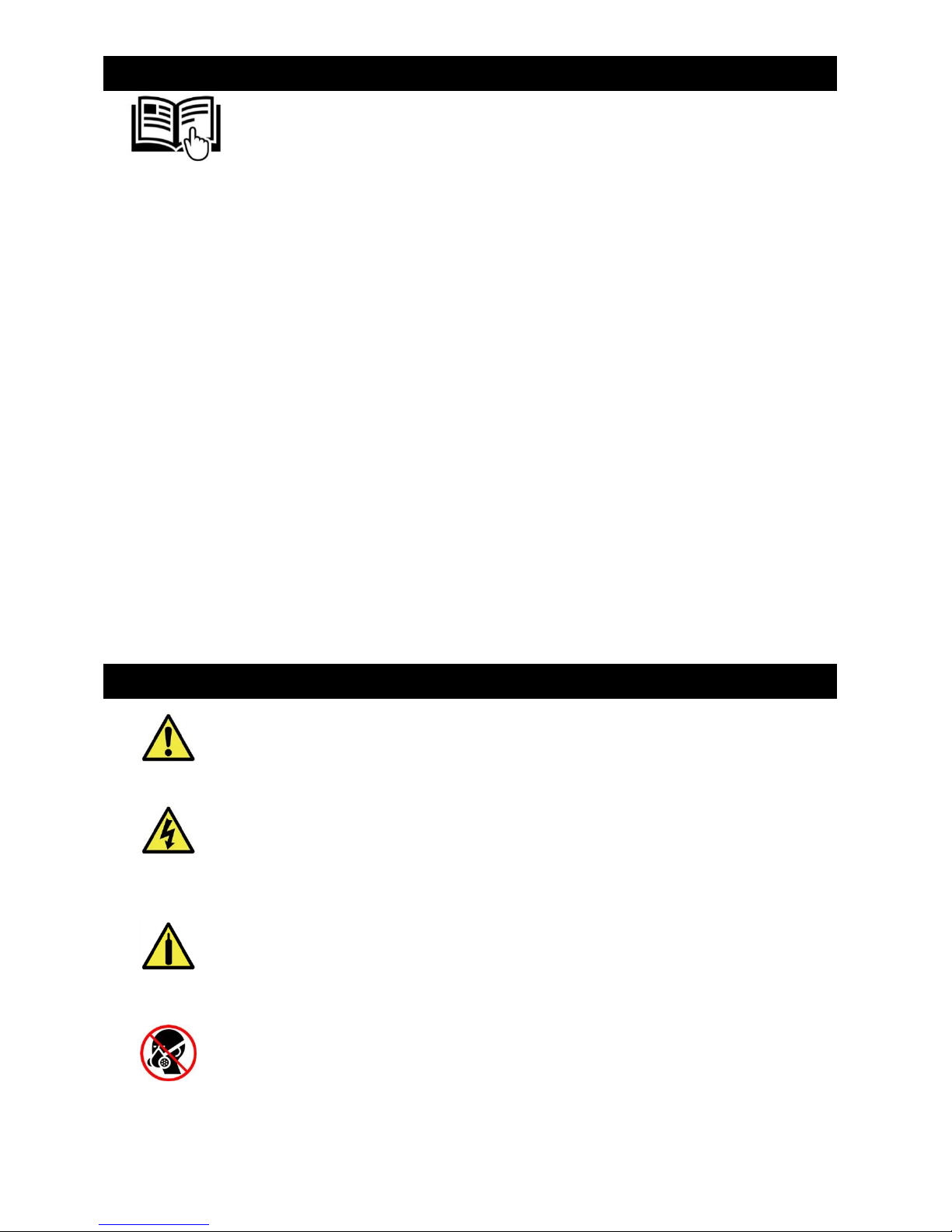

Great Lakes Air Products EDR series, EDR-A1 series, EDR-B1 series, EDR-B2 series, EDR-A2 series Instruction Manual

...

Great Lakes Air Products

1515 S. Newburgh Road

Westland, MI 48186

PH: 734-326-7080

www.glair.com

COMPRESSED AIR DRYER

INSTRUCTION MANUAL

EDR-SERIES

REFRIGERATION TYPE

HIGH INLET

TEMPERATURE

Contents

Introduction

Page 2

General Safety & Warnings

Page 2

Proper Use of the Dryer

Page 3

Receiving Equipment

Page 3

Installation, Location and Piping

Page 3

Electrical Connection

Page 3

Recommended System Design

Page 4

Condensate Drain

Page 5

Start-up Procedure

Page 5

Shut-down Procedure

Page 5

Troubleshooting

Page 6

Required Maintenance

Page 7

Engineering Data

Page 7

Warranty

Page 8

Page 2

INTRODUCTION

Before attempting any installation or maintenance on the dryer, please

carefully read this entire manual.

Great Lakes Air Products genuine parts, manufactured to design tolerances, are developed for optimum

GENERAL SAFETY INFORMATION

General Warning

The associated text outlines conditions, which could indicate a hazardous situation that

has some probability of death or severe injury.

Electrical Hazard

The associated text outlines conditions, which could indicate a hazardous situation that

has some probability of death or severe injury.

Only qualified personnel can use and service electrically powered devices. Be sure that

the voltage is disconnected before any work is performed.

Danger Hazard

A compressed air dryer has two separate pressurized systems each with the potential

to be pressurized independently. First is the sealed refrigeration system which should

never be opened except by a licensed technician. Second is the actual compressed air

circuit. Depressurize the compressed system prior to performing any work or

maintenance on that system. Compressed air is a highly hazardous energy source.

Never work on equipment with parts under pressure.

Breathing Air

Air treated by this equipment may not be suitable for breathing without further

purification. Refer to applicable standards and specifications for the requirements of

breathing quality air.

dependability – specifically for Great Lakes Air Products dryer systems. Design and material innovations

are the result of years of experience with hundreds of different compressor and dryer applications.

Reliability in materials and quality assurance are incorporated in our genuine replacement parts.

Your authorized Great Lakes Air Products distributor offers all the backup and reassurance you’ll

need. Our network of authorized distributors provides the finest product support in the air compressor

industry.

Your authorized distributor can support your Great Lakes Air Products Dryer with these services:

1. Trained parts specialists to assist you in selecting the correct replacement parts.

2. Repair and maintenance kits designed with the necessary parts to simplify servicing

your dryer.

3. Authorized distributor service technicians are factory trained and skilled in compressor and dryer

maintenance and repair. They are ready to respond and assist you by providing fast, expert

maintenance and repair services.

To Contact Great Lakes Air Products or locate your local distributor:

Visit: www.glair.com or

Call: (734) 326-7080

Failure to install the compressed air dryer per this manual or any change to the dryer not previously

authorized by the manufacture will void the warranty.

The information and specifications in this manual are in accordance with the information in effect at the

time of printing. The manufacturer reserves the right to make changes without notice or incurring

obligation.

Page 3

PROPER USE OF DRYER

This dryer has been designed, manufactured and tested to separate humidity normally contained in

RECEIVING EQUIPMENT

INSTALLATION LOCATION PIPING & CONNECTION

Particular care is required in selecting the installation site, as an unsuitable location could

jeopardize the proper operation of the dryer. This unit is not suitable to be used in an

explosive atmosphere, or where the risk of fire could be present.

ELECTRICAL CONNECTION

The Nameplate/Data plate located on each unit identifies the power supply requirements and

maximum fuse specification. Units supplied with cord and plug requires the installation of a

receptacle rated for 15 amps. Units supplied with electrical junctions, require a suitable fused

disconnect in compliance with the National and Local Electrical Code requirements.

compressed air only. Any other unauthorized use will be considered improper. The manufacturer will void

the warranty and not be held responsible for any problem arising from improper use. The correct use

requires adherence to installation conditions specified in this manual.

This dryer is supplied tested and fully assembled. The only operation left to the user is the connection to

the plant in compliance with the instructions given in the following chapters.

Immediately upon receipt of equipment, remove all crating and packaging around equipment. Examine

machinery for any damages either external or internal that may have occurred in transit.

If there is any physical damage or a refrigerant leak, (suction/analyzer gauge reads zero) please note

all damages on bill of lading during delivery. If damage is detected after the equipment delivery; contact

the local terminal to report all damages and file a claim immediately with the transportation company. The

carrier is legally responsible for any damages, since the unit is shipped F.O.B.

The unit should be installed in an area that is clean and dry, allowing sufficient space on all sides for

routine maintenance and service. It should be located on a level floor or shelf free from vibrations and

sufficient to support the total weight of the machinery. Although the dryer package is a freestanding unit,

it may be secured by bolting the base to the floor but is not required. This standard dryer is designed

for indoor installation. Contact distributor if installing unit outdoors.

Installations at altitudes above 4000 feet (1219 meters) will experience a loss of capacity and may require

field adjustments of pressure settings. The unit has been factory adjusted to operate up to 4000 feet

(1219 meters), and if installation is above this altitude, contact your local distributor for correct refrigerant

settings.

Allow (2’) two feet, minimum clearance around the dryer for maintenance access and adequate free

circulation of cooling air to the dryer. The ambient temperature around the dryer must not exceed 110°F

(37.7°C) or be less than 50°F (10°C).

Ambient temperatures below 40°F (10°C) require optional equipment specified below. Sufficient

ventilation must be provided to maintain acceptable ambient for efficient operation. Consider heat

rejection when locating dryer.

The wiring of all functional electrical components has been completed and tested at the factory in

accordance with the electrical wiring schematic provided with this manual.

Loading...

Loading...