Great Plains 2420 Operator Manual

PURPLE

Operator’s Manual

2400, 2410 and 2420

Three-Point Drill

Manufacturing, Inc.

www.greatplainsmfg.com

17616

Read the operator’s manual entirely. When you see this symbol, the subsequent in-

!

structions and warnings are serious - follow without exception. Your life and the lives of

others depend on it!

Cover illustration may show optional equipment not supplied with standard unit.

© Copyright 1999 Printed

5/15/2006

118-706M

Table of Contents

Table of Contents

Great Plains Mfg., Inc.

Important Safety Information . . . . . . . . . . . . . . . . . 1

Personal Safety Equipment . . . . . . . . . . . . . . . . . 4

Safety Decals. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Description of Unit . . . . . . . . . . . . . . . . . . . . . . . . 9

Intended Usage. . . . . . . . . . . . . . . . . . . . . . . 9

Using This Manual. . . . . . . . . . . . . . . . . . . . . . . . 9

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . 9

Section 1 Preparation and Setup . . . . . . . . . . . . . 10

Prestart Checklist . . . . . . . . . . . . . . . . . . . . . . . 10

Hitching Tractor to Drill . . . . . . . . . . . . . . . . . . . 10

Hydraulic Hookup . . . . . . . . . . . . . . . . . . . . 10

Leveling Drill . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Model 2400 . . . . . . . . . . . . . . . . . . . . . . . . . 11

Models 2410 and 2420 . . . . . . . . . . . . . . . . 12

Section 2 Operating Instructions . . . . . . . . . . . . . 13

Prestart Checklist . . . . . . . . . . . . . . . . . . . . . . . 13

Opener Operation . . . . . . . . . . . . . . . . . . . . 13

Marker Operation . . . . . . . . . . . . . . . . . . . . 13

Shaft Monitor Operation . . . . . . . . . . . . . . . 13

Transporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Transporting with Markers . . . . . . . . . . . . . . 14

Parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Section 3 Adjustments . . . . . . . . . . . . . . . . . . . . . 15

Seeding Depth. . . . . . . . . . . . . . . . . . . . . . . . . . 15

Models 2400 and 2410 . . . . . . . . . . . . . . . . 15

Model 2420 . . . . . . . . . . . . . . . . . . . . . . . . . 15

Opener Down Pressure . . . . . . . . . . . . . . . . . . . 15

2400 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2410 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2420 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Opener Depth . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Frame Height. . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Seeding Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Adjust Drive Sprockets . . . . . . . . . . . . . . . . 17

Set Seed-Rate Handle . . . . . . . . . . . . . . . . 18

Position Seed-Cup Doors . . . . . . . . . . . . . . 18

Check Seeding Rate . . . . . . . . . . . . . . . . . . 18

Seed Rate Charts. . . . . . . . . . . . . . . . . . . . . . . . 19

Marker Adjustments . . . . . . . . . . . . . . . . . . . . . . 22

Folding Speed with Needle Valves. . . . . . . . 22

Folding Speed with Sequence Valve . . . . . . 22

Transport Carrier . . . . . . . . . . . . . . . . . . . . . 22

Marker Chain . . . . . . . . . . . . . . . . . . . . . . . . 23

Disk Adjustment . . . . . . . . . . . . . . . . . . . . . . 23

Bleeding Marker Hydraulics . . . . . . . . . . . . . 24

Disk Scraper Adjustment . . . . . . . . . . . . . . . . . . 24

Seed-Lok Lock Up . . . . . . . . . . . . . . . . . . . . . . . 24

Section 4 Troubleshooting . . . . . . . . . . . . . . . . . . . 26

Section 5 Maintenance and Lubrication . . . . . . . . 28

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Drive System . . . . . . . . . . . . . . . . . . . . . . . . 28

Marker Maintenance . . . . . . . . . . . . . . . . . . 28

Drive Chains. . . . . . . . . . . . . . . . . . . . . . . . . 29

Gauge Wheel Arm Pivots. . . . . . . . . . . . . . . 29

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Seed-Cup-Shaft Sprocket . . . . . . . . . . . . . . 29

Wheel Bearings . . . . . . . . . . . . . . . . . . . . . . 30

Marker Hinge Points. . . . . . . . . . . . . . . . . . . 30

Marker Disk Bearings. . . . . . . . . . . . . . . . . . 30

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Section 6 Options . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Markers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Parking Stand. . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Rear Mount Boom . . . . . . . . . . . . . . . . . . . . . . . 31

Seed-Cup Plugs . . . . . . . . . . . . . . . . . . . . . . . . . 32

Shaft Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Seed-Lok™ Firming Wheels . . . . . . . . . . . . . . . 32

Seed-Lok Firming Wheels . . . . . . . . . . . . . . . . . 32

Weight Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Section 7 Specifications and Capacities . . . . . . . 33

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Tire Inflation Chart . . . . . . . . . . . . . . . . . . . . . . . 34

Torque Values Chart for Common Bolt Sizes . . . 34

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

© Copyright 1999 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the preparation

of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at the

time of its publication, and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains, Seed-Lok

All other brands and product names are trademarks or registered trademarks of their respective holders.

2400, 2410 and 2420 Three-Point Drill 118-706M 5/15/06

Great Plains Manufacturing, Incorporated Trademarks

Printed in the United States of America.

Great Plains Mfg., Inc.

Important Safety Information

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a potential hazard to

personal safety involved and extra

safety precaution must be taken.

When you see this symbol, be alert

and carefully read the message that

follows it. In addition to design and

configuration of equipment, hazard

control and accident prevention are

dependent upon the awareness, concern, prudence and proper training of

personnel involved in the operation,

transport, maintenance and storage

of equipment.

!

Be Aware of Signal Words

Signal words designate a degree or

level of hazard seriousness. The signal words are:

!

DANGER!

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury. This

signal word is limited to the most

extreme situations, typically for

machine components that, for functional purposes, cannot be guarded.

!

WARNING!

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury, and

includes hazards that are exposed

when guards are removed. It may

also be used to alert against unsafe

practices.

CAUTION!

!

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

For Your Protection

▲ Thoroughly read and understand

Safety Labels, page 5.

▲ Read all instructions noted on the

labels.

OFF

Keep Riders

Off Machinery

▲ Riders obstruct the operator’s

view. They could be struck by foreign objects or thrown from the

machine.

▲ Never allow children to operate

equipment.

Shutdown and Storage

▲ Lower machine to ground, put

tractor in park, turn off engine,

and remove the key.

▲ Detach and store implements in a

area where children normally do

not play. Secure implement by

using blocks and supports.

5/15/06

2400, 2410 and 2420 Three-Point Drill 118-706M

1

Important Safety Information

Great Plains Mfg., Inc.

Use Safety

Lights and Devices

Slow-moving tractors, self-propelled

equipment and towed implements

can create a hazard when driven on

public roads. They are difficult to see,

especially at night.

▲ Use flashing warning lights and

turn signals whenever driving on

public roads.

▲ Use lights and devices provided

with implement.

Transport

Machinery Safely

Maximum transport speed for implement is 20 mph. Some rough terrains

require a slower speed. Sudden

braking can cause a towed load to

swerve and upset.

▲ Do not exceed 20 mph. Never

travel at a speed which does not

allow adequate control of steering

and stopping. Reduce speed if

towed load is not equipped with

brakes.

▲ Comply with state and local laws.

▲ Do not tow an implement that,

when fully loaded, weighs more

than 1.5 times the weight of towing vehicle.

Use A Safety Chain

▲ Use a safety chain to help con-

trol drawn machinery should it

separate from tractor drawbar.

▲ Use a chain with a strength rat-

ing equal to or greater than the

gross weight of towed machinery.

▲ Attach chain to tractor drawbar

support or other specified

anchor location. Allow only

enough slack in chain to permit

turning.

▲ Replace chain if any links or end

fittings are broken, stretched or

damaged.

▲ Do not use safety

chain for towing.

Practice Safe Maintenance

▲ Understand procedure before

doing work. Use proper tools and

equipment. Refer to this manual

for additional information.

▲ Work in a clean, dry area.

▲ Lower implement to ground, put

tractor in park, turn off engine,

and remove key before performing

maintenance.

▲ Allow implement to cool completely.

▲ Inspect all parts. Make sure parts

are in good condition and installed

properly.

▲ Remove buildup of grease, oil or

debris.

▲ Remove all tools and unused

parts from implement before operation.

2400, 2410 and 2420 Three-Point Drill 118-706M 5/15/06

2

Great Plains Mfg., Inc.

Important Safety Information

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extin-

guisher handy.

▲ Keep emergency numbers for

doctor, ambulance, hospital and

fire department near phone.

911

Wear

Protective Equipment

▲ Wear protective clothing and

equipment.

▲ Wear clothing and equipment

appropriate for the job. Avoid

loose-fitting clothing.

▲ Because prolonged exposure to

loud noise can cause hearing

impairment or hearing loss, wear

suitable hearing protection such

as earmuffs or earplugs.

▲ Because operating equipment

safely requires your full attention,

avoid wearing radio headphones

while operating machinery.

Avoid High

Pressure Fluids Hazard

Escaping fluid under pressure can

penetrate skin, causing serious

injury.

▲ Avoid the hazard by relieving

pressure before disconnecting

hydraulic lines.

▲ Use a piece of paper or card-

board, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety

glasses or goggles when working

with hydraulic systems.

▲ If an accident occurs, see a doc-

tor immediately. Any fluid injected

into the skin must be surgically

removed within a few hours or

gangrene may result.

Safety at All Times

Thoroughly read and understand this

manual before operating implement.

Refer to Safety Decals, page 4. Read

all instructions noted on decals.

▲ Be familiar with all implement

functions.

▲ Operate implement from driver’s

seat only.

▲ Do not leave tractor or implement

unattended with engine running.

▲ Do not dismount a moving tractor.

Dismounting a moving tractor could

cause serious injury or death.

▲ Do not stand between the tractor

and implement during hitching.

▲ Keep hands, feet and clothing

away from power-driven parts.

▲ Wear snug-fitting clothing to avoid

entanglement with moving parts.

▲ Watch out for wires, trees, etc.,

when raising implement. Make

sure all persons are clear of working area.

▲ Do not turn tractor too tight, caus-

ing towed implements to ride up

on wheels.

▲ Never stand on or use tires as a

step. Tires not in contact with the

ground will rotate easily.

▲ Keep bystanders well away when

folding markers. Falling or folding

markers can crush bystanders.

Tire Safety

Tire maintenance can be dangerous

and should be performed by trained

personnel using correct equipment.

▲ Inflate tires to proper pressure

and torque wheel bolts as recommended in “Appendix,” page 34.

▲ When inflating tires, use a clip-on

chuck and extension hose long

enough to allow you to stand to

one side–not in front of or over tire

assembly. Use a safety cage if

available.

▲ When removing and installing

wheels, use wheel-handling

equipment adequate for

weight involved.

5/15/06

2400, 2410 and 2420 Three-Point Drill 118-706M

3

Important Safety Information

Great Plains Mfg., Inc.

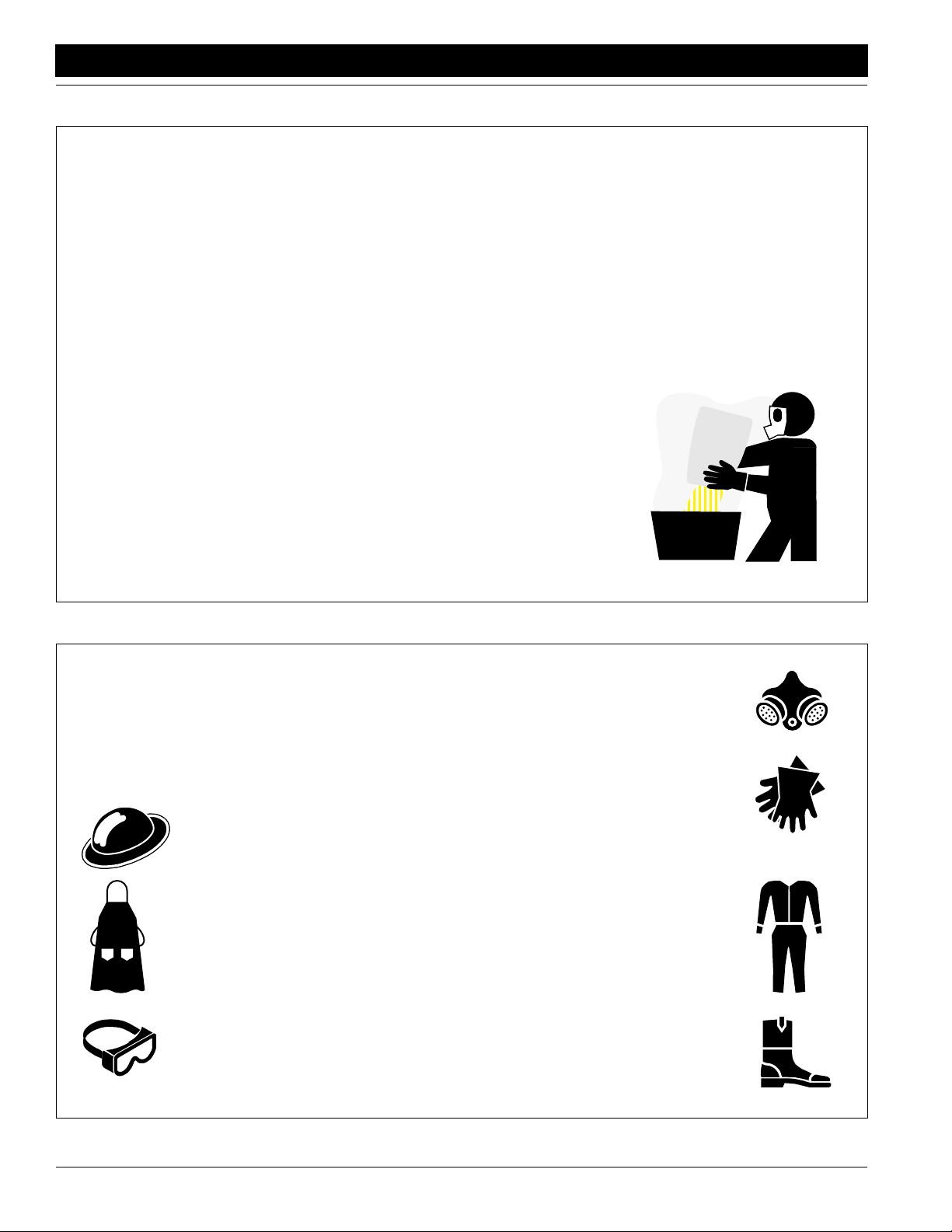

Handle

Chemicals Properly

▲ Read and follow chemical manu-

facturer’s instructions.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Agricultural chemicals can be

dangerous. Improper use can

seriously injure persons, animals,

plants, soil and property.

▲ Inhaling smoke from any type of

chemical fire is a serious health

hazard.

▲ Store or dispose of unused chem-

icals as specified by the chemical

manufacturer.

▲ Before adding chemical to the

tank, make sure tank is at least

half full. Do not pour concentrate

into an empty tank.

▲ Never leave fill hose attached to

the sprayer after filling tank.

Chemicals in tank can siphon out

of tank and contaminate freshwater source.

▲ Always keep clean water and

soap available in case of an emergency. Immediately and thoroughly flush any area of the body

that is contaminated by chemicals.

▲ Do not touch boom components

with mouth or lips.

▲ If chemical is swallowed, carefully

follow the chemical manufacturer’s recommendations and consult with a doctor.

▲ If persons are exposed to a chem-

ical in a way that could affect their

health, consult a doctor immediately with the chemical label or

container in hand. Any delay

could cause serious illness or

death.

▲ Dispose of empty chemical con-

tainers properly. By law rinsing of

the used chemical container must

be repeated three times. Puncture

the container to prevent future

use. An alternative is to jet-rinse

or pressure rinse the container.

▲ Wash hands and face before eat-

ing after working with chemicals.

Shower as soon as spraying is

completed for the day.

▲ Spray only with acceptable wind

conditions. Wind speed must be

below 5 mph. Make sure wind drift

of chemicals will not affect any

surrounding land, people or animals.

▲ Never wash out the sprayer tank

within 100 feet of any freshwater

source or in a car wash.

▲ Rinse out sprayer tank. Spray rinse

water on last field sprayed.

Personal Safety Equipment

Great Plains advises all users of chemical pesticides or

herbicides to use the following personal safety equipment. Always follow the chemical label instructions.

Operator safety and the effectivity of the product

depends upon operator actions.

▲ Waterproof, wide-brimmed hat

▲ Waterproof apron

▲ Face shield, goggles or full face

respirator. Goggles with side

shields or a full face respirator is

required if handling or applying

dusts, wettable powders, or granules or if being exposed to spray

mist.

▲ Cartridge-type respirator

approved for pesticide vapors

unless label specifies another

type of respirator.

▲ Waterproof, unlined gloves. Neo-

prene gloves are recommended.

▲ Cloth coveralls/outer clothing

changed daily; waterproof items

if there is a chance of becoming

wet with spray

▲ Waterproof boots or foot cover-

ings

2400, 2410 and 2420 Three-Point Drill 118-706M 5/15/06

4

Great Plains Mfg., Inc.

Important Safety Information

Safety Decals

Your implement comes equipped with all safety decals in place.

They were designed to help you safely operate your implement.

1. Read and follow decal directions.

2. Keep all safety decals clean and legible.

3. Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

4. When ordering new parts or components, also request corresponding safety decals.

5. To install new decals:

a. Clean the area on which the decal is to be placed.

b. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

17637

818-003C

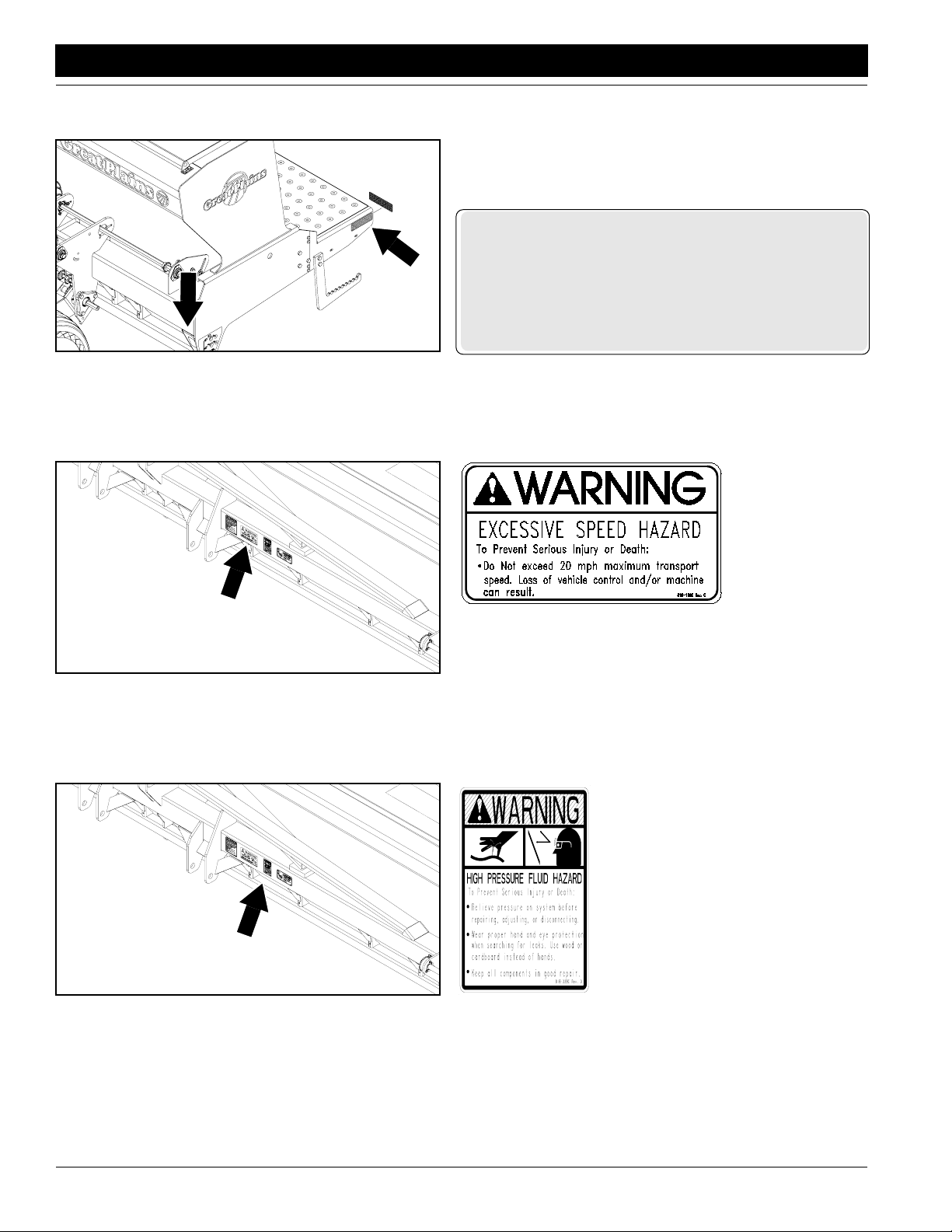

Slow Moving Vehicle Sign

838-266C

Red Reflector

Reflector on both ends of

drill; two reflectors total

17638

5/15/06

2400, 2410 and 2420 Three-Point Drill 118-706M

5

Important Safety Information

Great Plains Mfg., Inc.

838-265C

Amber Reflector

Reflectors on both ends

of drill; four reflectors

total

17638

17639

17639

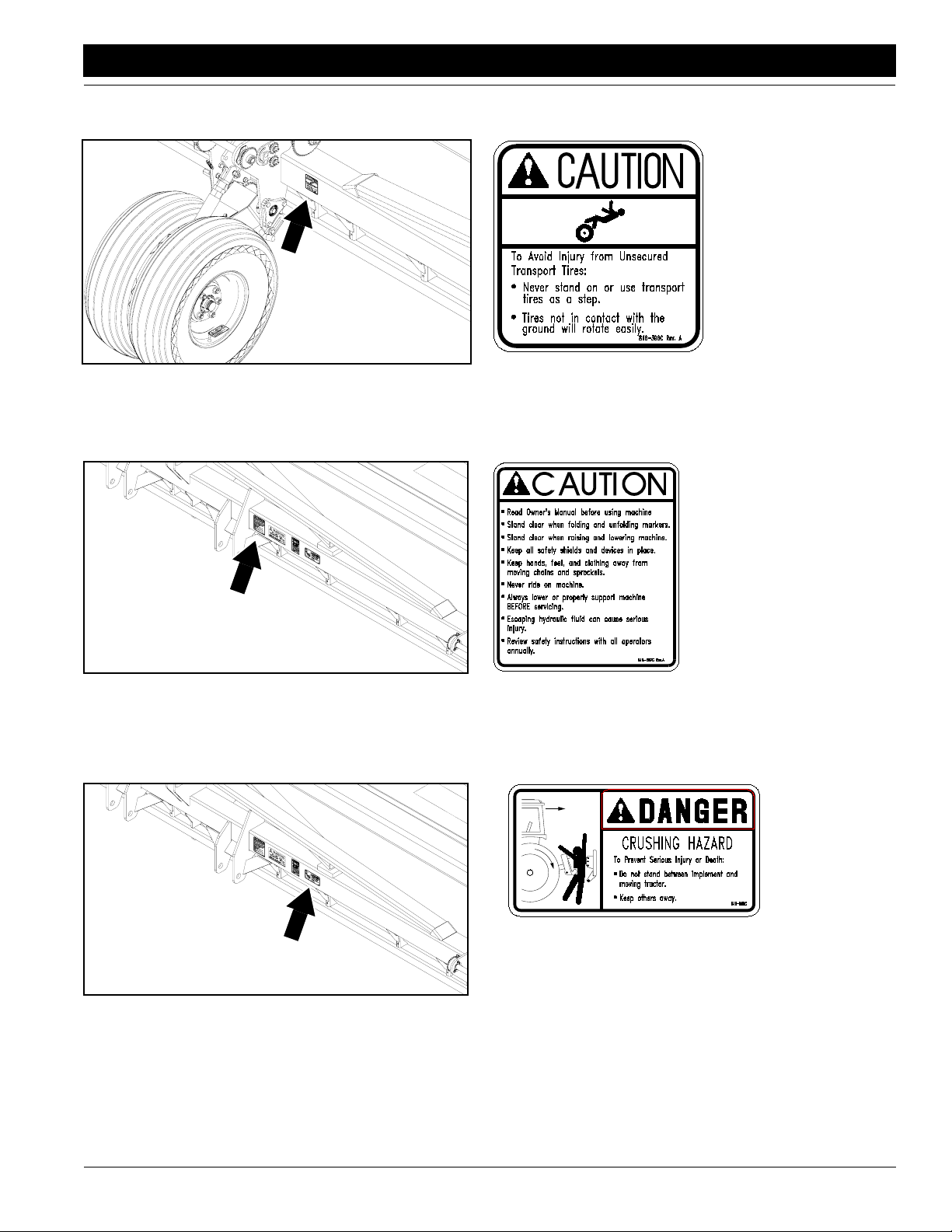

818-188C

Warning 20MPH Trans

Decal on frame tube near drill center

818-339C

Warning High Pressure SML

Decal on frame tube near drill center

2400, 2410 and 2420 Three-Point Drill 118-706M 5/15/06

6

Great Plains Mfg., Inc.

Important Safety Information

17640

818-398C

Caution Tires Not a Step

Decals on frame tube

near gauge wheels; two

decals total

17639

17639

818-587C

Caution Operational

Decal on frame tube near

drill center

818-590C

Danger Crush Tractor & Three Point

Decal on frame tube near drill center

5/15/06

2400, 2410 and 2420 Three-Point Drill 118-706M

7

Important Safety Information

17640

Great Plains Mfg., Inc.

818-855C

Caution Tire 36 PSI

Decals on wheel rims; four decals total

17667

818-682C

Warning Pinch/Crush Marker

Two decals on first section of each

optional marker; four decals total

2400, 2410 and 2420 Three-Point Drill 118-706M 5/15/06

8

Great Plains Mfg., Inc.

Introduction

Introduction

Great Plains welcomes you to its growing family of new

product owners. This implement has been designed with

care and built by skilled workers using quality materials.

Proper setup, maintenance and safe operating practices

will help you get years of satisfactory use from the machine.

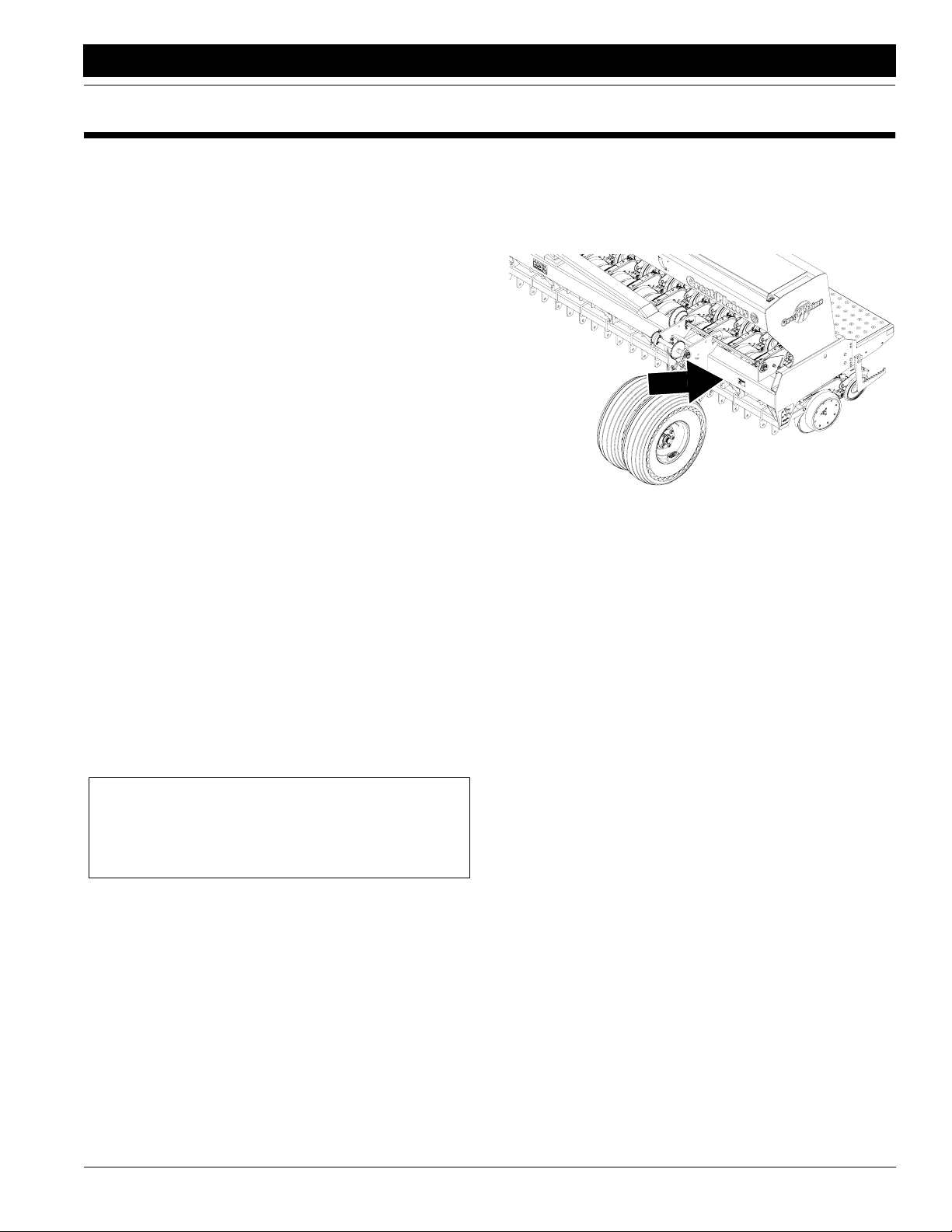

Description of Unit

The 2400, 2410 and 2420 model drills are mounted seeding implements.

The drills are equipped with either straight-arm (00 Series), parallel-arm (10 Series) or side-depth-control (20

Series) openers. The openers are staggered for easy residue flow. Opener depth can be adjusted. Drill-box capacity is 57.6 bushels, and the seeding rate can be adjusted

from 2 to 240 pounds per acre.

Intended Usage

Use the drill to seed production-agriculture crops only. Do

not modify the drill for use with attachments other than

Great Plains options and accessories specified for use

with the drill.

Using This Manual

This manual will familiarize you with safety, assembly, operation, adjustments, troubleshooting and maintenance.

Read this manual and follow the recommendations to help

ensure safe and efficient operation.

The information in this manual is current at printing. Some

parts may change to assure top performance.

Definitions

The following terms are used throughout this manual.

Right-hand and left-hand as used in this manual are determined by facing the direction the machine will travel while

in use unless otherwise stated.

IMPORTANT: A crucial point of information related to

the preceding topic. For safe and correct operation,

read and follow the directions provided before continuing.

NOTE: Useful information related to the preceding topic.

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. They have trained personnel, repair

parts and equipment specially designed for Great Plains

products.

Your machine’s parts were specially designed and should

only be replaced with Great Plains parts. Always use the

serial and model number when ordering parts from your

Great Plains dealer. The serial-number plate is located on

the main frame tube on the left end of the drill as shown in

Figure A.

17668

Figure A

Serial Number

Record your drill model and serial number here for quick

reference:

Model Number: _________________________________

Serial Number: _________________________________

Your Great Plains dealer wants you to be satisfied with

your new machine. If you do not understand any part of

this manual or are not satisfied with the service received,

please take the following actions.

1. Discuss the matter with your dealership service man-

ager. Make sure they are aware of any problems so

they can assist you.

2. If you are still not satisfied, seek out the owner or gen-

eral manager of the dealership.

3. For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

5/15/06

2400, 2410 and 2420 Three-Point Drill 118-706M

9

Section 1 Preparation and Setup

Section 1 Preparation and Setup

Great Plains Mfg., Inc.

This section will help you prepare your tractor and drill for

use. Before using the drill in the field, you must hitch the

drill to a suitable tractor (see Tractor Requirements, Spec-

ifications and Capacities, page 33) and level the drill.

Prestart Checklist

1. Read and understand “Important Safety Information,” page 1.

2. Check that all working parts are moving freely, bolts

are tight, and cotter pins are spread.

3. Check that all grease fittings are in place and lubricated. Refer to Lubrication,“Maintenance and Lubrica-

tion,” page 29.

4. Check that all safety decals and reflectors are correctly located and legible. Replace if damaged. See Safe-

ty Decals,“Important Safety Information,” page 5.

5. Inflate tires to pressure recommended and tighten

wheel bolts as specified. See “Appendix,” page 34.

Hitching Tractor to Drill

!

DANGER

You may be severely injured or killed by being crushed between

the tractor and drill. Do not stand or place any part of your

body between drill and moving tractor. Stop tractor engine and

set park brake before installing pins.

1. Raise or lower tractor three-point arms as needed and

pin lower arms to drill.

2. Pin upper arm to drill. For category III tractors, install

hitch pin in the lower hole. For category IV-N tractors,

install hitch pin in the upper hole.

3. Slowly raise drill. Watch for cab interference.

4. If using optional parking stands, unpin stand tubes.

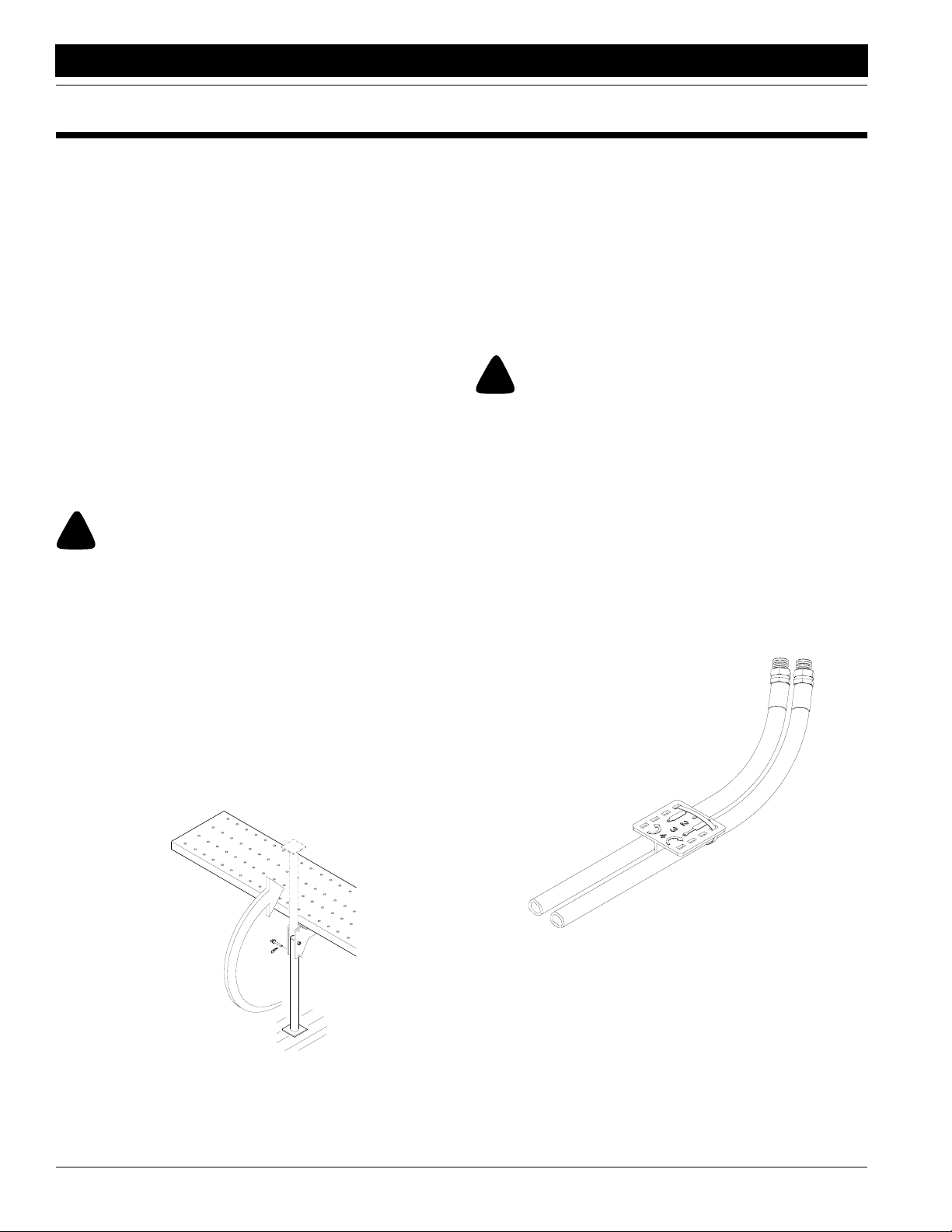

Rotate stands up into field position and repin. See Figure 1-1.

5. Adjust top three-point link so that top edge of drill box

is parallel with ground when drilling.

NOTE: Do not use link to adjust opener depth. For opener

adjustments, refer to Opener Down Pressure and Opener

Depth, “Adjustments,” starting on page 15.

6. Set your tractor three-point-draft control to float position.

7. Plug lead from drill light harness into tractor receptacle.

Hydraulic Hookup

!

WARNING

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin. Check all hydraulic lines and fittings before

applying pressure. Fluid escaping from a very small hole can be

almost invisible. Use paper or cardboard, not body parts, and

wear heavy gloves to check for suspected leaks. If injured, seek

medical assistance from a doctor that is familiar with this type

of injury. Foreign fluids in the tissue must be surgically removed

within a few hours or gangrene will result.

Great Plains hydraulic hoses are coded to help you hookup to your tractor outlets. To distinguish hoses on the

same hydraulic circuit, refer to plastic hose holder. See

Figure 1-2. Connect hose under extended cylinder to outlet you choose for cylinder extension. Connect hose under

retracted symbol to outlet for cylinder retraction.

Figure 1-2

Hydraulic Hose Color Ties

12151

Figure 1-1

Parking Stand

2400, 2410 and 2420 Three-Point Drill 118-706M 5/15/06

10

17641

Loading...

Loading...