Page 1

Manufacturing, Inc.

www.greatplainsmfg.com

Seed, Small Seeds and

Fertilizer Rate Charts

The following pages are to assist in the proper setting of seeding and fertilizer rates for the 1205NT End-Wheel, No-Till Drill.

The rates indicated in the charts are approximate values. To assure the

most accurate seeding rate it is recommended that the drill be calibrated for

the desired seed at the time of planting.

© Copyright 2007 Printed 04/12/2007 150-131B

Page 2

Table of Contents

Great Plains Mfg., Inc.

Main Seed Box Planting.....................................1

Select Drive Type.........................................................1

Set Seed-Rate Handle.................................................1

Position Seed Cup Doors.............................................2

Checking Main Box Seed Rate....................................2

Rate Charts, Main Seed Box ....................................... 4

Alfalfa or Rape .........................................................4

Barley (1 of 3) ..........................................................4

Buckwheat ...............................................................5

Buffalograss (1 of 4)................................................. 5

Flax or Sudan........................................................... 6

Millet......................................................................... 6

Milo ..........................................................................6

Oats .........................................................................7

Peas.........................................................................7

Pinto Beans.............................................................. 7

Rice, Short Grain (1 of 2).........................................7

Rice, Long Grain (1 of 4).......................................... 8

Rye........................................................................... 9

Soybeans (1 of 4)..................................................... 9

Sunflower...............................................................10

Wheat (1 of 2) ........................................................10

Wheatgrass............................................................11

Small Seeds Planting.......................................12

Small Seeds Seed Rate Charts.................................13

Alfalfa, Red Alsike, Crimson Clover....................... 13

Kentucky Bluegrass,

Fescue, Annual Rye Grass................................13

Bermuda, Red Top, Lespedeza Unhulled,

Sercia, Sand, Weeping Love Grass...................13

Red & Sweet Clover, Lespedeza Hulled................13

Orchard Grass .......................................................14

Millet, Reed Canary ...............................................14

Ladino Clover, Canary Grass,

Timothy, Canola.................................................14

Birdsfoot, Trefoil, Sudan ........................................14

Fertilizer Rate................................................... 15

Fertilizer Rate Charts.................................................16

Rates in Pounds per Acre......................................16

Density Conversion Charts.................................... 16

Metric Charts....................................................17

Metric Rate Charts, Main Seed Box .......................... 17

Alfalfa or Rape....................................................... 17

Barley (1 of 3) ........................................................ 17

Buckwheat ............................................................. 18

Buffalograss (1 of 4)............................................... 18

Flax or Sudan......................................................... 19

Millet....................................................................... 19

Milo ........................................................................ 20

Oats ....................................................................... 20

Peas....................................................................... 20

Pinto Beans ........................................................... 20

Rice, Short Grain (1 of 2).......................................21

Rice, Long Grain (1 of 4)........................................ 21

Rye ........................................................................ 22

Soybeans (1 of 4)................................................... 22

Sunflower...............................................................23

Wheat (1 of 2)........................................................ 24

Wheatgrass............................................................ 24

Metric Rate Charts, Small Seeds Box ....................... 25

Alfalfa, Red Alsike, Crimson Clover....................... 25

Kentucky Bluegrass,

Fescue, Annual Rye Grass................................ 25

Bermuda, Red Top, Lespedeza Unhulled,

Sercia, Sand, Weeping Love Grass...................25

Red & Sweet Clover, Lespedeza Hulled................ 25

Orchard Grass ....................................................... 26

Millet, Reed Canary ............................................... 26

Ladino Clover, Canary Grass,

Timothy, Canola.................................................26

Birdsfoot, Trefoil, Sudan ........................................ 26

Metric Fertilizer Rate Charts...................................... 27

Metric Rates in Kilograms per Hectare.................. 27

Density Conversion Charts.................................... 27

© Copyright 2005, 2006, 2007 All rights Reserved

Great Plains Manuf acturing,Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of

the information contained herein. Great Plains Manufacturing, Inc. reserv esthe rightto revise and improve its products as it sees fit. This publication describes the state of this

product at the time of its publication, and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains

All other brands and product names are trademarks or registered trademarks of their respective holders.

150-131B 04/12/2007

Great Plains Manufacturing, Incorporated Tr ademarks

Printed in the United States of America.

Page 3

Great Plains Mfg., Inc.

Main Seed Box Planting

Calibrating the seeding rate requires four steps:

1. selecting one of four drive types,

2. setting the seed-rate handle,

3. positioning the feed-cup door, and

4. checking the seed rate.

Refer to the seed rate charts beginning on page 4.

These charts list the proper drive type and seed-ratehandle settings for various seeds and seeding rates.

The seed rate charts are based on cleaned, untreated

seed of average size and test weight. The rates are

based on 295/75/R22.5 rib implement tires. Many factors will affect seeding rates including foreign material,

seed treatment, seed size, field conditions, tire pressure and test weight. Minor adjustments likely will be

needed. Set and check the seeding rate using the procedures on page 2, then adjust the rate as necessary.

2

1

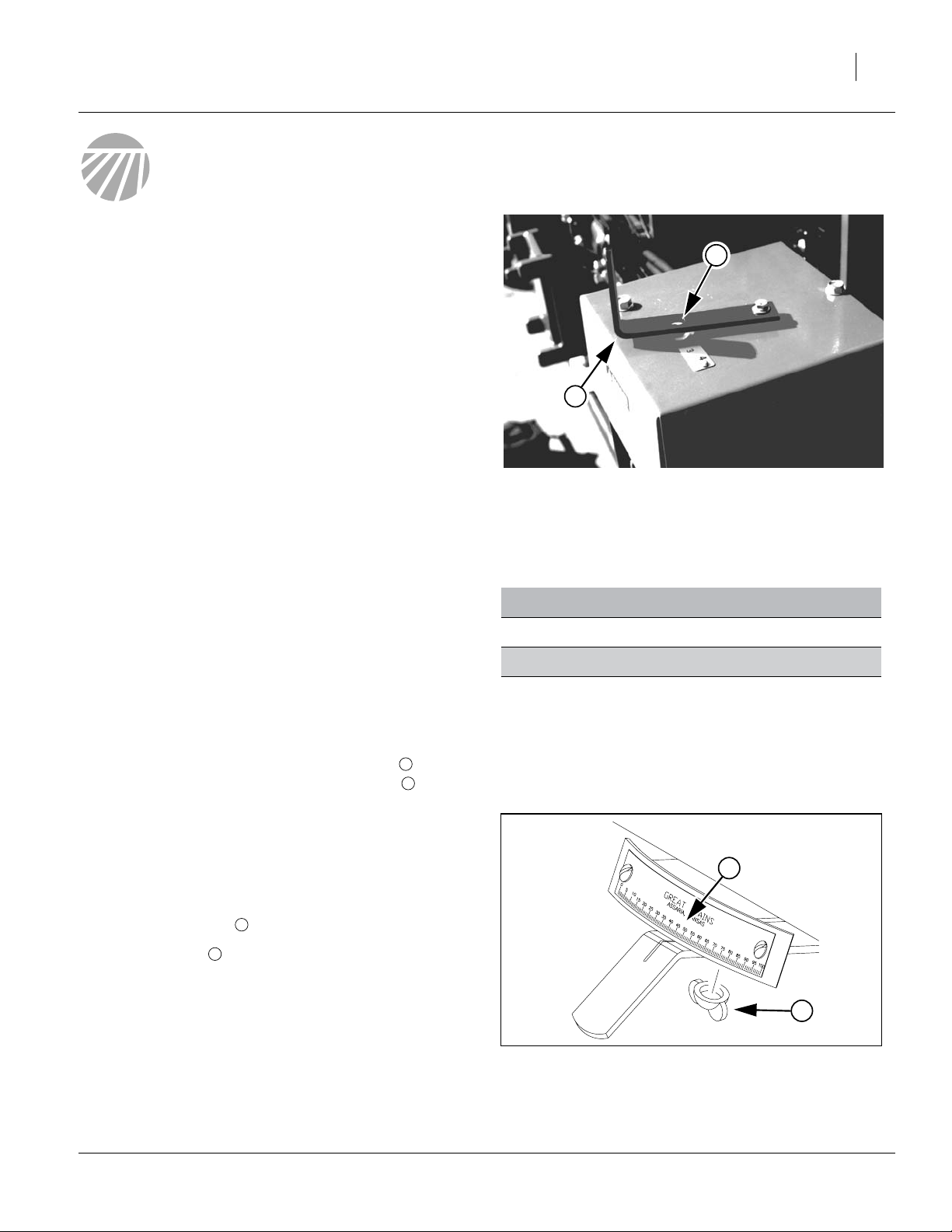

Figure 1

Gearbox Handle Adjustment

1

14742

Select Drive Type

Refer to Figure1

The gearbox is designed to give you a variety of drive

speeds for different types of seeds and rates. It is a linear shift pattern design with constant mesh gearing

and totally sealed to keep dirt out. No lubrication is

required unless service is needed.

The gearbox brass indicator plate is positioned so the

side with “1” is closest to the center of the drill.

To set the gearbox move the selector handle until

the desired drive type appears in the window on the handle

1

2

Set Seed-Rate Handle

Refer to Figure2

The seed rate handle controls the percent engagement of the seed sprocket in each seed cup.

1. Loosen wing nut under handle.

2. Set indicator to just past value from seed rate

chart.

3. Tighten wing nut.

1

2

Gear Box Ratios

Setting 2 is 2.06 Times Faster Than 1

Setting 3 is 3.08 Times Faster Than 1

Setting 4 is 5.03 Times Faster Than 1

2

1

Figure 2

Seed Rate Handle

04/12/2007 150-131B

12927

Page 4

2

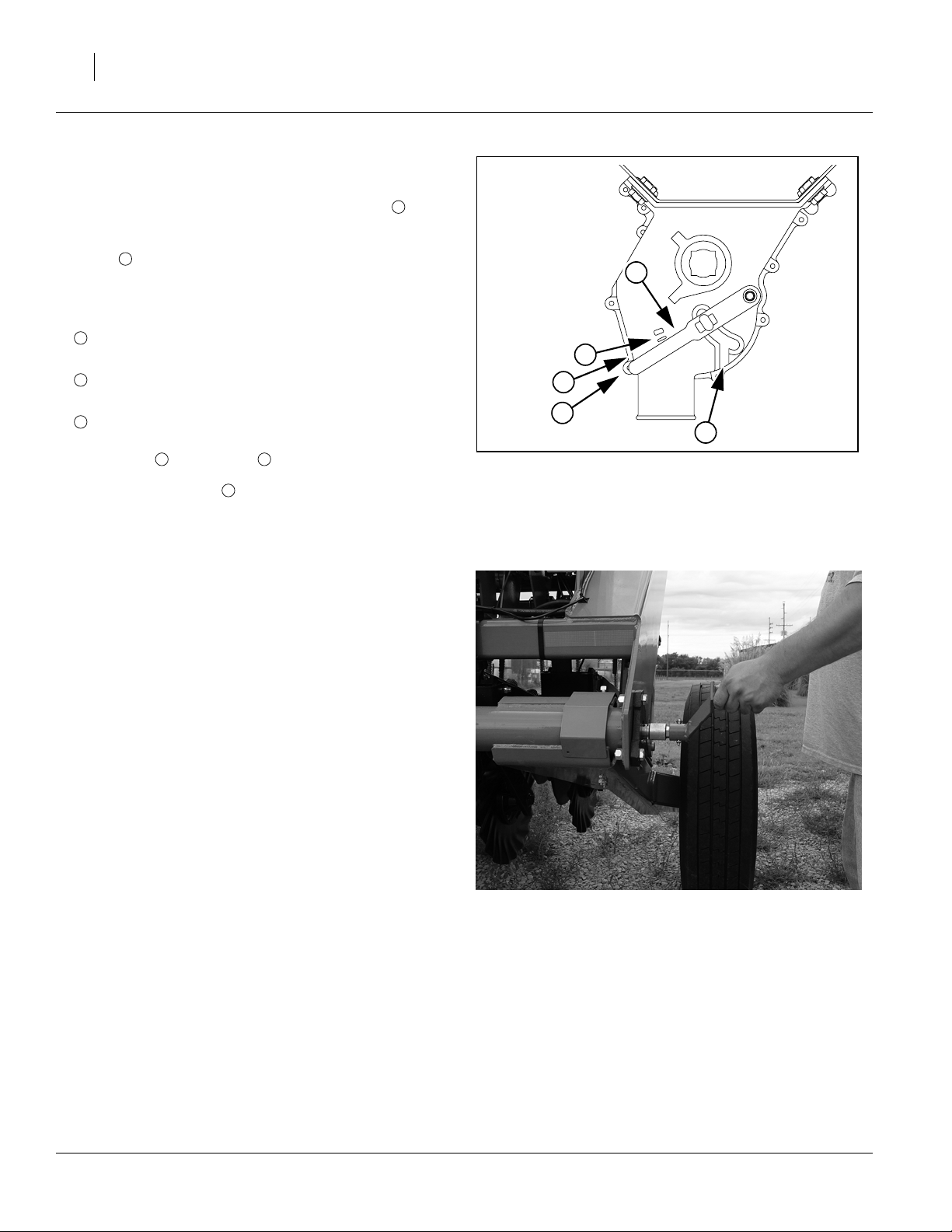

Position Seed Cup Doors

Refer to Figure3,

which depicts the seed cup door handle in position .

At each seed box seed tube, adjust the seed cup door

handle for the seed size.

The handle has three normal operating position

detents:

Note: Handleposition isused forcleanout,not plant-

4

(top detent) is for the smallest seeds.

1

Use it for wheat and similar small seeds.

(middle detent) is for larger seeds.

2

Use it for soybeans and similar larger seeds.

(bottom detent) is for oversize or fragile seeds.

3

If you experience excessive cracking with

setting , use setting .

ing.If set to this position with seed loaded, itmay

be difficult to reset it to a normal operating position.

2 3

5

3

4

1

2

3

Figure 3

Seed Cup Door Handle

Great Plains Mfg., Inc.

5

26211

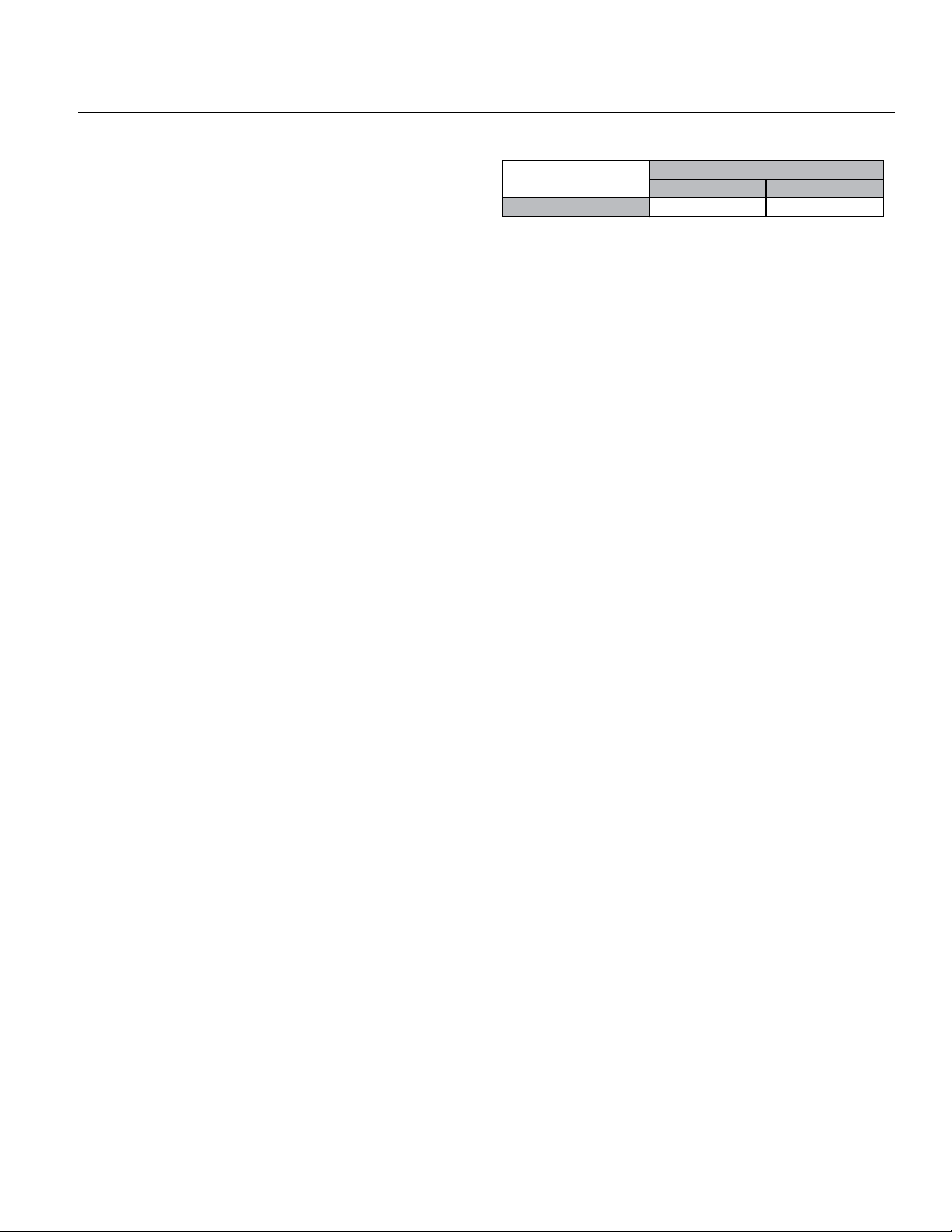

Checking Main Box Seed Rate

Note: For drills built after October 1, 2005,

use the gauge wheel tire or supplied calibration

crank to calibrate.

For drills built before October 1, 2005,

use the gauge wheel to calibrate or order the calibration crank kit available through your Great

Plains Dealer.

1. To calibrate, use either the left hand gauge wheel

or the supplied calibration crank. If using the calibration crank, attach crank to coupler on gauge

wheel jackshaft with retaining pin and disengage

lockout on drive wheel.

2. Rotate left hand gauge wheel or calibration crank

to see that feed cups and drive are working properly and are free from foreign matter.

3. To adjust seeding rate, decide which drive type

(gearbox) setting you need from the seeding

charts beginning on page 4. Set the gearbox.

Rotate drive tire or calibration crank a few turns to

confirm gearbox has engaged.

4. Record weight of an empty container large enough

to hold seed metered for one acre.

5. Place several pounds of seed over three seed

cups on an outside end of drill box. Pull seed

tubes off of these three openers.

Figure 4

1205NT Calibration Crank

23386

150-131B 04/12/2007

Page 5

Great Plains Mfg., Inc.

3

6. Turn drive gauge wheel or calibration crank several times to fill seed cups with seed. Turn wheel

or crank until seed falls to the ground from each

cup.

7. Rotate drive gauge wheel 346 rotations. This is

equal to one acre.

Note: Youcanalsorotate the gauge wheel jackshaftby

means of a wrench or socket. If rotating gauge

wheel jackshaft, disengage the lockout on the

drivewheel andusesame numberofrotations as

for rotating drive wheel.

8. Check that the three seed cups have plenty of

seed coming into them.

9. Weigh metered seed. Subtract initial weight of

container. Divide by three. Multiply by the number

of openers on your drill to determine total pounds

seeded per acre. If this figure is different than

desired, set your seed rate adjustment handle

accordingly.

Note: Youmaywanttorepeat the calibration procedure

if your results vary greatly from seed rate chart.

10. When drilling, check seeding rate by noting acres

drilled, amount of seed added to drill and seed

level in drill box. If you are seeding more or less

than desired, adjust seeding rate slightly to compensate for field conditions.

Drill

Model

1205NT 346 855

Revolutions for One

Acre Hectare

.

MeasuredSeed EmptyContainer–

----------------------------------------------------------------------------------

PoundsPerSeedCup NumberOfOpeners× PoundsPerAcre=

3

PoundsPerSeedCup=

04/12/2007 150-131B

Page 6

4

Great Plains Mfg., Inc.

Rate Charts, Main Seed Box

This section is in U.S. customary units.

See page 17 for Metric rates.

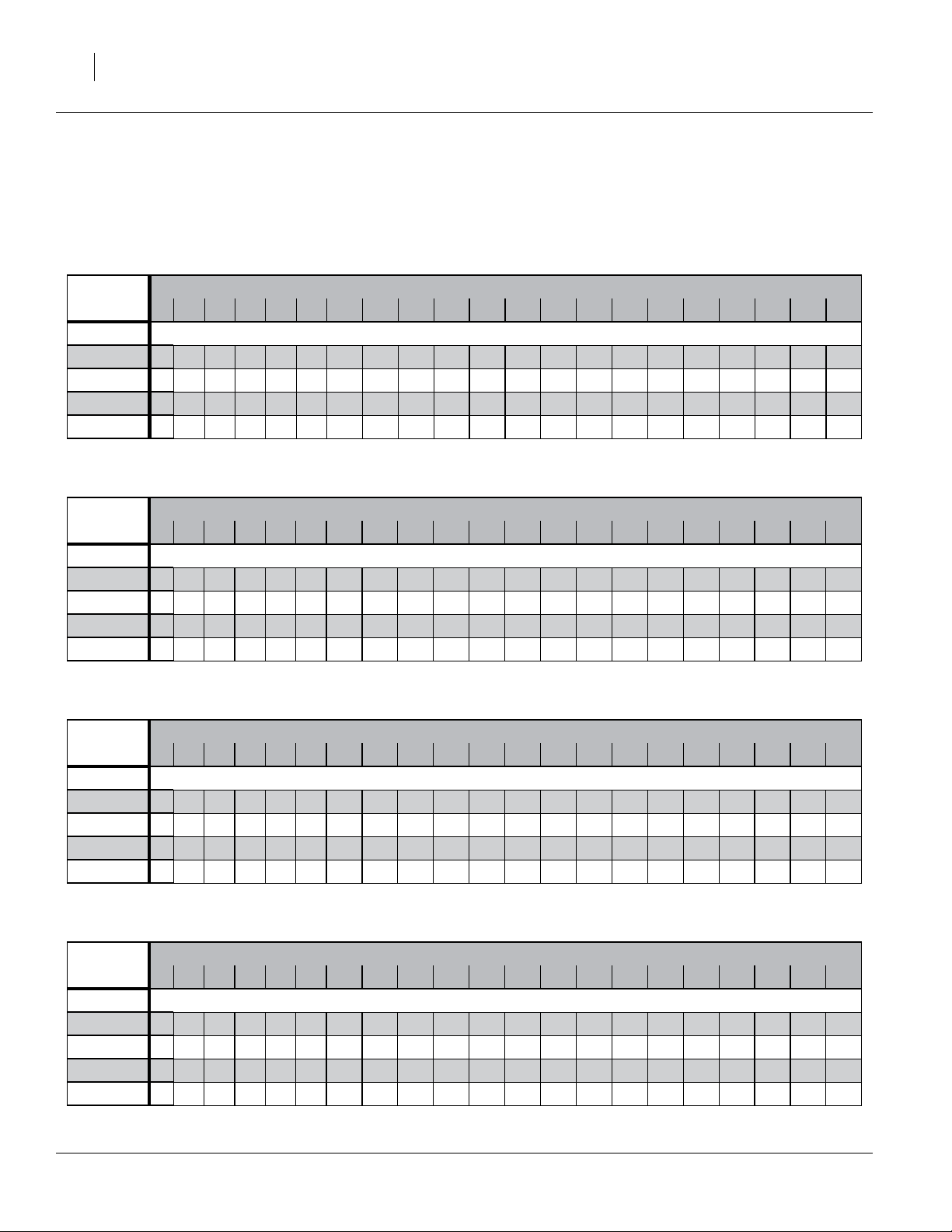

Alfalfa or Rape

(based on 60 pounds/bushel)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 5 7 10 13 16 20 23 27 32 35 38 43 47 51 54 59 63 68 70 72

7.5 inch 04 7101215182225293336404347515559636567

8 inch 0 4 6 9 12 14 17 20 24 28 31 34 37 41 44 47 52 55 60 61 63

10 inch 03 57912141619222527303335384144484950

Barley (1 of 3)

(based on 51 pounds/bushel)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 4 7 9 12 16 19 22 26 30 33 37 41 45 49 53 56 59 62 63 63

7.5 inch 0 4 6 9 12 15 18 21 24 28 31 35 38 42 46 49 52 55 58 59 59

8 inch 0 3 6 8 11 14 17 20 23 26 29 32 36 40 43 46 49 52 54 55 55

10 inch 0 3 5 6 9 11 13 16 18 21 23 26 29 32 34 37 39 42 44 44 44

Seed Rate Handle Setting

Seed Rate Handle Setting

Barley (2 of 3)

(based on 51 pounds/bushel)

Drive Type

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 7 14 19 26 32 39 46 53 61 68 75 82 89 97 105 114 122 130 132 134

7.5 inch 0 7 13 17 24 30 36 43 49 57 64 70 77 83 91 98 106 114 121 123 125

8 inch 0 7 12 16 22 28 34 40 46 53 60 65 72 78 85 92 100 107 114 116 117

10 inch 0 5 10 13 18 22 27 32 37 43 48 52 58 63 68 74 80 85 91 92 94

Seed Rate Handle Setting

Barley (3 of 3)

(based on 51 pounds/bushel)

Drive Type

4 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 18 33 45 63 78 95 113 130 149 166 182 201 218 238 257 278 299 318 323 328

7.5 inch 0 17 31 42 58 72 88 105 121 139 155 170 188 204 222 240 260 279 297 301 306

8 inch 0 16 29 40 55 68 83 99 113 130 146 160 176 191 208 225 244 261 278 282 287

10 inch 0 13 23 32 44 54 66 79 91 104 117 128 141 153 167 180 195 209 222 226 230

Seed Rate Handle Setting

150-131B 04/12/2007

Page 7

Great Plains Mfg., Inc.

Rate Charts, Main Seed Box, continued...

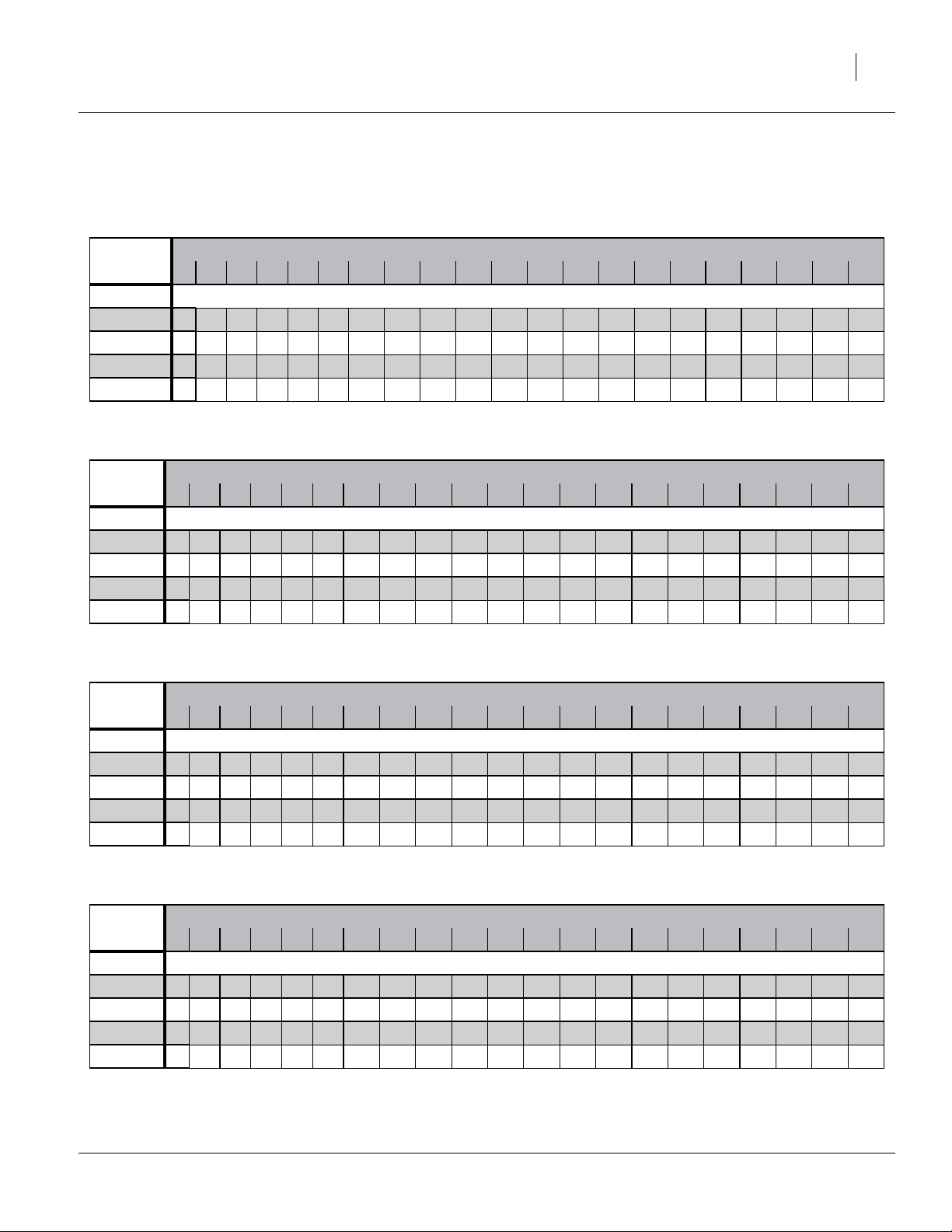

Buckwheat

(based on 48 pounds/bushel)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 10 18 25 36 45 56 67 79 92 106 116 129 142 154 168 179 192 205 207 210

7.5 inch 0 9 17 24 34 42 52 62 74 85 99 109 120 132 144 156 167 179 192 194 196

8 inch 0 8 16 22 31 39 49 59 69 80 92 102 113 124 135 147 157 168 180 181 183

10 inch 0 7 13 18 25 31 39 47 55 64 74 81 90 99 108 117 126 134 144 145 147

Buffalograss (1 of 4)

(based on 23 pounds/bushel)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 1 2 3 4 6 7 9 10 12 13 15 16 18 19 20 21 21 22 22 22

7.5 inch 0 1 2 3 4 5 7 8 10 11 13 14 15 17 18 19 20 20 20 20 20

8 inch 0 1 2 3 4 5 6 8 9 10 12 13 14 16 17 18 18 19 19 19 19

10 inch 0 1 2 2 3 4 5 6 7 8 9 11 12 12 13 14 15 15 15 15 15

Seed Rate Handle Setting

Seed Rate Handle Setting

5

Buffalograss (2 of 4)

(based on 23 pounds/bushel)

Drive Type

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 3 4 7 9 12 15 18 21 24 28 31 34 37 39 41 43 44 45 45 44

7.5 inch 024 6811141720232629323436384041424241

8 inch 0 2 4 6 8 10 13 16 19 21 24 27 30 32 34 36 38 39 39 39 39

10 inch 0 2 3 5 6 8 10 13 15 17 19 22 24 26 27 29 30 31 31 31 31

Seed Rate Handle Setting

Buffalograss (3 of 4)

(based on 23 pounds/bushel)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 5 7 10 13 17 21 26 31 36 41 46 50 55 59 62 65 67 69 69 69

7.5 inch 0 5 7 9 12 16 20 24 29 34 38 43 47 51 55 58 61 63 64 65 64

8 inch 0 4 6 9 12 15 19 23 27 31 36 40 44 48 51 54 57 59 60 61 60

10 inch 0357 912151822252932363841444647484848

Seed Rate Handle Setting

04/12/2007 150-131B

Page 8

6

Great Plains Mfg., Inc.

Rate Charts, Main Seed Box, continued...

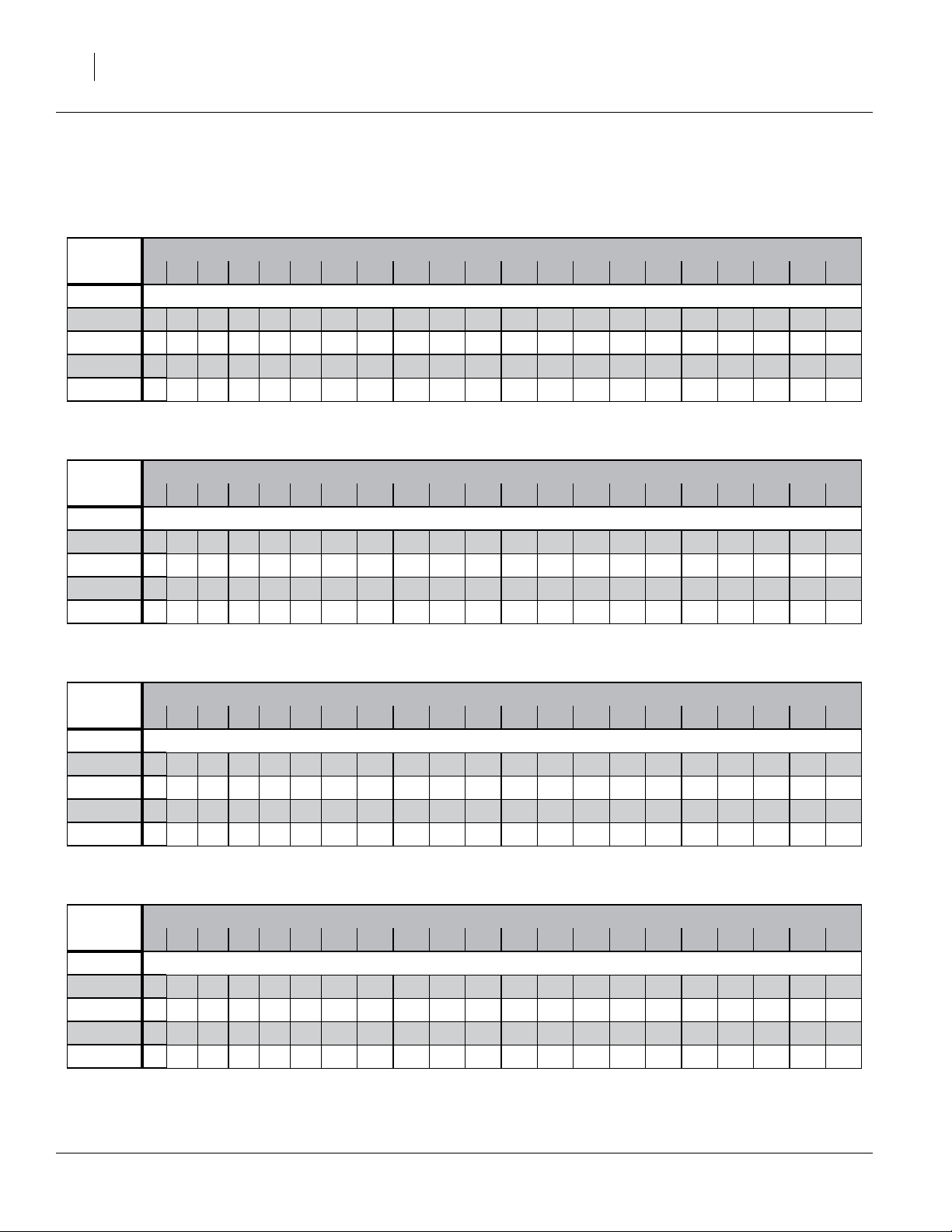

Buffalograss (4 of 4)

(based on 23 pounds/bushel)

Drive Type

4 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 8 11 16 22 28 36 43 50 59 67 75 82 89 96 101 106 110 112 113 112

7.5 inch 0 7 11 15 20 26 33 40 47 55 62 70 77 83 90 95 99 102 104 105 104

8 inch 0 7 10 14 19 24 31 37 44 51 58 65 72 78 84 89 93 96 98 99 98

10 inch 068111520253035414752586367717477787978

Flax or Sudan

(based on 55 pounds/bushel)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 3 7 10 14 17 21 24 28 32 36 39 43 47 51 55 60 65 70 71 73

7.5 inch 0 3 7 9 13 16 19 23 26 30 34 37 40 44 47 52 56 61 66 67 68

8 inch 0 3 6 9 12 15 18 21 25 28 31 34 37 41 44 49 52 57 61 62 64

10 inch 0 2 5 7 10 12 15 17 20 22 25 27 30 33 35 39 42 45 49 50 51

Seed Rate Handle Setting

Seed Rate Handle Setting

Millet

(based on 60 pounds/bushel)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 4 7 10 13 17 20 23 27 31 34 38 42 45 49 53 57 61 65 66 67

7.5 inch 0 4 7 9 13 16 19 22 25 29 32 35 39 42 46 49 53 57 61 62 63

8 inch 0 4 6 9 12 15 18 20 24 27 30 33 36 39 43 46 50 53 57 58 59

10 inch 0357 912141619212426293234374043464647

Seed Rate Handle Setting

Milo

(based on 64 pounds/bushel)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 4 8 11 15 19 24 29 34 38 44 49 54 59 64 69 74 79 84 86 88

7.5 inch 047101418222731364145505560656973788082

8 inch 0 4 7 10 13 17 21 25 29 34 39 43 47 52 56 61 65 69 73 75 77

10 inch 0 3 5 8 11 14 17 20 23 27 31 34 38 41 45 49 52 55 59 60 61

Seed Rate Handle Setting

150-131B 04/12/2007

Page 9

Great Plains Mfg., Inc.

Rate Charts, Main Seed Box, continued...

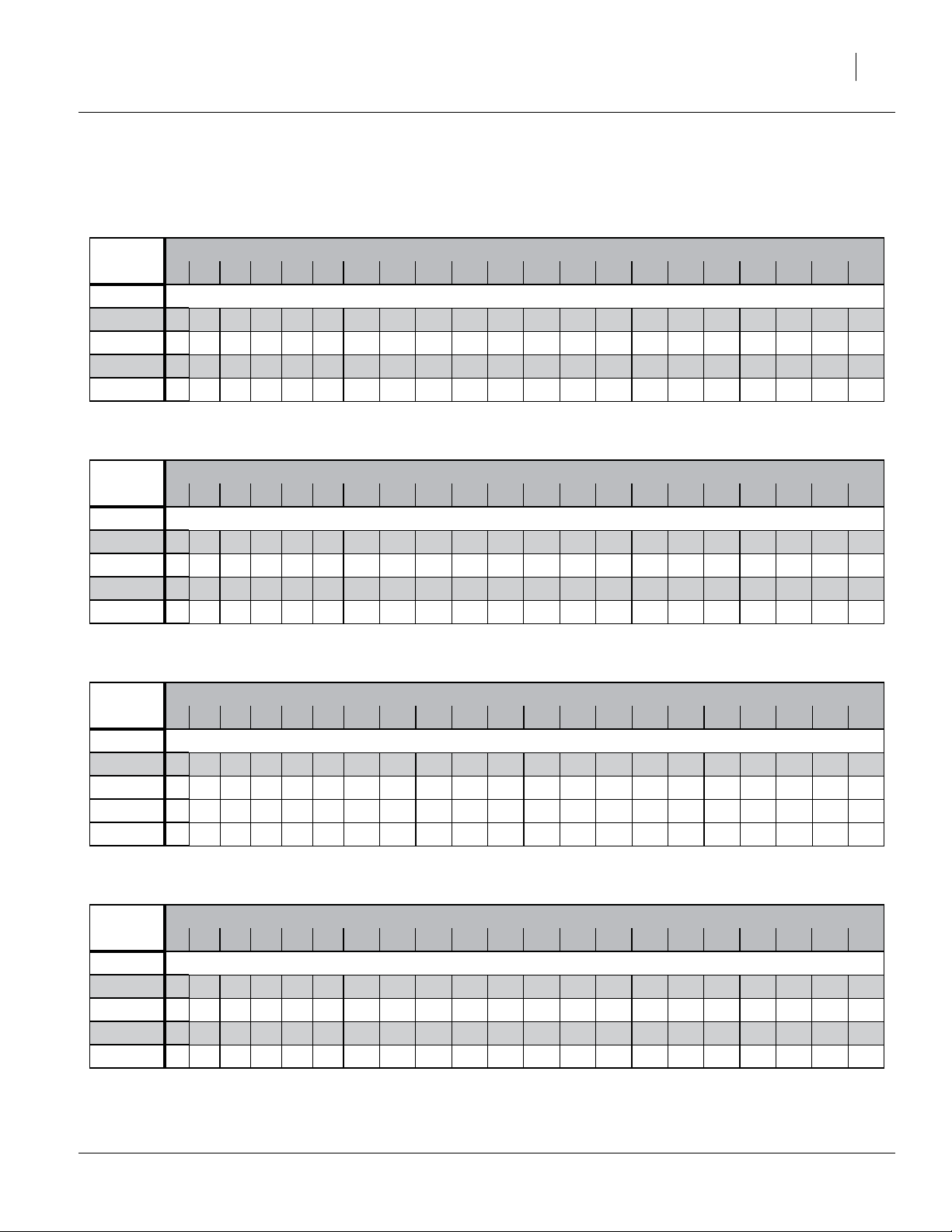

Oats

(based on 37 pounds/bushel)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 5 10 15 21 27 33 40 47 54 62 68 76 82 90 97 104 111 119 120 120

7.5 inch 0 4 10 14 19 25 31 37 44 51 58 64 70 77 84 90 97 104 111 112 112

8 inch 0 4 9 13 18 24 29 35 41 47 54 60 66 72 78 85 91 97 104 105 105

10 inch 037101419232833384348535863687378838484

Peas

(based on 61 pounds/bushel)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 0 16 29 45 59 72 87 102 118 132 145 160 173 187 202 215 228 241 243 244

7.5 inch 0 0 15 27 42 55 67 82 95 110 123 136 149 161 175 188 201 213 225 226 227

8 inch 0 0 14 26 39 52 63 76 89 103 116 127 140 151 164 177 188 200 211 212 213

10 inch 0 0 11 20 31 41 50 61 71 82 93 102 112 121 131 141 151 160 169 170 171

Seed Rate Handle Setting

Seed Rate Handle Setting

7

Pinto Beans

(based on 51 pounds/bushel)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 0 7 11 15 20 25 30 35 40 45 50 55 59 64 69 73 78 83 83 83

7.5 inch 007101419242833384247515560656873777777

8 inch 00 6101318222731354044485256616468727272

10 inch 0 0 5 8 10 14 18 21 25 28 32 35 38 41 45 49 51 54 58 58 58

Seed Rate Handle Setting

Rice, Short Grain (1 of 2)

(based on 43 pounds/bushel)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 9 16 24 33 39 48 54 63 72 82 92 101 110 119 127 134 142 149 149 149

7.5 inch 0 9 14 23 31 37 44 51 59 67 77 85 94 102 111 118 125 132 139 139 139

8 inch 0 8 14 21 29 34 42 48 55 63 72 80 88 96 104 111 117 124 131 131 131

10 inch 0 7 11 17 23 27 33 38 44 50 57 64 70 77 83 89 94 99 105 105 105

Seed Rate Handle Setting

04/12/2007 150-131B

Page 10

8

Great Plains Mfg., Inc.

Rate Charts, Main Seed Box, continued...

Rice, Short Grain (2 of 2)

(based on 43 pounds/bushel)

Drive Type

4 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 15 25 40 54 64 78 89 103 117 134 149 164 179 194 207 219 231 243 243 243

7.5 inch 0 14 24 37 50 60 72 83 96 109 125 139 153 167 181 193 204 215 227 227 227

8 inch 0 13 22 35 47 56 68 78 90 102 117 131 143 156 169 181 191 202 213 213 213

10 inch 0 11 18 28 38 45 54 62 72 82 94 105 115 125 136 145 153 162 170 170 170

Rice, Long Grain (1 of 4)

(based on 47 pounds/bushel)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 1.2 3.8 6.3 8.9 11.7 14.4 17.0 19.7 22.4 27.1 27.5 30.1 32.7 35.2 38.0 40.1 42.4 44.2 45.3 46.2

7.5 inch 0 1.1 3.6 5.9 8.3 10.9 13.5 15.9 18.4 20.9 25.3 25.7 28.1 30.5 32.9 35.4 37.5 39.5 41.2 42.3 43.1

8 inch 0 1.1 3.3 5.5 7.8 10.2 12.6 14.9 17.2 19.6 23.7 24.1 26.3 28.6 30.8 33.2 35.1 37.1 38.6 39.7 40.4

10 inch 0 0.8 2.7 4.4 6.2 8.2 10.1 11.9 13.8 15.7 19.0 19.3 21.1 22.9 24.7 26.6 28.1 29.7 30.9 31.7 32.3

Seed Rate Handle Setting

Seed Rate Handle Setting

Rice, Long Grain (2 of 4)

(based on 47 pounds/bushel)

Drive Type

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 3 8 13 18 24 30 35 40 46 56 57 62 67 72 78 83 87 91 93 95

7.5 inch 027121723283338435253586368737781858789

8 inch 0 2 7 11 16 21 26 31 35 40 49 50 54 59 63 68 72 76 80 82 83

10 inch 0 2 6 9 13 17 21 25 28 32 39 40 43 47 51 55 58 61 64 65 67

Seed Rate Handle Setting

Rice, Long Grain (3 of 4)

(based on 47 pounds/bushel)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 0 11 19 27 36 45 53 61 69 77 84 91 99 107 116 124 131 138 143 148

7.5 inch 0 0 11 17 25 34 42 49 57 65 72 79 85 92 100 108 116 123 129 134 138

8 inch 0 0 10 16 24 31 40 46 53 61 67 74 80 87 94 101 108 115 121 125 130

10 inch 00813192532374249545964697581879297100104

Seed Rate Handle Setting

150-131B 04/12/2007

Page 11

Great Plains Mfg., Inc.

Rate Charts, Main Seed Box, continued...

Rice, Long Grain (4 of 4)

(based on 47 pounds/bushel)

Drive Type

4 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 0 18 30 44 59 74 86 99 113 125 137 149 161 175 188 202 214 225 234 242

7.5 inch 0 0 17 28 41 55 69 80 92 105 117 128 139 151 163 176 188 200 210 218 226

8 inch 0 0 16 27 39 51 65 75 87 99 110 120 130 141 153 165 177 187 197 204 211

10 inch 0 0 13 21 31 41 52 60 69 79 88 96 104 113 123 132 141 150 158 164 169

Rye

(based on 57 pounds/bushel)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 2 7 11 16 21 24 30 35 40 45 50 54 59 63 69 74 80 87 87 88

7.5 inch 026101519222833384246505559646975818182

8 inch 0 2 6 10 14 18 21 26 31 35 40 44 47 51 55 60 65 70 76 76 77

10 inch 0 2 5 8 11 14 17 21 24 28 32 35 38 41 44 48 52 56 61 61 61

Seed Rate Handle Setting

Seed Rate Handle Setting

9

Soybeans (1 of 4)

(based on 58 pounds/bushel)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 2 7 11 17 20 25 29 34 38 42 48 52 57 61 67 70 75 79 80 80

7.5 inch 026111519232731364044495357626570747475

8 inch 0 2 6 10 15 17 22 25 29 34 37 42 46 50 54 58 61 65 69 70 70

10 inch 0 2 5 8 12 14 17 20 24 27 30 33 37 40 43 46 49 52 56 56 56

Seed Rate Handle Setting

Soybeans (2 of 4)

(based on 58 pounds/bushel)

Drive Type

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 5 14 23 34 41 51 59 69 79 87 98 107 117 126 136 144 153 163 164 164

7.5 inch 0 5 13 22 32 38 47 55 64 73 81 91 100 109 118 127 134 143 152 153 153

8 inch 0 4 12 20 30 36 44 52 60 69 76 86 94 102 110 119 126 134 143 143 144

10 inch 0 4 10 16 24 29 35 42 48 55 61 68 75 82 88 95 101 107 115 115 115

Seed Rate Handle Setting

04/12/2007 150-131B

Page 12

10

Great Plains Mfg., Inc.

Rate Charts, Main Seed Box, continued...

Soybeans (3 of 4)

(based on 58 pounds/bushel)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 10 19 35 51 61 76 87 100 113 127 141 155 168 183 195 213 227 244 243 244

7.5 inch 0 9 18 32 48 57 71 81 93 105 119 131 145 157 171 182 199 212 227 227 227

8 inch 0 9 17 30 45 53 67 76 87 99 111 123 136 147 160 171 186 199 213 213 213

10 inch 0 7 14 24 36 42 53 61 70 79 89 98 108 118 128 137 149 159 170 170 170

Soybeans (4 of 4)

(based on 58 pounds/bushel)

Drive Type

4 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 16 31 56 83 99 124 141 163 184 207 229 253 274 299 318 347 371 397 397 397

7.5 inch 0 15 29 53 78 92 116 132 152 171 193 214 236 256 279 297 324 346 370 371 371

8 inch 0 14 28 49 73 86 109 124 142 161 181 200 221 240 261 278 304 324 347 347 348

10 inch 0 11 22 40 58 69 87 99 114 128 145 160 177 192 209 223 243 260 278 278 278

Seed Rate Handle Setting

Seed Rate Handle Setting

Sunflower

(based on 28 pounds/bushel)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 0 2 4 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 34 35

7.5 inch 002 35 7 9 1012141618202224262729313233

8 inch 0 0 2 3 5 6 8 10 12 13 15 17 19 21 22 24 26 27 29 30 31

10 inch 0013 45 6 8 9 111214151618192022232424

Seed Rate Handle Setting

Wheat (1 of 2)

(based on 64 pounds/bushel)

Drive Type

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 11 19 26 34 43 49 60 69 78 90 99 109 120 131 141 152 163 174 176 177

7.5 inch 0 10 18 24 32 40 46 56 64 73 84 92 102 112 122 131 142 152 162 164 165

8 inch 0 9 17 23 30 37 43 52 60 69 79 86 96 105 114 123 133 143 152 153 154

10 inch 0 8 13 18 24 30 34 42 48 55 63 69 76 84 91 99 106 114 122 123 124

Seed Rate Handle Setting

150-131B 04/12/2007

Page 13

Great Plains Mfg., Inc.

Rate Charts, Main Seed Box, continued...

Wheat (2 of 2)

(based on 64 pounds/bushel)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 14 26 38 51 64 75 89 103 117 131 144 159 174 189 206 219 235 248 254 256

7.5 inch 0 13 25 36 48 59 70 83 96 109 123 134 149 162 176 192 205 219 232 237 239

8 inch 0 12 23 34 45 56 66 78 90 102 115 126 139 152 165 180 192 205 217 223 224

10 inch 0 10 18 27 36 45 53 62 72 82 92 101 111 121 132 144 154 164 174 178 179

Wheatgrass

(based on 23 pounds/bushel)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Pounds Per Acre

7 inch 0 1 2 3 4 4 5 6 7 8 9 10 11 12 13 14 15 17 16 18 18

7.5 inch 0 1 2 2 3 4 5 6 7 8 9 10 11 11 12 13 14 15 15 17 17

8 inch 0 1 2 2 3 4 5 6 6 7 8 9 10 11 12 13 13 15 14 16 16

10 inch 011233445677899101112111313

Seed Rate Handle Setting

Seed Rate Handle Setting

11

04/12/2007 150-131B

Page 14

12

Small Seeds Planting

To set and calibrate the seeding rate on the optional

small seeds attachment, follow these steps:

Note: For drills built after October 1, 2005,

calibrate using gauge wheel or supplied calibration crank.

For drills built before October 1, 2005,

calibrate using gauge wheel or order the calibration crank kit availablethroughyourGreat Plains

Dealer.

1. To calibrate, use either the left hand gauge wheel

or the supplied calibration crank. If using the calibration crank, attach crank to coupler on gauge

wheel jackshaft with retaining pin and disengage

lockout on drive wheel.

2. Rotate left hand gauge wheel or calibration crank

to see that feed cups and drive are working properly and are free from foreign matter.

3. From the small seeds seed rate chart on page 13

find the setting number for desired feeding rate

(and row spacing). Move the small seed cup

adjustment lever to that setting number.

4. Record weight of an empty container large enough

to hold seed metered for one acre.

5. Place several pounds of seed over three seed

cups on an outside end of drill box. Pull seed

tubes off of these three openers.

6. Turn drive gauge wheel or calibration crank several times to fill seed cups with seed. Turn wheel

or crank until seed falls to the ground from each

cup.

7. Rotate drive gauge wheel or calibration crank

346 rotations.

This is equal to one acre.

Note: Youcanalsorotate the gauge wheel jackshaftby

means of a wrench or socket. If rotating gauge

wheel jackshaft, disengage the lockout on the

drivewheel andusesame numberofrotations as

for rotating drive wheel.

8. Check that the three seed cups haveplenty of seed

coming into them.

9. Weigh metered seed. Subtract initial weight of container. Divide by three. Multiply by the number of

openers on your drill to determine total pounds

seeded per acre. If this figure is different than

desired, set your seed rate adjustment handle

accordingly.

Great Plains Mfg., Inc.

Figure 5

23386

1205NT Calibration Crank

Drill

Model

1205NT 346 855

MeasuredSeed EmptyContainer–

----------------------------------------------------------------------------------

PoundsPerSeedCup NumberOfOpeners× PoundsPerAcre=

3

Revolutions for One

Acre Hectare

PoundsPerSeedCup=

Note: You may want to repeat the calibration procedure

if your results vary greatly from seed rate chart.

10. When drilling, check seeding rate by noting acres

drilled, amount of seed added to small seed box

and seed level in small seeds box. If you are seeding more or less than desired, adjust seeding rate

slightly to compensate for field conditions.

150-131B 04/12/2007

Page 15

Great Plains Mfg., Inc.

Small Seeds Seed Rate Charts

This section is in U.S. customary units.

See page 25 for Metric rates.

Alfalfa, Red Alsike, Crimson Clover

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7 inch 0 0.0 1.9 3.0 4.1 5.1 6.4 7.5 8.4 9.5 10.8 11.8 12.9 14.0 15.0 16.3 17.3 18.3 20.0 20.6 21.6

7.5 inch 0 0.0 1.8 2.8 3.9 4.8 6.0 7.0 7.9 9.0 10.0 11.1 12.1 13.2 14.0 15.3 16.2 17.2 18.3 19.3 20.3

8 inch 0 0.0 1.6 2.6 3.6 4.5 5.6 6.6 7.4 8.4 9.4 10.3 11.3 12.3 13.1 13.0 15.2 16.1 17.1 18.0 18.9

10 inch 0 0.0 1.3 2.1 2.8 3.5 4.4 5.1 5.8 6.6 7.4 8.1 8.9 9.7 10.3 11.2 11.9 12.6 13.4 14.2 14.9

Kentucky Bluegrass,

Fescue, Annual Rye Grass

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7 inch 0 0.0 0.2 1.0 1.6 2.3 2.8 3.5 4.0 4.5 5.0 5.4 5.9 6.3 6.7 7.1 7.5 7.9 8.0 8.6 9.0

7.5 inch 0 0.0 0.2 .9 1.5 2.2 2.7 3.3 3.7 4.2 4.6 5.1 5.5 5.9 6.3 6.7 7.0 7.4 7.7 8.1 8.4

8 inch 0 0.0 0.2 0.9 1.4 2.0 2.5 3.0 3.5 3.9 4.3 4.8 5.1 5.5 5.9 6.2 6.6 6.9 7.5 7.5 7.9

10 inch 0 0.0 0.1 0.7 1.1 1.6 2.0 2.4 2.7 3.1 3.4 3.7 4.0 4.3 4.6 4.9 5.2 5.4 5.7 5.9 6.2

13

Bermuda, Red Top, Lespedeza Unhulled,

Sercia, Sand, Weeping Love Grass

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7 inch 0 0.0 0.6 0.9 1.5 2.2 2.8 3.6 4.3 5.1 5.6 6.2 6.7 7.1 7.7 8.1 8.7 9.4 10.0 10.5 11.0

7.5 inch 0 0.0 0.5 0.9 1.4 2.1 2.6 3.3 4.0 4.7 5.3 5.8 6.3 6.7 7.2 7.6 8.2 8.8 9.3 9.8 10.4

8 inch 0 0.0 0.5 0.8 1.3 2.0 2.5 3.1 3.8 4.4 4.9 5.4 5.9 6.5 6.7 7.1 7.6 8.2 8.7 9.2 9.7

10 inch 0 0.0 0.4 0.6 1.0 1.5 1.9 2.4 3.0 3.5 3.9 4.2 4.6 4.9 5.3 5.6 6.0 6.4 6.8 7.2 7.6

Red & Sweet Clover, Lespedeza Hulled

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7 inch 0 0.0 1.3 2.9 4.5 6.1 7.7 9.7 11.3 13.1 14.6 16.3 17.8 19.3 21.0 22.7 24.6 25.8 27.5 29.0 30.5

7.5 inch 0 0.0 1.2 2.7 4.2 5.7 7.2 9.1 10.6 12.3 13.7 15.3 16.7 18.1 19.7 21.2 22.7 24.2 25.8 27.2 28.6

8 inch 0 0.0 1.1 2.5 3.9 5.3 6.7 8.5 9.9 11.5 12.8 14.3 15.6 16.9 18.3 19.8 21.2 22.6 24.1 25.4 26.7

10 inch 0 0.0 0.9 2.0 3.1 4.2 5.3 6.7 7.8 9.0 10.0 11.2 12.2 13.3 14.4 15.6 16.6 17.8 18.9 19.9 20.9

04/12/2007 150-131B

Page 16

14

Great Plains Mfg., Inc.

Rate Charts, Small Seeds Box, continued...

Orchard Grass

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7 inch 0 0.0 0.0 0.2 0.6 .7 1.1 1.3 1.7 2.1 2.4 2.8 3.0 3.4 3.7 4.1 4.3 4.7 5.0 5.2 5.4

7.5 inch 0 0.0 0.0 0.2 0.5 0.7 1.1 1.2 1.6 1.9 2.3 2.6 2.8 3.2 3.5 3.9 4.0 4.4 4.6 4.9 5.1

8 inch 0 0.0 0.0 0.2 0.5 0.7 1.0 1.1 1.5 1.8 2.1 2.5 2.6 2.9 3.3 3.6 3.8 4.1 4.3 4.6 4.8

10 inch 0 0.0 0.0 0.1 0.4 0.5 .8 0.9 1.2 1.4 1.7 1.9 2.1 2.3 2.6 2.8 3.0 3.2 3.3 3.6 3.7

Millet, Reed Canary

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7 inch 0 0.4 1.2 2.1 3.0 3.8 4.7 5.6 6.4 7.3 8.1 9.0 9.9 10.7 11.6 12.5 13.3 14.2 15.1 15.9 16.1

7.5 inch 0 0.3 1.2 2.0 2.8 3.6 4.4 5.2 6.0 6.8 7.6 8.4 9.3 10.1 10.9 11.7 12.5 13.3 14.1 14.9 15.1

8 inch 0 0.3 1.1 1.8 2.6 3.3 4.1 4.9 5.6 6.4 7.1 7.9 8.6 9.4 10.2 10.9 11.7 12.4 13.2 13.9 14.1

10 inch 0 0.3 0.8 1.4 2.0 2.6 3.2 3.8 4.4 5.0 5.6 6.2 6.8 7.4 8.0 8.6 9.2 9.8 10.4 10.9 11.5

Ladino Clover, Canary Grass,

Timothy, Canola

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7 inch 0 0.0 0.9 1.7 2.8 4.1 5.2 6.6 7.9 9.2 10.5 11.8 13.3 14.6 15.9 17.4 18.7 20.0 22.0 23.4 25.1

7.5 inch 0 0.0 0.9 1.6 2.6 3.9 4.9 6.1 7.4 8.6 9.8 11.1 12.5 13.7 14.9 16.3 17.6 18.8 20.4 21.9 23.5

8 inch 0 0.0 0.8 1.5 2.5 3.6 4.6 5.7 6.9 8.0 9.2 10.3 11.6 12.8 13.9 15.2 16.4 17.5 19.0 20.5 21.9

10 inch 0 0.0 0.6 1.5 1.9 2.5 3.6 4.5 5.4 6.3 7.2 8.1 9.1 10.0 10.9 12.0 12.9 13.8 14.9 16.1 17.2

Birdsfoot, Trefoil, Sudan

Small Seeds Cup Lever Setting

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Pounds per Acre

7 inch 0 0.0 1.5 2.8 4.5 5.8 7.5 9.2 10.9 12.5 14.4 16.5 18.2 20.0 21.9 24.0 25.6 27.5 29.0 31.1 32.9

7.5 inch 0 0.0 1.4 2.6 4.2 5.4 7.0 8.6 10.2 11.9 13.5 15.4 17.0 18.8 20.5 22.5 24.0 25.8 27.6 29.1 30.9

8 inch 0 0.0 1.3 2.5 3.9 5.1 6.6 8.1 9.5 11.0 12.6 14.4 15.9 17.5 19.2 21.0 22.4 24.1 25.7 27.2 28.8

10 inch 0 0.0 1.0 1.9 3.1 4.0 5.1 6.3 7.5 8.6 9.9 11.3 12.5 13.8 15.1 16.5 17.6 18.9 20.2 21.4 22.7

150-131B 04/12/2007

Page 17

Great Plains Mfg., Inc.

e

Fertilizer Rate

Fertilizer application rates will vary with fertilizer type,

density and particle size. Relative humidity and field

conditions can also affect application rates. Initially set

rate according to the charts, then calibrate the drill to

your material as described below.

Note: For drills built after October 1, 2005,

calibrate using gauge wheels or supplied

calibration crank.

For drills built before October 1, 2005,

calibrate using gauge wheels or order

calibration crank kit available through

your Great Plains Dealer.

1. To calibrate using gauge wheels, raise drill with

tractor hydraulics so drive wheels are off the

ground. To calibrate using supplied calibration

crank, attach crank to coupler on gauge wheel

jackshaft with retaining pin. Disengage lockout on

the drive wheels.

Figure 6

23386

1205NT Calibration Crank

IMPORTANT !

The fertilizer rate chart is for granular fertilizer with a

density of 65 pounds per cubic foot (1.04 kg/L). If

you are applying fertilizer with a different density,

use the density conversion chart.

15

2. Rotate drive wheels or calibration crank to see that

metering system is working properly and free from

foreign material.

3. From the chart on page 16, find the setting number for your row spacing and desired application

rate. Rotate gate adjustment knob to the number

obtained from the chart.

4. Check that gauge-wheel tires are the correct size

and properly inflated. Refer to “Tire Inflation

Chart” in Appendix of Operator’s manual.

5. Record the weight of an empty container large

enough to hold fertilizer metered for one acre.

6. Place several pounds of fertilizer over three fertilizer drop tubes on outside end of drill box. Pull fertilizer tubes off these three openers.

7. Turn gauge wheels or calibration crank a fewturns

to meters with material. Continue to turn until fertilizer drops to the ground from all three tubes.

8. Place a container under the three tubes to gather

metered fertilizer.

9. Turn gauge wheel for 346 rotations (one acre).

Check that the three meters have plenty of fertilizer coming into them.

10. Weigh metered material. Subtract initial weight of

the empty container. Divide by three. Multiply by

the number of openers on your drill to determine

total pounds-per-acre metered. If this figure is different than desired, reset adjustment knob accordingly.

Drill

Model

1205NT 346 855

easuredMaterial EmptyContainer–

--------------------------------------------------------------------------------------------

PoundsPerDropTube NumberOfTubes× PoundsPerAcre=

3

Revolutions for One

Acre Hectare

PoundsPerDropTub

=

Note: You can also rotate the gauge wheel jackshaft by

means of a wrench or socket. If rotating gauge

wheel jackshaft, disengage the lockout on the

drive wheel and use same number of rotations

as for rotating drive wheel.

04/12/2007 150-131B

Page 18

16

Great Plains Mfg., Inc.

Fertilizer Rate Charts

This section is in U.S. customary units.

See page 27 for Metric rates.

Rates in Pounds per Acre

Setting Number

15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Application Rate - Pounds per Acre

7 inch

7.5 inch

8 inch

10 inch

Density Conversion Charts

The fertilizer meter rate charts are based on fertilizer

with a density of 65 pounds per cubic foot. If you are

applying fertilizer of a different density, use the following table to convert application rate.

Density, lb/ft

Conversion Factor 1.45 1.30 1.20 1.10 1.00 0.93 0.87 0.81

13 23 41 57 78 95 111 131 148 165 184 199 221 235 246 256 259 261

11 20 38 54 72 89 105 123 138 157 174 187 209 223 234 242 245 247

11 20 36 50 69 84 98 115 130 146 163 176 195 207 219 226 228 231

8 16 29 40 54 67 79 92 104 118 131 140 157 167 175 182 183 185

3

45.0 50.0 55.0 60.0 65.0 70.0 75.0 80.0

Example: Your fertilizer has a density of 75 pounds per

cubic foot, and you want to apply 100 pounds per acre.

Multiply the desired application rate by the conversion

factor.

100 x 0.87 = 87

Adjust drill to the setting closest to 87 pounds per acre.

150-131B 04/12/2007

Page 19

Great Plains Mfg., Inc.

Metric Charts

Metric Rate Charts, Main Seed Box

For instructions see page 1.

For charts in U.S. customary units, see page 4.

Alfalfa or Rape

(based on 0.77 kg per liter)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 5.3 8.0 11.6 14.8 18.4 22.0 26.2 30.3 35.4 39.4 43.1 47.7 52.2 56.8 60.9 66.1 71.1 76.3 78.6 80.8

19.1cm 0 4.9 7.5 10.8 13.8 17.2 20.5 24.4 28.3 33.0 36.8 40.3 44.6 48.7 53.0 56.8 61.7 66.4 71.2 73.3 75.4

20.3cm 0 4.6 7.1 10.1 12.9 16.1 19.2 22.9 26.5 30.9 34.5 37.7 41.8 45.6 49.6 53.2 57.8 62.2 66.8 68.7 70.7

25.4cm 0 3.7 5.6 8.1 10.3 12.9 15.4 18.3 21.2 24.7 27.6 30.2 33.5 36.5 39.7 42.6 46.3 49.7 53.4 55.0 56.6

Seed Rate Handle Setting

17

Barley (1 of 3)

(based on 0.66 kg per liter)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 4.4 7.3 10.2 13.8 17.4 21.3 25.1 29.0 33.2 37.5 41.7 46.0 50.9 55.0 59.4 63.1 66.5 69.8 70.4 71.0

19.1cm 0 4.0 6.8 9.5 12.9 16.3 20.0 23.5 27.1 31.0 34.9 38.8 43.0 47.4 51.3 55.5 58.8 62.1 65.2 65.7 68.2

20.3cm 0 3.8 6.4 9.0 12.1 15.2 18.7 22.0 25.4 29.1 32.8 36.4 40.3 44.5 48.1 52.0 55.1 58.2 61.1 61.5 62.1

25.4cm 0 3.0 5.1 7.2 9.7 12.1 14.9 17.6 20.3 23.2 26.2 29.2 32.2 35.6 38.5 41.5 44.1 46.6 48.8 49.3 49.6

Seed Rate Handle Setting

Barley (2 of 3)

(based on 0.66 kg per liter)

Drive Type

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 8.3 15.3 20.8 28.6 35.6 43.4 51.6 59.4 68.4 76.3 83.8 92.2 100.1 109.2 118.1 127.8 137.1 145.8 148.2 150.4

19.1cm 0 7.7 14.3 19.3 26.7 33.2 40.5 48.3 55.5 63.8 71.3 78.1 86.1 93.5 101.9 110.1 119.2 127.9 136.1 138.2 140.4

20.3cm 0 7.3 13.4 18.2 25.0 31.1 37.9 45.2 52.0 59.8 66.8 73.2 80.7 87.7 95.7 103.3 111.8 119.9 127.7 129.7 131.7

25.4cm 0 5.8 10.7 14.5 20.1 24.9 30.4 36.2 41.7 47.8 53.4 58.6 64.6 70.2 76.5 82.6 89.5 95.9 100.1 103.7 105.3

Seed Rate Handle Setting

04/12/2007 150-131B

Page 20

18

Great Plains Mfg., Inc.

Metric Rate Charts, Main Seed Box, continued...

Barley (3 of 3)

(based on 0.66 kg per liter)

Drive Type

4 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 20.4 37.3 50.7 70.2 87.0 106.2 126.4 145.4 167.2 186.8 204.7 225.6 245.0 267.2 288.9 312.6 335.1 356.7 362.3 368.0

19.1cm 0 19.0 34.8 47.4 65.5 81.2 99.1 118.0 135.7 155.9 174.4 191.1 210.5 228.7 249.5 269.4 291.7 312.8 332.9 338.2 343.4

20.3cm 0 17.9 32.7 44.3 61.4 76.1 92.8 110.6 127.2 146.3 163.5 179.2 197.4 214.4 233.9 252.6 273.5 293.2 312.1 317.1 322.0

25.4cm 0 14.3 26.2 35.5 49.1 60.9 74.3 88.5 101.8 117.0 130.8 143.3 157.9 171.5 187.0 202.1 218.8 234.6 249.7 253.6 257.7

Buckwheat

(based on 0.62 kg per liter)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 10.9 20.2 28.3 40.3 50.3 62.5 75.0 88.9 102.8 118.4 130.6 144.7 159.2 172.8 188.1 201.4 215.6 226.7 229.3 233.1

19.1cm 0 10.1 18.9 26.5 37.6 46.9 58.4 70.1 83.0 95.9 110.6 121.8 135.1 148.5 161.2 175.6 187.9 201.2 214.4 214.6 218.9

20.3cm 0 9.4 17.6 24.8 35.3 44.0 54.8 65.7 77.8 89.9 103.6 114.3 126.6 139.3 151.2 164.6 176.3 188.6 201.0 201.7 202.6

25.4cm 0 7.6 14.1 19.9 28.2 35.1 43.8 52.5 62.2 72.0 83.0 91.4 101.3 111.4 120.9 131.7 141.0 150.9 160.8 164.7 170.1

Seed Rate Handle Setting

Seed Rate Handle Setting

Buffalograss (1 of 4)

((based on 0.30 kg per liter)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 1.1 2.3 3.4 4.5 6.8 7.9 10.1 11.3 13.5 14.6 16.9 18.0 20.3 21.4 22.5 23.7 23.7 24.8 24.8 24.8

19.1cm 0 1.1 2.3 3.4 4.5 5.6 7.9 9.0 11.3 12.4 14.6 15.8 16.9 19.2 20.3 21.4 22.5 22.5 22.5 22.5 22.5

20.3cm 0 1.1 2.3 3.4 4.5 5.6 6.8 9.0 10.1 11.3 13.5 14.6 15.8 18.0 19.2 20.3 20.3 21.4 21.4 21.4 21.4

25.4cm 0 1.1 2.3 2.3 3.4 4.5 5.6 6.8 7.9 9.0 10.1 12.4 13.5 13.5 14.6 15.8 16.9 16.9 16.9 16.9 16.9

Seed Rate Handle Setting

Buffalograss (2 of 4)

(based on 0.30 kg per liter)

Drive Type

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 3.4 4.5 7.9 10.1 13.5 16.9 20.3 23.7 27.0 31.6 34.9 38.3 41.7 43.9 46.2 48.5 49.6 50.7 50.7 49.6

19.1cm 0 2.3 4.5 6.8 9.0 12.4 15.8 19.2 22.5 25.9 29.3 32.7 36.1 38.3 40.6 42.8 45.1 46.2 47.3 47.3 46.2

20.3cm 0 2.3 4.5 6.8 9.0 11.3 14.6 18.0 21.4 23.7 27.0 30.4 33.8 36.1 38.3 40.6 42.8 43.9 43.9 43.9 43.9

25.4cm 0 2.3 3.4 5.6 6.8 9.0 11.3 14.6 16.9 19.2 21.4 24.8 27.0 29.3 30.4 32.7 33.8 34.9 34.9 34.9 34.9

Seed Rate Handle Setting

150-131B 04/12/2007

Page 21

Great Plains Mfg., Inc.

Metric Rate Charts, Main Seed Box, continued...

Buffalograss (3 of 4)

(based on 0.30 kg per liter)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 5.6 7.9 11.3 14.6 19.2 23.7 29.3 34.9 40.6 46.2 51.8 56.3 62.0 66.5 69.9 73.2 75.5 77.7 77.7 77.7

19.1cm 0 5.6 7.9 10.1 13.5 18.0 22.5 27.0 32.7 38.3 42.8 48.5 53.0 57.5 62.0 65.4 68.7 71.0 72.1 73.2 72.1

20.3cm 0 4.5 6.8 10.1 13.5 16.9 21.4 25.9 30.4 34.9 40.6 45.1 49.6 54.1 57.5 60.8 64.2 66.5 67.6 68.7 67.6

25.4cm 0 3.4 5.6 7.9 10.1 13.5 16.9 20.3 24.8 28.2 32.7 36.1 40.6 42.8 46.2 49.6 51.8 53.0 54.1 54.1 54.1

Buffalograss (4 of 4)

(based on 0.30 kg per liter)

Drive Type

4 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 9.0 12.4 18.0 24.8 31.6 40.6 48.5 56.3 66.5 75.5 84.5 92.4 100.0 108.2 113.8 119.4 123.9 126.2 127.3 126.2

19.1cm 0 7.9 12.4 16.9 22.5 29.3 37.2 45.1 53.0 62.0 69.9 78.9 86.8 93.5 101.4 107.0 111.6 114.9 117.2 118.3 117.2

20.3cm 0 7.9 11.3 15.8 21.4 27.0 34.9 41.7 49.6 57.5 65.4 73.2 81.1 87.9 94.7 100.3 104.8 108.2 110.4 111.6 110.4

25.4cm 0 6.5 9.0 12.4 16.9 22.5 28.2 33.8 39.4 46.2 53.0 58.6 65.4 71.0 75.5 80.0 83.4 86.8 87.9 89.0 87.9

Seed Rate Handle Setting

Seed Rate Handle Setting

19

Flax or Sudan

(based on 0.71 kg per liter)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 3.6 7.9 11.2 15.5 19.4 23.2 27.2 31.5 35.6 40.3 44.0 48.1 52.3 56.8 62.2 67.1 72.9 78.8 80.2 81.6

19.1cm 0 3.4 7.4 10.6 14.5 18.1 21.7 25.4 29.4 33.2 37.6 41.1 44.8 48.8 53.1 58.0 62.6 68.0 73.5 74.8 76.2

20.3cm 0 3.1 6.8 9.9 13.6 17.0 20.3 23.8 27.6 31.1 35.3 38.5 42.0 45.8 49.7 54.5 58.7 63.8 68.9 70.1 71.4

25.4cm 0 2.5 5.5 7.9 10.9 13.6 16.3 19.1 22.1 24.9 28.2 30.8 33.6 36.6 39.7 43.6 47.0 51.0 55.2 56.0 57.1

Seed Rate Handle Setting

Millet

(based on 0.77 kg per liter)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 4.5 7.9 11.2 15.0 18.7 22.6 26.3 30.3 34.4 38.3 42.3 46.7 50.4 54.9 59.4 63.5 68.1 73.0 74.1 75.2

19.1cm 0 4.2 7.4 10.6 14.0 17.5 21.0 24.5 28.3 32.0 35.7 39.5 43.6 47.0 51.2 55.5 59.3 63.5 68.0 69.2 70.2

20.3cm 0 3.9 6.8 9.9 13.1 16.4 19.8 22.9 26.5 30.0 33.5 37.0 40.9 44.1 48.1 52.0 55.6 59.6 63.8 64.8 65.8

25.4cm 0 3.1 5.5 7.9 10.6 13.1 15.7 18.3 21.2 24.0 26.8 29.6 32.7 35.4 38.4 41.5 44.5 47.7 51.1 51.9 52.7

Seed Rate Handle Setting

04/12/2007 150-131B

Page 22

20

Great Plains Mfg., Inc.

Metric Rate Charts, Main Seed Box, continued...

Milo

(based on 0.82 kg per liter)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 4.5 8.4 12.6 17.1 21.7 26.7 32.2 37.6 43.1 49.5 54.6 60.5 66.2 71.9 77.8 83.3 88.2 94.0 96.6 98.2

19.1cm 0 4.2 7.9 11.7 15.9 20.2 24.9 30.1 35.0 40.3 46.3 51.0 56.5 61.9 67.1 72.5 77.8 82.3 87.7 90.0 91.6

20.3cm 0 3.9 7.4 11.0 14.9 18.9 23.4 28.2 32.9 37.7 43.3 47.7 52.9 57.9 62.9 68.0 72.9 77.1 82.2 84.4 85.9

25.4cm 0 3.1 6.0 8.8 11.9 15.2 18.7 22.6 26.3 30.2 34.7 38.2 42.3 46.4 50.3 54.5 58.4 61.7 65.8 67.6 68.7

Oats

(based on 0.48 kg per liter)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 5.1 11.7 16.6 23.0 30.3 37.3 45.0 52.8 60.9 69.5 76.7 84.8 92.5 100.6 108.6 116.6 124.7 133.4 133.4 136.5

19.1cm 0 4.7 10.9 15.6 21.5 28.3 34.7 42.0 49.3 56.8 64.8 71.5 79.0 86.3 93.9 101.4 108.9 116.4 124.4 124.5 127.5

20.3cm 0 4.4 10.2 14.6 20.2 26.5 32.6 39.4 46.1 53.2 60.7 67.1 74.1 80.9 88.0 95.1 102.1 109.1 116.6 116.7 119.7

25.4cm 0 3.5 8.2 11.7 16.2 21.2 26.0 31.5 36.9 42.6 48.6 53.7 59.3 64.8 70.4 76.0 81.6 87.3 93.3 93.4 95.6

Seed Rate Handle Setting

Seed Rate Handle Setting

Peas

(based on 0.79 kg per liter)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 9.2 18.2 32.8 50.0 66.1 80.7 98.0 114.4 132.3 148.4 163.0 179.2 193.9 210.1 226.6 241.4 256.1 270.9 272.3 273.5

19.1cm 0 8.4 17.1 30.5 46.6 61.7 75.3 91.5 106.8 123.4 138.5 152.2 167.2 181.0 196.0 211.5 225.3 239.0 252.8 254.1 255.2

20.3cm 0 7.9 15.9 28.6 43.7 57.8 70.6 85.8 100.1 115.8 129.9 142.7 158.7 169.6 183.8 198.2 211.2 224.1 237.0 238.2 239.2

25.4cm 0 6.4 12.8 22.9 34.9 46.3 56.5 68.6 80.2 92.5 104.0 114.2 125.4 135.7 147.0 158.6 169.0 179.3 189.6 190.5 191.4

Seed Rate Handle Setting

Pinto Beans

(based on 0.66 kg per liter)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 0.0 8.2 12.5 16.7 22.7 28.4 34.0 39.6 45.4 51.0 56.0 61.3 66.2 71.6 77.7 82.2 87.3 92.3 92.5 92.6

19.1cm 0 0.0 7.6 11.6 15.8 21.2 28.5 31.7 37.0 42.3 47.8 52.3 57.1 61.9 66.8 72.3 76.7 81.5 86.1 87.9 88.3

20.3cm 0 0.0 7.2 10.9 14.7 19.9 24.9 29.8 34.7 39.8 44.8 49.1 53.6 57.9 62.8 67.9 71.9 76.3 80.8 80.9 81.0

25.4cm 0 0.0 5.7 8.8 11.7 15.9 19.9 23.8 27.7 31.8 35.7 39.2 42.9 46.4 50.2 54.5 57.5 61.1 64.6 64.8 64.8

Seed Rate Handle Setting

150-131B 04/12/2007

Page 23

Great Plains Mfg., Inc.

Metric Rate Charts, Main Seed Box, continued...

Rice, Short Grain (1 of 2)

(based on 0.55 kg per liter)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 10.6 17.4 27.2 38.9 43.9 53.4 61.1 70.6 80.6 92.1 102.8 112.8 123.0 133.4 142.4 150.6 158.9 167.5 170.1 171.9

19.1cm 0 9.9 16.2 25.4 34.5 41.0 49.8 57.0 65.9 75.2 85.9 95.9 105.3 114.9 124.4 132.9 140.6 148.3 156.4 158.9 159.4

20.3cm 0 9.2 15.2 23.8 32.3 38.4 46.7 53.4 61.7 70.5 80.5 89.9 98.7 107.7 116.6 124.6 131.7 139.0 146.6 148.6 150.0

25.4cm 0 7.4 12.1 19.1 25.8 30.8 37.4 42.8 49.4 56.4 64.4 72.0 78.9 86.1 93.3 99.7 105.4 111.3 117.3 119.8 120.7

Rice, Short Grain (2 of 2)

(based on 0.55 kg per liter)

Drive Type

4 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 17.2 28.3 44.3 60.2 71.5 87.0 99.7 115.1 131.4 150.0 167.6 183.9 200.6 217.4 232.2 245.5 259.1 273.2 279.8 285.0

19.1cm 0 16.1 26.4 41.4 56.1 66.8 81.3 93.0 107.3 122.6 140.0 158.4 171.7 187.3 202.9 216.7 229.1 241.8 255.0 262.3 268.2

20.3cm 0 15.0 24.8 38.8 52.7 62.8 78.1 87.2 100.7 115.0 131.2 148.8 180.9 175.8 190.2 203.1 214.8 226.7 239.0 243.2 247.1

25.4cm 0 12.0 19.9 31.1 42.1 50.1 61.0 69.7 80.5 91.9 105.0 117.3 128.8 140.4 152.2 162.5 171.9 181.3 191.2 196.6 199.8

Seed Rate Handle Setting

Seed Rate Handle Setting

21

Rice, Long Grain (1 of 4)

(based on 0.60 kg per liter)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 1 5 7 10 14 16 19 23 25 30 31 34 37 39 43 45 47 50 51 52

19.1cm 01 5 7912161820242829323537394345464748

20.3cm 0 1 3 7 9 11 15 17 19 23 29 27 29 33 35 37 39 42 44 45 45

25.4cm 0 1 3 5 7 9 11 14 16 18 21 21 24 26 28 30 32 34 35 36 36

Seed Rate Handle Setting

Rice, Long Grain (2 of 4)

(based on 0.60 kg per liter)

Drive Type

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 3 9 15 20 27 34 39 45 52 63 64 70 75 81 88 94 98 103 105 107

19.1cm 02 81419263237434859606571778287919698100

20.3cm 0 2 8 12 18 24 29 35 39 45 55 56 61 66 71 77 81 86 90 92 94

25.4cm 02 7101519242832363745485357626569727375

Seed Rate Handle Setting

04/12/2007 150-131B

Page 24

22

Great Plains Mfg., Inc.

Metric Rate Charts, Main Seed Box, continued...

Rice, Long Grain (3 of 4)

(based on 0.60 kg per liter)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 0.0 12.7 20.9 30.4 40.3 50.7 58.9 68.0 77.8 88.3 94.4 102.5 111.1 120.6 129.7 138.9 147.5 154.9 160.9 166.4

19.1cm 0 0.0 11.8 19.4 28.4 37.6 47.4 55.0 63.5 72.6 80.6 88.1 95.7 103.7 112.5 121.0 129.7 137.6 144.6 150.1 155.3

20.3cm 0 0.0 11.1 18.2 26.8 35.3 44.3 51.5 59.5 68.0 75.6 82.6 89.7 97.2 105.5 113.4 121.6 129.1 135.5 140.8 145.6

25.4cm 0 0.0 8.9 14.6 21.2 28.2 35.5 41.2 47.6 54.5 60.5 66.1 71.7 77.8 84.4 90.7 97.2 103.3 108.5 112.6 116.4

Rice, Long Grain (4 of 4)

(based on 0.60 kg per liter)

Drive Type

4 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 0.0 20.7 34.0 49.5 65.7 82.7 96.0 110.9 126.9 140.8 154.0 167.2 181.2 196.6 211.4 226.4 240.5 252.6 262.3 271.2

19.1cm 0 0.0 19.3 31.7 46.3 61.3 77.2 89.6 103.6 118.3 131.5 143.7 155.9 169.1 183.4 197.3 211.4 224.4 235.8 244.7 253.2

20.3cm 0 0.0 18.1 29.8 43.3 57.5 72.4 84.0 97.1 110.9 123.3 134.7 148.3 158.5 172.0 184.9 198.2 210.4 221.1 229.5 237.3

25.4cm 0 0.0 14.5 23.8 34.7 45.9 57.9 67.2 77.7 88.8 98.6 107.8 117.0 126.9 137.6 148.0 158.5 168.4 176.8 183.6 189.8

Seed Rate Handle Setting

Seed Rate Handle Setting

Rye

(based on 0.73 kg per liter)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 2.7 7.5 12.1 17.7 23.0 26.9 33.3 39.2 45.2 51.0 55.8 60.5 65.8 71.0 77.5 83.3 90.0 97.2 97.9 98.2

19.1cm 0 2.5 7.1 11.3 16.6 21.6 25.1 31.1 36.6 42.2 47.6 52.1 56.5 61.4 66.2 72.3 77.7 84.0 90.7 91.3 91.6

20.3cm 0 2.4 6.6 10.7 15.5 20.2 23.6 29.2 34.2 39.5 44.6 48.8 53.0 57.5 62.1 67.7 72.9 78.7 85.0 85.5 85.9

25.4cm 0 1.9 5.3 8.5 12.5 16.2 18.9 23.4 27.4 31.7 35.7 39.1 42.4 46.0 49.7 54.2 58.3 63.0 68.0 68.5 68.7

Seed Rate Handle Setting

Soybeans (1 of 4)

(based on 0.75 kg per liter)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 2.7 7.5 12.6 18.5 22.2 27.6 32.4 37.6 43.0 47.6 53.3 58.7 63.7 68.7 74.1 78.4 83.6 89.0 89.5 89.7

19.1cm 0 2.5 7.0 11.8 17.3 20.8 25.7 30.3 35.1 40.1 44.3 49.7 54.8 59.5 64.2 69.2 73.2 78.0 83.1 83.5 83.8

20.3cm 0 2.4 6.5 11.0 16.3 19.4 24.1 28.4 32.9 37.6 41.7 46.7 51.3 55.7 60.2 64.8 68.6 73.1 77.9 78.3 78.5

25.4cm 0 1.9 5.3 8.9 13.0 15.6 19.3 22.7 26.4 30.1 33.3 37.4 41.1 44.6 48.2 51.9 54.9 58.5 62.3 62.8 62.9

Seed Rate Handle Setting

150-131B 04/12/2007

Page 25

Great Plains Mfg., Inc.

Metric Rate Charts, Main Seed Box, continued...

Soybeans (2 of 4)

(based on 0.75 kg per liter)

Drive Type

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 5.5 15.4 25.9 38.2 45.7 56.7 66.7 77.4 88.4 97.8 109.6 120.6 130.9 141.3 152.2 161.1 171.9 183.0 183.9 184.5

19.1cm 0 5.2 14.4 24.3 35.6 42.7 52.9 62.2 72.3 82.4 91.3 102.3 112.5 122.1 131.9 142.1 150.3 160.4 170.8 171.7 172.1

20.3cm 0 4.8 13.5 22.7 33.3 40.1 49.6 58.4 67.7 77.4 85.5 96.0 105.5 114.5 123.6 133.2 141.0 150.3 160.1 160.9 161.4

25.4cm 0 3.9 10.8 18.2 26.7 32.0 39.6 46.7 54.2 61.9 68.5 76.8 84.4 91.6 98.9 106.5 112.8 120.4 127.6 128.8 129.1

Soybeans (3 of 4)

(based on 0.75 kg per liter)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 11.1 21.7 38.8 57.3 68.0 85.5 97.2 111.9 126.4 142.5 157.7 173.9 189.0 205.6 218.9 238.9 255.3 272.0 272.4 254.5

19.1cm 0 10.3 20.2 36.3 53.4 63.5 79.8 90.7 104.5 118.0 133.0 147.3 162.3 176.3 191.9 204.3 223.0 238.2 253.9 254.1 254.5

20.3cm 0 9.8 19.0 34.0 50.1 59.5 74.9 85.1 98.0 110.6 124.7 138.1 152.1 165.3 179.9 191.5 209.0 223.4 238.0 238.2 238.6

25.4cm 0 7.7 15.2 27.2 40.1 47.6 59.8 68.0 78.4 88.5 99.7 110.5 121.7 132.3 143.9 153.2 167.2 178.7 190.5 190.8 190.8

Seed Rate Handle Setting

Seed Rate Handle Setting

23

Soybeans (4 of 4)

(based on 0.75 kg per liter)

Drive Type

4 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 18 35 63 94 112 140 159 184 207 233 258 285 309 337 358 391 418 447 447 447

19.1cm 0 17 33 60 88 104 131 149 171 193 217 241 266 288 314 335 365 390 417 418 418

20.3cm 0 16 32 55 82 97 123 140 160 181 204 225 249 270 294 313 343 365 391 391 392

25.4cm 0 12 25 45 65 78 98 112 128 144 163 163 199 216 236 251 274 293 313 313 313

Seed Rate Handle Setting

Sunflower

(based on 0.36 kg per liter)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 0.0 2.0 4.0 6.0 8.0 10.3 12.5 14.8 17.1 19.4 21.7 23.9 26.3 28.5 30.6 32.8 34.7 36.9 37.9 39.2

19.1cm 0 0.0 1.8 3.8 5.5 7.5 9.5 11.6 13.8 15.9 18.2 20.2 22.3 24.6 26.6 28.6 30.6 32.3 34.5 35.4 36.5

20.3cm 0 0.0 1.7 3.8 5.2 7.0 9.0 10.9 12.9 14.9 17.0 18.9 21.0 23.0 25.0 26.8 28.7 30.3 32.2 33.2 34.2

25.4cm 0 0.0 1.3 2.8 4.2 5.6 7.2 8.8 10.3 12.0 13.6 15.2 16.7 18.4 20.0 21.4 22.9 24.3 25.8 26.6 27.4

Seed Rate Handle Setting

04/12/2007 150-131B

Page 26

24

Great Plains Mfg., Inc.

Metric Rate Charts, Main Seed Box, continued...

Wheat (1 of 2)

based on 0.82 kg per liter)

Drive Type

2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 12.0 21.1 29.3 37.9 47.8 55.2 67.2 77.4 87.9 100.7 110.7 122.6 134.9 146.5 158.0 170.3 182.8 195.3 197.9 196.2

19.1cm 0 11.2 19.8 27.3 35.5 44.6 51.5 62.8 72.3 82.1 94.1 103.4 114.4 126.0 136.7 147.4 159.0 170.7 182.3 184.8 184.9

20.3cm 0 10.6 18.5 25.6 33.2 41.8 48.3 58.8 67.7 77.0 88.1 96.9 107.3 118.1 128.2 138.2 149.1 160.0 171.0 173.2 173.3

25.4cm 0 8.4 14.8 20.4 26.6 33.5 38.6 47.0 54.2 61.5 70.5 77.6 85.8 94.5 102.5 110.6 119.2 128.0 136.7 138.5 138.8

Wheat (2 of 2)

(based on 0.82 kg per liter)

Drive Type

3 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 15.3 29.4 43.1 57.3 71.4 84.2 99.7 115.5 131.4 147.5 161.7 178.6 194.8 212.0 230.8 246.1 263.4 278.9 285.6 287.5

19.1cm 0 14.3 27.5 40.2 53.4 66.6 78.6 93.1 107.9 122.6 137.6 150.9 166.7 181.8 197.8 215.4 229.7 245.8 260.4 266.5 268.3

20.3cm 0 13.4 25.7 37.7 50.1 62.4 73.6 87.2 101.2 115.0 129.1 141.5 156.3 170.4 185.5 202.0 215.3 230.4 244.1 249.9 251.6

25.4cm 0 10.7 20.7 30.1 40.1 50.0 58.9 69.5 80.8 91.9 103.3 113.2 125.1 138.3 148.3 161.6 172.3 184.3 195.2 199.8 201.3

Seed Rate Handle Setting

Seed Rate Handle Setting

Wheatgrass

(based on 0.30 kg per liter)

Drive Type

1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seed Rate in Kilograms per Hectare

17.8cm 0 0.0 0.9 2.0 2.9 4.0 4.9 5.7 7.1 8.1 9.3 10.4 11.5 12.6 13.7 14.8 16.2 17.2 17.4 17.9 20.0

19.1cm 0 0.0 0.8 1.9 2.7 3.8 4.6 5.4 6.6 7.5 8.6 9.7 10.7 11.8 12.8 13.9 15.0 16.1 16.3 16.6 18.6

20.3cm 0 0.0 0.8 1.8 2.5 3.6 4.4 5.1 6.2 7.1 8.1 9.1 10.0 11.0 12.0 13.0 14.1 15.0 15.3 15.6 17.5

25.4cm 0 0.0 0.7 1.5 2.0 2.8 3.5 4.0 4.9 5.7 6.5 7.3 8.0 8.9 9.5 10.4 11.3 12.0 12.2 12.5 14.0

Seed Rate Handle Setting

150-131B 04/12/2007

Page 27

Great Plains Mfg., Inc.

Metric Rate Charts, Small Seeds Box

For instructions see page 12.

For charts in U.S. customary units, see page 13.

Alfalfa, Red Alsike, Crimson Clover

Metric

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Kilograms per Hectare

17.8cm 0 0.0 2.1 3.4 4.6 5.7 7.2 8.5 9.5 10.7 12.2 13.3 14.5 15.8 16.9 18.4 19.5 20.6 22.5 23.2 24.3

19.1cm 0 0.0 2.0 3.2 4.4 5.4 6.8 7.9 8.9 10.1 11.3 12.5 13.6 14.9 15.8 17.2 18.3 19.4 20.6 21.7 22.9

20.3cm 0 0.0 1.8 2.9 4.1 5.1 6.3 7.4 8.3 9.5 10.6 11.6 12.7 13.9 14.8 14.8 17.1 18.1 19.3 19.3 21.3

25.4cm 0 0.0 1.5 2.4 3.2 3.9 5.0 5.7 6.5 7.4 8.3 9.1 10.0 10.9 11.6 12.6 13.4 14.2 15.1 15.1 15.1

Kentucky Bluegrass,

Fescue, Annual Rye Grass

Metric

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Kilograms per Hectare

17.8cm 0 0.0 0.2 1.1 1.8 2.6 3.2 3.9 4.5 5.1 5.6 6.1 6.6 7.1 7.5 8.0 8.5 8.9 9.0 9.7 10.1

19.1cm 0 0.0 0.2 1.0 1.7 2.5 3.0 3.7 4.2 4.7 5.2 5.7 6.2 6.6 7.1 7.5 7.9 8.3 8.3 9.1 9.5

20.3cm 0 0.0 0.2 1.0 1.6 2.3 2.3 3.4 3.9 4.4 4.8 5.4 5.4 6.2 6.6 7.0 7.4 7.4 8.5 8.5 8.9

25.4cm 0 0.0 0.1 0.8 0.8 1.8 2.3 2.3 2.3 3.5 3.5 4.2 4.5 4.8 5.2 5.5 5.5 6.1 6.1 6.6 7.0

Small Seeds Cup Lever Setting

Small Seeds Cup Lever Setting

25

Bermuda, Red Top, Lespedeza Unhulled,

Sercia, Sand, Weeping Love Grass

Metric

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Kilograms per Hectare

17.8cm 0 0.0 0.7 1.0 1.7 2.5 3.2 4.1 4.8 5.7 6.3 7.0 7.0 8.0 8.7 9.1 9.8 10.6 11.3 11.8 12.4

19.1cm 0 0.0 0.6 1.0 1.6 2.4 2.9 3.7 4.5 5.3 6.0 6.5 7.1 7.5 8.1 8.6 9.2 9.9 10.5 11.0 11.7

20.3cm 0 0.0 0.6 0.9 1.5 2.3 2.8 3.5 4.3 5.0 5.5 6.1 6.6 7.3 7.5 8.0 8.6 9.2 9.8 10.4 10.9

25.4cm 0 0.0 0.5 0.7 1.1 1.7 2.1 2.7 3.4 3.9 4.4 4.7 5.2 5.2 6.0 6.3 6.8 7.2 7.7 8.1 8.1

Small Seeds Cup Lever Setting

Red & Sweet Clover, Lespedeza Hulled

Metric

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Kilograms per Hectare

17.8cm 0 0.0 1.5 3.3 5.1 6.9 8.7 10.9 12.7 14.8 16.5 18.4 20.1 21.7 23.7 25.6 27.7 29.1 31.0 32.7 34.4

19.1cm 0 0.0 1.4 3.0 4.7 6.4 8.1 10.3 11.9 13.9 15.4 17.2 18.8 20.4 22.2 23.9 25.6 27.3 29.1 30.6 32.2

20.3cm 0 0.0 1.2 2.8 4.4 4.4 7.5 9.6 11.2 13.0 14.4 16.1 17.6 19.0 20.6 22.3 23.9 25.5 27.2 28.6 30.1

25.4cm 0 0.0 1.0 2.3 3.5 4.7 6.0 7.5 8.8 10.1 11.3 12.6 13.7 15.0 16.2 17.6 18.7 20.1 21.3 21.3 23.6

Small Seeds Cup Lever Setting

04/12/2007 150-131B

Page 28

26

Great Plains Mfg., Inc.

Metric Rate Charts, Small Seeds Box, continued...

Orchard Grass

Metric

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Kilograms per Hectare

17.8cm 0 0.0 0.0 0.2 0.7 0.8 1.2 1.5 1.9 2.4 2.7 3.2 3.4 3.8 4.2 4.6 4.8 5.3 5.6 5.6 6.1

19.1cm 0 0.0 0.0 0.2 0.6 0.8 0.8 1.4 1.4 1.4 1.4 1.4 3.2 3.6 3.9 4.4 4.5 5.0 5.2 5.5 5.5

20.3cm 0 0.0 0.0 0.2 0.6 0.8 1.1 1.2 1.7 2.0 2.4 2.8 2.9 3.3 3.7 4.1 4.3 4.6 4.8 5.2 5.4

25.4cm 0 0.0 0.0 0.1 0.5 0.6 0.9 1.0 1.4 1.6 1.9 2.1 2.4 2.6 2.9 3.2 3.4 3.6 3.7 4.1 4.2

Millet, Reed Canary

Metric

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Kilograms per Hectare

17.8cm 0 0.5 1.4 2.4 3.4 4.3 5.3 6.3 7.2 8.2 9.1 10.1 11.2 12.1 13.1 14.1 15.0 16.0 17.0 17.9 18.1

19.1cm 0 0.3 1.4 1.4 1.4 4.1 5.0 5.9 6.8 7.7 8.6 9.5 10.5 11.4 12.3 13.2 14.1 15.0 15.9 16.8 17.0

20.3cm 0 0.3 1.2 2.0 2.9 3.7 4.6 5.5 5.5 7.2 8.0 8.9 9.7 10.6 11.5 12.3 13.2 14.0 14.9 15.7 15.9

25.4cm 0 0.3 0.9 1.6 2.3 2.3 3.6 4.3 5.0 5.6 6.3 7.0 7.0 8.3 9.0 9.7 10.4 11.0 11.7 12.3 13.0

Small Seeds Cup Lever Setting

Small Seeds Cup Lever Setting

Ladino Clover, Canary Grass,

Timothy, Canola

Metric

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Kilograms per Hectare

17.8cm 0 0.0 1.0 1.9 1.9 4.6 5.9 7.4 8.9 10.4 11.8 13.3 15.0 16.5 17.9 19.6 21.1 22.5 24.8 26.4 28.3

19.1cm 0 0.0 1.0 1.8 2.9 4.4 4.4 4.4 8.3 9.7 11.0 12.5 14.1 15.4 16.8 18.4 19.8 21.2 23.0 24.7 26.5

20.3cm 0 0.0 0.9 1.7 1.7 4.1 5.2 6.4 7.8 7.8 10.4 11.6 13.1 14.4 15.7 15.7 18.5 19.7 21.4 21.4 24.7

25.4cm 0 0.0 0.7 1.7 2.1 2.8 4.1 5.1 6.1 7.1 8.1 9.1 10.3 11.3 12.3 13.5 14.5 15.5 16.8 18.1 19.4

Small Seeds Cup Lever Setting

Birdsfoot, Trefoil, Sudan

Metric

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Seeding Rate in Kilograms per Hectare

17.8cm 0 0.0 1.7 3.2 5.1 6.5 8.5 10.4 12.3 14.1 16.2 18.6 20.5 22.5 22.5 27.0 28.8 31.0 32.7 35.0 37.1

19.1cm 0 0.0 1.6 1.6 1.6 1.6 7.9 9.7 11.5 11.5 15.2 17.4 17.4 17.4 17.4 25.4 27.0 29.1 31.1 32.8 32.8

20.3cm 0 0.0 1.5 2.8 4.4 5.7 7.4 9.1 10.7 12.4 14.2 16.2 17.9 19.7 21.6 23.7 25.2 27.2 29.0 30.6 32.5

25.4cm 0 0.0 1.1 2.1 3.5 4.5 5.7 7.1 8.5 9.7 11.2 12.7 12.7 15.5 17.0 18.6 19.8 21.3 22.8 24.1 25.6

Small Seeds Cup Lever Setting

150-131B 04/12/2007

Page 29

Great Plains Mfg., Inc.

Metric Fertilizer Rate Charts

See page 16 for rates in U.S. customary units.

Metric Rates in Kilograms per Hectare

Metric

10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Rows Application Rate - Kilograms per Hectare

17.8cm 15 22 29 43 61 83 104 119 134 161 186 201 214 237 258 282 305 329 353

19.1cm 13 20 27 42 57 76 98 112 126 150 175 189 202 222 243 265 287 310 331

20.3cm 12 19 26 40 54 70 92 106 118 141 164 177 190 209 228 248 269 291 311

25.4cm 10 16 21 33 43 58 74 84 94 113 131 141 152 167 182 199 216 232 248

Density Conversion Charts

The fertilizer meter rate charts are based on fertilizer

with a density of 1.04 kilograms per liter. If you are

applying fertilizer of a different density, use the following table to convert application rate.

Density, kg/l 725 800 875 950 1041 1125 1200 1275

Conversion Factor 1.44 1.30 1.19 1.10 1.00 0.93 0.87 0.82

Setting Number

27

04/12/2007 150-131B

Page 30

28

EOD

Great Plains Mfg., Inc.

Great Plains Manufacturing, Inc.

Corporate Office: PO Box 5060

Salina, KS 67402-5060 USA

150-131B 04/12/2007

Loading...

Loading...