Page 1

Operator’s Manual

1520F, 2020F, 2420F, 1510HDF, & 2010HDF

15’, 20’, and 24’ 3-Point Drills

Manufacturing, Inc.

www.greatplainsmfg.com

Read the operator’s manual entirely. When you see this symbol, the subsequent

instructions and warnings are serious - follow without exception. Your life and

!

the lives of others depend on it!

24137

Cover illustration may show optional equipment not supplied with standard unit.

© Copyright 2006 Printed 2/28/2006

288-196M

Page 2

Table of Contents

Important Safety Information . . . . . . . . . . . . . . . . 1

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Description of Unit . . . . . . . . . . . . . . . . . . . . . 12

Intended Usage . . . . . . . . . . . . . . . . . . . . 12

Models Covered in this Manual . . . . . . . . 12

Using This Manual . . . . . . . . . . . . . . . . . . . . . 13

Definitions . . . . . . . . . . . . . . . . . . . . . . . . 13

Owner Assistance. . . . . . . . . . . . . . . . . . . . . . 14

Preparation and Setup . . . . . . . . . . . . . . . . . . . . 15

Prestart Checklist . . . . . . . . . . . . . . . . . . . . . . 15

Hitching Tractor to Drill . . . . . . . . . . . . . . . . . . 15

Hydraulic Hose Hookup . . . . . . . . . . . . . . 16

Leveling the Drill . . . . . . . . . . . . . . . . . . . . . . . 17

Operating Instructions . . . . . . . . . . . . . . . . . . . . 21

Prestart Checklist . . . . . . . . . . . . . . . . . . . . . . 21

Field Operation . . . . . . . . . . . . . . . . . . . . . . . . 22

Opener Operation . . . . . . . . . . . . . . . . . . 23

Marker Operation . . . . . . . . . . . . . . . . . . . 23

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Transporting with Markers . . . . . . . . . . . . 24

Parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Side Gauge Wheels for 20 Series Openers . . 25

20 Series Openers . . . . . . . . . . . . . . . . . . . . . 26

Opener Down Pressure . . . . . . . . . . . . . . 26

Opener Seeding Depth . . . . . . . . . . . . . . 27

Press Wheel. . . . . . . . . . . . . . . . . . . . . . . 27

Seed-Lok Lock Up . . . . . . . . . . . . . . . . . . . . . 28

HD 10 Series Openers . . . . . . . . . . . . . . . . . . 29

Opener Down Pressure . . . . . . . . . . . . . . 29

Spring Down Pressure . . . . . . . . . . . . . . . 30

Opener Seeding Depth . . . . . . . . . . . . . . 30

Double V Press Wheel Adjustment . . . . . 31

Lock-Up . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Frame Height . . . . . . . . . . . . . . . . . . . . . . . . . 33

Single Gauge Wheel . . . . . . . . . . . . . . . . 33

Dual Gauge Wheels . . . . . . . . . . . . . . . . . 33

Seeding Rate . . . . . . . . . . . . . . . . . . . . . . . . . 34

Adjust Drive Sprockets . . . . . . . . . . . . . 34

Set Seed Rate Handle . . . . . . . . . . . . . 34

Position Seed Cup Doors . . . . . . . . . . . 35

Check Seeding Rate . . . . . . . . . . . . . . . 35

Tire Revolutions Per Acre . . . . . . . . . . . . . . 36

Seed Rate Chart (pounds per acre) . . . . . . 37

Marker Adjustments. . . . . . . . . . . . . . . . . . . 40

Bleeding Marker Hydraulics . . . . . . . . . 40

Folding Speed with Needle Valves . . . . 41

Folding Speed with Sequence Valve. . . 41

Marker Disk Adjustment . . . . . . . . . . . . 41

Changing disk angle . . . . . . . . . . . . . . . 41

Marker Chain. . . . . . . . . . . . . . . . . . . . . 42

Transport Carrier . . . . . . . . . . . . . . . . . . 42

Marker Width. . . . . . . . . . . . . . . . . . . . . 43

Seed-Lok™ Lock Up . . . . . . . . . . . . . . . . . . 44

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . 45

Maintenance and Lubrication . . . . . . . . . . . . . 47

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 47

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Torque Values Chart . . . . . . . . . . . . . . . . . . 56

Tire Inflation Chart . . . . . . . . . . . . . . . . . . . . 57

Specifications and Capacities . . . . . . . . . . . 57

Sprocket Configuration . . . . . . . . . . . . . . . . 58

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

© Copyright 2005 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either express or implied. While every precaution has been taken in the

preparation ofthis manual,Great PlainsManufacturing, Inc.assumes noresponsibility for errors or omissions. Neither is any liability assumed fordamages resultingfrom

the use of the information contained herein. GreatPlains Manufacturing, Inc. reserves theright to revise and improve its products as it sees fit. Thispublication describes

the state of this product at the time of its publication, and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains

All other brands and product names are trademarks or registered trademarks of their respective holders.

8/14/2006

Great Plains Manufacturing, Incorporated Trademarks

Printed in the United States of America.

Page 3

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is

a potential hazard to personal safety involved and

extra safety precaution must be taken. When you

see this symbol, be alert and carefully read the

message that follows it. In addition to design and

configuration of equipment, hazard control and

accident prevention are dependent upon the

awareness, concern, prudence and proper training of personnel involved in the operation,

transport, maintenance and storage of

equipment.

Important Safety Information

!

1

Be Aware of Signal Words

Signal words designate a degree or level of hazard seriousness.

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. This signal word is limited to the

most extreme situations, typically for machine

components that, for functional purposes, cannot

be guarded.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury, and includes hazards that are exposed when guards are removed. It may also be

used to alert against unsafe practices.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury. It may also be used to alert

against unsafe practices.

DANGER

!

WARNING

!

CAUTION

!

8/14/2006

Page 4

1520F, 2020F, 2420F, 1510HDF, &

2

2010HDF

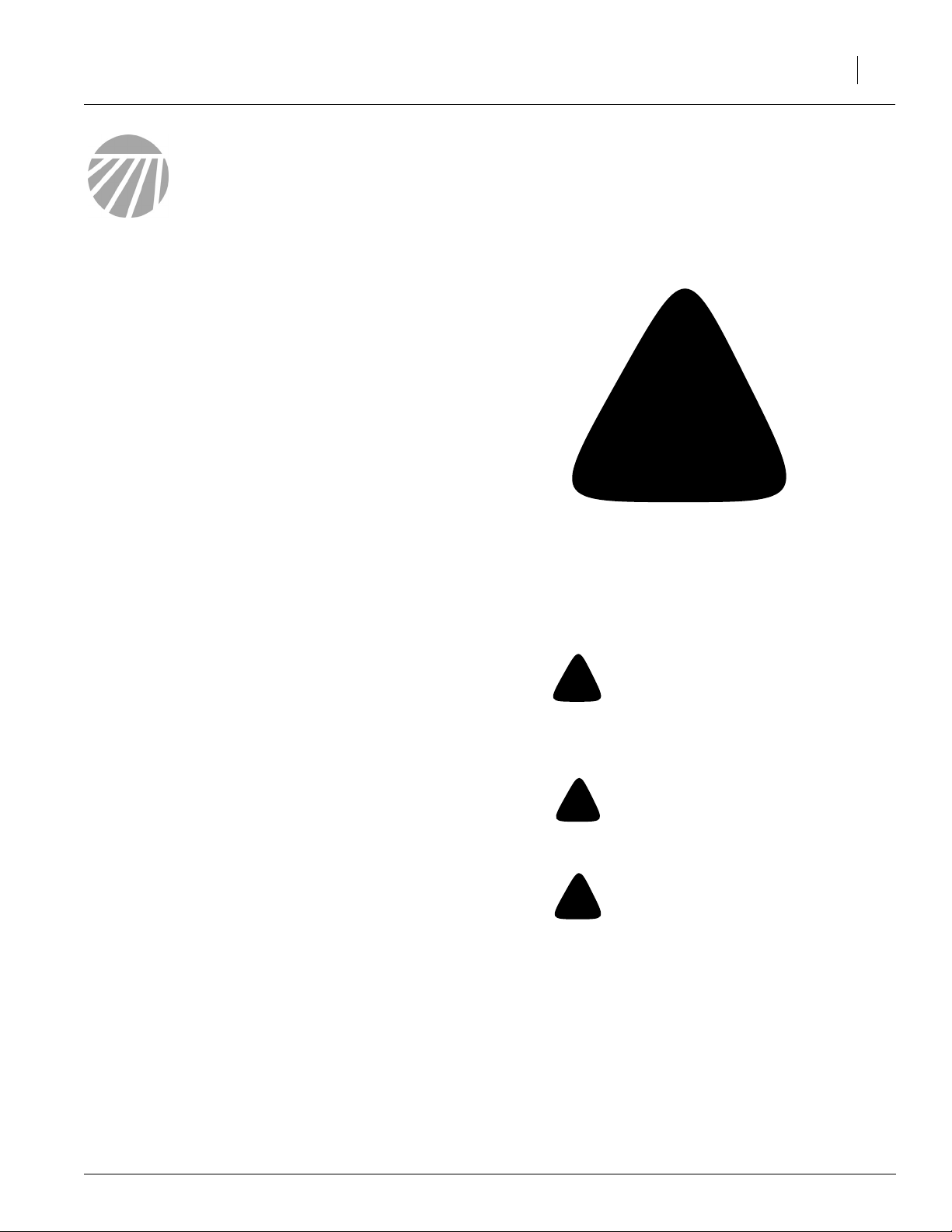

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals,” page 7,

thoroughly.

▲ Read all instructions noted on the decals.

Keep Riders Off Machinery

Riders obstruct the operator’s view. Riders could

be struck by foreign objects or thrown from the

machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine dur-

ing operation.

Shutdown and Storage

▲ Lower drill, put tractor in park, turn off engine,

and remove the key.

▲ Secure drill using blocks and supports pro-

vided.

▲ Detach and store drill in an area where chil-

dren normally do not play.

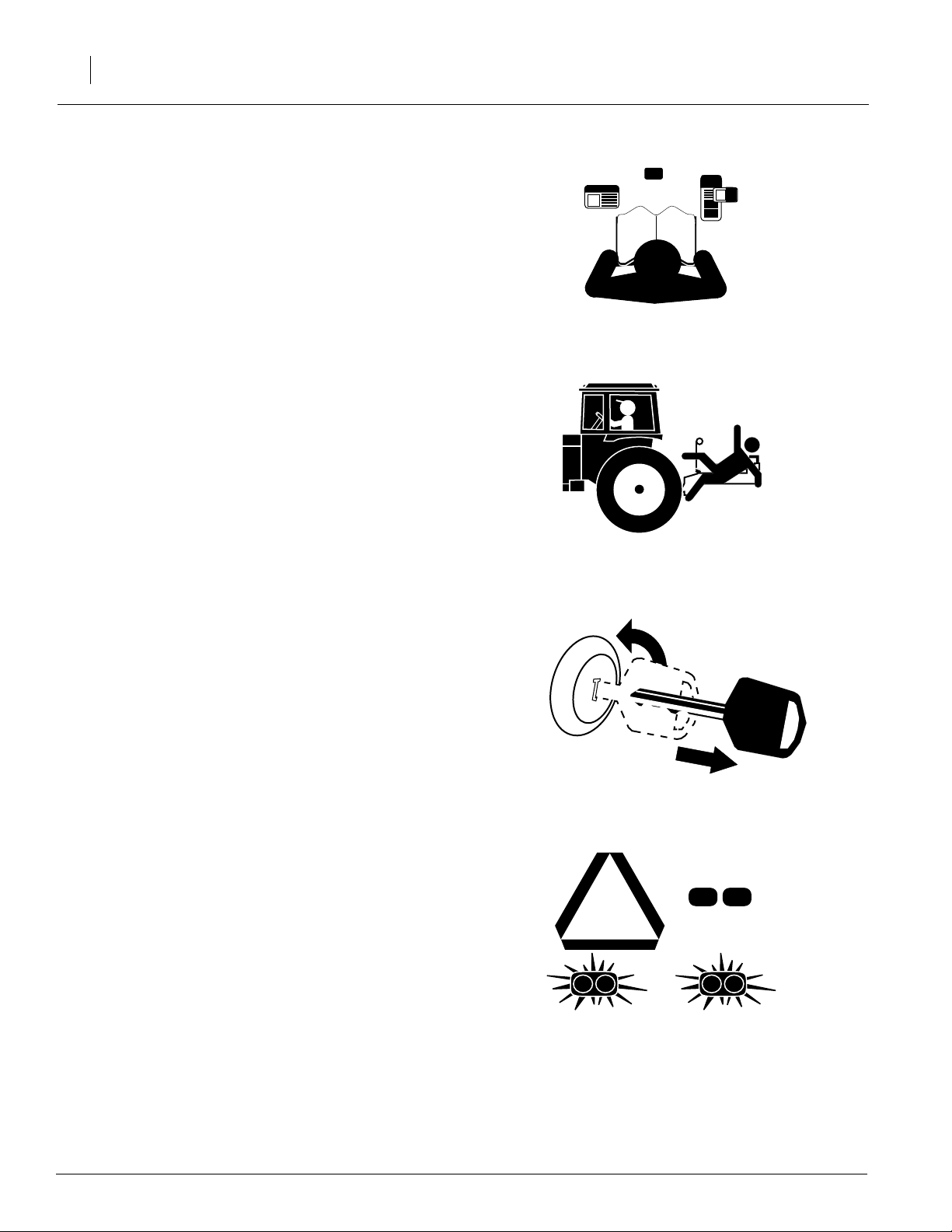

Use Safety Lights and Devices

Slow-moving tractors and towed implements can

create a hazard when driven on public roads.

They are difficult to see, especially at night.

▲ Use flashing warning lights and turn signals

whenever driving on public roads.

▲ Use lights and devices provided with imple-

ment.

OFF

8/14/2006

Page 5

Transport Machinery Safely

Maximum transport speed for implement is 20

mph. Some rough terrains require a slower

speed. Sudden braking can cause a towed load to

swerve and upset.

▲ Do not exceed 20 mph. Never travel at a

speed which does not allow adequate control

of steering and stopping. Reduce speed if

towed load is not equipped with brakes.

▲ Comply with state and local laws.

▲ Do not tow an implement that, when fully

loaded, weighs more than 1.5 times the weight

of towing vehicle.

▲ Carry reflectors or flags to mark drill in case of

breakdown on the road.

▲ Keep clear of overhead power lines and other

obstructions when transporting.

Important Safety Information

3

Avoid High Pressure Fluids

Escaping fluid under pressure can penetrate the

skin, causing serious injury.

▲ Avoid the hazard by relieving pressure before

disconnecting hydraulic lines.

▲ Use a piece of paper or cardboard, NOT

BODY PARTS, to check for suspected leaks.

▲ Wear protective gloves and safety glasses or

goggles when working with hydraulic systems.

▲ If an accident occurs, see a doctor immedi-

ately. Any fluid injected into the skin must be

surgically removed within a few hours or gangrene may result.

8/14/2006

Page 6

1520F, 2020F, 2420F, 1510HDF, &

4

2010HDF

Practice Safe Maintenance

▲ Understand procedure before doing work. Use

proper tools and equipment. Refer to this manual for additional information.

▲ Work in a clean, dry area.

▲ Lower the drill, put tractor in park, turn off

engine, and remove key before performing

maintenance.

▲ Make sure all moving parts have stopped and

all system pressure is relieved.

▲ Allow drill to cool completely.

▲ Disconnect battery ground cable (-) before

servicing or adjusting electrical systems or

before welding on drill.

▲ Inspect all parts. Make sure parts are in good

condition and installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from drill

before operation.

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extinguisher handy.

OFF

▲ Keep emergency numbers for doctor, ambu-

lance, hospital and fire department near

phone.

Wear Protective Equipment

▲ Wear protective clothing and equipment.

▲ Wear clothing and equipment appropriate for

the job. Avoid loose-fitting clothing.

▲ Because prolonged exposure to loud noise

can cause hearing impairment or hearing loss,

wear suitable hearing protection such as earmuffs or earplugs.

▲ Because operating equipment safely requires

your full attention, avoid wearing radio headphones while operating machinery.

911

8/14/2006

Page 7

Handle Chemicals Properly

Agricultural chemicals can be dangerous. Improper use can seriously injure persons, animals,

plants, soil and property.

▲ Read and follow chemical manufacturer’s

instructions.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Avoid inhaling smoke from any type of chemi-

cal fire.

▲ Store or dispose of unused chemicals as

specified by chemical manufacturer.

Use A Safety Chain

▲ Use a safety chain to help control drawn

machinery should it separate from tractor

drawbar.

Important Safety Information

5

▲ Use a chain with a strength rating equal to or

greater than the gross weight of towed

machinery.

▲ Attach chain to tractor drawbar support or

other specified anchor location. Allow only

enough slack in chain to permit turning.

▲ Replace chain if any links or end fittings are

broken, stretched or damaged.

▲ Do not use safety chain for towing.

Tire Safety

Tire changing can be dangerous and should be

performed by trained personnel using correct

tools and equipment.

▲ When inflating tires, use a clip-on chuck and

extension hose long enough for you to stand

to one side–not in front of or over tire assembly. Use a safety cage if available.

▲ When removing and installing wheels, use

wheel-handling equipment adequate for

weight involved.

8/14/2006

Page 8

1520F, 2020F, 2420F, 1510HDF, &

6

2010HDF

Safety At All Times

Thoroughly read and understand the instructions

in this manual before operation. Read all instructions noted on the safety decals.

▲ Be familiar with all drill functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave drill unattended with tractor

engine running.

▲ Do not dismount a moving tractor. Dismount-

ing a moving tractor could cause serious injury

or death.

▲ Do not stand between the tractor and drill dur-

ing hitching.

▲ Keep hands, feet and clothing away from

power-driven parts.

▲ Wear snug-fitting clothing to avoid entangle-

ment with moving parts.

▲ Watch out for wires, trees, etc., when folding

markers or raising drill. Make sure all persons

are clear of working area.

▲ Do not turn tractor too tightly, causing drill to

ride up on wheels. This could cause personal

injury or equipment damage.

8/14/2006

Page 9

Important Safety Information

7

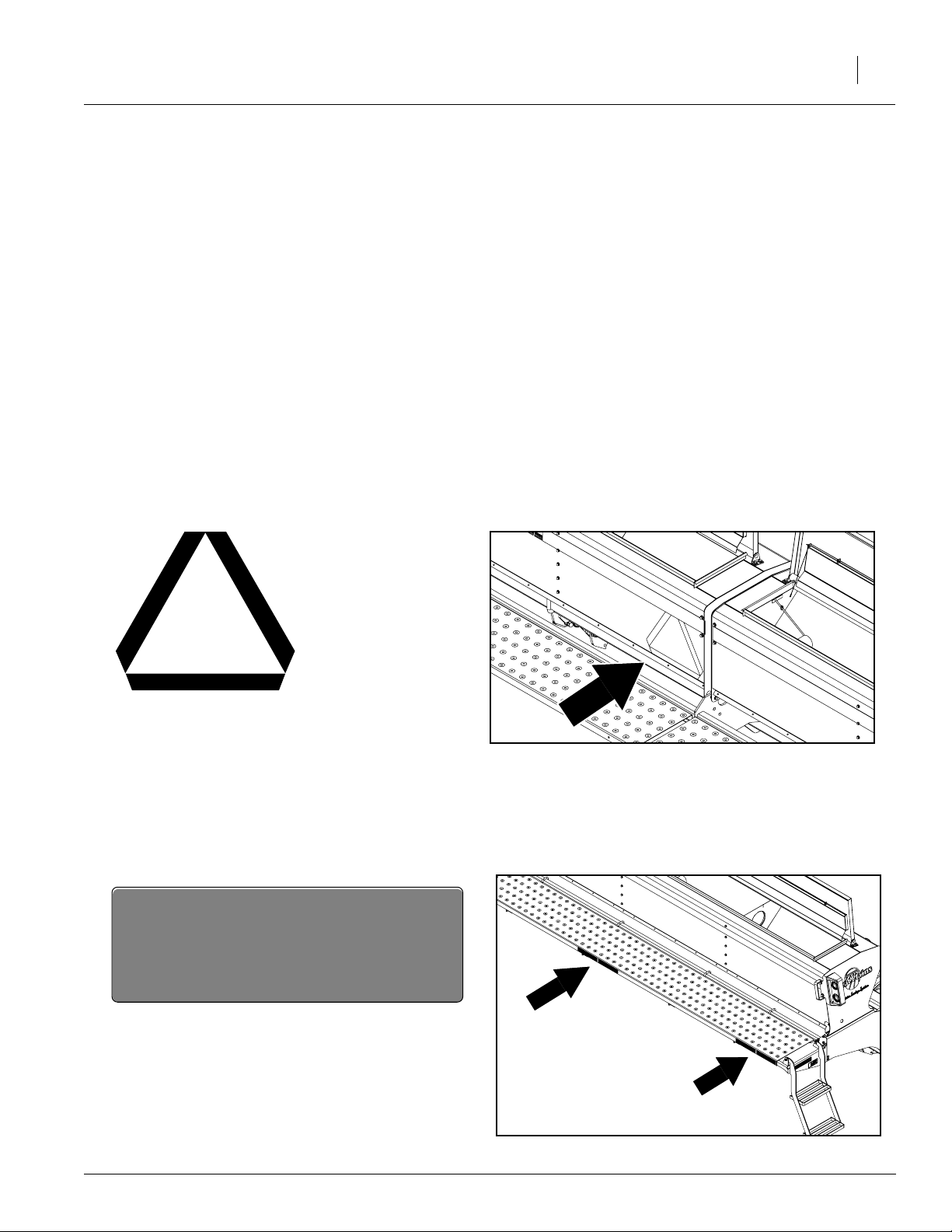

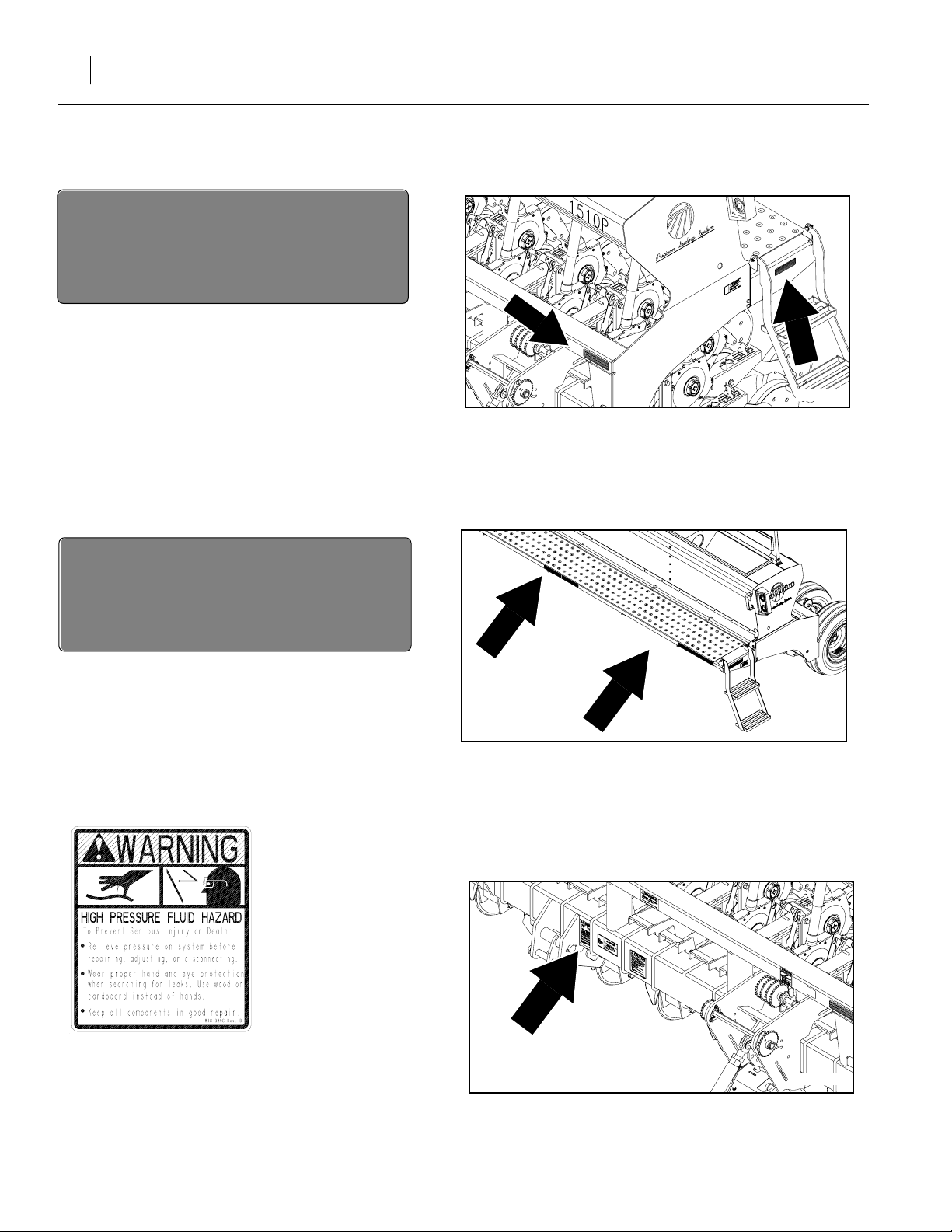

Safety Decals

Your implement comes equipped with all safety

decals in place. They were designed to help you

safely operate your implement.

▲ Read and follow decal directions.

▲ Keep all safety decals clean and legible.

▲ Replace all damaged or missing decals. Order

new decals from your Great Plains dealer.

Refer to this section for proper decal placement.

▲ When ordering new parts or components, also

request corresponding safety decals.

▲ To install new decals:

1. Clean the area on which the decal is to be

placed.

2. Peel backing from decal. Press firmly on

surface, being careful not to cause air

bubbles under decal.

818-003C

818-003C

Slow Moving Vehicle Label

Slow Moving Vehicle Label

838-266C

Red Reflectors

Reflectors on outside ends and off center of walkboards; four reflectors total.

17769

19189

8/14/2006

Page 10

1520F, 2020F, 2420F, 1510HDF, &

8

2010HDF

838-265C

Amber Reflectors

Reflector on both ends of drill; four reflectors total.

18262

838-267C

Decal Reflectors Daytime

Reflectors on inside ends and off center on walkboards next to red reflectors; four reflectors total.

818-339C

High Pressure Hazard

19189

18262

8/14/2006

Page 11

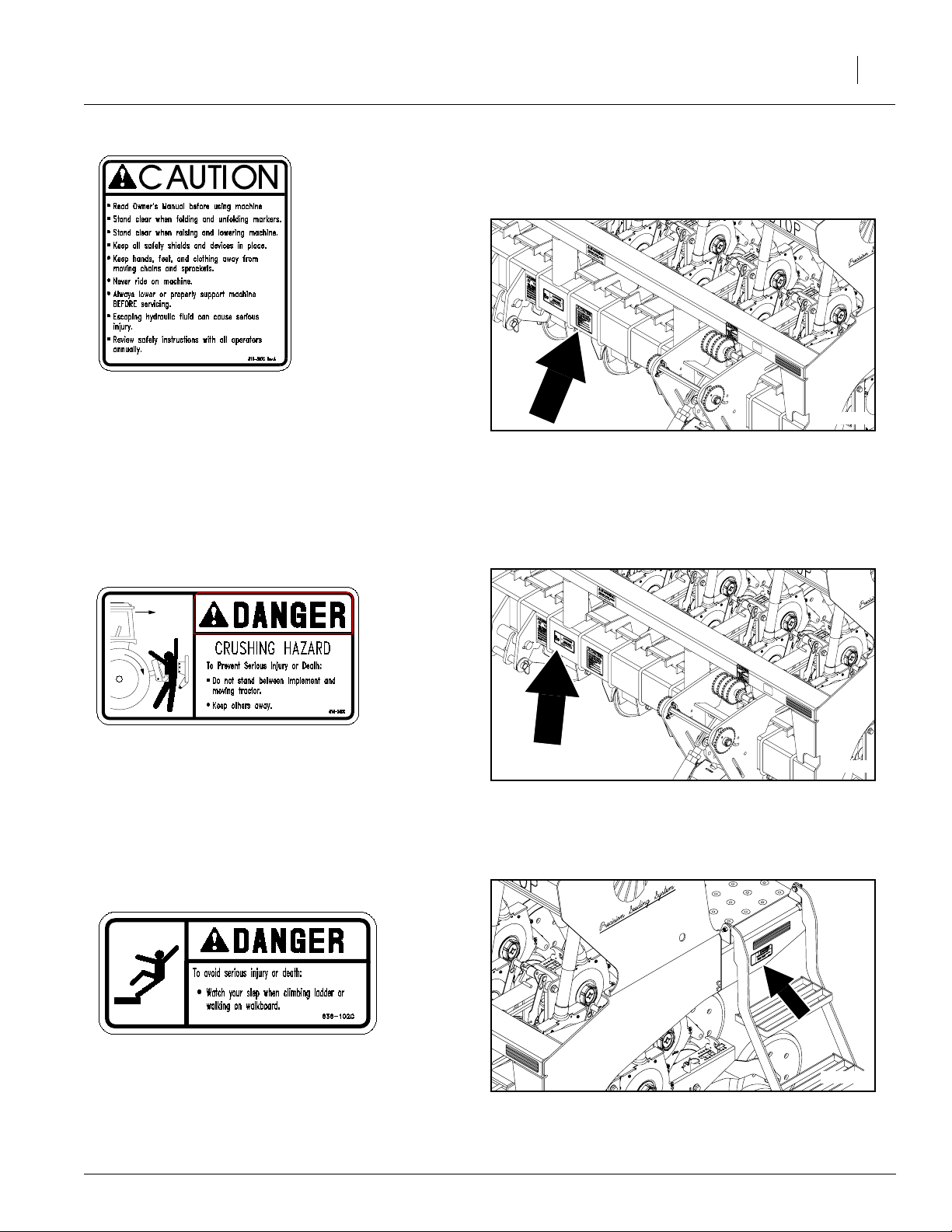

818-587C

General Instructions

Important Safety Information

18262

9

818-590C

Crushing Hazard

838-102C

Falling Hazard

8/14/2006

1826218262

19195

Page 12

1520F, 2020F, 2420F, 1510HDF, &

10

2010HDF

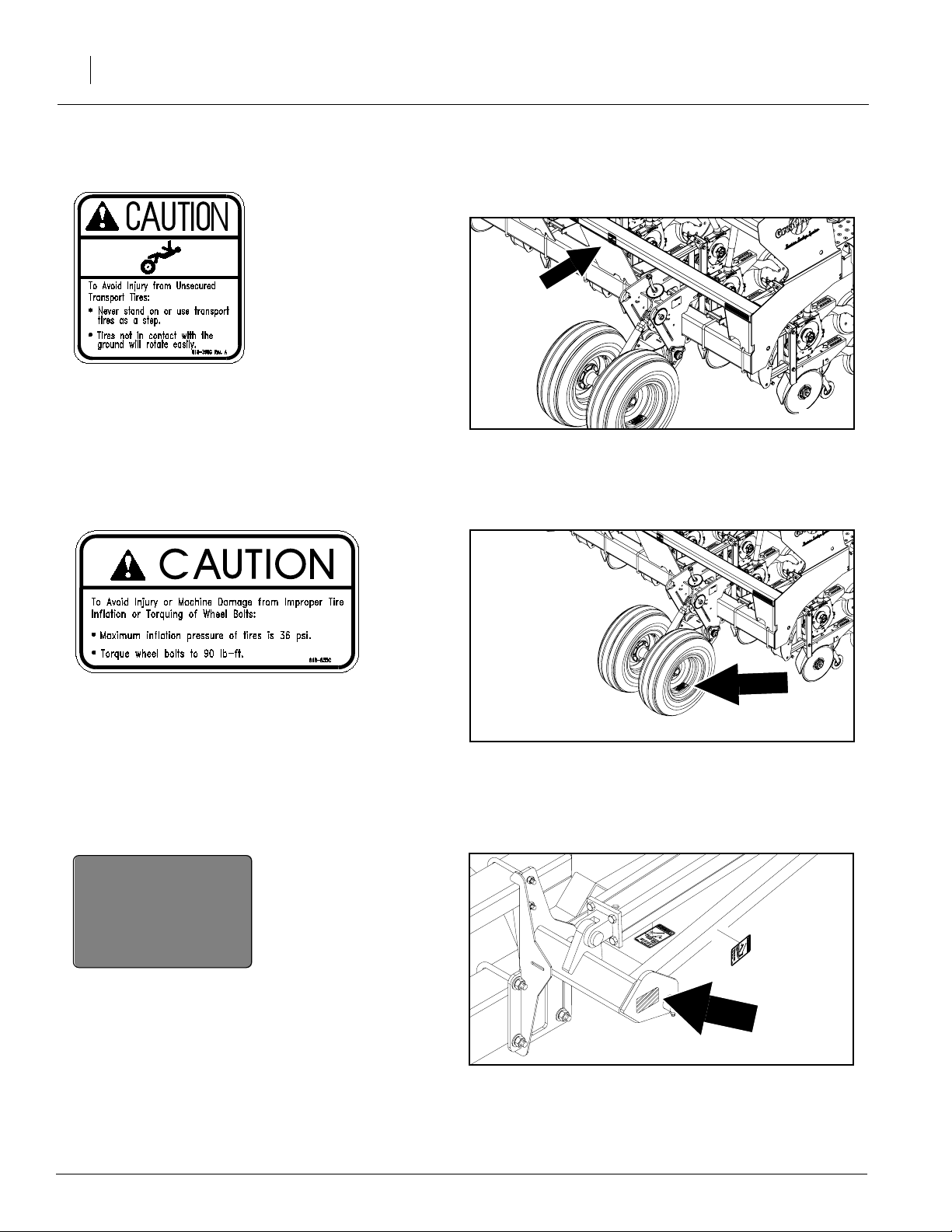

818-398C

Falling Hazard

19197

818-855C

Tire Pressure

818-229C

Amber Reflector

Reflector on each optional marker.

19197

18270

8/14/2006

Page 13

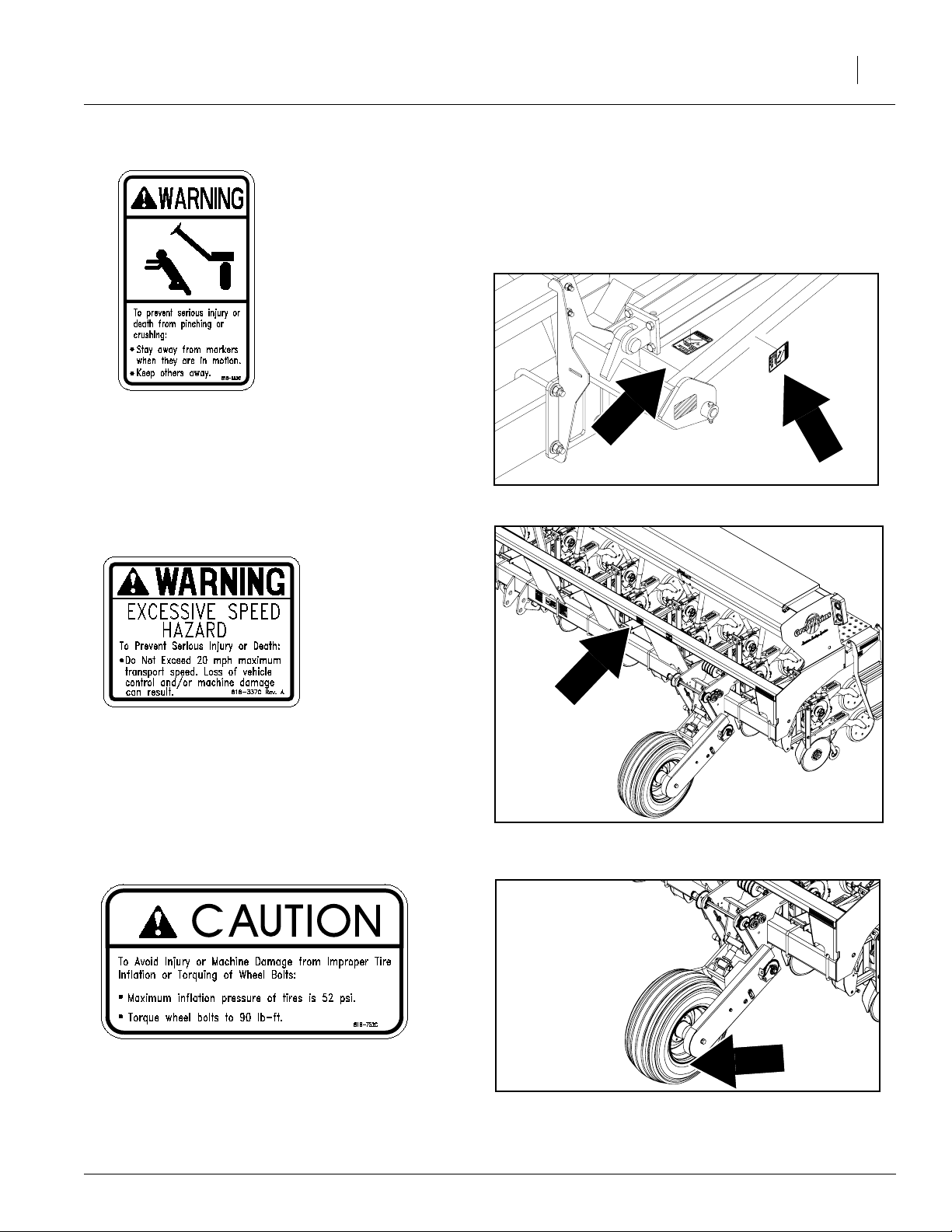

818-682C

7

Crushing Hazard

Two decals on first section of each optional marker;

four decals total.

Important Safety Information

1827018270

11

818-337C

Excessive Speed Hazard

818-752C

Tire Pressure

8/14/2006

182

21641

21641

Page 14

1520F, 2020F, 2420F, 1510HDF, &

12

2010HDF

Introduction

Great Plains welcomes you to its growing family of

new product owners. This drill has been designed

with care and built by skilled workers using quality

materials. Proper setup, maintenance and safe

operating practices will help you get years of satisfactory use from the machine.

Description of Unit

The 15 ft, 20 ft, and 24 ft 3-point drills are

equipped with HD 10 Series and 20 Series openers. The HD 10 Series Opener is outfitted with

heavy duty parallel-arm openers. The 20 Series

Opener is outfitted with side-depth-control openers. These openers are staggered for easy

residue flow. Opener depth can be adjusted.

Intended Usage

Use the drill to seed production-agriculture crops

only. Do not modify the drill for use with attachments other than Great Plains options and

accessories specified for use with the drill.

Models Covered in this Manual

1520F, 2020F, 2420F, 1510HDF, & 2010HDF

24137

8/14/2006

Page 15

Using This Manual

This manual will familiarize you with safety, assembly, operation, adjustments, troubleshooting

and maintenance. Read this manual and follow

the recommendations to help ensure safe and efficient operation.

The information in this manual is current at printing. Some parts may change to assure top

performance.

Definitions

The following terms are used throughout this

manual.

Machine travel

direction

Introduction

Right-hand

side

13

Refer to Figure 1

Right-hand and left-hand as used in this manual

are determined by facing the direction the machine will travel while in use unless otherwise

stated.

IMPORTANT: A crucial point of information related to the preceding topic. For safe and correct operation, read and follow the directions

provided before continuing.

NOTE: Useful information related to the preceding topic.

Left-hand

side

Figure 1

18327

8/14/2006

Page 16

1520F, 2020F, 2420F, 1510HDF, &

14

2010HDF

Owner Assistance

If you need customer service or repair parts, contact a Great Plains dealer. They have trained

personnel, repair parts and equipment specially

designed for Great Plains products.

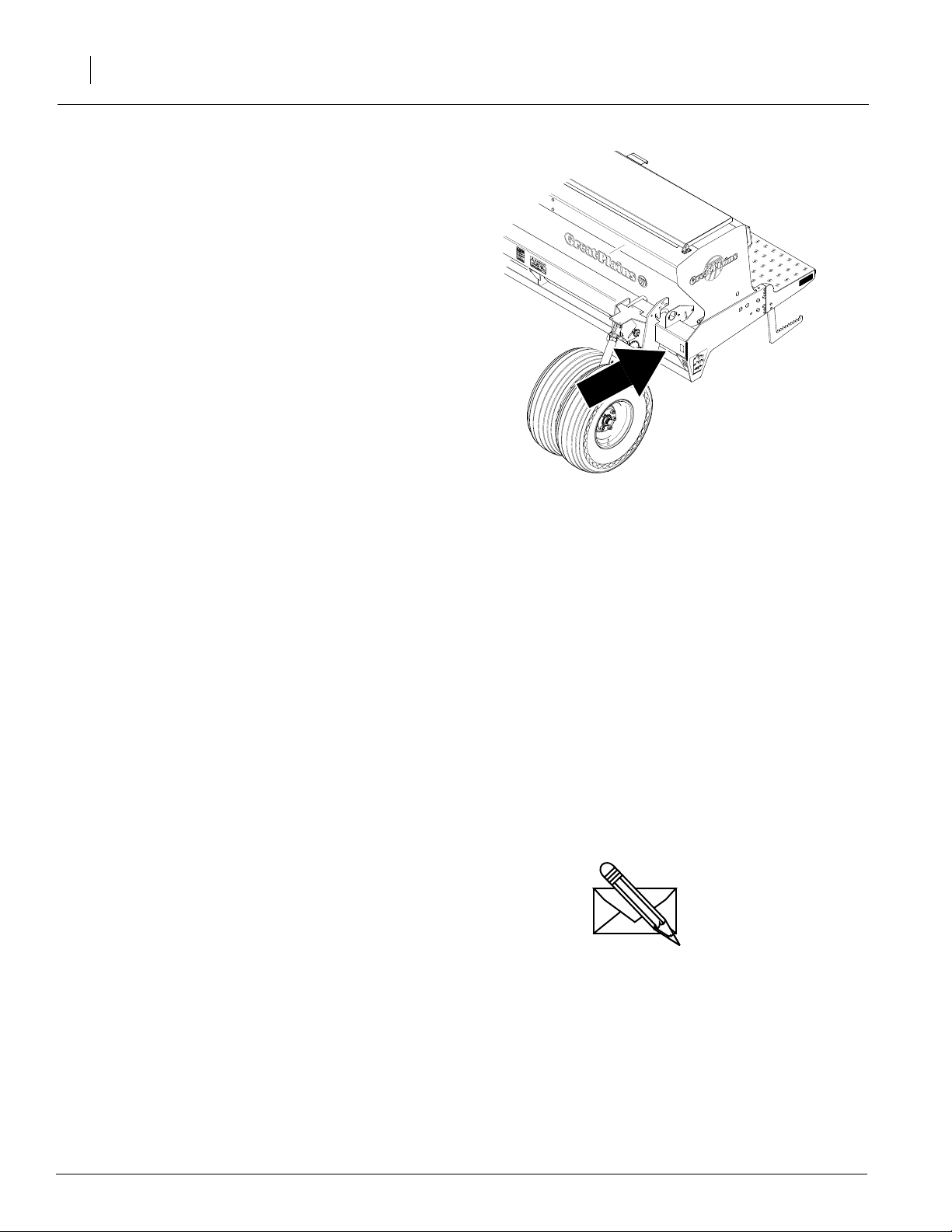

Refer to Figure 2

Your machine’s parts were specially designedand

should only be replaced with Great Plains parts.

Always use the serial and model number when ordering parts from your Great Plains dealer. The

serial-number plate is located on the main frame

tube on the left end of the drill.

Record your drill model and serial number here for

quick reference:

Model Number:__________________________

Serial Number: ___________________________

Figure 2

Serial Number Plate

16490

Your Great Plains dealer wants you to be satisfied

with your new machine. If you do not understand

any part of this manual or are not satisfied with the

service received, please take the following

actions.

1. Discuss the matter with your dealership service manager. Make sure they are aware of

any problems so they can assist you.

2. If you are still unsatisfied, seek out the owner

or general manager of the dealership.

3. For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

8/14/2006

Page 17

Preparation and Setup

This section will help you prepare your tractor and

drill for use. Before using the drill in the field, you

must hitch the drill to a suitable tractor and level

the drill.

Prestart Checklist

1. Read and understand “Important Safety Information,” page 1.

2. Check that all working parts are moving freely, bolts are tight, and cotter pins are spread.

3. Check that all grease fittings are in place and

lubricated. Refer to “Lubrication,” page 52.

4. Check that all safety decals and reflectors are

correctly located and legible. Replace if damaged. See “Safety Decals,” page 7.

Preparation and Setup

15

5. Inflate tires to pressure recommended and

tighten wheel bolts as specified. See “Appendix,” page 56.

Hitching Tractor to Drill

!

DANGER

You may be severely injured or killed by being crushed

between the tractor and drill. Do not stand or place

any part of your body between drill and moving tractor. Stop tractor engine and set park brake before installing the hitch pin.

1. Raise or lower tractor three-point arms as

needed and pin lower arms to drill.

2. Pin upper arm to drill. For category III and IIIN tractors, install hitch pin in the lower hole.

For category IV-N tractors, install hitch pin in

the upper hole.

3. Slowly raise drill. Watch for cab interference.

4. Adjust top three-point link so that top edge of

drill box is parallel with ground when drilling.

NOTE: Do not use link to adjust opener depth. For

opener adjustments, refer to page 25.

5. Set your tractor three-point-draft control to

float position.

6. Plug lead from drill light harness into tractor

receptacle.

8/14/2006

Page 18

1520F, 2020F, 2420F, 1510HDF, &

16

2010HDF

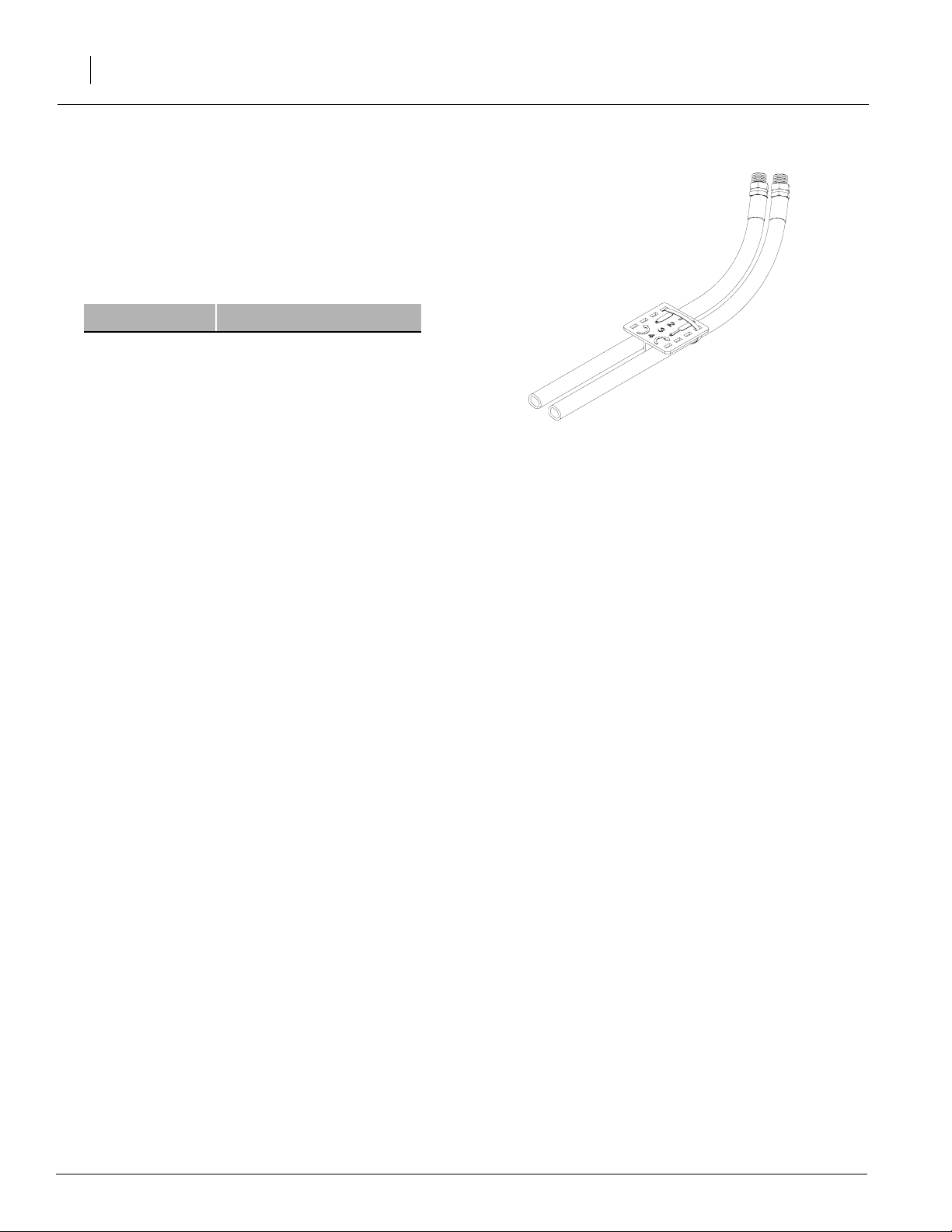

Hydraulic Hose Hookup

Refer to Figure 3

Great Plains hydraulic hoses are color coded to

help you hookup hoses to your tractor outlets.

Hoses that go to the same remote valve are

marked with the same color.

Color Hydraulic Function

Orange Marker Cylinders

To distinguish hoses on the same hydraulic circuit, refer to plastic hose holder. Hose under

extended-cylinder symbol feeds cylinder base

ends. Hose under retracted-cylinder symbol

feeds cylinder rod ends.

17641

Figure 3

Hydraulic Hose Label

8/14/2006

Page 19

Leveling the Drill

20 Series Opener Single Gauge Wheel

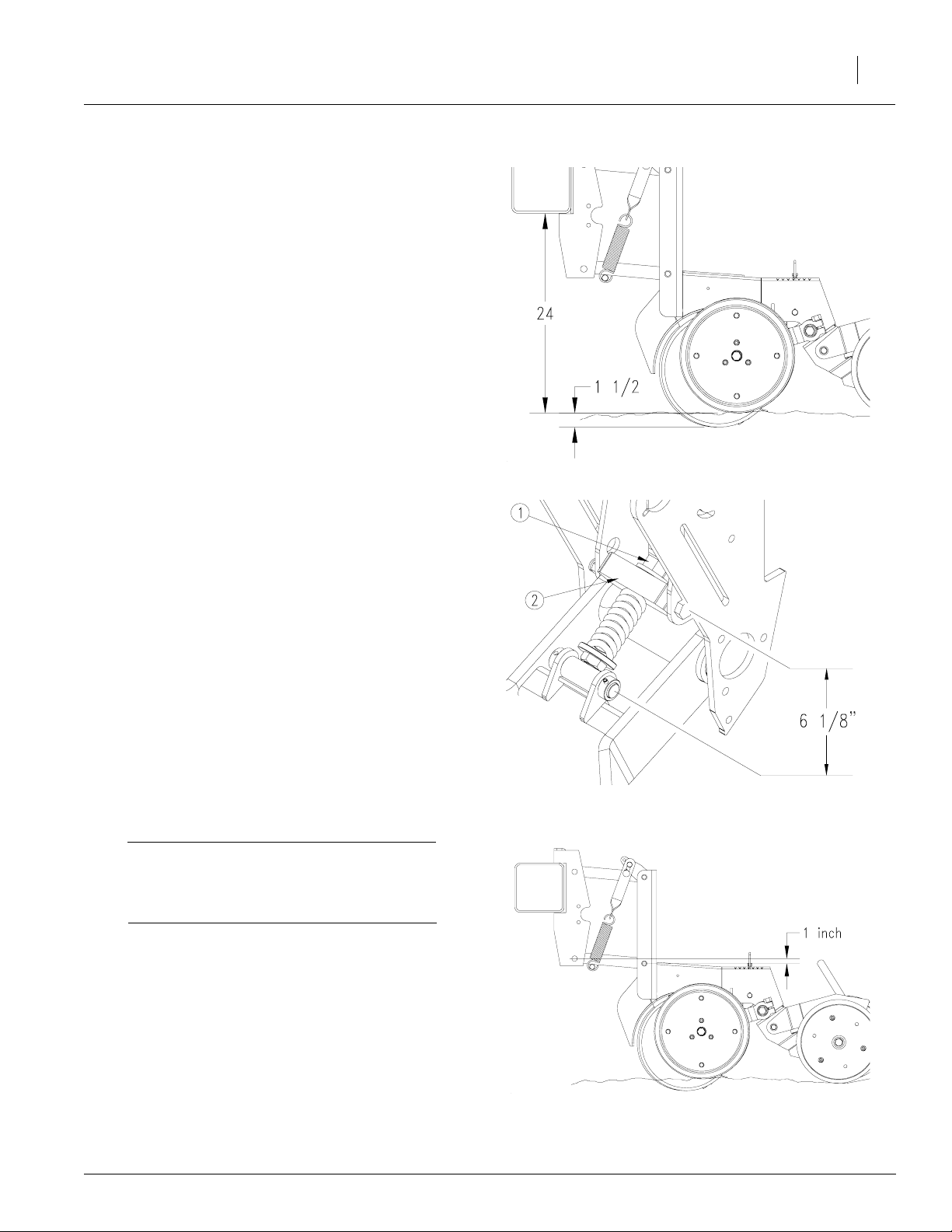

Refer to Figure 4

Initially adjust drill so bottom of opener tube runs

24 inches above ground when drill is lowered in

the field.

Refer to Figure 5

To adjust:

Preparation and Setup

17

1. Make sure block mount of the spring linkage

(2) is in the lower mount hole for planting in

bedded irrigation. The upper hole is for nonbedded ground.

2. Set spring linkage length. Turn spring linkage

to shorten or lengthen as necessary. Initially

set length to 6 1/8 inches between pin centers

to achieve the 24-inch dimension mentioned

above. When adjusting the linkage length, remember:

• Lengthening linkage raises drill.

• Shortening linkage lowers drill.

3. Level drill with top three-point link.

Refer to Figure 6

NOTE: When drill is level, parallel links will be running slightly uphill towards the front.

The 1-inch dimension shown is a general dimension that will vary with planting conditions.

IMPORTANT: Make sure the opener mount is

running higher than the opener body. This will

ensure an ample reserve for opener upfloat in

case the opener strikes a rock or other object.

Figure 4

Initial Operating Height

Figure 5

Spring Linkage

24301

21685

8/14/2006

Figure 6

Leveling the Drill

23402

Page 20

1520F, 2020F, 2420F, 1510HDF, &

18

2010HDF

20 Series Opener Dual Gauge Wheels

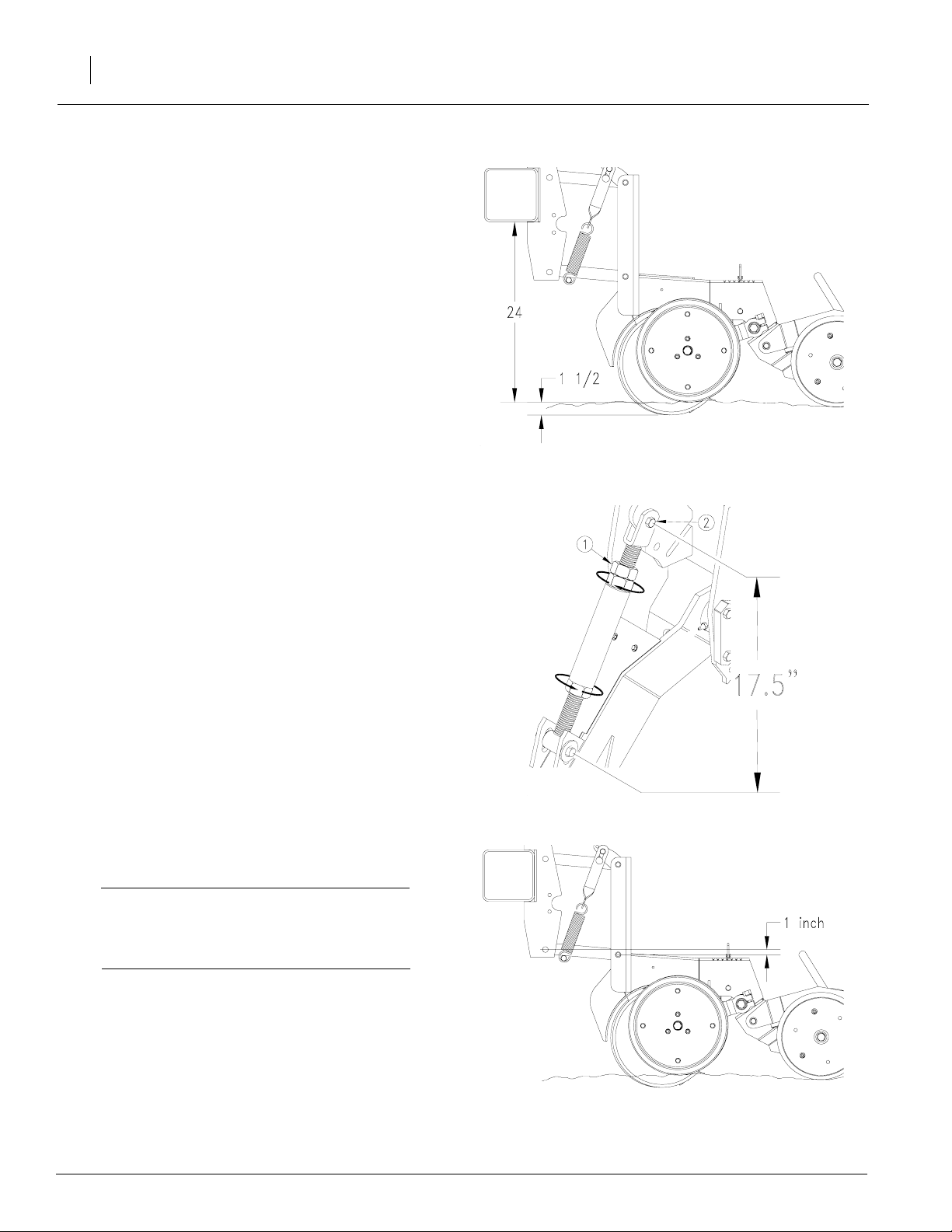

Refer to Figure 7

Initially adjust drill so bottom of opener tube runs

24 inches above ground when drill is lowered in

the field.

Refer to Figure 8

To adjust:

1. Loosen jam nut near top clevis of each

gauge-wheel turnbuckle.

NOTE: Jam nut is left-hand threaded.

2. Make sure upper clevis (2) is in upper mount

hole as shown.

3. Set turnbuckle length. Turn turnbuckle to

shorten or lengthen as necessary. Initially set

length to 17 1/2 inches between pin centers to

achieve the 24-inch dimension mentioned

above. When adjusting the turnbuckle length,

remember:

Figure 7

Initial Operating Height

24301

• Lengthening turnbuckle raises drill.

• Shortening turnbuckle lowers drill.

4. After adjusting both turnbuckles to the same

length, tighten jam nuts.

5. Level drill with top three-point link.

Refer to Figure 9

NOTE: When drill is level, parallel links will be running slightly uphill towards the front.

The 1-inch dimension shown is a general dimension that will vary with planting conditions.

IMPORTANT: Make sure the opener mount is

running higher than the opener body. This will

ensure an ample reserve for opener upfloat in

case the opener strikes a rock or other object.

Figure 8

Gauge-Wheel Turnbuckle

22845

Figure 9

Leveling the Drill

24302

8/14/2006

Page 21

HD 10 Series Openers with Single Gauge Wheel

Refer to Figure 10

Initially adjust drill so bottom of opener tube runs 26

inches above ground when drill is lowered in the

field.

Refer to Figure 11

To adjust:

1. Make sure block mount of the spring linkage (2)

is in the lower mount hole for planting in bedded

irrigation. The upper hole is for non-bedded

ground.

Preparation and Setup

19

2. Set spring linkage length. Turn spring linkage to

shorten or lengthen as necessary. Initially set

length to 6 1/2 inches between pin centers to

achieve the 26-inch dimension mentioned

above. When adjusting the linkage length, remember:

• Lengthening linkage raises drill.

• Shortening linkage lowers drill.

3. Level drill with top three-point link.

Refer to Figure 12

NOTE: When drill is level, parallel links will be running level or slightly uphill towards the front.

The 1-inch dimension shown is a general dimension that will vary with planting conditions.

IMPORTANT: Make sure the opener mount is

running higher than the opener body. This will

ensure an ample reserve for opener upfloat in

case the opener strikes a rock or other object.

22847

Figure 10

Initial Operating Height

Figure 11

Spring Linkage

24046

8/14/2006

Figure 12

Leveling the Drill

24047

Page 22

1520F, 2020F, 2420F, 1510HDF, &

20

2010HDF

HD 10 Series Openers Dual Gauge Wheels

Refer to Figure 2

Initially adjust drill so bottom of opener tube

runs 26 inches above ground when drill is lowered in the field.

Refer to Figure 3

To adjust:

1. Make sure the top turnbuckle clevis is in

the lower mount hole.

2. Set turnbuckle length. Turn turnbuckle to

shorten or lengthen as necessary. Initially

set length to 17 1/2 inches between pin

centers to achieve the 26-inch dimension

mentioned above. When adjusting the

turnbuckle length, remember:

• Lengthening turnbuckle raises drill.

Figure 2

Initial Operating Height

24050

• Shortening turnbuckle lowers drill.

3. Level drill with top three-point link.

Refer to Figure 4

NOTE: When drill is level, parallel links will be

running slightly uphill towards the front.

The 1 inch dimension shown is a general dimension that will vary with planting conditions.

IMPORTANT: Make sure the opener mount

is running higher than the opener body.

This will ensure an ample reserve for opener upfloat in case the opener strikes a rock

or other object.

Figure 3

Gauge Wheel Turnbuckle

22845

Figure 4

Leveling the Drill

24049

8/14/2006

Page 23

Operating Instructions

This section covers general operating procedures. Experience, machine familiarity and the

following information will lead to efficient operation and good working habits. Always operate

farm machinery with safety in mind.

Prestart Checklist

!

WARNING

Escaping fluid under pressure can have sufficient pressure to penetrate the skin. Check all hydraulic lines

and fittings before applying pressure. Fluid escaping

from a very small hole can be almost invisible. Use paper or cardboard, not body parts, and wear heavy

gloves to check for suspected leaks. If injured, seek

medical assistance from a doctor that is familiar with

this type of injury. Foreign fluids in the tissue must be

surgically removed within a few hours or gangrene

will result.

Operating Instructions

21

1. Carefully read “Important Safety Information,”

page 1.

2. Lubricate drill as indicated under “Lubrication,” page 52.

3. Check all tires for proper inflation. See “Appendix,” page 56.

4. Check all bolts, pins and fasteners. Torque as

shown in “Appendix,” page 56.

5. Check drill for worn or damaged parts. Repair

or replace parts before going to the field.

6. Check hydraulic hoses, fittings and cylinders

for leaks. Repair or replace before going to

the field.

7. Rotate both gauge wheels to see that the

drive and meters are working properly and

free from foreign material.

!

DANGER

Watch your step when walking on drill ladder and

walkboard. Falling from drill could cause severe injury or death.

8/14/2006

Page 24

1520F, 2020F, 2420F, 1510HDF, &

22

2010HDF

Field Operation

!

You may be severely injured or killed by being crushed

between the tractor and drill. Do not stand or place

any part of your body between drill and moving tractor. Stop tractor engine and set park brake before installing pins.

1. Hitch drill to asuitable tractor orhitch. Refer to

2. Set and calibrate seeding rate as explained

3. Check that seed-cup-doorhandles areset the

DANGER

“Hitching Tractor to Drill,” page 15 or your

hitch operator’s manual.

under Seeding Rate, “Adjustments,” page

15.

same across the drill. Refer to Seeding Rate,

“Adjustments,” page 15.

NOTE: If you notice excessive cracking on large

seeds, adjust all seed-cup doors to a wider setting. Use the widest setting only for seed-cup

clean out.

4. Load box with clean seed.

5. Record acremeter readout. Subtract inital

reading from later readings to determine area

drilled.

6. Pull forward, lower drill and begin seeding.

7. Always lift drill out of the ground when turning

at row ends and for other short-radius turns.

Seeding wil stop automatically as drill is

raised in the field.

8/14/2006

Page 25

Opener Operation

IMPORTANT: Do not back up with openers in

the ground. To do so will cause severe damage and opener plugging.

For information on opener adjustments, refer to

page 26 or page 29. For more information on troubleshooting opener problems, see

“Troubleshooting”, page 45.

Marker Operation

Optional marker attachments are available from

your Great Plains dealer. Before operating markers, make sure hydraulics are properly bled as

described under “Marker Adjustments”, page 40.

Dual markers equipped witha sequence valve are

powered off the same hydraulic circuit. Starting

with both markers folded, the folding sequence is:

Operating Instructions

23

1. Activate lever - Right unfolds; left stays

folded.

2. Reverse lever - Right folds; left stays folded.

3. Activate lever - Left unfolds; right stays

folded.

4. Reverse lever - Left folds up; right stays

folded.

5. Sequence repeats.

You can adjust marker folding speed. Refer to

“Marker Adjustments”, page 40, and adjustfolding

speed to a safe rate. Folding markers at high

speed can damage markers.

Transporting

!

WARNING

Towing the drill at high speeds or with a vehicle that is

not heavy enough could lead to loss of vehicle control.

Loss of vehicle control could lead to serious road accidents, injury and death. To reduce the hazard, do not

exceed 20 mph. Check that your tractor has enough

ballast to handle the weight of the drill. Refer to your

tractor operator’s manual for ballast requirements.

NOTE: For transporting with drill attached to a

hitch, refer to your hitch operator’s manual.

Before transporting the drill, follow and check

these items:

8/14/2006

Page 26

1520F, 2020F, 2420F, 1510HDF, &

24

2010HDF

Unload seed box. Unload seed box before trans-

porting if at all possible. To do so:

• Place tarp under drill or a bucket under each

seed meter.

• Use large bucket to empty box as much as

possible. Make sure sliding seed tubes are in

the open position. Open seed meter clean out

to empty seed out of sliding seed tube and

meter.

The drill can be transported with a full box of grain,

but the added weight will increase stopping distance and decrease maneuverability.

NOTE: To maintain steering control, you may

need to add ballast to your tractor front end. Refer

to your tractor operator’s manual for ballast required.

Road rules. Comply with all federal, state and local safety laws when traveling on public roads.

Refer to Figure 17

Clearance. Remember that the drill is wider than

the tractor. Allow safe clearance. Fold up walkboard ladder for maximum clearance.

Transporting with Markers

Always transport markers in the folded position.

Parking

For information on long-term storage, refer to

“Storage”, page 51.

!

WARNING

Empty seed box before unhitching drill to prevent drill

from falling backward.

NOTE: For parking with drill attached to a hitch,

refer to your hitch operator’s manual.

1. Empty seed box.

2. Park drill on a level, solid surface.

3. Lower three-point hitch until drill is on the

ground.

Figure 17

Ladder Folded for Transport

22878

4. Extend or retract the top link of the tractor until

top three-point pin is free. Remove pin.

5. Remove pins from lower links.

8/14/2006

Page 27

Adjustments

Adjustments

25

Side Gauge Wheels for 20 Series

Openers

Refer to Figure 18

The side gauge wheels have two, interrelated adjustments:

• angle of side gauge wheel, and

• distance between side gauge wheel and row unit disk.

Refer to Figure 19

Adjust side-gauge-wheel angle so wheels contact the row

unit disks at bottom of wheel at 2” planting depth.

At the same time, keep side gauge wheels close to the

opener disks so openers do not plug with soil or trash but

far enough out so the disks and wheels turn freely.

• If contact point is between 4 to 8 o’clock but distance to tire is not correct, then add or remove shims

as needed. DO NOT ADJUST BEARING AS THAT

WILL ADJUST WHEEL-TO-DISK CONTACT AREA

ONLY.

Refer to Figure 20

Opener

Disks

Side Gauge

Wheel

Incorrect Correct

Note: Wheel touches at bottom and gaps open 3/8”

to 5/8” at top.

Figure 18

Side Gauge Wheels

8 o’clock

Side Gauge

Wheel

4 o’clock

To adjust Wheel-to-Disk contact area of side gauge

wheels:

1. Raise drill slightly to remove weight from side gauge

wheels.

2. Loosen hex-head bolt (1). Move wheel and arm out on

o-ring bushing.

3. Loosen pivot bolt (2). Turn hex adjuster (3) so indicator

notch (4) is at 5 o’clock to 7 o’clock. Use this as the

starting point for adjustment.

4. Move wheel arm in so side gauge wheel contacts row

unit disk. Tighten hex-head bolt (1) to clamp arm

around bushing and shank.

5. Check wheel-to-disk contact at 2” planting depth. Lift

wheel and arm. When let go, wheel should fall freely.

• If wheel does not contact disk at bottom to area

where blade leaves contact with soil, move hex ad-

juster until wheel is angled for proper contact with disk.

• If wheel does not fall freely, loosen hex-head bolt (1)

and slide wheel arm out just until wheel and arm move

freely. Retighten hex-head bolt (1) according to grade:

• 7/16” Gr 8 bolt on 20 series, 70 ft-lbs.

• 5/8” Gr 8 bolt on 20 series, 150 ft-lbs.

Figure 19

Wheel-to-Disk Contact Area

24006

3

1

2

4

Starting Point

Figure 20

Side Gauge Wheel Adjustment

6. Keep turning hex adjuster and moving wheel arm

until the wheel is adjusted properly. When satisfied, tighten pivot bolt (2) to 110 foot-pounds.

22525

NOTE: Use “Torque Values Chart”, page 56 for reference.

8/14/2006

Page 28

1520F, 2020F, 2420F, 1510HDF, &

26

2010HDF

20 Series Openers

Opener Down Pressure

Refer to Figure 21

Opener springs provide the down pressure necessary for opener disks to open a seed trench.

The springs allow the openers to float down into

depressions and up over obstructions.

You can adjust down pressure individually for

each opener. This is useful for penetrating hard

soil and planting in tire tracks.

Use enough down pressure to cut the seed trench

and maintain proper soil-firming over seed. Excessive opener down force will lead to premature

wear on opener components.

Refer to Figure 22

To adjust down pressure, use adjustment tool

stored under walkboard. Position tool in holes on

spring mounting plates, and pull down. Move the

adjustment cam to the new setting.

Opener Spring

Disk

Figure 21

20 Series Opener with Meter

20451

Refer to Figure 23

Minimum and maximum settings are indicated by

position of adjustment cam.

Press Wheel Adjustment

Press Wheel Adjustment

Minimum setting

Adjustment Cam Settings

Adjustment

Figure 22

Figure 1

Figure 23

Tool

20450

18409

Maximum setting

12104

8/14/2006

Page 29

Adjustments

27

Opener Seeding Depth

Refer to Figure 24

Side depth wheels beside the opener disks control opener seeding depth. The position of an

adjustable stop determines seeding depth.

Refer to Figure 25

Set opener seeding depth by adjusting T-handles.

To adjust, first raise openers slightly, then lift and

slide T-handles on top of openers. Adjust all Thandles to the same setting.

• For shallower seeding, slide T-handles forward toward drill.

• For deeper seeding, slide T-handles back

away from drill.

Disk

Handle

Figure 24

20 Series Opener

20451

Side Depth

Wheel

Press Wheel

Refer to Figure 26

Press wheels are attached to each opener body.

The press wheels close the seed trench and gently press soil over seed.

An adjustable spring in the press-wheel mechanism creates the down pressure needed to close

the seed trench. The amount of force needed will

vary with field conditions.

To adjust, move adjustment handle.

• For less down pressure,move handle forward

toward drill.

• For more down pressure, move handle back

away from drill.

NOTE: Increased press wheel spring force may

require increased opener down force to maintain

depth.

Figure 25

20 Series Opener Depth

Less down

pressure

More down

pressure

Figure 26

Closing Wheel Down Pressure

18285

16629

8/14/2006

Page 30

1520F, 2020F, 2420F, 1510HDF, &

28

2010HDF

NOTE: The factory setting on the press wheel is

staggered to achieve optimum residue flow.

Refer to Figure 27

If you want to adjust press wheels from staggered

to even, remove 5/8 inch bolt (1), lock washer (2)

and nut (3). Reinstall spacer (4), press wheel (5)

and hardware to the other hole location.

Seed-Lok Lock Up

Optional Seed-Lok firming wheels provide additional seed-to-soil contact. The wheels are spring

loaded and do not require adjusting. In some wet

and sticky conditions the wheels may accumulate

soil.

Refer to Figure 28

NOTE: Side gauge wheel and seed meter is removed for clarity.

To lock up Seed-Lok wheels, raise drill. Rotate

lock-up handle (1) 90 degrees down on top of

opener body. Push up on Seed-Lok wheel (2) until

wheel arm latches up.

Hole

locations

Figure 27

Press Wheel Stagger

18410

!

CAUTION

Opener disk blades may be sharp. Use caution when

making adjustments in this area.

To unlock Seed-Lok wheels, pull up lock-up handle (1). Seed-Lok is spring loaded so it will snap

back into place.

18282

Figure 28

Seed-Lok Adjustment

8/14/2006

Page 31

HD 10 Series Openers

Opener Down Pressure

Refer to Figure 38

IMPORTANT: Do not back up with openers in

the ground. To do so will cause severe damage and opener plugging.

Opener springs provide the down pressure necessary for opener disks to open a seed trench.

The springs allow the openers to float down into

depressions and up over obstructions.

You can adjust down pressure individually for

each opener. This is useful for penetrating hard

soil and planting in tire tracks.

Use only enough down pressure to cut the seed

trench and maintain proper soil-firming over seed.

Excessive opener down force will lead to premature wear of opener components. Excessive down

force will also cause uneven seed depth.

Opener spring

Figure 38

Opener Spring

Adjustments

21947

29

Refer to Figure 39

To adjust down pressure, use adjustment wrench

stored under the walkboard or a 1 1/8” open end

wrench. Position wrench on the nutand pulldown.

Move the adjustment cam to the new setting.

Important: Always adjust the Opener Down

Pressure with the drill raised and the openers

in their completely lowered position.

Figure 39

Opener Down Pressure Adjustment

21948

8/14/2006

Page 32

1520F, 2020F, 2420F, 1510HDF, &

30

2010HDF

Refer to Figure 40

Minimum and maximum settings are indicated by

position of adjustment cam.

Each notch on the adjustment cam will increase

the down pressure on the opener springs. Use the

chart below as a setting reference.

Spring Down Pressure

Cam Notch Pounds

one 250

two 275

three 310

four 370

five 430

six 490

Opener Seeding Depth

A press wheel attached to each opener body controls seeding depth. To maintain consistent depth,

the relationship between the bottom of the opener

disks and press wheel is fixed upwardly.

The press wheels also close the seed trench and

gently press soil over seed. To provide consistent

soil firming, press wheels are free to move down

from normal operating position. This maintains

pressing action even if opener disks encounter

obstructions or hard soil.

Minimum setting

Maximum setting

Figure 40

Adjustment Cam Settings

21966

21967

Refer to Figure 41

Set opener seeding depth by adjusting T-handles.

To adjust, first raise openers slightly, then lift and

slide T-handles on top of openers as shown. Adjust all T-handles to the same setting.

• For shallower seeding, slide T-handles forward toward drill.

• For deeper seeding, slide T-handles back

away from drill.

Figure 41

Seed Depth Adjustment

12100

8/14/2006

Page 33

Double V Press Wheel Adjustment

Refer to Figure 42

The double V closing wheels (4) can be moved inward and outward to alter how they close the seed

trench and press soil over the seed.

To move the wheels (4) in toward the center of the

trench, remove one of the 1/4 bushings (2) next to

the press wheel arm and position it under the

head of the bolt (1). On wider row spacings the

closing wheels (4) can be moved outward by placing two 1/4 spacers (2) inside next to the press

wheel arm (3).

Adjustments

31

8/14/2006

23428

Figure 42

Double V Press Wheel

Page 34

1520F, 2020F, 2420F, 1510HDF, &

32

2010HDF

Lock-Up

The openers can be pinned in the up position to

accommodate 30” row spacing.

Refer to Figure 43

1. Select the individual opener you want to keep

in the raised position. It is suggested that the

down pressure springs be set to the minimum

setting first.

Lower parallel

arm

2. Raise the opener high enough that the hole

for the pin is above the lower parallel arm.

This can easily be done by placing a small

block below the disc blades and setting the

drill down upon it.

3. Insert locking pin through both holes and lower the opener allowing the pin to rest on the

top of the lower parallel arm.

NOTE: Do not pin the opener while it is in the lowered position. If the pin is inserted below the parallel arm it WILL damage opener soon after

planting begins.

Refer to Figure 44

When pin is not being used for opener lock-up always return pin to the storage position.

21981

22517

Pin in place

Figure 43

Hole for Lock-Up Pin

Pin in storage

position

Figure 44

Hole for Lock-Up Pin Storage

8/14/2006

Page 35

Frame Height

Drill operating height directly affects the working

range of the drill openers. Initially adjust frame

height as explained under “Leveling Drill”, page 17.

You can make further adjustments to compensate

for field conditions.

Single Gauge Wheel

Refer to Figure 45

1. Make sure block mount of the spring linkage (2)

is in the lower mount hole for planting in bedded

irrigation. The upper hole is for non-bedded

ground.

2. Set spring linkage length. Turn spring linkage to

shorten or lengthen as necessary. Initially set

length to 6 1/2 inches between pin centers to

achieve a 26-inch frame height for HD 10 series

openers and 6 1/8 inches to achieve a 24-inch

frame height for 20 series openers. When adjusting the linkage length, remember:

Adjustments

33

• Lengthening linkage raises drill.

• Shortening linkage lowers drill.

Level drill with top three-point link.

NOTE: Lowering the drill increases the risk of opener damage on rocks or obstructions.

Dual Gauge Wheels

Refer to Figure 46

1. Loosen jam nut near top clevis of each gaugewheel turnbuckle.

NOTE: Jam nut is left-hand threaded.

2. Make sure upper clevis (2) is in upper mount

hole as shown for 20 series and in the lower

mount hole for HD 10 series.

3. Set turnbuckle length. Turn turnbuckle to shorten or lengthen as necessary. Initially set length

to 17 1/2 inches between pin centers to achieve

a 24-inch dimension for 20 series openers and

26-inch dimension for HD 10 series openers.

When adjusting the turnbuckle length, remember:

Figure 45

Single Gauge Wheel Linkage

22848

• Lengthening turnbuckle raises drill.

• Shortening turnbuckle lowers drill.

4. After adjusting both turnbuckles to the same

length, tighten jam nuts.

5. Level drill with top three-point link.

NOTE: Lowering the drill increases the risk of opener damage on rocks or obstructions.

8/14/2006

Figure 46

Dual Gauge Wheel Turnbuckle

22845

Page 36

1520F, 2020F, 2420F, 1510HDF, &

34

2010HDF

Seeding Rate

Adjusting the seeding rate requires the following:

1. adjusting drive sprockets,

2. setting seed-rate handle,

3. positioning seed-cup doors,

4. checking seeding rate.

Refer to the seed rate charts on page 37. These

charts list proper sprocket sizes and seed rate

handle settings for various seeds and seeding

rates.

The seed rate charts are based on cleaned, untreated seed of average size and test weight. The

charts are based on 9.5L x 15 rib implement tires

for 15ft drills and 11L x 15 rib implement tires for

20ft and 24ft drills.

Many factors will affect seeding rates including

foreign material, seed treatment, seed size, seed

weight, field conditions, and tire pressure. You

likely will need to make minor adjustments. Set

and check the seeding rate, then readjust the rate

as necessary.

Before setting the seeding rate, rotate the gauge

wheels. Check that seed cups and drive are working properly and free from foreign material.

Adjust Drive Sprockets

Install drive sprockets for the drive type for your

desired seeding rate.

For correct drive type, refer to seed rate charts beginning on page 18. The charts list drive types as

1, 2, 3, or 4. Refer to the following table for the correct-sized sprocket for each drive type.

Reroute drive chain over sprockets and idlers as

shown in Figure 5. Move idlers into chain so

chain has 1/4-inch slack in its longest span.

Tighten idlers.

17669

Figure 5

Driver and Driven Sprockets

Set same drive type on both drill sections.

Set Seed Rate Handle

Position seed rate handle for each drill box as indicated on seed rate chart. One handle is shown

in Figure 6.

To adjust seed rate handle, loosen wing nut under handle. Slide handle until indicator isjust past

the correct setting. Retighten wing nut.

Drive Type Driver Driven Speed

Type 1 14 Tooth 44 Tooth Slowest

Type 2 24 Tooth 36 Tooth Two Times Faster

Than Type 1

Type 3 24 Tooth 24 Tooth Three Times Faster

Than Type 1

Type 4 24 Tooth 15 Tooth Five Times Faster

Than Type 1

To change drive sprockets, refer to Figure 5. Loosen idler plate (1) and remove drive chain (2) .

Remove lynch pins from shafts and rearrange

driver (3) and driven (4) sprockets.

17618

Figure 6

Seed Rate Handle

8/14/2006

Page 37

Adjustments

35

Position Seed Cup Doors

For wheat and other smal seeds, move seed cup

door handles to highest position. For soybeans

and other large seeds, lower handles to second

position. If excessive seed cracking occurs, lower

handles to third position. For seed cup clean out,

move handles to fourth, wide-open position. Make

sure all handles are in same position before

drilling.

NOTE: If your results vary greatly from the charts,

you may want to repeat the calibration procedure.

8. When drilling, note acres drilled, amount of

seed added and level of seed in drill box. If

you are seeding more or less than desired,

adjust seeding rate slightly to compensate for

your field conditions.

Check Seeding Rate

1. Record the weight of an empty container

large enough to hold seed metered for one

acre.

2. Place several pounds of seed over three

seed cups on an outside end of drill box. Pull

seed tubes off these three openers.

3. Raise drill off ground.

4. Turn gauge wheel a few turns to fill cups with

seed. Turn wheel until seed drops to ground

from all three cups.

5. Place a container under the three seed tubes

to gather seed as it is metered.

6. Turn drive gauge wheel for one acre. Refer to

the chart on the next page for the exact number of tire revolutions to equal one acre.

Check that three seed cups have plenty of

seed coming into them.

7. Weigh metered seed. Subtract initial weight

of empty container. Divide by three for the

amount metered by each seed cup, then multiply by the number of drill openers for the

pounds per acre seeding rate. If this figure is

different than desired, adjust the seed rate

handle and recheck the rate.

8/14/2006

Page 38

1520F, 2020F, 2420F, 1510HDF, &

36

2010HDF

Tire Revolutions Per Acre

Planted Row

Spacing (Inches)

7 1/2” 24 365 32 268 38 225

9 1/2” 26 260

10” 18 365 24 268 28 229

10” 19 346 25 257

15” 12 365 16 268 19 225

15” 13 337 17 252 20 214

19” 13 260

20” 9 365 12 268 14 229

20” 10 329

30” 6 365 8 268 10 214

36” 6 297

38” 6 282

40” 6 268

Twin Row 30” beds 12 365 16 268 20 214

Number of

Rows for 15ft

drills

Tire

Revolutions

per Acre for

15ft drills

Number of

Rows for 20ft

drills

Tire

Revolutions

per Acre for

20ft drills

Number of

Rows for

24ft drills

Tire

Revolutions

per Acre for

24ft drills

Twin Row 36” beds 12 297 16 223

Twin Row 38” beds 12 282 16 211

Twin Row 40” beds 12 268 16 201

Twin Row 30” W/S 19 346 25 257 29 221

15” Skip Row 14 268

NOTE: Blank spaces denote row spacings that are not available for specific drill models.

8/14/2006

Page 39

Adjustments

Seed Rate Chart (pounds per acre)

Setting number 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Alfalfa or

Rape

Drive Type 1

(Based on

60#/bu)

Barley

Drive Type 1

(Based on

51#/bu)

Barley

Drive Type 2

(Based on

51#/bu)

6" 2 6 8 12 15 19 23 27 32 37 41 45 50 54 59 63 69 74 79 82 84

7" 2 5 7 10 13 16 20 23 27 32 35 38 43 47 51 54 59 63 68 70 72

7.5" 2 4 7 10 12 15 18 22 25 29 33 36 40 43 47 51 55 59 63 65 67

8" 2 4 6 9 12 14 17 20 24 28 31 34 37 41 44 47 52 55 60 61 63

Row Spacing

10"

1 3 5 7 9 12 14 16 19 22 25 27 30 33 35 38 41 44 48 49 50

6" 2 5 8 11 14 18 22 26 30 35 39 43 48 53 57 62 66 69 73 73 74

7" 2 4 7 9 12 16 19 22 26 30 33 37 41 45 49 53 56 59 62 63 63

2 4 6 9 12 15 18 21 24 28 31 35 38 42 46 49 52 55 58 59 59

7.5"

8" 1 3 6 8 11 14 17 20 23 26 29 32 36 40 43 46 49 52 54 55 55

Row Spacing

10"

1 3 5 6 9 11 13 16 18 21 23 26 29 32 34 37 39 42 44 44 44

6" 4 9 16 22 30 37 45 54 62 71 76 87 96 104 114 123 133 142 152 154 156

7" 3 7 14 19 26 32 39 46 53 61 68 75 82 89 97 105 114 122 130 132 134

7.5" 3 7 13 17 24 30 36 43 49 57 64 70 77 83 91 98 106 114 121 123 125

8" 3 7 12 16 22 28 34 40 46 53 60 65 72 78 85 92 100 107 114 116 117

Row Spacing

10" 2 5 10 13 18 22 27 32 37 43 48 52 58 63 68 74 80 85 91 92 94

37

Barley

Drive Type 4

(Based on

51#/bu)

Buck

Wheat

Drive Type 3

(Based on

48#/bu)

Flax or

Sudan

Drive Type 1

(Based on

55#/bu)

Millet

Drive Type 1

(Based on

60#/bu)

Milo

Drive Type 1

(Based on

64#/bu)

6" 9 21 39 53 73 90 110 131 151 174 194 213 234 255 278 300 325 348 371 377 382

7" 7 18 33 45 63 78 95 113 130 149 166 182 201 218 238 257 278 299 318 323 328

7.5" 7 17 31 42 58 72 88 105 121 139 155 170 188 204 222 240 260 279 297 301 306

8" 6 16 29 40 55 68 83 99 113 130 146 160 176 191 208 225 244 261 278 282 287

Row Spacing

10" 5 13 23 32 44 54 66 79 91 104 117 128 141 153 167 180 195 209 222 226 230

6" 0 11 21 29 42 52 65 78 92 107 123 136 150 165 180 195 209 224 240 242 245

7" 0 10 18 25 36 45 56 67 79 92 106 116 129 142 154 168 179 192 205 207 210

7.5" 0 9 17 24 34 42 52 62 74 85 99 109 120 132 144 156 167 179 192 194 196

8" 0 8 16 22 31 39 49 59 69 80 92 102 113 124 135 147 157 168 180 181 183

Row Spacing

10" 0 7 13 18 25 31 39 47 55 64 74 81 90 99 108 117 126 134 144 145 147

6" 0 4 8 12 16 20 24 28 33 37 42 46 50 54 59 65 70 76 82 83 85

7” 0 3 7 10 14 17 21 24 28 32 36 39 43 47 51 55 60 65 70 71 73

7.5" 0 3 7 9 13 16 19 23 26 30 34 37 40 44 47 52 56 61 66 67 68

8" 0 3 6 9 12 15 18 21 25 28 31 34 37 41 44 49 52 57 61 62 64

Row Spacing

10” 0 2 5 7 10 12 15 17 20 22 25 27 30 33 35 39 42 45 49 50 51

6" 1 5 8 12 16 20 23 27 32 36 40 44 49 52 57 62 66 71 76 77 78

7" 1 4 7 10 13 17 20 23 27 31 34 38 42 45 49 53 57 61 65 66 67

7.5" 1 4 7 9 13 16 19 22 25 29 32 35 39 42 46 49 53 57 61 62 63

8" 1 4 6 9 12 15 18 20 24 27 30 33 36 39 43 46 50 53 57 58 59

Row Spacing

10" 1 3 5 7 9 12 14 16 19 21 24 26 29 32 34 37 40 43 46 46 47

6" 0 5 9 13 18 23 28 34 39 45 52 57 63 69 75 81 87 92 98 100 102

7" 0 4 8 11 15 19 24 29 34 38 44 49 54 59 64 69 74 79 84 86 88

7.5” 0 4 7 10 14 18 22 27 31 36 41 45 50 55 60 65 69 73 78 80 82

8" 0 4 7 10 13 17 21 25 29 34 39 43 47 52 56 61 65 69 73 75 77

Row Spacing

10" 0 3 5 8 11 14 17 20 23 27 31 34 38 41 45 49 52 55 59 60 61

Oats

Drive Type 3

(Based on

37#/bu)

8/14/2006

6" 0 5 12 17 24 32 39 47 55 63 72 80 88 96 105 113 121 130 139 140 140

7" 0 5 10 15 21 27 33 40 47 54 62 68 76 82 90 97 104 111 119 120 120

7.5" 0 4 10 14 19 25 31 37 44 51 58 64 70 77 84 90 97 104 111 112 112

8" 0 4 9 13 18 24 29 35 41 47 54 60 66 72 78 85 91 97 104 105 105

Row Spacing

10" 0 3 7 10 14 19 23 28 33 38 43 48 53 58 63 68 73 78 83 84 84

Page 40

1520F, 2020F, 2420F, 1510HDF, &

38

2010HDF

Setting number 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

6" 0 0 19 34 52 69 84 102 119 137 154 169 186 202 218 235 251 266 281 283 284

Peas

Drive Type 3

(Based on

61#/bu)

Pinto

Beans

Drive Type 1

(Based on

61#/bu)

Rice

Short Grain

Drive Type 3

(Based on

43#/bu)

Rice

Short Grain

Drive Type 4

(Based on

43#/bu)

7" 0 0 16 29 45 59 72 87 102 118 132 145 160 173 187 202 215 228 241 243 244

7.5”

0 0 15 27 42 55 67 82 95 110 123 136 149 161 175 188 201 213 225 226 227

8" 0 0 14 26 39 52 63 76 89 103 116 127 140 151 164 177 188 200 211 212 213

Row Spacing

0 0 11 20 31 41 50 61 71 82 93 102 112 121 131 141 151 160 169 170 171

10"

6" 0 0 9 13 17 24 30 35 41 47 53 58 64 69 74 81 85 91 97 96 96

7" 0 0 7 11 15 20 25 30 35 40 45 50 55 59 64 69 73 78 83 83 83

7.5"

0 0 7 10 14 19 24 28 33 38 42 47 51 55 60 65 68 73 77 77 77

8" 0 0 6 10 13 18 22 27 31 35 40 44 48 52 56 61 64 68 72 72 72

Row Spacing

0 0 5 8 10 14 18 21 25 28 32 35 38 41 45 49 51 54 58 58 58

10"

6" 3 11 18 28 38 46 56 64 73 84 96 107 117 128 139 148 167 165 174 174 174

7" 3 9 16 24 33 39 48 54 63 72 82 92 101 110 119 127 134 142 149 149 149

7.5" 2 9 14 23 31 37 44 51 59 67 77 85 94 102 111 118 125 132 139 139 139

8" 2 8 14 21 29 34 42 48 55 63 72 80 88 96 104 111 117 124 131 131 131

Row Spacing

10" 2 7 11 17 23 27 33 38 44 50 57 64 70 77 83 89 94 99 105 105 105

6" 5 18 29 46 63 74 91 104 120 137 156 174 191 209 226 241 255 269 284 284 284

7" 4 15 25 40 54 64 78 89 103 117 134 149 164 179 194 207 219 231 243 243 243

7.5" 4 14 24 37 50 60 72 83 96 109 125 139 153 167 181 193 204 215 227 227 227

8" 4 13 22 35 47 56 68 78 90 102 117 131 143 156 169 181 191 202 213 213 213

Row Spacing

10" 3 11 18 28 38 45 54 62 72 82 94 105 115 125 136 145 153 162 170 170 170

Rice

Long Grain

Drive Type 1

(Based on

47#/bu)

Rice

Long Grain

Drive Type 2

(Based on

47#/bu)

Rice

Long Grain

Drive Type 3

(Based on

47#/bu)

Rice

Long Grain

Drive Type 4

(Based on

47#/bu)

Rye

Drive Type 1

(Based on

57#/bu)

6" 0.0 1.4 4.4 7.4 10.4 13.7 16.8 19.8 22.9 26.1 31.6 32.1 35.1 38.1 41.1 44.3 46.8 49.4 51.5 52.9 53.9

7" 0.0 1.2 3.8 6.3 8.9 11.7 14.4 17.0 19.7 22.4 27.1 27.5 30.1 32.7 35.2 38.0 40.1 42.4 44.2 45.3 46.2

7.5" 0.0 1.1 3.6 5.9 8.3 10.9 13.5 15.9 18.4 20.9 25.3 25.7 28.1 30.5 32.9 35.4 37.5 39.5 41.2 42.3 43.1

8" 0.0 1.1 3.3 5.5 7.8 10.2 12.6 14.9 17.2 19.6 23.7 24.1 26.3 28.6 30.8 33.2 35.1 37.1 38.6 39.7 40.4

Row Spacing

10" 0.0 0.8 2.7 4.4 6.2 8.2 10.1 11.9 13.8 15.7 19.0 19.3 21.1 22.9 24.7 26.6 28.1 29.7 30.9 31.7 32.3

6" 0 3 9 15 21 28 35 41 47 54 65 66 72 78 85 91 96 102 106 109 111

7" 0 3 8 13 18 24 30 35 40 46 56 57 62 67 72 78 83 87 91 93 95

7.5" 0 2 7 12 17 23 28 33 38 43 52 53 58 63 68 73 77 81 85 87 89

8" 0 2 7 11 16 21 26 31 35 40 49 50 54 59 63 68 72 76 80 82 83

Row Spacing

10" 0 2 6 9 13 17 21 25 28 32 39 40 43 47 51 55 58 61 64 65 67

6" 0 0 13 22 32 42 53 61 71 81 90 98 107 116 125 135 144 153 161 167 173

7” 0 0 11 19 27 36 45 53 61 69 77 84 91 99 107 116 124 131 138 143 148

7.5" 0 0 11 17 25 34 42 49 57 65 72 79 85 92 100 108 116 123 129 134 138

8" 0 0 10 16 24 31 40 46 53 61 67 74 80 87 94 101 108 115 121 125 130

Row Spacing

10" 0 0 8 13 19 25 32 37 42 49 54 59 64 69 75 81 87 92 97 100 104

6" 0 0 22 35 52 68 86 100 115 132 146 160 174 188 204 220 235 250 263 273 282

7" 0 0 18 30 44 59 74 86 99 113 125 137 149 161 175 188 202 214 225 234 242

7.5" 0 0 17 28 41 55 69 80 92 105 117 128 139 151 163 176 188 200 210 218 226

8" 0 0 16 27 39 51 65 75 87 99 110 120 130 141 153 165 177 187 197 204 211

Row Spacing

10” 0 0 13 21 31 41 52 60 69 79 88 96 104 113 123 132 141 150 158 164 169

6" 0 3 8 13 19 24 28 35 41 47 53 58 63 68 74 81 87 94 101 102 102

7" 0 2 7 11 16 21 24 30 35 40 45 50 54 59 63 69 74 80 87 87 88

7.5" 0 2 6 10 15 19 22 28 33 38 42 46 50 55 59 64 69 75 81 81 82

8" 0 2 6 10 14 18 21 26 31 35 40 44 47 51 55 60 65 70 76 76 77

Row Spacing

10" 0 2 5 8 11 14 17 21 24 28 32 35 38 41 44 48 52 56 61 61 61

8/14/2006

Page 41

Adjustments

Setting number 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

6" 0 3 8 13 19 23 29 34 39 45 49 55 61 66 71 77 82 87 93 93 93

Soybeans

Drive Type 1

(Based on

58#/bu)

Soybeans

Drive Type 2

(Based on

58#/bu)

Soybeans

Drive Type 3

(Based on

58#/bu)

Soybeans

Drive Type 4

(Based on

58#/bu)

7" 0 2 7 11 17 20 25 29 34 38 42 48 52 57 61 67 70 75 79 80 80

0 2 6 11 15 19 23 27 31 36 40 44 49 53 57 62 65 70 74 74 75

7.5"

8" 0 2 6 10 15 17 22 25 29 34 37 42 46 50 54 58 61 65 69 70 70

Row Spacing

10" 0 2 5 8 12 14 17 20 24 27 30 33 37 40 43 46 49 52 56 56 56

6" 0 6 16 27 40 48 59 69 80 92 102 114 125 136 147 158 167 179 190 191 192

7" 0 5 14 23 34 41 51 59 69 79 87 98 107 117 126 136 144 153 163 164 164

7.5” 0 5 13 22 32 38 47 55 64 73 81 91 100 109 118 127 134 143 152 153 153

8" 0 4 12 20 30 36 44 52 60 69 76 86 94 102 110 119 126 134 143 143 144

Row Spacing

10" 0 4 10 16 24 29 35 42 48 55 61 68 75 82 88 95 101 107 115 115 115

6" 0 12 23 40 60 71 89 101 116 131 148 164 181 196 214 228 248 265 284 284 284

7" 0 10 19 35 51 61 76 87 100 113 127 141 155 168 183 195 213 227 244 243 244

7.5" 0 9 18 32 48 57 71 81 93 105 119 131 145 157 171 182 199 212 227 227 227

8" 0 9 17 30 45 53 67 76 87 99 111 123 136 147 160 171 186 199 213 213 213

Row Spacing

10" 0 7 14 24 36 42 53 61 70 79 89 98 108 118 128 137 149 159 170 170 170

6" 0 19 37 66 97 115 145 165 190 214 241 267 295 320 348 371 405 433 463 463 464

7" 0 16 31 56 83 99 124 141 163 184 207 229 253 274 299 318 347 371 397 397 397

7.5" 0 15 29 53 78 92 116 132 152 171 193 214 236 256 279 297 324 346 370 371 371

8" 0 14 28 49 73 86 109 124 142 161 181 200 221 240 261 278 304 324 347 347 348

Row Spacing

10" 0 11 22 40 58 69 87 99 114 128 145 160 177 192 209 223 243 260 278 278 278

39

Sun

flowers

Drive Type 1

(Based on

28#/bu)

Wheat

Drive Type 2

(Based on

64#/bu)

Wheat

Drive Type 3

(Based on

64#/bu)

Wheat

Grass

Drive Type 1

(Based on

23#/bu)

6" 0 0 2 4 6 8 11 13 15 18 20 23 25 27 30 32 34 36 38 39 41

7" 0 0 2 4 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 34 35

7.5" 0 0 2 3 5 7 9 10 12 14 16 18 20 22 24 26 27 29 31 32 33

8" 0 0 2 3 5 6 8 10 12 13 15 17 19 21 22 24 26 27 29 30 31

Row Spacing

10" 0 0 1 3 4 5 6 8 9 11 12 14 15 16 18 19 20 22 23 24 24

6" 0 13 22 30 40 50 57 70 80 91 105 115 127 140 152 164 177 190 203 205 206

7" 0 11 19 26 34 43 49 60 69 78 90 99 109 120 131 141 152 163 174 176 177

7.5" 0 10 18 24 32 40 46 56 64 73 84 92 102 112 122 131 142 152 162 164 165

8" 0 9 17 23 30 37 43 52 60 69 79 86 96 105 114 123 133 143 152 153 154

Row Spacing

10" 0 8 13 18 24 30 34 42 48 55 63 69 76 84 91 99 106 114 122 123 124

6" 0 16 31 45 60 74 88 104 120 137 153 168 186 202 220 240 256 274 290 297 299

7" 0 14 26 38 51 64 75 89 103 117 131 144 159 174 189 206 219 235 248 254 256

7.5" 0 13 25 36 48 59 70 83 96 109 123 134 149 162 176 192 205 219 232 237 239

8" 0 12 23 34 45 56 66 78 90 102 115 126 139 152 165 180 192 205 217 223 224

Row Spacing

10" 0 10 18 27 36 45 53 62 72 82 92 101 111 121 132 144 154 164 174 178 179

6" 0 1 2 3 4 5 6 7 8 10 11 12 13 14 15 17 18 19 19 21 21

7" 0 1 2 3 4 4 5 6 7 8 9 10 11 12 13 14 15 17 16 18 18

7.5" 0 1 2 2 3 4 5 6 7 8 9 10 11 11 12 13 14 15 15 17 17

8" 0 1 2 2 3 4 5 6 6 7 8 9 10 11 12 13 13 15 14 16 16

Row Spacing

10" 0 1 1 2 3 3 4 4 5 6 7 7 8 9 9 10 11 12 11 13 13

8/14/2006

Page 42

1520F, 2020F, 2420F, 1510HDF, &

40

2010HDF

Marker Adjustments

Bleeding Marker Hydraulics

To fold properly, the marker hydraulics must be

free of air. If the markers fold in jerky, uneven motions, follow these steps.

!

CAUTION

You may be injured if hit by a folding or unfolding

marker. Markers may fall quickly and unexpectedly if

the hydraulics fail. Never allow anyone near the drill

when folding or unfolding the markers.

!

WARNING

Escaping fluid under pressure can have sufficient pressure to penetrate the skin. Check all hydraulic lines

and fittings before applying pressure. Fluid escaping

from a very small hole can be almost invisible. Use paper or cardboard, not body parts, and wear heavy

gloves to check for suspected leaks. If injured, seek

medical assistance from a doctor that is familiar with

this type of injury. Foreign fluids in the tissue must be

surgically removed within a few hours or gangrene

will result.

Check that tractor hydraulic reservoir is full.

1. With both markers lowered into field position,

loosen hydraulic-hose fittings at rod and base

ends of marker cylinders. If applicable, loosen

fittings on back side of sequence valve.

IMPORTANT: Never bleed an O-ring fitting. Instead, bleed a nearby pipe or JIC fitting.

2. With tractor idling, activate tractor hydraulic

valve until oil seeps out around a loosened fitting. Tighten that fitting.

IMPORTANT: JIC fittings do not require high

torque. JIC and O-ring fittings do not require

sealant. Always use liquid pipe sealant when

adding or replacing pipe-thread fittings. To

avoid cracking hydraulic fittings from over

tightening, do not use plastic sealant tape.

3. Reactivate tractor hydraulic valve until oil

seeps out around another loosened fitting.

Tighten that fitting. Repeat process until all

loosened fittings have been bled and tightened.

8/14/2006

Page 43

Folding Speed with Needle Valves

Refer to Figure 78

A needle valve controls the folding speed of markers that areplumbed separately. The needle valve

is near the rod end of the marker cylinder.

With tractor idling at a normal operating speed,

adjust marker folding to a safe speed. Turn adjustment knob clockwise to reduce folding speed or

counterclockwise to increase folding speed. Excessive folding speed could damage markers and

void the warranty.

Adjustments

41

Folding Speed with Sequence Valve

Refer to Figure 79

If markers are tied together with an optional sequence valve (P/N 113-466A), adjust folding

speed with hex adjustment screws on the sequence-valve body. There is one adjustment

screw for raising speed (1) and one for lowering

speed (2). Identify adjustment screws by markings stamped in valve body.

With tractor idling at a normal operating speed,

adjust marker folding to a safe speed. Turn adjustment screws clockwise to decrease folding speed

and counterclockwise to increase folding speed.

Excessive folding speed could damage markers

and void the warranty.

After adjusting the folding speed, tighten jam nuts

on hex adjustment screws to hold settings.

Marker Disk Adjustment

Figure 78

Needle Valve

Hex adjustment

screws

Figure 79

Speed Adjustment, Sequence Valve

Increase

speed

Decrease

speed

17620

14048

!

CAUTION

Marker disks may be sharp. Use caution when making

adjustments in this area.

Changing disk angle

Refer to Figure 80

If mark left by marker disk is not clearly visible, adjust disk angle to make a wider mark. Loosen two

1/2 inch bolts (1) holding disk assembly (2). Rotate disk assembly as desired.

8/14/2006

Figure 80

Disk Angle

11757

Page 44

1520F, 2020F, 2420F, 1510HDF, &

42

2010HDF

Marker Chain

There are two, interrelated adjustments for the

marker chain. Make these adjustments in the following order.

Refer to Figure 81

1. Lifting Slack. With marker unfolded, back fullthreaded adjustment bolt (1) down until head

extends as little as possible. Slowly fold marker

while observing disk. If marker disk slides

across ground more than a foot before chain

and linkage lifts it up, the chain is too long.

Shorten chain one or two links by moving clevis

(2). Check adjustment by repeating folding process.

If chain is too short when marker is unfolded, it

will prevent end of marker from dropping into

field depressions, causing skips in your marker

line. Correct this condition by lengthening chain

one or two links at clevis (2).

2. Folding Slack. Fold marker. Use full-threaded

adjustment bolt (1) to take slack out of chain

while marker is folded. Extend bolt until there is

no chain slack. Lock bolt in this position by tightening nuts (3) on either side of upright channel

(4).

Shear Bolt

15669

Figure 81

Marker Chain Adjustment

Transport Carrier

When marker is folded, the second section should

rest in transport-carrier saddle.

Refer to Figure 82

To adjust front-to-rear position of saddle, loosen the

5/8 X 7-inch u-bolts (1) that fasten transport-carrier

mount onto box frame. Slide transport-carrier assembly forward or back as needed.

To adjust height of saddle, loosen 1/2-by-2-inch ubolts (2) that hold carrier tube to mounting bracket.

Slide carrier tube up or down as needed.

15632

Figure 82

Adjusting Marker Carrier

8/14/2006

Page 45

Marker Width

Refer to Figure 83

To adjust marker width, loosen jam nuts (1) and

1/2-inch set screws (2). Move marker disk tube in

or out to get the proper dimension.

Adjustments

Figure 83

Marker Width Adjustment

43

19204

8/14/2006

Page 46

1520F, 2020F, 2420F, 1510HDF, &

44

2010HDF

Seed-Lok™ Lock Up

Optional Seed-Lok™ firming wheels provide additional seed-to-soil contact. The wheels are

spring loaded and do not require adjusting. In

some wet and sticky conditions the wheels may

accumulate soil.

Refer to Figure 85

NOTE: Side gauge wheel and seed meter is removed for clarity.

To lock up Seed-Lok™ wheels, raise drill. Rotate

lock-up handle (1) 90 degrees down on top of

opener body, see insert. Push up on Seed-Lok™

wheel (2) until wheel arm latches up.

!

CAUTION

Opener disk blades may be sharp. Use caution when

making adjustments in this area.

To unlock Seed-Lok™ wheels, pull up lock-up

handle (1). Seed-lok™ is spring loaded so it will

snap back into place.

Locked

position.

Unlocked

position.

Push Seed-Lok™

up to lock.

18282

Figure 85

Seed-Lok™ Lock Up

8/14/2006

Page 47

Troubleshooting

Problem Solution

Troubleshooting

45

Uneven seed spacing or uneven stand

Opener disks not turning freely

Check for plugging in seed cups.

Check for plugging in seed tubes.

Reduce ground speed.

Check if opener disks are turning freely.

Use faster drive type and position seed rate handle to a lower setting.

Increase opener spring pressure to penetrate low spots. Refer to

Opener Down Pressure, “Adjustments,” page 25.

Check for trash or mud build-up on Seed-Lok wheels.

Check for trash or mud build-up on disk scraper. Adjust scraper.

Refer to HD 10 Series Disk Spreaders and Scrapers, “Maintenance,”

page 50.

Check if scraper is adjusted too tight, restricting disk movement.

Refer to HD 10 Series Disk Spreaders and Scrapers, “Maintenance,”

page 50.

Check disk bearings.

Check opener frame for damage.

If opener disks turn freely by hand but not in field, reduce down pressure on disk opener. Refer to Opener Down Pressure, “Adjustments,”

page 25.

Check press wheel adjustment. On HD10 Series Openers, refer to

Opener Seeding Depth, “Adjustments,” page 30. On 20 Series Openers, refer to Opener Down Pressure, “Adjustments,” page 26.

Actual metering rate is different than

desired

Acremeter does not measure accurately

Press wheels not compacting the soil as

desired

Check tire pressure. Proper inflation is listed on the Tire Inflation

Chart, “Appendix,” page 57.

Check tire size. Proper size is 9.5L x 15 for 15 foot drills and 11L x 15

for 20 foot drils and 24 foot drills.

Regularly clean seed treatment from seed cups.

Check drill box setting.

Refer to Seeding Rate, “Adjustments,” page 34.

Check tire pressure. Proper inflation is listed on the Tire Inflation

Chart, “Appendix,” page 57.

Check tire size. Proper size is 9.5L x 15 for 15 foot drills and 11L x 15

for 20 foot and 24 foot drills.

Check planting operation for excessive overlap or gaps between

passes.

Consider soil conditions. Loose soil and slippage will cause variations in acres registered.

Check that acremeter is correct for width of drill. Refer to the parts

manual.

Reset press wheel depth. On HD10 Series Openers, refer to Opener

Seeding Depth, “Adjustments,” page 30. On 20 Series Openers, refer

to Opener Down Pressure, “Adjustments,” page 26.

Increase down pressure on disk openers. Refer to Opener Down Pres-

sure, “Adjustments,” page 26.

8/14/2006

Page 48

1520F, 2020F, 2420F, 1510HDF, &

46

2010HDF

Problem Solution

Excessive seed cracking

Drill boxes not emptying evenly

Press wheel or openers plugging

Seed cup sprockets locked up or twisted

seed cup drive shaft

Drill is not pulling level (parallel to

ground, front to rear)

Gauge wheel leans to left or right

Use slower drive type and position seed rate handle to higher setting.

Position seed cup handle to a lower notch.

Certain models do not have the same number of cups between each

divider of bulkhead. The section with more cups will empty sooner.

Consider soil conditions - may be too damp or wet.

Reduce down pressure on openers. Refer to Opener Down Pressure,

“Adjustments,” page 26.

Do not back up or allow drill to roll backward with openers in the

ground.

Check Seed-Lok wheels. If conditions are too wet, you may need to

remove the wheels.

Check for foreign material stuck in the seed cup sprockets.

Check for dried liquid insecticide in seed cups. Remove the build-up