Page 1

Great Plains Mfg., Inc.

Installation Instructions

705/1005 End Wheel No-Till Drill

Calibration Kit

Used with:

• 705 End Wheel No-Till Drill

• 1005 End Wheel No-Till Drill

General Information

When you see this symbol, the subsequent instructions and

warnings are serious - follow without exception. Your life and

!

!

the lives of others depend on it!

These instructions explain how to install the Calibration Kit Option.

These instructions apply to:

152-289A 705 Calibration Kit

152-290A 1005 Calibration Kit

Manual Update

Refer to the 705/1005 End Wheel No-Till Drill operator’s manual for detailed information on safely

operating, adjusting, troubleshooting and maintaining the calibration kit. Refer to the parts

manual for part identification.

150-213M Operator’s Manual

150-213P Parts Manual

Assembly Instructions

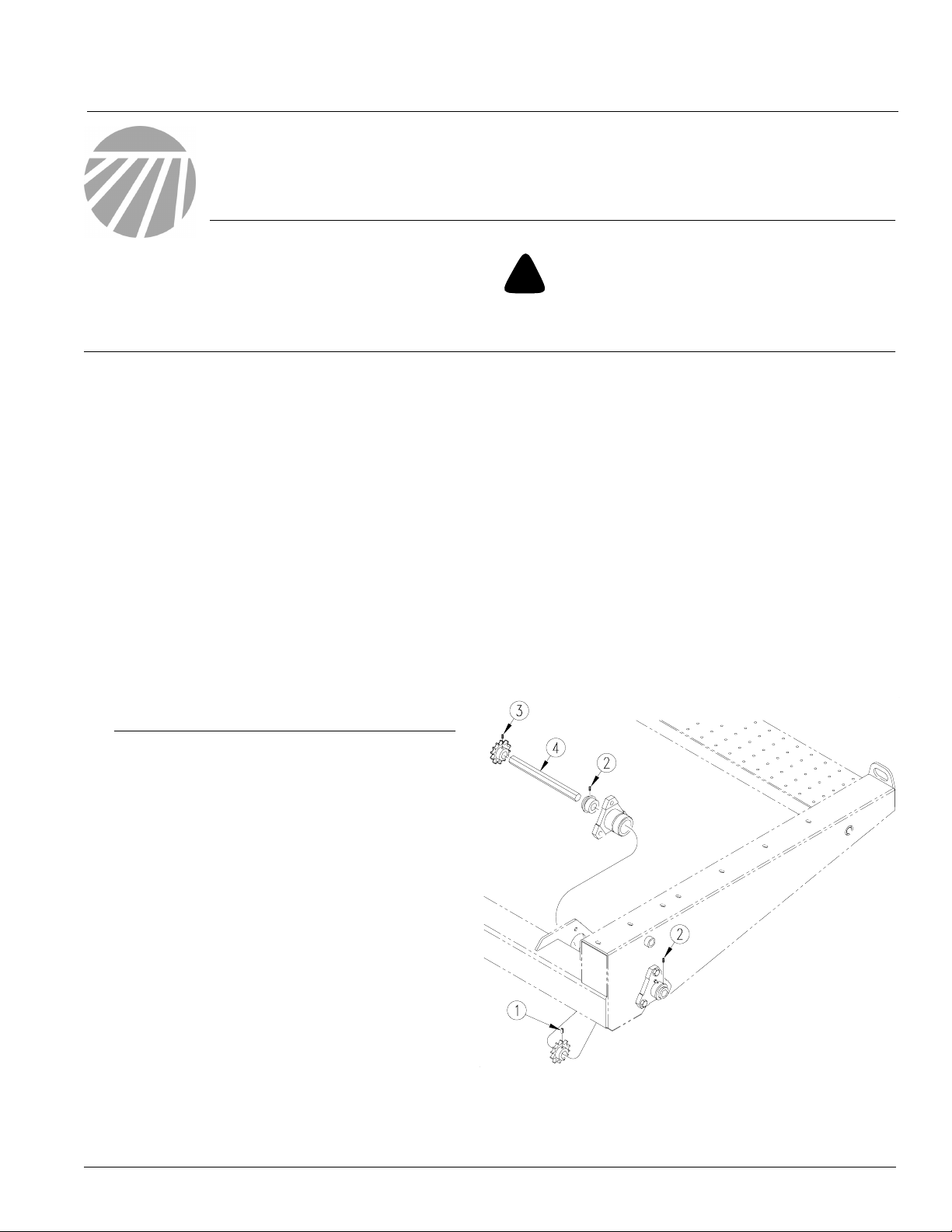

Refer to Figure 1

1. Loosen the drive chain tensioners on both the

drive chains on the left-hand gauge wheel.

Before You Start

Page 3 is a detailed listing of parts included in the

Calibration Kit package. Use this list to inventory

parts received.

Tools Required

• Basic hand tools

• Welder

Definitions

Right-hand and left-hand as used in this manual

are determined by facing the direction the machine will travel while in use unless otherwise

stated.

2. Rotate the left-hand gauge wheel until the roll

pin (1) on the drive sprocket is in a position to

be driven out. Drive out roll pin (1) and keep.

3. Use wire or clamp to hold the sprocket in

place. There is no need to remove drive chain

once the chain has been loosened.

4. Loosen the set screws (2) from both bearings.

5. Loosen the set screw (3) and remove the

sprocket from the end of the jackshaft (4). You

may need to remove the chain if loosening the

tensioner does not allow enough slack for removal of the sprocket.

© Copyright 2003 Printed

3/5/2003

21515

Figure 1

Jackshaft

152-291M

Page 2

Calibration Kit

2

Great Plains Mfg., Inc.

6. Remove the old jackshaft (4) and replace it with

the new one supplied in the kit. Use the new

shaft to push the old shaft out. Position the new

shaft so the end with the 9/32" hole is to the outside of the drill. Make sure the hole for the

sprocket is turned the same direction as the

hole in the sprocket to allow installation of the

sprocket roll pin (1).

7. Align sprocket hole with the hole in the shaft

and reinstall the roll pin (1). Position shaft and

sprocket so the sprocket aligns with the sprockets on the tensioner.

8. Once the sprocket is aligned retighten the set

screws (2) on the bearings to secure shaft in

place.

9. Reinstall the sprocket on the end of the shaft

and tighten the set screw (3). Retighten the

drive chains.

10. Position the crank handle stob on the top side

of the tongue and weld in place. Repaint the

area with green paint (P/N: 821-001C) purchased from your Great Plains dealer.

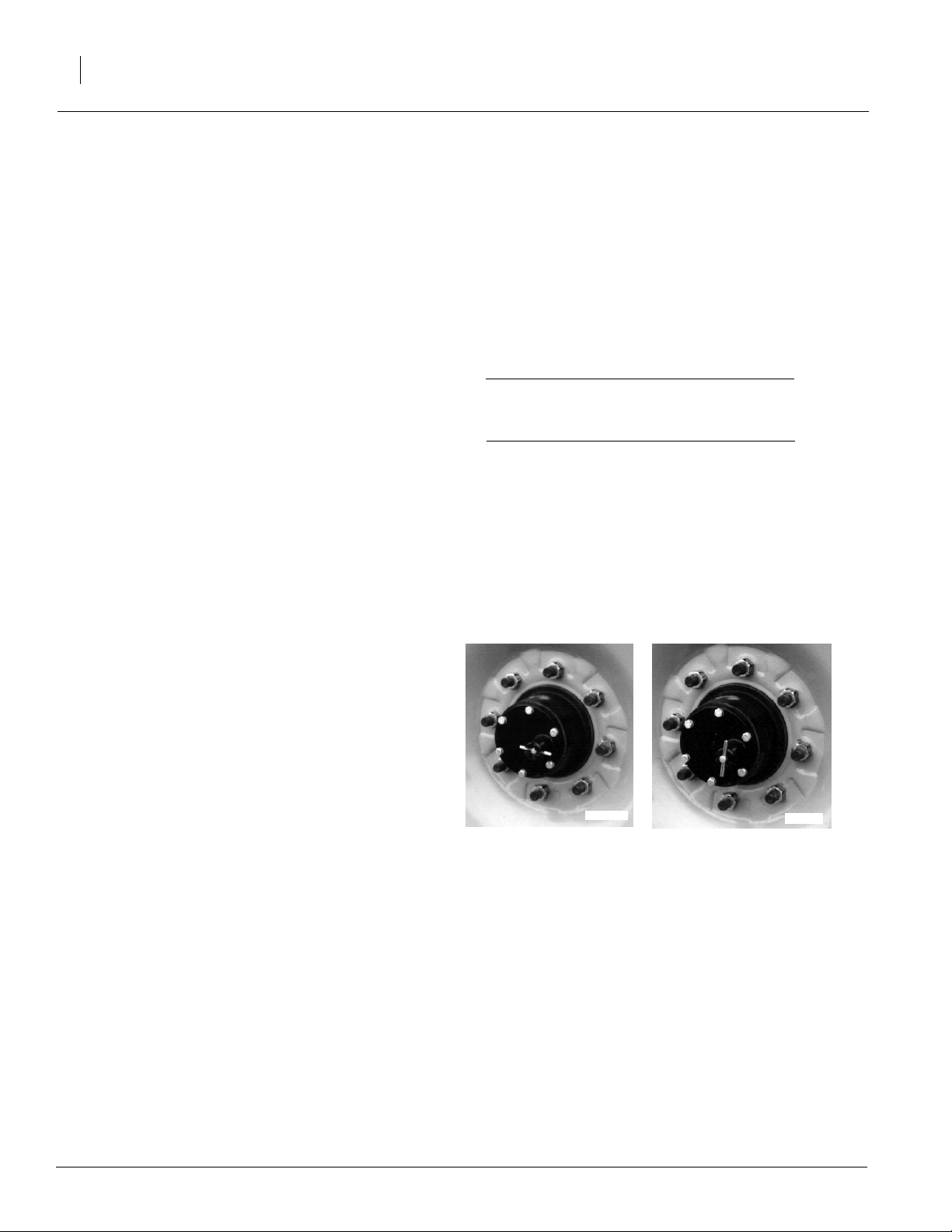

Refer to Figure 2

9. If rotating gauge wheel jackshaft, disengage the

lockout on the drive wheel and use same number of rotations as for rotating drive wheel.

Check that the three seed cups have plenty of

seed coming into them.

10. Weigh metered seed. Subtract initial weight of

container. Divide by three. Multiply by the number of openers on your drill to determine total

pounds seeded per acre. If this figure is different

than desired, reset sprockets accordingly.

NOTE: You may want to repeat the calibration

procedure if your results vary greatly from the

seed-rate chart.

11. When drilling, check seeding rate by noting

acres drilled, amount of seed added to drill and

seed level in drill box. If you are seeding more or

less than desired, adjust seeding rate slightly to

compensate for field conditions.

Use the following instructions to check seeding

rate.

1. Hydraulically lower drill to planting position to

activate clutch.

2. Check that tires are 9.0 x 24 rib implement and

properly inflated. Refer to "Tire Inflation

Chart," page 35 in the operator’s manual.

3. Jack drive (left) end wheel off ground. Rotate

wheel to see that drive system is working properly and seed cups are free from foreign material.

4. Record weight of an empty container large

enough to hold seed metered for one acre.

5. Place several pounds of seed over three seed

cups on an outside end of the drill box.Pull the

seed tubes off of these three openers.

6. Turn drive end wheel several times to fill seedcups with seed. Turn wheel until seed falls to

the ground from each cup.

7. Place container under the three tubes to gather

metered seed.

Engaged

17458

Figure 2

Drive Wheel Lockout

17459

Disengaged

8. Rotate drive wheel until 1 acre is tallied on

acremeter. This will be 592 rotations on a 7-foot

drill or 422 rotations on a 10-foot drill. You can

also rotate the gauge wheel jackshaft by means

of a wrench or socket or by means of the calibration handle stored on the tongue.

152-291M 9/19/2005

Page 3

Great Plains Mfg., Inc.

152-289A 705 Calibration Kit

Your kit includes:

Qty. Part No. Part Description

1 152-278H EWNT CALIBRATION HANDLE

1 152-291M INSTRUCTIONS, CALIBRATION

1 152-538D 705 NC GW JACKSHAFT

1 152-539D HANDLE STORAGE STOB

1 805-093C PIN COTTERLESS HITCH 1/4 X

Installation Instructions

3

152-290A 1005 Calibration Kit

Your kit includes:

Qty. Part No. Part Description

1 152-278H EWNT CALIBRATION HANDLE

1 152-291M INSTRUCTIONS, CALIBRATION

1 152-506D 100 NC GW JACKSHAFT

1 152-539D HANDLE STORAGE STOB

1 805-093C PIN COTTERLESS HITCH 1/4 X

152-291M9/19/2005

Loading...

Loading...