Page 1

Great Plains Mfg., Inc.

Installation Instructions

12’ Center Pivot Hitch

Dual Marker Option

Used with:

• 12’ Center Pivot Hitch

General Information

When you see this symbol, the subsequent instructions and

warnings are serious - follow without exception. Your life

!

!

and the lives of others depend on it!

These instructions explain how to install the Dual Marker

Option. The 12’ Center Pivot Hitch Dual Markers are

ground marking disk units that are mounted on both sides

of the drill. These instructions apply to:

113-219A 12’ CPH Dual Marker

Manual Update

Refer to the 12’ Center Pivot Hitch Operator’s Manual for

detailed information on safely operating, adjusting, troubleshooting and maintaining the Dual Marker Option.

Assembly Instructions

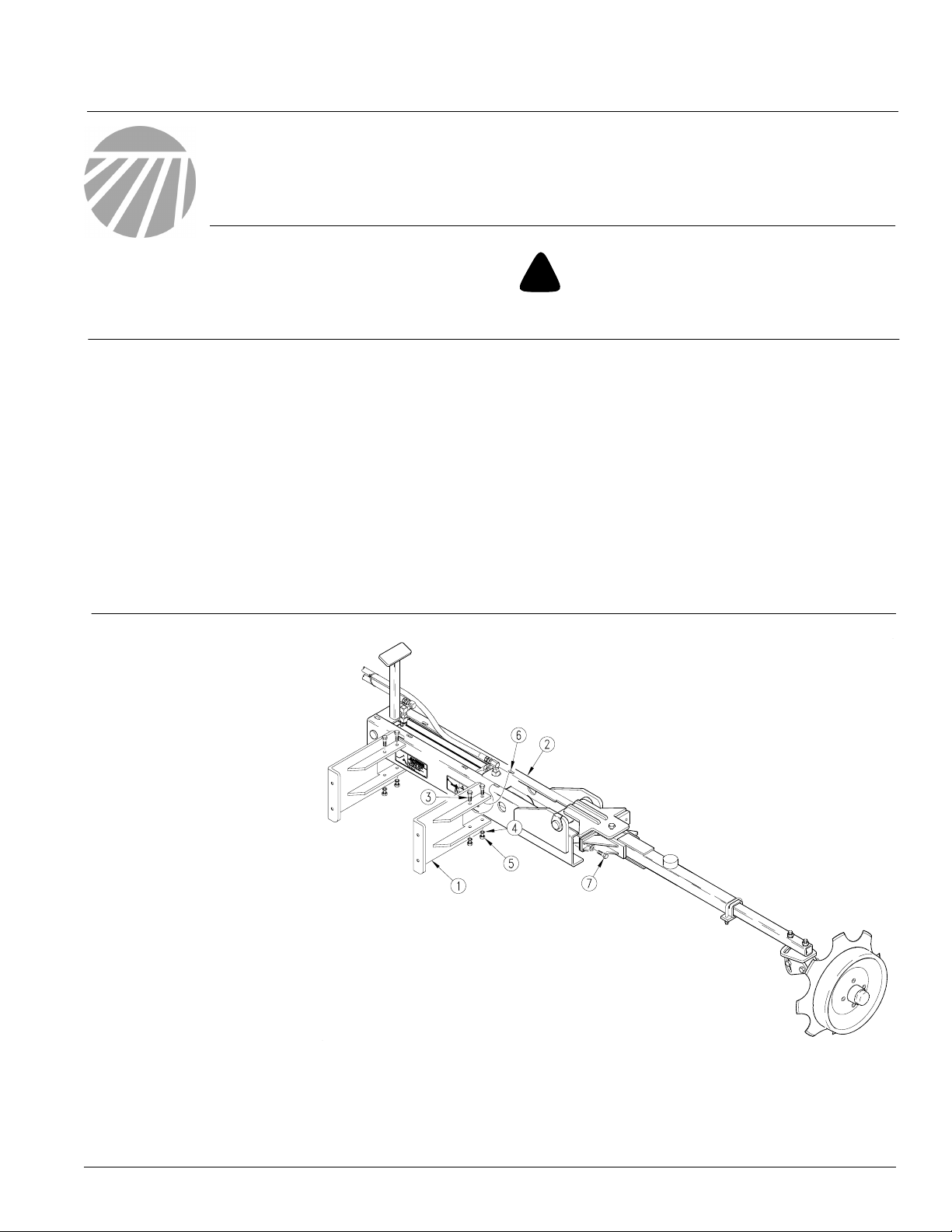

Marker Assembly

Refer to Figure 1

NOTE: The RH and LH marker assemblies are identical.

The multiple mounting slots

(6) in the assembly channel

allow for the marker to be attached to the right or left

side of the drill with the

proper mounting brackets

(1).

Use the shear bolt (7) to determine which is the lefthand marker and which is

the right-hand marker. When

markers are installed properly, shear bolt (7) will be oriented towards the front of

the hitch.

Refer to the Parts Manual for part identification.

148-152M 12’, 15’, & 20’ CPH Operator’s Manual

148-152P 12’, 15’, & 20’ CPH Parts Manual

Before You Start

Pages 5 and 6 are a detailed listing of parts included in

the Dual Marker Option. Use this list to inventory parts

received.

Tools Required

• Basic Hand Tools

24485

1. Attach two mounting

brackets (1) to each marker mount (2). NOTE: Each

marker mounts to backside of coulter toolbar.

Make sure shear bolt (7) will be positioned twoards front of

hitch once markers are attached to toolbar.

2. Secure mounting brackets (1) on marker mount (2) using 3/816 X 5 bolts (3), 3/8 lock washers (4), and 3/8-16 hex nuts (5).

© Copyright 2006 Printed

5/5/2009

Figure 1

Marker Mounting Brackets

113-479M

Page 2

Dual Marker Option

2

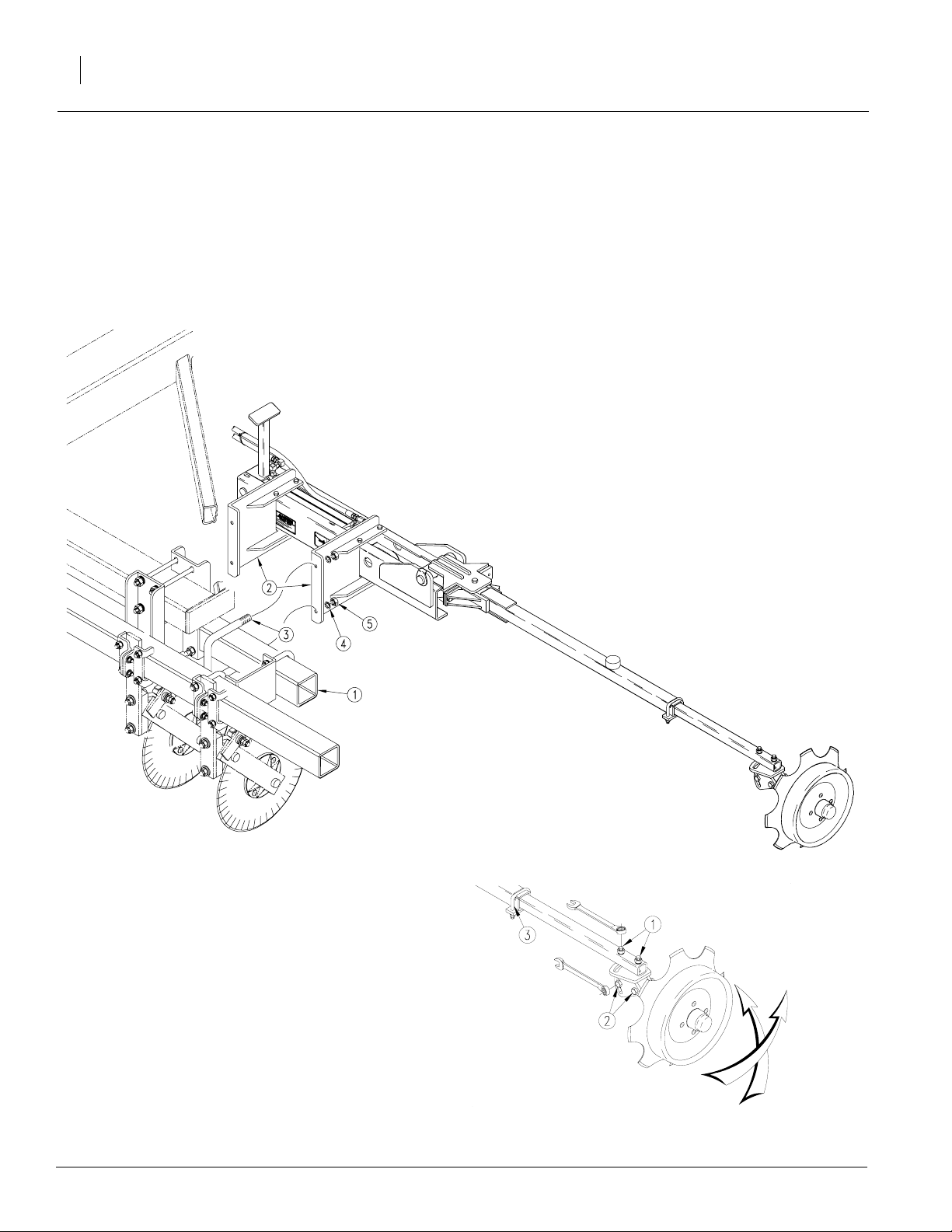

Refer to Figure 2

3. U-bolt mounting brackets (2) to rear coulter toolbar (1) as coulter spacing allows. Use 5/8-11 X 4

X 5 1/4 u-bolts (3), 5/8 lock washers (4), and 5/811 hex nuts (5) to secure mounting brackets (2) to

coulter toolbar (1).

4. Check to make sure shear bolt is oriented towards front of hitch.

5. Complete steps 3 and 4 to attach opposite marker

and mount to rear coulter toolbar.

Great Plains Mfg., Inc.

Marker Assembly

Disk Adjustment

Refer to Figure 3

The agressiveness and the mark left by the disk

may be changed by two methods:

a. Disk Angle: To change the angle of cut,

loosen the two vertical bolts (1) in the

marker arm and rotate the disk assembly.

Retighten bolts.

b. Disk Tip: To change the tip of the disk,

loosen the two horizontal bolts (5) in the

pivot adjustment. Rotate the disk assembly and retighten. The marker width adjustments are made by loosening the

marker tube u-bolt (3) and sliding it in or

out to the desired width. Retighten the ubolt.

24486

Figure 2

14061

Figure 3

Disk Adjustment

5/5/2009

Page 3

Great Plains Mfg., Inc.

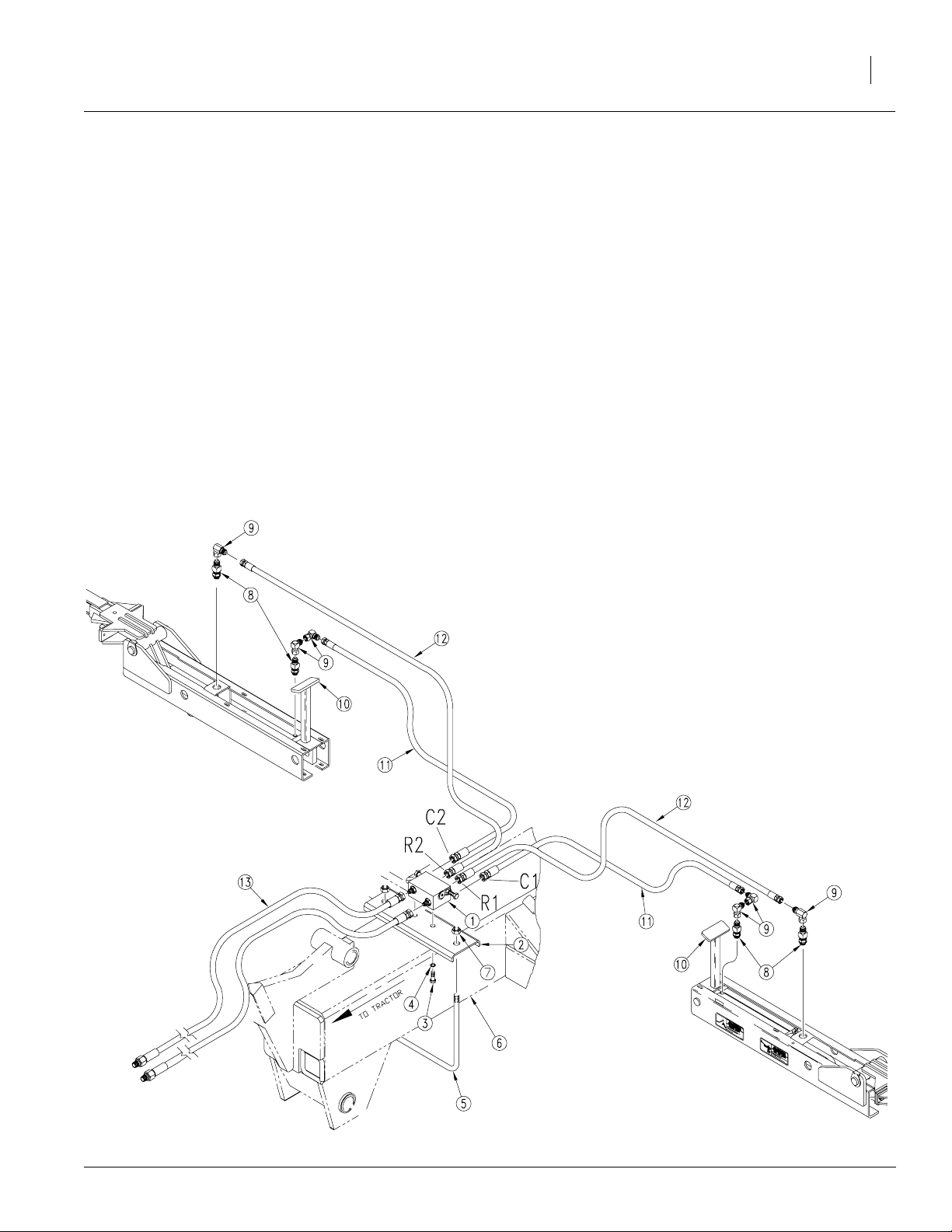

Hydraulic Assembly

NOTE: JIC fittings do not require high torque. JIC

and O-Ring fittings do not require sealant. Always

use liquid pipe sealant when adding or replacing

pipe thread fittings. To avoid possible danger of

cracking hydraulic fittings from overtightening -DO

NOT use plastic sealant tape.

Refer to Figure 4

1. Mount sequence valve (1) on sequence valve mount

(2). Secure valve (1) on mount (2) with 3/8-16 X 1

bolts (3) and 3/8 lock washers (4).

2. U-bolt sequence valve mount (2) on hitch (6) using

1/2-13 X 8 1/16 X 9 u-bolt (5). Position sequence

valve (1) so four ports point to the rear of the implement and two ports face the tractor. Secure u-bolt

(5) with 1/2-13 nylock nuts (7).

3. If not already done, install a 9/16" male o-ring boss

x 9/16" male JIC adapter (8) into each end of both

hydraulic cylinders.

Installation Instructions

4. Install a 9/16" female JIC X 9/16" male JIC 90 degree

elbow (9) into each end of the marker cylinders.

5. Two more 9/16" female JIC x 9/16" male JIC 90 degree

elbows (9) are required on on the base end of the

marker cylinders to offset the hoses around the marker

rest post (10).

6. Route the 57" long hydraulic hoses (11) from the elbows (9) at the ports marked C1 & C2 on the sequence

valve (1) to the elbows (9) on the base ends of the

marker cylinders.

7. The 70" hoses (12) attach to the elbows (9) on the sequence valve (1) ports marked R1 & R2 and the elbows (9) on the rod end of the marker cylinders.

8. The two 156" hoses (13) attach to the remaining two

elbows (9) on the sequence valve (1) opposite the

marker ports and are routed to the hitch (6).

9. Tie all loose hoses together with cable ties provided.

3

5/5/2009

24484

Figure 4

Hydraulic Hose Assembly

Page 4

Dual Marker Option

4

Great Plains Mfg., Inc.

Bleeding the Hydraulic System

!

Escaping fluid under pressure can have sufficient force to penetrate the skin. Check all hydrualic lines and hoses before applying pressure. Fluid escaping from a very small hole can be

almost invisible. Use paper or cardboard, not body parts, to

check for suspected leaks. If injured, seek medical assistance

from a doctor that is familiar with this type of injury. Foreign

fluids in the tissue must be surgically removed within a few

hours or gangrene will result.

NOTE: JIC fittings do not require high torque. JIC

and o-ring fittings do not require sealant. Always use

liquid pipe sealant when adding or replacing pipe

thread fittings. To avoid possible danger of cracking

hydraulic fittings from overtightening - DO NOT use

plastic sealant tape.

NOTE: Check the hydraulic fluid level in the tractor

reservoir and fill to the proper level before starting

procedure. Add fluid to the system as needed. A low

reservoir level may draw air back into the system,

and can cause jerky or uneven cylinder movements.

Keep all persons clear.

NOTE: The following instructions must be followed

to bleed the markers hydraulic system. The markers

must be properly bled to displace air in the hydraulic

system and for the sequence valve to work properly.

Failure bleed the hydraulic system could cause the

marker to drop quickly to the ground causing damage to the marker and voiding the warranty.

Refer to Figure 5

1. Markers should be manually folded into transport po-

2. Connect hoses to tractor’s remote hydraulic outlets.

3. Loosen hydraulic hose fittings at rod end of marker

CAUTION!

!

DANGER!

sition when charging the hydraulic system for the first

time. Remove cylinder pin securing rod end of each

cylinder to marker link arms. Swing link arm up and

out of the way.

cylinders. With tractor at idle speed, slowly work tractor remote lever in the direction which would retract

the cylinder. DO NOT try to retract the cylinder. The

goal is to push the air from the lines leading to the

cylinder. This will only happen on one side which is

dependent on which way the sequence valve is shifted. When the air is expelled and oil starts being

pushed out, tighten hose connection at this cylinder.

cylinder base port. When the air is expelled and oil

starts being pushed out, tighten hose connection at

this cylinder.

5. Once again, slowly work tractor’s remote lever in the

direction to fully extend the cylinder and hold it there for

a few seconds. This will shift the sequence valve which

will allow you to bleed the opposite cylinder.

6. Repeat steps 3 - 5 for opposite marker cylinder.

7. Once the system is bled, operate tractor’s remote lever

several times until both cylinders stop when fully extended. Reconnect cylinders to marker link arms.

14021

Figure 5

Bleeding the Marker Cylinder

8. The marker hydraulic system is equipped with needle

valves to control how fast each marker operates. Needle valves are built into the sequence valve body.

There are two hex adjustment screws, one for raising

and one for lowering the markers. The "raise" and

"lower" needle valves are identified by stamped markings in the valve body next to the adjustment screws.

Turn adjustment screws clockwise to slow the speed

down and counter-clockwise to speed it up. Adjustments should be made for safe speeds at operating

rpm. Excessive folding speeds can cause marker

damage and may void the warranty. Be sure to tighten

the jam nuts on the hex adjustment screws to hold desired settings.

The markers cycle in the following sequence:

a. right up, left up

b. right down, left up

c. right up, left up

d. right up, left down

e. sequence repeats

4. Slowly work tractor’s remote lever in the same direction to retract the cylinder. When it is retracted, loosen hose fitting at base end of the same cylinder. With

tractor at idle speed, slowly work tractor remote lever

in the opposite direction which should put oil to the

14048

Figure 6

Sequence Valve Speed Adjustments

5/5/2009

Page 5

Great Plains Mfg., Inc.

113-219A 12’ CPH Dual Marker

Your kit includes:

Qty. Part No. Part Description

1 113-220K 12’ CPH DUAL MARKER HRDW BDL

Includes:

4 113-538H MARKER MOUNTING BRACKET WLMT

1 148-629D 1000 MARKER SEQUENCE VALVE MNT

6 800-035C CABLE TIE .31X28 8DIA 120LB

4 800-150C CABLE TIE 22.2 LONG REL

2 802-017C HHCS 3/8-16 X 1 GR5

8 802-318C HHCS 3/8-16 X 5 GR5

8 803-014C NUT HEX 3/8-16 PLT

8 803-021C NUT HEX 5/8-11 PLT

2 803-178C NUT NYLOCK JAM NUT 1/2-13

10 804-013C WASHER LOCK SPRING 3/8 PLT

8 804-022C WASHER LOCK SPRING 5/8 PLT

4 806-008C U-BOLT 5/8-11 X 4 X 5 1/4

1 806-038C U-BOLT 1/2-13 X 8 1/16 X 9 1038

1 810-197C VALVE, SEQUENCE SHOEMAKER

6 811-169C EL 9/16 MJIC 9/16 FJIC

4 811-170C AD 9/16 MORB 9/16 MJIC

1 113-434V 12’ CPH DUAL MARKER HOSE BDL

Includes:

2 811-180C HH1/4R1 057 9/16FJIC

2 811-436C HH1/4R1 156 9/16FJIC

2 811-518C HH1/4R1 070 9/16FJIC

Installation Instructions

5

2 113-541K 12’ EWNT MARKER ASSY

Includes:

1 113-534H MARKER HINGE WELDMENT

1 113-535H MARKER CYLINDER CHANNEL WLMT

1 113-536H MARKER ARM WELDMENT

1 113-537H MARKER DISC ADJUSTMENT WLMT

1 113-539H MARKER PIVOT PIN WLMT

1 113-546D MARKER LINK ARM

1 113-547S NO-TILL MARKER DISC HUB ASSY

1 113-548D MARKER DISC MOUNTING TUBE

2 800-001C GREASE ZERK STRAIGHT 1/4-28

1 802-012C HHCS 5/16-18 X 1 1/2 GR5

2 802-039C HHCS 1/2-13 X 3 GR5

3 802-041C HHCS 1/2-13 X 3 1/2 GR5

1 802-130C HHCS 1/2-13 X 2 1/2 GR5

2 802-440C RHSNB 1/2-13 X 2 3/4 GR5

1 803-011C NUT LOCK 5/16-18 PLT

4 803-020C NUT HEX 1/2-13 PLT

2 803-078C NUT LOCK 3/8-16 NYLON INSERT

1 803-147C NUT HEX NYLOCK 1/2-13

1 804-010C WASHER FLAT 5/16 USS PLT

5 804-015C WASHER LOCK SPRING 1/2 PLT

2 804-017C WASHER FLAT 1/2 USS PLT

2 804-028C WASHER FLAT 1 USS PLT

1 804-035C WASHER FLAT 1 1/4 USS PLT

2 805-058C PIN COTTER 3/16 X 2

1 805-060C PIN COTTER 7/32 X 2

1 805-187C PIN CLEVIS 1 X 2 1/4 GR5 PLT

1 806-004C U-BOLT 3/8-16 X 2 X 2 3/4

1 810-269C CYL 2 X 14X 1.12 ROD (TIE ROD)

5/5/2009

Page 6

Dual Marker Option

6

113-219A 12’ CPH Dual Marker

Your kit includes:

Qty. Part No. Part Description

1 816-170C RD BUMP STOP 2 X 1 X 1/2-13

2 818-579C DECAL WARNING PINCH

2 818-580C DECAL WARNING OVERHEAD MKR

2 890-005C BUSHING CYL 1 1/4 X 1 X 1

1 113-479M 12’ CPH DUAL MARKER MANUAL

1 502-067D HYD HOSE CLAMP LABEL

1 502-068D HYD HOSE CLAMP BRACKET

1 800-300C CABLE TIE 2 DIA MIN - ORG

1 802-009C RHSNB 5/16-18 X 1 1/4 GR5

1 803-199C NUT HEX FLANGE 5/16-18 PLT

2 838-265C DECAL REFLECTOR AMBER 1 1/2 X 9

Great Plains Mfg., Inc.

5/5/2009

Page 7

Great Plains Manufacturing, Inc.

Corporate Office: P.O. Box 5060

Salina, Kansas 67402-5060 USA

Loading...

Loading...