Page 1

Great Plains Mfg., Inc.

Installation Instructions

1515, 2015, 2515, 2015P and 2515P

Marker Option

Used with:

• 1515 Soybean Machine

• 2015 Soybean Machine

• 2515 Soybean Machine

• 2015P Bean Machine

• 2515P Bean Machine

General Information

When you see this symbol, the subsequent instructions and

warnings areserious- follow without exception. Your life and

!

!

the lives of others depend on it!

Theseinstructions explainhowtoinstallthe Marker Option for 3-point soybeanmachines. The

markers fold and unfold hydraulically for field operation.Themarkerdisks leavealineforthe bean

machine operator tofollowon the next field pass.

Markersaremountedonthebeanmachineframe

and require two hydraulic remote valves on the

tractor.A sequence valve is availableso markers

can be operated on one hydraulic circuit.

These instructions apply to:

113-666A 15 Ft. Bean Machine Dual Marker

113-682A 20 Ft. Bean Machine Dual Marker

113-663A 25 Ft. Bean Machine Dual Marker

113-466A 3-Pt Sequence Valve Kit-Field

113-686A 15 Ft. BM MarkerBolt PlateKit

Assembly Instructions

Marker Assembly, 1515, 2015 and

2015P

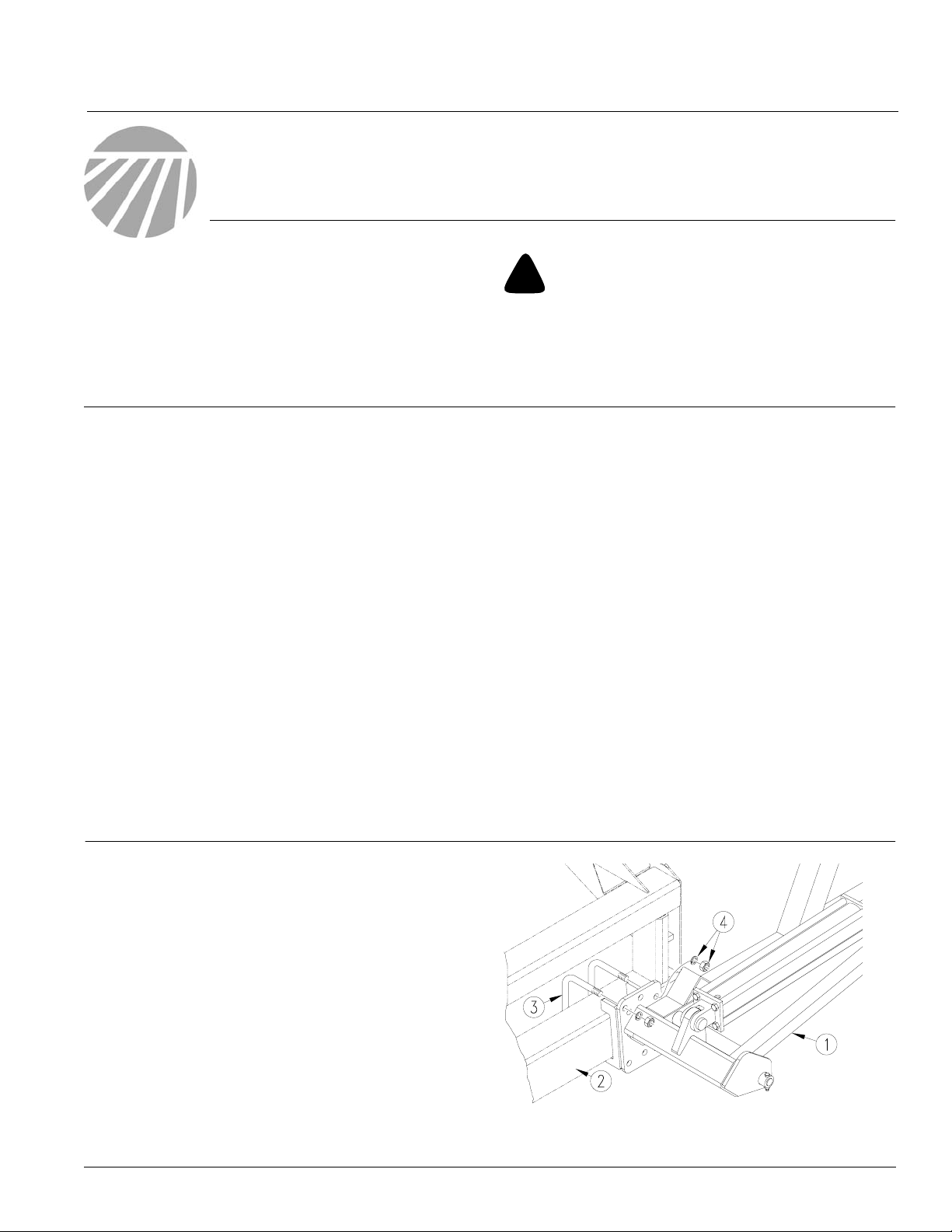

Refer to Figure 1.

Manual Update

Refer to thesoybean machine operator’s manual

for detailed information on safelyoperating, adjusting, troubleshooting and maintaining the

Marker Option. Refer to the parts manual for part

identification.

Manual Numbers

173-159M 1515, 2015 and 2515 Operator’s

Manual

173-159P 1515, 2015 and 2515 Parts

Manual

173-208M 2015P and 2515P Operator’s

Manual

173-208P 2015P and 2515P Parts Manual

Before You Start

Pages 9 and 10 are a detailed listing of parts includedin the Marker Option package.Usethis list

to inventory parts received.

1. Lowerbean machine into fieldposition. Allow

9 feeton each end of a15-foot bean machine

and11feeton each endof a 20-footbeanmachine for marker assembly.

2. Mount first marker section (1) on bean machine 7 x5 inch frametube (2). Mountmarker

as far outon the frame as possible .Secure

marker with 3/4 inchu-bolts (3),lockwashers

and nuts (4).

© Copyright 2000 Printed

3/19/2003

Figure 1

First Marker Section Assembly

113-685M

17727

Rev. A

Page 2

Marker Option

2

Great Plains Mfg., Inc.

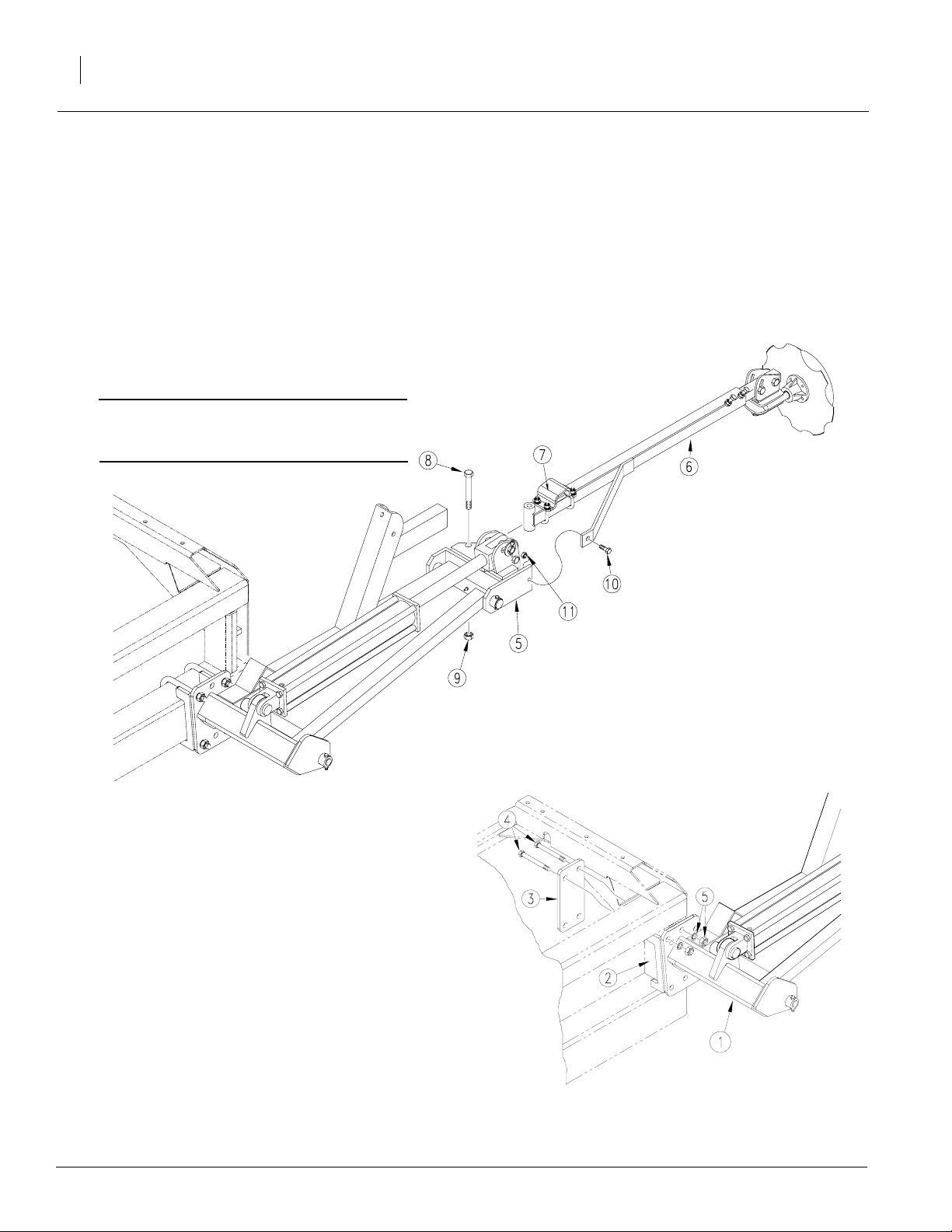

Refer to Figure 2.

3. Remove port plugs on cylinder and carefully

unfold first marker section. Rotate hinge section (5) into a horizontal position.

4. Align holes of break-away section (6) with

holes in hingesection. Bolt sectionstogether

with stop block (7) onbreak-away section facingup.Use 5/8inch pivot bolt (8), lock nut (9),

3/8 x 1 3/4 inch, grade 2 shear bolt (10) and

lock nut (11).

IMPORTANT: Be sure shear bolt is a grade 2

bolt. Failure to use a gr ade 2 bolt can cause

marker damage.

5. Repeat steps for other marker.

6. Adjust markerdisks sothey are square with

ground when markersare lowered in field position. Refer to Marker Adjustments in operator’s manual.

Figure 2

Marker Breakaway Assembly

18534

Marker Assembly, 1515 Alternate Location

If you will beusing the15-footbean machine with

adual-tiretractor,mountmarkersonthe2x 5 inch

vertical frametube toaccommodate thegauge

wheels. To mount markers in alternate location,

you will need Great Plains kit 113-686A.

Refer to Figure 3.

1. Lowerbean machine into fieldposition. Allow

9 feet on eachend of bean machineformarker assembly.

2. Mount first marker section (1) on 2 x 5 inch

vertical frame tube (2).Place mounting plate

(3) behind vertical tube. Use3/4 inch bolts (4)

through markerand mounting plate. Secure

bolts with lock washers and nuts (5).

3. Complete steps 3 through 6 on page 2 to

1515 Alternate Mounting

Figure 3

17814

complete markerassembly.

113-685M 3/19/2003

Page 3

Great Plains Mfg., Inc.

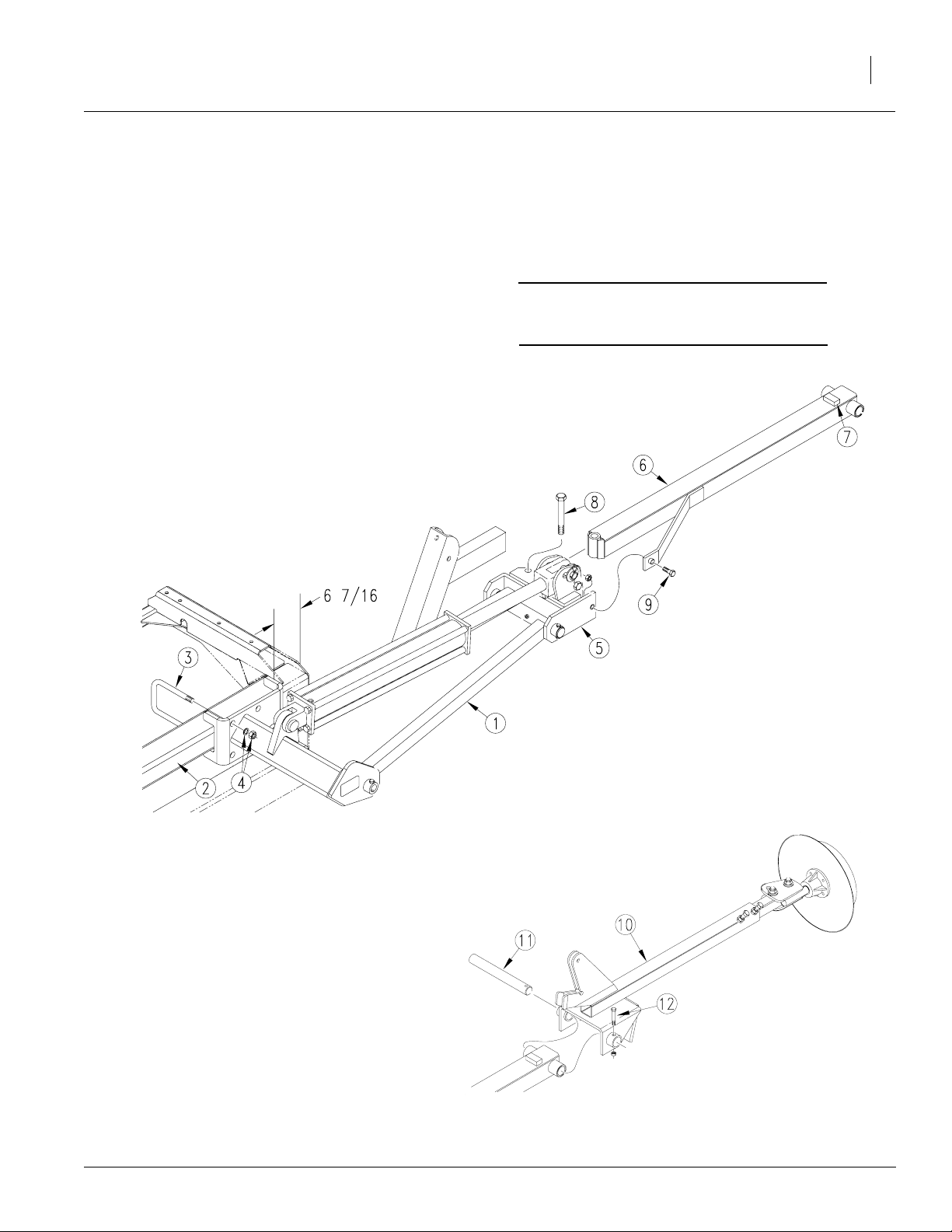

Marker Assembly, 2515 and 2515P

Refer to Figure 4.

1. Lowerbean machine into fieldposition. Allow

15 feet of clearance from each end of bean

machine box formarker assembly.

2. Attach first marker section (1) to 4 x 5 inch

frame tube (2). Mount marker so edge of

mount is 6 7/16 inches in from edge of bean

machine. Secure marker to bean machine

frame with 5/8 inch

u-bolts (3), lock washers and hex nuts (4).

3. Removeport plugs from markercylinder and

carefully unfold first marker section. Rotate

hinge (5) into a horizontal position.

Installation Instructions

4. Assemble second marker section (6) onto

first section so that stop block (7) on second

section faces up.Secure sections with 5/8

inch bolt (8) and lock nut and 3/8 x 2 inch,

grade 2 shear bolt (9) and lock nut.

IMPORTANT:Use a grade 2bolt f orthe shear

bolt or marker damage will occur during field

operation.

3

Marker First and Second Section Assembly

5. Refer to Figure 5. Place third marker section

(10) over end of second section and insert

hinge pin (11)through second- andthird-section pivot. Secure hinge pin with the 1/4 x 2

inch bolt (12) and lock nut.

Figure 4

Figure 5

Marker Third Section Assembly

17728

18535

3/19/2003

113-685M

Page 4

Marker Option

4

Refer to Figure 6.

6. Bolt chain pivot (13) to first marker section

with 3/8 x 3 1/4 inch bolt (14) and lock nut so

chain pivot pivots freely on bolt.

7. Boltchainbar (15) tothirdmarkersectionwith

the 3/8 x 1 1/2 inch bolt (16) and lock nut so

chain bar pivots freely on bolt.

8. Connect markerchain (17)to chainbar and

chainpivotwithutilityclevis(18). With marker

disk adjusted for seeding width and disk

touching the ground, remove chain slack with

utility clevis nearest bean machine.

9. Assemble full-threaded, 3/8 inch stop bolt

(19) and lock nuts on lift-arm extension (20)

so head ofstop bolt extends aslittle as possible.After the markerisbledand folded,adjust

stop bolt to remove slack from chain.Refer to

Marker Chain Adjustments in the operator’s

manual.

Great Plains Mfg., Inc.

Figure 6

Marker Chain Assembly

113-685M 3/19/2003

18536

Page 5

Great Plains Mfg., Inc.

Carrier Assembly, 2015 and 2515

To assemble carrier onto bean machine frame,refer to Figure 7. Referto Table1 for mounting

dimensions.

1. Assemble transport-carrier mount (1) on

bean machine frame. Centermount A inches

fromoutsideend of bean machineframe.Use

1/2 x 6 1/32 x 7 inch

u-bolts (2), flat washers, lock washers and

hex nuts (3). Slide mount forward so its leading edge is about B inches ahead of front

edge of bean machine frame tube.

2. Bolt transport carrier (4) to transport-carrier

mount so topsurfaceof saddle (5)is about C

inches above top of bean machine frame

tube. Secure transportcarrier with 1/2x2x3

inch u-bolts (6), lock washers and hexnuts

(7).

Installation Instructions

Dimension 20-Foot

Bean Machine

Bean Machine

A 38 inches 55 1/2 inches

B 3 1/16 inches 2 5/8 inches

C 29 inches 36 3/8 inches

Table 1

Carrier Mounting Dimensions

5

25-Foot

3. After installing and bleeding hydraulics, trans-

port carrier may require further adjustment.

When folded, the second marker section

should rest in the transport-carrier saddle.

Referto MarkerAdjustments in the operator’s

manual.

3/19/2003

Figure 7

Transport Carrier Assembly

17796

113-685M

Page 6

Marker Option

6

Installing Marker Hydraulics

Without Sequence Valve

Refer to Figure 8.

1. Install elbow fittings (1) in cylinder ports.

2. At rod end ofeach cylinder, install anadaptor

(2) into elbow fitting. Installaneedle valve(3)

in adaptor.

Great Plains Mfg., Inc.

Needle Valve Assembly

3. Connect hydraulic hosesto fittings and route

hydraulic hoses to tractor outlets.Route hydraulichoses throughtransport-carrier mount

at cutout. Use black cableties tosecure hydraulic hoses to bean machine frame.

4. Usingorange cableties, secureaplastic hose

holder to each pair of hydraulic hoses near

tractor outlets. See Figure 9.

5. Proceed with "Bleeding MarkerHydraulics,"

page 8.

Figure 8

Plastic

hose label

Cable tie

Figure 9

Hose Label and Cable Tie

17642

17641

113-685M 3/19/2003

Page 7

Great Plains Mfg., Inc.

With Sequence Valve

Refer to Figure 10.

1. Mount sequence valve (1) on bean machine

using mounting plate (2). Bolt plate to inside

end of left-hand-box panel (3) using one 1/2inch hex bolt (4).

2. Bolt valve to mounting plate with two3/8 x

3/4-inch hex bolts and lock washers (5).

3. Install elbow fittings in cylinderports.Discard

adaptorfitting andtwoneedle valvesprovided

in markerkit.

4. Use hoses provided toconnect valve ports to

cylinders. Refer to Figure 11 for port connections.

5. Connectyourown hydraulichoses to ports on

front of valve.Route hoses to tractor outlets.

Installation Instructions

Figure 10

Sequence Valve Assembly

7

18416

6. Using orange cable tie, secure plastic hose

label to hydraulic hoses near tractor outlets.

See Figure 9 on the previous page.

7. Proceed with "Bleeding MarkerHydraulics,"

page 8.

3/19/2003

Figure 11

Hydraulic Hose Connections

18417

113-685M

Page 8

Marker Option

8

Bleeding Marker Hydraulics

You may be injured if hit by a folding or unfolding

marker. Markers may fall quickly and unexpectedly if

the hydraulics fail. Neverallow anyone near the bean

machine when folding or unfolding the markers.

Escaping fluid under pressurecan have sufficient pressure to penetrate the skin. Check all hydraulic lines

and fittings before applying pressure. Fluid escaping

froma very smallhole can bealmost invisible. Use paper or cardboard, not body parts, and wear heavy

gloves to check for suspected leaks. If injured, seek

medical assistance from a doctor that is familiar with

this type of injury. Foreign fluids in the tissue must be

surgically removed within a few hours or gangrene

will result.

!

CAUTION!

!

WARNING!

Great Plains Mfg., Inc.

1. Check that tractor hydraulic reservoir is full.

2. With both markerslowered into fieldposition,

loosenhydraulic-hosefittings at rod and base

endsof marker cylinders.If applicable,loosen

fittings on back side of sequence valve.

IMPORTANT:Neverbleed anO-ringfitting. Instead, bleed a nearby pipe or JIC fitting.

3. With tractor idling, activate tractor hydraulic

valveuntil oilseeps outarounda loosened fitting. Tighten that fitting.

IMPORTANT: JIC fittings do not require high

torque. JIC and O-ring fittings do not require

sealant. Always use liquid pipe sealant when

adding or replacing pipe-thread fittings. To

avoid crac king hydraulic fittings from over

tightening, do not use plastic sealant tape.

4. Reactivate tractor hydraulic valveuntil oil

seeps out around another loosened fitting.

Tighten that fitting. Repeat process until all

loosened fitting have been bledand tightened.

5. Adjust markerfolding to a safe speed. Refer

to Marker Adjustmentin the operator’s manual.

113-685M 3/19/2003

Page 9

Great Plains Mfg., Inc.

113-666A 15 Ft. Bean Machine Dual Marker

Your kit includes:

Qty. Part No. Part Description

1 113-598V 15’ DUAL FF HOSE BUNDLE

1 113-680K 15FT BM DUAL MARKER BUNDLE

1 113-681K 15FT BM DUAL MARKER HRDWR

1 113-685M MANUAL BM MARKERS-99

2 800-300C CABLE TIE 2 DIA MIN - ORG

2 817-348C PLASTIC HOSE LABEL

113-682A 20 Ft. Bean Machine Dual Marker

Your kit includes:

Installation Instructions

9

Qty. Part No. Part Description

1 113-597V 20’ DUAL FF HOSE BUNDLE

1 113-683K 20FT BM DUAL MARKER BUNDLE

1 113-684K 20FT BM DUAL MARKER HRDWR

1 113-685M MANUAL BM MARKERS-99

2 800-300C CABLE TIE 2 DIA MIN - ORG

2 817-348C PLASTIC HOSE LABEL

2 838-265C DECAL REFLECTOR AMBER 1 1/2

113-663A 25 Ft. Bean Machine Dual Marker

Your kit includes:

Qty. Part No. Part Description

1 113-624V 24’ 3PT DUAL MARKER HOSE B

1 113-678K 25FT BM DUAL MARKER BUNDLE

1 113-679K 25FT BM DUAL MARKER HRDWR

1 113-685M MANUAL BM MARKERS-99

2 800-300C CABLE TIE 2 DIA MIN - ORG

2 817-348C PLASTIC HOSE LABEL

2 838-265C DECAL REFLECTOR AMBER 1 1/2

113-685M3/19/2003

Page 10

Marker Option

10

113-466A 94 3Pt Sequence V alve Field Kit

Your kit includes:

Qty. Part No. Part Description

1 113-488D SEQUENCE VALVE MOUNT BRACK

2 802-014C HHCS 3/8-16X3/4 GR5

2 804-013C WASHER LOCK SPRING 3/8 PLT

1 810-197C VALVE,SEQUENCE SHOEMAKER

4 811-169C EL 9/16MJIC 9/16FJIC

4 811-440C AD 1/2FNPT X 9/16FJICS

1 113-488D SEQUENCE VALVE MOUNT BRACK

2 802-014C HHCS 3/8-16X3/4 GR5

2 804-013C WASHER LOCK SPRING 3/8 PLT

1 810-197C VALVE,SEQUENCE SHOEMAKER

4 811-169C EL 9/16MJIC 9/16FJIC

4 811-440C AD 1/2FNPT X 9/16FJICS

1 113-671H 25 BM LH MARKER MOUNT

Great Plains Mfg., Inc.

113-686A 15 Ft. BM Marker Bolt Plate Kit

Your kit includes:

Qty. Part No. Part Description

2 113-661D BM MARKER MOUNT BOLT PLATE

8 802-095C HHCS 3/4-10X7 GR5

8 803-027C NUT HEX 3/4-10 PLT

8 804-023C WASHER LOCK SPRING 3/4 PLT

3/19/2003

113-685M

Loading...

Loading...