Great Outdoors 1000k Owner's Manual

GAS

BARBECUE

F

"there's

nothing like...

the

great

ou.tdoors."

r*l

Leave

all these

Read

a safe

OWNER'S

MANUAL

and

Assembly Guide

ASSEMBLER

these

instructions with the

CONSUMER / USER:

instructions and save them

place

/ INSTALLER:

for future reference.

consumer.

in

@

FOR YOUR

you

lf

1. Shut

2. Extinguish

3. Open lid.

4. lf odor

your gas

SAFETY

smell

.

gas:

gas

off

continues,

supplier

the Great Outdoors

Joplin,

the appliance.

to

any open flame.

or

1520 West B

Missouri USA 64801

telephone

imrnediately call

fire departrnent.

Grill Company

Street

888-869-5454

FOR YOUR

1. Do

Not store

flammable

cinity of

2. An

shall

or

LP cylinder

not be stored

any other

SAFETY

vapors and liquids

this or

1 000

or use

any other

appliance.

gasoline

appliance.

not connected

in the

vicinity of this

or other

in the

for use

vi-

Fh

AO000r02

Congratulations

ttre Blackstone

of

and

have recognized

quality of

function,

Great Outdoori

believe

and

is the

it

Grill

finest

thank

1000.

value

the

Company

you for

pleased that

are

We

the

of

components

product.

grill

on

the

your

design,

used

market'

purchase

you

this

in

We

q

The Great

producing

to

enjby

Outdoors

yearl

for

quality

wiltryour-new

know.

call our

can

You

you

want

We

your purchase

up to our

"lhere's

to

as we

motto.

nothing

the Great

Joplin,

is committed

your

family

not

please let

any

at

come.

to

grill,

toll

Company

Grill

grills that

you are

If

reason,

any

for

number

free

1-888-869-54s4.

be completely

demand

Simply,

the

like...

Outdoors

West B

1520

Missouri

printing Oct.

lst

satisfied

products

our

you to agtee,

want

we

great outdos;'5.

ComPanY

Grill

Street

USA

64801

1998 @

will

satisfied

us

time:

'

with

live

"rrr

The Great

Outdoors

Great

permission by

express

Outdoors Grill

Company

Crill

Outdoors

Patents

Company

Grill

usA

and

ComPanY.

Pending

1998.

the owners

logo

nbt

managers

and

Trademark

is a

used

to be

without

the Great

of

of

the

6

F\

Teem

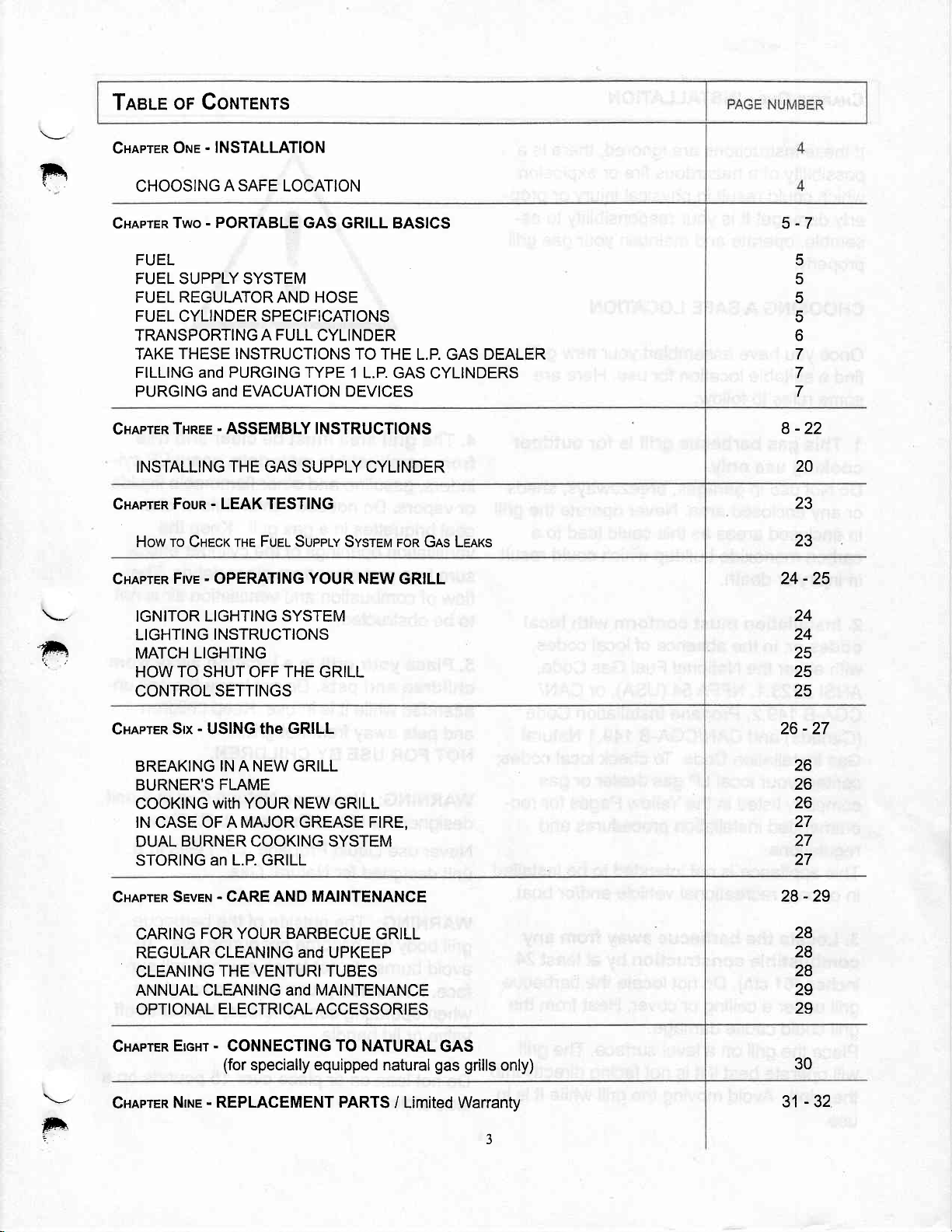

CxnprcR

oF CoNTENTS

Orue

CHOOSING

-

INSTALLATION

A SAFE

LOCATION

.&

Cxeprgn

CrlprER

GnnpreR Foun - LEAK

Cnrpren

Two - PORTABLE GAS

FUEL

FUEL SUPPLY SYSTEM

FUEL REGULATORAND HOSE

FUEL CYLINDER SPECIFICATIONS

TRANSPORTING A

THESE INSTRUCTIONS

TAKE

FILLING and PURGING TYPE

PURGING

INSTALLING

How ro Cnecx

IGNITOR

LIGHTING

MATCH

HOW TO SHUT OFF THE GRILL

CONTROL

and EVACUATION DEVICES

Txnee - ASSEMBLY INSTRUCTIONS

THE

-

Fve

OPERATING

LIGHTING SYSTEM

INSTRUCTIONS

LIGHTING

SETTINGS

FULL

GAS SUPPLY CYLINDER

TESTING

rHe FuEr- Suppl

GRILL BASICS

CYLINDER

1 L.P. cAS

Sysrem ron Gns Lexs

YOUR

TO THE

NEW GRILL

L.P. GAS DEALER

CYLINDERS

-7

5

c

5

5

5

o

7

7

7

-22

I

20

23

23

24-25

24

24

25

25

25

F-!.

GxapreR Sx - USING the GRILL

BREAKING

BURNER'S

COOKING

IN

CASE

DUAL BURNER COOKING SYSTEM

STORING an

Cxapren

SeveH - CARE

CARING

REGULAR

CLEANING

ANNUAL

OPTIONAL

Guapren

GHaprEn

Erenr - CONNECTING TO NATURAL

IN A NEW

FLAME

with YOUR NEW GRILL

OF A MAJOR GREASE FIRE,

L.P.

GRILL

GRILL

AND MAINTENANCE

FOR

YOUR

BARBECUE

CLEANING and UPKEEP

THE VENTURI TUBES

CLEANING and

ELECTRICAL

(for

specially

-

REPLACEMENT PARTS

NrHe

MAINTENANCE

ACCESSORIES

equipped natural

GRILL

GAS

gas grills

/ Limited Warrantv

3

only)

26-27

26

26

26

27

27

27

-29

28

28

28

28

29

29

30

-32

31

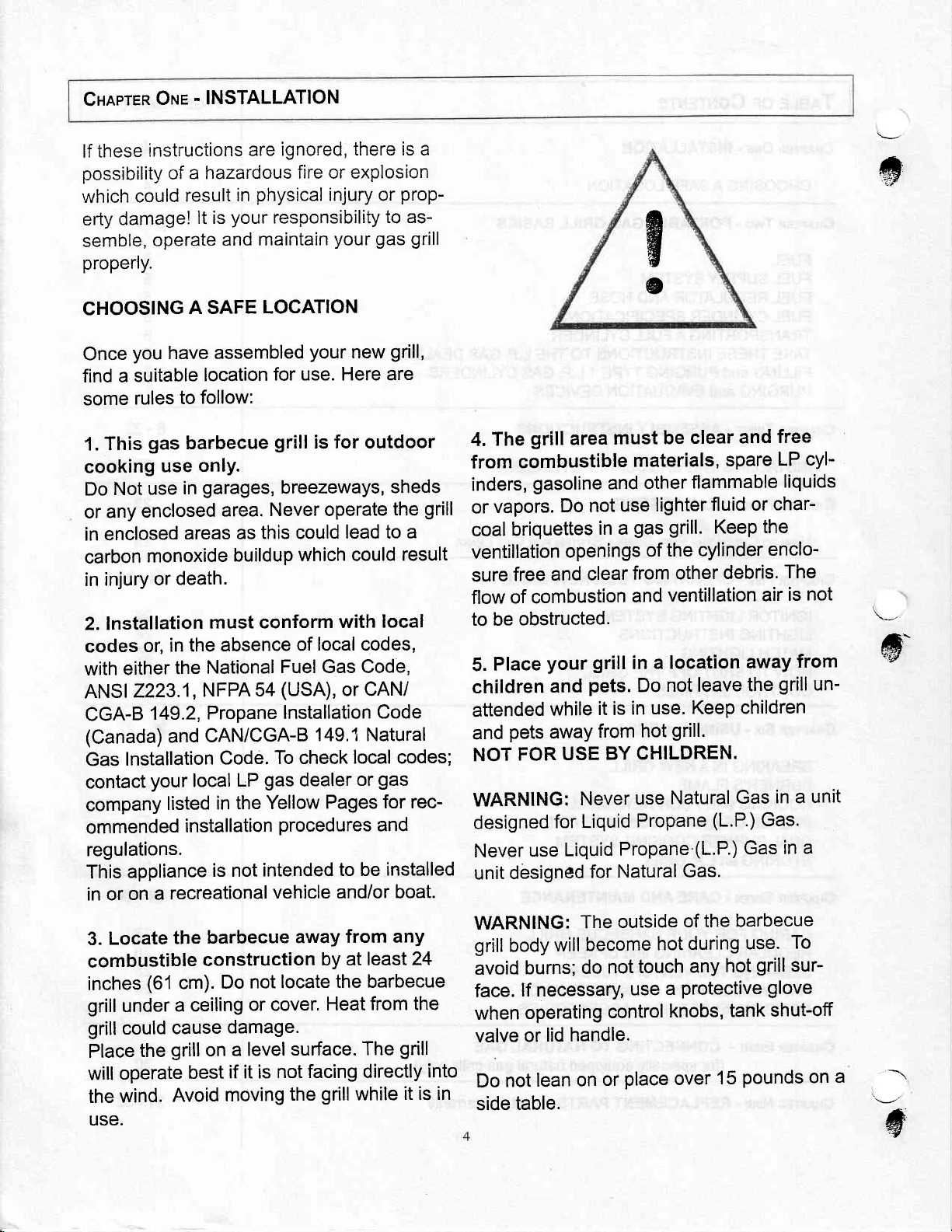

CHapren

OHe

-

INSTALLATION

these

lf

possibility

which

erty

semble,

properly.

CHOOSING

Once

find a

some

1. This

cooking

Do

or

in enclosed

carbon

in

2. lnstallation

codes

with

ANSI

CGA-B

(Canada) and

Gas

contact

company

ommended

regulations.

This

in or

instructions

of

could

damage!

you

suitable

rules

Not

any

injury

either

2223.1,

Installation

appliance

on a

result

operate

have

to

gas

barbecue

use

in

use

enclosed

areas

monoxide

death.

or

in the

or,

the

149.2,

your

listed

installation

recreational

a hazardous

lt is

A SAFE

location

follow:

onlY.

garages,

National

NFPA

Propane

CAN/CGA-B

local

ignored,

are

fire or explosion

physical

in

your

responsibility

maintain

and

LOCATION

assembled

area.

this could

as

buildup

nrust

conform

absence

54

Code.

LP

in the

is not

your

for use. Here are

grill

breezeways,

Never operate

which could

of

Fuel Gas Code,

(USA),

lnstallation

To check

gas

dealer

Yellow

procedures

intended

vehicle

there is a

injury or

your

new

is for outdoor

lead to a

with

local codes,

or CAN/

149.1 Natural

local codes;

Pages

to be

and/or boat.

prop-

to as-

gas grill

grill,

sheds

the

result

local

Code

gas

or

for rec-

and

installed

grill

grill

The

4.

combustible

from

inders,

vapors.

or

briquettes

coal

ventillation

free

sure

of combustion

flow

to be

5.

children

obstructed.

Place

attended

pets

and

FOR

NOT

WARNING:

designed

Never

designed

unit

area

gasoline and

Do not

openings

and

your

and

while

away

USE

for

Liquid

use

must

materials,

use

gas

in a

from

clear

and

grill

in

pets.

in

it is

from

CHILDREN.

BY

Never

Liquid

use

Propane

Propane

Natural

for

a

o

clear

be

flammable

other

lighter

of

a location

Do

use. Keep

hot

fluid

grill.

Keep

the cylinder

other

ventillation

not leave

grill.

Natural

(L.P.)

(L.P.)

Gas.

free

and

spare

debris.

LP

liquids

char-

or

the

enclo-

The

air

away

grill

the

children

in a

Gas

Gas.

in

Gas

cyl-

not

is

from

un-

unit

a

e,

@

Locate

3.

combustible

inches

grill

under

grill

could

Place

operate

will

wind.

the

use.

the

(61

cm).

a ceiling

cause

grill

the

Avoid

construction

on

best

barbecue

not locate

Do

or cover.

damage.

a level

if it is

moving

surface.

not facing directly

the

away

from any

least 24

by at

the barbecue

Heat

The

grill

while

from the

grill

into

it is in

WARNING:

grill

body

avoid

face.

when

valve

Do

side

burns;

lf necessary,

operating

or

not

table.

The

will

do

lid handle.

on

lean

outside

become

not

control

or

hot

touch

use

place

any

15

hot

barbecue

tank

pounds

of the

during

protective

a

knobs,

over

use'

grill

glove

shut-off

To

sur-

on

a

I

Cnepren

FUEL

Two - PORTABLE

GAS

GRILL BASICS

B

@

This appliance

Propane

pane).

comes

sure inside a cylinder

released.

tends to collect in low areas. lt is

that there are no leaking connections

your gas grill

plosion.

manual

FUEL SUPPLY

Your

tem

cylinder,

trol

The fuel regulator of

is equipped

Not attempt

der not equipped

der valve. This

any

FUEL

The

with the Type 1 fitting supplied must be

with the appliance.

and regulator assembly other than the

supplied

placement

gas

LP

liquid when

Refer

on

gas grill

LP

which is

a

valve.

other cylinder connection

REGULATOR AND

pressure

with the

is

designed to use Liquid

(abbreviated

gas

is

highly flammable.

stored under high

and

gas

LP

"Testing

fuel regulator,

pressure

is heavier

that

could cause a fire

the

to

made up of a LP

with a Type

to connect to any

grill

regulator

section later in

for

Gas

SYSTEM

requires a fuel

your

1 coupling nut.

with

a mating Type

is not to

and hose

Do

not use another

grill

or a manufacturer's

regulator

gas

LP

vaporizes

than air

Leaks".

gas

hose and

new barbecue

other LP cylin-

be used with

device.

HOSE

assembly.

pro-

or

lt be-

pres-

when

and

important

on

or ex-

this

delivery

supply

gas

1 cylin-

assembly

one

sys-

con-

grill

Do

used

hose

re-

4. The

bly

sure of

sq. inch).

WARNING:Any

tor is

causing

Consult

regulator is not working

FU EL CYLINDER

Any

grill

eter

capacity must

Full cylinder

38

pressure

provided

11 inches water column

dangerous

personal

your

gas

LP

must be approximately 12

and 18 inches

pounds (43.7

regulator and hose assem-

is factory set at an outlet

(.4

lb.

attempt

and could

injury

gas

LP

SPECIFICATIONS

supply cylinder used

be 20

weight

lbs. nominal water capac-

to adjust the regula-

create a situation

property

or

dealer if

properly.

high. The maximum

pounds

should

of Propane.

be approximately

damage.

you

think

with

inches

pres-

per

the

this

diam-

fuel

itv).

The LP cylinder

terminating

valve

with

seating connection

gas

tained.

DANGER: Do Not insert any foreign objects

into the valve outlet.

back check.

cause

sion, fire, severe

outlet.

a Type 1 cylinder valve

flow, until a

a leak,

must have a shut-off valve

in

a Type

A Type 1 compatible cylinder

which does

positive

You may damage

Adamaged back

which could result in explo-

personal

gas

1 LP

seal

cylinder

has

not

has

check can

injury or death.

positive

a

permit

been

ob-

the

F

The Type

lowing features:

1. The system will not allow

positive

a

2.The system

will shut-off

and 3000

The

3.

which,

gas

to 10 cubic

1 connection system

connection has been

has a thermal

the flow of

F.

system

when activated,

has a flow limiting

feet

gas

will limit

per

hour.

between 2400 F

has the fol-

gas

to flow

made.

element that

device

the flow

until

of

The

cylinder

withdrawal. lt must also

protect

vice having

vapor

This will

der

All LP

shall be constructed

dance with

inders of the U.S.

the cylinder

direct communication

space of cylinder must be

expel

is

overfilled

gas

cylinders

the specifications

be arranged for

must

valve. A

pressure gas

high

or overheated.

used with this

and marked

Department of Transporta

vapor

include a collar to

safety

relief de-

with the

provided.

if the cylin-

appliance

in accor-

for LP

gas

cyl-

(DOT)

tion

Canada,

Spheres

Dangerous

plicable;

overfilling

LP Gas

the

cylinders

New

safety.

for

to

ers

or the

CAN/CSA-8339, Cylinders

and Tubes

Goods;

and

prevention

Supply Cylinder.

Allow only

fill or repair

der.

gas

Inform

cylinder

Caution

the

be filled.

to

the

gas

cylinder.

filling,

After

leaks

and

mains

have the

to see that the relief valve re-

to function.

free

National

for Transportation

and

shall be

provided

device.

are always

your

dealer

if it is

dealer not to

gas

Standard

of

,

of

Commission, as ap-

with a listed

Read labels on

shipped empty

qualified

gas

LP

gas

LP

supply

cylin-

deal-

a new or used

overfill the

dealer check for

fuel

should

You

Transport

time.

and secure

and

off

Do Not

partment

Do Not

high

a

heat areas

High

vent

to

Do Not

or any

well

in a

out of

and

a

Use

during

connected

closed

transport only one cylinder

manner

POL

the

transport

of

leave cylinder

heat area such

gas.

store

other

ventilated

the reach

cylinder

transport

to

when

the cylinder in

with control valve

plug

in

cylinder

vehicle,

a

in direct sunlight or in

as a closed car trunk.

could

cylinder

in a building,

enclosed

area, away from

of

cap on

when the cylinder

and

grill.

Keep cylinder

not in

use.

an upright

place.

passenger

in

cause the

relief

garage

area.

Store

outdoors

people

children.

cylinder valve

outlet

valve

at

a

turned

com-

valve

is

not

a

gas

Have the

ing to ensure

dealer

that the cylinder is not over-

weigh

filled.

TRANSPORTING

WARNING!

is under

Gas

Handle

A FULL CYLINDER

a full cylinder with

pressure.

high

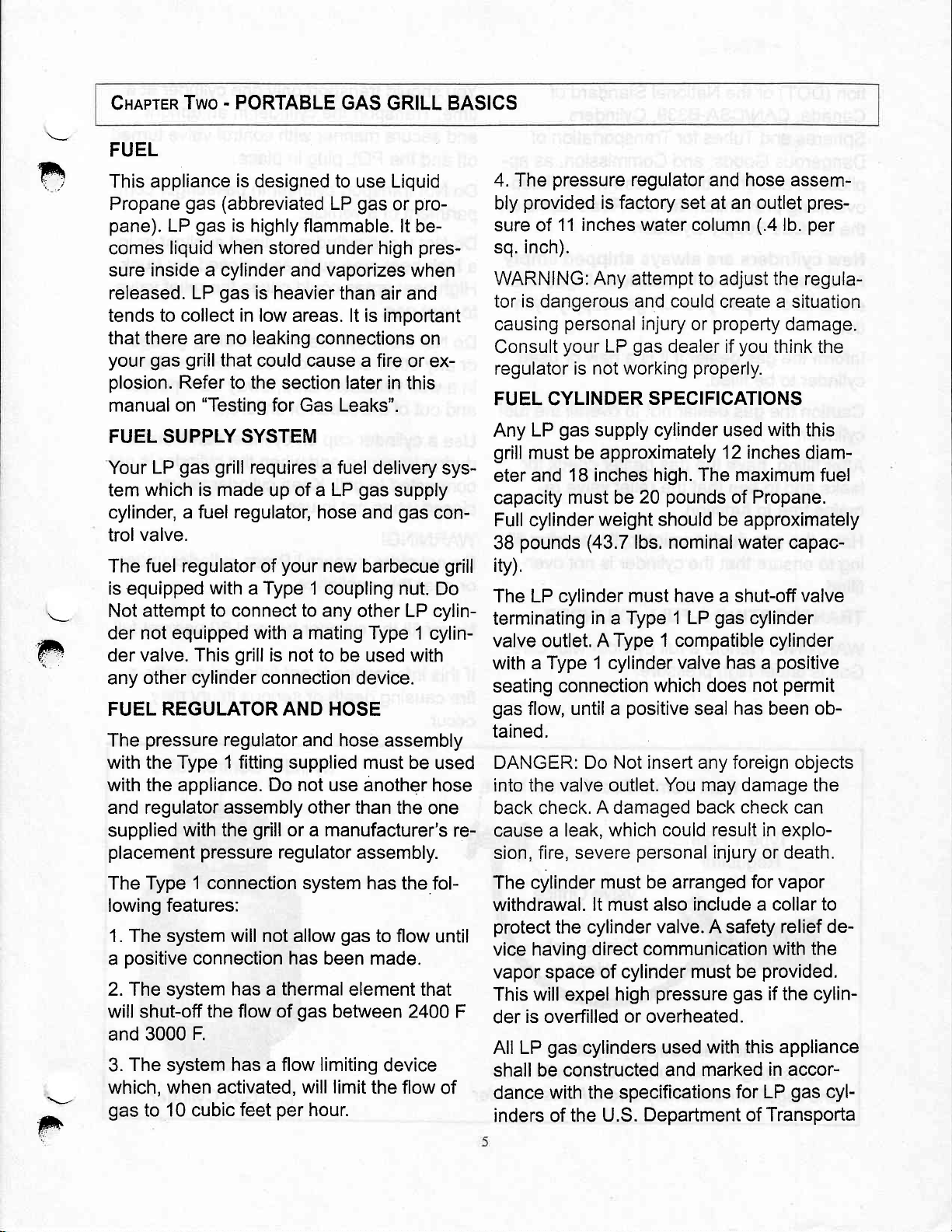

Dual Burner Fuel Control Valve

Type

1 Fuel

Regulator

cylinder

after fill-

care.

Valve Orifice

Fuel Supply

Hose

WARNING!

not store

Do

or near

Never

lf this

this appliance.

the cylinder

fill

information

fire causing

occur.

I

I

a spare

is not

death or

Cylinder

LP-gas cylinder

beyond

80

under

percent

followed exactly,

serious

injury may

Control

Valve

full.

a

The Fuel Supply System

consisfrng

regulaforassembly

and

of fuel control valve

with hose

and L.P.gas cylinder

6

L.P. Gas

Cylinder

^4.

EVACUATION

TAKE

GAS

When

*

exchanged

a 510

THESE

DEALER.

using

POL

INSTRUCTIONS TO

a cylinder exchange

cylinder

cylinder

is

will not fit Type 1 regula-

a Type

1 cylinder, as

THE LP

be sure the

tor.

FILLING

and PURGING

TYPE

1 LP GAS

PURGING

LP GAS

VALVES

DER

Hose

A.

be accomplished

can

valve containing

for evacuation

lows

adapter.

and

CYLINDERS

end valve

with ryPE

with a bleed

using

a bleed

without

port

DEVIGES for

1 GYLIN-

port:

Purging

hose

a

end

which also al-

the use of an

CYLINDERS

port:

have a

must be used

LP-

a Type

has

hand thread

DANGER!

inders

been

have

LP Gas

low this

fire,

severe

IMPORTANT

filling.

dard CGA

Purging and

must be

thoroughly trained in accepted

industry

instruction

personal

Purge new cylinders before

This tank

510

filling

per{ormed

procedures.

may result

injury, or

of LP Gas cyl-

personnel

by

Failure to fol-

in

explosion,

death.

is easily filled with a stan-

POL filling connection.

who

valve

B. Hose

When a

bleed

end

hose

port,

a separate

end

for evacuation.

Purging using

C.

cylinder

Gas

plished

1 connection.

an external

which

will accept

evacuation

during

each

The Type

I 5116"

without a bleed

valve does not

device

Type 1 connection:

a

can be accom-

purging

by using

1 valve outlet

ACME right

this connection.

The LP Gas

valve

r-

w4'

which will not

evacuation

with a back-check

LP Gas

be opened

must

cylinder has a

permit gas

device

cylinder,

the backcheck module

with

is

installed.

an evacuation device.

Type 1

cylinder

module in its

to flow until an

purge

To

outlet

the

CAUTION:After

cylinder,

Do Not

valve outlet.

vent the

ONLY

back-check

provided

the

to the outlet.

before

returning

purging

insert

Insertion

Close

the cylinder

or filling

a POL

this

of

closing. Use

from

and strap attached

cap

cylinder valve

the

an LP Gas

plug

plug

will

to the

into the

pre-

knob

cus-

tomer.

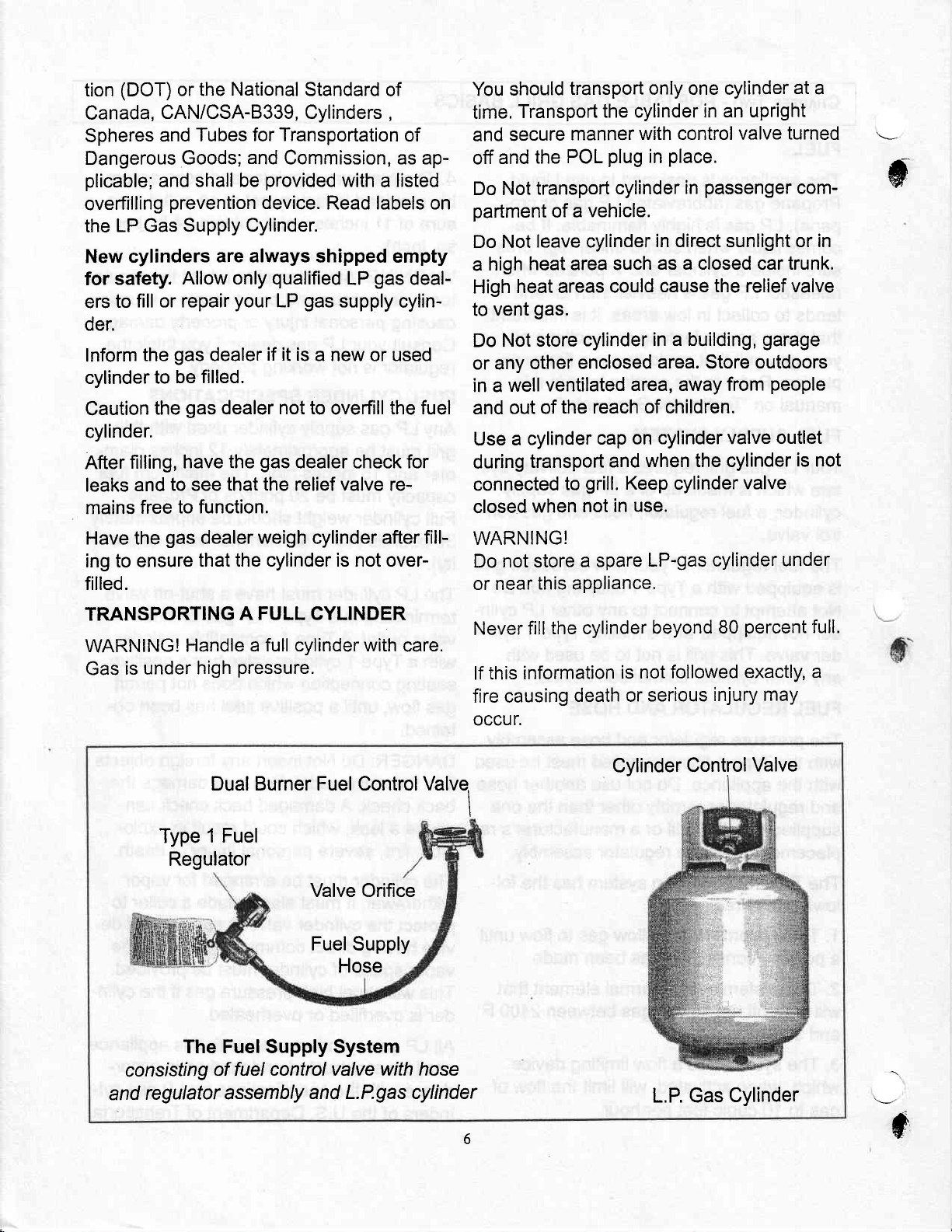

CGA.slO POL

proper

For

to: Safety

refer

LP-Gas

ing

NPGA #

for Filling

130,

Cylinders".

purging

Cylinders,"

procedures

Bulletin

NPGA #

and

"Recommended

in the U.S.A.

133,

Safety

Procedures

"Purg-

Bulletin

TYPE 1

Type 1

Filling

a

Two examples;

using

drawing

a CGA-510

shor,vs

Cylinder

The

top

POLfitting. The right

using a Type 1 POL fitting.

Valve

drawing

shows

F

\..

Csapren

THnEe

-

ASSEMBLY

INSTRUCTIONS

Getting

1. Please

they

Assemble

2.

intend

You

3.

cloth

scratches

nuts

4. Have

of lightweight

An

by

the nuts

Your

5.

Liquid

beiore,

reasons.

immediately,

filled

dealer.

Started;

follow

presented.

are

the

use

to

want

may

at the

and

assistaht

holding

with

assembly

your

to

bolts

friend

a

can

the

and

barbecue

Propane

shipped

it is

order

In

L.P.

it.

from becoming

aluminum,

parts

bolts

please

gas

steps

the

grill

at the

place

to

site

and/or

deck

While

help.

make the

place

in

in

Place.

been

has

(L.P.)

gas

empty

to be

ready

have

an authorized

by

in the order

location

an old towel

prevent

to

the unit

there

assembly

while

provided

cylinder.

for safety

your

that

prevent

to

lost.

is made

is a.lot of

fastening

As

to barbecue

fuel cylinder

L.P.

that

you

or

it!

easier,

with a

stated

gas

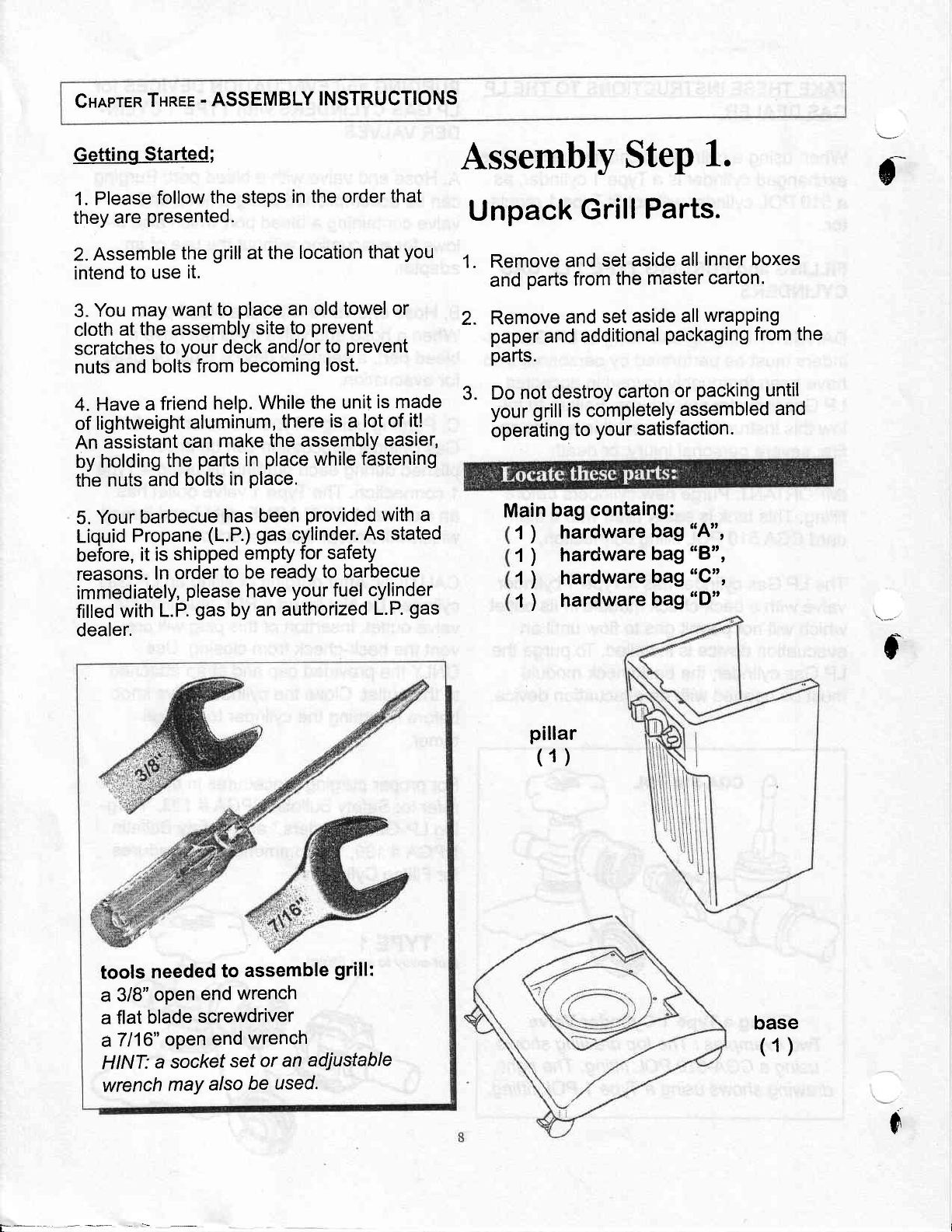

Assembly

Unpack

Remove

1.

and

Remove

2.

paper

parts.

Do

3.

your

bperaling

Main

1

1

1

1

and

parts

and

and

destroy

not

grill

is completely-assembled

bag

hardware

)

hardware

)

hardware

)

hardware

)

from

to

Step

Grill

aside

set

the

aside

set

additional

carton

your

satisfaction.

containg:

1.

Parts.

inner boxes

all

master

bag

bag

bag

bag

carton.

wrapping

all

packaging

packing

or

"A",

"B",

"C",

"D"

a

from the

until

and

f

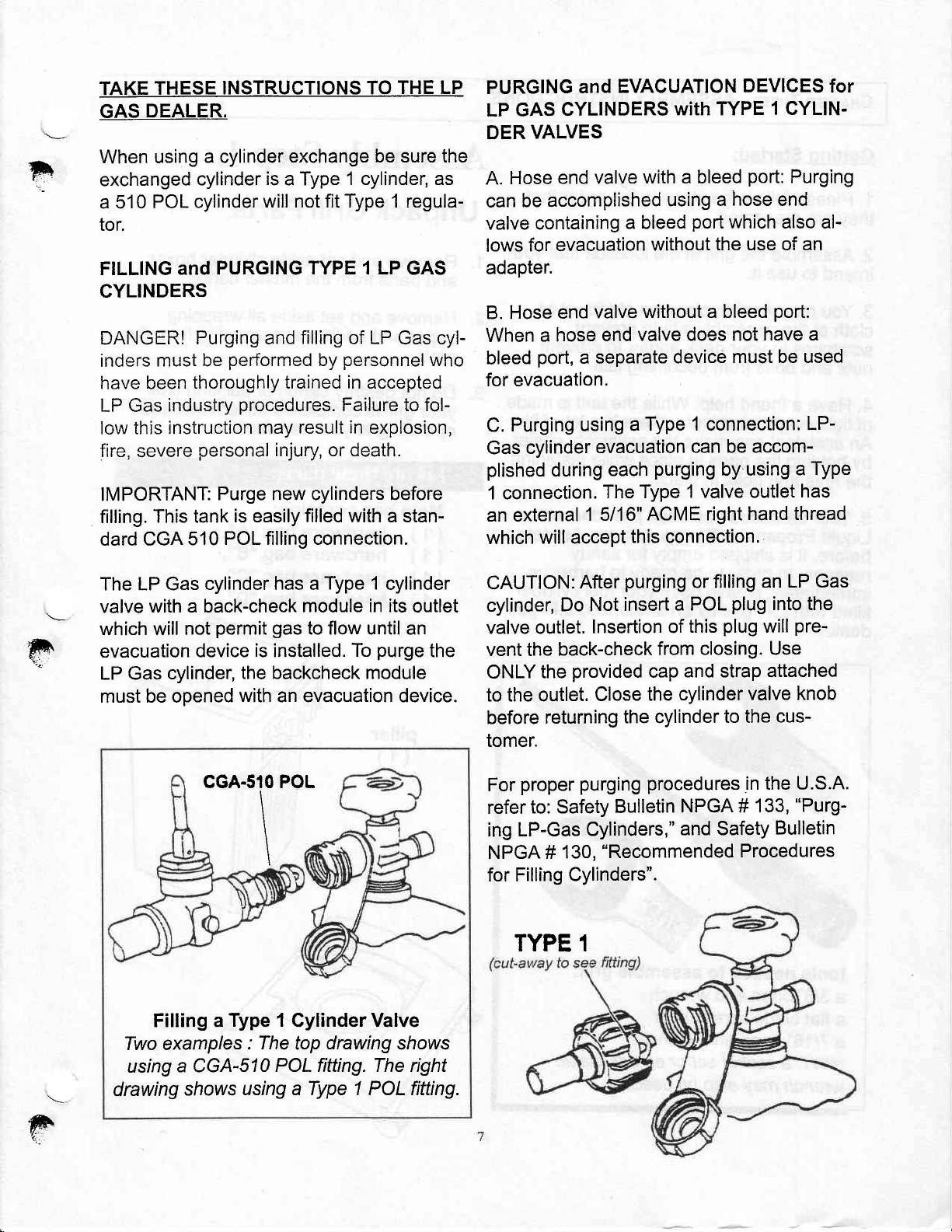

318"

blade

HINT

needed

open

open

a socket

may

tools

a

a flat

aT116"

wrench

assemble

to

wrench

end

screwdriver

wrench

end

an

or

sef

be used.

also

grill:

adiustable

pillar

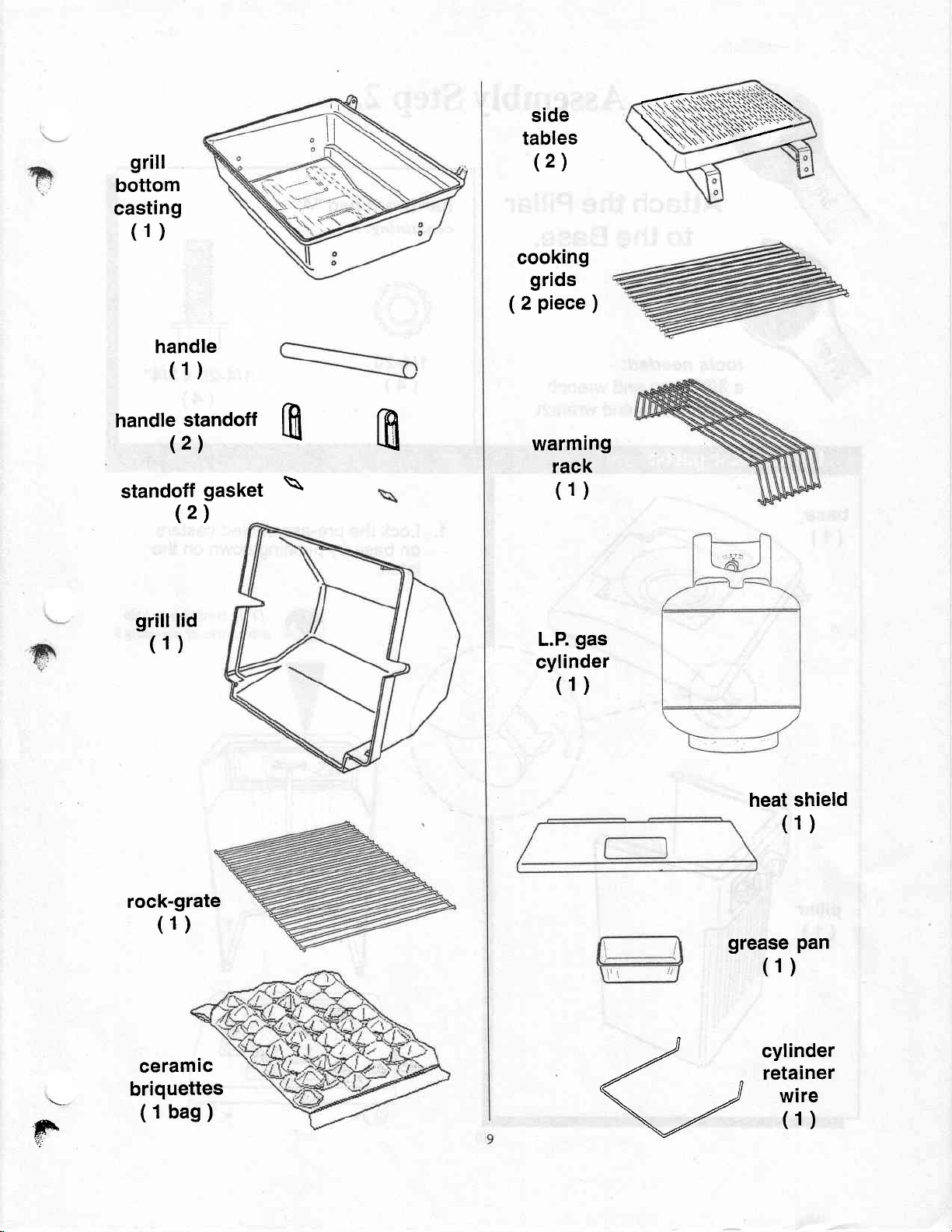

(1)

base

(1)

A

U]

grill

bottom

casting

(1)

handle

(1)

side

tables

(2)

cooking

grids

piece

(

2

N

)

handle

standoff

(21

standoff

(2)

grill

lid

(1)

gasket

m

\

m

warming

rack

(1)

gas

L.P.

cylinder

(1)

heat shield

(1)

rock-grate

(1)

grease

ceramrc

briquettes

(1

.Iq

Y

bag)

2

/

\ ))

\/

\z'

.

pan

(1)

cYlinder

retainer

wire

(1)

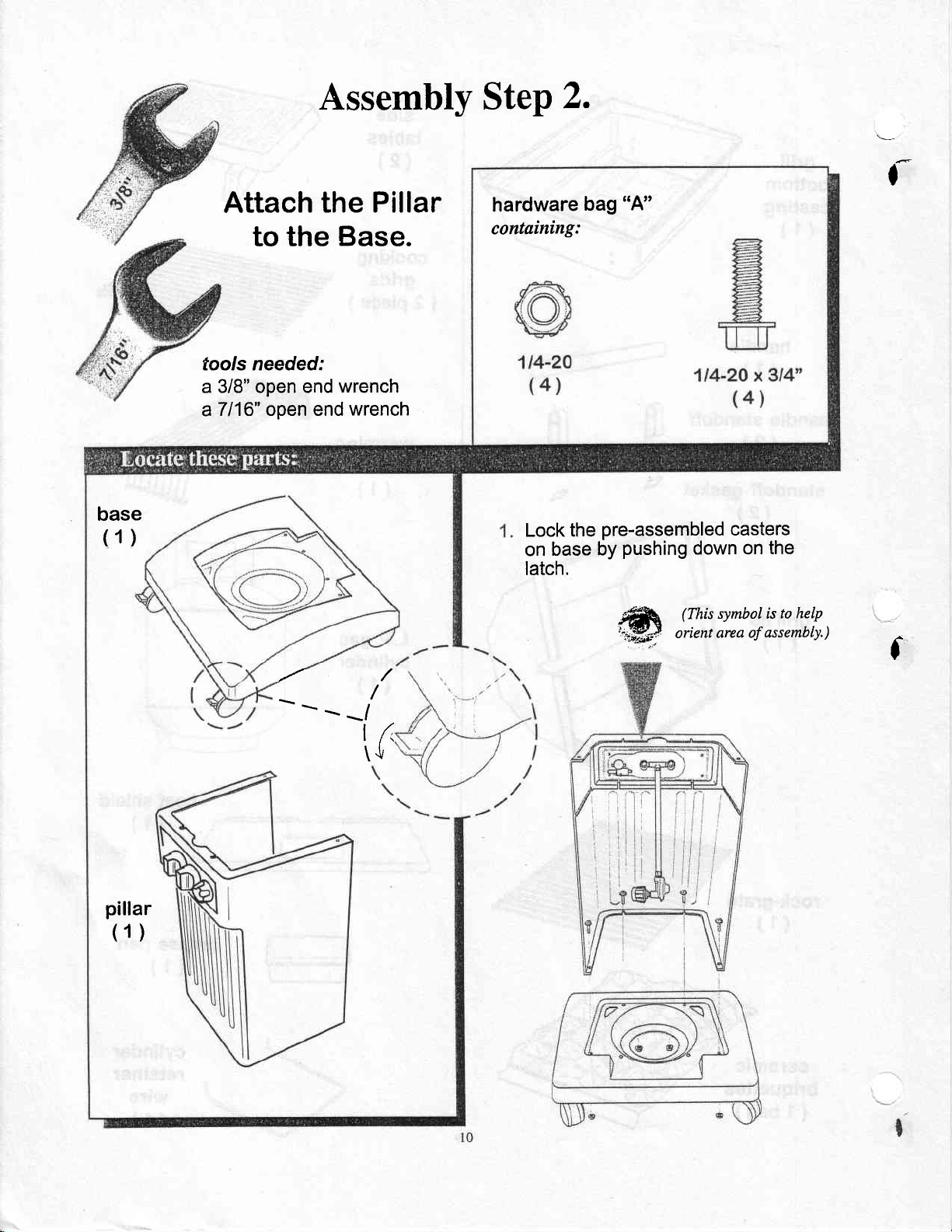

Assernbly Step

Attach the Pillar

the

to

tools needed:

a 318" open end

a7l16"

open end

Base.

wrench

wrench

2.

hardware

containing:

bag

I

"A"

base

(1)

pillar

(1)

tl

\{

Lock the

base

on

latch.

pre-assembled

pushing

by

,iffi

lr'ffiJ

(Th.is

orient

casters

down on

symbol is

area of

the

to help

assembly.)

f

Loading...

Loading...