Page 1

Operator’ s Manual

2015P and 2515P

3-Point Precision Bean Machine

Manufacturing, Inc.

www.greatplainsmfg.com

Read the operator’s manual entirely.Whenyouseethissymbol, the subsequent

instructions and warnings are serious - follow without exception. Your life and

!

the lives of others depend on it!

g18394

Cover illustration may show optional equipment not supplied with standard unit.

© Copyright 2000 Printed 4/11/2005

173-208M

Page 2

Table of Contents

Important Safety Information . . . . . . . . . . . . . . . . . . . . . .1

Safety Decals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Description of Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Intended Usage . . . . . . . . . . . . . . . . . . . . . . . . . 12

Models Covered . . . . . . . . . . . . . . . . . . . . . . . . . 12

Using This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Preparation and Setup . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Prestart Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Hitching Tractor to Bean Machine . . . . . . . . . . . . . . . 15

Hydraulic Hose Hookup. . . . . . . . . . . . . . . . . . . . . . . 17

Lift Assist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Bleeding Lift Assist Hydraulics. . . . . . . . . . . . . . . . . . 18

Leveling Bean Machine . . . . . . . . . . . . . . . . . . . . . . . 18

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Prestart Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Field Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Meter and Sliding Seed Tube . . . . . . . . . . . . . . . 22

Talc Lubricant . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Graphite Lubricant . . . . . . . . . . . . . . . . . . . . . . . .22

Row Unit Operation . . . . . . . . . . . . . . . . . . . . . . 23

Marker Operation . . . . . . . . . . . . . . . . . . . . . . . . 23

Transporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Transporting with Markers . . . . . . . . . . . . . . . . . .24

Transporting with Lift Assist . . . . . . . . . . . . . . . . 24

Parking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Row Unit Adjustments . . . . . . . . . . . . . . . . . . . . . . . . 26

Down Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . 26

Coulter Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Row Unit Seeding Depth . . . . . . . . . . . . . . . . . . 27

Side Gauge Wheels . . . . . . . . . . . . . . . . . . . . . . 28

1 x 12 Closing Wheel Option . . . . . . . . . . . . . . . 29

Closing Disk Option . . . . . . . . . . . . . . . . . . . . . . 30

Frame Height. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Seeding Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Drive Speed Range Sprockets . . . . . . . . . . . . . . 31

Transmission Sprockets . . . . . . . . . . . . . . . . . . . 31

Shutting Off Seed Flow. . . . . . . . . . . . . . . . . . . . 32

Cleaning Out Meters. . . . . . . . . . . . . . . . . . . . . . 33

Changing Seed Meter Wheels . . . . . . . . . . . . . . 34

Checking Singulated Seeding Rate . . . . . . . . . . 37

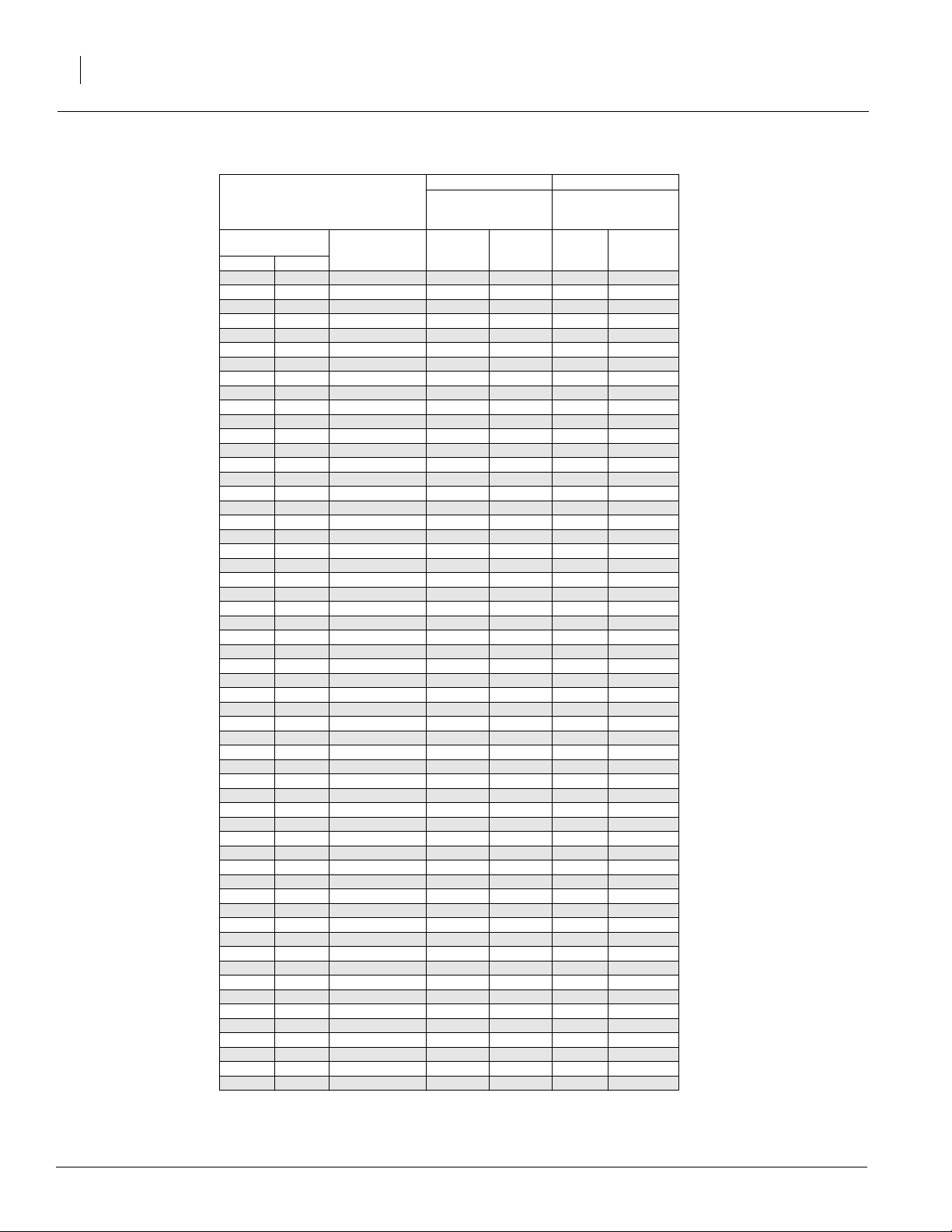

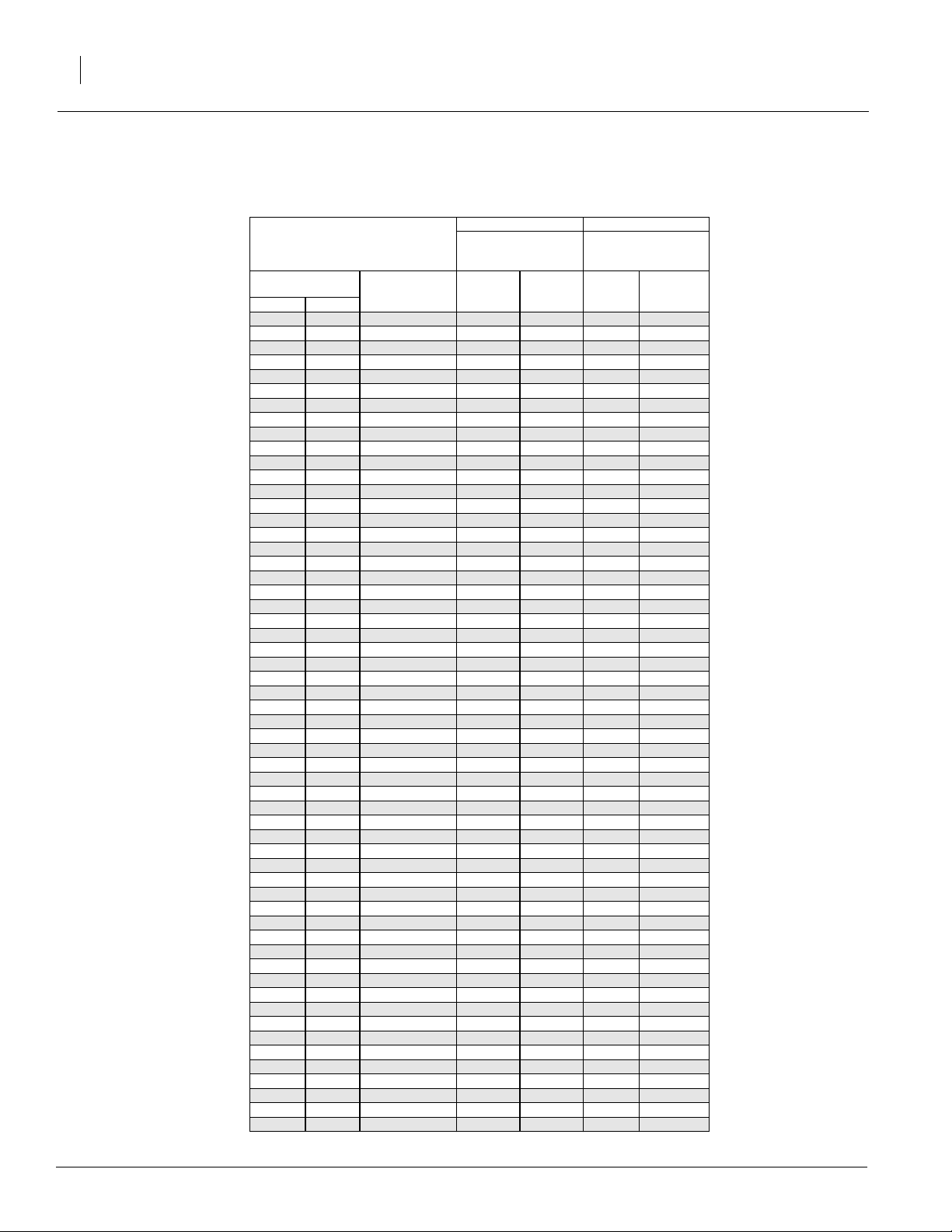

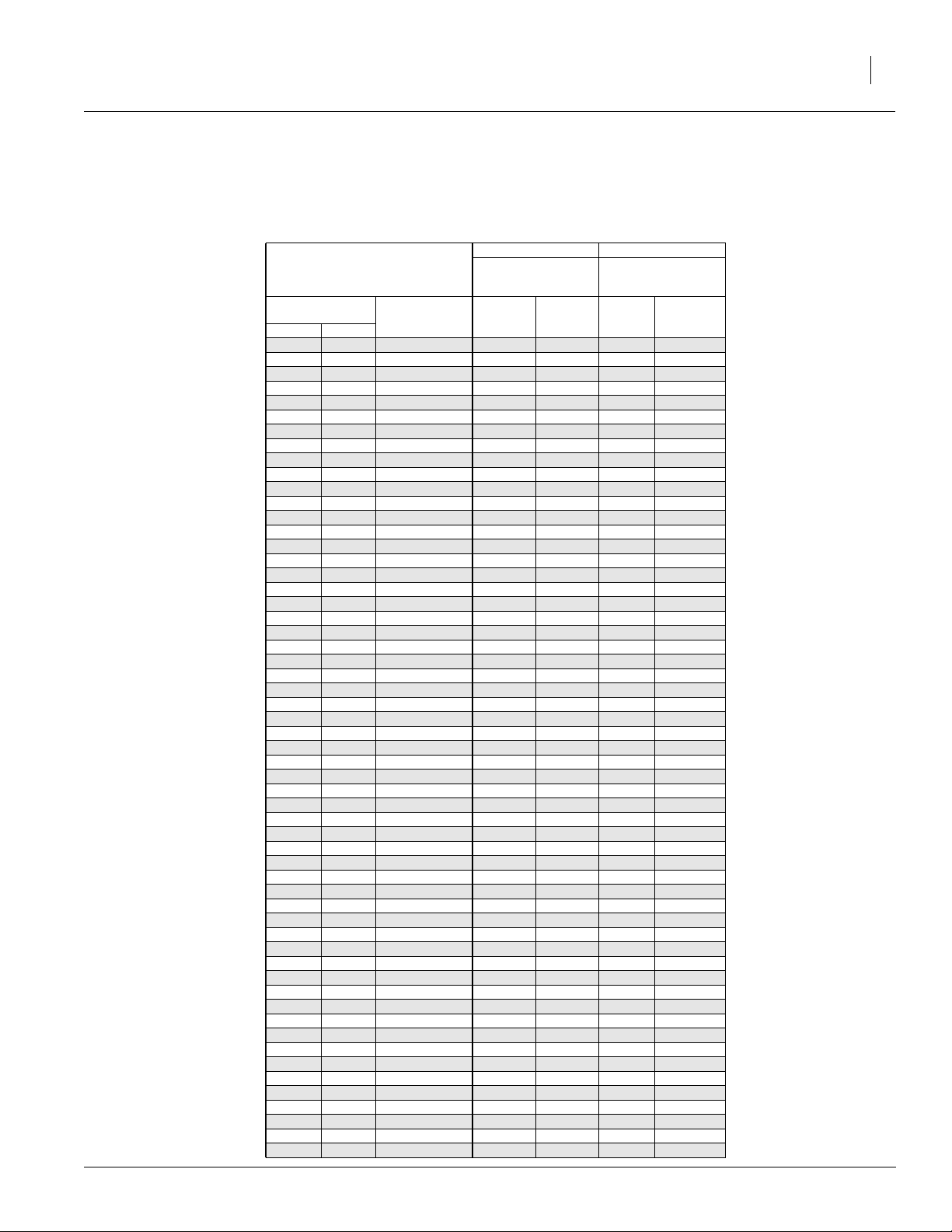

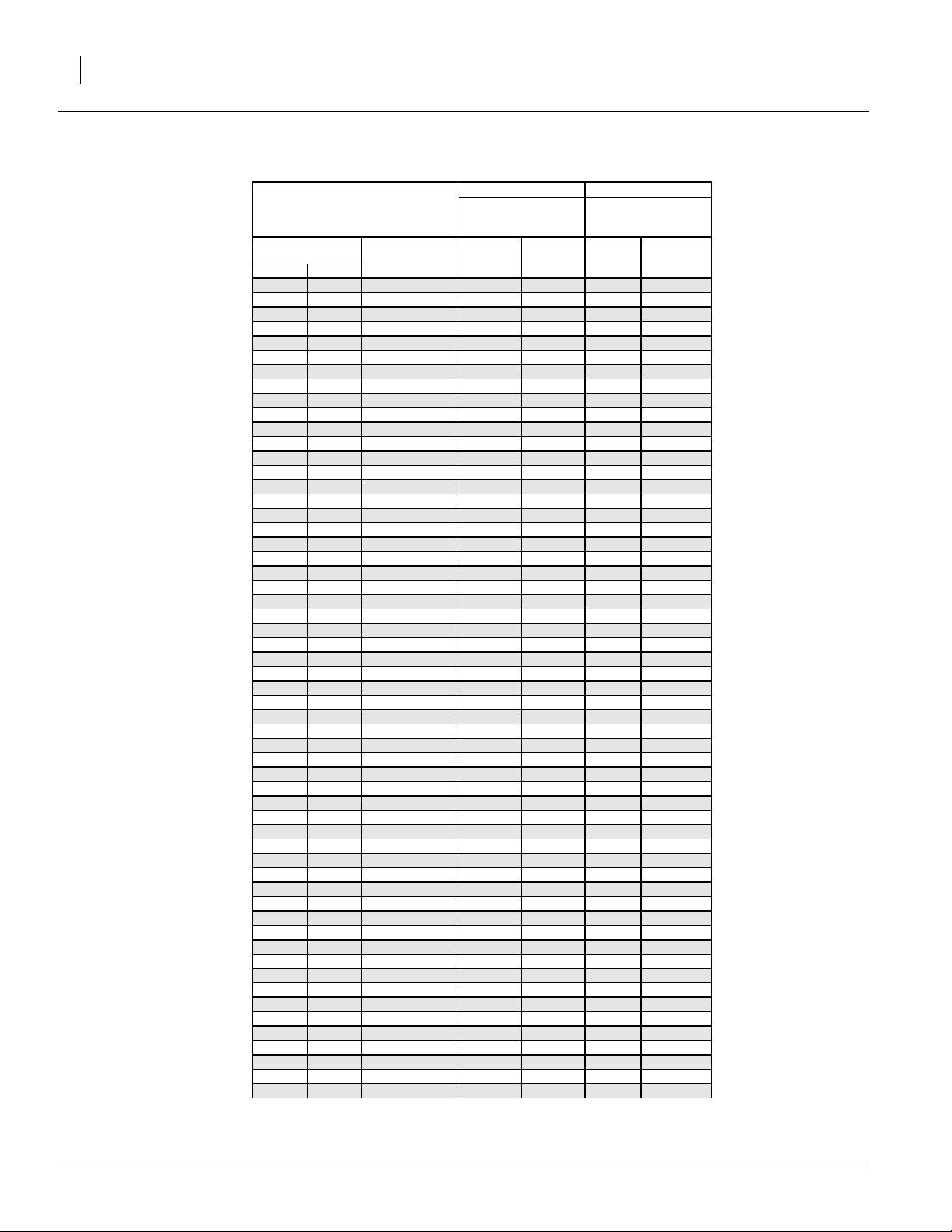

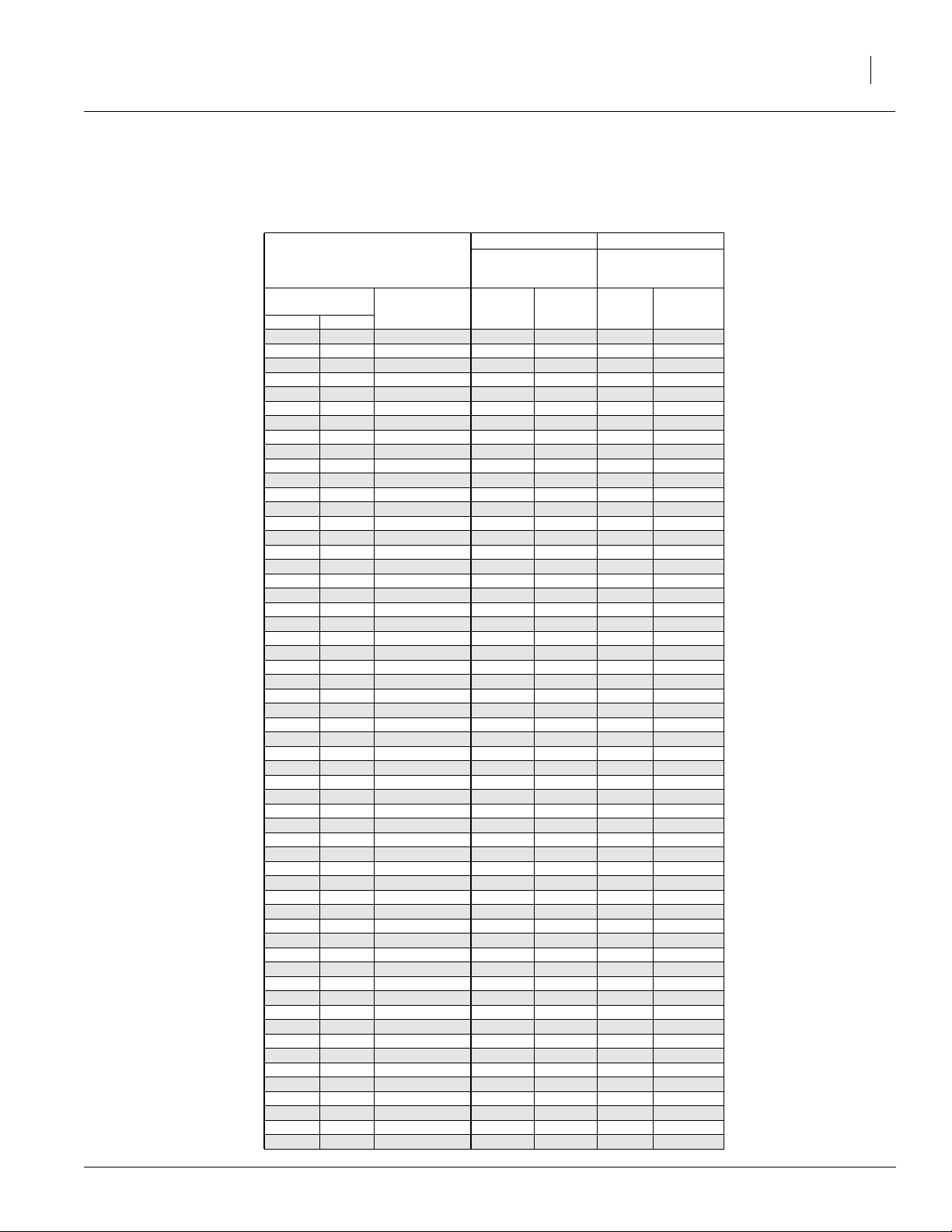

Seed rate charts . . . . . . . . . . . . . . . . . . . . . . . . . 37

Marker Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . 38

Bleeding Marker Hydraulics . . . . . . . . . . . . . . . . 38

Folding Speed with Needle Valves . . . . . . . . . . . 39

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Specifications and Capacities. . . . . . . . . . . . . . . . . . . . 65

Seed Rate Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Folding Speed with Sequence Valve . . . . . . . . . 39

Marker Disk Adjustment . . . . . . . . . . . . . . . . . . . 39

Changing disk angle. . . . . . . . . . . . . . . . . . . . . . 39

Leveling marker disk. . . . . . . . . . . . . . . . . . . . . . 40

Transport Carrier . . . . . . . . . . . . . . . . . . . . . . . . 40

Marker Chain (2515P only). . . . . . . . . . . . . . . . . 41

Marker Width . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Seed-Lok Lock Up. . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Maintenance and Lubrication . . . . . . . . . . . . . . . . . . 50

Meter Maintenance. . . . . . . . . . . . . . . . . . . . . . . 51

Meter Slide Maintenance . . . . . . . . . . . . . . . . . . 51

Chain Tension. . . . . . . . . . . . . . . . . . . . . . . . . . . 53

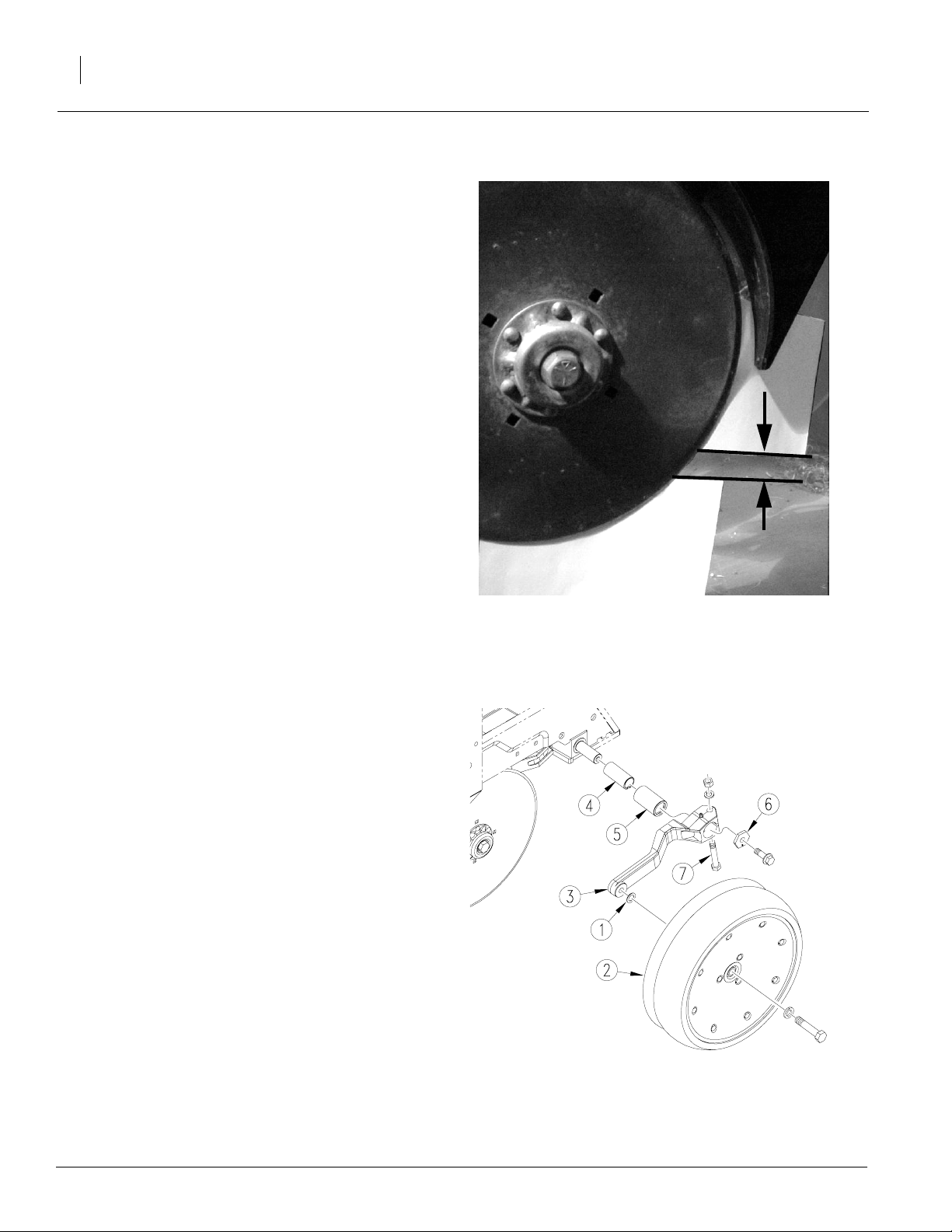

Inner Sliding Seed Tube Replacement. . . . . . . . 54

Outer Sliding Seed Tube Replacement . . . . . . . 54

Grommet Maintenance. . . . . . . . . . . . . . . . . . . . 55

Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Row Unit Disk Spreaders and Scrapers. . . . . . . 55

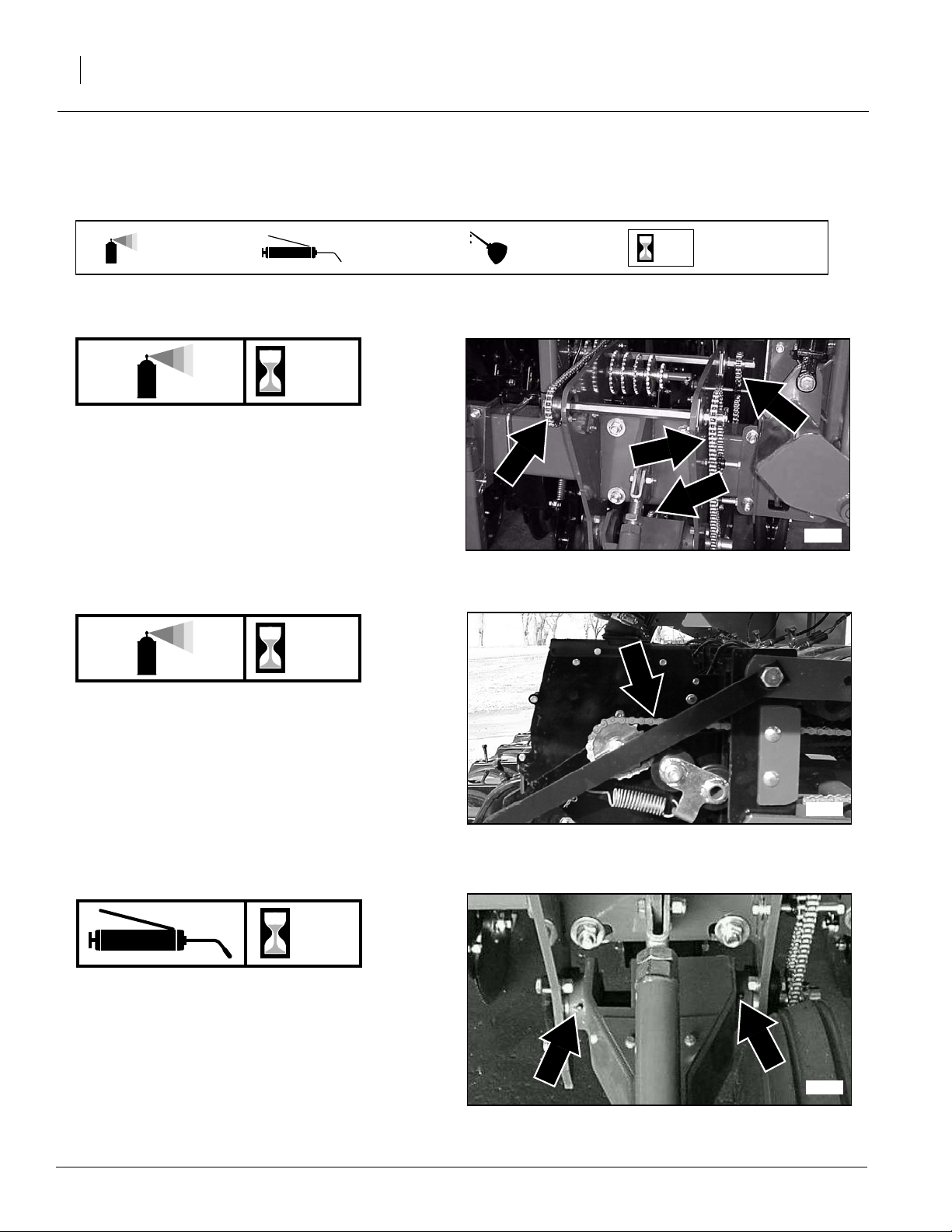

Row Unit Disks. . . . . . . . . . . . . . . . . . . . . . . . . . 56

Row Unit Side Wheels . . . . . . . . . . . . . . . . . . . . 56

Marker Maintenance. . . . . . . . . . . . . . . . . . . . . . 57

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Drive Chains. . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Drive Chains. . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

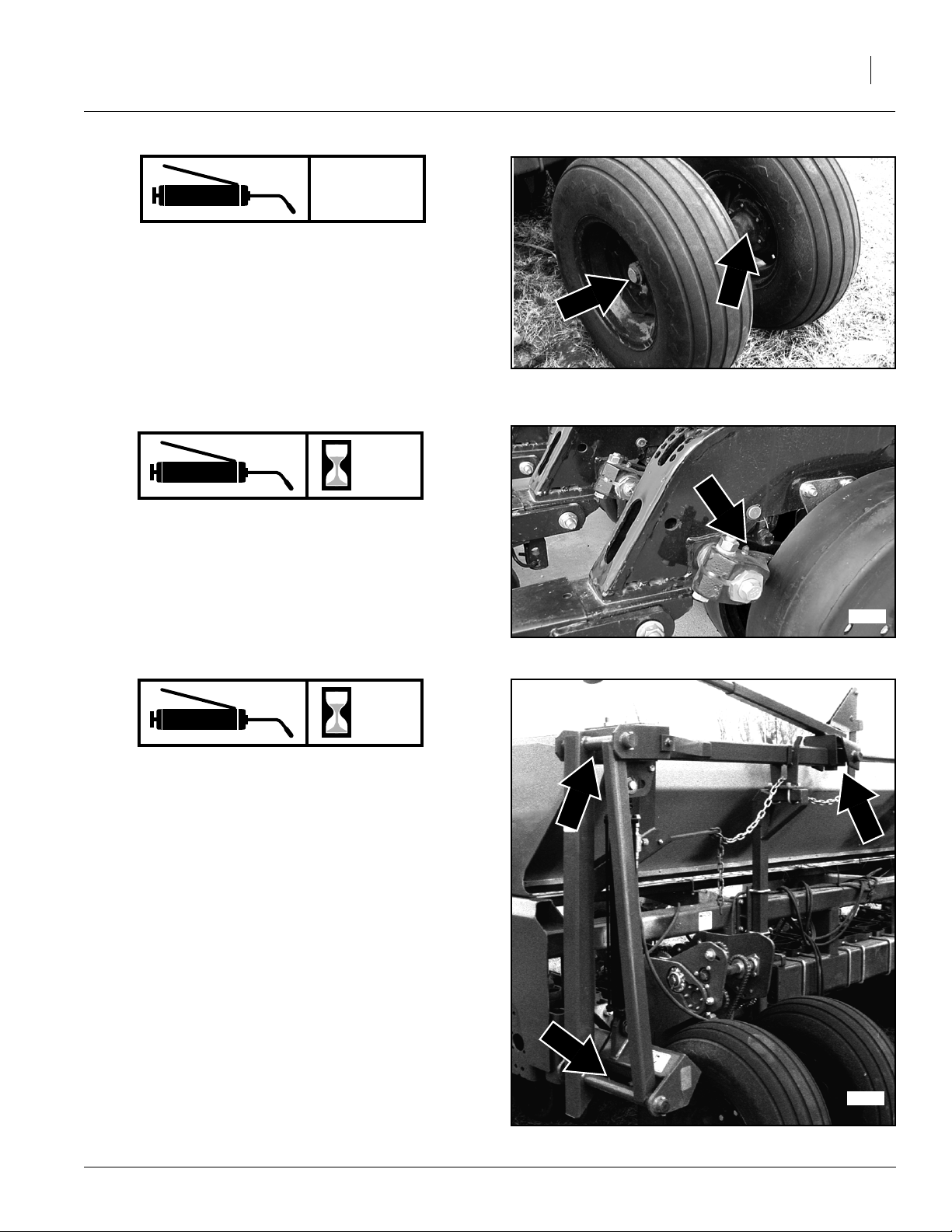

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Gauge Wheel Arm Pivots. . . . . . . . . . . . . . . . . . 58

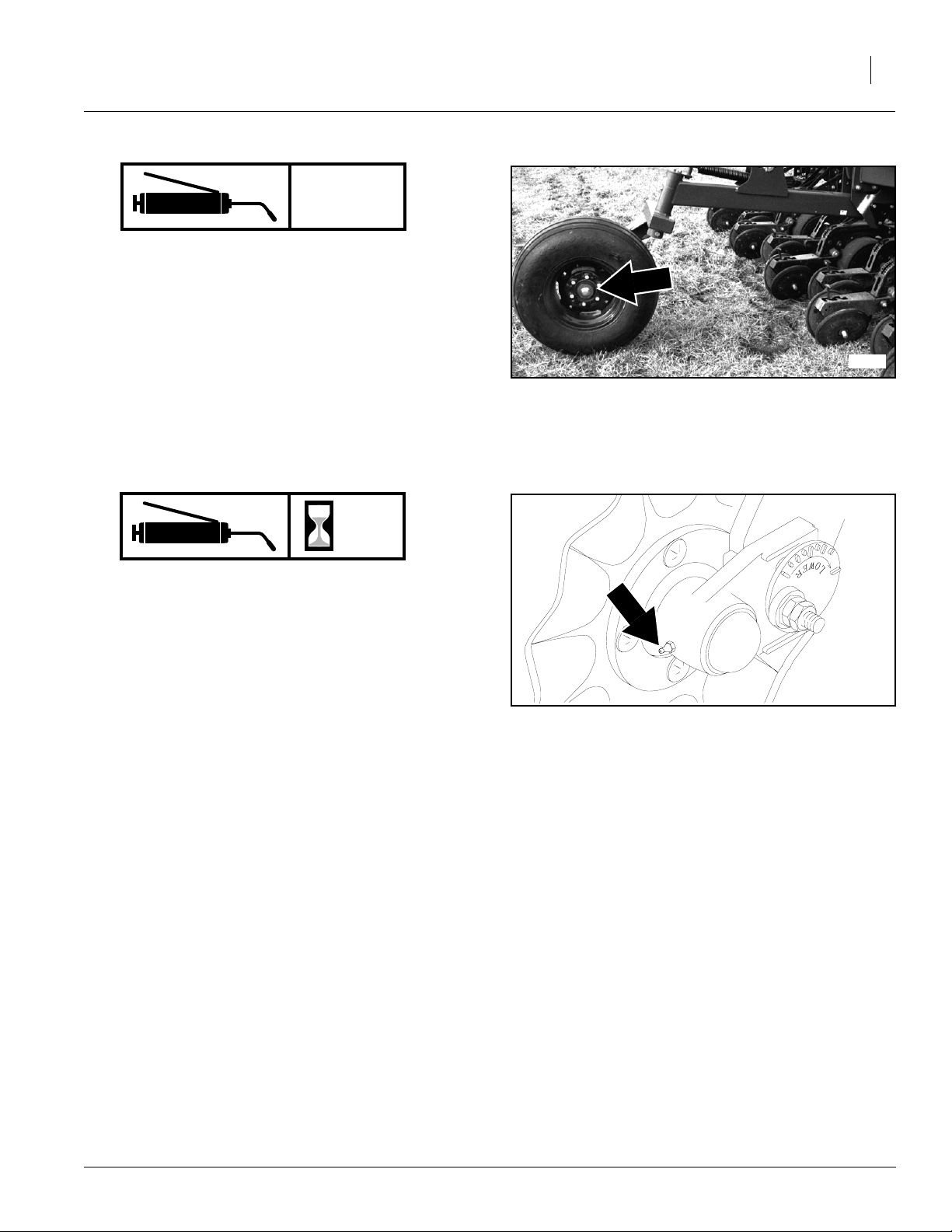

Wheel Bearings . . . . . . . . . . . . . . . . . . . . . . . . . 59

Marker Hinge Points. . . . . . . . . . . . . . . . . . . . . . 59

Side Wheel Arm, Row Unit. . . . . . . . . . . . . . . . . 59

Lift Assist Arm Pivots . . . . . . . . . . . . . . . . . . . . . 60

Lift Assist Castors. . . . . . . . . . . . . . . . . . . . . . . . 60

Marker Disk Bearings. . . . . . . . . . . . . . . . . . . . . 60

Lift Assist Wheel Bearings . . . . . . . . . . . . . . . . . 61

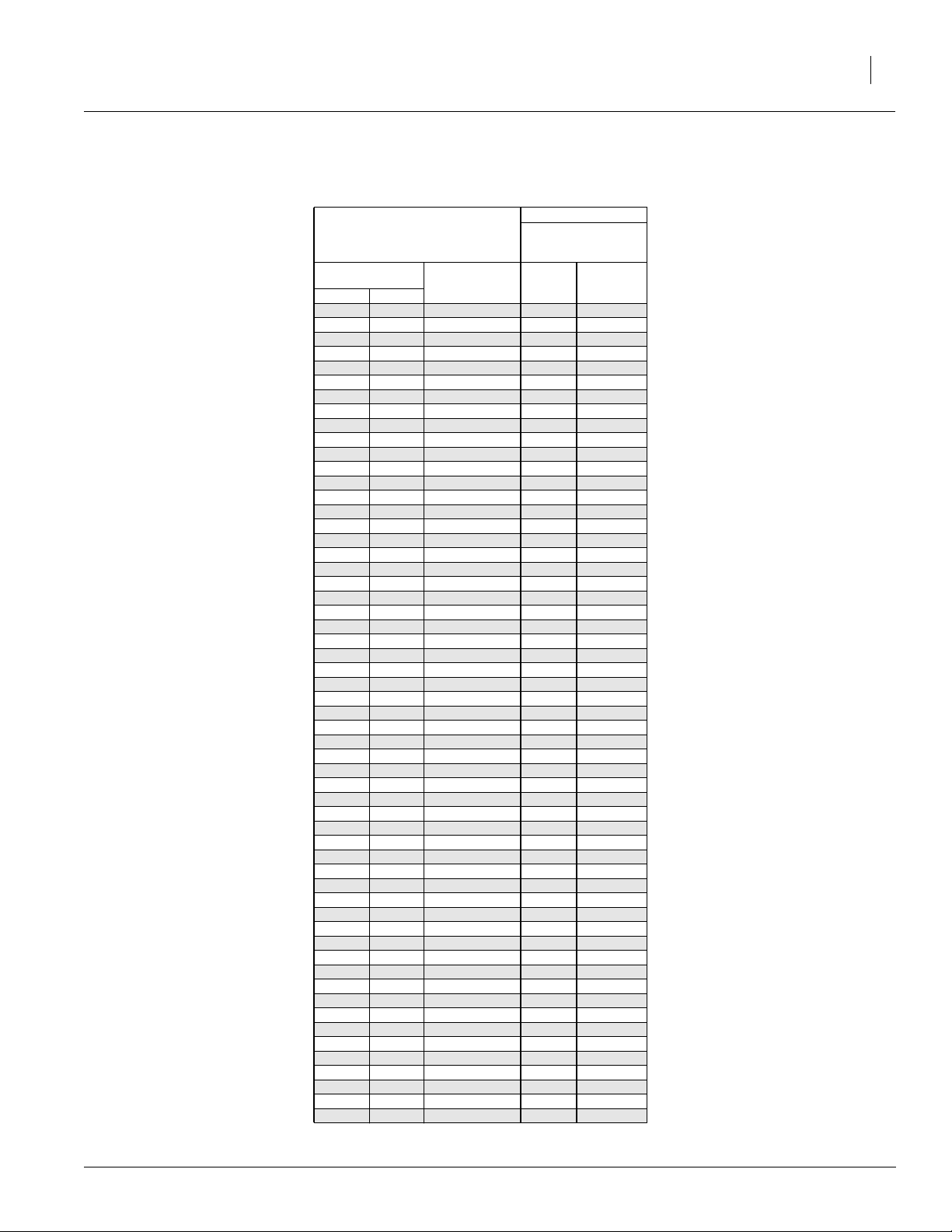

Unit-Mounted Coulter . . . . . . . . . . . . . . . . . . . . . 61

Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Lift Assist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Spring Packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Coulter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Seed-Lok® Firming Wheels . . . . . . . . . . . . . . . . . . . 64

DICKEY-john® Monitor . . . . . . . . . . . . . . . . . . . . . . . 64

Torque Values Chart . . . . . . . . . . . . . . . . . . . . . . . . . 80

Tire Inflation Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

© Copyright 2000Allrights Reserved

Great Plains Manufacturing, Inc. provides this publication“as is” without warranty of any kind, either expressed or implied. While every precaution has been takenin the

preparationofthismanual,GreatPlainsMan uf acturing,Inc.assumesno responsibility for errorsoromissions.Neither is any liabilityassumedfordamages resulting from

theuseof the information contained herein. Great Plains Manufacturing,Inc. reservestheright to reviseandimproveits products as it sees fit. This publication describes

the state of this product at the time of its publication, and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains

All other brands and product names are trademarks or registered trademarks of their respective holders.

Great Plains Manufacturing, Incorporated Trademarks

Printed in the United States of America.

4/11/2005

173-208M

Page 3

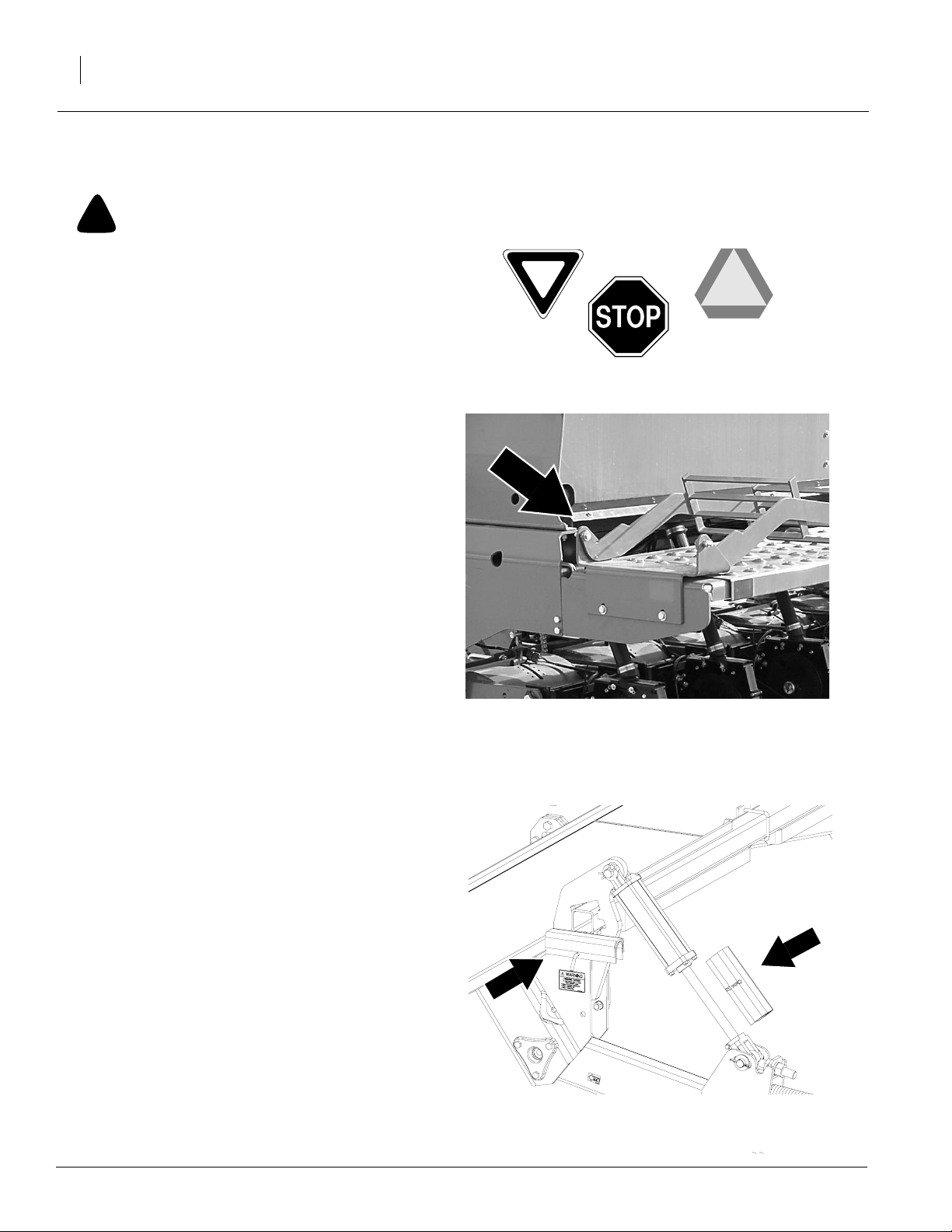

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is

apotential hazard to personal safetyinvolvedand

extrasafety precaution must be taken. When you

see this symbol, be alert and carefully read the

message that follows it. In addition to design and

configuration of equipment, hazard control and

accident prevention are dependent upon the

awareness, concern, prudence and proper training of personnel involved in the operation,

transport, maintenance and storage of

equipment.

Important Safety Information

!

1

Be Aware of Signal Wor ds

Signal words designate a degree or level of hazard seriousness.

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. This signal word is limited to the

most extreme situations, typically for machine

components that, for functional purposes, cannot

be guarded.

WARNINGindicates a potentially hazardous situationwhich, if not avoided,could resultin death or

serious injury, and includes hazards that are exposed when guards are removed. It may also be

used to alert against unsafe practices.

CAUTION indicates a potentially hazardous situation which, if not avoided,may result in minor or

moderate injury. It may also be used to alert

against unsafe practices.

DANGER

!

WARNING

!

CAUTION

!

4/11/2005

173-208M

Page 4

2015P and 2515P

2

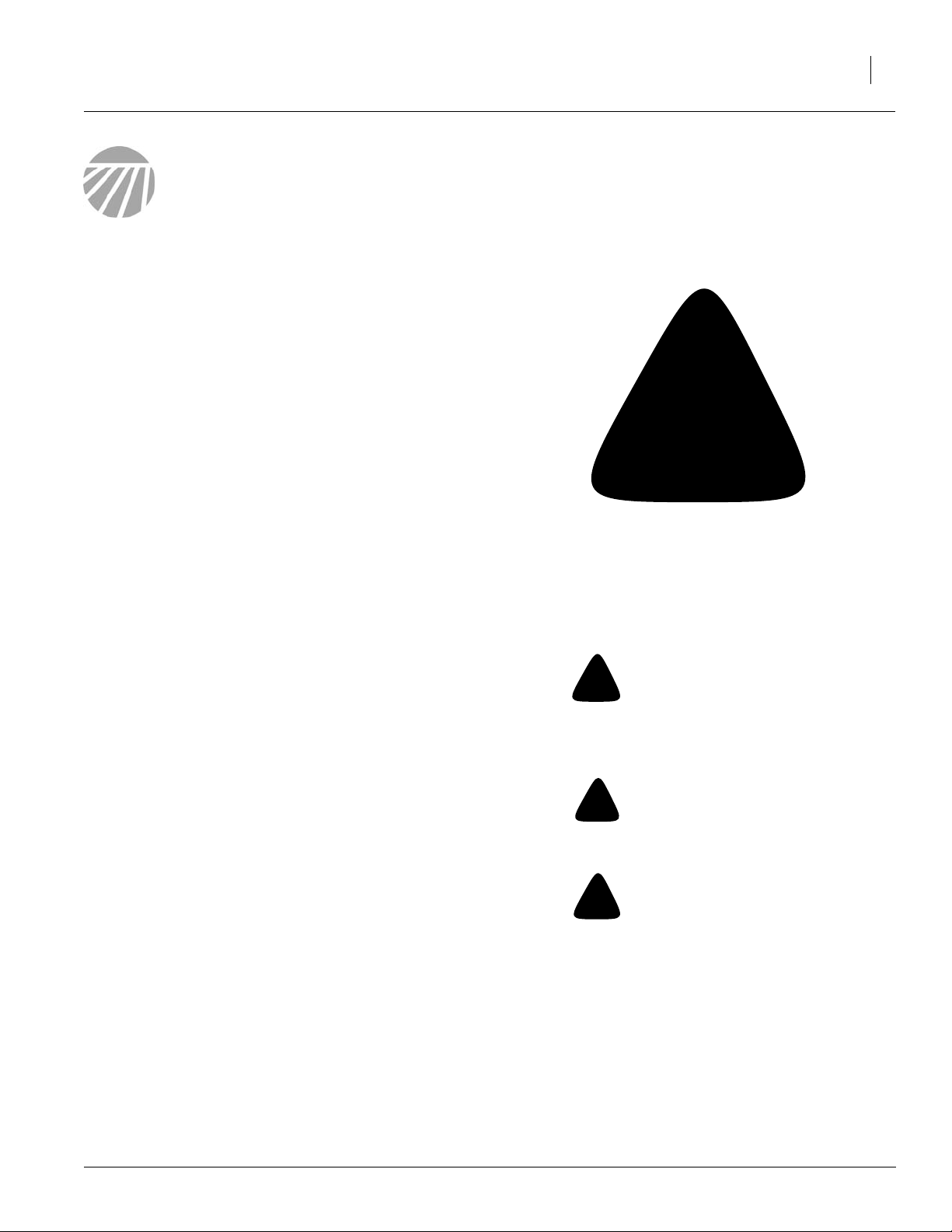

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals,”page 7,

thoroughly.

▲ Read all instructions noted on the decals.

Keep Riders Off Machinery

Riders obstruct the operator’s view. Riders could

be struck by foreign objects or thrown from the

machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine dur-

ing operation.

Shutdown and Storage

▲ Lower 3-Point Precision Bean Machine, put

tractor in park, turn off engine, and remove the

key .

▲ Secure 3-Point Precision Bean Machine using

blocks and supports provided.

▲ Detach and store 3-Point Precision Bean

Machine in an area where children normally

do not play.

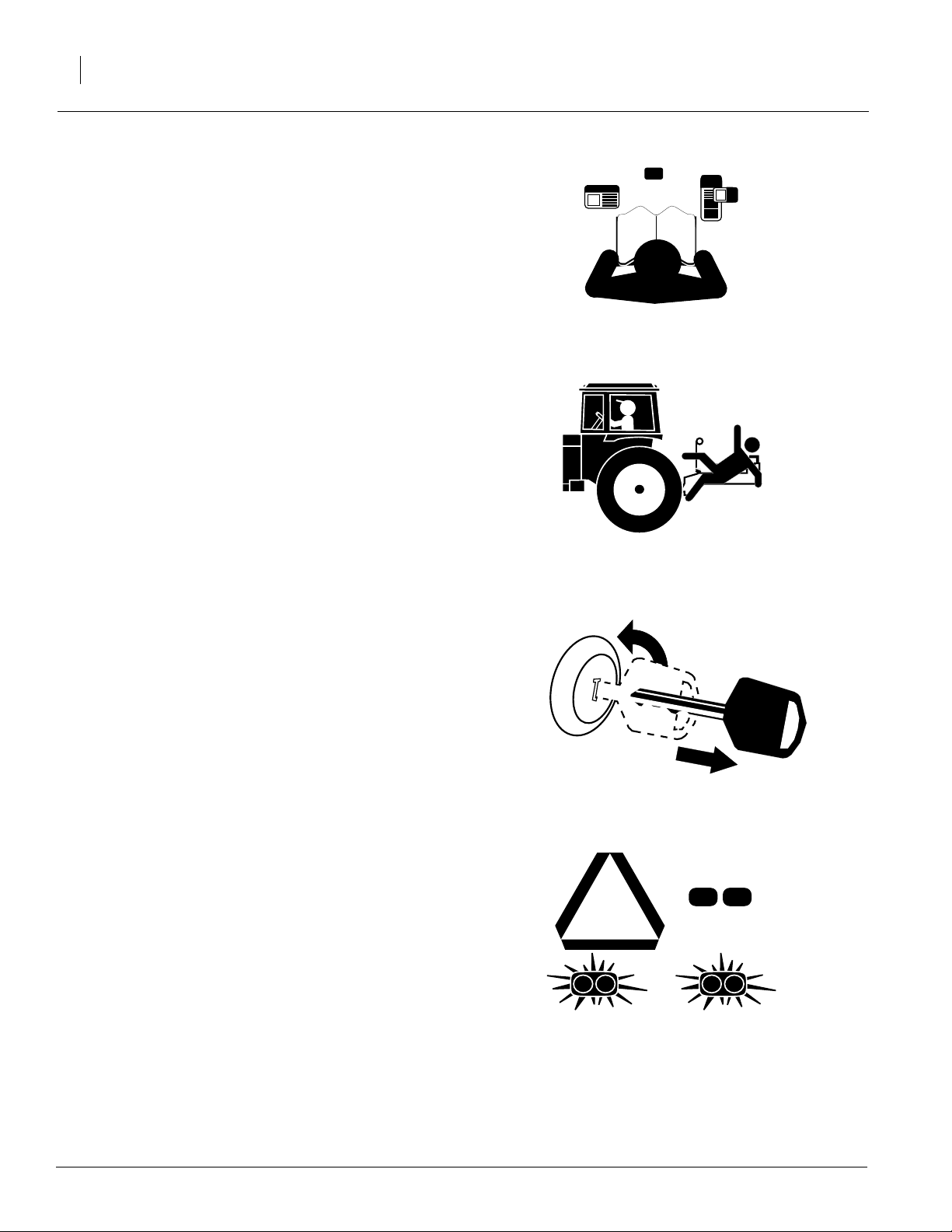

Use Safety Lights and Devices

Slow-moving tractors and towed implements can

create a hazard when driven on public roads.

They are difficult to see, especially at night.

▲ Use flashing warning lights and turn signals

whenever driving on public roads.

▲ Use lights and devices provided with imple-

ment.

OFF

173-208M

4/11/2005

Page 5

Transport Machinery Safely

Maximum transport speed for implement is 20

mph. Some rough terrains require a slower

speed.Sudden brakingcan cause atowed loadto

swerve and upset.

▲ Do not exceed 20 mph. Never travel at a

speed which does not allow adequate control

of steering and stopping. Reduce speed if

towed load is not equipped with brakes.

▲ Comply with state and local laws.

▲ Do not tow an implement that, when fully

loaded, weighs more than 1.5 times the weight

of towing vehicle.

▲ Carry reflectors or flags to mark 3-Point Preci-

sion Bean Machine in case of breakdown on

the road.

Important Safety Information

3

▲ Keep clear of overhead power lines and other

obstructions when transporting. Refer to transport dimensions under “Specifications and

Capacities,” page 65.

▲ Do not fold or unfold the 3-Point Precision

Bean Machine markers while the tractor is

moving.

Avoid High Pressure Fluids

Escaping fluid under pressure can penetrate the

skin, causing serious injury.

▲ Avoid the hazard by relieving pressure before

disconnecting hydraulic lines.

▲ Use a piece of paper or cardboard, NOT

BODY PARTS, to check for suspected leaks.

▲ Wear protective gloves and safety glasses or

goggles when working with hydraulic systems.

▲ If an accident occurs, see a doctor immedi-

ately. Any fluid injected into the skin must be

surgically removed within a few hours or gangrene may result.

4/11/2005

173-208M

Page 6

2015P and 2515P

4

Practice Safe Maintenance

▲ Understand procedure before doing work. Use

proper tools and equipment. Refer to this manual for additional information.

▲ Work in a clean, dry area.

▲ Lower the 3-Point Precision Bean Machine,

put tractor in park, turn off engine, and remove

key before performing maintenance.

▲ Make sure all moving parts have stopped and

all system pressure is relieved.

▲ Allow 3-Point Precision Bean Machine to cool

completely.

▲ Disconnect battery ground cable (-) before

servicing or adjusting electrical systems or

before welding on 3-Point Precision Bean

Machine.

▲ Inspect all parts. Make sure parts are in good

condition and installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from 3-

Point Precision Bean Machine before operation.

Prepare for Emergencies

▲ Be prepared if a fire starts.

OFF

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambu-

lance, hospital and fire department near

phone.

Wear Pr otective Equipment

▲ Wear protective clothing and equipment.

▲ Wear clothing and equipment appropriate for

the job. Avoid loose-fitting clothing.

▲ Because prolonged exposure to loud noise

can cause hearing impairment or hearing loss,

wear suitable hearing protection such as earmuffs or earplugs.

▲ Because operating equipment safely requires

your full attention, avoid wearing radio headphones while operating machinery.

173-208M

911

4/11/2005

Page 7

Handle Chemicals Properly

Agricultural chemicals can be dangerous. Improperusecan seriously injurepersons,animals,

plants, soil and property.

▲ Read and follow chemical manufacturer’s

instructions.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Avoid inhaling smoke from any type of chemi-

cal fire.

▲ Store or dispose of unused chemicals as

specified by chemical manufacturer.

Use A Safety Chain

▲ Use a safety chain to help control drawn

machinery should it separate from tractor

drawbar.

Important Safety Information

5

▲ Use a chain with a strength rating equal to or

greater than the gross weight of towed

machinery.

▲ Attach chain to tractor drawbar support or

other specified anchor location. Allow only

enough slack in chain to permit turning.

▲ Replace chain if any links or end fittings are

broken, stretched or damaged.

▲ Do not use safety chain for towing.

Tire Safety

Tire changing can be dangerous and should be

performed by trained personnel using correct

tools and equipment.

▲ When inflating tires, use a clip-on chuck and

extension hose long enough for you to stand

to one side–not in front of or over tire assembly. Use a safety cage if available.

▲ When removing and installing wheels, use

wheel-handling equipment adequate for

weight involved.

4/11/2005

173-208M

Page 8

2015P and 2515P

6

Safety At All Times

Thoroughly read and understand the instructions

in this manual before operation. Read all instructions noted on the safety decals.

▲ Be familiar with all 3-Point Precision Bean

Machine functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave 3-Point Precision Bean Machine

unattended with tractor engine running.

▲ Do not dismount a moving tractor. Dismount-

ing a moving tractor could cause serious injury

or death.

▲ Do not stand between the tractor and 3-Point

Precision Bean Machine during hitching.

▲ Keep hands, feet and clothing away from

power-driven parts.

▲ Wear snug-fitting clothing to avoid entangle-

ment with moving parts.

▲ Watch out for wires, trees, etc., when folding

markers and raising 3-Point Precision Bean

Machine. Make sure all persons are clear of

working area.

▲ Do not turn tractor too tightly, cause 3-Point

Precision Bean Machine to ride up on wheels.

This could cause personal injury or equipment

damage.

173-208M

4/11/2005

Page 9

Important Safety Information

7

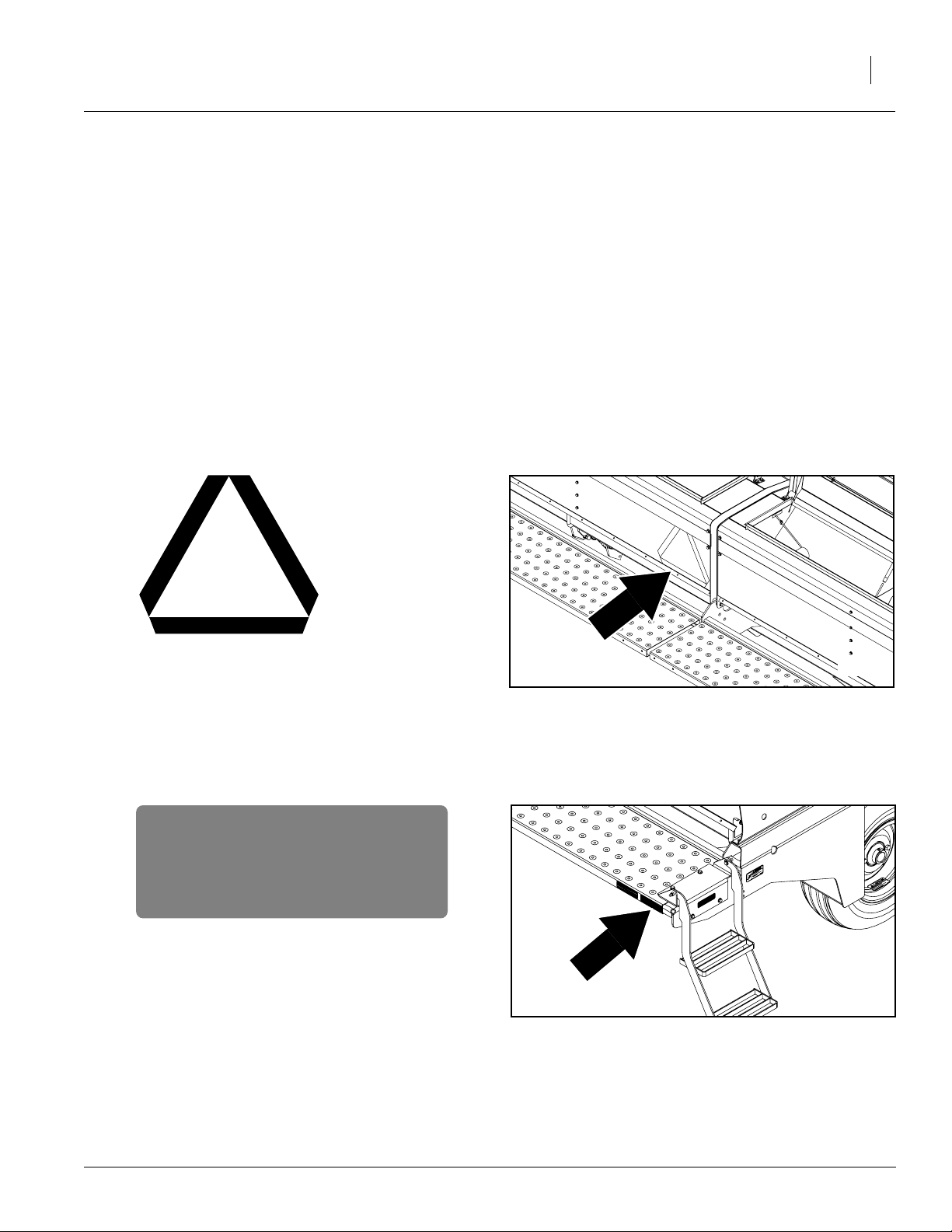

Safety Decals

Your implement comes equipped with all safety

decals in place. They were designed to help you

safely operate your implement.

▲ Read and follow decal directions.

▲ Keep all safety decals clean and legible.

▲ Replace all damaged or missing decals. Order

new decals from your Great Plains dealer.

Refer to this section for proper decal placement.

▲ When ordering new parts or components, also

request corresponding safety decals.

▲ To install new decals:

1. Cleanthe areaonwhich the decalis tobe

placed.

2. Peel backing from decal. Press firmly on

surface, being careful not to cause air

bubbles under decal.

818-003C

Slow Moving Vehicle Sign

838-266C

Red Reflectors

Reflector on both ends of bean machine;

two reflectors total.

17769

17769

4/11/2005

173-208M

Page 10

2015P and 2515P

8

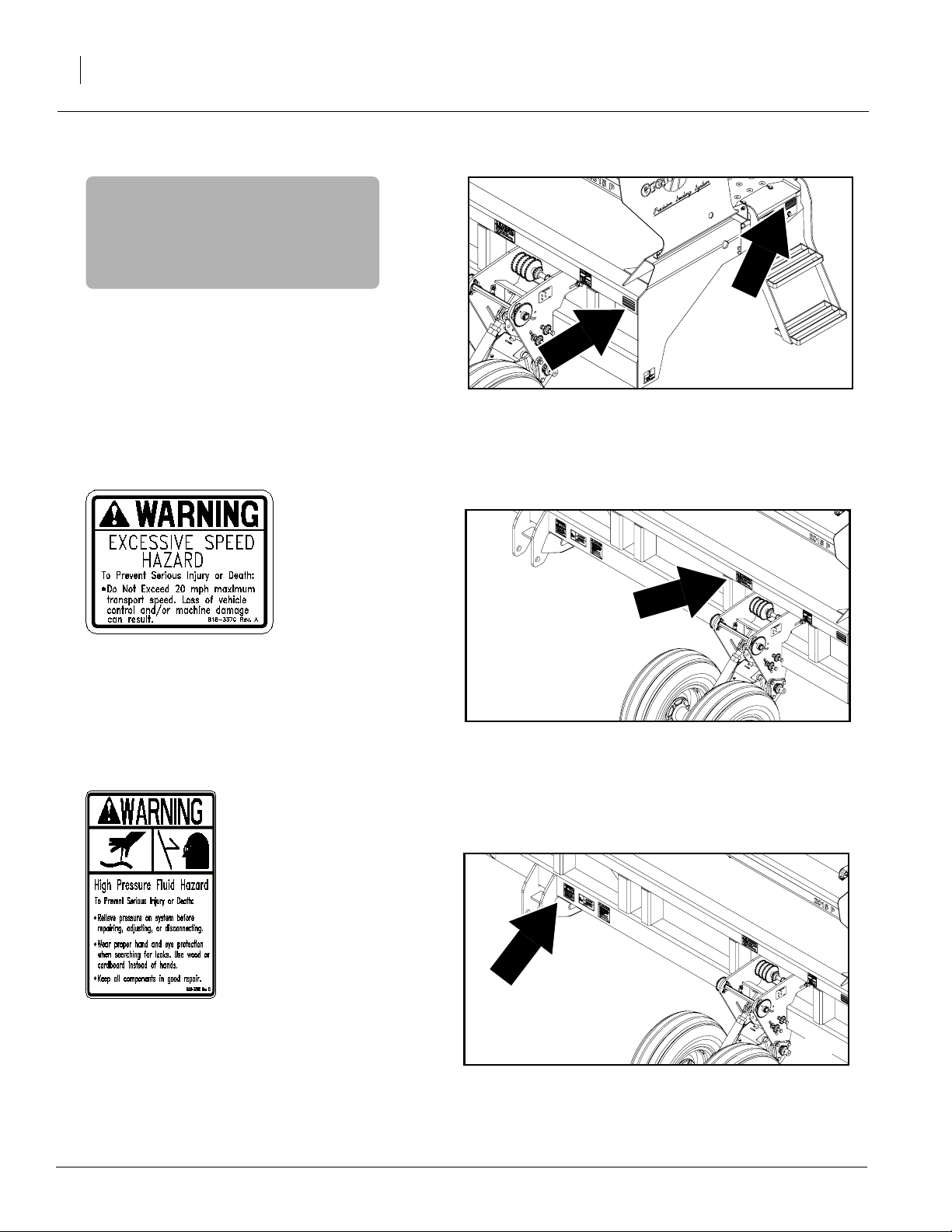

838-265C

Amber Reflectors

Reflectorson both ends ofbeanmachine;

four reflectors total.

18542

818-337C

Excessive Speed Hazard

818-339C

High Pressure Fluid Hazard

18542

18542

173-208M

4/11/2005

Page 11

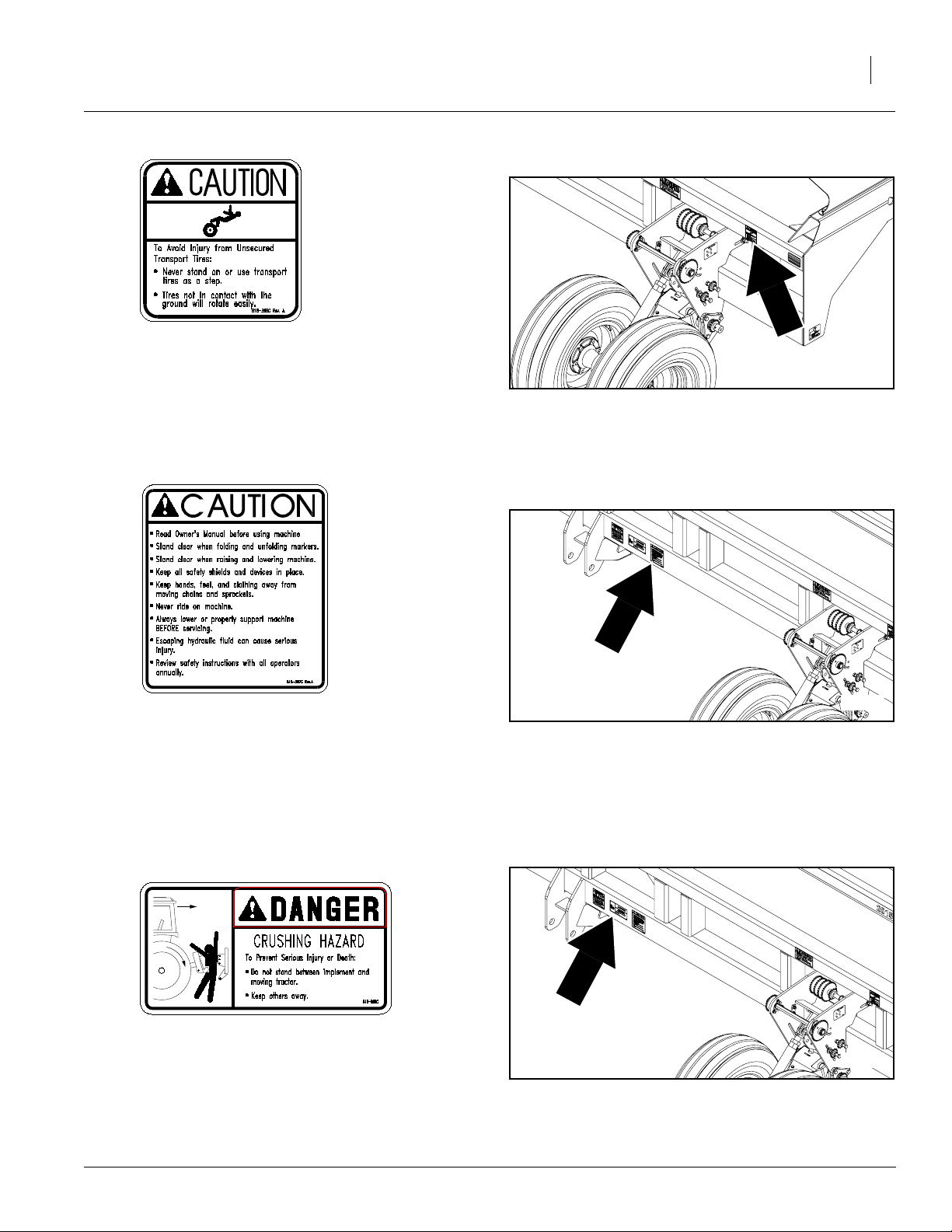

818-398C

Caution Tires Not a Step

Important Safety Information

18542

9

818-587C

Caution Operational

818-590C

Crushing Hazard

18542

18542

4/11/2005

173-208M

Page 12

2015P and 2515P

10

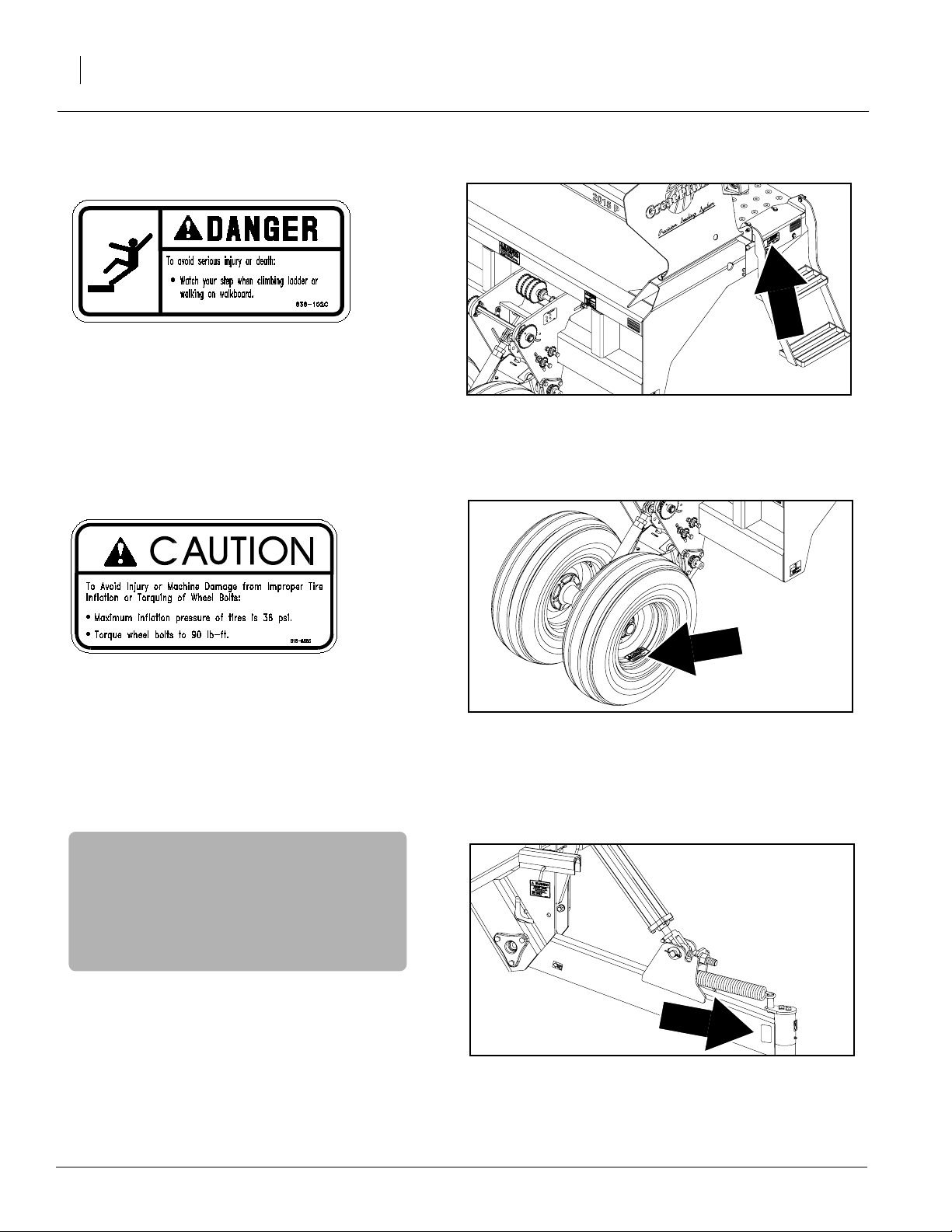

838-102C

Falling Hazard

18542

818-855C

Caution Tire 36 PSI

838-265C

Amber Reflector

Reflector on each optional lift-

assist arm; two reflectors total

18542

17770

173-208M

4/11/2005

Page 13

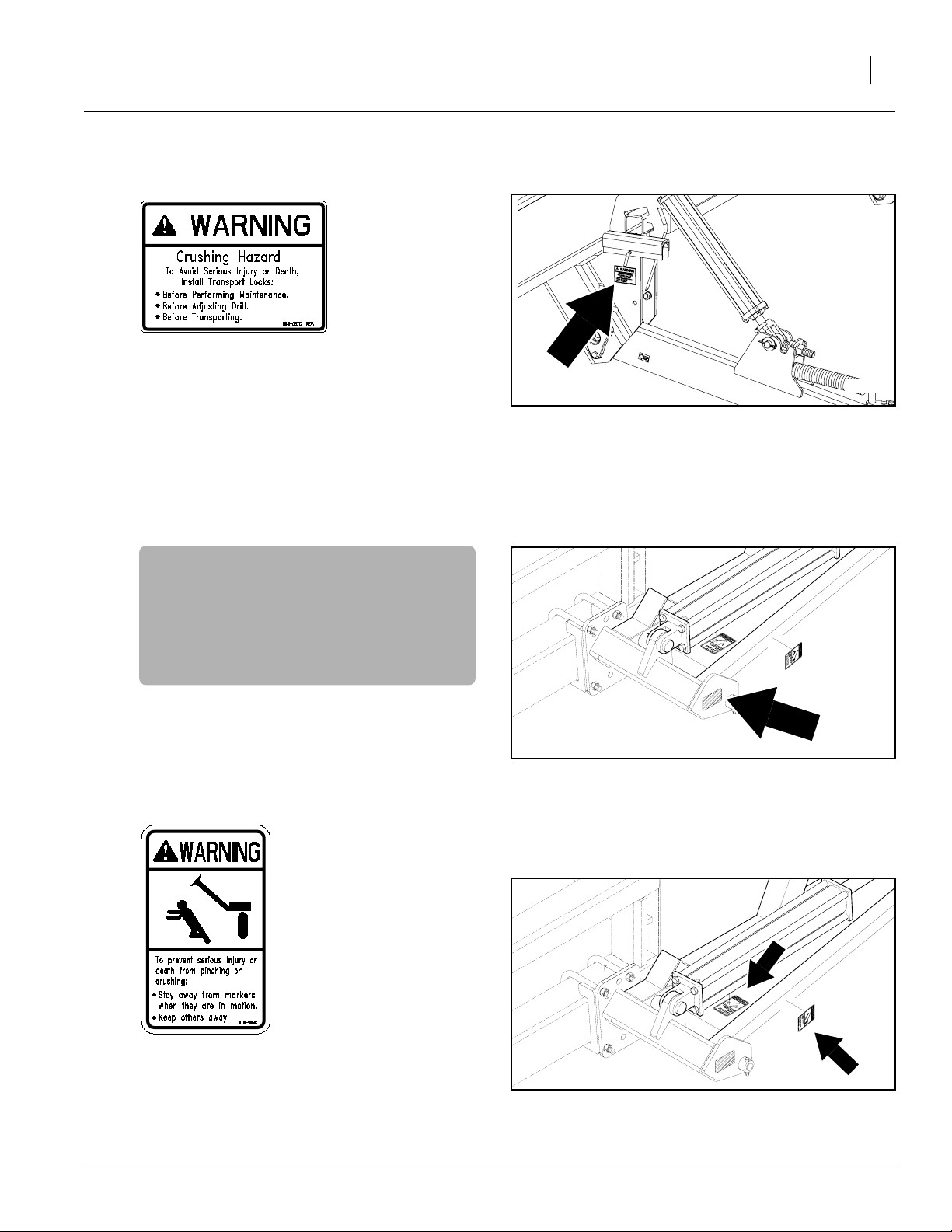

838-057C

Crushing Hazard

Important Safety Information

17770

11

838-265C

Amber Reflector

Reflector on each optional marker

818-682C

Warning Pinch/Crush Marker

17843

17843

4/11/2005

173-208M

Page 14

2015P and 2515P

12

Introduction

GreatPlains welcomesyouto itsgrowingfamilyof

newproduct owners. This 3-Point Precision Bean

Machinehas beendesignedwith careandbuiltby

skilled workers using quality materials. Proper

setup, maintenance and safe operating practices

willhelp you get yearsof satisfactory use from the

machine.

Description of Unit

The 2015P and 2515P model bean machines are

3-point mounted precision seeding bean machines equipped with double-disk, planter-style

rowunits.Seeding depth, closing wheel pressure

and row unit down force can be adjusted.

Intended Usage

Use the bean machine to seed production-agriculture crops only. Do not modify the bean

machine for use with attachments other than

Great Plains options and accessories specified

for use with the bean machine.

Models Covered

2015P and 2515P

18394

173-208M

4/11/2005

Page 15

Using This Manual

This manual will familiarize you with safety, assembly, operation, adjustments, troubleshooting

and maintenance. Read this manual and follow

the recommendations to help ensure safe and efficient operation.

The information in this manual is current at printing. Some parts may change to assure top

performance.

Definitions

The following terms are used throughout this

manual.

Singulated Seeds - seeds that are metered individually, such as soybeans, corn, cotton and milo.

The seed meter separates individual seeds from

the seed pool and distributes them one at a time.

The seed rates are designated as seeds per acre.

Introduction

13

Sliding seed tubes - telescoping tubes which connect the seed box and seed meters.

Seed meter - the component which separates the

seeds for distribution.

Seed meter wheel - a changeable wheel inside

the seed meter with small pockets for separating

seeds.

Seed wheel pockets - indentations on the seed

meterwheel which collect seedsfor distributionto

the opener seed tube.

Right-hand and left-hand as used in this manual

are determined by facing the direction the machine will travel while in use unless otherwise

stated.

IMPORTANT: A crucial point of information related to the preceding topic. For safe and correct operation, read and follow the directions

provided before continuing.

NOTE: Useful information related to the preceding topic.

Machine travel

direction

Left-hand

side

Right-hand

side

18540

4/11/2005

173-208M

Page 16

2015P and 2515P

14

Owner Assistance

If you need customer service or repair parts, contact a Great Plains dealer. They have trained

personnel, repair parts and equipment specially

designed for Great Plains products.

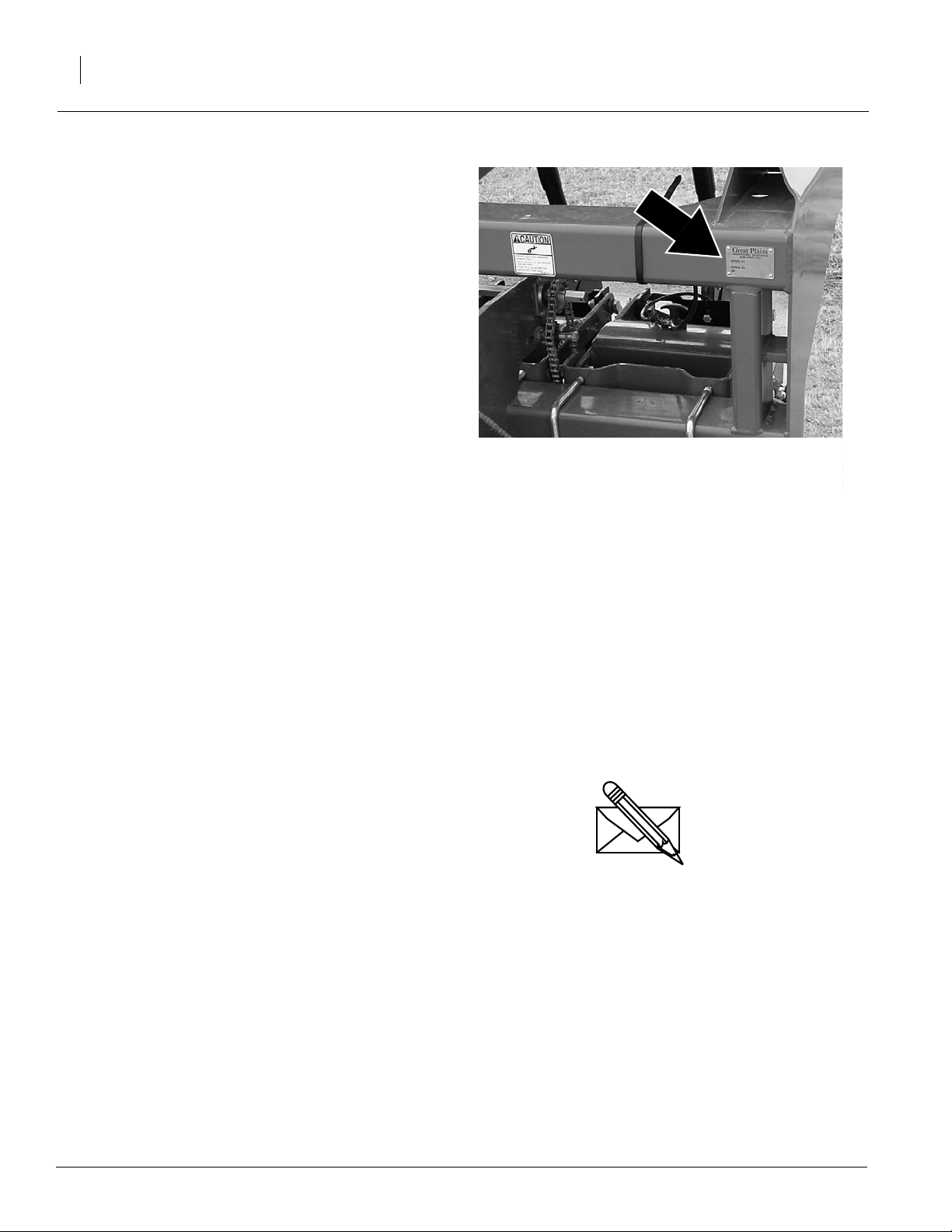

Refer to Figure 1

Yourmachine’spartswerespecially designedand

should only be replaced with Great Plains parts.

Alwaysuse the serial and model number when ordering parts from your Great Plains dealer. The

serial-number plate is located on the front left

hand end.

Record your bean machine model and serial number here for quick reference:

Model Number:__________________________

Serial Number: ___________________________

Your Great Plains dealer wants you to be satisfied

with your new machine. If you do not understand

anypartof thismanual orare not satisfiedwith the

service received, please take the following

actions.

1. Discuss the matter with your dealership service manager. Make sure they are aware of

any problems so they can assist you.

2. If you are still unsatisfied, seek out the owner

or general manager of the dealership.

3. For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

Figure 1

Serial Number Locations

18455

173-208M

4/11/2005

Page 17

Preparation and Setup

Thissection will help youprepareyour tractor and

3-Point Precision Bean Machine for use. Before

using the 3-Point Precision Bean Machine in the

field, you must hitch the bean machine to a suitabletractor(see“TractorRequirements,”page65)

and level the bean machine.

Prestart Checklist

1. Readand understand “ImportantSafetyInformation,” page 1.

2. Check that all working parts are moving freely, bolts are tight, and cotter pins are spread.

Preparation and Setup

15

3. Checkthat all grease fittings are in place and

lubricated. Refer to “Lubrication,” page 58.

4. Checkthatallsafety decalsand reflectors are

correctly located and legible. Replace if damaged. See “Safety Decals,” page 7.

5. Inflate tires to pressure recommended and

tighten wheel bolts as specified. See “Appendix,” page 80.

Hitching T ractor to Bean Machine

!

DANGER

You may be severelyinjured or killed by being crushed

betweenthe tractor and bean machine.Donot standor

place any part of your body between bean machine

and moving tractor. Stop tractor engine and set park

brake before installing the hitch pin.

1. Allowlowerthree-point links on tractor to float

independent of each other. Do not pin lower

links together.

2. Raise or lower tractor three-point arms as

needed and pin tractor lower links to bean

machine.

4/11/2005

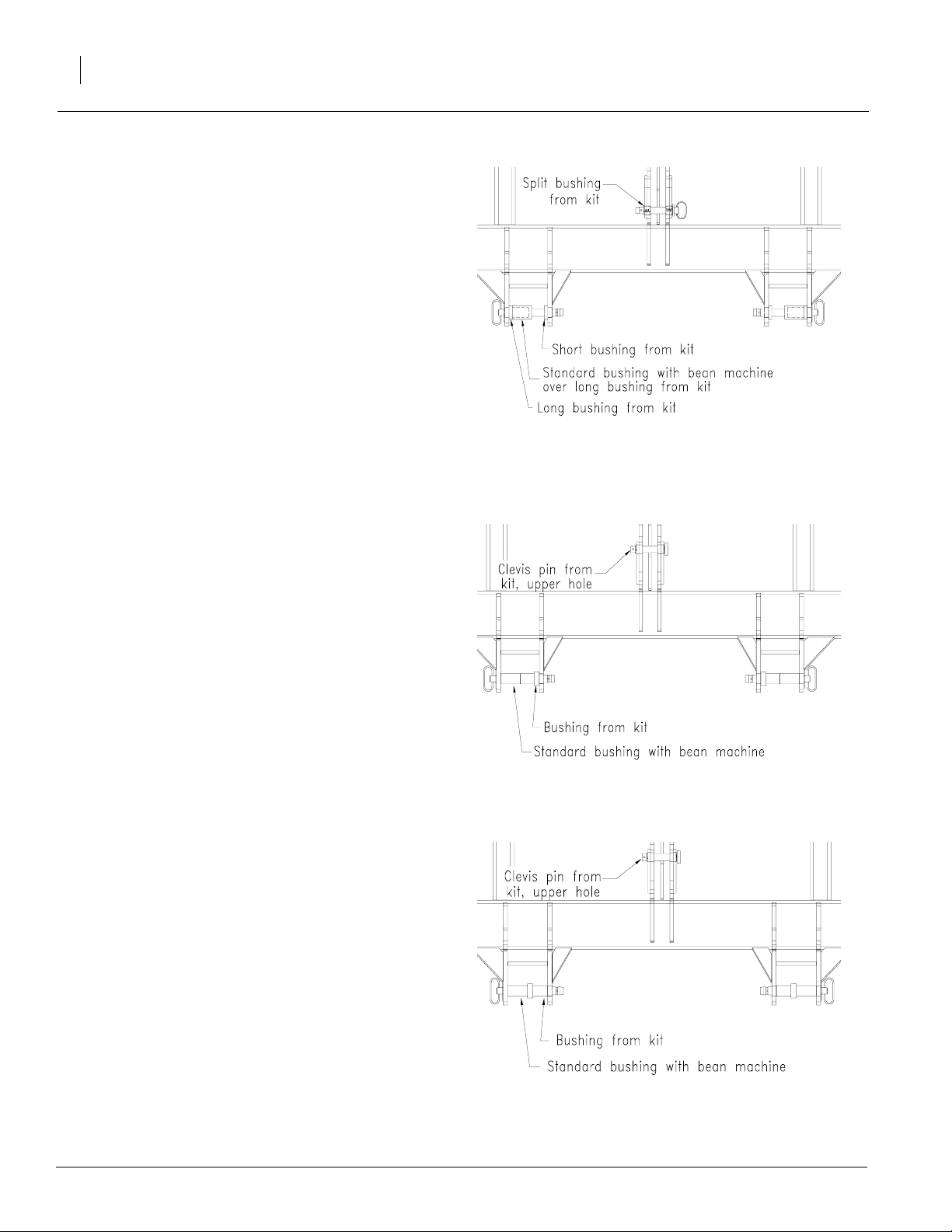

Refer to Figure 2

Category II and III tractors with quick

hitch: Use pins provided with bean machine.

Discard bushings provided with bean machine.

Figure 2

Category II and III Tractors with Quick Hitch

18550

173-208M

Page 18

2015P and 2515P

16

Refer to Figure 3

Category II tractors, no quick hitch: Discard pins provided with bean machine. Order

Great Plains kit, part number 173-170A. Use

pins and bushings as shown. See Figure 4.

Category III tractors, no quick hitch: Use

pins provided with bean machine. Use bushings provided with bean machine to space

lower tractor links to the outside.

Refer to Figure 4

Figure 3

17984

Category II Tractors, No Quick Hitch

Category IV tractors with Cat IV-N quick

hitch: Discard upper pin provided with bean

machine.Use other pinsand bushings provided with bean machine. Also, order Great

Plains kit, part number 173-171A. Use pins

and bushings as shown.

Refer to Figure 5

Category IV tractors, no quick hitch: Discard upper pin provided with bean machine.

Use other pins and bushings provided with

bean machine. Also, order Great Plains kit,

part number173-171A. Usepins andspacers

as shown.

1. Pin top three-point link to bean machine.

Figure 4

Category IV Tractors with Quick Hitch

17986

NOTE: If bean machine is outfitted with optional

lift assist, operate tractor and bean machine without tractor top link. On quick hitches, pin quick

hitch tobeanmachineandremovetractor top link.

2. Slowly raise bean machine. Watch for cab interference.

173-208M

Figure 5

Category IV Tractors, No Quick Hitch

17985

4/11/2005

Page 19

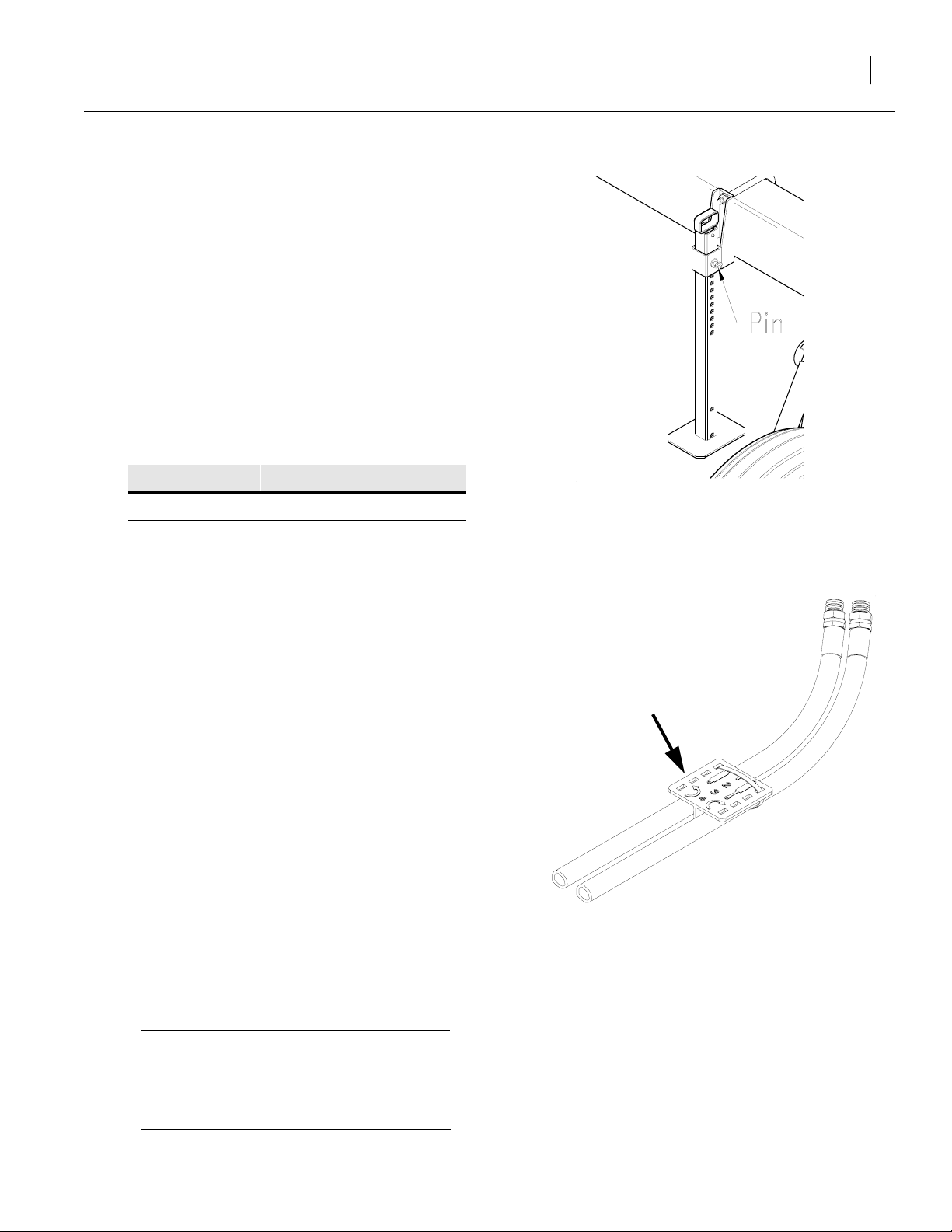

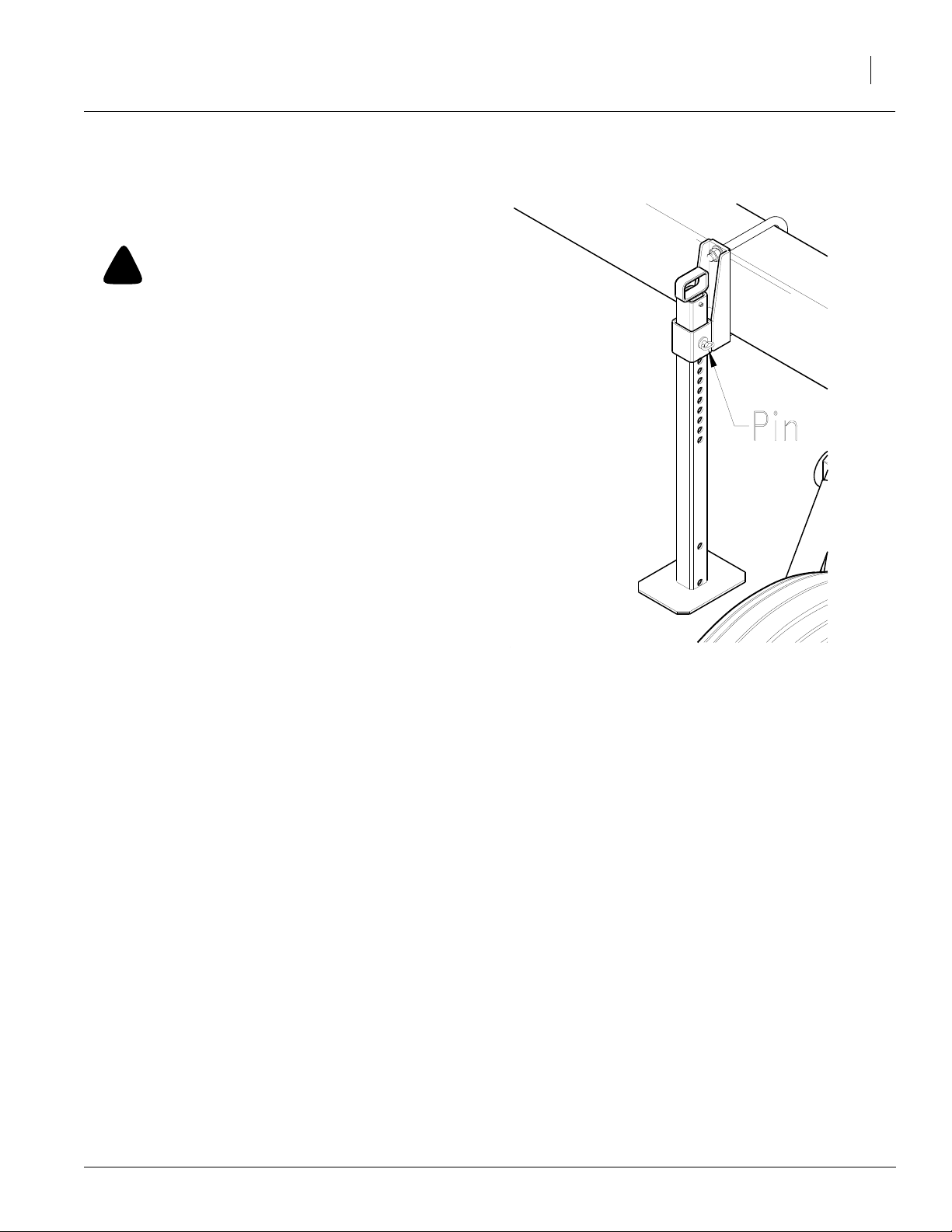

Refer to Figure 6

3. Remove pins holding parking stands and

raise stands. Replace pins in lowest hole in

each stand.

4. Set your tractor three-point-draft control to

float position.

5. Plug lead from bean machine light harness

into tractor receptacle.

Hydraulic Hose Hookup

Great Plains hydraulic hoses are color coded to

help you hookup hoses to your tractor outlets.

Hoses that go to the same remote valve are

marked with the same color.

Color Hydraulic Function

Red Field Lift Cylinders

Orange Marker Cylinders

Preparation and Setup

Figure 6

Parking Stand

17

13508

Refer to Figure 7

To distinguishhoseson thesame hydrauliccircuit,

referto plastic hose holder.Hose under extendedcylinder symbol feeds cylinder base ends. Hose

under retracted-cylinder symbol feeds cylinder

rod ends.

Lift Assist

Hydraulics for the optional lift assist can be

plumbed three different ways.

• Tractor remote valve drives lift assist alone

• Tractor remote valve drives lift assist and

three-point hitch

• Tractor hydraulic circuit for three-point hitch

drives lift assist and three-point hitch

To operate the lift assist on its on remote valve,

plug hydraulic hoses into valve outlets.

To plumb together the lift-assist and three-point

hydraulics,contact your tractor dealer for specific

instructions.

Hose label

Figure 7

Hydraulic Hose Label

17641

4/11/2005

IMPORTANT: Before plumbing the lift assist

into your tractor three-point circuit, contact

your tractor dealer for detailed instructions.

Failure to properly plumb the hydr aulics can

cause tractor damage.

173-208M

Page 20

2015P and 2515P

18

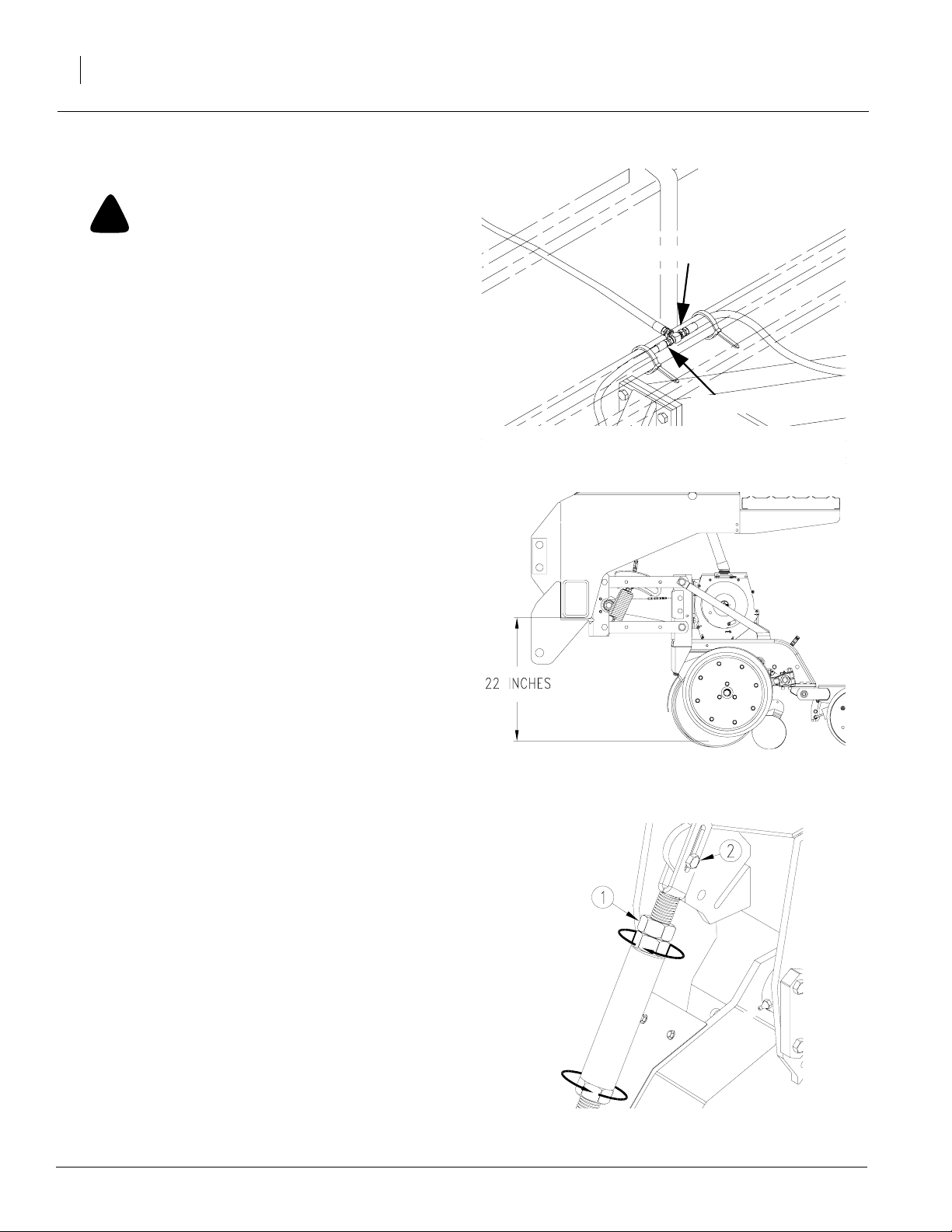

Bleeding Lift Assist Hydraulics

!

WARNING

Crushing hazard. The hydraulics could fail, causing

the bean machine to fall and crush you. Never work

under the raised bean machine unless secured with

channel locks. Never bleed an O-ring fitting, which

could damage the seal and cause the implement to

drop rapidly.

The lift-assist hydraulics must be free of air.If the

lift assist raises with jerky, uneven motions, or if a

hydrauliccomponent is replaced during the life of

the lift assist, follow these steps to bleed air from

the hydraulics.

1. Check that the tractor hydraulic reservoir is

full.

Loosen

Loosen

Figure 8

Lift Assist Hydraulic Tee Fitting

18554

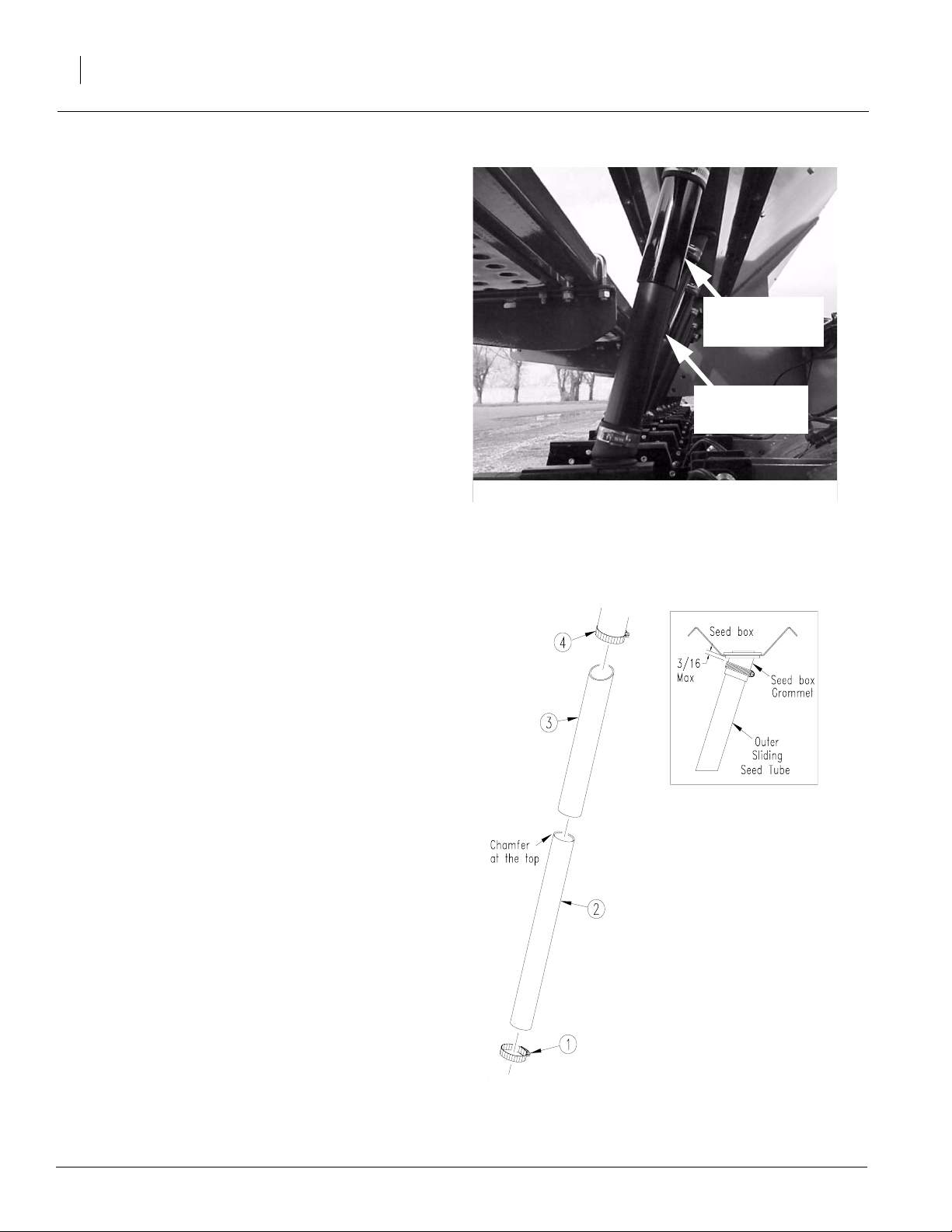

Refer to Figure 8

2. Loosenteefittingon bothsides of thetee. Tee

fitting is located under bean machine box.Engage tractor hydraulic lever for the lift assist

until oil appears at loosened fittings. Tighten

fittings.

Leveling Bean Machine

Refer to Figure 9

Adjust bean machine so opener tube runs 22

inches above ground when bean machine is lowered in field.

Refer to Figure 10

1. Loosen jam nut (1) near top clevis of each

gauge-wheel turnbuckle.

NOTE: Jam nut is left-hand threaded.

2. Bolt upper clevis in upper mount hole (2).

3. Set turnbuckle length. Turn turnbuckle to

shortenorlengthen as necessary. Initially set

lengthto 151/4 inchesbetween pincenters to

achievethe 22-inch dimension mentioned

above.When adjusting turnbuckle, remember:

Figure 9

Initial Operating Height

18543

• Lengthening turnbuckle raises bean machine.

• Shortening turnbuckle lowers bean machine.

4. After adjusting both turnbuckles to same

length, tighten jam nuts.

173-208M

Figure 10

17773

Gauge-Wheel Turnbuckle

4/11/2005

Page 21

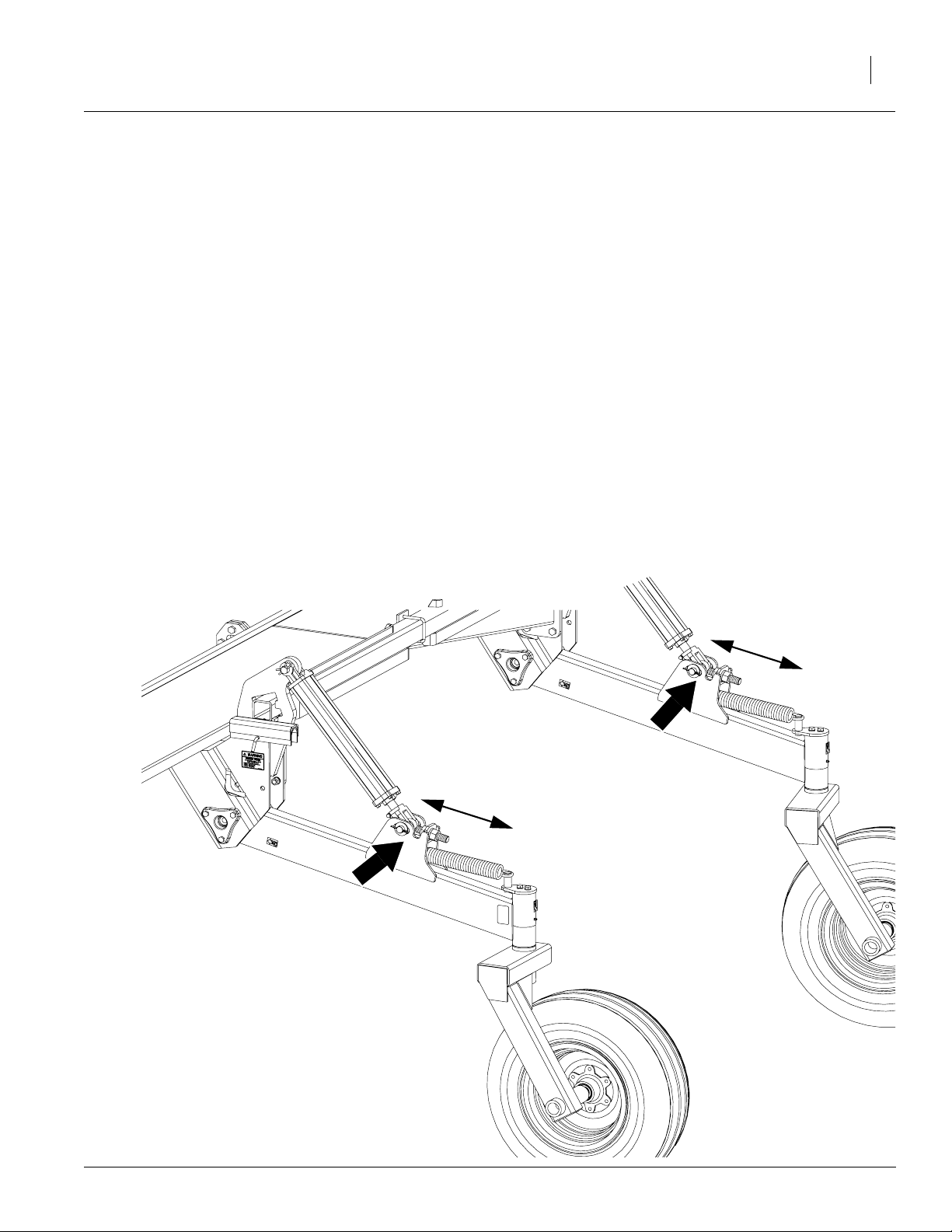

5. Ifusing the bean machine without optional lift

assist, level bean machine with top threepoint link. Shorten or lengthen link until the

top of the bean machine box is parallel with

the ground.

6. Ifusing bean machine withoptional lift assist,

useeyeboltadjustmenton lift-assist cylinders

to level bean machine.

Refer to Figure 11

With the row-unit springs at the lightest setting, loosen jam nutsand shorten or lengthen

eyebolts until top of bean machine boxis leveland lift-assistcylinders collapsecompletely

when bean machine is lowered. To raise or

lower bean machine, adjust eyebolts.

Preparation and Setup

19

Raise

Raise

Lower

Lower

4/11/2005

Figure 11

Eyebolt Adjustment for Lift Assist

17770

173-208M

Page 22

2015P and 2515P

20

Operating Instructions

This section covers general operating procedures. Experience, machine familiarity and the

following information will lead to efficient operation and good working habits. Always operate

farm machinery with safety in mind.

Prestart Checklist

!

WARNING

Escaping fluid under pressure can have sufficient pressure to penetrate the skin. Check all hydraulic lines

and fittings before applying pressure. Fluid escaping

froma very small hole can be almost invisible.Use paper or cardboard, not body parts, and wear heavy

gloves to check for suspected leaks. If injured, seek

medical assistance from a doctor that is familiar with

this type of injury. Foreign fluids in the tissue must be

surgically removed within a few hours or gangrene

will result.

1. Carefullyread “Important SafetyInformation,”

page 1.

2. Lubricate bean machine as indicated under

“Lubrication,” page 58.

3. Check all tires for proper inflation. See “Appendix,” page 80.

4. Checkall bolts, pinsandfasteners. Torque as

shown in “Appendix,” page 80.

5. Check bean machine for worn or damaged

parts. Repair or replace parts before going to

the field.

6. Check hydraulic hoses, fittings and cylinders

for leaks. Repair or replace before going to

the field.

7. Rotate both gauge wheels to see that the

drive and meters are working properly and

free from foreign material.

!

DANGER

Watchyourstep when walkingon bean machineladder

and walkboard. Falling from bean machine could

cause severe injury or death.

173-208M

4/11/2005

Page 23

Field Operation

!

DANGER

You may be severelyinjured or killed by being crushed

betweenthe tractor and bean machine.Donot standor

place any part of your body between bean machine

and moving tractor. Stop tractor engine and set park

brake before installing pins.

Hitch bean machine to a suitable tractor or hitch.

Refer to “Hitching Tractor to Bean Machine,”.

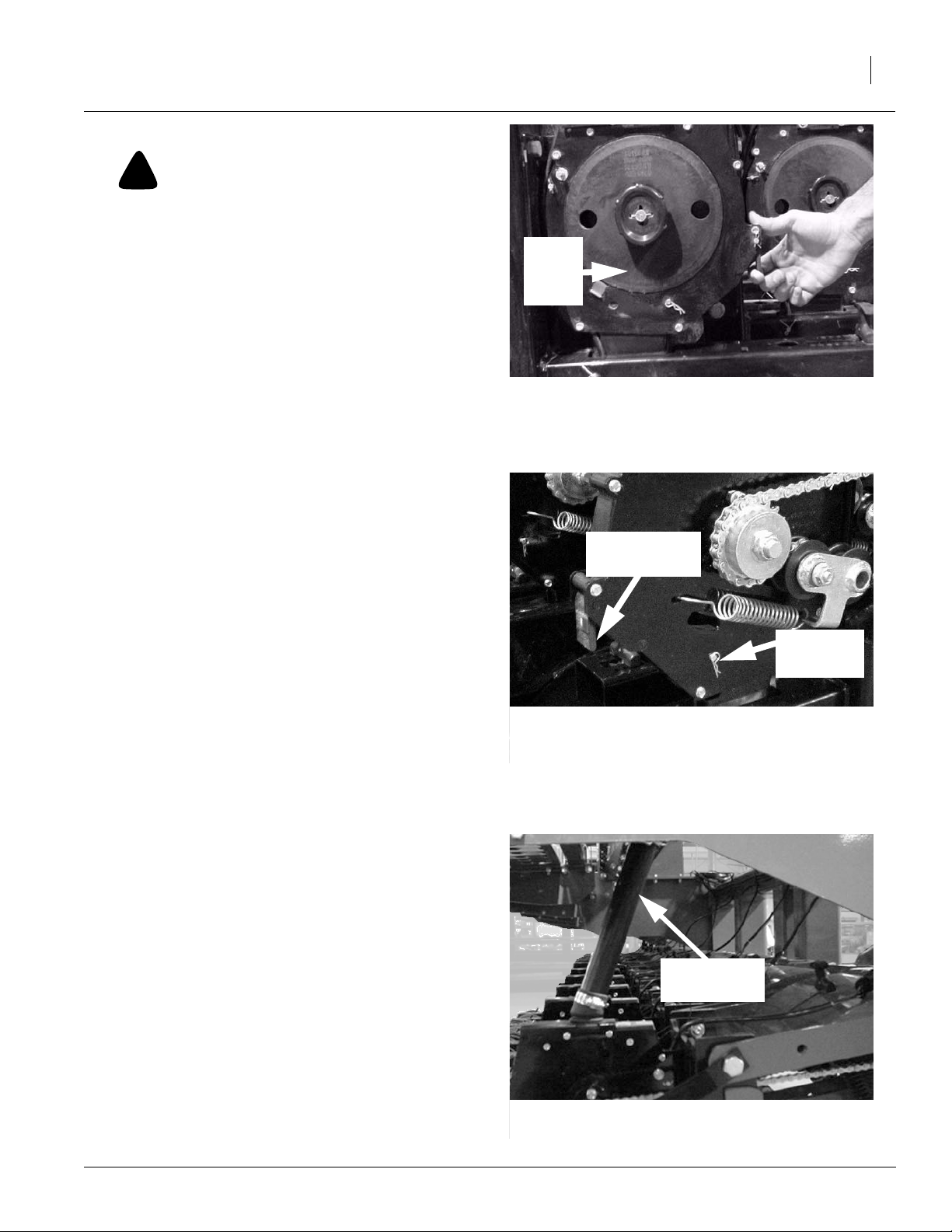

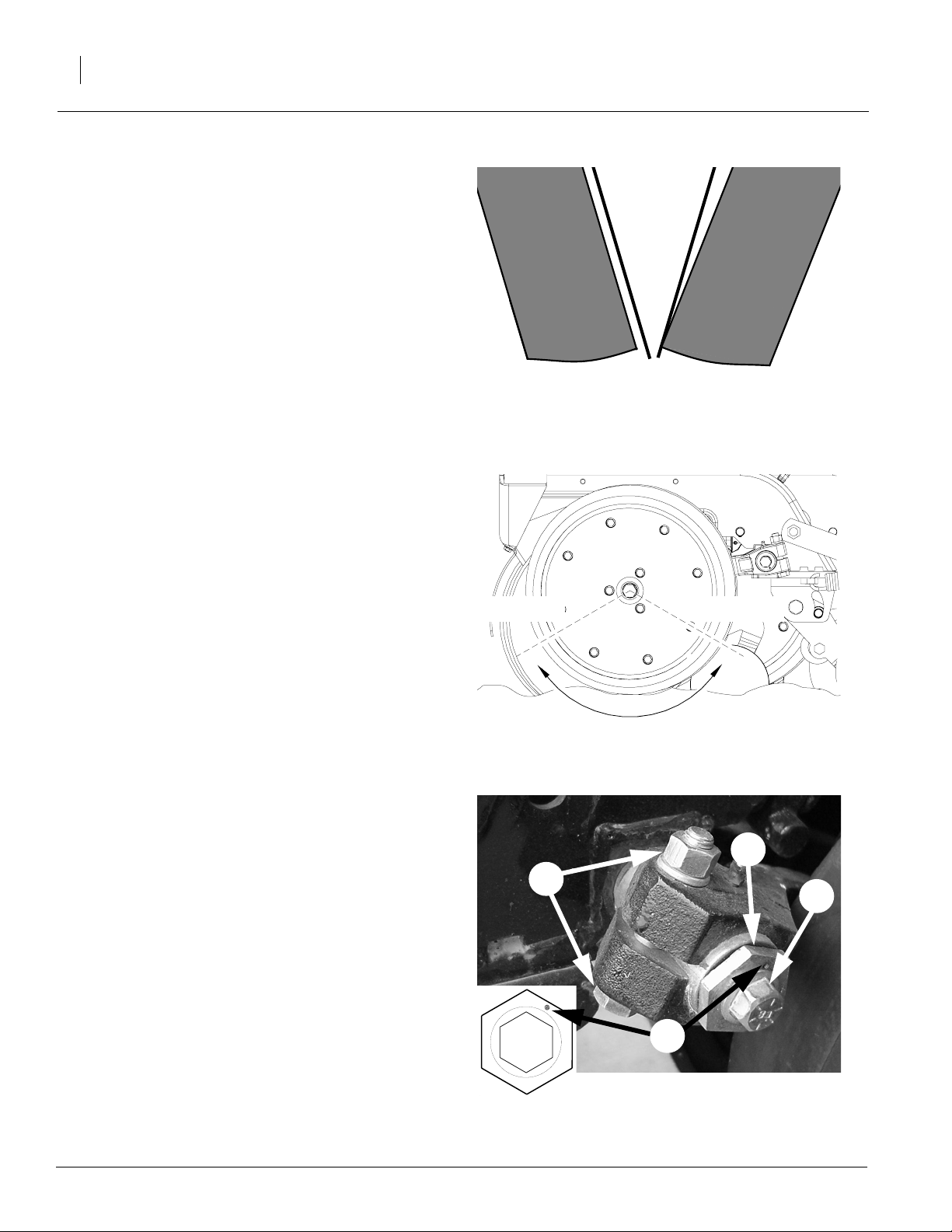

Refer to Figure 12

1. Make sure proper seed meter wheels are in

place. For information on how to change the

seed meter wheels see page 34.

Refer to Figure 13

2. Makesure all seed meter clean out doors are

closed and pinned. Formore information see

page 33.

3. Set seeding rate as explained in “Seeding

Rate”, page 30.

Seed

meter

wheel

Operating Instructions

Figure 12

Seed meter wheel in place

Seed meter

clean out door

21

19190

Refer to Figure 14

4. Open and pin sliding seed tubes. For further

information see page 32.

5. Adjust row unit for necessary down pressure

and desired seeding depth. Refer to “Adjustments”, page 26.

6. If bean machine has optional lift assist, lower

bean machine in the field and check that liftassist cylinders are retracted fully. If not, add

weights to weight brackets until cylinders retract completely.

7. Load box with clean seed and talc.

8. Raise bean machine. Rotate gauge wheel.

Check that seed meters, seed tubes and

drives are working properly and free from foreign material by looking for seed flow under

each row opener.

9. Record acremeter readout. Subtract initial

reading from later readings to determine

acres planted.

10. Pull forward, lower bean machine and begin

seeding.

Retaining

clip

Figure 13

Seed meter clean out door in closed position

Sliding seed

tubes

18261

11. Always lift bean machine out of the ground

when turning at row ends and for other shortradius turns. Seeding will stop automatically

as bean machine is raised.

4/11/2005

Figure 14

Sliding seed tubes in open position

18448

173-208M

Page 24

2015P and 2515P

22

Meter and Sliding Seed Tube

Refer to Figure 15

Figure 15 shows the seed meter and seed tubes.

Before operation, make sure you are using the

correct seed meter wheel for the seed you are

using.

For information on meter adjustments, refer to

“Seeding Rate”, page 30.

If your bean machine has been exposed to the elementsfor aperiodof time withseedin the boxes,

check to make sure the seed in the seed tubes

and meters has not become wet.

Seed tube

Seed

meter

Opener

seed tube

Sliding

Figure 15

Seed Meter

Spring-loaded

idler

18458

Talc Lubricant (821-046C)

IMPORTANT!

All talc is not created equal, use Great Plains

brand talc for optimum seed flow.

Talc lubricant is mandatory forall seeds, especially treated or inoculated seed.

Recommended usage:

For clean seeds sprinkle (1) one cup of talc per 3

bushels of seed.

For seed with excessive treatment, or for humid

plantingenvironments,double ortriple talc rateas

needed.

!

CAUTION

Do not use hands or any part or your body to mix talc

lubricant.

Graphite Lubricant (821-042C)

IMPORTANT!

For Milo Planting Only

Powdergraphitemust bemixedwith themiloseed

in combination with talc for proper seed

singulation.

Recommended usage:

For clean seeds sprinkle (1) one cup of graphite

per 9 bushels of seed.

For seed with excessive treatment, or for humid

planting environments, double or triple graphite

rate as needed.

!

CAUTION

Do not use hands or any part of your body to mix

graphite lubricant.

173-208M

4/11/2005

Page 25

Row Unit Operation

IMPORTANT: Do not back up with row units in

the ground. To do so will cause severe damage and plugging.

For information on row unit adjustments, refer to

page26. Formore information on troubleshooting

row unit problems, see “Troubleshooting”, page

45.

Marker Operation

Optional marker attachments are available from

your Great Plains dealer. Before operating markers, make sure hydraulics are properly bled as

described under “Marker Adjustments”, page 38.

Dualmarkersequippedwith asequence valveare

powered off the same hydraulic circuit. Starting

with both markers folded,the foldingsequence is:

Operating Instructions

23

1. Activate lever - Right unfolds; left stays

folded.

2. Reverselever- Right folds up; left stays

folded.

3. Activate lever - Left unfolds; right stays

folded.

4. Reverse lever - Left folds up; right stays

folded.

5. Sequence repeats.

You can adjust marker folding speed. Refer to

“MarkerAdjustments”,page 38,andadjustfolding

speed to a safe rate. Folding markers at high

speed can damage markers.

4/11/2005

173-208M

Page 26

2015P and 2515P

24

Transporting

!

WARNING

Towing the bean machine at high speeds or with a vehicle that is not heavy enough could lead to loss of vehicle control. Loss of vehicle control could lead to

seriousroadaccidents, injuryand death. Toreduce the

hazard,do not exceed 20 mph. Check that your tractor

has enough ballast to handle the weight of the bean

machine. Refer to your tractor operator’s manual for

ballast requirements.

Beforetransporting the bean machine, followand

check these items:

Unload seed box. Unload seed boxbefore transporting if at all possible. To do so:

• Place tarp under bean machine or a bucket

under each seed meter.

• Use large bucket to empty box as much as

possible. Make sure sliding seed tubes are in

theopen position. Openseed meter cleanout

to empty seed out of sliding seed tube and

meter.

The bean machine can be transported with a full

box of grain, but the added weight will increase

stopping distance and decrease maneuverability.

NOTE: To maintain steering control, you may

needto add ballast to your tractorfront end. Refer

to your tractor operator’s manual for ballast required.

Road rules. Comply with all federal, state and local safety laws when travelingon public roads.

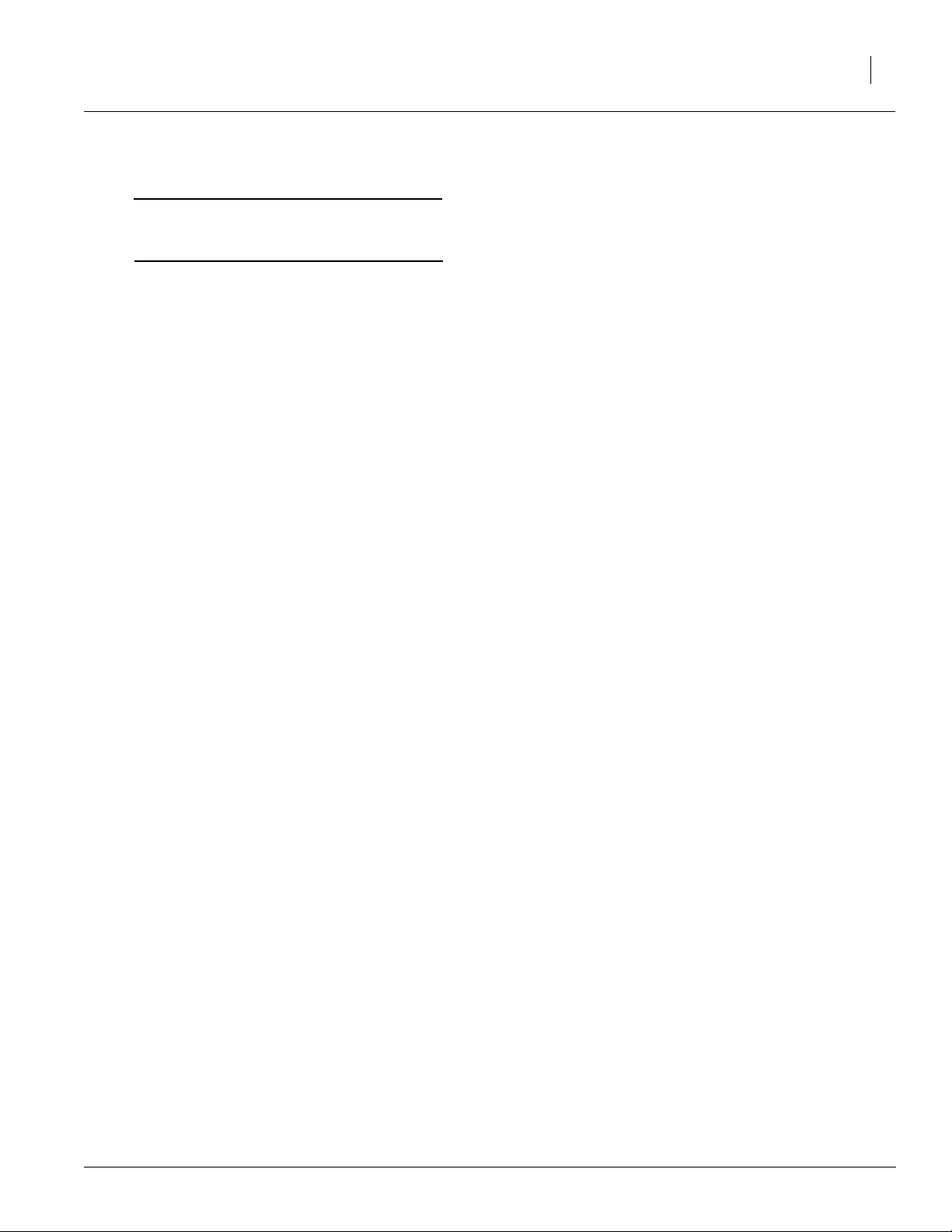

Refer to Figure 16

Clearance. Remember that the bean machine is

wider than the tractor. Allow safe clearance. Fold

up walkboard ladder for maximum clearance.

Transporting with Markers

Always transport markers in the folded position.

Figure 16

Ladder Folded for Transport

18456

Refer to Figure 17

Transporting with Lift Assist

Before transporting or servicing bean machine,

install cylinder lock channels over extended cylinder rods.

During field use, store lock channels on side

plates of lift-assist arms.

173-208M

Figure 17

Lock Channels

17733

4/11/2005

Page 27

Parking

See ”Storage”, page 57 for additional information

on long-term storage.

!

WARNING

Empty seed box before unhitching bean machine to

prevent bean machine from falling backward.

1. Park bean machine on a level, solid area.

2. Lowerthree-point hitch until bean machine is

on ground.

Refer to Figure 18

3. Removepins from parking stands and lower

standsto the ground. If groundissoft, place a

board or plate under stands to increase contact area. Replace pins in stands.

25

4. Extendorretract thetop link ofthe tractoruntil

top three-point pin is free. Remove pin.

5. Removepins from lower links.

13508

Figure 18

Parking Stand

4/11/2005

173-208M

Page 28

2015P and 2515P

26

Adjustments

Row Unit Adjustments

Down Pressure

Springs providethe down pressure necessary for

rowunit disks to open a seed trench. The springs

allow the row unit to float down into depressions

and up over obstructions.

You can adjust down pressure individually for

eachrow unit. Use onlyenoughdown pressure to

cut the seed trench and maintain proper soil-firming overseed. Excessivedown pressure will lead

to premature wear on row-unit components.

Refer to Figure 19

To adjust, lift T-handle:

• Move T-handle back to increase spring pressure.

• Move T-handle ahead toward tractor to decrease spring pressure.

Refer to the Down Pressure Charts on the right

for the amount of spring pressure at the row unit

for each spring setting.

Medium-Duty Spring Package

First Holes (Closest to Tractor) 260 lb

Second Holes 280 lb

Third Holes 310 lb

Fourth Holes 330 lb

Fifth Holes (Closest to Press Wheels) 350 lb

Heavy-Duty Spring Package

First Holes (Closest to Tractor) 360 lb

Second Holes 400 lb

Third Holes 440 lb

Fourth Holes 470 lb

Fifth Holes (Closest to Press Wheels) 530 lb

Down Pressure Charts

173-208M

Increase

spring pressure

Down pressure

T-handle

Decrease

spring pressure

Figure 19

Row Unit Spring Adjustment

Front of bean

machine

18449

4/11/2005

Page 29

Coulter Depth

Optional coulters allow bean machine to penetrate tough ground conditions. Adjust coulters to

the same depth as the row unit disks.

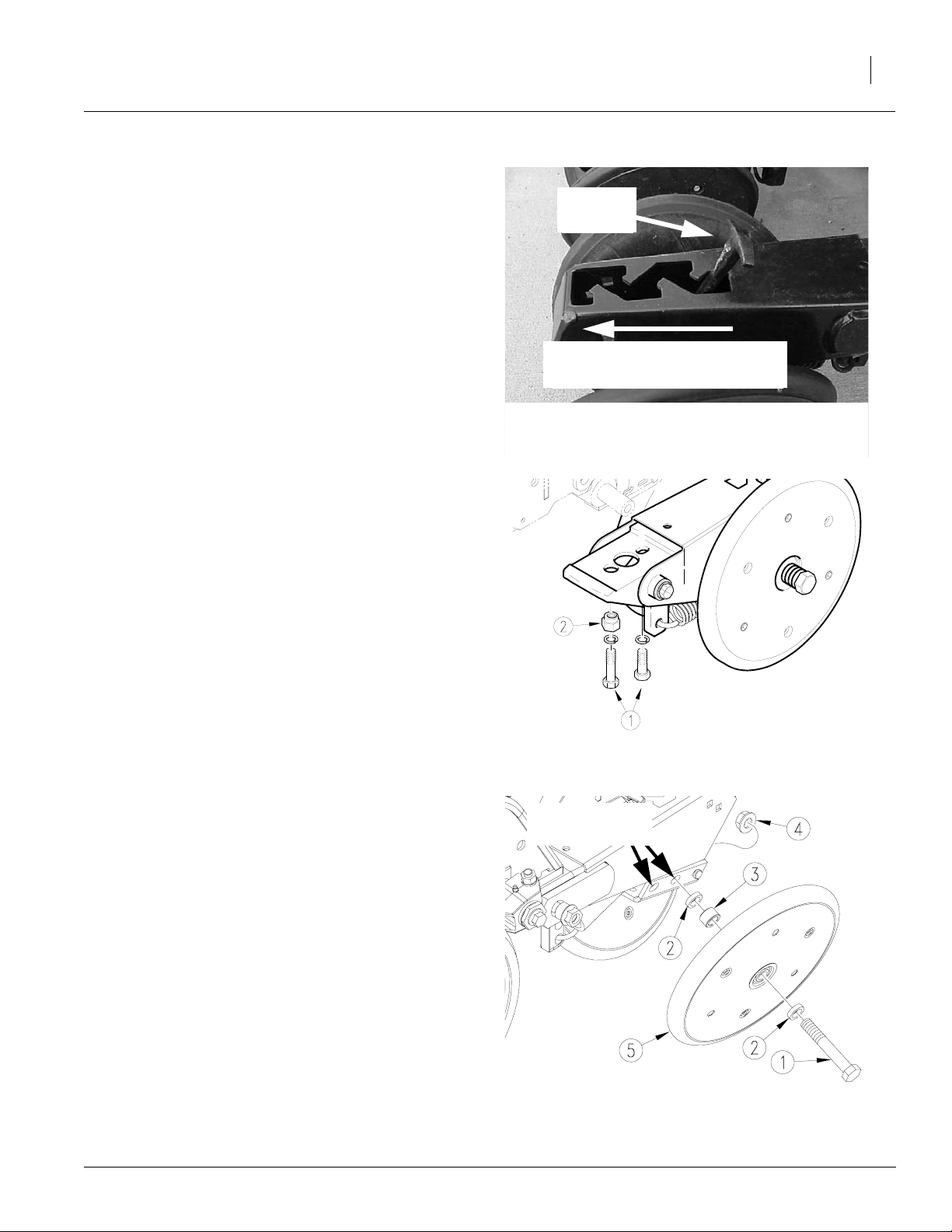

Refer to Figure 20

1. To adjust coulter depth, loosen 3/4-inch jam

nut (1) and 3/4-by-3-inch hex bolt (2).

2. Byturning camhex(3), rotatethe camcasting

to the desired height. Each notch represents

about 1/4 inch of depth.

3. Torque bolt and jam nut to values recommended in the “Appendix,” page 80.

Row Unit Seeding Depth

Seeding depth is controlled by gauge wheels

mounted on the sides of the row unit disks.

Figure 20

Row Unit Mounted Coulter

Adjustments

15053

27

Refer to Figure 21

To adjust seeding depth:

1. Raise bean machine to remove weight from

gauge wheels.

2. Raise and move T-handle.

• Move T-handle ahead to decrease seeding

depth.

• Move T-handle back to increase seeding

depth.

3. MoveT-handles on all row units to the same

location.

T-handle

Increase

seeding depth

Opener Depth Adjustment

Figure 21

Decrease

seeding depth

18459

4/11/2005

173-208M

Page 30

2015P and 2515P

28

Side Gauge Wheels

Refer to Figure 22

The side gauge wheels have two, interrelated

adjustments:

• angle of side gauge wheel, and

• distance between side gauge wheel and row

unit disk.

Refer to Figure 23

Side Gauge

Wheel

Opener

Disks

Side Gauge

Wheel

Adjust side-gauge-wheel angle so the wheels

contact the row unit disks between 4 and 8

o’clock.

At the same time, keep the side gauge wheels

close to the opener disks so openers do not plug

with soil or trash but far enough out so the disks

and wheels turn freely.

Refer to Figure 24

To adjust side gauge wheels:

1. Raise implement slightly to remove weight

from side gauge wheels.

2. Loosen hex-head bolt (1). Move wheel and

arm out on o-ring bushing.

3. Loosenpivot bolt (2). Turn hex adjuster (3) so

roll pin (4) is at 1 o’clock. Use this as the starting point for adjustment.

4. Movewheel arm in so side gauge wheel contacts row unit disk. Tighten hex-head bolt (1)

to clamp arm around bushing and shank.

8 o’clock

Incorrect Correct

Figure 22

Side Gauge Wheels

4 o’clock

17812

Figure 23

Wheel-to-Disk Contact Area

5. Check the wheel-to-disk contact. Lift wheel

and arm. When let go, the wheel should fall

freely.

• If wheel does not contact disk from 4 to 8

o’clock, move hex adjuster until wheel is an-

gled for proper contact with disk.

• If wheel does not fall freely, loosen hexheadbolt (1) andslide wheel armout just until

wheel and arm move freely. Retighten hexhead bolt.

6. Keepturning hex adjuster and moving wheel

arm until the wheel is adjusted properly.

When satisfied, tighten pivot bolt to 110 footpounds. Tighten pivot bolt (2).

173-208M

1

Starting Point

Side Gauge Wheel Adjustment

3

2

4

18450

Figure 24

4/11/2005

Page 31

1 x 12 Closing Wheel Option

The closing wheels can be adjusted for down

pressure, alignment and offset.

Down Pressure. Adjust closing wheel so it has

enough down force to close the seed trench without unnecessary compaction.

Refer to Figure 25

Starting

position

Adjustments

29

Start with T-handle in first notch. If seed trench

doesnotclose, move handle tonextnotch and try

again.Keepmoving handleback untilseed trench

closes.

Alignment. If one closing wheel is running in the

seed trench or closing wheels are not centered

over the seed trench, adjust closing wheels as

follows.

Refer to Figure 26

1. Raisebeanmachineslightly toremoveweight

from closing wheels.

2. Loosen two 1/2-inch mounting bolts (1).

3. Turn adjuster cam (2) left or right to center

wheels over the seed trench.

4. Torque 1/2-inch mounting bolts as recom-

mended, see “Appendix,” page 80.

Move handle back for more

down pressure

Figure 25

Closing Wheel Down Pressure

Figure 26

Closing Wheel Alignment

17888

17719

Offset. The closing wheels can be offset to help

preventtrash from plugging the closing wheels.

To offset the closing wheels:

Refer to Figure 27

1. Raisebeanmachineslightly toremoveweight

from closing wheels.

2. Remove5/8-inch bolt (1), spacers (2), pivot

tube (3) and hex flange nut (4) attaching

wheel (5) to press-wheel arm.

3. Move closing wheel (5) to other mounting hole

and reattach with hardware. Torque bolt as recommended, see “Appendix,”page 80.

4/11/2005

mounting hole

locations

Closing Wheel Offset

Figure 27

12347

173-208M

Page 32

2015P and 2515P

30

Closing Disk Option

For proper seed-to-soil contact, the closing disks

must have enough down pressure to close the

seed trench without unnecessary soil

compaction.

Refer to Figure 28

To adjust downpressure on closing disks, ratchet

spring cam to next cam height by turning head of

support bolt (1) clockwise.

Frame Height

Bean machine operating height directly affects

the working range of the row units. Initially adjust

frame height as explained under “Leveling Bean

Machine”, page 18. You can make further adjustments to compensate for field conditions.

Figure 28

Closing Disk and Tube Holes

17720

Refer to Figure 29

NOTE: Jam nut is left-hand threaded.

Make sure upper clevis (2) is in the upper mount

hole. Loosen jam nut (1) to lengthen or shorten

gauge-wheel turnbuckle.

• Lengthening turnbuckles raises bean machine and allows less row unit down float.

• Shortening turnbuckleslowersbean machine

and allows less row unit up float.

Adjust both turnbuckles to the same length and

tighten jam nuts.

After adjusting gauge-wheel turnbuckles, be sure

to level the bean machine with top hitch link.

NOTE:Lowering the bean machine increases the

risk of row unit damage on rocks or obstructions.

Seeding Rate

Adjusting the seeding rate requires the following:

1. adjusting drive speed range sprockets,

Figure 29

Gauge Wheel Turnbuckle

17773

2. adjusting transmission sprockets,

3. preparing seed meters,

4. checking seeding rate.

Before setting the seeding rate, rotate the gauge

wheels. Check that seed meters, seed tubes and

drives are working properly and free from foreign

material.

173-208M

4/11/2005

Page 33

Drive Speed Range Sprockets

Selectthe correct drivespeedrange sprocketsfor

your seed by referring to the Seed Rate Charts

beginning on page 66.

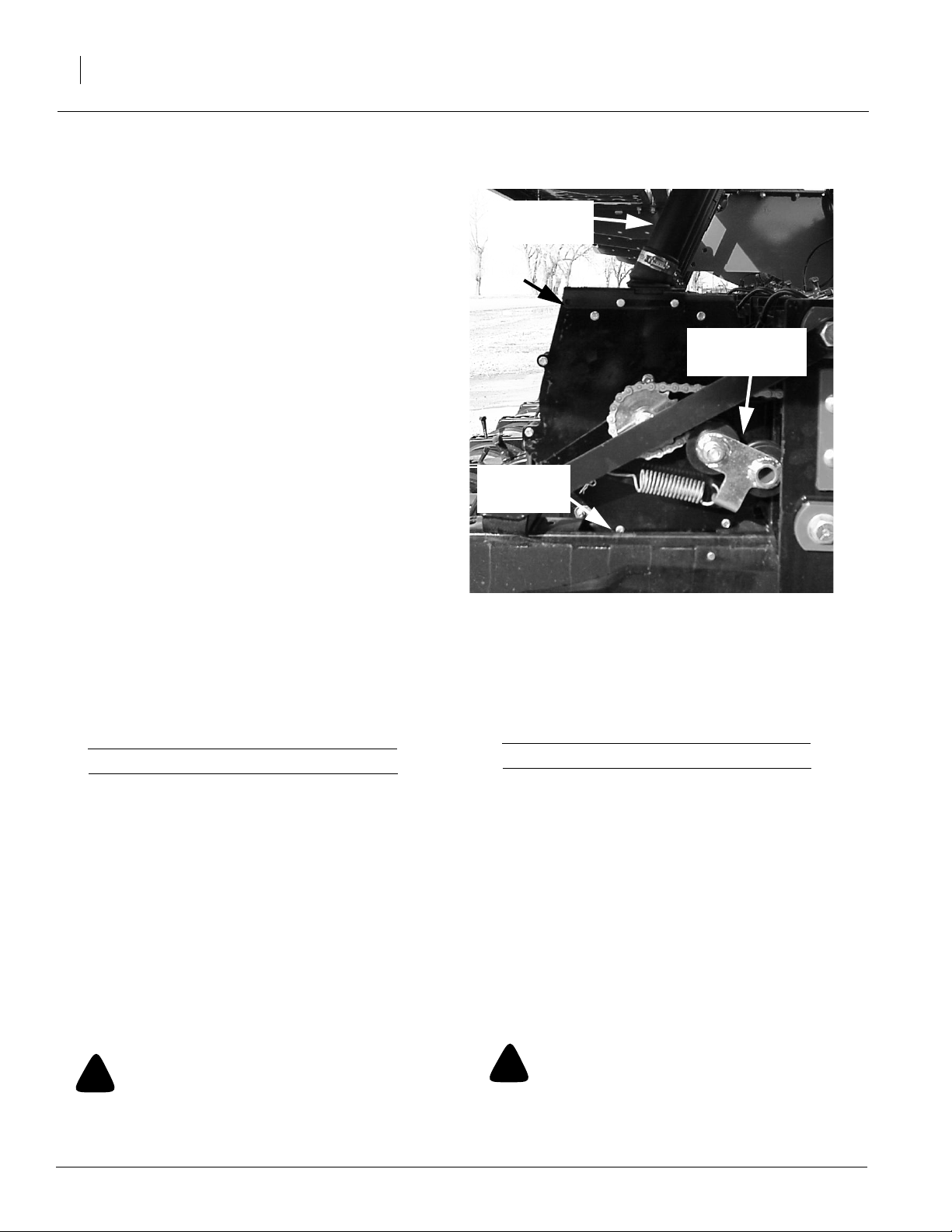

Refer to Figure 30

Loosen idler (1) and remove chain (2). Remove

retaining pins (3) from shafts and install speed

range sprockets as necessary.

NOTE: Make sure the correct sprockets have

been installed in the DRIVER and DRIVEN locations as shown.

Reroute chain over sprockets and idlers as

shown. Move idler into chain so chain has 1/4inch slack in its longest span. Tighten idler and install retaining pins.

Driven

3

2

Adjustments

31

Set the same drive range sprocket combination

on both gauge wheels.

Transmission Sprockets

To change the seeding rate, change the transmission sprocket combination. Refer to the Seed

Rate Charts beginning on page 66.

Refer to Figure 31

Loosen idler plate (1) and remove drive chain (2).

Removelynch pins (3) from shafts and rearrange

drive and driven sprockets as necessary.

Reroute drive chain over sprockets and idlers as

shown. Move idlers into chain so chain has 1/4inch slack in its longest span. Tighten idlers and

install lynch pins.

1

Driver

Figure 30

Drive Speed Range Sprockets Adjustment

Driven

Driver

3

2

3

18277

Set the same transmission sprocket combination

on both gauge wheels.

4/11/2005

1

Figure 31

Transmission Sprockets Adjustment

3

18278

173-208M

Page 34

2015P and 2515P

32

Shutting Off Seed Flow

Refer to Figure 32

Figure 32 shows the sliding seed tubes in the

open position. To shut off seed flow, move tubes

forward.The following instructions explain how to

shut off seed flow to each meter.

Sliding seed

tubes

Shut off

Refer to Figure 33

1. Removethe retaining clipand pullpin. Do not

remove cotter pin.

Refer to Figure 34

2. Movemeter cap to position seed tube over

shut off pad.

3. Place pin in hole of meter cap and install retaining clip.

Figure 32

Sliding Seed Tubes in open position

Slidingseed

tube

Retaining

clip

Figure 33

Sliding

seed tube

18290

Shut off

pad

18302

4. Repeat steps 1 through 3 for each meter.

NOTE: When pin with retaining clip is located in

the slot, sliding seed tube is open. When pin with

retaining clip is located in the hole, sliding seed

tube is closed.

173-208M

Retaining

clip

Figure 34

Figure 1

18303

18303

4/11/2005

Page 35

Cleaning Out Meters

NOTE:Shut off sliding seed tubes before attempting to clean out seed meters.

Refer to Figure 35

For seed meter clean out:

1. Position tarp or buckets under the row unit(s)

whose meter(s) you will be cleaning out.

Retaining clip

Adjustments

33

2. Removeretaining clip and pull pin.

Refer to Figure 36

3. Pull up on meter clean out door to open.

Refer to Figure 37

Clean out door

Meter clean out door

Clean out door

Figure 35

Meter clean out

Figure 36

18261

19190

4. When meter is empty, push meter clean out

door back to its original position to close.

NOTE:You mayneed to shake the clean out door

a little before closing to make sure all seeds fall

out.

5. Replace pin and retaining clip.

4/11/2005

Clean out door

Close and pin clean out door

Figure 1

Figure 37

Meter Clean Out

18293

19192

173-208M

Page 36

2015P and 2515P

34

Changing Seed Meter Wheels

Choose the correct seed meter wheel for the type

ofseed you will beusing. Be sure to usethe same

wheel type on all meters.

Refer to Figure 38

To change seed meter wheels:

1. Shutoff seedflow to metersby movingsliding

seed tubes. For more information see page

32.

Refer to Figure 39

2. Clean out meter. For more information see

page 33.

Sliding seed

tube

Figure 38

Sliding seed tube shut off

18298

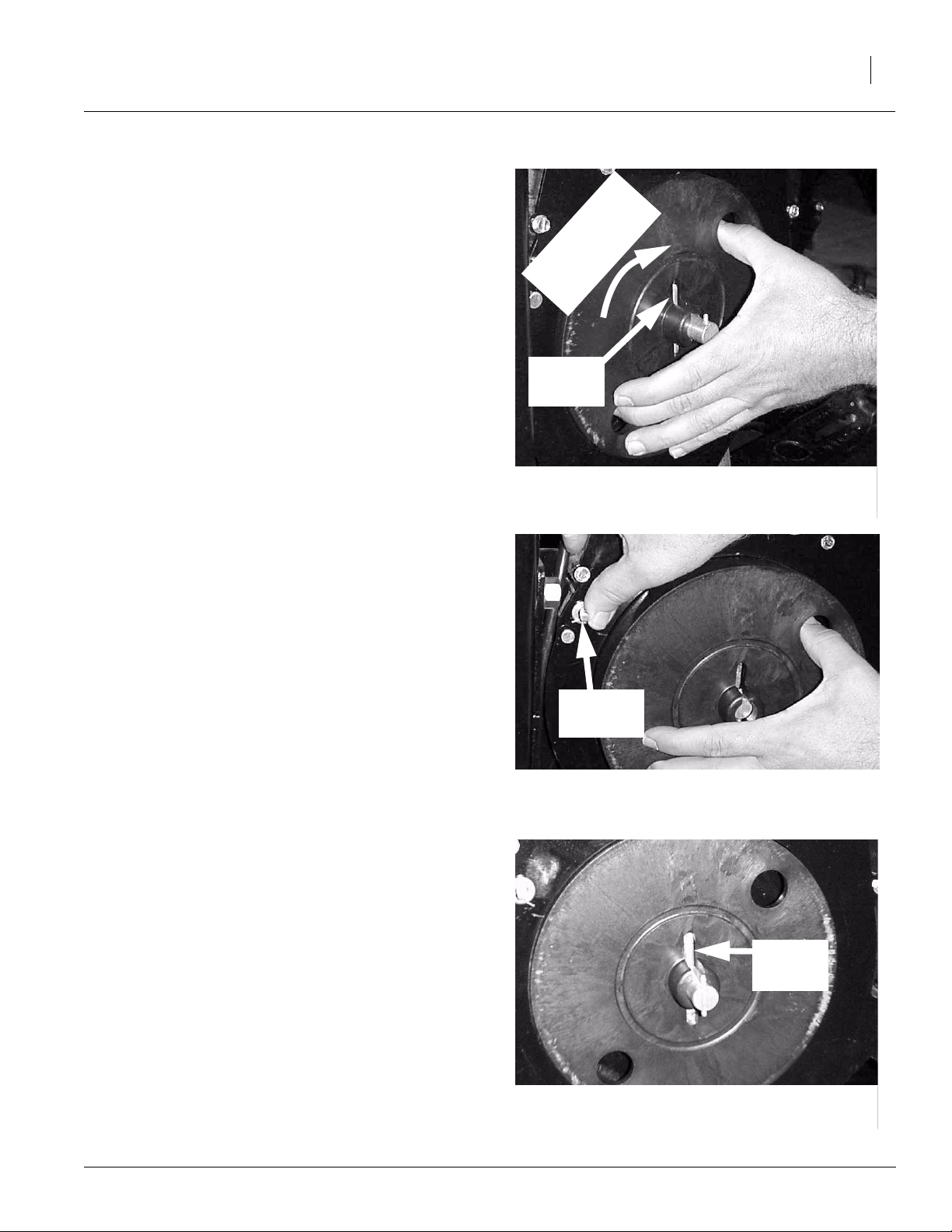

Refer to Figure 40

3. Push in spring-loaded wheel retainer and

turn. Pull off wheel retainer and spring.

173-208M

Figure 37

Figure 39

Meter clean out

Meter clean out

Wheel retainer

and spring

Figure 40

Remove wheel retainer and spring

19192

19192

18294

4/11/2005

Page 37

Refer to Figure 41

4. Pull seed meter wheel out about 1/4 inch, or

pastthewheel drivepin, andspin backwardto

clean out seeds from top pockets.

Adjustments

35

5. Removeseed meter wheel.

NOTE: With the seed meter wheel removed, you

may want to check the meter for internal damage

or trash.

Refer to Figure 42

6. Place new wheel on meter wheel shaft and

push meter slide retaining clip forward while

pushing in seed meter wheel.

Spin wheel

backward before

removing

Wheel

drive pin

Remove seed meter wheel

Retaining

clip

Figure 41

18295

Refer to Figure 43

7. Be sure slots in the center of seed meter

wheel are aligned with the wheel drive pin on

the meter shaft.

4/11/2005

Figure 42

Place new seed meter wheel on wheel shaft

18296

Wheel

drive pin

Figure 43

Position seed meter wheel

18299

173-208M

Page 38

2015P and 2515P

36

Refer to Figure 44

8. Reinstallspring and lock wheel knob in place.

Wheel

knob

Refer to Figure 45

9. Close and pin seed meter clean out.

Refer to Figure 46

10. Open sliding seed tubes and pin in place.

Figure 44

Wheel retainer locked in place

Figure 45

Close and pin clean out

19190

19192

173-208M

Figure 46

Open and pin sliding seed tube

18300

4/11/2005

Page 39

Checking Singulated Seeding Rate

The seed charts are based on cleaned and sized

seed. Extreme seed size variations, foreign material and tire pressure will affect the seeding rate.

Check the seed population rate as described

below.

1. Adjust the planting depth to a shallow setting.

2. Plantat the desired planting speed fora short

distance.

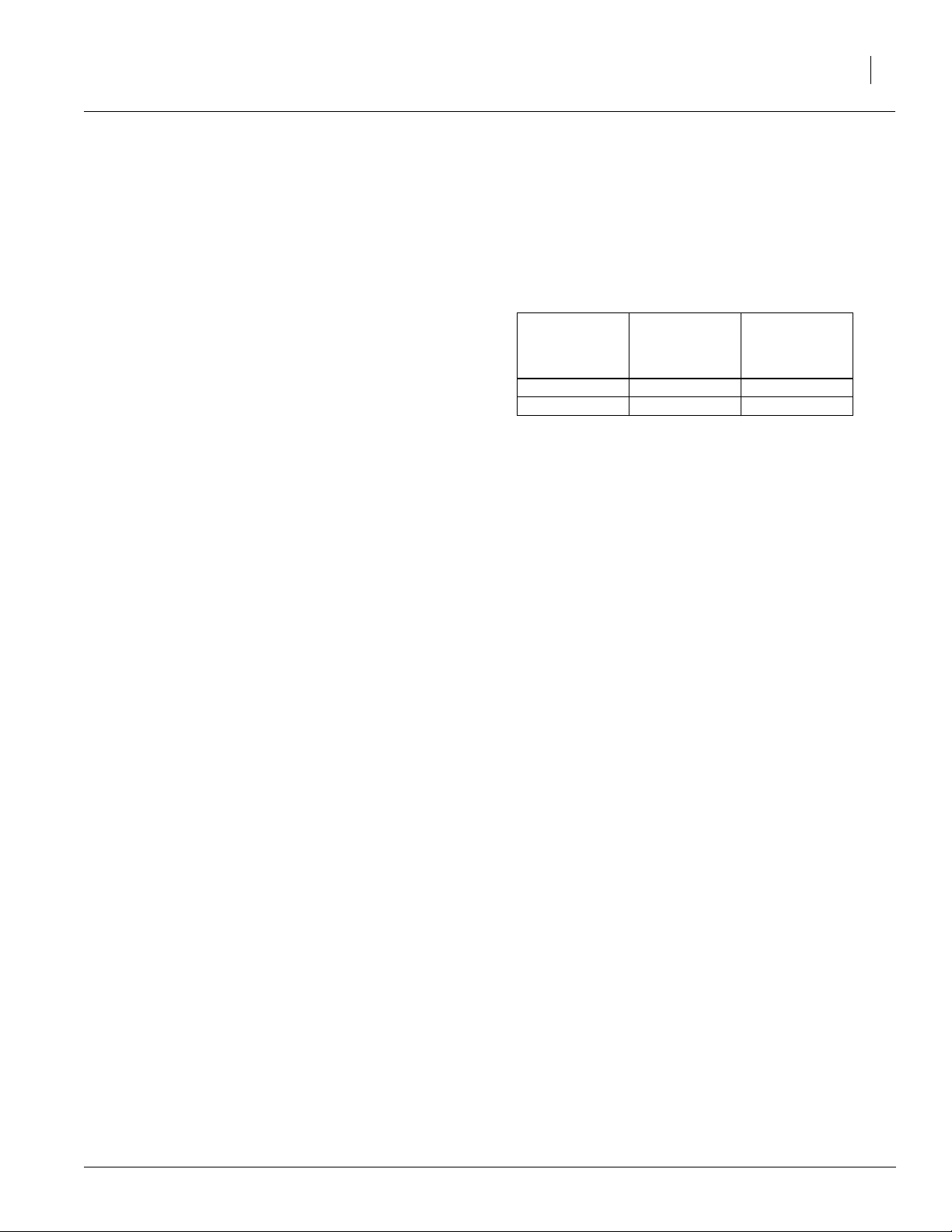

3. Using Table 1, determine how many rows

need to be counted.

4. Measurea distance of 17’ 5” in the planted area.

5. Count the number of seeds, in the appropriate number of rows, over the distance measured.

Planted row

spacing

(inches)

15 2 17’ 5”

30 1 17’ 5”

Number of

rows to count

Table 1

Adjustments

Length of row

to measure

37

6. Multiply the number of seeds counted by

1,000. This is the plant population in seeds

per acre.

Example 1:

If you have a 15-inch row spacing bean machine,

according to Table 1, two rows must be counted.

Measure 17’ 5” and count the number of seeds in

two rows. If the number is, for example, 180, multiply 180 by 1,000.

180 x 1,000 = 180,000 seeds per acre.

Example 2:

If you have a 15-inch row spacing bean machine,

butdesire to plant soybeans on 30-inch row spacing, according to Table 1, one row must be

counted. Measure 17’ 5” and count the number of

seeds in one row. If the number is, for example,

180, multiply 180 by 1,000.

180 x 1,000 = 180,000 seeds per acre.

7. Ifthe plantingpopulation is significantly different than desired, make the following checks:

• Double check the transmission and range

sprocket combinations. Refer to the seed

population chart for the seed being planted.

Seed rate charts

Seed rate charts begin on page 66. The charts

givetransmission sprocketcombination and drive

range sprockets for row spacing used, to achieve

the population or pounds per acre desired. The

charts also giveseedspacing for singulated seed.

4/11/2005

• Check the air pressure in the gauge wheel

tires. Refer to “Tire Inflation Chart” on page

81.

• Refer to Troubleshooting on page 45.

Each seed chart has a corresponding page showing the different drive ranges for that seed and a

transmission sprocket reference.

173-208M

Page 40

2015P and 2515P

38

Marker Adjustments

Bleeding Marker Hydraulics

To fold properly, the marker hydraulics must be

free of air.If the markers fold in jerky, uneven motions, follow these steps.

!

CAUTION

You may be injured if hit by a folding or unfolding

marker. Markers may fall quickly and unexpectedly if

the hydraulics fail. Never allow anyone near the bean

machine when folding or unfolding the markers.

!

WARNING

Escaping fluid under pressure can have sufficient pressure to penetrate the skin. Check all hydraulic lines

and fittings before applying pressure. Fluid escaping

froma very small hole can be almost invisible.Use paper or cardboard, not body parts, and wear heavy

gloves to check for suspected leaks. If injured, seek

medical assistance from a doctor that is familiar with

this type of injury. Foreign fluids in the tissue must be

surgically removed within a few hours or gangrene

will result.

Check that tractor hydraulic reservoir is full.

1. Withboth markers lowered into field position,

loosenhydraulic-hose fittingsat rod and base

endsof markercylinders.If applicable,loosen

fittings on back side of sequence valve.

IMPORTANT: Neverbleed an O-ring fitting. Instead, bleed a nearby pipe or JIC fitting.

2. With tractor idling, activate tractor hydraulic

valveuntil oil seeps out around a loosened fitting. Tighten that fitting.

IMPORTANT: JIC fittings do not require high

torque. JIC and O-ring fittings do not require

sealant. Always use liquid pipe sealant when

adding or replacing pipe-thread fittings. To

avoid crac king hydraulic fittings from over

tightening, do not use plastic sealant tape.

3. Reactivate tractor hydraulic valve until oil

seeps out around another loosened fitting.

Tighten that fitting. Repeat process until all

loosened fittings have been bled and tightened.

173-208M

4/11/2005

Page 41

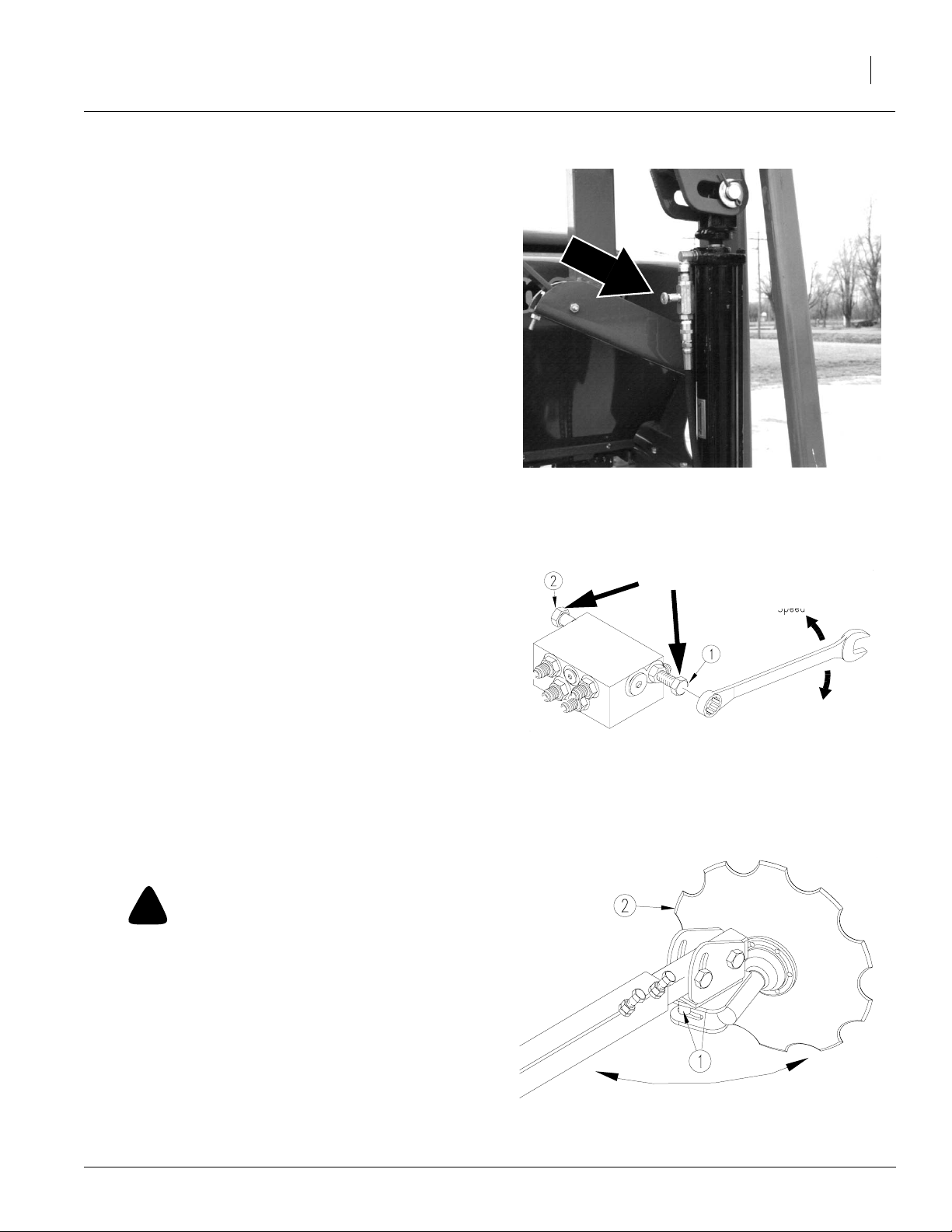

Folding Speed with Needle Valves

Refer to Figure 47

A needle valvecontrols the folding speed of markersthat areplumbed separately.The needlevalve

is near the rod end of the marker cylinder.

With tractor idling at a normal operating speed,

adjust markerfoldingto a safe speed. Turn adjustment knob clockwise to reduce folding speed or

counterclockwise to increase folding speed. Excessivefoldingspeed could damage markersand

void the warranty.

Adjustments

39

Folding Speed with Sequence Valve

Refer to Figure 48

If markers are tied together with an optional sequence valve, adjust folding speed with hex

adjustment screws on the sequence-valve body.

There is one adjustment screw for raising speed

(1) and one forlowering speed (2). Identifyadjustment screws by markings stamped in valve body.

With tractor idling at a normal operating speed,

adjust markerfoldingto a safe speed. Turn adjustmentscrews clockwise to decrease foldingspeed

and counterclockwise to increase folding speed.

Excessive folding speed could damage markers

and void the warranty.

Afteradjustingthefoldingspeed, tighten jam nuts

on hex adjustment screws to hold settings.

Marker Disk Adjustment

!

CAUTION

Marker disks may be sharp. Use caution when making

adjustments in this area.

Figure 47

Needle Valve

Hex adjustment

screws

Figure 48

Speed Adjustment, Sequence Valve

Increase

speed

Decrease

speed

17620

14048

Changing disk angle

Refer to Figure 49

Ifmark leftbymarker disk is not clearly visible,adjust disk angle to make a wider mark. Loosen two

1/2 inch bolts (1) holding disk assembly (2). Rotate disk assembly as desired.

4/11/2005

Figure 49

Disk Angle

17676

173-208M

Page 42

2015P and 2515P

40

Leveling marker disk

Refer to Figure 50

If the marker disk is not square with the ground

when the marker is lowered in the field, or if the

marker arm tends to fold up while lowered in the

field, adjust the marker mount.

To adjust, loosen 1/2-inch bolts (1) and rotate

marker mount (2) until marker disk is square with

the ground (3).

Transport Carrier

Refer to Figure 51

Whenmarker isfolded,the second sectionshould

rest in transport-carrier saddle.

To adjust front-to-rear position of saddle, loosen

1/2-by-6-inch u-bolts (1) that fasten transport-carrier mount onto boxframe.Slide transport-carrier

assembly forward or back as needed.

To adjust height of saddle, loosen 1/2-by-2-inchubolts (2) that hold carrier tube to mounting bracket. Slide carrier tube up or down as needed.

17635

Figure 50

Squaring Disk Marker

173-208M

Figure 51

Adjusting Marker Carrier

15632

4/11/2005

Page 43

Marker Chain (2515P only)

Refer to Figure 52

There are two interrelated adjustments for the

marker chain. Make these adjustments in the following order.

1. Lifting Slack. With marker unfolded, back

full-threaded adjustment bolt (1) down until

head extends as little as possible. Slowly fold

marker while observing disk. If marker disk

slides across ground more than a foot before

chain and linkage lifts it up, the chain is too

long.

Shorten chain one or two links by moving clevis(2). Checkadjustmentby repeatingfolding

process.

If chain is too short when marker is unfolded,

it will prevent end of marker from dropping

into field depressions, causing skips in your

marker line. Correct this condition by lengthening chain one or two links at clevis (2).

2. FoldingSlack.Fold marker.Usefull-threaded

adjustment bolt (1) to take slack out of chain

whilemarkerisfolded.Extend boltuntil thereis

no chain slack. Lock bolt in this position by

tightening nuts (3) on either side of upright

channel (4).

Figure 52

Marker Chain Adjustment

Adjustments

15669

41

4/11/2005

173-208M

Page 44

2015P and 2515P

42

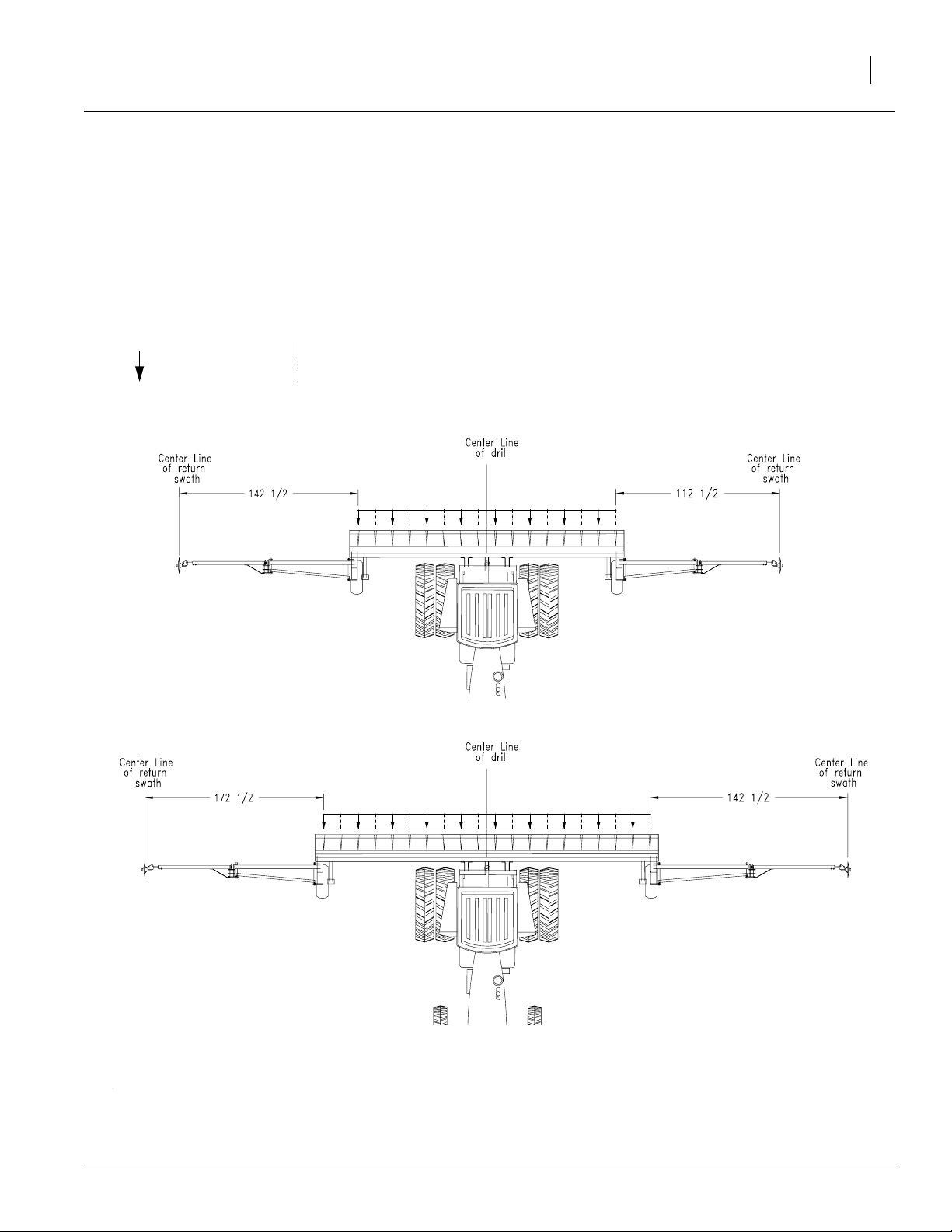

Marker Width

Refer to Figure 53

To adjust marker width, loosen jam nuts (1) and

1/2-inchset screws(2). Movemarkerdisk tube (3)

in or out to get the proper dimension.

Refer to Figure 54

The diagram below shows marker widths for 15inch spacing with all meters open.

To measure for marker width adjustment:

1. Lowerbean machine in the field and drive forward a few feet.

2. Measurefrom themiddle of theoutside rowto

the mark in the ground made by the marker

disk.

NOTE:If planting 30 inch rowspacing byshutting

off meters, markers may need to be readjusted.

Refer to page 43 for more information.

2015P

18304

Figure 53

Marker Width

173-208M

2515P

Figure 54

Marker Width

18530

4/11/2005

Page 45

Refer to Figure 55

A 30 inch row spacing can be achieved by shutting off certain meters.The diagrambelow shows

which rows to shut off, which to leave on and the

marker width to use.

Legend:

= planting rows = non planting rows

Adjustments

43

2015P

2515P

Figure 55

Marker Width

18551

4/11/2005

173-208M

Page 46

2015P and 2515P

44

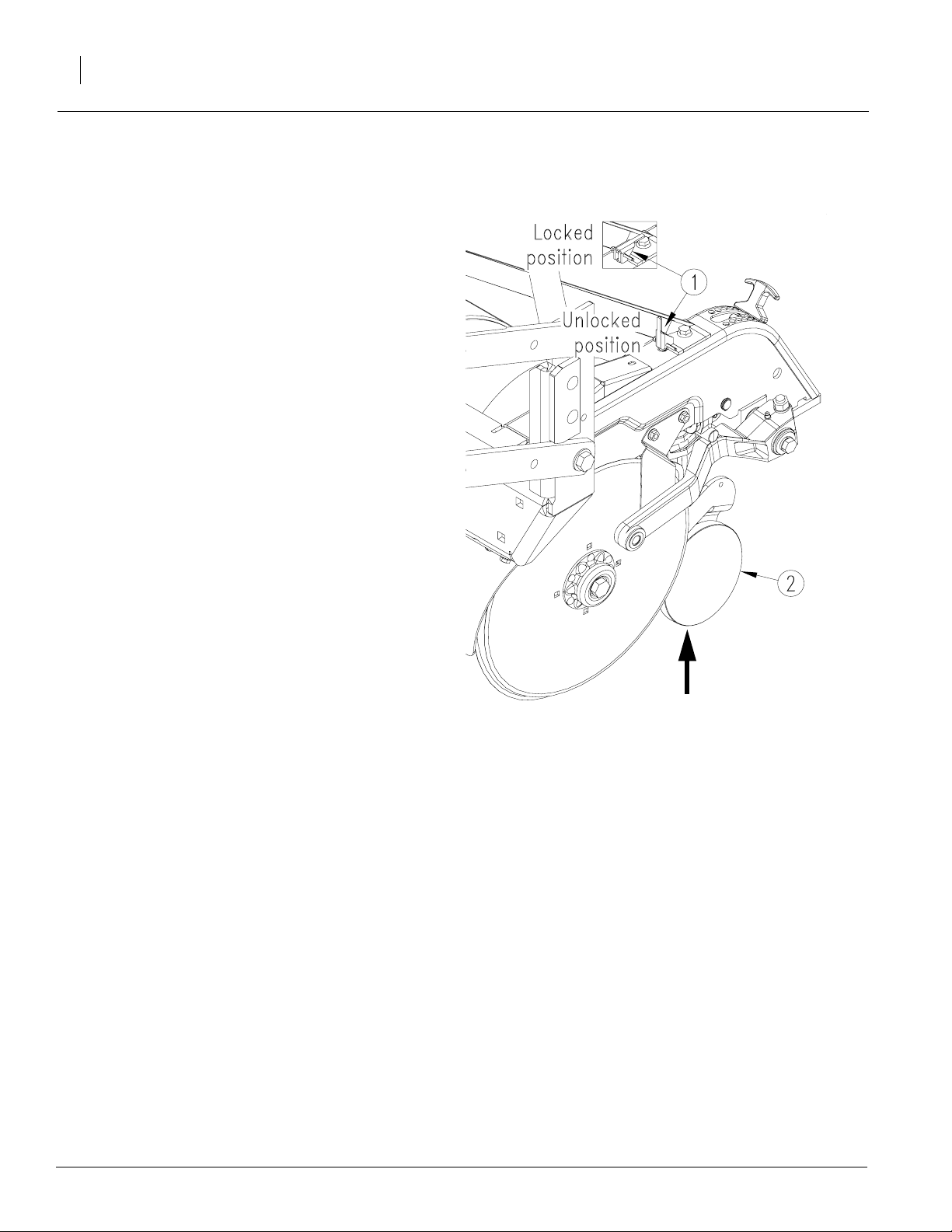

Seed-Lok Lock Up

Refer to Figure 56

Optional Seed-Lok firming wheels provide additional seed-to-soil contact. The wheels are spring

loaded and do not require adjusting. In some wet

and stickyconditions the wheels may accumulate

soil.

To lock up the firming wheels in wet conditions,

raise bean machine. Push the lock-up handle (1)

on top of the row-unit body up into the position.

Push up on the firming wheel (2) until the wheel

arm latches up.

To unlock the firming wheels, turn the lock-up

handle back to its 90-degree position.

NOTE:Side gauge wheel is removed in figure 56

for clarity.

Push Seed-Lok

up to lock.

Figure 56

Seed-Lok Lock Up

18454

173-208M

4/11/2005

Page 47

Troubleshooting

Problem Cause Solution

Troubleshooting

45

Planting too much

Planting too little

Incorrect seed rate or sprocket combination.

Wrong seed meter wheel installed. Install correct seed meter wheel.

Actual field size is different. Verify field size.

Excessive overlap.

Irregular shaped field.

Incorrect tire size or air pressure. Correct tire size and air pressure, page

Meter clean out door is open. Close and pin meter clean out door,

Seed meter wheel spring or retaining

cap damaged or missing.

Incorrect seed meter wheel for seed

size.

Seed meter wheel not seated correctly

on meter shaft.

Seed meter wheel damaged or missing. Check seed meter wheel and replace if

Seed meter slide is sticking open. Remove and clean seed meter slide and

Seed meter slide worn. Replace seed meter slide, page 51.

Incorrect seed rate or sprocket combina-

tion.

Check seed rate information beginning

on page 30.

Adjust marker, page 42.

81.

page 33.

Check seed meter wheel spring and

retaining cap, page 34.

Verify seed count on seed bag with seed

meter wheel.

Check installation of seed meter wheel,

page 34.

damaged.

check for wear, page 51.

Check seed rate information beginning

on page 30.

4/11/2005

Excessive field speed. Slow down. Check Seeding Rate Chart

Incorrect seed meter wheel for seed

size.

Incorrect tire size or air pressure. Correct tire size and air pressure, page

Check seed level in seed box. Fill seed box.

Actual field size is different. Verify field size.

Excessive gaps between bean machine

passes.

Not enough talc lubricant Add more talc lubricant, page 22.

Build up of seed treatment in meter. Clean out seed meter, page 33. Add

for correct maximum field speed.

Verify seed count on seed bag with seed

meter wheel.

81.

Adjust marker, page 38.

more talc lubricant.

173-208M

Page 48

2015P and 2515P

46

Problem Cause Solution

Planting too little (cont’ d)

Uneven seed spacing

Seed flow shut off not 100% open and

pinned.

Plugged sliding seed tube. Clean out sliding seed tube.

Plugged row unit seed tube. Lift up bean machine, expose bottom of

Seed meter wheel damaged. Replace seed meter wheel.

Obstruction in meter (foreign material or

uncleaned seed).

Thrown or worn drive chains. Check drive chains.

Worn sprockets and/or chain idlers. Replace sprockets and/or chain idlers,

Excessive field speed. Slow down. Check Seeding Rate Chart

Unclean seed. Use clean seed.

Lack of talc lubricant. Add talc lubricant, page 22.

Build up of seed treatment in meter. Clean out seed meter, page 33. Add

Seed-Lok plugging. Lock up Seed-Lok, page 44.

Opener disks not turning. See “Opener disks not turning freely” in

Check seed flow shut off, page 32.

seed tube and clean out.

Clean seed meter.

page 55.

for correct maximum field speed.

more talc lubricant.

this Troubleshooting chart.

Uneven seed depth

Plugged or damaged opener seed tube. Lift up bean machine, expose bottom of

Worn/rusted sprockets and/or chain

idler.

Seed meter wheel damaged or worn. Check seed meter wheel and replace.

Seed meter slide worn. Replace seed meter slide, page 51.

Plugged sliding seed tube. Clean out sliding seed tube.

Incorrect seed meter wheel for seed

size.

Excessive field speed. Slow down. Check Seeding Rate Chart

Coulter depth adjustment Check adjustment, see page 27.

Planting conditions too wet. Wait until drier weather.

Bean machine frame height incorrect. Check bean machine frame height, page

Bean machine not level front-to-back in

field.

Row unit side depth wheels are set too

deep for soil conditions or coulter depth.

Row unit spring force is set too high. Check row unit adjustments, page 26.

seed tube and clean out.

Check and replace any worn/rusted

sprockets or chain idlers.

Verify seed count on seed bag with seed

meter wheel.

for correct maximum field speed.

30.

Readjust top link to level bean machine.

Check row unit adjustments, page 26.

173-208M

Seed-Lok building up with dirt. Lock up Seed-Lok, page 44.

4/11/2005

Page 49

Problem Cause Solution

Troubleshooting

47

Uneven seed depth (cont’ d)

Opener disks not turning

freely .

Acremeter does not measure

accurately

NOTE:Acremeter is most accu-

rate when seeding back and forth

with markers with few headlands,

curves and pointrows.

Seed bouncing out of furrow. Engage Seed-Lok in dry conditions,

Damaged row unit seed tube. Check disk spreader, page 55.

Partially plugged row unit seed tube. Lift up bean machine, expose bottom of

Row unit plugged with dirt. Clean row unit.

Planting conditions too wet. Wait until drier weather.

Seed-Lok is plugging opener. Lock up Seed-Lok, page 44.

Bean machine frame height incorrect. Check bean machine frame height, page

Bean machine not level front-to-back in

the field.

Opener side depth wheels not adjusted

correctly.

too tight - dragging on blade

too loose - allowing dirt between

blade and wheel

Row unit spring force is set too high. Check row unit adjustments, page 26.

Too much blade-to-blade contact. Take shims under head of bolt and put

Failed disk bearings. Replace disk bearings.

Bent or twisted opener frame. Replace opener frame.

Incorrect tire size or air pressure Correct tire size or air pressure, page 81.

Excessive overlap or gaps between

passes.

Soil conditions. Loose soil and slippage will cause varia-

Check that acremeter is for your width of

bean machine.

page 44.

seed tube and clean out.

30.

Readjust top link to level bean machine.

Check row unit adjustments, page 26.

between opener and disk bearing, see

page 56 for information.

Avoid overlap or gaps. Check marker

adjustment, page 42.

tions in acres registered.

Refer to bean machine parts manual.

4/11/2005

Press wheels not compacting

the soil as desired

Actual field size different. Verify field size.

Too wet or cloddy. Wait until drier weather or rework

Coulter set too shallow. Check coulter adjustment, page 27.

Bean machine not running level front-to-

back in the field.

Row unit spring pressure too high. Reduce row unit spring pressure.

Not enough pressure on press wheels. Check row unit adjustment, page 26.

ground.

Readjust top link to level bean machine.

173-208M

Page 50

2015P and 2515P

48

Problem Cause Solution

Excessive seed cracking

Bean machine boxes do not

empty evenly

Excessive field speed. Slow down. Check Seed Rate Chart for

Unclean seed. Use clean seed.

Incorrect seed meter wheel. Change seed meter wheel, page 34.

Incorrect seed size for seed meter

wheel.

Build up of seed treatment in seed meter

wheel pockets.

Worn or damaged seed meter wheel. Replace seed meter wheel.

Worn or damaged meter slide. Replace meter slide, page 51.

Damaged, old or dry seed. Use clean, new seed.

Right and left hand seed rates are not

set the same.

Tire sizes or tire inflation not equal on

right and left gauge wheels.

Meter(s) are shut off. Open meter(s).

Row unit seed tube plugged. Lift up bean machine, expose bottom of

Sliding seed tube plugged. Clean out sliding seed tube.

Drive chains damaged or missing. Replace drive chains.

Drive torque requirements different on

right and left gauge wheel drives.

correct maximum field speed.

Verify seed count on seed bag with seed

meter wheel.

Clean seed meter wheel. Add more talc

lubricant.

Readjust rates, see Seed Rate Chart.

Correct tire size or tire inflation, page 81.

seed tube and clean out with wire.

Check gauge wheels and tires.

Press wheel or row units plugging

Unequal number of sliding seed tubes in

each box compartment.

Planting around fields vs. back-andforth.

Rough field conditions maymove seed in

the box.

Planting conditions too wet. Wait until drier weather.

Bean machine not running level front-to-

back in the field.

Bean machine frame height incorrect. Adjust bean machine frame height, page

Row unit set too deep. Readjust, page 26.

Row unit spring force is set too high. Check row unit adjustments, page 26.

Row unit 1 x 12 press wheel stagger

adjustment not correct.

Backed up with row units in the ground Clean out and check for damage.

Failed disk bearings Replace disk bearings.

Disk blades worn. Adjust or replace disk blades, page 56.

Correct planting operation.

Readjust top link to level bean machine.

30.

Correct press wheel stagger.

173-208M

4/11/2005

Page 51

Problem Cause Solution

Troubleshooting

49

Bean machine is not pulling

level front-to-back

Hydraulic marker functioning

improperly

Marker disk does not mark

Chain

Row unit side depth wheels not adjusted

correctly.

Scraper worn or damaged. Replace scraper.

Incorrect top link adjustment. Readjust top hitch link to level bean

Air or oil leaks in hose fittings or connections.

Low tractor hydraulic oil level. Check tractor hydraulic oil level.

Loose or missing bolts or fasteners. Check all bolts and fasteners.

Needle valve plugged. Open needle valve,cycle markers slowly

Needle valve(s) in sequence valve

plugged.

Marker folding linkage does not have

enough slack to allow marker disk to

drop into field depressions.

Disk orientation not correct for field conditions.

Debris in retainer clip Be sure retainer clip is facing opposite

Readjust, page 26.

machine.

Check all hose fittings and connections

for air or oil leaks.

and reset needle valve, refer to page 39.

Open needle valves, cycle markers