Page 1

Table of Contents Index

Installation, Operation and

Parts Manual

207-092S, 207-093S, 207-098S

207-213K, 207-215K, 207-216K

2008+ Unit-Mount Row Cleaners

and 207-221A Field Update Kit

Manufacturing, Inc.

www.greatplainsmfg.com

Read the operator manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without

exception. Your life and the lives of others depend on it!

22816

Illustrations may show optional equipment not supplied with standard unit or may

depict row units and/or implements that differ from yours.

ORIGINAL INSTRUCTIONS

© Copyright 2014 Printed 2014-02-12 204-085M-A

Table of Contents Index

EN

Page 2

Table of Contents Index

Table of Contents Index

Page 3

Great Plains Manufacturing, Inc. Cover Index iii

Table of Contents

Important Safety Information .....................................1

Safety Reflectors and Decals .........................................3

Introduction ..................................................................4

Description of Unit ..........................................................4

Intended Usage ..........................................................4

Document Family ...........................................................4

Supporting Implements for UMRC .................................4

Using This Manual..........................................................4

Definitions................................................................... 4

Call-Outs ....................................................................4

Kits Covered by this Manual...........................................5

Individual Row Kits .....................................................5

Owner Assistance ..........................................................5

Assembly Instructions.................................................6

Before You Start.............................................................6

General Assembly Instructions.......................................6

Tools Required ...............................................................6

Where to Start ................................................................6

UMRC Installation or Update..........................................7

207-221A Update Kit - Prepare Site...........................7

Update Kit: Remove Arms ......................................7

Update Kit: Remove Mount ....................................8

Install UMRC Adjuster Parts....................................... 8

Install UMRC Mount Weldment .................................. 9

Install UMRC Cleaner Arm ......................................... 9

Install UMC-RC Cleaner Arms .....................................10

Install Cleaner Wheel Assemblies................................11

Wheel Identification ..................................................11

Wheel Placement .....................................................11

Mount a Left Wheel ..................................................12

Mount a Right Wheel................................................12

Install Down Stop (UMC-RC Only) ........................... 13

Adjustment and Operation ........................................14

Wheel Placement .........................................................14

Dual Wheel Placement.............................................14

Offset Dual Wheel ................................................14

Retracted Dual Wheel .......................................... 14

Intersected Dual Wheel........................................ 14

Single Wheel Placement .......................................... 15

Single Wheel Forward.......................................... 15

Single Wheel Retracted ....................................... 15

Row Cleaner Depth...................................................... 16

Selecting Depth........................................................16

Row Cleaner Lock-Up .......................................... 16

Adjusting UMRC Depth ............................................ 16

Adjusting UMC-RC Depth ........................................ 17

Troubleshooting......................................................... 18

Maintenance and Lubrication ................................... 19

Maintenance ................................................................ 19

Row Cleaner Maintenance....................................... 19

Lubrication ................................................................... 19

Appendix..................................................................... 20

Torque Values.............................................................. 20

Parts Lists .................................................................... 21

207-213K Dual UMRC Kit ........................................ 21

207-215K Single LH UMRC Kit ................................ 22

207-216K Single RH UMRC Kit ............................... 23

207-092S Single LH UMC-RC Kit ............................ 24

207-093S Single RH UMC-RC Kit............................ 25

207-098S Dual UMC-RC Kit .................................... 26

207-149S Down Stop ............................................... 27

207-221A Mount Update Kit.....................................28

207-217S Dual Arm Assembly ................................. 29

207-218S Left Arm Assembly .................................. 30

207-219S Right Arm Assembly ................................ 31

207-142V Right Hand Cleaner Wheel...................... 32

207-143V Left Hand Cleaner Wheel ........................ 33

815-255C Hub Assembly ......................................... 34

815-255C_HUB Row Cleaner Hub .......................... 35

Abbreviations ............................................................... 36

Warranty ...................................................................... 37

Index............................................................................ 39

© Copyright 2007, 2008, 2010, 2012, 2014 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

2014-02-12 Cover Index 204-085M-A

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand,

Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo Max, Turbo-Till, Ultra-Till, Ver ti-Till, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

Page 4

iv UMRC Table of Contents Index Great Plains Manufacturing, Inc.

204-085M-A Table of Contents Index 2014-02-12

Page 5

Great Plains Manufacturing, Inc. Table of Contents Index 1

Important Safety Information

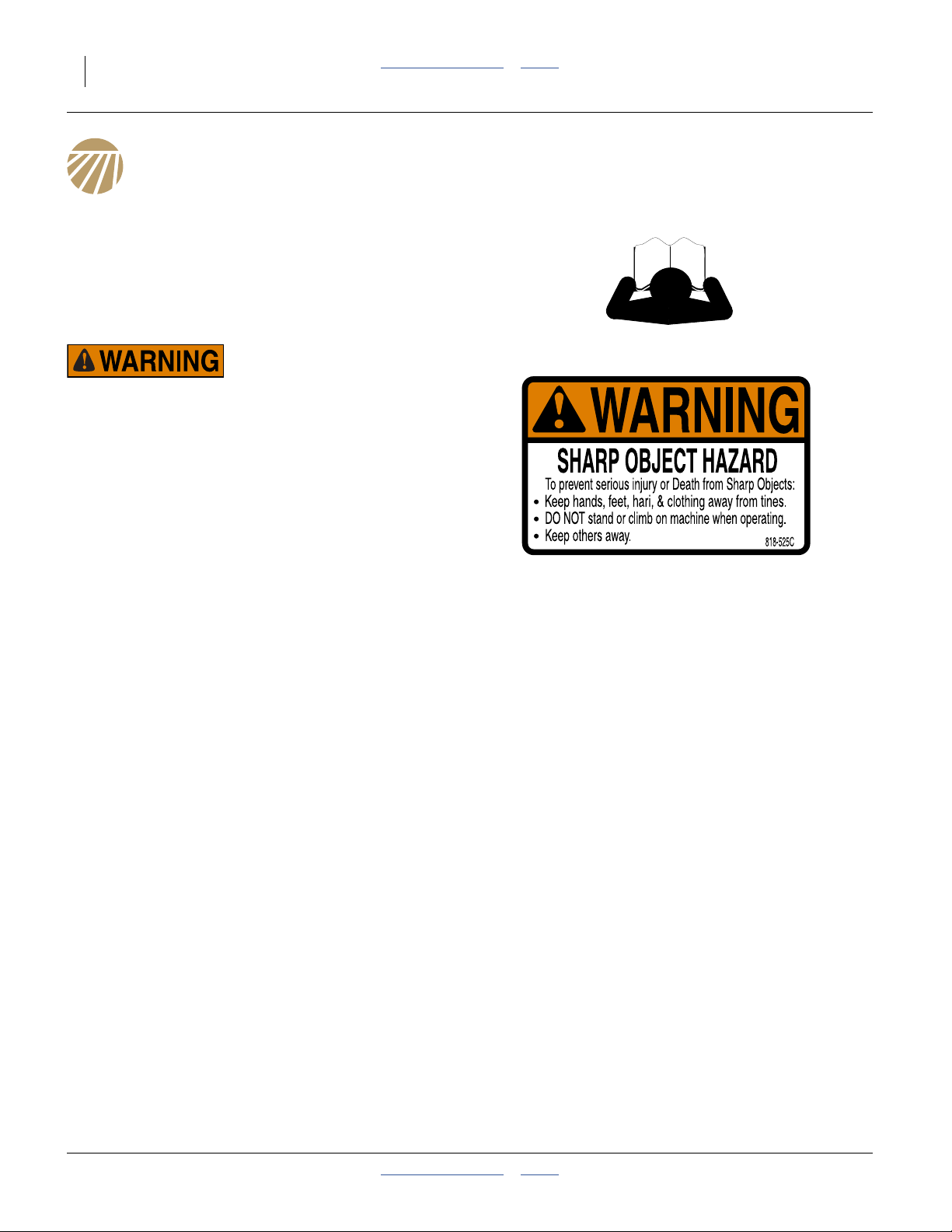

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that

follows it. In addition to design and configuration of

equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

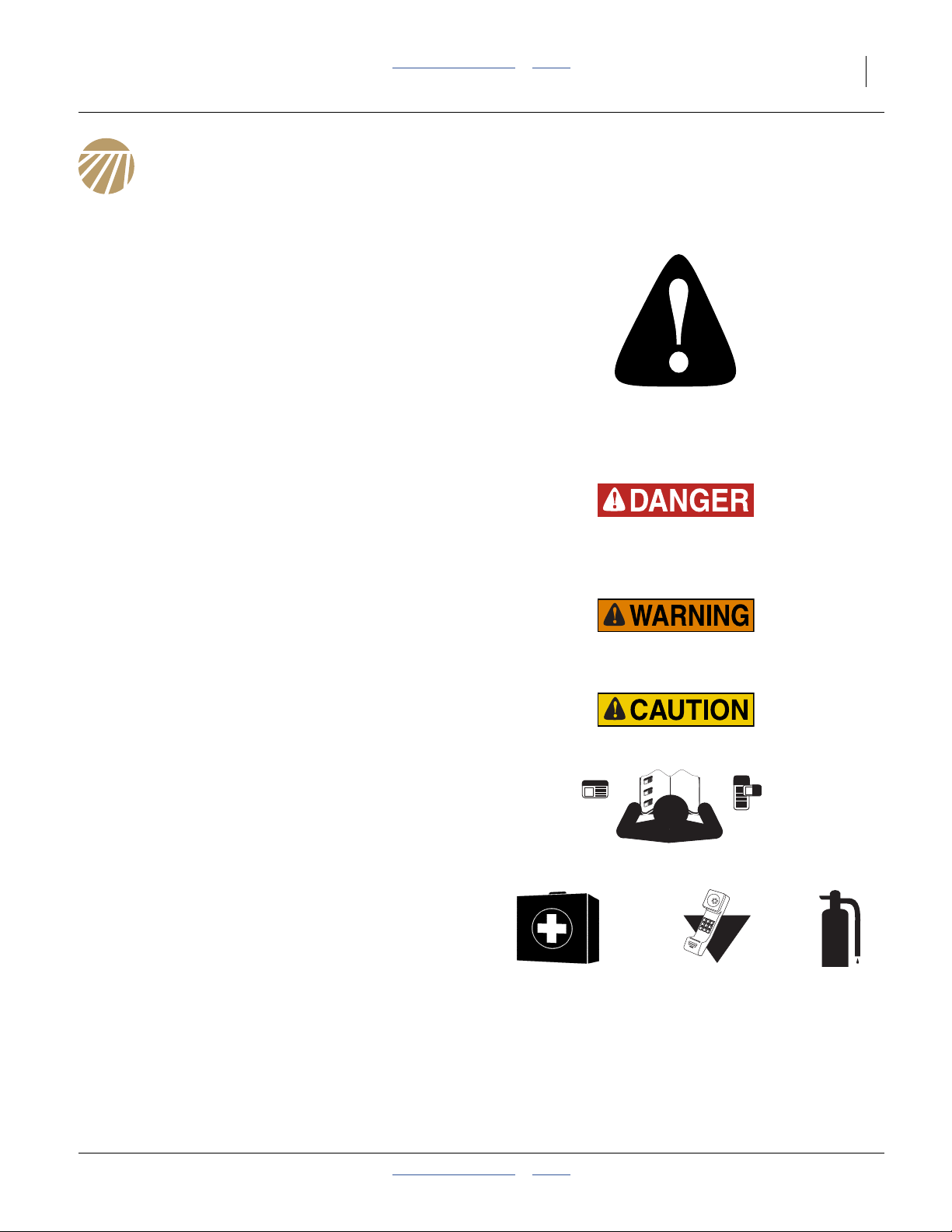

Be Aware of Signal Words

Signal words designate a degree or level of hazard

seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme situations,

typically for machine components that, for functional

purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against

unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices.

Be Familiar with Safety Decals

▲ Read and understand “Safety Reflectors and Decals” in

your Operator manual.

▲ Read all instructions noted on the decals.

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

2014-02-12 Table of Contents Index 204-085M-A

000

112

911

999

Page 6

2UMRC Table of Contents Index Great Plains Manufacturing, Inc.

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper tools

and equipment. Refer to this manual for additional

information.

▲ Work in a clean, dry area.

▲ Wear gloves when handling row cleaner tines.

▲ Make sure all moving parts have stopped and all system

pressure is relieved.

▲ Inspect all parts. Make sure parts are in good condition and

installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from implement before

operation.

Safety At All Times

▲ Thoroughly read and understand the instructions in this

manual before operation. Read all instructions noted on the

safety decals.

▲ Be familiar with all implement functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave implement unattended with tractor engine

running.

▲ Wear snug-fitting clothing to avoid entanglement with

moving parts.

204-085M-A Table of Contents Index 2014-02-12

Page 7

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 3

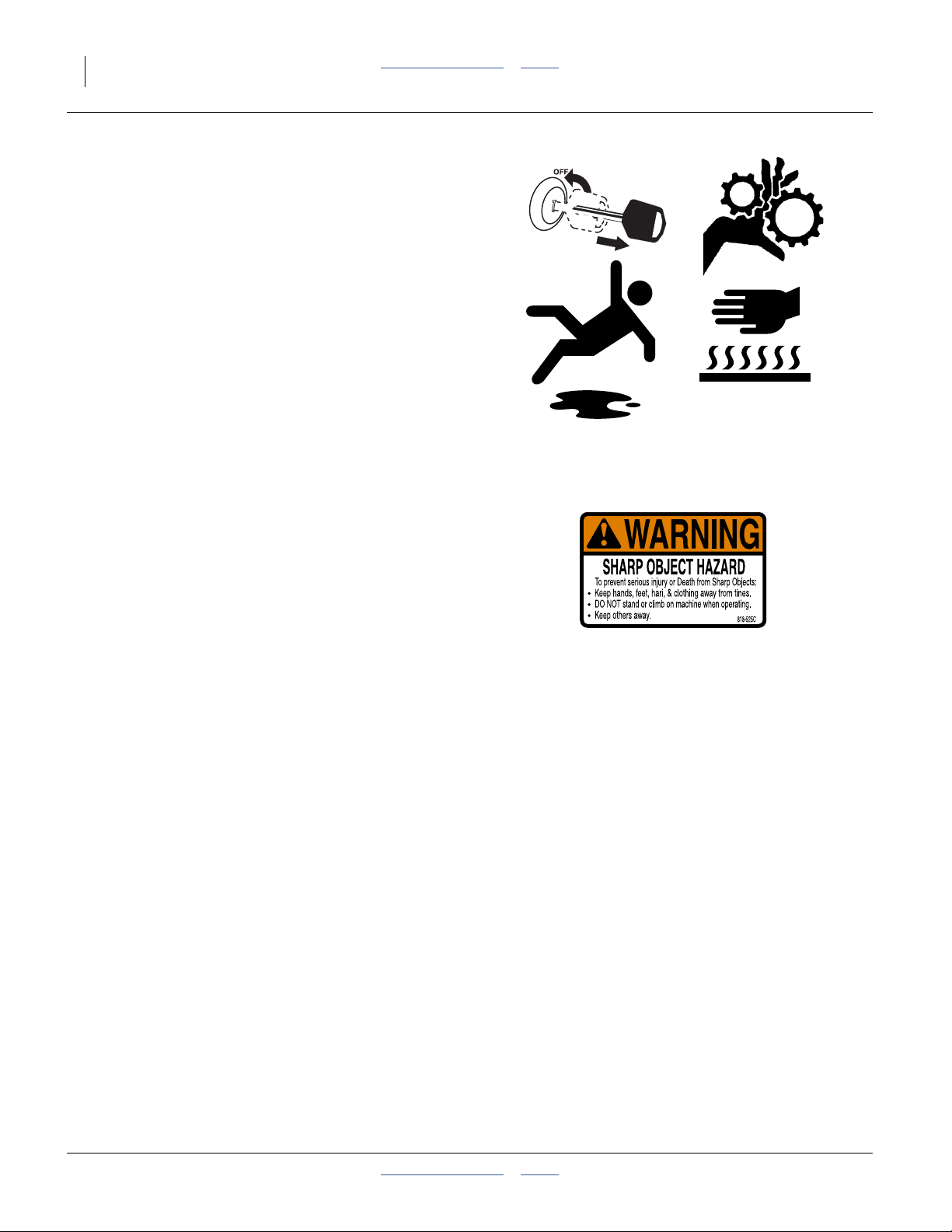

Safety Reflectors and Decals

Your row cleaner comes equipped with safety decals in

place. They were designed to help you safely install,

operate and maintain your row cleaner.

▲ Read and follow decal directions.

▲ Keep all safety decals clean and legible.

▲ Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

▲ When ordering new parts or components, also request

corresponding safety decals.

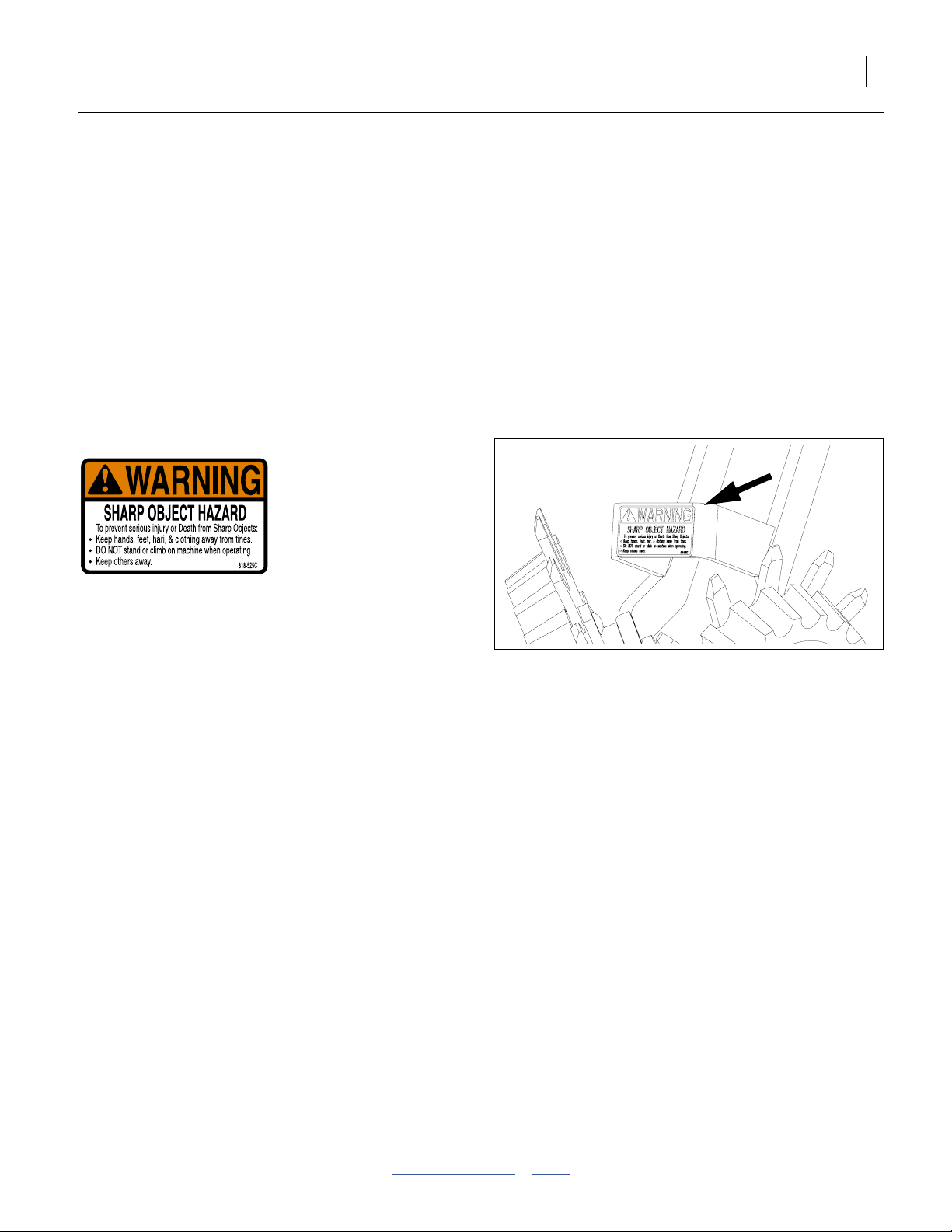

Warning: Sharp Object Hazard

818-525C

top of RC arm gusset;

1 total per RC

To install new decals:

1. Clean the area on which the decal is to be placed.

2. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

22816

2014-02-12 Table of Contents Index 204-085M-A

Page 8

4UMRC Table of Contents Index Great Plains Manufacturing, Inc.

Introduction

Great Plains welcomes you to its growing family of new

product owners. Your Unit-Mount Row Cleaners (UMRC)

have been designed with care and built by skilled

workers using quality materials. Proper setup,

maintenance, and safe operating practices will help you

get years of satisfactory use from these accessories.

Description of Unit

The row accessories covered by this manual are rigid

toothed wheel row cleaners. They are provided as a

pivoting assembly that attaches to either its own mount

(UMRC) or to a unit-mount coulter (UMC-RC). In either

case, the row cleaner assembly is coupled to the

individual row unit (opener body). It follows the terrain

with the row unit, and raises and lowers with the row unit.

Adjustments are provided for setting the amount of

residue clearing desired.

R

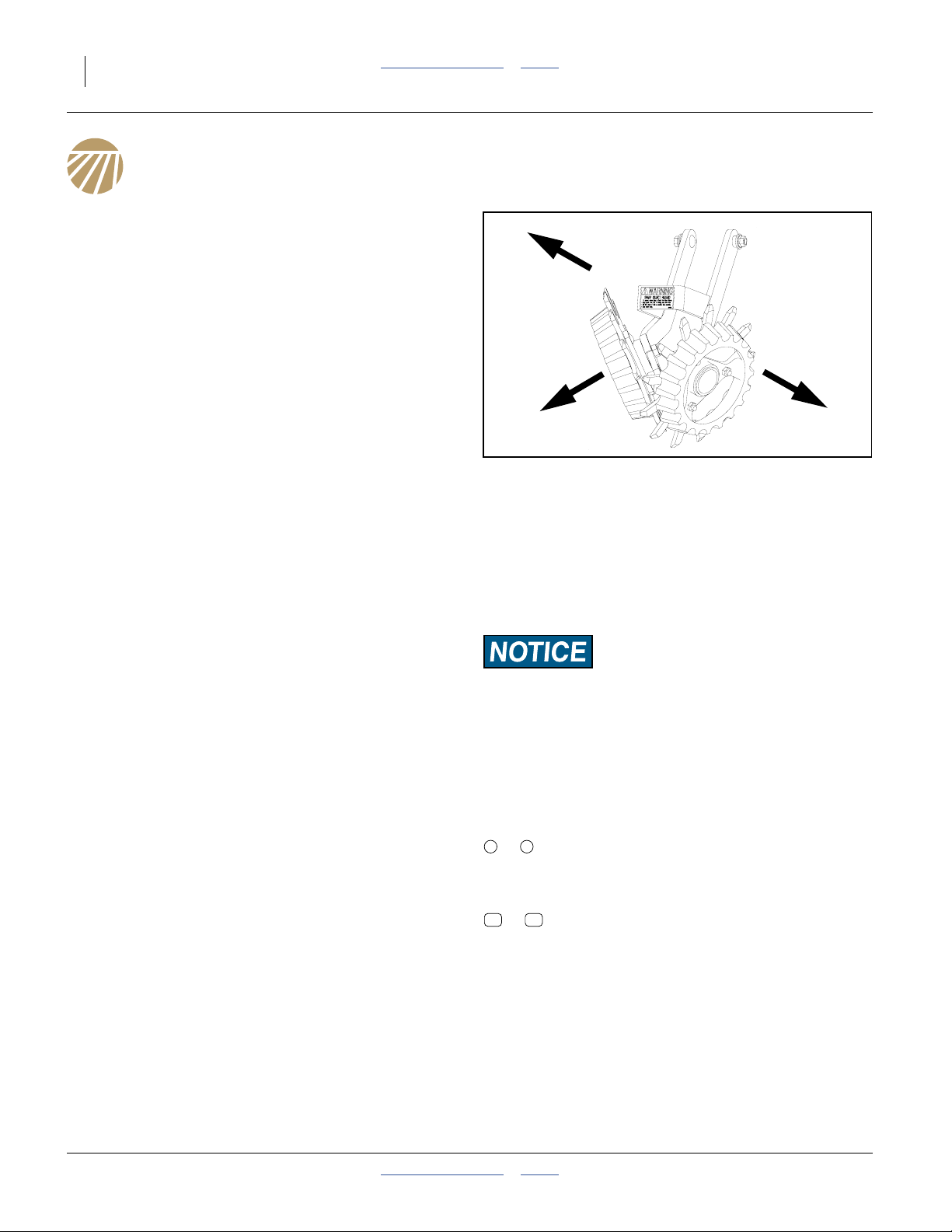

Figure 1:

Row Cleaner Arm

L

22816

Intended Usage

Use row cleaners on supporting implements equipped

with Great Plains 25 Series row units or any implements

with unit-mount coulters (UMCs). Use the row cleaners

for residue management with production-agriculture

crops only. Do not modify row cleaner for use with

attachments other than those approved by Great Plains.

Document Family

204-085M-A Installation, Operation and Parts Manual

(this document)

For routine operation and maintenance, you also need to

have your implement Operator and Parts Manuals.

The information in this manual is current at printing.

Some parts may change to assure top performance.

Supporting Implements for UMRC

Tighter row spacings and twin-row spacings do not allow

dual row cleaners. Some implements may only support

UMRC or UMC-RC only.

The row cleaners may not be compatible with other

planters and drills that have 25 Series row units. In

particular, 3-Point 25 Series drills often have insufficient

forward clearance to permit UMRC or UMC-RC use.

Using This Manual

Definitions

The following terms are used throughout this manual.

Right-hand and left-hand as used in this manual are

determined by facing the direction the machine will travel

while in use unless otherwise stated.

Paragraphs in this format present a crucial point of information

related to the current topic. Read and follow the directions to:

- remain safe,

- avoid serious damage to equipment and

- ensure desired field results.

Note: Paragraphs in this format provide useful

information related to the current topic.

Call-Outs

1 9

to

11 64

to

Check with your Great Plains dealer.

Single-digit callouts identify components in

the currently referenced Figure or Figures.

These numbers may be reused for different

items from page to page.

Two-digit callouts reference new parts from

the new parts lists beginning on page 21.

The descriptions match those on the parts,

cartons, bags or item tags, as well as

descriptions your updated Parts Manual.

This manual familiarizes you with safety, assembly,

operation, adjustments, troubleshooting, and

maintenance. Read this manual and follow the

recommendations to help ensure safe and efficient

operation.

204-085M-A Table of Contents Index 2014-02-12

Page 9

Great Plains Manufacturing, Inc. Table of Contents Index Introduction 5

Kits Covered by this Manual

Individual Row Kits

Part

Number

Single Row UMRC Kits

207-213K DOUBLE ROW CLEANER UNIT

207-215K LH ROW CLEANER UNIT

207-216K RH ROW CLEANER UNIT

Individual UMC-RC Row Cleaner Kits

207-092S SINGLE ARM RC ASM LH

207-093S SINGLE ARM RC ASM RH

207-098S DOUBLE ARM RC ASM

UMRC Update Kit

207-221A UMRC MNT WELDMENT FIELD UPDATE

Description

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. They have trained personnel, repair

parts and equipment specially designed for Great Plains

products.

Your machine’s parts were specially designed and

should only be replaced with Great Plains parts. Always

use the serial and model number when ordering parts

from your Great Plains dealer. The serial-number plate is

located on the front face of the left vertical tube of the

3-point frame.

Record your row cleaner kit model number here for quick

reference:

Model Number:__________________________

Date Purchased: __________________________

Your Great Plains dealer wants you to be satisfied with

your updated machine. If you do not understand any part

of this manual or are not satisfied with the service

received, please take the following actions.

1. Discuss the matter with your dealership service

manager. Make sure they are aware of any problems

so they can assist you.

2. If you are still unsatisfied, seek out the owner or

general manager of the dealership.

For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

785-823-3276

2014-02-12 Table of Contents Index 204-085M-A

Page 10

6UMRC Table of Contents Index Great Plains Manufacturing, Inc.

Assembly Instructions

Before You Start

Most accidents are the result of negligence and

carelessness, usually caused by failure of the operator to

follow simple but necessary safety precautions.

Allow no one to work on or use a row cleaner before

carefully reading this manual.

Sharp Object Hazard:

Row cleaner tines are sharp. The edges of row cleaner wheels

are sharp. UMC blades are sharp. Wear gloves when handling

these parts. Maintain awareness of installed coulters and row

cleaners when working in front of row units.

Perform these steps before installing your row cleaners.

1. Read and understand “Important Safety

Information” starting on page 1.

2. Hitch the implement to a suitable tractor. Refer to the

hitching topic in the Operator Manual.

3. Position the implement in a level, dry, well-lighted

area. Pick a location with a clear surface beneath, so

that any dropped tools or parts can be easily located.

4. Unfold the implement.

5. Raise the row units (or leave them raised).

6. Install any lift locks provided.

Set all hydraulic circuits to neutral.

7. Shut off the tractor. Set the parking brake.

General Assembly Instructions

Start mounting with the left-most row unit of the

implement. Single-arm row cleaners are provisioned as

left and right hand pairs. Start with a left hand row

cleaner, and alternate left-right-left-right across the

implement.

Some fasteners may be loosely assembled. Remove

them before mounting that component. Due to evolving

manufacturing practices, some assemblies may already

be completely pre-assembled. If so, check that fasteners

are tight, and skip the unneeded assembly steps.

Torque values for fasteners are shown on page 20.

Wheel bearings are pre-greased and should not require

additional lubrication until the first service interval.

204-085M-A Table of Contents Index 2014-02-12

Tools Required

• Basic hand tools, including an extension for any socket

or air wrench to be used

• Screw thread adhesive, such as Loctite

Where to Start

UMRC: Unit-Mount Row Cleaner installation

instructions begin on page 7.

UMC-RC: Unit-Mount Coulter Row Cleaner installation

instructions begin on page 10.

Page 11

Great Plains Manufacturing, Inc. Table of Contents Index Assembly Instructions 7

UMRC Installation or Update

For Unit-Mount Row Cleaners (no UMC disk coulters).

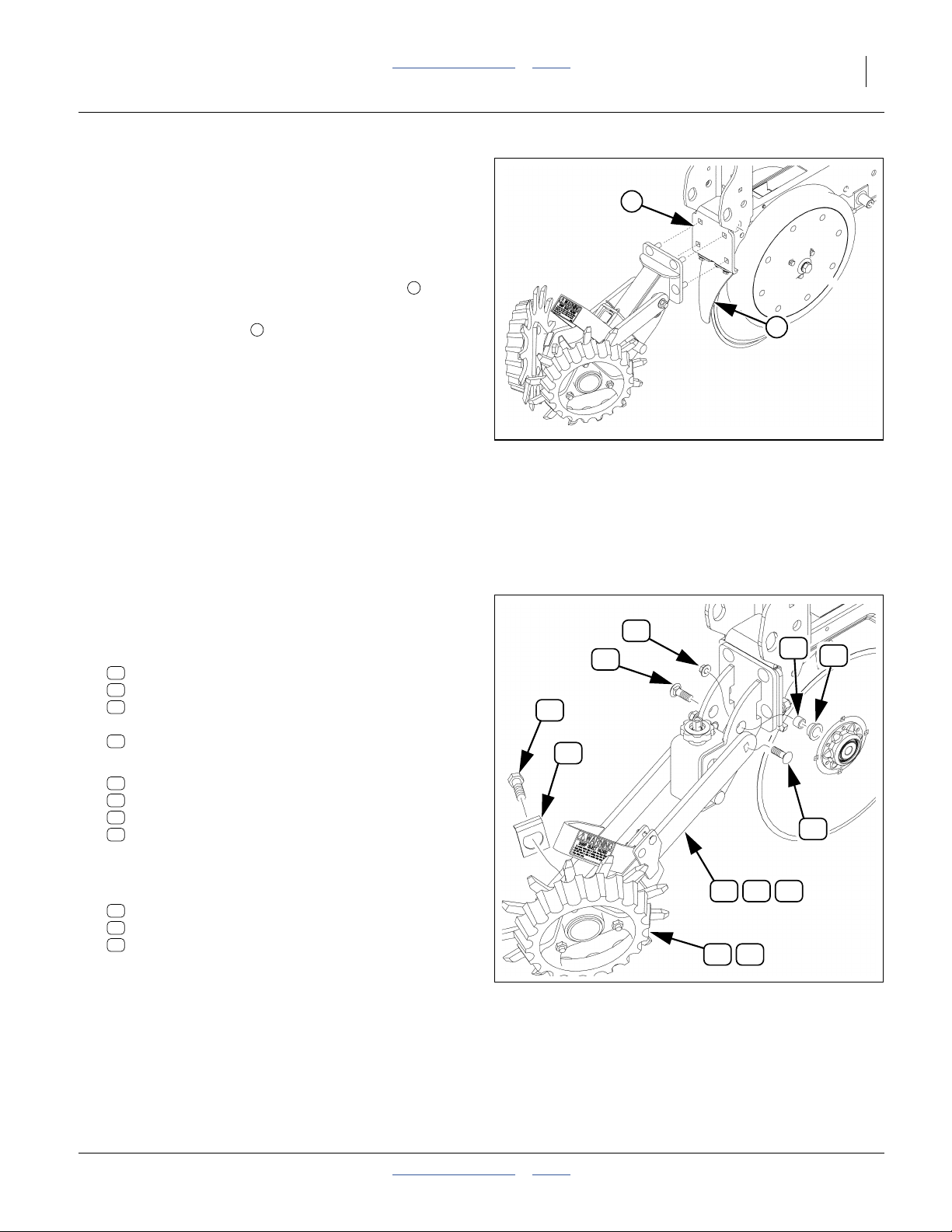

Refer to Figure 2 (which depicts dual RC mounting;

mounting of the single-wheel RCs is identical)

Unit-Mount Row Cleaners (UMRCs) are used only on

25 Series row units which either have no accessories

forward of the openers (other than a disk shield ).

1

In the case of plain 25 Series row unit, the UMRC

mounts on the front face of the row unit shank.

2

Note: 25 Series row units with unit-mount coulters use

different models of row cleaner (UMC-RC), for

which the assembly instructions begin on page 10.

207-221A Update Kit - Prepare Site

If installing an all new row cleaner, and not updating an

existing row cleaner, begin at step 1 on page 8.

Update Kit: Remove Arms

For safety and convenience, remove the old wheel, then

the old arm, before removing the old mount. Some parts

are re-used.

Refer to Figure 3

A. Remove and save one or both wheels:

51

802-228C HHCS 5/8-11X1 1/2 GR5 NYL

47

828-057C RC HUB LOCK

31

207-143V RIGID ROW CLEANER ASM LH

or

38

207-142V RIGID ROW CLEANER ASM RH

B. Remove two sets of:

29

207-067D UMC RC PIVOT TUBE

33

802-331C RHSNB 1/2-13X1 3/4 GR5

21

803-169C NUT HEX FLG. LOCK 1/2-13 PLT.

36

817-615C RC ARM PIVOT BUSHING

These parts are not re-used. They are replaced by a

single new bolt and nut.

C. Remove and save the arm, which is one of:

30

207-094H SINGLE ARM RC WLD LH (odd rows)

39

207-095H SINGLE ARM RC WLD RH (even rows)

40

207-099H DOUBLE ARM RC WLD

If your left-right arm installation is not standard

(left-most row is a left arm, then alternating

right-to-left), note from which row each arm was

removed.

Note: Wheelsare also handed (left or right). Keep left and

right wheels in separate collection areas.

, and

51

47

2

Figure 2:

UMRC Shank Mounting

21

33

30 39 40

31 38

Figure 3:

Remove Old Arm

1

27310

29

36

33

27348

2014-02-12 Table of Contents Index 204-085M-A

Page 12

8UMRC Table of Contents Index Great Plains Manufacturing, Inc.

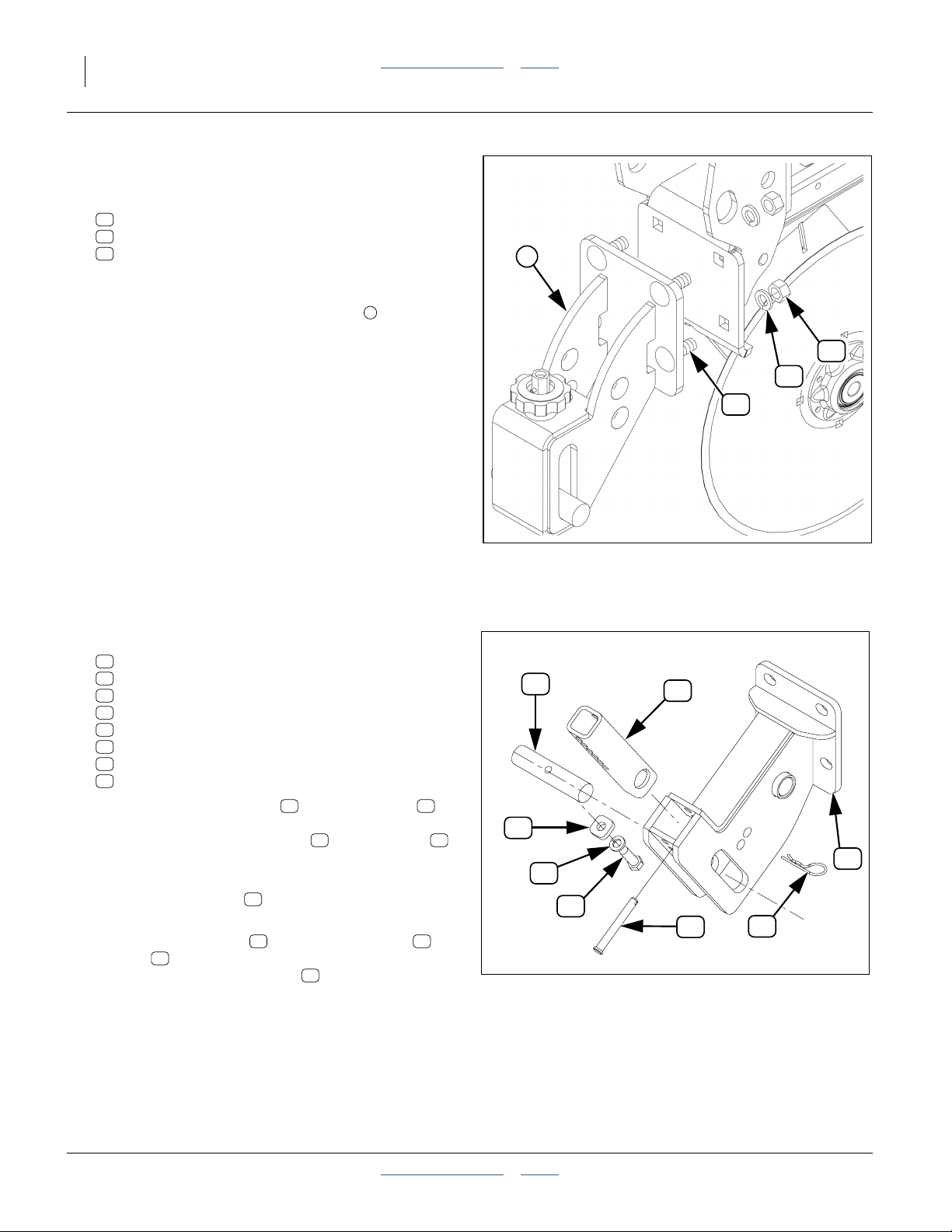

Update Kit: Remove Mount

Refer to Figure 4

D. Remove four sets of:

17

802-106C RHSNB 1/2-13X1 1/2 GR5

23

804-015C WASHER LOCK SPRING 1/2 PLT

20

803-020C NUT HEX 1/2-13 PLT

1

Although identical to new parts in the kit, these

fasteners are not re-used.

E. Remove the old knob-adjust weldment . The

1

weldment, and all parts still installed in it, are not

re-used.

20

23

17

Install UMRC Adjuster Parts

Refer to Figure 5

1. Select one each:

11

207-072D UMRC MOUNT ROUND TUBE

13

207-107D UMRC ADJUSTMENT TUBE

14

207-108D SPACER

15

207-214H UMRC MOUNT WELD

19

802-673C HHCS 7/16-14X1 1/4 GR5 PLT

22

804-014C WASHER LOCK 7/16 PLT

24

805-031C PIN HAIR COTTER .092 WIRE

25

805-385C PIN CLEVIS 3/8 X 3 PLT

2. Insert the adjustment tube in the weldment

with the large holes facing the slots in the weldment.

Hold in place with the clevis pin and cotter pin .

Pin the tube at the highest position that has the large

tube hole fully visible in the slots.

3. Insert the round tube through both the weldment

and the adjustment tube.

4. Place the lock washer and then the spacer on

the bolt . Apply thread adhesive to the threads,

19

and secure bolt in round tube .

13 15

25 24

11

22 14

11

14

11

22

Figure 4:

Remove Old Mount

19

Figure 5:

UMRC Adjuster Parts

13

25

27349

15

24

27318

204-085M-A Table of Contents Index 2014-02-12

Page 13

Great Plains Manufacturing, Inc. Table of Contents Index Assembly Instructions 9

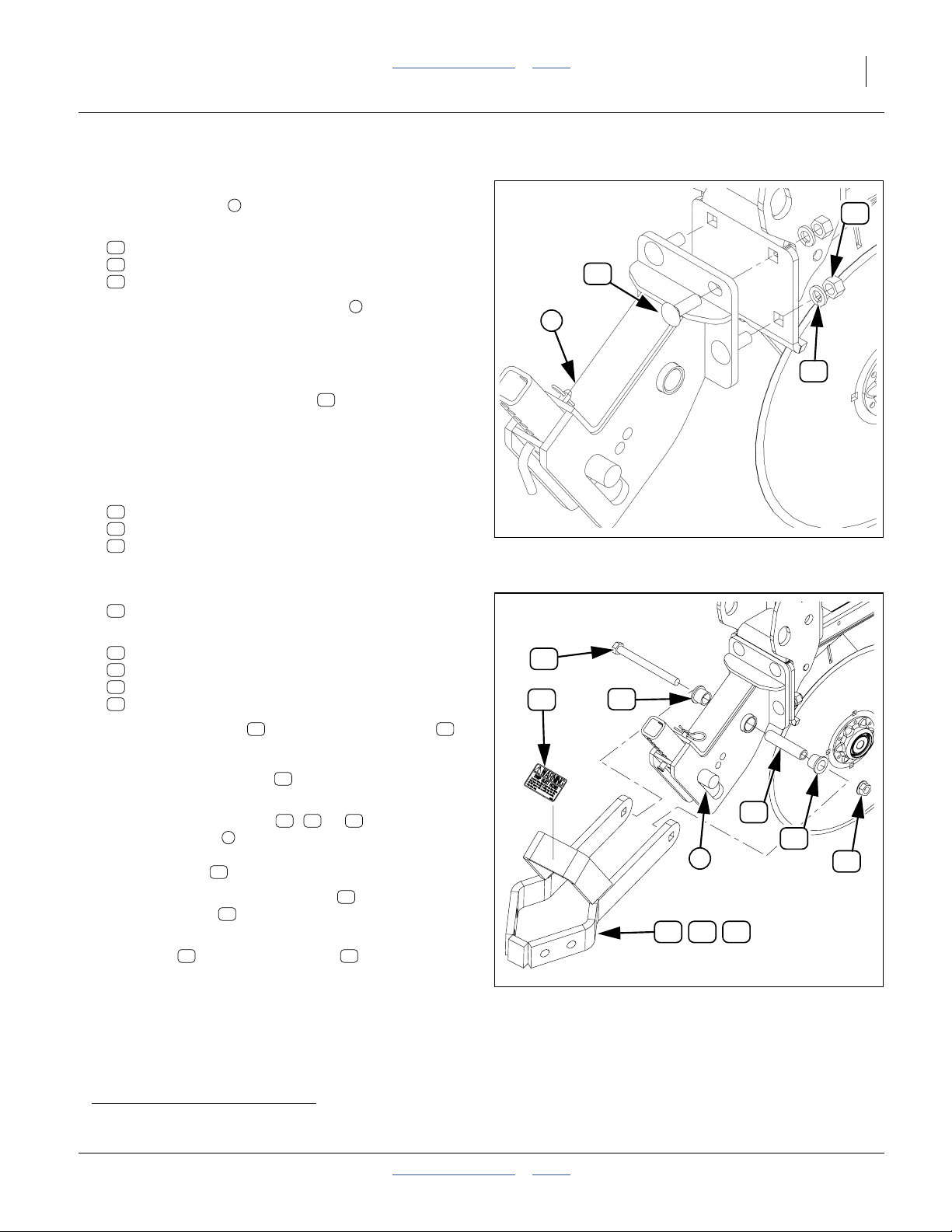

Install UMRC Mount Weldment

Refer to Figure 6 (which depicts a shank mounting)

5. Select the mount partially assembled above.

1

20

6. Select four sets of:

17

802-106C RHSNB 1/2-13X1 1/2 GR5

23

804-015C WASHER LOCK SPRING 1/2 PLT

20

803-020C NUT HEX 1/2-13 PLT

7. Attach the UMRC mount weldment to the row unit

1

shank face using the four sets of fasteners. Loosely

17

1

tighten fasteners, as the alignment of the complete

unit may require adjustment before final tightening.

Note: Depending on tools available, it may be more

convenient to insert the bolt from behind row

17

23

face, and install the lock washers and nuts in front.

Install UMRC Cleaner Arm

Refer to Figure 7 (which depicts a dual RC arm)

8. Select one of the following, depending on kits:

30

207-094H SINGLE ARM RC WLD LH (odd rows)

39

207-095H SINGLE ARM RC WLD RH (even rows)

40

207-099H DOUBLE ARM RC WLD

Figure 6:

UMRC Weldment Mounting

27314

9. Select two:

26

817-084C PARALLEL ARM PIVOT BUSHING

10. Select one each:

12

207-106D ROW CLEANER PIVOT PIPE

37

818-525C DECAL SHARP OBJECT WARNING

18

802-046C HHCS 1/2-13X5 1/2 GR5

20

803-020C NUT HEX 1/2-13 PLT

11. Insert the pivot pipe in one end of a bushing .

12 26

12. Insert these in the pivot holea, as shown in the figure.

13. Place the other bushing on the other end of the

26

tube.

14. With the arm weldment ( , or ) above the

adjustment tube , align the end holes of the arm

2

30 39 40

with the bushing assembly, and temporarily hold in

place with bolt .

15. Apply thread adhesive to the bolt .

Secure with nut .

18

18

20

16. Clean and dry the surface of the gusset on the arm

weldment and apply the decal .

40 37

17. Repeat UMRC step 1 through step 16 for all rows.

Skip to “Install Cleaner Wheel Assemblies” on

page 11.

18

37

26

2

30

39 40

Figure 7:

UMRC Arm Mounting

12

26

20

27315

a. 2013 and earlier weldments may have two pivot holes. Only the upper hole is used.

2014-02-12 Table of Contents Index 204-085M-A

Page 14

10 UMRC Table of Contents Index Great Plains Manufacturing, Inc.

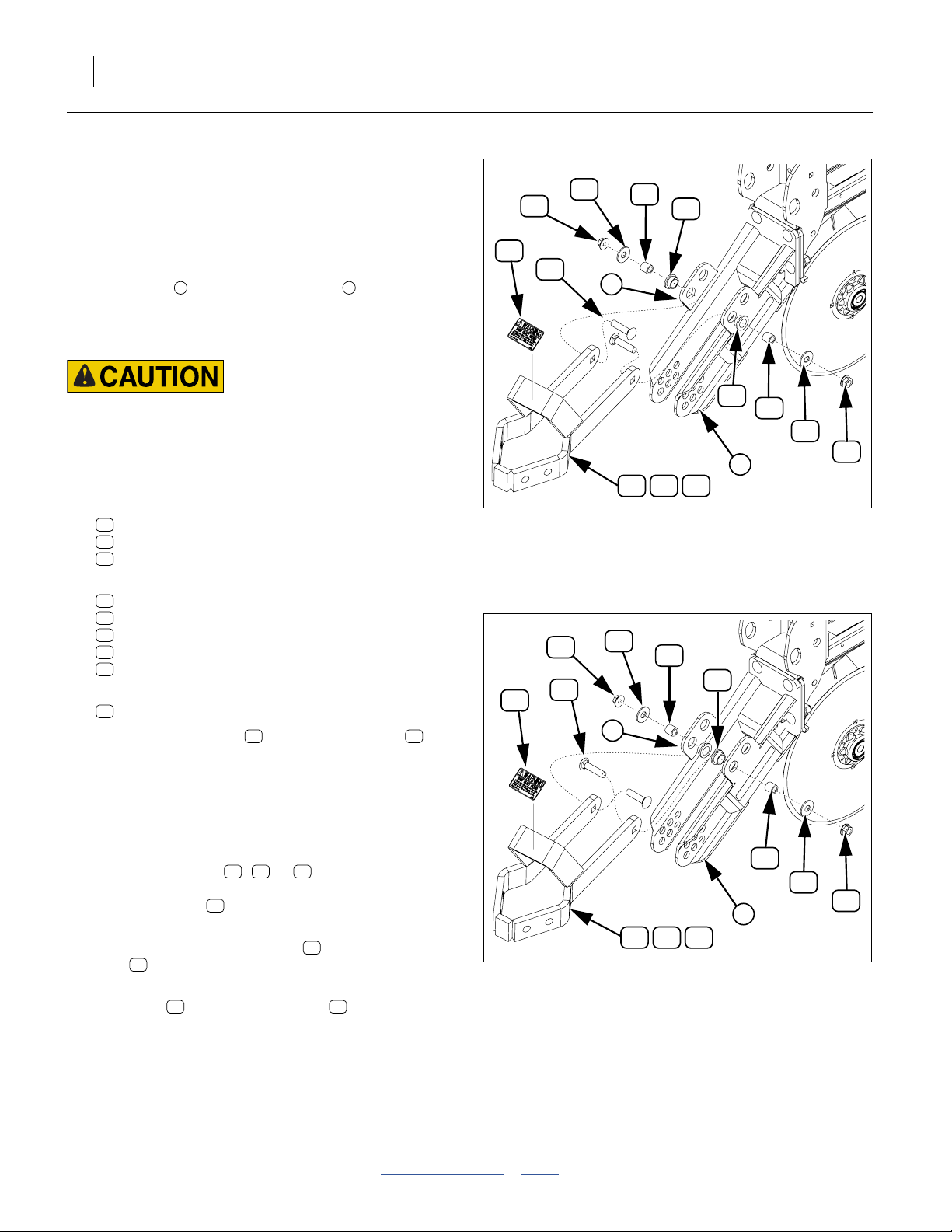

Install UMC-RC Cleaner Arms

For Unit-Mount Coulter - Row Cleaners (disk coulters

present).

Refer to Figure 8 or Figure 9

(which depicts a shank mounted UMC and a dual RC arm).

UMC-RC kits do not include a mount weldment, as they

rely on mounts on the UMC brackets . If the UMCs

are not yet on the implement, install them before

installing the row cleaners, but do not install the coulter

blades until step 9 below.

Sharp Object Hazards:

If the UMC blades are already installed, exercise extra care

while installing the row cleaners.

The UMC itself is mounted directly on the row unit shank.

Refer to Figure 7 (which depicts a shank mounting)

1. Select one of the following, depending on kits:

30

207-094H SINGLE ARM RC WLD LH (odd rows)

39

207-095H SINGLE ARM RC WLD RH (even rows)

40

207-099H DOUBLE ARM RC WLD

2. Select two each:

29

207-067D UMC RC PIVOT TUBE

33

802-331C RHSNB 1/2-13X1 3/4 GR5

21

803-169C NUT HEX FLG. LOCK 1/2-13 PLT.

34

804-017C WASHER FLAT 1/2 USS PLT

36

817-615C RC ARM PIVOT BUSHING

3. Select one:

37

818-525C DECAL SHARP OBJECT WARNING

4. Insert the pivot tubes inside the bushings .

Insert these two assemblies in the UMC mount

holes, from the outside (preferred placement,

Figure 8). If clearance difficulties are encountered,

use the alternate placement in Figure 9.

5. Insert these in the lower/forward holes (for a 15 inch

coulter blade, upper/rear holes for a 14 inch blade).

6. Align the RC arm ( , or ) in between the

holes with the new bushing assemblies, and hold in

place with bolts .

7. Snug square shanks of bolts in arm holes, and

secure bolts with flat washers and flanged lock

nuts .

8. Clean and dry the surface of the gusset on the arm

weldment and apply the decal .

9. If a coulter is also being installed, mount the blade.

10. Repeat UMC-RC step 1 through step 8 for all rows.

1 2

29 36

30 39 40

33

34

21

40 37

37

37

21

34

29

36

33

1

30 39 40

Figure 8:

UMC-RC Arm Mounting

Preferred Bushing Placement

21

34

29

33

1

30 39 40

Figure 9:

UMC-RC Arm Mounting

Alternate Bushing Placement

36

36

29

34

21

2

27316

29

34

21

2

27491

204-085M-A Table of Contents Index 2014-02-12

Page 15

Great Plains Manufacturing, Inc. Table of Contents Index Assembly Instructions 11

Install Cleaner Wheel Assemblies

Wheel Identification

Refer to Figure 10 (which depicts a Left wheel )

Row cleaner wheels are pre-assembled. Each assembly

is intended for either Left or a Right mounting.

38

207-142V RIGID ROW CLEANER ASM RH

31

207-143V RIGID ROW CLEANER ASM LH

If any identifying tags or packaging are separated from a

wheel, you can identify the wheel type by a part number

stamped in spoked wheel face. Left and Right wheels

have part numbers ending in “L” and “R”, respectively.

The first wheel to be mounted is a Left wheel. Whether

single- or dual-arm, the next wheel is a Right, and they

alternate Left-Right across the implement.

Field Results Risk:

Be sure to mount Left wheels on Left arms or on the left side of

dual arms, and vice-versa for Right. Unsatisfactory row

cleaning and premature cleaner wear may otherwise result.

31

Figure 10:

Wheel Identification

27317

Wheel Placement

Refer to Figure 11 (which depicts a Left single-arm RC)

Each arm (and each side of a dual arm) has two

mounting holes for cleaner wheels. Which hole(s) to use

is dependent on your field conditions and field

experience.

Review the topic “Wheel Placement” on page 14, and

make a determination as to which hole(s) to use for the

initial mounting. If no clear choice emerges, use the

forward holes.

Figure 11:

27319

Wheel Placement Choice

2014-02-12 Table of Contents Index 204-085M-A

Page 16

12 UMRC Table of Contents Index Great Plains Manufacturing, Inc.

Mount a Left Wheel

Refer to Figure 12 (which depicts mounting the wheel

assembly in the aft arm hole of a single arm; left side

51

dual-wheel mounting is identical)

11. Select one:

31

207-143V RIGID ROW CLEANER ASM LH

12. Partially disassemble it (some parts may be attached

by cable ties), freeing the:

47

828-057C RC HUB LOCK

51

802-228C HHCS 5/8-11X1 1/2 GR5 NYL

13. Insert the bolt through the selected arm hole from

inside the arm . If a

52

804-195C WASHER FLAT 1.31ODX.65IDX.188T

51

1

is present, it is not used.

14. Place the hub lock over the bolt threads from

47

47

1

2

outside the arm, with the bent edge of the lock up

and toward the inside of the arm. This lock prevents

the back face of the hub from rotating while you

secure the bolt in the next step.

15. Place the cleaner wheel assembly on the bolt,

2

and screw the bolt into the wheel hub. Use the lock,

up against the hub, to prevent hub rotation. Torque

bolt to specifications once hub and lock are fully

seated.

Figure 12:

Left RC Wheel Install

27320

Mount a Right Wheel

Refer to Figure 13 (which depicts mounting the wheel

assembly in the aft arm hole of a single arm; right-side dual

mounting is identical)

16. Select one:

38

207-142V RIGID ROW CLEANER ASM RH

17. Partially disassemble it (some parts may be attached

by cable ties), freeing the:

47

828-057C RC HUB LOCK

51

802-228C HHCS 5/8-11X1 1/2 GR5 NYL

18. Insert the bolt through the selected arm hole from

inside the arm . If a

52

804-195C WASHER FLAT 1.31ODX.65IDX.188T

51

1

is present, it is not used.

19. Place the hub lock over the bolt threads from

47

outside the arm, with the bent edge of the lock up

and toward the inside of the arm. This lock prevents

the back face of the hub from rotating while you

secure the bolt in the next step.

20. Place the cleaner wheel assembly on the bolt,

2

and screw the bolt into the wheel hub. Use the lock,

up against the hub, to prevent hub rotation. Torque

bolt to specifications once hub and lock are fully

seated.

3

Figure 13:

Right RC Wheel Install

51

47

4

27320

204-085M-A Table of Contents Index 2014-02-12

Page 17

Great Plains Manufacturing, Inc. Table of Contents Index Assembly Instructions 13

Install Down Stop (UMC-RC Only)

If you have installed UMRCs, the adjuster hardware is

already installed. Skip this section and make final

adjustments per the instructions in the next section.

The height adjustment for UMC-RC units is a sliding

stop.

21. Select one:

41

207-148H UM ROW CLEAN DOWN STOP WLDM

22. Set two sets of:

42

802-270C RHSNB 5/16-18X1 1/2 GR5

43

803-008C NUT HEX 5/16-18 PLT

44

804-009C WASHER LOCK SPRING 5/16 PLT

45

804-036C WASHER FLAT 5/16 SAE PLT

Note: On single-wheel arms, the down stop mounts on

the side of the arm with the wheel. On dual-wheel

arms, the down stop may be mounted on either

side, and you may want to select the location on a

per-row basis, for ease of access for adjustments.

23. Swing the cleaner arm up until the tines are well

above the height of the bottom edge of the row unit

opener disks. Support the arms at this height.

24. From underneath the arm , orient the tip end of the

down-stop forward (longer bolt slot aft), and slide

41

1

the down stop up onto the arm. Temporarily secure

with one or two bolts .

42

42

41

45

Figure 14:

Right RC Down-Stop

44

1

43

27321

Insert the bolts from the inside of the arm. Placing

the threads outside the arm minimizes collection of

residue during operations.

25. Place a flat washer , and then a lock washer

onto each bolt, and loosely add a nut .

45 44

43

26. If you know the initial height at which you desire to

operate the cleaner (from the next section), set the

cleaner arm at that height and support it there.

27. Slide the adjuster back until it contacts the coulter

bracket. Secure the nuts. Remove the support

holding up the arm.

2014-02-12 Table of Contents Index 204-085M-A

Page 18

14 UMRC Table of Contents Index Great Plains Manufacturing, Inc.

Adjustment and Operation

Wheel Placement

Cleaner arms have two alternate mounting holes for

cleaner wheels. Which hole to use depends on your field

conditions, experience and preference. Great Plains

suggests starting with the “more aggressive” positions.

Too aggressive row cleaner use can remove treated soil

from the seed furrow area, reducing effectiveness of

treatments.

Make the placement choice prior to setting row cleaner

depth, as moving the wheel position changes the depth.

When changing placement, be sure to re-adjust the

depth.

Dual Wheel Placement

Offset Dual Wheel

Refer to Figure 15

Start with this “more aggressive” configuration. Mounting

one wheel forward and one wheel retracted allows the

wheels to rotate independently while still keeping one

close to center-line.

It is not possible to set both tines to the same depth in

this configuration. Adjust row cleaner height based on

the tines closer to row unit center-line.

Retracted Dual Wheel

Refer to Figure 16

This setting is the least aggressive. If clogging occurs

with offset, try retracted.

Retracted may also be necessary to shorten the overall

length of the row cleaner, and provided greater clearance

from leading equipment or accessories.

Intersected Dual Wheel

Not Recommended

Refer to Figure 17

In this configuration, the disk tines mesh. This is an

extremely aggressive placement, and is not

recommended by Great Plains, as it causes excess tine

wear and is prone to clogging and rotation stoppages.

Figure 15:

Dual Wheel Offset

Figure 16:

Dual Wheel Retracted

27340

27340

Figure 17:

Dual Wheel Intersected

204-085M-A Table of Contents Index 2014-02-12

27340

Page 19

Great Plains Manufacturing, Inc. Table of Contents Index Adjustment and Operation 15

Single Wheel Placement

Single Wheel Forward

Refer to Figure 18

This is the most aggressive placement, putting the disk

closest to row unit centerline, and is suggested for no-till

conditions.

Single Wheel Retracted

Refer to Figure 19

This is a less aggressive placement, and may be

preferred for tilled conditions.

Figure 18:

Single Wheel Forward

Figure 19:

Single Wheel Retracted

27339

27339

2014-02-12 Table of Contents Index 204-085M-A

Page 20

16 UMRC Table of Contents Index Great Plains Manufacturing, Inc.

Row Cleaner Depth

Make adjustments to wheel placement (page 14) before

setting row cleaner depth. Changing placement changes

depth. Make any planned changes to opener disk height

(T-handle) before adjusting row cleaner.

Sharp Object Hazards:

Be careful when working around row cleaners. Tines and disk

corners are sharp. Coulter blades present are sharp. Use a

jack or block to support the tines while setting the adjuster.

Selecting Depth

Refer to Figure 20 (which depicts a UMC-RC)

Set the depth so that the row cleaner tines are at or

slightly above the soil line.

Monitor your results, and adjust the height as needed to

clear residue but not overly disturb soil (or trench).

Row Cleaner Lock-Up

To prevent a row cleaner from operating at all, set the

height to maximum.

Figure 20:

Row Cleaner Depth

27341

Adjusting UMRC Depth

Equipment Damage Risk:

For planter model YP825AR, on the row unit immediately left

of the center pivot, do use the top two holes of the vertical

tube. If those holes are used, the row cleaner can contact the

center pivot.

Refer to Figure 21

1. Remove the bent pin from the adjustment tube .

2. Raise the row cleaner arm to slightly higher than

desired operating height and support it at this height.

3. Slide the tube up until the round cross-tube

contacts the arm.

4. Re-insert the bent pin in whichever hole pair aligns.

Secure with cotter pin. The minimum height

increment at the tines is about3⁄8inch (19 mm).

5. Relax the cleaner arm on the cross-tube and check

height relative to opener disks.

1 2

3

2

1

Figure 21:

UMRC Height Adjust

3

27308

204-085M-A Table of Contents Index 2014-02-12

Page 21

Great Plains Manufacturing, Inc. Table of Contents Index Adjustment and Operation 17

Adjusting UMC-RC Depth

Refer to Figure 22

1. Raise the cleaner arm slightly. Loosen the nuts on

the adjuster stop . Slide the stop forward.

2. Raise the row cleaner arm to slightly higher than

desired operating height and support it at this height.

3. Slide the adjuster stop up until it contacts the coulter

bracket. Tighten the nuts.

4. Relax the cleaner arm on the cross-tube and check

height relative to opener disks.

1

1

Figure 22:

UMC-RC Height Adjust

27341

2014-02-12 Table of Contents Index 204-085M-A

Page 22

18 UMRC Table of Contents Index Great Plains Manufacturing, Inc.

Troubleshooting

Problem Likely Cause Solutions

Too Much Residue at

Openers

Cleaner Wheels Do Not

Turn

Tines Clogging With

Residue

Cleaners Lifting Off Stops

Cleaners Cutting Deep

Trench

Cleaners set too high Lower cleaners.

Cleaner wheels not set

aggressively.

Cleaners set too high Lower cleaners.

Excessive residue clogging

wheels

Bearings failed Re-pack or replace.

Excessive residue Use less aggressive placement and depth. if

Cleaning too deep Raise cleaner height.

Conditions may be too wet Wait for dryer weather or don’t use row

Depth too great for conditions Raise cleaner height.

Row unit down-force too high Reduce down force or raise cleaners.

Depth too deep Raise cleaner height.

Move single wheel forward.

Change to less aggressive wheel placement

and/or reduce depth.

using dual wheels, change placement to less

aggressive.

cleaners.

204-085M-A Table of Contents Index 2014-02-12

Page 23

Great Plains Manufacturing, Inc. Table of Contents Index 19

Maintenance and Lubrication

Maintenance

Proper servicing and adjustment is the key to long life for

any implement. With careful and systematic inspection,

costly maintenance, repairs and down time can be

avoided.

Crushing and High Pressure Fluid Hazard:

Before working on, servicing or making adjustments on

implement, raise it, install lift locks, and always disengage

power, shut off tractor engine, make sure all moving parts have

stopped, and all pressure in the system is relieved.

Lubrication

Multi-purpose

spray lubricant

Row Cleaner Hub

Multi-purpose

grease lubricant

Multi-purpose

oil lubricant

Row Cleaner Maintenance

1. After several hours of operation, check row cleaners

for loose bolts, and loose or missing pins.

Check wheels for free rotation.

2. At the end of the season, lubricate per the

instructions below.

Intervals

(operating hours)

Inspection

34208

50

at which service

is required

Seasonal

1 zerk each cleaner tine wheel; 1 or 2 per row

Type of Lubrication: Grease

Quantity: Until resistance is felt

Do not apply excessive pumping pressure. There is

some risk of damaging the seals.

27342

2014-02-12 Table of Contents Index 204-085M-A

Page 24

20 UMRC Table of Contents Index Great Plains Manufacturing, Inc.

Appendix

Torque Values

Bolt

Size

in-tpi

1

⁄4-20

1

⁄4-28

5

⁄16-18

5

⁄16-24

3

⁄8-16

3

⁄8-24

7

⁄16-14

7

⁄16-20

1

⁄2-13

1

⁄2-20

9

⁄16-12

9

⁄16-18

5

⁄8-11

5

⁄8-18

3

⁄4-10

3

⁄4-16

7

⁄8-9

7

⁄8-14

1-8

1-12

1

⁄8-7

1

1

1

⁄8-12

1

1

⁄4-7

1

1

⁄4-12

3

⁄8-6

1

3

1

⁄8-12

1

1

⁄2-6

1

1

⁄2-12

Bolt Head Identification

Grade 2 Grade 5 Grade 8 Class 5.8 Class 8.8 Class 10.9

a

b

N-m

7.4 11 16

8.5 13 18

15 24 33

17 26 37

27 42 59

31 47 67

43 67 95

49 75 105

66 105 145

75 115 165

95 150 210

105 165 235

130 205 285

150 230 325

235 360 510

260 405 570

225 585 820

250 640 905

340 875 1230

370 955 1350

480 1080 1750

540 1210 1960

680 1520 2460

750 1680 2730

890 1990 3230

1010 2270 3680

1180 2640 4290

1330 2970 4820

d

ft-lb

N-m N-m

5.6 8 12

61014 5 811

11 17 25 12 19 27

13 19 27 13 21 29

20 31 44 24 39 53

22 35 49 29 45 62

32 49 70 42 67 93

36 55 78 44 70 97

49 76 105 66 77 105

55 85 120 68 105 150

70 110 155 73 115 160

79 120 170 105 165 230

97 150 210 115 180 245

110 170 240 145 230 300

170 265 375 165 260 355

190 295 420 205 325 450

165 430 605 230 480 665

185 475 670 355 560 780

250 645 910 390 610 845

275 705 995 705 1120 1550

355 795 1290 785 1240 1710

395 890 1440 1270 1950 2700

500 1120 1820 1380 2190 3220

555 1240 2010

655 1470 2380

745 1670 2710

870 1950 3160

980 2190 3560

Bolt Head Identification

Bolt

Size

ft-lb ft-lb ft-lb ft-lb ft-lb

mm x pitch

M 5 X 0.8

M 6 X 1

M 8 X 1.25

M 8 X 1

M10 X 1.5

M10 X 0.75

M12 X 1.75

M12 X 1.5

M12 X 1

M14 X 2

M14 X 1.5

M16 X 2

M16 X 1.5

M18 X 2.5

M18 X 1.5

M20 X 2.5

M20 X 1.5

M24 X 3

M24 X 2

M30 X 3.5

M30 X 2

M36 X 3.5

M36 X 2

a. in-tpi = nominal thread diameter in inches-threads per inch

b. N· m = newton-meters

c. mm x pitch = nominal thread diameter in mm x thread pitch

d. ft-lb = foot pounds

c

5.8 8.8 10.9

N-m N-m N-m

357

71115

17 26 36

18 28 39

33 52 72

39 61 85

58 91 125

60 95 130

90 105 145

92 145 200

99 155 215

145 225 315

155 240 335

195 310 405

220 350 485

280 440 610

310 650 900

480 760 1050

525 830 1150

960 1510 2100

1060 1680 2320

1730 2650 3660

1880 2960 4100

946

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

204-085M-A Table of Contents Index 2014-02-12

25199m

25199

Page 25

Great Plains Manufacturing, Inc. Table of Contents Index Appendix 21

Parts Lists

207-213K Dual UMRC Kit

207-213K DOUBLE ROW CLEANER UNIT

17

15

16

18

*

21

11

22

25

13

27336

Callout Part Number Quantity Part Description

11

12

13

14

15

a

16

17

18

19

20

21

22

23

24

25

26

a. This part of 207-213K is a sub-assembly containing additional parts. See following tables.

207-072D

207-106D

207-107D

207-108D

207-214H

207-217S

802-106C

802-046C

802-673C

803-020C

803-169C

804-014C

804-015C

805-031C

805-385C

817-084C

1

1

1

1

1

1

4

1

1

4

1

1

4

1

1

2

UMRC MOUNT ROUND TUBE

ROW CLEANER PIVOT PIPE

UMRC ADJUSTMENT TUBE

SPACER

UMRC MOUNT WELD

DOUBLE ARM ROW CLEANER ASM

RHSNB 1/2-13X1 1/2 GR5

HHCS 1/2-13X5 1/2 GR5

HHCS 7/16-14X1 1/4 GR5 PLT

NUT HEX 1/2-13 PLT

NUT HEX FLG. LOCK 1/2-13 PLT.

WASHER LOCK 7/16 PLT

WASHER LOCK SPRING 1/2 PLT

PIN HAIR COTTER .092 WIRE

PIN CLEVIS 3/8 X 3 PLT

PARALLEL ARM PIVOT BUSHING

20

23

12

26

24

14

19

2014-02-12 Table of Contents Index 204-085M-A

Page 26

22 UMRC Table of Contents Index Great Plains Manufacturing, Inc.

207-215K Single LH UMRC Kit

207-215K LH ROW CLEANER UNIT

18

*

27

27337

21

25

15

17 20

23

12

24

14

11

22

19

13

26

Callout Part Number Quantity Part Description

11

12

13

14

15

a

27

17

18

19

20

21

22

23

24

25

26

a. This part is a sub-assembly containing additional parts. See following tables.

207-072D

207-106D

207-107D

207-108D

207-214H

207-218S

802-106C

802-046C

802-673C

803-020C

803-169C

804-014C

804-015C

805-031C

805-385C

817-084C

1

1

1

1

1

1

4

1

1

4

1

1

4

1

1

2

UMRC MOUNT ROUND TUBE

ROW CLEANER PIVOT PIPE

UMRC ADJUSTMENT TUBE

SPACER

UMRC MOUNT WELD

LH ROW CLEANER ARM ASM

RHSNB 1/2-13X1 1/2 GR5

HHCS 1/2-13X5 1/2 GR5

HHCS 7/16-14X1 1/4 GR5 PLT

NUT HEX 1/2-13 PLT

NUT HEX FLG. LOCK 1/2-13 PLT.

WASHER LOCK 7/16 PLT

WASHER LOCK SPRING 1/2 PLT

PIN HAIR COTTER .092 WIRE

PIN CLEVIS 3/8 X 3 PLT

PARALLEL ARM PIVOT BUSHING

204-085M-A Table of Contents Index 2014-02-12

Page 27

Great Plains Manufacturing, Inc. Table of Contents Index Appendix 23

207-216K Single RH UMRC Kit

207-216K RH ROW CLEANER UNIT

17

18 15

*

28

21

11

14

25

13

27338

Callout Part Number Quantity Part Description

11

12

13

14

15

a

28

17

18

19

20

21

22

23

24

25

26

a. This part is a sub-assembly containing additional parts. See following tables.

207-072D

207-106D

207-107D

207-108D

207-214H

207-219S

802-106C

802-046C

802-673C

803-020C

803-169C

804-014C

804-015C

805-031C

805-385C

817-084C

1

1

1

1

1

1

4

1

1

4

1

1

4

1

1

2

UMRC MOUNT ROUND TUBE

ROW CLEANER PIVOT PIPE

UMRC ADJUSTMENT TUBE

SPACER

UMRC MOUNT WELD

RH ROW CLEANER ARM ASM

RHSNB 1/2-13X1 1/2 GR5

HHCS 1/2-13X5 1/2 GR5

HHCS 7/16-14X1 1/4 GR5 PLT

NUT HEX 1/2-13 PLT

NUT HEX FLG. LOCK 1/2-13 PLT.

WASHER LOCK 7/16 PLT

WASHER LOCK SPRING 1/2 PLT

PIN HAIR COTTER .092 WIRE

PIN CLEVIS 3/8 X 3 PLT

PARALLEL ARM PIVOT BUSHING

20

23

12

26

24

22

19

2014-02-12 Table of Contents Index 204-085M-A

Page 28

24 UMRC Table of Contents Index Great Plains Manufacturing, Inc.

207-092S Single LH UMC-RC Kit

33

*

32

29

37

31

35

*

32

*

32

36

*

32

21

34

*

30

207-092S SINGLE ARM RC ASM LH

Callout Part Number

207-067D

207-094H

207-143V

207-149S

802-331C

803-169C

804-017C

804-029C

817-615C

818-525C

31

32

29

30

a

a

33

21

34

35

36

37

Quantity

31

in Kit

2

2

1

1

2

2

2

2

1

1

*

31

*

Part Description

UMC RC PIVOT TUBE

SINGLE ARM RC WLD LH

RIGID ROW CLEANER ASM LH

UM ROW CLEAN DOWN STOP ASY

RHSNB 1/2-13X1 3/4 GR5

NUT HEX FLG. LOCK 1/2-13 PLT.

WASHER FLAT 1/2 USS PLT

WASHER FLAT 1 SAE

RC ARM PIVOT BUSHING

DECAL SHARP OBJECT WARNING

32

*

27333

* See washer note on page 34.

204-085M-A Table of Contents Index 2014-02-12

Page 29

Great Plains Manufacturing, Inc. Table of Contents Index Appendix 25

207-093S Single RH UMC-RC Kit

33

*

32

21

34

36

32

207-093S SINGLE ARM RC ASM RH

35

32

*

29

37

*

32

*

*

38

*

32

39

*

38

*

38

27334

Callout Part Number

21

29

a

38

a

32

33

34

35

36

37

39

a. This part is a sub-assembly containing additional parts. See following tables.

* See washer note on page 34.

2014-02-12 Table of Contents Index 204-085M-A

803-169C

207-067D

207-142V

207-149S

802-331C

804-017C

804-029C

817-615C

818-525C

207-095H

Quantity

in Kit

2

2

1

1

2

2

2

2

1

1

Part Description

NUT HEX FLG. LOCK 1/2-13 PLT.

UMC RC PIVOT TUBE

RIGID ROW CLEANER ASM RH

UM ROW CLEAN DOWN STOP ASY

RHSNB 1/2-13X1 3/4 GR5

WASHER FLAT 1/2 USS PLT

WASHER FLAT 1 SAE

RC ARM PIVOT BUSHING

DECAL SHARP OBJECT WARNING

SINGLE ARM RC WLD RH

Page 30

26 UMRC Table of Contents Index Great Plains Manufacturing, Inc.

207-098S Dual UMC-RC Kit

29

38

32

37

33

32

*

34

21

*

*

32

32

*

*

31

31

36

*

32

*

*

31

40

207-098S DOUBLE ARM RC ASM

Callout Part Number

21

29

a

38

a

31

a

32

33

34

36

40

37

a. This component of 207-098S is a sub-assembly containing additional parts. See following tables.

* See washer note on page 34.

204-085M-A Table of Contents Index 2014-02-12

803-169C

207-067D

207-142V

207-143V

207-149S

802-331C

804-017C

817-615C

207-099H

818-525C

Quantity

in Kit

2

2

1

1

1

2

2

2

1

1

Part Description

NUT HEX FLG. LOCK 1/2-13 PLT.

UMC RC PIVOT TUBE

RIGID ROW CLEANER ASM RH

RIGID ROW CLEANER ASM LH

UM ROW CLEAN DOWN STOP ASY

RHSNB 1/2-13X1 3/4 GR5

WASHER FLAT 1/2 USS PLT

RC ARM PIVOT BUSHING

DOUBLE ARM RC WLD

DECAL SHARP OBJECT WARNING

27335

Page 31

Great Plains Manufacturing, Inc. Table of Contents Index Appendix 27

207-149S Down Stop

32

43

44

45

41

42

32

Callout Part Number Quantity Part Description

41

42

43

44

45

207-148H

802-270C

803-008C

804-009C

804-036C

1

2

2

2

2

UM ROW CLEAN DOWN STOP WLDM

RHSNB 5/16-18X1 1/2 GR5

NUT HEX 5/16-18 PLT

WASHER LOCK SPRING 5/16 PLT

WASHER FLAT 5/16 SAE PLT

27332

2014-02-12 Table of Contents Index 204-085M-A

Page 32

28 UMRC Table of Contents Index Great Plains Manufacturing, Inc.

207-221A Mount Update Kit

207-221A UMRC MNT WELDMENT FIELD UPDATE

27347

18

21

15

17

20

23

12

26

24

11

22

14

19

13

25

Callout Part Number Quantity Part Description

11

12

13

14

15

17

18

19

20

22

23

24

25

26

204-085M-A Table of Contents Index 2014-02-12

207-072D

207-106D

207-107D

207-108D

207-214H

802-106C

802-046C

802-673C

803-020C

804-014C

804-015C

805-031C

805-385C

817-084C

1

1

1

1

1

4

1

1

4

1

4

1

1

2

UMRC MOUNT ROUND TUBE

ROW CLEANER PIVOT PIPE

UMRC ADJUSTMENT TUBE

SPACER

UMRC MOUNT WELD

RHSNB 1/2-13X1 1/2 GR5

HHCS 1/2-13X5 1/2 GR5

HHCS 7/16-14X1 1/4 GR5 PLT

NUT HEX 1/2-13 PLT

WASHER LOCK 7/16 PLT

WASHER LOCK SPRING 1/2 PLT

PIN HAIR COTTER .092 WIRE

PIN CLEVIS 3/8 X 3 PLT

PARALLEL ARM PIVOT BUSHING

Page 33

Great Plains Manufacturing, Inc. Table of Contents Index Appendix 29

207-217S Dual Arm Assembly

16

40

*

31

*

31

38

37

Callout Part Number Quantity Part Description

a

38

a

31

37

40

a. This component of 207-217S is a sub-assembly containing additional parts. See following tables.

Note: If you obtain a complete replacement hub or wheel

assembly, it may contain a washer (GP 804-195C

or comparable, see page 34). This washer is not

used when these cleaner wheels are installed on

unit-mount arms.

207-142V

207-143V

818-525C

207-099H

1

1

1

1

RIGID ROW CLEANER ASM RH

RIGID ROW CLEANER ASM LH

DECAL SHARP OBJECT WARNING

DOUBLE ARM RC WLD

31

27328

*

2014-02-12 Table of Contents Index 204-085M-A

Page 34

30 UMRC Table of Contents Index Great Plains Manufacturing, Inc.

207-218S Left Arm Assembly

27

37

*

31

30

*

31

*

31

Callout Part Number Quantity Part Description

30

a

31

37

a. This component of 207-218S is a sub-assembly containing additional parts. See following tables.

Note: If you obtain a complete replacement hub or wheel

assembly, it may contain a washer (GP 804-195C

or comparable, see page 34). This washer is not

used when these cleaner wheels are installed on

unit-mount arms.

207-094H

207-143V

818-525C

1

1

1

SINGLE ARM RC WLD LH

RIGID ROW CLEANER ASM LH

DECAL SHARP OBJECT WARNING

27330

204-085M-A Table of Contents Index 2014-02-12

Page 35

Great Plains Manufacturing, Inc. Table of Contents Index Appendix 31

207-219S Right Arm Assembly

28

39

37

38

*

38

*

Callout Part Number Quantity Part Description

39

a

38

37

a. This component of 207-219S is a sub-assembly containing additional parts. See following tables.

Note: If you obtain a complete replacement hub or wheel

assembly, it may contain a washer (GP 804-195C

or comparable, see page 34). This washer is not

used when these cleaner wheels are installed on

unit-mount arms.

207-095H

207-142V

818-525C

1

1

1

SINGLE ARM RC WLD RH

RIGID ROW CLEANER ASM RH

DECAL SHARP OBJECT WARNING

38

*

27329

2014-02-12 Table of Contents Index 204-085M-A

Page 36

32 UMRC Table of Contents Index Great Plains Manufacturing, Inc.

207-142V Right Hand Cleaner Wheel

38

48

47

49

46

Callout Part Number Quantity Part Description

a

46

47

48

49

a. This component of 207-142V is a sub-assembly containing additional parts. See following tables.

815-255C

828-057C

828-059C

828-060C

1

1

1

1

Note: If you obtain a complete replacement hub or wheel

assembly, it may contain a washer (GP 804-195C

or comparable, see page 34). This washer is not

used when these cleaner wheels are installed on

unit-mount arms.

ROW CLEANER HUB ASM

RC HUB LOCK

RIGID 13" ROW CLEANER RH

DEPTH BEND WHEEL

27331

204-085M-A Table of Contents Index 2014-02-12

Page 37

Great Plains Manufacturing, Inc. Table of Contents Index Appendix 33

207-143V Left Hand Cleaner Wheel

31

50

47

46

31

Callout Part Number Quantity Part Description

a

46

47

49

50

a. This component of 207-143V is a sub-assembly containing additional parts. See following tables.

815-255C

828-057C

828-060C

828-058C

1

1

1

1

ROW CLEANER HUB ASM

RC HUB LOCK

DEPTH BEND WHEEL

RIGID 13" ROW CLEANER LH

49

27331

Note: If you obtain a complete replacement hub or wheel

assembly, it may contain a washer (GP 804-195C

or comparable, see page 34). This washer is not

used when these cleaner wheels are installed on

unit-mount arms.

2014-02-12 Table of Contents Index 204-085M-A

Page 38

34 UMRC Table of Contents Index Great Plains Manufacturing, Inc.

815-255C Hub Assembly

46

55

51

52

54

53

27326

Callout Part Number Quantity Part Description

51

52

53

54

a

55

a. This component of 815-255C is a sub-assembly containing replaceable parts. See next table.

802-228C

804-195C

802-787C

803-052C

815-255C_HUB

1

1

3

3

1

Note: If you obtain a complete replacement hub or wheel

assembly, it may contain a washer (GP 804-195C

or comparable). This washer is not used when

these cleaner wheels are installed on unit-mount

arms.

HHCS 5/8-11X1 1/2 GR5 NYL

WASHER FLAT 1.31ODX.65IDX.188T

Not used in Great Plains unit-mount applications.

RHSNB 7/16-14X1 1/2 GR5

NUT HEX WHIZ 7/16-14 PLT

NSO: ROW CLEANER HUB

Not separately orderable as a complete assembly.

Order the parent 815-255C part, or the individual replacement parts of the

815-255C_HUB from the list on page 35.

204-085M-A Table of Contents Index 2014-02-12

Page 39

Great Plains Manufacturing, Inc. Table of Contents Index Appendix 35

815-255C_HUB Row Cleaner Hub

55

61

62

59

59

57

60

64

58

Callout Part Number Quantity Part Description

The 815-255C_HUB is not separately orderable from Great Plains. Order a complete:

60

46

These replacement parts for the 815-255C_HUB are separately orderable from Great Plains.

56

57

58

59

60

61

62

63

64

815-255C

803-053C

804-025C

805-045C

822-030C

822-080C

A270

CR14971

HS1328

HU13

1

1

1

1

2

2

1

1

1

1

ROW CLEANER HUB ASM

NUT HEX SLOTTED 3/4-16

WASHER FLAT 3/4 SAE PLT

PIN COTTER 5/32 X 1 1/4 LG

BEARING CONE L44643

BEARING CUP L44610

MARTIN HA13270 SPINDLE

MARTIN 3 LIP SEAL (JD AA26234)

MARTIN HUB CAP

MARTIN HA13270 HUB HOUSING

56

63

27327

2014-02-12 Table of Contents Index 204-085M-A

Page 40

36 UMRC Table of Contents Index Great Plains Manufacturing, Inc.

Abbreviations

3P

ASM

COT

FLG

GR5

HEX

HHCS

LG

LH

MACH

MNT

NYL

PLT

RC

Three Point

Assembly

Cotter pin

Flanged

Grade 5

Hexagonal

Hex Head Cap Screw (Bolt)

Long

Left Hand

Machine

Mount

Nylock

Plated

Row Cleaner

RH

RHSNB

RHSNB

SAE

TR

UM

UMC

UMC-RC

UMRC

USS

W/

WLD

WLDM

YP

Right Hand

Round Head Shank Neck Bolt

Round Head Shank Neck Bolt

Society of Automotive Engineers (standards)

Twin Row

Unit-Mount

Unit-Mounted Coulter

UMC Row Cleaner

Unit-Mounted Row Cleaner

United States Standard (heavy-duty)

with

Weldment

Weldment

Yield Pro

204-085M-A Table of Contents Index 2014-02-12

Page 41

Great Plains Manufacturing, Inc. Table of Contents Index Appendix 37

Warranty

Warranty

Great Plains Manufacturing, Incorporated warrants to the original

Great Plains Manufacturing, Incorporated warrants to the original pur-

purchaser that this seeding equipment will be free from defects in

chaser that this spraying equipment will be free from defects in material

material and workmanship for a period of one year from the date of

and workmanship for a period of one year from the date of original pur-

original purchase when used as intended and under normal service and

chase when used as intended and under normal service and conditions

conditions for personal use; 90 days for commercial or rental purposes.

for personal use; 90 days for commercial or rental purposes. This War-

This Warranty is limited to the replacement of any defective part by Great

ranty is limited to the replacement of any defective part by Great Plains

Plains Manufacturing, Incorporated and the installation by the dealer of

Manufacturing, Incorporated and the installation by the dealer of any

any such replacement part. Great Plains reserves the right to inspect

such replacement part. Great Plains reserves the right to inspect any

any equipment or part which are claimed to have been defective in

equipment or part which are claimed to have been defective in material

material or workmanship.

or workmanship.

This Warranty does not apply to any part or product which in Great

This Warranty does not apply to any part or product which in Great

Plains’ judgement shall have been misused or damaged by accident or

Plains’ judgement shall have been misused or damaged by accident or

lack of normal maintenance or care, or which has been repaired or

lack of normal maintenance or care, or which has been repaired or al-

altered in a way which adversely affects its performance or reliability, or

tered in a way which adversely aects its performance or reliability, or

which has been used for a purpose for which the product is not

which has been used for a purpose for which the product is not de-

designed. This Warranty shall not apply if the product is towed at a

signed. This Warranty shall not apply if the product is towed at a speed

speed in excess of 20 miles per hour.

in excess of 20 miles per hour.

Claims under this Warranty must be made to the dealer which originally

Claims under this Warranty must be made to the dealer which originally

sold the product and all warranty adjustments must by made through

sold the product and all warranty adjustments must by made through

such dealer. Great Plains reserves the right to make changes in

such dealer. Great Plains reserves the right to make changes in mate-

materials or design of the product at any time without notice.

rials or design of the product at any time without notice.

This Warranty shall not be interpreted to render Great Plains liable for

This Warranty shall not be interpreted to render Great Plains liable for

damages of any kind, direct, consequential, or contingent, to property.

damages of any kind, direct, consequential, or contingent, to property.

Furthermore, Great Plains shall not be liable for damages resulting from

Furthermore, Great Plains shall not be liable for damages resulting from

any cause beyond its reasonable control. This Warranty does not extend

any cause beyond its reasonable control. This Warranty does not ex-

to loss of crops, losses caused by harvest delays or any expense or loss

tend to loss of crops, losses caused by harvest delays or any expense

for labor, supplies, rental machinery or for any other reason.

or loss for labor, supplies, rental machinery or for any other reason.

No other warranty of any kind whatsoever, express or implied, is

No other warranty of any kind whatsoever, express or implied, is

made with respect to this sale; and all implied warranties of

made with respect to this sale; and all implied warranties of mer-

merchantability and fitness for a particular purpose which exceed

chantability and tness for a particular purpose which exceed

the obligations set forth in this written warranty are hereby

the obligations set forth in this written warranty are hereby dis-

disclaimed and excluded from this sale.

claimed and excluded from this sale.

This Warranty is not valid unless registered with Great Plains

This Warranty is not valid unless registered with Great Plains Manufac-

Manufacturing, Incorporated within 10 days from the date of original

turing, Incorporated within 10 days from the date of original purchase.

purchase.

Warranty

2014-02-12 Table of Contents Index 204-085M-A

Page 42

38 UMRC Table of Contents Index Great Plains Manufacturing, Inc.

204-085M-A Table of Contents Index 2014-02-12

Page 43

Great Plains Manufacturing, Inc. Table of Contents Index 39

Index

A

abbreviations ...................................... 36

address, Great Plains .......................... 5

adjustment ......................................... 16

A270, spindle ..................................... 35

C

callouts, defined ................................... 4

CR14971, seal ................................... 35

D

decals ................................................... 3

depth .................................................. 16

Document Family ................................. 4

F

fire ........................................................ 1

G

Great Plains address ........................... 5

H

HS1328, cap ...................................... 35

HU13, housing ................................... 35

L

left-hand, defined ................................. 4

lubrication ........................................... 19

M

maintenance ...................................... 19

Models Covered ................................... 4

N

Note, defined ........................................ 4

NOTICE, defined .................................. 4

NTW (Negative Tongue Weight) .......... 3

P

placement, wheel ............................... 14

R

right-hand, defined ............................... 4

row unit ................................................ 4

S

Safety ................................................... 1

safety reflectors .................................... 3

Signal Words

CAUTION ....................................... 1

DANGER........................................ 1

WARNING...................................... 1

soil line ............................................... 16

support ................................................. 5

T

T-handle ............................................. 16

torque ................................................ 20

troubleshooting .................................. 18

U

UMC-RC, defined ................................ 6

UMRC, defined .................................... 6

W

Warning decals

NTW ............................................... 3

warranty ............................................. 37

Y

YP825AR ........................................... 16

Numerics

204-085M-A, manual ........................... 4

207-067D, tube ..........7, 10, 24,25,26

207-072D, tube ..........8,21, 22,23,28

207-092S, kit..................................5, 24

207-093S, kit..................................5, 25

207-094H, weldment....7,9, 10, 24,30

207-095H, weldment.......... 7, 9,10,31

207-098S, kit..................................5, 26

207-099H, weldment....7,9, 10, 26,29

207-106D, pipe ..........9,21,22, 23,28

207-107D, tube ..........8,21, 22,23,28

207-108D, spacer ......8,21,22, 23,28

207-142V, assembly 7,11, 12, 25,26,

29, ..........................................31, 32

207-143V, assembly 7,11, 12, 24,26,

29, ..........................................30, 33

207-148H, weldment....................13, 27

207-149S, assembly ...... 24,25,26, 27

207-213K, kit .................................5,21

207-214H, weldment..8,21, 22, 23,28

207-215K, kit .................................5,22

207-216K, kit .................................5,23

207-217S, assembly .................... 21,29

207-218S, assembly .................... 22,30

207-219S, assembly.................... 23

207-221A, kit ................................. 5, 28

25 Series ..............................................4

802-046C, bolt ........... 9,21,22, 23,28

802-106C, bolt ............. 8,9,21, 22,23

802-106C. bolt ....................................28

802-228C, bolt ........................ 7,12, 34

802-270C, bolt ............................. 13

802-331C, bolt ........... 7

802-673C, bolt ........... 8,21,22, 23,28

802-787C, bolt ....................................34

803-008C, nut.............................. 13,27

803-020C, nut....... 8, 9,21, 22, 23,28

803-052C, nut.....................................34

803-053C, nut.....................................35

803-169C, nut...7, 10,21,22, 23,24,

25, .................................................26

804-009C, washer .......................13,27

804-014C, washer .....8, 21,22,23, 28

804-015C, washer 8,9, 21,22,23, 28

804-017C, washer ..........10,24, 25, 26

804-025C, washer ..............................35

804-029C, washer .......................24,25

804-036C, washer .......................13,27

804-195C, washer .12,29,30, 31,32,

33, .................................................34

805-031C, cotter........8,21, 22,23,28

805-045C, cotter.................................35

805-385C, pin ............ 8,21,22, 23,28

815-255C, assembly ............ 32,33,34

815-255C, hub....................................35

815-255C_HUB ...........................34,35

817-084C, bushing .... 9, 21,22,23, 28

817-615C, bushing .... 7, 10,24,25, 26

818-019C, warning decal, NTW ...........3

818-525C, decal . 3,9,10, 24,25,26,

29, .......................................... 30, 31

822-030C, cone ..................................35

822-080C, cup ....................................35

828-057C, lock .................7, 12,32, 33

828-058C, tines .................................. 33

828-059C, tines .................................. 32

828-060C, wheel ......................... 32, 33

,10,24, 25,26

,31

,27

2014-02-12 Table of Contents 204-085M-A

Page 44

40 UMRC Table of Contents Index Great Plains Manufacturing, Inc.

204-085M-A Table of Contents Index 2014-02-12

Page 45

Table of Contents Index

Table of Contents Index

Page 46

Table of Contents Index

Great Plains Manufacturing, Inc.

Corporate Office: P.O. Box 5060

Salina, Kansas 67402-5060 USA

Loading...

Loading...