Page 1

Table of Contents Index

20- and 25-Foot 3-Point Drills

Operator Manual

2025A and 2525A

®

with Air-Pro

Manufacturing, Inc.

www.greatplainsmfg.com

Seed Meters

Read the operator manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without

exception. Your life and the lives of others depend on it!

29792

Illustrations may show optional equipment not supplied with standard unit or may

depict similar models where a topic is identical.

ORIGINAL INSTRUCTIONS

© Copyright 2013 Printed 2013-06-04 118-999M

Table of Contents Index

EN

Page 2

Table of Contents Index

Table of Contents Index

Page 3

Great Plains Manufacturing, Inc. Cover Index iii

Table of Contents

Important Safety Information......................................1

Safety Decals.................................................................5

Introduction ................................................................10

Models Covered...........................................................10

Description of Unit........................................................10

Intended Usage........................................................10

Document Family......................................................10

Using This Manual........................................................10

Definitions.................................................................10

Owner Assistance ........................................................11

Preparation and Setup...............................................12

Initial Setup...................................................................12

Post-Delivery/Seasonal Setup......................................12

Pre-Planting Setup.......................................................12

Hitching Tractor to Drill.................................................13

3-Point Hitch.............................................................13

Hydraulic Hose Hookup............................................14

Protecting Fan Hydraulic Motor Seals......................14

Electrical Hookup......................................................15

Raise Parking Stands (2025A only)..........................15

Leveling the Drill...........................................................16

Leveling: Offset-Single Wheel..................................16

Meter and Row Setup...................................................18

Marker Setup................................................................18

Operating Instructions...............................................19

Pre-Start Checklist .......................................................19

Drill Weight...................................................................19

Transporting.................................................................20

Check Tractor Capacity and Configuration...............20

Remove Extra Drill Weights......................................20

Unload Seed Box .....................................................20

Secure Markers........................................................20

Transport Checklist...................................................20

Loading Seed...............................................................21

Air System Operation...................................................22

Air and Seeding System Overview...........................23

Fan Circuit Operation ...........................................24

Fan General Operating Information......................25

Butterfly Valve Operation:.....................................25

Acremeter Operation....................................................26

Normal Operating Sequence....................................26

Acremeter Programming ......................................26

Dormant Display.......................................................26

Ladder Operation .........................................................27

Monitor Operation (Option)..........................................27

Marker Operation (Option)...........................................28

Independent Marker Operation................................ 28

Single-Circuit Sequenced Marker Operation............28

Both Sides Unfolded (with Sequence Valve) .......28

Field Set-Up Checklists................................................29

Planting........................................................................30

Checking Planting Rate ............................................... 30

Short-Term Parking......................................................31

Long-Term Storage......................................................31

Adjustments ...............................................................32

Setting Planting Rate...................................................33

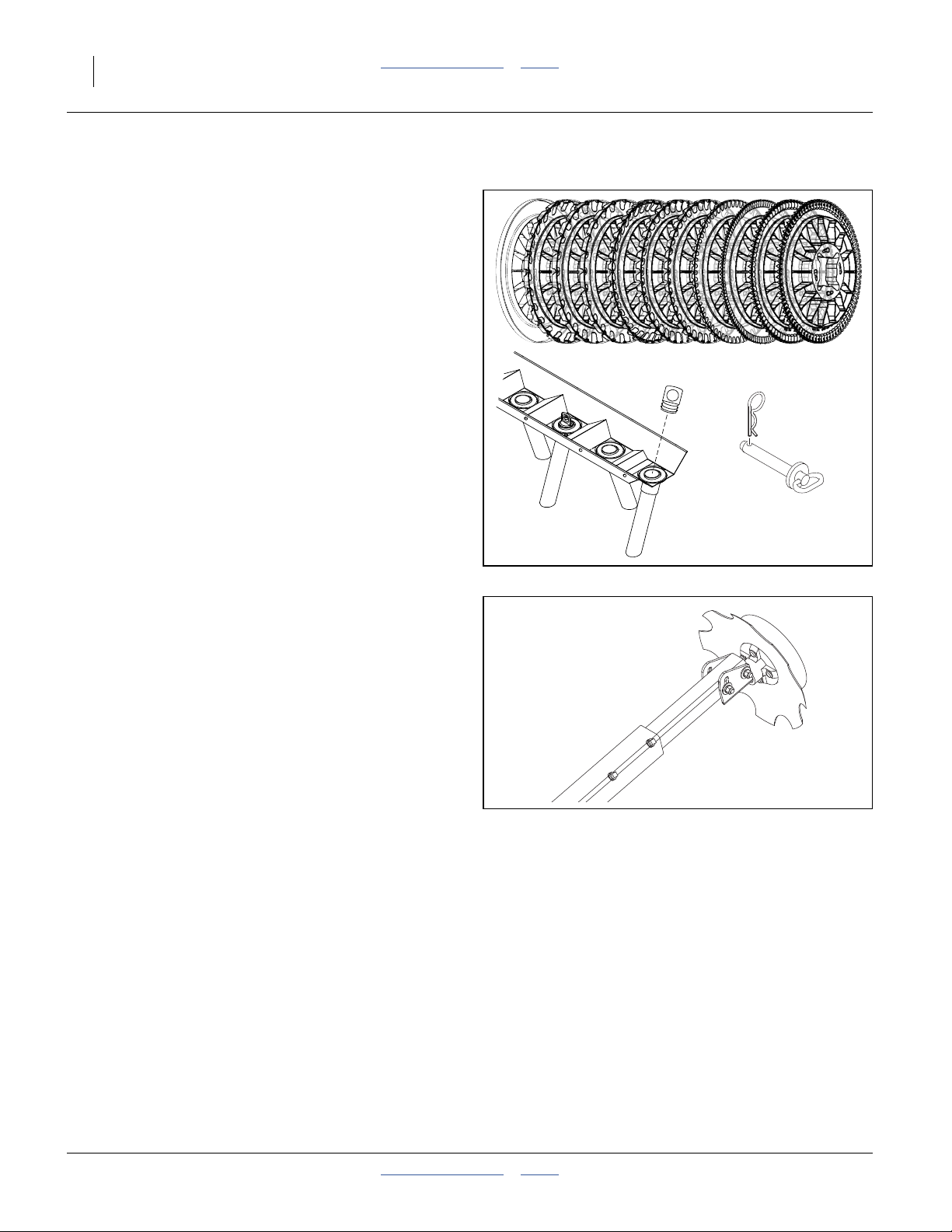

Seed Disk Selection and Installation........................33

Range and Transmission......................................... 33

Drive Speed Range Sprockets.............................33

Transmission Sprockets.......................................33

Shutters and Manifold Pressure...............................33

Checking Planting Rate............................................33

Marker Adjustments.....................................................34

Marker Disk Adjustment...........................................34

Fan and Adjustment.....................................................35

Furrow Check:......................................................35

Fine-Tuning (with optional Seed Monitor)................ 36

Alternate Skip/Double Check ...............................36

25AP Series Row Unit Adjustments.............................37

Row Unit Down Pressure.........................................38

Adjusting Down-Force..........................................38

Unit-Mount Cleaner Adjustments............................. 40

Coulter Adjustments.................................................41

Coulter Depth Adjustment....................................41

Coulter Row Alignment ........................................42

Row-Unit Opener Disk Adjustments.........................43

Setting Planting Depth .........................................43

Opener Disc Contact Region ...............................43

Adjusting Disc Contact.........................................43

Side Gauge Wheel Adjustment................................44

Adjusting Gauge Wheel Scrapers........................45

Seed Meter Setup and Adjustment.......................... 46

Meter Rain Cover.................................................46

Seed Inlet Shutter Adjustment .............................46

Optimal Seed Pool Slopes ...................................47

Meter Re-Fill......................................................... 47

Air-Pro® Meter Disk Installation ............................... 48

Removing a Seed Disk......................................... 49

Row Unit Shut-Off.................................................... 49

© Copyright 2009, 2010, 2011, 2013 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication“as is” without warrantyofanykind,eithere xpressedorimplied.Whilee v eryprecaution has been

takeninthe preparation of this manual, Great Plains Manufacturing,Inc. assumes no responsibility forerrors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing,Inc. reserves the rightto revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

2013-06-04 Cover Index 118-999M

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Discovator,Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand,

Terra-Guard, Turbo-Chisel,Turbo-Chopper, TurboMax, Turbo-Till, Ultra-Till, Verti-Till, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

Page 4

iv 2025A/2525A Table of Contents Index Great Plains Manufacturing, Inc.

Sprocket Indexing (Stagger) ................................ 52

Seed Firmer Adjustments ........................................52

Keeton Seed Firmer Adjustment..........................52

Seed-Lok

®

Seed Firmer Lock-Up ........................53

Seed-Lok® Seed Firmer Lock-Up (old style) ....... 53

Press Wheel Adjustment.......................................... 54

Press Wheel Down Pressure...............................54

Press Wheel Stagger...........................................54

Press Wheel Centering........................................55

Troubleshooting......................................................... 56

Planting Rate Problems............................................... 56

Suggested Furrow Check:.................................... 56

Seed Pool Troubleshooting..........................................57

Population Troubleshooting Charts..............................58

Maintenance and Lubrication...................................65

Maintenance ................................................................ 65

Material Clean-Out ......................................................66

Seed Box Clean-Out................................................ 66

Meter Clean-Out ......................................................66

Funnel Conversion...............................................66

Alternate Meter Clean-Out...................................67

Meter Brush Maintenance............................................68

Meter Brush Replacement .......................................69

Tufted Brush Replacement .................................. 69

Strip Brush Replacement.....................................69

Seed Disk Maintenance........................................... 70

Cleaning and Storing Seed Disks ........................ 70

Seed Tube Maintenance..............................................71

Sliding Seed Tube Replacement .............................71

Boot and Grommet Maintenance............................. 71

Chain Maintenance......................................................72

Chain Slack..............................................................72

Chain Clips............................................................... 72

Meter Drive Chain.................................................... 72

Spreaders and Scrapers..............................................73

Row-Unit Side Wheels.................................................73

Seed Flap Replacement ............................................74

Marker Maintenance.................................................... 75

Marker Shear Bolt.................................................... 75

Marker Grease Seal Cap .........................................75

Bleeding Marker Hydraulics..................................... 76

Lubrication ................................................................... 77

Seed Lubricants...........................................................80

Options ....................................................................... 81

Seed Monitor................................................................81

Speed Sensors ........................................................81

Radar Y-Cables .......................................................81

Hitch Setback Kit..........................................................82

Weight Bracket Kit ....................................................... 82

Markers........................................................................82

Seed Lubricant.............................................................83

Seed Tube Plug........................................................... 83

Lock-Up Pin..................................................................83

Unit-Mounted Row Options ..........................................84

Row Cleaners...........................................................84

Unit-Mounted Disk Coulters......................................84

Coulter Blades......................................................84

Gauge Wheel Scrapers ............................................85

Inside Disk Scrapers.................................................85

Seed Meter Disks .....................................................86

Clean-Out Container.................................................86

Seed Firmers............................................................87

Seed-Lok® Seed Firmer.......................................87

Keeton Seed Firmer..............................................87

Row Unit Press Wheels............................................87

Appendix A - Reference Information ........................88

Specifications and Capacities.......................................88

2025A Specifications and Capacities .......................88

Tire Inflation Chart........................................................88

2525A Specifications and Capacities .......................89

Torque Values Chart ....................................................90

Hydraulic Diagrams......................................................91

Fan Hydraulics (standard) ........................................91

Marker Hydraulics.....................................................92

Dual Sequenced Markers (Option) .......................92

Independent Markers (Option)..............................93

Chain Routing...............................................................94

25AP Final Meter Drive.............................................94

Ground Drive Chains................................................95

Appendix B - Initial and Option Setup......................96

Pre-Delivery Items........................................................96

Install Press Wheels.................................................96

Initial Setup...................................................................97

Seed Monitor Console Installation (Option)..............97

Speed Sensor Setup (Option)...................................97

Magnetic Sensor Gap...........................................97

Initial Marker Setup...................................................98

Marker Speed Adjustment ....................................98

Sequenced Dual Marker Speed Adjustment.........98

Independent Marker Speed Adjustment ...............98

Marker Chain Adjustment .....................................99

Marker Lifting Slack ..............................................99

Folding Slack........................................................99

Marker Transport Carrier..........................................99

Marker Extension................................................100

Marker Extension Adjustment.............................100

Marker Extension Values....................................101

Reading a Marker Extension Diagram................101

Model 2025A Marker Extension..........................101

Model 2525A Marker Extension..........................102

Option Installation...................................................104

122-278S Scraper Installation ............................104

Warranty.....................................................................105

Index ..........................................................................107

118-999M Table of Contents Index 2013-06-04

Page 5

Great Plains Manufacturing, Inc. Table of Contents Index 1

Important Safety Information

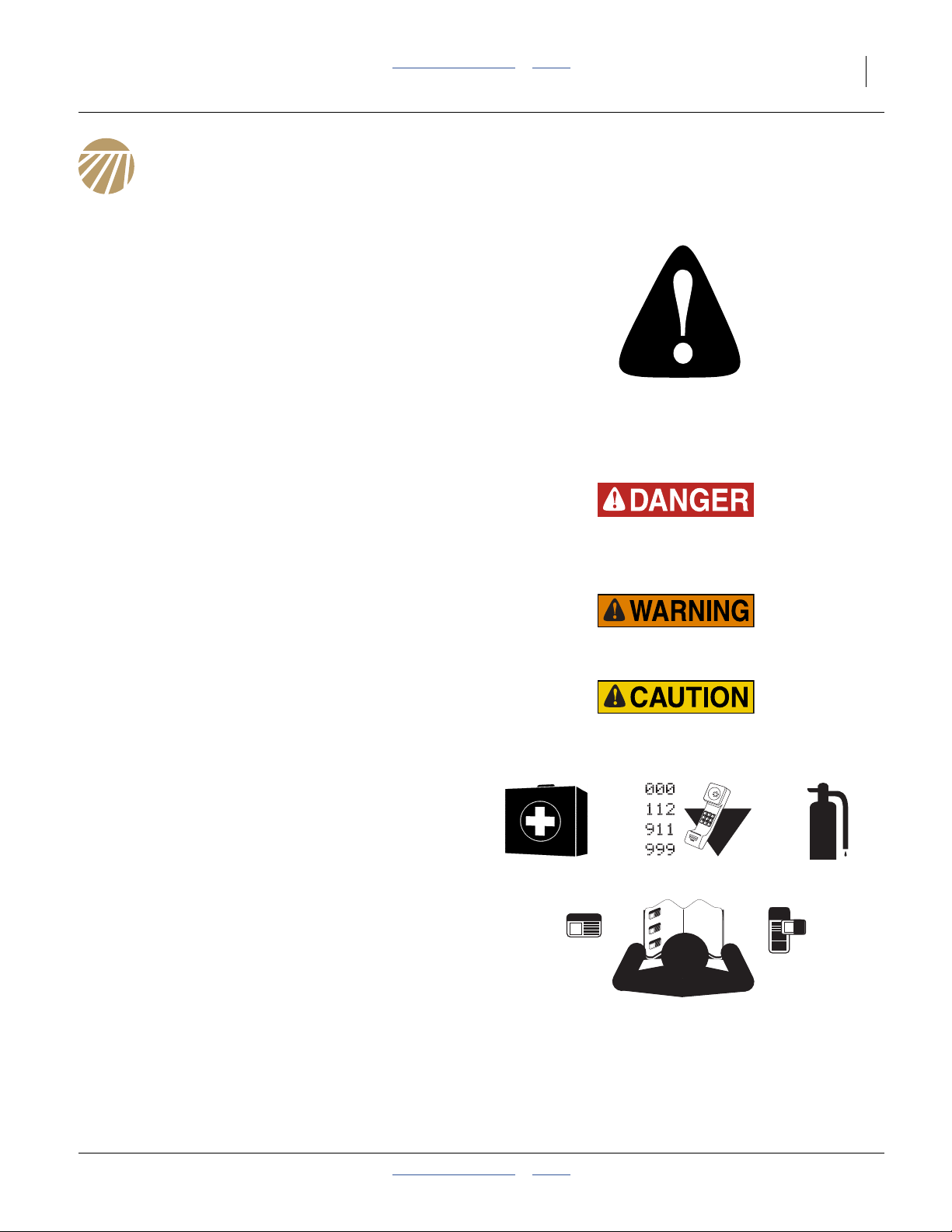

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that follows it. In addition to design and configuration of equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided, will resultin death or serious injury.

This signal word is limitedto themost extreme situations,

typically for machine components that, for functional purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed.It may also be used to alert against

unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe practices.

Prepare for Emergencies

▲ Be prepared if a fire starts

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals” on page 5, thor-

oughly.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

2013-06-04 Table of Contents Index 118-999M

Page 6

2 2025A/2525A Table of Contents Index Great Plains Manufacturing, Inc.

Wear Protective Equipment

▲ Wear protective clothing and equipment.

▲ Wear clothing and equipment appropriate forthe job. Avoid

loose-fitting clothing.

▲ Because prolonged exposure to loud noise can cause hear-

ing impairment or hearing loss, wear suitable hearing protection such as earmuffs or earplugs.

▲ Because operating equipment safely requires your full

attention, avoid wearing entertainment headphones while

operating machinery.

Handle Chemicals Properly

Agricultural chemicals can be dangerous. Improper use

can seriously injure persons, animals, plants, soil and

property.

▲ Read and follow chemical manufacturer’s instructions.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Avoid inhaling smoke from any type of chemical fire.

▲ Store or dispose of unused chemicals as specified by chemi-

cal manufacturer.

Avoid High Pressure Fluids

Escaping fluid under pressure can penetrate the skin,

causing serious injury.

▲ Avoid the hazard by relieving pressure before disconnecting

hydraulic lines.

▲ Use a piece of paper or cardboard, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety glasses or goggles when

working with hydraulic systems.

▲ If an accident occurs, seek immediate medical assistance

from a physician familiar with this type of injury.

Use Safety Lights and Devices

Slow-moving tractors and towed implements can create

a hazard when driven on public roads. They are difficult

to see, especially at night.

▲ Useflashing warning lights and turn signals whenever driv-

ing on public roads.

Use lights and devices provided with implement

118-999M Table of Contents Index 2013-06-04

Page 7

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 3

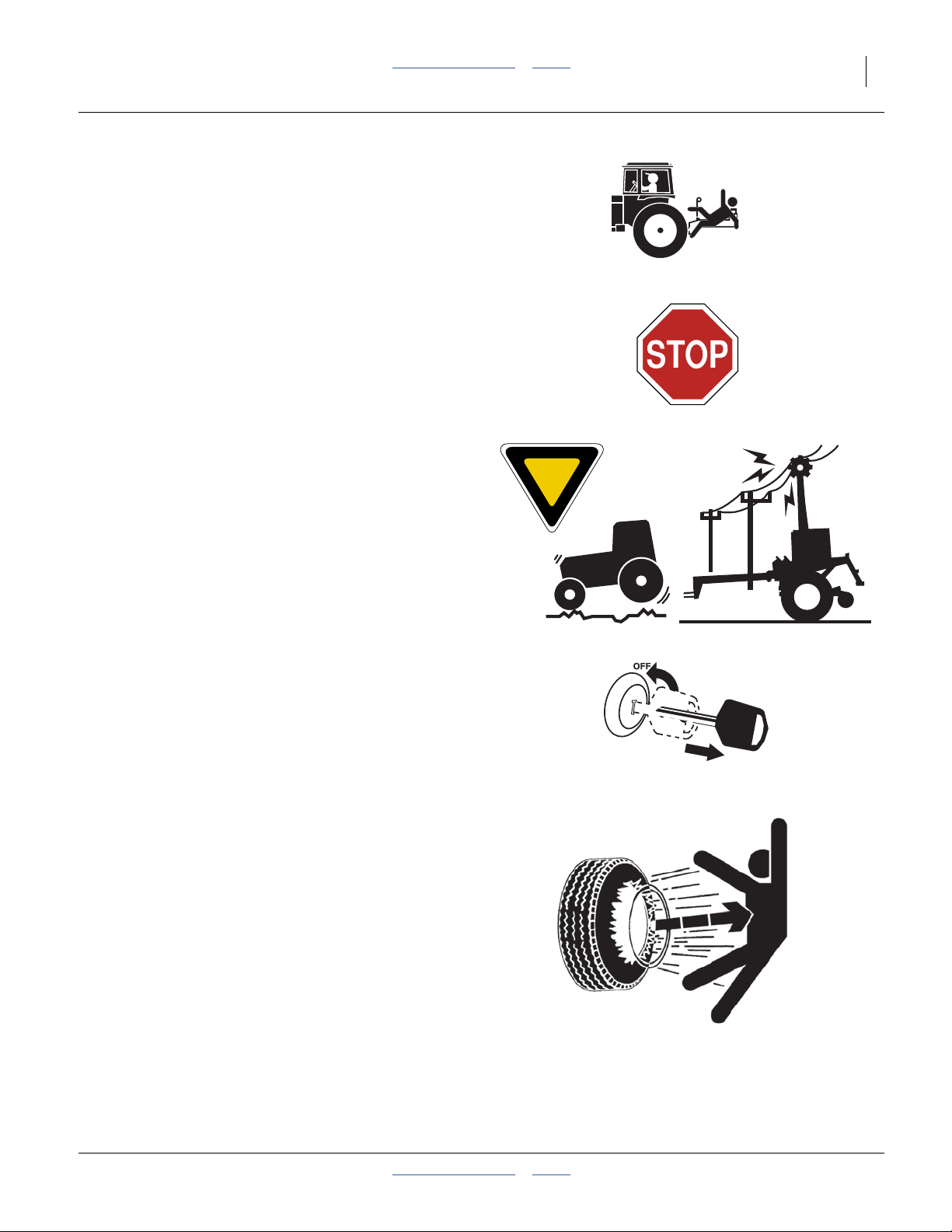

Keep Riders Off Machinery

Riders obstruct the operator’s view. Riders could be

struck by foreign objects or thrown from the machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine during operation.

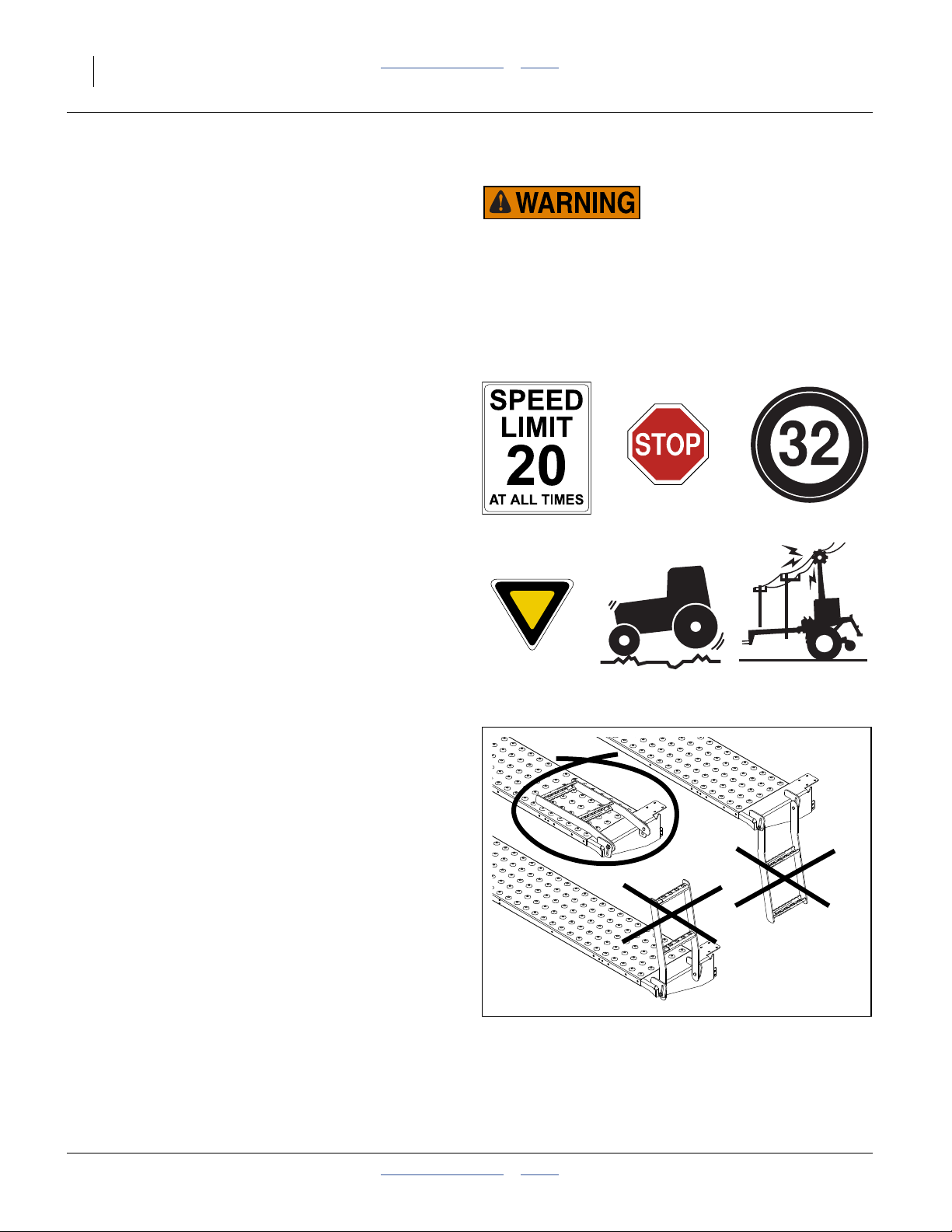

Transport Machinery Safely

Maximum transport speed for implement is 20 mph (32

kph), 13 mph (22 kph) in turns. Some rough terrains

require a slower speed. Sudden braking can cause a

towed load to swerve and upset.

▲ Do not exceed 20 mph. Never travel at a speed which does

not allow adequate control ofsteering andstopping. Reduce

speed if towed load is not equipped with brakes.

▲ Comply with state and local laws.

▲ Do not tow an implement that, when fully loaded, weighs

more than 1.5 times the weight of towing vehicle.

▲ Carry reflectors or flags to mark drill in case of breakdown

on the road.

▲ Keep clear of overhead power lines and other obstructions

when transporting. Refer to transport dimensions under

“Specifications and Capacities” on page 88.

▲ Do not fold or unfold the drill while the tractor is moving

Shutdown and Storage

▲ Lower drill, put tractor in park, turn off engine, and remove

the key.

▲ Secure drill using blocks and supports provided.

▲ Detach and store drill in an area where children normally

do not play.

Tire Safety

Tire changing can be dangerous and should be performed by trained personnel using correct tools and

equipment.

▲ When inflating tires, use a clip-on chuck and extension hose

long enough for you to stand to one side–not in front of or

over tire assembly. Use a safety cage if available.

▲ When removing and installing wheels, use wheel-handling

equipment adequate for weight involved.

2013-06-04 Table of Contents Index 118-999M

Page 8

4 2025A/2525A Table of Contents Index Great Plains Manufacturing, Inc.

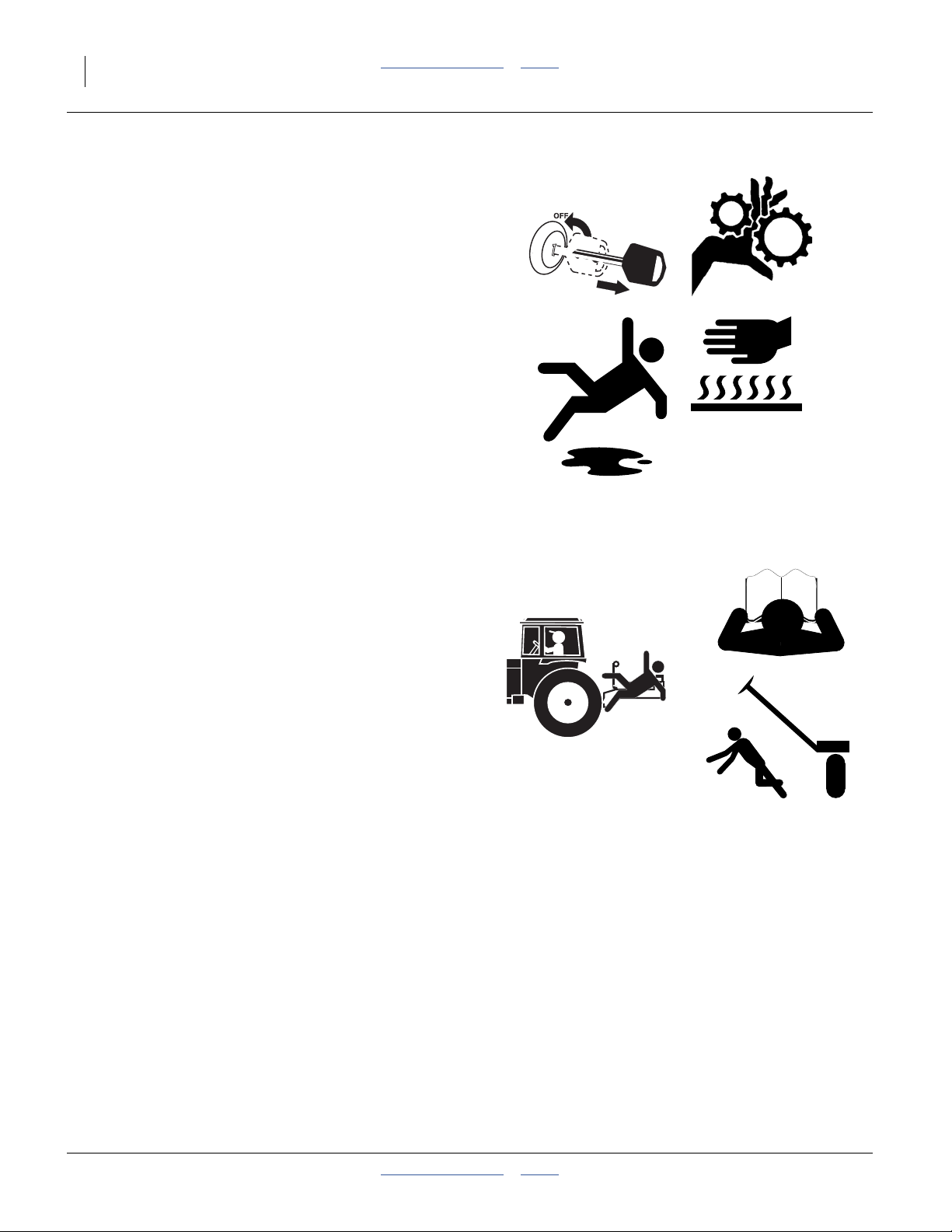

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper

tools and equipment. Refer to this manual for additional

information.

▲ Work in a clean, dry area.

▲ Lower the drill, put tractor in park, turn off engine, and

remove key before performing maintenance.

▲ Make sure all moving parts have stopped and all system

pressure is relieved.

▲ Allow drill to cool completely.

▲ Disconnect battery ground cable (-) before servicing or

adjusting electrical systems or before welding on drill.

▲ Inspect all parts. Make sure parts are in good condition

and installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from drill before oper-

ation.

Safety At All Times

Thoroughly read and understand the instructions in this

manual before operation. Read all instructions noted on

the safety decals.

▲ Be familiar with all drill functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave drill unattended with tractor engine running.

▲ Do not stand between the tractor and drill during hitching.

▲ Keep hands, feet and clothing away from power-driven

parts.

▲ Wear snug-fitting clothing to avoid entanglement with mov-

ing parts.

▲ Watch out for wires, trees, etc., when folding and raising

drill. Make sure all persons are clear of working area.

118-999M Table of Contents Index 2013-06-04

Page 9

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 5

%

%

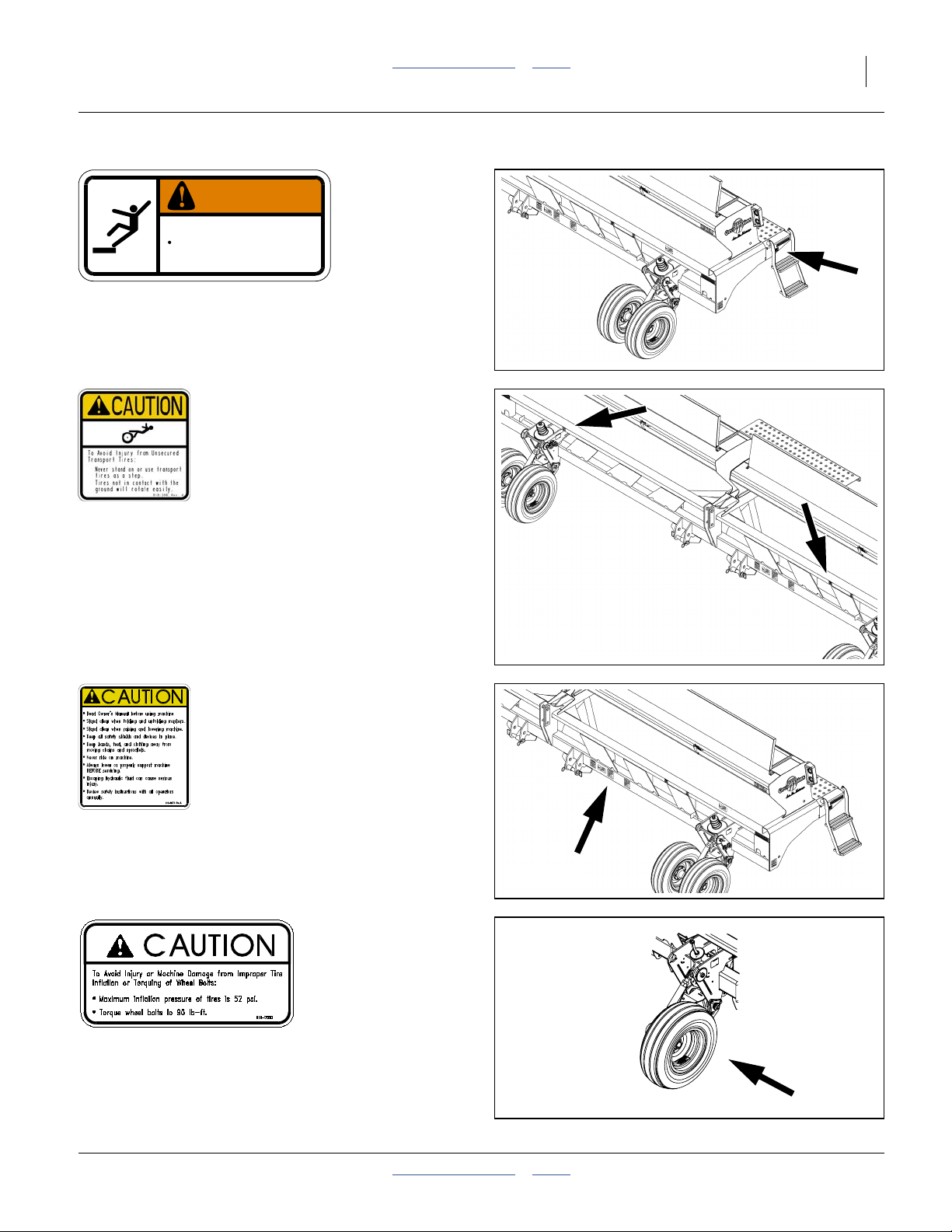

Safety Decals

Safety Reflectors and Decals

Your implement comes equipped with all lights, safety

reflectors and decals in place. They were designed to

help you safely operate your implement.

▲ Read and follow decal directions.

▲ Keep lights in operating condition.

▲ Keep all safety decals clean and legible.

▲ Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

▲ When ordering new parts or components, also request cor-

responding safety decals.

To install new decals:

1. Clean the area on which the decal is to be placed.

2. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

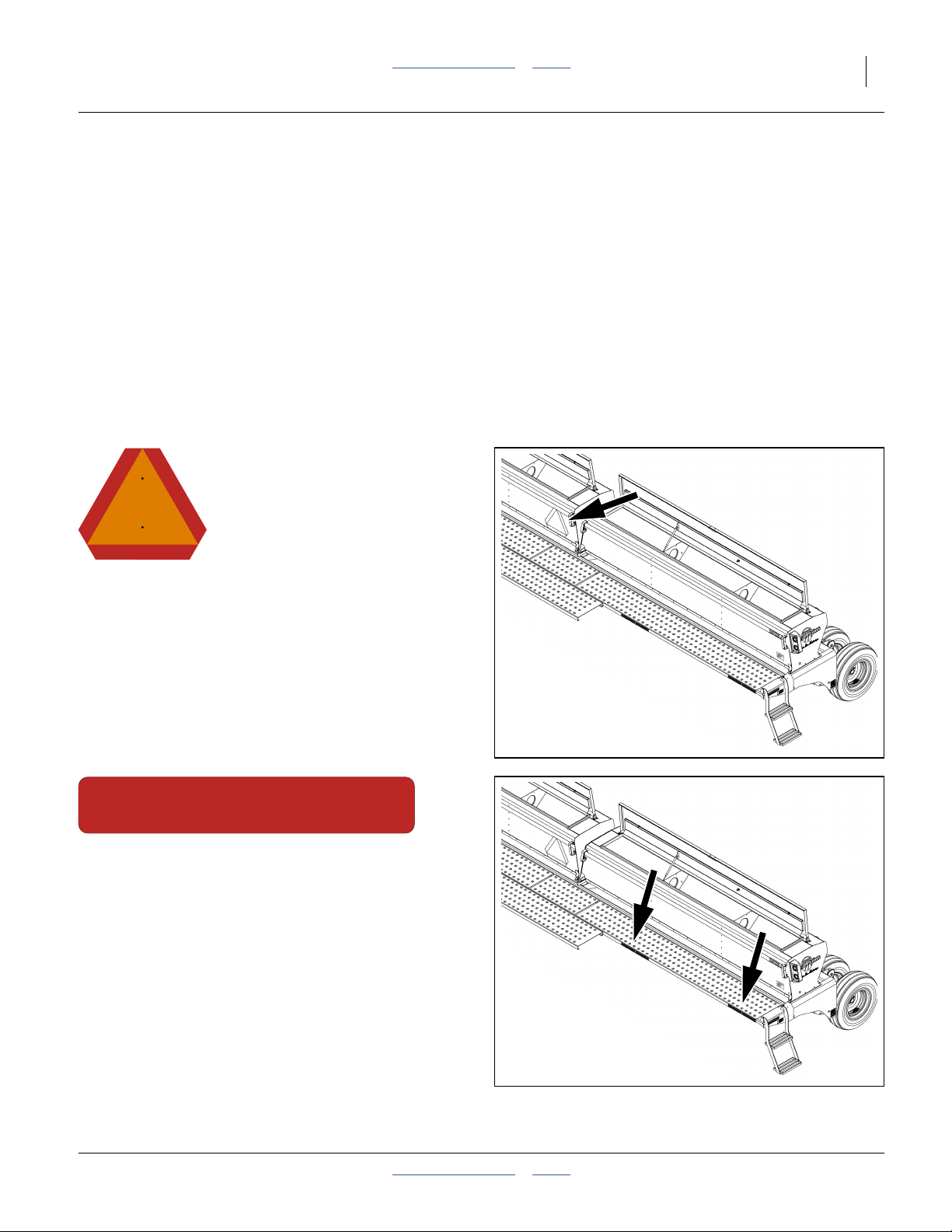

818-003C

Slow Moving Vehicle Reflector

On the back of the left seed box, near drill center;

1 total

838-266C

Red Reflectors

On rear of walkboards, outside ends,

and near center of each seed box;

four total

29791_66

29791_66

2013-06-04 Table of Contents Index 118-999M

Page 10

6 2025A/2525A Table of Contents Index Great Plains Manufacturing, Inc.

%

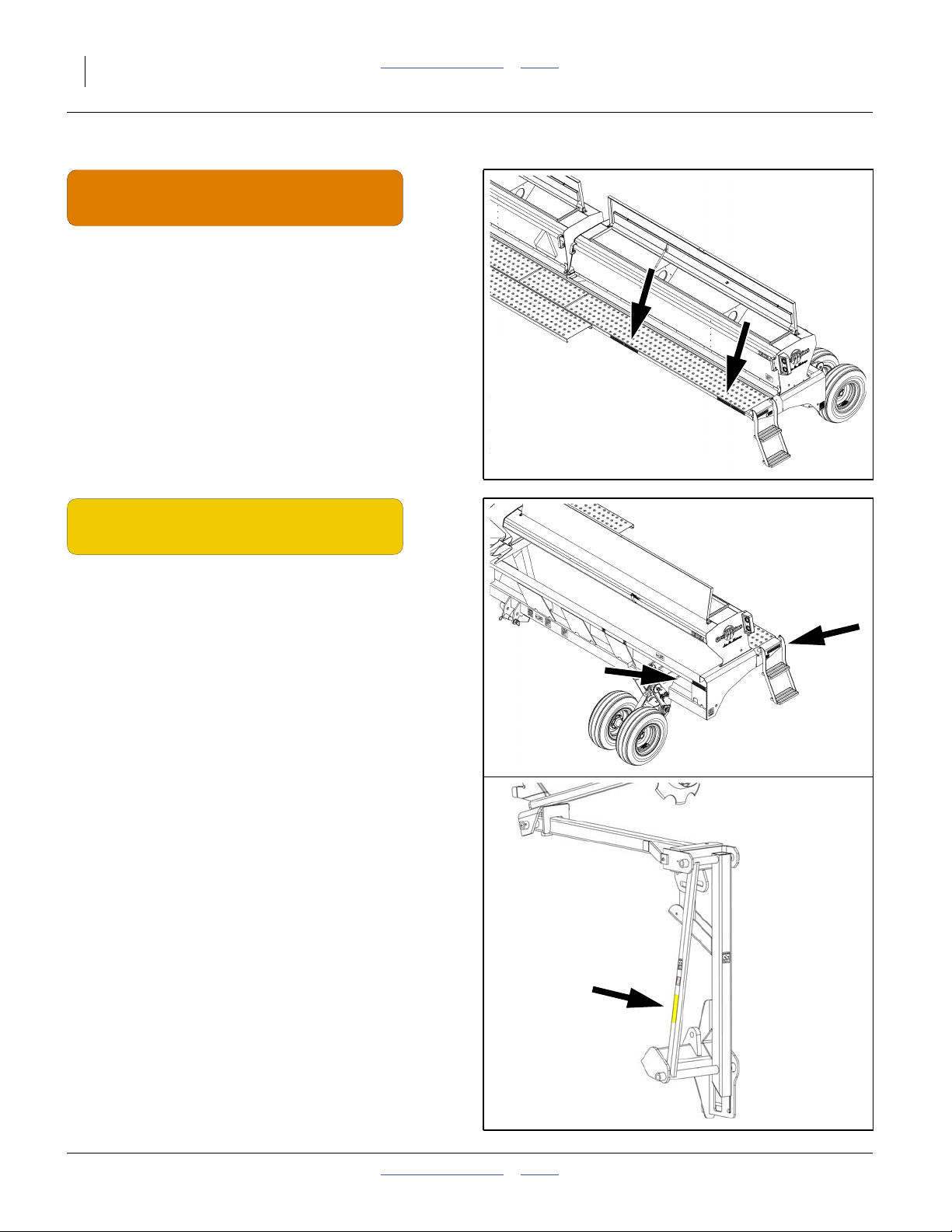

838-267C

Daytime Reflectors

On rear of walkboards, outside ends (inboard of reds),

and near center of each seed box (inboard of reds);

four total

29791_66

838-265C

Amber Reflectors

On walkboard ends above ladders,

on the front face of the top front tool bar, outside ends;

four total

On markers (option),

front face of smaller inner arm tube;

one or two total

29791_66%

19196_33%

118-999M Table of Contents Index 2013-06-04

Page 11

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 7

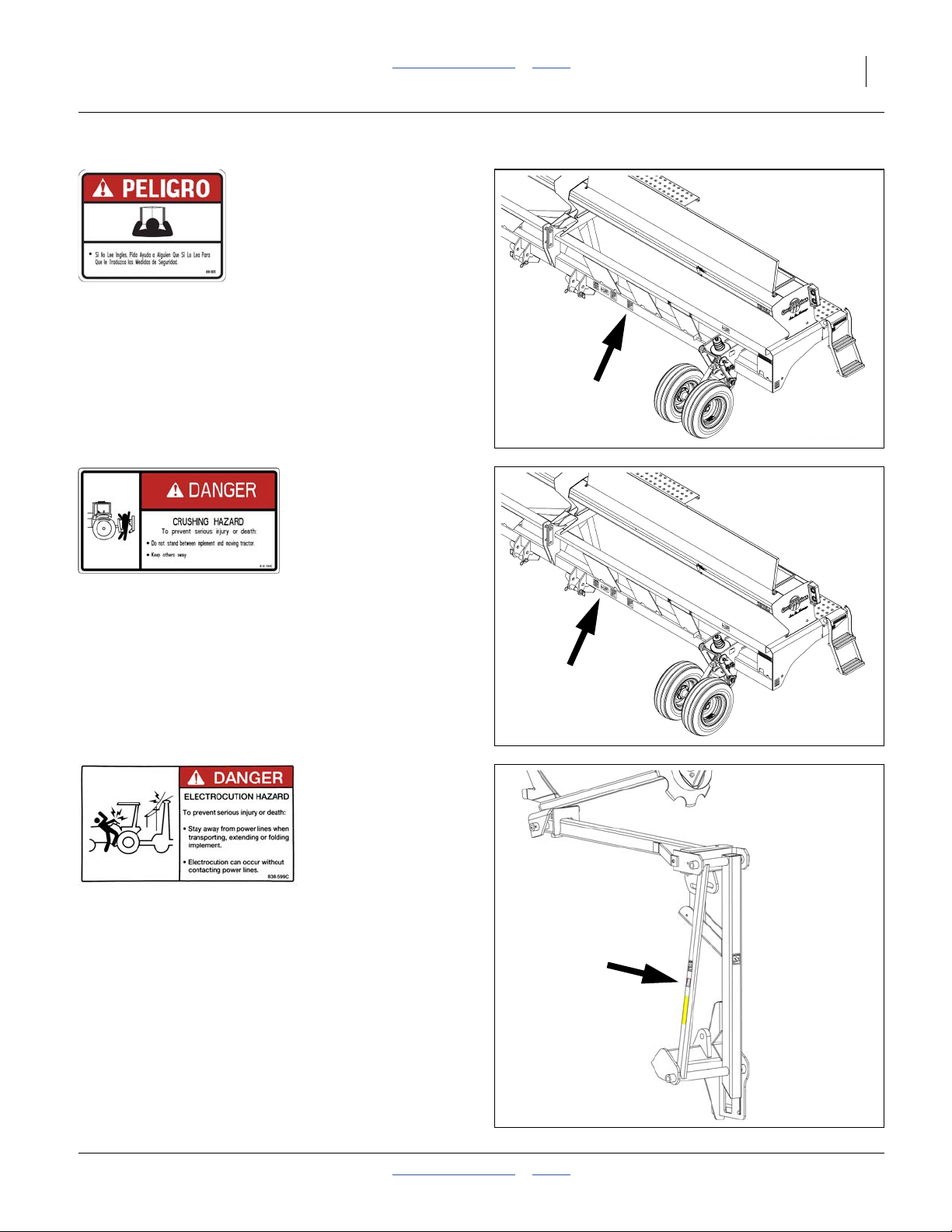

818-557C Danger (in Spanish):

Advising non-English readers to seek translation

On side of tongue; one total

29791_66%

818-590C Danger: Crushing Hazard

Front face of lower front tool bar, left of 3-point hitch;

one total

818-599C Danger: Electrocution Hazard

front face of smaller inner arm tube;

one or two total

29791_66%

19196_33%

2013-06-04 Table of Contents Index 118-999M

Page 12

8 2025A/2525A Table of Contents Index Great Plains Manufacturing, Inc.

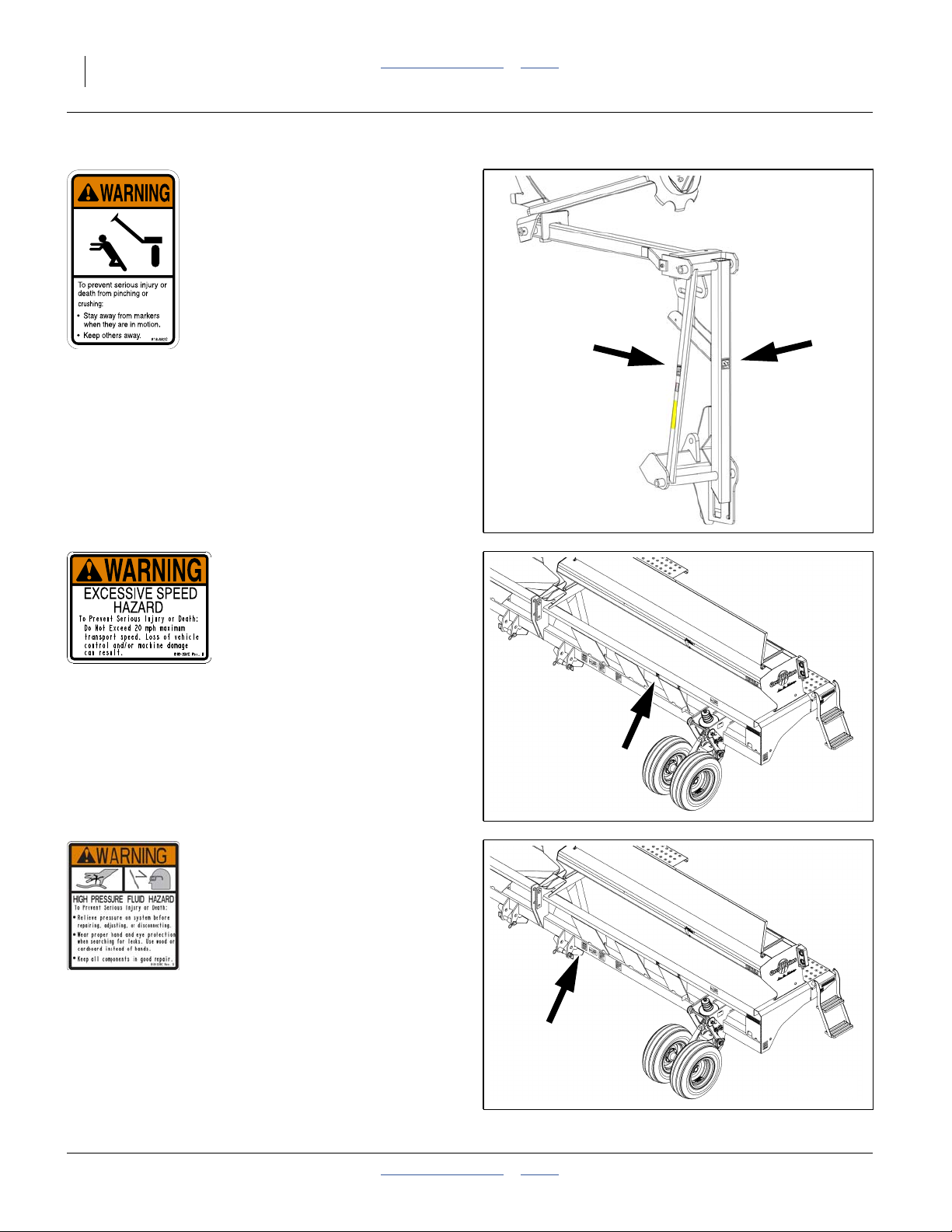

818-682C (Option) Warning: Marker Pinch/Crush

On markers (option),

On outside face of main inner arm tube when folded,

on front face of smaller inner arm tube;

two or four total

818-337C Warning: Speed Hazard

On front of top front tool bar, left of hitch;

one total

19196_33%

29791_66%

818-339C Warning: High Pressure Fluid Hazard

On front of lower front tool bar, left of hitch;

one total

29791_66%

118-999M Table of Contents Index 2013-06-04

Page 13

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 9

WARNING

To avoid serious injury or death:

Watch your step when climbing ladder or

walking on walkboard.

818-339C Warning: Falling Hazard

On walkboard ends, at top of ladder;

two total

838-102C

29791_66%

818-398C Caution: Tires Not A Step

On front of top front tool bar, near gauge wheels;

two total

818-587C Caution: Read Operator’s Manual

On front face of lower front tool bar, left of hitch;

one total

29791_66%

29791_66%

.tif

Standard(non-twin)

600 dpi

single is hidden

behind this mask.

818-752C (single gauge wheels) Caution: Tire Pressure and Torque

On outside rim of each wheel;

four total

2013-06-04 Table of Contents Index 118-999M

26215

Page 14

10 2025A/2525A Table of Contents Index Great Plains Manufacturing, Inc.

Introduction

Great Plains welcomes you to its growing family of new

product owners. The 20- and 25-Foot 3-Point Drills

with Air-Pro

been designed with care and built by skilled workers

using quality materials. Proper setup, maintenance, and

safe operating practices will help you get years of satisfactory use from the machine.

®

Seed Meters (2025A and 2525A) have

Models Covered

2025A-12TR36 20-Foot, 12-Row (6 Twin 8in), 36in

2025A-12TR38 20-Foot, 12-Row (6 Twin 8in), 38in

2525A-16TR36 25-Foot, 16-Row (8 Twin 8in), 36in

2525A-16TR38 25-Foot, 16-Row (8 Twin 8in), 38in

2525A-16TR3815 25-Foot, 16-Row (8 Twin 15in), 38in

2525A-16TR40 25-Foot, 16-Row (8 Twin 8in), 40in

2525A-20TR30 25-Foot, 20-Row (10 Twin 8in), 30in

Description of Unit

The 2025Aand 2525A are fully-mounted three-point precision seeding implements. The 2025A and 2525A

include 25AP Series openers with Air-Pro® meters supporting a wide choice of seed disks. The drill accepts

optional unit-mounted row accessories.

R

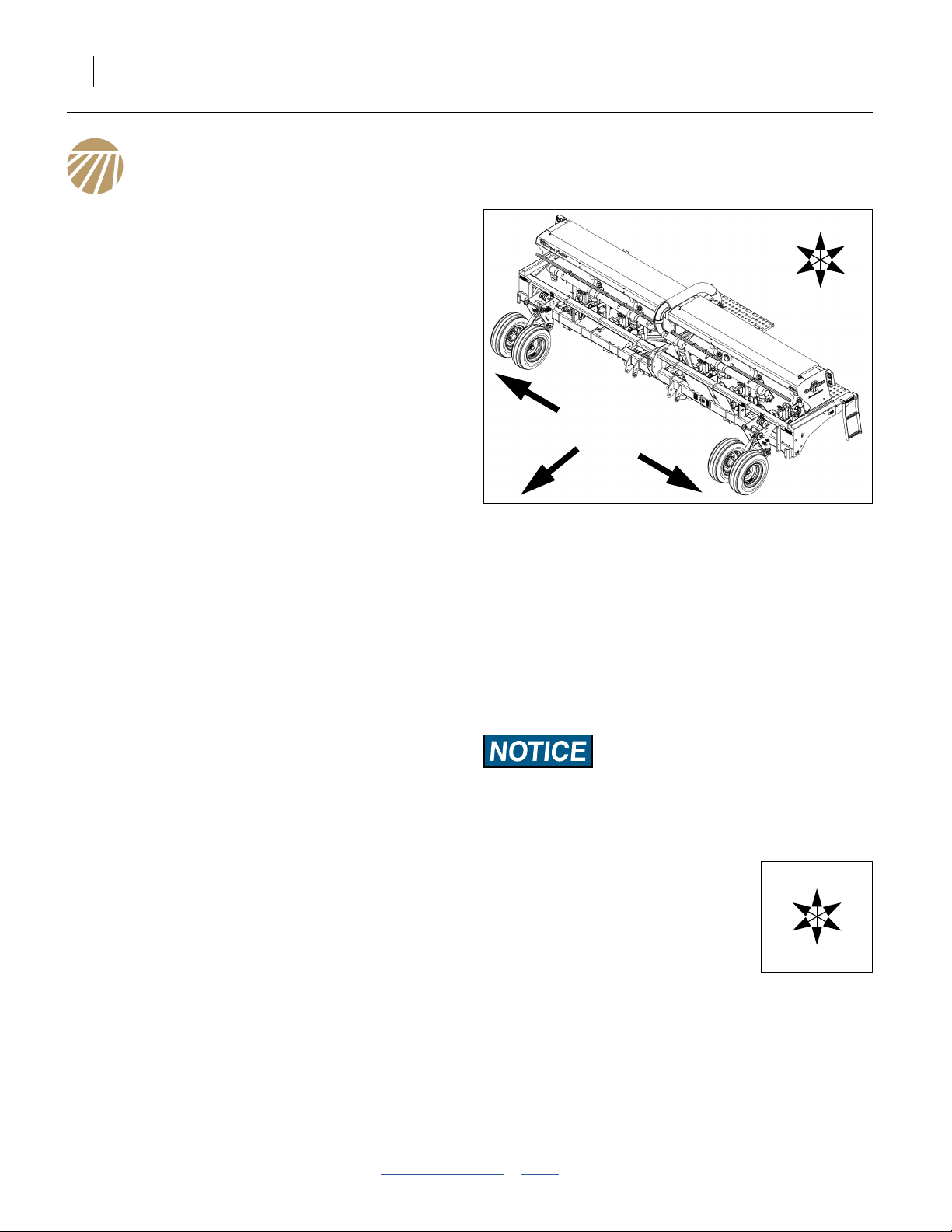

L

Figure 1

3-Point Drill

R

F

U

B

L

D

29792

_45%

Intended Usage

Use the 3-Pointdrill toseed production-agriculture crops

in conventional or minimum tillage conditions. Do not

modify the drill for use withattachments other thanGreat

Plains options and accessories specified for use with the

2025A and 2525A.

Document Family

118-999M Owner’s Manual (this document)

118-999B Seed Rate Charts

118-999P Parts Manual

Using This Manual

This manual will familiarize you with safety, assembly,

operation, adjustments, troubleshooting, and maintenance. Read this manual and follow the recommendations to help ensure safe and efficient operation.

The information in this manual is current at printing.

Some parts may change to assure top performance.

Definitions

The following terms are used throughout this manual.

A crucial point of information related to the pr eceding topic.

Read and follow the directions to r emain safe , avoid serious

damage to equipment and ensure desired field results.

Note: Useful information related to the preceding topic.

Right-hand and left-hand as used in

this manual are determined by facing

the direction the machine will travel

while in use unless otherwise stated.

An orientation rose in some line art

illustrations shows the directions of:

Up, Back, Left, Down, Front, Right.

F

R

U

B

L

D

118-999M Table of Contents Index 2013-06-04

Page 15

Great Plains Manufacturing, Inc. Table of Contents Index Introduction 11

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. They have trained personnel, repair

parts and equipment specially designed for Great Plains

products.

Refer to Figure 2

Your machine’s parts were specially designed and

should only be replaced with Great Plains parts. Always

use the serial and model number when ordering parts

from your Great Plains dealer.The serial-number plate is

located on the left end of the top front tool bar.

Record your 3-Point drill model and serial number here

for quick reference:

Model Number:__________________________

Serial Number: __________________________

Your Great Plains dealer wants you to be satisfied with

your new machine. If you do not understand any part of

this manual orare not satisfiedwith the service received,

please take the following actions.

1. Discuss the matter with your dealership service

manager.Make sure they areawareof any problems

so they can assist you.

2. If you are still unsatisfied, seekout theowner or general manager of the dealership.

Figure 2

Serial Number Plate

For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

18307

785-823-3276

2013-06-04 Table of Contents Index 118-999M

Page 16

12 2025A/2525A Table of Contents Index Great Plains Manufacturing, Inc.

Preparation and Setup

This section helps you prepare your tractor and 2025A

and 2525A Drill for use, and covers tasks thatneed to be

done seasonally, or when the tractor/drill configuration

changes.

Before using the drill in the field, you must hitch it to a

suitable tractor, inspect systems and level the drill.

Before using the drill for the first time, and periodically

thereafter, certain adjustments and calibrations are

required.

Initial Setup

See “Appendix B - Initial and Option Setup” on

page 96 for pre-delivery items (normally completed by

dealer), and first-time/infrequent setup tasks, including:

• (Marker option) adjust marker extension and speed

(page 98).

• (Option) install seed monitor console in tractor

(page 97).

Post-Delivery/Seasonal Setup

On initial delivery,use witha new tractor, andseasonally,

check and as necessary, complete these items before

continuing to the routine setup items:

• (Marker option) bleed hydraulic system (page 72).

• (Option) radar calibration (separate manual).

• (Marker option) de-grease exposed cylinder rods if so

protected at last storage.

Pre-Planting Setup

Complete this checklist before routine setup:

❑ Read and understand “Important Safety Informa-

tion” on page 1.

❑ Check that all working parts are moving freely, bolts

are tight, and cotter pins are spread.

❑ Check that all grease fittings are in place and lubri-

cated. See “Lubrication” on page 77.

❑ Check that all safety decals and reflectors are cor-

rectly located and legible. Replace if damaged. See

“Safety Decals” on page 5.

❑ Inflate tires to pressure recommended and tighten

wheel bolts as specified. See “Tire Inflation Chart”

on page 88.

28341

118-999M Table of Contents Index 2013-06-04

Page 17

Great Plains Manufacturing, Inc. Table of Contents Index Preparation and Setup 13

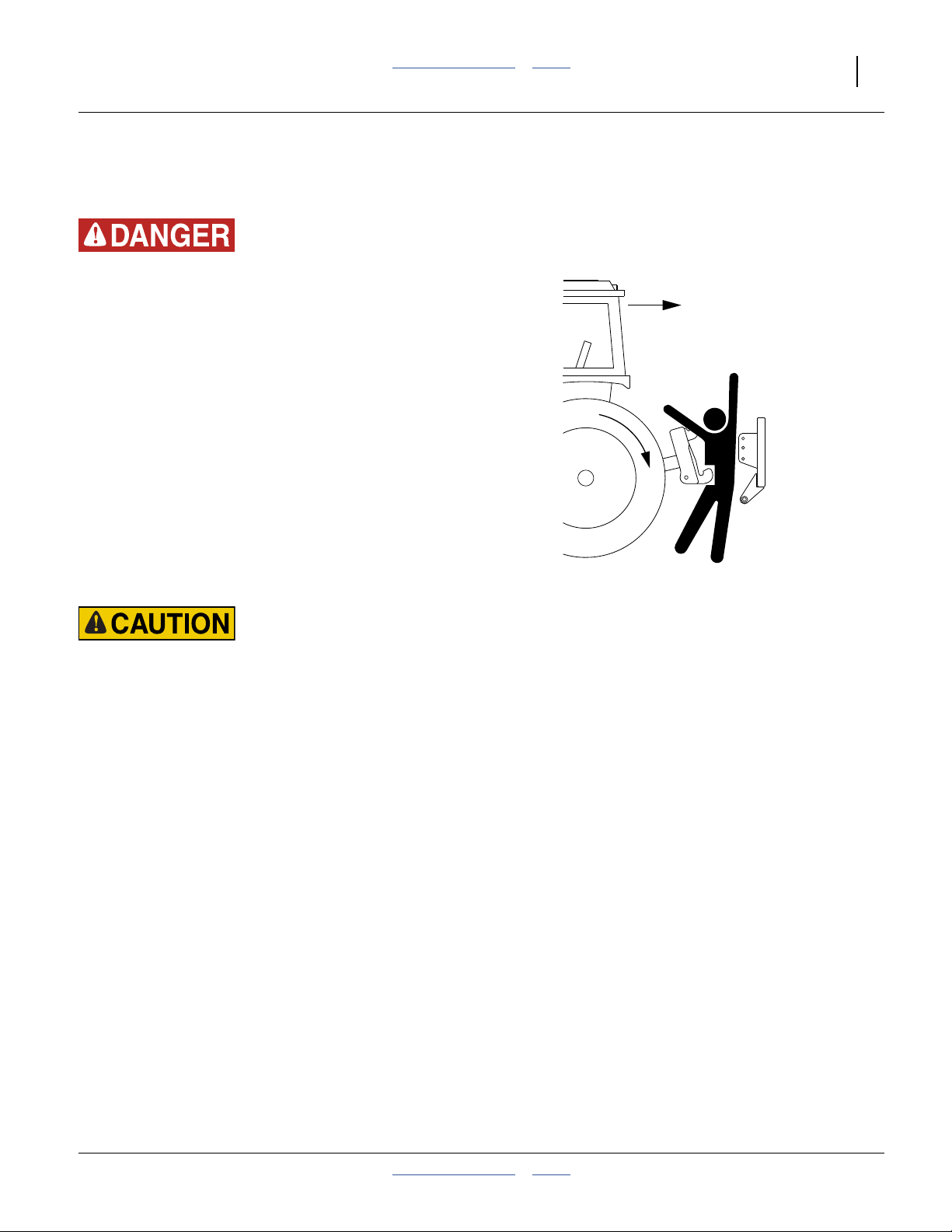

Hitching Tractor to Drill

3-Point Hitch

Crushing Hazard:

Do not stand or place any body part between planter andmoving tractor. You may be severely injured or killed by being

crushed between the tractor and planter. Stop tractor engine

and set parking brake before attaching cables and hoses.

1. Raise or lower tractor three-point arms as needed

and pin lower arms to drill.

2. Pin upper arm to drill. For category III and III-N tractors, install hitch pin in the lower hole. For category

IV-N tractors, install hitch pin in the upper hole.

3. Slowly raise drill. Watch for cab interference.

4. Adjust top three-point link so that top edge of drill

box is parallel with ground when drilling.

Note: Do notuse linkto adjust openerdepth. For opener

adjustments, refer to page 43.

5. Set your tractor three-point-draft control to float position.

Load Sway Hazard:

Adjust 3-point hitch arms and sway blocks to minimize any

side-to-side sway to assure proper tracking in the field, and

safe road travel.

2013-06-04 Table of Contents Index 118-999M

Page 18

14 2025A/2525A Table of Contents Index Great Plains Manufacturing, Inc.

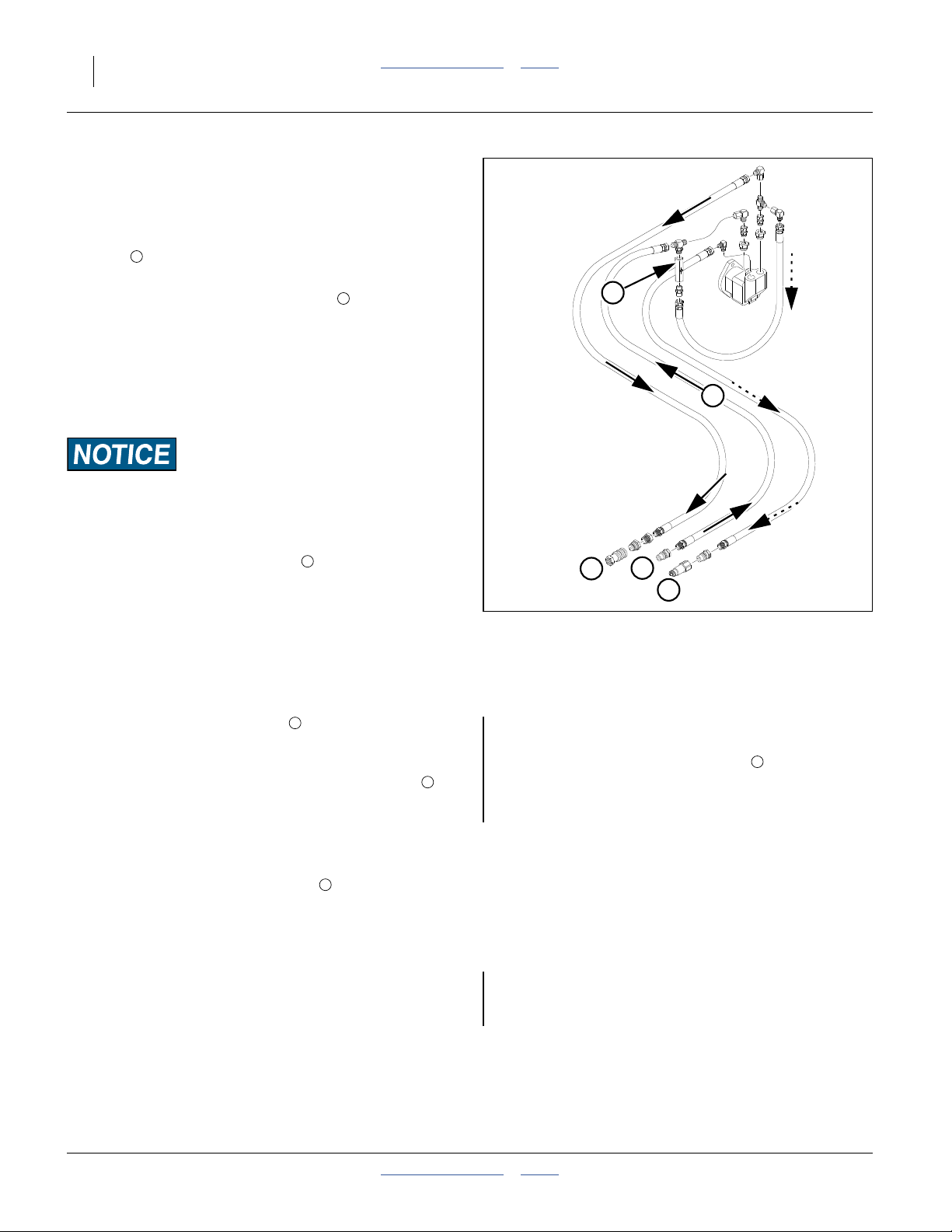

Hydraulic Hose Hookup

Great Plains hydraulichoses are color coded to help you

hookup hoses to your tractor outlets. Hoses that go to

the same remote valve are marked with the same color.

Color Hydraulic Function

Black Fan (3 hoses)

Green Markers

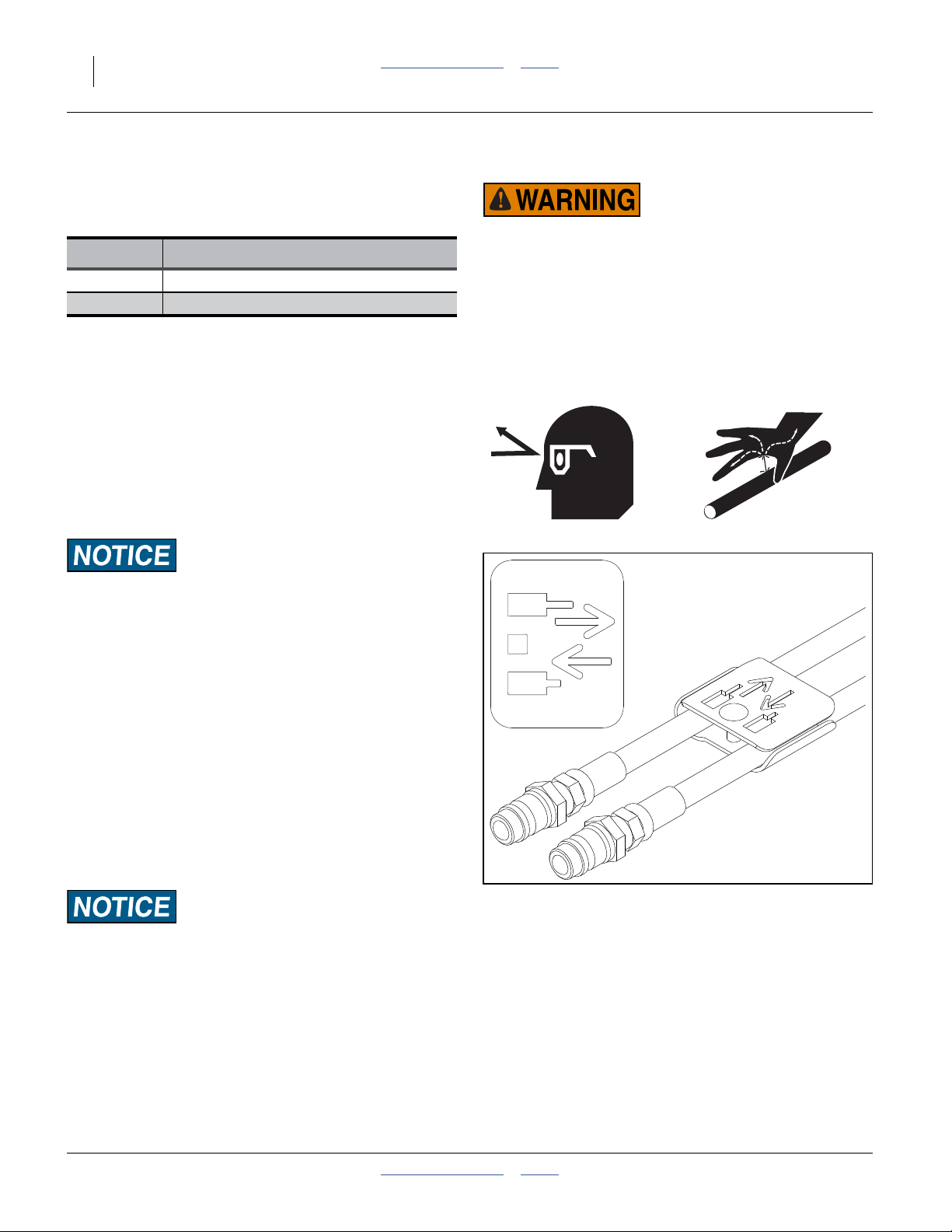

Refer to Figure 3

To distinguish hoses on the same hydraulic circuit, refer

to hose label. The hose under an extended-cylinder symbol feeds a cylinder base end. The hose under a

retracted-cylinder symbol feeds a cylinder rod end.

For the hydraulic motor, connect the hose under the

retracted cylinder symbol to the pressure side of the

motor. Connect the hose under the extended cylinder

symbol to the return side of the motor.

The fan motor further requires hookup of a third line,

which returns hydraulic fluid from the fan motor case.

High Pressure Fluid Hazard:

Relieve pressure before disconnecting hydraulic lines. Use

paper or cardboard, NOT BODY PARTS, to check for leaks.

Wear protective gloves and safety glasses or goggles when

working with hydraulic systems. Escaping fluidunder pressure

can have sufficient pressure to penetrate the skin causing serious injury. If an accident occurs, seek immediate medical

assistance from a physician familiar with this type of injury.

Only trained personnel should work on system hydraulics.

Machine Damage Risk:

Case Drain Hose must be attached first,

prior to inlet and return hoses being connected.

Case Drain Hose must be detached last,

to prevent damage to the fan motor.

Protecting Fan Hydraulic Motor Seals

Low Pressure (Case) Drain Connection

1. Attach case drain hose to low pressure drain connection.

Note: Case drain hose has the smaller1⁄4in I.D. hose

and small, flat-face, connector.

2. Connect low pressure motor return hoseto low pressure return connector. It is distinguished by a large

(1.06in/2.7cm diameter) quick coupler.

Machine Damage Risk:

DO NOT connect the case drain line to a

power-beyond-port.

3. Connect hydraulic hoses to tractor remotes.

Figure 3

Marker Hose Label

27270

118-999M Table of Contents Index 2013-06-04

Page 19

Great Plains Manufacturing, Inc. Table of Contents Index Preparation and Setup 15

Electrical Hookup

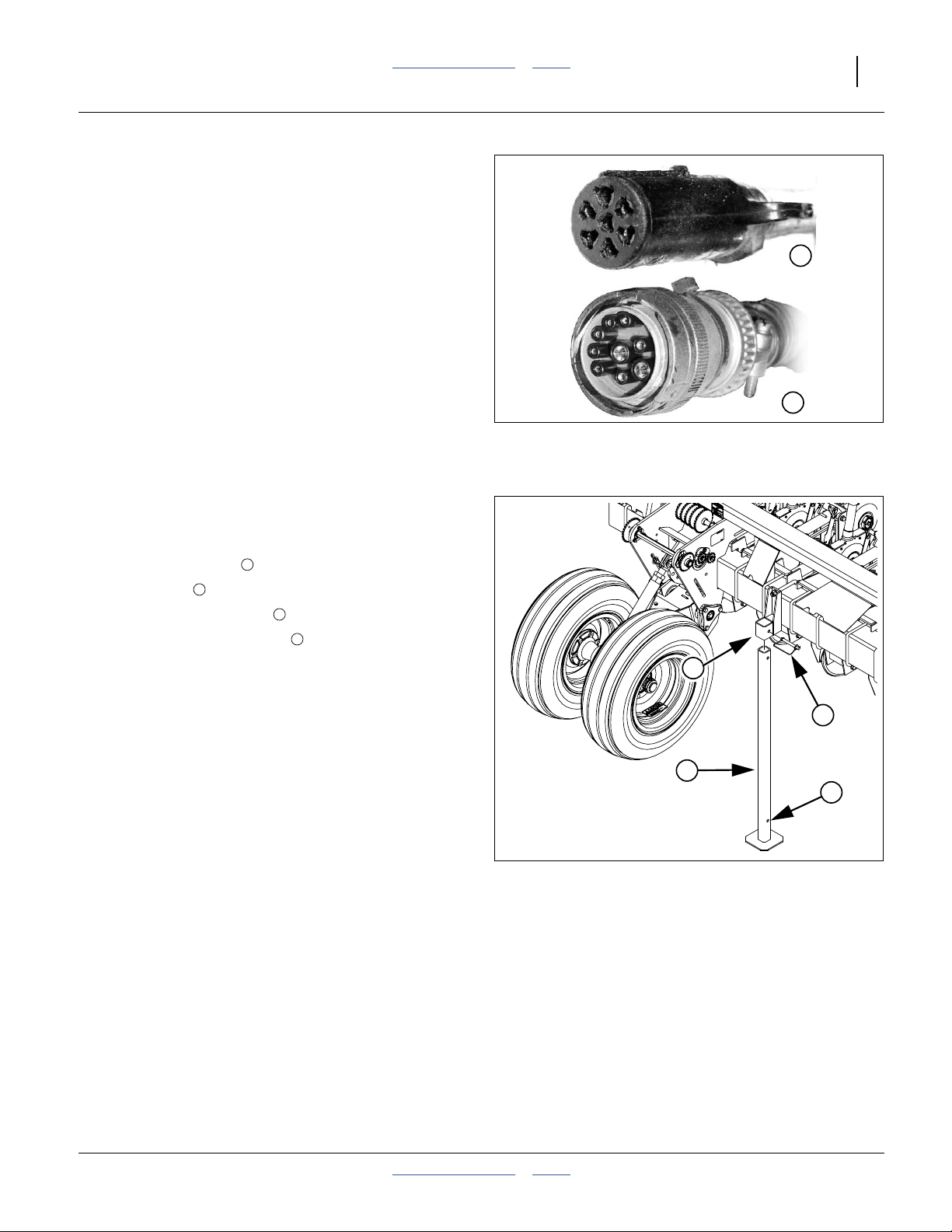

Refer to Figure 4

Make sure tractor isshut down with accessory power off

before making connections.

1. Mate lighting connector to tractor outlet.

2. Option: mate monitor connector to tractor harness.

3. Mate any accessory or aftermarket electrical connectors.

Make connections prior to drill movement. Some drill

hydraulic circuits are under monitor control.

1

2

Raise Parking Stands (2025A only)

Refer to Figure 5

1. Use tractor 3-point to raise drill enough to relieve

weight from stands .

2. Remove pin .

3. Slide stand up in mount .

4. Re-pin at lower stand hole .

4

3

5

6

Figure 4

Connector Identification

5

3

Figure 5

Model 2025A Parking Stand

25236

25237

4

6

26221

2013-06-04 Table of Contents Index 118-999M

Page 20

16 2025A/2525A Table of Contents Index Great Plains Manufacturing, Inc.

Leveling the Drill

For proper operation, and maximum compensation for

varying ground conditions, the openerparallel armsneed

to be parallel to slightly up-hill in normal lowered field

operation. This is controlled by two factors:

• the opener tool bar height, which is controlled by

adjustments to the gauge wheels, and;

• front-to-back level, which is controlled by the 3-point

hitch.

The procedure for setting initial drill height and checking

front-to-back level is:

1. Set gauge wheel adjustments to bedded or non-bed-

ded, via turnbuckle or link and block.

2. Lower drill onto gauge wheels with 3-point.

Set circuit to Float.

3. Adjust 3-point to recommended initial opener tool

bar height.

4. Verify front-to-back level, and adjust with 3-point.

Re-check height.

Make the same adjustmenton both gauge wheel assemblies.

Check that drill is still level side-to-side after setup.

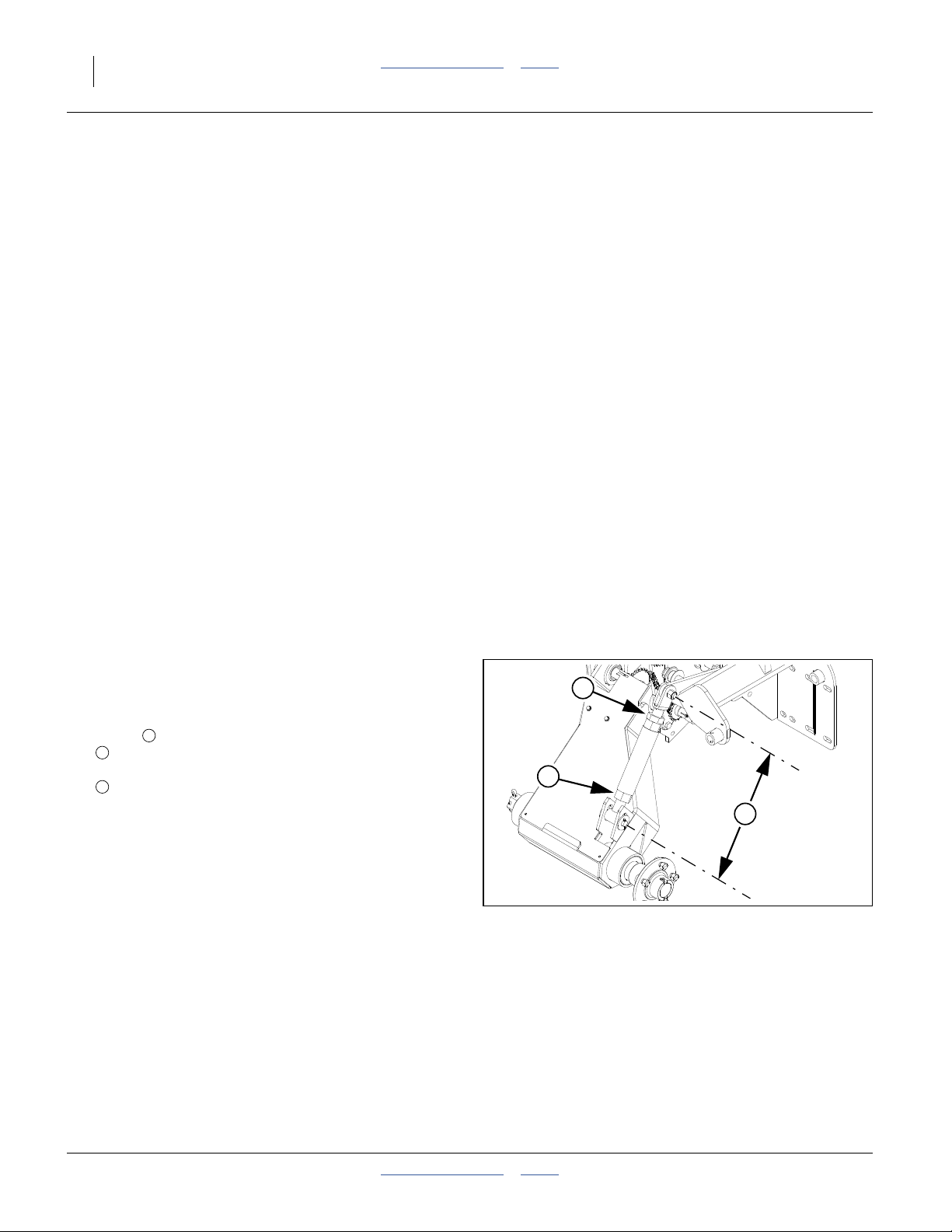

Leveling: Offset-Single Wheel

The offset-single gauge wheel adjusts for bedding by

changing the turnbuckle length.

Refer to Figure 6

1. Check the link length. The factory setting for link

1

4

26in

1

171⁄2in

length , measured at center-lines, is:

This corresponds to an opener tool bar height of:

This is for non-bedded planting.

To adjust the drill for bedded planting:

2. Hitch it to a suitabletractor.Move it torepresentative

bedded ground, with the wheels between beds.

3. Lower the drill toplanting position andset the3-point

hitch circuit to Float.

2

3

Figure 6

Offset-Single Wheel Turnbuckle

1

27221

118-999M Table of Contents Index 2013-06-04

Page 21

Great Plains Manufacturing, Inc. Table of Contents Index Preparation and Setup 17

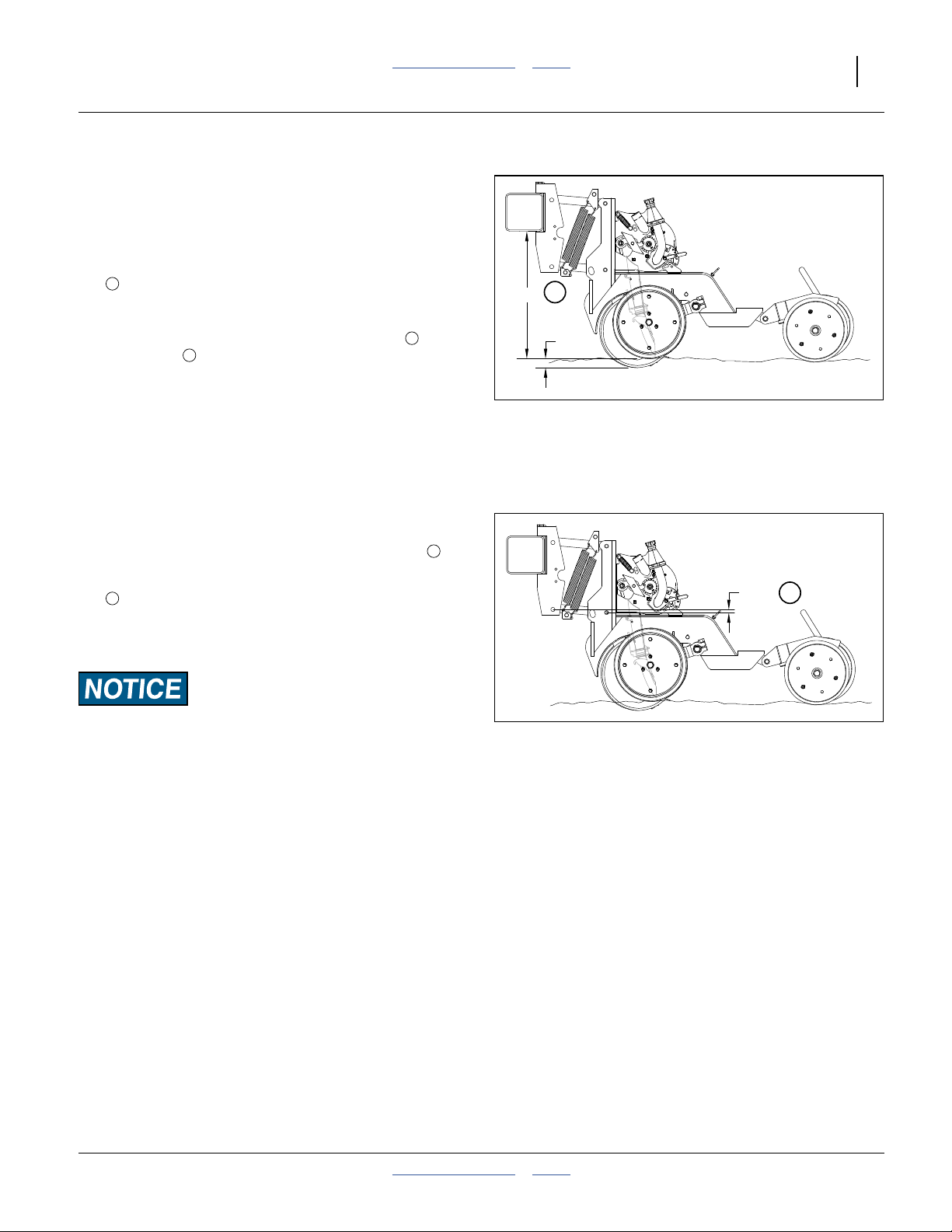

Refer to Figure 7

Note: This presumes a planting depth of 1.75in. If your

depth is different, re-adjust the tool bar height

when adjusting the press-wheels (page 54).

4. Adjust drill distance between bottom of opener tool

bar and planting ground (bed tops):

Tool bar height 26in (66cm)

4

26in

4

Refer to Figure 6 on page 16

5. To adjust turnbuckle length, loosen jam nut . Turn

turnbuckle to shorten or lengthen as necessary.

3

2

13/4in

When adjusting the turnbuckle length, remember:

+ Lengthening turnbuckle raises drill.

- Shortening turnbuckle lowers drill.

Re-tighten jam nut when height is final.

Figure 7

Offset-Single Wheel Height

29820

Note: Do not expose more than 3in (7.6cm) of thread at

either end of turnbuckle.

6. Level drill with top three-point link.

Refer to Figure 8

7. Level drill with top of three-point link. Adjust so that

row units are inclined slightly uphill, measured at

5

the ends of the parallel arms:

1 inch

Arm inclination 1in maximum

5

5

The 1in dimension shown is a general dimension that

varies with planting conditions.

Equipment Damage/Planting Depth Risks:

Ensure the opener mount is running higher than the opener

body. This ensures ample reserve for opener up-float if the

opener strikes a rock or other object.

Figure 8

Offset-Single Wheel Opener Level

29821

2013-06-04 Table of Contents Index 118-999M

Page 22

18 2025A/2525A Table of Contents Index Great Plains Manufacturing, Inc.

Meter and Row Setup

❑ Select and install correct seed disks forcrop, popula-

tion and desired field speed.

See Seed Rate Manual for disk selection criteria.

See page 48 for disk installation.

If planting at a non-standard row spacing:

❑ Have blank seed disks (page 86) available for bal-

ancing meter pressureat unusedrows, andreducing

meter brush wear.

See page 50 for disk installation.

❑ Have seed tube plugs (page 50) available for block-

ing seed flow to unused rows.

29594

See page 49 for plug installation.

❑ If planting at a non-standard row spacing, have

lock-uppins (page 83)availablefor reducing wear on

unused rows.

See page 51 for row lock-up.

Marker Setup

Prior to first use, check and adjust:

•“Marker Speed Adjustment” on page 98.

Prior to first use, and whenever changing row spacings,

set or reset:

•“Marker Extension” on page 100.

Prior to each planting session, check and adjust:

•“Marker Chain Adjustment” on page 99

•“Marker Disk Adjustment” on page 34.

27226

26226

118-999M Table of Contents Index 2013-06-04

Page 23

Great Plains Manufacturing, Inc. Table of Contents Index 19

Operating Instructions

This section covers general operating procedures. Experience, machine familiarity, and the following information

will lead to efficient operation and good working habits.

Always operate farm machinery with safety in mind.

Pre-Start Checklist

Perform the following steps before transporting the

3-Point drill to the field.

❑ Carefully read “Important Safety Information” on

page 1.

❑ Install seed disks appropriate for crop. See

“Air-Pro® Meter Disk Installation” on page 48.

❑ Lubricate drill as indicated under “Lubrication” on

page 77.

❑ Check all tires for proper inflation. See “Tire Infla-

tion Chart” on page 88.

❑ Check all bolts, pins, and fasteners. Torque as

shown in “Torque Values Chart” on page 90.

❑ Check drill for worn or damaged parts. Repair or

replace parts before going to the field.

❑ Rotate both gauge wheels to see that the drive and

meters are working properly and free from foreign

material.

❑ Check hydraulic hoses, fittings, and cylinders for

leaks. Repair or replace before going to the field.

High Pressure Fluid Hazard:

Relieve pressure before disconnecting hydraulic lines. Use a

piece of paper or cardboard, NOT BODY PARTS, to check for

leaks. Wear protective gloves and safety glasses or goggles

when working with hydraulic systems. Escaping fluid under

pressure can have sufficient pressure to penetrate the skin

causing serious injury. If an accident occurs, seek immediate

medical assistance from a physician familiar with this type of

injury.

Drill Weight

You need to know the weight of your drill, for safe transport, and to assure optimal field operations.

The table below shows typical weights for various models and configurations, with and without seed loaded.

If the ratings for your tractor are marginal, have your drill

weighed at a scale.

Approximate¹ Weights of

Typical Drill Configurations

Empty Drill (standard)

Base Drill with Full Seed Load

Empty Drill (w/options²)

Optioned Drill, Full Seed Load

¹ Weight of your drill weight can vary by hundreds of pounds depending on installed features.

² With Dual Markers, Unit-Mount Coulters and full Weight Kits

2013-06-04 Table of Contents Index 118-999M

2025A 2525A 2525A

-12TR36, -16TR36, -16TR38, -20TR30

-12TR38 -16TR3815, -16TR40

5520 lbs. 7360 lbs. 8200 lbs.

8400 lbs. 10600 lbs. 11440 lbs.

7752 lbs. 9847 lbs. 10847 lbs.

10632 lbs. 13087 lbs. 14087 lbs.

Page 24

20 2025A/2525A Table of Contents Index Great Plains Manufacturing, Inc.

Transporting

Fortransporting with drillattached to ahitch, refer toyour

hitch operator’s manual.

Check Tractor Capacity and Configuration

3-point implements can dangerously reduce weight on

tractor steering wheels.

• Know the transport weight of your drill (see table on

previous page).

• Consult your tractor manual for 3-point limitations.

• Add weights to tractor as required.

When determining the weight of your drill, be sure to

include the weight of any seed loaded and row options.

Remove Extra Drill Weights

Remove weights from optional weight brackets. Move

weights to tractor as needed for ballasting.

Loss of Control Hazard:

Use a tractor rated for theload. Addtractor ballast as needed.

Do not exceed 20 mph. Towing the drill with a vehicle that is

not adequate, or at high speeds, could lead to loss of vehicle

control. Loss of vehicle can result in a serious road accident,

severe injury or death. Check that your tractor has enough to

handle the weight of the drill. Refer to your tractor’s operator

manual for capacities and ballast requirements.

Unload Seed Box

Unload seed box before transporting if at all possible.

See “Material Clean-Out” on page 66.

The drill can be transported with a full box of grain, but

the added weight will increase stopping distance and

decrease maneuverability.

To maintain steeringcontrol, you may need toadd ballast

to your tractor front end. Refer to your tractor operator’s

manual for ballast required.

Secure Markers

Always transport markers in the folded position and

marker hydraulic circuit(s) in neutral (to prevent unintended marker movement in cradles).

Transport Checklist

❑ Plan the route. Avoid steep hills.Keep Clearances in

mind.

❑ Hitch: Make all electrical and hydraulic connections.

See “Hitching Tractor to Drill” on page 13.

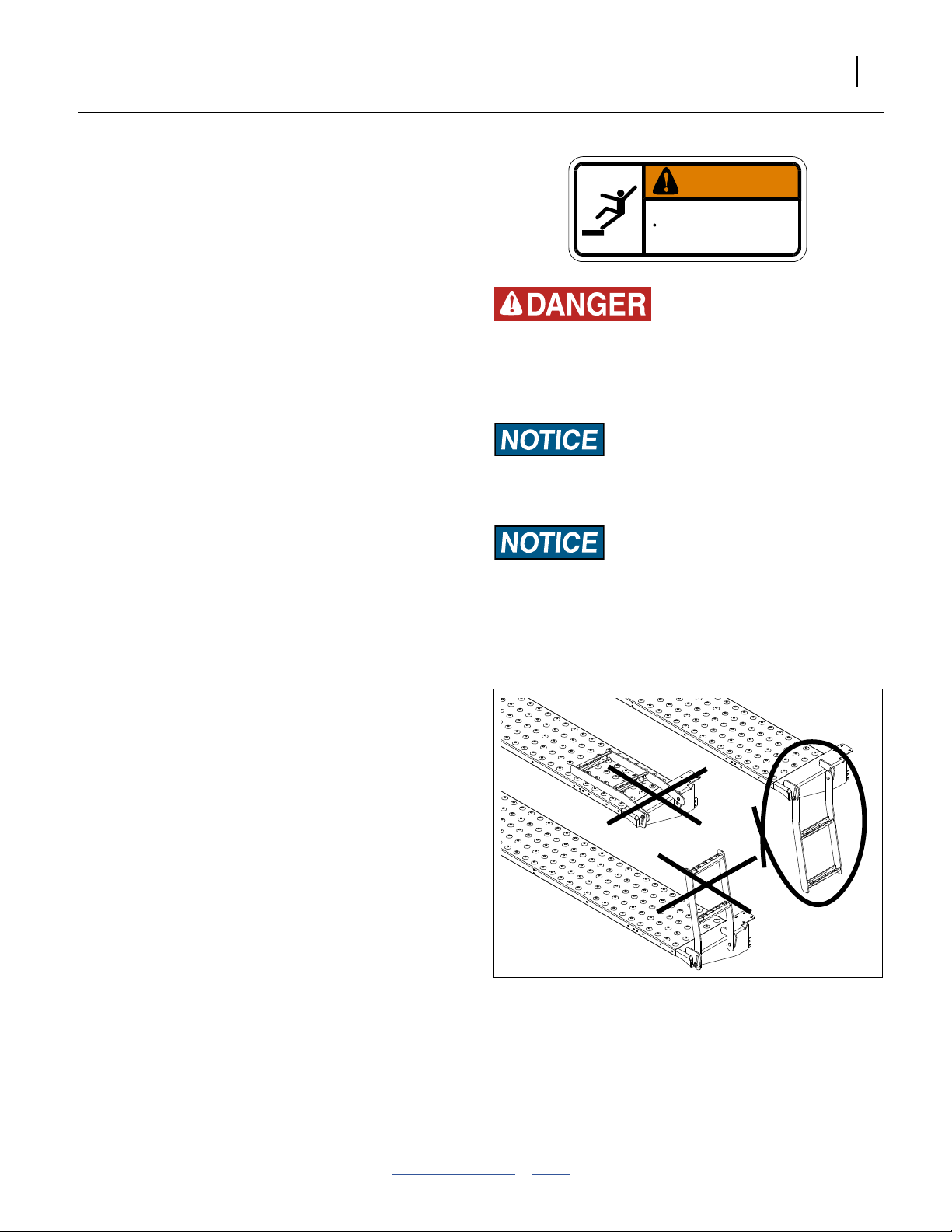

Refer to Figure 9

❑ Fold up walkboard ladders for maximum clearance.

❑ Fold markers. Lock circuit with Neutral setting.

See “Marker Operation (Option)” on page 28.

❑ Raise drill.

❑ Close all seed inlet shutters if transporting with seed.

❑ Always have lights on for highway operation.

❑ Comply with all federal, state and local safety laws

when traveling on public roads.

❑ Travel with caution. Allow safe clearance.

Remember that the drill is wider than the tractor.

Figure 9

Walkboard Ladder for Transport

28828

118-999M Table of Contents Index 2013-06-04

Page 25

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 21

Loading Seed

Watch your step when walking on drill ladder and walkboard. Falling from drill could cause severe injury or

death.

Great Plains recommends loadingmaterials afterthe drill

has been transported to the planting ground.

Seed is heavy.

Pre-loading substantially increases transport hazards:

• Stopping distance increases.

• The center of gravity moves aft:

Tractor steering wheels have less weight on them,

reducing steering effectiveness.

• Turning hazards increase:

Even with effective steering, turns are more difficult to

initiate and more difficult to stop, due to the inertia of

the wide load.

To load materials:

1. Load only in dry conditions.

2. If the seed is treated, wear protective equipment rec-

ommended for the hazards.

3. If loading seed prior to transport, close all seed inlet

shutters (page 46).

4. Lower the drill.

Refer to Figure 10

5. Fold down the ladders.

6. Open the lids for the boxes. Handle is also a latch,

pull out and up to release.

7. Remove any debris or obstructions from the boxes.

8. If planting at a non-standard row spacing, insert

seed plugs in unused rows (page_page 50).

9. Load seed.

Agricultural Chemical Hazard:

Follow seed supplier and chemical manufacturer instructions

for treated seed. Avoid contact with skin or eyes. Avoid breathing dust or fumes - use a respirator. Know what to do if an

accident occurs.

Equipment Damage/Population Risk:

Do not use liquid seed treatments. Pre-treat and dry seed

before loading. Excessively sticky seed does not meter reliably.

Population Risk:

Seed lubricant is required. All seed must be mixed with Ezee

Glide Plus seed lubricant. See page 80.

WARNING

To avoid serious injury or death:

Watch your step when climbing ladder or

walking on walkboard.

838-102C

Mix seed lubricant as you load (page 80).

Load or spread seedevenlyacross all partitions.Use

a tool or gloved hand.

10. Make a note of the quantity loaded, for later confir-

mation of population or application density desired.

Note also the acremeter reading.

11. Close and latch the box lids.

12. Raise the ladders (page 27).

Figure 10

Walkboard Ladder for Loading

28828

Before the firstplanting each season, orwhen using new

meters or meter wheels for thefirst time, orat the start of

each season, before filling with seed, add

<numerator>1⁄<denominator>3 cup Ezee Glide Plus

seed lubricant to bottom of seed box.

2013-06-04 Table of Contents Index 118-999M

Page 26

22 2025A/2525A Table of Contents Index Great Plains Manufacturing, Inc.

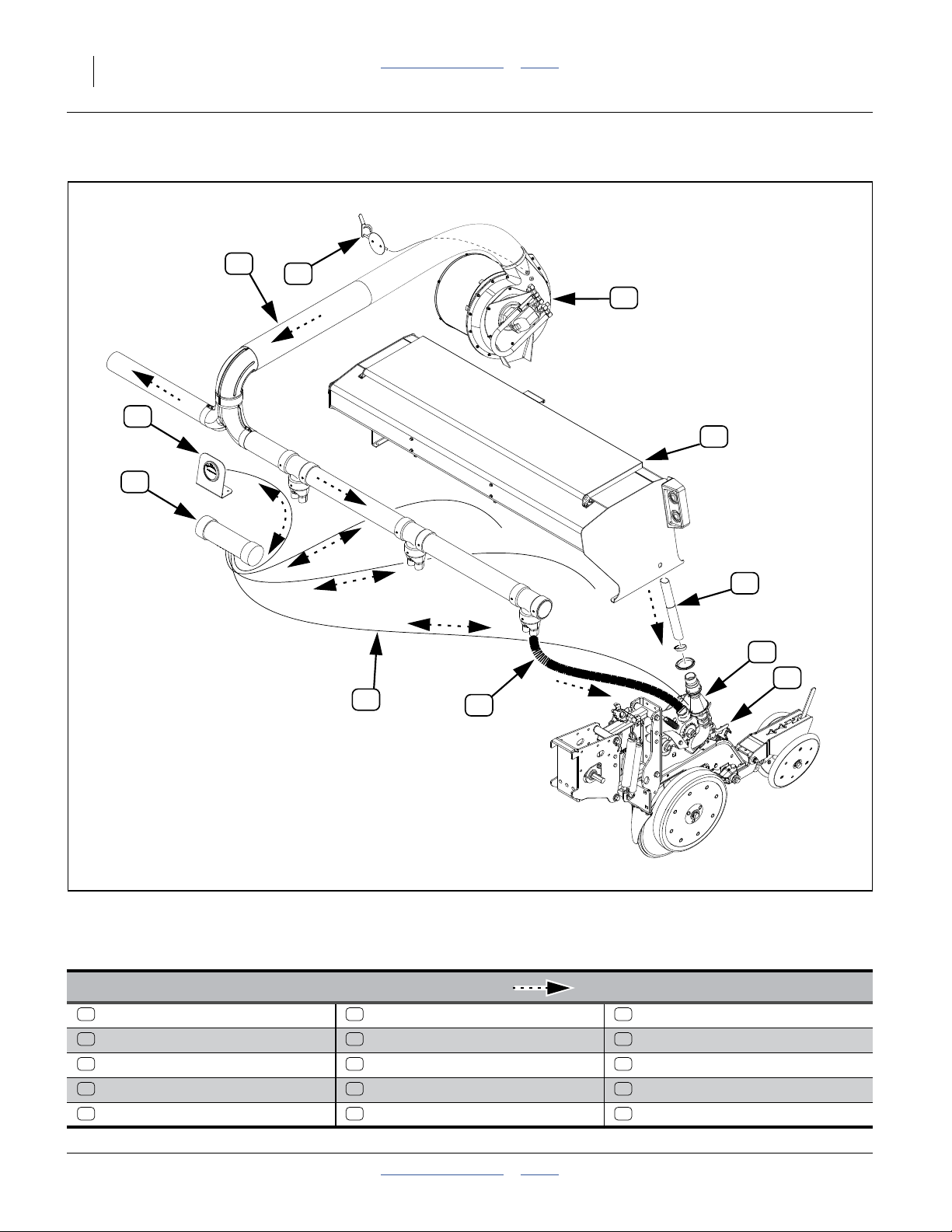

Air System Operation

15

14

3

2

1

5

6

7

8

13

4

Figure 11

Drill Air System for Air-Pro® Seed Metering

29823

29825

Manifold Pressure System Elements ( shows air direction)

1 6 11

Hydraulic Fan Sliding Seed Tubes Seed Tube (Figure 12)

2 7 12

Butterfly Valve Air-Pro® Seed Meter Sensor Port (Figure 12)

3 8 13

Manifold Pressure Air Seed Inlet Shutter Pressure Sensor Lines

4 9 14

Row Pressurizing Tube Seed Pool (Figure 12) Pressure Sensor Chamber

5 10 15

Seed Box Disk Seed Pocket (Cell) Magnehelic® Pressure Gauge

118-999M Table of Contents Index 2013-06-04

Page 27

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 23

Air and Seeding System Overview

Refer to Figure 11, on page 22, and Figure 12.

The hydraulic fan supplies air exclusively for meter

1

operation. Fan rpm is operator-adjusted (page 25), normally via the tractor circuit’s hydraulic flow control.

A manually-adjusted butterfly valve is providedat the

2

fan outlet. See page 25 for valve adjustment.

The manifold system delivers fan air across thedrill.It

3

includes passive internal design features to balance

pressure across the drill.

Separate pressurization tubes route manifold air to

4

each row unit.

Seed is delivered from the seed box by gravity

through the sliding seed tubes , to the inlet of the

Air-Pro® seed meter .

7

A manually adjusted inlet shutter controls the size of

the seed pool at the base of the meter. The shutter

9

5

6

8

also minimizes air loss back up the seed inlet tube, and

is also used during row shut off. See page 46 for shutter

adjustments.

At the meter, pressurization air exits the meter through

the seed pockets of the disk, and holds seed in the

pockets until released above the seed tube .

Several rows have a pressure sensor port for the

meter pressure system. A line from each of these

rows is connected to a chamber to average the pres-

10

11

12

13

14

sures.

The averaged pressure is reported by a Magnehelic®

gauge visible to the tractor operator. See page 35 for

15

use of the gauge in making fan adjustments.

If the optional seed monitor system is installed, a sensor

in each seed tube (not shown) reports seed passage.

Larger seeds are countedindividually.For smaller seeds,

the system acts as a blockage monitor.

10

8

Use ofthe specialblank disk (page 50),and closingthe

seed inlet shutter (page 46), are particularly important

when a sensor row is shut off.

On any row, running a normal diskwith noseed, or with

an open empty inlet, unbalances the air system. Doing

either at a sensor row causes the gauge to mis-report

as well.

7

12

9

Figure 12

Air-Pro® Meter, Disk Side

4

11

29825

2013-06-04 Table of Contents Index 118-999M

Page 28

24 2025A/2525A Table of Contents Index Great Plains Manufacturing, Inc.

Fan Circuit Operation See also “Fan and Adjustment” on page 35.

Refer to Figure 13

Three hydraulic hoses serve the fan, and must be properly connected for the fan to operate in the correct

direction , at recommended speeds, and without dam-

1

age. See “Hydraulic Hose Hookup” on page 14.

1. Always connect the case drain line first.

2

5

This line protectsthe outer shaft seal ofthe hydraulic

motor.The casedrain is a small line to the hitch, provisioned with a specialized low-seep flat-face case

drain Quick Disconnect. Pressure spikes during

motor operation, and pressure cycles due to temper-

1

ature change are bled off by the case drain.

Motor Seal Damage Hazard

Do not apply pressure to thecase drain line. Do not changethe

special QD connector. A restricted or sealed case drain line

will promptly result in motor seal damage.

2. Connect the motor return line second, to sump.

The drill includes a 1<numerator>1⁄<denomina-

tor>16in low back-pressure QD coupler set. Install

the receptacle on a tractor sump port, and not at a

normal remote return port. The unusual size aids in

3

3

4

2

Figure 13

Hydraulics at Fan

29781

ensuring correct connection,so that themotor return

line handles high volume at low back-pressure,

ensuring full motor performance.

3. Connect the motor inlet line to a tractor remote

capable of 4.5 gallons/minute. If a priority remote is

available, use it for the fan.

4. The fan hydraulic circuit includes a check valve ,

which provides a relief path for oil at motor shutoff.

If the fan is connected in reverse, flow through this

4

If the fan is connected in reverse, it may not run at all

(due to no oil source at the return connection). If oil is

present, oil bypass at the check valve prevents the

5

fan from reaching high rpm. A reversed fan may send

5

some airto themeters, but is incapable of providing reliable air flow for planting.

valve results in low fan rpm provides strong indication reversed connection.

Correct fan directionis shown at . If reversed fan is

1

suspected, observeit during shutoff, as the direction

of motion iseasier to see at lower rpms as it slows to

a stop (initial startup is virtually instantaneous, making observation at start difficult).

Fan speed is controlled by the tractor circuit and butterfly

valve (and not the seed monitor).

You may stop the fan by setting the circuit to neutral or

Fan speed can change as oil heats to operating temperature. Re-check meter pressure more oftenduring early

operations.

float. The check valve slows the blades to a stop by

locally recirculating the oil.

118-999M Table of Contents Index 2013-06-04

Page 29

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 25

l

r

f

r

d

d

Fan General Operating Information

Adjust the fan to provide the meter pressure recommended for the seed disk, seed, and seed density. See

the tables and charts for recommended values in the

Seed Rate Manual.

Normal gauge readings are in the 0.8in to 4.0in water

pressure range, and vary considerably with crop.

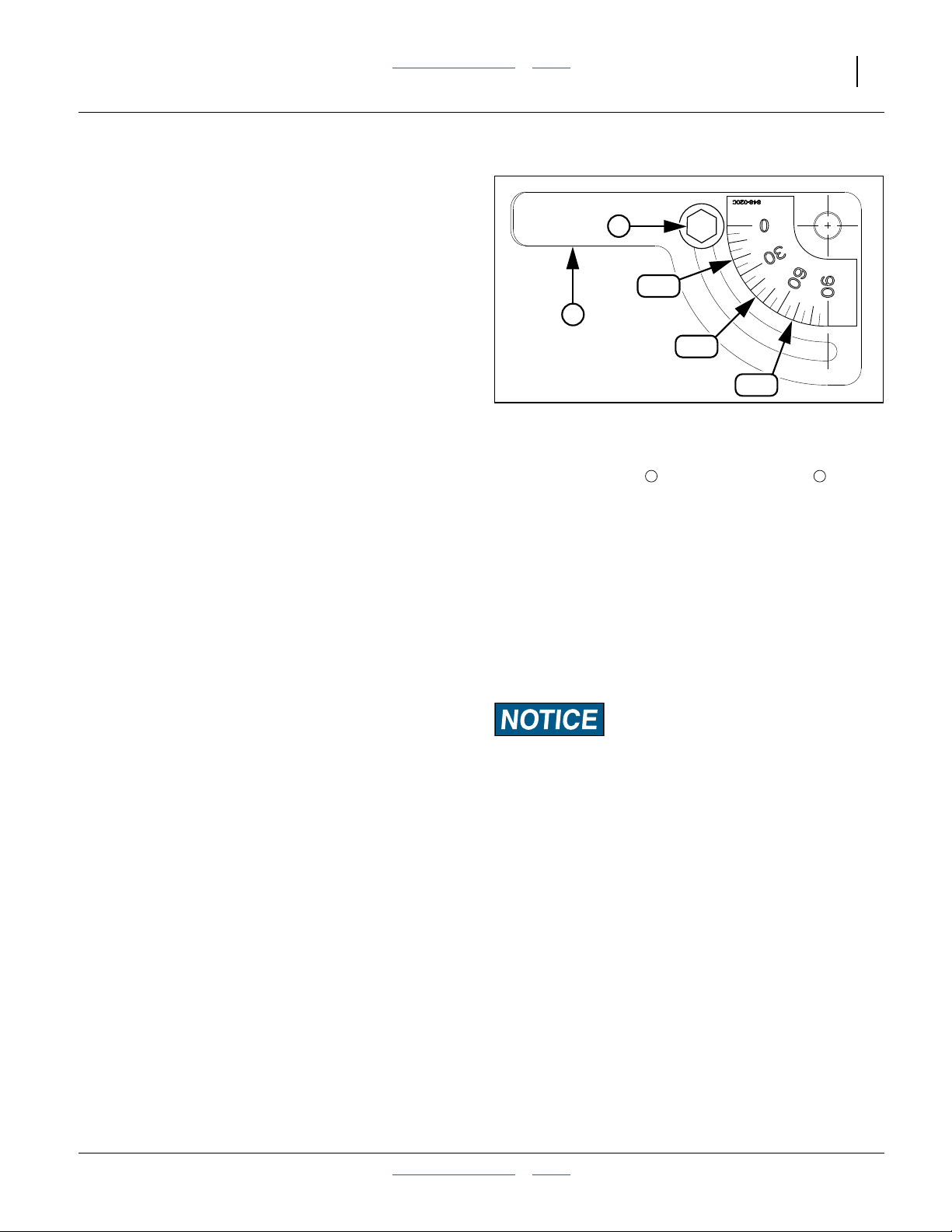

Refer to Figure 14

Use tractor remote hydraulic valve flow control to set fan

speed and butterfly valve adjustment to make fineadjustments tometer pressure. Precise technique depends on

tractor capabilities:

• The objective isobtain recommended meter pressure,

and maintain it during end-of-pass marker fold,lift and

turn.

• For any setup adjustment, operate the tractor engine

at typical field rpms, and not at idle.

• Preset the butterfly valve:

If the tractor has fine control of remote flow rates, and

consistent flow at varying tractor engine rpm, initially

set the butterfly valve to 30° or less.

If the tractorhas onlycoarse controlof flow,initially set

the butterfly valve to 45°.

• Set the fan circuit flow to bring the gauge reading to

near the recommended value.

• Fine tune the meter pressure with the butterfly valve.

• If the tractor has marginal flow available, or the list circuit has priority, you may need to experiment with

combinations of fan flow and butterfly valve settings.

Always start the fan with a low flow setting.

Gradually bring fan up to the recommended initial meter

pressure.

At excessive rpm, too much air flow can cause:

• oil heating

• slow lift times

If desired pressure cannot be reached, or require unusually high oil flow at low butterfly valve settings, chances

are the fan is running backwards. Reverse the

inlet/return lines at the hitch.

Butterfly Valve Operation:

To adjust, loosen bolt and rotate the handle .

Re-tighten bolt.

0° is wide open - maximum air flow.

90° is closed - minimum air flow.

The valve provides the most effect at settings between

20° and 70°.

Starting at 30° reduces the fan workload.

Starting at45° provides themost adjustment rangeup or

down.

Low Population Risk at Turns:

The fan requires up to 4.5 gpm. This figure does not include oi

for lift/lower or oil for marker operation. Aggressive lift/lowe

operations, and simultaneous lift/marker operations, can

reduce fan rpm below that needed to pressurize meter disks. I

seed falls out of pockets, low population bands will occu

shortly after turns.

Unless the tractor has generous oil flow capacity, raise/fol

markers before lift, and lift slowly. Watch meter pressure an

tune operations to keep it at planting levels in turns.

1

20°

2

45°

Figure 14

Fan Butterfly Valve Handle

1 2

70°

25137

2013-06-04 Table of Contents Index 118-999M

Page 30

26 2025A/2525A Table of Contents Index Great Plains Manufacturing, Inc.

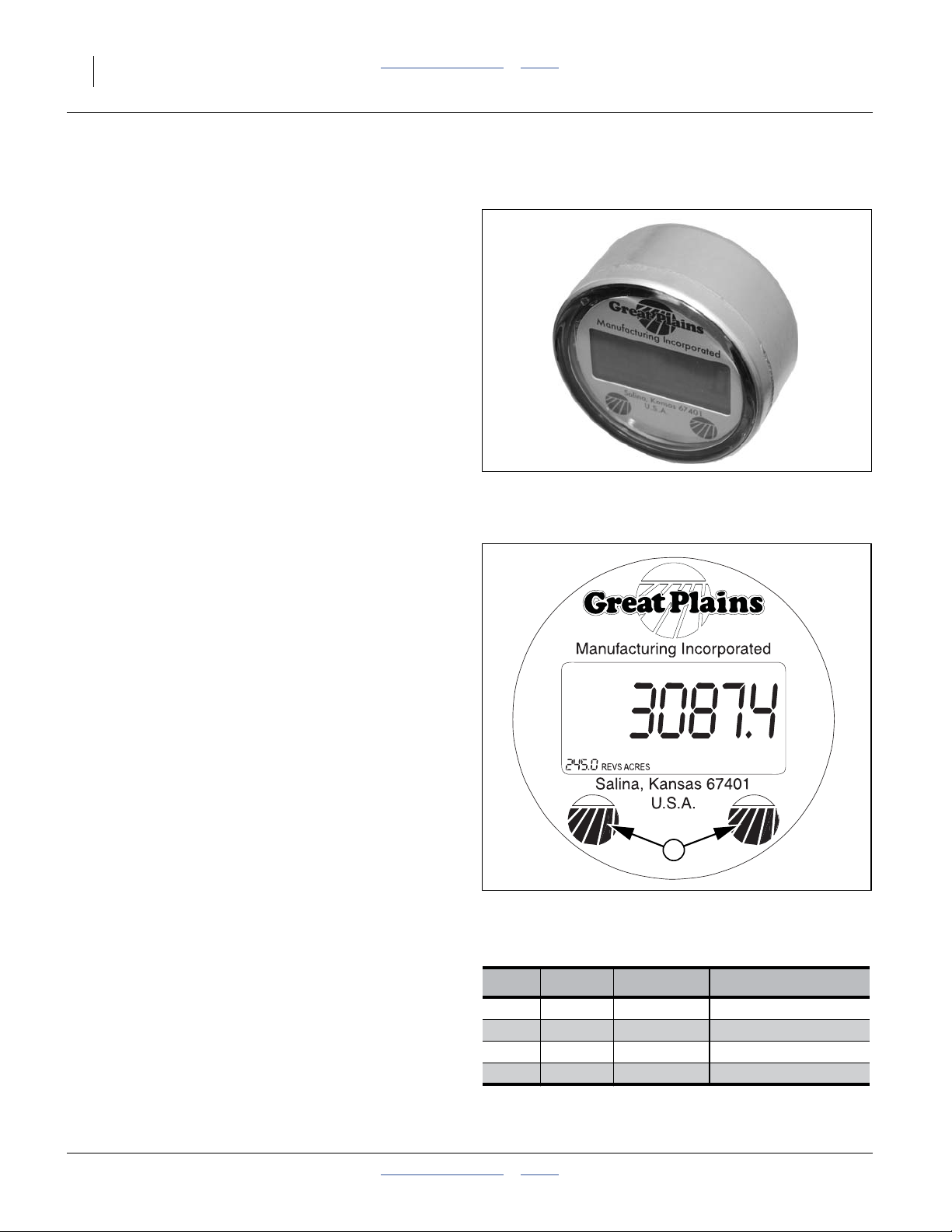

Acremeter Operation

Refer to Figure 15

The acremeter counts shaft rotations whenever the shaft

is rotating - this is with the drill lowered and in motion or

during crank operation. The meter is programmed to display rotations as acres or hectares, when using all rows,

factory-specified tires and tire inflations.

Note: Unusual conditions and/or non-standard row

spacings can cause the acremeter tally to vary

from actual acres planted.

Normal Operating Sequence

1. Record the acremeter reading atthe start of planting

(and after calibration). The large “12345.6” format

display is the grand total area planted since meter

installation. If the display is blank, see “Dormant Display” below.

2. Lower drill and plant. Acremeter counts shaft rotations, calculates acres or hectares, and adds to the

running grand total.

3. During planting (drill lowered and moving forward),

the display blanks (goes dormant), but areatally continues.

4. When raised for turns, obstructions and transport,

the drive wheel stops, and the meter counts no additional (non-planting) rotations.

5. Whenever shaft rotation stops, the LCD display activates after 30 to 60 seconds,and remains visible for

30 to 45 minutes.

6. At the completion ofplanting, record the finalreading

or the grand total. Ifthe display goes dormant before

you can read it, see “Dormant Display”.

7. Subtract the reading at Step 1 from the reading at

Step 6 for the total planted in the present session.

Figure 15

Electronic Acremeter

27378

Dormant Display

Refer to Figure 16

To conserve power, the LCDdisplay blanks itself most of

the time. If you need to read the display after it has

“timed out” and gone dormant:

• use the left gauge wheel to turn the meter shaft once,

or

• gently tap or wave a magnet at either of the Great

Plains logo spotson thelower region of thedisplay. Be

careful not to scratch the window.

When active the lowerleft corner displays the revolutions

per area for which the meter is factory-programmed.

118-999M Table of Contents Index 2013-06-04

Acremeter Programming

Drill Units

2025A Acres 891-087C 316.2 REVS/ACRE

2025A Hectare 891-088C 781.3 REVS/HA

2525A Acres 891-101C 245.0 REVS/ACRE

2525A Hectare 891-102C 605.4 REVS/HA

891-101C Meter Display

1

Figure 16

Part No. Program

29827

Page 31

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 27

Ladder Operation

WARNING

Falling Hazard:

Lower drill before using ladders andwalkboards. Facetoward

ladder when ascending or descending. Use hand holds provided. Watch your step. A fall from the walkboard could result

in serious injury or death.

Refer to Figure 17

The ladders at each end of the walkboard have three

positions:

1. Locked up for storage:

To put the ladder in this position, swing to the fully

inverted vertical position,and letthe boltsslide tothe

bottom of the slot. Use this position to discourage

climbers when the drill is parked or in storage. This

position is not ideal when the drill is in motion.

2. Folded for transport and field operation:

Use this position when the drill is in motion, as it minimizes stress and wear on the slotted ladder mounts.

3. Down for materials and maintenance:

Use this position for loading seed, unloading seed,

and drill maintenance. Do not use this position during transport, as it reduces lateral clearance. Do not

store the drill with ladders down.

2

3-Point Walkboard Ladder

To avoid serious injury or death:

Watch your step when climbing ladder or

walking on walkboard.

1

Figure 17

838-102C

3

28828

Monitor Operation (Option)

Monitor operation is described in a separatemanual supplied with the DICKEY-john® Seed Manager SE system.

Operations covered in that manual (and therefore not in

this manual) include:

• population monitoring

• setting rate limits and detecting out-of-limits

• GPS integration

Figure 18

Seed Monitor Console

28341

2013-06-04 Table of Contents Index 118-999M

Page 32

28 2025A/2525A Table of Contents Index Great Plains Manufacturing, Inc.

Marker Operation (Option)

Optional marker attachments are available from your

Great Plains dealer.

The operating procedure is different, depending on

whether dual-circuit independent markers or single-circuit sequenced markers are installed.

When fully extended or foldedduring operationsor transport, leave circuit control in Neutral. Set circuit to Float

only for unhitching.

Before operating markers, make sure hydraulics are

properly bled as described under “Bleeding Marker

Hydraulics” on page 76,and markers are operating at a

safe speed, per “Marker Speed Adjustment” on

page 98.

This section presumes correct marker length for your

pass spacing. If this has not been set, or needs to be

changed, see “Marker Extension” on page 100.

This section presumes correctmarker chainslack. Ifyour

chain has been replaced, repaired or stretched, adjust

the links to the correct slack length. see “Marker Chain

Adjustment” on page 99.

Independent Marker Operation

Each marker is on a dedicated tractor hydraulic circuit.

Either or both may be extended or retracted independently by operating the circuit for that marker.

Single-Circuit Sequenced Marker Operation

Dual markers equipped with a sequence valve are powered by the same hydraulic circuit. Starting with both

markers folded, the folding sequence is:

Activate lever - Right unfolds; left stays folded.

Reverse lever - Right folds; left stays folded.

Activate lever - Left unfolds; right stays folded.

Reverse lever - Left folds up; right stays folded.

Sequence repeats.

Both Sides Unfolded (with Sequence Valve)

With both markers in their cradles:

Unfold either side, and when completely deployedMove lever/switch to Retract momentarily, and return to

Extend to deploy other side.

Electrocution Hazard:

Beware of overhead electrical lines. If the markers contact

lines, the tractor, raised drill and any cart can become “hot”

with no indication. A person standing on the ground and

touching equipment can complete the circuit. Serious injuryor

death is likely. At higher voltages electrocution can occur

without direct contact.

Overhead Crushing and Sharp Object Hazard:

Do not allow anyone to stand near or beyond the end of the

wings during marker operations. Marker arms are heavy and

marker discs may be sharp. Serious injury or death is possible.

Equipment Damage / Low Population Risks:

Folding markers at high speed can damage markers, and

starve seed meters of pressurization air. Refer to “Marker

Speed Adjustment” on page 98, and adjust folding speed to a

safe rate.

Note: If one or both markers are extended, they may

drag or shove if left extended during drill raise or

lower operations. To avoid this, fold markers prior

to raise or lower.

118-999M Table of Contents Index 2013-06-04

Page 33

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 29

Field Set-Up Checklists

Use the following tables to develop a final checklist for

your tractor/drill configuration. Additional or fewer steps

may be necessary depending on tractor features, drill

options and planting accessories.

Mechanical Checklist Page

Tool bar height set with 3-point 16

Drill level front to back 16

Ground drive sprockets set for seed disk,

rate, and set alike on each section.

Check chain tension. Re-connect any

loose idler tensioning springs.

33

-

Rotate gauge wheels (top forward), checking that drive system, and meters are

working smoothly.

Record acremeter reading.

Marker extension set 100

Marker disc angle set 34

Electrical Checklist Page

Verify electrical hookups solid 15

Option: Check seed monitor terminal and

observe any diagnostic messages

a

Option: Verify, with drill lowered, that radar

speed sensor is pointed at ground, at an

b

angle approximately 35° below horizontal.

a. Refer to monitor manual.

b. Refer to sensor documentation.

Hydraulic System Checklist Page

Check tractor hydraulic reservoir full Inspect connections for leaks Perform a raise and lower operation Check fan speed and airflow direction a

Check marker circuit 28

a. Operate fan briefly and observe rotor blades spinning toward

exit port. Check rpm on seed monitor.

Air System Checklist Page

Add <numerator>1⁄<denominator>3 cup of

seed lubricant to each air box, prior to first

80

use, and prior to loading seed

Load seed 21

No air leaks (except at meter pockets) -

Row Units Checklist Page

Preset depth handles alike. 43

Preset down force springs alike, except in

tracks.

Set all unit-mounted coulters to1⁄4in shal-

lower than opener blades.

38

41

Check coulter alignment to row 42

Check closing wheel alignment 54

Set press wheels alike. 54

Check action and contact of side depth

wheels

44

Check wheel scraper gaps (if installed) 45

Meters Checklist Page

Correct disks for seed a

Seed inlet shutters set. a

Corn?

Check timing of meters for twin-row

Start fan and bring manifold up to operat-

ing pressure.

Rotate gauge wheels to fill seed disks.

Continue rotation and check for seed flow

below each opener.

a. Refer to Seed Rate Manual.

a

-

2013-06-04 Table of Contents Index 118-999M

Page 34

30 2025A/2525A Table of Contents Index Great Plains Manufacturing, Inc.

Planting

Perform all steps in “Pre-Start Checklist” on page 19

and “Field Set-Up Checklists” on page 29.

First Pass Operation Checklist Page

1. Set tractor 3-point hitch to “depth con-

trol” operation (and not load control)

2. Unfold marker on next-row side. 28

3. Set fan hydraulic circuit to low flow,

engage circuit. Gradually adjust fan

hydraulic flow to obtain recommended

initial meter pressure.

4. Pull forward, lower drill, and begin

planting for a short distance.

5. Stop. Assess:

• planting depth

• seed spacing

• press wheel operation

• fertilizer application (if in use)

6. Make necessary adjustments 32

Sharp Field Turns Checklist Page

-

25

Checking Planting Rate

Although the optional seed monitor can report useful full

pass results, cautious practice includes manually checking the seed rate early in the first pass.

The Seed Rate Chart book for this drill (manual part

number 118-999B) contains sampling instructions.

1. Fold marker 28

2. Raise drill -

3. Make turn -

4. Lower drill -

5. Unfold marker on next-row side. 28

6. Resume planting.

Suspending Planting Checklist Page

1. Stop tractor -

2. Fanhydraulic circuit toFloat or Neutral 24

3. Fold Marker 24

4. Raise drill -

Ending Planting Checklist Page

1. Suspend operations as above, then

2. Unload seed 66

3. Lights ON -

4. Transport 20

118-999M Table of Contents Index 2013-06-04

Page 35

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 31

Short-Term Parking

1. Fold markers. See “Marker Operation (Option)” on

page 28.

2. Choose a location with level firm ground. Do not

unhitch on a slope.

3. Raise the drill.

4. Lower parking stand (page 31).

5. Disconnect hydraulic lines. Secure them so that they

do not touch the ground.

6. Disconnect electrical cables, capping where provisioned.

Long-Term Storage

Complete Parking steps first.

1. Park the drillindoors ifpossible, per the stepsabove.

Great Plains recommends parking/storing in the

raised configuration and on any provided parking

stands.

2. Unload seed from boxes (page 66). Store drill only

without seed.

3. Unload seed from meters (page 66).

4. Remove seed disks from meters (this is primarily to

relieve pressure on brushes). Clean disks of residue

build-up (see Caution at right). Use mild soap,

non-abrasive scrubbers, and hot or warm water. If

using sealed storage, dry disks prior to storage.

Possible Chemical Hazard:

Seed disks will have talc and graphite residue, and may have

residues of hazardous seed treatments. Do not wash disks

where food is prepared, or where cookware or dinnerware is

washed. Wear gloves when washing disks. Avoid spray.

Although the disks are dishwasher-safe, do not wash them in

an appliance also used for food cookware or dinnerware.

5. Close seed inlet shutters at meters (to prevent pest

entry to seed hoses). Thoroughly clean seed and

seed treatment residue from seed meters. See

“Meter Clean-Out” on page 66, for more information.

6. Lubricate all points listed in Maintenance to prevent

rust.

7. Clean drill of mud, dirt, excess oil and grease.

8. Inspect for worn or damaged parts. Make repairs

and service during off season.

9. Use spray paint to cover scratches, chips, and worn

areas on the drill to protect the metal.

10. Cover drill with a tarp if stored outside.

2013-06-04 Table of Contents Index 118-999M

Page 36

32 2025A/2525A Table of Contents Index Great Plains Manufacturing, Inc.

Adjustments

To get full performance from your 3-Point drill, you need

an understanding of allcomponent operations, andmany

provide adjustments for optimal field results. Some of

these have been covered earlier in this manual.

Even if your planting conditions rarely change, some of

these items need periodic adjustment due to normal

wear.

Adjustment Page The Adjustment Affects

Frame height 21 Planting depth consistency

Frame level 16 Planting consistency

Manifold Pressure (values from SRMa) 35 Consistent seed flow and disk singulation

Planting Rate SRMaRefer to Seed Rate Manual

Marker Adjustments

Marker Extension 100 Intended swath spacing

Marker Chain Length Adjustment 54 Marker folding operation

Dual Marker Speed Adjustment 98 Reliable marker operation

25AP Row Unit Adjustments

Opener Depth 43 Planting depth

Row Unit Down Pressure 38 Planting depth uniformity

Row Unit Lock-Up 51 Single/twin-row operation

Row Cleaner Adjustments (Option) 40 Row preparation

Coulter Adjustments (Option) 41 Seed depth uniformity

Opener Disk Adjustments 43 Seed depth, seed-to-soil contact

Side Depth Wheels 43 Seed depth, prevents plugging

Adjusting Gauge Wheel Scrapers 45 Consistent seed furrow depth

Seed Meter Setup and Adjustment 46 Consistent seed population

Seed Inlet Shutter 46 Seed flow to meter; seed pool slope

Seed Pool Slopes 47 Minimal skips and doubles

Seed Disk Installation 48 Correct seeding of your crop and population

Row Shut-Off 49 Alternate row spacings

Seed Firmer Adjustments (Option) 52 Seed-soil contact

Press Wheel Adjustment 54 Effective soil coverage

Speed Sensor Gap (Option) 97

a. SRM: Seed Rate Manual (118-999B)

118-999M Table of Contents Index 2013-06-04

Page 37

Great Plains Manufacturing, Inc. Table of Contents Index Adjustments 33

Setting Planting Rate

Full detailson ratesetting sprocket selection and installation are found inthe Seed RateManual (pub. number

118-999B). This is a summary. Adjusting the seeding

rate requires the following: