Page 1

Great Plains Mfg., Inc.

Installation Instructions

706/1006 No-Till Drill

Option Installation

Used with:

• 706 End Wheel No-Till Drill

• 1006 End Wheel No-Till Drill

General Information

TheseinstructionsexplainhowtoinstalltheSmall Grass

Seeds, Fertilizer and Native GrassSeeds options.

These instructions apply to:

133-251A 706-7 Seed to SGS in row

133-252A 706-7 Seed to SGS side del.

133-253A 706-7 1/2 & 8 Seed to SGS in row

133-254A 706-7 1/2 & 8 Seed to SGS side del.

133-255A 1006-7 Seed to SGS in row

133-256A 1006-7 Seed to SGS side del.

133-257A 1006-7 1/2 Seed to SGS in row

133-258A 1006-7 1/2 Seed to SGS side del.

133-259A 1006-8 Seed to SGS in row

133-260A 1006-8 Seed ti SGS side del.

133-261A 706-7 NG to SGS in row

133-262A 706-7 NG to SGS side del.

133-263A 706-7 1/2&8NGtoSGSinrow

133-264A 706-7 1/2&8NGtoSGSside del.

133-265A 1006-7 NG to SGS in row

133-266A 1006-7 NG to SGS side del.

133-267A 1006-7 1/2 NG to SGS in row

133-268A 1006-7 1/2 NG to SGS side del.

133-269A 1006-8 NG to SGS in row

133-270A 1006-8 NG to SGS side del.

133-271A 706-7 Fert. to SGS in row

133-272A 706-7 Fert. to SGS side del.

133-273A 706-7 1/2&8Fert.toSGSinrow

133-274A 706-7 1/2&8Fert.toSGSside del.

133-275A 1006-7 Fert. to SGS in row

133-276A 1006-7 Fert. to SGS side del.

133-277A 1006-7 1/2 Fert. toSGS inrow

133-278A 1006-7 1/2 Fert. toSGS sidedel.

133-279A 1006-8 Fert. to SGS in row

133-280A 1006-8 Fert. to SGS side del.

142-920A 706-7 Seed to Fert.

142-921A 706-7 1/2 & 8 Seed to Fert.

142-922A 1006-7 Seed to Fert.

142-923A 1006-7 1/2 Seed to Fert.

142-924A 1006-8 Seed to Fert.

142-925A 706-7 Seed & SGS to Fert.

142-926A 706-7 1/2 & 8 Seed & SGS to Fert.

142-927A 1006-7 Seed & SGS to Fert.

142-928A 1006-7 1/2 Seed & SGS to Fert.

142-929A 1006-8 Seed & SGS to Fert.

© Copyright 2004 Printed

8/2/2005

When you see this symbol, the subsequent instructions and

warnings areserious- follow without exception. Your life and

!

!

the lives of others depend on it!

142-930A 706-7 Seed to Fert. & SGS

142-931A 706-7 1/2 & 8 Seed to Fert. &SGS

142-932A 1006-7 Seed to Fert. & SGS

142-933A 1006-7 1/2 Seed to Fert. &SGS

142-934A 1006-8 Seed to Fert. & SGS

202-546A 706-7 Seed to NG

202-547A 706-7 1/2 & 8 Seed to NG

202-548A 1006-7 Seed to NG

202-549A 1006-7 1/2 Seed to NG

202-550A 1006-8 Seed to NG

202-563A 706-7 Seed & SGS to NG

202-564A 706-7 1/2 & 8 Seed & SGS to NG

202-565A 1006-7 Seed & SGS to NG

202-566A 1006-7 1/2 Seed & SGS to NG

202-567A 1006-8 Seed & SGS to NG

202-569A 706-7 Seed to NG & SGS

202-570A 706-7 1/2 & 8 Seed to NG & SGS

202-571A 1006-7 Seed to NG & SGS

202-572A 1006-7 1/2 Seed to NG & SGS

202-573A 1006-8 Seed to NG & SGS

Manual Update

Refer to the 706/1006 No-Till Drill operator’s manual for detailed information on safely operating, adjusting,

troubleshooting and maintaining the various options mentioned in this installation manual.Refer to theparts manual

for part identification. Refer to the seed ratebook for setup,

calibration and seed rates.

150-285M Operator’sManual

150-285P Parts Manual

150-285B Seed Rate Book

Before You Start

Pages23 through 40 are adetailed listing ofparts included

in the various option packages. Use these lists to inventory

parts received. Detailed illustrationsof sprock configurations for the various option packages arelocated onpages

17 through 22.

Tools Required

• Basic hand tools

Definitions

Right-hand and left-hand as used in this manual are determined by facing the direction themachine willtravel while in

use unless otherwise stated.

151-118M

Page 2

Option Installation

2

Assembly Instructions

Great Plains Mfg., Inc.

Small Grass Seed

1. Lower drill to the ground.

2. Remove walkboard, walkboard mounts and

walkboard supports. Save hardware.

3. Remove and save all box handles and hardware.

4. Assemble new walkboardend panelsand

harrowsupports. Re-attach existingladder to

left-hand walkboard end using hardware removed in step 2.

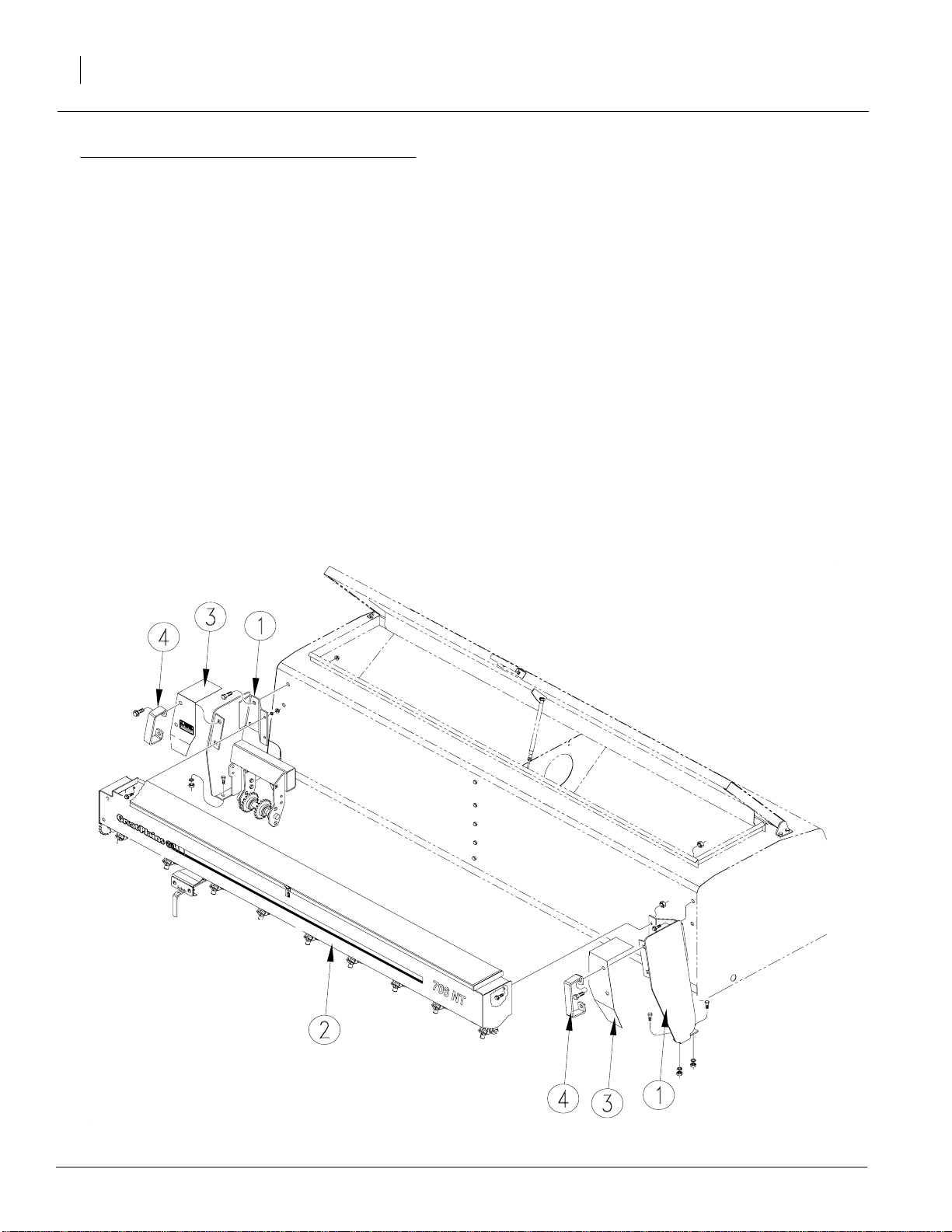

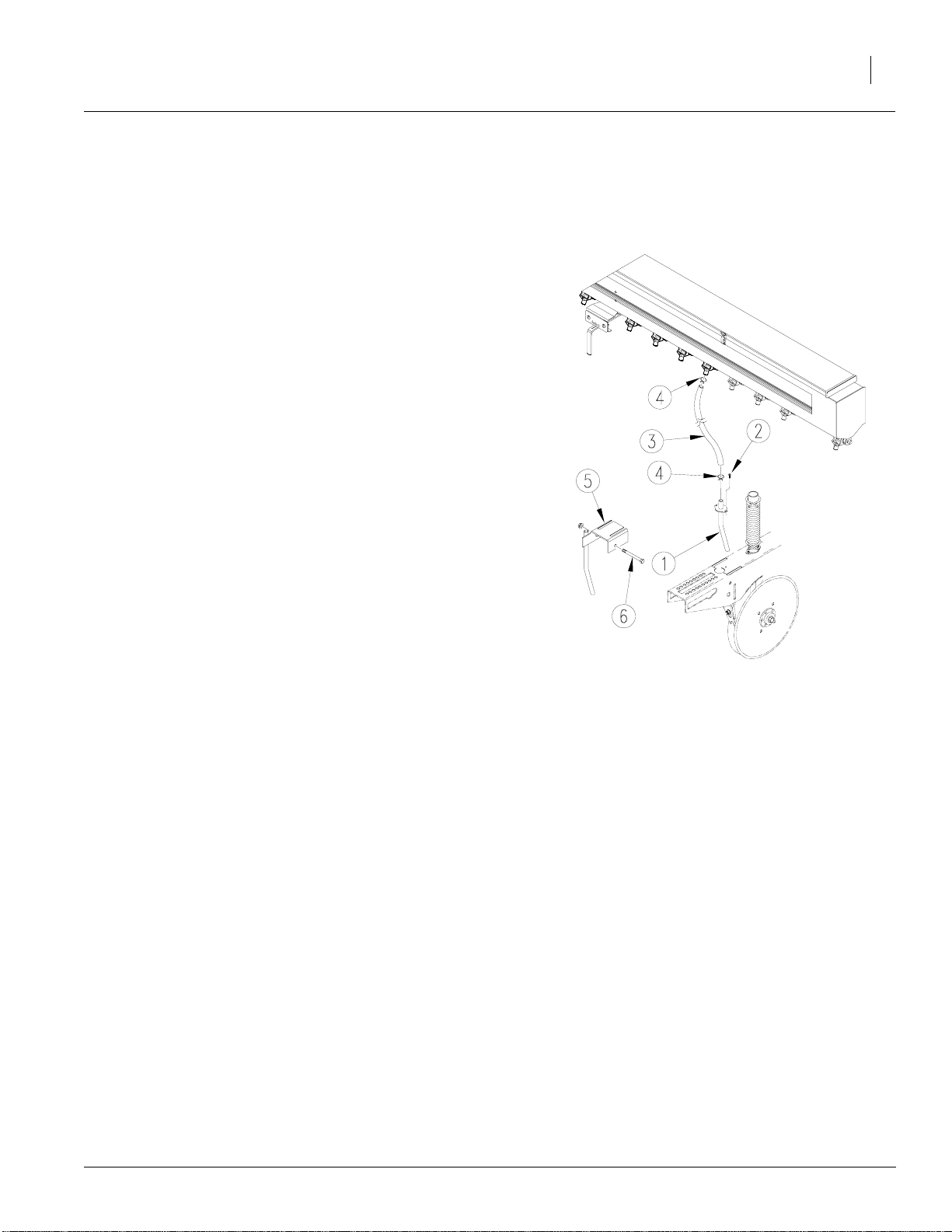

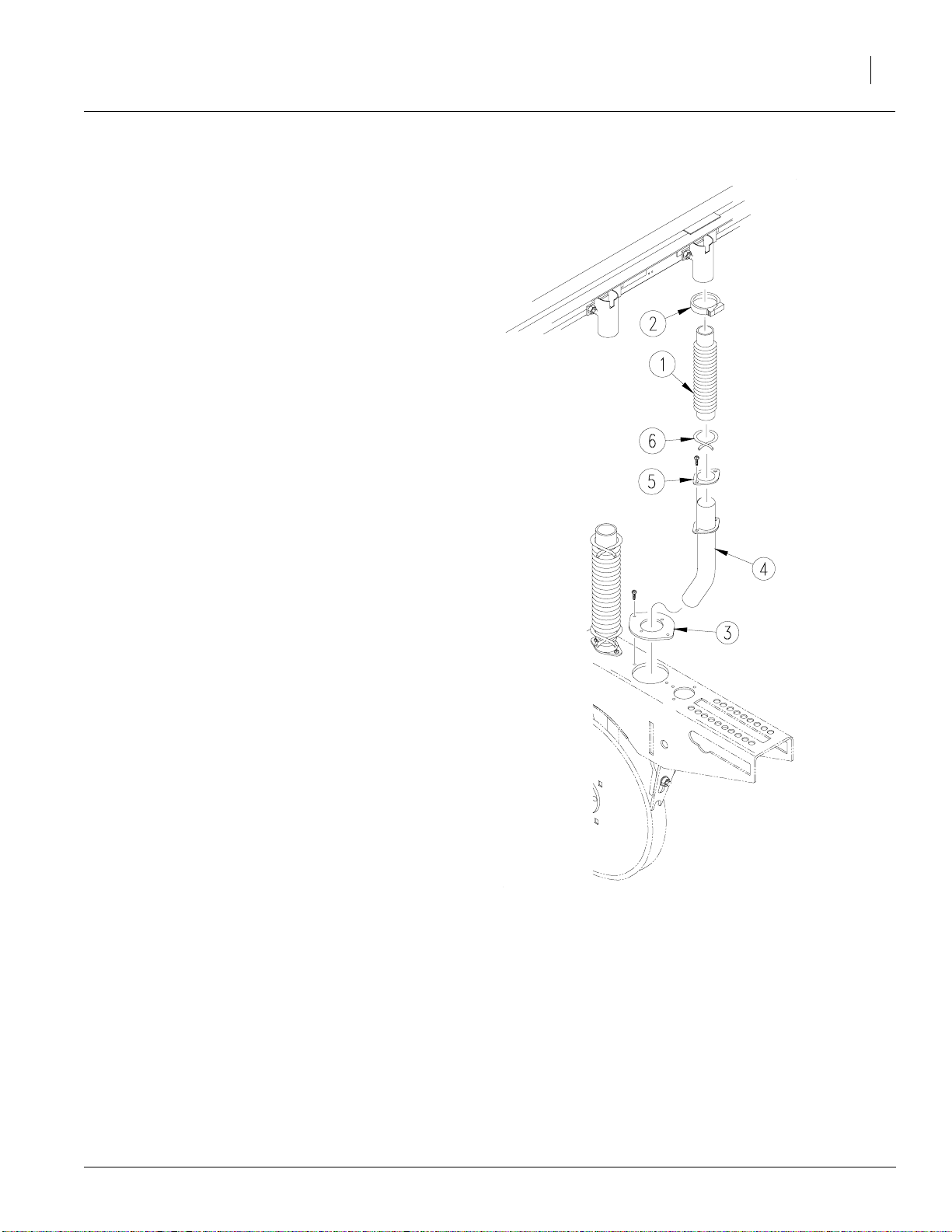

Refer to Figure 1

5. Assemblethesmallgrassseed box mounting

brackets (1) to the back of the drill box, fertilizer box or native grass seed box asshown.

Use 1/2" x 1 1/4" bolts and 1/2" flange lock

nuts to attach to the box. Use 1/2" x 1" bolts,

1/2" lock washers and 1/2" nuts to attach the

bracket to the drill frame.

6. Mount the small grass seed box (2) to the

mounting brackets (1) using 3/8" x 1" bolts,

3/8" lock washers and 3/8" nuts.

22556

Figure 1

Small Grass Seed Box

151-118M 8/2/2005

Page 3

Great Plains Mfg., Inc.

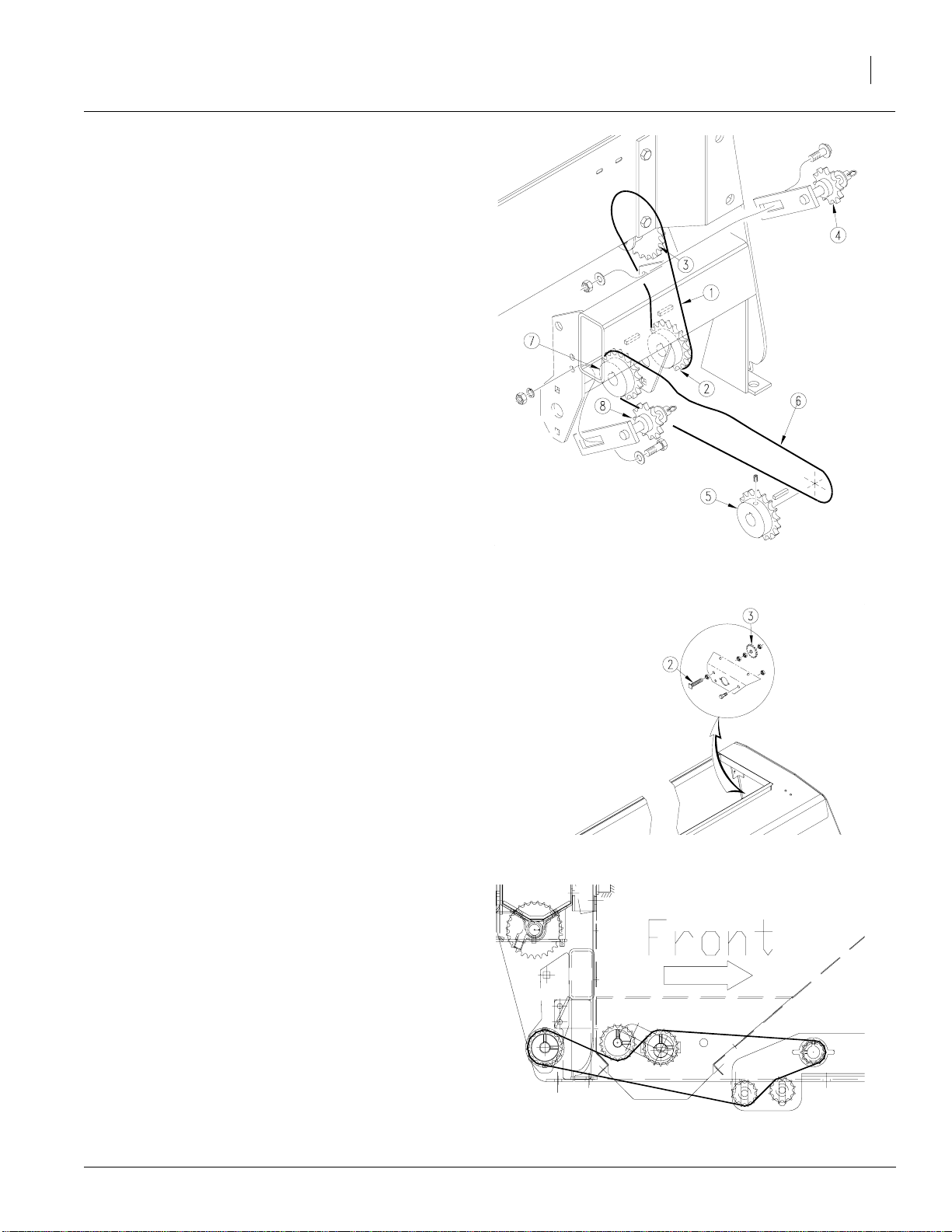

Refer to Figure 2

7. Assemble and route the chain (1) from the

sprocket (2) on the drive bracket to the

sprocketon the small grass seed box(3). Adjust idler (4) to remove chain slack.

NOTE:With fertilizer and/or seed box agitatoroptions already installed, alarge portionof the drive

is already completed.

With Fertilizer

Refer to Figure 2

8. Add 17 tooth sprocket (5) to the fertilizer box

shaft. Assemble and route chain (6) from

sprocket (5) to the sprocket (7) on the drive

bracket. Adjust idler (8) to remove chain

slack.

Installation Instructions

3

With Seed Box Agitator

Refer to Figure 3

9. Remove the current bolt and hardware from

the rear hole of the seed box and install the

agitator idler bolt (2), jamnut, flatwasher and

idlersprocket(3) into the rear hole of the false

end panel on the left-hand side of the seed

box.

Refer to Figure 4

10. Replacethe agitator drive chain with the longer one provided. Route chain as shown and

adjust idlers to remove chain slack.

22557

Figure 2

Chain Routing

21831

Figure 3

Idler Sprocket

11. Attach the chain guards and the handles removedin 3tothemounting bracketsusing the

hardware removed instep 3on page2.

8/2/2005

22558

Figure 4

Chain Routing

151-118M

Page 4

Option Installation

4

Great Plains Mfg., Inc.

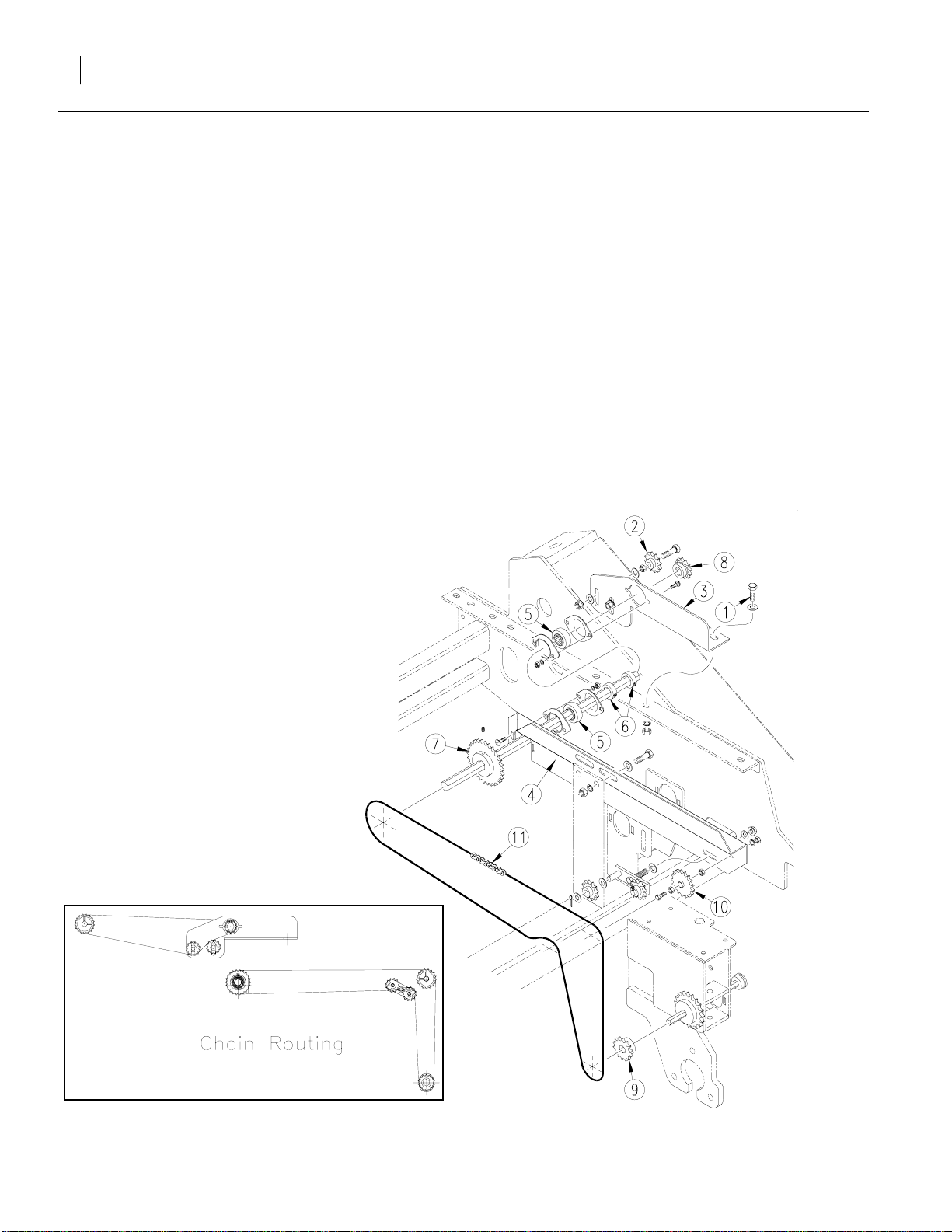

Without Fertilizer or Seed Box Agitator and

Drills with Native Grass Seed

Refer to Figure 5

12. Working at the front left side of the drill, remove the second and third front 1/2"x 11/4"

long bolts (1) that jointhe boxto the frame. Install the idler (2) 1/2" x 3" long bolt, 1/2" flat

washer,1/2" jam nut and 1/2" flange lock nut

to bracket (3) as shown.

13. Install bracket (3) and (4) as shown.Leave

loose until final assembly. Install the 7/8" hex

bore bearings (5) and flangettes with 5/16" x

1" carriage bolts and hardware as shown on

plates (3) and (4). Be careful to place the

bearings on the side of the plate as illustrated.

14. Slide the 7/8" hexjackshaft and 7/8"hexlocking collars (6) on theinside between the bear-

ings. Place the 22 tooth sprocket (7)on the

inboard side of the shaft and the 12 tooth

sprocket(8) on theout boardside of theshaft.

15. Add14tooth sprocket(9)to the gearboxdriver

shaft already installed on the drill.

16. Attach the 17 tooth idler sprocket (10) with

5/8" x 3 1/2" bolt, with 5/8" jam nuts and 5/8"

flat washer as shown on plate (4).

17. Align the 7/8"hex shaft frontto back and level

with the drill. Tighten brackets (3) and (4).

Alignsprocketsandidlersonplate(4) and add

chain (11) and route as shown.

18. Add chain between sprocket (8) and the

sprocket on the drive bracket for thesmall

grass seed drive, route chain as shownand

tighten with idler (2).

22596

Figure 5

Lower Drive Assembly

151-118M 8/2/2005

22597

Page 5

Great Plains Mfg., Inc.

Seed Tube Assembly

The openers on the 706/1006 havetwo locations

for small grass delivery. In row or side delivery.

The in row delivery is installed in the rear opener

holewhile the side delivery attaches to theside of

the opener.

Refer to Figure 6

19. Insert the seed tube (1) into the hole on the

topof the opener.Secure in place with a number 10-16 x 1/2” screw (2).

20. Slidea hose clamp(4)overthehose(3). Slide

the end of the hose over the seed tube and

secure it in place with the hose clamp.

21. Slide a hose clamp (4) over the other end of

thehoseandslidethehoseoverthe seed outlet which corresponds with the appropriate

opener. Secure hose in place with the hose

clamp. Repeat the above steps to install the

rest of the seed tubes and hoses.

Installation Instructions

5

22. Set the side delivery tube (5) down over the

top of the opener directly in front of the fertilizer tube. Line up the holes with the holes in

theopener and insert the 3/8”x35/8” boltand

secure bolt with a 3/8” lock nut flange.

23. Slidea hose clamp(4)overthehose(3). Slide

the end of the hose over the seed tube and

secure it in place with the hose clamp.

24. Slide a hose clamp (4) over the other end of

thehoseandslidethehoseoverthe seed outlet which corresponds with the appropriate

opener. Secure hose in place with the hose

clamp. Repeat the above steps to install the

rest of the seed tubes and hoses.

Walkboard Assembly

25. Assemble walkboard on the end panels and

walkboardsupports using hardwareremoved

in step 2 on page 2.

26. Attach SMV sign andadd allsafetyand warning decals to the walkboard.

27. Referto yourGreatPlainsseed rate book and

operator’smanual for setup, calibration and

use.

22559

Figure 6

Seed Tube Assembly

8/2/2005

151-118M

Page 6

Option Installation

6

Great Plains Mfg., Inc.

Fertilizer Box

1. Lower drill to the ground.

2. Remove walkboard, walkboard mounts and

walkboard supports. Save hardware.

3. Remove and save all box handles and hardware.

4. Assemble new walkboardend panelsand

harrowsupports. Re-attach existingladder to

left-hand walkboard end using hardware removed in step 2.

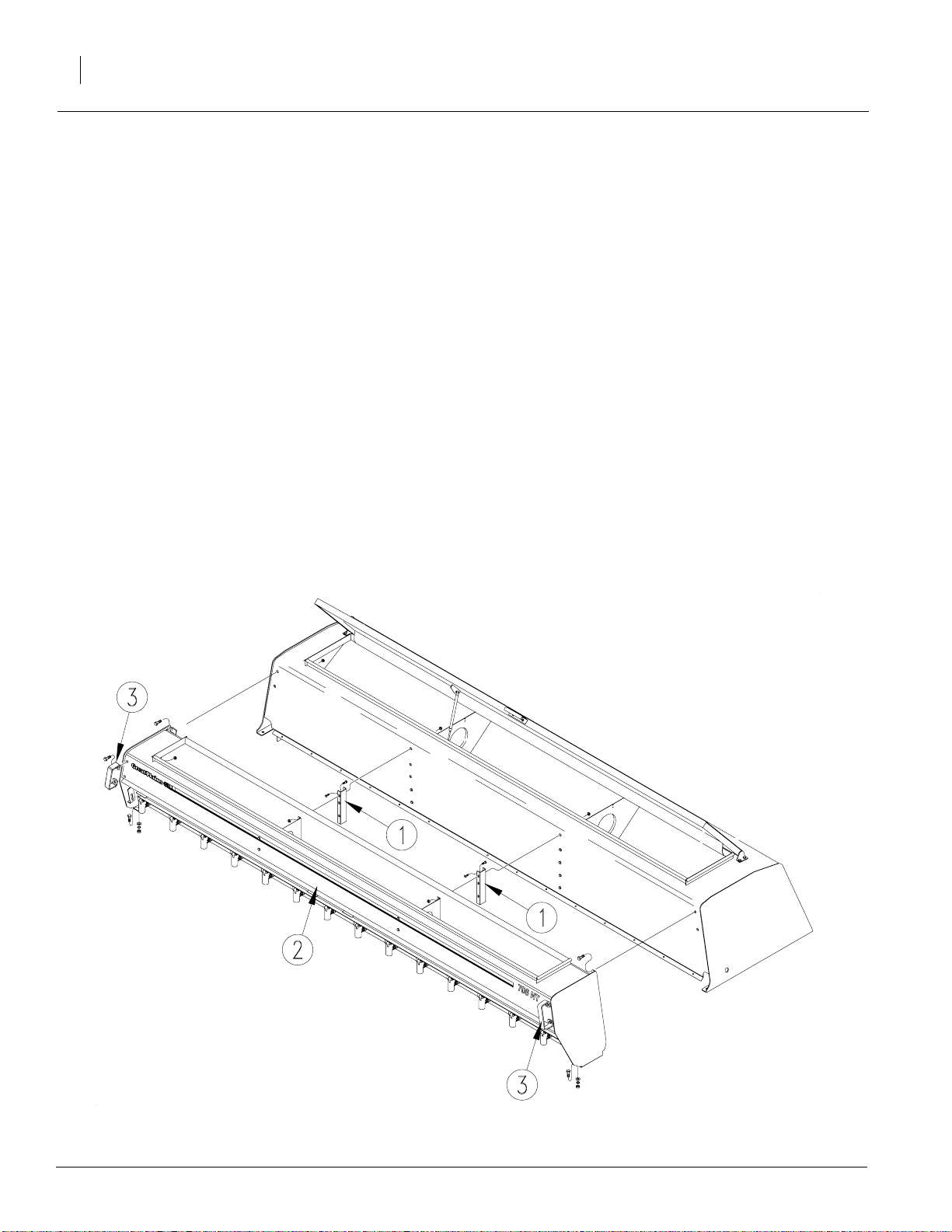

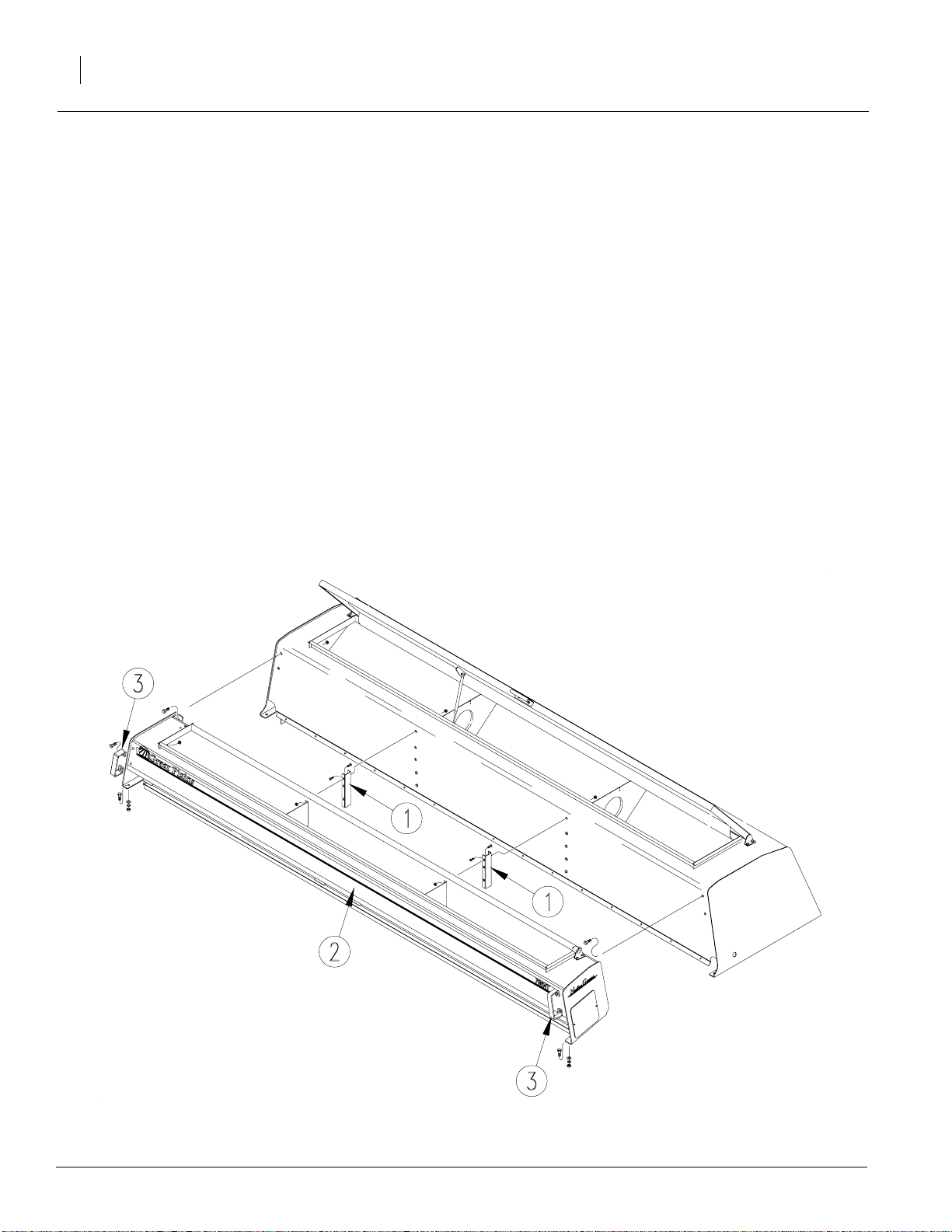

Refer to Figure 7

5. Attach the fertilizer box mountbrackets(1) to

the fertilizerbox (2) where the fertilizer box

partitions arelocated. Use thebolts and nuts

holding the partitions.

6. Mount the fertilizer box (2) to theseed boxusing 1/2" x1 1/4" boltsand 1/2" flangenuts on

the outside ends.Use existing bolts and nuts

from the seed box partitions toattach thebox

mount brackets (1). Use 1/2" x 1" bolts, 1/2"

lock washers and 1/2" nuts to attach the box

to the drill frame.

7. Attach the handles (3) removed in step 3 to

the fertilizerbox (2) using the hardware removed in step 3.

22560

Figure 7

Fertilizer Box

151-118M 8/2/2005

Page 7

Great Plains Mfg., Inc.

With Seed Box Agitator

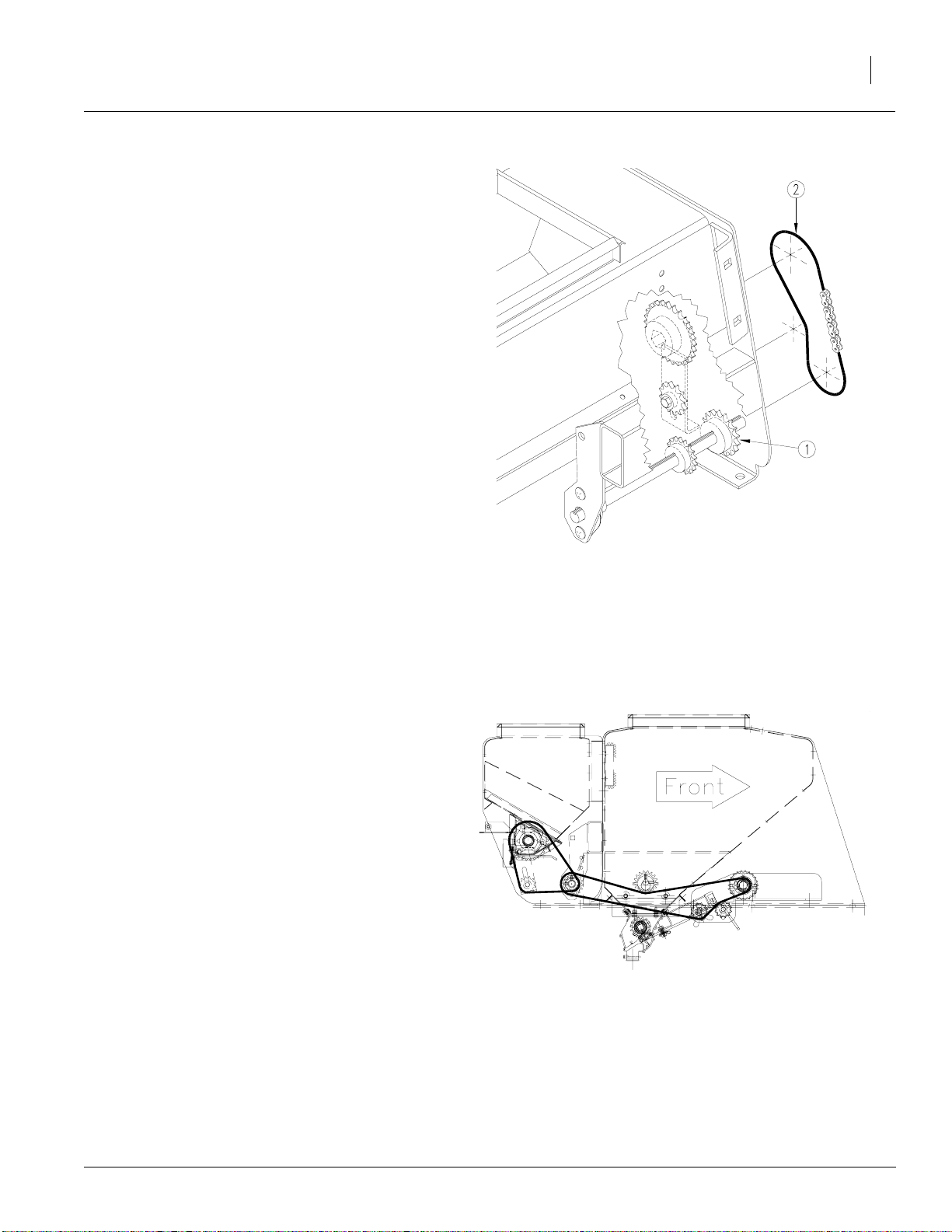

Refer to Figure 8

8. Install the 17 tooth sprocket (1) onthe end of

the fertilizerjackshaft. Align it with the fertilizer drivesprocket on the end to the shaft.

Route the 103 pitch chain (2) and remove

slack with the idler sprocket.

Installation Instructions

7

Refer to Figure 9

9. Replacethe agitator drive chain with the longer one provided. Route chain as shown and

adjust idlers to remove chain slack.

22615

Figure 8

Sprocket and Chain

22614

8/2/2005

Figure 9

Chain Routing

151-118M

Page 8

Option Installation

8

Great Plains Mfg., Inc.

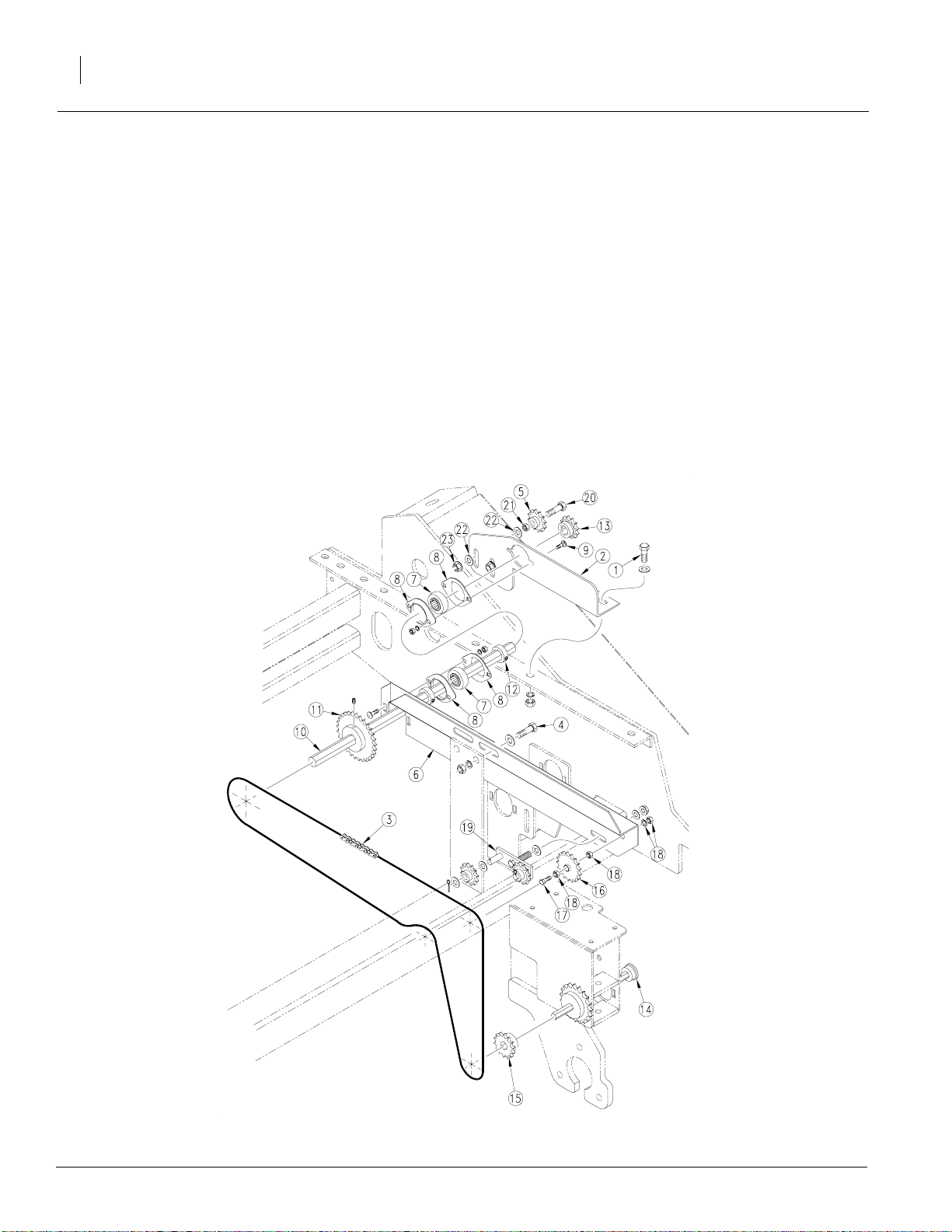

Without Seed Box Agitator

Refer to Figure 10

10. Working at the front left side of the drill, remove the second and third front 1/2"x 11/4"

long bolts (1) that jointhe boxto the frame. Install the idler (5) 1/2" x 3" long bolt (20), 1/2"

flat washer, 1/2" jam nut and 1/2" flange lock

nut (23) to bracket (2)as shown.

11. Install bracket (2) and (6) as shown.Leave

loose until final assembly. Install the 7/8" hex

borebearings(7)andflangettes(8) with5/16"

x 1" round head square neck bolts (9) and

hardware as shown on plates(2) and (6). Be

carefulto place thebearingsonthe side ofthe

plate as illustrated.

12. Slide the 7/8" hexjackshaft and 7/8"hexlocking collars (12) on the inside between the

bearings. Place the 22 tooth sprocket (11) on

the inboard side of the shaft and the 12 tooth

sprocket (13) on the out board side of the

shaft.

13. Add14tooth sprocket(15)tothegearboxdriver shaft already installed on the drill.

14. Attach the 17 tooth idler sprocket (16) with

5/8" x 3 1/2" bolt (17), with 5/8" jam nuts (18)

and 5/8" flat washer as shown on plate (6).

15. Align the 7/8"hex shaft frontto back and level

with the drill. Tighten brackets (2) and (6).

Alignsprocketsandidlersonplate(6) and add

chain (3) and route as shown.

16. Add chain between sprocket (13) and the

sprocket on the drive bracket for thesmall

grass seed drive and tighten with idler (5).

21830

Figure 10

Lower Drive Assembly

151-118M 8/2/2005

Page 9

Great Plains Mfg., Inc.

Seed Tube Assembly

Refer to Figure 11

17. Attach the fertilizer hoses (1) to the drop

tubes on the fertilizer box with ratchet clamps

(2).

18. Route the hosesbehind the rearframe tubes

on the drill. Attach the opener adapter (3) to

the large hole in the opener and secure in

place with 10 x 3/8" machine screws.

19. Insert the fertilizer tube (4) into the opener

adapter (3) with the tube opening facing forward.Secure in place with reinforcement ring

(5) and 10 x 3/8" machine screws.

NOTE:If smallseedsarenotbeing used youhave

the option of using the rear most opener hole for

yourpreference infertilizerplacement.insert tube

(4) into the smaller hole. Attach with reinforcement ring (5) and 10 x 3/8" machine screws.

20. Attach the fertilizer hoses (1) to the fertilizer

tubes using hose clamp (5).

Installation Instructions

9

Walkboard Assembly

21. Assemble walkboard on the end panels and

walkboardsupports using hardwareremoved

in step 2 on page 6.

22. Attach SMV sign andadd allsafetyand warning decals to the walkboard.

23. Referto yourGreatPlainsseed rate book and

operator’smanual for setup, calibration and

use.

22565

Figure 11

Seed Tube Assembly

8/2/2005

151-118M

Page 10

Option Installation

10

Great Plains Mfg., Inc.

Native Grass

1. Lower drill to the ground.

2. Remove walkboard, walkboard mounts and

walkboard supports. Save hardware.

3. Remove and save all box handles and hardware.

4. Assemble new walkboardend panelsand

harrowsupports. Re-attach existingladder to

left-hand walkboard end using hardware removed in step 2.

Refer to Figure 12

5. Attach the native grass seed box mount

brackets (1) to the native grass seed box (2)

where the native grass seed box partitions

are located. Use the bolts and nuts holding

the partitions. (On 706NT models, these

brackets are not used.)

6. Mount the native grass seed box (2) to the

seed box using 1/2" x 1 1/4" bolts and 1/2"

flange nuts on the outside ends. Use existing

bolts and nuts from the seed box partitions to

attach the box mount brackets (1). Use 1/2" x

1" bolts, 1/2" lock washers and 1/2" nutsto attach the box to the drill frame.

7. Attachthehandles (3) removedin step 3 tothe

native grass seed box (2) using the hardware

removed in step 3.

Native Grass Seed Drive

8. Support right-handdrill and gaugewheel arm

by blocking upwith jacks and supports. Remove gauge wheel tire.

22566

Figure 12

Native Grass Seed Box

151-118M 8/2/2005

Page 11

Great Plains Mfg., Inc.

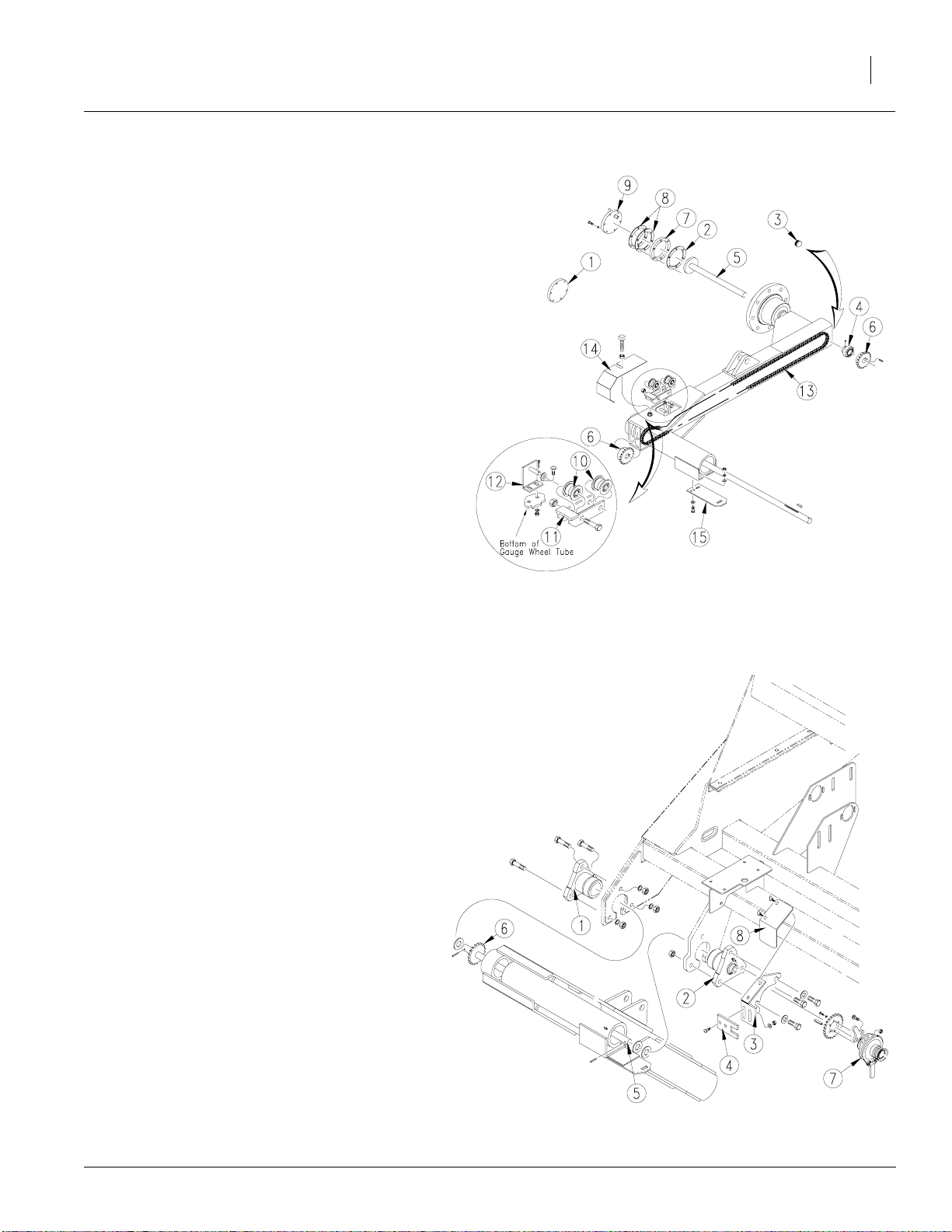

Refer to Figure 13

9. Access drivegauge wheelhub by removing

endcap(1). Be careful and leavethe hub seal

(2) in place.Removeplastic cap (3)on the inside end of the gauge wheel spindle. Insert

spindle bearing (4) into the area where the

plastic cap (3) was removed.Make sure the

set screws are accessible.

10. Insert right-hand lockout driveshaft (5)

throughdrivespindle,throughbearing(4)and

through 19 tooth sprocket (6). The sprocket

will be located inside the gauge wheel arm.

Lock set screws on bearing.

11. Addlockouthub spacer (7), lockouthubseals

(8) and lockout end cap (9).

12. Assemble the idler assemblyusing one roller

(10), 1/2" x 2" bolt and 1/2" jam nut through

the hole nearest the cross piece on the idler

arm (11) as shown.Place 3/8"flat washer

overthe pivotshaft on idler mount (12). Place

the other roller (10) between the remaining

holes in arm (11). Insert pivot shaft on idler

mount (12) through the arm and roller and insert cotter pin in end of shaft.

Installation Instructions

Figure 13

Gauge Wheel Assembly

11

22572

13. Mount idler assembly to thebottom of gauge

wheeltubeasshown.Thread the 5/8" jam nut

on to the 5/8" x 3 1/2" square head screw.

Threadtheidler adjustment into the top of the

gauge wheel tube.

Refer to Figure 14

14. Withthe gaugewheelarmsupported,remove

the pivot castings one at a time and replace

with 1" bore bearings (1) and (2). Place the

shorter one (1) in the outboard position and

use existing hardware.Place the longer casting (2) in the inboard position along with the

right-hand clutch mount (3) as shown.Use

5/8" x 2 1/2" bolts, 5/8" flat washers and 5/8"

lock nuts.

15. Attach clutch adjuster(4) to the clutch mount

(3) with a 3/8" x 3/4" carriage bolt, 3/8" lock

washer and 3/8" nut.

16. Insert the gauge wheel jackshaft (5) through

the outboard bearing. Add 19 tooth sprocket

(6) to the shaft so it is inside of the gauge

wheel tube. Add one 1" flat washer and roll

pin on the outboard end. Slide shaft inward

through the other bearing until the washer

rest against the outboard bearing. Lock set

screws to hold jackshaft in place.

22573

Figure 14

Pivot Castings

8/2/2005

151-118M

Page 12

Option Installation

12

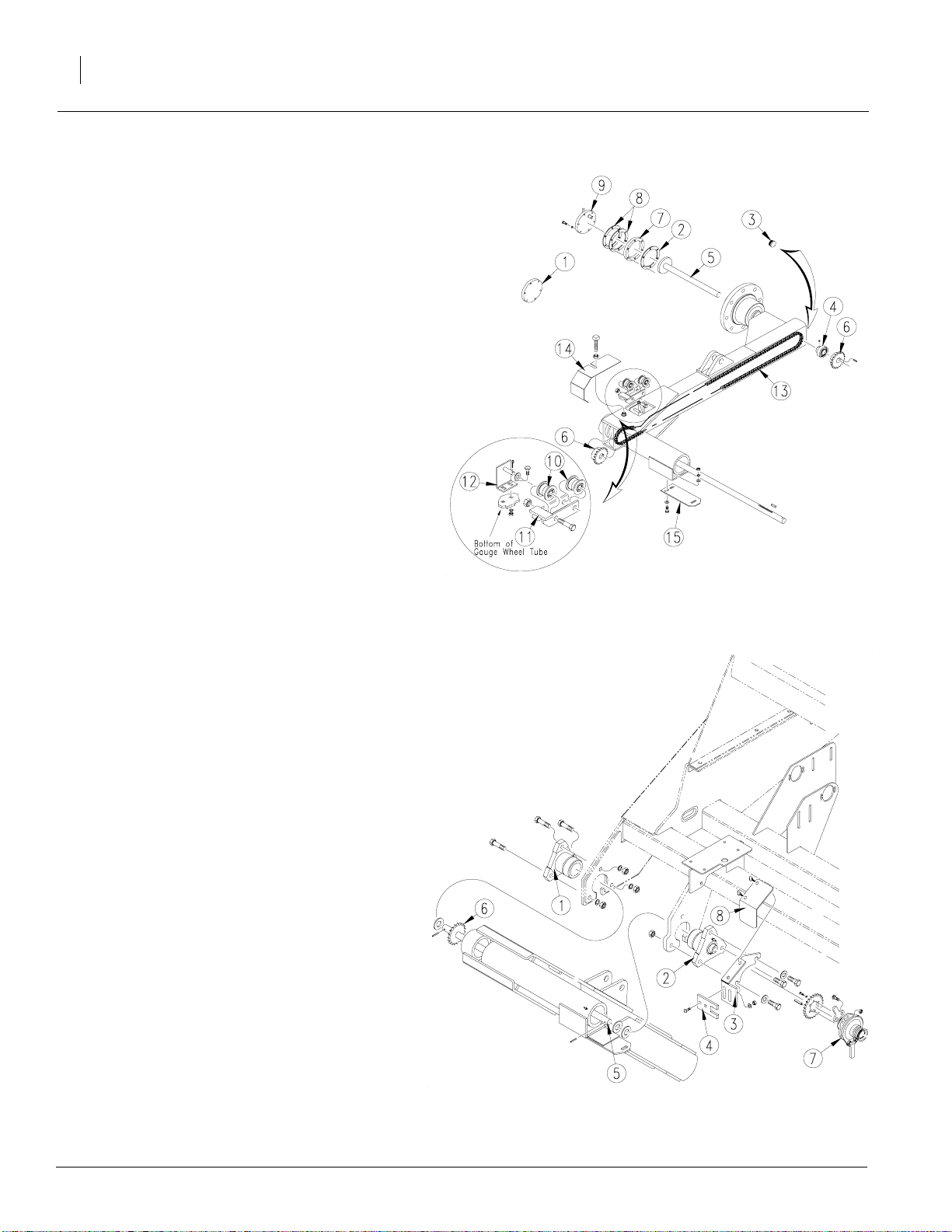

Refer to Figure 15

17. Alignthe two 19 tooth sprockets (6) with each

other and tighten theset screws to holdthem

in place.

18. Feed the 188 pitch chain (13) through the

gauge wheel tube and around the sprockets

and idler assembly.

19. Adjust the square head idler adjustment

screw to give tension to the chain. Place the

access cover (14) over the hole andsecure it

and the adjustment screw in place with the

jam nut.

20. Attach the clutch adjuster (15) to the bottom

of the gauge wheel weldment with 3/8" x

11/4" bolts and3/8"flat washers.Leaveloose

at this time.

Great Plains Mfg., Inc.

Refer to Figure 16

21. Attach the 25 tooth sprocket and clutch tabs

to the clutch assembly (7) as shown.

22. Slide the clutch assembly (7) on to the shaft

with the sprocket towards the outboard side.

With the bottom clutch adjuster loose, position the clutch so the outboard tab will fit into

the square slot of the bottom clutch adjuster

andtheinboardtab will fit into the open slot of

adjuster (4). Tighten bottom clutch adjuster.

23. Align the hole in the end of the shaft with the

hole in the clutch end and insert roll pin.

24. Place clutch shield (8) over clutch and hold it

in place with 1/4" x 1/2" thumb screws.

22572

Figure 15

Gauge Wheel Assembly

22573

Figure 16

Clutch Assembly

151-118M 8/2/2005

Page 13

Great Plains Mfg., Inc.

Refer to Figure 17

25. Mount the gearbox (1) to the frame using 3/8"

x 1" self tapping screws. Make sureit is

square with the frame.

26. Slide the 19tooth spline boresprocket(2) on

the rear inboard shaft and secure it in place

with an external snap ring.

27. Slide the 25 tooth clutch sprocket (3) on the

outboard shaft and secure it in place with an

external snap ring.

28. Slide the acremeter mount (4) on the front

outboard shaft and secure it in place with an

externalsnapring. Bolt the acremeter hub (5)

to the acremeter mount (4) with 1/4" x 5/8"

bolts and 1/4" flat washers. Thread the

acremeter (6) on to the acremeter hub (5).

29. Add two 12 tooth idler sprockets (7) to the

frame using 1/2" x 3" bolt, 1/2" jam nut, 1/2"

flat washers and1/2" flange lock nut oneach

one.

30. Routethe96pitchchain(8)aroundtheclutch

(9)and sprocket(3) andremoveslackin chain

with idler.

22594

Installation Instructions

Figure 17

Gearbox

13

Refer to Figure 18

31. Assemble the 7/8" hex bearings (1) and

flangettes.Mount them to the outside surface

of the mounting platesas shown. Use 5/16" x

1" carriage bolts, 5/16" flat washers, 5/16"

lock washers and 5/16" nuts.

32. Insert the 7/8" hex shaft (2) into the one of the

bearings keeping the end with the holes towards the inboardside. Slide on both locking

collars (3) and continue to slide the shaft

through the other bearing making sure both

holes are throughthe inboard bearing.Insert

the roll pin into the hole closest the center.

33. The sprockets that assemble tothe drive

shaft (2) are 15 tooth through 24 tooth (11).

Select one (4) and addit to theshaft with the

sprockethubresting against the rollpin. Hold

sprocketin placewith a lynchpin.The remainingsprocketsare stored on the round storage

bars on the end of the frame held on with retaining clips.

22595

Figure 18

Drive Shaft

8/2/2005

151-118M

Page 14

Option Installation

14

34. Align sprocket (4) with the sprocket on the

gearbox. Slide both of the locking collars (3)

against the bearings (1) and tighten set

screws.Makesure sprocket(4)is still aligned

with the sprocket on the gearbox.

35. Add two idlers(5) to the frame plateusing using 1/2" x 3" bolt, 1/2" jam nut, 1/2" flat washers and 1/2" flange lock nut on each one.

36. Route108 pitch chain (8) around the gearbox

sprocket and sprocket (4) and tighten with

idlers (5).

37. Add a 24 tooth sprocket with set screws (7) to

the outboard end of shaft (2). Add two idlers

(5) to the frameplate using1/2" x3" bolt,1/2"

jamnut,1/2"flat washersand 1/2" flange lock

nut on each one.

Refer to Figure 19

Great Plains Mfg., Inc.

38. Remove the right-hand access cover(1) for

the native grass seed box. Add the 30 tooth

3/4" hex sprocket (2) tothe agitatorshaft, the

17 tooth sprocket (3) tothe cup shaftand the

bearing idler sprocket (4).

Refer to Figure 18 on page 13

39. Align the 25 tooth sprocket (7) with the 30

tooth sprocket at the nativegrass seed box

and tighten set screws.

Refer to Figure 20

40. Route 176 pitch chain around sprockets and

remove slack withidlers.

Refer to Figure 18 on page 13

41. Installgearboxcover(9) overgearboxmaking

sure selector handle rod sticks through the

hole in top. Secure cover in place with 3/8" x

1"selftappingscrews.Attach selector handle

(10) to the selector rod with 1/4" x 3/8",

1/4" flat washer and 1/4" lock washer.

42. Re-installgauge wheeltire.With gaugewheel

tire off the ground, clutch engaged and lockout cap in driveposition, rotatetire toengage

drive. Check to make sure all chains are turing and in alignment.

22598

Figure 19

Right-Hand of Native Grass Box

22616

Figure 20

Chain Routing

43. Install cover backon native grass seed box.

44. Remove jacks andsupports from drill. Raise

and lower the drill hydraulically making sure

the clutch engages anddisengages properly.

Adjust as needed.

45. Grease all fittings on the gauge wheel.

151-118M 8/2/2005

Page 15

Great Plains Mfg., Inc.

Native Grass Seed Tube Installation

Refer to Figure 21

46. Insert the native grass seed tube (1) in the

hole behind the springs and secure in place

with two 10-16 x 3/8" screws and 1/4" flat

washers.

47. Attach one end of the seed hose (2) to the

seedtube(1)witha#42hose clamp the other

end to the native seed cup with a #42 hose

clamp.

Walkboard Assembly

48. Assemble walkboard on the end panels and

walkboardsupports using hardwareremoved

in step 2 on page 10.

49. Attach SMV sign andadd allsafetyand warning decals to the walkboard.

Installation Instructions

15

50. Referto yourGreatPlainsseed rate book and

operator’smanual for setup, calibration and

use.

22617

Figure 21

Seed Tube

8/2/2005

151-118M

Page 16

Option Installation

16

Adding Native Grass or Fertilizer to

Drills with Seed & SGS

1. Lower drill to the ground.

2. Remove walkboard, walkboard mounts and

walkboard supports. Save hardware.

3. Disassemble small grass drive chain from

front of drill. Remove SGS box and mount

bracketsfrom rear of seed box and frame end

panels. Keep allhardware for reuse.

4. Assemble new walkboardend panelsand

harrowsupports. Re-attach existingladder to

left-hand walkboard end using hardware removed in step 2.

Great Plains Mfg., Inc.

5. To attach and assemble native grass or fertilizer box refer to appropriate corresponding

assembly instructions found in this manual.

6. Refer to small grass seeds assembly instructions found on page 2 of this manual to reassemble SGS box.

151-118M 8/2/2005

Page 17

Great Plains Mfg., Inc.

Seed Box Sprocket Configuration

Installation Instructions

17

8/2/2005

21754

151-118M

Page 18

Option Installation

18

Seed Box Agitator Sprocket Configuration

Great Plains Mfg., Inc.

21753

151-118M 8/2/2005

Page 19

Great Plains Mfg., Inc.

Small Grass Seeds Sprocket Configuration

Installation Instructions

19

8/2/2005

21755

151-118M

Page 20

Option Installation

20

Native Grass Sprocket Configuration

Great Plains Mfg., Inc.

21756

151-118M 8/2/2005

Page 21

Great Plains Mfg., Inc.

Fertilizer Sprocket Configuration

Installation Instructions

21

8/2/2005

21757

151-118M

Page 22

Option Installation

22

Fertilizer with Small Grass Seeds Box Sprocket Configuration

Great Plains Mfg., Inc.

21758

151-118M 8/2/2005

Page 23

Great Plains Mfg., Inc.

133-251A 706-7 Seed to SGS in row delivery

Your kit includes:

Qty. Part No. Part Description

1 119-306L 706 SEED & SGS WALKBOARD A

1 133-227L 706-7" SGS BOX ASSY

1 133-243L 706 SGS DRIVE BUNDLE

11 133-249L SGS OPENER IN-ROW BUNDLE

1 151-118M MANUAL 706/1006 OPTION INS

133-252A 706-7 Seed to SGS side delivery

Your kit includes:

Qty. Part No. Part Description

Installation Instructions

23

1 119-306L 706 SEED & SGS WALKBOARD A

1 133-227L 706-7" SGS BOX ASSY

1 133-243L 706 SGS DRIVE BUNDLE

11 133-250L SGS OPENER SIDE DELIVERY B

1 151-118M MANUAL 706/1006 OPTION INS

133-253A 706-7 1/2 & 8 Seed to SGS in row delivery

Your kit includes:

Qty. Part No. Part Description

1 119-306L 706 SEED & SGS WALKBOARD A

1 133-228L 706-7 1/2-8" SGS BOX ASSY

1 133-243L 706 SGS DRIVE BUNDLE

10 133-249L SGS OPENER IN-ROW BUNDLE

1 151-118M MANUAL 706/1006 OPTION INS

133-254A 706-7 1/2 & 8 Seed to SGS side delivery

Your kit includes:

Qty. Part No. Part Description

1 119-306L 706 SEED & SGS WALKBOARD A

1 133-228L 706-7 1/2-8" SGS BOX ASSY

1 133-243L 706 SGS DRIVE BUNDLE

10 133-250L SGS OPENER SIDE DELIVERY B

1 151-118M MANUAL 706/1006 OPTION INS

151-118M8/2/2005

Page 24

Option Installation

24

133-255A 1006-7 Seed to SGS in row delivery

Your kit includes:

Qty. Part No. Part Description

1 119-307L 1006 SEED & SGS WALKBOARD

1 133-229L 1006-7" SGS BOX ASSY

1 133-246L 1006 SGS DRIVE BUNDLE

16 133-249L SGS OPENER IN-ROW BUNDLE

1 151-118M MANUAL 706/1006 OPTION INS

133-256A 1006-7 Seed to SGS side delivery

Your kit includes:

Qty. Part No. Part Description

Great Plains Mfg., Inc.

1 119-307L 1006 SEED & SGS WALKBOARD

1 133-229L 1006-7" SGS BOX ASSY

1 133-246L 1006 SGS DRIVE BUNDLE

16 133-250L SGS OPENER SIDE DELIVERY B

1 151-118M MANUAL 706/1006 OPTION INS

133-257A 1006-7 1/2 Seed to SGS in row delivery

Your kit includes:

Qty. Part No. Part Description

1 119-307L 1006 SEED & SGS WALKBOARD

1 133-230L 1006-7 1/2" SGS BOX ASSY

1 133-246L 1006 SGS DRIVE BUNDLE

15 133-249L SGS OPENER IN-ROW BUNDLE

1 151-118M MANUAL 706/1006 OPTION INS

133-258A 1006-7 1/2 Seed to SGS side delivery

Your kit includes:

Qty. Part No. Part Description

1 119-307L 1006 SEED & SGS WALKBOARD

1 133-230L 1006-7 1/2" SGS BOX ASSY

1 133-246L 1006 SGS DRIVE BUNDLE

15 133-250L SGS OPENER SIDE DELIVERY B

1 151-118M MANUAL 706/1006 OPTION INS

151-118M 8/2/2005

Page 25

Great Plains Mfg., Inc.

133-259A 1006-8 Seed to SGS in row delivery

Your kit includes:

Qty. Part No. Part Description

1 119-307L 1006 SEED & SGS WALKBOARD

1 133-231L 1006-8" SGS BOX ASSY

1 133-246L 1006 SGS DRIVE BUNDLE

14 133-249L SGS OPENER IN-ROW BUNDLE

1 151-118M MANUAL 706/1006 OPTION INS

133-260A 1006-8 Seed to SGS side delivery

Your kit includes:

Qty. Part No. Part Description

Installation Instructions

25

1 119-307L 1006 SEED & SGS WALKBOARD

1 133-231L 1006-8" SGS BOX ASSY

1 133-246L 1006 SGS DRIVE BUNDLE

14 133-250L SGS OPENER SIDE DELIVERY B

1 151-118M MANUAL 706/1006 OPTION INS

133-261A 706-7 NG to SGS in row delivery

Your kit includes:

Qty. Part No. Part Description

1 133-227L 706-7" SGS BOX ASSY

1 133-245L 706 NG/SGS DRIVE BUNDLE

11 133-249L SGS OPENER IN-ROW BUNDLE

1 151-101H LH NG & SGS WALKBOARD MOUN

1 151-102H RH NG & SGS WALKBOARD MOUN

2 151-103H NG & SGS HARROW MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

133-262A 706-7 NG to SGS side delivery

Your kit includes:

Qty. Part No. Part Description

1 133-227L 706-7" SGS BOX ASSY

1 133-245L 706 NG/SGS DRIVE BUNDLE

11 133-250L SGS OPENER SIDE DELIVERY B

1 151-101H LH NG & SGS WALKBOARD MOUN

1 151-102H RH NG & SGS WALKBOARD MOUN

2 151-103H NG & SGS HARROW MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

8/2/2005

151-118M

Page 26

Option Installation

26

133-263A 706-7 1/2 & 8 NG to SGS in row delivery

Your kit includes:

Qty. Part No. Part Description

1 133-228L 706-7 1/2-8" SGS BOX ASSY

1 133-245L 706 NG/SGS DRIVE BUNDLE

10 133-249L SGS OPENER IN-ROW BUNDLE

1 151-101H LH NG & SGS WALKBOARD MOUN

1 151-102H RH NG & SGS WALKBOARD MOUN

2 151-103H NG & SGS HARROW MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

133-264A 706-7 1/2 & 8 NG to SGS side delivery

Your kit includes:

Qty. Part No. Part Description

Great Plains Mfg., Inc.

1 133-228L 706-7 1/2-8" SGS BOX ASSY

1 133-245L 706 NG/SGS DRIVE BUNDLE

10 133-250L SGS OPENER SIDE DELIVERY B

1 151-101H LH NG & SGS WALKBOARD MOUN

1 151-102H RH NG & SGS WALKBOARD MOUN

2 151-103H NG & SGS HARROW MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

133-265A 1006-7 NG to SGS in row delivery

Your kit includes:

Qty. Part No. Part Description

1 133-229L 1006-7" SGS BOX ASSY

1 133-248L 1006 NG/SGS DRIVE BUNDLE

16 133-249L SGS OPENER IN-ROW BUNDLE

1 151-101H LH NG & SGS WALKBOARD MOUN

1 151-102H RH NG & SGS WALKBOARD MOUN

2 151-103H NG & SGS HARROW MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

133-266A 1006-7 NG to SGS side delivery

Your kit includes:

Qty. Part No. Part Description

1 133-229L 1006-7" SGS BOX ASSY

1 133-248L 1006 NG/SGS DRIVE BUNDLE

16 133-250L SGS OPENER SIDE DELIVERY B

1 151-101H LH NG & SGS WALKBOARD MOUN

1 151-102H RH NG & SGS WALKBOARD MOUN

2 151-103H NG & SGS HARROW MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

151-118M 8/2/2005

Page 27

Great Plains Mfg., Inc.

133-267A 1006-7 1/2 NG to SGS in row delivery

Your kit includes:

Qty. Part No. Part Description

1 133-230L 1006-7 1/2" SGS BOX ASSY

1 133-248L 1006 NG/SGS DRIVE BUNDLE

15 133-249L SGS OPENER IN-ROW BUNDLE

1 151-101H LH NG & SGS WALKBOARD MOUN

1 151-102H RH NG & SGS WALKBOARD MOUN

2 151-103H NG & SGS HARROW MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

133-268A 1006-7 1/2 NG to SGS side delivery

Your kit includes:

Qty. Part No. Part Description

Installation Instructions

27

1 133-230L 1006-7 1/2" SGS BOX ASSY

1 133-248L 1006 NG/SGS DRIVE BUNDLE

15 133-250L SGS OPENER SIDE DELIVERY B

1 151-101H LH NG & SGS WALKBOARD MOUN

1 151-102H RH NG & SGS WALKBOARD MOUN

2 151-103H NG & SGS HARROW MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

133-269A 1006-8 NG to SGS in row delivery

Your kit includes:

Qty. Part No. Part Description

1 133-231L 1006-8" SGS BOX ASSY

1 133-248L 1006 NG/SGS DRIVE BUNDLE

14 133-249L SGS OPENER IN-ROW BUNDLE

1 151-101H LH NG & SGS WALKBOARD MOUN

1 151-102H RH NG & SGS WALKBOARD MOUN

2 151-103H NG & SGS HARROW MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

133-270A 1006-8 NG to SGS side delivery

Your kit includes:

Qty. Part No. Part Description

1 133-231L 1006-8" SGS BOX ASSY

1 133-248L 1006 NG/SGS DRIVE BUNDLE

14 133-250L SGS OPENER SIDE DELIVERY B

1 151-101H LH NG & SGS WALKBOARD MOUN

1 151-102H RH NG & SGS WALKBOARD MOUN

2 151-103H NG & SGS HARROW MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

8/2/2005

151-118M

Page 28

Option Installation

28

133-271A 706-7 Fert. to SGS in row delivery

Your kit includes:

Qty. Part No. Part Description

1 133-227L 706-7" SGS BOX ASSY

1 133-244L 706 FERT/SGS DRIVE BUNDLE

11 133-249L SGS OPENER IN-ROW BUNDLE

1 151-104H LH FERT & SGS WALKBOARD MO

1 151-105H RH FERT & SGS WALKBOARD MO

2 151-106H FERT & SGS HARROW MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

133-272A 706-7 Fert. to SGS side delivery

Your kit includes:

Qty. Part No. Part Description

Great Plains Mfg., Inc.

1 133-227L 706-7" SGS BOX ASSY

1 133-244L 706 FERT/SGS DRIVE BUNDLE

11 133-250L SGS OPENER SIDE DELIVERY B

1 151-104H LH FERT & SGS WALKBOARD MO

1 151-105H RH FERT & SGS WALKBOARD MO

2 151-106H FERT & SGS HARROW MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

133-273A 706-7 1/2 & 8 Fert. to SGS in row delivery

Your kit includes:

Qty. Part No. Part Description

1 133-228L 706-7 1/2-8" SGS BOX ASSY

1 133-244L 706 FERT/SGS DRIVE BUNDLE

10 133-249L SGS OPENER IN-ROW BUNDLE

1 151-104H LH FERT & SGS WALKBOARD MO

1 151-105H RH FERT & SGS WALKBOARD MO

2 151-106H FERT & SGS HARROW MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

133-274A 706-7 1/2 & 8 Fert. to SGS side delivery

Your kit includes:

Qty. Part No. Part Description

1 133-228L 706-7 1/2-8" SGS BOX ASSY

1 133-244L 706 FERT/SGS DRIVE BUNDLE

10 133-250L SGS OPENER SIDE DELIVERY B

1 151-104H LH FERT & SGS WALKBOARD MO

1 151-105H RH FERT & SGS WALKBOARD MO

2 151-106H FERT & SGS HARROW MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

151-118M 8/2/2005

Page 29

Great Plains Mfg., Inc.

133-275A 1006-7 Fert. to SGS in row delivery

Your kit includes:

Qty. Part No. Part Description

1 133-229L 1006-7" SGS BOX ASSY

1 133-247L 1006 FERT/SGS DRIVE BUNDLE

16 133-249L SGS OPENER IN-ROW BUNDLE

1 151-104H LH FERT & SGS WALKBOARD MO

1 151-105H RH FERT & SGS WALKBOARD MO

2 151-106H FERT & SGS HARROW MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

133-276A 1006-7 Fert. to SGS side delivery

Your kit includes:

Qty. Part No. Part Description

Installation Instructions

29

1 133-229L 1006-7" SGS BOX ASSY

1 133-247L 1006 FERT/SGS DRIVE BUNDLE

16 133-250L SGS OPENER SIDE DELIVERY B

1 151-104H LH FERT & SGS WALKBOARD MO

1 151-105H RH FERT & SGS WALKBOARD MO

2 151-106H FERT & SGS HARROW MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

133-277A 1006-7 1/2 Fert. to SGS in row delivery

Your kit includes:

Qty. Part No. Part Description

1 133-230L 1006-7 1/2" SGS BOX ASSY

1 133-247L 1006 FERT/SGS DRIVE BUNDLE

15 133-249L SGS OPENER IN-ROW BUNDLE

1 151-104H LH FERT & SGS WALKBOARD MO

1 151-105H RH FERT & SGS WALKBOARD MO

2 151-106H FERT & SGS HARROW MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

133-278A 1006-7 1/2 Fert. to SGS side delivery

Your kit includes:

Qty. Part No. Part Description

1 133-230L 1006-7 1/2" SGS BOX ASSY

1 133-247L 1006 FERT/SGS DRIVE BUNDLE

15 133-250L SGS OPENER SIDE DELIVERY B

1 151-104H LH FERT & SGS WALKBOARD MO

1 151-105H RH FERT & SGS WALKBOARD MO

2 151-106H FERT & SGS HARROW MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

8/2/2005

151-118M

Page 30

Option Installation

30

133-279A 1006-8 Fert. to SGS in row delivery

Your kit includes:

Qty. Part No. Part Description

1 133-231L 1006-8" SGS BOX ASSY

1 133-247L 1006 FERT/SGS DRIVE BUNDLE

14 133-249L SGS OPENER IN-ROW BUNDLE

1 151-104H LH FERT & SGS WALKBOARD MO

1 151-105H RH FERT & SGS WALKBOARD MO

2 151-106H FERT & SGS HARROW MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

133-280A Fert. to SGS side delivery

Your kit includes:

Qty. Part No. Part Description

1 133-231L 1006-8" SGS BOX ASSY

1 133-247L 1006 FERT/SGS DRIVE BUNDLE

14 133-250L SGS OPENER SIDE DELIVERY B

1 151-104H LH FERT & SGS WALKBOARD MO

1 151-105H RH FERT & SGS WALKBOARD MO

2 151-106H FERT & SGS HARROW MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

Great Plains Mfg., Inc.

142-920A 706-7 Seed to Fert.

Your kit includes:

Qty. Part No. Part Description

1 119-294D 706 WALKBOARD

1 142-706H FERTILIZER WALKBOARD END R

2 142-707H FERTILIZER HARROW SUPPORT

10 142-909L FERTILIZER OPENER BUNDLE

1 142-911L 706-7 1/2 & 8" TRAY ASSEMB

1 142-915L 706 FERTILIZER BOX ASSEMBL

1 142-917L 706 FERTILIZER DRIVE ASSEM

1 142-919L FERTILIZER MOUNTING HARDWA

1 151-099H LH FERT. WALKBOARD MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

142-921A 706-7 1/2 & 8 Seed to Fert.

Your kit includes:

Qty. Part No. Part Description

1 119-294D 706 WALKBOARD

1 142-706H FERTILIZER WALKBOARD END R

2 142-707H FERTILIZER HARROW SUPPORT

11 142-909L FERTILIZER OPENER BUNDLE

1 142-910L 706-7" TRAY ASSEMBLY

1 142-915L 706 FERTILIZER BOX ASSEMBL

1 142-917L 706 FERTILIZER DRIVE ASSEM

1 142-919L FERTILIZER MOUNTING HARDWA

1 151-099H LH FERT. WALKBOARD MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

151-118M 8/2/2005

Page 31

Great Plains Mfg., Inc.

142-922A 1006-7 Seed to Fert.

Your kit includes:

Qty. Part No. Part Description

1 119-296D 1006 WALKBOARD

1 142-706H FERTILIZER WALKBOARD END R

2 142-707H FERTILIZER HARROW SUPPORT

16 142-909L FERTILIZER OPENER BUNDLE

1 142-912L 1006-7" TRAY ASSEMBLY

1 142-916L 1006 FERTILIZER BOX ASSEMB

1 142-918L 1006 FERTILIZER DRIVE ASSE

1 142-919L FERTILIZER MOUNTING HARDWA

1 151-099H LH FERT. WALKBOARD MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

142-923A 1006-7 1/2 Seed to Fert.

Your kit includes:

Installation Instructions

31

Qty. Part No. Part Description

1 119-296D 1006 WALKBOARD

1 142-706H FERTILIZER WALKBOARD END R

2 142-707H FERTILIZER HARROW SUPPORT

15 142-909L FERTILIZER OPENER BUNDLE

1 142-913L 1006-7 1/2" TRAY ASSEMBLY

1 142-916L 1006 FERTILIZER BOX ASSEMB

1 142-918L 1006 FERTILIZER DRIVE ASSE

1 142-919L FERTILIZER MOUNTING HARDWA

1 151-099H LH FERT. WALKBOARD MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

142-924A 1006-8 Seed to Fert.

Your kit includes:

Qty. Part No. Part Description

1 119-296D 1006 WALKBOARD

1 142-706H FERTILIZER WALKBOARD END R

2 142-707H FERTILIZER HARROW SUPPORT

14 142-909L FERTILIZER OPENER BUNDLE

1 142-913L 1006-7 1/2" TRAY ASSEMBLY

1 142-916L 1006 FERTILIZER BOX ASSEMB

1 142-918L 1006 FERTILIZER DRIVE ASSE

1 142-919L FERTILIZER MOUNTING HARDWA

1 151-099H LH FERT. WALKBOARD MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

8/2/2005

151-118M

Page 32

Option Installation

32

142-925A 706-7 Seed & SGS to Fert.

Your kit includes:

Qty. Part No. Part Description

1 133-051H SLOTTED IDLER ARM 1/2 X 3 5/8

1 136-014D CHAIN RL #40 79 PITCHES

11 142-909L FERTILIZER OPENER BUNDLE

1 142-910L 706-7" TRAY ASSEMBLY

1 142-915L 706 FERTILIZER BOX ASSEMBLY

1 142-917L 706 FERTILIZER DRIVE ASSEMBLY

1 142-919L FERTILIZER MOUNTING HARDWARE

1 151-104H LH FERT & SGS WALKBOARD MOUNT

1 151-105H RH FERT & SGS WALKBOARD MOUNT

2 151-106H FERT & SGS HARROW MOUNT

1 168-127D 3/16 X 1 KEY

1 808-170C SPKT 40B17 X 3/4 BORE W/KW&SS

1 817-025C NO. 40 12T IDLER SPKT.

1 151-118M MANUAL 706/1006 OPTION INSTALLATION

142-926A 706-7 1/2 & 8 Seed &SGS to Fert.

Your kit includes:

Great Plains Mfg., Inc.

Qty. Part No. Part Description

1 133-051H SLOTTED IDLER ARM 1/2 X 3 5/8

1 136-014D CHAIN RL #40 79 PITCHES

10 142-909L FERTILIZER OPENER BUNDLE

1 142-911L 706-7 1/2 & 8" TRAY ASSEMBLY

1 142-915L 706 FERTILIZER BOX ASSEMBLY

1 142-917L 706 FERTILIZER DRIVE ASSEMBLY

1 142-919L FERTILIZER MOUNTING HARDWARE

1 151-104H LH FERT & SGS WALKBOARD MOUNT

1 151-105H RH FERT & SGS WALKBOARD MOUNT

2 151-106H FERT & SGS HARROW MOUNT

1 168-127D 3/16 X 1 KEY

1 808-170C SPKT 40B17 X 3/4 BORE W/KW&SS

1 817-025C NO. 40 12T IDLER SPKT.

1 151-118M MANUAL 706/1006 OPTION INSTALLATION

142-927A 1006-7 Seed & SGS to Fert.

Your kit includes:

Qty. Part No. Part Description

1 133-051H SLOTTED IDLER ARM 1/2 X 3 5/8

1 136-014D CHAIN RL #40 79 PITCHES

16 142-909L FERTILIZER OPENER BUNDLE

1 142-912L 1006-7" TRAY ASSEMBLY

1 142-916L 1006 FERTILIZER BOX ASSEMBLY

1 142-918L 1006 FERTILIZER DRIVE ASSEMBLY

1 142-919L FERTILIZER MOUNTING HARDWARE

1 151-104H LH FERT & SGS WALKBOARD MOUNT

1 151-105H RH FERT & SGS WALKBOARD MOUNT

2 151-106H FERT & SGS HARROW MOUNT

1 168-127D 3/16 X 1 KEY

1 808-170C SPKT 40B17 X 3/4 BORE W/KW&SS

1 817-025C NO. 40 12T IDLER SPKT.

1 151-118M MANUAL 706/1006 OPTION INSTALLATION

151-118M 8/2/2005

Page 33

Great Plains Mfg., Inc.

142-928A 1006-7 1/2 Seed & SGS to Fert.

Your kit includes:

Qty. Part No. Part Description

1 133-051H SLOTTED IDLER ARM 1/2 X 3 5/8

1 136-014D CHAIN RL #40 79 PITCHES

15 142-909L FERTILIZER OPENER BUNDLE

1 142-913L 1006-7 1/2" TRAY ASSEMBLY

1 142-916L 1006 FERTILIZER BOX ASSEMBLY

1 142-918L 1006 FERTILIZER DRIVE ASSEMBLY

1 142-919L FERTILIZER MOUNTING HARDWARE

1 151-104H LH FERT & SGS WALKBOARD MOUNT

1 151-105H RH FERT & SGS WALKBOARD MOUNT

2 151-106H FERT & SGS HARROW MOUNT

1 168-127D 3/16 X 1 KEY

1 808-170C SPKT 40B17 X 3/4 BORE W/KW&SS

1 817-025C NO. 40 12T IDLER SPKT.

1 151-118M MANUAL 706/1006 OPTION INSTALLATION

142-929A 1006-8 Seed & SGS to Fert.

Your kit includes:

Installation Instructions

33

Qty. Part No. Part Description

1 133-051H SLOTTED IDLER ARM 1/2 X 3 5/8

1 136-014D CHAIN RL #40 79 PITCHES

14 142-909L FERTILIZER OPENER BUNDLE

1 142-914L 1006-8" TRAY ASSEMBLY

1 142-916L 1006 FERTILIZER BOX ASSEMBLY

1 142-918L 1006 FERTILIZER DRIVE ASSEMBLY

1 142-919L FERTILIZER MOUNTING HARDWARE

1 151-104H LH FERT & SGS WALKBOARD MOUNT

1 151-105H RH FERT & SGS WALKBOARD MOUNT

2 151-106H FERT & SGS HARROW MOUNT

1 168-127D 3/16 X 1 KEY

1 808-170C SPKT 40B17 X 3/4 BORE W/KW&SS

1 817-025C NO. 40 12T IDLER SPKT.

1 151-118M MANUAL 706/1006 OPTION INSTALLATION

142-930A 706-7 Seed to Fert. & SGS

Your kit includes:

Qty. Part No. Part Description

1 119-310L 706 FERTILIZER & SGS WB ASSEMBLY

1 133-227L 706 -7" SGS BOX ASSY

1 133-244L 706 FERT/SGS DRIVE BUNDLE

11 133-249L SGS OPENER IN ROW BUNDLE

11 142-909L FERTILIZER OPENER BUNDLE

1 142-910L 706-7" TRAY ASSEMBLY

1 142-915L 706 FERTILIZER BOX ASSEMBLY

1 142-917L 706 FERTILIZER DRIVE ASSEMBLY

1 142-919L FERTILIZER MOUNTING HARDWARE

1 151-118M MANUAL 706/1006 OPTION INSTALLATION

8/2/2005

151-118M

Page 34

Option Installation

34

142-931A 706-7 1/2 & 8 Seed to Fert. & SGS

Your kit includes:

Qty. Part No. Part Description

1 119-310L 706 FERTILIZER & SGS WB ASSEMBLY

1 133-228L 706-7 1/2 & 8" SGS BOX ASSY

1 133-244L 706 FERT/SGS DRIVE BUNDLE

10 133-249L SGS OPENER IN ROW BUNDLE

10 142-909L FERTILIZER OPENER BUNDLE

1 142-911L 706-7 1/2 & 8" TRAY ASSEMBLY

1 142-915L 706 FERTILIZER BOX ASSEMBLY

1 142-917L 706 FERTILIZER DRIVE ASSEMBLY

1 142-919L FERTILIZER MOUNTING HARDWARE

1 151-118M MANUAL 706/1006 OPTION INSTALLATION

142-932A 1006-7 Seed to Fert. & SGS

Your kit includes:

Great Plains Mfg., Inc.

Qty. Part No. Part Description

1 119-311L 1006 FERTILIZER & SGS WB ASSEMBLY

1 133-229L 1006-7" SGS BOX ASSY

1 133-247L 1006 FERT/SGS DRIVE BUNDLE

16 133-249L SGS OPENER IN ROW BUNDLE

16 142-909L FERTILIZER OPENER BUNDLE

1 142-912L 1006-7" TRAY ASSEMBLY

1 142-916L 1006 FERTILIZER BOX ASSEMBLY

1 142-918L 1006 FERTILIZER DRIVE ASSEMBLY

1 142-919L FERTILIZER MOUNTING HARDWARE

1 151-118M MANUAL 706/1006 OPTION INSTALLATION

142-933A 1006-7 1/2 Seed to Fert. & SGS

Your kit includes:

Qty. Part No. Part Description

1 119-311L 1006 FERTILIZER & SGS WB ASSEMBLY

1 133-230L 1006-7 1/2" SGS BOX ASSY

1 133-247L 1006 FERT/SGS DRIVE BUNDLE

15 133-249L SGS OPENER IN ROW BUNDLE

15 142-909L FERTILIZER OPENER BUNDLE

1 142-913L 1006-7 1/2" TRAY ASSEMBLY

1 142-916L 1006 FERTILIZER BOX ASSEMBLY

1 142-918L 1006 FERTILIZER DRIVE ASSEMBLY

1 142-919L FERTILIZER MOUNTING HARDWARE

1 151-118M MANUAL 706/1006 OPTION INSTALLATION

151-118M 8/2/2005

Page 35

Great Plains Mfg., Inc.

142-934A 1006-8 Seed to Fert. & SGS

Your kit includes:

Qty. Part No. Part Description

1 119-311L 1006 FERTILIZER & SGS WB ASSEMBLY

1 133-231L 1006-8" SGS BOX ASSEMBLY

1 133-247L 1006 FERT/SGS DRIVE BUNDLE

14 133-249L SGS OPENER IN ROW BUNDLE

14 142-909L FERTILIZER OPENER BUNDLE

1 142-913L 1006-7 1/2" TRAY ASSEMBLY

1 142-916L 1006 FERTILIZER BOX ASSEMBLY

1 142-918L 1006 FERTILIZER DRIVE ASSEMBLY

1 142-919L FERTILIZER MOUNTING HARDWARE

1 151-118M MANUAL 706/1006 OPTION INSTALLATION

202-546A 706-7 Seed to NG

Your kit includes:

Installation Instructions

35

Qty. Part No. Part Description

1 119-294D 706 WALKBOARD

1 142-703H 05 FERT/SGS; 06 NG WB END

2 142-704H FERT & SGS HARROW SUPPORT

1 151-100H LH NG WALKBOARD MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

1 202-519L 706-7" NG BOX & TRAY ASSY

1 202-542K 706/1006 NG RH GW ASSEMBLY

1 202-543K NG GW DRIVE BUNDLE

1 202-544L NG DRIVE BUNDLE

11 202-545L NG OPENER BUNDLE

1 821-042C POWDERED GRAPHITE 1 LB BOT

1 890-807C ACREMETER 706 600 REVS

202-547A 706-7 1/2 & 8 Seed to NG

Your kit includes:

Qty. Part No. Part Description

1 119-294D 706 WALKBOARD

1 142-703H 05 FERT/SGS; 06 NG WB END

2 142-704H FERT & SGS HARROW SUPPORT

1 151-100H LH NG WALKBOARD MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

1 202-520L 706-7 1/2&8" BOX & TRAY AS

1 202-542K 706/1006 NG RH GW ASSEMBLY

1 202-543K NG GW DRIVE BUNDLE

1 202-544L NG DRIVE BUNDLE

10 202-545L NG OPENER BUNDLE

1 821-042C POWDERED GRAPHITE 1 LB BOT

1 890-807C ACREMETER 706 600 REVS

8/2/2005

151-118M

Page 36

Option Installation

36

202-548A 1006-7 Seed to NG

Your kit includes:

Qty. Part No. Part Description

1 119-296D 1006 WALKBOARD

1 142-703H 05 FERT/SGS; 06 NG WB END

2 142-704H FERT & SGS HARROW SUPPORT

1 151-100H LH NG WALKBOARD MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

1 202-521L 1006-7" BOX & TRAY ASSY

1 202-543K NG GW DRIVE BUNDLE

1 202-544L NG DRIVE BUNDLE

16 202-545L NG OPENER BUNDLE

1 821-042C POWDERED GRAPHITE 1 LB BOT

1 890-808C ACREMETER 1006 416 REVS

Great Plains Mfg., Inc.

202-549A 1006-7 1/2 Seed to NG

Your kit includes:

Qty. Part No. Part Description

1 119-296D 1006 WALKBOARD

1 142-703H 05 FERT/SGS; 06 NG WB END

2 142-704H FERT & SGS HARROW SUPPORT

1 151-100H LH NG WALKBOARD MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

1 202-522L 1006-7 1/2" BOX & TRAY ASS

1 202-543K NG GW DRIVE BUNDLE

1 202-544L NG DRIVE BUNDLE

15 202-545L NG OPENER BUNDLE

1 821-042C POWDERED GRAPHITE 1 LB BOT

1 890-808C ACREMETER 1006 416 REVS

202-550A 1006-8 Seed to NG

Your kit includes:

Qty. Part No. Part Description

1 119-296D 1006 WALKBOARD

1 142-703H 05 FERT/SGS; 06 NG WB END

2 142-704H FERT & SGS HARROW SUPPORT

1 151-100H LH NG WALKBOARD MOUNT

1 151-118M MANUAL 706/1006 OPTION INS

1 202-523L 1006-8" BOX & TRAY ASSY

1 202-543K NG GW DRIVE BUNDLE

1 202-544L NG DRIVE BUNDLE

14 202-545L NG OPENER BUNDLE

1 821-042C POWDERED GRAPHITE 1 LB BOT

1 890-808C ACREMETER 1006 416 REVS

151-118M 8/2/2005

Page 37

Great Plains Mfg., Inc.

202-563A 706-7 Seed & SGS to NG

Your kit includes:

Qty. Part No. Part Description

1 136-128D CHAIN RL #40 190 PITCHES

1 151-101H LH NG & SGS WALKBOARD MOUNT

1 151-102H RH NG & SGS WALKBOARD MOUNT

2 151-103H NG & SGS HARROW MOUNT

1 202-519L 706-7" NG BOX & TRAY ASSY

1 202-543K NG GW DRIVE BUNDLE

1 202-544L NG DRIVE BUNDLE

11 202-545L NG OPENER BUNDLE

1 821-042C POWDERED GRAPHITE 1 LB BOTTLE

1 890-807C ACREMETER 706 600 REVS

1 151-118M MANUAL 706/1006 OPTION INS

202-564A 706-7 1/2 & 8 Seed & SGS to NG

Your kit includes:

Installation Instructions

37

Qty. Part No. Part Description

1 136-128D CHAIN RL #40 190 PITCHES

1 151-101H LH NG & SGS WALKBOARD MOUNT

1 151-102H RH NG & SGS WALKBOARD MOUNT

2 151-103H NG & SGS HARROW MOUNT

1 202-520L 706-7 1/2 & 8" BOX & TRAY ASSY

1 202-543K NG GW DRIVE BUNDLE

1 202-544L NG DRIVE BUNDLE

10 202-545L NG OPENER BUNDLE

1 821-042C POWDERED GRAPHITE 1 LB BOTTLE

1 890-807C ACREMETER 706 600 REVS

1 151-118M MANUAL 706/1006 OPTION INS

202-565A 1006-7 Seed & SGS to NG

Your kit includes:

Qty. Part No. Part Description

1 136-128D CHAIN RL #40 190 PITCHES

1 151-101H LH NG & SGS WALKBOARD MOUNT

1 151-102H RH NG & SGS WALKBOARD MOUNT

2 151-103H NG & SGS HARROW MOUNT

1 202-521L 1006-7" BOX & TRAY ASSY

1 202-543K NG GW DRIVE BUNDLE

1 202-544L NG DRIVE BUNDLE

16 202-545L NG OPENER BUNDLE

1 821-042C POWDERED GRAPHITE 1 LB BOTTLE

1 890-808C ACREMETER 1006 416 REVS

1 151-118M MANUAL 706/1006 OPTION INS

8/2/2005

151-118M

Page 38

Option Installation

38

202-566A 1006-7 1/2 Seed & SGS to NG

Your kit includes:

Qty. Part No. Part Description

1 136-128D CHAIN RL #40 190 PITCHES

1 151-101H LH NG & SGS WALKBOARD MOUNT

1 151-102H RH NG & SGS WALKBOARD MOUNT

2 151-103H NG & SGS HARROW MOUNT

1 202-522L 1006-7 1/2" BOX & TRAY ASSY

1 202-543K NG GW DRIVE BUNDLE

1 202-544L NG DRIVE BUNDLE

15 202-545L NG OPENER BUNDLE

1 821-042C POWDERED GRAPHITE 1 LB BOTTLE

1 890-808C ACREMETER 1006 416 REVS

1 151-118M MANUAL 706/1006 OPTION INS

202-567A 1006-8 Seed & SGS to NG

Your kit includes:

Great Plains Mfg., Inc.

Qty. Part No. Part Description

1 136-128D CHAIN RL #40 190 PITCHES

1 151-101H LH NG & SGS WALKBOARD MOUNT

1 151-102H RH NG & SGS WALKBOARD MOUNT

2 151-103H NG & SGS HARROW MOUNT

1 202-523L 1006-8" BOX & TRAY ASSY

1 202-543K NG GW DRIVE BUNDLE

1 202-544L NG DRIVE BUNDLE

14 202-545L NG OPENER BUNDLE

1 821-042C POWDERED GRAPHITE 1 LB BOTTLE

1 890-808C ACREMETER 1006 416 REVS

1 151-118M MANUAL 706/1006 OPTION INS

202-569A 706-7 Seed to NG & SGS

Your kit includes:

Qty. Part No. Part Description

1 119-314L 706 NG & SGS WALKBOARD ASSY

1 133-227L 706-7" SGS BOX ASSY

1 133-245L 706 NG/SGS DRIVE BUNDLE

11 133-249L SGS OPENER IN ROW BUNDLE

1 202-519L 706-7" NG BOX & TRAY ASSY

1 202-544L NG DRIVE BUNDLE

11 202-545L NG OPENER BUNDLE

1 202-568K NG FIELD GW KIT

1 821-042C POWDERED GRAPHITE 1 LB BOTTLE

1 890-807C ACREMETER 706 600 REVS

1 151-118M MANUAL 706/1006 OPTION INS

151-118M 8/2/2005

Page 39

Great Plains Mfg., Inc.

202-570A 706-7 1/2 & 8 Seed to NG & SGS

Your kit includes:

Qty. Part No. Part Description

1 119-314L 706 NG & SGS WALKBOARD ASSY

1 133-228L 706 7 1/2 & 8" SGS BOX ASSY

1 133-245L 706 NG/SGS DRIVE BUNDLE

10 133-249L SGS OPENER IN ROW BUNDLE

1 202-520L 706 - 7 1/2 & 8" BOX & TRAY ASSY

1 202-544L NG DRIVE BUNDLE

10 202-545L NG OPENER BUNDLE

1 202-568K NG FIELD GW KIT

1 821-042C POWDERED GRAPHITE 1 LB BOTTLE

1 890-807C ACREMETER 706 600 REVS

1 151-118M MANUAL 706/1006 OPTION INS

202-571A 1006-7 Seed to NG & SGS

Your kit includes:

Installation Instructions

39

Qty. Part No. Part Description

1 119-315L 1006 NG & SGS WALKBOARD ASSY

1 133-229L 1006-7" SGS BOX ASSY

1 133-248L 1006 NG/SGS DRIVE BUNDLE

16 133-249L SGS OPENER IN ROW BUNDLE

1 202-521L 1006-7" BOX & TRAY ASSY

1 202-544L NG DRIVE BUNDLE

16 202-545L NG OPENER BUNDLE

1 202-568K NG FIELD GW KIT

1 821-042C POWDERED GRAPHITE 1 LB BOTTLE

1 890-808C ACREMETER 1006 416 REVS

1 151-118M MANUAL 706/1006 OPTION INS

202-572A 1006-7 1/2 Seed to NG & SGS

Your kit includes:

Qty. Part No. Part Description

1 119-315L 1006 NG & SGS WALKBOARD ASSY

1 133-230L 1006-7 1/2" SGS BOX ASSY

1 133-248L 1006 NG/SGS DRIVE BUNDLE

15 133-249L SGS OPENER IN ROW BUNDLE

1 202-522L 1006-7 1/2" BOX & TRAY ASSY

1 202-544L NG DRIVE BUNDLE

15 202-545L NG OPENER BUNDLE

1 202-568K NG FIELD GW KIT

1 821-042C POWDERED GRAPHITE 1 LB BOTTLE

1 890-808C ACREMETER 1006 416 REVS

1 151-118M MANUAL 706/1006 OPTION INS

8/2/2005

151-118M

Page 40

Option Installation

40

202-573A 1006-8 Seed to NG & SGS

Your kit includes:

Qty. Part No. Part Description

1 119-315L 1006 NG & SGS WALKBOARD ASSY

1 133-231L 1006-8" SGS BOX ASSY

1 133-248L 1006 NG/SGS DRIVE BUNDLE

14 133-249L SGS OPENER IN ROW BUNDLE

1 202-523L 1006-8" BOX & TRAY ASSY

1 202-544L NG DRIVE BUNDLE

14 202-545L NG OPENER BUNDLE

1 202-568K NG FIELD GW KIT

1 821-042C POWDERED GRAPHITE 1 LB BOTTLE

1 890-808C ACREMETER 1006 416 REVS

1 151-118M MANUAL 706/1006 OPTION INS

Great Plains Mfg., Inc.

151-118M 8/2/2005

Loading...

Loading...