Page 1

Great Plains Mfg., Inc.

Installation Instructions

3-Point Precision Seeding System

Marker Option

Used with:

• 2410P and 2420P

General Information

When you see this symbol, the subsequent instructions and

warnings areserious- follow without exception. Your life and

!

!

the lives of others depend on it!

Theseinstructions explainhowtoinstallthe MarkerOptionon the 24 foot3-point Precision Seeding

Systems.

The markers fold and unfold hydraulically for field

operation. The marker disks leavea linefor the

drill operator to followon thenextfieldpass.Markersaremountedonthe drillframe and requiretwo

hydraulic remote valves on the tractor. Asequence valve is available so markerscan be

operated on one hydraulic circuit.

These instructions apply to:

113-729A 24P Dual Marker Package

Assembly Instructions

Marker Assemble

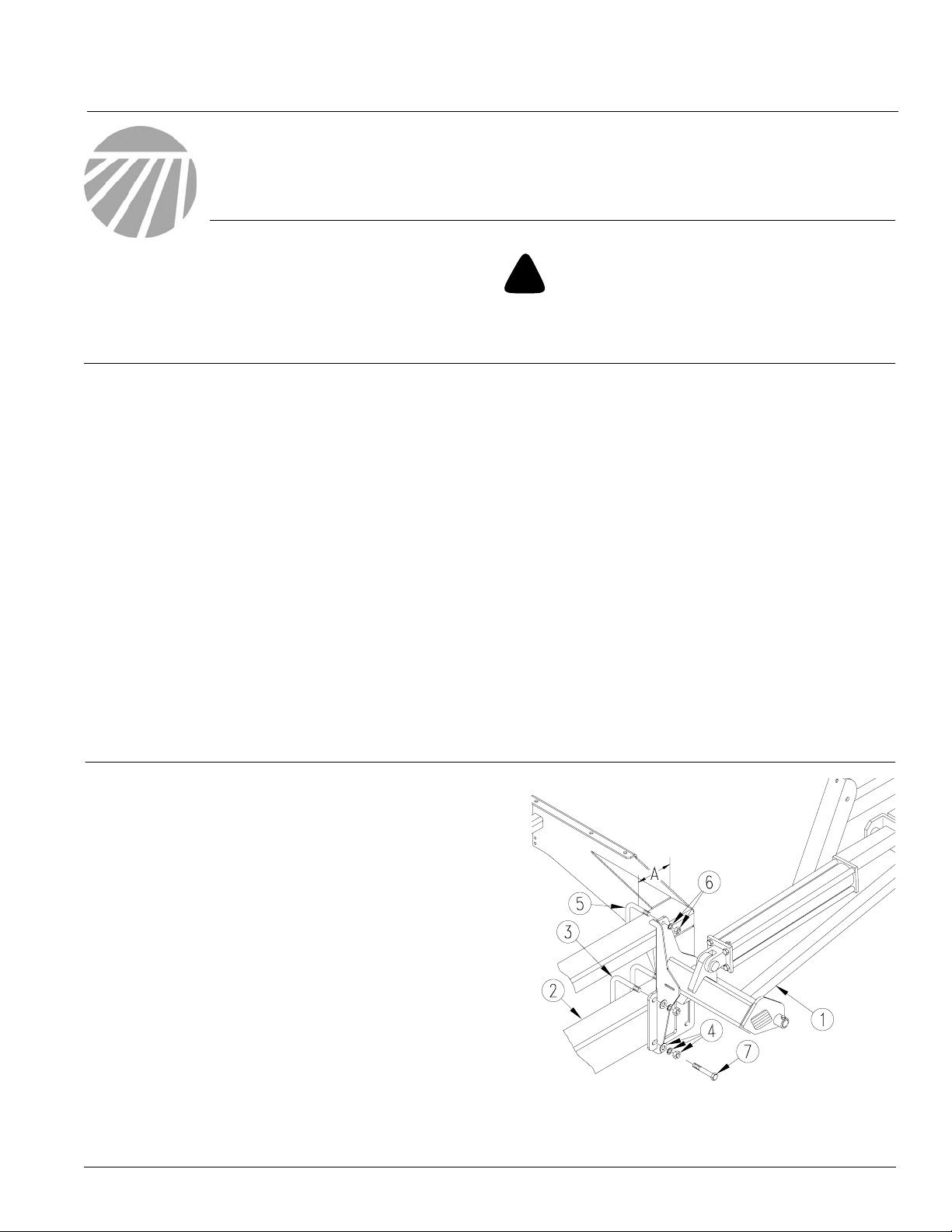

Refer to Figure 1.

Manual Update

Refer to the 3-Point Precision Seeding System

operator’smanual for detailed information on

safely operating, adjusting, troubleshooting and

maintaining the Marker Option. Refer to theparts

manual for part identification.

118-769M 2410P and 2420P Operator’s

Manual

118-769P 2410P and 2420P Parts Manual

Before You Start

Page7is a detailed listing ofpartsincluded in the

Marker Option package. Use this list toinventory

parts received.

24 foot A = 11 1/2 inches

1. Lowerdrill into fieldposition. Allow 13feet on

each end of a 24-foot drill.

2. Mount first marker section (1) on drill 7 x 5

inchframe tube(2).Mount markerattheend of

thedrillusingdimension"A" asastartingpoint.

3. Secure markersection with 5/8 inch u-bolts

(3), lock washers, washers and nuts (4). and

1/2inchu-bolts(5),lockwashers and nuts(6).

NOTE: On the 24-foot drill with 7 1/2" inch row

spacing, the last two openers are bolted to the

marker mount using 5/8x 61/2 inch straight bolts

(7).

© Copyright 2000 Printed

3/21/2001

Figure 1

First Marker Section Assembly

18413

113-742M

Page 2

Marker Option

2

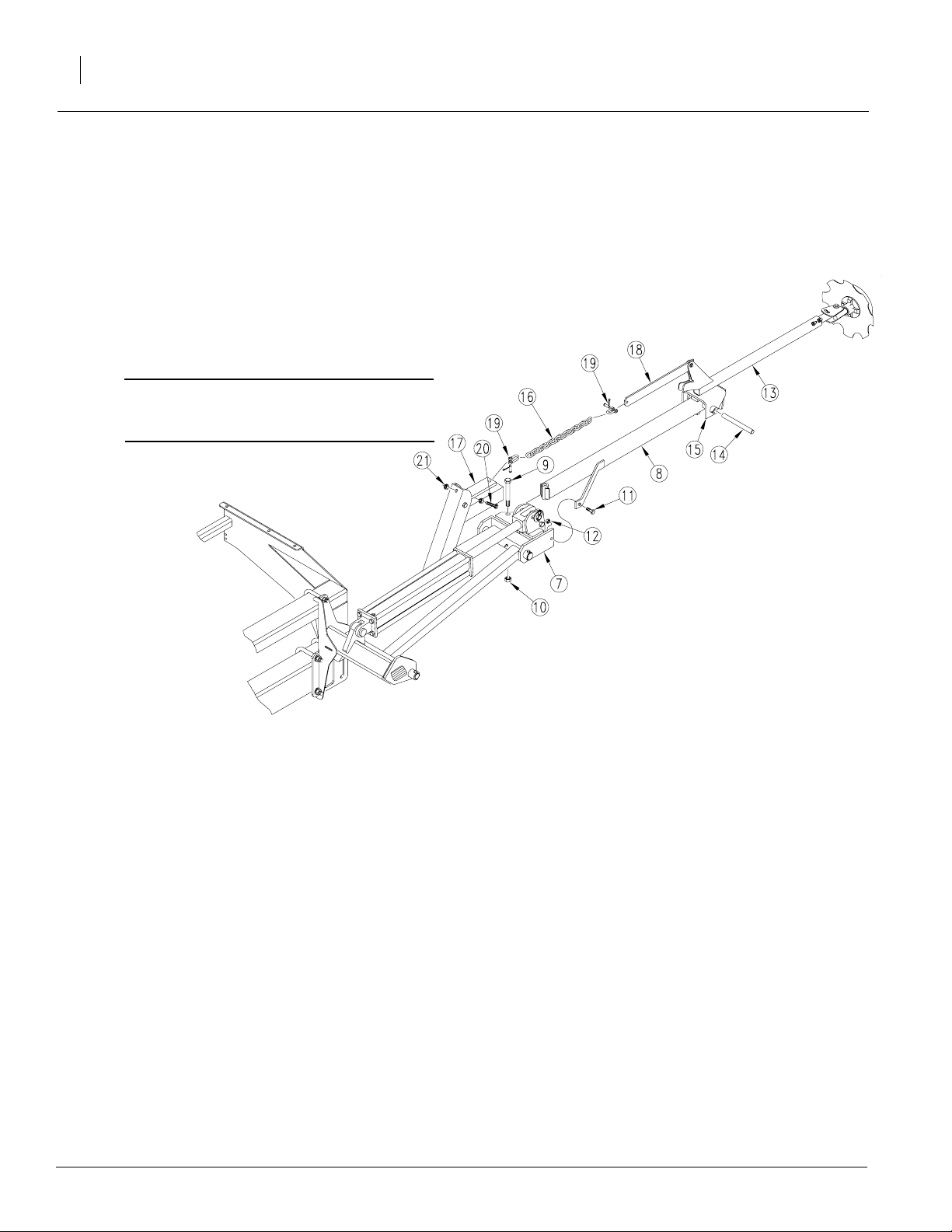

Refer to Figure 2

4. Remove port plugs on cylinder and carefully

5. Align holes of break-away section (8) with

Great Plains Mfg., Inc.

unfold first marker section. Rotate hinge section (7) into a horizontal position.

holes in hingesection. Bolt sectionstogether

using a 5/8-inch pivotbolt (9),locknut (10), 3/

8-by-1 3/4-inch, grade 2 shear bolt (11) and

lock nut (12).

IMPORTANT: Be sure shear bolt is a grade 2

bolt. Failure to use a gr ade 2 bolt can cause

marker damage.

Marker Breakaway Assembly

6. Place third marker sections (13) over end of

second section (8) and insert hinge pin

through second and third section pivot (14)

with the 1/4 X 2 inch bolt and lock nut.*

7. Connect markerchain (16)to chainbar (17)

and chain pivot (18) with utility clevis(19).

With markerdisk adjustedto seedingwidth

and disk touching the ground, remove chain

slack with utility clevis (19) nearest drill.*

8. Assemblefull-threaded 3/8 inch stop bolt (20)

andlocknut(21)onlift armextensionso head

of stop bolt extendsas littleas possible. After

themarker is bled and folded, adjust stop bolt

to remove slackfrom chain.*

9. Repeat steps for other marker.

10. To adjust markers, refer toMarker Adjust-

ments in the operator’s manual.

*NOTE: Parts are located in bolt bag.

Figure 2

19207

113-742M 4/9/2004

Page 3

Great Plains Mfg., Inc.

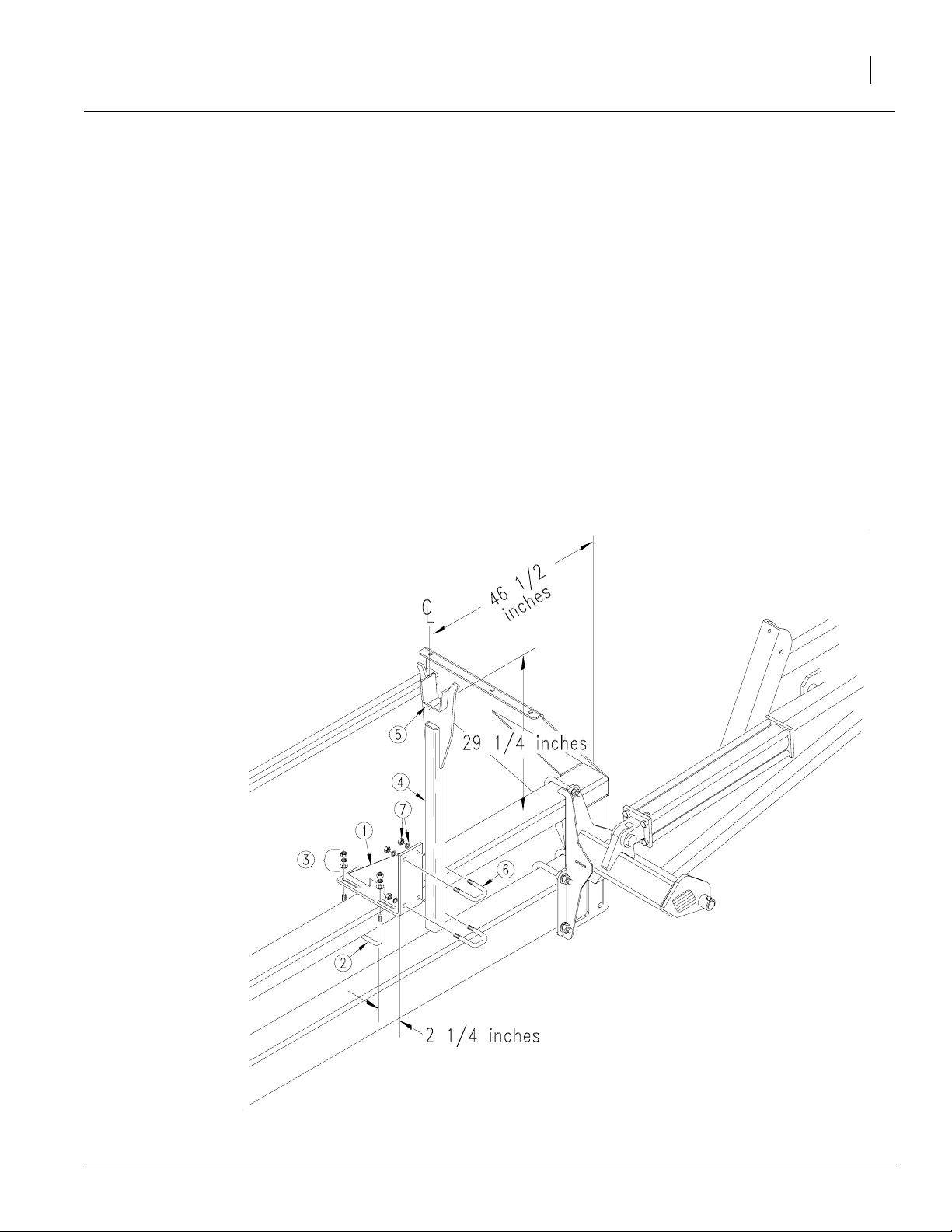

Carrier Assembly for 24P drill

To assemble carrier ontodrill frame, refertoFigure 3.

1. Assemble transport-carrier mount (1) on drill

frame. Center mount 46 1/2inches from outside

end of drill frame. Use 1/2 x 6 1/32 x 7-inch ubolts(2), flat washers,lock washersandhexnuts

(3). Slide mount forward so its leading edge is

about 2 1/4 inches ahead of front edge of drill

frame tube.

2. Bolt transport carrier (4) to transport-carrier

mount so top surface of saddle (5) is about

29 1/4 inches above top of drill frame tube. Secure transport carrier with 1/2x2x3-inch

u-bolts (6), lock washers and hex nuts (7).

3. After installing and bleeding hudraulics, transport carrier may require further adjustment.

When folded, the second marker section should

rest in the transport-carrier saddle..

Installation Instructions

3

4/9/2004

Figure 3

19208

Carrier Assembly

113-742M

Page 4

Marker Option

4

4. After installing and bleeding hydraulics, trans-

Installing Marker Hydraulics

Without Sequence Valve

Refer to Figure 4.

1. Install elbow fittings (1) in cylinder ports.

2. At rod end ofeach cylinder, installan adaptor

Great Plains Mfg., Inc.

port carrier may require further adjustment.

When folded, the second marker section

should rest in the transport-carrier saddle.

(2) into elbow fitting. Installaneedle valve(3)

in adaptor.

3. Connect hydraulic hosesto fittings and route

hydraulic hoses to tractor outlets.Route hydraulichoses throughtransport-carrier mount

at cutout. Use black cableties tosecure hydraulic hoses to drill frame.

4. Usingorange cableties, secureaplastic hose

label, see Figure 5, to each pair of hydraulic

hoses near tractor outlets.

5. Proceed with "Bleeding MarkerHydraulics"

on page 5.

Needle Valve Assembly

Plastichose

label

Figure 4

Cable tie

17642

Figure 5

Hose label and cable tie

113-742M 4/9/2004

17641

Page 5

Great Plains Mfg., Inc.

With Sequence Valve

Refer to Figure 6.

1. Mount sequence valve (1) 810-197C on drill

usingmountingplate(2)113-488D.Bolt plate

to inside end of left-hand-box panel (3) using

one1/2-inchhexbolt (4). The sequencevalve

and mounting plate can be purchased seper

ately from your Great Plains Dealer.

2. Bolt valve(1) to mountingplate (2)with two 3/

8 x 3/4-inch hex bolts and lock washers (5).

3. Install elbow fittings in cylinderports.Discard

adaptorfitting andtwoneedle valvesprovided

in markerkit.

4. Use hoses provided toconnect valve ports to

cylinders. Refer to Figure 7 for port connections .(1) 811-440C and (2) 811-169C, dealer

and customer must order these seperately.

Installation Instructions

5

5. Connectyourown hydraulichoses to ports on

front of valve.Route hoses to tractor outlets.

6. Using orange cable tie, secure plastic hose

label, see Figure 5, to hydraulic hoses near

tractor outlets.

7. Proceed with "Bleeding MarkerHydraulics"

on page 5.

Figure 7

Hydraulic Hose Connection

Figure 6

Sequence Valve Assembly

18416

4/9/2004

19209

Bleeding Marker Hydraulics

113-742M

Page 6

Marker Option

6

You may be injured if hit by a folding or unfolding

marker. Markers may fall quickly and unexpectedly if

the hydraulics fail. Never allow anyone near the drill

when folding or unfolding the markers.

Escaping fluid under pressurecan have sufficient pressure to penetrate the skin. Check all hydraulic lines

and fittings before applying pressure. Fluid escaping

froma very smallhole can bealmost invisible. Use paper or cardboard, not body parts, and wear heavy

gloves to check for suspected leaks. If injured, seek

medical assistance from a doctor that is familiar with

this type of injury. Foreign fluids in the tissue must be

surgically removed within a few hours or gangrene

will result.

!

CAUTION!

!

WARNING!

Great Plains Mfg., Inc.

1. Check that tractor hydraulic reservoir is full.

2. With both markerslowered into fieldposition,

loosenhydraulic-hosefittings at rod and base

endsof marker cylinders.If applicable,loosen

fittings on back side of sequence valve.

IMPORTANT: Neverbleedan O-ring fitting.Instead, bleed a nearby pipe or JIC fitting.

3. With tractor idling, activate tractor hydraulic

valveuntil oilseeps outarounda loosened fitting. Tighten that fitting.

IMPORTANT: JIC fittings do not require high

torque. JIC and O-ring fittings do not require

sealant. Always use liquid pipe sealant when

adding or replacing pipe-thread fittings. To

avoid crac king hydraulic fittings from over

tightening, do not use plastic sealant tape.

4. Reactivate tractor hydraulic valve until oil

seeps out around another loosened fitting.

Tighten that fitting. Repeat process until all

loosened fitting have been bledand tightened.

5. Adjust markerfolding to a safe speed. Refer

to "MarkerAdjustments" inthe operator’s

manual.

113-742M 4/9/2004

Page 7

Great Plains Mfg., Inc.

113-729A MARKER, 3PT 24P DUAL

Your kit includes:

Qty. Part No. Part Description

1 113-740K MARKER BUNDLE 24-P 3PT DUAL

1 113-180H LH FIRST SECTION

1 113-181H LIFT LUG CHANNEL LH

1 113-183H 30’ FF MARKER 3RD SECTION

1 113-188H RH FIRST SECTION

1 113-189H LIFT LUG CHANNEL RH

2 113-195H 3 SECTION MARKER BREAKAWAY

1 113-196H 24’ FF MARKER 3RD SECTION

2 113-200H CHAIN BAR WELDMENT

2 113-248D PIN 1 OD X 4.34 USABLE.

2 113-311D HINGE PIN

2 113-312D FIRST PIVOT SHAFT

2 113-313D SECOND PIVOT SHAFT

2 113-323D CHAIN BAR

2 113-324D CYLINDER STOP

4 113-325D STOP BUSHING

1 113-352D MARKER TUBE 30 LONG

1 113-354D 13’ MARKER TUBE 46 1/2 LONG

2 113-560H MARKER CARRIER

2 113-563S MARKER DISC & HUB ASSEMBLY

2 113-568H MARKER TRANSPORT MOUNT

1 113-689H MARKER MOUNT LH

1 113-690H MARKER MOUNT RH

6 800-001C GREASE ZERK STRAIGHT 1/4-28

4 801-054C SCREW SET SQ HD 1/2-13X1 GR5

2 802-022C HHCS 3/8-16X1 1/2 GR5

4 802-039C HHCS 1/2-13X3 GR5

6 802-115C HHCS 5/16-18X2 GR5

2 802-168C HHCS 5-16-18X2 GR5

2 802-249C HHCS 1/2-13X4 1/2 GR5 SPTHD

2 802-254C HHCS 5/8-11X5 1/2 GR5

2 802-261C HHCS 3/8-16X2 GR5 FTHD

2 802-266C HHCS 3/8-16X2 GR2

6 803-011C NUT LOCK 5/16-18 PLT

10 803-013C NUT LOCK 3/8-16 PLT

2 803-019C NUT LOCK 1/2-13 PLT

12 803-020C NUT HEX 1/2-13 PLT

2 803-024C NUT LOCK 5/8-11 PLT

4 803-036C NUT HEX JAM 1/2-13 PLT

4 804-011C WASHER FLAT 3/8 USS PLT

12 804-015C WASHER LOCK SPRING 1/2 PLT

8 804-017C WASHER FLAT 1/2 USS PLT

4 804-029C WASHER FLAT 1 SAE

4 805-058C PIN COTTER 3/16 X 2

2 806-005C U-BOLT 1/2-13 X 2 X 3 GR 5

1 810-118C CYL 2.5X20X1.12 ROD (TIE) 1

2 818-229C DECAL AMBER REFLECTOR

4 818-682C DECAL WARNING PINCH/CRUSH MRKR

6 803-011C NUT LOCK 5/16-18

4 803-021C NUT HEX 5/8-11 PLT

Installation Instructions

7

113-742M4/9/2004

Page 8

Marker Option

8

113-729A MARKER, 3PT 24P DUAL

Your kit includes:

Qty. Part No. Part Description

1 113-741K MARKER HRDWR 24P DUAL

2 113-328D 24’ MARKER CHAIN

1 113-351D MARKER TUBE 42 LG

12 800-082C CABLE TIE .31X21.5 6 DIA 120

2 800-300C CABLE TIE 2 DIA MIN - ORG

4 802-335C HHCS 5/8-11X6 1/2 GR5

12 803-020C NUT HEX 1/2-13 PLT

8 803-021C NUT HEX 5/8-11 PLT

12 804-015C WASHER LOCK SPRING 1/2 PLT

8 804-017C WASHER FLAT 1/2 USS PLT

8 804-021C WASHER FLAT 5/8 SAE PLT

8 804-022C WASHER LOCK SPRING 5/8 PLT

4 806-053C U-BLOT 5/8-11X7 1/32X6

4 806-159C U-BOLT 1/2-13 X 5 1/32 X 4

2 810-058C VAVLE 3/8 NEEDLE

2 811-044C AD 3/8MNPT

2 811-281C EL 3/8FNPT 9/16MORB

2 817-348C PLASTIC HOSE LABEL

4 890-018C 5/16X1 1/4 UTILITY CLEVIS

1 113-742M MANUAL MARKERS 24-P 3PT

Great Plains Mfg., Inc.

1 113-624V 24’ 3PT DUAL MARKER HOSE BUNDLE

2 811-129C HH1/4R1 234 3/8MNPT 1/2MNPT

2 811-297C SP HH1/4R1 212 3/8MNPT-W/AD

4/9/2004

113-742M

Loading...

Loading...