Page 1

Table of Contents Index

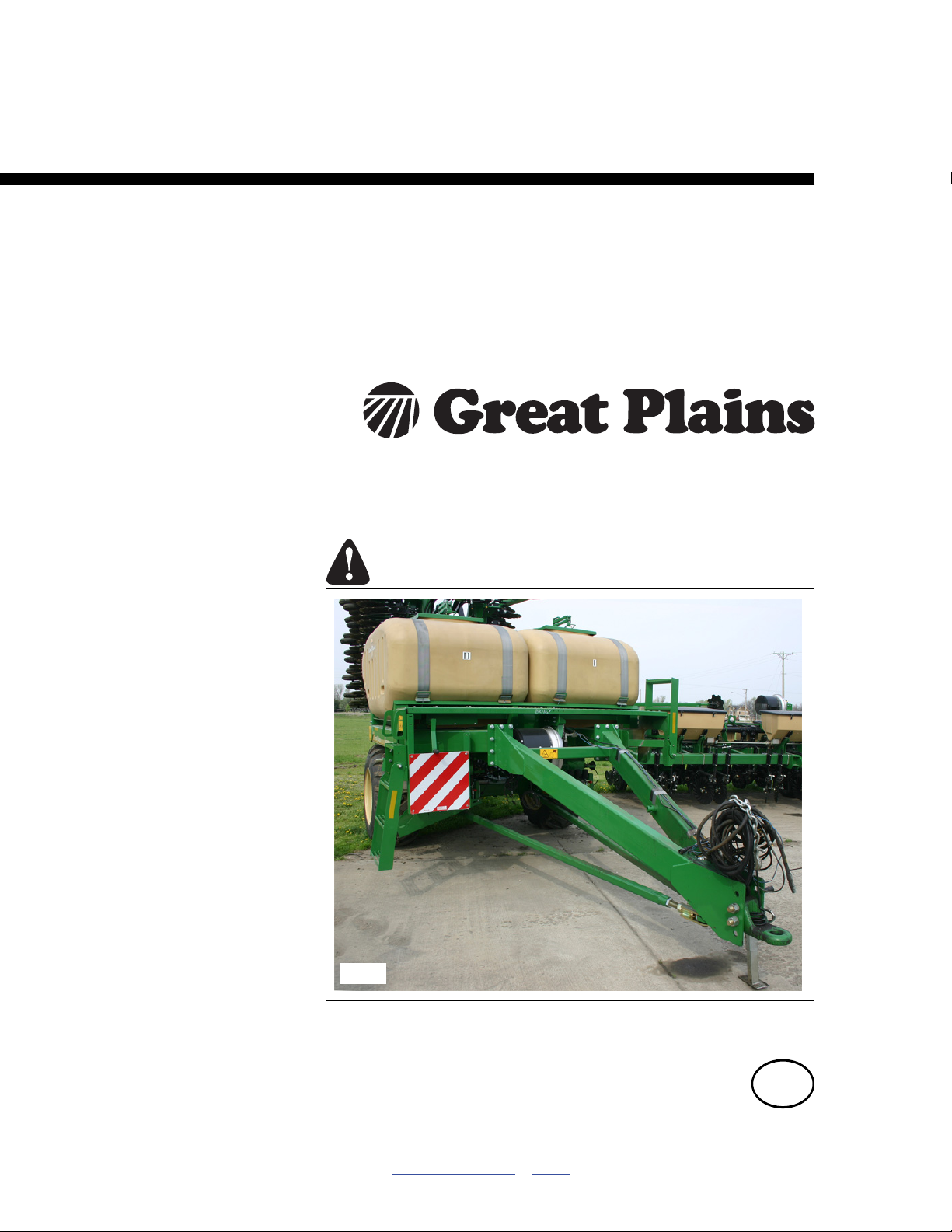

166-369A Update Installation

NTA607HD or NTA2007HD

6 Meter No-Till Air Drills

Manufacturing, Inc.

www.greatplainsmfg.com

Read the update manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without

exception. Your life and the lives of others depend on it!

32109

Illustrations may show optional equipment not supplied with standard unit.

EN

© Copyright 2011 Printed 05/25/2011 166-370M

Table of Contents Index

Page 2

Table of Contents Index

Table of Contents Index

Page 3

Great Plains Manufacturing, Inc. Cover Index iii

Table of Contents

Important Safety Information ......................................1

General Information .....................................................3

Related Documents........................................................3

Notations and Conventions ............................................3

Call-Outs ....................................................................3

Tools Required ...............................................................4

Regarding Parts .............................................................4

About New Parts ........................................................4

About Existing Parts ...................................................4

Pre-Assembly Preparation .............................................4

Work Location ............................................................4

Update Underside Weldments ....................................5

Configure Implement ......................................................5

Tack Rear Bottom Gussets ............................................5

LH Rear Bottom Gussets............................................5

RH Rear Bottom Gussets...........................................6

Install Nut Blocks............................................................7

Install LH Nut Block ....................................................7

Install RH Nut Block....................................................7

Finish Weld Blocks and Gussets................................7

Install Box Plates............................................................8

Install Corner Gussets....................................................8

Disconnect Implement .................................................9

Prepare Implement.........................................................9

Disconnect Primary Hoses .............................................9

Clear Weight Transfer Cylinders ..................................10

Clear Link Lift Cylinders ...............................................10

Recover Pull Link Components ....................................11

Release Lift-Assist Link ................................................11

Uncouple Cart ..............................................................12

Remove Pull Link .........................................................12

Dismount Hoppers .....................................................13

Disconnect Sensors and Chain ....................................13

Disconnect Level Sensors........................................13

Dismount Rate Sensor .............................................13

Dismount Final Drive Chain...................................... 13

Dismount Meters ..........................................................14

Disconnect Meter Inlet Elbows ................................. 14

Remove Meters ........................................................14

Hoist Hoppers...............................................................15

Release Hopper Mount.............................................15

Remove Hopper Assembly....................................... 15

Update Meters.............................................................16

Remove Existing Top Seal ...........................................16

Remove Meter Flute Shaft ........................................... 16

Remove Old Flanges ............................................... 16

Enlarge Mounting Slots................................................ 17

Drill Weep Holes .......................................................... 17

Install Meter Seal Flange ............................................. 18

Replace Meter Shaft Mount Plates .............................. 18

Replace Right End Plates ........................................ 18

Replace Left End Plates........................................... 19

Install New Top Seal ................................................ 19

Update Cart................................................................. 21

Cart Frame Update Overview ...................................... 21

Rear Gusset Plates (page 22).................................. 21

Front Gusset Triangles (page 23) ............................ 21

Pull Bar Anchors (page 25) ...................................... 21

Meter Mount Tabs (page 27).................................... 21

Install Rear Gussets..................................................... 22

Install Left Rear Gusset............................................ 22

Install Right Rear Gusset ......................................... 22

Install Front Gussets .................................................... 23

Install Right Front Gusset......................................... 23

Install Left Front Gusset ........................................... 23

Install Pull Bar Attach Points........................................ 24

Install Pull Bar Plate ................................................. 24

Install Pull Bar Anchors ............................................ 25

Install Left Anchor ................................................ 25

Install Right Anchor .............................................. 25

Update Meter Mounts .................................................. 26

Position New Meter Mounts ..................................... 26

Prepare Tab Welding Sites ..................................26

Mark Tab Welding Sites ....................................... 27

Attach New Front Tabs ............................................ 27

Install New Meter Mounts......................................... 27

Re-Install Meters.......................................................... 28

Install Hopper Supports............................................ 28

Install Pull Bars ............................................................ 28

Assemble Pull Bars .................................................. 28

Attach Pull Bars........................................................ 29

Update Cart Hydraulics................................................ 30

Route Dedicated Fold Hose ..................................... 32

Mark Dedicated Fan Hose ....................................... 32

Re-Route Fold Hose ................................................ 32

Disconnect Bypass Hose ......................................... 32

Re-Configure Inlet Fittings ....................................... 32

Re-connect Fan Hoses ............................................ 32

Re-Install Hoppers ....................................................... 33

© Copyright 2011 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

05/25/2011 Cover Index 166-370M

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

Page 4

iv NTA607HD, NTA2007HD Table of Contents Index Great Plains Manufacturing, Inc.

Align Meters ............................................................. 33

Re-Install Final Drive Chain ..................................... 34

Re-Connect Inlets/Outlets........................................ 34

Re-Install Gears ....................................................... 34

Re-Install Sensors.................................................... 34

Update Hopper Lids ..................................................... 35

Update Implement Frame .......................................... 36

Dismount Lift-Assist ..................................................... 36

Disconnect Lights..................................................... 36

Release Lift Link ...................................................... 36

Dismount Parallel Arms............................................ 37

Remove Pull Link ..................................................... 37

Update Rear Link Anti-Rotation ................................... 37

Update Wing Pivot Anti-Rotation ................................. 38

Update Wing Pivot Extension Tops ............................. 39

Update Front Extension Tops .................................. 39

Update Rear Extension Tops................................... 40

Update Harness.......................................................... 41

Dismount Existing Harnesses ...................................... 41

Enumerate WSMBs ..................................................... 42

Install WSMBs.............................................................. 43

Mount Center WSMBs ............................................. 43

Mount Tower B WSMB......................................... 43

Mount Tower C WSMB ........................................ 43

Mount Wing WSMBs................................................ 44

Mount Tower A (Left Wing) WSMBs .................... 44

Mount Tower D (Right Wing) WSMBs.................. 44

Install Row Harnesses ................................................. 45

Connector ID............................................................ 45

Connect WSMB #1 .................................................. 46

Connect WSMB #4 .................................................. 47

Connect WSMB #2 .................................................. 48

Connect WSMB #5 .................................................. 49

Connect WSMB #3 .................................................. 50

Connect New WSMB #6 .......................................... 51

Install Rear Pull Link.................................................. 52

Pin Link to Main Frame ................................................ 52

Connect Lift-Assist Link ............................................... 52

Connect Lift Assist ....................................................... 53

Re-Install Parallel Arms ............................................... 53

Re-Connect Lights ....................................................... 53

Update Implement Hydraulics .................................. 54

Extend Valve Hoses..................................................... 54

Relocate Valve Group.................................................. 54

Protect Hose Extensions.............................................. 55

Re-Hitch Implement ................................................... 57

Install Front Pull Link.................................................... 57

Re-Connect Lift Link .................................................... 57

Connect Cart and Implement ....................................... 58

Re-Install Link Components......................................... 58

Store Spacers .......................................................... 58

Store New Lift Pins .................................................. 58

Re-Install Link Lift Cylinders ........................................ 59

Re-Install Weight Transfer Cylinders............................59

Route Hoses and Harnesses........................................60

Hose ID for Pull Link Clamping.............................61

Connect Hoses and Harnesses....................................61

Update Markers...........................................................62

Remove Tension Spring ...............................................62

Release Swing Pivot.....................................................62

Release Cylinder ..........................................................62

Remove Arm.................................................................62

Remove Old Pivot Frame .............................................63

Install New Pivot Frame................................................63

Re-Install Arm...............................................................64

Re-Attach Spring ..........................................................64

Update Coulters..........................................................65

Prepare Implement .......................................................65

Replace Coulter Bars ...................................................65

Remove Existing Bar ................................................65

Install New Bar..........................................................66

Close-Out ....................................................................67

Reconfigure Monitor .....................................................67

Appendix A - Reference Information ........................68

Chain Setup..................................................................68

Chain Clip Orientation...............................................68

Chain Slack...............................................................68

Torque Values Chart ....................................................69

Hydraulic Connectors and Torque................................70

Appendix D - Drawings ..............................................71

160-795D PIN RETAINER TAB....................................71

160-801D FRAME NUT BLOCK...................................72

160-802D FRAME EXT BOT GUSSET LH REWORK .73

160-803D FRAME EXT BOX PLATE ...........................74

160-804D FRAME EXT BOT GUSSET LH REWORK .75

160-805D FRAME EXT BOT GUSSET REWORK......76

160-806D FRAME EXT BOT GUSSET REWORK.......77

160-807D FRAME EXT CORNER GUSSET................78

160-808D FRAME EXT 100 DEG GUSSET.................79

160-809D FR EXT 100 DEG GUSSET REWORK .......80

160-810D FR EXT 100 DEG GUSSET REWORK .......81

160-811D WING HINGE PIN ROTATION STOP .........82

Appendix G - Glossary...............................................83

Part Descriptor Abbreviations.......................................83

Appendix H - Harness ................................................85

Tower ID .......................................................................85

Secondary Hose Routing, 40-Row ...............................86

Turrets, 40-Row, Double-Shoot, Seed..................86

Turrets, 40-Row, Double-Shoot, Fertilizer ............87

Harness (LH) ................................................................88

Appendix P - Part Lists ..............................................90

Existing Parts Affected..............................................90

166-369A New Parts.................................................94

Index ............................................................................97

166-370M Table of Contents Index 05/25/2011

Page 5

Great Plains Manufacturing, Inc. Table of Contents Index 1

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that follows it. In addition to design and configuration of equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme situations,

typically for machine components that, for functional purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against

unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe practices.

Possible Chemical Hazard:

Have chemical gloves, respirator and goggles available. Have

clean wash water available. Have the MSDSa available for

recently applied dry fertilizer. This installation requires disconnecting one or two meters. Fertilizer can be hazardous,

and can cause lung irritation, respiratory distress, sickness or

poisoning. Know what steps to take if adverse exposure occurs.

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone. Have contact numbers

available.

a. MSDS: Material Safety Data Sheet

05/25/2011 Table of Contents Index 166-370M

Page 6

2 NTA607HD or NTA2007HD Table of Contents Index Great Plains Manufacturing, Inc.

Avoid High Pressure Fluids

High Pressure Fluid Hazard:

Wear gloves and goggles when opening hydraulic connections.

Use cardboard to check for leaks. This update requires opening existing hydraulic connections. Pre-installation steps may

not relieve all residual pressure. This update requires making

new hydraulic connections. Check for leaks carefully. If an

accident occurs, seek immediate medical assistance from a

physician familiar with this type of injury.

Sharp Object Hazard:

Be careful working near openers. Discs are sharp.

Be Familiar with Safety Decals

▲ Read and understand the “Safety Decals” in the Operator

manual.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

166-370M Table of Contents Index 05/25/2011

Page 7

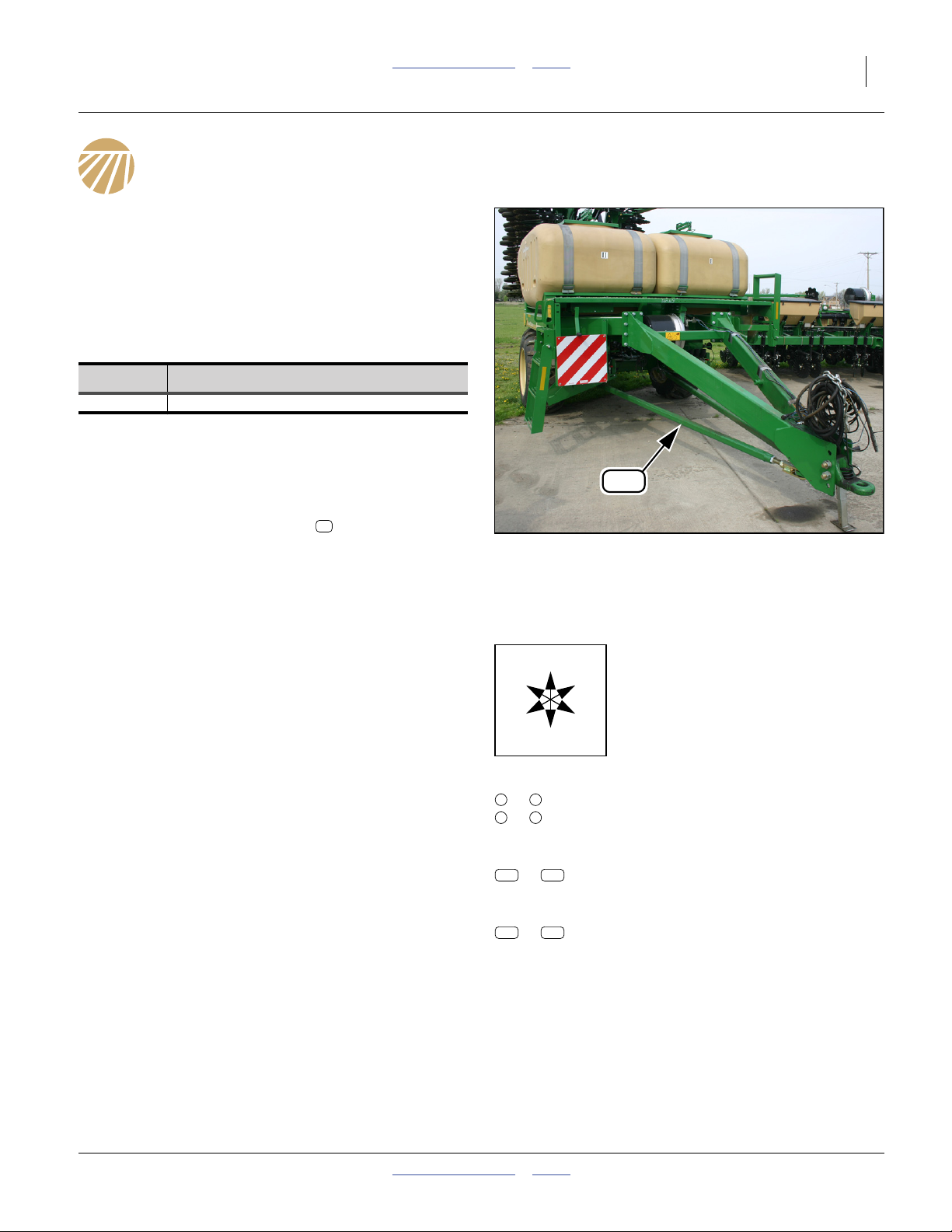

Great Plains Manufacturing, Inc. Table of Contents Index 3

General Information

These instructions explain how to update multiple drill

components. The kit improves drill durability in extremely

challenging conditions, and adds some convenience features.

One kit updates drill. Applies to models:

NTA607HD-4006 Option 72

NTA2007HD-4006 Option 72

These instructions apply to an installation of:

Kit Kit Description

166-369A 6 Meter No-Till Air Drill

• This kit applies only to dual-hopper (Option 72) drills.

It does apply to single-hopper models (whether single

150 bu or single 82 bu with liquid fertilizer tanks). The

kit is not fully documented for 64-row drills.

• This kit is not required for drills manufactured after

May 2011. If the lower pull-bars are present, kit

features are already installed.

• This kit is not required for any NTA607- or NTA2007(non-HD) drills.

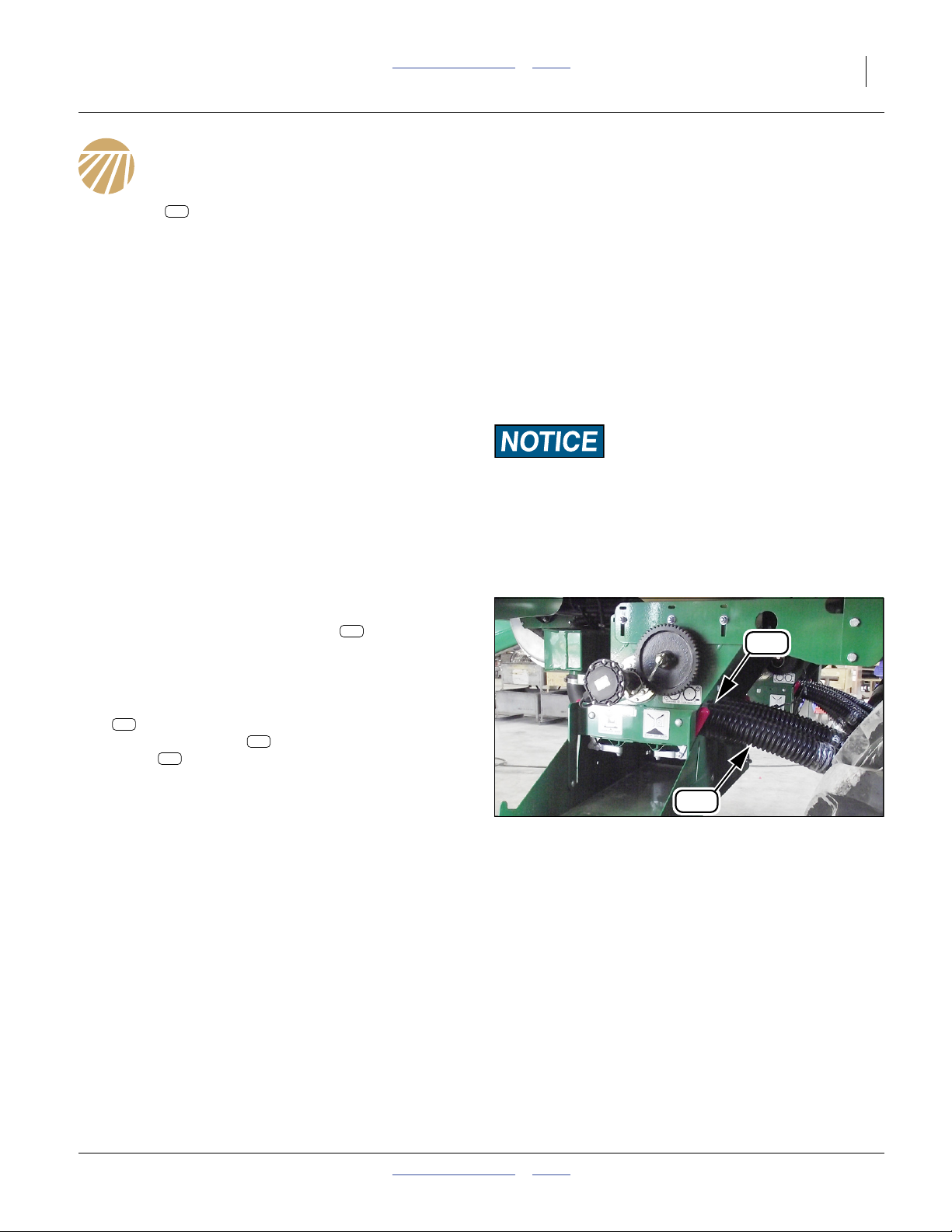

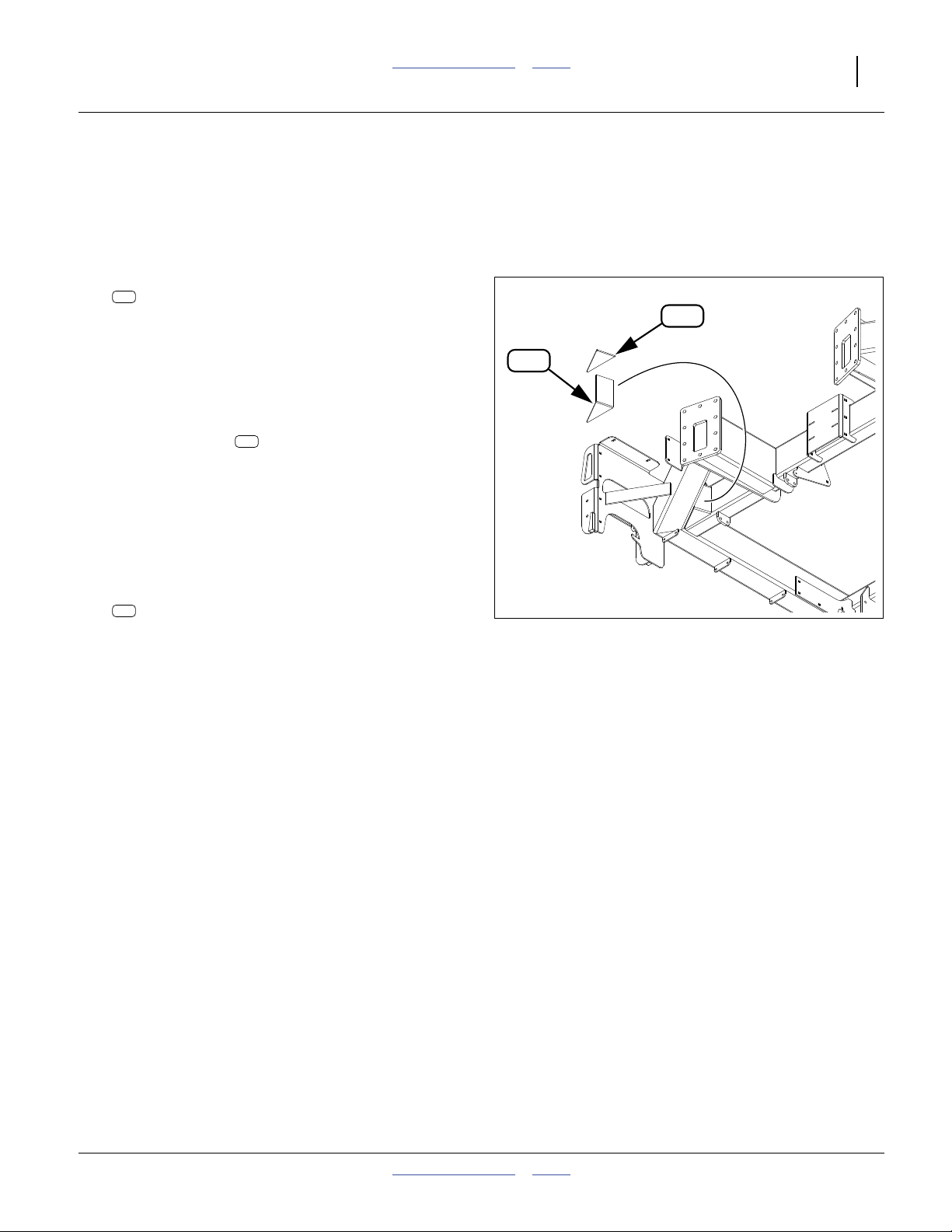

91

916

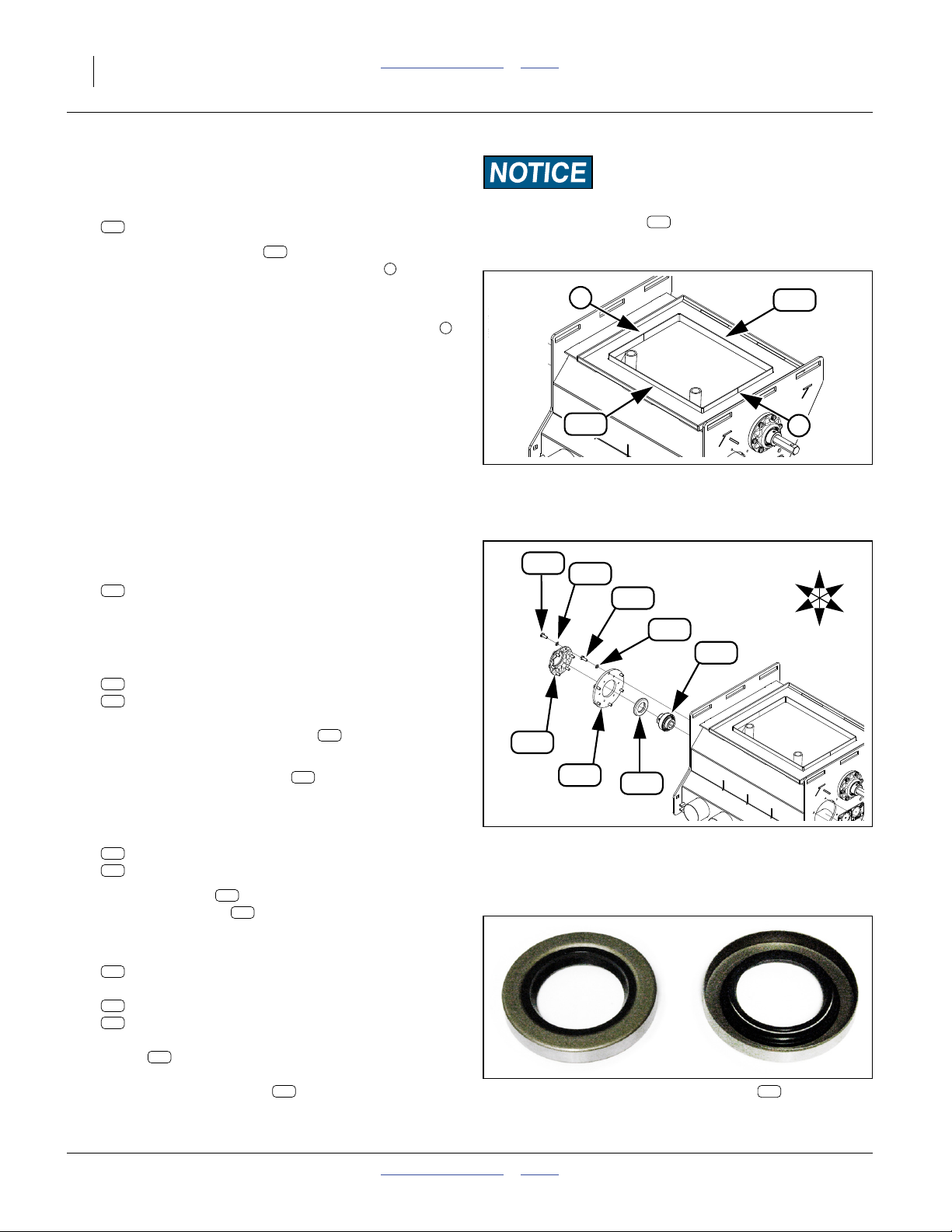

Figure 1

Kit Installed

32109

Related Documents

Have your drill Operator and Parts manuals available for

implement operations and parts identification. Have the

Pre-Delivery manual available for disassembly.

166-283M

166-283P

110011512

110011544

166-283Q

113-850M

All of the above drill manuals, including Pre-Delivery, are

available as PDF files on the Great Plains web site:

Manuals > No-Till Drills > No-Till Air Drills >

NTA607HD & NTA2007HD No-Till Air Drill

NTA607HD/2007HD Operator

NTA607HD/2007HD Parts

ACC (Air Cart Control) User Level 2/3

NTA607HD Quick Setup Guide

NTA607HD/2007HD Pre-Delivery

20ft Swing-Arm Marker Installation

Notations and Conventions

U

F

L

D

Call-Outs

1 9

to

a z

to

101

to Three-digit callouts in the range 101 to 239

900 982

to Three-digit callouts in the range 900 to 982

Single-digit or single-letter callouts identify

components in the currently referenced

Figure. These numbers may be reused for

different items from page to page.

239

reference existing parts from the list on

page 90.

reference new parts from the list on page 94.

“Left”/LH and “Right”/RH are facing in

the direction of machine travel. An ori-

R

entation rose in the line art illustrations

shows the directions of Left, Right,

Front, Back, Up, Down.

B

05/25/2011 Table of Contents Index 166-370M

Page 8

4 NTA607HD or NTA2007HD Table of Contents Index Great Plains Manufacturing, Inc.

Tools Required

• suitable tractor for lowering and unfolding drill

• hoist or other lifter with a capacity of at least

300 kg (660 pounds)

• jacks, supports or stands with a capacity of 1500 kg

(3500 pounds), for rear frame support

• fire extinguisher

• wire or rod welder, and welding safety equipment

• ground (earthing) rod, cable and clamp (or access to

suitable electrical safety ground reference conductor)

• welding blankets

• silicone sealant

• clamps (for welding), covering sizes:

13 mm (1⁄2in)

2.5 cm (1.0 in)

21 cm (8.25 in)

27 cm (10.5 in

• MSDSb for fertilizers recently applied

• chemical safety equipment (see DANGER on page 1)

• vehicle jack

• fish line for pulling hydraulic hose through tongue

• cutting wheel or grinder suitable for enlarging a slot

from 9 mm to 13mm wide

• basic hand tools, including drill bit size:

6 to 7 mm (1⁄4in, letter size E)

• Great Plains 821-001C green spray paint,

or green exterior enamel close to Pantone 356C,

DuPont 262 or PPG 43817

Regarding Parts

About New Parts

To aid in part identification, engineering drawings for

many new parts are included in “Appendix D - Draw-

ings”, pages 71 to 82.

After identifying a new part, just prior to installation,

remove and discard any tape or tags with part numbers

that might interfere with installation. Part numbers not

removed, or applied with grease or paint pencil, may be

removed at close-out.

A number of new cotter and roll pins are provided. Use

as needed when saved parts are unserviceable.

A large number of cable ties are provided. Use as

needed to secure cables and hoses. They are not called

out at every step.

About Existing Parts

This kit relies on re-use of some parts. Follow “remove

and save” instructions carefully. Parts that are “not

re-used” may be salvaged or discarded. They are not

returned to Great Plains.

Pre-Assembly Preparation

1. Perform a clean-out of both hoppers. This update

requires meter removal.

Work Location

2. Move the drill to a location with:

• ample room to unfold and separate the implement

from the cart

• adequate illumination

• a surface that is non-flammable, and has no

deposits or residues of flammable substances

• clear surface beneath for recovery of any falling or

dropped parts

b. Material Safety Data Sheet - consult the fertilizer supplier

166-370M Table of Contents Index 05/25/2011

High Pressure Fluid Hazard:

Wear gloves and goggles when opening hydraulic connections.

Use cardboard to check for leaks. This update requires opening existing hydraulic connections. Setting circuits to Float

may not relieve all residual pressure. This update requires

making new hydraulic connections. Check for leaks carefully.

If an accident occurs, seek immediate medical assistance from

a physician familiar with this type of injury.

Page 9

Great Plains Manufacturing, Inc. Table of Contents Index 5

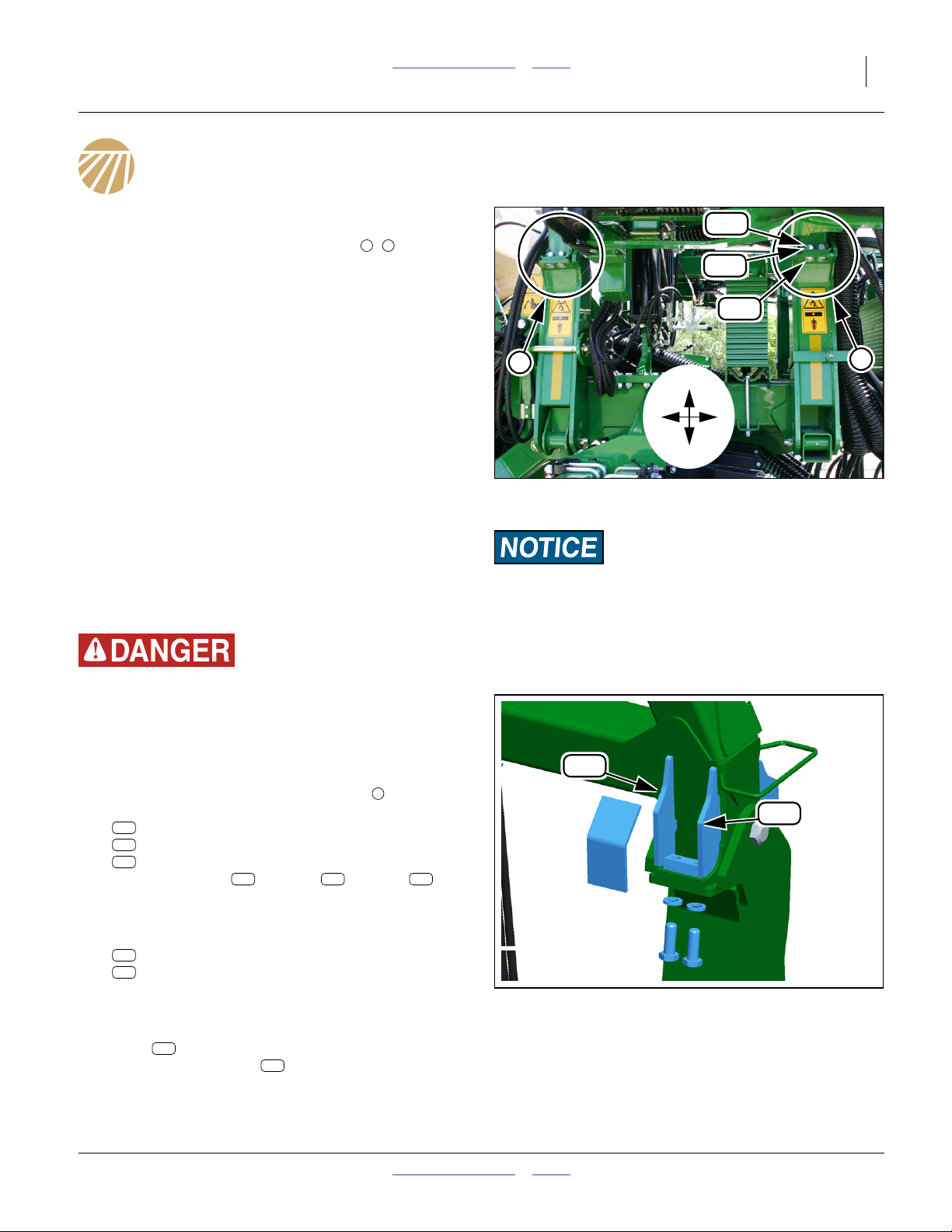

Update Underside Weldments

Refer to Figure 2

Gussets, nut blocks and a box plate are added to the

underside of the wing pivot extensions (4 , locations,

two on each wing). This work is considerably easier with

the implement folded, and needs to be done prior to

cart-implement separation.

B F

Configure Implement

3. Raise, fold and configure as if for transport (lift locks

and wing fold locks installed). Set all hydraulic

remotes to Float to relieve pressure in lines.

4. Disconnect all harnesses and cables at cart hitch.

5. Take steps to protect hoses and cables near weld

regions. Cover with welding blankets, or temporarily

remove, as needed.

Tack Rear Bottom Gussets

LH Rear Bottom Gussets

Start with the left (LH) side. The left and right side new

parts are not identical, although they are similar and

install in mirror-image locations.

179

190

174

F

B

U

F

B

D

Figure 2

Underside Work Locations

Equipment Damage Risk:

Disconnect all electrical connections between cart and tractor

prior to welding. Welding can induce high voltages and/or

high current flows that could damage sensors, WSMB and

WSMTs on the cart or implement.

Q0113

Crushing Hazard:

Remove only the underside bolts. Do not remove the

cross-bolts or the top side bolts. Removing all the fasteners at

a joint could allow a dangerous joint separation resulting in

serious injury or death, and extensive machine damage.

Refer to Figure 2

6. At the Back wing pivot extension joint , remove

two sets:

179

803-027C NUT HEX 3/4-10 PLT

190

804-023C WASHER LOCK SPRING 3/4 PLT

174

802-910C RHSNB 3/4-10 X 2 GR5 PLT

Save the washer . The nut and bolt are

not re-used.

Refer to Figure 3

7. Select one each new:

908

160-804D FRAME EXT BOT GUSSET LH REWORK

909

160-805D FRAME EXT BOT GUSSET REWORK

Hold these in their intended positions. Mark paint for

removal.

8. Remove paint. Tack weld gusset plates in position.

908

Plate is to implement front, against the existing

smaller gusset. Plate is to implement rear,

against the existing smaller gusset. Place both as

close to the joint and up against the wing as allowed

by pre-existing weld fillets.

190 179 174

909

B

908

Figure 3

LH Rear Underside Gussets

909

Q0120

05/25/2011 Table of Contents Index 166-370M

Page 10

6 NTA607HD or NTA2007HD Table of Contents Index Great Plains Manufacturing, Inc.

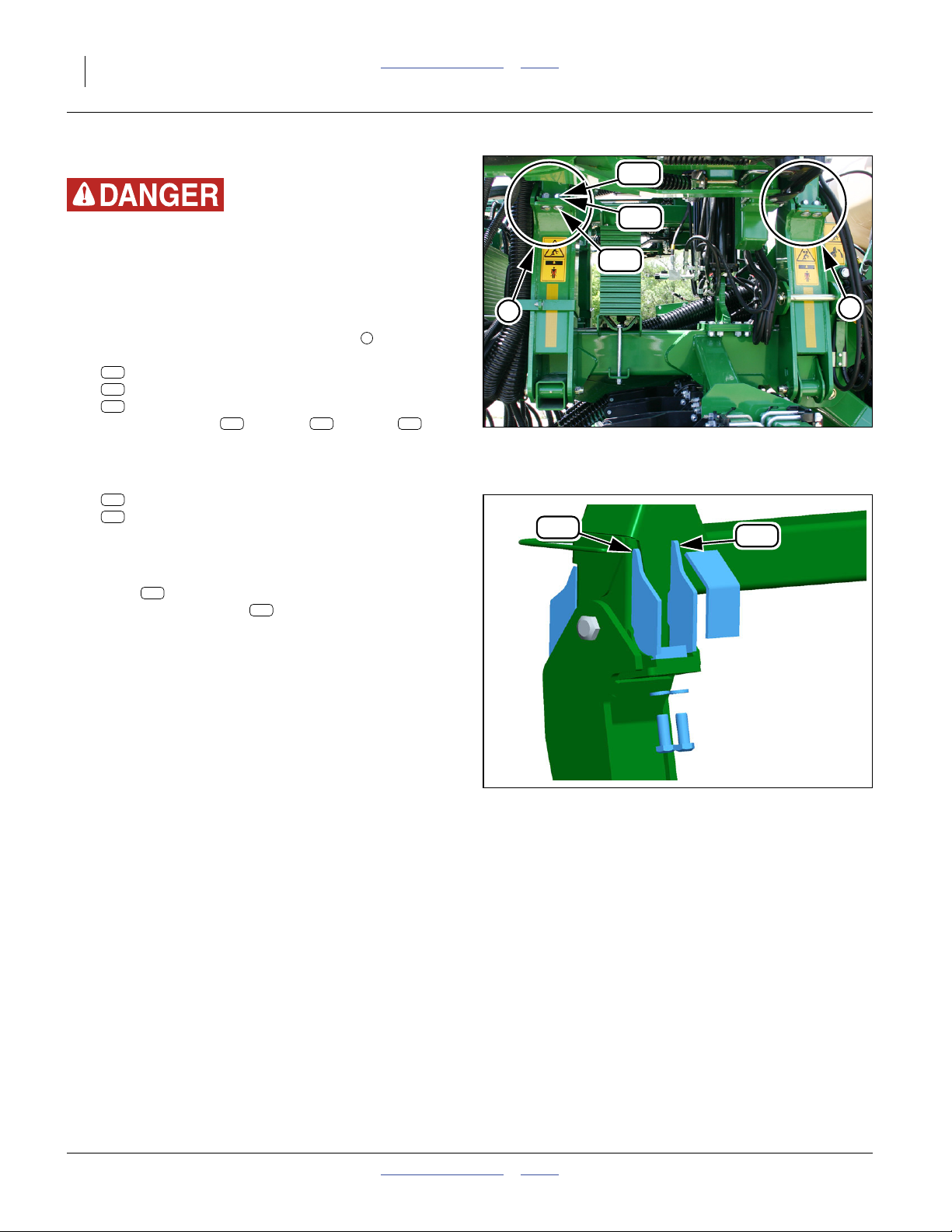

RH Rear Bottom Gussets

Crushing Hazard:

Remove only the underside bolts. Do not remove the

cross-bolts or the top side bolts. Removing all the fasteners at

a joint could allow a dangerous joint separation resulting in

serious injury or death, and extensive machine damage.

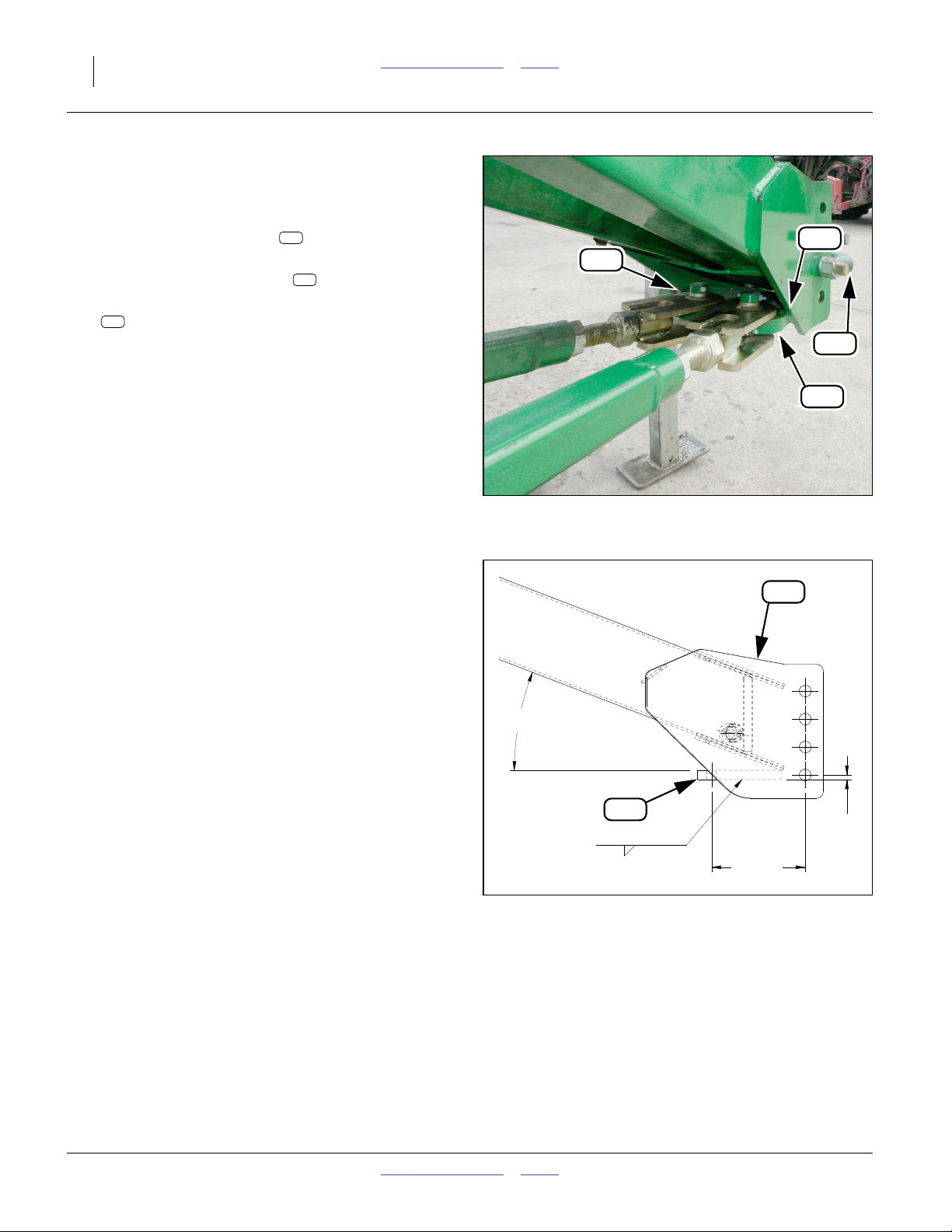

Refer to Figure 4

9. At the Back wing pivot extension joint , remove

two sets:

179

803-027C NUT HEX 3/4-10 PLT

190

804-023C WASHER LOCK SPRING 3/4 PLT

174

802-910C RHSNB 3/4-10 X 2 GR5 PLT

Save the washer . The nut and bolt are

190 179 174

not re-used.

Refer to Figure 5

10. Select one each new:

906

160-802D FRAME EXT BOT GUSSET LH REWORK

910

160-806D FRAME EXT BOT GUSSET REWORK

Hold these in the their intended positions. Mark

paint for removal.

11. Remove paint. Tack weld gusset plates in position.

906

Plate is to implement front, against the existing

smaller gusset. Plate is to implement rear,

910

against the existing smaller gusset. Place both as

close the joint and up against the wing as allowed

by pre-existing weld fillets.

B

B

910

179

190

174

Figure 4

Remove RH Fasteners

906

F

Q0113

Figure 5

Q0120

RH Rear Underside Gussets

166-370M Table of Contents Index 05/25/2011

Page 11

Great Plains Manufacturing, Inc. Table of Contents Index Update Underside Weldments 7

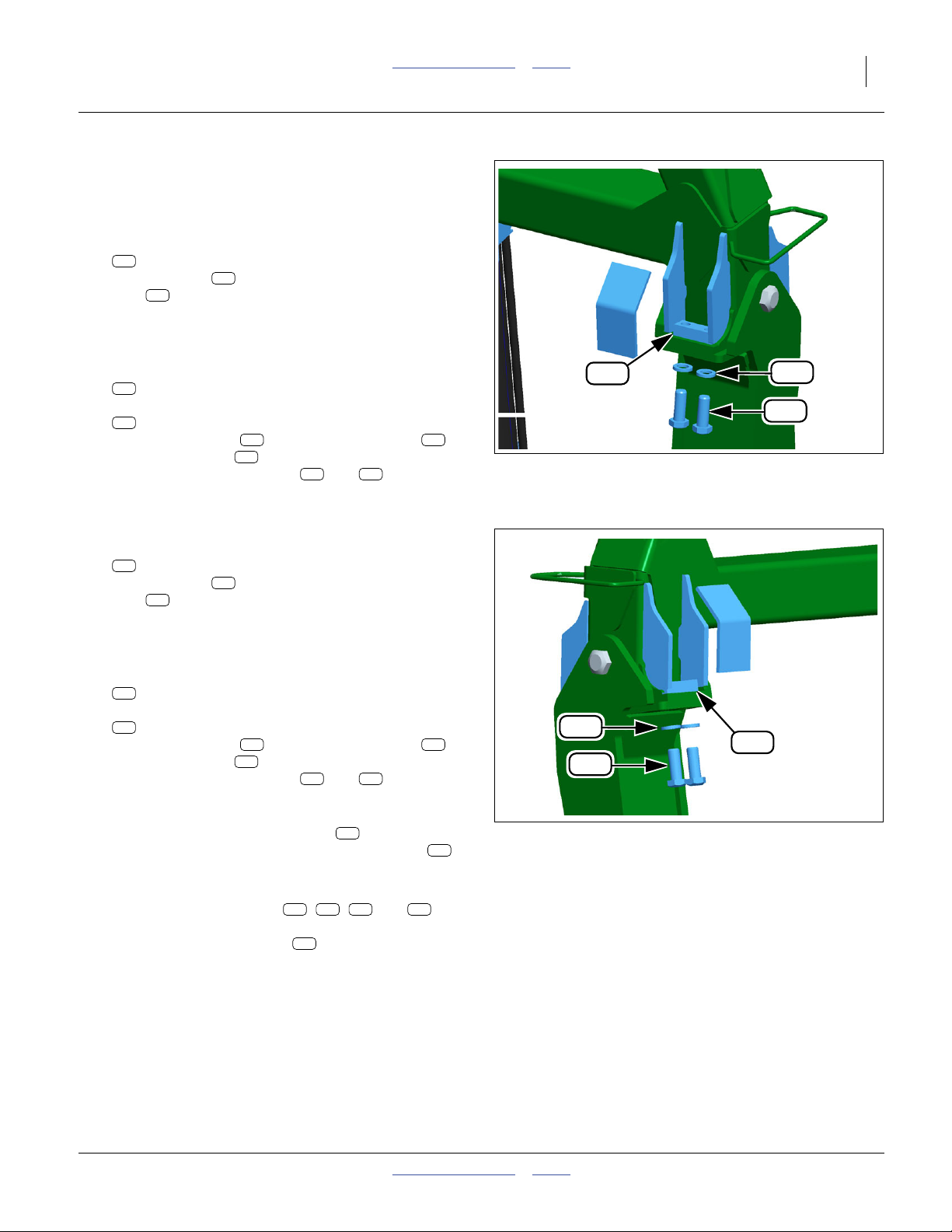

Install Nut Blocks

Install LH Nut Block

Refer to Figure 6

12. Select one new:

905

160-801D FRAME NUT BLOCK

This nut block replaces the removed individual

179

nuts . Prepare the site for welding. Using the nut

block as a template, mark an area for a width of at

least 5 cm (2 in) along the edges of the block.

Remove the paint from the pivot extension plate.

13. Select two new:

943

802-064C HHCS 3/4-10X2 GR5

and two saved:

190

804-023C WASHER LOCK SPRING 3/4 PLT

Hold the nut block in place with the bolts

and lock washers . Tack weld the nut block to the

wing and the new gussets ( and ).

Install RH Nut Block

Refer to Figure 7

14. Select one new:

905

160-801D FRAME NUT BLOCK

This nut block replaces the removed individual

179

nuts . Prepare the site for welding. Using the nut

block as a template, mark an area for a width of at

least 5 cm (2 in) along the edges of the block.

Remove the paint from the pivot extension plate.

15. Select two new:

943

802-064C HHCS 3/4-10X2 GR5

and two saved:

190

804-023C WASHER LOCK SPRING 3/4 PLT

Hold the nut block in place with the bolts

and lock washers . Tack weld the nut block to the

wing and the new gussets ( and ).

905

905 943

190

908 909

905

905 943

190

906 910

190

943

905

Figure 6

LH Nut Block

190

943

Q0119

905

Finish Weld Blocks and Gussets

16. Back off all four of the new bolts until the

threads are just emerging from the nut blocks .

943

905

Figure 7

RH Nut Block

This protects the block threads from weld splatter,

and leaves the bolts loose for checking.

17. Finish weld the gussets ( , , and ) all

906 908 909 910

around (as accessible) with a fillet of 7 mm (1⁄4in.).

Finish weld the nut blocks along any accessible

905

edges.

18. Clean off any slag and weld splatter.

05/25/2011 Table of Contents Index 166-370M

Q0120

Page 12

8 NTA607HD or NTA2007HD Table of Contents Index Great Plains Manufacturing, Inc.

Install Box Plates

Refer to Figure 8

19. Select two new:

907

160-803D FRAME EXT BOX PLATE

Position each plate to fully enclose the space define

by the new gussets, the existing joint plate and the

wing rear tube. Tack weld in place.

20. Finish weld all around on each box plate.

21. Clean off any weld splatter and slag.

22. Remove or mask the new bolts . Paint the new

gussets and each entire welded area green.

23. Insert the new bolts . Tighten to Grade 5 torque

943

specification.

24. Re-connect any hydraulic hoses or cables removed

for weld protection. They may be required for unfolding and lowering.

943

907

Figure 8

Box Plate

Q0120

Install Corner Gussets

Refer to Figure 9

The corner gussets are added near the joint

between the wing and the pivot extensions, at the junction between the rear-most (longer) of the existing

gussets , and the front-to-back wing tie plate .

1 2

25. Remove paint at the plate and gusset edges where

the corner gussets are to be installed.

26. Select two new:

911

160-807D FRAME EXT CORNER GUSSET

Tack weld each at the plate/gusset junctions.

27. Finish weld with a fillet of 9 cm (3⁄8in.).

28. Clean off all weld splatter and slag. Paint green.

911

2

1

911

Figure 9

Corner Gusset

Q0121

166-370M Table of Contents Index 05/25/2011

Page 13

Great Plains Manufacturing, Inc. Table of Contents Index 9

Disconnect Implement

The pull link that is the hitch between implement and

cart is replaced during this update. Removing the old link

early eases access for cart and implement updates.

106

Prepare Implement

29. Re-connect all harnesses and cables at cart hitch.

30. Raise and unfold the implement.

31. Set jacks or stands under the rear mainframe, under

the weights. Set their height to slightly higher than

the lowered position of the frame.

32. Lower the implement.

33. Set all hydraulic remotes to Float to relieve pressure.

34. Connect jack to tongue. Unhitch tractor. Disconnect

all electrical connections between tractor and cart.

35. Adjust tongue height with jack until bottom edges of

hitch side plates are level.

Disconnect Primary Hoses

Refer to Figure 10

36. Verify that each primary air hose , at the meter

end, is marked with the letter of the port to which it

is connected. If any markings are missing, write the

port letter on tape, and wrap it around the hose.

37. The the meter outlets, loosen eight:

159

800-180C 2 1/2 AIR HOSE BAND CLAMP

Slide these clamps several spirals onto to the

hoses . Re-tighten the clamps enough to prevent loss. Pull the hoses off the meter outlets.

132

159

132

Equipment Damage Risk:

Disconnect all electrical connections between cart and tractor

prior to welding. Welding can induce high voltages and/or

high current flows that could damage sensors, WSMB and

WSMTs on the cart or implement.

159

132

Figure 10

Primary Air Hoses at Meters

05/25/2011 Table of Contents Index 166-370M

Q0114

Page 14

10 NTA607HD or NTA2007HD Table of Contents Index Great Plains Manufacturing, Inc.

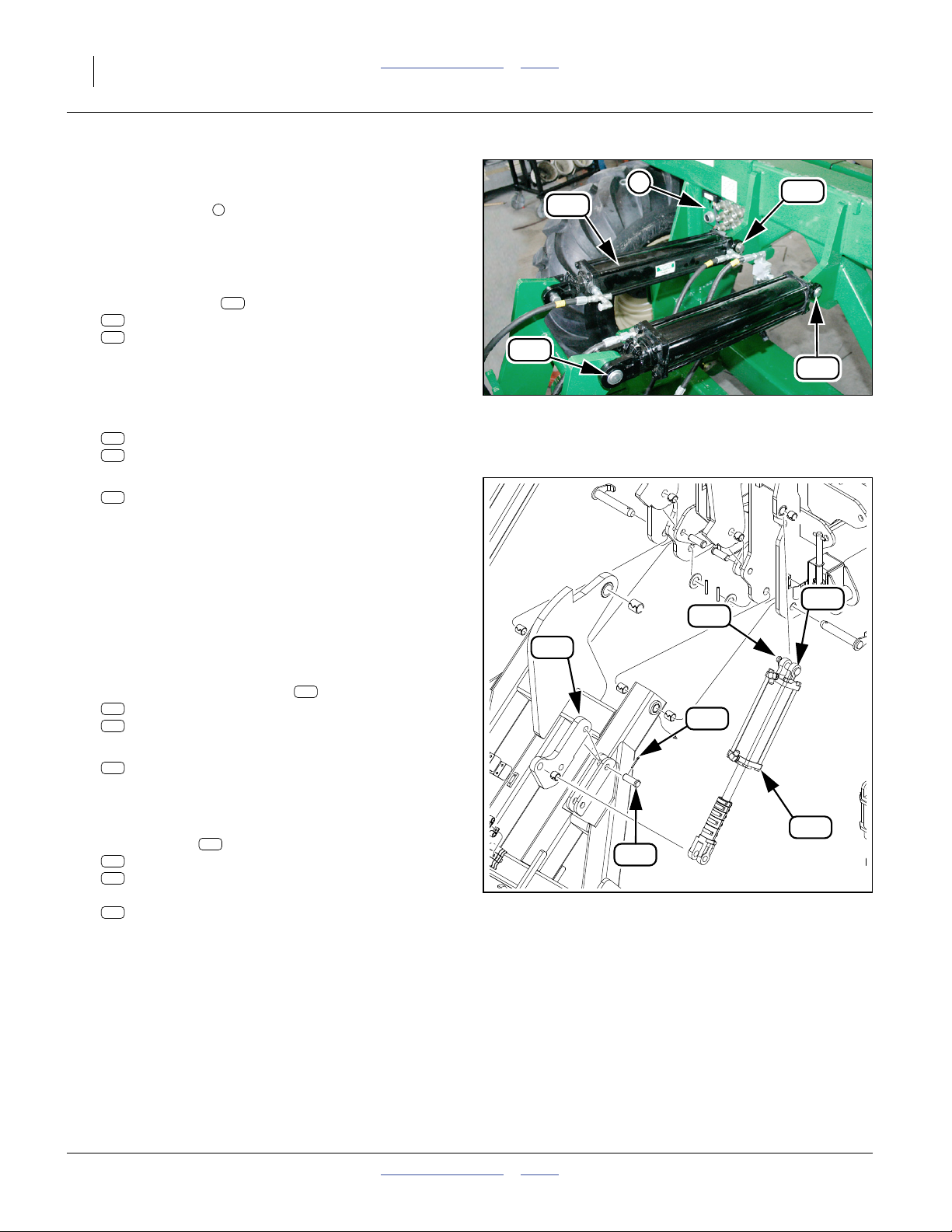

Clear Weight Transfer Cylinders

Refer to Figure 11

38. At the bulkhead at the left rear of the cart, unplug

1

all hydraulic hoses and cables. Some cable connects may not be at the bulkhead.

39. At the cart-implement pull link, remove and save

two sets of base end pins of the weight transfer

(upper) cylinders :

141

2A0132 MW PIN CLIP

140

2A0206 MW PIN SHORT

206

40. Release the cylinder hoses from any clamps on the

pull link.

41. At the rod ends of the weight transfer cylinders,

remove and save two sets:

141

2A0132 MW PIN CLIP

197

805-124C PIN CLEVIS 1 X 3 11/16 GR5 PLT

42. Lift the cylinders

206

810-219C CYL 3.5X16X2 ROD (TIE ROD)

off the pull link and rest them on the implement

frame. It may not be necessary to disconnect their

hoses.

206

197

Clear Weight Transfer Cylinders

1

Figure 11

141

140

Q0047

Clear Link Lift Cylinders

Refer to Figure 12

43. Release the cylinder hoses from any clamps on the

pull link.

44. Remove and save the clevis pins at each end of the

(lower) pull link lift cylinders :

141

2A0132 MW PIN CLIP

197

805-124C PIN CLEVIS 1 X 3 11/16 GR5 PLT

45. Lift the cylinders

205

810-170C CYL REP 3.5X10X1.25 ROD (TIE)

off the pull link and rest them on the implement

frame. It may not be necessary to disconnect their

hoses.

46. At the lift lugs , remove and save two sets:

195

805-104C PIN COTTER 3/16 X 1 1/2 PLT

199

805-187C PIN CLEVIS 1 X 2 1/4 GR5 PLT

115

then remove and save the lugs:

115

160-754D NTA607 PULL LINK CYLINDER LUG

205

115

141

195

199

Figure 12

Clear Link Lift Cylinders

197

205

Q0129

166-370M Table of Contents Index 05/25/2011

Page 15

Great Plains Manufacturing, Inc. Table of Contents Index Disconnect Implement 11

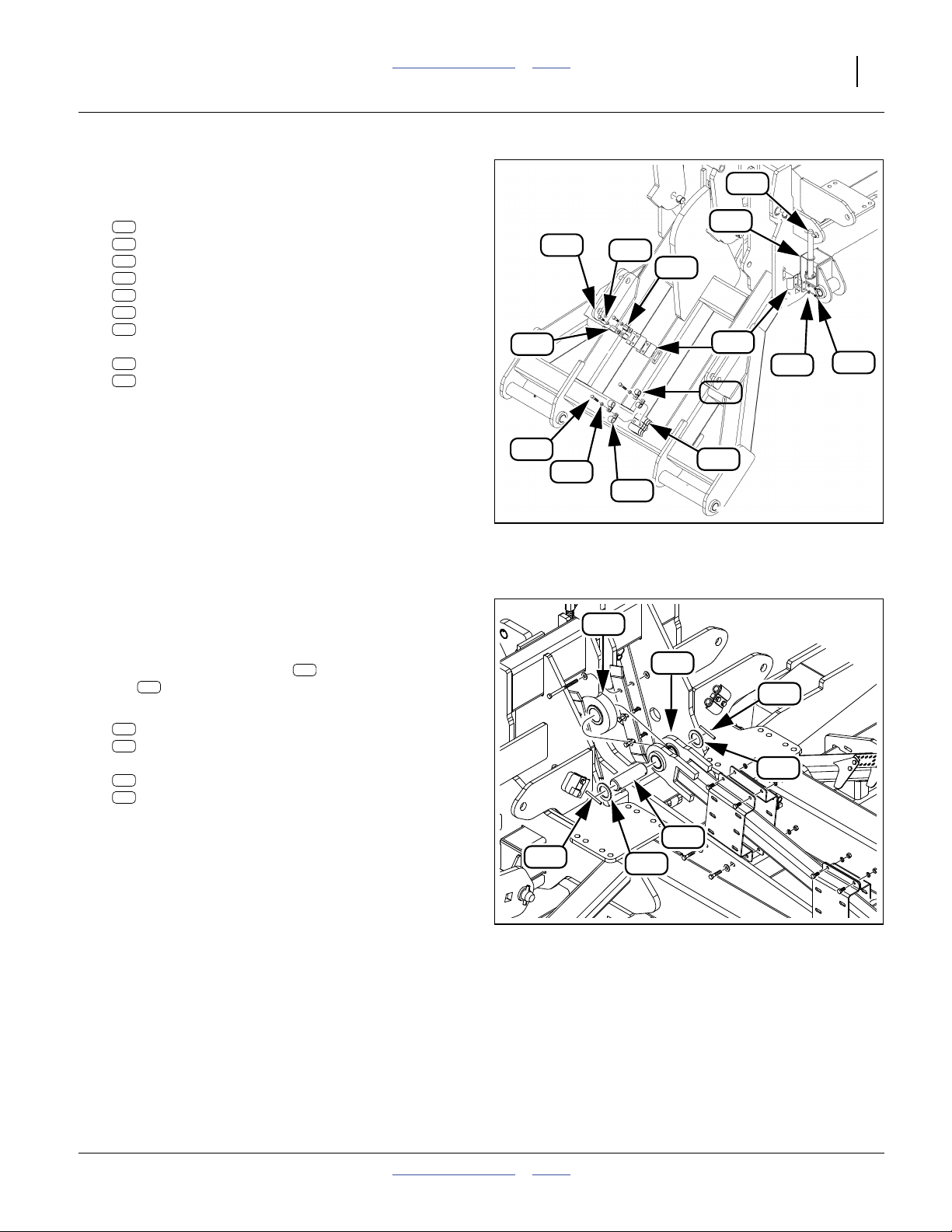

Recover Pull Link Components

Refer to Figure 13

47. Remove and save all clamps and their fasteners:

155

502-068D HYD HOSE CLAMP BRACKET

156

800-052C HOSE CLIP 5/8 I.D.

158

800-064C HOSE CLIP 13/16 ID

164

802-007C HHCS 5/16-18X3/4 GR5

165

802-012C HHCS 5/16-18X1 1/2 GR5

169

802-115C HHCS 5/16-18X2 GR5

184

804-009C WASHER LOCK SPRING 5/16 PLT

plus the:

116

160-760D TRANSPORT LOCK PIN 1 X 8.25

117

160-763D NTA607HD PIN STORAGE BRACKET

158

165

184

156

116

117

155

184

164

156

Release Lift-Assist Link

Refer to Figure 14

48. Verify that there is no tension at the connection

between the lift-assist link and the front pull link

106

lug .

49. Remove and save one roll pin and washer:

196

805-117C PIN ROLL 1/4 X 2 1/2 PLT

194

804-117C WASHER FLAT 1/4 HARD ASTMF436

then the link pin and remaining washer

118

160-781D PIN 1 1/2 X 4 USABLE 1045

194

804-117C WASHER FLAT 1/4 HARD ASTMF436

112

169

196

184

158

Clamp Recovery

106

194

155

Figure 13

112

118

Q0068

196

194

Figure 14

Lift-Assist Link

05/25/2011 Table of Contents Index 166-370M

31423

Page 16

12 NTA607HD or NTA2007HD Table of Contents Index Great Plains Manufacturing, Inc.

Uncouple Cart

Refer to Figure 15

50. At the forward (cart) end of the pull link , remove

and save two roll pins:

200

805-255C PIN ROLL 3/8 X 2 1/2 PLT

51. Support the weight of the pull link front end (or the

weight of the entire link), then remove and save two:

110

160-323H PIN WLDMNT 1.25 X 15.66 NR

106

110

200

200

110

106

Remove Pull Link

Pinch / Crush Hazards:

Use an adequate hoist or lifter. Use three or more lines. Place

lines where they cannot slip. The weldment weighs over

270 kg (600 pounds).

Refer to Figure 16

52. Remove and save two roll pins and washers:

200

805-255C PIN ROLL 3/8 X 2 1/2 PLT

193

804-039C WASHER FLAT 1 1/4 SAE PLT

53. Support the weight of the pull link . Remove and

save two pivot pins:

104

160-201H WING PIVOT PIN WELDMENT

54. Remove the weldment:

106

160-315H NTA607HD FRONT PULL LINK WLDMT

This weldment, and its bushings, are not re-used.

It is replaced by a new 160-315H weldment at

step 331 on page 57.

106

106

902

106

104

Figure 15

Pull Link at Cart

31422

193

200

Figure 16

Remove Pull Link

166-370M Table of Contents Index 05/25/2011

Q0129

Page 17

Great Plains Manufacturing, Inc. Table of Contents Index 13

Dismount Hoppers

Hoppers and their mount, are removed to:

• provide clearance to install new hopper braces;

• protect the hoppers from welding damage; and,

• ease update of meter supports.

The hoppers must be empty.

Supports are required. If an original export shipping rack

is available, it would be ideal. Otherwise, provide two

wide or four narrow supports of equal height, at least

33 cm (13 in.) in height.

Disconnect Sensors and Chain

151

146

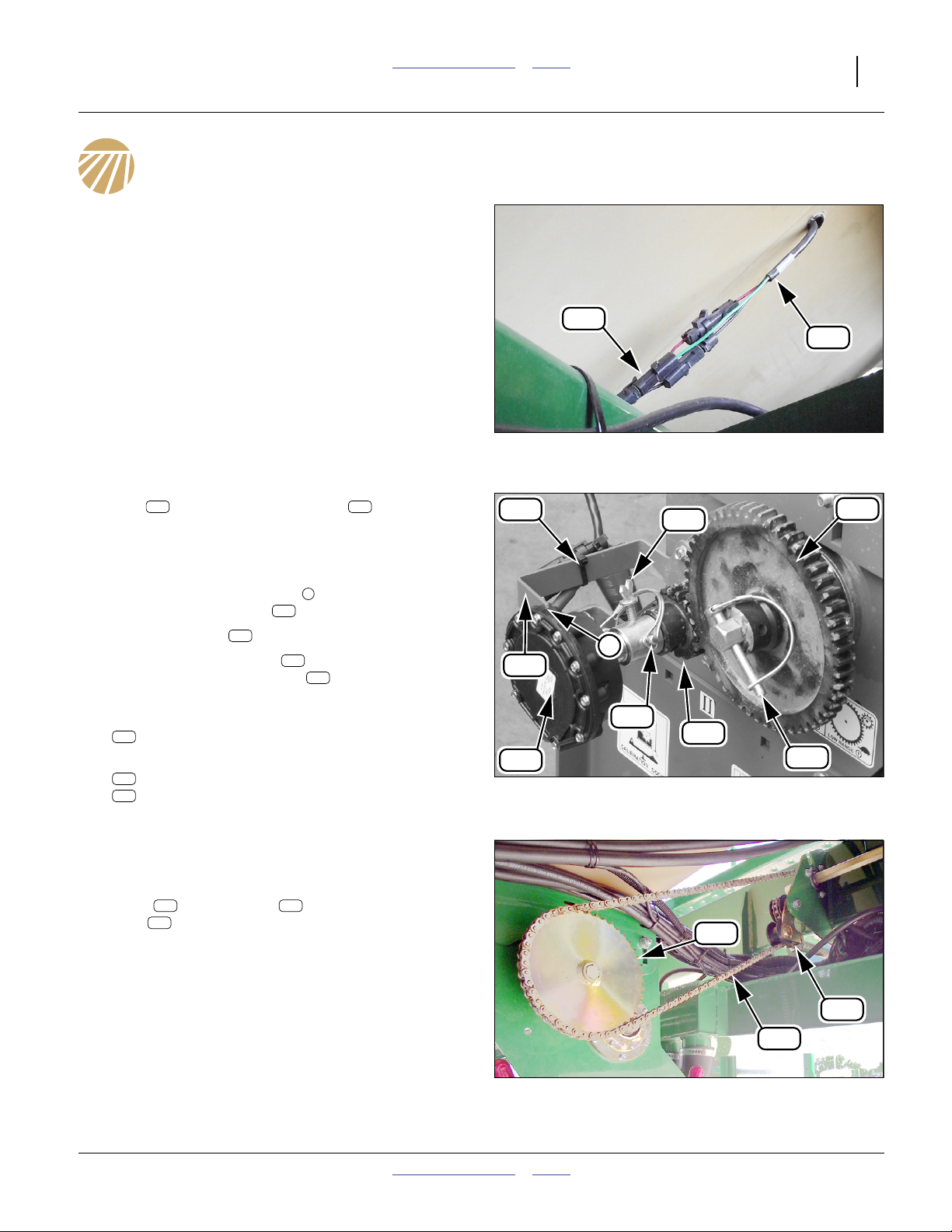

Disconnect Level Sensors

Refer to Figure 17

55. At each hopper, disconnect the hopper level sensor

146 151

lead from the air cart harness .

Dismount Rate Sensor

Refer to Figure 18

56. At the left end of each meter box, disconnect the

sensor’s anti-rotation strap ( , not visible in Figure),

from the sensor mount .

57. Cut the cable tie .

58. Loosen the thumbscrew .

Swing away the rate sensor .

Re-tighten the thumbscrew to prevent loss.

59. Remove and save two pins:

198

805-155C PIN WIRE RETAIN 5/16 X 2 1/2

60. Remove and save both gears:

130

168-243D GEAR 54 TOOTH QUICK CHANGE

204

808-192C GEAR 17 TOOTH QUICK CHANGE

157

2

162

162

145

Dismount Final Drive Chain

Refer to Figure 19

61. At the right end of each meter, loosen the final drive

221 102

idlers . Lift the chain off the meter input

129

gear . It is not necessary to remove the chain

entirely. The sprocket is left installed.

157

139

145

Figure 17

Hopper Level Sensor Lead

162

2

198

204

Figure 18

Rate Sensor

129

Q0101

130

198

31373

221

102

Figure 19

Final Drive Chain

05/25/2011 Table of Contents Index 166-370M

Q0033

Page 18

14 NTA607HD or NTA2007HD Table of Contents Index Great Plains Manufacturing, Inc.

Dismount Meters

Disconnect Meter Inlet Elbows

Refer to Figure 20 and Figure 21

62. At the meter inlets, loosen each clamp . Slide it

well onto the elbow . Re-tighten enough to pre-

219

160

vent clamp loss. It may be difficult to remove elbows

until the meter is freed in its mounts.

63. Close the meter chute (not shown).

Remove Meters

Pinch / Crush Hazards:

Use a jack or at least two strong people. The meter assembly

weighs up to 78 kg (171 pounds), with chute installed.

Refer to Figure 21 (depicting a meter with chute removed)

64. Loosen the six nuts that secure the meter to

its mounts . Pull the meter back from the

elbows .

138

219

65. With the loose bolts still in place, allow the meter to

drop in the vertical slots of the mount. If it does not

drop, this suggests that the meter vent tubes have

bonded to the vent structure inside the hopper.

66. With the meter freed from the hopper vent structure,

support the full weight of the meter. At each meter,

completely remove six sets (not all shown):

176

803-014C NUT HEX 3/8-16 PLT

186

804-013C WASHER LOCK SPRING 3/8 PLT

185

804-011C WASHER FLAT 3/8 USS PLT

172

802-155C RHSNB 3/8-16X1 1/4 GR5

These fasteners are replaced by new1⁄2in fasteners

at step 158 on page 28.

67. At the rear end of the existing meter mounts ,

remove and save six sets (not shown):

177

803-020C NUT HEX 1/2-13 PLT

187

804-015C WASHER LOCK SPRING 1/2 PLT

167

802-082C HHCS 1/2-13X1 3/4 GR5

and the two:

138

266-174D METER BOX MOUNT

The mount is not re-used.

176 124

138

124

219

Meter Hoses

Confined Space and Agricultural Chemical Hazards:

If the meter vents have bonded to the hopper vent structure,

hopper entry may be required to free the connection. Consult

the Operator manual (166-283M) for safe entry procedures.

The hopper may be a low-oxygen environment with risk of

asphyxiation. Dust and chemical residues can be an inhalation

and skin contact hazard, causing irritation, respiratory distress, illness or death.

176

160

Figure 20

138

31149

219

124

160

Figure 21

Q0030

Lowering Meter on a Jack

166-370M Table of Contents Index 05/25/2011

Page 19

Great Plains Manufacturing, Inc. Table of Contents Index Dismount Hoppers 15

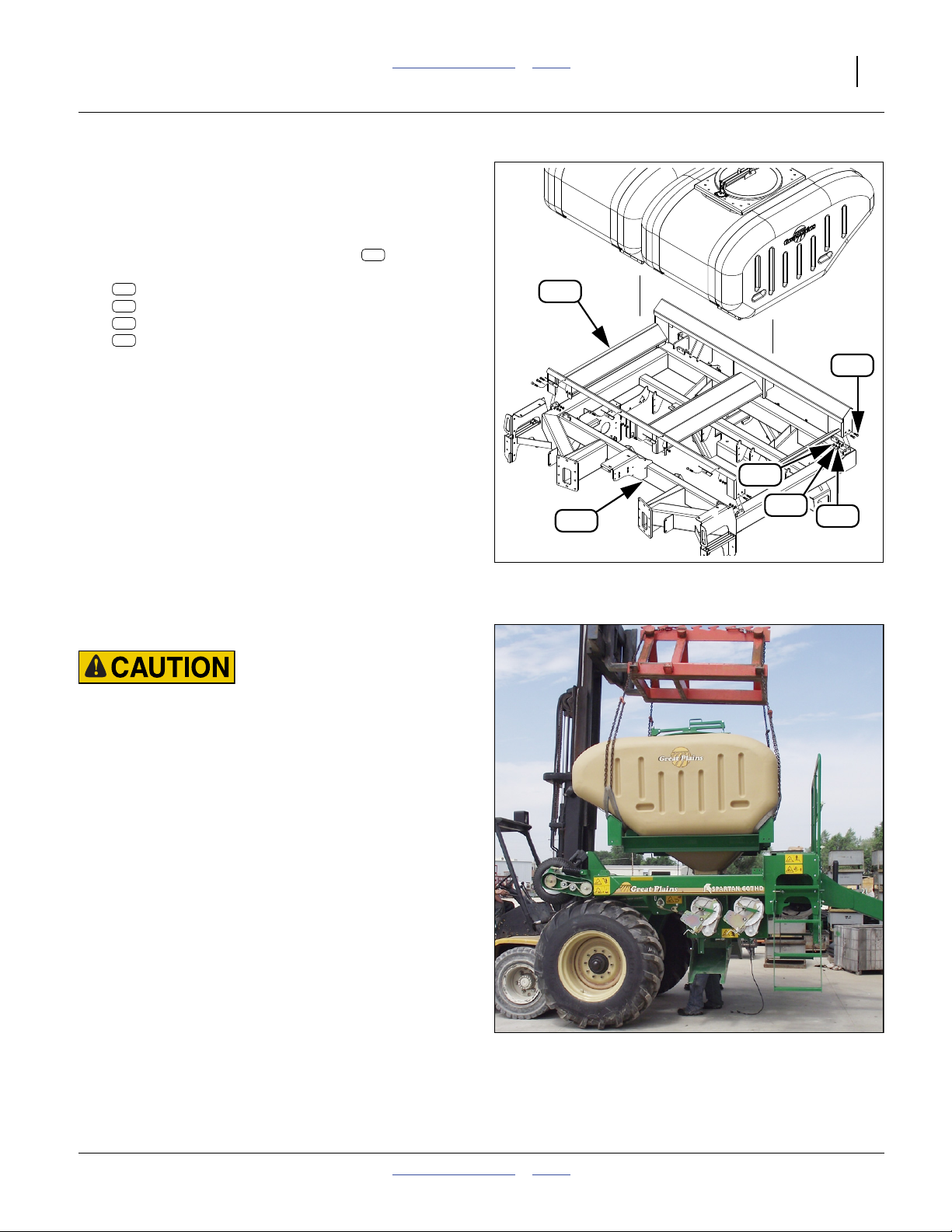

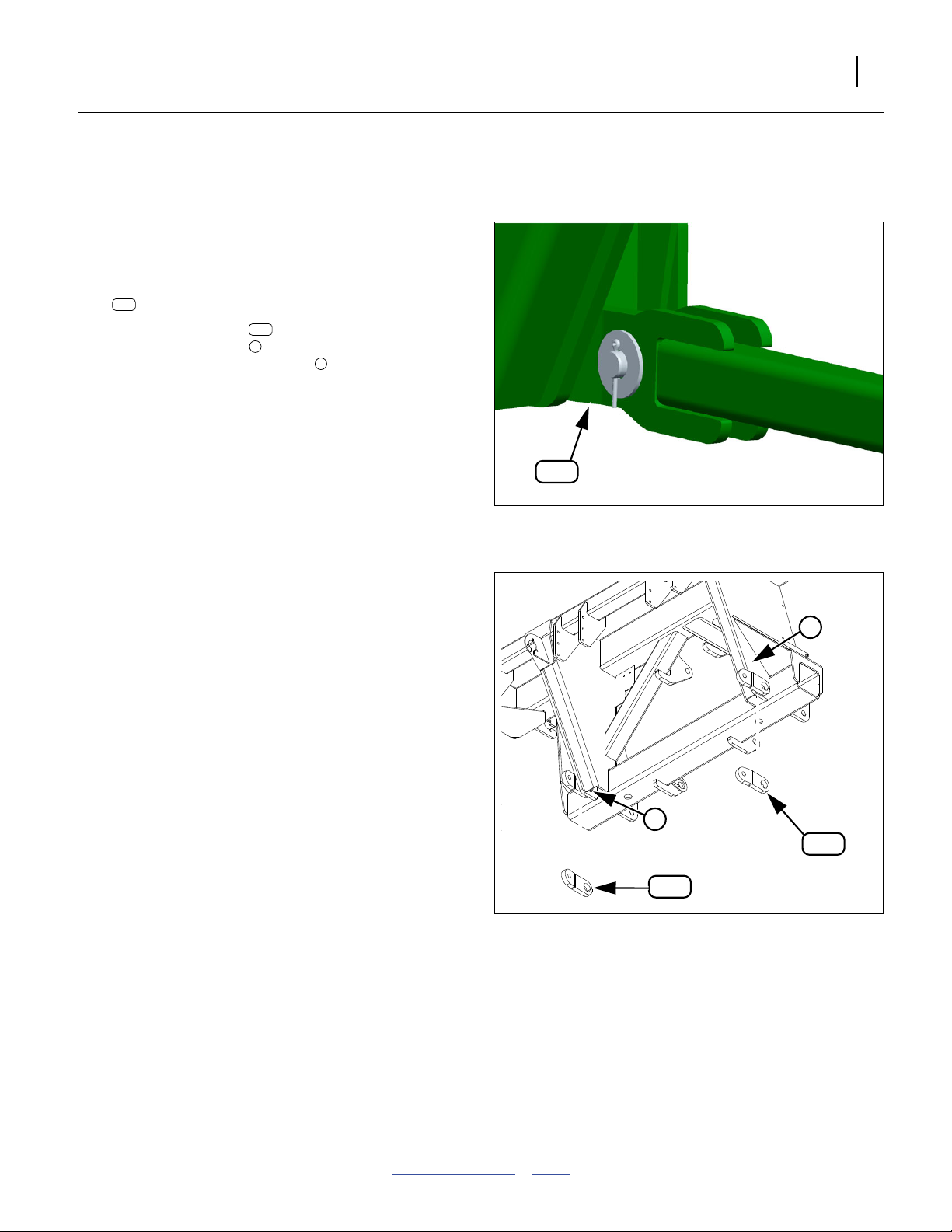

Hoist Hoppers

Release Hopper Mount

Refer to Figure 22 (shown with hoppers floating - leave hoppers attached to mount)

68. At each corner of the hopper mount , remove

and save two sets (8 sets total) of:

177

803-020C NUT HEX 1/2-13 PLT

187

804-015C WASHER LOCK SPRING 1/2 PLT

188

804-017C WASHER FLAT 1/2 USS PLT

167

802-082C HHCS 1/2-13X1 3/4 GR5

122

122

167

177

Remove Hopper Assembly

Pinch / Crush Hazards:

Use an adequate hoist or lifter. Use three or more lines, each

rated for at least half the load. Place lines where they cannot

slip. The assembly weighs nearly 550 kg (1200 pounds).

Refer to Figure 23

69. Attach lines to the hopper assembly. Carefully lift it

off the cart frame. Set it on the supports.

121

Figure 22

Hopper Mount at Frame

187

188

31108

Figure 23

Hoisting Hopper Mount

05/25/2011 Table of Contents Index 166-370M

Q0102

Page 20

16 NTA607HD or NTA2007HD Table of Contents Index Great Plains Manufacturing, Inc.

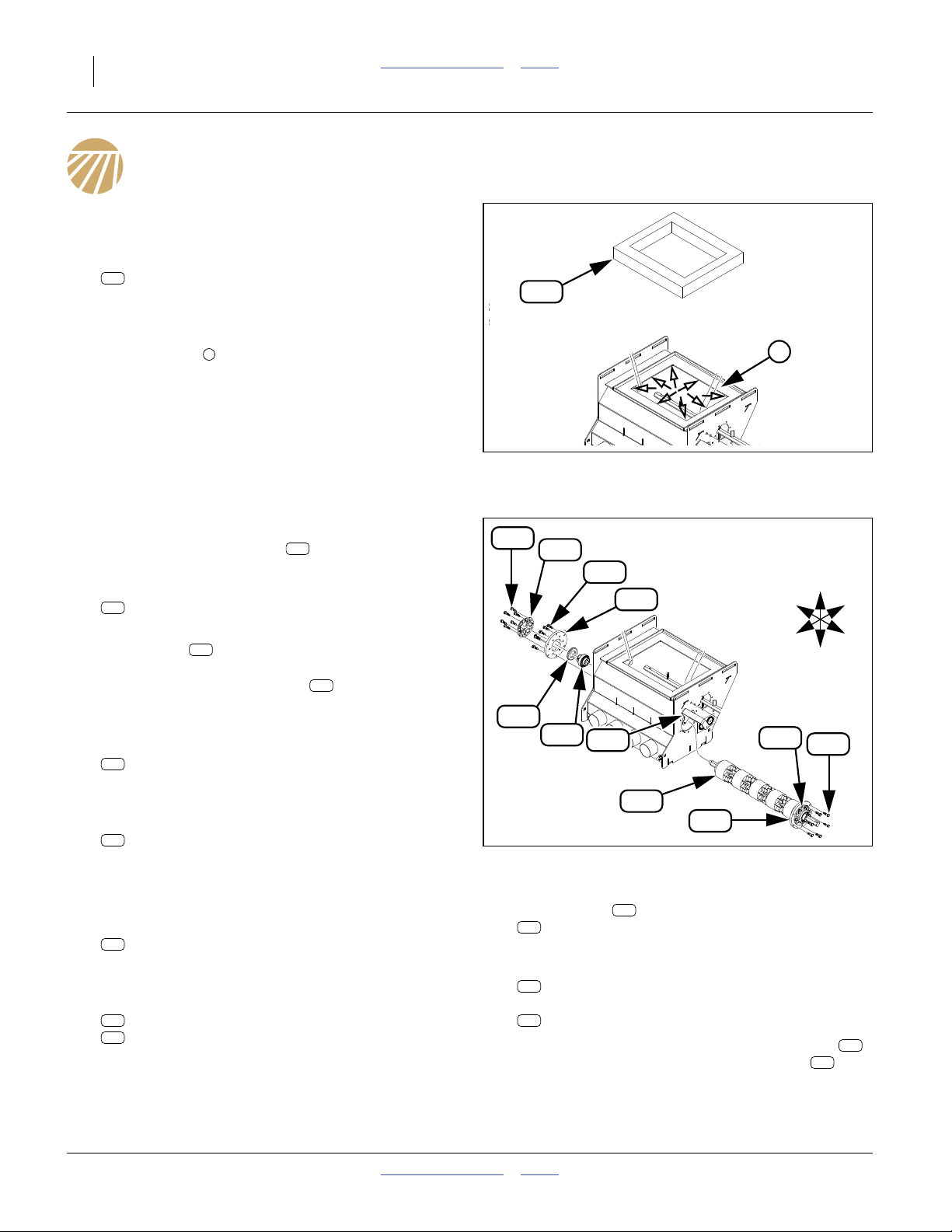

Update Meters

Remove Existing Top Seal

Refer to Figure 24

70. Remove the existing top seal:

220

816-662C METER TOP SEAL

This part is replaced by a new seal at step 104.

71. Prepare the top panel for welding and re-sealing.

Clean all top seal adhesive residue from the top

panel opening . If necessary, use sandpaper or

other abrasives.

72. Prepare the top panel for tack welding. Remove a

3

1cm(

way along each side of the top panel opening,

shown as small open arrows.

⁄8in) circle of paint at each corner, and half-

1

Remove Meter Flute Shaft

220

Figure 24

Meter Top Seal

1

Q0103

Refer to Figure 25

73. At the right end of the flute shaft, release the set

screw in the bearing collar .

74. At the left end of each meter, remove the six outer

screws:

163

801-151C SCR HEX SELF TAP 1/4-20X1TYPEF

These screws are not re-used.

Note: The plates is usually have a silicone sealant

bead around their circumference, and possibly on

the face. The bearing flange also has a silicone seal bead. Use a knife to cut the fillets, and a

sharp flat tool to pry components apart.

75. Withdraw and save the flute shaft assembly, one of:

125

166-308S 4-OUTLET METER 2-STAR SHFT ASY

166-320S 4-OUTLET METER 3-STAR SHFT ASY

166-321S 4-OUTLET METER 4-STAR SHFT ASY

76. Recover and save the sensor mount:

139

266-187D METER SENSOR MOUNT

131

134

231

Remove Old Flanges

77. At the right end of each meter, remove the six outer

screws:

163

801-151C SCR HEX SELF TAP 1/4-20X1TYPEF

These screws are not re-used.

78. Pry the flange assembly off the meter wall. Recover

and save one set:

134

188-009V BRG .755 HEX BORE W/S-S

218

816-199C SEAL 1.33IDX2.23ODX.31T

163

231

163

131

U

R

F

D

218

134

139

231

163

125

131

Figure 25

Meter Flute Shaft

79. At each plate , remove the six inner screws:

163

801-151C SCR HEX SELF TAP 1/4-20X1TYPEF

These screws are not re-used.

80. Separate (and save) bearing flange:

231

890-466C HSG RIBB FLG 6BOLT PLT

and mount plate (which is not saved):

131

168-409D METER SHAFT MOUNT PLATE

81. Clean the meter wall and both bearing flanges

of any silicone sealant residue. The plates are

not re-used and do not require cleaning.

131

Q0103

131

B

L

231

166-370M Table of Contents Index 05/25/2011

Page 21

Great Plains Manufacturing, Inc. Table of Contents Index Update Meters 17

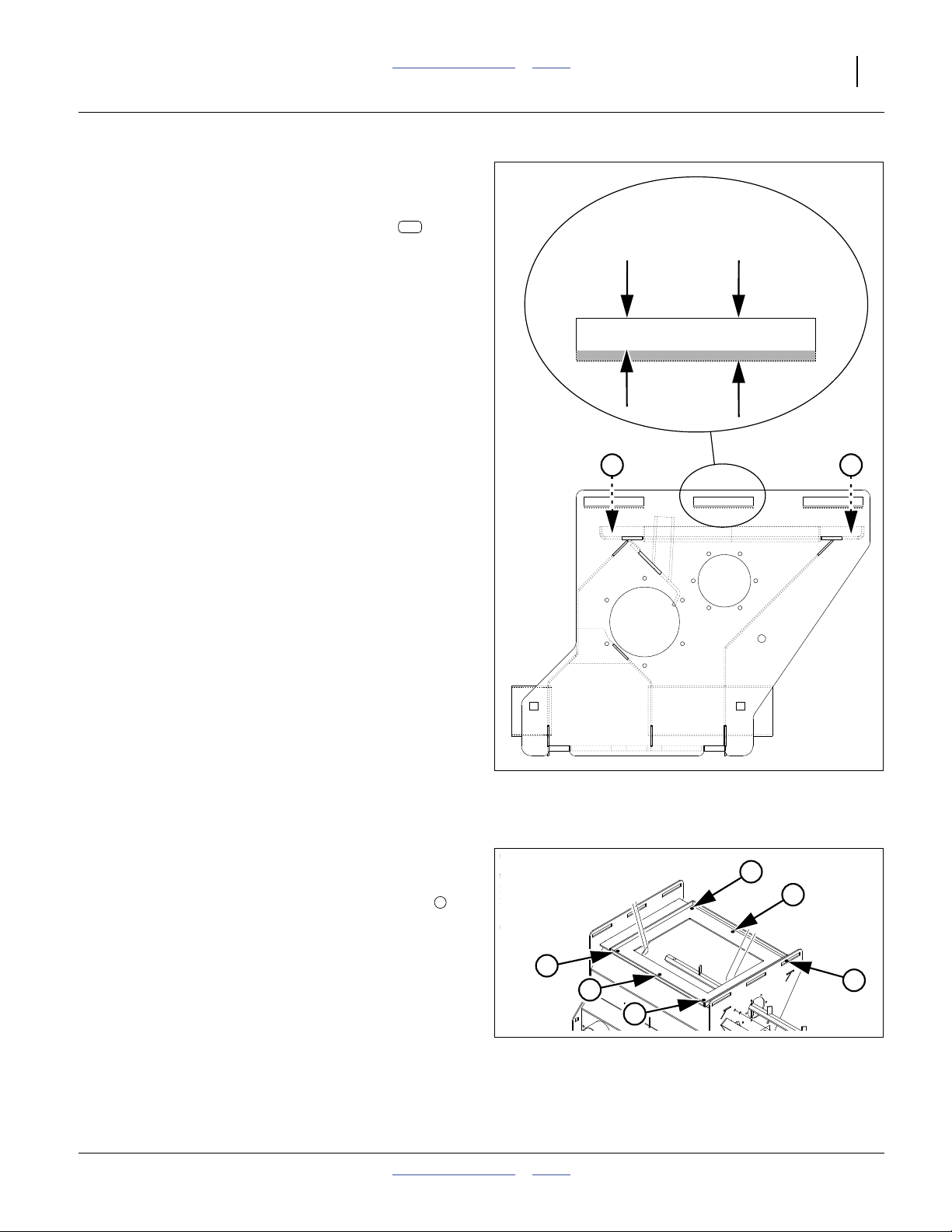

Enlarge Mounting Slots

Refer to Figure 26

The previous

with new1⁄2in (13 mm) bolts. The new mounts (not

shown) have 13.5 mm slots, but the existing slots in the

meter sidewalls do not. They need to be enlarged.

82. Use a cutting wheel, die grinder, or any suitable tool

to enlarge the six 10 mm slots to 13.5 mm.

Enlarge down (away from the top edge of the meter

sidewall). In the Figure, cut away the gray area.

3

⁄8in (9 mm) mounting bolts are replaced

919

Previously:

10 mm

(0.41 in.)

Enlarge to:

13.5 mm

(0.53 in.)

2 2

Figure 26

Mounting Slot Enlargement

Q0108

Drill Weep Holes

Refer to Figure 26 and Figure 27

83. Mark the meter top panel for six hole positions .

Each hole is to be 6 to 7 mm in diameter (1⁄4in). The

location needs to be clear of the existing outer

flange, and clear of the front and back meter faces

under the top panel (so that any future drainage is

outside the meter, and so that the weep holes do

not compromise air pressure control inside the

meter).

84. Drill and de-burr six holes.

05/25/2011 Table of Contents Index 166-370M

2

2

2

2

Figure 27

Top Panel Weep Holes

2

2

2

Q0103

Page 22

18 NTA607HD or NTA2007HD Table of Contents Index Great Plains Manufacturing, Inc.

Install Meter Seal Flange

Refer to Figure 28 (new holes not shown)

85. For each meter, select two new:

924

266-306D METER SEAL FLANGE

86. Clamp the flange seals on the meter top panel,

around the opening. Make sure the ends of the

924

3

seals touch each other.

87. Tack weld the seal to the top panel at the corners,

halfway point on front and back, and at end joints .

88. Clean off any splatter or burned paint.

89. Allow the welds to cool.

90. Touch up bare/discolored areas with green enamel.

91. Allow paint to dry. Apply a bead of silicone sealant

to the inside corner of the top panel / seal flange

joint. Smooth the bead into a fillet shape.

Replace Meter Shaft Mount Plates

Replace Right End Plates

Refer to Figure 29

92. For each meter, select one new:

918

168-472D METER SHAFT MOUNT PLATE

Apply a bead of silicone sealant to one face of the

plate, in a circle around each outer bolt hole, and in

a circle on the outer bolt hole center-lines.

93. Select six sets new:

942

802-001C HHCS 1/4-20X3/4 SS

959

804-033C WASHER LOCK 1/4 SS

Apply silicone sealant under bolt heads and under

washer faces. Secure the plate to the right end

of the meter. Smooth excess sealant to fillet shape.

94. Select the saved flute shaft . Temporarily insert

the flute shaft from meter left.

Refer to Figure 30

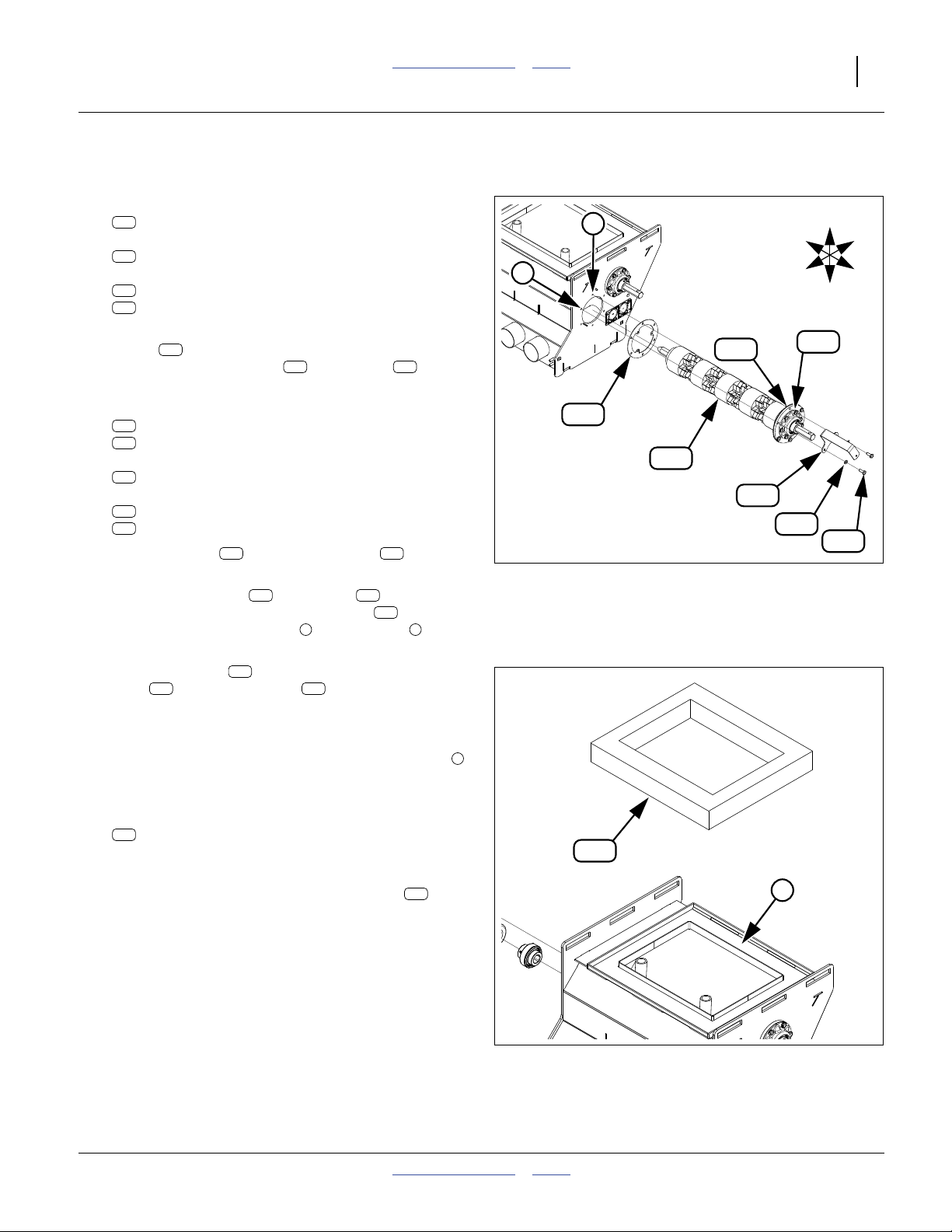

95. Select one set saved:

134

188-009V BRG .755 HEX BORE W/S-S

218

816-199C SEAL 1.33IDX2.23ODX.31T

Add the bearing , with set screw collar to the

right. Add the seal with the solid face to the out-

134

218

side and the open face toward the meter.

96. Select one saved:

231

890-466C HSG RIBB FLG 6BOLT PLT

and six sets new:

942

802-001C HHCS 1/4-20X3/4 SS

959

804-033C WASHER LOCK 1/4 SS

Apply silicone sealant to the outer rim of the

flange . Place the flange over the bearing. Apply

231

silicone sealant under bolt heads and under washer

faces. Secure the flange to the right end of the

meter. Smooth any excess sealant into a fillet

shape.

918

125

231

Equipment Damage Risk:

Check that the flute shaft ( in Figure 25 on page 16) is

125

removed prior to welding. Slag and splatter can rapidly and

severely damage meter flutes and fillers.

3

3

924

Figure 28

Meter Seal Flange

942

959

942

959

134

231

918

Figure 30: 816-199C Seal

218

Figure 29

Right Shaft Mount Plate

218

Orientation: Outside / Inside

924

3

R

F

Q0103

U

B

L

D

Q0103

32122

166-370M Table of Contents Index 05/25/2011

Page 23

Great Plains Manufacturing, Inc. Table of Contents Index Update Meters 19

Replace Left End Plates

Refer to Figure 31

97. For each meter, select one new:

R

F

231

U

B

L

D

918

168-472D METER SHAFT MOUNT PLATE

one saved:

231

890-466C HSG RIBB FLG 6BOLT PLT

and six sets new:

942

802-001C HHCS 1/4-20X3/4 SS

959

804-033C WASHER LOCK 1/4 SS

98. Apply silicone sealant to the outer rim of the

flange , under bolt heads and under washer

faces. Secure the flange to the plate .

231

231 918

4

5

918

Smooth excess sealant to fillet shape.

99. Select one each saved:

125

166-308/20/21S 4-OUTLET STAR SHAFT ASY

139

266-187D METER SENSOR MOUNT

and one new:

977

816-693C AIR DRILL METER SHAFT GASKET

and six sets new:

942

802-001C HHCS 1/4-20X3/4 SS

959

804-033C WASHER LOCK 1/4 SS

100. Insert the shaft through the gasket , left wall

125 977

of meter, and bearing at right wall of meter.

101. Place lock washers on all bolts . Insert two

of the bolts through the sensor mount . The

sensor mount uses the top and top-front bolt

959 942

139

4 5

977

125

139

Figure 31

Left Shaft Mount Plate

959

942

Q0103

holes at the left meter wall.

102. Secure the plate to the left end of the meter with

942 959

bolts and lock washers .

918

Install New Top Seal

Refer to Figure 32

103. At each meter, clean and de-grease the top panel

6

in the area between the outer flange and the new

inner flange.

104. Select one new:

976

816-662C METER TOP SEAL

Before removing the release paper backing, make a

976

trial fit of the seal on the top panel.

105. Remove the backing paper. Bond the seal to

976

6

the top panel.

Figure 32

Q0103

Install Top Seal

05/25/2011 Table of Contents Index 166-370M

Page 24

20 NTA607HD or NTA2007HD Table of Contents Index Great Plains Manufacturing, Inc.

166-370M Table of Contents Index 05/25/2011

Page 25

Great Plains Manufacturing, Inc. Table of Contents Index 21

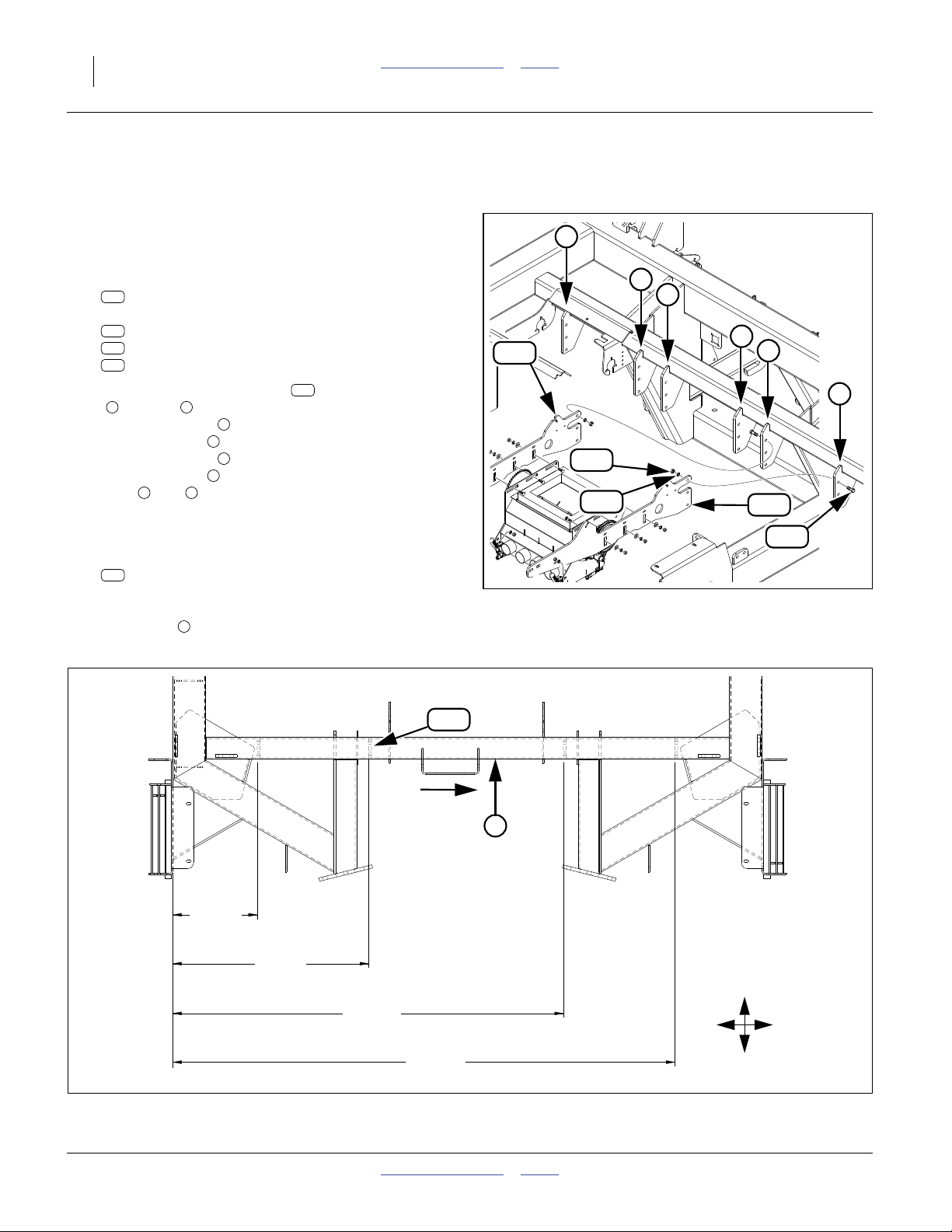

Update Cart

Cart Frame Update Overview

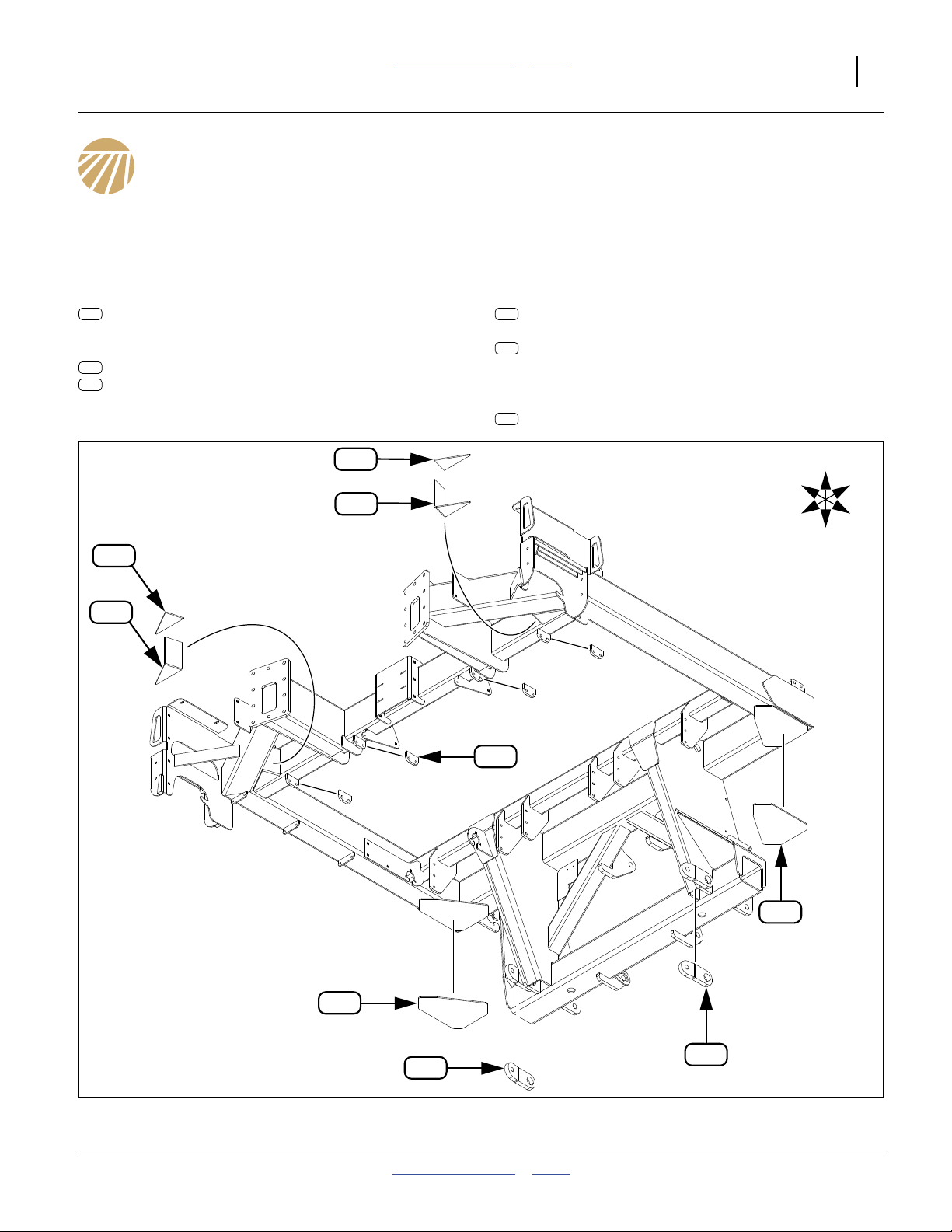

Twelve new parts are welded on the cart main frame,

and one on the tongue (not shown below):

Rear Gusset Plates (page 22)

Pull Bar Anchors (page 25)

925

266-307D REAR MAIN FRAME LAP GUSSET

Front Gusset Triangles (page 23)

926

266-308D FRONT MAIN FRAME CORNER GUSSET

927

266-309D FRNT MAIN FRAME CRNR CAP PLT

926

927

926

927

923

266-302D NTA2007 PULL BAR ANCHOR

A plate (not shown)

922

266-300D NTA2007 PULL BAR BOLT PLT

is also welded inside the tongue (page 24).

Meter Mount Tabs (page 27)

920

266-289D FRONT METER BOX MNT TAB

920

F

R

U

L

B

D

925

925

923

923

Figure 33

Cart Mainframe Update Weldments

05/25/2011 Table of Contents Index 166-370M

32124

Page 26

22 NTA607HD or NTA2007HD Table of Contents Index Great Plains Manufacturing, Inc.

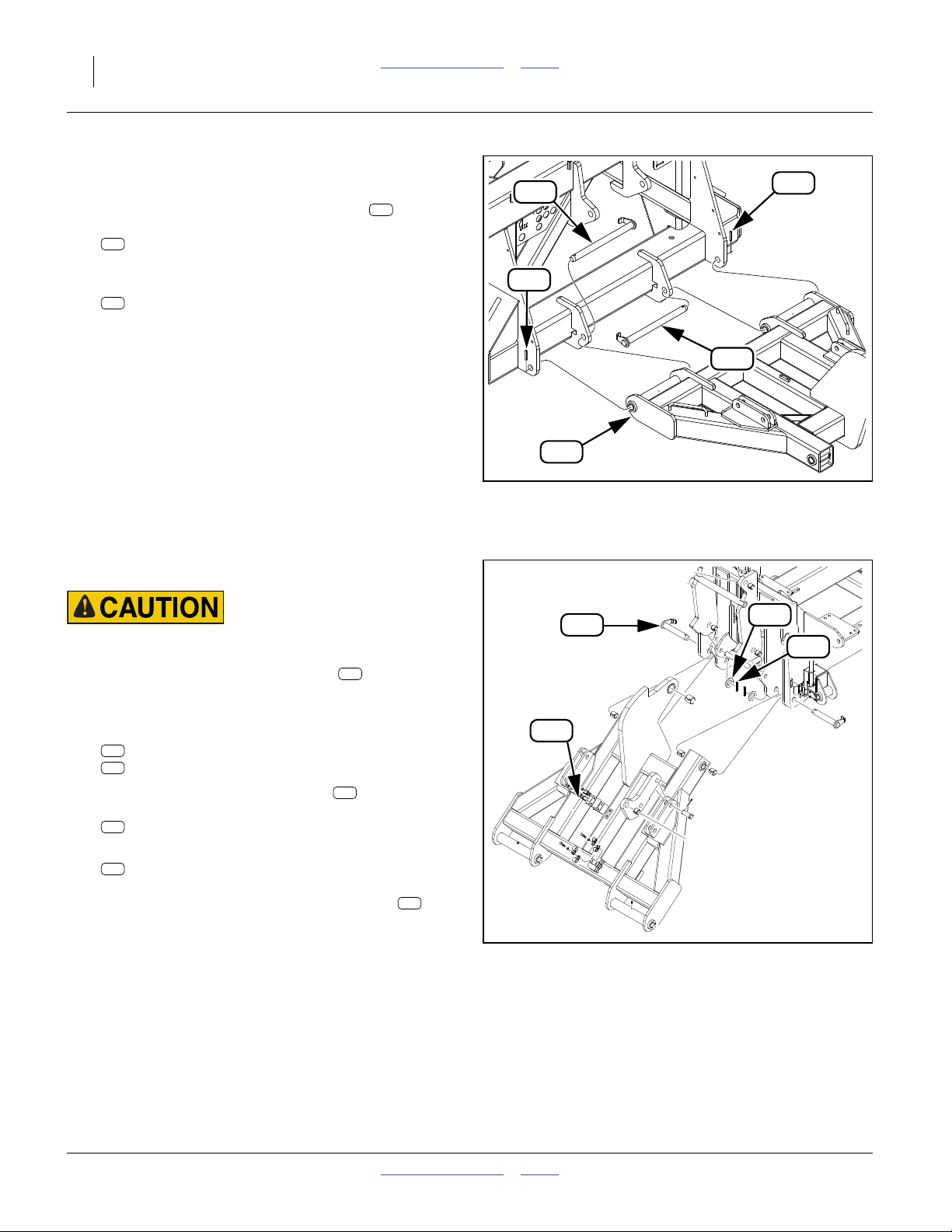

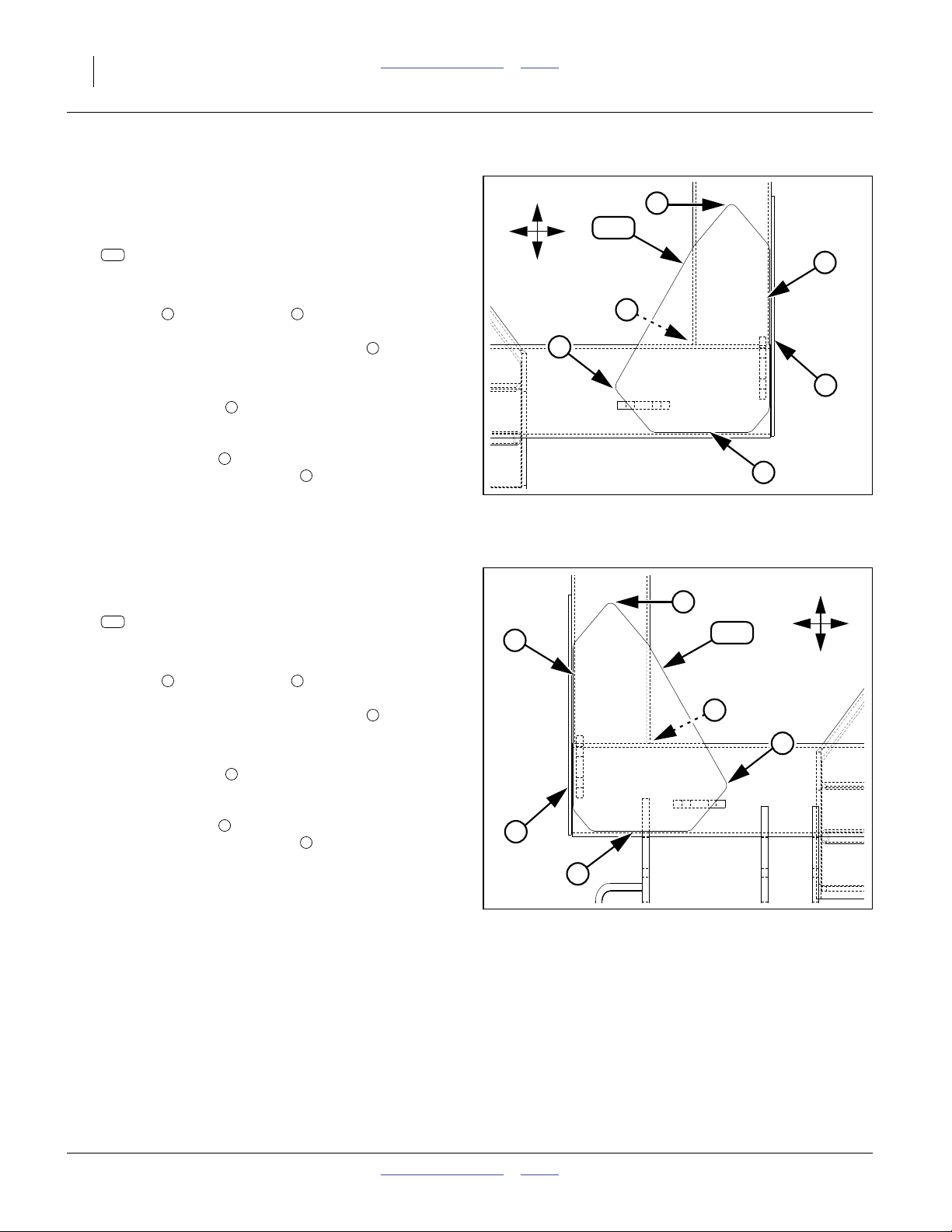

Install Rear Gussets

Install Left Rear Gusset

Refer to Figure 34

106. Select one new:

925

266-307D REAR MAIN FRAME LAP GUSSET

107. Roughly position the gusset on the bottom left rear

corner of the cart mainframe. Mark the frame using

the right and front edges of the gusset.

Remove the paint from the frame in these areas,

and long the inside edge of the corner .

108. Clamp the gusset on the frame.

Set the rear edge to slightly overlap the rounded

corner of the frame tube.

Set the left edge to provide a fillet space to the

existing outside gusset plate .

Tack weld in place.

109. Finish weld with a 6 mm (1⁄4in) fillet.

1 2

3

4

5

6

Install Right Rear Gusset

Refer to Figure 35

110. Select one new:

925

266-307D REAR MAIN FRAME LAP GUSSET

111. Roughly position the gusset on the bottom left rear

corner of the cart mainframe. Mark the frame using

the right and front edges of the gusset.

Remove the paint from the frame in these areas,

and long the inside edge of the corner .

112. Clamp the gusset on the frame.

1 2

3

R

F

925

L

B

2

5

3

1

6

4

Figure 34

Left Rear Gusset (from below)

32126

F

2

5

925

R

L

B

3

1

Set the rear edge to slightly overlap the rounded

corner of the frame tube.

Set the left edge to provide a fillet space to the

existing outside gusset plate .

Tack weld in place.

113. Finish weld with a 6 mm (1⁄4in) fillet.

114. Remove all slag and splatter. Clean and de-grease

all bare and discolored areas. Paint green.

166-370M Table of Contents Index 05/25/2011

4

5

6

6

4

Figure 35

Right Rear Gusset (from below)

32126

Page 27

Great Plains Manufacturing, Inc. Table of Contents Index Update Cart 23

Install Front Gussets

Install Right Front Gusset

115. Remove the front reflector panels (if any) and walkboard to provide access.

Refer to Figure 36

116. Select one new:

927

266-309D FRNT MAIN FRAME CRNR CAP PLT

Note: Despite the “CAP” descriptor, this part is used as

the base of the new gusset structure.

117. Position this plate in the outer crevice of the front

outside tool bars. Mark the weld region along the

edges. Remove paint on the tubes in the weld

regions.

118. Position the plate fully into the crevice, with the

927

bottom triangle about 6 cm (1⁄4in) higher than the

bottom faces of the tube, and parallel with the tube

bottom faces. Tack weld in position.

119. Finish weld all around (inside and out), except near

the tip of the triangle (leave the tip unwelded to provide a weep/breather opening). Use at least a 6 cm

(1⁄4in) fillet.

120. Select one new:

926

266-308D FRONT MAIN FRAME CORNER GUSSET

121. Position this gusset at the top of the plate just

installed, fully into the crevice, and parallel to the top

of the adjacent tubes. Tack weld in position.

122. Finish weld all around.

Install Left Front Gusset

927

Right Front Gusset (from below)

926

Figure 36

32126

123. Repeat step 116 through step 122 for the left side.

124. Remove all slag and splatter. Clean and de-grease

all bare and discolored areas. Paint green.

Note: To ease access to fan hydraulics, walkboard

re-installation is deferred until step 184 on

page 32.

05/25/2011 Table of Contents Index 166-370M

Page 28

24 NTA607HD or NTA2007HD Table of Contents Index Great Plains Manufacturing, Inc.

Install Pull Bar Attach Points

Install Pull Bar Plate

Refer to Figure 37 and Figure 38

125. Remove the hitch casting from the tongue.

126. Remove the paint from the lower inside surfaces of

the front tongue side plates .

127. Select one new:

922

266-300D NTA2007 PULL BAR BOLT PLT

128. Position the plate for tack welding inside the tongue.

One method would be to place four 13 mm clamps

along the bottom edges of the hitch side plate. Rest

the bolt plate on the clamps. Check alignment.

129. Tack weld the bolt plate to the hitch plates. Finish

weld all around with a 13 mm (1⁄2in) fillet.

130. Remove all slag and splatter. Clean and de-grease.

Allow welds to cool.

131. Paint all bare and discolored surfaces of the bolt

plate and hitch side plates.

Note: Pull bars are installed at step 161 on page 28.

133

123

123

Figure 37

Plate and Pull Bars

123

133

922

Q0105

21.1°

922

13 mm

0.5 in

Figure 38

266-300D Plate Alignment

25.5 cm

10.04in

123

13 mm

0.5 in

Q0106

166-370M Table of Contents Index 05/25/2011

Page 29

Great Plains Manufacturing, Inc. Table of Contents Index Update Cart 25

Install Pull Bar Anchors

Install Left Anchor

Refer to Figure 39 and Figure 40

132. Jack up the side of the cart sub-frame being worked

on. Dismount the wheel for access to the welding

site.

133. Select one new:

923

266-302D NTA2007 PULL BAR ANCHOR

134. Position the anchor on the outside (wheel side)

of the subframe leg , with the anchor’s larger hole

aligned with the existing hole in the leg plate.

135. Mark the left at the edges of the anchor. Remove

the paint from the leg in this weld region.

136. Make sure the break in the small-hole end of the

anchor is pointing forward and toward cart center,

with the lower edge parallel to the cart frame. The

break should be pointing directly at a hole on the

new hitch pull bar plate.

137. Clamp the anchor in this position. Tack weld.

138. Finish weld all around with a 13 mm (

It is not necessary to weld inside the large holes.

139. Remove all slag and splatter. Clean and de-grease

all bare and discolored areas. Paint green.

140. Re-mount the removed wheel.

Install Right Anchor

141. Repeat step 132 through step 140 for the right side.

923

7

8

923

Q0112

1

⁄2in) fillet.

Figure 39

Pull Bar Anchor Installed

7

8

923

923

Figure 40

Pull Bar Anchors (from below)

05/25/2011 Table of Contents Index 166-370M

32126

Page 30

26 NTA607HD or NTA2007HD Table of Contents Index Great Plains Manufacturing, Inc.

Update Meter Mounts

Position New Meter Mounts

The new meter mounts are temporarily installed to aid in

placement of the new front mount tabs.

Refer to Figure 41

142. Select four new:

919

266-288D METER BOX MOUNT

and six sets saved:

177

803-020C NUT HEX 1/2-13 PLT

187

804-015C WASHER LOCK SPRING 1/2 PLT

167

802-082C HHCS 1/2-13X1 3/4 GR5

143. Loosely attach each mount to a rear mount tab

1 6

( through ), as follows:

Right side of tab (for left meter)

Left side of tab (for left meter)

Right side of tab (for right meter)

Left side of tab (for right meter).

3 4

Tabs and (single center meter) are not used.

Prepare Tab Welding Sites

Refer to Figure 42

144. Select one new:

920

266-289D FRONT METER BOX MNT TAB

Use this tab to mark the general locations for tab

welding on the underside of the front cart

cross-tube . Remove the paint at these locations.

1

2

5

6

7

919

919

6

5

167

187

Figure 41

New Meter Mounts

4

3

2

1

919

177

32131

920

7

39.2 cm

15.44 in

90.9 cm

35.81 in

B

181.5 cm

71.44 in

233.3 cm

91.81 in

Figure 42

Front Meter Mount Tab Stations

166-370M Table of Contents Index 05/25/2011

R

L

F

32135

Page 31

Great Plains Manufacturing, Inc. Table of Contents Index Update Cart 27

Mark Tab Welding Sites

Refer to Figure 41 and Figure 42 on page 26

145. Select two sets new:

944

802-082C HHCS 1/2-13X1 3/4 GR5

950

803-020C NUT HEX 1/2-13 PLT

146. Using the bolts and nuts , loosely attach the

mounting tab at the front slots of a meter

mount , flat edge up, and on the same side of

919

944 950

920

the mount as the rear tab.

147. Consult the station layout in Figure 42. Re-mark

each station position precisely on the frame

cross-tube . Dimensions are from the right outside

7

face of the right frame tube to the tab right faces.

To measure to the face of a mount , add or subtract the thickness of the tab (12.7mm, 0.5in).

Use the meter mount as a check against posi-

919

919

7

tion errors. Each mount should be exactly perpendicular to the front cross-tube . Mark the tab side

edges on the cross-tube. Slide the tab to the center

7

920

of each mount slot. Mark the front and back edge

location on the cross-tube.

148. Repeat step 146 and step 147 for all four tabs.

Attach New Front Tabs

Refer to Figure 43

149. Remove two rear bolts from each meter mount .

919

Swing the mounts clear of the tab weld locations.

150. Select one new:

920

266-289D FRONT METER BOX MNT TAB

Clamp the tab at a weld location, flat side up against

frame cross-tube . Tack weld in position.

7

151. Finish weld all around, using a 9 mm (3⁄8in) fillet.

152. Remove weld slag and splatter.

153. Repeat step 150 through step 152 for all four tabs.

154. Paint the tabs, and all bare or discolored metal.

Install New Meter Mounts

Figure 43

Front Mount Tabs

919

944

32126

Wait for paint to dry. For each meter mount:

Refer to Figure 43 and Figure 44

155. Select two sets new:

944

802-082C HHCS 1/2-13X1 3/4 GR5

960

804-113C WASHER FLAT 1/2 USS HARD PLT

956

804-015C WASHER LOCK SPRING 1/2 PLT

950

803-020C NUT HEX 1/2-13 PLT

Swing the meter mount up against its new front

920

tab , on the same side of the tab as the rear tab.

156. Insert the bolts through the tab. Loosely add a

flat washer , lock washer and nut .

944

960 956 950

919

157. Re-install the rear tab fasteners removed at

960

956

950

Figure 44

New Meter Mounts

32131

step 149. Tighten all nuts to Grade 5 torque.

05/25/2011 Table of Contents Index 166-370M

Page 32

28 NTA607HD or NTA2007HD Table of Contents Index Great Plains Manufacturing, Inc.

Re-Install Meters

Meters are loosely re-installed, with final positioning after

hoppers are re-installed. For each meter:

Refer to Figure 45

158. Select one updated meter and six sets new:

945

802-106C RHSNB 1/2-13X1 1/2 GR5

960

804-113C WASHER FLAT 1/2 USS HARD PLT

956

804-015C WASHER LOCK SPRING 1/2 PLT

950

803-020C NUT HEX 1/2-13 PLT

159. With the meter in between the mounts ,

124 919

124

bring the meter sidewall slots into alignment with the

mount slots. Insert bolts from the meter side.

Add a flat washer , lock washer and nut ,

945

960 956 950

loosely secured (bolts at bottom of vertical slots).

Install Hopper Supports

921

956

960

945

950

921

124

Refer to Figure 45 (and Figure 53 on page 33)

160. Select four new:

921

266-290D LOWER HOPPER SUPPORT ANGLE

Insert the notched leg of the support angles into the

tab slots of the meter mounts . These are held

8

919

in place by the hoppers (installed starting on

page 33).

Install Pull Bars

Assemble Pull Bars

Refer to Figure 46

161. Select two sets:

916

166-368H NTA2007 PULL BAR

928

401-167H 16 ROW PULLBAR ADJUSTER

952

803-073C NUT HEX 1 1/2-6 PLT

Spin the jam nut well onto the adjuster .

Thread the adjuster a few full turns into the pull

916

bar .

162. Remove and save the end pin components:

967

805-412C PIN CLEVIS 1 X 4.13 USBL

949

803-007C NUT LOCK 1/4-20 PLT

929

402-011D SLEEVE, SPRING LINK MOUNT

946

802-152C HHCS 1/4-20X2 GR5

965

805-134C PIN CLEVIS 1 X 2 29/64 USABLE

958

804-028C WASHER FLAT 1 USS PLT

962

805-058C PIN COTTER 3/16 X 2

952 928

967

919

928

Figure 45

Hopper Supports

952

958

8

8

32131

949

929

946

916

965

962

Figure 46

Pull Bar Assembly & Parts ID

166-370M Table of Contents Index 05/25/2011

31098

Page 33

Great Plains Manufacturing, Inc. Table of Contents Index Update Cart 29

Attach Pull Bars

Refer to Figure 47

163. Select two sets:

967

805-412C PIN CLEVIS 1 X 4.13 USBL

958

804-028C WASHER FLAT 1 USS PLT

962

805-058C PIN COTTER 3/16 X 2

164. Bring the non-adjustable ends of the pull bars into

alignment with the anchors at the main wheels.

Secure with pin , washer and cotter .

967 958 962

923

958

967

Refer to Figure 48

165. At the hitch, adjust the turnbuckles until the adjuster

928 922

clevis holes align with the hole in the plate .

166. Select two sets:

965

805-134C PIN CLEVIS 1 X 2 29/64 USABLE

929

402-011D SLEEVE, SPRING LINK MOUNT

946

802-152C HHCS 1/4-20X2 GR5

949

803-007C NUT LOCK 1/4-20 PLT

Insert the pin from below. Add a sleeve ,

secure with bolt and lock nut .

167. With the jam nut still loose, tighten the

turnbuckle nut to a torque of:

965 929

946 949

952

8

136 N-m (100 foot-pounds)

168. Tighten the jam nut to just over Grade 2 torque:

952

1336 N-m (1000 foot-pounds)

923

962

Figure 47

Pull Bar on Anchor

946

952

Figure 48

Pull Bars on Plate

929

9

Q0112

949

922

928

Q0105

05/25/2011 Table of Contents Index 166-370M

Page 34

30 NTA607HD or NTA2007HD Table of Contents Index Great Plains Manufacturing, Inc.

Update Cart Hydraulics

This section splits the shared fan/fold hydraulic circuit

into separate dedicated circuits. Using the revised system requires an additional remote circuit on the tractor.

The figure below identifies affected existing components.

C

E

A

B

G

F

D

Note: This hydraulic update is optional. Do not update

the hydraulic system unless the tractor has an

available additional remote circuit.

211

210

213

223

209

207

161

209

210

161

214

228

Existing Parts

c/o Part Description

800-301C CABLE TIE 2 DIA MIN - YLW

161

810-345C VALVE 90 DEGREE SHUT-OFF

207

811-080C TE 3/4MJIC 3/4MORB 3/4MJIC

209

811-150C EL 3/4FJIC 3/4MJIC

210

811-195C HH1/2R1 028 3/4FJIC 3/4MORB

211

811-324C AD 3/4MORB 3/4FJIC

213

811-512C HH1/2R2 219 3/4FJIC 3/4MORB

214

841-002C AD 1 1/16MORB 3/4FORB

223

841-480C HH1/2R2 084 3/4FJIC 3/4MORB

228

G

F

E

D

C

B

A

Figure 49

Existing Cart Hydraulics

166-370M Table of Contents Index 05/25/2011

Q0107

Page 35

Great Plains Manufacturing, Inc. Table of Contents Index Update Cart 31

The figure below identifies new and re-routed existing

components.

169. Snake a fish line through the right tongue tube,

between hitch and near fan.

C

A

B

G

D

211

210

Note: The walkboard and left front reflector panel (if any)

are presumed to be still removed from the forward

gusset update on page 23.

E

F

G

F

E

D

C

B

A

971

209

937

936

937

214

936

978

Figure 50

Updated Cart Hydraulics

972

228

New Parts

c/o Part Description

800-301C CABLE TIE 2 DIA MIN - YLW

936

800-303C CABLE TIE 2 DIA MIN - BLK

937

811-394C CP 3/4FORB MALE QD POPPET TYPE

971

811-430C AD 3/4MJIC 3/4MJIC

972

841-555C HH1/2R2 156 3/4FJIC 3/4MORB

978

Q0132

05/25/2011 Table of Contents Index 166-370M

Page 36

32 NTA607HD or NTA2007HD Table of Contents Index Great Plains Manufacturing, Inc.

Route Dedicated Fold Hose

Refer to Figure 49 and Figure 50 on page 30 and 31

170. Select one new:

978

841-555C HH1/2R2 156 3/4FJIC 3/4MORB

With the MORB end forward (to hitch) and FJIC end

to the rear, pull this hose through the tongue tube

using the fish line.

171. Select four new:

936

800-301C CABLE TIE 2 DIA MIN - YLW

Secure two ties to each end of hose .

978

Mark Dedicated Fan Hose

172. Locate the (existing) fan supply hose . This hose

runs from the hitch to a tee at the fan shut-off

207

valve . This hose may be marked with two yellow

209

ties (or plain yellow tape). Pull on the hose from the

fan end to confirm its identity.

173. Remove any yellow ties or plain yellow tape from

the fan supply hose . Do not remove any printed

214

labels.

174. Select four new:

937

800-303C CABLE TIE 2 DIA MIN - BLK

Secure two ties to each end of the fan supply

214

hose .

175. Disconnect fan supply hose from the tee .

214 209

214

Re-Route Fold Hose

176. At the elbow connected to the inlet side of the

shut-off valve , disconnect the existing fold

228

hose (which runs to rear bulkhead Port F).

177. Select one new:

972

811-430C AD 3/4MJIC 3/4MJIC

Use this adaptor to join the ends of existing fold

228 978

hose to new fold hose .

210

207

Disconnect Bypass Hose

178. At the tee on the fan side of the shut-off

valve , disconnect the short spin-down loop

hose .

209

207

211

Re-Configure Inlet Fittings

179. Remove and disassemble all fittings at the fan inlet.

Removed items are, from motor to hoses:

223

841-002C AD 1 1/16MORB 3/4FORB

209

811-324C AD 3/4MORB 3/4FJIC

210

811-150C EL 3/4FJIC 3/4MJIC

209

811-080C TE 3/4MJIC 3/4MORB 3/4MJIC

207

810-345C VALVE 90 DEGREE SHUT-OFF

209

811-080C TE 3/4MJIC 3/4MORB 3/4MJIC

210

811-150C EL 3/4FJIC 3/4MJIC

Save the final 11⁄16in adaptor , one elbow

and one tee . The other fittings are not re-used.

209

223 210

See “Hydraulic Connectors and Torque” on page 70.

180. Select one each saved:

209

811-080C TE 3/4MJIC 3/4MORB 3/4MJIC

210

811-150C EL 3/4FJIC 3/4MJIC

Connect the elbow to the MJIC side port of the

209

tee , opposite the MORB port. When tightening,

210

align the MJIC end of the elbow to face in the same

direction as the center MJIC port of the tee.

181. Select one saved:

223

841-002C AD 1 1/16MORB 3/4FORB

Connect the MORB port of the tee to the FORB

end of the adaptor . Connect the MORB end of

the adaptor to the motor inlet. When tightening,

223

223

209

point the open MJIC fittings away from the motor,

and toward the hoses.

Re-connect Fan Hoses

182. Connect the short loop hose to the tee at

the motor inlet.