Page 1

Great Plains Mfg., Inc.

Installation Instructions 1

Baffle Kit

20-Foot 16-Row Precision Drill

Used with:

• 2020P-16TR30

• 2025P-16TR30

• 2010HDP-16TR

General Information

These instructions explain how to install a Baffle Kit. The

baffle kit prevents seed pile-up in the gaps between pairs

of meter tubes on 16-row drills.

These instructions apply to an installation of:

Kit Kit Description

118-254A

One kit updates one drill.

Note: This kit does not block any active rows. It does not

convert a 16-row drill to an 8-row drill.

This kit is only for 20-foot 16-row drills with 10HD-Series,

20-Series or 25-Series Precision openers. For altering

row count on these drills, or for different drill widths, different row spacings or fluted feed seed meters, alternate

baffle kits or seed tube plugs are available.

BAFFLE KIT 20P 30TR

When you see this symbol, the subsequent instructions

and warnings are serious - follow without exception.

!

Your life and the lives of others depend on it!

R

F

U

B

L

D

Related Documents

Have the Operator Manual at hand for drill movements.

118-231M Operator, 2020P- & 2025P-16TR30

118-928M Operator, 2010HDP-16TR

Have the current Parts Manual at hand for parts ID.

118-231P Parts, 2020P- & 2025P-16TR30

118-928P Parts, 2010HDP-16TR

Notations and Conventions

“Left” and “Right” are facing in the

direction of machine travel. An orientation rose in the line art illustrations

shows the directions of Left, Right,

Front, Back, Up, Down.

U

F

L

R

B

D

Call-Outs

1 9

to

11 19

to

Figure 1

Baffle Strapped in Place

Single-digit callouts identify components in

the currently referenced Figure or Figures.

These numbers may be reused for different

items from page to page.

Two-digit callouts in the range 11 to 19 reference new parts from the new parts lists

beginning on page 6.

29558

©Copyright 2009 Printed 02/15/2010 118-255M

Page 2

2 Baffle Kit

Before You Start

Compatibility

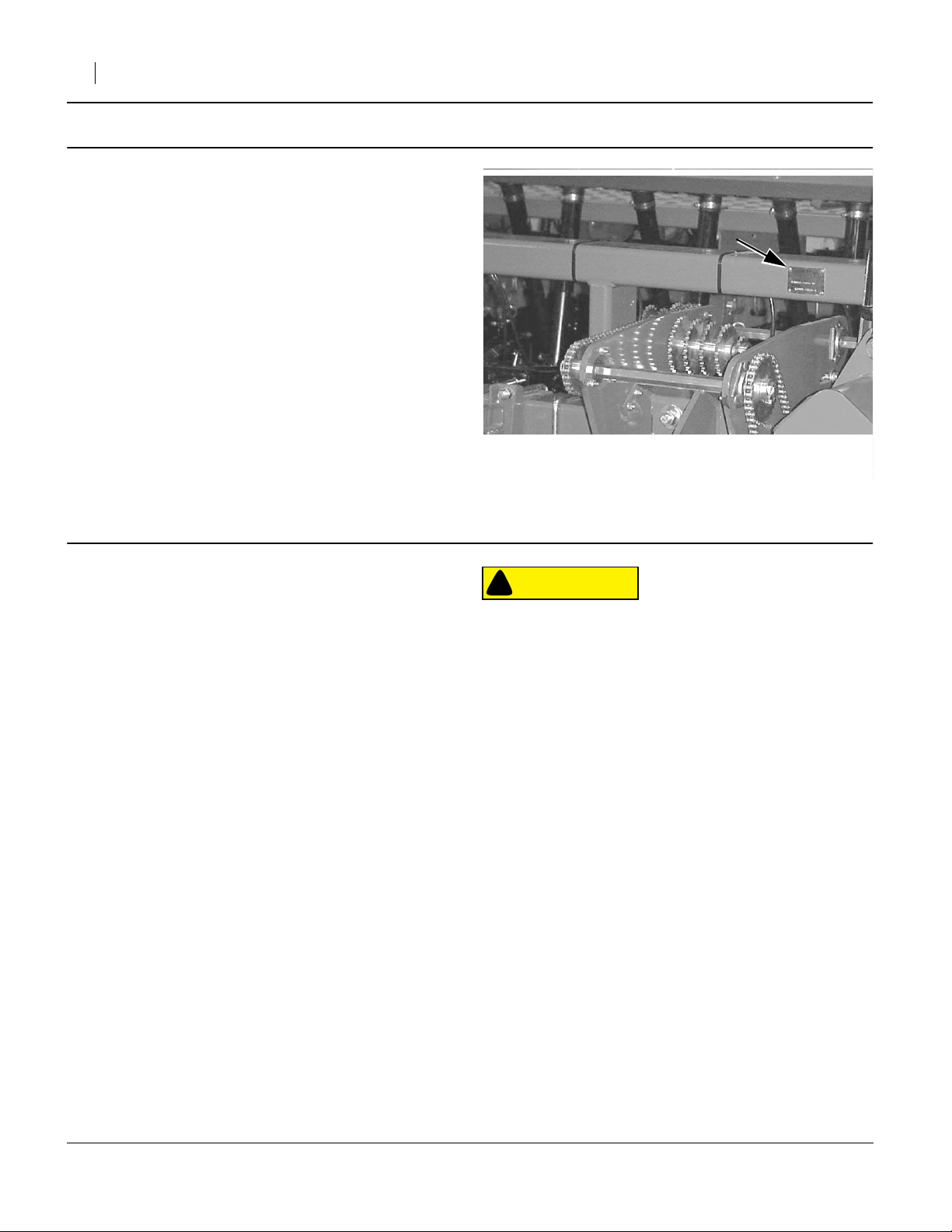

Refer to Figure 2

1. Verify from the serial number plate that the drill is

compatible with this kit.

Inventory

2. Make sure all parts are present (page 6).

Comprehension

3. Review these instructions. Make sure the installers

understand where each part or assembly is

installed, and what tools are required for the task.

Great Plains Mfg., Inc.

Pre-Assembly Preparation

Tools Required

basic hand tools, including:

• indelible marker

• center-punch

• drill bit:

Work Location

4. Clean out the main seed boxes. See Operator Man-

5. Move the drill to a location with:

9

⁄

in (letter size K, or 7.1mm)

32

ual for instructions. If treated seed has been used,

• disconnect seed tubes at meters,

• wash out the boxes,

• thoroughly rinse the boxes, and

• allow them to dry.

Do this in a suitable location other than where the

installation work is to be performed.

• a solid surface to prevent tipping,

• adequate illumination, and;

• clear surface beneath for recovery of any falling

or dropped parts - if the surface is not clear, have

a tarp or drop cloth available.

Figure 2

Serial Number Plate

CAUTION

!

Chemical Hazard

This installation requires contact with interior components of

the main seed boxes. If treated seed has ever been used in the

boxes, follow chemical supplier instructions for protective

equipment and cleaning residue from the seed boxes.

18307

Prepare Drill

6. Install any parking stands and lower the drill.

118-255M 02/15/2010

Page 3

Great Plains Mfg., Inc.

Prepare Tie Point Holes

Identify Baffle Locations

Baffles are symmetrical left-to-right, but are shaped for a

specific front-to-back orientation.

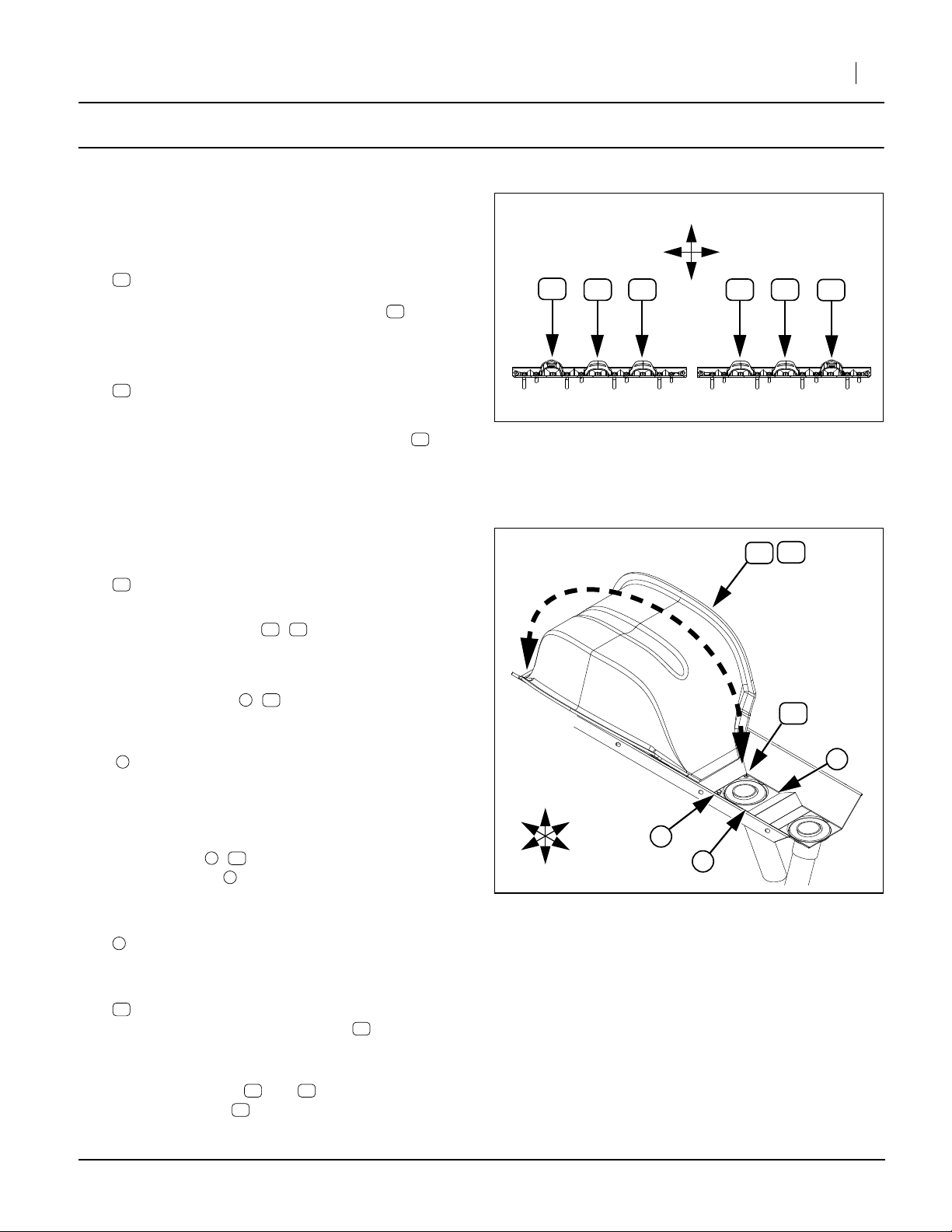

Refer to Figure 3

7. Select four (4) new:

17

817-466C TWIN ROW METER COVER

Temporarily position these wider covers over the

unused meter wells in between the three inner pairs

of seed tubes in each box.

8. Select two (2) new:

18

817-807C 25FT 7 1/2 TO 30TR SPAC COVER

Note that these baffles have “807” molded in.

Temporarily position these narrower covers over

the unused meter wells in between the two outside

pairs of seed tubes in each box.

17

18

Installation Instructions 3

F

L

18

17 17 17 17

Left Seed Box

Baffle Locations

B

Figure 3

R

18

Right Seed Box

29559

Identify Eyebolt Locations

Refer to Figure 4 (showing both suitable eyebolt locations on

one side of a baffle - only one eyebolt per side is installed)

9. Select one (1) new:

15

804-007C WASHER FLAT 1/4 SAE PLT

This is used as a template for marking holes.

For use, prepared baffles ( , ) are held in place by

straps which take a diagonal path across the top of the

baffle (the dotted double-arrow line in the Figure). They

attach to eyebolts supplied in this kit, which are installed

in the nearest corners ( , ) of the adjacent seed box

wells.

Depending on vintage, your drill may or may not have

1

bolts in suitable locations. If it does, these bolts may

be replaced with the eyebolts in this kit (holes are drilled

otherwise).

10. Check the seed tube wells immediately adjacent to

the baffles. Suitable hole locations are in the cor-

ners closest ( , ) to the baffle. Do not use the

outside corners (this can cause the strap to inter-

fere with the sliding seed tube, as well as obstruct

seed flow).

1

Mark any bolt heads at suitable locations. At the

diagonally opposite location, mark any bolt head

there, or use the washer to mark a hole location.

115

17 18

115

0

R

F

U

D

B

1

L

Figure 4

Bolt Hole Requirement

17

18

15

0

0

29556

15

If there are no suitable existing holes on a side,

chose a location. Slide the washer into the corner. Use the washer hole as a template to mark the

hole location.

11. Remove all baffles and .

Save the washer .

02/15/2010 118-255M

17 18

15

15

Page 4

4 Baffle Kit

Prepare Baffles

Apply Initial Foam Seals

Refer to Figure 5

12. Select all baffles ( , ).

Clean, de-grease and dry the lower flanged edges

of each baffle. This edge is the surface that will be

against the seed box walls and well dividers when in

use.

13. Select both rolls of the new:

19

890-750C FOAM SEAL 1/2 X 3/4 X 204

14. Apply a single continuous layer of foam seal to the

flanged edges.

Test Fit Baffles

Refer to Figure 3 on page 3

15. Place each baffle in the same locations used for

determining the hole locations at step 7 and step 8.

16. Press down firmly and check the entire flange for

gaps.

17. Mark the first foam layer at any regions showing

gaps.

17 18

17

18

19

Figure 5

First Layer of Foam Seal

Great Plains Mfg., Inc.

19253

Apply Additional Foam Seal (As Needed)

Refer to Figure 6

18. Cut and apply additional foam seal at marked

regions .

19. Place baffle at its assigned location in the seed box,

and re-check seal seating.

20. Mark baffles (on foam) with numbers of adjacent

rows. Unless all baffles with the same part number

received identical foam application, baffles are now

customized to specific locations in the seed boxes.

2

19

Prepare Eyebolt Locations

21. Use a punch to make a detent at the center of any

locations, marked at step 10, where a hole needs to

be drilled.

22. Use the

tions.

23. Remove all marked bolts. These bolts, washers and

nuts are not re-used. No precautions need to be

taken to secure parts held together by removed

bolts.

9

⁄

in drill to make holes at all marked loca-

32

2

Figure 6

Second Layer of Foam Seal

2

19254

118-255M 02/15/2010

Page 5

Great Plains Mfg., Inc.

Install Eyebolts

Refer to Figure 7

24. Working from drill left to right, select one (1) set:

12

802-233C SP EYE 1/4-20X2 3/4

14

804-006C WASHER LOCK SPRING 1/4 PLT

and two (2) sets:

15

804-007C WASHER FLAT 1/4 SAE PLT

13

803-006C NUT HEX 1/4-20 PLT

Installation Instructions 5

12

13

15

25. Spin one nut fully onto the eyebolt . Add a flat

washer .

26. Insert this eyebolt assembly into a strap hole .

27. From beneath the drill add another flat washer ,

lock washer , and secure with second nut .

There is no preferred orientation for the eye of the

eyebolt.

28. Repeat for all 12 eyebolt locations .

13 12

15

3

15

14 13

3

Install Baffles

Refer to Figure 8

29. Place all baffles ( , ) in their assigned positions.

30. Select six (6)new:

16

816-169C TARP STRAP 15 WITH HOOKS

Secure each baffle by hooking strap to

eyebolts .

31. Re-check seal seating with strap in place. Apply

additional foam seal as required.

32. Select all remaining foam seal . Store it under the

left-most baffle.

12

17 18

16

19

19

Baffle Operation

R

F

12

U

D

15

14

13

B

L

Figure 7

Eyebolt Installation

Figure 8

Install Baffle

3

29557

1817

16

12

29558

Baffles slightly reduce the raw capacity of the seed

boxes (the usable capacity remains about the same).

There are no other operational considerations.

Baffle Maintenance

Baffle: Seals

Seasonally

When cleaning out the seed box for the season, inspect

the seals on each baffle, or remove the baffles and check

for any seed flow under the baffle. Add foam seal as necessary (spare foam seal stored under left-most baffle).

02/15/2010 118-255M

29558

Page 6

6 Baffle Kit

Appendix

New Parts

Quantities are units (“ea”) except for foam seal, where

each of the two supplied is a 204in (518cm) roll.

Great Plains Mfg., Inc.

The part call-out numbers in this list match all Figures in

these installation instructions. Part descriptions match

those in your updated Parts Manual.

12

19

13

15

15

14

16

13

Fi S

118-254A Kit Contents

Callout

11

12

13

14

15

16

17

18

19

Quantity

in Kit

1 118-255M

12 802-233C

24 803-006C

12 804-006C

24 804-007C

6 816-169C

4 817-466C

2 817-807C

2 890-750C

Part Number

17

Figure 9

New Parts

Part Description

MANUAL BAFFLE KIT 20P 30TR

SP EYE 1/4-20X2 3/4

NUT HEX 1/4-20 PLT

WASHER LOCK SPRING 1/4 PLT

WASHER FLAT 1/4 SAE PLT

TARP STRAP 15 WITH HOOKS

TWIN ROW METER COVER

25FT 7 1/2 TO 30TR SPAC COVER

FOAM SEAL 1/2 X 3/4 X 204

18

29555

Abbreviations

20P

30TR

HEX

PLT

118-255M 02/15/2010

20 Series Precision

30 Inch Twin Row

Hexagonal

Plated

SAE

SP

SPAC

X

Society of Automotive Engineers (standards)

Special

Spacing

By

Page 7

Great Plains Mfg., Inc.

Torque Values

Installation Instructions 7

Bolt

Size

in-tpi

1

⁄4-20

1

⁄4-28

5

⁄16-18

5

⁄16-24

3

⁄8-16

3

⁄8-24

7

⁄16-14

7

⁄16-20

1

⁄2-13

1

⁄2-20

9

⁄16-12

9

⁄16-18

5

⁄8-11

5

⁄8-18

3

⁄4-10

3

⁄4-16

7

⁄8-9

7

⁄8-14

1-8

1-12

11⁄8-7

11⁄8-12

11⁄4-7

11⁄4-12

13⁄8-6

13⁄8-12

11⁄2-6

11⁄2-12

Bolt Head Identification

Bolt Head Identification

Bolt

Size

Grade 2 Grade 5 Grade 8 Class 5.8 Class 8.8 Class 10.9

1

N-m2ft-lb

7.4 5.6 11 8 16 12

8.5 6 13 10 18 14

15 11 24 17 33 25

17 13 26 19 37 27

27 20 42 31 59 44

31 22 47 35 67 49

43 32 67 49 95 70

49 36 75 55 105 78

66 49 105 76 145 105

75 55 115 85 165 120

95 70 150 110 210 155

105 79 165 120 235 170

130 97 205 150 285 210

150 110 230 170 325 240

235 170 360 265 510 375

260 190 405 295 570 420

225 165 585 430 820 605

250 185 640 475 905 670

340 250 875 645 1230 910

370 275 955 705 1350 995

480 355 1080 795 1750 1290

540 395 1210 890 1960 1440

680 500 1520 1120 2460 1820

750 555 1680 1240 2730 2010

890 655 1990 1470 3230 2380

1010 745 2270 1670 3680 2710

1180 870 2640 1950 4290 3160

1330 980 2970 2190 4820 3560

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

3

N-m ft-lb N-m ft-lb

mm x pitch

M 5 X 0.8

M 6 X 1

M 8 X 1.25

M 8 X 1

M10 X 1.5

M10 X 0.75

M12 X 1.75

M12 X 1.5

M12 X 1

M14 X 2

M14 X 1.5

M16 X 2

M16 X 1.5

M18 X 2.5

M18 X 1.5

M20 X 2.5

M20 X 1.5

M24 X 3

M24 X 2

M30 X 3.5

M30 X 2

M36 X 3.5

M36 X 2

1. in-tpi = nominal thread diameter in inches-threads per inch

2. N· m = newton-meters

3. ft-lb = foot pounds

4. mm x pitch = nominal thread diameter in millimeters x thread

pitch

4

5.8 8.8 10.9

N-m ft-lb N-m ft-lb N-m ft-lb

43659 7

7 5 11 8 15 11

17 12 26 19 36 27

18 13 28 21 39 29

33 24 52 39 72 53

39 29 61 45 85 62

58 42 91 67 125 93

60 44 95 70 130 97

90 66 105 77 145 105

92 68 145 105 200 150

99 73 155 115 215 160

145 105 225 165 315 230

155 115 240 180 335 245

195 145 310 230 405 300

220 165 350 260 485 355

280 205 440 325 610 450

310 230 650 480 900 665

480 355 760 560 1050 780

525 390 830 610 1150 845

960 705 1510 1120 2100 1550

1060 785 1680 1240 2320 1710

1730 1270 2650 1950 3660 2700

1880 1380 2960 2190 4100 3220

02/15/2010 118-255M

Page 8

8 Baffle Kit

Great Plains Mfg., Inc.

Great Plains Manufacturing, Inc.

Corporate Office P.O. Box 5060

Salina, Kansas 67402-5060 USA

118-255M 02/15/2010

Loading...

Loading...