Great Plains 116-283A User Manual

Installation Instructions

Loup Shaft Monitor

Used with Drill models:

• Compatible with most 1995 and later two- and

three-box drills with

meter drive shafts. Have your dealer contact the

factory if there is any question.

• Compatible with many pre-1995 drills with5⁄8-inch

square main seed box meter drive shafts. Have your

dealer contact the factory if there is any question.

5

⁄8-inch square main seed box

General Information

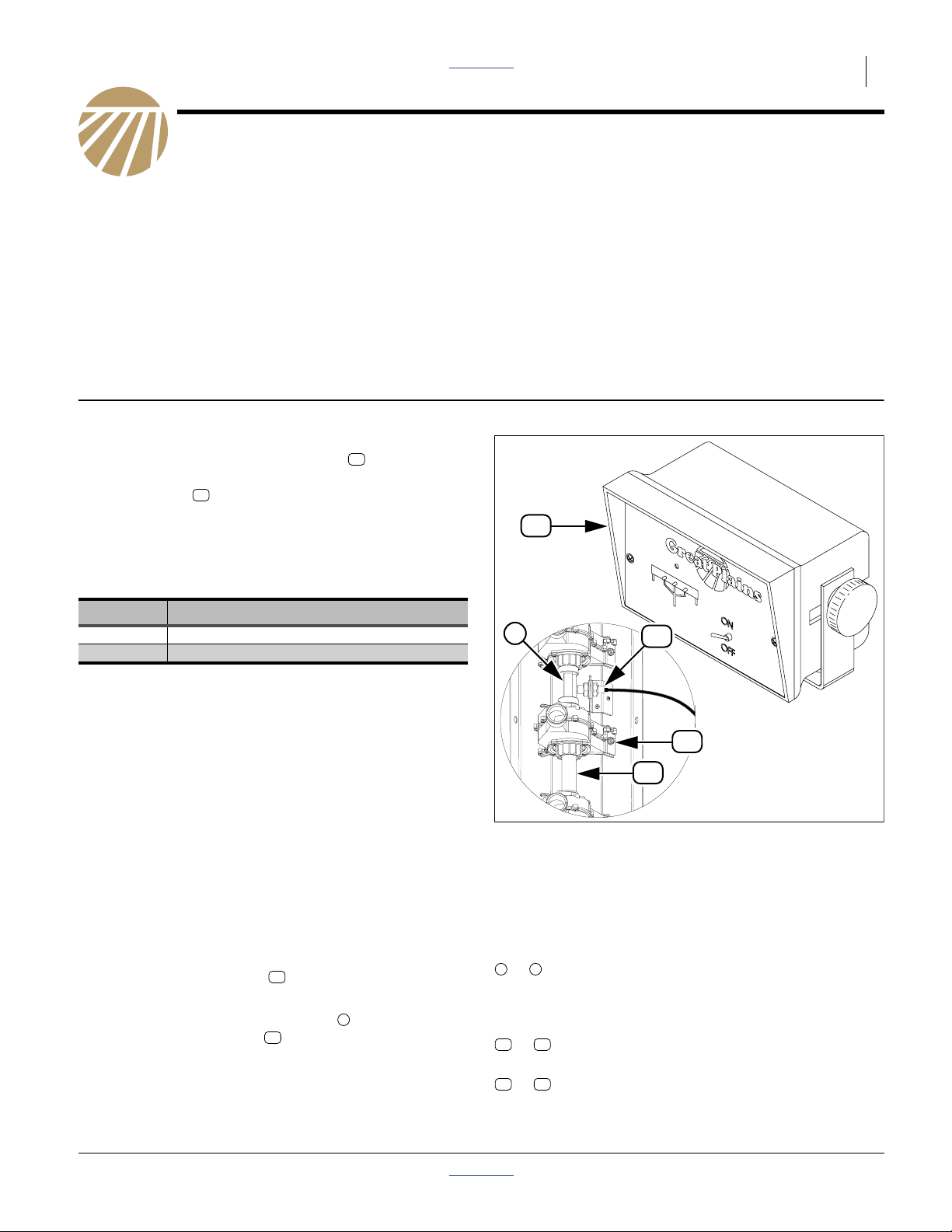

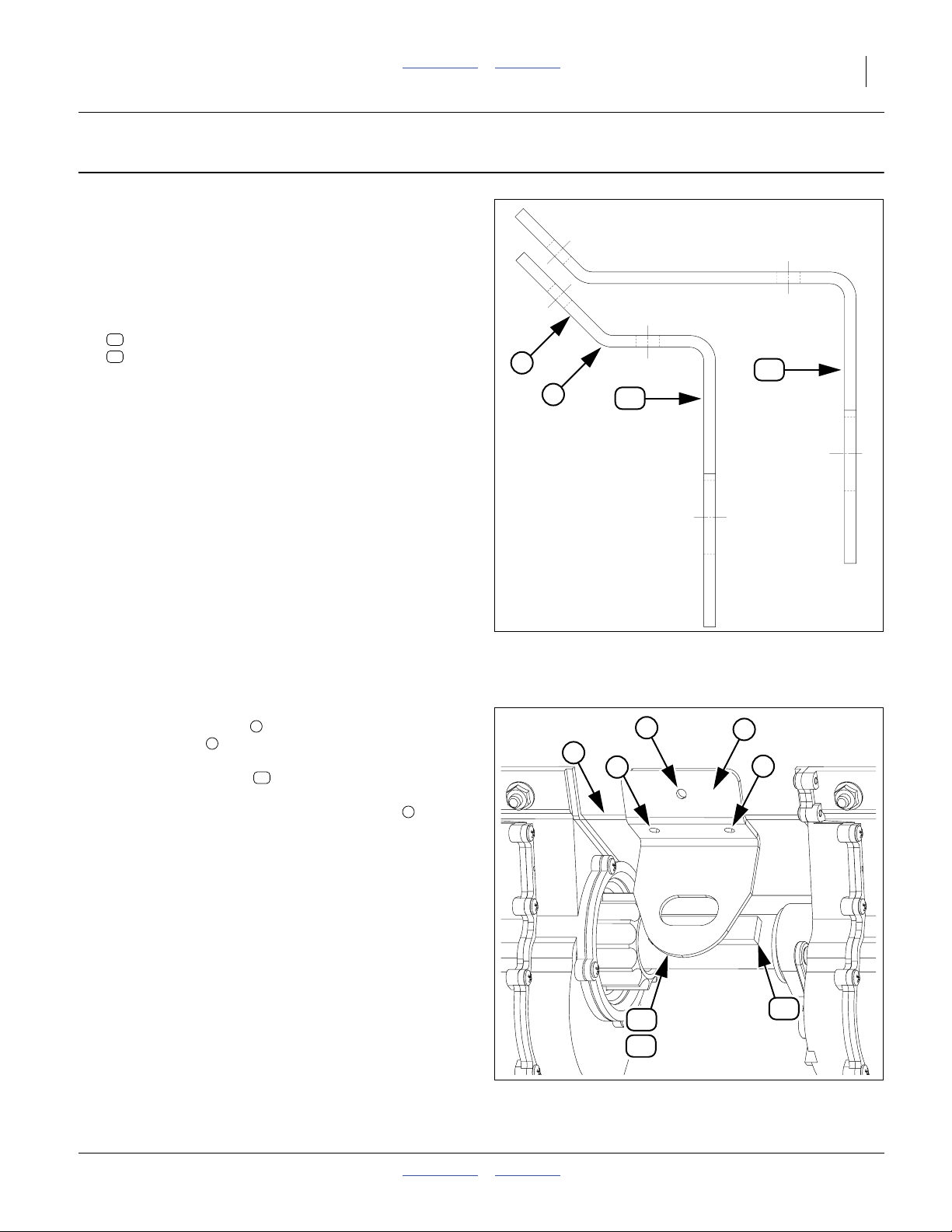

Refer to Figure 1

These instructions explain how to install a Loup Shaft

Monitor. The kit adds a rotation sensor to the main

seed box meter drive shaft of each drill box, and a

monitor console in the tractor.

In operation, when the main seed box shaft of any drill

box stops rotating for more than 20 seconds, an alarm

sounds in the tractor cab.

One kit updates one entire drill:

23

24

Part Lists Great Plains Manufacturing, Inc. 1

Note: Although the kit components may be mechanically

compatible with the Small Seeds Attachment, the

kits have not been tested in that application, and

the harnesses may be too short.

Note: The kits are compatible with current single-box

drills. Only one sensor would be used. The system

ignores disconnected channels.

23

Kits Kit Description

116-282A LOUP 2 CHANNEL SHAFT MONITOR

116-283A LOUP 3 CHANNEL SHAFT MONITOR

Tools Required:

• calibration crank and/or instructions for performing a

calibration on this model drill,

• basic hand tools, including drill and tap wrench,

•3⁄16 inch (#12, 4.8 mm) drill bit,

•1⁄4-20 tap, and #7 drill bit (or 5.1 mm),

• three1⁄4inch (6.3 mm) fasteners for installing the

console in the tractor cab, and

• a knife or saw capable of cutting hard rubber

(may not be required for larger row spacings).

Compatibility Check

Refer to Figure 1

At one drill box, inspect the shaft passing through the

main seed box feeder cups . Verify that it is square

(not hexagonal) and is5⁄8inches on a side (15.9 mm).

The kit is compatible with bare shafts , or shafts inside

round plastic spacer tubes between meters. It is

compatible with large 817-075C (13⁄4inch flute width)

and small 817-094C (11⁄4inch) feeder cups.

54

1

51

1

24

54

51

Figure 1

3 Channel Console and Sensor

Notations and Conventions

Call-Outs

1 9

to Single-digit callouts identify components in

the currently referenced Figure. These

numbers may be reused for different items

from page to page.

21

11

to Two-digit callouts in the range 11 to 21

reference new parts from the list on page 13.

51 55

to Two-digit callouts in the range 51 to 55

reference existing parts.

18943

34210

© Copyright 2012 Printed 2013-08-27 Part Lists 116-284M

2 Great Plains Manufacturing, Inc. Front Page Part Lists LOUP 2/3 CHANNEL SHAFT MONITOR

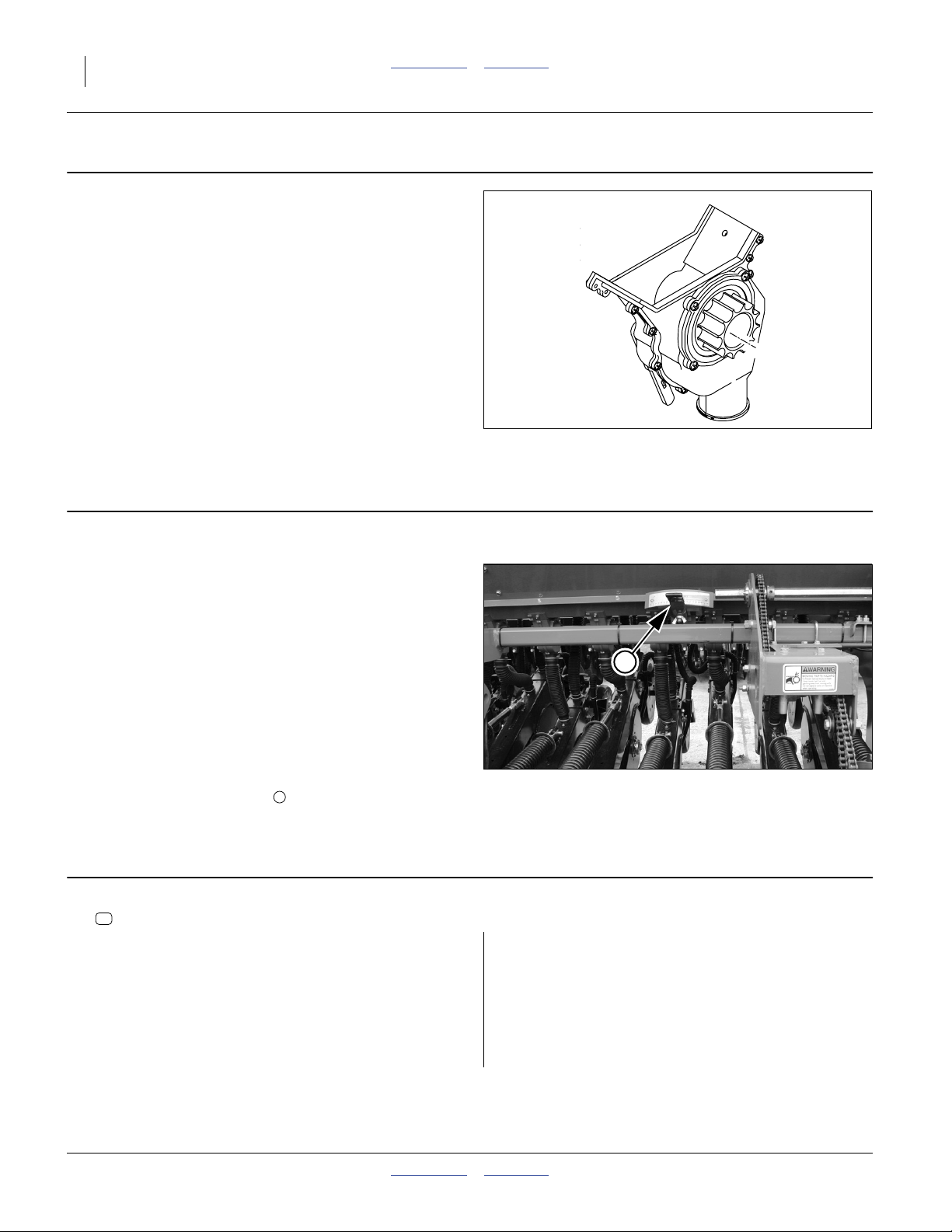

Identify Meter Type

1. Determine whether the drill has large or small feeder

cups.

Large cups, used on most drills still in production,

have a

13⁄4inch flute width,

and an approximate external width of

2 inches at the side walls.

Small cups, used on older drill designs have a

11⁄4inch flute width,

and an approximate external width of

11⁄2inches at the side walls.

Prepare the Drill

2. Move the drill to a location with adequate lighting,

and a clear surface beneath for recovery of any

falling parts.

3. If a folding model, unfold the drill. Consult the

Operator manual for details and safety

considerations.

4. Raise the drill or otherwise configure it so that the

meter drive shaft may be rotated while the drill is

stationary.

5. Install all locks or supports necessary to support the

drill while it is being worked on.

6. Shut off any tractor used to position the drill.

Refer to Figure 3

7. Settheseedratehandles , forall main seed boxes,

to 50 on the 0-to-100 scales.

2

Identify Mounting Positions

Figure 2

Meter Feeder Cup

2

Figure 3

Set Rate Handles to 50

17951

28066

8. Select one new:

27

540017 MAGNET, ADHESIVE BACKED, LARGE

Do not remove the release backing at this time.

On each main seed box, use the magnet to identify

locations between cups with the following attributes:

• close to drill center, on wing boxes,cups closest to the

center box section.

• not obstructed to the front by a seed rate handle, and

• adequate exposed surface on the drive shaft to place

the magnet - or adequate length of polymer tube to

provide cuts for magnet mounting.

9. Tag each location with a short length of tape on the seed box.

116-284M Front Page Part Lists 2013-08-27

Notes:

Gaps with lock collars generally provide exposed shaft.

Tube mounting requires that the tube be at least as long

as the magnet for surface mounting, and at least

11⁄2inches longer than the magnet for cut-away

mounting (see footnote on page 4).

Smaller row spacings may require reducing magnet

length, to not less than 13⁄4inch.

Install Magnets Front Page Part Lists Great Plains Manufacturing, Inc. 3

Install Magnets

Apply the instructions for “Tube Install” (step 10) or

“Shaft Face Install” (step 17 on page 4) for each

mounting position.

Shaft Face Install

If the location has a polymer tube over the shaft,

continue at “Tube Install” on page 4.

10. De-grease and dry the shaft .

11. Using the calibration crank or other means to rotate

the shaft so that two faces are at vertical, and two

are horizontal.

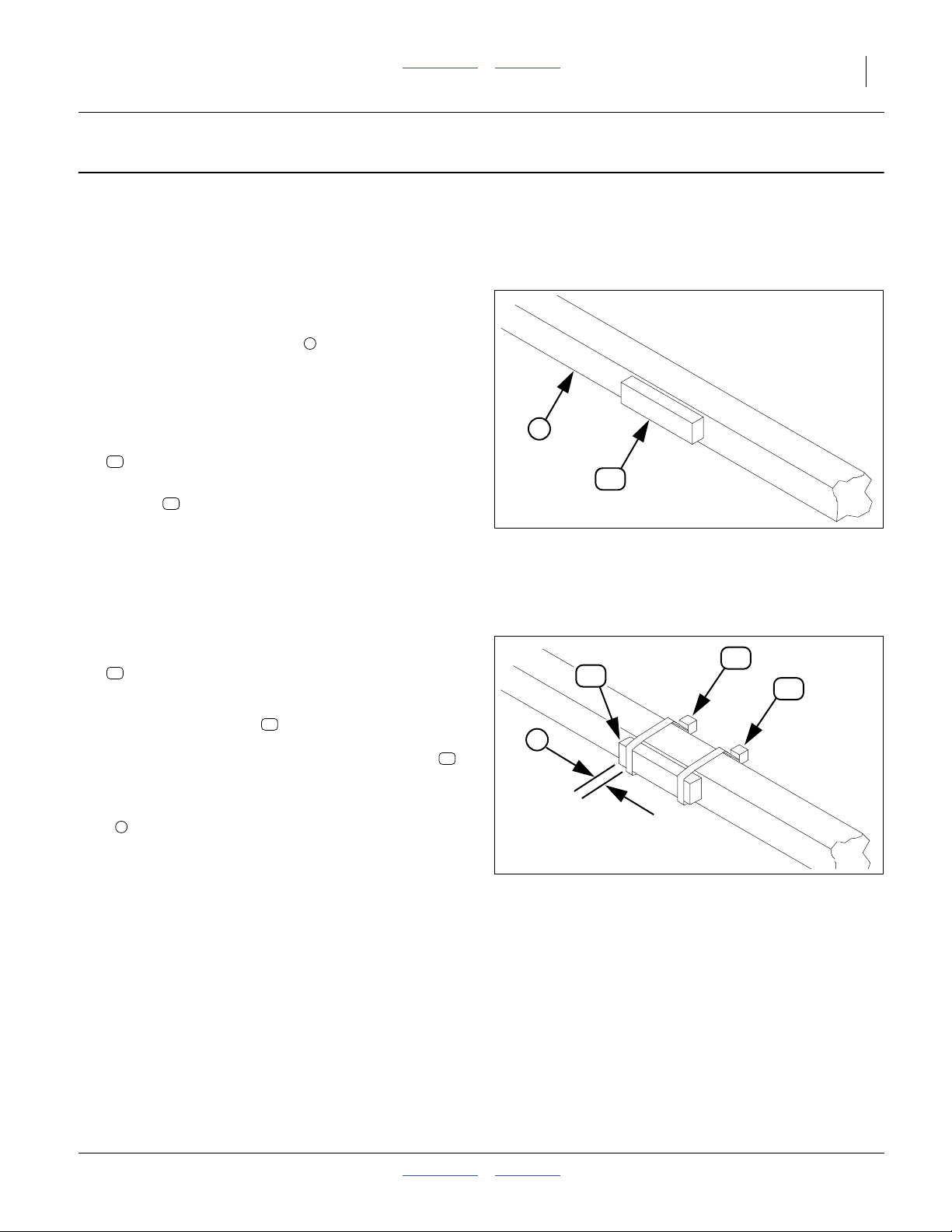

Refer to Figure 4

12. Select one new:

27

540017 MAGNET, ADHESIVE BACKED, LARGE

13. Before removing the release backing, check that the

magnet fits. If it does not fit, trim it as required,

keeping it longer than the minimum length specified

in the “Notes:” on page 2.

14. Remove the release backing film. Aligning with the

shaft center-line (and to the extent possible, in the

center of the cup-to-cup gap), apply the adhesive

side of the magnet to the shaft.

Refer to Figure 5

15. Select two new:

29

(These are the smaller ties)

27

770026 CABLE TIE

3

3

27

Figure 4

Magnet on Shaft

34212

29

27

29

Loosely install the ties at each end of the magnet,

so that when finally tightened, the ratchet end of the

tie will be on the shaft face opposite the magnet .

Position the ties so that the ends of the magnet are

exposed by at least dimension:

1

a

⁄4inch (6 mm).

Tighten the ties.

16. Continue with the next magnet location at step , or if

all magnets are installed, at “Drill Mounting Holes”

on page 5.

2013-08-27 Front Page Part Lists 116-284M

29

27

a

Figure 5

Magnet Secured by Ties

34212

4 Great Plains Manufacturing, Inc. Front Page Part Lists LOUP 2/3 CHANNEL SHAFT MONITOR

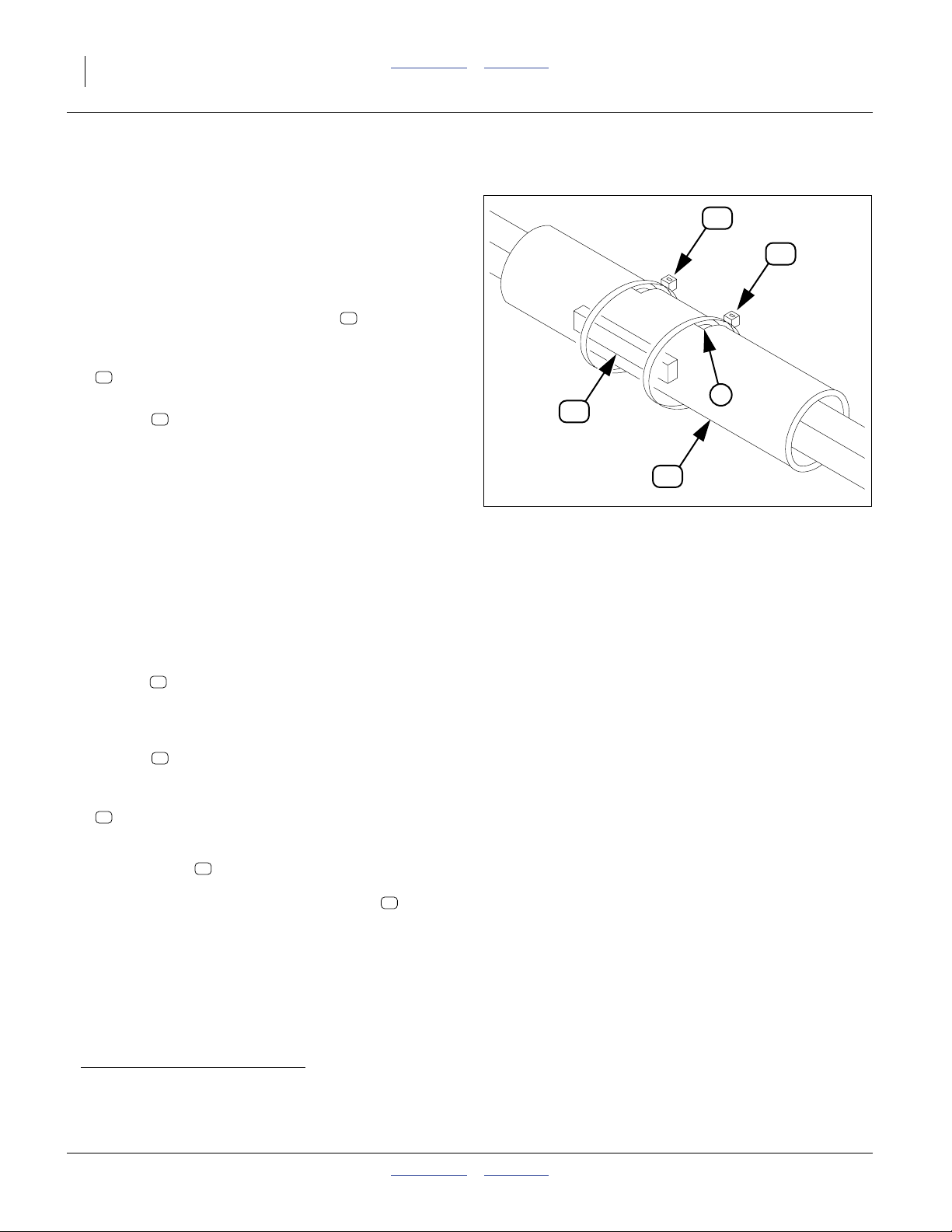

Tube Install

If the magnet location has a bare shaft, continue at

“Shaft Face Install” on page 3.

Tube install requires that tube rotation be coupled to

shaft rotation (it is normally free to spin). There are two

ways to accomplished this. The method enumerated

below may be easier. See footnotea for an alternative

method.

17. De-grease and dry the spacer tube .

51

Refer to Figure 6

18. Select one new:

27

540017 MAGNET, ADHESIVE BACKED, LARGE

19. Before removing the release backing, check that the

magnet fits. If it does not fit, trim it as required,

27

keeping it longer than the minimum length specified

in the “Notes:” on page 2.

20. Aligning with the shaft center-line (and to the extent

possible, in the center of the cup-to-cup gap), outline

the magnet position with a marker. Add a vertical

mark that is approximately

3

⁄8inch inside each end

of the outline.

21. Brace your arm against the seed box, and rotate the

tube while holding the marker at the vertical marks.

22. On the side of the tube opposite the magnet position,

make vertical cuts on the scribed lines.

27

51

Figure 6

Magnet on Tube

29

29

4

13198

Make the cuts wide enough for the ratchet ends of

the ties , and approximately1⁄4 of the tube

29

circumference. Be careful to not cut the shaft. Clean

away any cutting debris.

23. Remove the backing release film from the

magnet . Apply the adhesive side of the magnet to

27

the outlined area.

24. Select two new:

29

770026 CABLE TIE

(These are the smaller ties)

Install the ties at each end of the magnet, so that

29

when finally tightened, the ratchet end of the tie will

be on the shaft face opposite the magnet .

27

Tighten the ties so that they lay flat against a shaft

face in the cuts. This prevents independent tube

rotation.

25. Continue with the next magnet location at “Install

Magnets” on page 3, or if all magnets are installed,

at “Drill Mounting Holes” on page 5.

a. Cut-away Mounting: You may also cut or grind a slot in the tube, and mount the magnet directly on the shaft face, as in the

“Shaft Face Install” method. Be sure to use the cable ties to secure the magnet (ties may be tied around the tube, with or

without cuts).

116-284M Front Page Part Lists 2013-08-27

Drill Mounting Holes Front Page Part Lists Great Plains Manufacturing, Inc. 5

Drill Mounting Holes

Identify and Select Mount

Refer to Figure 7

(which is 1:1 scale

when printed at 100%

on U.S. letter size paper)

26. Based whether the drill has large or small cups,

select one of:

12

116-019D SHAFT SENSOR MOUNT (“Large”)

13

116-020D SMALL CUP SENSOR MOUNT (“Small”)

5

6

12

Large

Feeder Cup

Sensor Mount

13

Small

Feeder Cup

Sensor Mount

Refer to Figure 7 and Figure 8

27. With the short break of the mount forward and up,

and the break aligned on the break of the seed

box, position the center of the slotted hole over the

center of the magnet .

Mark the positions of the three small holes on the

seed box wall. Center-punch the positions.

28. Drill3⁄16 inch (#12, 4.8 mm) holes into the seed box

wall at each marked position.

29. Repeat step 27 and step 28 for each sensor position.

5

6

27

7

Figure 7

Identify Mount

7

6

7

13

12

Figure 8

Use Mount as Template

34213

5

7

27

34211

2013-08-27 Front Page Part Lists 116-284M

Loading...

Loading...