Page 1

1-1

03-01-92

2020 SOLID STAND

DRILL

FLAT FOLD

MARKER

OWNER’S MANUAL

Great Plains Manufacturing, Inc.

P.O. Box 218

Assaria, KS 67416

(913)667-4755

Page 2

03-01-92

INTRODUCTION

Your 2020 Solid Stand Flat Fold Marker is designed to give you many years of dependab le service. This manual has

been prepared to instruct you on how to service and keep your marker operating in good condition. Read and f ollow

ALL instructions and safety precautions carefully.

The parts on your 2020 Solid Stand Flat Fold Marker have been specially designed. Should your Flat Fold Marker

ever require replacement parts, go to your Great Plains Dealer.

Thank you for buying an Great Plains Flat Fold Marker.

TABLE OF CONTENTS

Introduction .....................................................2

Table Of Contents ...........................................2

Nut & Bolt Torquing Chart ...............................2

Safety Rules & Features 3

Bleeding the Hydraulics...................................4

Cycling the Markers.........................................4

Flat Fold Marker Assembly Instructions...........5

Flat Fold Marker Parts Illustration....................7

Single Marker Hydraulic Assembly 9

Dual Marker Hydraulic Assembly...................11

Service ..........................................................14

Rod Cylinder {810-118C}...............................15

Warranty .......................................................18

1-2

NUT & BOLT TORQUING CHART

This chart is based on torque requirements in foot pounds for grade 5 bolts.

BOLT DIAMETER MINIMUM TORQUE MAXIMUM TORQUE BOLT DIAMETER MINIMUM TORQUE MAXIMUM TORQUE

1/4” 9 11 3/4" 270 324

5/16" 17 20 7/8" 400 480

3/8" 35 42 1" 580 696

7/16" 54 64 1 1/8" 800 880

1/2" 80 96 1 1/4" 1120 1240

9/16" 110 132 1 3/8" 1460 1680

5/8" 150 180 1 1/2" 1940 2200

NOTE: Torque requirements listed above do not apply to self-locking nuts. For self-locking nuts increase torque

requirements listed above by 15%.

113-379M

Effective 03-01-92

Page 3

1-3

SAFETY RULES & FEATURES

!

The SAFETY ALERT SYMBOL indicates that there is a potential hazard to personal

safety involved and extra safety precautions must be taken. When you see this symbol, be alert

and carefully read the message that follows it. In addition to design and configuration of equip

ment; hazard control and accident prevention are dependent upon the awareness, concern, prudence and proper training of personnel involved in the operation, transport, maintenance and

storage of equipment.

Most accidents are the result of negligence and carelessness, usually caused by failure of the

operator to follow simple but necessary safety precautions. The following safety precautions are

suggested to help prevent such accidents. The safe operation of any machinery is a big concern

to consumers and manufactures. Your Flat Fold Marker has been designed with many built-in

safety features. However, no one should operate this product before carefully reading this Own

er’s Manual.

03-01-92

-

-

1. DO NOT allow anyone near the marker while it is in operation.

2. Excessive speed can cause marker damage.

3. DO NOT allow anyone near the grain drill while cycling the markers.

4. Reduce speed while transporting over uneven or rough terrain. Avoid all chuck holes and

washboard areas in roads.

5. DO NOT lubricate, adjust or repair the marker while it is in operation.

6. When in transport, use accessory lights and devices for adequate warning to operators of other vehicles and use safety chains. Comply with ALL Federal, State and Local Laws when

traveling on public roads.

7. DO NOT permit smoking, sparks or an open flame where combustible lubricants or liquids

are being used.

8. Escaping fluid under pressure can have sufficient force to penetrate the skin. Check

!

all hydraulic lines and hoses for leaks before applying pressure. Use paper or cardboard and

not body parts to check for suspected leaks. If injured seek immediate medical assistance

from a doctor familiar with this type of injury.

9. Refer to parts illustration on page 7 for the following instructions. The marker arm (#17) is

attached to the marker body with a 3/8” shear bolt (#14). If excessive force is put on the

marker during operation, the shear bolt will break allowing the marker arm to swing away

thereby reducing the damage that could be caused otherwise. Should this occur, replace the

bolt with a 3/8” x 2” long Gr 2 bolt only. {Great Plains part number 802-266C.}

Page 4

03-01-92

BLEEDING THE HYDRAULICS

1. Be sure tractor hydraulic reservoir is full.

2. With the markers in field position, crack the hydraulic hose fittings located at the base end of

the cylinder(s). With your tractor at an idle speed, activate your tractor hydraulic’s valve until h y

draulic oil seeps out around the hose ends. Tighten the hose end fittings and repeat this process

with the hose end fitting(s) located at the rod end of the cylinder(s).

3. Fold and unfold the marker(s) slowly in order to work all the air out of your mark er hydraulics.

4. Adjust the speed of the marker with the needle valve, single markers only, to a low setting.

Fold the marker up and down a few times and recheck f or pinching and kinking of hoses. Reset

folding speed with the needle valve to a safe speed.

CYCLING THE MARKERS

1-4

-

THE MARKERS CYCLE IN THE FOLLOWING SEQUENCE:

(1) Right Up, Left Up

(2) Right Down, Left Up

(3) Right Up, Left Up

(4) Right Up, Left Down

(5) Sequence Repeats

NOTE: Raising and lowering speed of the markers is due to the internal orifice in the sequence valve necessary for

proper operation of the valve spool.

EXCESSIVE SPEED CAN CAUSE MARKER DAMAGE.

!

!

CAUTION! Escaping fluid under pressure can ha ve sufficient f orce

to penetrate the skin. Check all hydraulic lines and hoses BEFORE applying

pressure. Fluid escaping from a very small hole can be almost invisib le. Use

paper or cardboard, NOT BODY PARTS, to check for suspected leaks. If

injured, seed medical assistance from a doctor that is familiar with this type

of injury . Foreign fluids in the tissue must be sur gically removed within a fe w

hours or gangrene will result.

Page 5

1-5

03-01-92

FLAT FOLD MARKER ASSEMBLY

11009

Page 6

03-01-92

FLAT FOLD MARKER ASSEMBLY INSTRUCTIONS

FOR THE FOLLOWING INSTRUCTIONS, REFER TO THE ILLUSTRATIONS ON PAGE 5:

1. Lower the drill to field position and allow clearance of 16’ on drill for marker assembly from

each end of the box.

2. Attach the marker first section (#1) to the marker bracket at the end of the drill frame using 5/

8” x 2” long bolt (#35), lock washer (#9) and hex nut (#10).

3. Assemble the marker in a horizontal position, remove the port plugs in the hydraulic cylinder

to allow the fold cylinder to be extended. Then fold the first section and the lift lug (#1) to a hor

izontal position.

4. With the stop block position on top of second section (#2) align the holes of the second section

with the holes of the first section (#1)and bolt together with the 5/8” x 5 1/2” long bolt (#5), lock

nut (#4) 3/8” x 2” long shear bolt (#6) and lock nut (#7).

5. Place the third section (#3) over the end of the second section (#2) and insert the hinge pin

(#19) through the second and third section pivot. Secure the hinge pin (#10) with 1/4” x 2” long

bolt (#17) and lock nut (#16).

1-6

-

6. Bolt the chain bar weldment (#13) to the first section (#1) with 3/8” x 3 1/4” long bolt (#11), and

lock nut (#7). The chain bar weldment (#13) should pivot freely on the 3/8” bolt (#11). Bolt the

chain bar (#18) to the third section (#3) with the 3/8” x 1 1/2” long bolt (#21) and lock nut (#7).

The chain bar (#18) should pivot freely on the 3/8” bolt (#21). Connect the marker chain (#15)

between the chain bar (#18) and chain bar weldment (#13) with 5/16” utility clevis (#14). With

the marker disk adjusted for seeding width and disk touching the ground adjust chain length to

remove the slack. Adjustment should be made at the utility clevis (#14) nearest to the drill.

7. The purpose of the 3/8” stop bolt (#12) is to hold tension on the marker chain (#15). ONLY

when the marker is in folding position. Therefore; the 3/8” stop bolt (#12) lock nuts (#7) should

be positioned in the lift arm (#1) so the head of the stop bolt extends as little as possible. After

marker is folded adjust stop bolt to tighten chain.

8. Mount the marker carrier (#27) with the transport arm mount weldment (#26) using 1/2” x 2” x

3” long u-bolts (#30), lock washers (#28), and hex nuts (#29) approximately 50” to 60” from the

outer end of the drill. Clamp the transport arm mount weldment (#23) to the drill frame with 3/8”

x 6” x 6 3/4” long u-bolts (#31) flat washers (#20) lock washers (#32) and hex nuts (#33). The

carrier arm should be set at 31 3/8” high above the drill frame.

9. Mount the support arm saddle (#34) to the support arm (#27) with 1/2” x 2” x 3” long u-bolts

(#30), lock washers (#28) and he x nuts (#29). The support saddle should be centered under the

marker chain and the square tube of the second section (#2) when folded to pre vent wear. The

support arm should support the second section is parallel with the seed box lid. Adjustment can

be made by loosening u-bolts that clamp the marker carrier and slide marker carrier up or down

to parallel marker with drill box lid.

10.Fold the marker to transport position. With the marker chain (#15) in the slot of the support

arm saddle (#34) take up the slack in the marker chain by threading the 3/8” x 2 1/2” long hex

bolt (#13) out against the chain bar weldment (#13) lock this stop bolt in position with the two he x

nuts (#7).

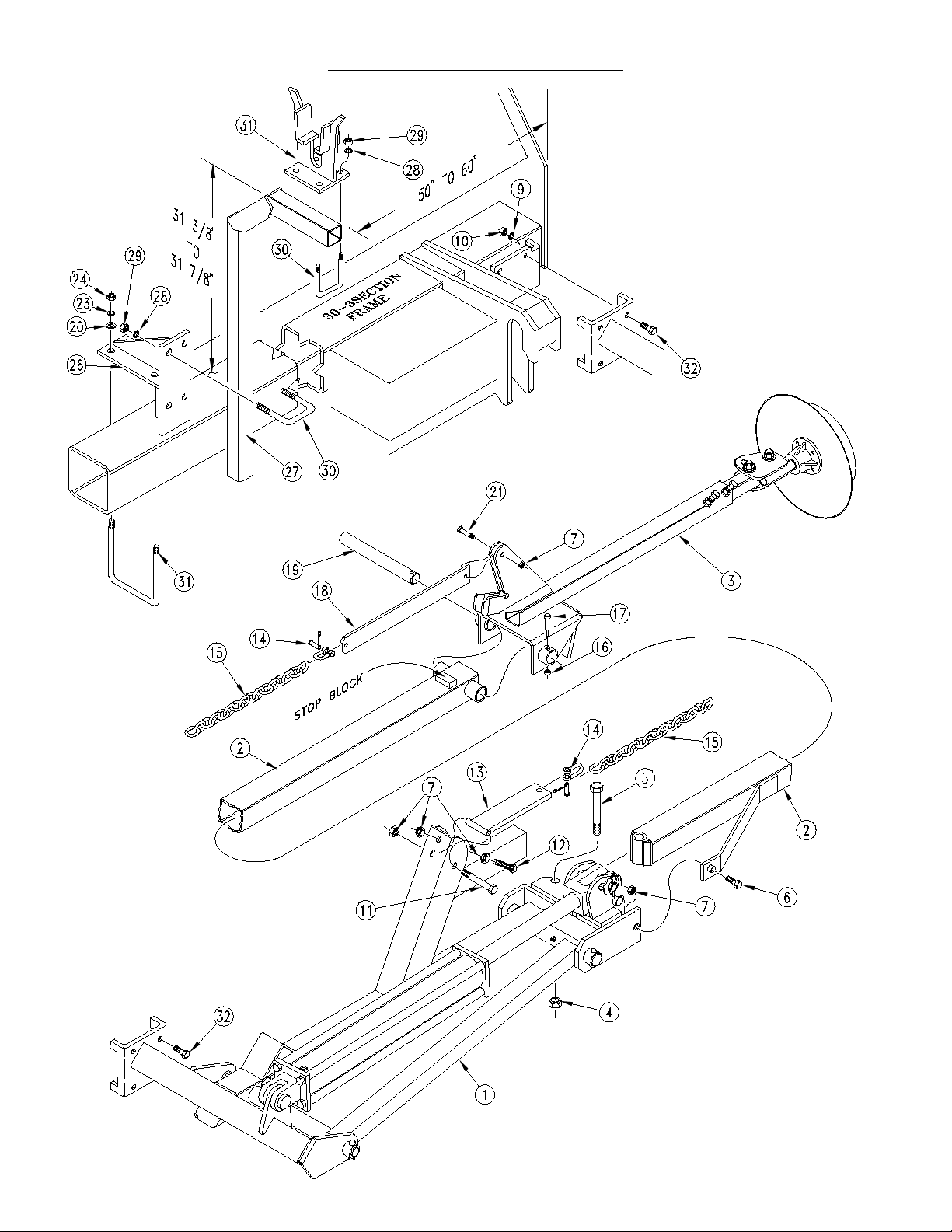

Page 7

1-7

03-01-92

FLAT FOLD MARKER

10106

Page 8

03-01-92

FLAT FOLD MARKER (CON’T.)

Ref. Part No. Description

1. 803-021C Nut, Hex 5/8"-11

2. 804-022C Washer, Lock Spring 5/8"

3. 802-058C Bolt, Hex 5/8"-11 x 2 1/2" Long

4. 113-199H Right Hand Marker Mount

113-179H Left Hand Marker Mount

5. 113-188H Right Hand First Section

113-180H Left Hand First Section

6. 890-005C Bushing, Cylinder 1 1/4" x 1" x 1" Long

7. 800-001C Zerk, Straight 1/4"-28

8. 113-312D First Pivot Shaft

9. 802-168C Bolt, Hex 3/8"-16 x 3 1/4" Long

10. 803-013C Nut, Lock 3/8"-16

11. 113-189H Lift Lug Channel Right Hand

113-181H Lift Lug Channel Left Hand

12. 113-313D Second Pivot Shaft

13. 804-029C Washer, Flat 1"

14. 113-248D Marker Cylinder Pin Body

15. 805-058C Pin, Cotter 3/16" x 2"

16. 802-201C Bolt, Hex Head 1/2"-13 x 4 3/4" Long

17. 803-019C Nut, Lock 1/2"-13

18. 802-066C Bolt, Hex 3/8"-16 x 2" Long Gr 2

19. 113-324D Cylinder Stop

20. 113-325D Stop Bushing

21. 113-190H Right Hand Second Section

113-182H Left Hand Second Section

22. 804-011C Washer, Flat 3/8"

23. 802-022C Bolt, Hex 3/8"-16 x 1 1/2" Long

24. 113-311D Hinge Pin

25. 113-183H Marker Third Section

26. 803-036C Nut, Hex, Jam 1/2"-13

27. 801-054C Screw, Set, Square Head 1/2"-13 x 1"

28. 804-017C Washer, Flat 1/2" USS

29. 113-351D Marker Tube 40 1/2" Long

113-184H 27’ & 30’ Marker Tube Weldment

30. 113-305K Marker Disk, Bearing & Depth Band Assembly

31. 107-111D Bearing Flange Dust Cover

32. 802-059C Bolt, Hex 5/8"-11 x 3" Long

33. 810-118C Cylinder 2 1/2" x 20" x 1 1/4" Rod

34. 113-200H Chain Bar Weldment

35. 802-261C Bolt, Hex 3/8"-16 x 2 1/2" Long

36. 803-148C Nut, Hex Nylock 5/8"-11

37. 802-254C Bolt, Hex 5/8"-11 x 5 1/2" Long

38. 113-319D Marker Chain 71" Long

39. 890-018C Utility Clevis 5/16"

40. 113-323D Chain Bar

41. 113-197D Marker Carrier

42. 113-316H Transport Arm Mount Weldment

43. 113-281H Blade Adjuster Weldment

44. 804-015C Washer, Lock Spring 1/2"

45. 803-020C Nut, Hex 1/2"-13

46. 806-005C U-Bolt, 1/2"-13 x 2" x 3" Long

47. 113-198H Support Arm Saddle

48. 802-152C Bolt, Hex 1/4"-20 x 2" Long

49. 803-007C Nut, Lock 1/4"-20

50. 806-060C U-Bolt, 1/2"-13 x 6 1/32" x 7 1/4" Long

51. 802-041C Bolt, Hex 1/2"-13 x 3 1/2" Long

52. 803-008C Nut, Hex 5/16"-18

53. 804-009C Washer, Lock 5/16"

54. 113-304H Marker Depth Band Weldment

55. 800-010C Rivet, Button Head 3/16" x 9/16" Long

56. 107-110D Ribbed Bearing Flange

57. 188-001V Bearing AA 205 DO

58. 820-083C Marker Disk

59. 113-303S Marker Disk & Bearing Assembly

60. 802-092C Bolt, Carriage 5/16"-18 x 3/4" Long Gr 5

1-8

Page 9

1-9

SINGLE FLAT FOLD MARKER HYDRAULIC ASSEMBLY INSTRUCTIONS

1. Attach fittings (#16) & (#18) to cylinder ports. Attach the needle valve (#14) & (#15) to the

cylinder fittings as show below . Bolt selector v alv e (#11) to the selector valv e mount on T-F rame

with 3/8” x 3” long bolts (#20), flat washers (#21) lock washer (#22) and n ut (#23). Route the hy

draulic hoses (#7) & (#10) from the fold h ydraulic cylinders and marker hydraulic cylinders (hoses

(#14) & (#15)) to the selector valve as sho wn in illustration. Route h ydraulic hoses (#24) & (#25)

from the tractor , through the drill tongue to the selector valv e. Secure the h ydr aulic hoses to the

frame with plastic tie straps (#13) to prevent kinking and pinching during folding operations.

SINGLE MARKER HYDRAULICS

03-01-92

-

10060

Page 10

03-01-92

SINGLE MARKER HYDRAULICS

Ref. Part No. Description

1. 810-065C Cylinder 3 1/2" x 24" x 1 1/2" Rod

2. 811-172C Hydraulic Fitting 1/16" Orifice Plate

3. 811-133C Hydraulic Fitting 3/4" O-RING x 9/16" JICM

4. 811-061C Hydraulic Fitting 6 JIC M x 6 JIC F Tee

5. 811-169C Hydraulic Fitting 3/8" M-F Elbow

6. 811-171C Hydraulic Fitting -8 MORB x -6 JIC M Elbow

7. 811-056C Hydraulic Hose 3/8" x 42 R1

8. 811-307C Hydraulic Hose 1/4" x 108 R1

9. 811-308C Hydraulic Hose 1/4" x 54 R1

10. 811-309C Hydraulic Hose 1/4" x 66 R1

11. 810-023C Double Selector Valve

12. 811-134C Hydraulic Fitting 9/16" JIC x 1/2" MNPT 90

13. 800-082C Cable Tie

14. 811-035C Hydraulic Hose, 1/4" x 21’ Long

15. 811-293C Hydraulic Hose, 1/4" x 272" Long

16. 811-301C Hydraulic Fitting 1/2" MNPT x 3/8"Swivel 90 Degree

17. 810-058C Needle Valve 3/8"

18. 811-044C Hydraulic Fitting 3/8" NPT Close Nipple

19. 810-118C Hydraulic Cylinder 2 1/2" x 20" Stroke

20. 802-024C Bolt, Hex Head 3/8"-16 x 3" Long

21. 804-013C Washer, Lock Spring 3/8"

22. 804-011C Washer, Flat 3/8" USS

23. 803-014C Nut, Hex 3/8"-16

24. 811-306C Hydraulic Hose 1/4" x 360 R1

25. 811-305C Hydraulic Hose 1/4" x 336 R1

26. 810-019C Hydraulic Cylinder 3" x 20" Stroke

27. 811-214C Hydraulic Fitting 1/2" MNPT x 3/8" FNPT 90 Degree Street L

28. 811-213C Hydraulic Fitting 1/2" MNPT x 3/8" MNPT 90 Degree Elbow

1-10

Page 11

1-11

DUAL FLAT FOLD MARKER HYDRAULIC ASSEMBLY INSTRUCTIONS

NOTE: JIC fittings DO NOT require high torque. JIC and O-ring fittings DO NOT require sealant. ALWAYS use

liquid pipe sealant when adding or replacing pipe thread fittings. To avoid possible danger of cracking hydraulic fittings from over tightening, DO NOT use plastic sealant tape.

Refer to figure below and page 13 for the following instructions:

1. Attach the selector / sequence valve to the selector valv e mount the T-Fr ame (#11) using 3/8”

bolts (#20) flat washers (#22) lock washers (#21) and hex nuts (#23).

2. Route hoses from the selector / sequence valve down the drill box frame tube. Check hose

routing for pinching and kinking of hoses and securely attach with plastic cable ties (#13).

3. Attach hoses to cylinder ports. Be certain to double check for correct port location back to the

sequence valve.

4. Detach existing tractor hoses (#18) & (#19) from fold cylinders. Attach 66” hose (#10) and 42”

hose (#7) and tractor hoses (#18) & (#19) to selector / sequence valv e (#11) and wing cylinders.

Assemble remaining hoses as indicated.

03-01-92

IMPORTANT! BEFORE CONTINUING WITH THESE INSTRUCTIONS, READ

“BLEEDING THE HYDRAULICS” INSTRUCTIONS ON

PAGE 4. BLEED ALL

THE AIR OUT OF THE HYDRAULIC SYSTEM BEFORE FOLDING THE

MARKER.

5. Cycle marker as instructed on page 4.

6. When ready to fold wing boxes f or tr ansporting, position the handle on the selector/sequence

valve towards the port marked "G". Hydraulic oil is now diverted to the fold cylinders

NOTE: Raising and low ering speed of the markers is due to the internal orifice in the sequence

valve necessary for proper operation of the valve spool.

DOUBLE SELECTOR VALVE

MOUNT ON T-FRAME

EXCESSIVE SPEED CAN CAUSE MARKER DAMAGE.

!

DO NOT ALLOW ANYONE NEAR THE DRILL WHEN CYCLING THE MARKER!

!

NOTE: To avoid crac king the hydraulic pipe fittings , DO NOT use plastic sealant tape . Use liquid

sealant to seal hydraulic pipe fittings only.

Page 12

03-01-92

1-12

FLAT FOLD

MARKER

TABLE OF CONTENTS

Marker Assembly-------------------------------------------- 1-13

Marker Disk & Bearings ----------------------------------- 1-15

Single Hydraulic Schematic ------------------------------ 1-17

Dual Hydraulic Schematic--------------------------------- 1-19

2 1/2" x 20" Cylinder {810-118C}------------------------ 1-21

Double Selector Valve {810-023C} --------------------- 1-23

Selector / Sequence Valve {810-085C}---------------- 1-25

PARTS BOOK

Page 13

1-13

03-01-92

DUAL MARKER HYDRAULICS

10059

Page 14

03-01-92

DUAL MARKER HYDRAULICS (CON’T)

Ref. Part No. Description

1. 810-065C Cylinder 3 1/2" x 24" x 1 1/2" Rod

2. 811-172C Hydraulic Fitting 1/16" Orifice Plate

3. 811-133C Hydraulic Fitting 3/4" O-RING x 9/16" JICM

4. 811-061C Hydraulic Fitting 6 JIC M x 6 JIC F Tee

5. 811-169C Hydraulic Fitting 3/8" M-F Elbow

6. 811-171C Hydraulic Fitting -8 MORB x -6 JIC M Elbow

7. 811-056C Hydraulic Hose 3/8" x 42 R1

8. 811-307C Hydraulic Hose 1/4" x 108 R1

9. 811-308C Hydraulic Hose 1/4" x 54 R1

10. 811-309C Hydraulic Hose 1/4" x 66 R1

11. 810-085C Selector/Sequence Valve

12. 811-250C Hydraulic Fitting -8 JICF x -6 JICM Elbow (Pre July 1990)

811-319C Hydraulic Fitting -6 JICF x -6 JICM Swivel Elbow

13. 800-082C Cable Tie

14. 811-035C Hydraulic Hose, 1/4" x 21’ Long

15. 811-293C Hydraulic Hose, 1/4" x 272" Long

16. 811-281C Hydraulic Fitting 3/8" FNPT Swivel x 9/16" MORB

17. 810-118C Hydraulic Cylinder 2 1/2" x 20" Stroke

18. 811-306C Hydraulic Hose 1/4" x 360 R1

19. 811-305C Hydraulic Hose 1/4" x 336 R1

20. 802-024C Bolt, Hex Head 3/8"-16 x 3" Long

21. 804-013C Washer, Lock Spring 3/8"

22. 804-011C Washer, Flat 3/8" USS

23. 803-014C Nut, Hex 3/8"-16

24. 810-019C Hydraulic Cylinder 3" x 20" Stroke

25. 811-301C Hydraulic Fitting 1/2" MNPT x 3/8" FNPT 90 Degree Swivel

1-14

SERVICE

Keep marker adequately lubricated. Use a heavy duty multipurpose grease for lubrication.

Recommended Greasing - every 20 - 25 Hours.

Lubrication Points:

2 - Zerks on right and left hand first section (#5)

Page 15

03-01-92

1-18

WARRANTY

Great Plains warrants to the original purchaser of new Great Plains

Products, that they are free of defects in material and workmanship.

This warranty is applicable only for the normal life expectancy of the

unit or individual components for a period of one year from date of

original purchase if for personal use; 90 days for commercial or rental

purposes. Warranty coverage is limited to replacing any part, at no

charge to the original purchaser, that in our judgment shows

evidence of a defect: provided that upon written request, any such

defective part is returned to Great Plains within (30) days of failure.

This Warranty does not apply to any part or product which in Great

Plains’s judgment shall have been misused or damaged by accident

or lack of normal maintenance or care, or which has been repaired or

altered in a way which adversely affects its performance or reliability,

or which has been used for a purpose for which the product is not

designed.

Claims under this Warranty must be made to the dealer which

originally sold the product. Great Plains reserves the right to make

changes in materials or design of the product at any time without

notice.

This Warranty shall not be interpreted to render Great Plains

liable for damages of any kind, direct, consequential, or

contingent, to property. Furthermore, Great Plains shall not be

liable for damages resulting from any cause beyond its

reasonable control. This Warranty does not extend to any

expense due to loss for labor, supplies, rental machinery or for

any other reason.

No other Warranty of any kind whatsoever, express or implied, is

made with respect to this sale; and all implied warranties of

merchantability and fitness for a particular purpose which exceed the

obligations set forth in this written warranty are hereby disclaimed

and excluded from this sale.

Loading...

Loading...