Great Plains 2515 Operator Manual

PURPLE

Operator’ s Manual

1515, 2015 and 2515

Three-Point Soybean Machine

Manufacturing, Inc.

www .g reatplainsmfg.com

Read the operator’s manual entirely. When you see this symbol, the subsequent in-

!

structions and warnings are serious- follow without exception. Your life and the lives of

others depend on it!

17715

© Copyright 1999 Printed

4/20/2005

Cover illustration may show optional equipment not supplied with standard unit.

173-159M

Table of Contents

Table of Contents

Great Plains Mfg., Inc.

Important Safety Information . . . . . . . . . . . . . . . . . 1

Safety Decals. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Description of Unit. . . . . . . . . . . . . . . . . . . . . . . . 8

Intended Usage. . . . . . . . . . . . . . . . . . . . . . . . . . 8

Using This Manual. . . . . . . . . . . . . . . . . . . . . . . . 8

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . 8

Section 1 Preparation and Setup . . . . . . . . . . . . . . 9

Prestart Checklist . . . . . . . . . . . . . . . . . . . . . . . . 9

Hitching Tractor to Drill . . . . . . . . . . . . . . . . . . . . 9

Hydraulic Hookup . . . . . . . . . . . . . . . . . . . . . . . 10

Lift Assist . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Bleeding the Lift Assist Hydraulics . . . . . . . . . . 11

Leveling Drill . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Section 2 Operating Instructions . . . . . . . . . . . . . 12

Prestart Checklist . . . . . . . . . . . . . . . . . . . . . . . 12

Field Operation . . . . . . . . . . . . . . . . . . . . . . . . . 12

Row Unit Operation. . . . . . . . . . . . . . . . . . . 12

Marker Operation . . . . . . . . . . . . . . . . . . . . 12

Shaft Monitor Operation . . . . . . . . . . . . . . . 12

Transporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Transporting with Markers. . . . . . . . . . . . . . 13

Transporting with Lift Assist. . . . . . . . . . . . . 13

Parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Section 3 Adjustments . . . . . . . . . . . . . . . . . . . . . 14

Row Unit Adjustments. . . . . . . . . . . . . . . . . . . . 14

Down Pressure . . . . . . . . . . . . . . . . . . . . . . 14

Down Pressure Charts . . . . . . . . . . . . . . . . 14

Coulter Depth . . . . . . . . . . . . . . . . . . . . . . . 14

Opener Seeding Depth . . . . . . . . . . . . . . . . 14

Side Gauge Wheels . . . . . . . . . . . . . . . . . . 15

1 x 12 Closing Wheel Option. . . . . . . . . . . . 16

Closing Disk Option. . . . . . . . . . . . . . . . . . . 16

Frame Height. . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Seeding Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Adjust Drive Sprockets . . . . . . . . . . . . . . . . 17

Set Seed-Rate Handle . . . . . . . . . . . . . . . . 17

Position Seed-Cup Doors . . . . . . . . . . . . . . 18

Check Seeding Rate. . . . . . . . . . . . . . . . . . 18

Seed Rate Charts . . . . . . . . . . . . . . . . . . . . . . . 18

Marker Adjustments . . . . . . . . . . . . . . . . . . . . . . 19

Folding Speed . . . . . . . . . . . . . . . . . . . . . . . 19

Disk Adjustment. . . . . . . . . . . . . . . . . . . . . . 19

Marker Chain (2515 only) . . . . . . . . . . . . . . 20

Transport Carrier (2015 and 2515 only). . . . 21

Bleeding Marker Hydraulics. . . . . . . . . . . . . 21

Seed-Lok Lock Up . . . . . . . . . . . . . . . . . . . . . . . 22

Section 4 Troubleshooting. . . . . . . . . . . . . . . . . . . 23

Section 5 Maintenance and Lubrication. . . . . . . . 25

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Marker Maintenance . . . . . . . . . . . . . . . . . . 25

Opener Disks, Scrapers, Gauge Wheels. . . 25

Drive System . . . . . . . . . . . . . . . . . . . . . . . . 26

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Drive Chains. . . . . . . . . . . . . . . . . . . . . . . . . 27

Seed-Cup-Shaft Sprocket . . . . . . . . . . . . . . 27

Gauge Wheel Arm Pivots. . . . . . . . . . . . . . . 27

Marker Hinge Points. . . . . . . . . . . . . . . . . . . 28

Side Wheel Arm, Row Unit . . . . . . . . . . . . . 28

Wheel Bearings . . . . . . . . . . . . . . . . . . . . . . 28

Marker Disk Bearings. . . . . . . . . . . . . . . . . . 28

Lift Assist Castors . . . . . . . . . . . . . . . . . . . . 29

Lift Assist Arm Pivots . . . . . . . . . . . . . . . . . . 29

Section 6 Options . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Lift Assist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Coulter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Gauge Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Spring Packages . . . . . . . . . . . . . . . . . . . . . . . . 31

Markers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Seed-Cup Plugs . . . . . . . . . . . . . . . . . . . . . . . . . 32

Shaft Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Seed-Lok Firming Wheels . . . . . . . . . . . . . . . . . 32

Section 7 Specifications and Capacities . . . . . . . 33

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Tire Inflation Chart . . . . . . . . . . . . . . . . . . . . . . . 34

Torque Values Chart for Common Bolt Sizes. . . 34

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

© Copyright 1999 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the preparation

of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at the

time of its publication,and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains, Seed-Lok

All other brands and product names are trademarks or registered trademarks of their respective holders.

1515, 2015 and 2515 Three-Point Soybean Machine 173-159M 4/20/05

Great Plains Manufacturing, Incorporated T r ademarks

Printed in the United States of America.

Great Plains Mfg., Inc.

Important Safety Information

Important Safety Information

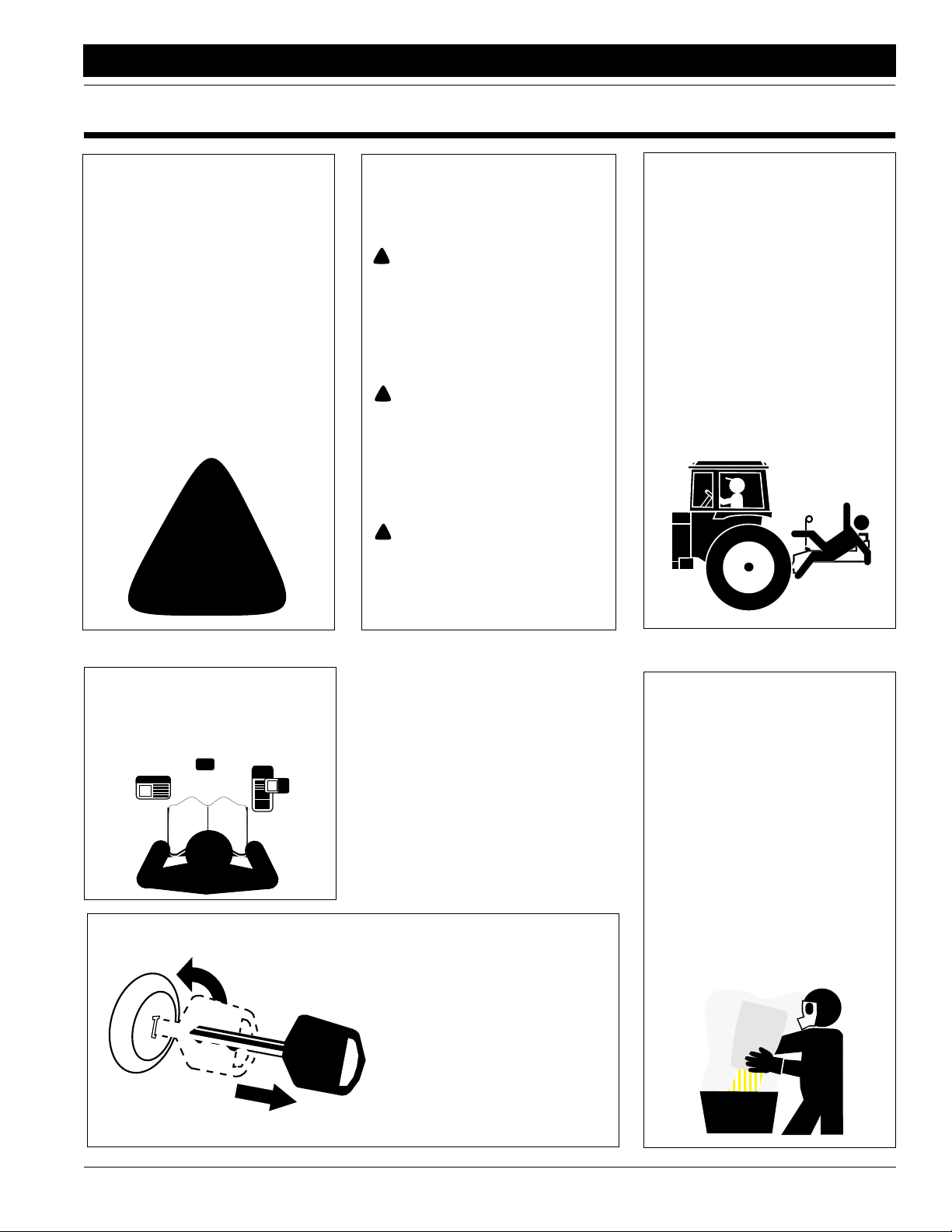

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a potential hazard to

personal safety involved and extra

safety precaution must be taken.

When you see this symbol, be alert

and carefully read the message that

follows it. In addition to design and

configuration of equipment, hazard

control and accident prevention are

dependent upon the awareness,concern, prudence and proper training of

personnel involved in the operation,

transport, maintenance and storage

of equipment.

!

Be Aware of Signal Words

Signal words designate a degree or

level of hazard seriousness. The signal words are:

!

DANGER!

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury. This

signal word is limited to the most

extreme situations, typically for

machine components that, for functional purposes, cannot be guarded.

!

WARNING!

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury, and

includes hazards that are exposed

when guards are removed. It may

also be used to alert against unsafe

practices.

!

CAUTION!

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

Keep Riders

Off Machinery

Riders obstruct the operator’s view.

Riders could be struck by foreign

objects or thrown from machine.

▲ Never allow riders on implement.

▲ Never allow children to operate

equipment.

For Your Protection

▲ Thoroughly read and understand

Safety Decals, page 4. Read all

instructions noted on decals.

OFF

Shutdown and Storage

▲ Lower machine to ground, put

tractor in park, turn off engine,

and remove key.

▲ Detach and store implement in an

area where children normally do

not play. Secure implement with

blocks and supports.

Handle

Chemicals Properly

Agricultural chemicals can be dangerous. Improper use can seriously

injure persons, animals, plants, soil

and property.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Follow instructions on container

label.

▲ Avoid inhaling smoke from any

type of chemical fire.

▲ Store or dispose of unused chem-

icals as specified by chemical

manufacturer.

4/20/05

1515, 2015 and 2515 Three-Point Soybean Machine 173-159M

1

Important Safety Information

Great Plains Mfg., Inc.

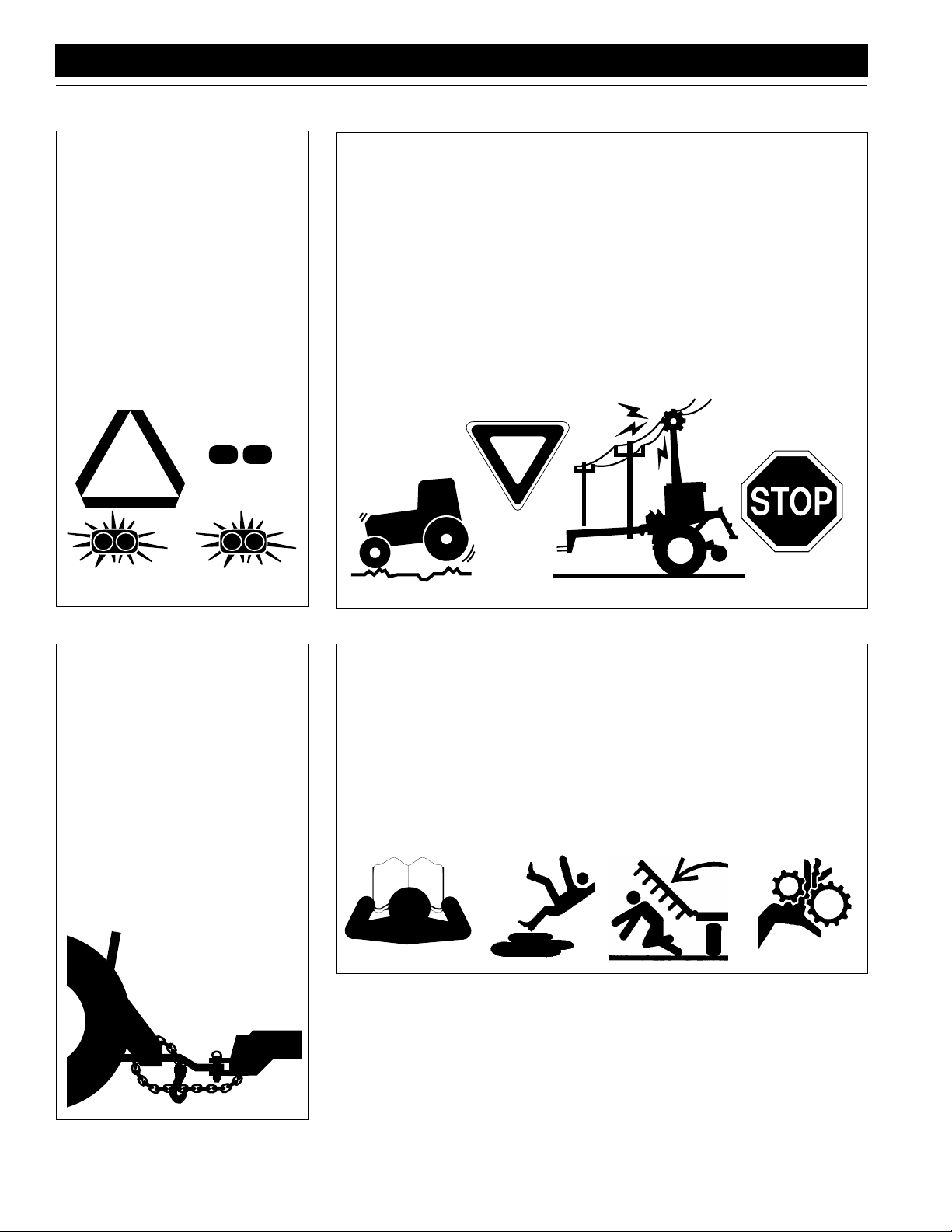

Use Safety

Lights and Devices

Slow-moving tractors, self-propelled

equipment and towed implements

can create a hazard when driven on

public roads. They are difficult to see,

especially at night.

▲ Use flashing warning lights and

turn signals whenever driving on

public roads.

▲ Use lights and devices provided

with implement.

Transport

Machinery Safely

Maximum transport speed for implement is 20 mph. Some rough terrains

require a slower speed. Sudden

braking can cause a towed load to

swerve and upset.

▲ Do not exceed 20 mph. Never

travel at a speed which does not

allow adequate control of steering

and stopping. Reduce speed if

towed load is not equipped with

brakes.

▲ Comply with state and local laws.

▲ Do not tow an implement that,

when fully loaded, weighs more

than 1.5 times the weight of towing vehicle.

▲ For three-point mounted imple-

ments, make sure tractor has

enough front-end ballast to handle

the weight of the load. Refer to

your tractor operator’s manual

Use A Safety Chain

▲ Use a safety chain to help con-

trol drawn machinery should it

separate from tractor drawbar.

▲ Use a chain with a strength rat-

ing equal to or greater than the

gross weight of towed machinery.

▲ Attach chain to tractor drawbar

support or other specified

anchor location. Allow only

enough slack in chain to permit

turning.

▲ Replace chain if any links or end

fittings are broken, stretched or

damaged.

▲ Do not use safety

chain for towing.

Practice Safe Maintenance

▲ Understand procedure before

doing work. Use proper tools and

equipment. Refer to this manual

for additional information.

▲ Work in a clean, dry area.

▲ Lower implement to ground, put

tractor in park, turn off engine,

and remove key before performing

maintenance.

▲ Allow implement to cool completely.

▲ Inspect all parts. Make sure parts

are in good condition and installed

properly.

▲ Remove buildup of grease, oil or

debris.

▲ Remove all tools and unused

parts from implement before operation.

1515, 2015 and 2515 Three-Point Soybean Machine 173-159M 4/20/05

2

Great Plains Mfg., Inc.

Important Safety Information

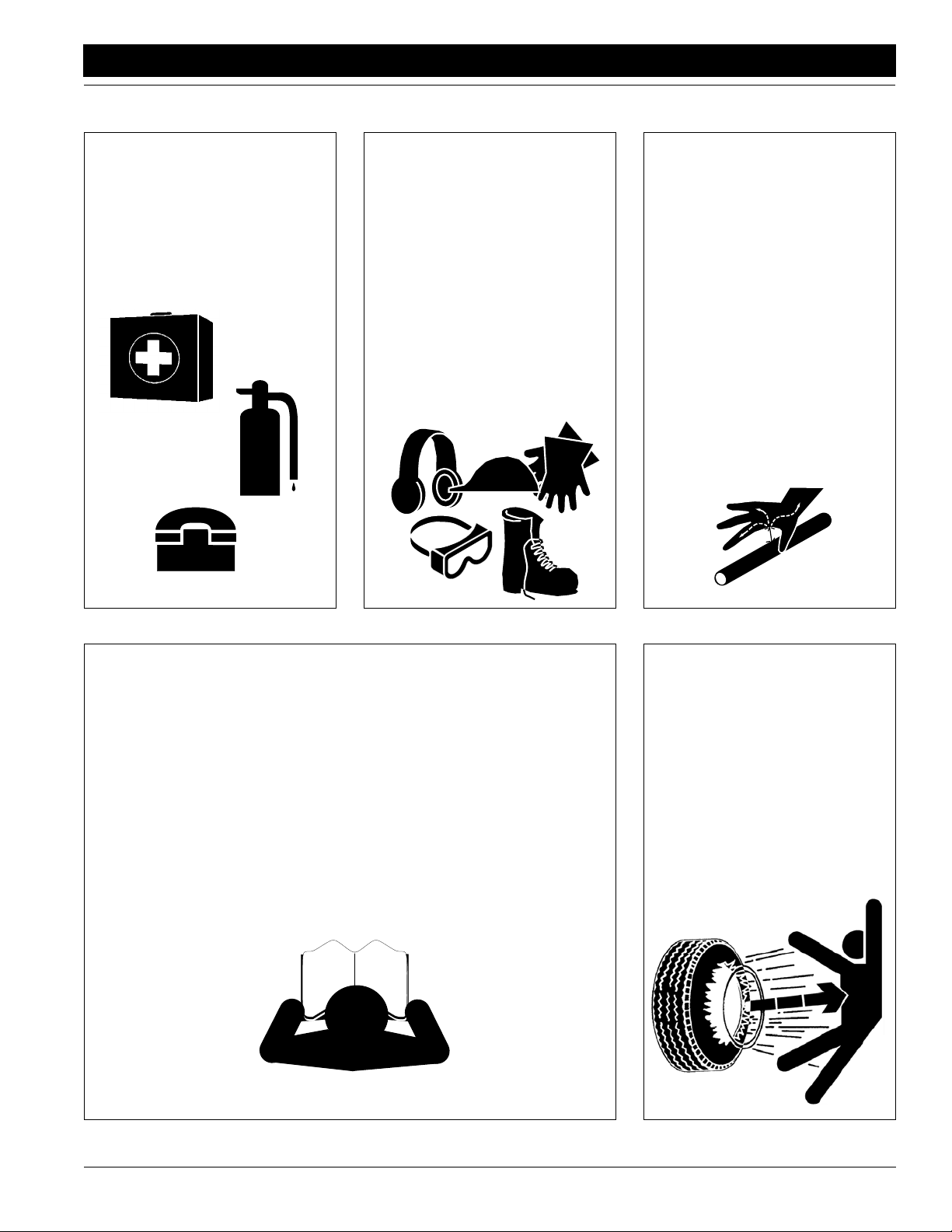

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extin-

guisher handy.

▲ Keep emergency numbers for

doctor, ambulance, hospital and

fire department near phone.

911

Wear

Protective Equipment

▲ Wear protective clothing and

equipment.

▲ Wear clothing and equipment

appropriate for the job. Avoid

loose-fitting clothing.

▲ Because prolonged exposure to

loud noise can cause hearing

impairment or hearing loss, wear

suitable hearing protection such

as earmuffs or earplugs.

▲ Because operating equipment

safely requires your full attention,

avoid wearing radio headphones

while operating machinery.

Avoid High

Pressure Fluids Hazard

Escaping fluid under pressure can

penetrate skin, causing serious

injury.

▲ Avoid the hazard by relieving

pressure before disconnecting

hydraulic lines.

▲ Use a piece of paper or card-

board, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety

glasses or goggles when working

with hydraulic systems.

▲ If an accident occurs, see a doc-

tor immediately. Any fluid injected

into the skin must be surgically

removed within a few hours or

gangrene may result.

Safety at All Times

Thoroughly read and understand this

manual before operating implement.

Refer to Safety Decals, page 4. Read

all instructions noted on decals.

▲ Be familiar with all implement

functions.

▲ Operate implement from driver’s

seat only.

▲ Do not leave tractor or implement

unattended with engine running.

▲ Do not dismount a moving tractor.

Dismounting a moving tractor could

cause serious injury or death.

▲ Do not stand between the tractor

and implement during hitching.

▲ Keep hands, feet and clothing

away from power-driven parts.

▲ Wear snug-fitting clothing to avoid

entanglement with moving parts.

▲ Watch out for wires, trees, etc.,

when raising implement. Make

sure all persons are clear of working area.

▲ Do not turn tractor too tight, caus-

ing towed implements to ride up

on wheels.

Tire Safety

Tire changing can be dangerous and

should be performed by trained personnel using correct tools and equipment.

▲ When inflating tires, use a clip-on

chuck and extension hose long

enough to allow you to stand to

one side–not in front of or over tire

assembly. Use a safety cage if

available.

▲ When removing and installing

wheels, use wheel-handling

equipment adequate for weight

involved.

4/20/05

1515, 2015 and 2515 Three-Point Soybean Machine 173-159M

3

Important Safety Information

Safety Decals

Your implement comes equipped with all safety decals in place.

They were designed to help you safely operate your implement.

1. Read and follow decal directions.

2. Keep all safety decals clean and legible.

3. Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

Great Plains Mfg., Inc.

4. When ordering new parts or components, also request corresponding safety decals.

5. To install new decals:

a. Clean the area on which the decal is to be placed.

b. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

17770

17770

818-003C

Slow Moving Vehicle Sign

838-266C

Red Reflector

Reflector onboth ends of

drill; two reflectors total

838-265C

17771

1515, 2015 and 2515 Three-Point Soybean Machine 173-159M 4/20/05

4

Amber Reflector

Reflectors on both ends

of drill; four reflectors

total

Great Plains Mfg., Inc.

Important Safety Information

17771

818-188C

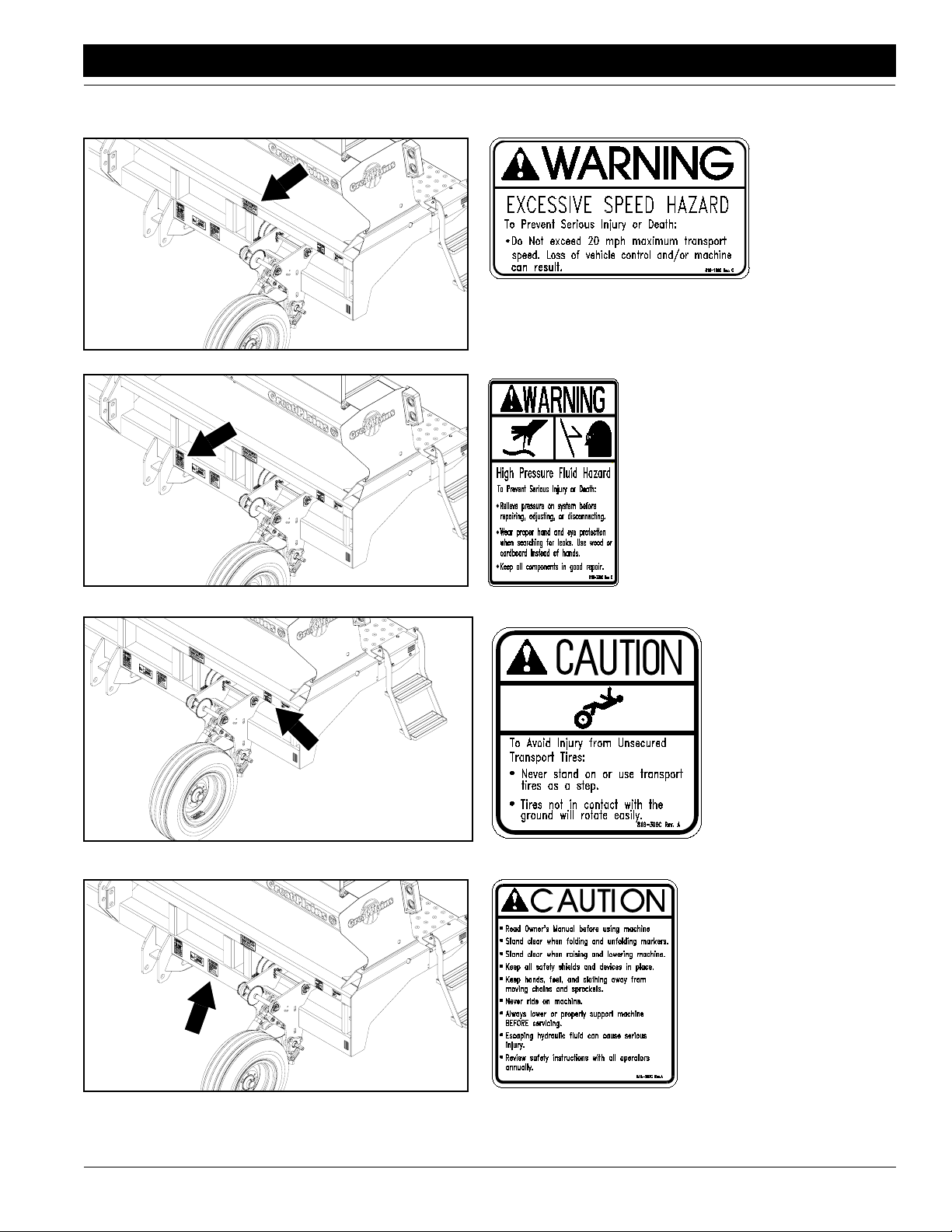

Warning 20MPH Trans

Decal on frame tube near drill center

17771

17771

818-339C

Warning High Pressure SML

Decal on frame tube near drill center

818-398C

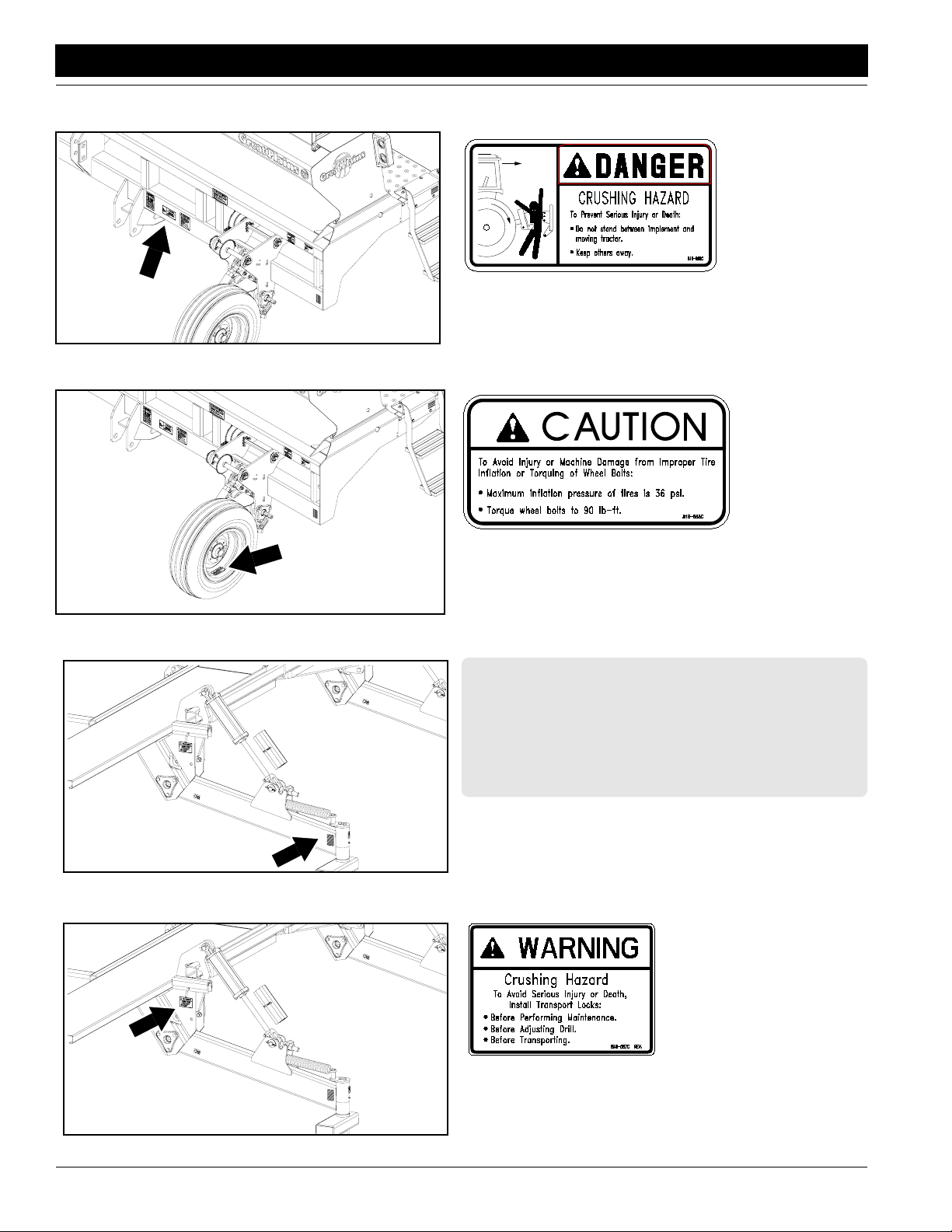

Caution Tires Not a Step

Decals on frame tube

near gauge wheels; two

decals total

17771

4/20/05

818-587C

Caution Operational

Decal on frame tube near

drill center

1515, 2015 and 2515 Three-Point Soybean Machine 173-159M

5

Important Safety Information

17771

Great Plains Mfg., Inc.

818-590C

Danger Crush Tractor & Three Point

Decal on frame tube near drill center

17771

17740

818-855C or 818-751C

1515: Caution Tire 36 PSI

2015 and 2515: Caution Tire 32 PSI

Decals on wheel rims; fourdecals total

838-265C

Amber Reflector

Reflector on each option-

al lift-assist arm; two

reflectors total

838-057C

17740

1515, 2015 and 2515 Three-Point Soybean Machine 173-159M 4/20/05

6

Warning Gen Transp Lock

Decals on each optional lift-assist arm; twodecals total

Great Plains Mfg., Inc.

Important Safety Information

17843

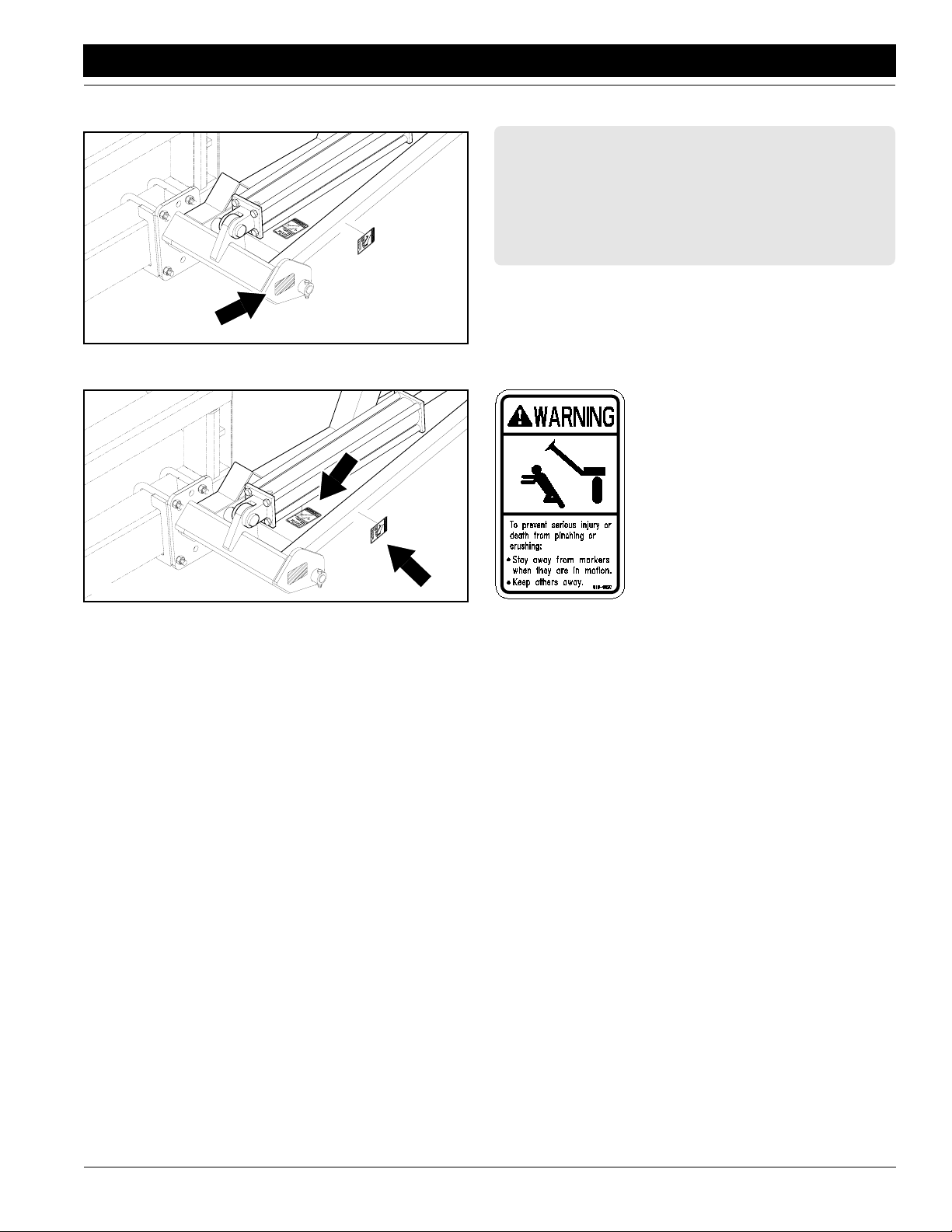

838-265C

Amber Reflector

Reflector on each option-

al marker

17843

818-682C

Warning Pinch/Crush Marker

Two decals on first section of each

optional marker; four decals total

4/20/05

1515, 2015 and 2515 Three-Point Soybean Machine 173-159M

7

Introduction

Introduction

Great Plains Mfg., Inc.

Great Plains welcomes you to its growing family of new

product owners. This implement has been designed with

care and built by skilled workersusing quality materials.

Proper setup, maintenance and safe operating practices

will help you get years of satisfactory use from the machine.

Description of Unit

The 1515, 2015 and 2515 model drills are mounted seeding implements. The drills are equipped with double-disk,

planter-style row units.The row units are staggered for

easy residue flow. Seeding depth can be adjusted. The

seeding rate can be adjusted from 2 to 240 pounds per

acre.

Intended Usage

Use the drill to seed production-agriculture cropsonly.Do

not modify the drill foruse with attachments other than

Great Plains options and accessories specified for use

with the drill.

Using This Manual

This manual will familiarize you with safety, assembly, operation, adjustments, troubleshooting and maintenance.

Readthis manualand followthe recommendationsto help

ensure safe and efficient operation.

Theinformation in this manual iscurrent at printing. Some

parts maychange to assure top performance.

Definitions

The following terms are used throughout this manual.

Right-handand left-hand as used in thismanual are deter-

mined by facing the direction the machinewill travel while

in use unless otherwise stated.

IMPORTANT: A crucial point of information related to

the preceding topic. For safe and correct oper ation,

read and follow the directions provided before continuing.

NOTE: Useful information related to the preceding topic.

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. Great Plains dealers have trained

personnel, repairparts and equipment specially designed

for Great Plains products.

Your machine’sparts were specially designed and should

only be replaced with Great Plains parts. Always use the

serial and model number when ordering parts from your

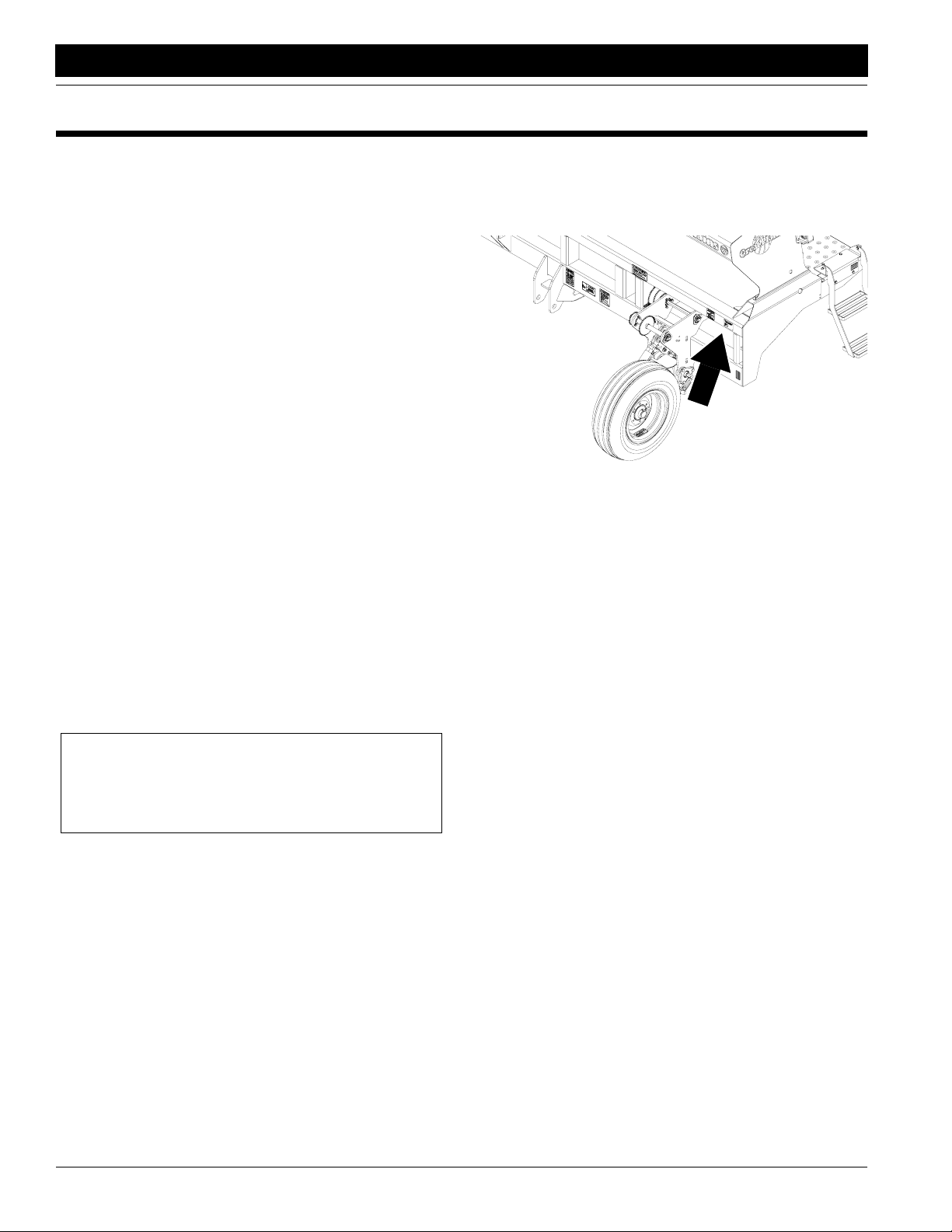

GreatPlains dealer. Theserial-number plateis located on

the left end of the drill as shown in Figure A.

17771

Figure A

Serial Number

Record your drill model and serial number here forquick

reference:

Model Number: _________________________________

Serial Number: _________________________________

Your Great Plains dealer wants youto be satisfied with

your new machine. If you do not understand any part of

this manual or are not satisfied with the service received,

please take the following actions.

1. Discuss the matter with the service manager at your

Great Plains dealership.

2. If you are still not satisfied, seek out theowner or gen-

eral manager of the dealership.

3. For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

1515, 2015 and 2515 Three-Point Soybean Machine 173-159M 4/20/05

8

Great Plains Mfg., Inc.

Section 1 Preparation and Setup

Section 1 Preparation and Setup

This section will helpyou prepareyour tractorand drill for

use. Before using the drill in the field, you must hitch the

drill to a suitable tractor (see Tractor Requirements, Spec-

ifications and Capacities, page 33) and level the drill.

Prestart Checklist

1. Read and understand “Important Safety Information,” page 1.

2. Check that all working parts are moving freely, bolts

are tight, and cotter pins are spread.

3. Check that all grease fittings are inplace andlubricated. Refer to Lubrication,“Maintenance and Lubrica-

tion,” page 27.

4. Checkthat all safety decals and reflectors are correctly located and legible. Replace if damaged.See Safe-

ty Decals,“Important Safety Information,” page 4.

5. Inflate tires to pressure recommended and tighten

wheel bolts as specified. See “Appendix,” page 34.

Hitching Tractor to Drill

!

DANGER!

You may be severely injured or killed by being crushed between

the tractor and drill. Do not stand or place any part of your

body between the drill and moving tractor. Stop tractor engine

and set park brake before installing pins.

1. Allow lower three-point links on tractor to float independentof each other.Do notpin lower linkstogether.

2. Raiseor lowertractorthree-point arms asneeded and

pin tractor lowerlinks to drill.

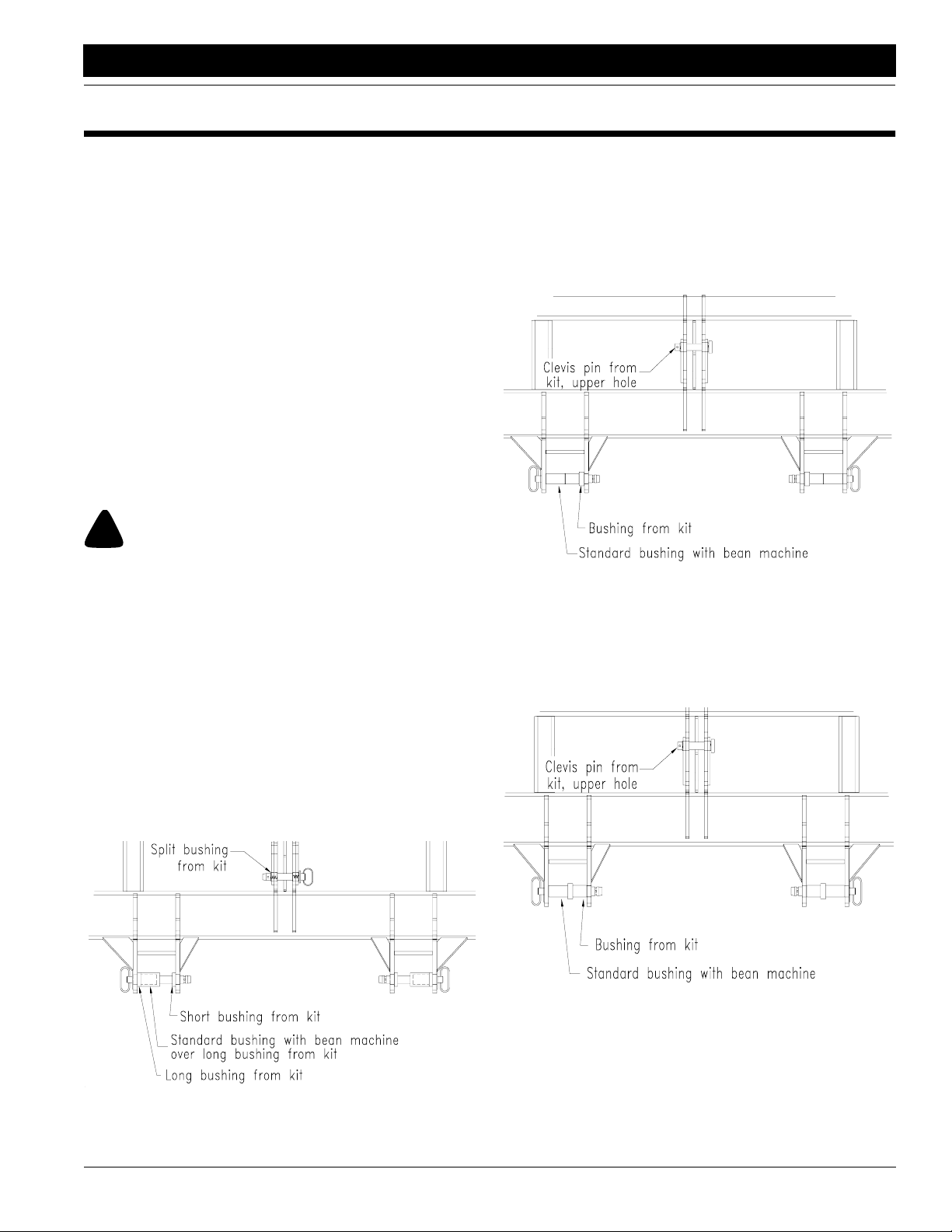

Category II and III tractors with quick hitch: Use

pins provided with drill. Discard bushings provided

with drill.

Category II tractors, no quick hitch: Discard pins

providedwith drill. OrderGreat Plains kit,part number

173-170A. Use pins and bushings as shown. See Figure 1-1.

Category III tractors, no quick hitch: Use pins provided with drill. Use bushingsprovided with drill to

space lower tractor links to the outside.

Category IV tractors with Cat IV-N quick hitch: Discard upper pin provided with drill. Use other pins and

bushings provided with drill. Also, order Great Plains

kit, part number 173-171A. Use pinsand bushings as

shown. See Figure 1-2.

17986

Figure 1-2

Category IV Tractors with Quick Hitch

Category IV tractors,no quick hitch: Discard upper

pin provided with drill. Use other pins and bushings

provided with drill. Also, order Great Plains kit, part

number 173-171A. Use pins and spacers as shown.

See Figure 1-3.

4/20/05

Figure 1-1

Category II Tractors, No Quick Hitch

17984

Figure 1-3

Category IV Tractors, No Quick Hitch

3. Pin top three-point link to drill.

NOTE: If drill is outfitted with optional lift assist, operate

tractor and drill without tractortop link. On quick hitches,

pin quick hitch to drill and remove tractor top link.

4. Slowly raise drill. Watch for cab interference.

1515, 2015 and 2515 Three-Point Soybean Machine 173-159M

17985

9

Section 1 Preparation and Setup

Great Plains Mfg., Inc.

5. Remove pins holding parking stands and raise

stands. Replace pins in lowest hole in each stand.

13508

Figure 1-4

Parking Stand

6. Set your tractor three-point-draft control to float position.

7. Plug lead from drill light harness into tractor receptacle.

Hydraulic Hookup

!

WARNING!

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin. Check all hydraulic lines and fittings before

applying pressure.Fluid escaping froma very smallhole can be

almost invisible. Use paper or cardboard, not body parts, and

wear heavy gloves to check for suspected leaks. If injured, seek

medical assistance from a doctor that is familiar with this type

of injury. Foreign fluids in the tissue must be surgicallyremoved

within a few hours or gangrene will result.

Great Plains hydraulic hoses are color coded to help you

hookup hoses to your tractor outlets.Hoses that goto the

same remote valve are marked with the same color.

same hydraulic circuit, refer to plastic hose holder. See

Figure 1-5. Connect hose under extended cylinder to outletyou choosefor cylinderextension. Connect hoseunder

retracted symbol to outlet for cylinder retraction.

17641

Figure 1-5

Hydraulic Hose Color Ties

Lift Assist

Hydraulicsfor the optional lift assistcan be plumbed three

different ways.

• Tractor remote valve drives lift assist alone

• Tractor remote valve drives lift assist and three-point

hitch

• Tractor hydraulic circuitfor three-pointhitch driveslift

assist and three-point hitch

To operatethe lift assist on its on remote valve, plug hydraulic hoses into valve outlets.

To plumb together the lift-assist and three-point hydraulics, contact yourtractor dealer for specific instructions.

Color Hydraulic Function

Red Lift Assist

Orange Marker Cylinders

Great Plains hydraulic hoses are codedto help you hookup to your tractor outlets. To distinguish hoses on the

1515, 2015 and 2515 Three-Point Soybean Machine 173-159M 4/20/05

10

IMPORTANT: Before plumbing the lift assist into y our

tractorthree-point circuit, contact your tractordealer for

detailed instructions. Failure to properly plumb the hydraulics can cause tractor damage.

Loading...

Loading...