Page 1

Operator’ s Manual

Serial Number S1347 and Above

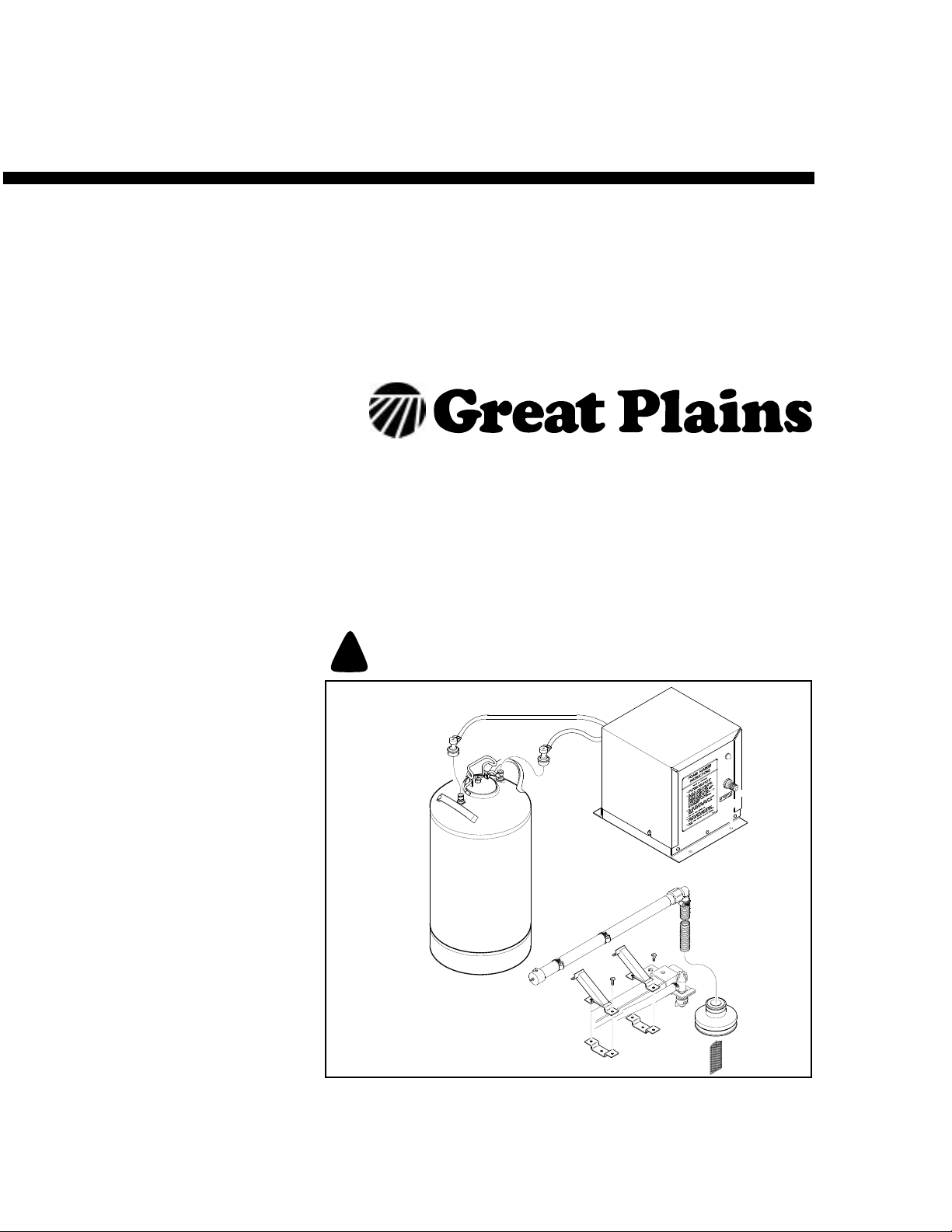

Foam Marker

Manufacturing, Inc.

Read the operator’s manual entirely.Whenyouseethissymbol, the subsequent

instructions and warnings are serious - follow without exception. Your life and

!

the lives of others depend on it!

12453

Cover illustration may show optional equipment not supplied with standard unit.

© Copyright 1998 Printed 4/21/2003

500-033M-A

Page 2

Table of Contents

Important Safety Information . . . . . . . . . . . . . . . . . 1

Wear Protective Equipment . . . . . . . . . . . . . . . . 5

Handle Chemicals Properly . . . . . . . . . . . . . . . . 6

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Intended Usage . . . . . . . . . . . . . . . . . . . . . . 9

Models Covered . . . . . . . . . . . . . . . . . . . . . . 9

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . 9

Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Owner Assistance. . . . . . . . . . . . . . . . . . . . . . . . 9

Preparation and Setup . . . . . . . . . . . . . . . . . . . . . 10

Tandem Axle Sprayer / Foam Marker Assembly

Instructions and Set-Up . . . . . . . . . . . . . . . . . . 10

Single Axle Sprayer / Foam Marker Assembly

Instructions and Set-Up . . . . . . . . . . . . . . . . . . 11

Tractor Mount Sprayer / Foam Marker Assembly

Instructions and Set-Up . . . . . . . . . . . . . . . . . . 12

200/300 Gallon 3-Point Mounted Sprayer / Foam.

Marker Assembly Instructions and Set-Up . . . . 12

Tractor Requirements . . . . . . . . . . . . . . . . . . . . 13

Operating Instructions . . . . . . . . . . . . . . . . . . . . . 14

Basic Foam Marker Operating Procedures. . . . 14

Filling Foam Tank . . . . . . . . . . . . . . . . . . . . 14

Operating the Foam Control Valve . . . . . . . 14

Operating Checklist. . . . . . . . . . . . . . . . . . . . . . 14

Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Field Adjustments . . . . . . . . . . . . . . . . . . . . . . . 15

Foam Marker . . . . . . . . . . . . . . . . . . . . . . . 15

Foam Marker Preparation. . . . . . . . . . . . . . . . . 15

General Notes for Field Operation . . . . . . . 15

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Torque Values Chart . . . . . . . . . . . . . . . . . . . . . 17

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

© Copyright 1998Allrights Reserved

Great Plains Manufacturing, Inc. provides this publication“as is” without warranty of any kind, either expressed or implied. While every precaution has been takenin the

preparationofthismanual,GreatPlainsMan uf acturing,Inc.assumesno responsibility for errorsoromissions.Neither is any liabilityassumedfordamages resulting from

theuseof the information contained herein. Great Plains Manufacturing,Inc. reservestheright to reviseandimproveits products as it sees fit. This publication describes

the state of this product at the time of its publication, and may not reflect the product in the future.

Great Plains Manufacturing, Incorporated Trademarks

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains

All other brands and product names are trademarks or registered trademarks of their respective holders.

Printed in the United States of America.

4/21/2003

500-033M-A

Page 3

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is

apotential hazard to personal safetyinvolvedand

extrasafety precaution must be taken. When you

see this symbol, be alert and carefully read the

message that follows it. In addition to design and

configuration of equipment, hazard control and

accident prevention are dependent upon the

awareness, concern, prudence and proper training of personnel involved in the operation,

transport, maintenance and storage of

equipment.

Important Safety Information

!

1

Be Aware of Signal Words

Signal words designate a degree or level of hazard seriousness.

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. This signal word is limited to the

most extreme situations, typically for machine

components that, for functional purposes, cannot

be guarded.

WARNINGindicates a potentially hazardous situationwhich, if not avoided,could resultin death or

serious injury, and includes hazards that are exposed when guards are removed. It may also be

used to alert against unsafe practices.

CAUTION indicates a potentially hazardous situation which, if not avoided,may result in minor or

moderate injury. It may also be used to alert

against unsafe practices.

DANGER

!

WARNING

!

CAUTION

!

4/21/2003

500-033M-A

Page 4

Foam Marker

2

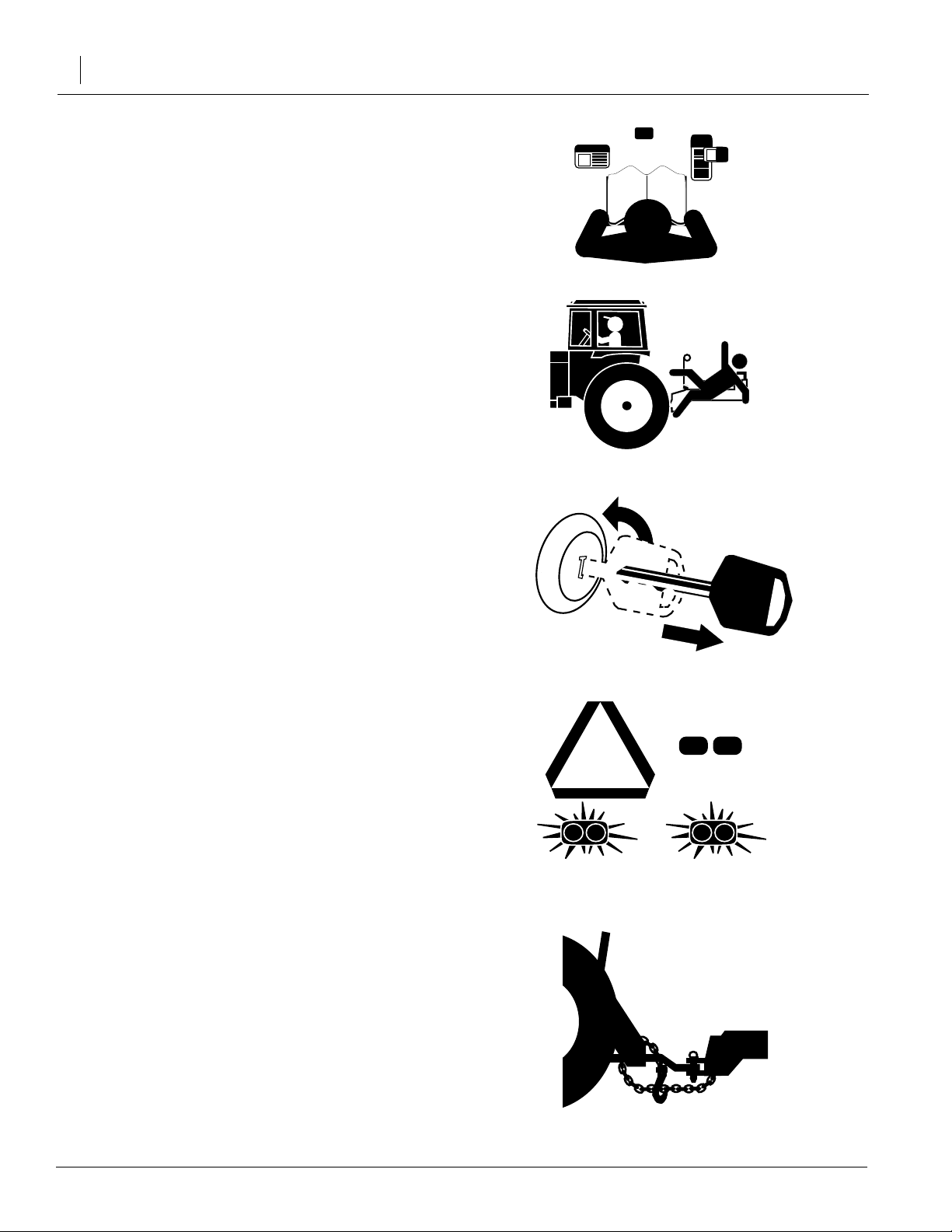

Be Familiar with Safety Decals

▲ Read and understand “Safety decals,” thor-

oughly.

▲ Read all instructions noted on the decals.

Keep Riders Off Machinery

Riders obstruct the operator’s view.Riders could

be struck by foreign objects or thrown from the

machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine dur-

ing operation.

Use Safety Lights and Devices

Slow-moving tractors and towed implements can

create a hazard when driven on public roads.

They are difficult to see, especially at night.

OFF

▲ Use flashing warning lights and turn signals

whenever driving on public roads.

▲ Use lights and devices provided with imple-

ment.

Use A Safety Chain

▲ Use a safety chain to help control drawn

machinery should it separate from tractor

drawbar.

▲ Use a chain with a strength rating equal to or

greater than the gross weight of towed

machinery.

▲ Attach chain to tractor drawbar support or

other specified anchor location. Allow only

enough slack in chain to permit turning.

▲ Replace chain if any links or end fittings are

broken, stretched or damaged.

▲ Do not use safety chain for towing.

500-033M-A

4/21/2003

Page 5

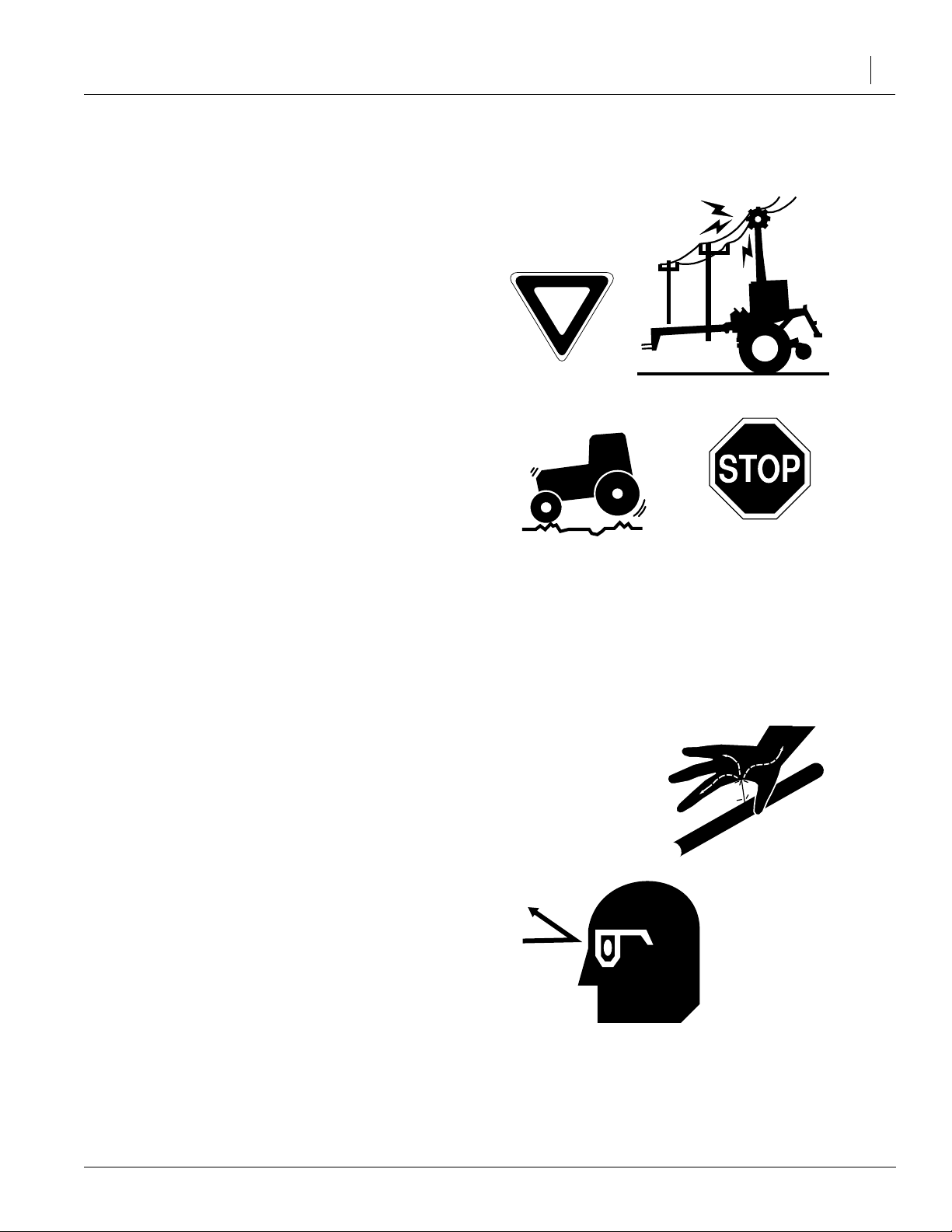

Transport Machinery Safely

Maximum transport speed for implement is 20

mph. Some rough terrains require a slower

speed.Sudden brakingcan cause atowed loadto

swerve and upset.

▲ Do not exceed 20 mph. Never travel at a

speed which does not allow adequate control

of steering and stopping. Reduce speed if

towed load is not equipped with brakes.

▲ Comply with state and local laws.

▲ Do not tow an implement that, when fully

loaded, weighs more than 1.5 times the weight

of towing vehicle.

▲ Carry reflectors or flags to mark implement in

case of breakdown on the road.

▲ Keep clear of overhead power lines and other

obstructions when transporting.

Important Safety Information

3

▲ Do not fold or unfold the sprayer while the trac-

tor is moving.

Avoid High Pressure Fluids

Escaping fluid under pressure can penetrate the

skin, causing serious injury.

▲ Avoid the hazard by relieving pressure before

disconnecting hydraulic lines.

▲ Use a piece of paper or cardboard, NOT

BODY PARTS, to check for suspected leaks.

▲ Wear protective gloves and safety glasses or

goggles when working with hydraulic systems.

▲ If an accident occurs, see a doctor immedi-

ately. Any fluid injected into the skin must be

surgically removed within a few hours or gangrene may result.

4/21/2003

500-033M-A

Page 6

Foam Marker

4

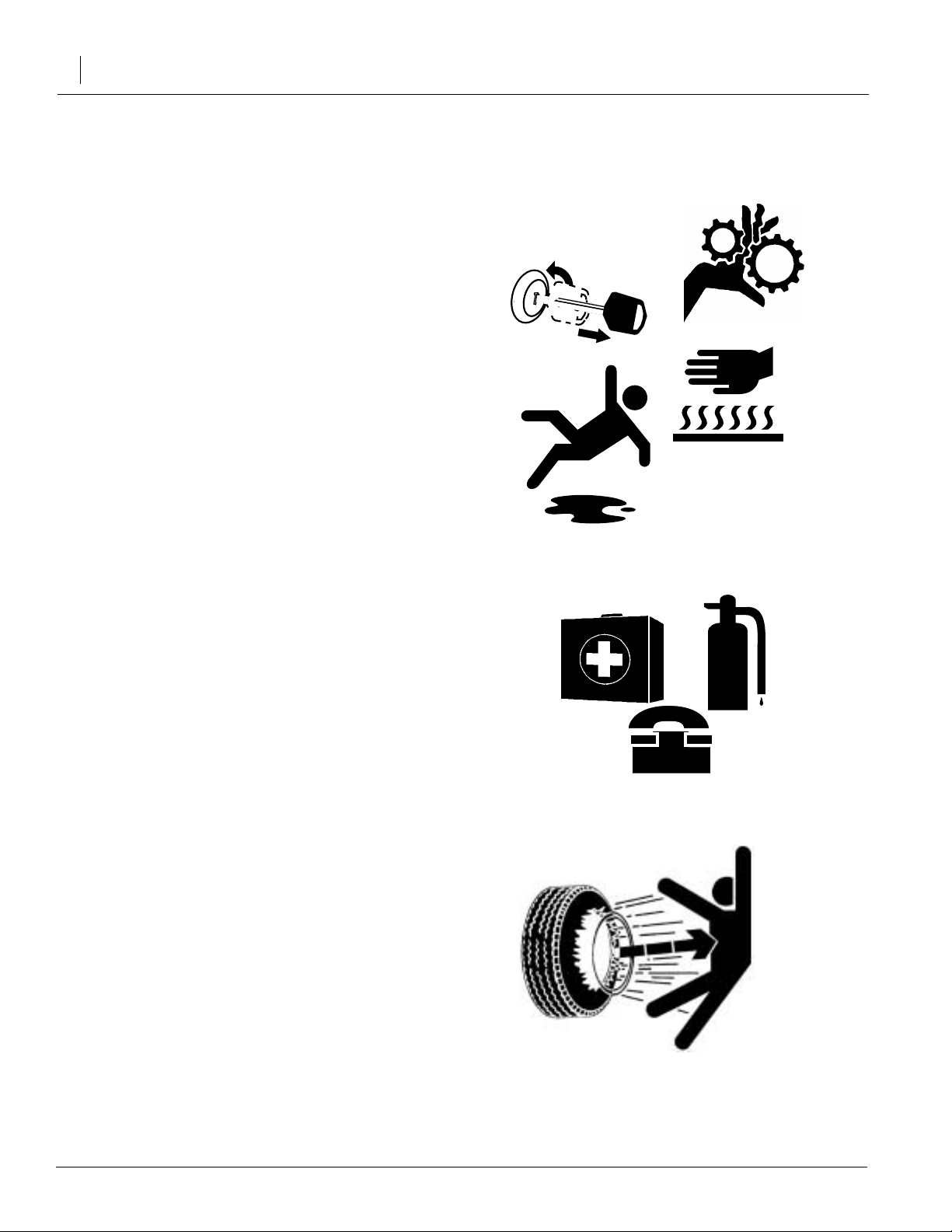

Practice Safe Maintenance

▲ Understand procedure before doing work. Use

proper tools and equipment. Refer to this manual for additional information.

▲ Work in a clean, dry area.

▲ Put tractor in park, turn off engine, and

remove key before performing maintenance.

▲ Make sure all moving parts have stopped and

all system pressure is relieved.

▲ Allow sprayer to cool completely.

▲ Disconnect battery ground cable (-) before

servicing or adjusting electrical systems or

before welding on sprayer.

▲ Inspect all parts. Make sure parts are in good

condition and installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from

sprayer before operation.

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambu-

lance, hospital and fire department near

phone.

Tire Safety

Tire changing can be dangerous and should be

performed by trained personnel using correct

tools and equipment.

OFF

911

▲ When inflating tires, use a clip-on chuck and

extension hose long enough for you to stand

to one side–not in front of or over tire assembly. Use a safety cage if available.

▲ When removing and installing wheels, use

wheel-handling equipment adequate for

weight involved.

500-033M-A

4/21/2003

Page 7

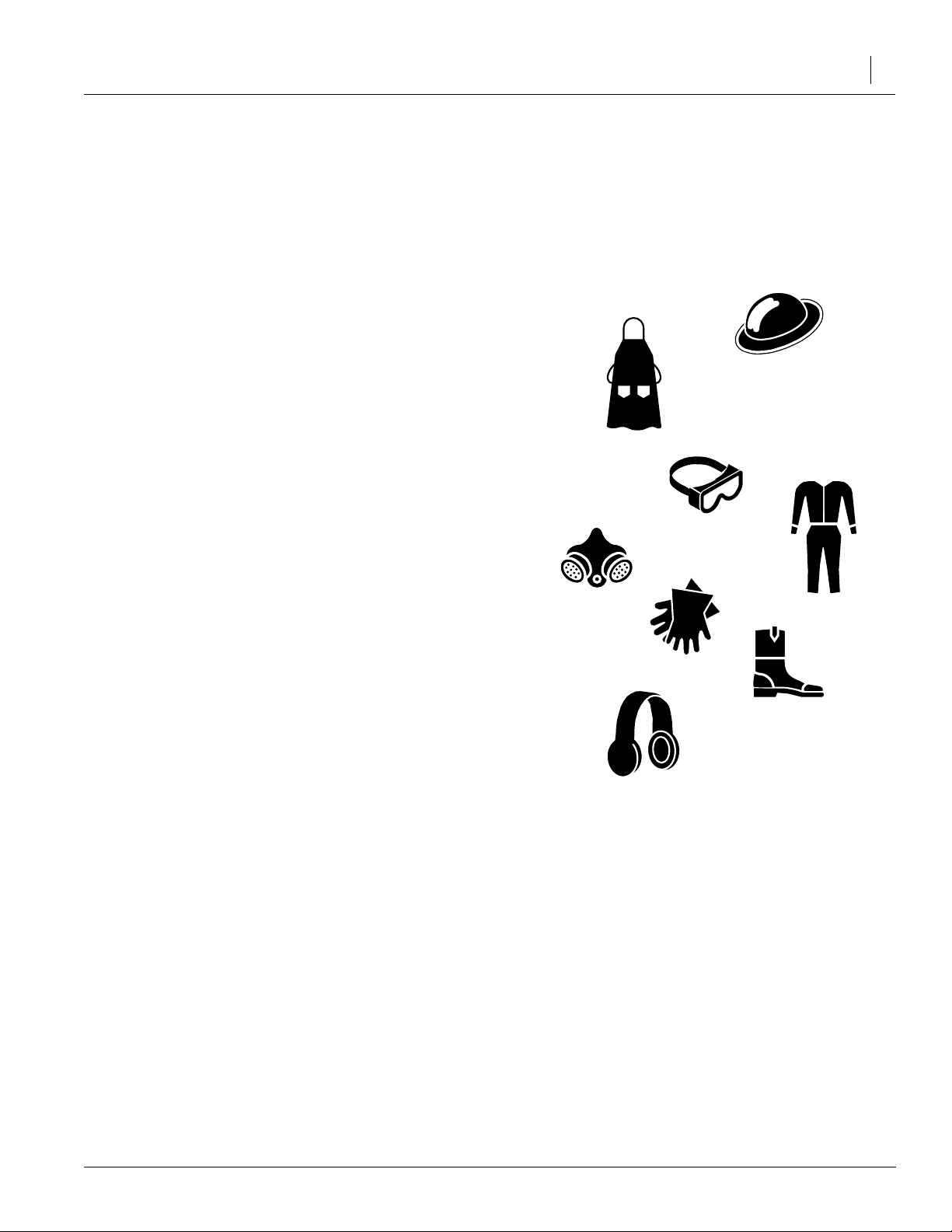

Wear Pr otective Equipment

Great Plains advises all users of chemical pesticides or

herbicides to use the following personal safety

equipment.

▲ Waterproof, wide-brimmed hat.

▲ Waterproof apron.

▲ Face shield, goggles or full face respirator.

▲ Goggles with side shields or a full face respirator is

required if handling or applying dusts, wettable powders, or granules or if being exposed to spray mist.

▲ Cartridge-type respirator approved for pesticide

vapors unless label specifies another type of respirator.

▲ Waterproof, unlined gloves. Neoprene gloves are

recommended.

Important Safety Information

5

▲ Cloth coveralls/outer clothing changed daily; water-

proof items if there is a chance of becoming wet with

spray.

▲ Waterproof boots or foot coverings.

▲ Do not wear contaminated clothing. Wash protective

clothing and equipment with soap and water after

each use. Personal clothing must be laundered separately from household articles.

▲ Clothing contaminated with certain pesticides must

be destroyed according to state and local regulations. Read chemical label for specific instructions.

▲ Wear clothing and equipment appropriate for the job.

Avoid loose-fitting clothing.

▲ Prolonged exposure to loud noise can cause hear-

ing impairment or loss. Wear suitable hearing protection such as earmuffs or earplugs.

▲ Avoid wearing radio headphones while operating

machinery. Operating equipment safely requires the

full attention of the operator.

4/21/2003

500-033M-A

Page 8

Foam Marker

6

Handle Chemicals Properly

▲ Read and follow chemical manufacturer’s

instructions.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Agricultural chemicals can be dangerous.

Improper use can seriously injure persons,

animals, plants, soil and property.

▲ Inhaling smoke from any type of chemical fire

is a serious health hazard.

▲ Store or dispose of unused chemicals as

specified by the chemical manufacturer.

▲ Before adding chemical to the tank, make

sure tank is at least half full. Do not pour concentrate into an empty tank.

▲ Never leave fill hose attached to the sprayer

after filling tank. Chemicals in tank can siphon

out of tank and contaminate freshwater

source.

▲ Always keep hand-wash tank filled with clean

water and have soap available in case of an

emergency. Immediately and thoroughly flush

any area of the body that is contaminated by

chemicals.

▲ Spray only with acceptable wind conditions.

Wind speed must be below 5 mph. Make sure

wind drift of chemicals will not affect any surrounding land, people or animals.

▲ Never wash out the sprayer tank within 100

feet of any freshwater source or in a car wash.

▲ Rinse out the tank. Spray rinse water on last

field sprayed.

▲ Do not touch sprayer components with mouth

or lips.

▲ If chemical is swallowed, carefully follow the

chemical manufacturer’s recommendations

and consult with a doctor.

▲ If persons are exposed to a chemical in a way

that could affect their health, consult a doctor

immediately with the chemical label or container in hand. Any delay could cause serious

illness or death.

▲ Dispose of empty chemical containers prop-

erly. By law rinsing of the used chemical container must be repeated three times. Puncture

the container to prevent future use. An alternative is to jet-rinse or pressure rinse the container.

▲ Wash hands and face before eating after

working with chemicals. Shower as soon as

spraying is completed for the day.

500-033M-A

4/21/2003

Page 9

Safety At All Times

Thoroughly read and understand the instructions

in this manual before operation. Read all instructions noted on the safety decals.

▲ Be familiar with all machinery functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave sprayer unattended with tractor

engine running.

▲ Do not dismount a moving tractor. Dismount-

ing a moving tractor could cause serious injury

or death.

▲ Do not stand between the tractor and sprayer

during hitching.

▲ Keep hands, feet and clothing away from

power-driven parts.

Important Safety Information

7

▲ Wear snug-fitting clothing to avoid entangle-

ment with moving parts.

▲ Watch out for wires, trees, etc., when folding

and raising sprayer. Make sure all persons are

clear of working area.

▲ Do not turn tractor too tightly, causing sprayer

to ride up on wheels. This could cause personal injury or equipment damage.

▲ Use only water without pesticides added to

calibrate the sprayer. Do not exceed the calibrated sprayer speed and pressure when

operating.

▲ When using a PTO pump, be sure that PTO

shield is in place on the tractor, PTO coupler

bolts are torqued to the correct specification,

and torque bar is properly chained to tractor

drawbar.

▲ Spray with the boom in the unfolded position

only.

▲ The boom has many pinch points during field

operation and folding. Keep all bystanders

away.

4/21/2003

500-033M-A

Page 10

Foam Marker

8

Safety Labels

Your implement comes equipped with all safety labels in place.

They were designed to help you safely operate your implement.

1. Read and follow label directions.

2. Keep all safety labels clean and legible.

3. Replace all damaged or missing labels.

4. Some new equipment installed during repair require safety

labels to be affixed to the replaced component as specified

by the manufacturer. When ordering new components make

sure the correct safety labels are included in the request. To

order new labels go to your Great Plains dealer.

5. Refer to this section for proper label placement.

To install new labels:

a. Clean the area the label is to be placed.

b. Peel backing from label. Press firmly on surface

being careful not to cause air bubbles under label.

10044

10213

818-328C

Warning! Pressure Relief Valve Information

818-384C

Caution! General Safety Precautions for Foam Concentrate Use.

500-033M-A

4/21/2003

Page 11

Introduction

Introduction

9

GreatPlains welcomesyouto itsgrowingfamilyof

newproduct owners.ThisFoam Marker hasbeen

designedwith care and built byskilledworkers using quality materials. Proper setup, maintenance

and safe operating practices will help you get

years of satisfactory use from the machine.

Intended Usage

Use this Foam Marker as part of a pressurized

sprayersystem to apply liquid pesticides, herbicides or fertilizers to production-agriculture crops

only. Do not modify sprayer for use with attachmentsother than those approvedbyGreat Plains.

Models Covered

Foam Marker S/N S1347 and above.

Using This Manual

This manual will familiarize you with safety, assembly, operation, adjustments, troubleshooting

and maintenance. Read this manual and follow

the recommendations to help ensure safe and efficient operation.

The information in this manual is current at printing. Some parts may change to assure top

performance.

Definitions

The following terms are used throughout this

manual.

Right-hand and left-hand as used in this manual

are determined by facing the direction the machine will travel while in use unless otherwise

stated.

Owner Assistance

If you need customer service or repair parts, contact a Great Plains dealer. They have trained

personnel, repair parts and equipment specially

designed for Great Plains products.

Your machine’sparts were specially designed and

should only be replaced with Great Plains parts.

Alwaysuse the serial and model number when ordering parts from your Great Plains dealer.

Record your model and serial number here for

quick reference:

Model Number:__________________________

Serial Number: ___________________________

Your Great Plains dealer wants you to be satisfied

with your new machine. If you do not understand

anypart of this manualor are not satisfied with the

service received, please take the following

actions.

1. Discuss the matter with your dealership service manager. Make sure they are aware of

any problems so they can assist you.

2. If you are still unsatisfied, seek out the owner

or general manager of the dealership.

3. For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

4/21/2003

IMPORTANT: A crucial point of information related to the preceding topic. For safe and correct operation, read and follow the directions

provided before continuing.

NOTE: Useful information related to the preceding topic.

500-033M-A

Page 12

Foam Marker

10

Preparation and Setup

Tandem Axle Sprayer / Foam Marker

Assembly Instructions and Set-Up

Refer to Figure 1

1. Mount the support brackets (1) and (2) on the right

walkboard with 3/8" x 1" long bolts (3), flat washers,

and flange nuts required.

2. Mount the foam marker box (4) and the foam tank

base (6) on the support bracketswith 3/8" x 1" long

bolts and flange nuts required.

3. Secure the foam tank (5) to the foam tank base (6)

with the hose clamp (7) provided.

4. Attach a section of the clear hose from the hose

barb on the foam marker box(4) labeled "AIRTANK

IN" to the hose barb on the foam tank (5) that has a

white coupling. In a similar manner,attach a section

of the clear hose from the hose barb on the foam

marker box (4) labeled "FOAM TANK OUT" to the

blackcoupler on the tank. Attach the hoses with the

hose clamps provided.

Refer to Figure 2

5. Attach the foamgeneratorcylinder (1) onboth boom

wings using the foam cylinder brackets(2), the 1/4"

screws and flange nuts. Make sure that the hose

barb (9) is on the top side of the cylinder. Use the

hose clamps (3) to attach the foam generator cylinder brackets.

Important: Mount the foam generator cylinders on

the back side of the boom. F ailure to do so may

cause damage to the foam generator cylinders if the

boom strikes an object.

6. In your foammarkerkit there are some C-clips (4) to

help route the foam marker hose. These C-clips are

attached underneath the top side of the nozzle

check valve brackets (5). Assemble the T-clip (6)

and screw (7) to the C-clips. Loosen the nozzle

check valve brackets (5), slide the assembled

C-clips under the bracket and retighten the nozzle

checkvalvebrackets. Assemblethe C-clips uniformly across the boom.

Figure 1

Tandem Axle Foam Marker Assembly Illustration

500-033M-A

11997

Figure 2

Foam Generator Assembly Illustration

11998

7. Enclosed in the foam marker kit is some 1/4" clear

vinyl hose. Route a section of hose from the "AIR

LEFT" hose barb on the foam marker box to the

hose barb (8) that comes out the end of the foam

generatorcylinderon theleft boomwing. Routevinyl

4/21/2003

Page 13

Preparation and Setup

11

hose with boom feeder hose through boom pivot areas to ensure adequate hose length. Attach vinyl

hose to boom feeder hose with tie straps provided,

being careful not to pinch the vinyl hose. Before you

cut the hose, make sure that there is enough length

on the hose so that the boom can be completely

raised an lowered without stretching the hose. Position the hose through the T-clips (6) along the boom

wing.Pull up the tabs on the T-clips and position the

hose in the T-clips after the hose has been routed.

8. Route a section of hose from the "FOAM LEFT"

hose barb on the foam marker box to the hose barb

(9) that comes out the side of the foam generator

cylinderon the leftboom wing. Routevinyl hosewith

boom feeder hose through boom pivot areas to ensure adequate hose length. Attach vinyl hose to

boom feeder hose with tie straps provided, being

careful not to pinch the vinyl hose. As before, make

sure that there is enough length on the hose so that

the boom can be completely raised and lowered

without stretching the hose. Position the hose

through the other side of the T-clip (6) along the

boom wing.

9. Repeat steps 6, 7 and 8 for the right boom wing.

white coupling. In a similar manner,attach a section

of the clear hose from the hose barb on the foam

marker box (5) labeled "FOAM TANK OUT" to the

blackcoupler on the tank. Attach the hoses with the

hose clamps provided.

5. Follow the instructions step 5 through step 10 on

page 10 to attach the foam generator cylinders.

Refer to Figure 1, on page 10

10. Attach the foam marker extension cord (8) from the

foammarker box (4) to the foammarker plug on the

control box.

Note: If your sprayer does not have the manual control system with the Application Systems control box,

youwill need to purchase the 502-031A foammarker

kit which includes a small switch box to control the

foam marker.

Single Axle Sprayer / Foam Marker

Assembly Instructions and Set-Up

Refer to Figure 3

1. Mount the foam tank base (2) on the walkboard with

thetwo3/8" x 1" long bolts (1) and one 3/8" x 2"long

bolt with the flat washers (6) and flange nuts (7) required.

2. Mount the foam marker box (5) onto the expanded

metal with four 3/8" x 1" long bolts (1), flat washers

(6) and flange nuts (7).

3. Secure the foam tank (4) to the foam tank base (2)

with the hose clamp (3) provided.

11996

Figure 3

Single Axle Foam Marker Assembly Illustration

4. Attach a section of the clear hose from the hose

barb on the foam marker box(5) labeled "AIRTANK

IN" to the hose barb on the foam tank (4) that has a

4/21/2003

500-033M-A

Page 14

Foam Marker

12

Tractor Mount Sprayer / Foam Marker

Assembly Instructions and Set-Up

Refer to Figure 4

1. Mount the foam tank base (1) on the tank bracket

with two 3/8" x 1" long bolts (2), flat washers, and

flange nuts required.

2. Mount the foam marker box (4) and the foam tank

base (6) on the support brackets with 3/8" x 1" long

bolts and flange nuts required.

3. Secure the foam tank (5) to the foam tank base (6)

with the hose clamp (7) provided.

4. Attach a section of the clear hose from the hose

barb on the foam marker box(4) labeled "AIRTANK

IN" to the hose barb on the foam tank (5) that has a

white coupling. In a similar manner,attach a section

of the clear hose from the hose barb on the foam

marker box (4) labeled "FOAM TANK OUT" to the

blackcoupler on the tank. Attach the hoses with the

hose clamps provided.

5. Follow the instructions step 5 through step 10 on

page 10 to attach the foam generator cylinders.

200/300 Gallon 3-Point Mounted

Sprayer / Foam Marker Assembl y

Instructions and Set-Up

Refer to Figure 5

1. Mount the support brackets (1) and (2) on the right

walkboard with 3/8" x 1" long bolts (3), flat washers,

and flange nuts required.

2. Mount the foam marker box (4) and the foam tank

base (6) on the support bracketswith 3/8" x 1" long

bolts and flange nuts required.

3. Secure the foam tank (5) to the foam tank base (6)

with the hose clamp (7) provided.

4. Attach a section of the clear hose from the hose

barb on the foam marker box(4) labeled "AIRTANK

IN" to the hose barb on the foam tank (5) that has a

white coupling. In a similar manner,attach a section

of the clear hose from the hose barb on the foam

marker box (4) labeled "FOAM TANK OUT" to the

blackcoupler on the tank. Attach the hoses with the

hose clamps provided

5. Follow the instructions step 5 through step 10 on

page 10 to attach the foam generator cylinders.

Figure 4

Tractor Mount Foam Marker Assembly Illustration

500-033M-A

12442

13264

Figure 5

3-Point Sprayer Foam Marker Assembly Illustration

4/21/2003

Page 15

Tractor Requirements

Refer to Figure 6

To operate your Great Plains Foam Marker, a tractor using a 12 volt electrical system must be used.

Note: If your Sprayer does not have the manual control system with the Application Systems control box,

youwill need to purchase the 502-031A foammarker

kit which includes a small switch box to control the

foam marker.

11984

Preparation and Setup

Figure 6

Switch Box for Foam Marker Kit

13

4/21/2003

500-033M-A

Page 16

Foam Marker

14

Operating Instructions

Basic Foam Marker Operating Procedures

Filling Foam Tank

1. Open the pressurerelief valveon the topof the foam

tank before removing the tank lid. This will equalize

the pressure on the inside of the foamtank with that

of the atmosphere.

!

CAUTION

Open the pressurerelief valve and allow all pressure to be released before the tank cap is removed. Failure to do so may

cause bodily injury.

2. Mix 1/2 to 1 quart of foam marker concentrate in the

10 gallon foam tank. Use an Application Systems

foam concentrate quart container to measure the

correct volume of foam concentrate. For smaller

quantities,the ratio is 1 1/2 to 3 ounces per gallon of

water.

3. Fill the tank with water. With hard water, add more

foamingconcentrate.The lidmust besealed airtight

for proper foaming.

4. Check the condition of hoses and connections frequently.

11984

Figure 7

Foam Control Valve

Operating Checklist

Operating the Foam Control Valve

1. Turn the foam marker on.

Refer to Figure 7

2. Open the foamcontrol valveon the foamcontrolbox

gradually, allowing several minutes for the liquid to

feed into the foaming cylinder on the boom.

3. Adjust the foam control valveto the desired output.

Pre-Assembly Checklist

Check the volume of soap in the foam marker tank.

Check if the power light is on when the marker is turned on.

Check the foam marker’ s 1/4" clear hose f or kinking.

Make sure the marker’s components are securely fastened.

500-033M-A

4/21/2003

Page 17

Adjustments

Adjustments

15

Field Adjustments

Foam Marker

The foam marker should be set so that when a pass is

makein the field with the foammarker on, you shouldbe

able to clearly see the foam marker on the next pass. If

too much foam is being applied, you will have to fill up

the foam marker more often. The rate of foam coming

out of the foam marker can be adjusted with the foam

control valve, refer to Figure 7, page 14.

If youfind thatthe dropsof foamare not large enough to

see, a foam marker bell can be placed on the end of the

drop hose to make larger foamdrops. Referto the parts

manual on page 1-1 to purchase a foam marker bell.

Foam Marker Preparation

General Notes for Field Operation

1. Check to make sure the foam marker is securely attached to its mount, and the foam generator cylinders are securely fastened to the boom.

2. Check the volume of soap in the foamtank to make

surethere is enough soap tooperate the foammarker for the time you will be spraying.

3. Check the foammarkerclear hose that routes along

the boom to be sure her are no kinks in the hose.

4. Turn on the foammarker by turning the foammarker

switchto the left orrightandsee if the powerlighton

the foam marker lights up. If the light does not turn

on, the foam marker does not have power. Check

the wiring harness plug.

5. DO NOT substitute other substances for the foam

marker concentrate. The foam marker concentrate

is specially formulated for the foam marker to produce high quality, long lasting foam. Other soap formulas are not made for this purpose.

Storage

Storage

1. Empty the left over sop in the foam marker tank.

2. Open the foam marker control valve full open and

operate the foam marker on both wings until all the

soapy water is purged from the system.

3. Inspect all parts of the foam marker for wear and

rust. Repair and paint parts as necessary. Replace

anydecals thatare worn orhard to read.Parts, paint

and decals may be obtained for your marker from

your Application Systems Dealer.

4/21/2003

500-033M-A

Page 18

Foam Marker

16

Troubleshooting

Foam Marker

Light* Reading

No Foam

{Power Light OFF}

No Foam

{Power Light ON}

Problem Area Specific Checks Corrections

Electrical Power

Source

Foam Marker

Hoses

Electric Solenoids 1. Check that all three sole-

Foam Tank Lid 1. Lid not fastened properly

Compressor 1. Compressor not running

1. Plugs on wiring harness

2. Faulty switch on control box

1. Foam marker hoses kinked

or pinched

noids are functioning

2. Check that all three solenoids are functioning

2. Pressure relief is on

2. Compressor not running

1. Plug in the connections on

the wiring harness

2. Check connections on

switch, or replace switch if

faulty

1. Use cableties to secure the

hose so it will not pinch

1. Correct electrical connectors on solenoids

2. Adjust nut on the top of the

solenoid so it will operate

1. Install the lid squarely on

tank

2. Turn off pressure relief on

the lid

1. Correct electrical connections

2. Replace compressor

*The foam marker light is located on the foam marker box, Figure 8.

13266

500-033M-A

Figure 8

Foam Marker Light

4/21/2003

Page 19

Appendix

Torque V alues Chart

Bolt Head Identification

Appendix

Bolt Head Identification

17

Bolt Size

(Inches)

1

in-tpi

1/4" - 20 7.4 5.6 11 8 16 12 M 5 X 0.8 4 3 6 5 9 7

1/4" - 28 8.5 6 13 10 18 14 M 6 X 1 7 5 11 8 15 11

5/16 - 18 15 11 24 17 33 25 M 8 X 1.25 17 12 26 19 36 27

5/16" - 24 17 13 26 19 37 27 M 8 X 1 18 13 28 21 39 29

3/8" - 16 27 20 42 31 59 44 M10 X 1.5 33 24 52 39 72 53

3/8" - 24 31 22 47 35 67 49 M10 X 0.75 39 29 61 45 85 62

7/16" - 14 43 32 67 49 95 70 M12 X 1.75 58 42 91 67 125 93

7/16" - 20 49 36 75 55 105 78 M12 X 1.5 60 44 95 70 130 97

1/2" - 13 66 49 105 76 145 105 M12 X 1 90 66 105 77 145 105

1/2" - 20 75 55 115 85 165 120 M14 X 2 92 68 145 105 200 150

9/16" - 12 95 70 150 110 210 155 M14 X 1.5 99 73 155 115 215 160

9/16" - 18 105 79 165 120 235 170 M16 X 2 145 105 225 165 315 230

5/8" - 11 130 97 205 150 285 210 M16 X 1.5 155 115 240 180 335 245

5/8" - 18 150 110 230 170 325 240 M18 X 2.5 195 145 310 230 405 300

3/4" - 10 235 170 360 265 510 375 M18 X 1.5 220 165 350 260 485 355

3/4" - 16 260 190 405 295 570 420 M20 X 2.5 280 205 440 325 610 450

7/8" - 9 225 165 585 430 820 605 M20 X 1.5 310 230 650 480 900 665

7/8" - 14 250 185 640 475 905 670 M24 X 3 480 355 760 560 1050 780

1" - 8 340 250 875 645 1230 910 M24 X 2 525 390 830 610 1150 845

1" - 12 370 275 955 705 1350 995 M30 X 3.5 960 705 1510 1120 2100 1550

1-1/8" - 7 480 355 1080 795 1750 1290 M30 X 2 1060 785 1680 1240 2320 1710

1 1/8" - 12 540 395 1210 890 1960 1440 M36 X 3.5 1730 1270 2650 1950 3660 2700

1 1/4" - 7 680 500 1520 1120 2460 1820 M36 X 2 1880 1380 2960 2190 4100 3220

1 1/4" - 12 750 555 1680 1240 2730 2010

1 3/8" - 6 890 655 1990 1470 3230 2380

1 3/8" - 12 1010 745 2270 1670 3680 2710

1 1/2" - 6 1180 870 2640 1950 4290 3160

1 1/2" - 12 1330 980 2970 2190 4820 35604mm x pitch = nominal thread diameter in millimeters x thread pitch

Grade 2 Grade 5

N · m2ft-lb3N · m ft-lb N · m ft-lb mm x pitch4N · m ft-lb N · m ft-lb N · m ft-lb

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

Grade 8

Bolt Size

(Metric)

1

in-tpi = nominal thread diameter in inches-threads per inch

5.8 8.8 10.9

Class 5.8 Class 8.8 Class 10.9

2

N· m = newton-meters

3

ft-lb= foot pounds

4/21/2003

500-033M-A

Page 20

Foam Marker

18

Warranty

Great Plains Manufacturing, Incorporated warrants to the original purchaser that this spraying equipment will be free from defects in material

and workmanship for a period of one year from the date of original purchasewhenusedas intended and under normal service and conditions

for personal use; 90 days for commercial or rental purposes. This Warranty is limited to the replacement of any defective part by Great Plains

Manufacturing, Incorporated and the installation by the dealer of any

such replacement part. Great Plains reserves the right to inspect any

equipment or part which are claimed to have been defective in material

or workmanship.

This Warranty does not apply to any part or product which in Great

Plains’ judgement shall have been misused or damaged by accident or

lack of normal maintenance or care, or which has been repaired or altered in a way which adversely affects its performance or reliability, or

which has been used for a purpose for which the product is not designed. This Warranty shall not apply if the product is towed at a speed

in excess of 20 miles per hour.

Claims under this Warranty must be made tothe dealerwhich originally

sold the product and all warranty adjustments must by made through

such dealer. Great Plains reserves the right to make changes in materials or design of the product at any time without notice.

This Warranty shall not be interpreted to render Great Plains liable for

damages of any kind, direct, consequential, or contingent, to property.

Furthermore,Great Plains shallnotbe liable fordamagesresulting from

any cause beyond its reasonable control. This Warranty does not extend to loss of crops, losses caused by harvest delays or any expense

or loss for labor, supplies, rental machinery or for any other reason.

No other warranty of any kind whatsoever, express or implied, is

made with respect to this sale; and all implied warranties of merchantability and fitness for a particular purpose which exceed

the obligations set forth in this written warranty are hereby disclaimed and excluded from this sale.

This Warranty is not valid unless registered with Great Plains Manufacturing, Incorporated within 10 days from the date of original purchase.

500-033M-A

4/21/2003

Page 21

Great Plains Manufacturing, Inc.

Corporate Office: P.O.Box 5060

Salina, Kansas 67402-5060 USA

Loading...

Loading...