.4 5.3 6.1 7.0 8.0 8.8 9.8 10.8 11.7 12.8 13.5 14.3 14.9 15.3 15.5

8" 0.0 0.7 1.4 2.1 2.8 3.5 4.1 5.0 5.7 6.6 7.5 8.3 9.2 10.1 11.0 12.0 12.7 13.4 14.0 14.3 14.6

10" 0.0 0.5 1.1 1.6 2.3 2.8 3.3 4.0 4.6 5.3 6.0 6.7 7.4 8.1 8.8 9.6 10.2 10.7 11.2 11.5 11.7

Row Space

Orchard Grass

Drive Type 2

(Based on

18#/bu)

Orchard Grass

Drive Type 3

(Based on

18#/bu)

Orchard Grass

Drive Type 4

(Based on

18#/bu)

Peas

Drive Type 3

(Based on

Peas

Drive Type 4

(Based on

12/17/2003

0.0 1.4 3.1 4.5 6.2 7.6 9.0 10.9 12.6 14.5 16.4 18.2 20.1 22.2 24.1 26.3 27.8 29.3 30.6 31.4 31.9

7.5"

0.0 1.4 2.9 4.2 5.8 7.1 8.5 10.3 11.8 13.6 15.4 17.1 18.9 20.9 22.7 24.7 26.1 27.5 28.7 29.5 30.0

8"

0.0 1.1 2.4 3.4 4.7 5.7 6.8 8.2 9.4 10.9 12.3 13.7 15.1 16.7 18.2 19.7 20.9 22.0 23.0 23.6 24.0

10"

Row Space

0.0 2.7 4.5 6.5 9.1 10.9 13.0 15.5 17.6 20.5 23.1 26.1 29.0 31.9 34.8 37.7 39.8 41.8 43.8 45.4 46.9

7.5"

0.0 2.5 4.2 6.1 8.6 10.2 12.2 14.5 16.5 19.3 21.6 24.5 27.2 29.9 32.6 35.4 37.4 39.2 41.2 42.6 44.0

8"

0.0 2.0 3.4 4.9 6.9 8.2 9.8 11.6 13.3 15.4 17.3 19.6 21.8 24.0 26.1 28.4 30.0 31.4 33.0 34.1 35.3

10"

Row Space

0.0 4.3 7.5 10.6 14.9 17.7 21.1 25.2 28.7 33.5 37.6 42.5 47.2 52.0 56.7 61.5 65.0 68.1 71.5 74.0 76.5

7.5"

0.0 4.1 6.9 10.0 14.0 16.6 19.8 23.7 27.0 31.4 35.3 39.9 44.3 48.8 53.2 57.7 61.0 63.9 67.1 69.5 71.8

8"

0.0 3.3 5.5 8.0 11.2 13.3 15.9 18.9 21.6 25.2 28.3 32.0 35.5 39.1 42.6 46.3 48.8 51.2 53.8 55.7 57.5

10"

Row Space

7.5" 0.0 0.0 15.8 28.5 43.4 57.5 70.2 85.2 99.5 114.9 129.0 141.7 155.7 168.5 182.5 196.9 209.8 222.6 235.4 236.6 237.7

0.0 0.0 14.9 26.7 40.7 53.9 65.9 80.0 93.4 107.9 121.1 133.0 146.2 158.2 171.3 184.9 197.0 209.0 221.0 222.1 223.1

8"

0.0 0.0 11.9 21.4 32.6 43.2 52.8 64.1 74.8 86.4 97.0 106.6 117.1 126.7 137.3 148.1 157.8 167.4 177.0 177.9 178.7

10"

Row Space

7.5" 0.0 0.0 18.5 39.4 61.0 82.7 102.7 126.4 148.8 171.2 191.9 213.7 233.8 255.9 276.7 297.7 318.9 338.9 358.0 358.6 359.2

0.0 0.0 17.3 37.0 57.2 77.6 96.4 118.6 139.7 160.8 180.3 200.7 219.5 240.2 259.8 279.5 299.3 318.2 336.1 336.7 337.2

8"

0.0 0.0 13.9 29.6 45.8 62.2 77.3 95.0 111.9 128.8 144.3 160.8 175.9 192.4 208.1 223.9 239.8 254.9 269.2 269.7 270.1

10"

Row Space

196-126B

Page 7

Great Plains Mfg., Inc.

Seed Rate Chart (Con’t.) (Pounds per acre)

Setting number 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Pinto Beans

Drive Type 1

(Based on

61#/bu)

0.0 0.0 7.1 10.8 14.6 19.7 24.7 29.5 34.5 39.4 44.3 48.7 53.2 57.6 62.3 67.5 71.4 75.9 80.8 80.7 80.5

7.5"

0.0 0.0 6.7 10.1 13.7 18.5 23.2 27.7 32.3 37.0 41.6 45.7 50.0 54.0 58.4 63.4 67.0 71.2 75.8 75.7 75.6

8"

0.0 0.0 5.3 8.1 11.0 14.8 18.6 22.2 25.9 29.6 33.3 36.6 40.0 43.3 46.8 50.8 53.7 57.1 60.7 60.7 60.5

10"

Row Space

7

Rape

Drive Type 1

(Based on

51#/bu)

Rice-Sh Grain

Drive Type 2

(Based on

43#/bu)

Rice-Sh Grain

Drive Type 3

(Based on

43#/bu)

Rice-Sh Grain

Drive Type 4

(Based on

43#/bu)

Rice-Lg Grain

Drive Type 2

(Based on

47#/bu)

Rice-Lg Grain

Drive Type 3

(Based on

47#/bu)

Rice-Lg Grain

Drive Type 4

(Based on

47#/bu)

0.0 3.4 6.5 8.8 11.9 14.6 17.5 20.8 23.9 26.9 30.2 32.9 35.9 38.9 42.2 45.3 49.0 52.7 56.6 57.9 59.5

7.5"

0.0 3.2 6.1 8.3 11.2 13.7 16.5 19.6 22.4 25.3 28.3 30.9 33.7 36.5 39.6 42.5 46.0 49.5 53.1 54.3 55.9

8"

0.0 2.5 4.9 6.7 9.0 11.0 13.2 15.7 18.0 20.3 22.7 24.7 27.0 29.3 31.7 34.0 36.9 39.6 42.6 43.5 44.8

10"

Row Space

0.0 4.8 9.1 15.8 21.6 26.2 32.9 37.2 42.7 48.4 54.3 59.7 65.2 70.8 76.9 83.0 88.5 94.5

7.5"

0.0 4.5 8.5 14.8 20.3 24.6 30.9 34.9 40.0 45.5 51.0 56.1 61.2 66.5 72.2 77.9 83.1 88.7

8"

0.0 3.6 6.8 11.9 16.3 19.7 24.8 28.0 32.1 36.4 40.9 44.9 49.0 53.3 57.9 62.4 66.6 71.1

10"

Row Space

2.4 9.2 15.1 23.7 32.1 38.1 46.4 53.1 61.3 70.0 80.0 89.3 98.0

7.5"

2.3 8.6 14.2 22.2 30.1 35.8 43.6 49.9 57.6 65.7 75.1 83.9 92.0

8"

1.8 6.9 11.3 17.8 34.1 28.7 34.9 39.9 46.1 52.7 60.1 67.2 73.7

10"

Row Space

3.9 15.0 24.8 38.6 52.3 62.2 75.7 86.6

7.5"

3.7 14.0 23.1 36.2 49.1 58.4 71.0 81.3

8"

3.0 11.3 18.5 29.0 39.3 46.8 56.9 65.1

10"

Row Space

0.0 2.4 7.6 12.7 17.9 23.5 28.9 34.1 39.4 44.9 54.3 55.2 60.4 65.5 70.7 76.1 80.5 85.0 88.6 90.9 92.6

7.5"

0.0 2.3 7.2 11.9 16.8 22.1 27.2 32.0 37.0 42.2 51.0 51.8 56.7 61.5 66.3 71.5 75.6 79.8 83.2 85.4 87.0

8"

0.0 1.8 5.7 9.6 13.4 17.7 21.8 25.7 29.7 33.8 40.9 41.5 45.4 49.3 53.1 57.2 60.5 63.9 66.6 68.4 69.7

10"

Row Space

0.0 0.0 11.0 18.1 26.4 35.0 44.1 51.2 59.2 67.6 75.1 82.1 89.1 96.6

7.5"

0.0 0.0 10.4 17.0 24.8 32.9 41.4 48.1 56.5 63.5 70.5 77.1 83.6 90.7

8"

0.0 0.0 8.3 13.6 19.9 26.3 33.2 38.5 44.5 50.8 56.5 61.7 67.0 72.6

10"

Row Space

0.0 0.0 18.0 29.5 43.1 57.1 71.9 83.5 96.4

7.5"

0.0 0.0 16.9 27.7 40.4 53.6 67.5 78.3 90.5

8"

0.0 0.0 13.5 22.2 32.4 42.9 54.1 62.8 72.5

10"

Row Space

100.0 114.2 130.4 145.6 159.8 174.4 188.9 201.7 213.4 225.2 237.4 237.4 237.4

93.9 107.2 122.4 136.7 150.0 163.7 177.4 189.4 200.3 211.4 222.9 222.8 222.9

75.2 85.9 98.1 109.5 120.2 131.2 142.1 151.7 160.5 169.3 178.6 178.5 178.6

110.2 122.4 133.8 145.3 157.5 170.8 183.7 196.8 209.0 219.5 227.9 235.8

103.5 114.9 125.6 136.4 147.8 160.4 172.5 184.8 196.2 206.1 214.0 221.3

82.9 92.1 100.7 109.2 118.4 128.5 138.2 148.0 157.2 165.1 171.4 177.3

107.0 115.9 123.7 130.9 138.1 145.6 145.6 145.6

100.4 108.8 116.2 122.8 129.6 136.7 136.7 136.7

80.4 87.2 93.1 98.4 103.9 109.5 109.5 109.5

104.8 112.7 120.7 128.2 134.6 139.8 144.6

98.4 105.8 113.3 120.4 126.4 131.2 135.8

78.8 84.7 90.8 96.4 101.3 105.1 108.8

100.6 101.1 101.6

94.4 94.9 95.4

75.7 76.0 76.4

Rye

Drive Type 1

(Based on

57#/bu)

Rye-Perennial

Drive Type 3

(Based on

36#/bu)

Rye-Perennial

Drive Type 4

(Based on

36#/bu)

Soybeans

Drive Type 1

(Based on

58#/bu)

Soybeans

Drive Type 2

(Based on

58#/bu)

12/17/2003

0.0 2.3 6.6 10.6 15.4 20.0 23.5 29.0 34.1 39.3 44.3 48.5 52.6 57.2 61.7 67.3 72.4 78.2 84.5 85.0 85.4

7.5"

0.0 2.2 6.2 9.9 14.5 18.8 22.0 27.2 32.0 36.9 41.6 45.5 49.4 53.7 57.9 63.2 67.9 73.4 79.3 79.8 80.1

8"

0.0 1.8 4.9 8.0 11.6 15.1 17.6 21.8 25.6 29.6 33.3 36.5 39.6 43.0 46.4 50.6 54.4 58.8 63.5 64.0 64.2

10"

Row Space

0.0 2.3 6.6 10.6 15.4 20.0 23.5 29.0 34.1 39.3 44.3 48.5 52.6 57.2 61.7 67.3 72.4 78.2 84.5 85.0 85.4

7.5"

0.0 2.2 6.2 9.9 14.5 18.8 22.0 27.2 32.0 36.9 41.6 45.5 49.4 53.7 57.9 63.2 67.9 73.4 79.3 79.8 80.1

8"

0.0 1.8 4.9 8.0 11.6 15.1 17.6 21.8 25.6 29.6 33.3 36.5 39.6 43.0 46.4 50.6 54.4 58.8 63.5 64.0 64.2

10"

Row Space

0.0 7.9 18.5 26.0 35.1 45.3 53.3 63.8 72.8 82.7 92.3

7.5"

0.0 7.4 17.4 24.4 32.9 42.5 50.0 59.9 68.4 77.6 86.6

8"

0.0 5.9 13.9 19.5 26.4 34.0 40.1 48.0 54.8 62.2 69.4

10"

Row Space

0.0 2.3 6.5 11.0 16.1 19.3 24.0 28.2 32.7 37.4 41.3 46.4 51.0 55.4 59.7 64.4 68.1 72.7 77.4 77.8 78.0

7.5"

0.0 2.2 6.1 10.3 15.1 18.2 22.5 26.5 30.7 35.1 38.8 43.5 47.9 52.0 56.1 60.4 64.0 68.2 72.6 73.0 73.2

8"

0.0 1.8 4.9 8.2 12.1 14.5 18.0 21.2 24.6 28.1 31.1 34.9 38.3 41.6 44.9 48.4 51.2 54.7 58.2 58.5 58.7

10"

Row Space

0.0 4.8 13.4 22.5 33.2 39.8 49.3 57.9 67.3 76.8 85.0 95.3

7.5"

0.0 4.5 12.5 21.2 31.1 37.3 46.2 54.4 63.2 72.1 79.8 89.5

8"

0.0 3.6 10.0 16.9 24.9 29.9 37.0 43.6 50.6 57.7 63.9 71.7

10"

Row Space

101.6 110.2 120.5 129.5 139.1 146.8 154.3 184.5 164.5 168.3

95.3 103.5 113.1 121.6 130.5 137.8 144.9 173.2 154.5 158.0

76.4 82.9 90.6 97.4 104.6 110.4 116.1 138.8 123.8 126.6

104.8 113.8 122.8 132.3 140.0 149.4 159.0 159.8 160.3

98.4 106.8 115.3 124.2 131.5 140.2 149.3 150.0 150.5

78.8 85.6 92.4 99.5 105.3 112.3 119.6 120.2 120.6

196-126B

Page 8

8

Great Plains Mfg., Inc.

Seed Rate Chart (Con’t.) (Pounds per acre)

Setting number 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Soybeans

Drive Type 3

(Based on

58#/bu)

Row Space

0.0 9.7 18.8 33.8 49.7 59.2 74.4 84.5 97.3 109.9 123.9 137.1 151.1 164.2 178.7 190.3 207.6 221.9 237.1 237.3 237.6

7.5"

0.0 9.1 17.7 31.7 46.7 55.5 69.8 79.3 91.3 103.1 116.3 128.7 141.9 154.1 167.7 178.6 194.9 208.3 222.6 222.8 223.0

8"

0.0 7.3 14.2 25.4 37.4 44.5 55.9 63.6 73.2 82.6 93.2 103.1 113.7 123.5 134.4 143.1 156.2 166.9 178.3 178.5 178.7

10"

Soybeans

Drive Type 4

(Based on

58#/bu)

Sunflowers

Drive Type 1

(Based on

28#/bu)

Hard Red

Winter Wheat

Drive Type 1

(Based on

64#/bu)

Hard Red

Winter Wheat

Drive Type 2

(Based on

64#/bu)

Wheat Grass

Drive Type 1

(Based on

23#/bu)

Soft WheatCardinal-Ba

Drive Type 2

(Based on

58#/bu)

0.0 15.7 30.7 55.1 81.1 96.4 121.2 137.8 158.6 179.1 201.9 223.6 246.4 267.7 291.3 310.2 338.5 361.8 386.6 387.0 387.3

7.5"

0.0 14.8 28.8 51.7 76.1 90.5 113.8 129.3 148.9 168.1 189.6 209.9 231.3 251.3 273.5 291.2 317.8 339.6 362.9 363.3 363.6

8"

0.0 11.8 23.1 41.4 61.0 72.5 91.2 103.6 119.3 134.7 151.9 168.2 185.3 201.3 219.1 233.3 254.6 272.1 290.7 291.0 291.3

10"

Row Space

0.0 0.0 1.7 3.5 5.1 7.0 8.9 10.8 12.8 14.9 16.9 18.8 20.8 22.9 24.8 26.7 28.5 30.1 32.1 33.0 34.0

7.5"

0.0 0.0 1.6 3.3 4.8 6.5 8.4 10.1 12.1 14.0 15.9 17.6 19.6 21.5 23.3 25.0 26.8 28.3 30.1 30.9 31.9

8"

0.0 0.0 1.3 2.7 3.9 5.2 6.7 8.1 9.7 11.2 12.7 14.1 15.7 17.2 18.7 20.1 21.4 22.7 24.1 24.8 25.6

10"

Row Space

0.0 5.1 8.9 12.4 16.1 20.2 23.3 28.4 32.7 37.2 42.6 46.8 51.8 57.1 61.9 66.8 72.0 77.3 82.6 83.7 83.8

7.5"

0.0 4.8 8.4 11.6 15.1 19.0 21.9 26.7 30.7 34.9 40.0 44.0 48.7 53.6 58.1 62.7 67.6 72.6 77.6 78.6 78.7

8"

0.0 3.8 6.7 9.3 12.1 15.2 17.5 21.4 24.6 28.0 32.0 35.2 39.0 42.9 46.6 50.2 54.2. 58.1 62.1 63.0 63.0

10"

Row Space

0.0 10.5 18.3 25.4 33.0 41.5 48.0 58.4 67.3 76.5 87.6 96.3

7.5"

0.0 9.8 17.2 23.9 31.0 39.0 45.0 54.8 63.2 71.8 82.2 90.4

8"

0.0 7.9 13.8 19.1 24.8 31.2 36.1 43.9 50.6 57.5 65.9 72.4

10"

Row Space

0.0 0.8 1.8 2.5 3.5 4.3 5.0 6.2 7.0 8.1 9.0 9.9 11.0 11.9 12.9 14.0 15.0 16.1 15.5 17.4 17.6

7.5"

0.0 0.7 1.7 2.4 3.3 4.0 4.7 5.8 6.6 7.6 8.5 9.3 10.3 11.2 12.1 13.2 14.0 15.1 14.5 16.3 16.6

8"

0.0 0.6 1.3 1.9 2.7 3.2 3.8 4.7 5.3 6.1 6.8 7.5 8.2 9.0 9.7 10.5 11.2 12.1 11.6 13.1 13.3

10"

Row Space

0.0 6.6 12.8 19.2 27.0 34.7 42.8 52.0 61.2 70.8 80.5 90.0 99.0

7.5"

0.0 6.3 12.1 18.2 25.6 32.9 40.5 49.3 58.0 67.1 76.3 85.3 93.8

8"

0.0 4.9 9.4 14.2 19.9 25.6 31.5 38.3 45.1 52.2 59.3 66.4 73.0

10"

Row Space

106.6 117.3 127.3 137.3 148.1 158.9 169.8 172.1 172.2

100.0 110.2 119.5 128.9 139.0 149.1 159.4 161.5 161.7

80.1 88.2 95.8 103.3 111.4 119.5 127.7 129.4 129.5

108.3 118.3 127.6 137.5 147.0 155.2 155.3 155.5

102.6 112.1 120.9 130.3 139.3 147.1 147.2 147.3

79.8 87.2 94.0 101.3 108.3 114.4 114.5 114.6

Soft WheatCardinal-Ba

Drive Type 3

(Based on

58#/bu)

1.2 9.7 18.7 27.9 37.4 48.5 61.7 74.0 87.9

7.5"

1.1 9.2 17.8 26.4 35.5 45.9 58.5 70.1 83.3

8"

0.9 7.1 13.8 20.6 27.6 35.7 45.5 54.5 64.8

10"

Row Space

101.9 116.5 131.9 146.3 161.0 175.6 189.8 205.6 221.0 232.3 239.7 224.2

96.5 110.3 124.9 138.6 152.5 166.4 179.8 194.8 209.4 220.0 227.1 231.3

75.1 85.8 97.2 107.8 118.6 129.4 139.9 151.5 162.8 171.1 176.6 179.9

196-126B 12/17/2003

Page 9

Great Plains Mfg., Inc.

Small Seeds Attachment Seed Rate Chart (Pounds per acre)

Setting number 10 20 30 40 50 60 70 80 90 100

Alfalfa;

Red, Alsike&

Ladino Clo-

vers

7.5" 3 6 10 15.5 19 23 29 33.5 39 43

8" 2.5 5.5 9 14 17.5 21 26 31 36 39.5

10" 2.25 5 7.5 12 14.5 17 21.5 25 29 32

Row Space

9

Lespedeza

Hulled,

Serecia, Crim-

son, Clover;

Birdsfoot Tre-

foil

Lespedeza

Unhulled

Timothy; Red

Top, Sand

& Love Grass

Kentucky

Bluegrass;

Fescue

Reed Canary

German Millet

7.5" 2.5 5.5 8.5 16.5 20.5 25.5 32 36.5 45.5 50.5

8" 2.25 5 8 15 19 23 29.5 33.5 41.5 46.5

Row Space

10" 2 4 6.5 12.5 15.5 19 24 27.5 34 38

7.5" 1.75 3.5 5.5 9.5 12 14.5 16.5 19 21.5 24

8" 1.5 3 5 8.5 11 13 15 17.5 19.5 22

Row Space

10" 1.25 2.5 4 7 9 10.5 12.5 14.5 16 18

7.5" 1.75 3.5 5 7.5 9.5 11.5 14 16 18.5 20.5

8" 1.5 3 4.5 6.5 8.5 10.5 12.5 14.5 17 19

Row Space

10" 1.25 2.5 3.5 5.5 7 8.5 10.5 12 14 15.5

7.5" -- 1.5 2.25 3.5 4.25 5 6 7 8 8.5

8" -- 1.25 2 3 4 4.5 5.5 6.5 7 8

Row Space

10" -- 1 1.5 2.5 3 3.5 4.5 5 6 6.5

7.5" 1 2.25 3.5 5 6.5 8 9.5 10.5 12 13

8" -- 2 3 4.5 5.5 7 8.5 10 11 12

10" -- 1.75 2.5 3.5 4.5 6 7 8 9 10

Row Space

7.5" 2.25 4.5 8.5 13 16.5 19.5 24 28.5 33 37

8" 2 4 7.5 12 15 18 22 26 30.5 34

10" 1.75 3.5 6 10 12 14.5 18 21 25 28

Row Space

Sudan Grass

7.5" 2.25 4.5 8.5 13 16.5 18 25 29.5 34.5 38.5

8" 2 4 7.5 12 15 19 23 27 32 35.5

10" 1.75 3.5 6 10 12 15.5 19 22 26 29

Row Space

12/17/2003

196-126B

Loading...

Loading...