Manual No. 692P

Revision 9-898

MODEL 692P

TWO-WIRE

pH TRANSMITTER

-1-

INSTRUMENT SETUP GUIDE

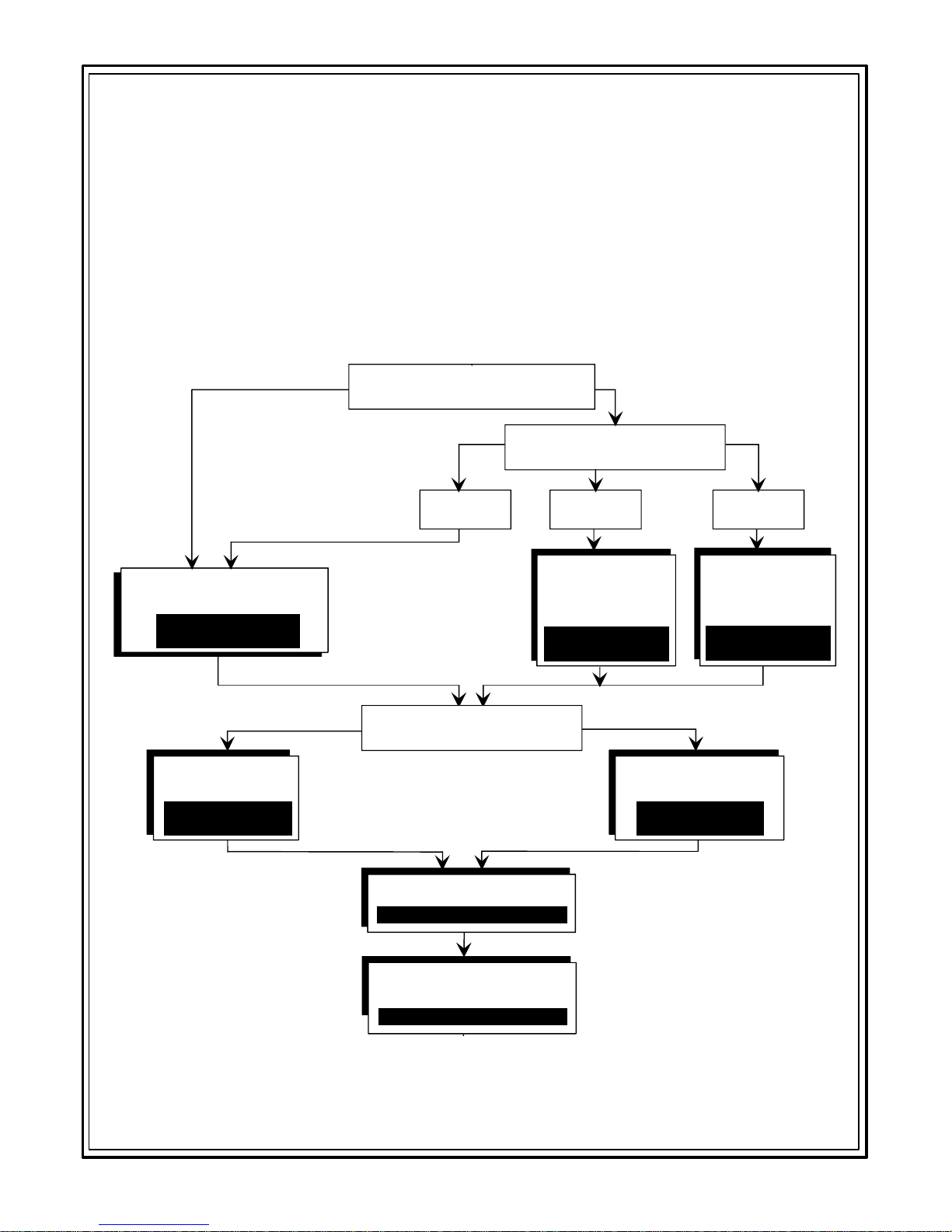

This manual contains detailed instructions for all operating aspects of this instrument.

Read Part One for a general description of the Model 692P. Part Two explains how to

install and wire the instrument. To familiarize yourself with the basic operation of the

692P, read Part Three, Sections 1, 2 and 3. For instrument startup, perform the setup

steps in Section 4. The following guide shows you the appropriate Section 5 and 6 subsections to use for temperature and pH calibration when using a GLI 5-wire Differential

Technique sensor or a conventional pH combination electrode.

5-Wire Sensor

Single Or Two-Point

Temperatue Calibration*

Section 5.2 or 5.3

(start on pg. 30)

"Two-key"

Two-Point Or

Table Method

Section 6.4 or 6.5

(start on pg. 34)

Which type of sensor are you

using with this transmitter?

300 Ohm

Thermistor

*

Temperature calibration is

only necessary w hen

extremely accurate

measurement is required.

Which pH calibration method

do you intend to use?

Combination Electrode

What type of temperature

compensation is used?

1000 Ohm

RTD

Two-Point

Temperature

Calibration

Section 5.3

(start on pg. 30)

Conventional

Single Or Two-Point

Method

Section 6.2 or 6.3

(start on pg. 32)

Fixed

Resistor

Single-Point

Temperature

Calibration

Section 5.2

(start on pg. 30)

Rev. 9-898 Model 692P

Output Setup

Section 7 (start on pg. 40)

Using Security

Lock Feature

Section 8 (start on pg. 42)

Model 692P Rev. 9-898

-2-

-3-

TABLE OF CONTENTS

PART ONE - INTRODUCTION

SECTION 1 GENERAL INFORMATION

1.1 Instrument Capability:

Input Versatility ........................................................7

Display Readouts.....................................................7

Operator Interface....................................................7

Output Flexibility ...................................................... 7

Operator Safety........................................................7

1.2 Battery Backup..........................................................7-8

1.3 Product Identification ...................................................8

SECTION 2 SPECIFICATIONS................................................................9

PART TWO - INSTALLATION

SECTION 1 UNPACKING......................................................................10

SECTION 2 MECHANICAL REQUIREMENTS

2.1 Location......................................................................10

2.2 Mounting ...............................................................10-12

2.3 Plugging Conduit Holes .............................................12

SECTION 3 ELECTRICAL CONNECTIONS

3.1 GLI 5-Wire Differential Technique Sensor.................12

3.2 Conventional Combination Electrode:

Direct Hookup (distances less than 10 feet) .....13-14

Indirect Hookup with Model 714 Preamp

(distances more than 10 feet) ............................15

3.3 Power Supply............................................................. 15

3.4 Analog Output.......................................................15-17

3.5 Hazardous Area Wiring.........................................17-18

PART THREE - OPERATION

SECTION 1 OPERATING CONTROLS

1.1 Keypad Switches...................................................19-22

` 1.2 Slide Switches.......................................................22-23

1.3 Program Jumper......................................................... 24

1.4 Status Indicators ........................................................ 25

SECTION 2 MEASURED VARIABLES.................................................. 25

Rev. 9-898 Model 692P

-4-

TABLE OF CONTENTS (continued)

SECTION 3 SETUP VARIABLES

3.1 Calling Up Setup Variables........................................ 26

3.2 Entering Values..........................................................26

3.3 Setup Variables Call-Up Chart and

Table of Descriptions........................................26-29

SECTION 4 INSTRUMENT STARTUP

4.1 Checking Battery Backup Jumper.............................. 29

4.2 Setting Sensor Input Type:

GLI 5-Wire Differential Technique Sensor.............29

Conventional Combination Electrode................29-30

4.3 Selecting Temperature Display Units (°C or °F) ........30

4.4 Understanding Calibration ......................................... 30

4.5 Selecting Default State for Out-of-Range Condition..30

SECTION 5 TEMPERATURE CALIBRATION

5.1 Temperature Effects on pH Reading:

300 Ohm Thermistor Compensation ...................... 30

1000 Ohm RTD Compensation.............................. 30

Fixed Resistor Compensation................................ 31

5.2 Single-Point Method...................................................31

5.3 Two-Point Method.................................................31-32

SECTION 6 pH CALIBRATION

6.1 Summary of Methods ............................................32-33

6.2 Conventional Single-Point Method........................33-34

6.3 Conventional Two-Point Method...........................34-35

6.4 “Two-Key” Two-Point Method:

Selecting This Method.......................................35-36

Entering Calibration Points

(by qualified person) .......................................... 36

Performing Calibration ......................................36-38

6.5 “Two-Key” Table Method:

Selecting This Method.......................................38-39

Entering Calibration Points

(by qualified person) .....................................39-40

Performing Calibration ......................................40-41

SECTION 7 OUTPUT SETUP

7.1 Using Range Expand Feature:

Setting Low Endpoint........................................41-42

Setting High Endpoint .......................................42-43

7.2 Using Output Hold Feature ........................................ 43

SECTION 8 USING SECURITY LOCK FEATURE

Model 692P Rev. 9-898

8.1 Locking Stored Values...............................................43

8.2 Unlocking Stored Values............................................44

-5-

TABLE OF CONTENTS (continued)

PART FOUR - OPERATING AIDS

SECTION 1 PRESERVING MEASUREMENT ACCURACY

1.1 Keeping Sensor Clean...............................................45

1.2 Keeping Instrument Calibrated................................... 45

1.3 Checking Sensor Slope.............................................. 45

1.4 Avoiding Ground Loop Errors.....................................45

1.5 Avoiding Electrical Interference ................................. 45

1.6 Checking Buffers for “Two-Key”

Table Method of pH Calibration........................45-46

SECTION 2 mV CALIBRATION

2.1 Single-Point Method...................................................47

2.2 Two-Point Method.................................................47-48

SECTION 3 SIMULATING MEASURED VALUES................................. 49

PART FIVE - PRINCIPLE OF OPERATION

.....................................................................................50-51

PART SIX - SERVICE AND MAINTENANCE

SECTION 1 GENERAL

1.1 Inspecting Sensor Cable............................................52

1.2 Checking System Periodically.................................... 52

SECTION 2 TROUBLESHOOTING

2.1 System Diagnostic Error Messages...........................52

2.2 Resetting Instrument to Factory-Default Values ........53

2.3 Isolating the Problem:

Checking Electrical Connections ...........................53

Checking Instrument .........................................54-55

2.4 Customer Assistance ............................................55-56

PART SEVEN - SPARE PARTS AND ACCESSORIES

..........................................................................................57

Rev. 9-898 Model 692P

-6-

TABLE OF CONTENTS (continued)

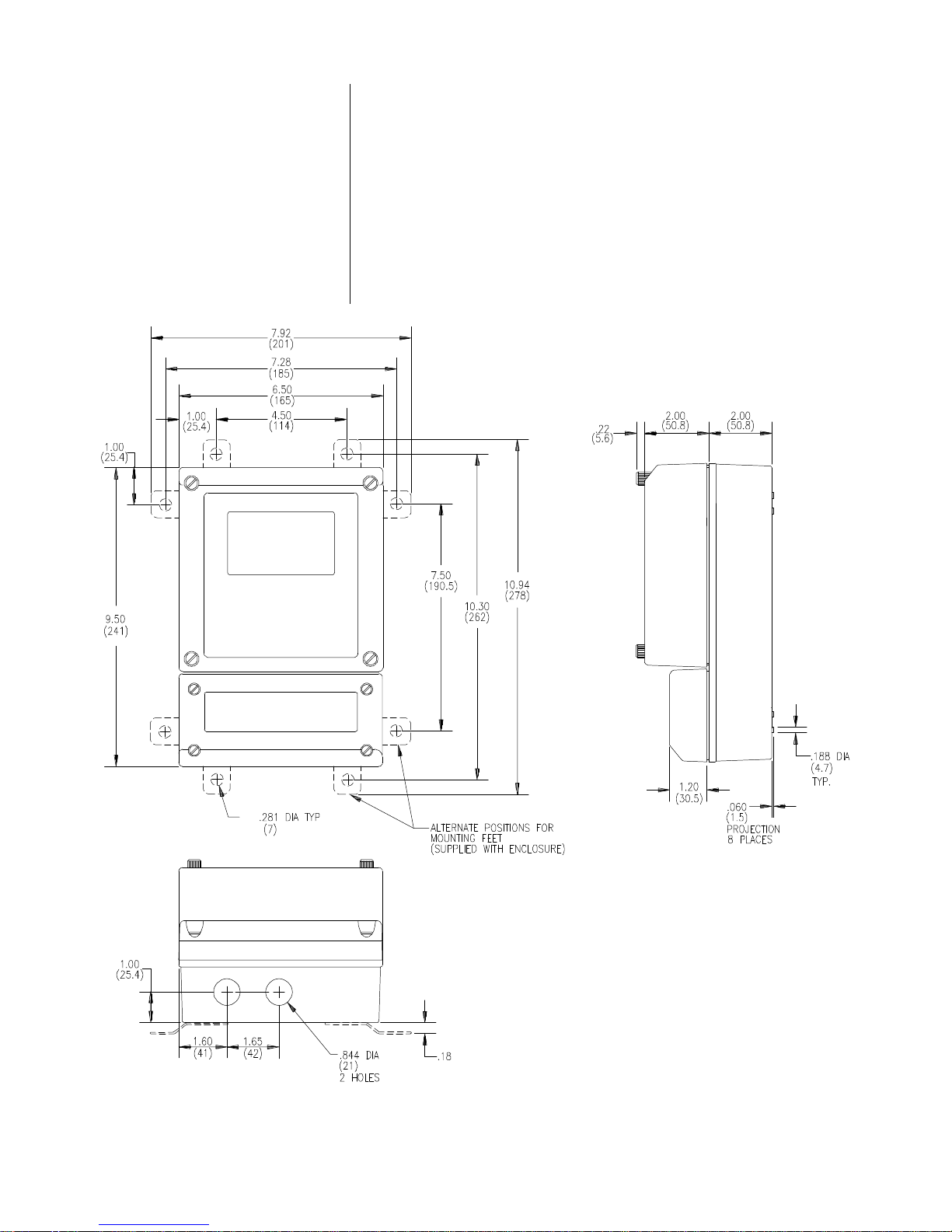

ILLUSTRATIONS: Figure 2-1 Enclosure Outline...........................................11

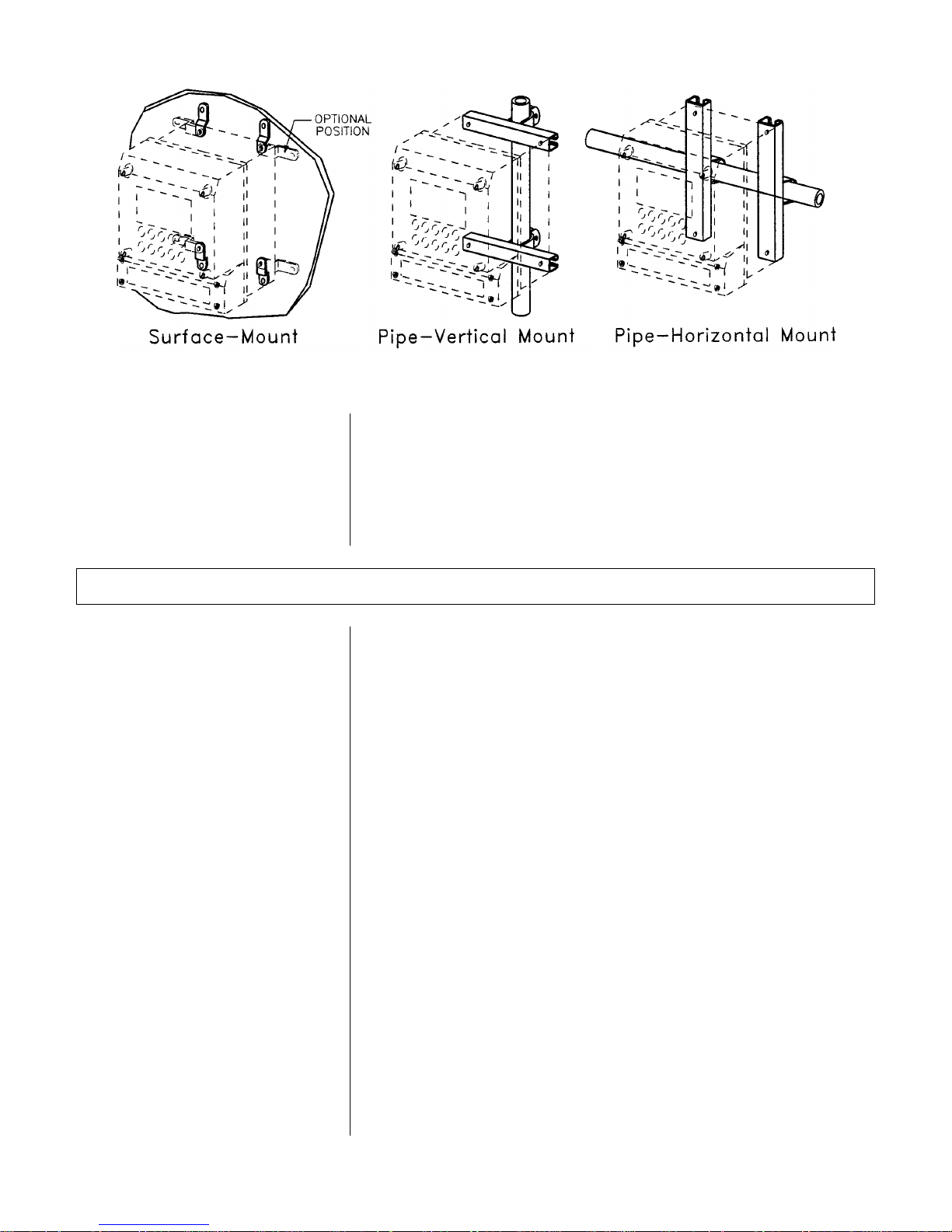

Figure 2-2 Mounting Configurations................................12

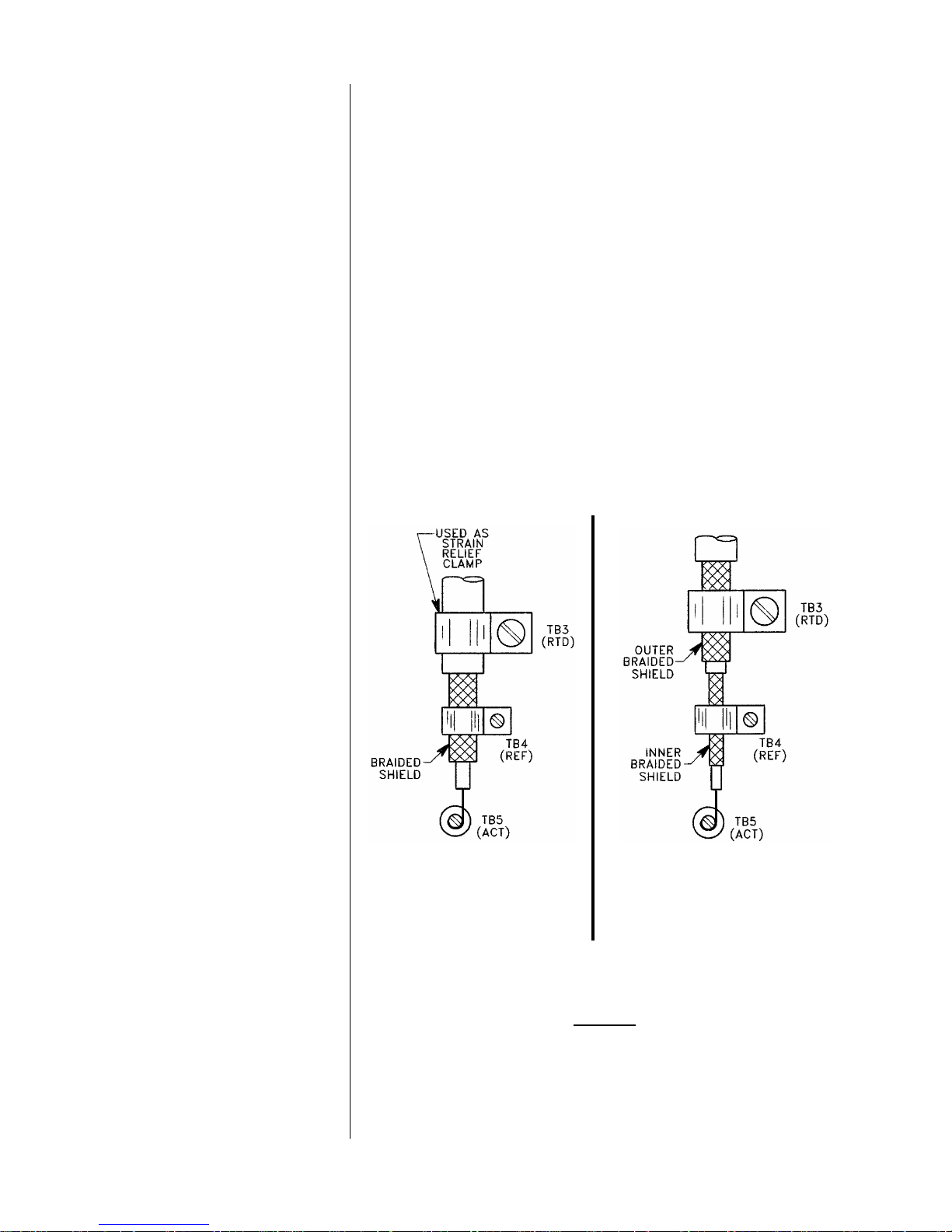

Figure 2-3 Connection Details for Combination

Electrode with Coaxial Cable.........................13

Figure 2-4 Connection Details for Combination

Electrode with Triaxial Cable .........................13

Figure 3-1 Keypad Switches............................................ 20

Figure 3-2 Controls on Backside of Display

Module Assembly and Electrical

Hookup Details...............................................24

Figure 3-3 Display Modes and Call-up Chart

of Setup Variables..........................................27

Figure 5-1 Instrument Operations Block Diagram...........50

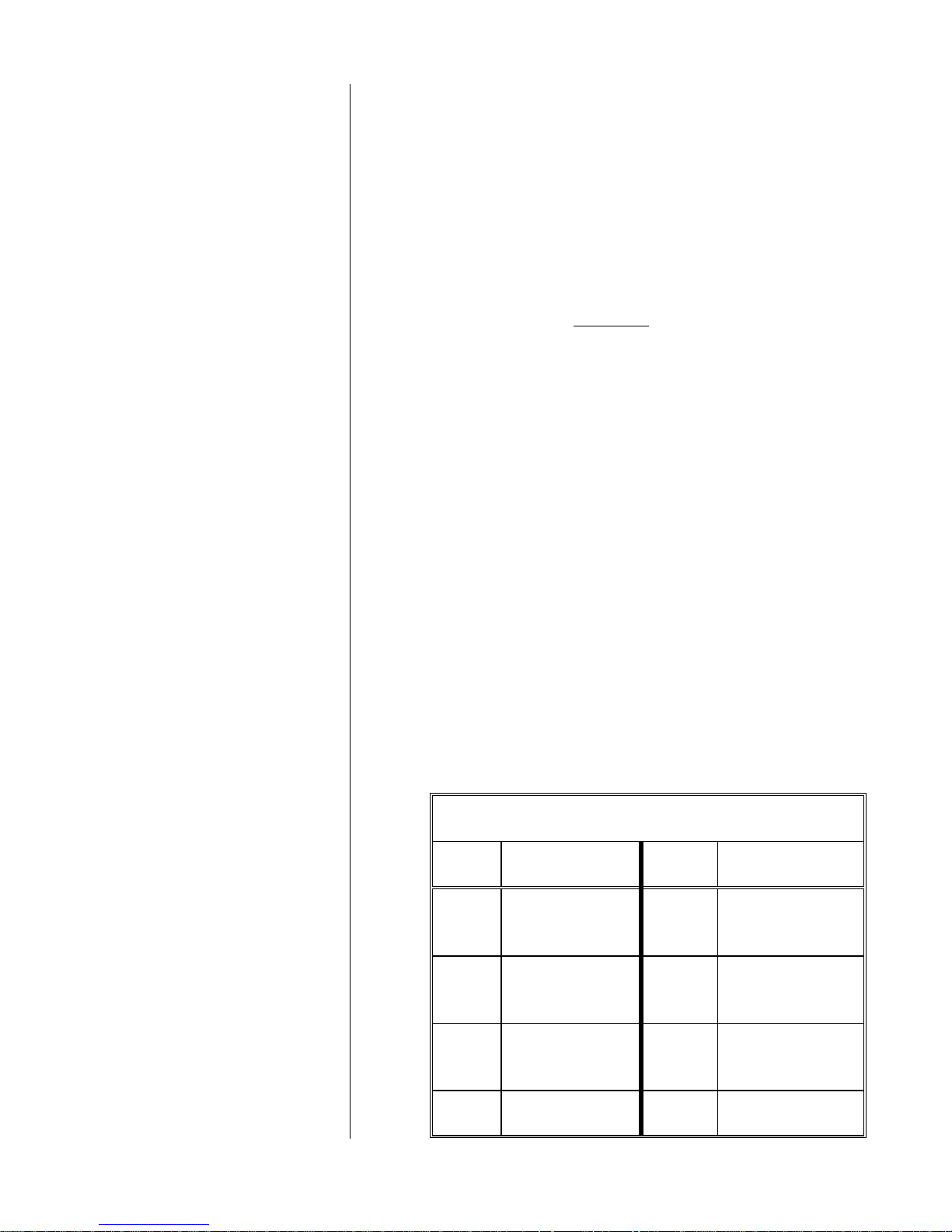

TABLES: Table A Resistor Values for Fixed

Temperature Compensation........................... 14

Table B Description of pH Setup Variables................. 28

Table C Description of Temperature

Setup Variables........................................... 28

Table D Description of mV Setup Variables ................ 29

Table E Buffer Values for “Two-Key” Table Method.... 39

Table F System Diagnostic Error

Messages/Meanings ...................................... 52

Model 692P Rev. 9-898

Table G Troubleshooting Common Problems.............. 55

PART ONE - INTRODUCTION SECTION 1 - GENERAL INFORMATION

PART ONE - INTRODUCTION

SECTION 1 - GENERAL INFORMATION

1.1 Instrument Capability

Input Versatility

The instrument may be used with any GLI Differential Technique pH sensor that has an integral preamplifier (identified

by its 5-wire cable) or a conventional pH combination electrode with integral or separate temperature sensor. A switch

sets the Model 692 for use with a 300 ohm thermistor or

1000 ohm RTD temperature sensor input to compensate the

pH measurement for variations in temperature.

Display Readouts

Operator Interface

Output Flexibility

Operator Safety

The large liquid crystal display can alternately indicate four

variables: pH, temperature (in °C or °F), the sensor's mV

signal, or the 4-20 mA instrument output.

Abbreviated identifiers are shown along with their related

numerical values to provide understandable readouts for

instrument setup, calibration and process monitoring. Procedure messages prompt the operator during instrument

setup and calibration. System diagnostic error messages

flash whenever the instrument detects an out-of-range input

for pH and/or temperature or a memory loss.

The 4-20 mA instrument output, which tracks the measured

pH, is isolated to eliminate problems caused by ground

loops. An output hold feature can be used to maintain the

latest output during calibration or instrument setup to suspend operation of a receiving device. A range expand

feature allows the 4-20 mA output to represent a one pH

unit or larger segment of the measuring scale.

Modular construction simplifies field servicing and provides

electrical safety for the operator. The printed circuit module

assemblies contain voltages no greater than 24 VDC and

are safe to handle. A terminal strip compartment, with separate access and weatherproof seals, permits electrical

hookup without exposing the instrument circuitry to the environment.

1.2 Battery Backup

Rev. 9-898 Model 692P

A lithium battery on the backside of the display board retains all user-entered setup values for approximately one

year (at 25°C), when loop power is removed. The battery's

capacity is one year of backup time which can occur over a

-7-

PART ONE - INTRODUCTION SECTION 1 - GENERAL INFORMATION

period of up to 10 years. A BATTERY ON/OFF jumper is

located next to the battery to disconnect the battery when

the instrument is not used for an extended time.

NOTE: If the instrument is operated with the battery

switched off, user-entered values are stored only as

long as power is applied. When power is removed,

all stored values will be lost. Factory-set defaults

will replace all user-entered values when power is

re-applied.

The back-up battery is replaceable.

WARNING: FOR HAZARDOUS AREA APPLICATIONS,

THE 692 TRANSMITTER MUST BE MOVED TO A SAFE

AREA FOR BATTERY REPLACEMENT, IF NEEDED.

1.3 Product Identification

The serial number of your instrument is located at the top of

the backside of the display module assembly (Figure 3-2).

Write the serial number in the space provided below for

convenient identification should technical assistance be required.

Serial Number

Model 692P Rev. 9-898

-8-

PART ONE - INTRODUCTION SECTION 2 - SPECIFICATIONS

SECTION 2 - SPECIFICATIONS

2.1 Operational

Display ......................... 4-1/2 digit LCD with measurement unit and

setup variable identifiers, 7/8" high digits

Measuring Range:

pH............................0.00 to 14.00 pH

mV ...........................(-)500 to (+)500 millivolts

Temperature............(-)10.0 to (+)110.0°C (14 to 230°F)

Ambient Conditions ......-30 to 50°C (-22 to 122°F), 0 to 95% relative

humidity, non-condensing

Temperature

Compensation .............. Automatic, 0-100°C (32-212°F), 300 ohm ther-

mistor or Pt 1000 RTD, switch selectable

Sensor-to-Transmitter

Distance .......................3000 feet maximum for GLI 5-Wire Differential

Technique sensor; 10 feet maximum for direct

connection of combination electrode (a GLI

Model 714 preamp is required for distances

greater than 10 feet)

Power Requirements .... 16 to 40 volts DC

Analog Output ..............Isolated 4-20 mA with output hold feature

Range Expand - The 4-20 mA output can be made to represent a

one pH unit or larger segment of the measuring scale.

Hazardous Area

Classification:

Intrinsic Safety.......UL and CSA: Class I, Div. 1 Groups A, B, C, & D

Class II, Div. 1 Groups E, F, & G

Baseefa: Zones 0 and 1, Groups IIC through IIA

Division 2 ............... CSA: Class I, Div. 2 Groups A, B, C, and D

♦

Maximum Loop Load

Class II, Div. 2 Groups E, F, and G

(in series with 692P

and power supply)....... With 24 VDC supply: 400 ohms

With 32 VDC supply: 800 ohms

With 40 VDC supply: 1200 ohms

2.2 Analyzer Performance

(Electrical, Analog

Output)

2.3 Mechanical

Rev. 9-898 Model 692P

NOTE - For long cable runs, the resistance of the wire must be

considered and may decrease maximum load capability.

♦

Not applicable when using barrier for intrinsic safety.

Sensitivity .....................0.05% of span

Stability ........................ 0.05% of span per 24 hours, non-cumulative

Non-linearity.................0.05% of span

Repeatability................. 0.01% of span or better

Temperature Drift.........Zero and Span: 0.01% of span per °C

Response Time ............1 second to 90% of value upon step change

Enclosure ..................... General purposesafe for Division 2; NEMA

4X, polycarbonate with two 1/2-inch conduit

holes and four stainless steel mounting tabs

Mounting

Configurations ..............Surface mount, optional vertical or horizontal

pipe mounting

Net Weight ...................3 lbs. (1.36 kg) approx.

-9-

PART TWO - INSTALLATION SECTION 1 - UNPACKING

PART TWO - INSTALLATION

SECTION 1 - UNPACKING

After unpacking, it is recommended to save the shipping

carton and packing materials in case the instrument is

stored or re-shipped. Inspect the equipment and carton for

damage. If there is evidence of shipping damage, notify the

carrier immediately.

SECTION 2 - MECHANICAL REQUIREMENTS

2.1 Location

An agency approved Model 692 is designed intrinsically

safe. That is, an explosionproof enclosure is not required

when the transmitter, powered through an approved barrier,

is located in Division 1 hazardous areas.

WARNING: THE POWER SUPPLY AND INTRINSIC

SAFETY BARRIER MUST ALWAYS BE LOCATED IN A

SAFE AREA.

1. Locate the 692 within 3000 feet of where the GLI 5-wire

Differential Technique sensor is to be installed. If a

combination electrode is used, the 692 must be within

10 feet of the electrode for a direct cable run. A GLI

Model 714 preamp may be used to extend this distance

to 3000 feet, but the preamp must be within 10 feet of

the electrode.

2. Mount the 692 in a location that is:

n Clean and dry where little or no vibration exists.

n Protected from falling corrosive fluids.

n Within ambient temperature limits (-22 to 122°F,

-30 to 50°C).

2.2 Mounting

Model 692P Rev. 9-898

CAUTION: MOUNTING IN DIRECT SUNLIGHT MAY

INCREASE TEMPERATURE ABOVE MAX. LIMIT.

Refer to Figure 2-1 for enclosure and mounting dimension

details. Figure 2-2 illustrates various mounting configurations. Use the four stainless steel tabs to surface-mount the

instrument. An optional hardware kit is required for pipe-

-10-

PART TWO - INSTALLATION SECTION 2- MECHANICAL REQUIREMENTS

mounting. The bracket attachment method determines vertical or horizontal pipe mounting configuration.

To surface mount the Model 692:

1. Place tabs in appropriate locations on back of enclosure

and fasten with screws provided.

2. Position instrument on flat surface and use appropriate

fasteners to secure it in place.

Rev. 9-898 Model 692P

FIGURE 2-1 Enclosure Outline

-11-

PART TWO - INSTALLATION SECTION 3 - ELECTRICAL CONNECTIONS

FIGURE 2-2 Mounting Configurations

2.3 Plugging Conduit

Holes

SECTION 3 - ELECTRICAL CONNECTIONS

3.1 GLI 5-Wire Differential

Technique Sensor

Use conduit hubs or cable feed-thru fittings where cables

enter the enclosure. Holes not used for cable entry should

be sealed with plugs.

NOTE: Use NEMA 4 rated fittings and plugs to maintain the

watertight integrity of the NEMA 4 enclosure.

To access terminal strips for electrical connections, loosen

bottom four captive fasteners and remove terminal compartment cover. Figure 3-2 shows terminal designations for

instrument hookup. If the transmitter is located in a hazardous area, refer to Section 3.5 for wiring details.

NOTE: For a CE-approved Model 692, the system must be

wired in accordance with GLI hookup drawing

1001X4N1306.

It is recommended that sensor signal wires be run in 1/2"

metal conduit for protection against moisture and mechanical damage. Do not run signal wires in same conduit with

power or control wiring (“electrical noise” may interfere with

sensor signal).

Model 692P Rev. 9-898

1. Place SWITCH 3 on back of display module assembly

(Figure 3-2) in DIFF. (off/right) position and TEMP.

COMP. switch to THERM.

2. Connect sensor (or interconnect cable) wires to

DIFFERENTIAL SENSOR terminals on TB2 (Figure 3-

2), matching colors as indicated.

-12-

PART TWO - INSTALLATION SECTION 3 - ELECTRICAL CONNECTIONS

3.2 Conventional

Combination Electrode

Direct Hookup

(distances less

1. Place SWITCH 3 on back of display module assembly

(Figure 3-2) in COMB. (on/left) position.

than 10 feet)

2. Active Electrode

Connect active electrode (center wire in coaxial or triax-

ial cable) to TB5 (ACTIVE) terminal post.

3. Reference Electrode

For a combination electrode that has a coaxial cable,

clamp the braided shield (reference electrode wire) under TB4 (REF.) terminal as shown in Figure 2-3.

If the electrode has a triaxial cable, clamp the inner

braided shield (reference electrode wire) under TB4

(REF.) terminal as shown in Figure 2-4.

Rev. 9-898 Model 692P

FIGURE 2-3 FIGURE 2-4

Connection Details for Connection Details for

Combination Electrode Combination Electrode

with Coaxial Cable with Triaxial Cable

4. Temperature Compensation Wiring

A. Automatic with Integral Temperature Sensor

1. The integral temperature sensor must be a 300

ohm thermistor or 1000 ohm RTD. Depending

which type of sensor it is, set TEMP.COMP.

switch to THERM. or RTD. position respectively.

-13-

PART TWO - INSTALLATION SECTION 3 - ELECTRICAL CONNECTIONS

2. For a combination electrode that has a coaxial

cable, connect separate temperature sensor wires

to TEMP COMP terminals on TB6 (Fig. 3-2).

If the electrode has a triaxial cable, clamp the

outer braided shield (temperature sensor wire)

under TB3 (RTD) terminal as shown in Figure 2-

4. In this case, set TEMP.COMP. switch to RTD.

position.

B. Automatic with Separate Temperature Sensor

1. The separate temperature sensor must be a 300

ohm thermistor or 1000 ohm RTD. Depending on

which type of sensor it is, set TEMP.COMP.

switch to THERM. or RTD. position respectively.

2. Connect separate temperature sensor (GLI p/n

60A2A9860-series) wires to TEMP COMP terminals on TB6 (Figure 3-2).

C. Fixed with External Resistor

1. Set TEMP.COMP. switch to THERM. position.

2. Connect the specific value resistor which corresponds with the desired temperature compensation across TEMP COMP terminals on TB6 (Fig.

3-2). The following table provides specific resistor

values required for the listed fixed temperature

compensation.

Table A RESISTOR VALUES FOR FIXED

TEMPERATURE COMPENSATION

°C

Resistor Value

(in ohms)

°C

Resistor Value

(in ohms)

0 771 55 114

5 631 60 99

10 519 65 85

15 430 70 74

20 358 75 65

25 300 80 57

30 252 85 50

35 213 90 44

40 181 95 39

45 155 100 35

50 133

Model 692P Rev. 9-898

-14-

PART TWO - INSTALLATION SECTION 3 - ELECTRICAL CONNECTIONS

Indirect Hookup

with Model 714 Preamp

(distances more

than 10 feet)

3.3 Power Supply

1. Place SWITCH 3 on back of display module assembly

(Figure 3-2) in DIFF. (off/right) position and TEMP.

COMP. switch to THERM.

2. Locate the GLI Model 714 preamp within 10 feet of the

combination electrode. Refer to the Model 714 preamp

instruction manual for electrical connection details between the combination electrode and the preamp.

3. The Model 692 can be located up to 3000 feet from the

Model 714 preamp. Connect interconnect cable from the

preamp to the Model 692 DIFFERENTIAL SENSOR terminals on TB2 (Figure 3-2), matching colors as

indicated.

Connect the DC voltage power supply to “4-20 mA” terminals on TB1, matching polarity as indicated.

NOTE: If the 692 is used in an intrinsically safe application,

it may be located in a Class I or II, Division 1 hazardous area without an explosionproof enclosure

when powered through an approved barrier. Refer

to Section 3.5 for details on hazardous area wiring

requirements.

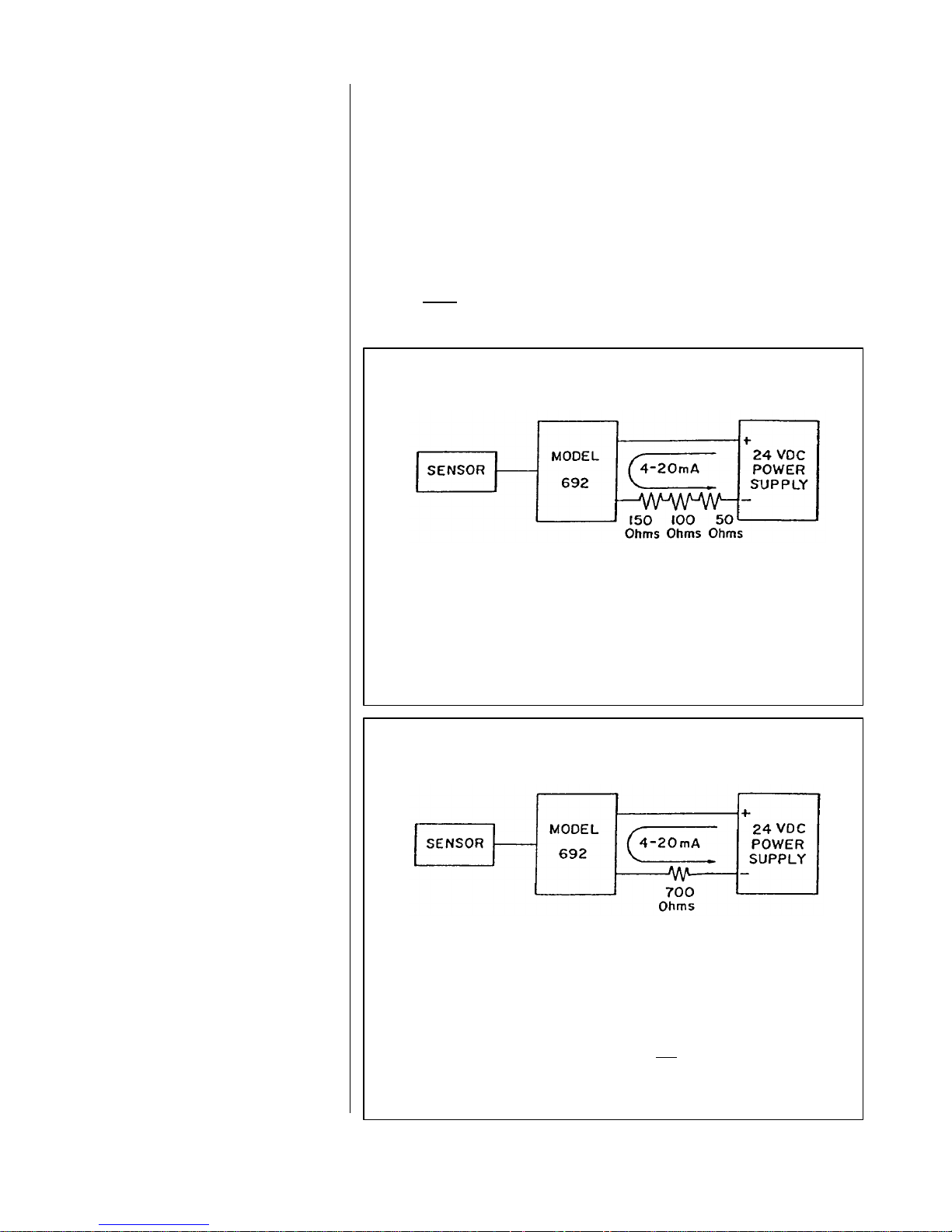

3.4 Analog Output

The isolated 4-20 mA output can represent either the

measuring scale or a selected segment of it. To use the

range expand feature, refer to Part Three, Section 7.1 for

details.

The isolated 4-20 mA output can drive auxiliary devices (resistive loads) such as displays, recorders and computers,

provided that the voltage supplied by the power supply is

adequate. Devices must be wired in series with the transmitter and power supply. The voltage drop across the

load(s) and the 16 volts DC minimum needed to drive the

transmitter determines the minimum voltage required from

the power supply.

1. Determine the necessary voltage required to adequately

drive the Model 692 and auxiliary device(s).

A. The Model 692 acts as a current controlling device.

Thus, the current output remains the same even if

the power supply voltage fluctuates or the load resistance changes. The current varies only with

respect to the sensor signal, as long as the voltage

Rev. 9-898 Model 692P

-15-

PART TWO - INSTALLATION SECTION 3 - ELECTRICAL CONNECTIONS

drop across the transmitter is at least 16 VDC, but

not more than 40 VDC.

B. The load(s) in the circuit will generally have some

electrical resistance, 100 ohms for example. The 420 mA loop current will produce a voltage drop

across each load. The maximum voltage drop will

exist when the loop current is 20 mA. The power

supply must provide enough voltage for this drop

plus the 16 VDC minimum required for the Model

692. Two examples illustrate this point:

EXAMPLE 1

Sufficient Power Supply Voltage

Total Load Resistance = 300 ohms

At 20 mA loop current, the voltage drop across the load(s) is 6 volts:

300 ohms x 20 mA = 6,000 mV or 6 volts

Subtract 6 volts from the 24 volt source to determine that 18 volts is

available to power the Model 692. The 18 volts is within the specified 16 to 40 volt range and is sufficient to power the transmitter.

EXAMPLE 2

Insufficient Power Supply Voltage

Total Load Resistance = 700 ohms

At 20 mA loop current, the voltage drop across the load is 14 volts:

700 ohms x 20 mA = 14,000 mV or 14 volts

Subtract 14 volts from the 24 volt source to determine that 10 volts

is available to power the Model 692. The 10 volts is below the

specified 16 to 40 volt range and is not adequate to power the

transmitter. If, for example, the power supply voltage was 40 volts

instead of 24 volts, the voltage available to power the Model 692

would be 26 volts, well within the specified range.

Model 692P Rev. 9-898

-16-

PART TWO - INSTALLATION SECTION 3 - ELECTRICAL CONNECTIONS

2. Connect load(s) in series with transmitter and power

supply.

NOTE: Connecting the transmitter output to some types

of computers may cause the computer display

reading to fluctuate. This is caused by “electrical

noise” in the signal line. To correct this condition,

connect a 4.7 microfarad/80 volt, metal foil capacitor across the computer input.

3.5 Hazardous Area

Wiring (Intrinsically

Safe - Div. 1)

UL Classified

System

All Model 692P regulatory agency certifications for installation in a hazardous area require that the transmitter must

be:

n Powered by a power supply that provides no more than

28 volts DC.

n Powered through a Pepperl & Fuchs KHD3-ICR/Ex130

200 transformer isolated barrier (GLI p/n 1F1054).

Furthermore, each respective regulatory agency requires

that you meet additional specific conditions. Refer to the

appropriate agency subheading for details.

The 692P is UL Classified as intrinsically safe in a Class I

or II, Div. 1 hazardous area (Groups A through G) only

when:

1. Using a GLI pH sensor with a model number listed on

GLI control drawing 1001X4N1138.

CSA Certified

System

Rev. 9-898 Model 692P

2. Wiring the system in accordance with GLI control drawing 1001X4N1138.

The 692P is CSA Certified as intrinsically safe in a Class I

or II, Div. 1 hazardous area (Groups A through G) only

when:

1. Using a GLI pH sensor with a model number listed on

GLI control drawing 1001X4N1179.

2. Wiring the system in accordance with GLI control drawing 1001X4N1179.

-17-

PART TWO - INSTALLATION SECTION 3 - ELECTRICAL CONNECTIONS

Baseefa Approved

System

The 692P is Baseefa Approved as intrinsically safe in a

Zone 0 or 1 hazardous area (Groups IIC through IIA) only

when:

1. Using a GLI pH sensor with a model number listed on

GLI control drawing number 1001X4N1266.

2. Wiring the system in accordance with GLI control drawing 1001X4N1266.

Model 692P Rev. 9-898

-18-

PART THREE - OPERATION SECTION 1 - OPERATING CONTROLS

PART THREE - OPERATION

SECTION 1 - OPERATING CONTROLS

The frequently used keypad switches (Figure 3-1) can be

used without opening the instrument enclosure. Seldom

used setup controls are located on the backside of the display module assembly (Figure 3-2). To access them, loosen

the upper four screw-type fasteners and open the enclosure

door. You can easily remove the complete door/display

module assembly from the enclosure by unsnapping it from

its hinge and disconnecting the ribbon-cable connector.

WARNING: DO NOT ADJUST THE FACTORY-SEALED

(RED SEALANT) POTENTIOMETERS. IF SEALS ARE

BROKEN, THE INSTRUMENT WARRANTY IS VOIDED. IF

THE INSTRUMENT IS RETURNED TO GLI AND ANY OF

THE FACTORY-SEALED POTENTIOMETERS REQUIRES

RE-ADJUSTMENT, A FACTORY SETUP CHARGE WILL

BE INCURRED.

1.1 Keypad Switches

All switches, status indicators and program jumpers used for

instrument operation are described in this section. Familiarize yourself with each item before operating the

instrument.

1. EXAM/CANCEL key (Figure 3-1)

Selects the normal “measurement” display mode or an

“examination” display mode. Successive key presses

alternate the display between these two modes.

n In measurement mode:

Display shows measured variable selected with DISP

VAR key: pH, temperature, the sensor's mV signal, or

the 4-20 mA instrument output.

n In “examination” mode:

Display shows setup variables and their stored values. Setup data such as calibration values, low and

high endpoints for range expand, etc. are called up in

the sequence shown in Figure 3-3 by pressing the

NEXT key (item 2). Values can be changed by using

the ññ and ïï keys (items 3 and 4) and are entered

by pressing the ENTER/CANCEL HOLD key (item

5). Any entry routine may be cancelled by pressing

the EXAM/CANCEL key which also returns display to

normal measurement mode.

Rev. 9-898 Model 692P

-19-

PART THREE - OPERATION SECTION 1 - OPERATING CONTROLS

2. NEXT key (Figure 3-1)

n With display in measurement mode:

This key has no effect.

n With display in “examination” mode:

Scrolls display to show next setup variable with each

press. Refer to Tables B, C, and D in Section 3 for a

complete listing of all setup variables.

3. ññ key (Figure 3-1)

n With display in measurement mode:

This key has no effect.

n With display in “examination” mode:

Increases flashing digit value by one with each key

press or continually advances digit value from 0 thru

9 by holding key down. This key is used with ïï key

(item 4) to change displayed value to a new value.

Model 692P Rev. 9-898

FIGURE 3-1 Keypad Switches

-20-

PART THREE - OPERATION SECTION 1 - OPERATING CONTROLS

4. ïï key (Figure 3-1)

n With display in measurement mode:

This key has no effect.

n With display in “examination” mode:

Progressively selects the next digit to the left to flash

with each press-and-release so that its value can be

changed with the ññ key (item 3). The flashing digit

“wraps around” from far left to far right.

5. ENTER/CANCEL HOLD key (Figure 3-1)

n With display in measurement mode:

Cancels output hold feature when pressed together

with OUTPUT key (item 9).

n With display in “examination” mode:

A. Enters displayed value into memory (if within ac-

ceptable range) for the indicated setup variable.

Display flashes “OK” for approximately 5 seconds

to confirm entry.

B. Cancels output hold feature when pressed to-

gether with OUTPUT key (item 9).

6. DISP VAR key (Figure 3-1)

n With display in measurement mode:

Scrolls display with each key press to show the following measured variables: pH, temperature (°C or

°F), the sensor's mV signal, and the 4-20 mA instrument output.

NOTE: To check the display to make sure all indi-

cators light up (as shown in Figure 3-1),

display the 4-20 mA output variable and

press the EXAM/CANCEL key.

Rev. 9-898 Model 692P

n With display in “examination” mode:

This key has no effect.

-21-

PART THREE - OPERATION SECTION 1 - OPERATING CONTROLS

7. BEGIN CAL key (Figure 3-1)

n With display in measurement mode:

A. Displays stored value for LO or HI CAL VALUE

setup variable used in “two-key” calibration (twopoint or table method). Each key press alternately

displays both stored values. To return display to

normal indication, pressed EXAM/CANCEL key.

B. Initiates calibration of a point used in “two-key”

calibration (two-point or table method). Specific

buffer values should be stored in memory before

using this key to initiate calibration (see Part

Three, Section 6.4 or 6.5 for details).

n With display in “examination” mode:

This key has no effect.

8. END CAL/HOLD recessed button (Figure 3-1)

n With display in measurement mode:

Activates output hold feature when pressed together

with OUTPUT key (item 9).

n With display in “examination” mode:

A. Completes calibration of a point used in “two-key”

two-point or “two-key” table method.

B. Activates output hold feature when pressed to-

gether with OUTPUT key (item 9).

9. OUTPUT key (Figure 3-1)

With display in measurement or “examination” mode:

A. Activates output hold feature when pressed together

with recessed END CAL/HOLD button.

B. Cancels output hold feature when pressed together

with ENTER/CANCEL HOLD key.

1.2 Slide Switches

Model 692P Rev. 9-898

10. SWITCH 2 (Figure 3-2)

Selects the state that the instrument will default to during

an out-of-range condition due to a defective pH sensor

or shorted sensor cable. The operator presets a low or

high out-of-range default state. In case of failure,

-22-

PART THREE - OPERATION SECTION 1 - OPERATING CONTROLS

this prevents a pump or valve from operating, therefore

conserving use of costly chemicals. For example, the

process may typically be controlled between 7 and 8 pH

with a tendency to increase without chemical addition. If

an out-of-range condition occurs in this example, you

can be prevent unwanted chemical addition by presetting the Model 692 for a low out-of-range default state.

This causes the display to indicate 0 pH and provides

the corresponding loop current (4 or 20 mA).

0 pH POSITION (on/left) - Selects the low out-of-range

state default. When the 692 detects a defective pH sensor or shorted sensor cable, the display indicates 0 pH

with an “ERR 1” or “ERR 3” diagnostic message, and the

692 provides a corresponding loop current (4 or 20 mA).

14 pH POSITION (off/right) - Selects the high out-of-range

state default. When the 692 detects a defective pH sensor

or shorted sensor cable, the display indicates 14 pH with

an “ERR 1” or “ERR 3” diagnostic message, and the unit

provides a corresponding loop current (4 or 20 mA).

11. SWITCH 3 (Figure 3-2)

COMB. POSITION (on/left) - Sets the 692 for use with a

combination electrode.

DIFF. POSITION (off/right) - Sets the 692 for use with a

GLI 5-wire Differential Technique sensor.

12. SWITCH 4 (Figure 3-2)

°F POSITION (on/left) - Selects measured temperature

to be displayed in °F.

°C POSITION (off/right) - Selects measured tempera-

ture to be displayed in °C.

13. TEMP. COMP. switch (Figure 3-2)

RTD - Sets the 692 for use with a 1000 ohm RTD

temperature sensor for automatic temperature compensation.

Rev. 9-898 Model 692P

THERM. - Sets the 692 for use with a 300 ohm thermistor temperature sensor for automatic temperature

compensation (or a specific-valued resistor for fixed

temperature compensation).

-23-

PART THREE - OPERATION SECTION 1 - OPERATING CONTROLS

1.3 Program Jumper 14. BATTERY jumper (Figure 3-2)

ON - Connects battery to store user-entered setup vari-

able values even when power is lost or turned off.

OFF - Disconnects battery when the 692 is not to be

used for an extended time.

CAUTION: If loop power is removed from the 692

and you disconnect the backup battery, all stored

setup values will revert back to factory defaults.

FIGURE 3-2 Controls on Backside of Display Module Assembly and Electrical Hookup Details

Model 692P Rev. 9-898

-24-

PART THREE - OPERATION SECTION 2 - MEASURED VARIABLES

1.4 Status Indicators 15. HOLD indicator (LCD display)

Indicates that the output hold feature is in use (Model

692 output value is maintained).

NOTE: After 30 minutes, HOLD indicator flashes to in-

dicate that output hold feature will be

automatically cancelled in 30 seconds. Pressing

OUTPUT key extends hold feature for another

30 minutes.

16. OK indicator (LCD display)

Flashes for approximately 5 seconds to confirm suc-

cessful entry of a setup variable value.

17. LOCK indicator (LCD display)

Indicates that Model 692 keypad entry is “locked” to

prevent unauthorized alteration of stored setup variable

values. Refer to Section 8 for security lock feature instructions.

NOTE: When the 692 is locked, you can still enter cali-

bration values and display stored entry values.

18. ERROR indicator (LCD display)

Flashes to indicate an incorrect entry or alternately

flashes with “Err 1”, “Err 2”, “Err 3” or “Err 4” to indicate

a system diagnostic error causing improper system operation.

SECTION 2 - MEASURED VARIABLES

The Model 692 can display four measured variables. With

the display in the measurement mode, each press of the

DISP VAR key sequentially displays:

Rev. 9-898 Model 692P

n pH.

n Temperature in °C or °F.

n The sensor's mV signal.

n The 4-20 mA instrument analog output.

-25-

PART THREE - OPERATION SECTION 3 - SETUP VARIABLES

SECTION 3 - SETUP VARIABLES

3.1 Calling Up

Setup Variables

3.2 Entering Values

1. Pressing the EXAM/CANCEL key while the display is in

the measurement mode changes the readout to an “examination” mode to show setup variables. The pH,

temperature, and mV displays each have a corresponding menu showing related setup variables to configure

the instrument.

2. Each press of the NEXT key displays the next setup

variable, in sequence, for its respective menu. Within

each menu, setup variables “wrap around” from last to

first.

Pressing the EXAM/CANCEL key at any time returns the

display to the measuring mode.

Use the ññ and ïï keys to change displayed setup values.

Each press of the ññ key increases the flashing digit value

by one. Holding down this key continually advances the

value. Pressing and releasing the ïï key selects the next

digit to the left (digit flashes) so it can be changed using the

ññ key. After establishing the desired value, press the

ENTER key to store it in memory. Thereafter, “OK” flashes

for approximately 5 seconds to confirm that the entry was

accepted, or “ERROR” flashes if the entry was invalid.

3.3 Setup Variables

Call-Up Chart and

Table of Descriptions

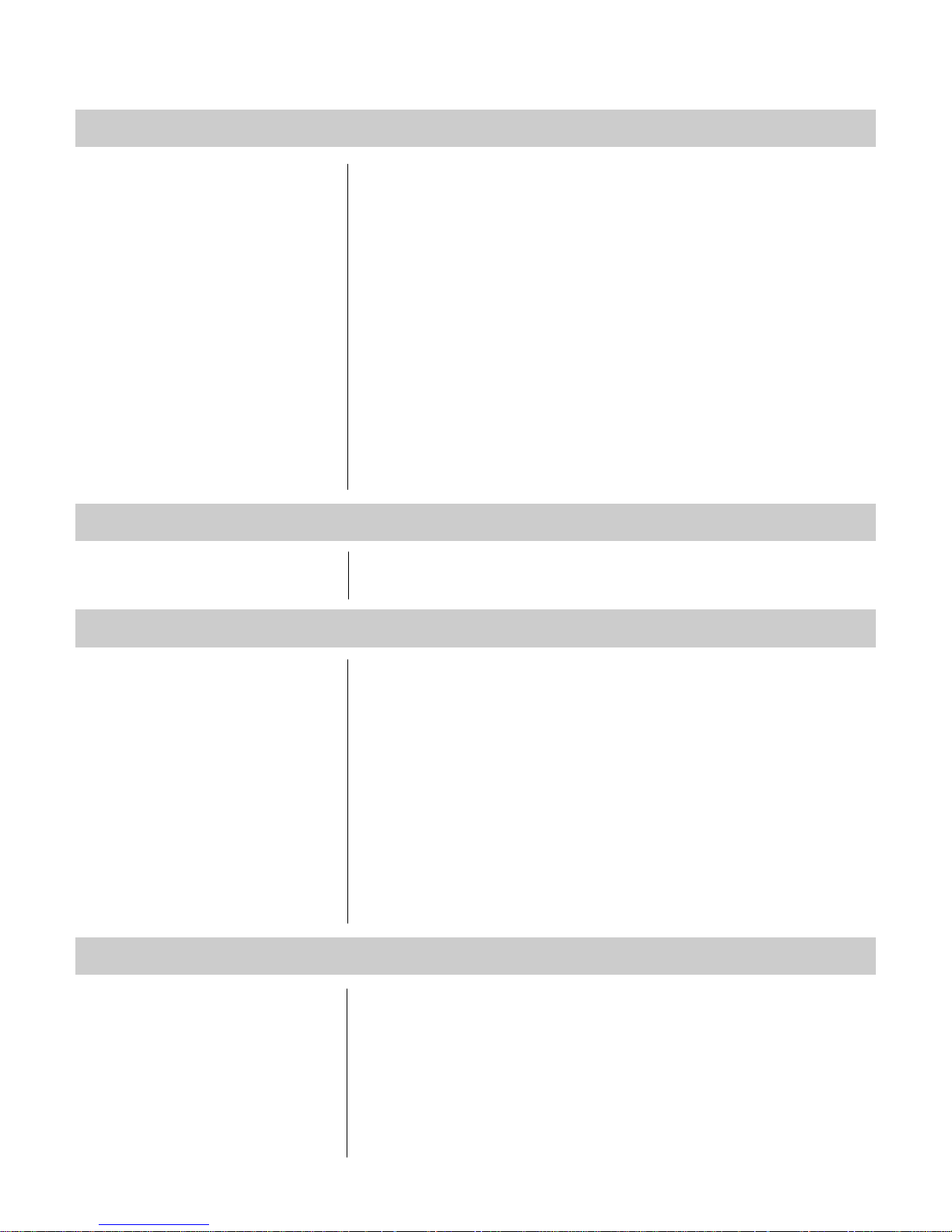

Figure 3-3 on the following page shows the four measured

variable display modes (shaded boxes at top of chart), and

their respective setup variable menus in the call-up order.

When using the output hold feature, the “SIM VALUE” setup

variable cannot be used or displayed (see footnote at bottom of chart).

Model 692P Rev. 9-898

-26-

PART THREE - OPERATION SECTION 3 - SETUP VARIABLES

All display

segments light

E

X

A

M

/

C

A

N

C

E

L

NEXT

NEXT

NEXT

NEXT

NEXT

"HI BUFFER

OUT VALUE"

OUT VALUE"

"LO BUFFER

E

X

A

M

/

C

A

N

C

E

L

E

X

A

M

/

C

A

N

C

E

L

E

X

A

M

/

C

A

N

C

E

L

E

X

A

M

/

A

N

C

E

L

R

e

l

e

a

s

e

E

X

A

M

/

C

A

N

C

E

L

DISP. VAR

DISP. VAR

X

A

M

/

A

N

C

E

L

"BUFFER CAL"

pH Display

C

EXAM /

CANCEL

EXAM /

CANCEL

EXAM/

CANCEL

EXAM/

CANCEL

"CAL

VALUE"

NEXT

"LO CAL

VALUE"

NEXT

"HI CAL

VALUE"

NEXT

"SLOPE"

DISP. VARDISP. VAR

EXAM /

CANCEL

EXAM /

CANCEL

EXAM/

CANCEL

NEXT

Temperature

Display

"CAL

VALUE"

NEXT

"LO CAL

VALUE"

NEXT

"HI CAL

VALUE"

NEXT

EXAM /

CANCEL

EXAM /

CANCEL

mV Display

"CAL

VALUE"

"LO CAL

VALUE"

"HI CAL

VALUE"

mA Display

NEXT

NEXT

EXAM/

CANCEL

EXAM/

CANCEL

"0000"

(Lock)

"SIM VALUE"

1

Displayed only when the output hold feature is not in use.

NEXT

1

NEXT

VALUE"

EXAM/

CANCEL

VALUE"

EXAM/

CANCEL

"LO

EXAM/

CANCEL

"HI

E

C

E X A M /

C A N C E L

FIGURE 3-3 Display Modes and Call-up Chart of Setup Variables

NEXT

Rev. 9-898 Model 692P

-27-

PART THREE - OPERATION SECTION 3 - SETUP VARIABLES

The following tables for each of the three setup variable

menus list the setup variables in exact order of call-up, their

use, entry value range, and factory default value. Use the

far right column to write in your entered setup values for

convenient referral.

Table B - DESCRIPTION OF pH SETUP VARIABLES

Entry Value

Displayed Use

Identifier

“CAL

VALUE”

“LO CAL

VALUE”

“HI CAL

VALUE”

“SLOPE” Display only of 0-100% slope (0-59mV/pH).

“0000” Activates the security lock feature. 0000 9999 0000

“SIM VALUE”

“LO BUFFER

VALUE”

“HI BUFFER

VALUE”

“LO

OUT VALUE”

“HI

OUT VALUE”

“BUFFER CAL”

Sets calibration point for conventional single-point

pH calibration.

Sets low calibration point for conventional two-point

pH calibration.

Sets high calibration point for conventional two-point

pH calibration.

Sets simulated pH value for diagnostic purposes. The

∆

analog output responds to the displayed value.

Sets the value of lower buffer used for

“two-key” pH calibration: Two point method

Table method

Sets the value of higher buffer used for

“two-key” pH calibration: Two-point method

Table method

Sets low endpoint of pH measuring range at which the

minimum output (4 mA) is provided.

Sets high endpoint of pH measuring range at which the

maximum output (20 mA) is provided.

Selects two-point or table method for “two-key” pH

calibration.

Range Default

Min. Max.

0.00 14.00 7.00

0.00 10.00 4.00

2.00 12.00 10.00

0.00 14.00 7.00

0.00

1.09

2.00

3.56

0.00 14.00 0.00

0.00 14.00 14.00

tABL 2 Pt 2 Pt

10.00

10 A

12.00

12.45

Record

Your

Value Entry

ê

4.00

4.00

10.00

10 A

∆

Only provided and displayed when the output hold feature is not in use.

Table C - DESCRIPTION OF TEMPERATURE SETUP VARIABLES

Displayed Use

Identifier

“CAL

VALUE”

“LO CAL

VALUE”

“HI CAL

VALUE”

Model 692P Rev. 9-898

Sets calibration point for single-point

temperature calibration: °C

Sets low calibration point for two-point

temperature calibration: °C

Sets high calibration point for two-point

temperature calibration: °C

-28-

°F

°F

°F

Entry Value

Range Default

Min. Max.

0.0

100.0

32.0

32.0

25.0

77.0

0.0

212.0

30.0

86.0

100.0

212.0

Record

Your

Value Entry

ê

25.0

77.0

0.0

32.0

100.0

212.0

PART THREE - OPERATION SECTION 4 - INSTRUMENT STARTUP

Table D - DESCRIPTION OF mV SETUP VARIABLES

Displayed Use

Identifier

“CAL

VALUE”

“LO CAL

VALUE”

“HI CAL

VALUE”

Sets calibration point for single-point millivolt

calibration.

Sets low calibration point for two-point millivolt

calibration.

Sets high calibration point for two-point millivolt

calibration.

SECTION 4 - INSTRUMENT STARTUP

4.1 Checking Battery

Backup Jumper

4.2 Setting Sensor

Input Type

Entry Value

Range Default

Min. Max.

(-)500 (+)500 (+)200

(-)500 (+)50 (-)180

(+)100 (+)500 (+)180

Value Entry

Record

Your

ê

In case loop power is lost, an internal battery powers the

Model 692 memory to retain all user-entered setup variable

values. The 692 is supplied with its BATTERY jumper (Figure 3-2) in the OFF position. Make sure to place this jumper

in the ON position before proceeding.

You must set the 692 sensor input to accept the type of

sensor that will be used.

GLI 5-Wire

Differential Technique

Sensor

Conventional

Combination Electrode

1. Locate the group of four switches on back of display

module assembly (Figure 3-2) and place SWITCH 3 in

DIFF. (off/right) position.

2. Set TEMP. COMP. switch to THERM position.

# # #

1. Direct Hookup (distances less than 10 feet)

A. Locate the group of four switches on back of display

module assembly (Figure 3-2) and place SWITCH 3

in COMB. (on/left) position.

B. Depending on the type of temperature sensor used

for temperature compensation, set TEMP. COMP.

switch as follows:

a. When using a 1000 ohm RTD, place in RTD po-

sition.

Rev. 9-898 Model 692P

b. When using a 300 ohm thermistor or a fixed re-

sistor, place in THERM position.

-29-

PART THREE - OPERATION SECTION 5 - TEMPERATURE CALIBRATION

2. Indirect Hookup with Model 714 Preamp (distances more

than 10 feet)

A. Locate the group of four switches on back of display

module assembly (Figure 3-2) and place SWITCH 3

in COMB. (on/left) position.

B. Set TEMP. COMP. switch to THERM position.

4.3 Selecting Temperature

Display Units (°°C or °°F)

4.4 Understanding

Calibration

4.5 Selecting Default State

for Out-of-Range

Condition

SECTION 5 - TEMPERATURE CALIBRATION

5.1 Temperature Effects

on pH Reading

Locate the group of four switches on back of display module

assembly (Figure 3-2) and place SWITCH 4 in °°F (on/left)

position for temperature values to be displayed in °F. Place

in opposite °°C (off/right) position for °C readout.

Before initially calibrating the instrument, read Section 5.1

“Temperature Effects on pH Reading” and Section 6.1

“Summary of Methods”. Then calibrate the instrument using

the desired method.

When an out-of-range condition occurs due to a defective

pH sensor or shorted sensor cable, the instrument will respond according to the default state selected with SWITCH

2 (Figure 3-2). Refer to Section 1.2 - item 10 for details

about this switch and its settings.

The instrument automatically compensates the pH reading

for changes in temperature and has temperature calibration

capabilities. For best accuracy, it is recommended to initially calibrate the instrument for temperature before

calibrating for pH measurement.

300 Ohm

Thermistor

Compensation

1000 Ohm RTD

Compensation

Model 692P Rev. 9-898

When using a GLI Differential Technique pH sensor or a pH

combination electrode with a 300 ohm thermistor, you can

disregard temperature calibration. (The 692 is factorycalibrated for this temperature sensor.) If, however, you

require extremely accurate temperature measurement, perform a single or two-point temperature calibration (Section

5.2 or 5.3) before calibrating the 692 for pH measurement.

When using a pH combination electrode with a 1000 ohm

RTD, always perform a two-point temperature calibration

before calibrating for pH to obtain the most accurate pH

readings.

-30-

PART THREE - OPERATION SECTION 5 - TEMPERATURE CALIBRATION

Fixed Resistor

Compensation

5.2 Single-Point Method

When using a pH combination electrode with an external

resistor for fixed temperature compensation, always perform

a single-point temperature calibration to provide the best pH

measurement accuracy. Instead of normally entering the

known temperature value of the process, enter the temperature compensation value (in °C) corresponding to the

value of the external resistor being used (see Table A on

page 14).

This method requires a container of water (or process solution) that has a known temperature value approximately

equal to the normal operating temperature of the process.

1. Place temperature sensor in water (or process solution)

of known temperature value.

2. Press DISP VAR key as needed to display temperature

and allow the reading to stabilize. The sensor may take

several minutes to attain temperature equilibrium with

the solution.

3. Press EXAM/CANCEL key to place display in “examination” mode and to indicate temperature “CAL VALUE.”

4. Use ïï and ññ keys to make display indicate the

known temperature value of the solution.

5. Press ENTER key to enter value (display flashes “OK” to

confirm entry and returns to temperature measuring

mode). “HI/LO ERROR” flashes if the difference between

the entry value and actual solution temperature is

greater than 5.0°C.

5.3 Two-Point Method

Rev. 9-898 Model 692P

This completes the single-point temperature calibration.

This method requires a container of ice water and a con-

tainer of water (or process solution) that has a known

temperature value of 90-100°C (194-212°F) or is approximately equal to the normal operating temperature of the

process.

1. Place temperature sensor in ice water.

2. Press DISP VAR key as needed to display temperature

and allow display reading to stabilize. The sensor may

take several minutes to attain temperature equilibrium

with the solution.

-31-

PART THREE - OPERATION SECTION 6 - pH CALIBRATION

3. Press EXAM/CANCEL key to place display in “exami-

nation” mode.

4. Press NEXT key once to make display indicate tem-

perature “LO CAL VALUE”.

5. Use ïï and ññ keys to make display indicate “0.0°C”

(or “32.0°F”).

6. Press ENTER key to enter value (display flashes “OK”

to confirm entry and returns to temperature measuring

mode). If “HI/LO ERROR” flashes, the difference between the entry value and actual solution temperature

is greater than 10.0°C.

7. Place temperature sensor in the known higher tem-

perature water (or process solution). Allow sensor to

attain temperature equilibrium with the solution.

8. Press EXAM/CANCEL key to place display in “exami-

nation” mode.

9. Press NEXT key twice to make display indicate tem-

perature “HI CAL VALUE.”

10. Use ïï and ññ keys to make display indicate the

known temperature value.

NOTE: Entry value must be between 25.0 and 100.0°C

and at least 10.0°C higher than the lower calibration point (0.0°C from step 5).

11. Press ENTER key to enter value (display flashes “OK”

to confirm entry and returns to temperature measuring

mode). “VALUE ERROR” flashes if the difference between entry values is less than 10.0°C. If “HI/LO

ERROR” flashes, entry value is out of range (less than

25.0°C or greater than 100.0°C) or the difference between the entry value and actual solution temperature

is greater than 10.0°C.

This completes the two-point temperature calibration.

SECTION 6 - pH CALIBRATION

Model 692P Rev. 9-898

The instrument must be calibrated periodically with pH

buffer solution(s) to maintain measurement accuracy. It is

highly recommended to establish a maintenance program to

-32-

PART THREE - OPERATION SECTION 6 - pH CALIBRATION

keep the sensor clean and the instrument calibrated. The

time period between performing maintenance (days, weeks,

etc.) is affected by the characteristics of the process solution and can only be determined by operating experience.

For example, a sensor operating in wastewater that contains oil and/or grease may require more frequent cleaning.

6.1 Summary of Methods

The instrument can be calibrated for pH in a number of different ways. Use the conventional single or two-point

method (Section 6.2 or 6.3 respectively) when you want to

actually enter the known buffer values into memory.

NOTE: The conventional two-point method is highly recom-

mended for initial calibration or when the pH sensor

has been replaced.

Two alternate “two-key” calibration methods are also available. These methods are highly recommended for the

novice operator since they eliminate the need for that person to enter buffer values, making them especially

convenient. When using the “two-key” two-point calibration

method (Section 6.4), a qualified person initially enters two

buffer values. Anytime thereafter, a novice operator can accurately calibrate the instrument for each point by simply

pressing two keys. The only requirement is placing the sensor in the appropriate buffer for each calibration point.

The other “two-key” calibration method is the table method

(Section 6.5). It is similar to the “two-key” two-point method

except that a qualified person initially selects the buffer values from a table of 14 specific buffer formulations. This

method provides the most accurate calibration because errors caused by small changes in buffer value due to

temperature variations are eliminated by the built-in pHversus-temperature curve related to that buffer. Also, the

instrument automatically recognizes and differentiates between the two pre-selected buffers during calibration. The

operator need not know the buffer values.

6.2 Conventional

Single-Point

Method

Rev. 9-898 Model 692P

This procedure requires a clean sensor and one fresh, accurate pH buffer with a value reasonably close to the normal

pH of the process (pH 7, 4, or 10 buffer is recommended

and readily available).

1. With display in pH measuring mode, place clean sensor,

with protective caps removed, in the known buffer. Allow

display reading to stabilize. The sensor may take several minutes attaining temperature equilibrium with the

buffer.

-33-

PART THREE - OPERATION SECTION 6 - pH CALIBRATION

NOTE: If a pH combination electrode is used with an

external temperature sensor, place the temperature sensor in the buffer along with the

electrode. If an external resistor is used for fixed

temperature compensation (Table A on page

14), it is recommended to bring the temperature

of the buffer to that specific temperature for best

accuracy.

2. Press EXAM/CANCEL key to place display in “examination” mode and to indicate pH “CAL VALUE.”

3. Use ïï and ññ keys to make display indicate the

known pH value of the buffer (from table on buffer bottle).

4. Press ENTER key to enter value (display flashes “OK” to

confirm entry and returns to pH measuring mode).

This completes the conventional single-point pH calibration.

6.3 Conventional

Two-Point

Method

This procedure requires a clean sensor and two fresh, accurate pH buffers. pH 7 and pH 4 buffers are recommended

and are readily available. If pH 4 buffer is not available,

substitute pH 10 buffer.

1. With display in pH measuring mode, place clean sensor,

with protective caps removed, in the lower value buffer.

Allow display reading to stabilize. The sensor may take

several minutes to attain temperature equilibrium with

the buffer.

NOTE: If a pH combination electrode is used with an

external temperature sensor, place the temperature sensor in the buffer along with the

electrode during this step and step 6. If an external resistor is used for fixed temperature

compensation (Table A on page 14), it is recommended to bring the temperature of buffer

used in this step and step 6 to the fixed compensation temperature for best accuracy.

2. Press EXAM/CANCEL key to place display in “examination” mode.

Model 692P Rev. 9-898

3. Press NEXT key once to make display indicate pH “LO

CAL VALUE.”

4. Use ïï and ññ keys to make display indicate the value

of the lower pH buffer (from table on buffer bottle).

-34-

PART THREE - OPERATION SECTION 6 - pH CALIBRATION

NOTE: Entry value must be between 0.00 and 10.00 pH

and at least 1.00 pH lower than the value of the

higher calibration point.

5. Press ENTER key to enter value (display flashes “OK” to

confirm entry and returns to pH measuring mode).

NOTE: If display indicates “Err 1” diagnostic message,

ignore it and proceed with step 6. This message

indicates that the new LO CAL VALUE entry is

significantly different than the previously entered

calibration values. After the HI CAL VALUE is

entered (step 10), the “Err 1” message will cancel

and the display will return to normal indication.

6. Remove sensor from lower value buffer. Rinse sensor in

clean water and place in higher value buffer. Allow sensor to attain temperature equilibrium with the buffer.

7. Press EXAM/CANCEL key to place display in “examination” mode.

8. Press NEXT key twice to make display indicate pH “HI

CAL VALUE.”

9. Use ïï and ññ keys to make display indicate the value

of the higher pH buffer (from table on buffer bottle).

6.4 “Two-Key”

Two-Point Method

NOTE: Entry value must be between 2.00 and 12.00 pH

and at least 1.00 pH higher than the value of the

lower calibration point.

10. Press ENTER key to enter value (display flashes “OK” to

confirm entry and returns to pH measuring mode).

“VALUE ERROR” flashes if the difference between entry

values is less than 1.00 pH.

This completes the conventional two-point pH calibration.

Use the conventional two-point method (Section 6.3) to ini-

tially calibrate the instrument, including when the pH sensor

has been replaced. Thereafter, you can use the “two-key”

two-point method, but first a qualified person must:

n Set the instrument for this method.

Rev. 9-898 Model 692P

-35-

PART THREE - OPERATION SECTION 6 - pH CALIBRATION

n Enter pH buffer (or known process solution) values to

be used as the two calibration points.

Thereafter, the instrument can be periodically calibrated

using the procedure described under the “Performing Calibration” subheading.

Selecting

This Method

Entering Calibration Points

(by qualified person)

1. With display in pH measuring mode, press EXAM/

CANCEL key to place display in “examination” mode.

2. Press NEXT key until display indicates “BUFFER CAL.”

3. Press ïï key to make display indicate “2 Pt.”

4. Press ENTER key to select “two-key” two-point method

(“OK” flashes to confirm entry).

# # #

1. Press NEXT key until display indicates “LO BUFFER

VALUE.”

2. Use ïï and ññ keys to make display indicate the de-

sired value for the lower calibration point.

NOTE: Entry value must be 10.00 pH or lower.

3. Press ENTER key to enter value (“OK” flashes to confirm entry).

4. Press NEXT key once to make display indicate “HI

BUFFER VALUE.”

5. Use ïï and ññ keys to make display indicate the de-

sired value for the higher calibration point.

NOTE: Entry value must be at least 2.00 pH units higher

than the value of the lower calibration point.

6. Press ENTER key to enter value (display flashes “OK” to

confirm entry or “VALUE ERROR” if difference between

entry value and LO BUFFER VALUE is less than 2.00

pH units).

7. Press EXAM/CANCEL key to return display to pH

measuring mode.

Performing Calibration

Model 692P Rev. 9-898

Use this “two-key” two-point method to calibrate the instrument after both calibration points have been entered. This

-36-

PART THREE - OPERATION SECTION 6 - pH CALIBRATION

calibration procedure requires a clean sensor and two fresh,

accurate pH buffers (or known process solutions) that have

the same values as the two preset calibration points.

1. Place clean sensor, with protective caps removed, in the

lower value buffer.

NOTE: If a pH combination electrode is used with an

external temperature sensor, place the temperature sensor in the buffer along with the

electrode during this step and step 4. If an external resistor is used for fixed temperature

compensation (Table A on page 14), it is recommended to bring the temperature of buffer

used in this step and step 4 to the fixed compensation temperature for best accuracy.

2. With display in pH measuring mode, press BEGIN CAL

key (display indicates one of the preset values “LO

CAL VALUE” or “HI CAL VALUE”). If display indicates

the higher value, press BEGIN CAL key again to display

lower value.

After pressing BEGIN CAL, you have 30 minutes to com-

plete the calibration of this point. During the routine,

another 30 minutes can be added by pressing any key

except END CAL.

The instrument checks the stability of the pH and tempera-

ture inputs. As each input changes, the respective pH

and °C (or °F) indicator flashes. When each input is stable, the respective indicator stops flashing and remains

on.

When the pH and °C (or °F) indicators are both on (not

flashing), press recessed END CAL button using a slender tool. The instrument checks that:

Rev. 9-898 Model 692P

n The pH input has a slope between 51 and 62 mV/pH.

If not, the display flashes “HI/LO SLOPE ERROR.”

n The pH input offset is within ±1.50 pH of the entry

value. If not, the display flashes “HI/LO ERROR.”

n This calibration point is at least 2.00 pH away from

the other calibration point. If not, the display flashes

“BUFFER VALUE ERROR.”

When these conditions are met, the display flashes “OK”

-37-

PART THREE - OPERATION SECTION 6 - pH CALIBRATION

to confirm entry was made and returns to the pH measuring mode.

NOTE: If display flashes “HI/LO SLOPE ERROR” or

“HI/LO ERROR,” an incorrect buffer value may

have been used or the sensor may be dirty or

defective. If the correct buffer value was used,

calibrate the instrument using the conventional

two-point method (Section 6.3) to check the

sensor slope which is based on the last successful calibration. Refer to Part Four, Section

1.3 for details on checking sensor slope.

4. Remove sensor from lower value buffer. Rinse sensor in

clean water and place in the higher value buffer.

5. Press BEGIN CAL key to initiate calibration of the second calibration point.

6. When the pH and °C (or °F) indicators are both on (not

flashing), press recessed END CAL button using a slender tool. See step 3 for additional details.

6.5 “Two Key”

Table Method

This completes the “two-key” two-point pH calibration.

Any buffer has some variation of pH value with temperature,

but few operators take the time to measure the buffer temperature with the sensor at equilibrium, and then enter the

pH of the buffer at that temperature. The basis for this “twokey” table method is that the 692 has the built-in pH valueversus-temperature curve for a set of buffers and monitors

the temperature and time response when the sensor is put

into a buffer. Using this method provides the most accurate

calibration.

Use the conventional two-point method (Section 6.3) to initially calibrate the instrument, including when the pH sensor

has been replaced. Thereafter, you can use the “two-key”

table method, but first a qualified person must:

n Set the instrument for this method.

n Select and enter one or two pH buffer values from the

buffer table to be used as the calibration point(s).

Model 692P Rev. 9-898

Thereafter, the instrument can be periodically calibrated

using the procedure described under the “Performing Calibration” subheading beginning on page 40.

-38-

PART THREE - OPERATION SECTION 6 - pH CALIBRATION

Selecting

This Method

Entering Calibration Points

(by qualified person)

1. With display in pH measuring mode, press EXAM/

CANCEL key to place display in “examination” mode.

2. Press NEXT key until display indicates “BUFFER CAL.”

3. Press ïï key to make display indicate “tAbL.”

4. Press ENTER key to select “two-key” table method

(“OK” flashes to confirm entry).

# # #

1. The following table lists the selection of pH values and

their buffer formulations. Choose and note one or two

table pH values for use as the calibration point(s).

NOTE: When two calibration point values are selected,

they must be at least one table value apart from

each other (non-adjacent values).

Table E BUFFER VALUES FOR

“TWO-KEY” TABLE METHOD

pH Buffer Value Buffer Formulation

1.09 HCl (DIN 19267)

1.68 Tetraoxalate (NBS 260-53)

3.56 Tartrate (NBS 260-53)

3.78 Citric acid (DIN 19266)

4.00* Pthalate (DIN 19266)

4.01 Pthalate (NBS 260-53)

4.65 Acetate (DIN 19267)

6.87 Phosphate (DIN 19266)

7.00 Phosphate

7.41 Phosphate (DIN 19266)

9.18 Borax (NBS 260-53)

10.00 (10 A on display)* Carbonate/bicarbonate

(0.5 Molar)

10.00 (10 b on display) Glycol

12.45 Calcium hydroxide (DIN 19266)

*Indicates default values for LO and HI BUFFER VALUES.

2. Press NEXT key until display indicates “LO BUFFER

VALUE.”

3. Use ïï and ññ keys to make display indicate the de-

sired value for the single or lower calibration point.

Rev. 9-898 Model 692P

-39-

PART THREE - OPERATION SECTION 6 - pH CALIBRATION

NOTE: If desired LO BUFFER VALUE is equal to or

higher than the current HI BUFFER VALUE,

change the HI BUFFER VALUE first (step 5)

before entering the LO BUFFER VALUE.

4. Press ENTER key to enter value (“OK” flashes to confirm entry).

5. If a second calibration point is used (or if single calibration point cannot be accessed using LO BUFFER

VALUE):

A. Press NEXT key once to make display indicate “HI

BUFFER VALUE.”

B. Use ïï and ññ key to make display indicate the de-

sired value for the calibration point (see Table E).

Performing Calibration

NOTE: If desired HI BUFFER VALUE is equal to or

lower than the current LO BUFFER VALUE,

change the LO BUFFER VALUE first before

entering the HI BUFFER VALUE.

C. Press ENTER key to enter value (“OK” flashes to

confirm entry).

6. Press EXAM/CANCEL key to return display to pH

measuring mode.

For best accuracy, be sure to use buffer values of the same

formulation as those selected from Table E. To verify buffers, refer to Part Four, Section 1.6 for the pH-versustemperature data of all Table E buffer formulations.

Use this “two-key” table method to calibrate the instrument

after calibration point(s) have been entered. This calibration

procedure requires a clean sensor and fresh, accurate pH

buffer(s) that have the same value(s) as the preset calibration point(s).

Model 692P Rev. 9-898

1. Place clean sensor, with protective caps removed, in

one of the calibration buffers. The operator need not

know which buffer it is, but it must be one of the entered

buffers selected from the table.

2. With display in pH measuring mode, press BEGIN CAL

key.

-40-

PART THREE - OPERATION SECTION 7 - OUTPUT SETUP

The operator has 30 minutes to complete the calibration

of this point. During the routine, pressing any key except

END CAL provides another 30 minutes if needed.

The instrument checks:

n The stability of the pH and temperature inputs. As

each input changes, the respective pH and °C (or °F)

indicator flashes. When each input is stable, the respective indicator stops flashing and remains on.

n That the pH input is within ±0.75 pH of the buffer

value. When outside this range, the display flashes

“OUT”; within this range the “OUT” indicator goes off.

When these conditions are met, the display will indicate

“LO CAL VALUE” or “HI CAL VALUE,” depending on

which buffer the sensor is in.

3. When display indicates “LO CAL VALUE” or “HI CAL

VALUE” and the pH and °C (or °F) indicators are both on

(not flashing), press recessed END CAL button using a

slender tool. The displayed identifier and value goes off,

“OK” flashes for 5 seconds to confirm entry and the display returns to the pH measuring mode.

4. If a second calibration point is used, remove sensor from

first buffer. Rinse sensor in clean water and place in the

second buffer.

5. With display in pH measuring mode, press BEGIN CAL

key. See step 2 for additional details.

6. Perform step 3.

This completes the “two-key” table pH calibration.

SECTION 7 - OUTPUT SETUP

7.1 Using Range Expand

Feature

Rev. 9-898 Model 692P

The isolated 4-20 mA analog output can represent the entire pH measuring scale or a desired segment of it. Use the

LO OUT VALUE and HI OUT VALUE setup variables to

enter low and high endpoints of the segment at which 4 mA

and 20 mA is desired. Note these important points:

n The desired segment, represented by the 4-20 mA

output, cannot be smaller than 1.00 pH unit.

-41-

PART THREE - OPERATION SECTION 7 - OUTPUT SETUP

n When the measured pH is below or above the selected

segment, the 4-20 mA output is limited to 4 mA or 20

mA respectively.

The procedure to use the range expand feature is described

with the following example.

RANGE EXPAND SETUP EXAMPLE

Suppose the 4-20 mA output is desired between 5.00

and 10.00 pH.

Setting

Low Endpoint

The low endpoint, entered with the LO OUT VALUE setup

variable, is the point at which the minimum output (4 mA) is

provided.

1. With display in pH measuring mode, press EXAM/

CANCEL key to place display in “examination” mode.

2. Press NEXT key until display indicates “LO OUT

VALUE.”

3. Use ïï and ññ keys to make display indicate the low

endpoint at which 4 mA is to be provided (5.00 pH for

this example).

NOTE: Entry value must be at least 1.00 pH unit away

from any previously entered HI OUT VALUE.

4. Press ENTER key to enter value (display flashes “OK” to

confirm entry or “VALUE ERROR” if difference between

entry value and HI OUT VALUE is less than 1.00 pH

unit).

Setting

High Endpoint

Model 692P Rev. 9-898

The high endpoint, entered with the HI OUT VALUE setup

variable, is the point at which the maximum output (20 mA)

is provided.

1. With the display still in “examination” mode, press NEXT

key once to make display indicate “HI OUT VALUE.”

2. Use ïï and ññ keys to make display indicate the high

endpoint at which 20 mA is to be provided (10.00 pH for

this example).

NOTE: Entry value must be at least 1.00 pH unit away

from LO OUT VALUE.

-42-

PART THREE - OPERATION SECTION 8 - USING SECURITY LOCK FEATURE

3. Press ENTER key to enter value (display flashes “OK” to

confirm entry or “VALUE ERROR” if difference between

entry value and LO OUT VALUE is less than 1.00 pH

unit).

7.2 Using Output Hold

Feature

SECTION 8 - USING SECURITY LOCK FEATURE

The isolated 4-20 mA analog output can be held during

calibration or while setting up the instrument to suspend

operation of a receiving device.

Simultaneously pressing the OUTPUT key and recessed

END CAL/HOLD button activates the hold mode feature.

Immediately, the HOLD status indicator appears and the

output value is held for 30 minutes -- unless the hold feature

is extended or cancelled. Thirty seconds before the 30minute hold period expires, the HOLD indicator flashes to

alert you that hold is about to be automatically canceled.

Pressing the OUTPUT key again extends the hold period

for another 30 minutes. You can cancel the output hold

feature at any time by simultaneously pressing the CANCEL

HOLD and OUTPUT keys.

The security lock feature prevents unauthorized alteration

of stored values. When the 692 is locked, the display shows

the LOCK status indicator, alerting you that stored setup

variable values including preset calibration points for

both “two-key” methods cannot be changed. However,

you can calibrate the 692 using any method, and you can

display all stored values.

8.1 Locking

Stored Values

Rev. 9-898 Model 692P

1. With display in pH measuring mode, press EXAM/

CANCEL key to place display in “examination” mode.

2. Press NEXT key until display indicates “SLOPE”. Then

press NEXT key once more to display “0000” (identifier

for security lock feature).

3. Use ññ key to make display indicate the lock code

“0001.”

4. Press ENTER key to enter lock code (LOCK status indicator appears and display flashes “OK” to confirm code

entry).

5. Press EXAM/CANCEL key to return display to pH

measuring mode.

# # #

-43-

PART THREE - OPERATION SECTION 8 - USING SECURITY LOCK FEATURE

8.2 Unlocking

Stored Values

1. With display in pH measuring mode, press EXAM/

CANCEL key to place display in “examination” mode.

2. Press NEXT key until display indicates “SLOPE.” Then

press NEXT key once more to display “0000” with LOCK

status indicator lit (identifiers for security lock feature).

3. Use ïï and ññ keys to make display indicate the un-

lock code “1234.”

4. Press ENTER key to enter unlock code (LOCK status

indicator turns off and display flashes “OK” to confirm

code entry).

5. Press EXAM/CANCEL key to return display to pH

measuring mode.

Model 692P Rev. 9-898

-44-

PART FOUR- OPERATING AIDS SECTION 1 - PRESERVING MEASUREMENT ACCURACY

PART FOUR - OPERATING AIDS

SECTION 1 - PRESERVING MEASUREMENT ACCURACY

1.1 Keeping Sensor Clean

1.2 Keeping Instrument

Calibrated

1.3 Checking Sensor

Slope

Clean the sensor as required using the recommended procedure described in the sensor operating instruction manual.

Calibrate the instrument using one of the methods described in Part Three, Section 6. Measurement errors may

be caused by calibrating with old, contaminated, or diluted