Page 1

Great Plains Mfg., Inc.

Installation Instructions

24 Series Drills

Folding Markers

Used with:

2400

•

2410

•

2420

•

When you see this symbol, the subsequent instructions and

warnings are serious - follow without exception. Your life and

!

!

the lives of others depend on it!

General Information

These instructions explain how to install the optional markers.

The markers fold and unfold h ydraulically for field oper ation. The

marker disks leave a line f or the drill operator to follow on the next

field pass. Markers are mounted on the drill frame and require

two hydraulic remote valves on the tractor. A sequence v alve is

available so markers can be oper ated on one hydraulic circuit.

These instructions apply to:

113-662A 24FT 3PT DUAL MARKERS

113-466A 94 3PT SEQ V ALVE KIT-FIELD

Manual Update

Refer to the drill operator’ s manual for detailed information on

safely operating, adjusting, troubleshooting and maintaining the

markers. Refer to the parts manual for part identification.

• 2400, 2410 and 2420 Operator’s Manual. . . . . . .118-706M

• 2400, 2410 and 2420 Parts Manual. . . . . . . . . . 118-706P

Before You Start

Starting on page 4 are detailed listings of parts included in

the option packages. Use these lists to in v entory parts received.

Assembly Instructions

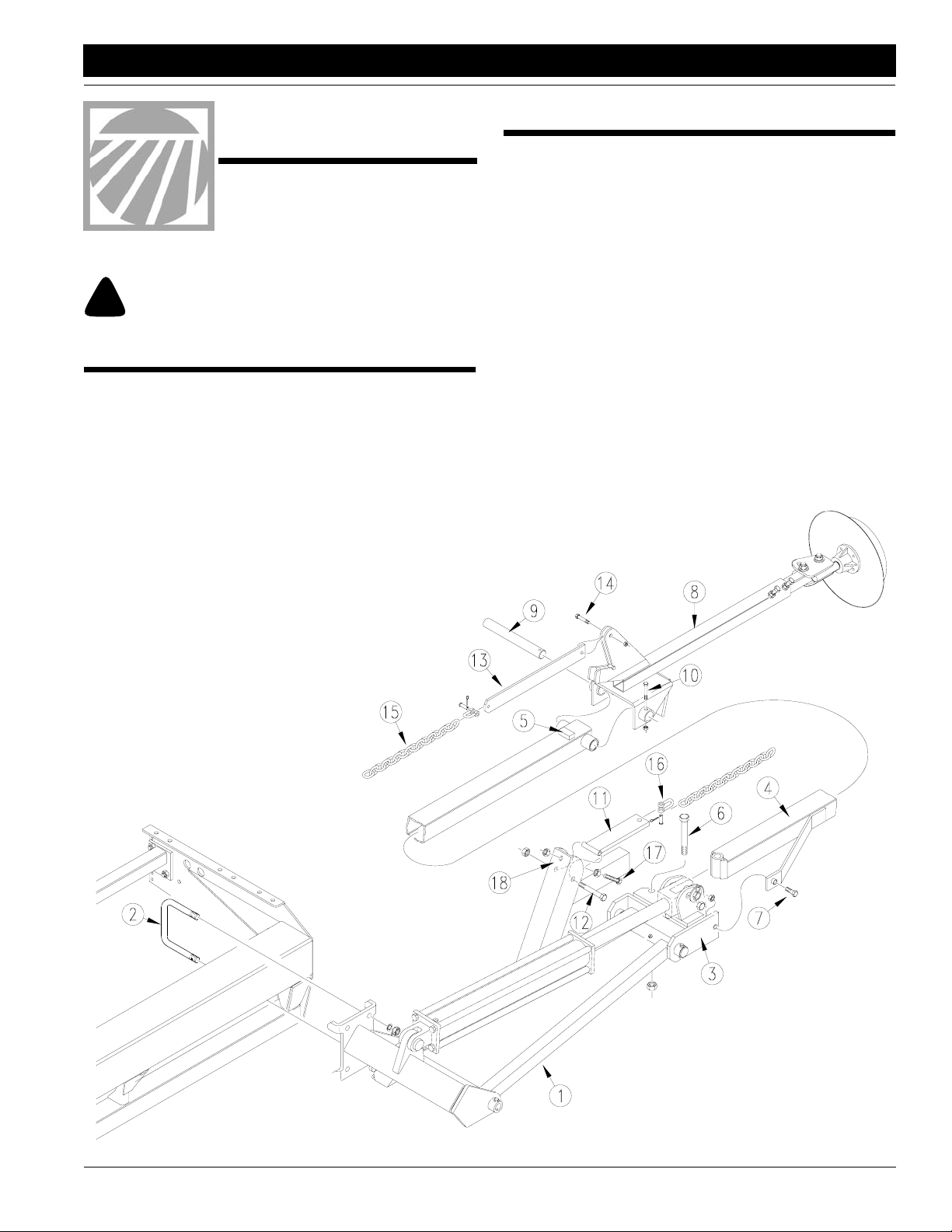

Marker Assembly

Refer to Figure 1.

1. Lower drill into field position. Allow 15 feet of clearance from

each end of drill box for marker assembly.

2. Attach first marker section (1) to drill frame. Mount marker

as far out on drill frame as possible. Secure marker to drill

frame with 5/8-inch u-bolts (2), lock washers and he x nuts .

3. Remove port plugs from marker cylinder and carefully unfold first marker section. Rotate hinge (3) into a horizontal

position.

4. Assemble second marker section (4) onto first section so

that stop block (5) on second section faces up. Secure sec

tions with 5/8-inch bolt (6) and lock nut and 3/8-by-2-inch,

grade 2 shear bolt (7) and lock nut.

IMPORTANT: Use a grade 2 bolt for the shear bolt or marker

damage will occur during field operation.

5. Place third marker section (8) over end of second section

and insert hinge pin (9) through second- and third-section

pivot. Secure hinge pin with the 1/4-by-2-inch bolt (10) and

lock nut.

6. Bolt chain pivot (11) to first marker section with 3/8-by-3 1/4inch bolt (12) and lock nut so chain pivot piv ots freely on bolt.

7. Bolt chain bar (13) to third marker section

with the 3/8-by-1 1/2-inch bolt (14) and

lock nut so chain bar pivots freely on bolt.

-

Figure 1

Marker Assembly

17628

© Copyright 1998 Printed 11/25/98

8. Connect

marker

chain

(15) to

chain bar

and chain

pivot with utility

clevis (16). With

marker disk adjusted

for seeding width and

ground, remove chain slack with

utility clevis nearest drill.

9. Assemble full-threaded, 3/8-inch stop bolt

(17) and lock nuts on lift-arm extension (18) so

head of stop bolt extends as little as possible.

After the marker is bled and folded, adjust stop

bolt to remove slack from chain. Ref er to Mark

er Chain Adjustments, "Adjustments" in the

operator’s manual.

disk touching the

113-672M

-

1

Page 2

Assembly

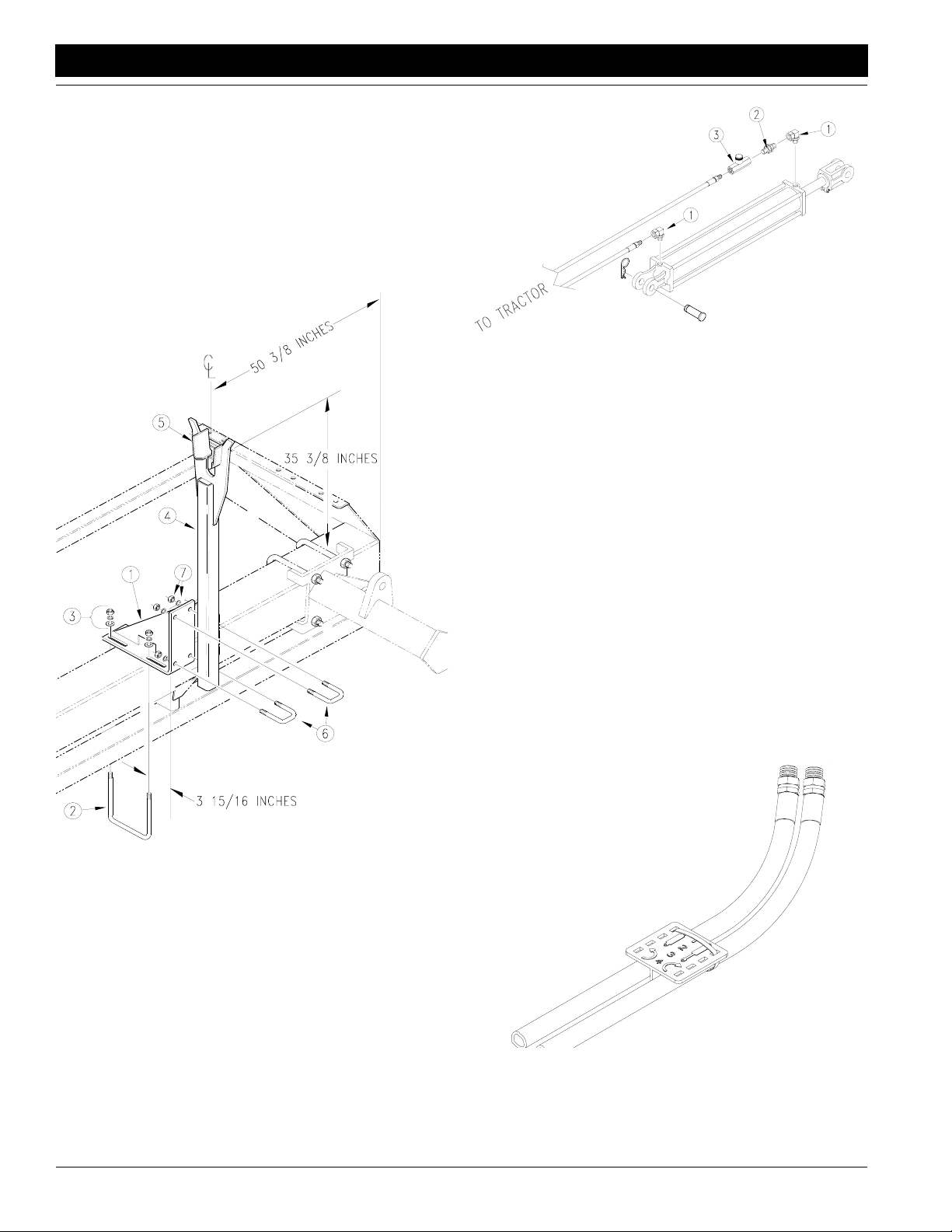

Transport Carrier Assembly

Refer to Figure 2.

1. Assemble transport-carrier mount (1) on drill frame. Center

mount 50 3/8 inches from outside end of drill frame. Use

1/2-by-6 1/32-by-7-inch u-bolts (2), flat washers, loc k w ashers and hex nuts (3). Slide mount forw ard so its leading edge

is about 3 15/16 inches ahead of front edge of drill frame

tube.

2. Bolt transport carrier (4) to transport-carrier mount so top

surface of saddle (5) is about 35 3/8 inches above top of drill

frame tube. Secure transport carrier with 1/2-by-2-by-3-inch

u-bolts (6), lock washers and hex nuts (7).

Great Plains Mfg., Inc.

17642

Figure 3

Assemble Needle Valves

3. Connect hydraulic hoses to fittings and route hydr aulic hoses to tractor outlets. Route hydraulic hoses through trans port-carrier mount at cutout. Use black cable ties to secure

hydraulic hoses to drill frame.

4. Using orange cable ties, secure a plastic hose holder to

each pair of hydraulic hoses near tractor outlets. See

4.

5. Proceed with "Bleeding Marker Hydraulics," page 3.

With Sequence Valve

Refer to Figure 5.

1. Mount sequence valve (1) on drill using mounting plate (2).

See Figure 5. Bolt plate to inside end of left-hand-bo x panel

(3) using one 1/2-inch hex bolt (4).

2. Bolt valve to mounting plate with two 3/8-b y-3/4-inch hex

bolts and lock washers (5).

3. Install elbow fittings in cylinder ports. Discard adaptor fitting

and two needle valves pro vided in marker kit.

4. Use hoses provided to connect valve ports to cylinders. Refer to Figure 5 for port connections.

5. Connect your own hydr aulic hoses to ports on front of valve.

Route hoses to tractor outlets.

6. Using orange cable tie, secure plastic hose label to h ydraulic hoses near tractor outlets. See Figure 4.

Figure

17629

Figure 2

Transport Carrier Assembly

3. After installing and bleeding hydraulics, tr ansport carrier

may require further adjustment. When folded, the second

marker section should rest in the transport-carrier saddle

and be parallel with the drill box. Refer to Marker Adjust-

ments, "Adjustments" in the operator’ s manual.

Installing Marker Hydraulics

Without Sequence Valve

Refer to Figure 3.

1. Install elbow fittings (1) in cylinder ports.

2. At rod end of each cylinder, install an adaptor (2) into elbow

fitting. Install a needle valve (3) in adaptor.

7. Proceed with "Bleeding Marker Hydraulics," page 3.

24 Series Drills Folding Markers 113-672M 4/9/04

2

Figure 4

Install Hose Label

17641

Page 3

Great Plains Mfg., Inc.

Assembly

17631

Figure 5

Mount Sequence Valve

Bleeding Marker Hydraulics

!

CAUTION!

You may be injured if hit by a folding or unfolding marker. Markers

may fall quickly and unexpectedly if the hydraulics fail. Never allow

anyone near the drill when folding or unfolding the markers.

!

WARNING!

Escaping fluid under pressure can have suf ficient pr essure to penetrate

the skin. Check all hydraulic lines and fittings before applying pressure. Fluid escaping from a very small hole can be almost invisible.

Use paper or cardboard, not body parts, and wear heavy gloves to

check for suspected leaks. If injured, seek medical assistance from a

doctor that is familiar with this type of injury. Foreign fluids in the tis

sue must be surgically remo ved within a few hours or gangrene will result.

1. Check that tractor hydraulic reservoir is full.

2. With both markers lowered into field position, loosen hy-

draulic-hose fittings at rod and base ends of marker cylinders. If applicable, loosen fittings on back side of sequence

valve.

IMPORTANT: Never bleed an O-ring fitting. Instead, bleed

a nearby pipe or JIC fitting.

3.

With tractor idling, activate tractor hydr aulic valve until oil

seeps out around a loosened fitting. Tighten that fitting.

IMPORTANT: JIC fittings do not require high torque. JIC

and O-ring fittings do not require sealant. Always use liquid

pipe sealant when adding or replacing pipe-thread fittings.

T o a void cr acking h ydraulic fittings from ov er tightening, do

not use plastic sealant tape.

4. Reactivate tractor hydraulic v alv e until oil seeps out around

-

another loosened fitting. Tighten that fitting. Repeat process

until all loosened fitting have been bled and tightened.

5. Adjust marker folding to a safe speed. Refer to Marker Ad-

justment, "Adjustments," in the operator’ s manual.

4/9/04

24 Series Drills Folding Markers 113-672M

3

Page 4

Great Plains Mfg., Inc.

Listing of Parts

113-662A 24Ft 3Pt Dual Markers

Your Kit Includes:

Qty. Part No. Part Description

2 811-129C HH1/4R1 234 3/8MNPT 1/2MNPT

2 811-297C SP HH1/4R1 212 3/8MNPT-W/AD

1 113-180H LH FIRST SECTION

1 113-181H LIFT LUG CHANNEL LH

1 113-188H RH FIRST SECTION

1 113-189H LIFT LUG CHANNEL RH

1 113-192H LH SECOND SECTION

1 113-195H RH SECOND SECTION

2 113-196H 24’ F.F. MKR. 3RD. SECTION

2 113-248D PIN 1 OD X 4.34 USABLE

2 113-312D FIRST PIVOT SHAFT

2 113-313D SECOND PIVOT SHAFT

2 113-324D CYLINDER STOP

4 113-325D STOP BUSHING

2 113-352D MARKER TUBE 30 LG

1 113-558H MARKER, L.H. MOUNT 96

1 113-559H MARKER, R.H. MOUNT 96

2 113-563S MARKER DISC & HUB ASSEMBLY

6 800-001C GREASE ZERK STRAIGHT 1/4-28

4 801-054C SCREW SET SQ HD 1/2-13X1 GR

4 802-039C HHCS 1/2-13X3 GR5

4 802-115C HHCS 5/16-18X2 GR5

2 802-249C HHCS 1/2-13X4 1/2 GR5 SPTHD

2 802-254C HHCS 5/8-11X5 1/2 GR5

2 802-266C HHCS 3/8-16X2 GR2

4 803-011C NUT LOCK 5/16-18 PLT

2 803-013C NUT LOCK 3/8-16 PLT

2 803-019C NUT LOCK 1/2-13 PLT

4 803-020C NUT HEX 1/2-13 PLT

2 803-024C NUT LOCK 5/8-11 PLT

4 803-036C NUT HEX JAM 1/2-13 PLT

4 804-015C WASHER LOCK SPRING 1/2 P +

8 804-017C WASHER FLAT 1/2 USS PLT

4 804-029C WASHER FLAT 1 SAE

4 805-058C PIN COTTER 3/16 X 2

2 810-118C CYL 2.5X20X1.12 ROD (TIE)1

4 818-682C DECAL WARNING PINCH/CRUSH M

2 113-200H CHAIN BAR WELDMENT

2 113-311D HINGE PIN

2 113-323D CHAIN BAR

2 113-328D 24’ MARKER CHAIN

2 113-560H MARKER CARRIER

2 113-568H MARKER TRANSPORT MOUNT

12 800-082C CABLE TIE 21" LONG

2 802-022C HHCS 3/8-16X1 1/2 GR5

2 802-115C HHCS 5/16-18X2 GR5

2 802-168C HHCS 3/8-16X3 1/4 GR5

2 802-261C HHCS 3/8-16X2 1/2 GR5 FTHD

2 803-011C NUT LOCK 5/16-18 PLT

8 803-013C NUT LOCK 3/8-16 PLT

16 803-020C NUT HEX 1/2-13 PLT

8 803-021C NUT HEX 5/8-11 PLT

4 804-011C WASHER FLAT 3/8 USS PLT

16 804-015C WASHER LOCK SPRING 1/2 PLT

8 804-017C WASHER FLAT 1/2 USS PLT

8 804-022C WASHER LOCK SPRING 5/8 PLT

4 806-005C U-BOLT 1/2-13 X 2 X 3 GR 5

4 806-039C U-BOLT 5/8-11 X 6 1/32 X 7

4 806-060C U-BOLT 1/2-13 X 6 1/32 X 7

2 810-058C VALVE 3/8 NEEDLE

2 811-044C AD 3/8MNPT

4 811-281C EL 3/8FNPT 9/16MORB

4 890-018C 5/16 X 1 1/4 UTILITY CLEVIS

1 113-672M MANUAL 24 FT 3PT MARKERS

2 800-300C CABLE TIE 2 DIA MIN - ORG

2 817-348C PLASTIC HOSE LABEL

4/9/04

■

24 Series Drills Folding Markers 113-672M

4

Page 5

Great Plains Mfg., Inc.

Listing of Parts

113-466A 94 3Pt Sequence V alve Field Kit

Your Kit Includes:

Qty. Part No. Part Description

1 113-488D SEQUENCE VALVE MOUNT BRACKE

2 802-014C HHCS 3/8-16X3/4 GR5

2 804-013C WASHER LOCK SPRING 3/8 PLT

1 810-197C VALVE,SEQUENCE SHOEMAKER

4 811-169C EL 9/16MJIC 9/16FJIC

4 811-440C AD 1/2FNPT X 9/16FJICS

4/9/04

■

24 Series Drills Folding Markers 113-672M

5

Loading...

Loading...