Page 1

Great Plains Manufacturing, Inc. 1

25P Eliminator Bushing Field Installation Manual

Null4:

25 SERIES OPENERS

General Information

These instructions explain how to install an eliminator

bushing update kit. Order and install either narrow or

wide bushings to match with the type (narrow or wide)

opener arm on the implement. It takes two of the same

kit to update one opener:

Kit Kit Description

498-254V 25P Narrow Bushing Installation Kit

498-256V 25P Wide Bushing Installation Kit

Tools Required

• basic hand tools

When you see this symbol, the subsequent instructions

and warnings are serious - follow without exception.

Your life and the lives of others depend on it!

U

R

F

B

L

D

Work Location

Move the implement to a flat location for installation.

Sharp Object Hazard:

Be careful working near opener discs. Disc edges may be

sharp.

Notations and Conventions

Null4:

U

F

L

D

Call-Outs

11 14

to

Two-digit callouts in the range 11 to 14 reference new parts from the list on page 6.

“Left” and “Right” are facing in the

direction of machine travel. An orienta-

R

tion rose in the line art illustrations

shows the directions of Left, Right,

Front, Back, Up, Down.

B

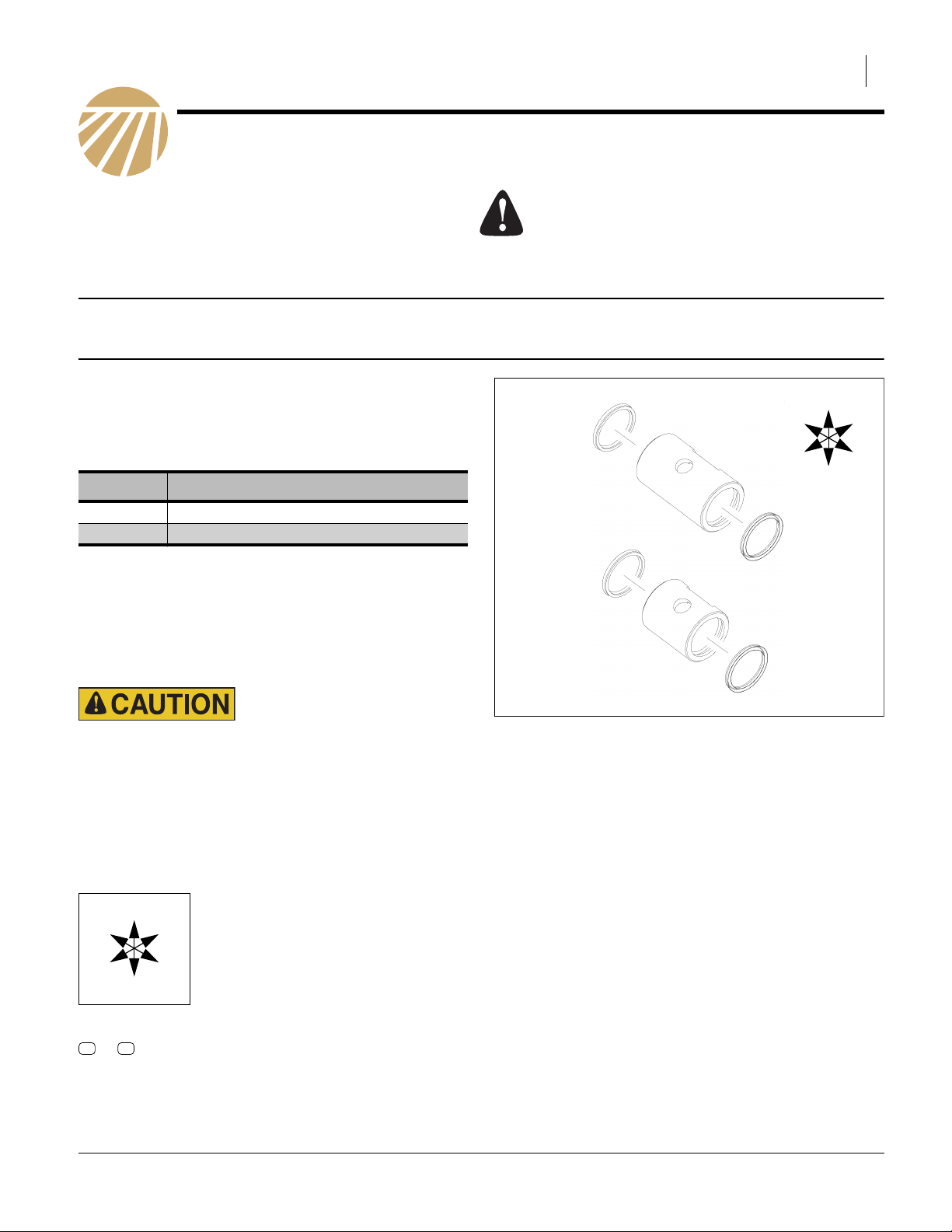

Figure 1

25P Bushing Installation Kit

Wide (top), Narrow (bottom)

31707

© Copyright 2010 Printed 11/15/2010 498-255M

Page 2

2 Great Plains Manufacturing, Inc. Eliminator Bushing Update Kit

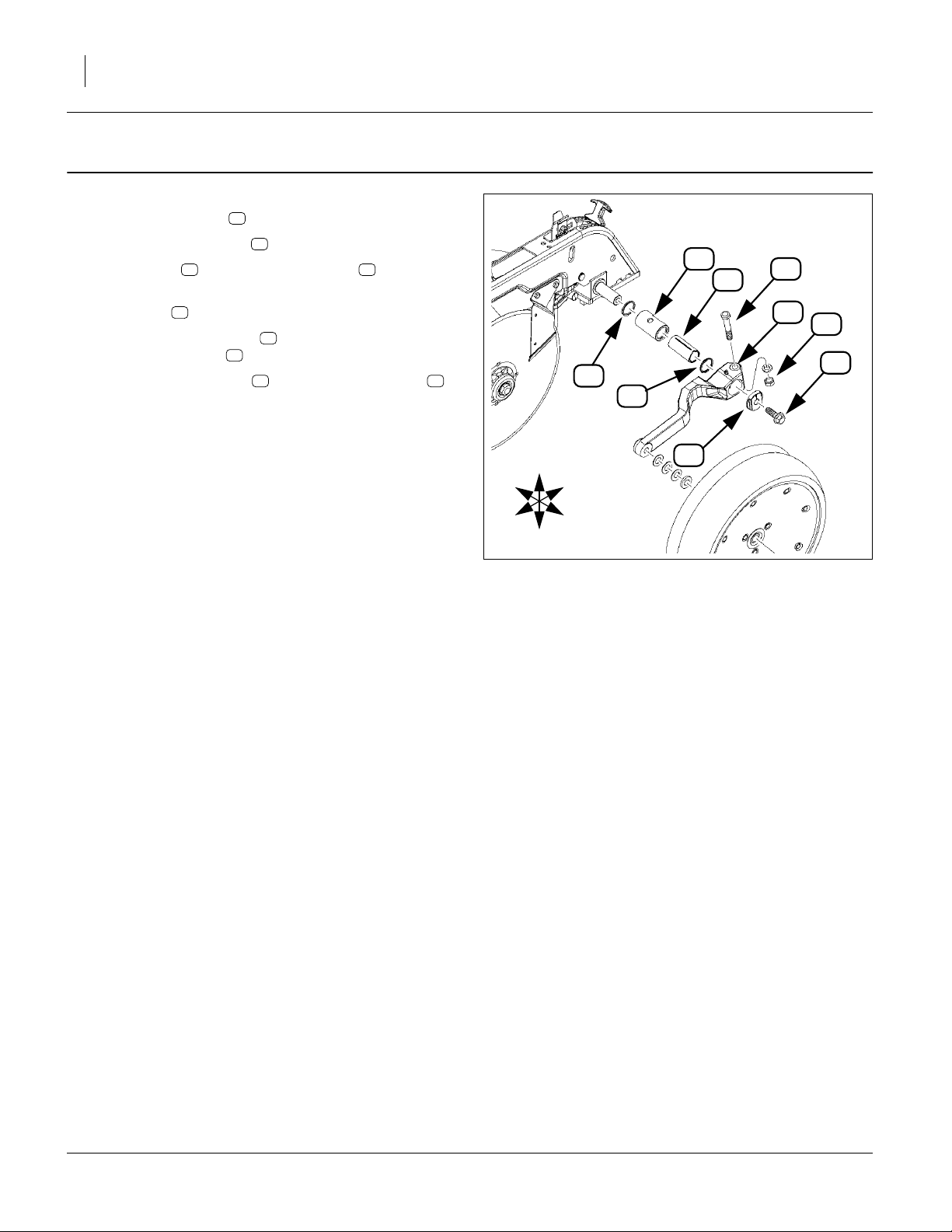

Remove Old Bushing and Seals

Refer to Figure 2

1. Remove pivot bolt . Save to reuse.

2. Remove hex adjuster . Save to reuse.

3. Loosen nut , remove hex-head bolt . Save both

to reuse.

4. Slide arm off.

5. Remove inner bushing from bushing pack.

Clean up bushing . Save to reuse.

6. Discard two old seals and old outer bushing .

38 36

34

28

32

25

25

39 40

39

39

40

25

36

34

38

28

Null4:

R

F

U

D

32

B

L

Figure 2

Remove Current Bushing

31700

498-255M 11/15/2010

Page 3

Replace with New Bushing and Seals Great Plains Manufacturing, Inc. 3

Replace with New Bushing and Seals

Refer to Figure 3 and Figure 4

Select New Outer Bushing

7. Select new outer bushing either:

Narrow:

11

198-360D OUTER BUSHING INNER CUP SEAL

or

Wide:

14

404-214D 25P O-RING BUSHING

Insert U-type Seals

Note: Do NOT damage the new seals by inserting them

in the wrong direction. If these instructions are followed the seals will not be damaged. When the

inner bushing passes through the inside of the

outer bushing it must not cut against the sealing

edge.

Note: The notch on the eccentric bushing must

face down and to the outside of opener arm.

8. Select one U cup seal .

Make sure U-shape part of seal (the open end)

faces OUT and not into the groove. Insert it in one

end of the new outer bushing . Make sure the

seal is placed securely in groove.

MAKE SURE TO ONLY INSTALL ONE SEAL AT

THIS TIME.

9. Before sliding the inner eccentric bushing into

the outer bushing put a small amount of grease

over the seal to lubricate. This makes it easier to

push the bushing through so it doesn’t damage the

seals.

10. Take the eccentric bushing flat end (not notched

24

end ) and slide it in the opposite end (end without

the seal). Push all the way through so it extends a

little past the end with the seal to allow room to get

second seal in.

11. Select second U cup seal :

Insert making sure U-shape part of seal (the open

end) faces OUT and not into the bushing groove.

Make sure it is securely in groove. Apply a small

amount of grease over the seal to lubricate.

12. Push inner bushing through this seal so it is centered inside outer bushing .

24 25

13

11

25

11

13

25

13

13

25

11

R

F

R

F

U

D

13

U

D

14

11

13

13

32

B

L

Figure 3

Replace with New Bushing

11

B

13

L

25

36

38

28

31700

25

24

Figure 4

Inner and Outer Bushings

Disassembled (top), Joined (bottom)

11/15/2010 498-255M

31699

Page 4

4 Great Plains Manufacturing, Inc. Eliminator Bushing Update Kit

Reassemble to Guage Wheel Arm

Reassemble Bushing to Arm

Refer to Figure 5 and Figure 6

13. With bushing pack all together, make sure flat

groove on outer bushing faces the back and

notch in inner bushing is to the outside of arm.

Slide pack into guage wheel arm .

14. Put hex-head bolt back through making sure it is

lined up with the flat groove in bushing .

15. Finger tighten hex-head bolt .

16. Put hex adjuster in place.

Line up notch on hex adjuster nut with notch in

eccentric bushing .

17. Reusing pivot bolt tighten finger tight.

18. Make sure bushing notch is on the bottom, this is

your starting point.

10 11

25

34

36

10 11

36

32

32

25

28

24

R

F

11

25

26

U

B

L

D

Figure 5

Bushings and Guage Wheel Arm

36

34

32

28

31700

13

R

F

10

11

U

B

13

L

D

Figure 6

Inner and Outer Bushings

Disassembled (top), Joined (bottom)

25

24

31699

498-255M 11/15/2010

Page 5

Adjust Wheel to Disc Great Plains Manufacturing, Inc. 5

Adjust Wheel to Disc

Adjusting Wheel to Disc

Refer to Figure 7 and Figure 8

Hex Head Adjuster

Check tire to disc contact location. Wheel should hit disc

at bottom of tire. At top of tire it should have3⁄8gap away

from disc. Adjust hex adjuster to obtain correct con-

tact location.

19. Move wheel arm in so side gauge wheel contacts

row unit disc at bottom. Tighten hex-head bolt to

clamp arm around bushing and shank.

Wheel and disc should touch but not be so tight

there is pressure. Pressure will cause it to bind up.

Allow for enough movement. Check wheel-to-disc

contact at 2in (5cm) planting depth. Lift wheel 2in

(5cm) and release. When let go, wheel should fall

freely.

If wheel does not contact disc at bottom to area

where blade leaves contact with soil, move hex

adjuster until wheel is angled for proper contact with

disc.

20. If wheel does not fall freely, loosen hex-head bolt

and slide wheel arm out just until wheel and arm

move freely. Retighten hex-head bolt per grade:

1

⁄2in Grade 5 bolt, 76 ft-lbs (105 N-m).

1

⁄2in Grade 8 bolt, 110 ft-lbs (150 N-m).

21. Keep turning hex adjuster and moving wheel arm

until the wheel is adjusted properly. When satisfied,

tighten pivot bolt to 110 ft-lbs.

28

32

36

36

36

Shims

Side Gauge

Wheel

Null4:

Opener

Discs

11

Correct

36

Incorrect

Figure 7

Disc/Gauge Wheel Alignment

25

Side Gauge

Wheel

34

32

28

22. If wheel does not contact blade when arm is slid into

end of bushing, then adjust the shims . Remove

shim from behind wheel to move tire closer to blade.

23. Retain removed shims by placing them on the outer

side of the gauge wheel bolt so there is always

access to them for any future adjustments.

26

R

26

U

B

Finish

24. Tighten the hex-head bolt .

25. Then tighten pivot bolt (roughly1⁄4in gap at top of

wheel).

11/15/2010 498-255M

36

28

F

L

D

Figure 8

Bushings and Guage Wheel Arm

31700

Page 6

6

Appendix

Part Lists

New Parts

The part call-out numbers in this list match all Figures in

these installation instructions. Part descriptions match

those in your updated Parts Manual.

Quantities are units (“ea”).

Kit Contents

498-254V

25P Narrow Bushing Installation Kit

Callout Quantity Part Number Part Description

11 1 198-360D OUTER BUSHING INNER CUP SEAL

12 1 498-255M 25P BUSHNG INSTALLATION MANUAL

13 2 816-686C U CUP SEAL

Kit Contents

498-256V

25P Wide Bushing Installation Kit

Callout Quantity Part Number Part Description

14 1 404-214D 25P O-RING BUSHING

15 1 498-255M 25P BUSHNG INSTALLATION MANUAL

16 2 816-686C U CUP SEAL

Great Plains Manufacturing, Inc.

Corporate Office P.O. Box 5060

Salina, Kansas 67402-5060 USA

498-255M 11/15/2010

Loading...

Loading...