Page 1

Apparel plotter TP-183P

User Manual

Great Computer Corporation ©

Page 2

NOTICE

GCC reserves the right to modify the information contained in this user

manual at any time without prior notice; un-authorised modification, copying

distribution or display is prohibited. All comments, queries or

suggestions concerning this manual please consult with your local dealer.

Page 3

TP-183P User Manual

Table of Contents

TTaabbllee ooff CCoonntteenntts

s

1. General Information

1.1 Introduction 1-1

1.2 Safety Precaution 1-4

2. Installation

2.1 Stand Components 2-1

2.2 Stand Installation 2-2

2.3 Plotter Setup 2-2

2.4 Pen Installation 2-4

2.5 Cable connection 2-5

2.5.1 USB Interface 2-5

2.5.2 Parallel Interface 2-6

2.5.3 RS-232 Interface 2-6

2.5.4 Data Transmitting 2-6

3. The Control Panel

3.1 The LCD Panel 3-1

3.2 Menu in on-line mode 3-2

3.3 Menu in off-line mode

3-3

3.4 Description of menu items

3-4

4. Operation

4.1 Paper Loading

4-1

4.2 Adjusting the plotter

4-3

4.3 Tracking performance

4-4

4.4 Adjusting the plotting force

4-5

5. Maintenance

5.1 Cleaning the apparel plotter 5-1

5.2 Cleaning the Grid Drum

5-1

5.3 Cleaning the Pinch Rollers 5-2

5.4 Cleaning the wheels on carriage 5-2

5.5 Cleaning the Motors 5-2

5.6 Cleaning the PC boards 5-3

6. Trouble Shooting

6.1 Non-Operational Problems 6-1

6.2 Operational Problems 6-2

6.3 Data Communication Problems 6-3

6.4 Software Problem 6-4

6.5 Plotting Quality Problem 6-5

Appendix

A-1 Vogue Specification A-1

A-2 Vogue CAD Output Accessory Instruction A-2

Page 4

TP-183P User Manual

General Information 1-1

1. General Information

1.1 Introduction

1.1.1 Check supplied items

Please check carefully whether you have received all the items listed below.

If there’s any item missing, consult your local dealer for further assistance.

SSttaannddaarrdd IItteemm

QQuuaannttiittyy

Apparel Plotter 1 set

Stand and Paper Tack-up System

2 pieces of Side Stands

2 pieces of Stand Bases

1 piece of Stand Beam

2 pieces of Paper Take-up and Feed shafts.

2 pieces of Dancer Bars

2 pieces of Paper Hubs ( 2”white colored )

2 pieces of Paper Hubs ( 3”black colored )

4 pieces of Stand-Holding Plug

1 piece of Hexagonal Wrench (M8)Φ6

1 piece of Hexagonal Wrench (M5)Φ4

1 piece of Hexagonal Wrench (M4)Φ3

20 pieces of Hexagonal Bolt

1 set

Accessory Bag

1 piece of Vogue Installation CD

1 piece of AC Power Cord (10A/250V 3M)

1 piece of RS-232C Cable (3M)

1 piece of USB Cable (3M)

1 set of Pen Holder Assembly

1 piece of Disposable Ink Pen

1 piece of Paper Slitter

1 piece of Plotting Pad

1 piece of Corrugated Pipe (30CM)

Warranty Card

1 set

Page 5

TP-183P User Manual

General Information 1-2

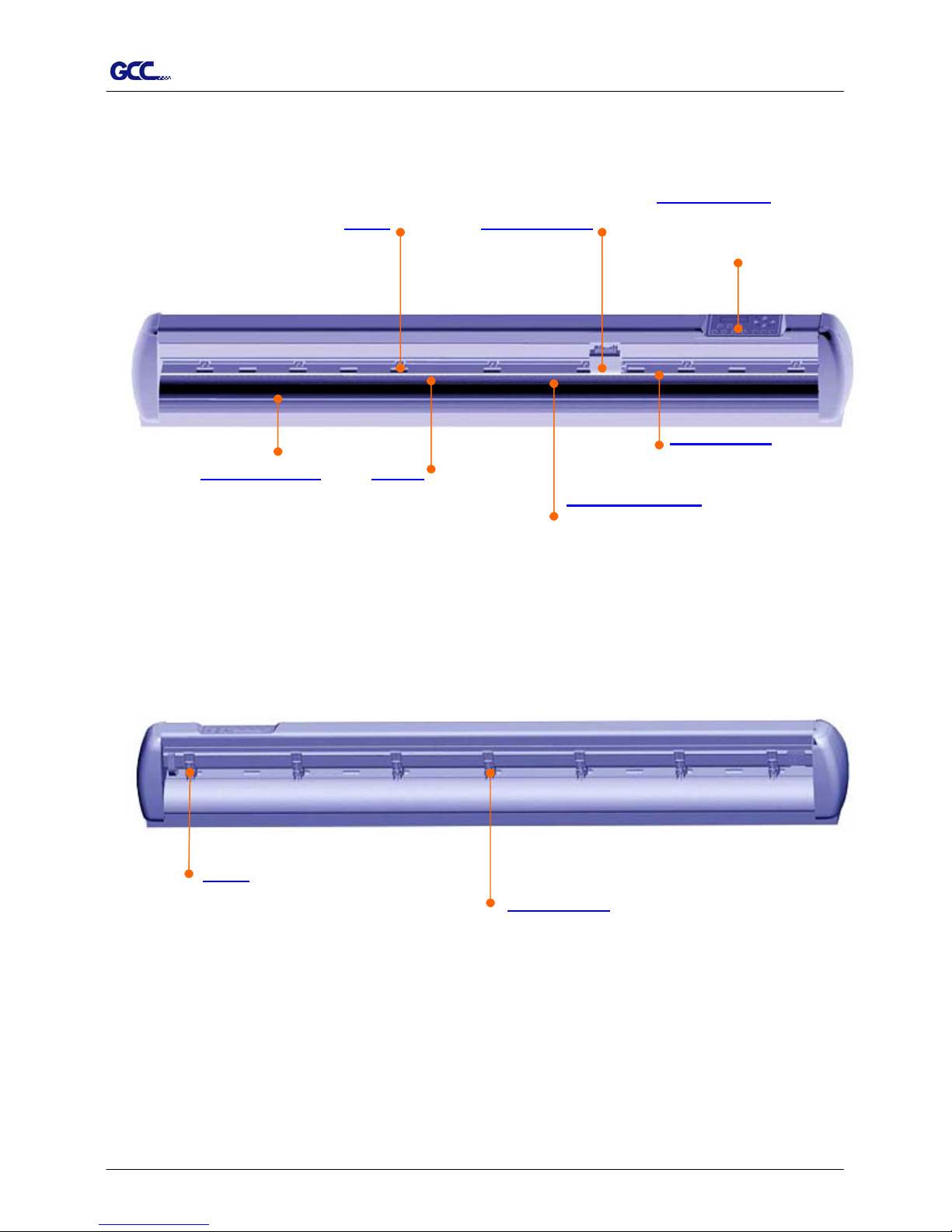

1.1.2 Front View of TP-183P

Control Panel

1.1.3 Back View of TP-183P

【Figure 1-1】

【Figure 1-2】

Pinch Roller

to hold media in the

process of plotting.

。

Lever

to raise up or lower down

the pinch rollers.

Plotting Pad

to protect the pen in the

process of plotting.

consists of 14 control keys, 1

LED, and 1 LCM to

show

messages and menus.

Drum Tool Carriage

to perform plotting with

the installed pen.

Alignment Ruler

To help align media with the

clear guideline marks

to help moving media

back and forth during

Slither Groove

to help cut off media

easily along the groove.

Platen

to support media in the

process of plotting.

Page 6

TP-183P User Manual

General Information 1-3

1.1.4 Left-Hand Side of TP-183P

【Figure 1-3】

1.1.5 Right-Hand Side of TP-183P

Parallel Interface Connector

to connect the plotter and a computer through

a

p

arallel interface cable.

Serial Interface Connector (RS232C)

to connect the plotter and a computer through

a serial interface cable.

USB Connector

to connect the plotter and a computer through

an USB cable.

AC Power Connector

to insert the AC power cord.

Main Power Switch

On when switches to [I]; Off to [O].

Fuse

3 Amp.

【Figure 1-4】

Power Switch of Take-up System

On when switches to [I]; Off to [O].

Page 7

TP-183P User Manual

General Information 1-4

1.2 Safety Precaution

Make sure the power switch is off before install the plotter.

Handle the plotter carefully to prevent damages.

Choose a proper place where meets the following conditions to set up the plotter

z The machine can be approached easily from any direction.

z Keep enough space for the plotter, accessories and supplies.

z Keep the working area stable and avoid vibration.

z Keep the temperature between 15 and 30 (

℃

60-86oF) in the workshop.

z Keep the relative humidity between 25% and 75% in the workshop.

z Protect the machine from dust and strong air current.

z Prevent the machine from direct sunlight or extremely bright lighting.

Connect the Power Supply Carefully

z Check the plug of the power cord to see if it mates with the wall outlet. If not,

consult your dealer for further assistance.

z Insert the plug (male) into a grounded power outlet.

z Insert the other end (female) of power cord into the AC connector of the cutting

plotter.

Make sure the power cord of the plotter is connected to a power outlet that is properly

grounded to earth to avoid exposing the plotter from the risk of electric shock.

The plotter must be only operated with a dedicated power outlet without any

branch-circuit power source.

Page 8

TP-183P User Manual

Installation 2-1

This chapter describes the installation procedure of Stand and Paper Take-Up System.

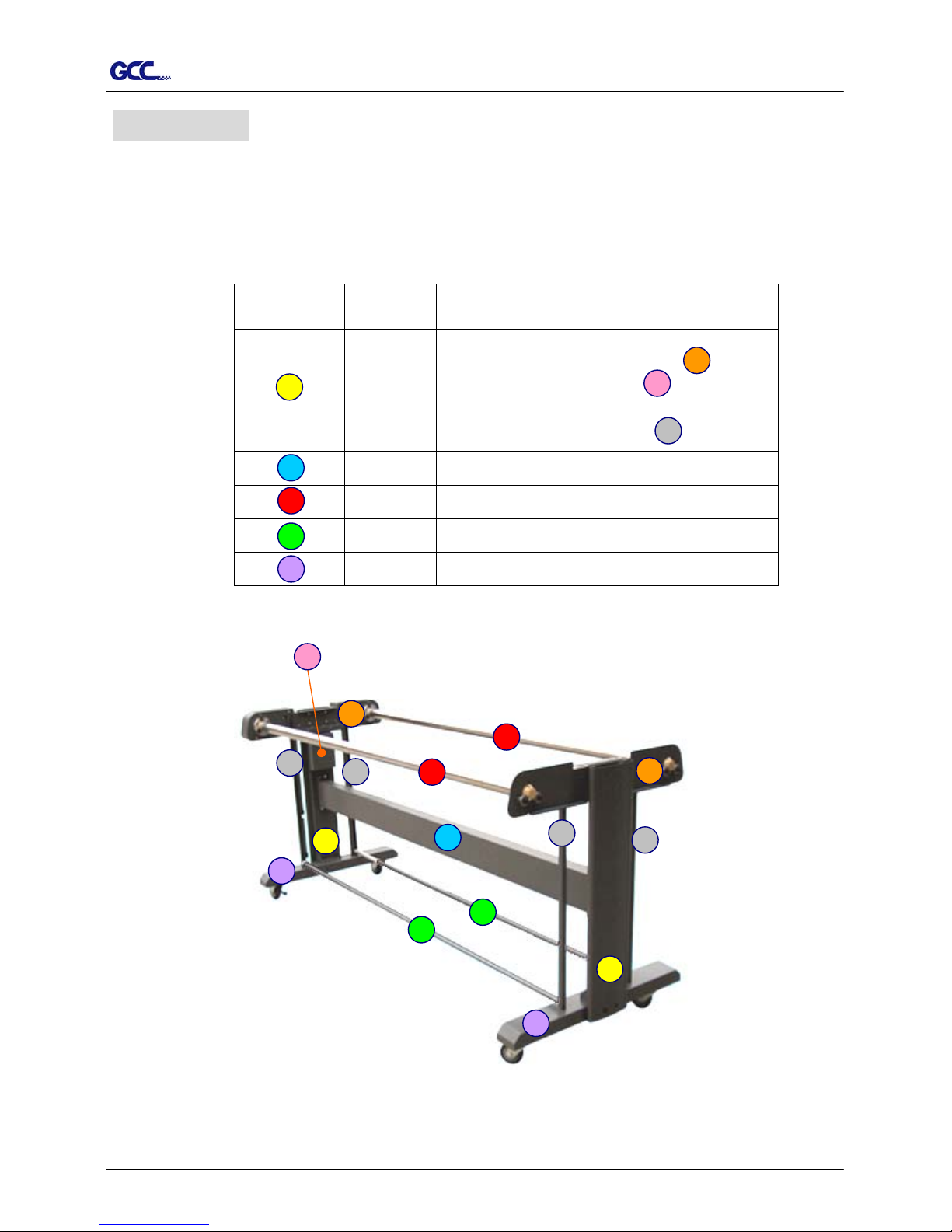

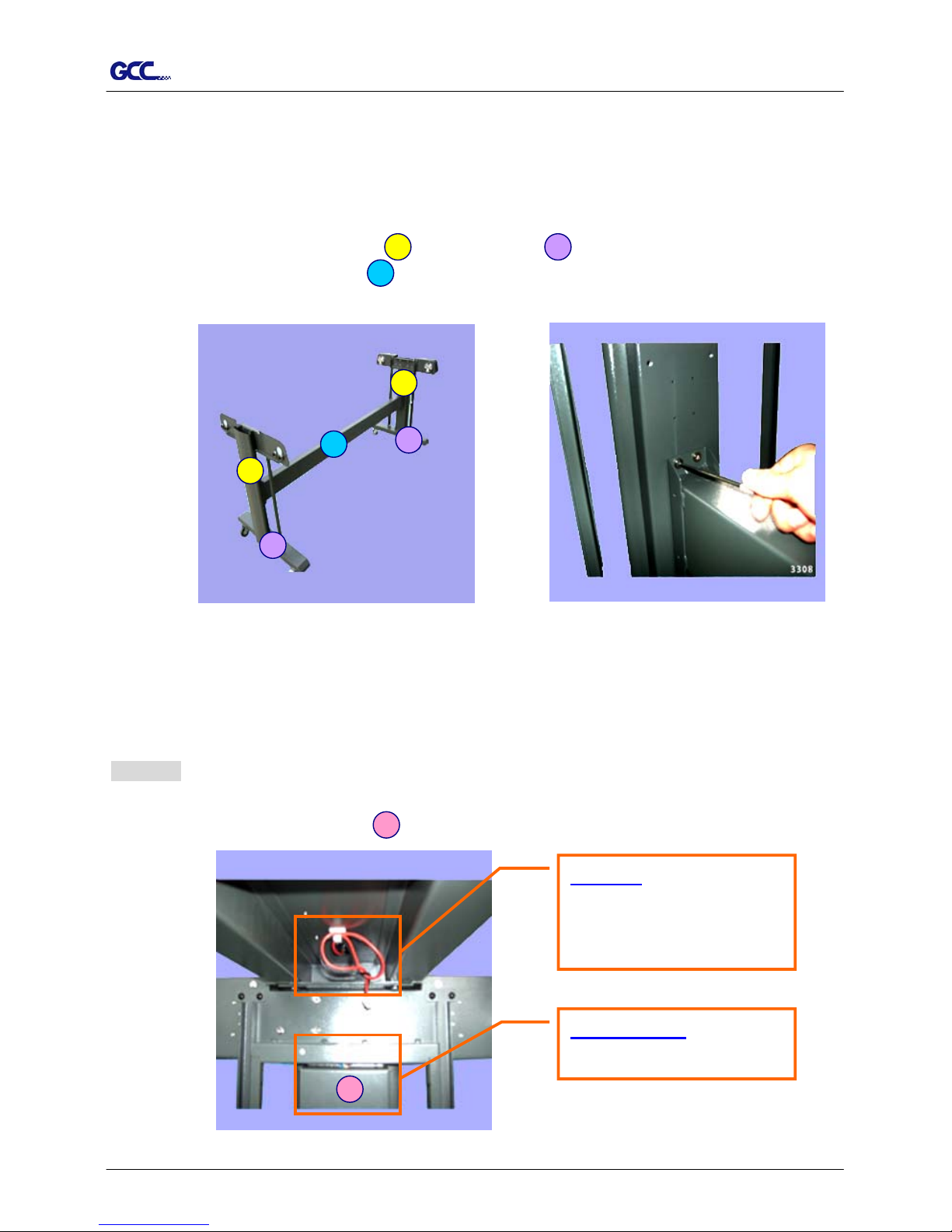

2.1 Stand Components

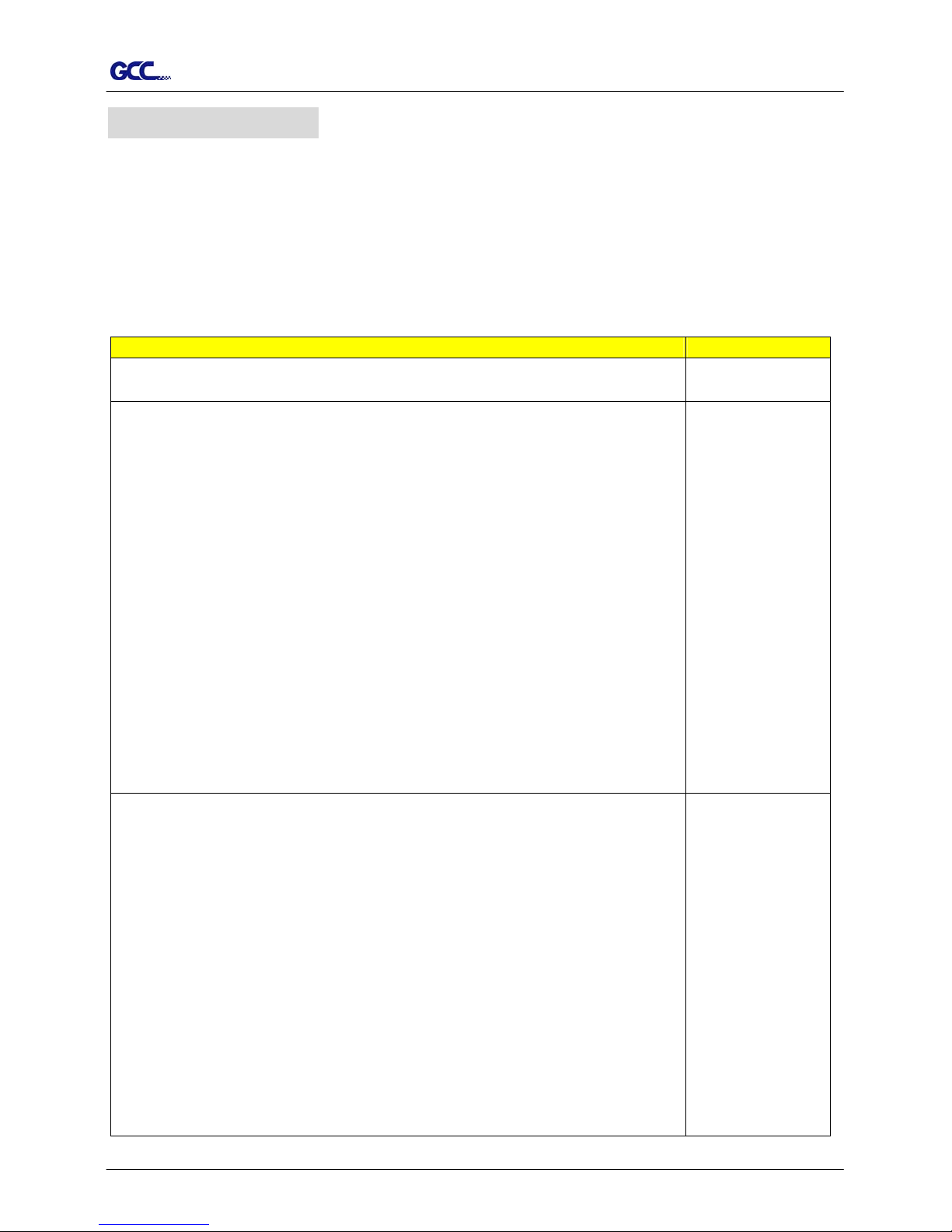

Component Quantity Description

2

Side Stand

Roll holder support * 2

Control board * 1

(for Paper Take-Up System)

Dancer guiders * 4

1 Stand Beam

2 Paper Take-Up & Feed Shafts

2 Dancer Bars

2 Stand Base

2. Installation

【Figure 2-1】

E

F

A

G

B

C

D

H

F

E

C

G

C

G E

G

B

G

A

H

D

D

A

H

Page 9

TP-183P User Manual

Installation 2-2

2.2 Stand Installation

It is recommended to assemble the stand by at least 2 people to prevent damages from

dropping components onto the ground.

Installation procedure:

1. Fasten 2 sets of side stand and Stand Base by supplied screws.

A H

2. Fasten with Stand Beam by supplied screws.

B

【Figure 2-3】

【Figure 2-2】

A

H

B

A

H

2.3 Plotter Setup

Proceed as following:

Step 1

Place the plotter onto the stand and fasten them up.

(Note: the wire and Control board must be located at the same side)

F

The wire

to connect the power board

of Paper Take-Up System

and plotte

r

Control board

for Paper Take-Up System

F

【Figure 2-4】

Page 10

TP-183P User Manual

Installation 2-3

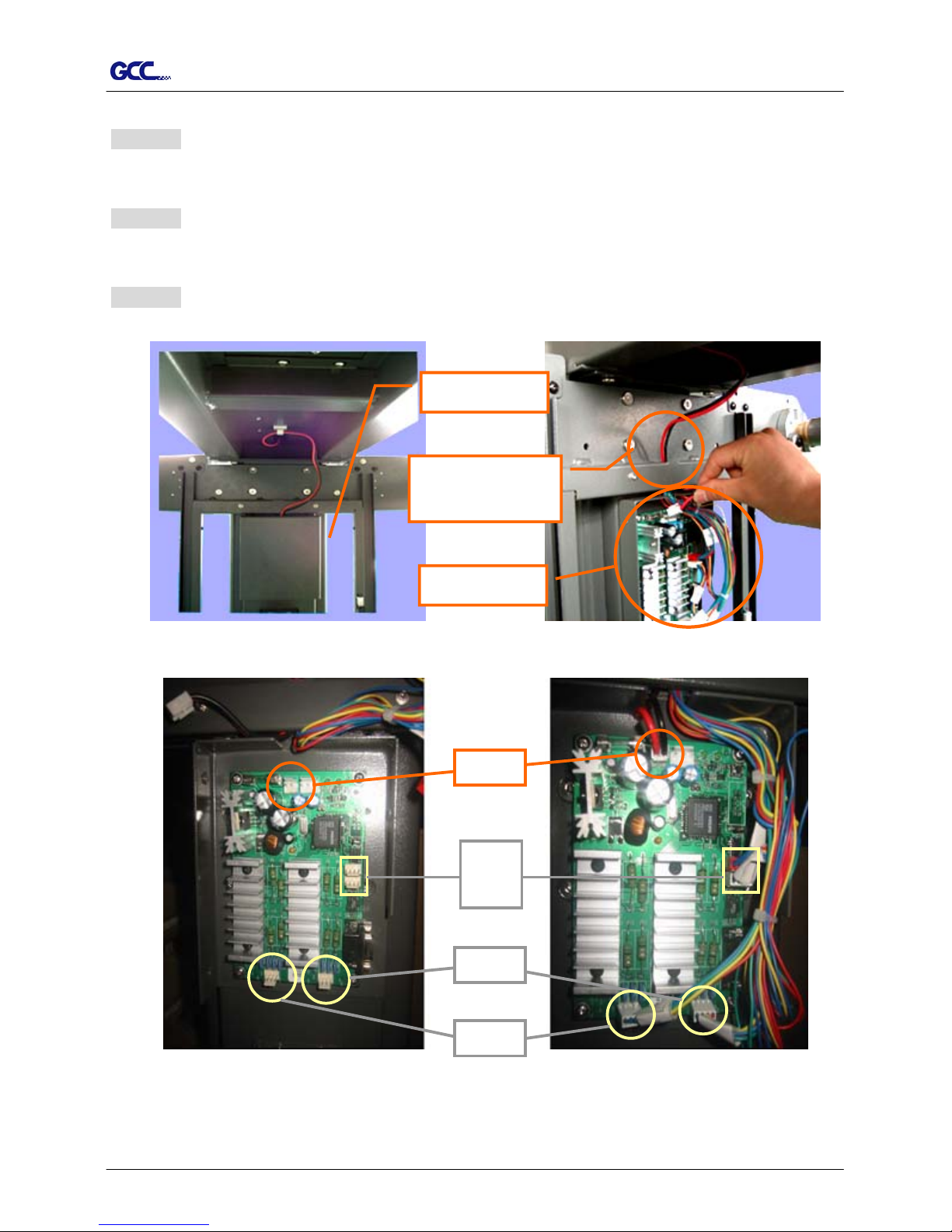

Step 2

Take off the cover of control board.

Step 3

The wire goes through the hole showing in Figure 2-5 to reach power board.

Step 4

Plug in the head to the power connector (see the details in Figure 2-5, 2-6, 2-7 and 2-8).

【Figure 2-5】

【Figure 2-6】

The Wire goes

through the hole

Cover

Control Board

【Figure 2-7】

power

JP 6

JP 7

JP 12

【Figure 2-8】

JP 11

Page 11

TP-183P User Manual

Installation 2-4

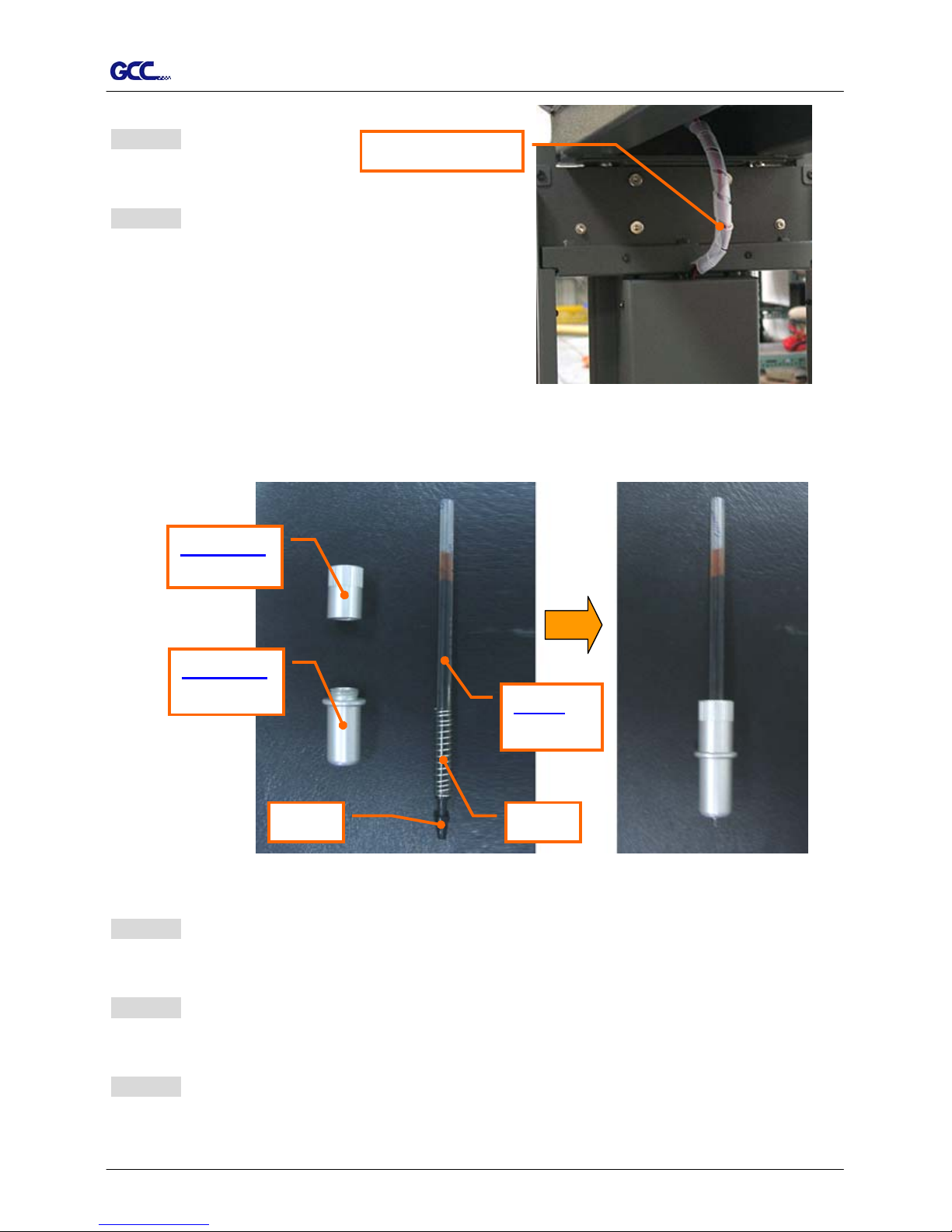

Step 5

Put the cover back.

Step 6

Wind the Corrugated Pipe around the wire for

protection from electric shock (see Figure 2-9).

Corrugated Pipe

【Figure 2-9】

2.4 Pen Installation

Penholder

Lower part

Penholder

Upper part

Cap

Refill

of ink pen

Spring

【Figure 2-11】【Figure 2-10】

Step 1

Take off the cap (Hint: put on the cap after jobs done to prolong the usage of the refill)

Step 2

Assemble the penholder, spring, and refill together (see Figure 2-10 & 2-11).

Step 3

Insert the pen holder into the carriage. The outward ring of the holder must be set onto the

grooves of the carriage firmly and locking up the grip (see Figure 2-12).

Page 12

TP-183P User Manual

Installation 2-5

【Figure 2-12】

2.4 Cable Connection

The apparel plotter communicates with a computer through a USB (Universal Serial Bus),

Parallel port (Centronics) or a Serial port (RS-232C). This section shows you how to

connect the apparel plotter to a host computer and how to set up the computer/apparel plotter

interconnection.

!! Notice: When USB connection is enabled, both parallel port and serial port will be disabled

automatically.

Parallel Port

Serial Port

USB Port

【Figure 2-13】

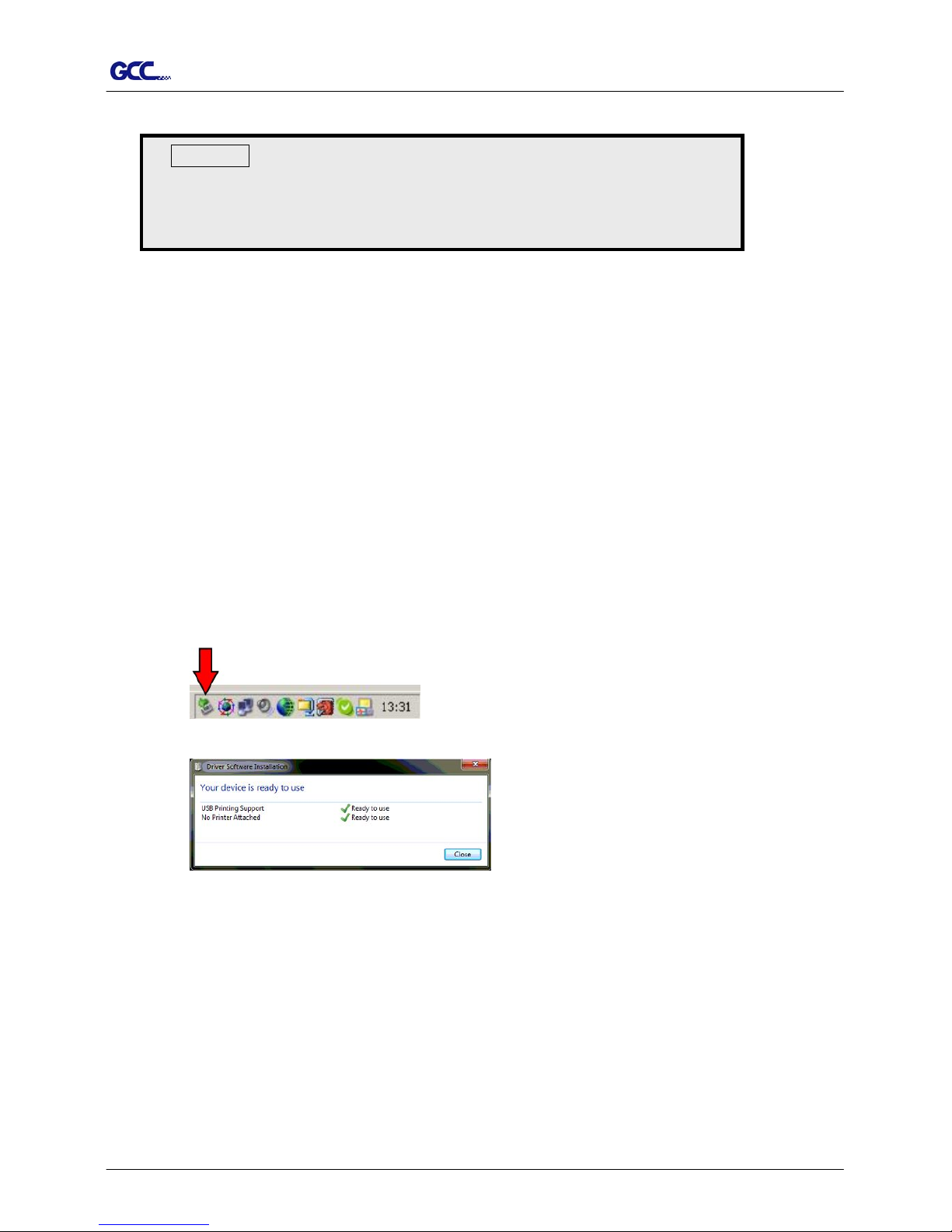

2.5.1 USB Interface

Vogue 183TP build-in USB interface are based on the Universal Serial Bus Specifications

Revision 1.1. (Operation system of Windows 95 and NT don’t support USB).

Page 13

TP-183P User Manual

Installation 2-6

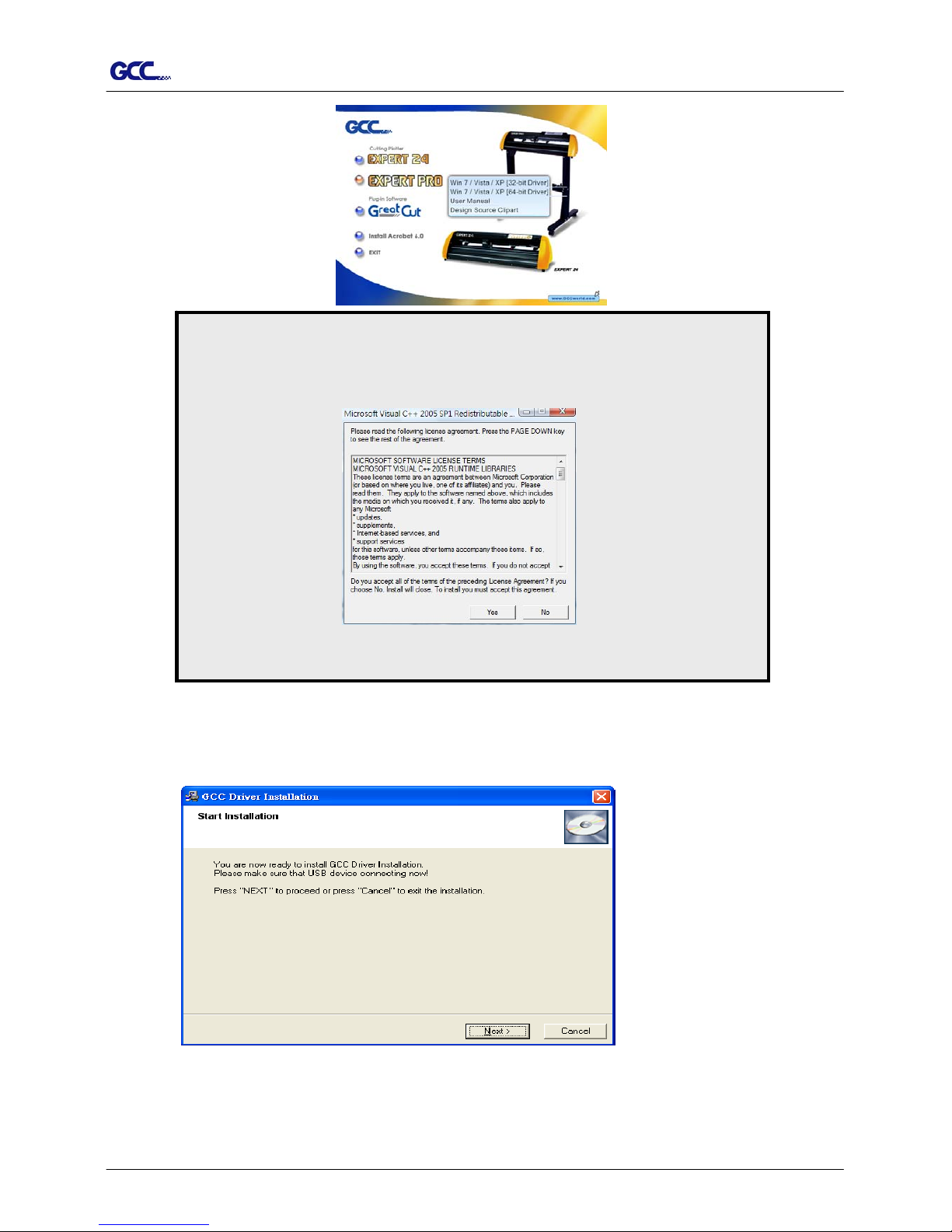

USB driver installation

Caution!!

9 If you are using Windows 2000 / XP / Vista / 7 as your

operating system, make sure you log in using the

“Administrator” account.

Use the USB One-click Installation for quick driver installation. Follow the simple steps

below for driver setup.

Step 1:

Connecting your GCC Vogue

(1) Turn on the machine.

(2) Connect the USB connector to the machine and then USB driver will installed

automatically. It will take a few minutes to find the device. Please DO NOT

disconnect the USB cable until the installation has completed.

(3) You can double click the USB icon on the taskbar to make sure the USB device is

detected.

Step 2: Installing the software

(1) Put the installation CD into your CD-ROM. Please make sure that the USB device

is connected before you start the driver installation.

(2) Choose the model you want to install from the driver list and click on either the 32 bit

or 64 bit driver installation depending on the operating system installed on your

computer to start the installation. (The Expert Pro model is used as an illustration in

the following steps.)

Page 14

TP-183P User Manual

Installation 2-7

Click “Yes” to continue.

NOTE

If you use the Windows 7 / Vista 64 bit program, please note that a

pop-up window will be shown upon the initial installation as shown below:

(3) Click “Next” to start the driver installation.

Page 15

TP-183P User Manual

Installation 2-8

(4) The installation will take a few minutes to complete and you will see a message below

and click on “OK” upon completion. Enjoy your GCC Vogue!

Note:

(1) If the driver is being installed for a second time, the user will be prompted as to whether a

second copy of the driver installation is required.

(2) If the user selects yes, a second copy of the driver will be installed.

Page 16

TP-183P User Manual

Installation 2-9

2.5.2 Parallel Interface

Connecting to the Parallel Port (Centronics)

a. Connect a parallel cable to the apparel plotter and the host computer.

b. Set up the output port LPT1 or LPT2 from your software package.

c. Send data to the apparel plotter directly from your software, or use DOS commands,

like TYPE or PRINT, to output data.

2.5.3 RS-232 Interface

Connecting to the Serial Port (RS-232C)

a. For IBM PC or compatible systems, connect the RS-232C cable to the serial connector

of your host computer at the assigned port (COM1 or COM2).

b. Set up the communication parameters (Baud Rate and Data Bits/Parity) to match the

setting of your software package. Refer to chapter 3.3 – “Misc” key description for

more details.

2.5.4 Data Transmitting

There are two options to transmit the data from the computer to the apparel plotter:

Option 1

With proper interface settings, the data can be transmitted from your application software

package to the apparel plotters directly.

Option 2

Most patterning software packages are able to emulate HP-GL or HP-GL/2 commands,

therefore. As long as the file is HP-GL or HP-GL/2 format, the apparel plotter can output the

data precisely.

Page 17

TP-183P User Manual

The Control Panel 3-1

3. The Control Panel

This chapter describes the button operations with the LCM menu flowcharts. When the apparel

plotter is ready for use as described in Chapter 1 & 2, all functions are under default parameters.

3.1 The LCD Panel

SPEED FORCE OFFSET

MISC TOOL SELECT DATA CLEAR CUT TEST

ON/OFF

LINE

PAUSE / RESUME ENTER

POWER

< LCD Control Panel on Vogue TP-183P>

Key Function

LCD Screen To display functions and error messages.

Power LED To indicate the power status ( light up: power on; light off: power off )

4 Arrow Keys To move position, select function, or change setting.

ENTER To set item or register the immediately preceding input value.

PAUSE/RESUME To temporarily halt plotting process or to continue.

ON/OFF LINE To switch modes, stop plotting job, or abort changes of settings.

OFFSET ( Non-functional at this model )

FORCE To adjust the value of plotting force.

SPEED To adjust the value of plotting speed and quality.

CUT TEST To perform plotting tests.

DATA CLEAR To clear up buffer memory.

TOOL SELECT To select tools.

MISC To set up functions.

Page 18

TP-183P User Manual

The Control Panel 3-2

3.2 Menu in On-line Mode

Power On

Firmw a re V -.-Copyright 2003

Place Media And Then

Lower Dow n The L ever

Sizing Media Width

Lever Up to Abort

Siziing Media Length

Lever Up to Abort

S---.- F ---.- O -.-- M

L:-----.-- W : ----.--

Top menu

D a ta In P ro c e s s in g

Sending data

Pause

Setup Resume

[PAUSE]

Force: 55 gf

OK : E NT E R

[Force key]

Vogue TP-183P in processing

Us e to s e lec t;

[EN T ER ] to enable the setting

Non-Functional

At This Model

Clear data memory

N: Cancel OK: ENTER

1S:72 F:80 O: 0.275 M

Se lec t O K : EN T E R

[Offs e t ke y ]

[Data Clear]

[Tool Select]

Speed: 108cm/s

Se lec t: O K : EN T E R

[Speed Key]

Up Speed: 108cm/s

Se lec t: O K : EN T E R

Qu a lity: N o rma l

Se lec t: O K : EN T E R

Sm oothing Plot

Se lec t: O K : E n te r

Panel Setup

Se lec t: O K : En ter

Restore default

Se lec t: O K : E n te r

Save parameter

Se lec t: O K : E n te r

Vogue TP-183P

LCM Version 1.0

Set Pen's Lifespan

Se lec t: O K : En ter

Page 19

TP-183P User Manual

The Control Panel 3-3

3.3 Menu in Off-line Mode

Press [ON/OFF LINE] to switch online and offline mode

Please [Enter] to finish setup of each function.

Offline For

System Setup

[Force Key]

[OFFSET KEY]

[Data Clear ]

[ ]

[Speed Key]

[Cut Test]

[Tool Select]

[Misc]

Force: 55 gf

OK: Enter

Non-Fubctional At This

Model

Clear Data Memory

N: Cancel OK: Enter

Move Origin

X: Y:

Speed: 108cm/s

Select: OK: Enter

Up Speed: 108cm/s

Select: OK: Enter

Quality: Normal

Select: OK: Enter

Square Plot

Select: OK: Enter

Repeat Last Plot

Select: OK: Enter

Media Back & Forth

Select: OK: Enter

Set Communication

Select: OK: Enter

Select Units

Select: OK: Enter

Scale Length

Select: OK:Enter

Scale Width

Select: OK: Enter

Smoothing Plot

Select: OK: Enter

Panel Setup

Select: OK: Enter

Speed: 3-153cm/s with an increment of 3cm/s

Upspeed: 3-153cm/s with an increment of 3cm/s

Draft, Fair, Normal, Fine, Small Letter

0-55gram with an increment of 5 gf

Metric (cm/ gf) or

English measurement(feet/ounce)

Firmware: x.x.xx

FPGA: Vx.x

Restore default

Select: OK: Enter

Save parameter

Select: OK: Enter

Set Pen's Lifespan

Select: OK: Enter

Replot # 1

Select: OK: Enter

Copy # 1

Select: OK: Enter

USB Printer Type

Select: OK:Enter

GCC USB Mode

Common USB Mode

Page 20

TP-183P User Manual

The Control Panel 3-4

3.4 Description of Menu Items

Below describes the functions of menu items:

Menu or Key Function Setting Default

--- POWER ---

to indicate the power status.

[ Arrow Keys ]

1. to move the tool carriage position on X or Y axis.

2. to select functions or change values of the setting.

[ ENTER ]

1. to effect the displayed parameters that will be saved

automatically.

2. to set a new origin at the present tool carriage position.

In “offline” mode, moving the tool carriage to desired

position by [Arrow Keys], then press [ENTER] key to set

a new origin. While moving with the parameters of

XY-axes displayed, press [MISC] key will enable

fine-tune movement; press [MISC] key again to disable

the function.

[ PAUSE/RESUME ]

to temporarily halt the plotting process; to resume the

process by press [Pause/Resume] key again.

[ ONLINE/OFFLINE ]

1. to switch between online mode and offline mode.

2. to stop the plotting job or abort the change of setting.

Once press this key, the plotting job will be terminated

immediately and cannot be resumed.

[ OFFSET ]

non-functional at this model

[ FORCE ]

to set or modify the value of tool force. 0~55gram;

5 gram/per step

55 gram

[ SPEED ]

Speed to set or modify tool speed at horizontal moving. 3~153cm/sec;

3cm/sec per

step

108cm/sec

Up Speed to set or modify tool speed at vertical moving. 3~153cm/sec;

3cm/sec per

step

108cm/sec

Quality to set or modify plotting quality.

While cutting small letter, set as “Small letter”;

while cutting in high speed, set as “Draft”;

for normal operation, set as “Normal”.

Draft, Fair,

Normal, Fine,

Small Letter

Normal

[ CUT TEST ]

Square Plot to perform a plotting test at present blade position.

for more information, please refer to page 2-7 to adjust

blade force and cutting speed.

Repeat Last

Plot

Replot

to repeat the last job without re-sending the data.

1~99;

1 per step

Page 21

TP-183P User Manual

The Control Panel 3-5

Copy:

to copy the last job without re-sending the data.

* 1mm gap will be auto-generated between 2 copies).

* if the media length is not enough to continue, it will show

below message on LCM:.

OpOtuSfa;ce #

iCfopoe isfn his ed

* if both functions are enabled at the same time, the cutter

will

perform the last setting only.

1~99;

1 per step

[ DATA CLEAR ]

to clear up data memory.

[ TOOL SELECT ]

Save

Parameter

to save plotting parameters for later use. Patterns1~4 Pattern 1

Accept setup command:

to accept commands of the Force, Speed, and Cutting

Quality only via software.

Panel Setup

Control panel only:

to accept commands of the Force, Speed, and Cutting

Quality only via control panel of the plotter.

Smoothing

Plot

to enable smooth-cutting function. Enable

Set Pen’s

Lifespan

To customize the length of Pen’s lifespan. Unit: M

Restore

default

to turn all parameters of the menu items to factory-default

settings.

[ MISC ]

Media Back

& Forth

to enable to save time on repeated plotting jobs and better

tracking.

After plotting job has finished, the media will move back to

the origin, then move to the end of the plot.

Disable

Set

Communication

to build up the communication between host computer and

plotter.

Baud Rate is to determine the speed of data transmission.

Data Bits refers to the size of one block of data.

Parity is used to check if data was revived correctly or not.

9600, n, 8, 1, p 9600pbs, 8 Bits with NO Parity

19200, n, 8, 1, p 19200pbs, 8 Bits with NO Parity

Firmware

Version

to display the version number of Firmware and FPGA

code.

Select Units Provides two unit systems for users convenient. cm/gram;

inch/oz

Metric

Page 22

TP-183P User Manual

The Control Panel 3-6

Scale Length

Scale Width

to adjust the scale of media length and width that may

cause by the thickness of the media.

The Denominator is the actual length, and the Numerator

is the ideal length measured from the resultant.

For example, cutting a line with 500.0 mm length. The

procedure as followng:

1. Press the [LEFT ARROW] to choose the Numerator and

select 500.0 mm,

2. Plot the length by sending a graph file,

3. Measure the length then use the [RIGHT ARROW] key

to choose the Denominator, then

4. Press [UP ARROW /DOWN ARROW] to change the

values of the actual length.

USB Printer

Type

To select USB Mode from the LCM panel. Two USB modes

are available: GCC USB Mode and Common USB Mode.

GCC USB Mode: For 32 bit driver

[Windows XP/2000/ 7 /Vista]

Common USB Mode: Both for 32 bit & 64 bit driver

[Windows XP/7/Vista]

Common

USB Mode

Page 23

TP-183P User Manual

Operation 4-1

4. Operation

4.1 Paper Loading

Step 1

Install one paper hub onto one side of paper roll.

Step 2

Slide the feed shaft through the paper roll.

Step 3

Install the other paper hub onto the other end of

Paper Roll

Paper Hub

Feed Shaft

paper roll and set it firmly/ (Figure 4.1).

【Figure 4-1】

Step 4

Install the shaft with Paper Roll onto the rear side of Roll Holder Support.

( to ; to : Figure 4-2 & 4-3).

C1

E 1

C2

E 2

Step 5

Draw out paper from upper side of the paper roll, then go through the plotter to the front side.

Make sure paper is loaded on center of the platen before press down Lever (Pinch Roller) .

(Figure 4-4 & 4-5)

【Figure 4-2】

【Figure 4-3】

Slot

C1

E 1

C2

E 2

Page 24

TP-183P User Manual

Operation

4-2

Step 6

Fix paper on the front shaft by twin adhesive tape (Figure 4-6).

Step 7

Place the two dancer bars into the dancer guiders . (Figure 4-7)

(Detailed composition refer to Figure 2-1)

Step 8

Adjust the two dancer bars to the position between

sensors by loose or tighten the paper roll.

(Figure 4-8)

【Figure 4-8】

Sensor

Dancer bar

【Figure 4-7】

GD

【Figure 4-5】

Draw out paper from upper

side of the roll.

【Figure 4-4】

【Figure 4-6】

Page 25

TP-183P User Manual

Operation 4-3

4.2 Adjust the Plotter

For loading media properly, follow below procedures to adjust the plotter:

Step 1

Use the lever on the upper right side of the plotter to raise or lower down pinch rollers. Pull the

lever forward until it makes a clicking sound then the pinch rollers are raised (Figure 4-9).

Lever

【Figure 4-9】

Step 2

Load your media on the platen and slide it under the pinch rollers from either the front side or

the backside. The color alignment rulers on the platen extension will help you to adjust the

media precisely.

Step 3

Move the pinch rollers manually to proper positions. Be sure the pinch rollers must be

positioned above the grid drum. The white marks on the main beam reveal where the grid

drums are located (Figure 4-10).

White marks

【Figure 4-10】

【Figure 4-11】

Note:

Always adjust the position with the pinch roller raised.

Move the pinch roller by applying force at the rear portion of the pinch roller support.

Do not move the pinch roller by holding its front rubber roller (Figure 4-11).

Page 26

TP-183P User Manual

Operation 4-4

Step 4

Push the lever backward to lower down the pinch rollers.

Step 5

Turn on the power. The tool carriage will measure the media size automatically.

4.3 Tracking Performance

In order to achieve the best tracking performance for a long plot, it’s recommended to

follow up below regulations:

If the media length is less than 4 m, leave the margin of 0.5mm ~ 25mm in the left and

right edges of the media (Figure 4-12).

Pinch roller

Pinch roller

0.5mm - 25mm

0.5mm - 25mm

【Figure 4-12】

If the media length is over 4m, leave at least 25mm margin on the left and right edges

of the media (Figure 4-13).

>25mm > 25mm

【Figure 4-13】

Page 27

TP-183P User Manual

Operation 4-5

4.4 Adjusting the Plotting Force

Before sending your designs for plotting, you may perform a “cut test” to generate

satisfactory plotting results.

“Cut Test” should be repeated until the appropriate plotting conditions for the media are

discovered.

After sizing the media, press [CUT TEST] button to select the “square cut”, and press

[ENTER KEY] to confirm.

The default pen force of the cutting test is 55gf. Press [ARROW KEY] to move the tool

carriage to the position where you like. Then, press the [ENTER KEY] to perform Cut

Test.

Note: At the same time, the new origin is also set at the cutting test position.

Page 28

TP-183P User Manual

Basic Maintenance 5-1

This chapter explains the basic maintenance required for the apparel plotter. All the other

maintenance without mention here must be performed by a qualified service technician.

5.1 Cleaning the Apparel Plotter

In order to keep the apparel plotter under good condition and best performance, it’s

Recommended to clean up the machine properly and regularly.

CAUTION !

Gently wipe the apparel plotter surface with a lint-free cloth. If necessary, clean with a damp

cloth or an alcohol-immersed cloth. Wipe with water to rinse off any residue and dry with a

soft, lint-free cloth.

Wipe all dust and dirt from the tool carriage rails.

Use a vacuum cleaner to empty any accumulated dirt and media residue beneath the pinch

roller housing.

Clean the platen and pinch rollers with a damp cloth or an alcohol-immersed cloth, then dry

with a soft, lint-free cloth.

Wipe dust and dirt from the stand.

5.2 Cleaning the Grid Drum

Step 1

Turn off the apparel plotter, and move the tool carriage

away from the area needed to be cleaned.

Step 2

Raise the pinch rollers and move them away from the grid drum for cleaning.

Step 3

Use a bristle brush (toothbrush is acceptable) to remove dust from the drum surface. Rotate the

drum manually while cleaning (Figure 5-1).

Unplug the apparel plotter before cleaning

to prevent electrical shock.

Never use solvents, abrasive cleaners or

strong detergents for cleaning. They may

damage the surface of the apparel plotter

and the moving parts.

5. Maintenance

【Figure 5-1】

Page 29

TP-183P User Manual

Basic Maintenance 5-2

5.3 Cleaning the Pinch Rollers

If the pinch rollers need a thorough cleaning, use a lint-free cloth or cotton swab to wipe

away the accumulated dust from the rubber portion of the pinch rollers. To prevent the

pinch rollers from rotating while cleaning, use finger to hold the pinch rollers not to rotate.

If need to remove the embedded or persistent dust, use the lint-free cloth or cotton swab

moistened with rubbing alcohol.

5.4 Cleaning the DU-typed and A-typed rollers on carriage

Step 1

Turn off the apparel plotter.

Step 2

Disassemble the top cover and the cover of carriage.

Step 3

Use a bristle brush (toothbrush is acceptable) to remove dust on the roller surfaces, meanwhile

move the carriage slowly along the rails (Figure 5-2 & 5-3).

5.5 Cleaning the Motors

Step 1

Turn off the apparel plotter.

【Figure 5-2】

DU-typed Roller

【Figure 5-3】

A-typed Roller

Page 30

TP-183P User Manual

Basic Maintenance 5-3

Step 2

Disassemble the top and side covers.

Step 3

Use a bristle brush (toothbrush is acceptable) to remove dust around the X-axis and Y-axis

motors (Figure 5-4 & 5-5).

5.6 Cleaning the PC boards

Step 1

Turn off the apparel plotter.

Step 2

Disassemble the front and rear platens.

Step 3

Use air gun or blower(cold air) to remove dust on the PCB surface.

【Figure 5-4】 【Figure 5-5】

Page 31

TP-183P User Manual

Troubleshooting 6-1

6. Trouble Shooting

This chapter helps you to correct some common problems that may come across. Prior to

getting into the details of this chapter, please be sure that your application environment is

compatible with the apparel plotter.

Note:

Before having your apparel plotter serviced, please make certain that the malfunction

is in your apparel plotter, not the result of an interface problem or a malfunction in your

computer or a software problem.

Why is the apparel plotter not functioning?

Possible Causes:

6.1 Non-Operational Problems

Check the following first:

Does the AC power cord plug in properly?

Does the AC power cord connected to the power connector properly?

Does the power LED still illuminate?

Solutions:

If the LCM is able to display the message, the apparel plotter should be in a normal

condition. Switch off the apparel plotter and turn it on again to see if the problem’s still

existing.

If the LCM is unable to display any message, contact the technician from your dealer.

Page 32

TP-183P User Manual

Troubleshooting 6-2

6.2 Operational Problems

Some mechanical problems or failure during operation will cause some problems. The error

messages shown on the LCM present the problem first, and followed by recommended actions.

If the problem still exists after the recommended actions have been done, have your apparel

plotter serviced.

Error, Check Media

Or Drum or X Motor

This message indicates that there might be a

problem on the X axis. Check if the drum is

working well and if the media is well loaded.

Correct the problem and re-power on to reboot

system.

Error, Check Media

Or Y Motor

This message indicates that there might be an

obstruction to carriage relating to a problem on

the Y axis. Correct the problem and re-power on

to reboot system.

Error, Check Carriage

Sensor or VC Motor

This message indicates that the blade up/down

sensor malfunction. Re-power on to re-boot

system. If the problem still exists, find a

serviceman.

Graph Was Clipped.

Data In Buffer

This message indicates that the apparel exceeds

the apparel limit. Reload larger media or re-scale

the plot to a smaller size; then press the key

followed by the display of LCM to continue.

Page 33

TP-183P User Manual

Troubleshooting 6-3

6.3 Data Communication Problems

The messages showed below present problems in relation to apparel plotter/computer

communication.

Communication Error

Setup: MISC. key

Is the connection cable connected

to the apparel plotter and computer

properly?

Yes No

Has the interface setting been

done correctly?

Refer to Chapter 4 Connecting your apparel

plotter.

Yes No

Refer to the “MISC” key in

Chapter 3 - Description of

Operation for the port setup.

Try the communication

between your apparel plotter

and computer. If it still does

not work, have your apparel

plotter serviced.

Note:

The computer also needs to set up compatible communication parameters to the

apparel plotter set up.

If your apparel plotter can not recognize the

HP-GL/2 or HP-GL commands, please check

the HP-GL/2 or HP-GL commands applied to

your apparel plotter are used properly.

HP-GL/2 Cmd. Error

Page 34

TP-183P User Manual

Troubleshooting 6-4

6.4 Software Problems

Check the following first:

Does your software support HP-GL and HP-GL/2 drivers?

(* check the configuration settings of your software.)

Yes

No

Does your software package indicate that it will work with your

computer and apparel plotter?

Does the apparel plotter interface

match the requirements of your

software?

Does your

software

recommend using

a different cable?

Yes No

Most well-known patterning software

in the world has drivers for our

apparel plotters. If your software

doesn’t support TP-183P driver, use

software that has HP-GL and

HP-GL/2 emulation supports and you

can chose the following three drivers:

z A3 size: HP7475A

z A1 size: HP7580A

z A0 size: HP Draf Pro Exl or HP

Yes

No

Refer to Chapter 4,

connecting your

apparel plotter.

No

Does the software

vendor provide a

sample file?

Yes

Try using the

recommended

cable.

Re-power on the

apparel plotter and

try to send the file

again.

Do something about the

error message display on

LCM, or consult your

software vendor.

Page 35

TP-183P User Manual

Troubleshooting 6-5

6.5 Plotting Quality Problems

Is the pen installed correctly and the pen holder

fastened securely?

No

Yes

Refer to Chapter 2-4

“Pen Installation”.

Is the pen dull or

chipped?

Yes No

Replace

with a new

pen

Is tool force set up

properly? (The default

for tool force is 55 gf)

Yes No

Is the tool offset set up

properly?

Adjust the tool force to obtain

an optimum pen force. Refer to

chapter 4-4 “Adjusting the

plotting force”.

Yes No

Is there any dirt adhered to the

pen?

Adjust the tool offset to

obtain an optimum value.

Yes

No

Remove the pen

and clean it.

Please contact your dealer for technician

support.

Page 36

TP-183P User Manual

Vogue Specification A-1

Vogue Specification

Model Name Vogue TP-183P

Max. Media Loading Width 1900mm(74.8”)

Min. Media Loading Width 900mm(35.4”)

Max. Plotting width 1830mm(72”)

Number of Pinch Rollers 7

Max. Plotting Speed Up to 1080mm/sec (42.5 ips)

Motor DC Servo Control

Acceptable Pens Disposable Ink and Ball Point Pens

Max. Plotting Length at one job 20m(65.6’)

Max. Roll-Media Weight 40kg

Acceptable Media (g/m²) 40g ~ 80g

Max. Roll Media Diameter 200mm(7.87”)

Roll Media Core Diameter 50mm or 76mm (2” or 3”)

Hardware Interfaces USB, Parallel, RS-232

Data Buffer 4MB

Commands HP-GL, HP-GL/2

Stand and Take-up System Yes

Net Weight 105kg

Dimension(W*L*H) 750*2170*1160mm (29.5”*85.4”*45.7”)

y Compatible with Windows 2000/XP/7.

y The specification and data sheet may vary with different materials used. In order to obtain

the best output quality, please maintain the machine regularly and properly.

y GCC reserves the right to change the specifications at any time without notice.

Page 37

TP-183P User Manual

Vogue CAD Output Accessory Instruction A-2

1

Vogue CAD Output Accessory Instruction

Chapter 1 Vogue CAD Output Accessory(GCC plotter software、Dongle)Instruction….2

Chapter 2 The setting of GCC Plotter output………………………………………………… …….4

Chapter 3 Automatic queuing function………………………………………… ……………………8

Page 38

TP-183P User Manual

Vogue CAD Output Accessory Instruction A-2

2

Chapter 1 Vogue CAD Output Accessory(software、dongle)Instruction

1、 If you have installed previous versions of the GCC plotter software, please remove it from the control

panel in your PC.

2、 Insert the installation CD and click “setup.exe”.

3、 Click “OK” to continue with the installation.

4、 Click on the button shown below to install GCC plotter software.

5、 Click “Yes” to continue with the installation.

6、 Click on the button shown below to copy the files from the installatio n CD to your PC. You do not need to

restart your PC.

Page 39

TP-183P User Manual

Vogue CAD Output Accessory Instruction A-2

3

7、 Plug-in the dongle and start the GCC plotter software. You will see the window below showing that the

installation has been completed correctly.

Page 40

TP-183P User Manual

Vogue CAD Output Accessory Instruction A-2

4

Chapter 2 The setting of GCC Plotter output

1、 Install the Vogue driver.

Install the Vogue driver and set up the ports as USB. (See Chapter 5 for details.)

Please note that if you output through the printer port, you need to set up the port to LPT port; if you

output by RS-232, you have to set up the port to the COM port.

2、 Please note that you must set the GCC plotter as the default printer.

3、 Click

to set up the parameter as below and then click “save”. (The resolution should be set to 1016

lpi)

Note:There are three different resolutions for different plotting ratio

0.025 correspond to 1016 lpi(Most markers use this plotting ratio);

0.0254 corresponds to 1000 lpi; (commonly used by Gerber software);

0.01 corresponds to 2540 lpi.

The setting of length: the length of the output paper

The setting of width: the width of the output paper

Note 1:The value of length cannot be over 60cm.

Page 41

TP-183P User Manual

Vogue CAD Output Accessory Instruction A-2

5

Note 2:Enter the length and width of the media in the corresponding fields.

4、 Click

and choose to import the file (PLT format) you want to plot.

Note: you can import the PLT file with different resolutions.

5、 Preview the file.

The length(X) and width(Y) of the image File name and path

Coordinates

Ratio

7. Adjust the ratio

Click “Tools” → “Regulation” to set up a ratio for each textile marker (for e.g. 0.2, 0.5, 1.2 etc) and press

“OK”.

Page 42

TP-183P User Manual

Vogue CAD Output Accessory Instruction A-2

6

Note: The coordinates must be a positive number or the output image might not be outputted completely.

You can move the coordinates manually to ensure that the coordinates are positive and thus will be

outputted correctly.

6、 Click the

icon to access the window below:

The following options are available:

1) Click

to modify the length and the width of the media.

Enter the length and the width of the media and press “Enter”.

2) Click

to set up the distance of each textile marker.

Enter the distance of each textile marker and press “Enter”.

Page 43

TP-183P User Manual

Vogue CAD Output Accessory Instruction A-2

7

3) Click to indicate the starting segment of the textile marker or continue with the last

plotting job.

4)Click

to output the file with a 1:1 ratio

Enter the number of copies and press the Enter key to output the file.

Page 44

TP-183P User Manual

Vogue CAD Output Accessory Instruction A-2

8

Chapter 3 Automatic queuing function

1、 Click Open Pool and keep GCC plotter software in the online status

2、 Copy the PLT file to C:\GCC\Spool (Assuming that the GCC plotter software has been installed in C:\ )

The files in the spool will be output automatically by the automatic queuing function. Note that the PLT

file will be deleted after the completion of each job.

Loading...

Loading...