Great Plains 2600-2S User Manual

Great Plains Mfg., Inc.

Installation Instructions

2600-2S

Small Seeds Option

Used with:

2600-2S

•

General Information

These instructions explainhow to install the small-seeds attachment. The small-seeds attachment delivers the smallest seeds

evenlyand gently.The attachment holds 0.24 bushels per foot.

These instructions apply to:

• 133-164A . . . . . . . . . . . . . . . . . . . . . . . 2600 Small Seeds 6"

• 133-165A . . . . . . . . . . . . . . . . . . . . 2600 Small Seeds 7 1/2"

• 133-166A . . . . . . . . . . . . . . . . . . . . . . 2600 SmallSeeds10"

• 133-167A . . . . . . . . . . . . . . . . . . . . . . 2600F Small Seeds 6"

• 133-168A . . . . . . . . . . . . . . . . . . . 2600F Small Seeds 7 1/2"

• 133-169A . . . . . . . . . . . . . . . . . . . . . 2600F Small Seeds 10"

Assembly Instructions

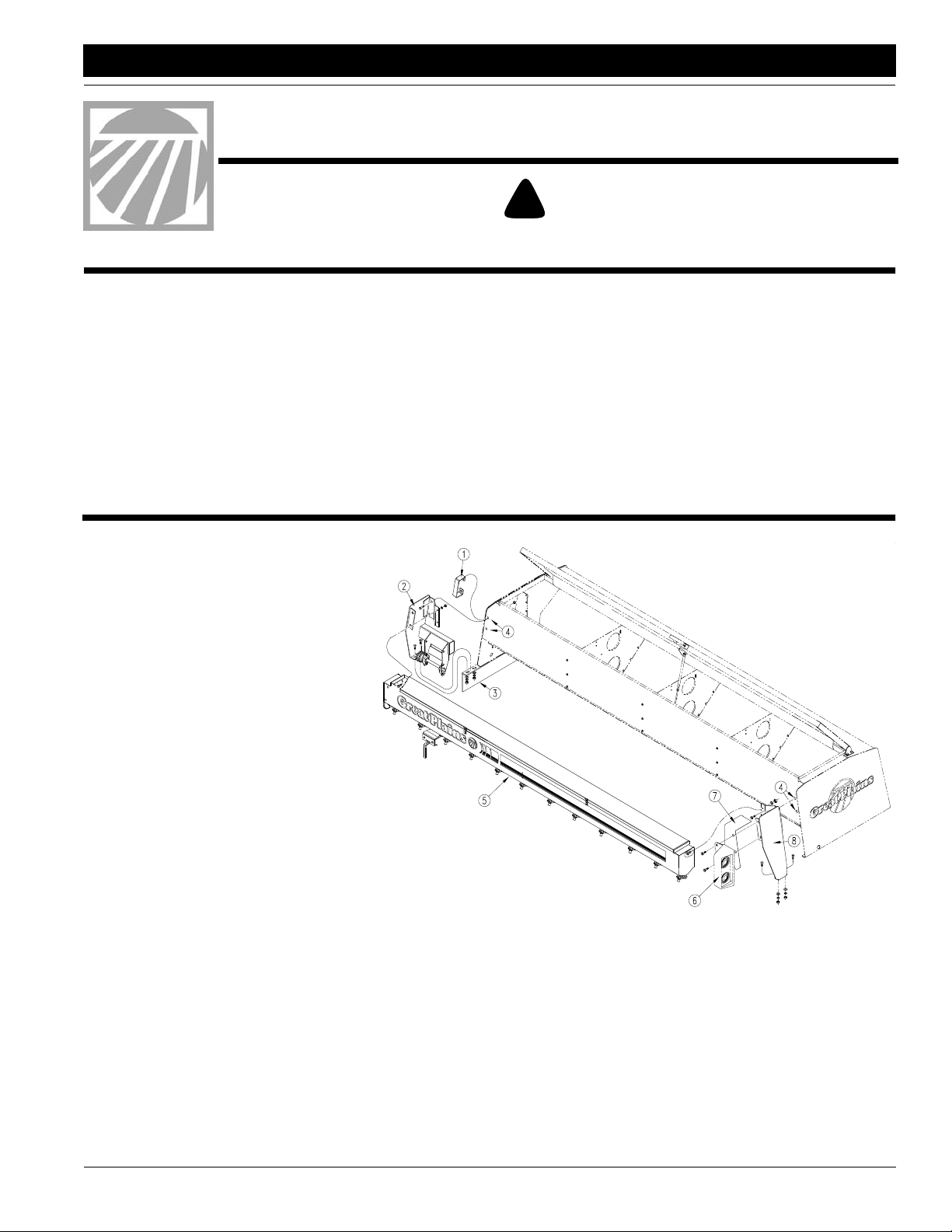

Box Assembl y

Refer to Figure 1

1. Workingon theleft-handside ofthedrill

removehandle (1) and warninglight(6)

from main seed box. Save bolts, nuts,

light and handle for later use.

2. Installtheleft-handmount and drive (2)

on the left side of drill frame (3) using a

1/2"x 11/4" bolt, 1/2"lock washerand a

1/2"nutsupplied in thekit.It will also be

necessary to remove and use the existing bolt.

3. At holes (4), where the handle was removed, fasten top of the left-hand

mount and drive (2) to main seed box.

Use 1/2" x 1 1/4" bolts and

1/2" locking flange nuts. Leave mounting hardware loose.

4. Install the right-hand mount (8) on the

right side of drill frame using a 1/2" x

1 1/4" bolt, 1/2" lock washer and a 1/2"

nutsupplied in the kit.Itwill also be necessary to remove and use the existing

bolt.

5. At holes (4), where the light was removed, fasten top of the right-hand

mount (8) to main seed box.Use 1/2" x

11/4" boltsand 1/2"locking flangenuts.

Leave mounting hardware loose.

6. Boltsmall-seeds box (5)to boxmounts.

Use 3/8" x 1" bolts, 3/8" lock washers

and 3/8" nuts.

7. Attach the warning light (6) and righthand chain guard (7) to the right mount

using bolts removedin step 1.

8. Tighten all hardware.

9. Repeat steps to assemble box on righthand drill section, mirroring box

mounts.

When you see this symbol, the subsequent instructions and

warnings are serious - follow without exception. Your life and

!

!

the lives of others depend on it!

Manual Update

Refertothedrill operator’smanualfor detailed informationon operating, adjusting, troubleshooting and maintaining the smallseeds attachment safely. Refer to the parts manual for partiden-

tification.

• 2600-2S Drill Operator’sManual . . . . . . . . . . . . . .195-200M

• 2600-2S Drill Parts Manual . . . . . . . . . . . . . . . . . . 195-200P

Definitions

Right-hand and left-hand as used in this manual are determined

byfacing the direction the machine will travelwhileinuseunless

otherwise stated.

17179

Figure 1

Mounting Box

© Copyright 2001 Printed

7/16/2002

133-170M

1

Assembly

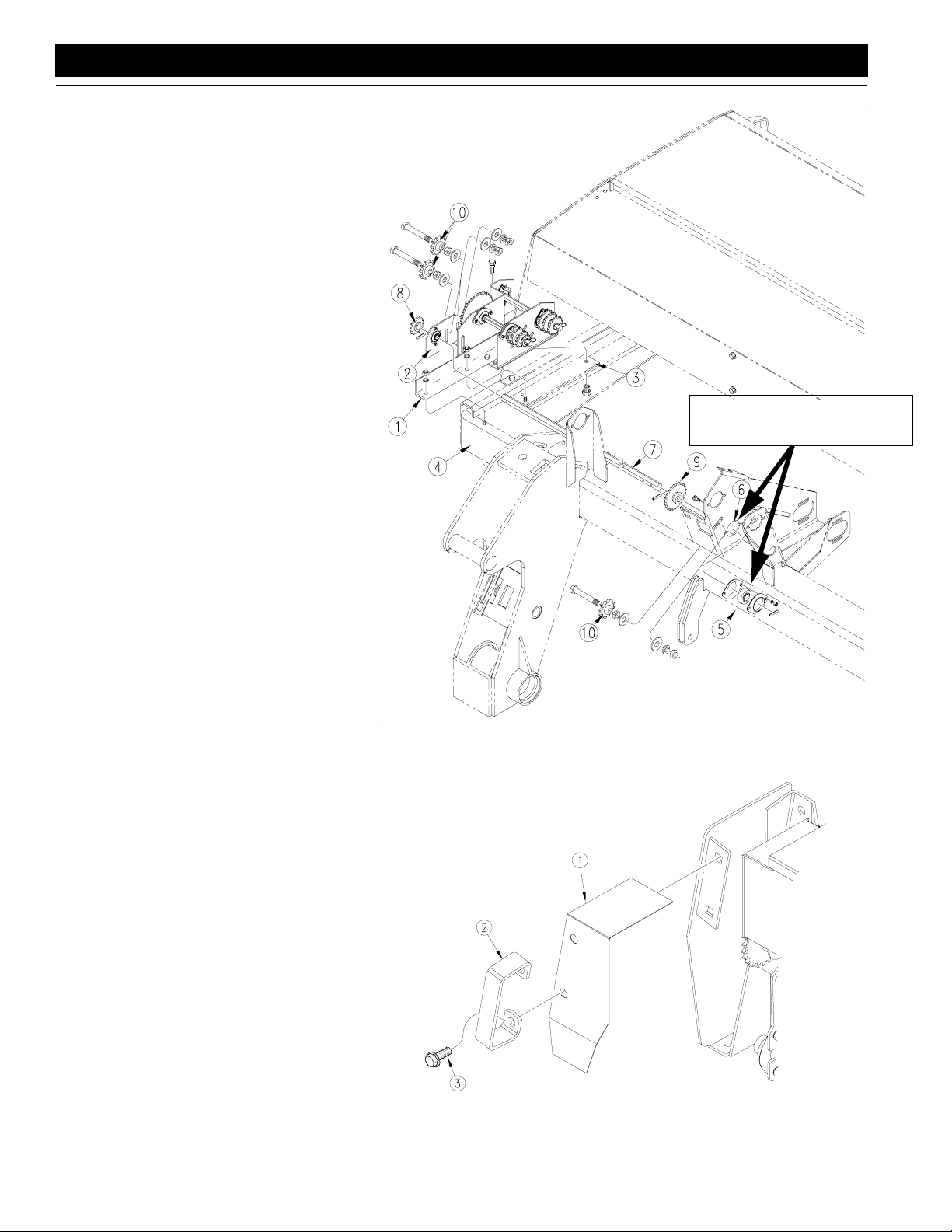

Drive Assembly (for drills without fertilizer kits)

Refer to Figure 2

1. Working on the right-hand side of the drill

mount angle channel (1) onto right-handintermediate drive (2) using 1/2" x 1 1/4" bolt, 1/2"

lock washers and 1/2" nuts.

2. Mount intermediate drive onto drill frame. Bolt

intermediate drive to side frame (3) using 1/2"

1 1/4" bolts, 1/2" lock washers and 1/2" nuts.

Fastentheintermediatedriveto frontframe(4)

Using a 1/2" x 6" x 7 1/4" U-bolt, 1/2" lock

washers and 1/2" nuts.

3. Mount bearing and flangettes (5) on open

shaft support near center of front frame (6),

see note. Use 5/16" x 1" carriagebolts, 5/16"

lock washers and 5/16" nuts to secure

flangettes to shaft support. Leave bolts loose.

4. Install new jackshaft (7) through bearings on

shaft support and bearings on intermediate

drive. As you install shaft, place 14-tooth

sprocket (8) and 23-tooth sprocket (9) on

shaft. Secure sprocketson shafts with roll

pins. When shaft and sprockets are installed

and shaft is aligned, tighten bolts on bearing

flangettes.

5. Install the three idler sprockets(10) using 1/2"

x 3" bolts, 1/2" flat washers, 1/2" lockwashers

and 1/2" jam nuts.

6. Remove old clutches and replace with the

clutches supplied in the kit.

7. Install drive chains and adjust chain tension

with the idlers.

8. Repeat steps for left-hand box.

Great Plains Mfg., Inc.

Note: Mount bearing on this side of

framebracketonly forbothrightand

left drives, do not mirror.

Drive Assembly (for drills with

fertilizer kits)

Refer to Figure 2

9. Add 14-tooth sprocket(8) to the end of jackshaft(7) and secureit inplacewith arollpin on

each side.

10. Install the two idler sprockets(10) using 1/2" x

3" bolts, 1/2" flat washers, 1/2" lock washers

and 1/2" jam nuts.

11. Route drive chain and adjust chain tension

with the idlers.

For All Drills

Refer to Figure 3

12. Install chain shields (1) over box ends. Install

handle (2) using bolts (3) that originally held

handle.

13. Repeatsteps forleft-hand box,using left-hand

intermediate drive.

18083

Figure 2

Right-Hand Drive

Figure 3

Handle and Guard

2600-2S Small Seeds Option 133-170M 3/31/04

2

Great Plains Mfg., Inc.

Assembly

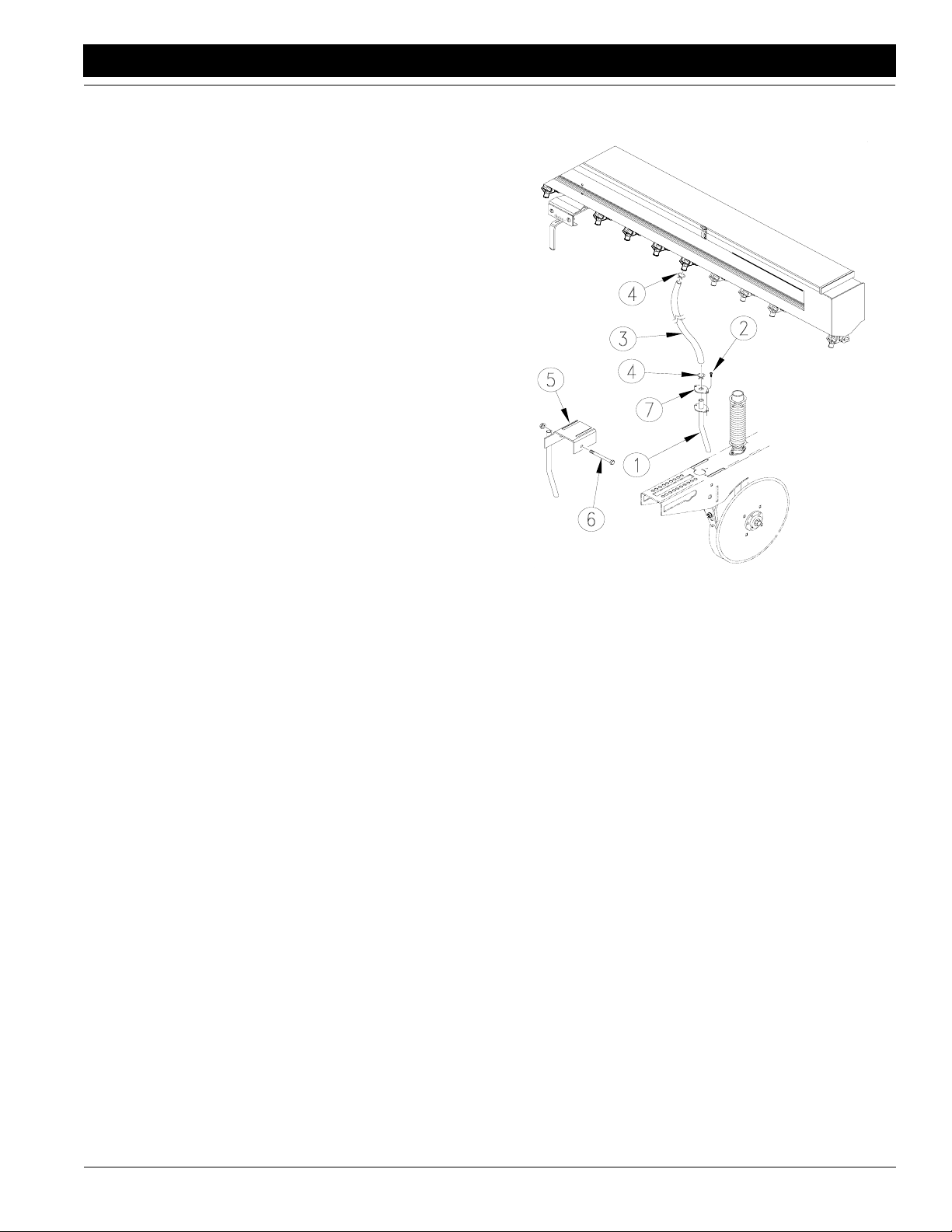

Seed Tube Assembly

Note: For drills without a fertilizer kit use seed tube P/N

123-939H and use the following instructions.

Refer to Figure 4

1. Insert the seed tube (1) into the hole on the top of the open-

er. Add reinforcement ring (7) and secure in place with a

number 10-16 x 1/2” screw (2).

2. Slidea hose clamp(4) overthe hose (3).Slidethe end ofthe

hose overthe seed tube and secureitin place with the hose

clamp.

3. Slide a hose clamp (4) over the other end of the hose and

slide the hose over the seed outlet which corresponds with

the appropriate opener. Secure hose in place with the hose

clamp.Repeat the abovestepstoinstall the rest of the seed

tubes and hoses.

Note: For drills with a fertilizer kit use seed tube P/N 133128H and use the following instructions.

Refer to Figure 4

4. Set the side delivery tube (5) downoverthe top ofthe open-

erdirectlyin front of the fertilizertube.Line up the holeswith

the holes in the opener and insert the 3/8” x 3 5/8” bolt and

secure bolt with a 3/8” lock nut flange.

5. Slidea hose clamp(4) overthe hose (3).Slidethe end ofthe

hose overthe seed tube and secureitin place with the hose

clamp.

6. Slide a hose clamp (4) over the other end of the hose and

slide the hose over the seed outlet which corresponds with

the appropriate opener. Secure hose in place with the hose

clamp.Repeat the abovestepstoinstall the rest of the seed

tubes and hoses.

Figure 4

Seed Tube and Hose

20101

3/31/04

■

2600-2S Small Seeds Option 133-170M

3

Assembly

Great Plains Mfg., Inc.

Seed Rate Calibration

NOTE: Seeding rates will v ary greatly with v ariations

in sizes of the seeds. The seeding rates listed in this

manual are based on average seed size. We recommend that you test and adjust your drill using the procedurebelowtohelp ensure an accurate seeding rate.

1. Jackup thewinggaugewheels and rotate themtosee

thatthe feedcupsand drives areworkingproperlyand

are free from foreign matter. The right wing gauge

wheeldrivesthecentersection, butthedrivedoesnot

engage unless the drill is completely unfolded.

2. Set the seed rate adjustment handle to the desired

chart setting. Make sure all the feed cup doors are in

the desired position.

3. Thereare manyfactorswhichwillaffectseedingrates:

seed treatment, weight of seed, size of seed, surface

condition of seed, tireconfiguration, tire pressure and

tire slippage. Minor adjustments will probably be

needed to compensate for these factors.

4. The pounds-per-acre in the seed rate charts are

based on the drill having 9.5L-15 6 PLY ribbed implement tires inflated to 32 psi. on the wing gauge

wheels. Check your tires forproper inflation pressure.

5. The large differences in seed size and treatment can

cause a wide variation in actual seeding rates. The

seed rate charts on the following pages are based on

averagesize seed. This may differ from the seed you

areusing.Use the seed ratecharts as a guide.Setthe

pounds per acre desired for your row spacing and

complete the following procedure to calibrate the drill

for your specific seed.

a. Place several pounds of seed overthree of the

feed cups at the outboard drive end of the drill

box.

b. Disconnect the seed tubes from these three disk

openers.

c. Lower the opener framestoplantingpositioninor-

der to activate the clutch and raise the proper

drive tire off the ground with a jackso it can be rotated by hand.

d. Place a container under the three seed tubes to

gather the seed as it is metered.

e. Rotatethedrivewheeluntiloneacre has been tal-

lied on the acremeter. This will be 203 rotations.

Be sure to check the three cups to make sure

each cup has plenty of seed coming into it.

f. Weigh the seed which has been metered. Divide

by three to get the ounces/pounds metered by

each feed cup.Multiply by the number of openers

on your drill to arrive at the total pounds-per-acre

your drill would meter at that setting. If this figure

is different than desired, set your feedcup adjustment handle accordingly.

g. Youmaywant to repeat the calibration procedure

if the results of your calibration vary greatly from

the suggested settings contained in this manual.

REMEMBER: Tire size, tire air pressure, and field conditions also affect seeding rates. When drilling, check the

amount of seed you are using by noting acres drilled,

amount of seed added to the drill, and level of seed in

each drill box. If you suspect that you are drilling more or

less than desired, you may need to adjust the seeding

rates slightly to compensate for your field conditions.

2600-2S Small Seeds Option 133-170M 3/31/04

4

■

Loading...

Loading...