Page 1

Part Lists Great Plains Manufacturing, Inc. 1

LEFT

Installation Instructions

Two Channel Shaft Monitor

Used with Drill models:

Used with: When you see this symbol, thesubsequentinstructionsandwarnings

• 2N-2410

• 2N-2420

are serious - follow without exception. Your life and the lives of

others depend on it!

• 2N-3010

• 2N-3020

General Information

This kit provides the implement components necessary

to enable the shaft monitor function of the

electro-hydraulic console that is standard on 2SNT drills.

Refer to Figure 1

These instructions explain how to install a Two Channel

Shaft Monitor Option. The kit adds a rotation sensor to

the main seed box meter drive shaft of each drill box.

In operation, when the main seed box shaft of any drill

box stops rotating for more than 20 seconds, an alarm

sounds in the tractor cab.

One kit updates one entire drill:

Kits Kit Description

197-106A 2 CHANNEL SHAFT MONITOR KIT

Parts and Tools Required:

• Instructions for performing a calibration on this

model drill.

• Basic hand tools, and

• two people suggested for bracket installation.

Compatibility Check

ON

1. RAISE DRILL WITH GUAGE WHEEL

CYLINDERS TO FULLY EXTENDED

POSITION.

2. TURN MASTER POWER SWITCH "ON".

RAISE DRILL TO FOLD POSITION.

1. TURN MASTER POWER SWITCH "ON".

RAISE BOXES OFF TRANSPORT

"RAISE-TO-FOLD" SWITCH "ON".

CARRIERS.

MASTER

HYDRAULIC CONTROLS

MARKERS

RAISE-TO

-FOLD

LEFT

"RAISE-TO-FOLD" SWITCH "ON".

MASTER

RAISE-TO

-FOLD

ON

OFF

TRANSPORT

LOCKS

FOLDING NO-TILL DRILL

OFF ON

MASTER

RAISE-TO

-FOLD

ON

OFF

3. "RAISE-TO-FOLD" SWITCH "OFF".

"TRANSPORT LOCKS" SWITCH "ON".

EXTEND "TRANSPORT LOCK" CYLINDERS.

UNFOLDING NO-TILL DRILL

OFF

ON

OFF ON

MASTER

MARKERS

HYDRAULIC CONTROLS

Great Plains

RAISE-TO

-FOLD

TRANSPORT

LOCKS

ON

FOLD

LEFT

ON

ON

RIGHT

OFF

ON

OFF

OFF

SHAFT MONITORS

ON

OFF

ON

OFF

EFT

ELECTRIC CLUTCHES

OFF

HT

TRANSPORT

LOCKS

ON

2. "RAISE-TO-FOLD" SWITCH "OFF".

OFF

"TRANSPORT LOCKS" SWITCH "ON".

RETRACT "TRANSPORT LOCK" CYLINDERS.

ON

ELECTRIC CLUTCHES

OFF

MASTER

ON

MARKERS

HYDRAULIC CONTROLS

RAISE-TO

-FOLD

ON

LEFT

ON

RIGHT

OFF

OFF

TRANSPORT

LOCKS

ON

OFF

OFF

LEFT

OFF

Great Plains

TRANSPORT

LOCKS

FOLD

ON

ON

OFF

SHAFT MONITORS

ON

OFF

ON

OFF

EFT

ELECTRIC CLUTCHES

HTOFF

ON

OFF

REFER TO OWNERS MANUAL FOR MORE

DETAILED INFORMATION ON FOLDING AND

UNFOLDING.

FOLD

3. "TRANSPORT LOCKS" SWITCH "OFF".

ON

"FOLD" SWITCH "ON".

SLOWLY EXTEND FOLD CYLINDERS.

4. "FOLD" SWITCH "OFF".

"RAISE-TO-FOLD" SWITCH "ON".

LOWER BOXES TO FIELD POSITION.

"RAISE-TO-FOLD" SWITCH "OFF".

IF DRILL IS EQUIPPED WITH OPTIONAL

MARKERS, ELECTRIC CLUTCHES, OR

SHAFT MONITORS, REFER TO OWNERS

MANUAL FOR SWITCH OPERATIONS.

P.N. 818-508C

RI

FOLD

4. "TRANSPORT LOCKS" SWITCH "OFF".

"FOLD" SWITCH "ON".

SLOWLY RETRACT FOLD CYLINDERS.

5. "FOLD" SWITCH "OFF".

"RAISE-TO-FOLD" SWITCH "ON".

LOWER BOXES ON CARRIERS.

"RAISE-TO-FOLD" SWITCH "OFF".

SHAFT MONITORSOFF

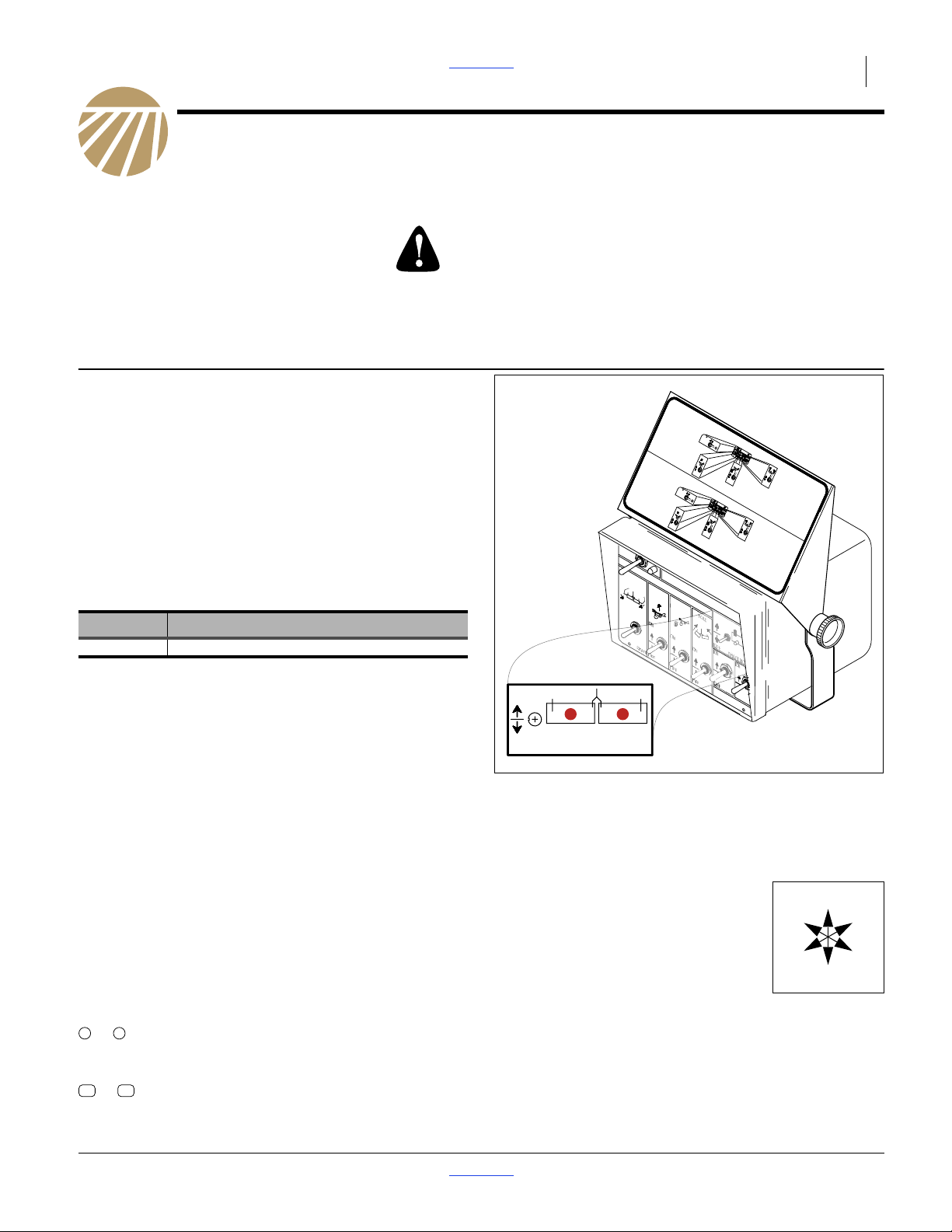

Figure 1

36319

2 Channel Console

Refer to Figure 1

This kit is compatible with bare shafts, or shafts inside

round plastic spacer tubes between meters. It is

compatible with large 817-075C seeder cups (13⁄4inch

flute width) on the above-listed models.

Note: Paragraphs in this format provide useful

information related to the current topic.

“Left” and “Right” are facing in the

direction of machine travel. An

orientation rose in the line art

R

U

B

illustrations shows the directions of

Notations and Conventions

The following terms are used throughout this manual.

Left, Right, Front, Back, Up, Down.

F

L

D

Call-Outs

1 9

to Single-digit callouts identify components in the

currently referenced Figure. These numbers may

be reused for different items from page to page.

11

24

to Two-digit callouts in the range 11 to 23 reference

new parts from the list on page 5.

© Copyright 2014 Printed 2014-08-27 Part Lists 197-114M

Page 2

2 Great Plains Manufacturing, Inc. Front Page Part Lists 2 CHANNEL SHAFT MONITOR

Prepare the Drill

1. Clean out main seed boxes.

Possible Chemical Hazard

This installation requires contact with interior components of

the main seed box. If treated seed has ever been used in the

box, follow chemical supplier instructions for protective

equipment and cleaning residue from the seed box.

2. Move the drill to a location with adequate lighting,

and a clear surface beneath for recovery of any

fallen parts.

3. Unfold the drill. Consult the Operator manual for

details and safety considerations.

4. Raise the drill or otherwise configure it so that the

meter drive shaft may be rotated while the drill is

stationary.

5. Install all locks or supports necessary to support the

drill while it is being worked on.

6. Shut off any tractor used to position the drill and

remove the key.

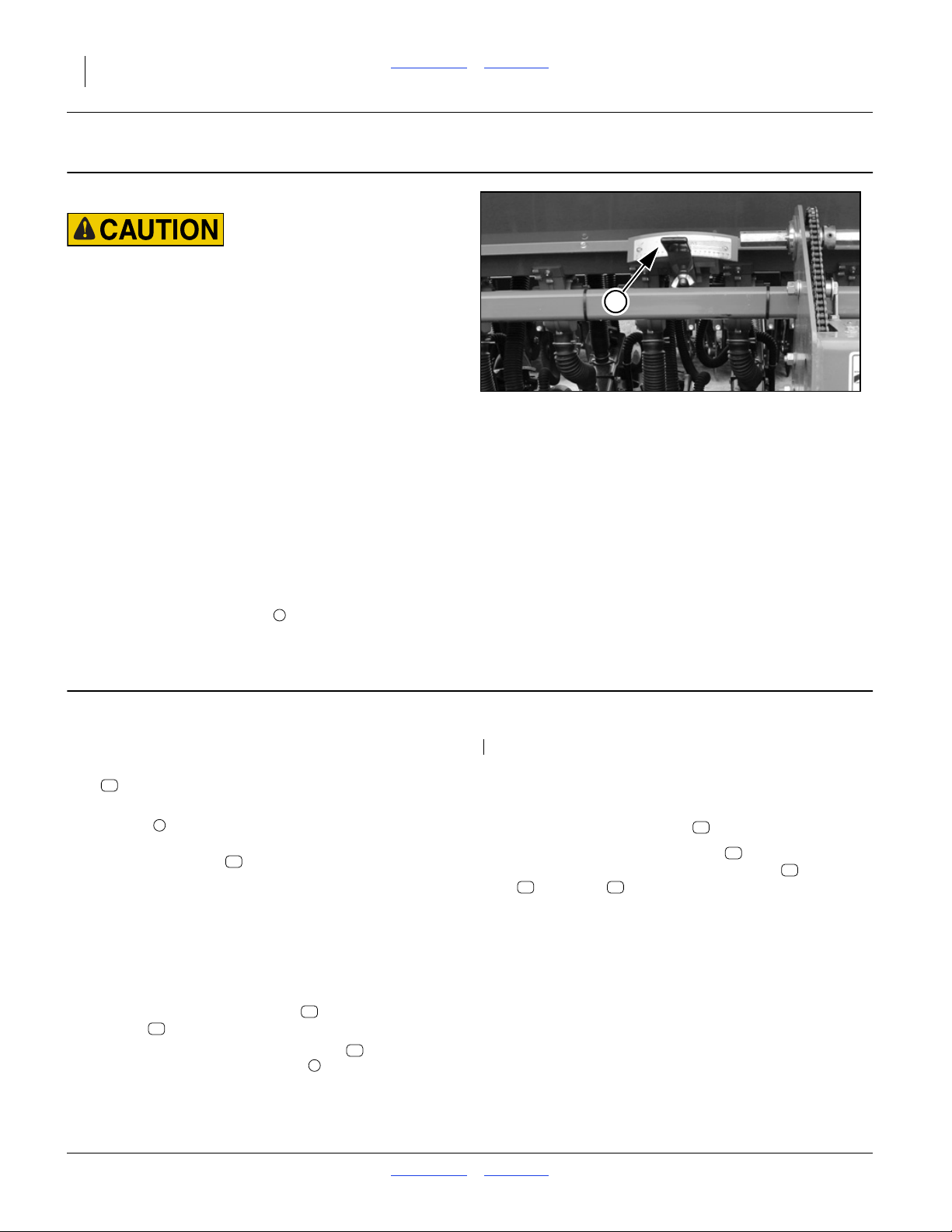

Refer to Figure 2

7. Setthe seed ratehandles ,forall main seed boxes,

1

to 50 on the 0-to-100 scales.

1

Figure 2

Set Rate Handles to 50

28066

Identify Mounting Positions

Sensor Mount Install

Refer to Figure 3 on page 3

1. Select one new:

12

116-029D, 2SNT SENSOR MOUNT

2. Find the box section between cups with the two, #8

screws , washers, and nuts already in place.

Removethe nuts and washers and use for installing

the sensor mount .

If any shaft protective tubing is installed, remove and

discard.

Make sure that the locations between cups have the

following attributes:

• not obstructed to the front by a seed rate handle, and

• there is adequate exposed surface on the drive shaft

to place the shaft monitor hose and shaft monitor

magnets .

3. Mount the end of the sensor mount with the

holes over the two, #8 screws . Make sure the

slotted-end of the mount is down and pointing

towards the front of the drill.

3

12

13

14

12

3

Notes:

Gaps with lock collars generally provide exposed shaft.

4. Install the washers and nuts removed in step 2 and

tighten the sensor mount in place.

5. Attach the reed sensor switch at the slotted end

of the bracket using two #4-40 screws , washers

17 18

, and nuts as shown in Refer to Figure 3. Do

12

15

16

not tighten screws at this time.

6. Repeat step 1 through step 4 to install the bracketin

the other main seed box.

197-114M Front Page Part Lists 2014-08-27

Page 3

Install Magnets Front Page Part Lists Great Plains Manufacturing, Inc. 3

Install Magnets

Shaft Install

13

2

3

14

Refer to Figure 3

1. De-grease and dry the seed box shaft .

2. Rotate the shaft so that two faces are vertical, and

two are horizontal.

3. Select one new:

13

197-270D SHAFT MONTITOR HOSE

4. Slip the shaft monitor hose over the shaft and

center approximately with the middle of the sensor

mount . If necessary, trim hose to fit between the

shaft lock collars.

5. Select two new:

14

6. Slip each magnet over the hose , and position

as shown in figure 3. Run each magnet clamp up

against each lock collar, then tighten the clamps.

7. Slide the reed sensor switch in the mount side-toside, and front-to-back until it is centered between

the magnets and tighten the #4-40 screws .

8. Repeat steps 1 through 7 to install the other sensor

and magnets.

12

10630171101 SHAFT MONITOR MAGNETS

14

13

15

2

2

13

16

14

18

17

12

Refer to Figure 4

• Typical installation.

15

16

Figure 3

Magnet on Shaft

Figure 4

Magnet/Sensor Clearance

R

F

U

B

L

D

34212

36404

2014-08-27 Front Page Part Lists 197-114M

Page 4

4 Great Plains Manufacturing, Inc. Front Page Part Lists 2 CHANNEL SHAFT MONITOR

Install Harness

General Harness Guidelines

• Before installing cable ties, uncoil and dress the cable

assembly and extensions across the drill and to

the hitch. This assures that the cables are long

enough, and correctly oriented left/right.

• Keep cables clear of moving parts and pinch points,

such as chains, sprockets and rotating shafts.

• Keep cables clear of sharp edges (or protect edges).

• Keep cables clear of any machine parts that get hot.

• Allow slack at hinge points, or route the cable so that it

passes through the hinge axis.

• Take advantage of holes and open tubes on the drill.

However, avoid routing through a tube if a mated

connector set would end up inside the tube.

• Evaluate routing and attachment points. Ample ties

are provided for most situations. The ties can also be

used around hydraulic hoses to secure the cable.

• Leave a little slack between attachment points.

A cable stretched taut could be damaged by normal

temperature swings.

• Where there is an extended run of unsupported cable,

makesure each end of the sag is supported by a cable

tie, and that there are no connections in the sag.

• Where excess cable exists (such as on two-point

drills), plan a location for coiling it up and securing it.

Having the coil near the hitch provides flexibility if any

later troubleshooting required.

• Before making outside connections, apply a generous

amount of dielectric grease around the inside surface

of all female (receptacle) connectors.

21 22

197-114M Front Page Part Lists 2014-08-27

Page 5

Appendix Front Page Part Lists Great Plains Manufacturing, Inc. 5

Appendix

Part Lists

New Parts

The part call-out numbers in this list match all Figures in

these installation instructions. Part descriptions match

those in your updated Parts Manual.

Kit Contents

197-106A

TWO CHANNEL SHAFT MONITOR OPTION

Quantities are units (“ea”).

Callout Number

Quantity in Kit Part Number Part Description

11 1 197-114M

12 2 116-029D

13 2 197-270D

14 4 10630171101

15 2 117-0159-964

16 4 311-0005-013

17 4 312-1001-008

18 4 313-1000-004

19 1 823-119C

20 2 063-0172-375

21 1 115-0159-661

22 2 115-0171-490

23 1 117-0159-564

a. Order replacements from Raven Industries, Inc.

24’ & 30’ SHAFT MONITOR MANUAL

2SNT SENSOR MOUNT

SHAFT MONTITOR HOSE

SHAFT MONITOR MAGNETS

a

REED SENSOR SWITCH (INCLUDES 21 & 23)

a

SCREW PHP HD 4-40 UNC-2A

a

WASHER #4 LOCK

a

NUT HEX #4 UNC-2B

2SNT SHAFT SENSOR CABLE

a

SENSOR SHAFT

SENSOR CABLE ASSSEMBLY

a

SENSOR CABLE EXTENSON 3FT

2SNT SHAFT MONITOR

2014-08-27 Front Page Part Lists 197-114M

Page 6

6 Great Plains Manufacturing, Inc. Front Page Part Lists 2 CHANNEL SHAFT MONITOR

Great Plains Manufacturing, Inc.

Corporate Office P.O. Box 5060

Salina, Kansas 67402-5060 USA

197-114M Front Page Part Lists 2014-08-27

Loading...

Loading...