Page 1

Operator’ s Manual

2N-2410 and 2N-3010

Folding No-Till Drill

Manufacturing, Inc.

www .g reatplainsmfg.com

Read the operator’s manual entirely. When you see this symbol, the subsequent in-

!

structions and warnings are serious -follow without exception. Your life andthelives of

others depend on it!

© Copyright 1999 Printed

7/27/2005

14570

Cover illustration may show optional equipment not supplied with standard unit.

196-126M

Page 2

Table of Contents

Table of Contents

Great Plains Mfg., Inc.

Important Safety Information . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Description of Unit . . . . . . . . . . . . . . . . . . . . . . . . 9

Intended Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Using This Manual. . . . . . . . . . . . . . . . . . . . . . . . . 9

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . . 9

Section 1 Drill Preparation and Setup . . . . . . . . . . 10

Prestart Checklist . . . . . . . . . . . . . . . . . . . . . . . . 10

Hitch Height Adjustment . . . . . . . . . . . . . . . . . . . 10

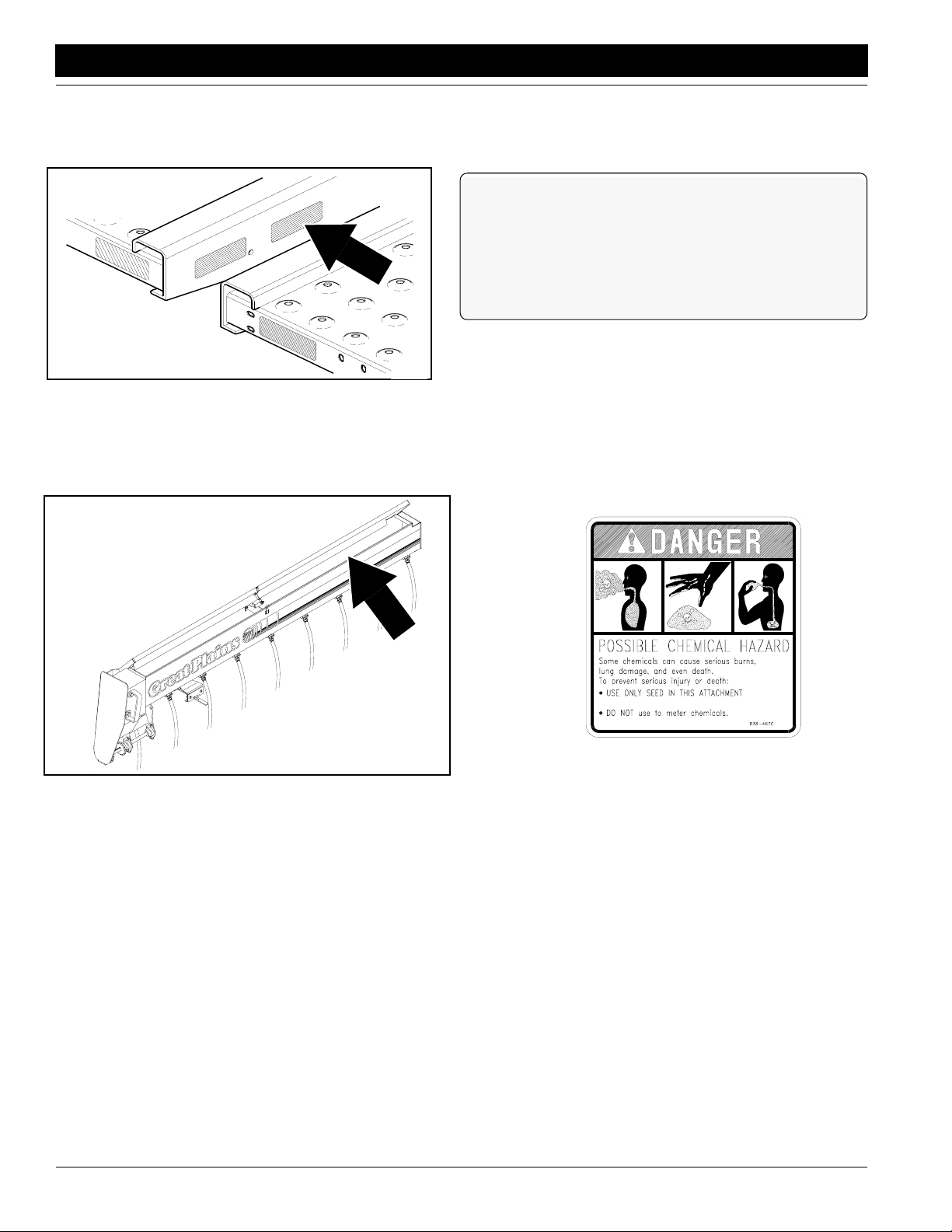

Installing Drill Control Consoles. . . . . . . . . . . . . . 11

Bleeding Hydraulic Systems . . . . . . . . . . . . . . . . 11

Field-Lift Hydraulics. . . . . . . . . . . . . . . . . . . . 11

Transport-Lock Hydraulics. . . . . . . . . . . . . . . 11

Raise-To-Fold Hydraulics . . . . . . . . . . . . . . . 12

Fold Hydraulics . . . . . . . . . . . . . . . . . . . . . . . 12

Marker Hydraulics. . . . . . . . . . . . . . . . . . . . . 13

Frame Leveling Adjustment . . . . . . . . . . . . . . . . . 13

Aligning Boxes. . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Section 2 Operating Instructions 15

Prestart Checklist . . . . . . . . . . . . . . . . . . . . . . . . 15

Tractor Requirements . . . . . . . . . . . . . . . . . . . . . 15

Recommended Minimum Tractor Size . . . . . 15

Minimum Towing Vehicle Weight. . . . . . . . . . 15

Hydrualics . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Safety Lights . . . . . . . . . . . . . . . . . . . . . . . . . 15

Hitching Tractor to Drill . . . . . . . . . . . . . . . . . . . . 15

Operating Control Console . . . . . . . . . . . . . . . . . 16

Operating Electric Clutch Consoles. . . . . . . . . . . 16

Folding the Drill . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Folding Harrow Attachment. . . . . . . . . . . . . . 16

Unfolding the Drill . . . . . . . . . . . . . . . . . . . . . . . . 16

Lifting the Drill in the Field. . . . . . . . . . . . . . . . . . 17

Field Operations . . . . . . . . . . . . . . . . . . . . . . . . . 17

Opener Operation . . . . . . . . . . . . . . . . . . . . . 17

Marker Operation . . . . . . . . . . . . . . . . . . . . . 17

Shaft Monitor Operation . . . . . . . . . . . . . . . . 18

Electric Clutch Operation . . . . . . . . . . . . . . . 18

Transporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Section 3 Adjustments . . . . . . . . . . . . . . . . . . . . . . 19

No-Till Seeding . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Coulter Adjustments . . . . . . . . . . . . . . . . . . . . . . 19

Hydraulic Depth Control . . . . . . . . . . . . . . . . . . . 19

Electric Clutch Switch Adjustment . . . . . . . . . . . 20

Weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Coulter Springs. . . . . . . . . . . . . . . . . . . . . . . . . . 21

Individual Coulters . . . . . . . . . . . . . . . . . . . . 21

Opener Down-Pressure Adjustment. . . . . . . . . . 22

Press Wheel Adjustment . . . . . . . . . . . . . . . . . . 22

Setting the Seeding Rate . . . . . . . . . . . . . . . . . . 22

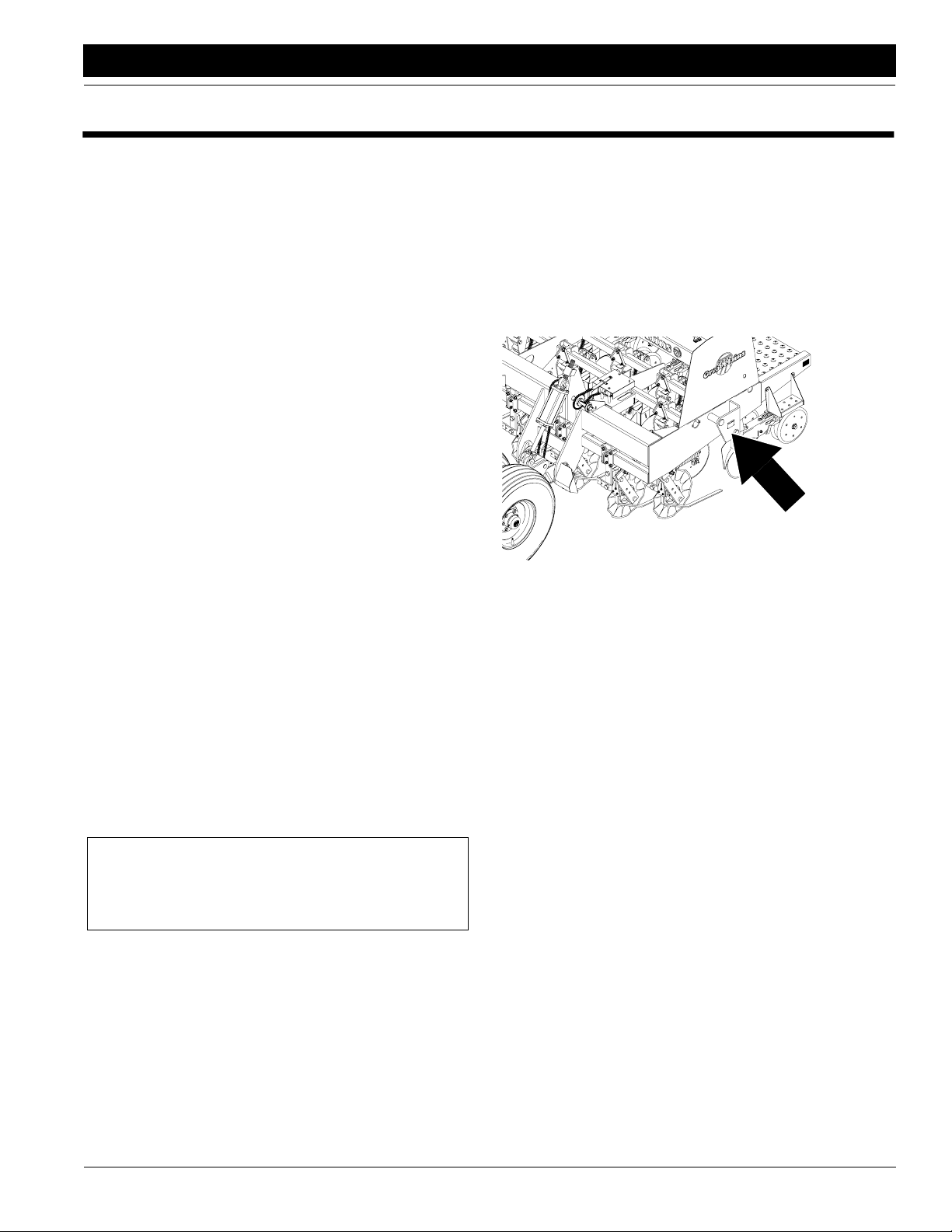

Small Seeds Attachment . . . . . . . . . . . . . . . . . . . 23

Seed Rate Charts. . . . . . . . . . . . . . . . . . . . . . . . . 24

Small Seeds Attachment Seed Rate Chart . . . . .32

Gauge-Wheel Drive Adjustment. . . . . . . . . . . . . 34

Disk Scraper Adjustment . . . . . . . . . . . . . . . . . . 34

Leveling Adjustment. . . . . . . . . . . . . . . . . . . . . . 34

Marker Adjustments . . . . . . . . . . . . . . . . . . . . . . 34

Marker Chain . . . . . . . . . . . . . . . . . . . . . . . . 34

Disk Adjustment. . . . . . . . . . . . . . . . . . . . . . 35

Folding Speed . . . . . . . . . . . . . . . . . . . . . . . 35

Coulter Tines . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Harrow Attachment Adjustment . . . . . . . . . . . . . 36

Seed-Lok . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Section 4 Troubleshooting. . . . . . . . . . . . . . . . . . . 37

Section 5 Maintenance and Lubrication. . . . . . . . 40

General Maintenance. . . . . . . . . . . . . . . . . . . . . 40

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Section 6 Options . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Coulter Tines . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Weight Brackets . . . . . . . . . . . . . . . . . . . . . . . . . 45

Shaft Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Markers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Small Seeds Attachment . . . . . . . . . . . . . . . . . . 46

Rear Mount Boom . . . . . . . . . . . . . . . . . . . . . . . 47

Harrow Attachment. . . . . . . . . . . . . . . . . . . . . . . 47

Seed Box Agitator. . . . . . . . . . . . . . . . . . . . . . . . 48

Seed-Lok Firming Wheels . . . . . . . . . . . . . . . . . 48

Seed-Cup Plugs . . . . . . . . . . . . . . . . . . . . . . . . . 48

Section 7 Specifications and Capacities . . . . . . . 49

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Tire Inflation Chart . . . . . . . . . . . . . . . . . . . . . . . 50

Torque Values Chart for Common Bolt Sizes. . . 50

Electric Clutch and Wire Harness Diagram . . . . .51

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

© Copyright 1999 All rights Reserved

Great PlainsManufacturing, Inc. providesthis publication“as is” withoutwarr antyof anykind,either expressedor implied. Whilee v eryprecaution has beentaken in thepreparation

of thismanual, GreatPlains Manufacturing,Inc. assumes noresponsibility forerrors oromissions.Neither isany liabilityassumed fordamages resulting fromthe useofthe information contained herein. GreatPlainsManufacturing, Inc. reserves the right to reviseand improve its products as it seesfit. This publication describes the state of this productat the

time ofits publication, and maynot reflect theproductin the future.

The followingare trademarks ofGreatPlains Mfg., Inc.: ApplicationSystems, Ausherman, LandPride, GreatPlains, Seed-Lok

All otherbrands and product namesare trademarks or registeredtrademarksof their respectiveholders.

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M 12/27/05

Great PlainsManufacturing, Incorporated Trademarks

Printed in the United StatesofAmerica.

Page 3

Great Plains Mfg., Inc.

Important Safety Information

Important Safety Information

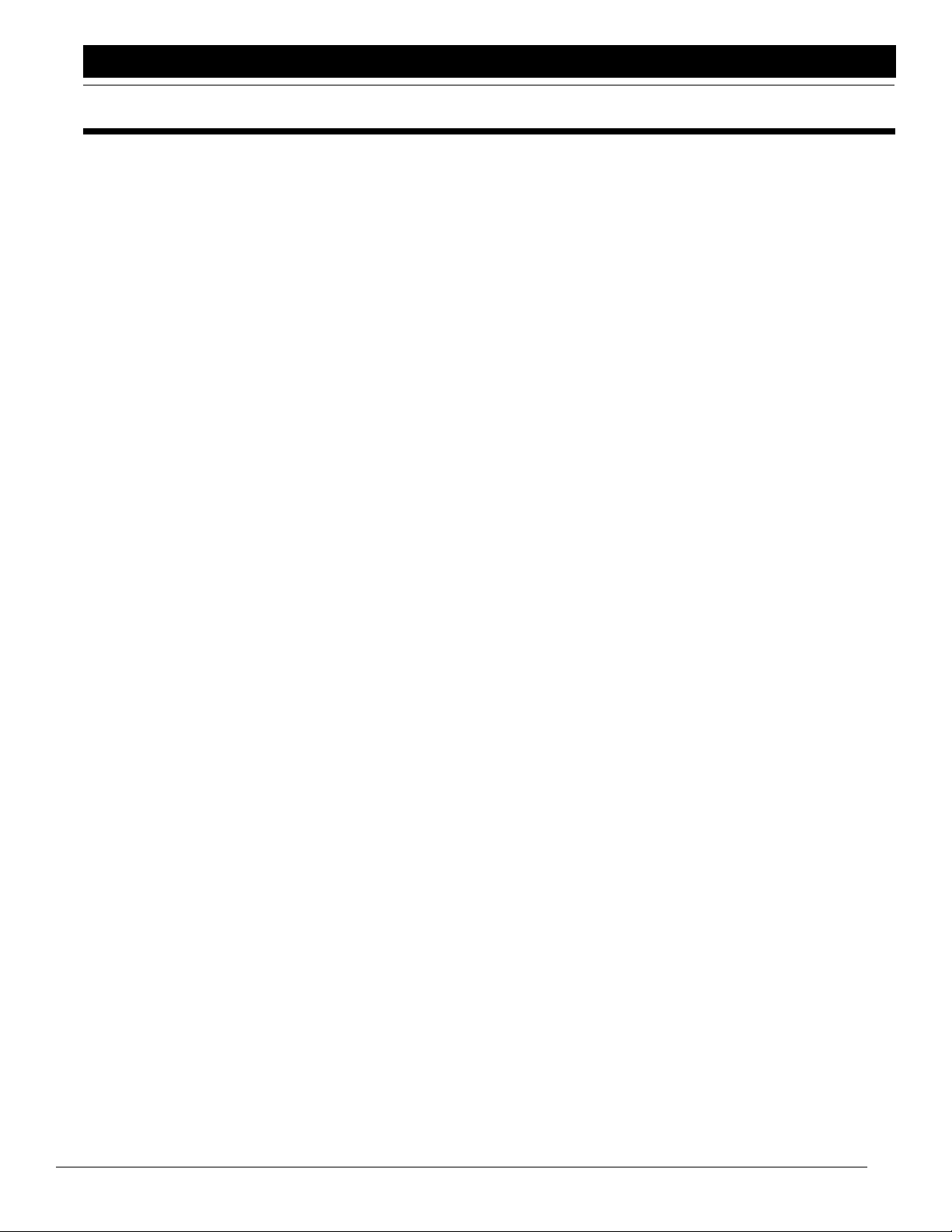

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a potential hazard to

personal safety involved and extra

safety precaution must be taken.

When you see this symbol, be alert

and carefully read the message that

follows it. In addition to design and

configuration of equipment, hazard

control and accident prevention are

dependent upon the awareness,concern, prudence and proper training of

personnel involved in the operation,

transport, maintenance and storage

of equipment.

!

Be Aware of Signal Words

Signal words designate a degree or

level of hazard seriousness. The signal words are:

!

DANGER!

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury. This

signal word is limited to the most

extreme situations, typically for

machine components that, for functional purposes, cannot be guarded.

!

WARNING!

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury, and

includes hazards that are exposed

when guards are removed. It may

also be used to alert against unsafe

practices.

CAUTION!

!

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

For Your Protection

▲ Thoroughly read and understand

Safety Labels, page 5.

▲ Read all instructions noted on the

labels.

OFF

Keep Riders

Off Machinery

▲ Riders obstruct the operator’s

view. They could be struck by foreign objects or thrown from the

machine.

▲ Never allow children to operate

equipment.

Shutdown and Storage

▲ Lower machine to ground, put

tractor in park, turn off engine,

and remove the key.

▲ Detach and store implements in a

area where children normally do

not play. Secure implement by

using blocks and supports.

12/27/05

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M

1

Page 4

Important Safety Information

Great Plains Mfg., Inc.

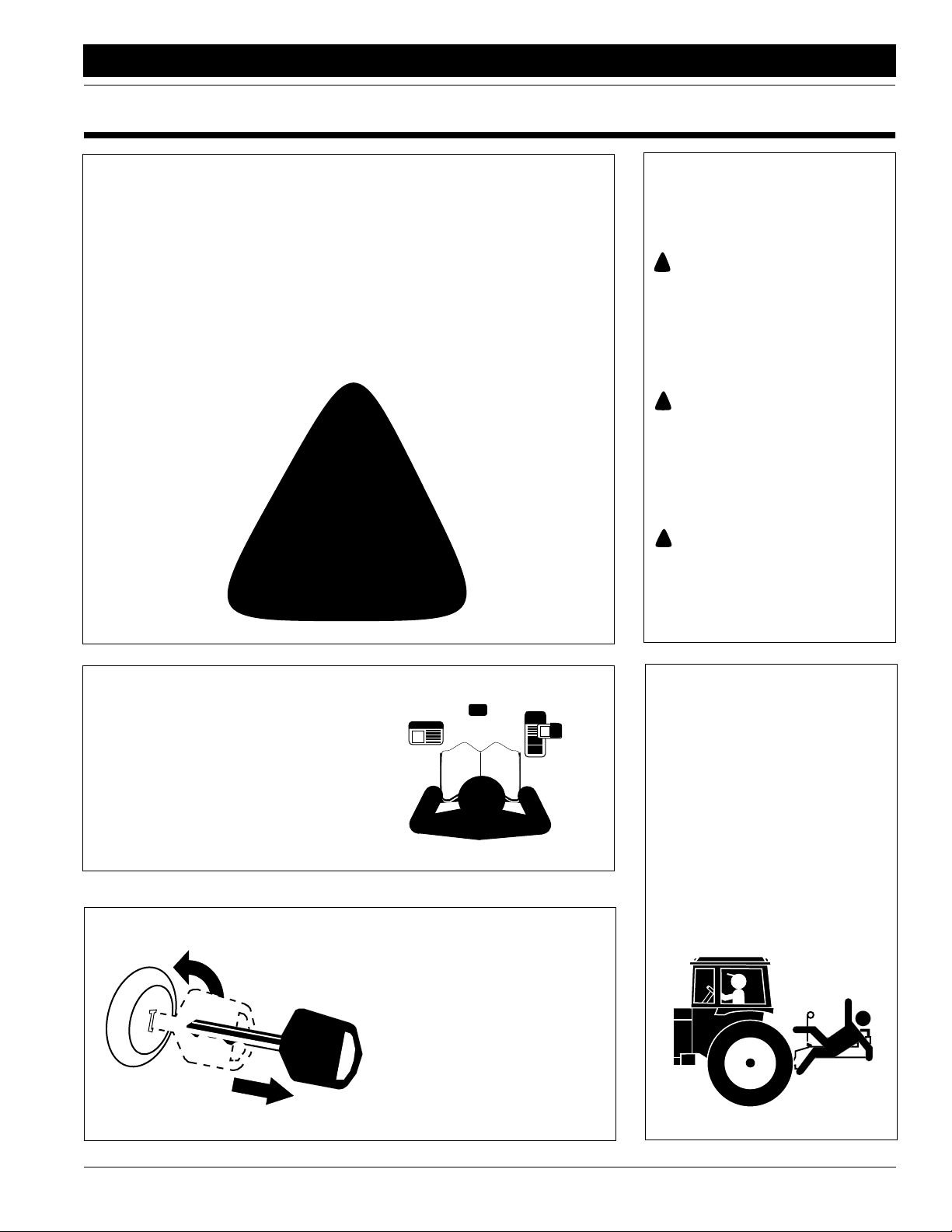

Use Safety

Lights and Devices

▲ Slow moving tractors, self-pro-

pelled equipment, and towed

implements can create a hazard

when driven on public roads. They

are difficult to see, especially at

night.

▲ Flashing warning lights and turn

signals are recommended whenever driving on public roads. Use

lights and devices provided with

implement.

Transport Machinery Safely

▲ Comply with state and local laws.

▲ Maximum transport speed for imple-

ment is 20 mph. DO NOT EXCEED.

Never travel at a speed which does

not allow adequate control of steering and stopping. Some rough terrains require a slower speed.

▲ Sudden braking can cause a towed

load to swerve and upset. Reduce

speed if towed load is not equipped

with brakes.

▲ Use the following maximum speed

guidelines:

20 mph when weight is less than

or equal to the weight of tractor.

10 mph when weight is double

the weight of tractor.

IMPORTANT: Do not tow a load that is

more than double the weight of tractor.

Use A Safety Chain

▲ A safety chain will help control

drawn machinery should it separate from the tractor drawbar.

▲ Use a chain with the strength

rating equal to or greater than

the gross weight of the towed

machinery.

▲ Attach the chain to the tractor

drawbar support or other specified anchor location. Allow only

enough slack in the chain to permit turning.

▲ Do not use safety chain for tow-

ing.

Practice Safe Maintenance

▲ Understand procedure before doing

work. Use proper tools and equipment. Refer to this manual for additional information.

▲ Work in a clean, dry area.

▲ Lower the implement to the ground,

put tractor in park, turn off engine,

and remove key before performing

maintenance.

▲ Allow implement to cool completely.

▲ Install all transport locks on raised drill

before working underneath. Refer to

the Folding the Drill,“Operating

Instructions,” page 16, for instructions

on engaging the transport locks.

▲ Do not grease or oil implement while

it is in operation.

▲ Disk edges are sharp. Be careful

when working in this area.

▲ Disconnect battery ground cable (-)

before servicing or adjusting electrical systems or before welding on

implement.

▲ Inspect all parts. Make sure parts

are in good condition and installed

properly.

▲ Remove buildup of grease, oil or

debris.

▲ Remove all tools and unused parts

from implement before operation.

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M 12/27/05

2

Page 5

Great Plains Mfg., Inc.

Important Safety Information

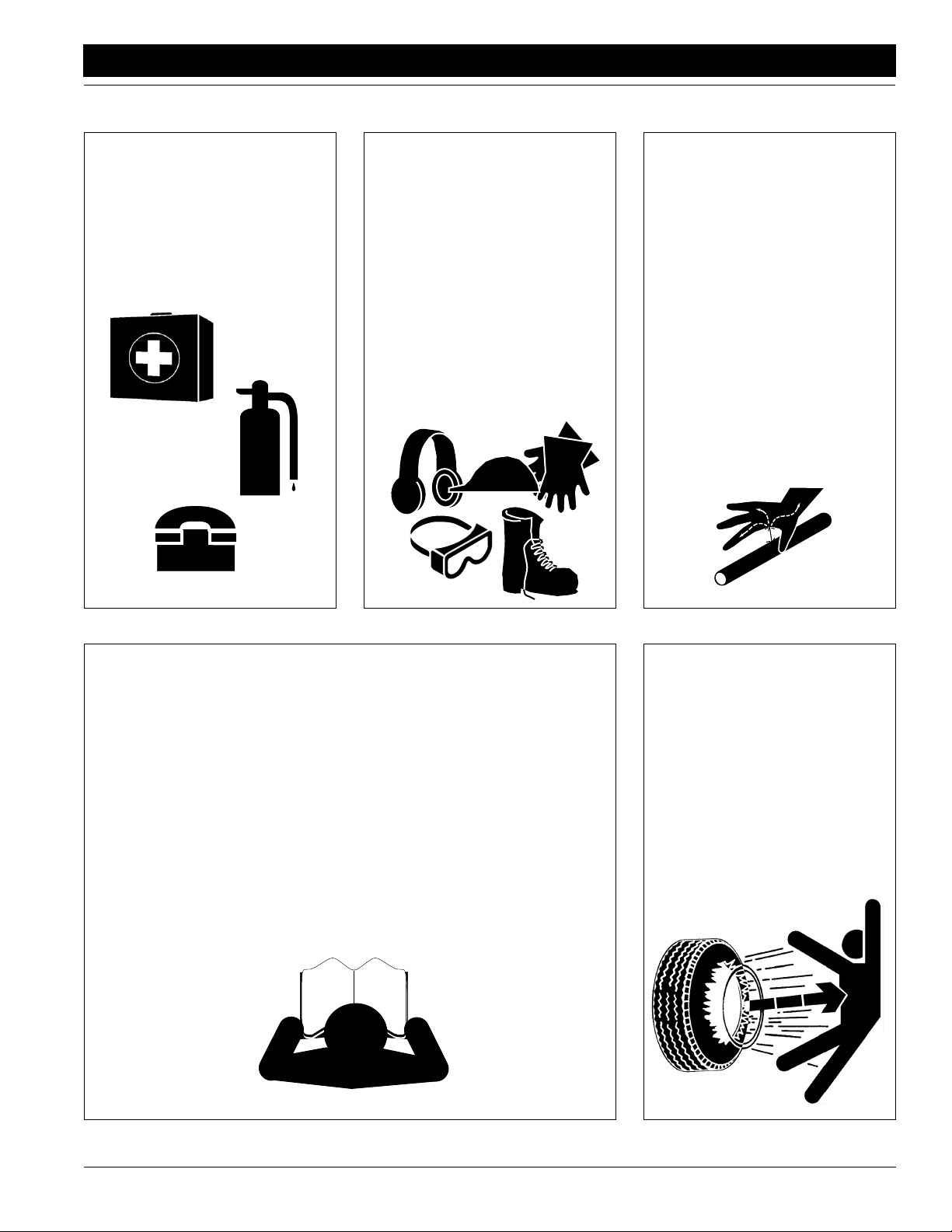

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extin-

guisher handy.

▲ Keep emergency numbers for

doctor, ambulance, hospital and

fire department near phone.

911

Wear

Protective Equipment

▲ Wear protective clothing and

equipment.

▲ Wear clothing and equipment

appropriate for the job. Avoid

loose-fitting clothing.

▲ Prolonged exposure to loud noise

can cause hearing impairment or

hearing loss. Wear suitable hearing protection such as earmuffs or

earplugs.

▲ Operating equipment safely

requires the full attention of the

operator. Avoid wearing radio

headphones while operating

machinery.

Avoid High

Pressure Fluids Hazard

▲ Escaping fluid under pressure can

penetrate the skin causing serious

injury.

▲ Avoid the hazard by relieving

pressure before disconnecting

hydraulic lines.

▲ Use a piece of paper or card-

board, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety

glasses or goggles when working

with hydraulic systems.

▲ If an accident occurs, see a doc-

tor immediately. Any fluid injected

into the skin must be surgically

removed within a few hours or

gangrene may result.

Safety at All Times

Thoroughly read and understand the

instructions given in this manual before

operation. Refer to the Safety Labels,

page 5. Read all instructions noted on

the labels.

▲ Operator should be familiar with all

functions of the unit.

▲ Operate implement from the driver’s

seat only.

▲ Do not leave tractor or implement

unattended with engine running.

▲ Dismounting from a moving tractor

could cause serious injury or death.

▲ Do not stand between the tractor

and implement during hitching.

▲ Keep hands, feet and clothing away

from power-driven parts.

▲ Wear snug-fitting clothing to avoid

entanglement with moving parts.

▲ Watch out for wires, trees, etc.,

when folding and raising implement.

Make sure all persons are clear of

working area.

▲ Turning tractor too tight may cause

implement to ride up on wheels.

This could result in injury or equipment damage.

Tire Safety

▲ Tire changing can be dangerous

and should be performed by

trained personnel using the correct tools and equipment.

▲ When inflating tires, use a clip-on

chuck and extension hose long

enough to allow you to stand to

one side and NOT in front of or

over the tire assembly. Use a

safety cage if available.

▲ When removing and installing

wheels, use wheel-handling

equipment adequate for the

weight involved.

12/27/05

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M

3

Page 6

Important Safety Information

Great Plains Mfg., Inc.

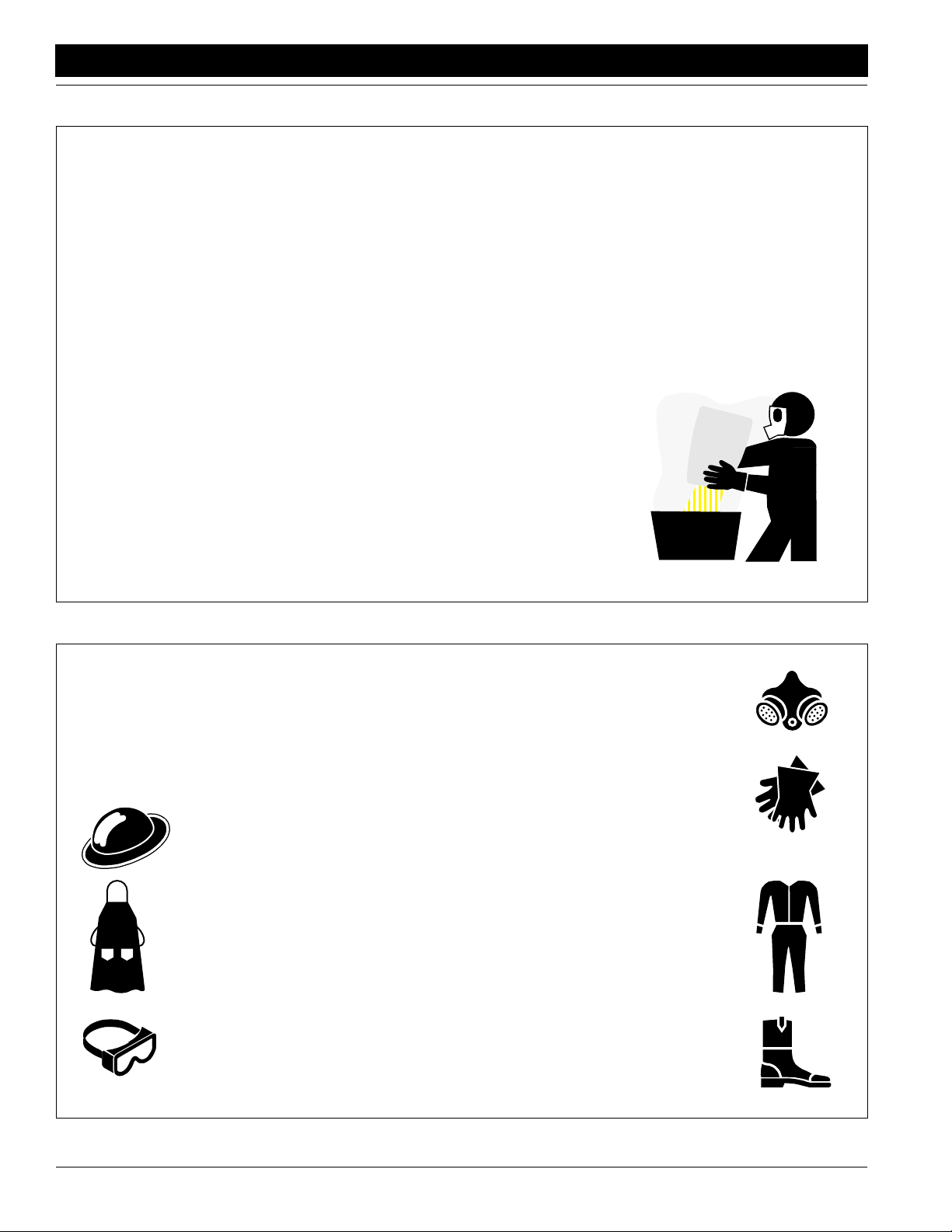

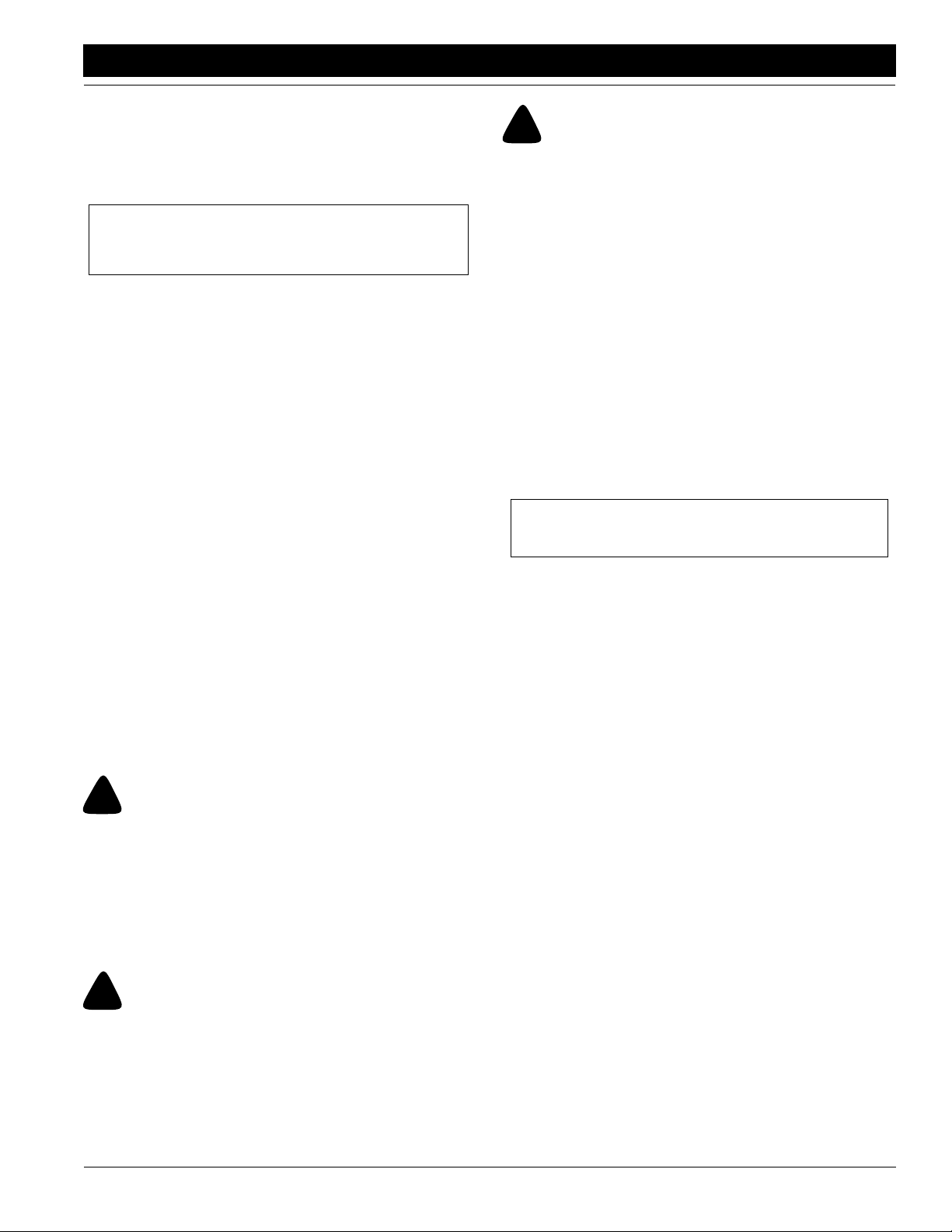

Handle

Chemicals Properly

▲ Read and follow chemical manu-

facturer’s instructions.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Agricultural chemicals can be

dangerous. Improper use can

seriously injure persons, animals,

plants, soil and property.

▲ Inhaling smoke from any type of

chemical fire is a serious health

hazard.

▲ Store or dispose of unused chem-

icals as specified by the chemical

manufacturer.

▲ Before adding chemical to the

tank, make sure tank is at least

half full. Do not pour concentrate

into an empty tank.

▲ Never leave fill hose attached to

the sprayer after filling tank.

Chemicals in tank can siphon out

of tank and contaminate freshwater source.

▲ Always keep clean water and

soap available in case of an emergency. Immediately and thoroughly flush any area of the body

that is contaminated by chemicals.

▲ Do not touch boom components

with mouth or lips.

▲ If chemical is swallowed, carefully

follow the chemical manufacturer’s recommendations and consult with a doctor.

▲ If persons are exposed to a chem-

ical in a way that could affect their

health, consult a doctor immediately with the chemical label or

container in hand. Any delay

could cause serious illness or

death.

▲ Dispose of empty chemical con-

tainers properly. By law rinsing of

the used chemical container must

be repeated three times. Puncture

the container to prevent future

use. An alternative is to jet-rinse

or pressure rinse the container.

▲ Wash hands and face before eat-

ing after working with chemicals.

Shower as soon as spraying is

completed for the day.

▲ Spray only with acceptable wind

conditions. Wind speed must be

below 5 mph. Make sure wind drift

of chemicals will not affect any

surrounding land, people or animals.

▲ Never wash out the sprayer tank

within 100 feet of any freshwater

source or in a car wash.

▲ Rinse out sprayer tank. Spray rinse

water on last field sprayed.

Personal Safety Equipment

Great Plains advises all users of chemical pesticides or

herbicides to use the following personal safety equipment. Always follow the chemical label instructions.

Operator safety and the effectivity of the product

depends upon operator actions.

▲ Waterproof, wide-brimmed hat

▲ Waterproof apron

▲ Face shield, goggles or full face

respirator. Goggles with side

shields or a full face respirator is

required if handling or applying

dusts, wettable powders, or granules or if being exposed to spray

mist.

▲ Cartridge-type respirator

approved for pesticide vapors

unless label specifies another

type of respirator.

▲ Waterproof, unlined gloves. Neo-

prene gloves are recommended.

▲ Cloth coveralls/outer clothing

changed daily; waterproof items

if there is a chance of becoming

wet with spray

▲ Waterproof boots or foot cover-

ings

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M 12/27/05

4

Page 7

Great Plains Mfg., Inc.

Important Safety Information

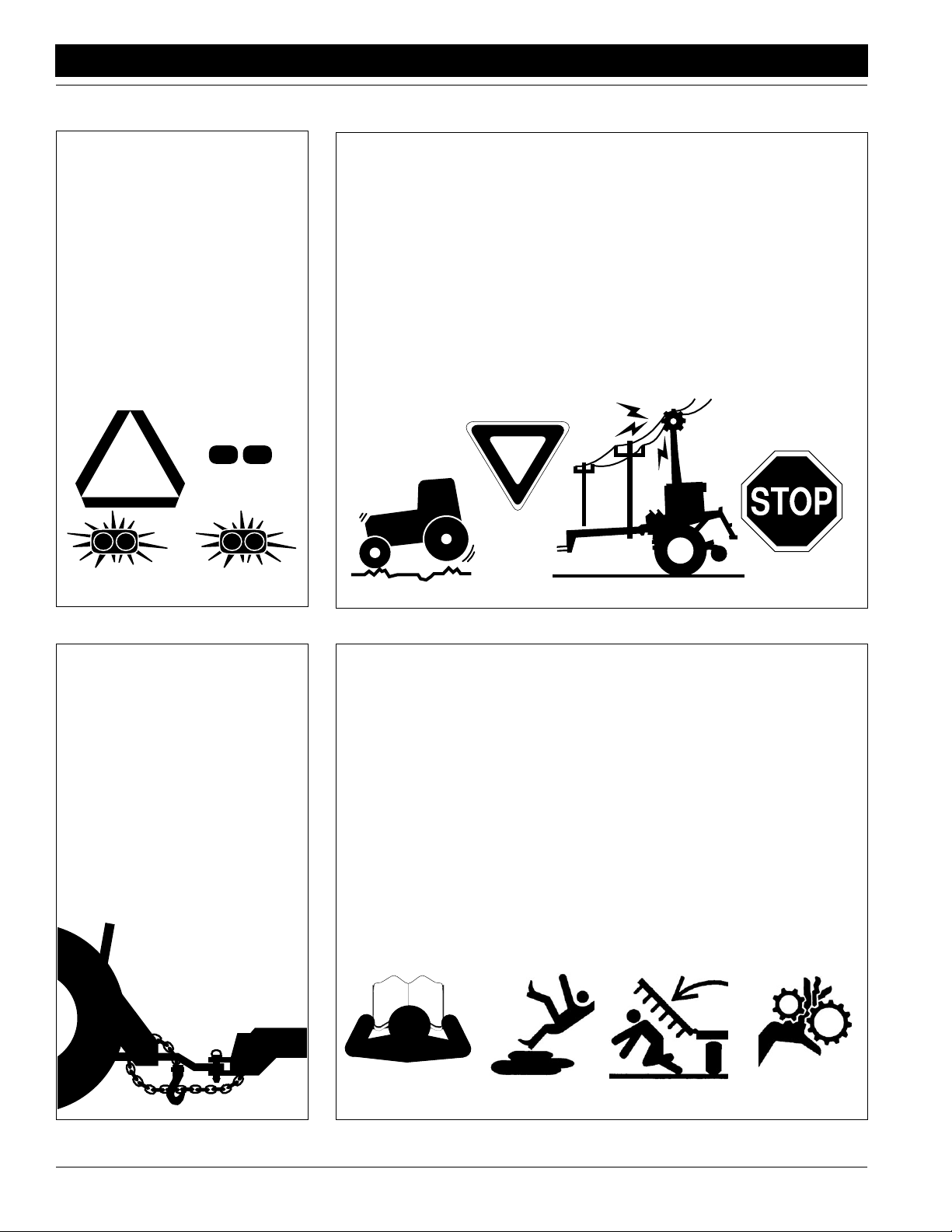

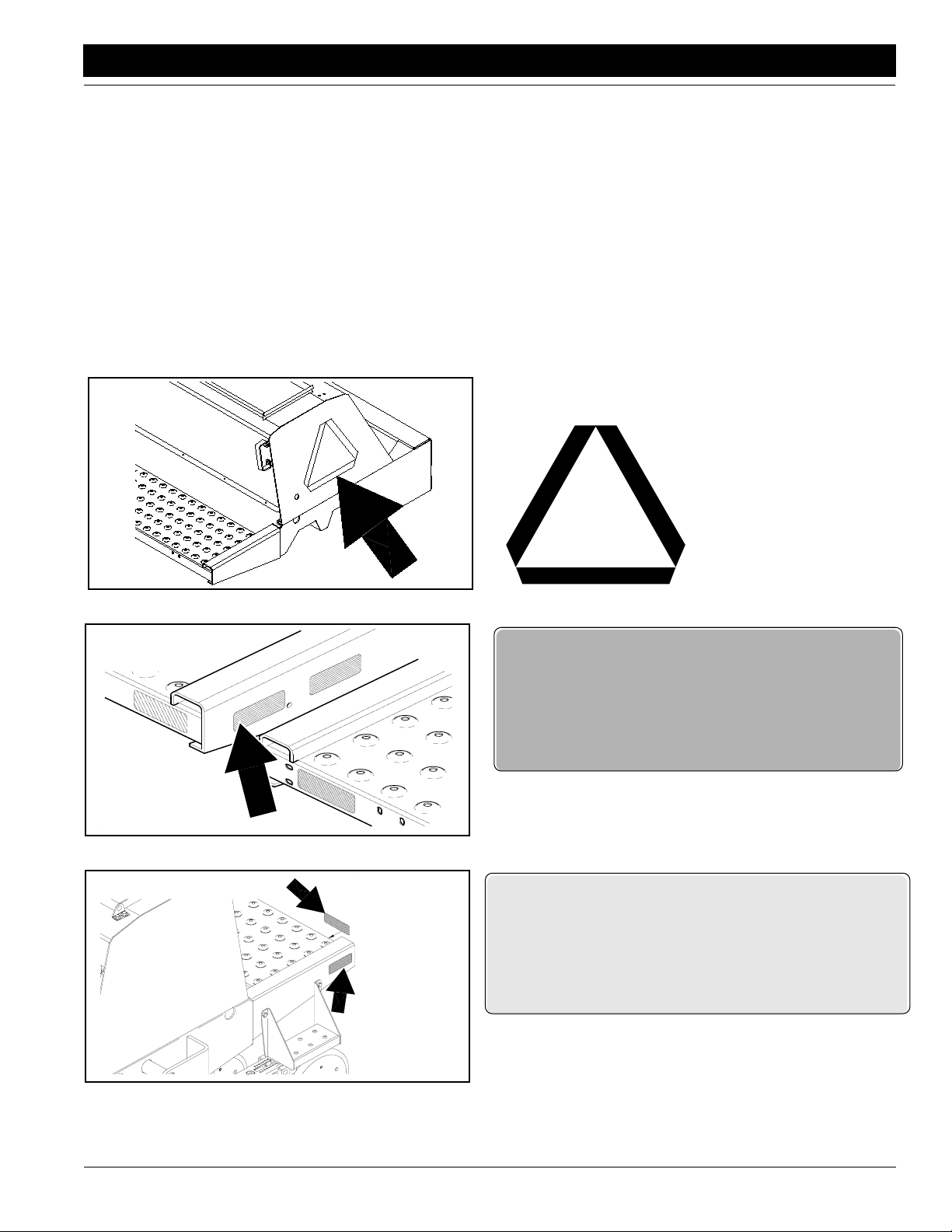

Safety Labels

Your implement comes equipped with all safety labels in place.

They were designed to help you safely operate your implement.

1. Read and follow label directions.

2. Keep all safety labels clean and legible.

3. Replace all damaged or missing labels. Order new labels

from your Great Plains dealer. Refer to this section for

proper label placement.

4. When ordering new parts or components, also request corresponding safety labels.

5. To install new labels:

a. Clean the area on which the label is to be placed.

b. Peel backing from label. Press firmly on surface,

being careful not to cause air bubbles under label.

12945

12942

818-003C

Slow Moving Vehicle

838-266C

Red Reflector

12/27/05

12943

838-265C

Amber Reflectors

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M

5

Page 8

Important Safety Information

Great Plains Mfg., Inc.

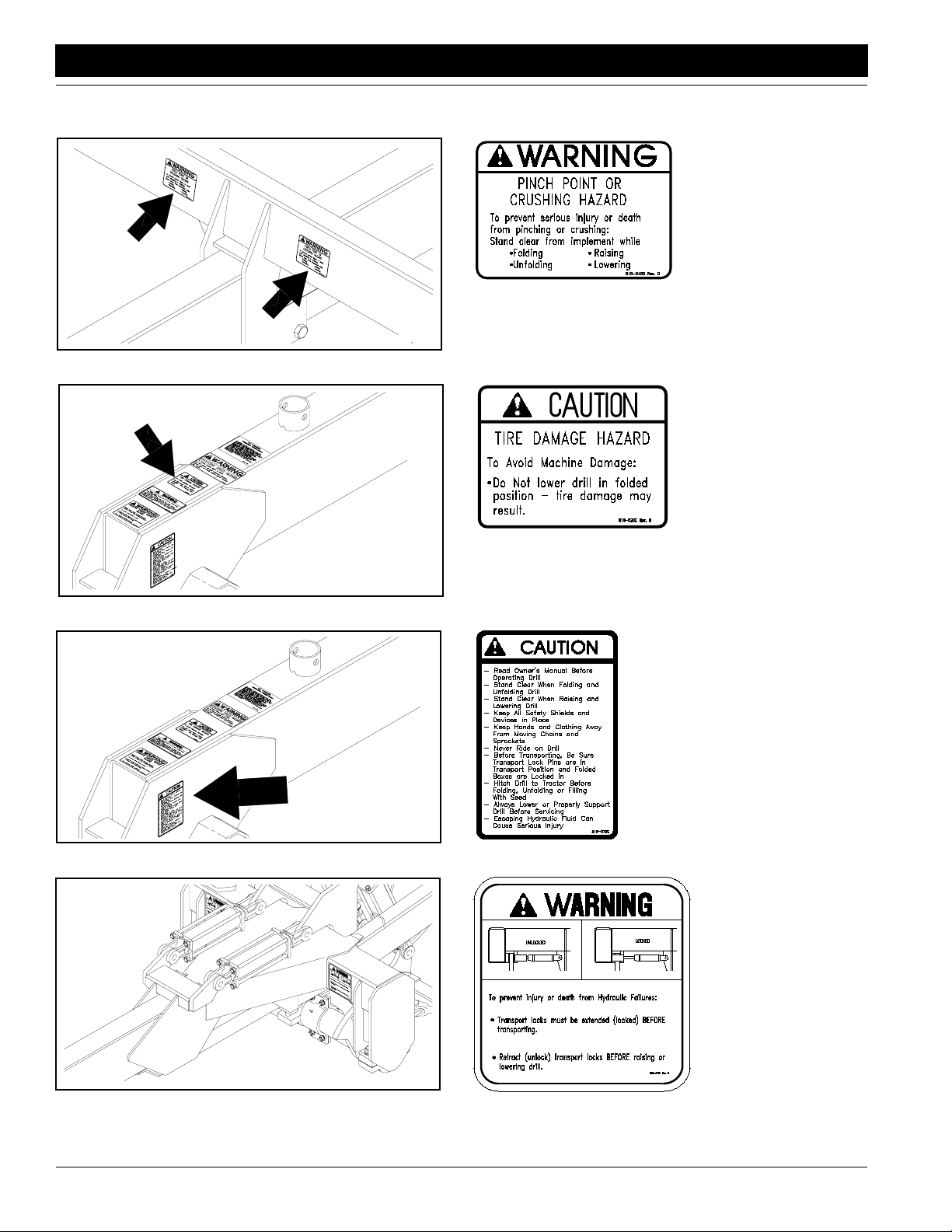

12941

12944

818-045C

Warning Folding-Raising

818-020C

Caution Lowering Drill

818-078C

12950

General Caution

818-477C

Warning Transport

14526

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M 12/27/05

6

Lock

Page 9

Great Plains Mfg., Inc.

Important Safety Information

12950

818-188C

20 MPH Transport

12950

12950

818-019C

Negative Tongue Weight

818-475C/818-476C

Warning 30-Ft./24-Ft. Tongue Weight

12/27/05

13317

818-398C

Caution! Tires - Not a Step

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M

7

Page 10

Important Safety Information

12942

Great Plains Mfg., Inc.

838-267C

Daytime Reflector

13734

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M 12/27/05

8

838-467C

Possible Chemical Hazard

Page 11

Great Plains Mfg., Inc.

Introduction

Introduction

Great Plains welcomes you to its growing family of new

product owners. This implement has been designed with

care and built by skilled workers using quality materials.

Proper assembly, maintenance and safe operating practices will help you get years of satisfactory use from the

machine.

Description of Unit

The two-section folding no-till drill is a towed seeding implement for no- or minimum-till soil conditions. The drill is

equipped with two hydraulic circuits. One is used to raise

and lower the drill for field operations. A separate electrohydraulic circuit lifts, locks and folds the implement for

transport. An in-cab control console allowstheoperatorto

switch between functions on the electro-hydraulic circuit.

Thedrillisoutfittedwithcoultersanddouble-diskopeners.

The openers are mounted on parallel arms. Press wheels

follow the opener disks to firm the seedbed and control

seeding depth.

Intended Usage

This machine is intended foruse in minimum- or no-till applications.

Using This Manual

This manual will familiarize you with safety, assembly, operation, adjustment, troubleshooting and maintenance.

Readthismanualandfollow the recommendations to help

ensure safe and efficient operation.

Fill out the warranty sheet with the dealer at the time of

purchase. Give the dealer the completed white copy and

send the pink copy to Great Plains.Keepyouryellowcopy

in the manual for use when corresponding with thedealer.

Thismanualiscurrent at printing. Someparts maychange

to assure top performance.

Definitions

Right and left as used in this manual are determined by

facingthe direction the machine will travelwhile in use unless otherwise stated.

IMPORTANT: A crucial point of information related to

the preceding topic. For safe and correct oper ation,

read and follow the directions provided before continuing.

Owner Assistance

If customer service or repair parts are needed contact

your Great Plains dealer. They have trained personnel,

parts and service equipment specially designed for Great

Plains products.

Your machine’sparts were specially designed and should

only be replaced with Great Plains parts. Always use the

serial and model number when ordering parts from your

Great Plains dealer. The serial number plate is located on

the outside end of the left drill box as shown in Figure A.

16537

Figure A

Serial Number Plate

Your Great Plains dealer wants you to be satisfied with

your new machine. If you do not understand any part of

this manual or are not satisfied with the service received,

please take the following actions:

1. Discuss the matter with your dealer service manager.

Makesurethey areawareofany problemssotheycan

assist you.

2. If you are still not satisfied, seek out the dealership

owner or general manager.

3. For further assistance, write to:

Product Support

Great Plains Mfg. Inc.

Service Department

P.O. Box 5060

Salina, KS 67402-5060

NOTE: Useful information related to the preceding topic.

12/27/05

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M

9

Page 12

Section 1 Drill Preparation and Setup

Section 1 Drill Preparation and Setup

Great Plains Mfg., Inc.

This section will help you prepare your tractor and drill for

use. The drill hitch must be adjusted to match drawbar

height, and the drill control console must be installed in

your tractor.

This section also covers bleeding the drill hydraulics and

making drill frame and box adjustments. As the operator,

you may need to perform these functions after dill repair.

Beforeoperatingthe drill, checkthatthehydraulic systems

are free or air, the frame is level, and boxes are aligned.

Prestart Checklist

1. Read and understand “Important Safety Information,” page 1.

2. Check that all working parts are moving freely, bolts

are tight, and cotter pins are spread.

3. Check that all grease fittings are in place and lubricated. Refer to Lubrication,“Maintenance and Lubrica-

tion,” page 41.

4. Checkthatallsafety labels and reflectorsarecorrectly

located and legible. Replace if damaged. See Safety

Labels,“Important Safety Information,”page 5.

5. Inflate tires to pressure recommended and tighten

wheel bolts as specified. See “Appendix,” page 50.

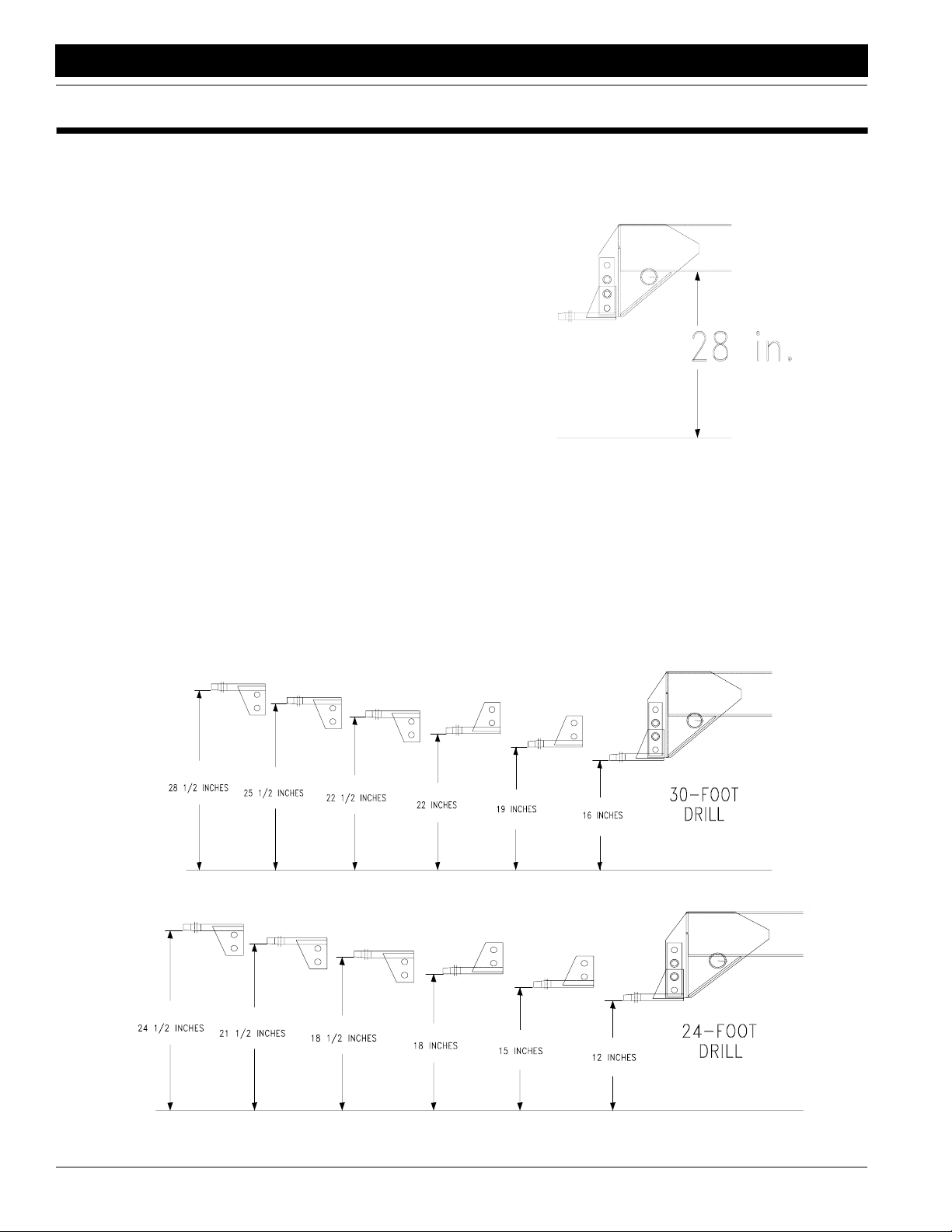

Hitch Height Adjustment

For proper operation, the drill tongue must run parallel to

the ground in field position. Follow these instructions to

adjust the drill hitch to match your tractor drawbar height.

1. Check the distance from under the tongue to the

groundasshowninFigure1-1.Using the drill jack, adjust the tongue up or down until the distance is about

28 inches.

16273

Figure 1-1

Tongue Height

2. Back the tractor drawbar up to the drill hitch. Determine how much adjustment is needed for the drill to

match drawbar height.

3. Unbolt the hitch from the tongue. Rebolt the hitch so

thedrillmatchesdrawbar height.Keepingin mind your

drill size, refer to Figure 1-2 or Figure 1-3 for the different ways you can bolt the hitch and the resulting hitch

heights.

16532

Hitch Height Adjustment, 30-Foot Drills

16274

Hitch Height Adjustment, 24-Foot Drills

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M 12/27/05

10

Figure 1-2

Figure 1-3

Page 13

Great Plains Mfg., Inc.

Section 1 Drill Preparation and Setup

4. Hitch the drill to the tractor using a hitch pin at least

one inch in diameter. Install a retaining clip on the

hitch pin to prevent it from working up.

NOTE:A clevis-style hitch, Great Plains part number 196136H, is available through your Great Plains dealer.

IMPORTANT: When hitching the drill to a different tractor,check for differencesin drawbar heights and re-adjust the drill hitch accordingly.

Installing Drill Control Consoles

1. Mountthecontrolboxes ataconvenientlocation in the

tractorcab.Connect the 12-footextensioncable to the

pin connector on the back of the control box. Route

thecabletothe tractordrawbararea.Secure the cable

to avoiddamage.

2. Connectthepowercordstoa12-voltpowersource on

the tractor.Thepolarity of the powersupply is very important. The red wire must be connected to the positive (+) battery terminal. The white wire must be

connected to the negative (-) battery terminal.

Note: To help with console and wire harness installation

refer to diagram on page 46.

Bleeding Hydraulic Systems

A hydraulic system with air in the circuit will movein jerky,

unevenmotions.Ifyourhydraulics havenotbeenproperly

bled or you replace a hydraulic component, bleed the hydraulics.

Field-Lift Hydraulics

The field-lift system is equipped with four rephasing-type

hydraulic cylinders that require a special procedure for

bleeding air. Read and follow the procedure carefully.Air

in the system will cause uneven seeding across the drill.

Do not loosen hose fittings in order to bleed air from this

system.

!

WARNING!

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin causing serious injury. Avoid the hazard by

relieving pressure before disconnecting hydraulic lines. Use a

piece of paper or cardboard, NOT BODY PARTS, to check for

leaks. Wear protective gloves and safety glasses or goggles

whenworkingwithhydraulic systems. If anaccidentoccurs,see

a doctor immediately. Any fluid injected into the skin must be

surgically removed within a few hours or gangrene will result.

!

CAUTION!

This drill has a negative tongue weight when unfolded and

raised. Be certain that the drill is hitched securely to your tractor drawbar and the hitch safety chain is securely attached to

the drill.

!

WARNING!

Never allow anyone under the drill when fittings are opened.

Escaping fluid may allow the drill to drop suddenly.

1. Check that the tractor reservoir is filled to the proper

level.It will take 4 gallons to charge the field-lift cylinders.

2. Put the tractor in park and set the parking brake. If

your tractor does not have these features, block

wheels to prevent tractor from rolling.

3. Raiseandsupportthemainframeand outside endsof

boxesjust high enough to take the weight off all four

field-lift cylinders.

4. With the drill blocked and supported, unpin both ends

of all four field-lift cylinders. The field-lift cylinders are

locatedonthewinggauge wheels andthemain-frame

transport wheels. Remove and safely position the cylinders so the rod ends are higher than the base ends.

Check that there is enough room forthe cylinder rods

to fully extend without contacting anything.

IMPORTANT: To prevent trapped air poc kets, the rod

end must be higher than any other part of the cylinder.

5. Withthetractoratidle,engage the lift-hydraulicslever.

When the cylinders for both gauge wheels have completely extended, hold the leveron for one minute.

6. Retract the cylinder rods. Extend the rods again and

hold the lever on for one more minute. Repeat this

step two more times to completely bleed the system.

7. Retract and reattach the hydraulic cylinders.

8. Recheck the tractor hydraulic reservoir level and add

clean fluid as necessary.

Transport-Lock Hydraulics

The transport-lock cylinders are not rephasing. The two

transport-lock cylinders are on each side of the main

frame above the transport axle pivot tubes. Follow these

steps to properly bleed the transport-lock hydraulics.

1. Check that the tractor reservoir is filled to the proper

level.It will take about one gallon to charge the transport-lock cylinders.

2. Raise the drill to field position and support the main

frame.

3. Select the locks system on the control console. Retract the lock cylinders completely.

4. Loosen the connection between the hose and baseend tee fitting on the left lockcylinder.With the tractor

at idle slowly work the remote leverto feed oil to the

base end of the lock cylinders. Stop when you see oil

coming from around the fitting. Do not attempt to fully

extend the lock cylinders when bleeding the base

ends.

12/27/05

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M

11

Page 14

Section 1 Drill Preparation and Setup

Great Plains Mfg., Inc.

5. With the cylinders completely extended, repeat step 4

for the rod-end fitting.

6. Recheck the tractor reservoir and add clean fluid as

necessary.

7. Retract and extendthe lock cylinders several times to

expelmost air from the system. The remaining air will

be expelled gradually during day-to-dayoperations.

8. Recheckthe tractor hydraulic reservoir and addclean

fluid as necessary.

Raise-To-Fold Hydraulics

The raise-to-foldcylinders are double acting but not

rephasing.Therearefourcylindersintheraise-to-foldsystem. Two are on the tool bar,and two are on the tongue.

Follow these steps to properly bleed the raise-to-fold hydraulics.

1. Check that the tractor reservoir is filled to the proper

level.Itwill take 3.4 gallons to charge the raise-to-fold

cylinders.

2. Select the raise-to-foldsystem on the control console.

3. Check that the drill is unfolded and resting safely on

the ground.

4. Disconnect the rod-end clevis of both tool-bar cylinders and both tongue cylinders. Support the cylinders

so the rods may extend and retract freely.

5. Retract the tongue cylinders completely. This will also

fully extend the tool-bar cylinders.

6. Loosen the hose-end fitting coming into the teeonthe

base end of the left tongue cylinder.

11. Slowly work the lever in the opposite direction to feed

oil to rod end of the tongue cylinders. Stop when you

see oil coming from around the fitting. Do not attempt

to retract the tongue cylinders while bleeding the rod

ends.

12. Loosen the hose-end fittings at the tee coming from

the base ends of the tool-bar cylinders. Slowly work

the lever to feed oil to the base end of the tool-bar cylinders.Stopwhenyouseeoilcomingfrom around the

fittings.Donotattempttoextend the tool-bar cylinders

while bleeding the base ends.

13. Extendandretractthecylindersseveral timestoexpel

most air from the system. The remaining air will gradually be pushed to the tractor during day-to-dayoperations.

14. Repin the tongue and tool-bar cylinders. Raise and

lower the wings several times to check for proper operation. If movementis erratic, repeat bleeding operation.

15. Recheck the tractor hydraulic reservoir level and add

clean fluid as necessary.

Fold Hydraulics

The fold cylinders are not rephasing. The two fold cylinders connect the main frame and drill boxes.Followthese

steps to properly bleed the fold hydraulics.

IMPORTANT: Check that the transport-lock and raiseto-fold systems are bled and completely operational

before working with the fold hydraulics.

IMPORTANT: Do not attempt to bleedanO-ringfitting

or O-ring damage may occur.

7. Slowly work the remote lever to feed oil to the base

end of the tongue cylinders. Stop when you see oil

coming from around the fitting. Do not attempt to extend the tongue cylinders while bleeding the base

ends.

8. Loosen the hose-end fittings at the tee on rod ends of

the tool-bar cylinders. Slowly work leverwhich feeds

oil to the rod end of the tool-bar cylinders. Stop when

you see oil coming from around the fittings. Do not attempt to retract the tool-bar cylinders while bleeding

the rod ends.

9. Fully extend the tongue cylinders and retract the toolbar cylinders.

10. Loosen the hose-end fitting at the tee on the rod end

of the left tongue cylinder.

IMPORTANT: Do not attempt to bleedanO-ringfitting

or O-ring damage may occur.

1. Make sure the tractor hydraulic fluid reservoir is filled

to the proper level. It will take about two gallons to

charge the fold cylinders.

2. With the boxesunfolded unpin the rod-end clevisand

support the fold cylinders so they can be extended

and retracted.

3. Select the foldsystem on the control console. Retract

the fold cylinders completely.

4. Loosen the connection between the hose-end and

base-end tee fitting on the left fold cylinder.

5. With the tractor at idle slowly work the tractor lever to

feed oil to the base end of the fold cylinders. Stop

when you see oil coming from around the fitting. Do

notattempttoextendthefoldcylinderswhenbleeding

base ends.

6. With cylinders completely extended, repeat the procedure for the hose connection at the rod end.

7. Retract and extend the cylinders several times to expel most air from this system. The remaining air will

gradually be pushed to the tractor during day-to-day

operations.

8. Recheckthetractorreservoir levelandaddcleanfluid

as necessary.

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M 12/27/05

12

Page 15

Great Plains Mfg., Inc.

Section 1 Drill Preparation and Setup

Marker Hydraulics

!

CAUTION!

Never allow anyone near the drill when cycling the markers.

1. Make sure the tractor hydraulic fluid reservoir is filled

to the proper level.It will take one gallon to charge the

dual marker cylinders.

2. Withthedrillunfoldedand lowered,turnmarkerswitch

on the control console to the left marker position.

3. With the marker unfolded, crack the hydraulic hose fittinglocatedatthebaseendoftheleftmarkercylinder.

4. With the tractor at idle slowly work the tractor remote

leverto feed oil to the base end. Stop when youseeoil

coming out around the hose ends. Tighten the hoseend fittings.

5. Repeat step 3 and 4 for the hose-end fitting at the rod

end of the cylinder.

6. If dual markers are used, repeat steps 2, 3 and 4 for

the right marker cylinder.

IMPORTANT: Leave the control console switch in the

left marker position when bleeding the right marker cylinder. Both markers are controlled b y the left mark er

switch if your markers ha ve a sequence valve.

7. Fold and unfold the marker slowly to work all the air

out of your marker hydraulics.

IMPORTANT: JIC fittings do not require high torque.

JICandO-ringfittingsdonotrequiresealant.Always

use liquid pipe sealant when adding or replacing

pipe thread fittings. To avoid possible danger of

cracking hydraulic fittings from over tightening, do

not use plastic sealant tape.

Frame Leveling Adjustment

Periodicframeleveling should notbenecessary,but if you

are having trouble maintaining equal coulter depth across

the drill, check that the frame is level. When the drill is level, the box frames will be the same distance from the

ground at both ends of the drill.

Completethestepsunder BleedtheFoldHydraulics,page

12, before proceeding.

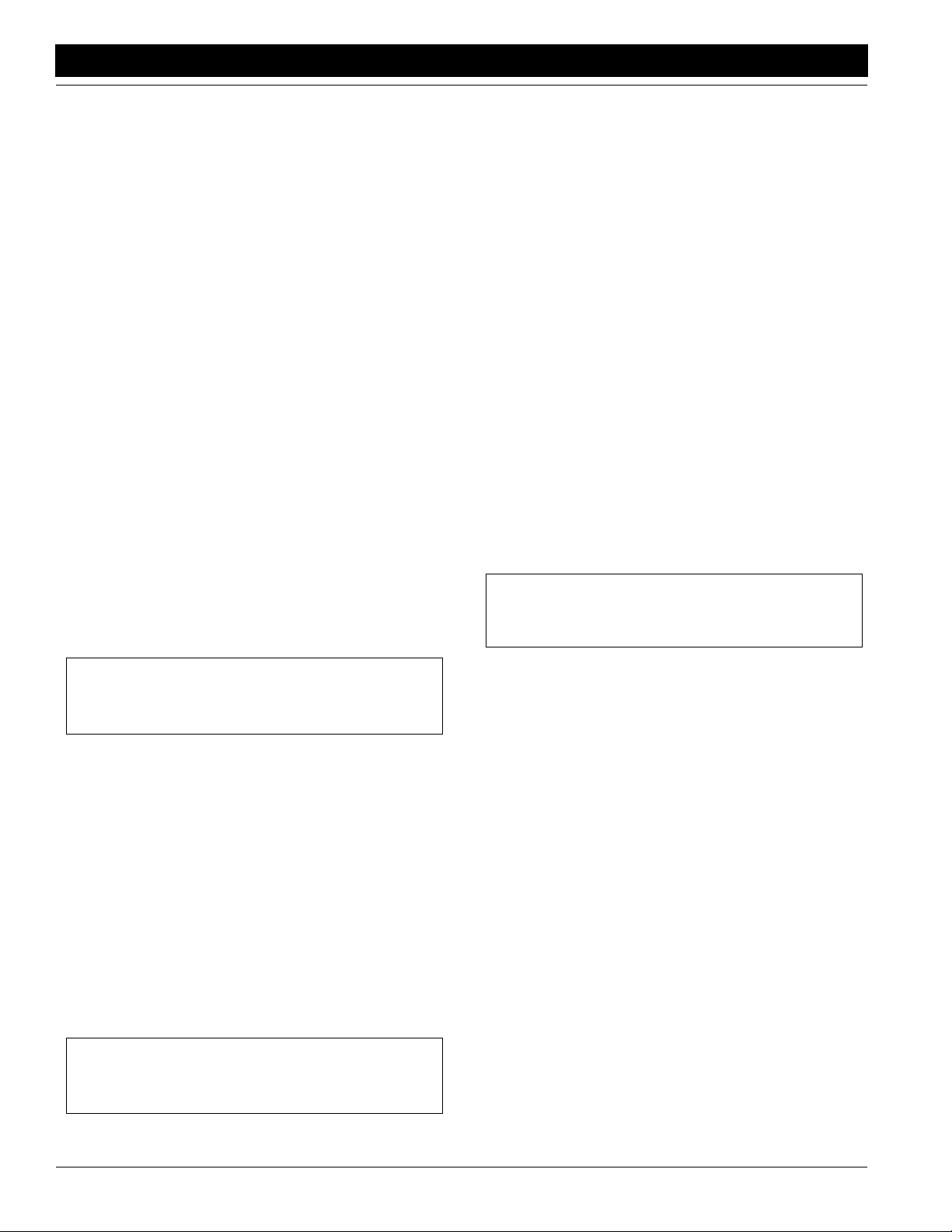

Refer to Figure 1-4.

1. Locate the threaded eye bolt at the base end of the

gauge-wheel cylinders (1). The eye bolt is locked in

place bya jam nuts. Observe the amountof thread exposed abovethe upper nut andbelow the lower nut. If

the exposed threads are roughly equal, no initial adjustment is needed. Go to step 3.

2. If the exposed threads above and below the nuts are

not equal, loosen and adjust the jam nuts until the exposed threads are within 3/8 inch of each other.Repeat for other end of drill.

12779

Figure 1-4

Wing Gauge Wheel Eye-Bolt Adjustment

3. Move the drill to a level area. With the drill unfolded,

check that the tool-bar cylinders are completely extended. Raise the drill to its highest position with the

field-lift cylinders. With the tractor idling, rephase the

cylinders by holding the hydraulic lever on for an additional 30 seconds. Immediately lower the boxes until

the coulters and openers are just ready to touch the

ground.

4. Move the gauge-wheel eye bolts (1) in or out until the

framesare level.Whentheframesare level,theopeners on the outside end of the drill will be the same

height as the center openers.

NOTE: Eye-bolt adjustments are easier if the drill is first

lowered to the ground to remove some of the force on the

cylinders.

5. Repeat the steps above until the drill is level end-toend when drilling in actual seeding conditions.

12/27/05

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M

13

Page 16

Section 1 Drill Preparation and Setup

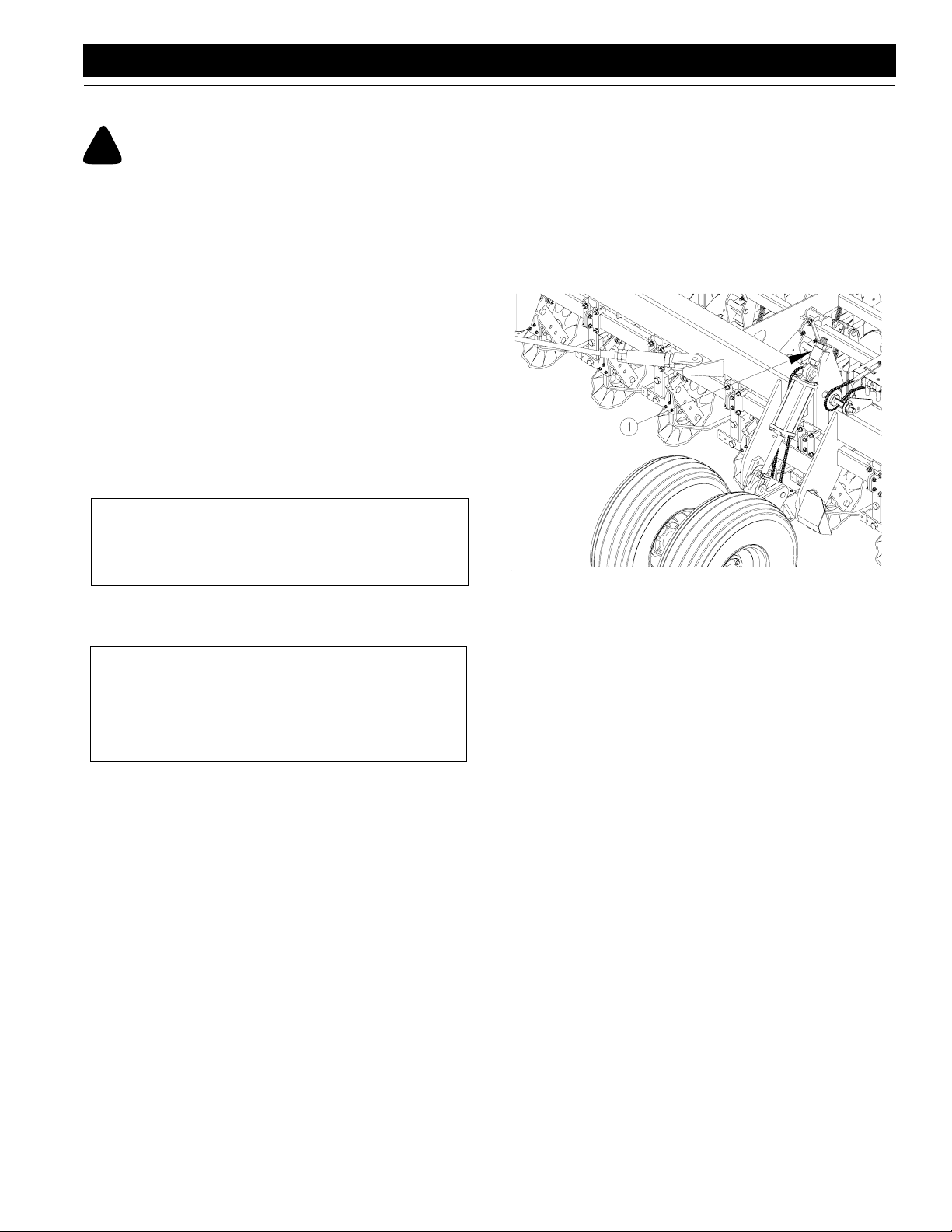

Aligning Boxes

For proper alignment, the outside ends of the drill boxes

mustbe 1 to 1 1/2 inches ahead of the inside ends. Follow

these steps to check box alignment and adjust as

necessary.

1. With the drill unfolded and lowered,pull forward a few

feet with the openers in the ground.

2. Extendastringlinetothe outer endsofthewingboxes

asshowninFigure 1-5. Measure fromthestringlineto

each box as shown. For each box, measurement A

shouldbe1to11/2inchesgreaterthan measurement

B.

3. If adjustment is needed, write down howmanyinches

the box should be moved to be within the 1- to 1 1/2inch tolerance mentioned above. Also note the direction you need to move the outside end of the box–forward or back.

String Line

Great Plains Mfg., Inc.

12778

Figure 1-6

Box Alignment Adjustment

Measurement A

Measurement B

Figure 1-5

Box Alignment Measurements

4. Makeadjustmentsattheboxend of each pull cable as

shown in Figure 1-6. Loosen the jam nuts on the adjustment trunnion screw. Turn the screw in or out to

move the box end forward or backward as required.

Retighten the jam nuts.

5. Pull ahead slightly and check the box alignment. Readjust the pull cables if necessary.

Measurement A

Measurement B

16306

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M 12/27/05

14

Page 17

Great Plains Mfg., Inc.

Section 2 Operating Instructions

Section 2 Operating Instructions

This section will help you prepare the tractor and drill for

use.Itwill also give you general operating procedures. Experience,machinefamiliarityand the followinginformation

will lead to efficient operation and good working habits. Always operate farm machinery with safety in mind.

Prestart Checklist

1. Carefully read “Important Safety Information,” page

1.

2. Lubricate the drill as indicated under Lubrication,

“Maintenance and Lubrication,” page 41.

3. Check all tires for proper inflation as indicated on Tire

Inflation Chart,“Appendix,”page 50.

4. Check all bolts, pins and fasteners. Torque as specified on TorqueValues Chart,“Appendix,” page 50.

5. Check the drill for worn or damaged parts. Repair or

replace them before going to the field.

6. Checkhydraulichoses, fittingsandcylindersforleaks.

Repair or replace them before going to the field.

7. Check disk scrapers for proper adjustment. Refer to

Disk Scraper Adjustment,“Adjustments,”page 34.

8. Check that the drive-clutch linkage is operating properly. The clutch jaws should be fully engaged with the drill

in seeding position. When the drill is fully raised the

clutch jaws should be completely separated.

9. Rotate both gauge wheels to see that seed cups and

drive are working and free from foreign material.

Tractor Requirements

Recommended Minimum Tractor Size

24-foot drill - 165 horsepower

30-foot drill - 200 horsepower

NOTE: When determining tractor size, soil type, terrain

and tillage practices must be considered.

Hitching Tractor to Drill

1. Use the drill jack to raise or lower the tongue as needed. Hitch the drill to the tractor using a hitch pin of adequate strength (at least one inch in diameter).

2. Installaretainingcliponthehitchpintopreventit from

workingup.Securelyattachdrillsafety chain to tractor

drawbar.

!

WARNING!

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin causing serious injury. Avoid the hazard by

relieving pressure before disconnecting hydraulic lines. Use a

piece of paper or cardboard, NOT BODY PARTS, to check for

leaks. Wear protective gloves and safety glasses or goggles

whenworkingwithhydraulic systems. If anaccidentoccurs,see

a doctor immediately. Any fluid injected into the skin must be

surgically removed within a few hours or gangrene will result.

3. Connect hydraulic hoses to tractor remotes. One pair

of hoses is for the field-lift cylinders. The other pair is

for raise-to-fold, transport-lock, fold and marker cylinders.

4. Plug the control-console cable to the drill harness.

Plug the drill light cable to the tractor.

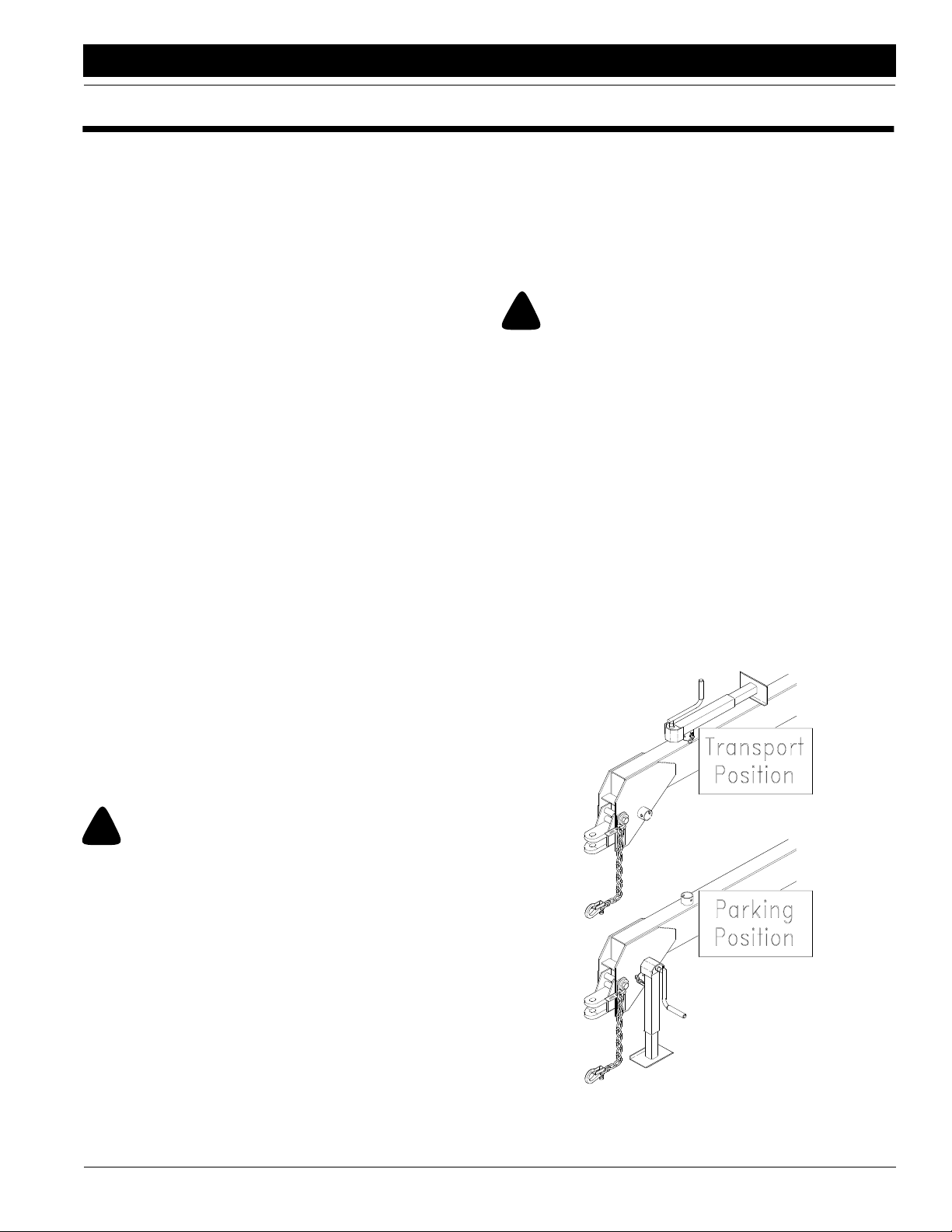

5. Crank the jack until tongue weight is resting on the

tractor drawbar. Unpin the tongue jack from the hitching stub.Pin the jack to the stub on top of the tongue

as shown in Figure 2-1.

!

WARNING!

Towing the drill at high speeds or with a vehicle that is not

heavy enough canleadtolossofvehiclecontrol. Loss of vehicle

control can lead to serious road accidents, injury and death.

The reduce the hazard:

• Do not exceed 20 mph.

• Use a towing vehicle heavy enough to controlthe drill.

Minimum Towing Vehicle Weight

16,000 pounds

Hydrualics

Your tractor must have two remote outlets.

Safety Lights

Your tractormustbe wired for the standard 7-pinelectrical

connector.If your tractor is not equipped with this connector, consult your dealer for installation.

12/27/05

12782

Figure 2-1

Jack Positions

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M

15

Page 18

Section 2 Operating Instructions

Great Plains Mfg., Inc.

Operating Control Console

Your drill is equipped with a control console that is mounted in the tractor cab. Refer to Drill Control Console Hook-

Up,“DrillPreparationandSetup,”page 11. Theconsole

is designed to control drill folding and optional markers,

electric clutches and shaft monitors. The console has a

master switch that must be on when operating any of

these systems.

The raise-to-fold,transport locks and foldswitchesare operated independently.Turn only one of these switches on

atonetime.Duringfieldoperations,turn all three switches

off.

To operate markers, turn the marker switch to the left position during field operation. Turn this switch to the center

position (off) when folding or in transport.

Operating Electric Clutch Consoles

To operate electric clutches, turn either the left or right

clutch switch to the off position to shut down the seeding

from the corresponding box. Turn the electric clutch

switches off when folding or in transport.

Tooperateshaftmonitors,turn the shaft monitor switchon

during field operation and off when folding or transporting.

Folding the Drill

!

CAUTION!

To prevent serious injury or death:

• Always use transport locks when drill is folded.

• Fold only if hydraulics are bled free of air and fully charged

with hydraulic oil.

• Stay away from frame sections when they are being raised or

lowered.

• Keep away and keep others away when folding or unfolding

the drill.

Fold the drill on level ground with the tractor in neutral. If

yourdrill has markers,be certain theyare folded and their

control switches are off before folding. If your drill has a

harrow attachment, fold the attachment beforefolding the

drill. Refer to Folding Harrow Attachment, page 16.

1. Raise drill with field-lift cylinders until cylinders are fully extended.

2. Turn on master power switch on control console. Turn

on raise-to-foldswitch.

3. Work tractor hydraulic lever to raise drill into fold position.

4. Turn off raise-to-fold switch. Turn on transport-locks

switch.

5. Worktractorhydrauliclever to extendlockcylinders.If

lockcylinderswillnotextend,drillisnotfullyraised;repeat steps 1 through 3.

NOTE: If your tractor is equipped with hydraulic flow controls,adjust flow-control valveforthiscircuit to the slowest

position.

6. Turn off transport-locks switch. Turn on fold switch.

7. Work tractor hydraulic leverto slowly retract foldcylinders.

IMPORTANT: Never attempt to fold without first operating the raise-to-fold and transport-lock systems. Otherwise, serious equipment damage will occur.

8. Once drill is foldedovertransportcarriers,turn off fold

switch. Turn on raise-to-fold switch.

9. Work tractor hydraulic lever to lower boxes onto carriers.

10. Turn off raise-to-fold switch.

Folding Harrow Attachment

Beforehydraulicallyfolding drill, foldoptional coil-tine harrow as explained below.

1. Fold right-hand harrow assembly up until locking pin

engages into the first slot on harrow bracket.

2. Fold left-hand harrow assembly up until locking pin

engages into the second slot on harrow bracket.

Unfolding the Drill

!

CAUTION!

This drill has negative tongue weight when unfolded and

raised. Be certain the drill is hitched securely to your tractor

drawbar and the hitch safety chain is securely attached to the

tractor before raising or unfolding the drill.

!

CAUTION!

To prevent serious injury or death:

• Always use transport locks when drill is folded.

• Fold only if hydraulics are bled free of air and fully charged

with hydraulic oil.

• Stay away from frame sections when they are being raised or

lowered.

• Keep away and keep others away when folding or unfolding

drill.

Unfold the drill on level ground with the tractor transmission in neutral.

1. On control console, turn on raise-to-fold switch.

2. Work tractor hydraulic leverto raise boxes off transport carriers.

3. Turn off raise-to-fold switch. Turn on fold switch.

4. Work tractor hydraulic leverto slowly unfold drill boxes.

5. When drill is unfolded completely, turn off fold switch.

Turn on transport-lock switch.

6. Work tractor hydraulic leverto retract transport-lock

cylinders.

NOTE:Iftransport-lockcylinderswillnotretract,drillisnot

raised fully.Make sure field-lift cylinders and transport-lift

cylinders are extended fully.

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M 12/27/05

16

Page 19

Great Plains Mfg., Inc.

Section 2 Operating Instructions

7. When transport-lock cylinders are retracted, turn off

transport-lock switch. Turn on raise-to-fold switch.

8. Work tractor hydraulic leverto lower drill.

9. Turn off raise-to-fold switch.

Lifting the Drill in the Field

Your drill is raised for field operations with hydraulic cylinders in a master-slave configuration. Overa period of normalusethecylindersmay get out ofphase.Thiswillcause

onesideofthedrilltorunhigher.To rephase the cylinders:

1. Raise the drill completely with the field-lift cylinders.

Holdthehydraulicleveronforseveral secondsuntilall

cylinders are fully extended. This should be done every time the implement is raised out of the ground.

2. When all field-lift cylinders are fully extended, momentarily reversethe hydraulic leverto retract the system

1/2 inch. This will help maintain levelness.

NOTE: Air in the field-lift system will cause jerky and unevencylinder movement. Follow procedures under Bleed-

ing the Hydraulic Systems,“Drill Preparation and

Setup,” page 11, to properly bled air from the system.

Field Operations

For normal seeding operations:

1. Hitch drill to a tractor with sufficient weight and horsepower. Refer to TractorRequirements, page 15, and

Hitching Tractorto Drill, page 15.

2. Perform all checks listed on Prestart Checklist, page

15.

3. Lower the drill into seeding position.

4. Observe the drill from the side. Check that the tongue

is running levelwith the ground. If not, refer to Hitch

Height Adjustment,“Drill Preparation and Setup,”

page 10.

5. Set the seeding rate for both boxes. Refer to Setting

the Seeding Rate,“Adjustments,”page 22. Make

sure the seeding rate is the same across the drill.

6. Load boxeswith clean seed.

7. Record the acremeter readout. The acremeter is

mounted on the outside end of the left gauge-wheel

shaft. Subtract this initial readout from later readings

to calculate area drilled.

8. Pull forward, lower drill, and begin seeding.

9. Always lift the drill out of the ground when turning at

row ends and for other short turns. Seeding will stop

automatically as the drill is raised in the field.

NOTE:This drill is offered in three different row spacings.

Some of the drill boxes do not have the same number of

seed cups between each internal boxdivider.Thesection

with the largest number of cups will empty sooner.

Opener Operation

Neverbackup with openers in ground. If you do,check all

openers to be sure none are clogged or damaged.

For information on setting seed depth and opener adjustments,seeNo-TillSeeding,“Adjustments,”page19,and

LevelingAdjustments,“Adjustments,” page 34. Formore

information on troubleshooting opener problems, see

“Troubleshooting,” page 37.

Marker Operation

Optionalmarkerattachmentsare sold assingle(left-hand)

or dual units. The markers are operated on the same electro-hydrauliccircuitastheraise-to-fold,transport-lockand

folding functions.

Before operating the markers, make sure they are properlybledasdescribedunderBleedMarkerHydraulics,“Drill

Preparation and Setup,” page 13.

To operate the markers,turn the control-console switch to

the left marker position after the drill is unfolded. Activate

the hydrauliclever to fold or unfold the marker.

Thedualmarkersareequippedwith a sequencing valveto

ease marker operation. Startingwith both markers folded,

the sequence is:

1. Activate lever. Right unfolds; left marker stays folded.

2. Reverse lever.Right folds up; left stays folded.

3. Activate lever. Left unfolds; right stays folded.

4. Reverse lever.Left folds up; right stays folded.

5. Sequence repeats.

NOTE: Because of the sequencing valve, do not turn

marker switch between the left and right positions on the

control console. The left-marker position controls both

markers.Ifyouwishtooperatethe markersindependently,

contact your Great Plains dealer for additional parts to

modify the marker hydraulics.

Markers are equipped with needle valves to set folding

speed. Refer to Folding Speed,“Adjustments,” page 35,

and adjust folding speed to a safe rate. Folding or unfolding markers at high speed can damage markers.

Whenmarkeroperationiscomplete,return markers to the

folded position and turn the marker switch to the center

(off) position.

12/27/05

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M

17

Page 20

Section 2 Operating Instructions

Great Plains Mfg., Inc.

Shaft Monitor Operation

To operate the optional shaft monitors,turn the shaft-monitor switch on the control console to the on position. If either seed-cup shaft stops for 20 seconds, an alarm will

sound. A light on the control console will designate the

failed shaft.

The 20-second delay is to prevent nuisance alarms when

turning at the end of the field. If the alarm sounds, remember you have traveled for 20 seconds without seeding.

Electric Clutch Operation

Electrical clutches on the upperjackshaftturn seeding off

and on as the drill is raised and lowered in the field. The

electricclutchesallowyouto turnseedingoffwhilethedrill

is lowered. A clutch for each drive shaft allows you to control each drill box independently. The clutches are controlled through the in-cab control console.

For regular field operation, turn the electric-clutch switches on the control console to the on position. This will activatethemagnetoneachclutchandallow the clutch shafts

to rotate.

To shut off seeding in one or both boxes while the drill is

lowered, turn one or both switches to the off position.

Transporting

!

CAUTION!

This implement should never be towed faster than 20 mph.

Before transporting, check and practice the following

items.

Fold Drill. Transport the drill in folded position with transport-lock cylinders extended. Refer to Folding the Drill,

page 16.

Loaded Boxes. This drill can be transported with boxes

loaded with grain, but only with extreme caution. The additional weight reduces maneuverability and increases

stopping distance.

Stopping Distance. Keep the weight of this drill in mind.

Allow sufficient stopping distance at all times. Reduce

speed prior to making any turns or other maneuvers. Increase stopping distance if transporting with loaded boxes.

Bystanders. Check that no one is in the way before moving. Do not allow anyone to ride on the drill.

Tractor Requirements. Check that the towing vehicle is

large enough to control the drill on the road. Refer to Trac-

tor Requirements, page 15.

Clearance. Know drill dimensions in transport position

and follow a route that provides adequate clearance from

all obstructions. Refer to Specifications and Capacities,

page 49.

Tires. Check that all tires areproperly inflated as listedon

Tire Inflation Chart,“Appendix,”page 50.

Road Rules. Comply with all federal, state and local laws

when transporting on public roads.

Warning Lights. Always use warning lights when trans-

porting the drill.

Watch Traffic.Be prepared for sudden maneuvers from

following vehicles.

Markers. Always transport optional markers folded flat.

Make sure the second marker section rests securely on

the transport carrier.

HarrowAttachment. Foldtheoptionalharrow attachment

beforehydraulically folding drill fortransport. RefertoFold-

ing the Harrow, page 16.

Parking

Performthefollowingsteps when parking the drill. Referto

Storage,“Maintenance and Lubrication,” page 40, for in-

formation on long-term storage preparation.

1. Raise, lock and fold the drill in the transport position.

Refer to Folding the Drill, page 16.

2. Park the drill on a level, solid area.

3. Securely block the tires to preventrolling.

4. Remove the jack from its storage stub. Pin the jack in

parking position. See Figure 2-1, page 15. If the

ground is soft, place a board or plate under the jack.

5. Extend the jack until tongue weight is off the drawbar.

6. Unplug the hydraulic lines from the tractor. Do not allow hose ends to rest on the ground.

7. Unplug the control-console cable from the tractor. Unplug the drill light cable from the tractor.

8. Remove hitch pin and safety chain from tractor drawbar.

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M 12/27/05

18

Page 21

Great Plains Mfg., Inc.

Section 3 Adjustments

Section 3 Adjustments

No-Till Seeding

To get full performance from your no-till drill, you need a

good understanding of coulter, opener and press wheel

operation.

Coulters. A no-till coulter is mounted independently and

directly ahead of each opener. The coulters cut through

heavy trash and make a groove in the soil. The coulters

are mounted directly on the box frame. Consequently,the

cutting depth of all coulters changes as the drill is raised

andlowered.Thecutting depth ofthecoultersiscontrolled

byan adjustable hydraulicdepth stop.Coulters that run directly in tire tracks can be lowered individually. Refer to

Coulter Adjustments, this page, for information on how to

make these adjustments.

Openers.Eachopeneris mounted onthedrillwithparallel

arms. This parallel-action mounting allows the opener to

move up and down while staying in-line with a coulter.

Opener double disks widen the coulter groove, making a

seed bed. A seed tube mounted between the disks delivers seed to the trench.The down force needed to cut and

widenthecoultergrooveis supplied by twospringsnested

in the parallel linkage. Adjusting these springs changes

opener down-force. Refer to Opener Down-Pressure Ad-

justment, page 22, forinformation on how to make this adjustment.

Press Wheels. Attached to the rear of each opener is one

of severalpress-wheeloptions. The press wheels provide

two important functions.

First, the press wheels close the furrow, gently pressing

the soil over the seed. To provideconsistent seed firming,

the press wheels are free to move downward from their

normal operating position. This system maintains pressing action even if the opener arm is lifted when the disks

encounter obstructions.

Second, the press wheels provide opener depth control.

The higher the press wheels run relative to the double

disks, the deeper seed will be placed. Tomaintain a consistentdepth,upwardpress-wheelmovementisrestricted

by an independently adjustable stop on each opener. Refer to PressWheelAdjustment,page 22,forinformationon

how to make this adjustment.

Coulter Adjustments

The drill is assembled so thatwhen the coulters are at two

inches deep, the seeding depth is about one inch. This is

a good baseline setting for most seeding operations. As

field conditions warrant, you can change settings on the

entire drill or individual coulters.

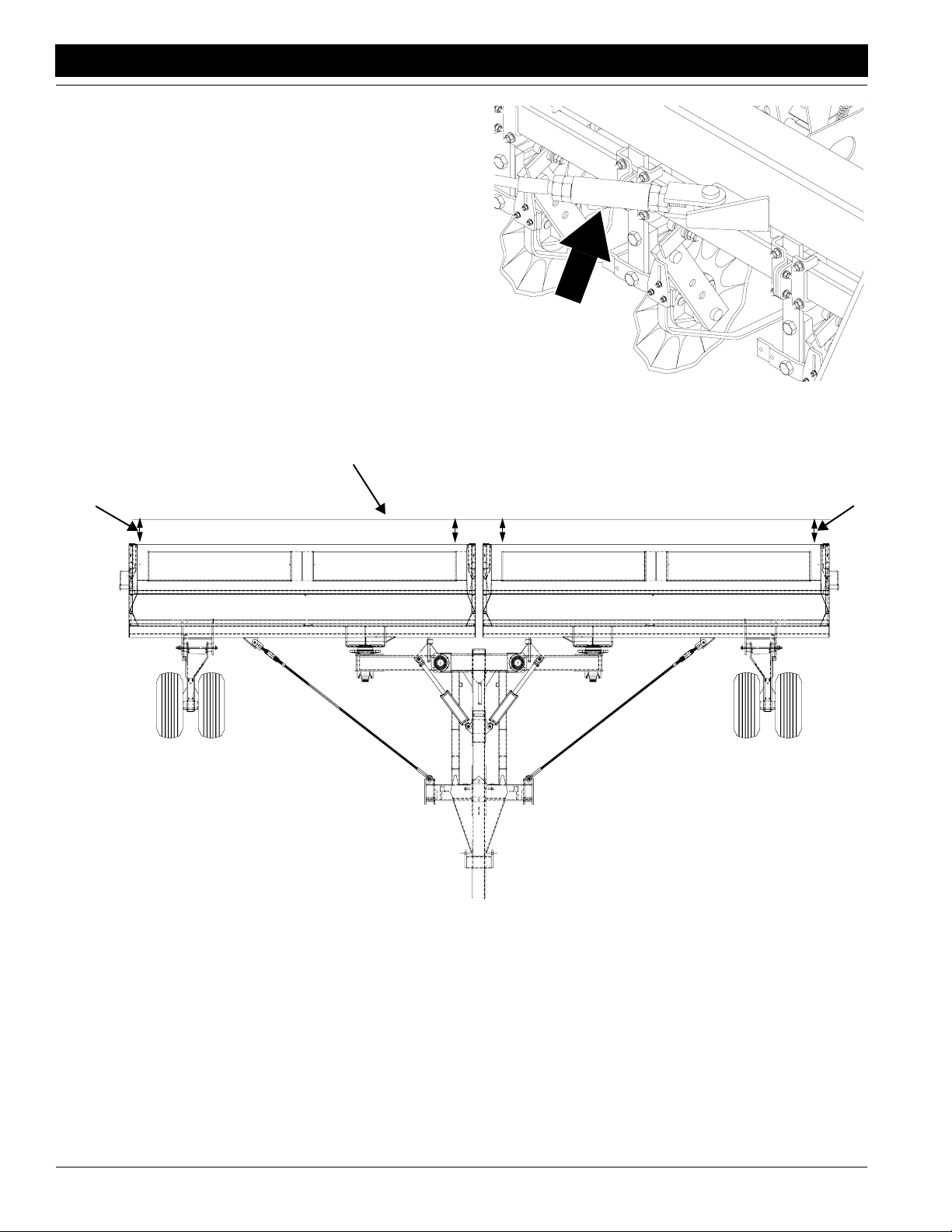

Hydraulic Depth Control

The master field-lift cylinder on the left transport wheel is

equipped with a hydraulic valvethat regulates coulter

depth.Figure3-1showsthevalve and knob used to adjust

coulter depth.

Raise Coulters

Lower Coulters

16271

Figure 3-1

Left Transport-Wheel Cylinder with Depth-Control Stop

Turn the knob clockwise to lower the coulters. Each clockwise rotation will lower the coulters about 3/32 inches.

Make depth adjustments with the implement slightly

raised.Afteradjusting the valve,raiseandlowertheimplement several times and recheck coulter depth.

The depth stop regulates depth on all coulters. If the ends

of either box run higher or lower than the center,the fieldlift system may be out of phase or have air in it, or the

framesections maynotbe level.RefertoLiftingtheDrill in

theField,“Operating Instructions,” page 17, Bleed Field-

LiftHydraulics,“Drill Preparation andSetup,” page11,or

LevelingAdjustment, page 34.

12/27/05

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M

19

Page 22

Section 3 Adjustments

Electric Clutch Switch Adjustment

To adjust the height at which seed metering is turned off,

follow these steps.

Refer to Figure 3-2

1. Locate the height switch at left-hand gauge wheel.

2. Lower the implement until it is at a height where seeding should start (usually just above the ground). Securely support frame at this height with jack stands or

blocks.

3. Turn off the tractor and remove the key.

Great Plains Mfg., Inc.

Refer to Figure 3-3

4. Loosen the cam clamp (1) on the gauge wheel rockshaft and turn until the switch roller (2) is just starting

to make contact with the ramp surface.

Refer to Figure 3-4

5. Raise the implement fully and check that the switchis

compressed as shown.

19711

Figure 3-2

15160

Figure 3-3

14550

Figure 3-4

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M 12/27/05

20

Page 23

Great Plains Mfg., Inc.

Section 3 Adjustments

Weights

Ifmoreweightis required forcoulterstopenetratethesoil,

weight bracket kits are available from your Great Plains

dealer. Refer to Weight Brackets,“Options,” page 45 for

part numbers and ordering information.

Referto the charts below forthe results of adding weights

toyourdrill.Always addanequalamountofweightto each

box frame. Never add more than 500 pounds to each box

frame.

Weight Chart, 24-Foot Drill

71/2-In.

Rows

8-In.

Rows

10-In.

Rows

Empty Drill, Pounds 17,400 17,100 16,000

Pounds Per Coulter,

305 320 390

No Weights

Pounds Per Coulter,

Brackets and 1000

330 340 420

Pounds Added

Weight Chart, 30-Foot Drill

71/2-In.

Rows

8-In.

Rows

10-In.

Rows

Coulter Down-Pressure Chart

Spring Length Coulter Force

10 1/4 in. 300 lb.

10 in. 400 lb.

9 3/4 in. 525 lb.

NOTE: Any attempt to reset the coulter spring length

shorter than 9 3/4 inches may contribute to premature failure of parts and warrantywillbe voided. If additional force

is necessary, add weights to the implement.

Individual Coulters

Whencoulters followintire tracksanddo not give satisfactory depth, individual coulters can be lowered by loosening the mounting clamps and adjusting the coulter to the

desired setting.

To retighten clamps, snug the hex-head clamp bolts (1)

just until the u-bolts are tight on each side of the spring

bar. Tighten nuts on u-bolts (2), then finish tightening the

hex-head clamp bolts.

Empty Drill, Pounds 20,100 19,600 18,400

Pounds Per Coulter,

285 300 335

No Weights

Pounds Per Coulter,

Brackets and 1000

305 325 385

Pounds Added

NOTE:Optional markers, harrows and small-seed attachments add about 25 pounds per coulter. Completely loading the grainor small-seed boxesaddsabout 100 pounds

per coulter.

Coulter Springs

The coulter spring length is preset at10 inches, giving the

coulter an initial operating force of 400 pounds. This setting is adequate for many difficult no-till conditions. For

lighter no-till conditions where rocks or other obstructions

are a problem, you can lengthen thesprings to protectthe

coultersfromimpact.Inheavierconditions, shorteningthe

spring will increase coulter force.Referto the chart below

for adjusting the coulter springs.

10300

Figure 3-5

Individual Coulter Height Adjustment

IMPORTANT: Neverlower any coulter more than 1 1/2

inches. Tire damage could result as the drill is folded.

Also note that when the drill is in the raised position,

ground clearance on lowered coulters is reduced.

NOTE:There may be as much as a 1/8-inch gap between

the clamp plates even when the coulter is mounted securely.

12/27/05

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M

21

Page 24

Section 3 Adjustments

Great Plains Mfg., Inc.

Opener Down-Pressure Adjustment

You can adjust spring down pressureindividually for each

opener. This is useful for penetrating hard soil and planting in tire tracks.

To adjust down pressure, use the adjustment tool stored

under the walkboard. Position the tool in the holes on the

spring mounting plates and pull down on the adjuster as

shown Figure 3-6.

12105

Figure 3-6

Opener-Spring Adjustment

Minimum and maximum settings are indicated by the position of spring adjuster as shown in Figure 3-7.

12104

MinimumForce

Figure 3-7

Spring Settings

Maximum Force

Press Wheel Adjustment

Changing the height of the press wheel automatically

changes seeding depth. To adjust, lift up on the T-handle

and slide it forward or back as shown in Figure 3-8.

• For shallower seeding, slide the handle toward the im-

plement.

• For deeper seeding, slide the handle away from the im-

plement.

Setting the Seeding Rate

Calibrating the seeding rate requires four steps: shifting

the speed-change gearbox, adjusting the seed-rate handle,settingthe seed-cup doors, and checking the seeding

rate.

Check the seed-rate charts starting on page 24 or in the

drill boxes. These charts list the proper settings for the

speed-change gearbox and seed-rate handle for various

seeds and seeding rates.

The seed-rate charts are based on cleaned, untreated

seed of averagesizeandtest weight. The rates are based

on 11L x 15 8-ply rib implement tires and 265/70B16 skid

steer tires. Many factors will affect seeding rates including

foreign material, seed treatment, seed size, field conditions, tire pressure and test weight. Minor adjustments

likelywillbeneeded.Setandcheckthe seeding rate using

the procedures below, then re-adjust the rate as necessary.

Beforesetting the seeding rate, rotate both gauge wheels

to see that the seed cups and drive are working properly

and free from foreign material.

NOTE: Each drill box has its own metering mechanism.

After adjusting and checking the rate on one box, set the

same rate on the other box.

1. Shift Speed-Change Gearbox

The speed-change gearbox, Figure 3-9, is designed

to give you a variety of speeds for different seeds and

seeding rates. You can shift between four different

drive types.

Refer to the seed-rate charts for the correct drive

type–1, 2, 3 or 4. Move the selector handle on the

gearbox until the correct number appears in the handle window as shown in Figure 3-9. Rotate the tires a

few turns to confirm the gearbox has engaged.

Figure 3-9

12100

Figure 3-8

Press Wheel Adjustment

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M 12/27/05

22

Speed-Change Gearbox

12916

Page 25

Great Plains Mfg., Inc.

Section 3 Adjustments

Gearbox Ratios:

Drive Type 2 is 2.06 Times Faster Than 1

Drive Type 3 is 3.08 Times Faster Than 1

Drive Type 4 is 5.03 Times Faster Than 1

2. Adjust Seed-Rate Handle

Positionthehandle(Figure3-10)tothesettingindicated on the seed-rate chart. To adjust, loosen the wing

nut under the handle and slide until indicator lines up

with desired setting. Retighten nut.

12927

Figure 3-10

Seed-Rate Handle

3. Set Seed-Cup Doors

Forwheat and other small seeds, move the seed-cupdoor handles to the highest position. For soybeans

and other large seeds, lower the handles to the secondposition. If excessiveseedcrackingoccurs,lower

the handles to the third position. For seed-cup clean

out, movethe handles to the fourth, wide-open position. Make sure all handles are in the same position

before drilling.

4. Check Seeding Rate

a. Place severalpoundsofseed overthe three seed

cups on the outside end of the drill box.

b. Disconnecttheseedtubes fromthethreeopeners

fed by the covered cups.

c. Raise the drill off the ground.

d. Record the empty weight of a container large

enough to hold the seed metered for one acre.

e. Turn gauge wheels until seed drops to the ground

from each cup.

f. Place a container under the three seed tubes to

gather the seed as it is metered.

g. Rotate the gauge wheel until one acre has been

tallied on the acremeter. This will be

about 225 rotations on a 24-foot drill and about

181 rotations on a 30-foot drill. Check that the

seed cups have plenty of seed coming into them.

h. Weigh the metered seed. Subtract the initial

weight of the container. Divide by three. Multiply

by the number of openers on your drill for the

pounds-per-acre seeding rate. If this figure is dif-

ferent than desired, re-adjust the seed-rate han-

dle and recheck the rate.

5. When satisfiedwiththeseedingrate,repeatsteps1

through3forthe other drill box,settingittothe same

rate.

Small Seeds Attachment

To set the seeding rate, refertothe small-seeds-rate chart

onpage32.Movetheseed-ratehandleontheattachment

to the setting indicated on the chart.

To calibrate the attachment to your material, followthe

steps listed under Check Seeding Rate, this page.

13867

12/27/05

Figure 3-11

Seed-Cup Door Handle

2N-2410 and 2N-3010 Folding No-Till Drill 196-126M

23

Page 26

Great Plains Mfg., Inc.

Section 3 Adjustments

Seed Rate Charts (Pounds per acre)

Setting number 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Alfalfa

Drive Type 1

(Based on

60#/bu)

Row Space

1.8 4.6 7.0 10.0 12.8 16.0 19.1 22.7 26.3 30.7 34.3 37.5 41.5 45.3 49.3 52.9 57.5 61.8 66.3 68.3 70.2

7.5"

1.7 4.3 6.5 9.4 12.1 15.0 17.9 21.3 24.7 28.8 32.2 35.2 39.0 42.6 46.3 49.6 54.0 58.0 62.3 64.1 65.9

8"

1.4 3.5 5.2 7.5 9.7 12.0 14.4 17.1 19.8 23.1 25.8 28.2 31.2 34.1 37.1 39.8 43.2 46.5 49.9 51.4 52.8

10"

Barley

Drive Type 1

(Based on

51#/bu)

Barley

Drive Type 2

(Based on

51#/bu)

Buckwheat

Drive Type 2

(Based on

48#/bu)

Buckwheat

Drive Type 3

(Based on

48#/bu)

Buffalo Grass

Drive Type 1

(Based on

23#/bu)

Bermuda Grass

Drive Type 1

(Based on

60#/bu)

BermudaGrass

Drive Type 2

(Based on

60#/bu)

1.6 3.8 6.3 8.9 12.0 15.1 18.6 21.8 25.2 28.9 32.5 36.2 40.0 44.2 47.8 51.6 54.8 57.8 60.7 61.2 61.7

7.5"

1.5 3.5 6.0 8.4 11.3 14.2 17.4 20.5 23.7 27.1 30.6 34.0 37.6 41.5 44.8 48.5 51.5 54.2 57.0 57.4 57.9

8"

1.2 2.8 4.8 6.7 9.0 11.4 14.0 16.4 19.0 21.7 24.5 27.2 30.1 33.2 35.9 38.8 41.2 43.5 45.6 46.0 46.4

10"

Row Space

7.5" 2.9 7.2 13.3 18.0 24.9 30.9 37.7 44.9 51.7 59.4 66.4 72.8 80.2 87.1 95.0 102.6 111.1 119.1 126.8 128.8 130.8

8" 2.7 6.8 12.4 16.9 23.4 29.0 35.4 42.2 48.5 55.8 62.3 68.3 75.2 81.7 89.2 96.3 104.3 111.8 119.0 120.9 122.8

10" 2.2 5.4 10.0 13.6 18.7 23.2 28.4 33.8 38.9 44.7 49.9 54.7 60.3 65.5 71.4 77.2 83.5 89.6 95.3 96.8 98.4

Row Space

0.0 4.5 11.7 17.2 24.3 30.6 36.5 43.8 51.2 58.3 65.7 72.4 79.5 86.9 93.7 101.9 107.8 114.4 121.2 122.0 122.7

7.5"

0.0 4.2 10.9 16.2 22.9 28.7 34.3 41.1 48.1 54.7 61.7 68.0 74.6 81.6 87.9 95.6 101.2 107.4 113.8 114.5 115.2

8"

0.0 3.4 8.8 13.0 18.3 23.0 27.5 32.9 38.5 43.8 49.4 54.5 59.8 65.4 70.5 76.6 81.1 86.1 91.2 91.8 92.3

10"

Row Space

0.0 9.4 17.6 24.6 35.0 43.7 54.4 65.2 77.3 89.3 103.0 113.5 125.8 138.3 150.2 163.5 175.0 187.4 211.3 202.3 204.5

7.5"

0.0 8.8 16.5 23.1 32.9 41.0 51.0 61.2 72.5 83.9 96.7 106.5 118.1 129.9 141.0 153.5 164.3 175.9 198.3 189.9 191.9

8"

0.0 7.1 13.2 18.5 26.3 32.9 40.9 49.0 58.1 67.2 77.4 85.3 94.6 104.0 112.9 122.9 131.6 140.9 158.9 152.2 153.8

10"

Row Space

0.0 0.4 1.8 3.1 4.5 5.9 7.3 8.8 10.3 11.7 13.0 14.0 15.1 16.1 17.3 18.6 20.0 21.5 23.0 21.7 20.4

7.5"

0.0 0.4 1.7 2.9 4.2 5.5 6.9 8.2 9.6 11.0 12.2 13.2 14.2 15.1 16.2 17.5 18.8 20.1 21.6 20.4 19.1

8"

0.0 0.3 1.4 2.3 3.4 4.4 5.5 6.6 7.7 8.8 9.8 10.5 11.4 12.1 13.0 14.0 15.1 16.1 17.3 16.3 15.3

10"

Row Space

0.0 2.1 3.7 5.6 7.9 9.7 11.5 14.0 16.3 18.4 20.5 22.5 24.4 26.5 28.7 30.7 32.9 34.9 37.1 38.7 40.5

7.5"

0.0 2.0 3.4 5.3 7.4 9.1 10.8 13.2 15.3 17.3 19.2 21.1 22.9 24.9 26.9 28.9 30.9 32.8 34.8 36.3 38.0

8"

0.0 1.6 2.8 4.2 6.0 7.3 8.6 10.5 12.2 13.8 15.4 16.9 18.4 20.0 21.6 23.1 24.7 26.3 27.9 29.1 30.5

10"

Row Space

0.0 4.3 7.5 11.6 16.2 20.0 23.6 28.8 33.5 37.8 42.1 46.2 50.2 54.6 58.9 63.2 67.6 71.8 76.2 79.5 83.3

7.5"

0.0 4.1 7.1 10.9 15.3 18.7 22.2 27.0 31.4 35.5 39.5 43.4 47.1 51.2 55.3 59.3 63.5 67.4 71.5 74.6 78.2

8"

0.0 3.3 5.7 8.7 12.3 15.0 17.8 21.7 25.2 28.4 31.6 34.7 37.8 41.0 44.3 47.5 50.8 54.0 57.3 59.8 62.7

10"

Row Space

BermudaGrass

Drive Type 3

(Based on

60#/bu)

BermudaGrass

Drive Type 4

(Based on

60#/bu)

Fescue K-31

Drive Type 2

(Based on

21#/bu)

Fescue K-31

Drive Type 3

(Based on

21#/bu)

Fescue K-31

Drive Type 4

(Based on

21#/bu)

0.0 5.1 11.5 16.9 24.1 29.9 36.6 42.5 48.8 55.3 61.2 67.6 73.6 79.9 86.0 92.9 97.5 103.6 109.7 114.0 119.1

7.5"

0.0 4.8 10.8 15.9 22.7 28.1 34.4 39.9 45.8 51.9 57.5 63.5 69.1 75.0 80.7 87.2 91.6 97.2 103.0 107.0 111.8

8"

0.0 3.8 8.7 12.7 18.2 22.5 27.5 32.0 36.7 41.6 46.0 50.8 55.4 60.1 64.6 69.9 73.4 77.9 82.5 85.7 89.5

10"

Row Space

7.5" 0.0 8.3 18.8 27.6 39.4 48.8 59.7 69.3 79.5 90.1 99.8 110.2 120.1 130.3 140.1 151.5 159.0 168.9 178.9 185.8 194.1

8" 0.0 7.8 17.6 25.9 37.0 45.8 56.0 65.0 74.6 84.6 93.7 103.5 112.7 122.3 131.6 142.2 149.3 158.5 168.0 174.4 182.2

10" 0.0 6.2 14.1 20.7 29.7 36.7 44.9 52.1 59.8 67.8 75.1 82.9 90.3 98.0 105.4 114.0 119.6 127.0 134.6 139.7 146.0

Row Space

2.3 4.2 6.3 8.9 11.3 13.8 17.1 19.2 22.1 24.8 28.4 30.3 33.0 35.9 38.6 41.3 43.9 46.0 47.8 48.9 49.2

7.5"

2.1 3.9 5.9 8.3 10.6 13.0 16.0 18.0 20.7 23.3 26.6 28.4 31.0 33.7 36.3 38.8 41.3 43.2 44.9 45.9 46.2

8"