Page 1

Great Plains Mfg., Inc.

Installation Instructions

20P, 24P, 25P 3-Point Precision Drills

20F and 24F 3-Point Drills

Weight Bracket Kit

Used with:

• 20P 3-Point Precision Seeding System

• 24P 3-Point Precision Seeding System

• 25P 3-Point Precision Seeding System

• 20F 3-Point Drill

• 24F 3-Point Drill

General Information

When you see this symbol, the subsequent instructions and

warnings are serious - follow without exception. Your life

!

!

and the lives of others depend on it!

These instructions explain how to install the Weight

Bracket Kit. This optional kit is used to add weight to

the drill frame.These instructions apply to:

118-071A 20P/24P/25P Weight Bracket Kit

118-072A 20F and 24F Weight Bracket Kit

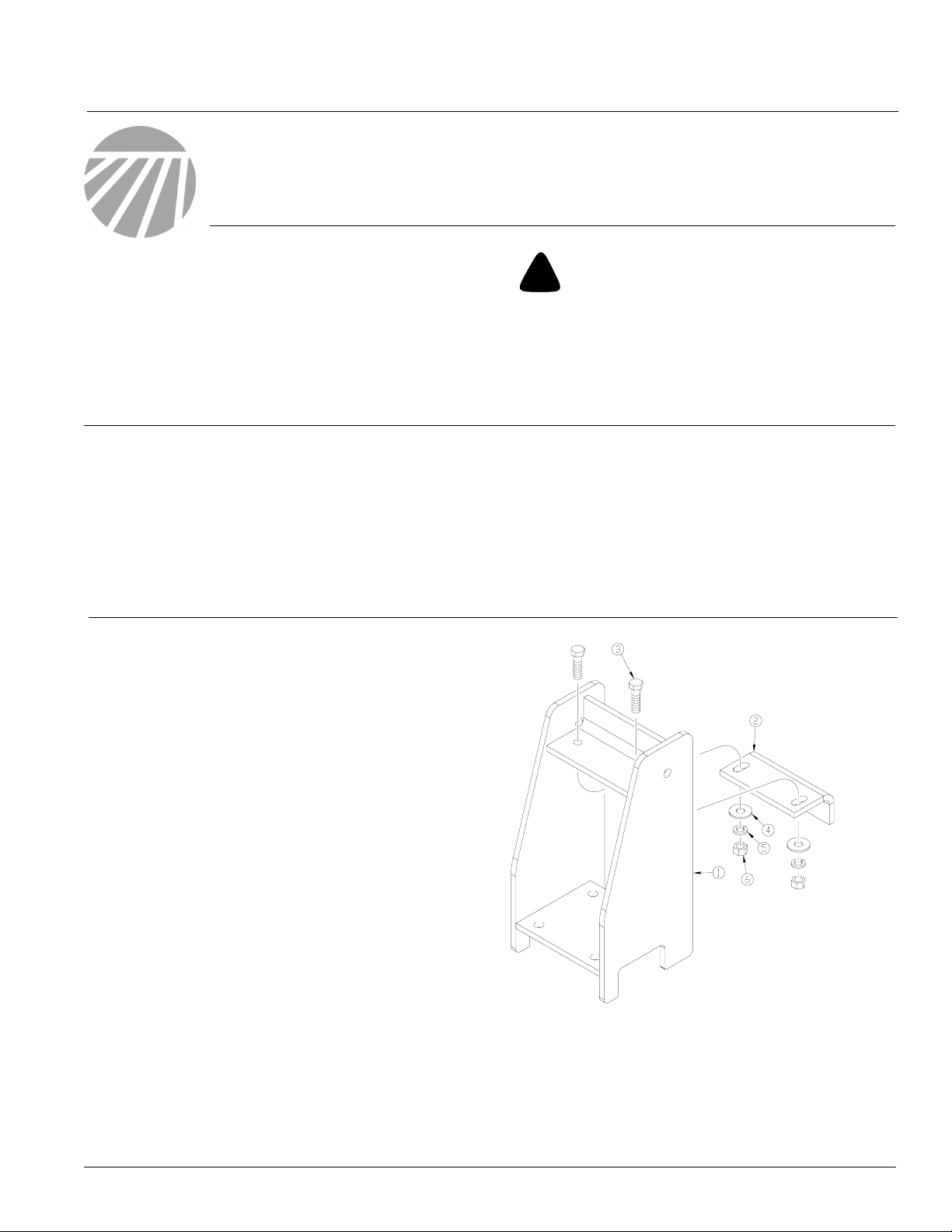

Assembly Instructions for 118-071A

Refer to Figure 1

1. Attach weight bracket adjustment leg (2) to

weight bracket weldment (1).

2. Secure adjustment leg (2) to weldment (1) using two 5/8-11 x 2 1/4 bolts (3), 5/8 flat washers

(4), 5/8 lock washers (5), and 5/8-11 hex nuts

(6). Leave bolts loosened for adjustment.

3. Complete steps one and two for both weight

brackets.

Before You Start

Page 5 is a detailed listing of parts included in the

Weight Bracket Kit. Use this list to inventory parts

received.

Tools Required

• Basic Hand Tools

© Copyright 2006 Printed

4/5/2006

24443

Figure 1

Weight Bracket and Adjustment Leg

118-073M

Page 2

Weight Bracket Kit

2

Great Plains Mfg., Inc.

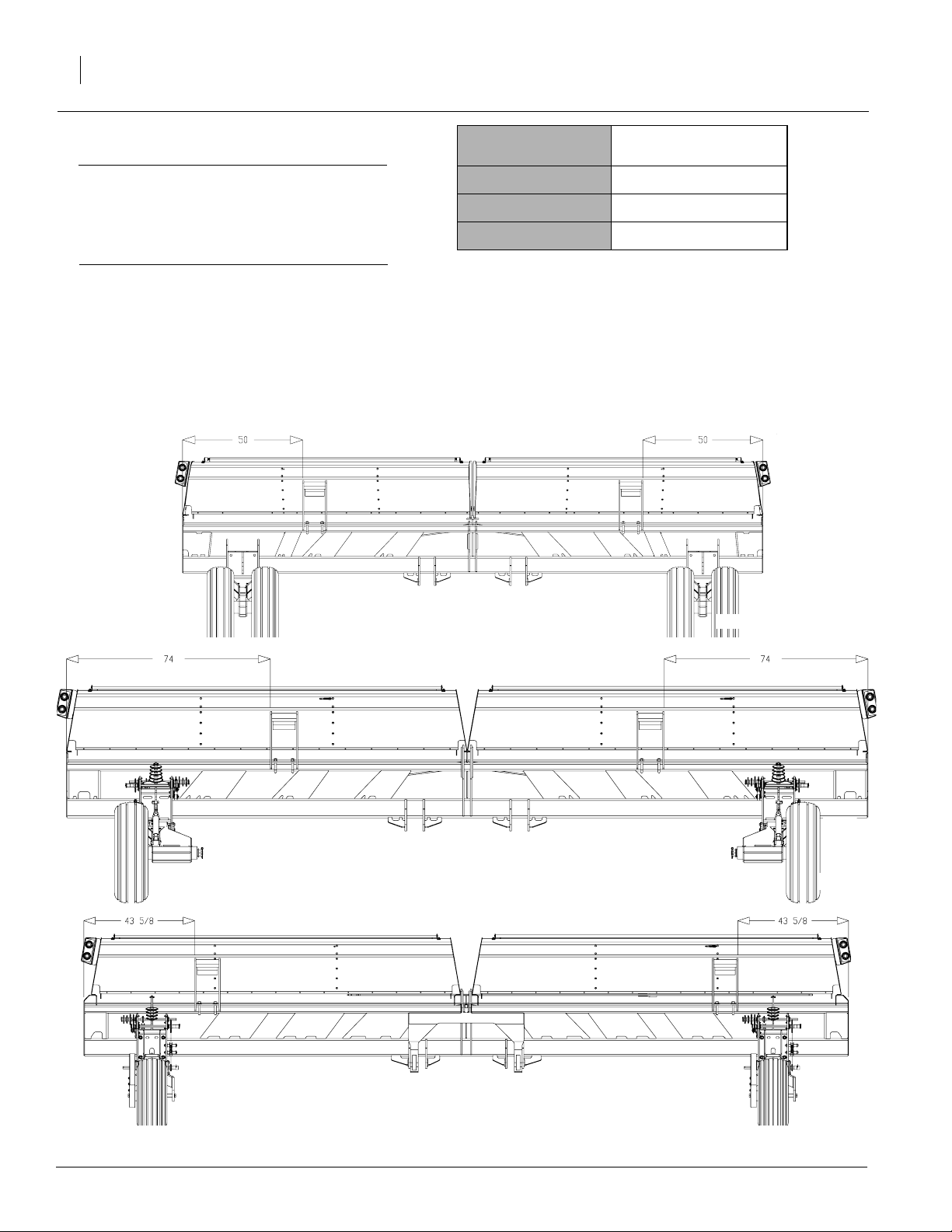

Refer to Table 1

IMPORTANT! The chart to the right gives the recommended placement for LH and RH weight brackets. However, weight brackets may be placed

anywhere along frame provided there are no clearance issues.

4. For both LH and RH brackets, measure the distance given in the chart for the appropriate drill

model. NOTE: Measure distance from each end

of drill frame towards center of drill.

Refer to Figure 2

5. Place weight bracket on drill frame.

Drill Model Distance From End of Drill

Frame

20P 50 inches

24P 74 inches

25P 43 5/8 inches

Table 1

20P Weight Bracket Layout

24P Weight Bracket Layout

24448

24447

25P Weight Bracket Layout

Figure 2

Weight Bracket Placement

118-073M 4/5/2006

24439

Page 3

Great Plains Mfg., Inc.

Refer to Figure 3

6. Secure weight bracket (1) to frame (3) using

two 3/4-10 x 5 1/32 x 4 u-bolts (2), 3/4 lock

washers (5), and 3/4-10 hex nuts (4).

7. Position adjustment leg (6) against weight edge

for additional support. Tighten bolts securing

adjustment leg to weight bracket.

8. Complete steps 5 through 8 for both weight

brackets.

Installation Instructions

Figure 3

Secure Weight Bracket to Frame

3

24446

Assembly Instructions for 118-072A

NOTE: The 20F and 24F Weight Bracket Kit

comes with specific LH and RH weight brackets.

Refer to Figure 1

1. Attach weight bracket adjustment leg (2) to

both LH and RH weight bracket weldments (1).

2. Secure adjustment leg (2) to weldment (1) using two 5/8-11 x 2 1/4 bolts (3), 5/8 flat washers

(4), 5/8 lock washers (5), and 5/8-11 hex nuts

(6). Leave bolts loosened for adjustment.

Refer to Table 1

IMPORTANT! The chart to the right gives the

recommended placement for LH and RH weight

brackets. However, weight brackets may be

placed anywhere along frame provided there

are no clearance issues.

24445

Figure 1

Weight Bracket and Adjustment Leg

Drill Model Distance From End of Drill

Frame

20F 55 1/2 inches

3. For both LH and RH weight brackets, measure

the distance given in the chart for the appropriate drill model. NOTE: Measure distance

from each end of drill frame towards center

of drill.

4/5/2006

24F 50 1/2 inches

Table 1

118-073M

Page 4

Weight Bracket Kit

4

Refer to Figure 2

4. Determine which weight bracket is LH

bracket and which is RH bracket. NOTE:

There is a cut-out notch on one side of

each bracket. The notched side goes

toward center of drill to allow clearance

for frame brace.

5. Place LH bracket on LH-side drill frame.

Place RH bracket on RH-side drill frame.

Great Plains Mfg., Inc.

20F Weight Bracket Layout

24F Weight Bracket Layout

Weight Bracket Placement

Refer to Figure 3

6. Secure weight bracket (1) to frame (2) using u-bolts (3 and 4), 3/4 lock washers (6),

and 3/4-10 hex nuts (5).

NOTE: Use longer u-bolt (3) to secure

frame (2) to raised portion of bottom of

weight bracket (1).

7. Position adjustment leg (7) against weight

edge for additional support. Tighten bolts

securing adjustment leg to bracket.

8. Complete steps 5 through 8 for both

weight brackets.

24440

24449

Figure 2

24444

Figure 3

Secure Weight Bracket to Frame

118-073M 4/5/2006

Page 5

Great Plains Mfg., Inc.

118-071A 20P/24P/25P Weight Bracket Kit

Your kit includes:

Qty. Part No. Part Description

2 118-068H WEIGHT BRACKET WELDMENT

2 197-062D WEIGHT BRACKET ADJ LEG

4 802-057C HHCS 5/8-11 X 2 1/4 GR5

4 803-021C NUT HEX 5/8-11 PLT

8 803-027C NUT HEX 3/4-10 PLT

4 804-019C WASHER FLAT 5/8 USS PLT

4 804-022C WASHER LOCK SPRING 5/8 PLT

8 804-023C WASHER LOCK SPRING 3/4 PLT

4 806-203C U-BOLT 3/4-10 X 5 1/32 X 4

1 118-073M MANUAL WEIGHT BRACKET

Installation Instructions

5

118-072A 20F and 24F Weight Bracket Kit

Your kit includes:

Qty. Part No. Part Description

1 118-069H WEIGHT BRACKET WELDMENT-LH

1 118-070H WEIGHT BRACKET WELDMENT-RH

2 197-062D WEIGHT BRACKET ADJ LEG

4 802-057C HHCS 5/8-11 X 2 1/4 GR5

4 803-021C NUT HEX 5/8-11 PLT

8 803-027C NUT HEX 3/4-10 PLT

4 804-019C WASHER FLAT 5/8 USS PLT

4 804-022C WASHER LOCK SPRING 5/8 PLT

8 804-023C WASHER LOCK SPRING 3/4 PLT

2 806-089C U-BOLT 3/4-10 X 6 1/16 X 9

2 806-093C U-BOLT 3/4-10 X 6 1/32 X 7 3/4

1 118-073M MANUAL WEIGHT BRACKET

118-073M4/5/2006

Loading...

Loading...