Page 1 GCR Class 8B

Page 1 GCR Class 8B

Great Central Models

Robinson GCR Class 8B Atlantic

(LNER C4)

Version 1.2 February 2013

Assembly Instructions Revised July 2014

Catalogue #GCM005

This kit is optimised for P4 and EM standards. The kit was designed by “Great Central Models” as part of an

expanding range of Great Central Railway locomotives.

Great Central Models Ltd is registered as a Private Limited Company - 7355519

Further details - www.greatcentralmodels.co.uk

Enquiries to sales@greatcentralmodels.co.uk or via the contacts page on the web site

The picture above is for illustration only, it is actually a 7 mm model painted and finished by a very well known artist, whose

writings on the subject are well worth reading. Also worthy of note is the newly released book by John Quick, “Robinson’s

Locomotive Liveries on the Great Central Railway”.

Page 2 GCR Class 8B

Page 2 GCR Class 8B

Robinson GCR Class 8B LNER C4

The Class 8B was a trial build of a 4-4-2 soon after Robinson decided on a big engine policy. While impressed by the work done

by Churchward at Swindon, he seems to have adopted a cautious approach so decided to build 4 locomotives, essentially with

all the major features the same, but the Class 8C as a 4-6-0 and the Class 8B as a 4-4-2 Atlantic. 6’ 9” coupled wheels were fitted.

The work was done by Beyer Peacock and was based on the earlier 4-6-0s, the so-called “fish” engines which were Class 8 under

the Great Central way of categorising locomotives.

In principle, the rear end of the Class 8B was designed so that it could be converted easily to the Class 8C but it was the ‘Atlantic’

design that prevailed.

All were built between 1903 and 1906 by Beyer-Peacock (7), North British Loco. Co. (12), and at Gorton (8) with saturated steam

boilers. The only difference was really the fire grate, in the first build it was rather shallow, matching the Class 8C. Once the

decision had been made to stick with the 8B design rather than the 8C, a deeper fire box was fitted. They were withdrawn over

a period from 1939 until 1950, having been replaced by the B17s, but mainly during 1948-1950. None of them received BR

numbers, their replacement meant that none were re-painted or re-numbered.

Superheating was started in 1912 and continued right up to 1936 - no rush then!

As with the other Robinson locomotives, chimneys were a varying feature. The classical GCR chimneys were not approved by the

LNER because of the loading gauge issues (in common with most of the GCR classes) so were replaced initially by the LNER

flower-pot version. Later a pseudo-GCR chimney was fitted. Use the “13 ft Gauge” column below as a guide to when this

happened, generally it was a lot later than other Robinson classes. Flattened or angular domes were used at various times, the

angular domes seemed to appear during WW 2. The movement of the whistle from the cab top onto the boiler happened for

the same reasons of loading gauge As always, a good picture is the best guide, provided the dating is accurate!

For guidance, according to RCTS data and Yeadon Vol 13:-

Manufacturer Built Withdrawn GCR # Superheated LNER 1924 LNER 1946 13 ft Gauge

Beyer, Peacock 12/1903 11/1950 192 9/1920 5192 (10/1925) 2900 (8/1946) 5/1937

Beyer, Peacock 12/1903 11/1950 194 10/1925 5194 (10/1925) 2901 (6/1946) 1/1938

Beyer, Peacock 7/1904 4/1949 263 6/1926 5263 (4/1924) 2902 (6/1946) 8/1938

Beyer, Peacock 7/1904 6/1949 264 7/1921 5264 (2/1924) 2903 (9/1946) 9/1937

Beyer, Peacock 7/1904 12/1947 265 9/1920 5265 (1/1925) 2904 (8/1946) 5/1937

Beyer, Peacock 7/1904 10/1943 266 5/1921 5266 (5/1922) 2905 5/1938

Beyer, Peacock 7/1904 11/1947 267 9/1920 5267 (2/1925) 2906 (3/1946) 3/1939

N.B. Loco. Co 10/1905 12/1947 1083 1/1921 6083 (9/1924) 2907 (6/1946) 4/1937

N.B. Loco. Co 10/1905 11/1950 1084 8/1929 6084 (7/1925) 2908 (6/1946) 7/1937

N.B. Loco. Co 10/1905 11/1950 1085 1/1925 6085 (1/1925) 2909 (6/1946) 1/1925

N.B. Loco. Co 10/1905 2/1949 1086 8/1914 6086 (2/1924) 2910 (6/1946) 10/1937

N.B. Loco. Co 10/1905 11/1944 1087 9/1920 6087 (12/1925) 2911 11/1937

N.B. Loco. Co 10/1905 8/1949 1088 12/1926 6088 (11/1924) 2912 (9/1946) 12/1936

N.B. Loco. Co 11/1905 4/1947 1089 6/1920 6089 (10/1924) 2913 (11/1946) 10/1937

N.B. Loco. Co 11/1905 11/1939 1090 3/1914 6090 (10/1924) 8/1936

N.B. Loco. Co 11/1905 3/1948 1091 4/1925 6091 (4/1925) 2914 (6/1946) 9/1937

N.B. Loco. Co 11/1905 6/1949 1092 3/1921 6092 (7/1925) 2915 (10/1946) 8/1936

N.B. Loco. Co 11/1905 11/1948 1093 11/1927 6093 (9/1925) 2916 (9/1946) 6/1937

N.B. Loco. Co 11/1905 5/1949 1094 1/1936 6094 (2/1924) 2917 (8/1946) 7/1937

Gorton 2/1906 12/1950 260 2/1935 5260 (12/1925) 2918 (8/1946) 5/1938

Gorton 3/1906 11/1950 261 1/1927 5261 (12/1925) 2919 (8/1946) 2/1937

Gorton 4/1906 2/1948 262 4/1925 5262 (12/1925) 2920 (8/1946) 1/1937

Gorton 5/1906 4/1948 358 5/1920 5358 (12/1925) 2921 (8/1946) 3/1937

Gorton 6/1906 6/1948 360 10/1920 5360 (12/1925) 2922 (8/1946) 12/1936

Gorton 7/1906 2/1949 361 3/1912 5361 (12/1925) 2923 (8/1946) 10/1937

Gorton 6/1906 1/1948 362 3/1928 5362 (12/1925) 2924 (8/1946) 3/1937

Gorton 8/1906 4/1949 363 2/1921 5363 (12/1925) 2925 (8/1946) 2/1937

Page 3 GCR Class 8B

Page 3 GCR Class 8B

Additional Notes

LNER Numbering - there were huge variations in how LNER numbering was applied. Sizes varied, location carried, style varied,

sometimes just ‘NE’, sometimes still with the GCR cab side plate and the letter ‘c’ added to the LNER number, sometimes on the

tender but mainly on the cab once the LNER got themselves sorted out.

Photographs should be consulted when deciding what number to have. Of course in GCR days it was all rather simpler.

Locomotives could have a carriage heater connection at the front as they became used on passenger trips which would mean

that a heating pipe should also be added to the tender.

Smoke box handles - for this class the wheel arrangement was kept throughout their lifetime.

There are more versions of the chimneys and domes than catered for by the kit. The original chimney was of a much finer

appearance and rapidly failed in service.

Ramsbottom 2 column valves were originally fitted and a branching arrangement used for the traditional 4-column appearance.

These were originally uncased but casing was added later. Ross valves replaced the Ramsbottom valves during superheating.

Tail rods on the cylinders were removed before grouping but I have no dates for this, it seemed to happen over a longer period

than other GCR classes, but before grouping. On super-heating a ‘snifting’ valve was fitted behind the chimney. At the same

time the ash ejector was fitted on the right of the Smoke Box.

Centre steps were removed before the grouping, at speed they could ‘whip’ and potentially hit the connecting rod.

Livery was perplexing. Originally in full GCR green regalia, they soon reverted to lined black and then the LNER painted them

green again until WW 2, when they all became black again. Under LNER management, the beading was always unpainted and

usually unpolished.

Tenders when built for 192, 194 were the GCR 3,250 gallon version but these were soon replaced by the group standard with

plated sides.

As with all models from this era, the best thing a modeller can do is refer to published literature such as

Ÿ “Locomotives of the LNER Part 3A” from RCTS

Ÿ “Locomotives of the Great Central Railway” by E. M. Johnson

Ÿ Photographs from various collections - usually available at shows such as Scaleforum and Scalefour North

Ÿ “Yeadon’s Register of LNER Locomotives - Part 13”

These locomotives, known as the “Jersey Lilies” ranged far and wide and could be seen as far away from GCR rails as Plymouth

and Weston-Super-Mare, even running a slip coach at one stage. They ended their days doing light duties on the BR Eastern

Region. Their visits to Plymouth are a good excuse to put a “Green, with rivets”, next to a GCR Class 8B, “Green, without rivets”

Important Note

This kit has been designed for P4 or EM standards. Alternative parts have been designed into the brass and nickel silver frets.

There are plenty of spare parts for the smaller items. Considerable additional work will be needed to build this kit to ‘00’

standards. Remember that ‘00’ and EM wheels will cut into the boiler space. For EM modellers care must be taken not to

increase the upward movement of the wheels if sprung or compensated by filing out the axle slots in the frames. If the kit, when

built, has a lot of side play then even the P4 version will find the wheels hitting the boiler. In all cases the boiler can be ground

out to clear this.

Notes on the kits and constituent parts

The etched parts in this kit have been designed using a CAD program (TurboCAD 18.2) to ensure accuracy when fitting the parts

together. Included in these notes are:-

Ÿ A list of etched and cast parts

Ÿ A list of additional and optional parts

Ÿ Drawings of the etch fret

Page 4 GCR Class 8B

Page 4 GCR Class 8B

Ÿ Detailed step-by-step instructions with the drawings extracted from the CAD originals

The original CAD drawings were prepared from GA drawings obtained from MOSI in Manchester and scaled at 12” to 1’. During

the design process a number of compromises had to be made (such as the frame widths) because of the materials and parts

available to the modeller and the P4 and EM standards. These compromises were used to draw a full size CAD drawing which

was then used to provide the instructions and construction drawings and the final etch parts. The etch parts of the drawing

were scaled down very accurately to produce etches for the 4 mm modeller.

The kit prototypes were built by the designer. The first trial etch was used as a feasibility project and to write outline

instructions. The second test etch was used to test the assembly, write instructions and produce the assembly diagrams as well

as a viable model. A modeller familiar with etch brass kit construction should be able to build an accurate model if these

instructions are followed, generally as written. However, fine-scale modellers being who we are, other ways of building the kit

will be tried!

The Instructions

More years ago than I care to remember I was involved in validating and writing Master Work Sheets for the Royal Air Force.

These were sets of instructions that had to be followed to the letter by technicians world-wide even though they may never

have met that particular piece of equipment before. Deviations were never permitted to the technicians – given that the

machines being tested were vital to safe flying – and any permission to be deviant granted by senior authority was subject to a

very close monitoring process.

However, senility and pending obsolescence have taken their toll – nobody is perfect – so if you find anything in these

instructions you feel to be wrong it will be examined closely and amended where appropriate. Likewise, with the measurements

of the parts, if there is something which you feel may be wrong then, please let me know. It would be nice if this was supported

by drawings, or copies of drawings with time stamps if possible. Photographs are useful as well. But be warned, the available

drawings are neither consistent nor accurate if my research means anything at all and there were so many cosmetic changes

made to these locomotives over nearly 50 years that photographs without a date stamp must be treated with some caution.

Things to note

In a few areas there are alternative ways of doing things. While there are traditional etched springs on Sheet 3, for this kit the

centre springs have been printed using 3D CAD technology. They are fitted to the horn blocks. Note that these are heat sensitive

and will melt as quickly as white metal castings. The etched or printed springs mean that the wheels can also be removed for

‘servicing’.

Continuous Springy Beams (CSBs) may be fitted - they seem to be all the vogue these days. I am a little uncomfortable with the

idea for a complex wheelbase such as a 4-4-2 and prefer to stick with the prototype idea where each axle is sprung by itself.

Short handrail knobs are used for the spring mounts. EM and ‘00’ modellers may use frame blanks to remove the need for

springing.

Stephenson’s Valve Gear would have been visible only by looking very carefully, for this engine. Extra parts are provided so you

can experiment with the way it fits together. If you are tempted to try this then please do remember not to solder the parts in

situ ‘after’ you have fitted your plastic centred wheels. The valve gear may be fitted in working order or as a very loose fit on the

centre axle. In the second case they will be visible but will not move except around the axis of the axle.

The Stephenson’s Valve Gear is tricky to get working well and may be left out. The rest of the engine will still look good when

finished and painted.

The builder will find an array of brake parts on the fret. While 3D brakes are an option and remove the possibility of shorts while

fitting closely to the wheels, they are vulnerable to handling errors. However, there are ways to strengthen them with the etch

base parts, or the builder may use etch parts only.

Rear and centre frame spacers - those supplied on the etch are to scale and may be fitted if desired - you can create frame

spacers which are a good representation of the originals with their strengthening brackets but these are difficult to see when

the model is completed. In practice the rear spacer construction was used to steady the front of the fire box but this may be

omitted without weakening the whole chassis. P4 and EM versions of these spacers are supplied together with some generic

spares. These are not standard widths though. Use the spares in appropriate places if you do not need the scale spacers or wish

to add your own parts for additional electrical pick-up.

There is substantial current collection capability in the tender. I was persuaded not to have pick-ups in the locomotive since they

would detract from the scale frame spacers and the valve gear and since there is plenty of space in the tender with or without

the optional DCC chip this may be a good option. The two wires for the motor may then represent the vacuum and heating

pipes.

Page 5 GCR Class 8B

Page 5 GCR Class 8B

The part numbers and descriptions (where space permits) are half etched on the frets as near to the parts as sensible and match

the description that appears in the Parts List. These annotations will appear in the form “212”, or “223,224” or 213-217” or 218225+3”. Where something like “212EM” appears on the fret then that is the EM version of a part that will also have a P4

(unlabelled) part on the fret. Where the “+” appears in the part number it shows that additional parts have been included and

the number following shows that 3 additional parts are on the fret. This allows for two possibilities

a) losing very small parts in the carpet after cutting them from the fret

b) practising the assembly in cases where some difficulty may be expected

Also on the fret there are a couple of blocks on which to practice your skill at pushing out rivets. Try these first to test the

consistency of your efforts. Refer to photographs to check if these parts were actually riveted early in life, Robinson abhorred

‘proud’ rivets and there is some photographic evidence to show that they may not have been used in the early days, even at the

bottom of the smoke box.

The instructions also use the Part Number and Full Description. This may seem a little pedantic but can help where there may be

some uncertainty. I also list all parts separately and do not group sets of parts together (i.e. Springs Qty 7) so that you will find

the parts list will show each layer in a built up assembly as an individual item.

Assembly Instructions

You may also find it easier to drill out all the locating holes while the parts are still within the main etch, and even to assemble

some of the parts together - simply because this helps to hold at least one of the parts firmly in place.

Do not use force at any time, you are likely to bend the parts beyond repair. The tabs and slots are designed to be a semi-tight

fit and on occasion a little easing with a strip of wet & dry sandpaper may be needed, especially on the slots in the smaller parts.

If needed, where parts fit into a slot, very lightly dress the mating edges with a fine file. Most slots are 2 mm long and the edge

strips on the etches may be used to ease them out a little if needed.

Unless otherwise stated, the folds are all done with the half etch on the inside.

TAGS are on the fret and hold the individual parts in place when the fret is etched. TABS are on the parts to fit into SLOTS in the

corresponding parts. In many areas on the fret TAGS have been arranged so that they fit onto TABS solely to help minimize any

possible damage to the component when the TAGS are removed since the TABS will all in the end be invisible.

Do not confuse TAGS and TABS and file off any TABS!

It may be easier to do a number of preparatory jobs before removing parts from the main etches. There are a few rivets that

may have to be pushed through from the rear of some parts, such as the main frames. The smoke box wrapper was flush riveted

when built but as the LNER super-heated the locomotives they would normally have been replaced by the usual, highly visible

rivets. Front buffers sometimes had rivets added after superheating but not necessarily at the same time. The smoke box

wrapper may also have had further rivets added as well as the smoke box front around the door, which seemed to have

happened in the late 1930s and early 1940s.

As always, if you are really keen on authenticity then the best thing to do is to examine a photograph of the engine you are

modelling.

Decision time

The kit has been designed to use frame spacers that approximate to the frames on the original engines, which means that

stiffeners are also added to the inside and outside of the frames. Should you decide that adding these scale spacers is a step too

far since they will be almost invisible then alternative spacers are included for P4 and EM. Or the builder may decide to provide

his own set of spacers, especially if there are concerns about side play for small radii curves.

Cosmetic spring mechanisms are provided. These are removable using screws for those of us who like to be able to remove the

wheel sets easily.

Sufficient parts are included to make this kit to either P4 or EM standards. Because the EM wheel back-to-back is a little smaller

than P4, the spacers for EM are narrower and the frames will not have the distinctive kink at 4’ 0” from the front of the frame.

Do not mix up the P4 and EM parts since you will find there a world of pain. Remember that EM parts are identified on the fret

with a suffix ‘EM’ after the Part Number.

The kit as designed will go around a 1250 mm radius curve before the bogie wheels hit the frames. A tighter turning circle will

mean that the bogie frames have to be cut back to allow the bogie wheels further side play and they are half-etched on the

inside as a guide. Note also that for something like a 1000 mm radius that the rear inside of the cylinders will need trimming.

Page 6 GCR Class 8B

Page 6 GCR Class 8B

Soldering

I use ‘Nealetin’, a liquid solder with its own flux. This allows very close control of the initial solder join. Most initial joints will be

secure using this (or a similar liquid solder). Motion parts should be soldered with a higher temperature solder. Once you are

convinced things are square then it is possible to run a small fillet of solder along critical joins by first priming with a little

‘Nealetin’.

I have never used lead free solder for making models.

Square Frames

There are a couple of mechanisms, neither of which I have used, which have been acclaimed for the ease with which they

permit a square frame to be built. While these are expensive to start, many modellers have sung their praises.

Under Etched parts

On occasion some parts may be a little under etched. The individual frets have outer frames which are the same width as the

vast majority of the slots (2 mm) - just use a short section of this to free up any dubious slots. In any event it is always wise to

prepare parts using a very fine file to remove any bits of ‘cusp’ left from the etching process, before assembly.

Health & Safety

Experienced modellers will know all this already but -

Ÿ The frets are made from 12’ brass and 15’ nickel silver. They are fragile and the edges are sharp. Take care when assembling

and especially when drilling out holes. Rotating brass (which tends to grab drill bits, especially near the end of their cut) or

nickel silver will cause a lot of skin and tissue damage if the drill sticks and tears. For preference use a hand drill or pin

chuck.

Ÿ Soldering entails the use of toxic materials such as lead and acid flux. Observe the warning notices that come with these

products and especially use adequate ventilation. Wear suitable eye protection where needed.

Ÿ Solder also gets very hot when melted, as do the parts when heated to solder them together. Take care to hold parts

carefully with insulating material where needed and to let them cool properly before handling. This is especially true if

annealing parts so they can be bent into shape more easily. It is also true where several layers may have been used to build

up an assembly.

Ÿ When painting, ensure proper ventilation, especially if using a two part etch solution. Some of these carry hazardous

chemicals.

Ÿ On a few occasions there will be a wire across the frames or bogie soldered at both ends. Do not be tempted to cut this

after assembly with the normal wire cutters, this will force the frames apart and cause some damage. Use something like a

triangular file or a disc cutter to make the first cut!

Note on bending parts with half etched lines

Tighter bends may be achieved as follows if thought to be necessary (notes extracted from some thoughts by Will Litchfield).

1. Deepen the fold line with a triangular 4 cut needle file till a witness line shows though to the other side.

2. Hold the etch on a flat surface with a your trusty steel rule along the fold line.

3. Run a craft knife blade along under the etch to start the fold on it way.

4. When the edge stands well way from the flat surface, use another steel rule to complete the fold.

You get a sharper bend this way, because a of step 1 and it is accurately placed on the centre of the fold line.

Notes on wheel choices

The frames on this kit are set to a design width of 16.15 mm for P4 so that with cusp removal on the spacers approximately

16.00 mm is the final frame width. This is slightly less than some kits, but more than other kits, especially those which were

designed for the ‘00’ market and then had options added for the finer scale gauges of ‘P4’ and ‘EM’. To this width must be

added the outer flange of the horn blocks, which will vary depending on horn block supplied - the ones supplied are from

Markits.

For the fine scale gauges, side play can be an important issue especially where small radius curves of less than 1200 mm are to

be tackled.

Page 7 GCR Class 8B

Page 7 GCR Class 8B

There are three wheel sets available, from Alan Gibson, Ultrascale and Exactoscale. For P4, the Alan Gibson wheels have a rear

boss which is 0.5 mm deep. This will impact side play, especially for P4 modellers and less so for EM modellers. This rear boss

should be removed from Alan Gibson wheels.

Potential purchasers in the fine scale gauges are urged to consider these points. There are, as always, strategies to ameliorate

such issues. Further reading on these points are in :-

Side Play Supplementary Notes

Design Notes

Both of which are available on the web site at www.greatcentralmodels.co.uk on the ‘instructions’ page.

Page 8 GCR Class 8B

Page 8 GCR Class 8B

Locomotive Chassis

0.015’ 0.375 mm Nickel Silver

Locomotive Frame

1. Frame Left - Sheet 1

2. Frame Right - Sheet 1

3. Front Buffer Beam - Sheet 1

4. Front Buffer Beam Overlay - Sheet 1

5. Rear Buffer Beam - Sheet 1

6. Rear Buffer Beam Overlay - Sheet 1

7. Cylinder Spacer Front - Sheet 1

8. Cylinder Spacer Rear - Sheet 1

9. Cab Base Support - Sheet 3

10. Firebox Base - Sheet 3

11. Smoke Box Base - Sheet 3

12. Rear Frame Spacer - Sheet 3

13. Rear Frame Spacer Brace - Sheet 3

14. Rear Frame Spacer Stiffener Left - Sheet 1

15. Rear Frame Spacer Stiffener Right - Sheet 1

16. Centre Frame Spacer - Sheet 3

17. Centre Frame Spacer Stiffener Left - Sheet 1

18. Centre Frame Spacer Stiffener Right - Sheet 1

19. Valve Guide Support Spacer - Sheet 3

20. Valve Guide Support Spacer Stiffener Left Sheet 1

21. Valve Guide Support Spacer Stiffener Right Sheet 1

22. Slide Bar Support Left - Sheet 3

23. Slide Bar Support Right - Sheet 3

24. Buffer Support Left - Sheet 1

25. Buffer Support Right - Sheet 1

26. Sandbox Left - Sheet 1

27. Sandbox Right - Sheet 1

28. Brake Cylinder Support Left - Sheet 1

29. Brake Cylinder Support Right - Sheet 1

30. Guard Iron Left - Sheet 1

31. Guard Iron Right - Sheet 1

32. Buffer Mount - Sheet 1

33. Buffer Mount - Sheet 1

34. Coupler - Sheet 1

35. Coupler - Sheet 1

36. Rear Buffer Housing Plate - Sheet 1

37. Rear Buffer Housing Plate - Sheet 1

38. Footplate Fixing Bracket - Sheet 2

39. Front Buffer Beam Draw Bar Plate - Sheet 1

40. Front Buffer Beam Draw Bar Plate - Sheet 1

41. Rear Buffer Beam Draw Bar Plate - Sheet 1

42. Fire Box Brace - Sheet 1

43. Drag Link - Sheet 1

44. Drag Link - Sheet 1

45. Drag Link - Sheet 1

46. Firebox Right - Sheet 1

47. Firebox Left - Sheet 1

48. Bogie Mount - Sheet 3

49. Cylinder Head - Sheet 3

50. Cylinder Head - Sheet 3

51. Cylinder Head - Sheet 3

52. Cylinder Head - Sheet 3

53. Safety Loop - Sheet 1

54. Safety Loop - Sheet 1

Brakes

55. Brake Frame Mount - Sheet 1

56. Brake Frame Mount - Sheet 1

57. Brake Frame Mount - Sheet 1

58. Brake Frame Mount - Sheet 1

59. Brake Frame Mount - Sheet 1

60. Brake Frame Mount - Sheet 1

61. Brake Pull - Sheet 3

62. Spare

63. Spare

64. Brake Pull Centre Bracket - Sheet 3

65. Brake Pull Centre Bracket - Sheet 3

66. Brake Pull Front Bracket - Sheet 3

67. Brake Pull Front Bracket - Sheet 3

68. Vacuum Cylinder Link - Sheet 3

69. Brake Mount - Sheet 3

70. Brake Mount - Sheet 3

71. Brake Mount - Sheet 3

72. Brake Mount - Sheet 3

73. Rear Wheel Brake Mount - Sheet 3

74. Rear Wheel Brake Mount - Sheet 3

75. Brake Mount Top Layer - Sheet 3

76. Brake Mount Top Layer - Sheet 3

77. Brake Mount Top Layer - Sheet 3

78. Brake Mount Top Layer - Sheet 3

79. Rear Wheel Brake Mount Top Layer - Sheet 3

80. Rear Wheel Brake Mount Top Layer - Sheet 3

81. Brake Shoe Base - Sheet 3

82. Brake Shoe Base - Sheet 3

83. Brake Shoe Base - Sheet 3

84. Brake Shoe Base - Sheet 3

85. Rear Wheel Brake Shoe Base - Sheet 3

86. Rear Wheel Brake Shoe Base - Sheet 3

87. Brake Shoe Top Layer - Sheet 3

88. Brake Shoe Top Layer - Sheet 3

89. Brake Shoe Top Layer - Sheet 3

90. Brake Shoe Top Layer - Sheet 3

91. Rear Wheel Brake Shoe Top Layer - Sheet 3

92. Rear Wheel Brake Shoe Top Layer - Sheet 3

93. Brake Cylinder Link - Sheet 3

94. Brake Cylinder Link - Sheet 3

95. Rear Brake Pull - Sheet 3

96. Spare

97. Rear Brake Pull Tag - Sheet 3

98. Rear Brake Pull Tag - Sheet 3

99. Small Brake Pull - Sheet 3

100. Small Brake Pull - Sheet 3

101. Actuator to Brake Lever - Sheet 3

102. Actuator to Brake Lever - Sheet 3

103. Brake Lever - Sheet 3

104. Brake Lever - Sheet 3

Coupling Rods

105. Coupling Rod Left Front - Sheet 2

106. Coupling Rod Left Front Overlay - Sheet 2

107. Coupling Rod Left Boss Front - Sheet 2

108. Coupling Rod Left Boss Front - Sheet 2

109. Coupling Rod Left Boss Front - Sheet 2

110. Coupling Rod Left Boss Front - Sheet 2

111. Coupling Rod Right Front - Sheet 2

112. Coupling Rod Right Front Overlay - Sheet 2

Page 9 GCR Class 8B

Page 9 GCR Class 8B

113. Coupling Rod Right Boss Front - Sheet 2

114. Coupling Rod Right Boss Front - Sheet 2

115. Coupling Rod Right Boss Front - Sheet 2

116. Coupling Rod Right Boss Front - Sheet 2

Connecting Rods

117. Connecting Rod Left - Sheet 2

118. Connecting Rod Left Overlay - Sheet 2

119. Connecting Rod Right - Sheet 2

120. Connecting Rod Right Overlay - Sheet 2

121. Connecting Rod End Overlay - Sheet 2

122. Connecting Rod End Overlay - Sheet 2

123. Connecting Rod End Overlay - Sheet 2

124. Connecting Rod End Overlay - Sheet 2

Slide Bars

125. Slide Bar Left Upper Main - Sheet 1

126. Slide Bar Left Lower Main - Sheet 1

127. Slide Bar Overlay - Sheet 1

128. Slide Bar Overlay - Sheet 1

129. Slide Bar Overlay - Sheet 1

130. Slide Bar Overlay - Sheet 1

131. Slide Bar Overlay - Sheet 1

132. Slide Bar Overlay - Sheet 1

133. Slide Bar Right Upper Main - Sheet 1

134. Slide Bar Right Lower Main - Sheet 1

135. Slide Bar Overlay - Sheet 1

136. Slide Bar Overlay - Sheet 1

137. Slide Bar Overlay - Sheet 1

138. Slide Bar Overlay - Sheet 1

139. Slide Bar Overlay - Sheet 1

140. Slide Bar Overlay - Sheet 1

Bogie

141. Bogie Frame - Sheet 1

142. Bogie Side Overlay - Sheet 1

143. Bogie Side Overlay - Sheet 1

144. Bogie Equalising Bar - Sheet 1

145. Bogie Equalising Bar - Sheet 1

146. Bogie Equalising Bar - Sheet 1

147. Bogie Equalising Bar - Sheet 1

148. Bogie Stretcher

149. Spring Face Plate - Sheet 1

150. Spring Face Plate - Sheet 1

151. Spring Backing Plate - Sheet 1

152. Spring Backing Plate - Sheet 1

153. Spring Backing Plate - Sheet 1

154. Spring Backing Plate - Sheet 1

155. Spring Backing Plate - Sheet 1

156. Spring Backing Plate - Sheet 1

157. Bogie Pivot - Sheet 1

158. Bogie Pivot - Sheet 1

159. Bogie Pivot - Sheet 1

160. Bogie Pivot - Sheet 1

161. Bogie Pivot - Sheet 1

162. Bogie Pivot - Sheet 1

163. Bogie Pivot - Sheet 1

164. Bogie Pivot - Sheet 1

165. Hex Bolt Head - Sheet 1

166. Hex Bolt Head - Sheet 1

167. Bogie Spring Hanger - Sheet 1

168. Bogie Spring Hanger - Sheet 1

169. Bogie Spring Hanger - Sheet 1

170. Bogie Spring Hanger - Sheet 1

Cross Heads

171. Cross Head Rear - Sheet 2

172. Cross Head Rear - Sheet 2

173. Cross Head Overlay - Sheet 2

174. Cross Head Overlay - Sheet 2

175. Cross Head Inner Layers A - Sheet 2

176. Cross Head Inner Layers A - Sheet 2

177. Cross Head Inner Layers A - Sheet 2

178. Cross Head Inner Layers A - Sheet 2

179. Cross Head Inner Layers B - Sheet 2

180. Cross Head Inner Layers B - Sheet 2

181. Cross Head Inner Layers B - Sheet 2

182. Cross Head Inner Layers B - Sheet 2

183. Cross Head Top Overlay - Sheet 2

184. Cross Head Top Overlay - Sheet 2

Valve Gear

185. Valve Rod Left Outer - Sheet 2

186. Valve Rod Left Inner - Sheet 2

187. Valve Rod Right Outer - Sheet 2

188. Valve Rod Right Inner - Sheet 2

189. Outer Rod End Strip - Sheet 2

190. Outer Rod End Strip - Sheet 2

191. Outer Rod End Strip - Sheet 2

192. Outer Rod End Strip - Sheet 2

193. Outer Rod End Spacer - Sheet 2

194. Outer Rod End Spacer - Sheet 2

195. Inner Rod End Strip - Sheet 2

196. Inner Rod End Strip - Sheet 2

197. Inner Rod End Strip - Sheet 2

198. Inner Rod End Strip - Sheet 2

199. Inner Rod End Spacer - Sheet 2

200. Inner Rod End Spacer - Sheet 2

201. Eccentric - Sheet 2

202. Eccentric - Sheet 2

203. Eccentric - Sheet 2

204. Eccentric - Sheet 2

205. Eccentric Bracket - Sheet 2

206. Eccentric Bracket - Sheet 2

207. Eccentric Bracket - Sheet 2

208. Eccentric Bracket - Sheet 2

209. Eccentric Short Bracket - Sheet 2

210. Eccentric Short Bracket - Sheet 2

211. Eccentric Short Bracket - Sheet 2

212. Eccentric Short Bracket - Sheet 2

213. Lifting Arm - Sheet 2

214. Lifting Arm - Sheet 2

215. Lifting Arm - Sheet 2

216. Lifting Arm - Sheet 2

217. Rotation Arm - Sheet 2

218. Rotation Arm - Sheet 2

219. Rotation Arm - Sheet 2

220. Rotation Arm - Sheet 2

221. Rotation Arm End Spacer - Sheet 2

222. Rotation Arm End Spacer - Sheet 2

223. Rotation Arm End Spacer - Sheet 2

224. Rotation Arm End Spacer - Sheet 2

225. Balance Arm - Sheet 2

Page 10 GCR Class 8B

Page 10 GCR Class 8B

226. Valve Rod End - Sheet 2

227. Valve Rod End - Sheet 2

Spares

228. Alternative Cylinder Cover Left

229. Alternative Cylinder Cover Right

Templates

230. Eccentric Template - Sheet 2

231. P4 Width Template - Sheet 3

232. P4 Width Template - Sheet 3

233. EM Width Template - Sheet 3

234. Spare

235. Spare

8C Frames

236. Rear Frame Left - Sheet 2

237. Rear Frame Right - Sheet 2

238. Rear Wheel Spring Mount Locator - Sheet 2

239. Rear Wheel Spring Mount Locator - Sheet 2

NiSi Springs (optional)

240. Spring Layers - Sheet 3

241. Spring Layers - Sheet 3

242. Spring Layers - Sheet 3

243. Spring Layers - Sheet 3

244. Spring - Sheet 3

245. Spring - Sheet 3

246. Spring Support Back - Sheet 3

247. Spring Support Back - Sheet 3

248. Spring Support Back - Sheet 3

249. Spring Support Back - Sheet 3

250. Spring Support Back - Sheet 3

251. Spring Support Back - Sheet 3

252. Spring Front - Sheet 3

253. Spring Front - Sheet 3

Common Parts

1. Drwg. 201 Backhead (1 supplied)

2. Drwg. 203 Footplate Side Cover (2 supplied)

3. Drwg. 205 Oil Box Covers (6 supplied)

4. Drwg. 206 Sand Box Filler (2 supplied)

5. Drwg. 209 Centre Axle Spring (2 supplied)

6. Drwg. 211 Counter Weight (1 supplied)

7. Drwg. 212 Cylinder Front (2 supplied)

8. Drwg. 215 Eccentric Plate (4 supplied)

9. Drwg. 216 Rear Buffer (2 supplied)

10. Drwg. 218 Vacuum Cylinder (1 supplied)

11. Drwg. 219 Bogie Pivot (1 supplied)

12. Drwg. 225 Bogie Axle Box (4 supplied)

13. Drwg. 229 Whistle Markits M4WhistGW2

14. Drwg. 244 Vacuum Pipe Markits (1 supplied) &

Steam Heating Pipe Markits (1 supplied)

15. Drwg. 245 Handrail Knobs

16. Drwg. 246 Reverser

17. Drwg. 249 GCR 3’ 6” Axle Box (2 supplied) - cast

items

18. Drwg. 258 Smoke Box Door (1 supplied)

19. Drwg. 260 Martkits M4HRKWDs (12 Supplied)

20. Drwg. 261 MarkitsRAXFBsq601 axle boxes (4

supplied)

21. Drwg. 262 GC Smoke Box Handle Markits

M4SBDH4

Board 1

22. Brass Wire 0.3 mm Eileen’s BSW031A (25 cm x 2

supplied)

23. Brass Wire 0.45 mm Eileen’s BSW045A (25 cm x

4 supplied)

24. Brass Wire 0.7 mm Eileen’s BSW070A (25 cm x 1

supplied)

25. Nickel Silver Wire 1.6 mm Eileens NSW160A (25

cm supplied)

26. Spring Wire Ernie Ball Gauge 12 (25 cm supplied)

Board 2

27. Reversing Axle Tube 1/16” x1 /32” (1.6 mm x 0.8

mm) Eileen’s BRT0201G (5 cm supplied)

28. Reversing Axle Rod 1/32” (0.8 mm) Eileen’s

BSW080A (5 cm supplied)

29. Valve Rod Tube 3/32” x 1/16” (2.4 mm x 1.6 mm)

Eileen’s BRT0302G 300 mm (10 cm supplied)

30. Cab Roof Front & Rear Brace (‘L’) Eileen’s Brass L

Section 1/32" x 1/32" x 12" (KS A1) (15 cm

supplied)

31. Cab Roof Centre Brace (‘T’) Brass T Section 1/32"

x 1/32" x 12" (KS T1) (5 cm supplied)

32. Brass Round Tube 0.8 mm x 0.4 x 305 mm (MT2)

Eileen’s BRT0804D (smoke box hinges) (5 cm

supplied)

Sundries (Drwg. 266)

33. Dome Head Rivet 08MBV07B (2 supplied)

34. 10 BA Bolts (4 supplied)

35. 10 BA Nuts (4 supplied)

36. 14 BA Bolts (4 supplied)

37. Washout Plugs Eileens LF4WP01 (9 supplied)

Alternative 3D printed components if required

1. Drwg. 224 Spring Hanger Blocks (2 supplied) may be used as an alternative to the etch version

2. Drwg. 247 B1C4 Brakes (4 supplied) - may be

used as an alternative to the etch version or top

of the etch base for additional strength - allows

brakes to sit very close to wheels

3. Drwg. 249 GCR 3' 6" Axle Box (2 supplied) replaces casting if not available

4. Drwg. 257 C4 Rear Brakes (2 supplied) - may be

used as an alternative to the etch version or top

of the etch base for additional strength - allows

brakes to sit very close to wheels

Page 11 GCR Class 8B

Page 11 GCR Class 8B

Locomotive Body

0.012’ 0.3 mm Brass

Boiler

1. Boiler - Sheet 4

2. Boiler Front - Sheet 4

3. Boiler Rear - Sheet 4

4. Smoke Box Frame +EM - Sheet 6

5. Smoke Box +EM - Sheet 6

6. Smoke Box Wrapper - Sheet 5

7. Smoke Box Wrapper Riveted - Sheet 5

8. Smoke Box Step - Sheet 4

Footplate

9. Footplate Left +EM - Sheet 6

10. Footplate Right +EM - Sheet 6

11. Footplate Rear +EM - Sheet 6

12. Footplate Front - Sheet 6

13. Footplate Hinge - Sheet 6

14. Footplate Hinge - Sheet 6

15. Lamp Bracket Footplate - Sheet 6

16. Lamp Bracket Footplate - Sheet 6

17. Lamp Bracket Footplate - Sheet 6

18. Valence Left - Sheet 4

19. Valence Right - Sheet 4

20. Splasher Side Left Front - Sheet 4

21. Splasher Side Left Centre - Sheet 4

22. Splasher Side Right Front - Sheet 4

23. Splasher Side Right Centre - Sheet 4

24. Not Defined

25. Not Defined

26. Splasher Top Left Front +EM - Sheet 6

27. Splasher Top Left Centre +EM - Sheet 6

28. Splasher Top Right Front +EM - Sheet 6

29. Splasher Top Right Centre +EM - Sheet 6

30. Footplate Support Top+EM - Sheet 6

31. Footplate Support Top+EM - Sheet 6

32. Footplate Support Top+EM - Sheet 6

33. Footplate Support Top+EM - Sheet 6

34. Footplate Support Bracket+EM - Sheet 6

35. Footplate Support Bracket+EM - Sheet 6

36. Footplate Support Bracket+EM - Sheet 6

37. Footplate Support Bracket+EM - Sheet 6

38. Oil Filler Caps - Sheet 4

39. Oil Filler Caps - Sheet 4

40. Oil Filler Caps - Sheet 4

41. Oil Filler Caps - Sheet 4

42. Oil Filler Caps - Sheet 4

43. Oil Filler Caps - Sheet 4

Fire Box

44. Fire Box - Sheet 4

45. Fire Box Cab - Sheet 4

46. Inspection Cover - Sheet 5

47. Inspection Cover - Sheet 5

48. Inspection Cover - Sheet 5

49. Inspection Cover - Sheet 5

50. Inspection Cover - Sheet 5

51. Fire Box Brace - Sheet 5

52. Fire Box Brace - Sheet 5

53. Fire Box Brace - Sheet 5

54. Fire Box Brace - Sheet 5

Cab

55. Cab Side Left - Sheet 5

56. Spare

57. Cab Side Right - Sheet 5

58. Spare

59. Not Defined

60. Not Defined

61. Edging Left Strip - Sheet 5

62. Edging Right Strip - Sheet 5

63. Cab Front - Sheet 5

64. Cab Window Overlay - Sheet 5

65. Cab Window Overlay - Sheet 5

66. Cab Window Overlay - Sheet 5

67. Cab Window Overlay - Sheet 5

68. Roof - Sheet 5

69. Reversing Arm Cab End - Sheet 4

70. Reversing Arm Chassis End - Sheet 4

71. Reversing Arm Cab Arm - Sheet 4

72. Reversing Arm Actuator - Sheet 4

73. Reversing Arm Actuator - Sheet 4

74. Reversing Lever Front Actuator - Sheet 4

Cupboards

75. Cupboard Left - Sheet 5

76. Cupboard Right - Sheet 5

77. Door Hinge - Sheet 5

78. Door Hinge - Sheet 5

79. Door Hinge - Sheet 5

80. Door Hinge - Sheet 5

81. Footboard Left - Sheet 5

82. Footboard Right - Sheet 5

83. Shelf Left - Sheet 5

84. Shelf Right - Sheet 5

85. Cab Handle - Sheet 5

86. Cab Handle - Sheet 5

87. Cab Handle - Sheet 5

88. Cab Handle - Sheet 5

89. Cab Floor - Sheet 6

Steps

90. Centre Step Plate Left - Sheet 4

91. Centre Step Left Upper - Sheet 4

92. Centre Step Left Lower - Sheet 4

93. Centre Step Plate Right - Sheet 4

94. Centre Step Right Upper - Sheet 4

95. Centre Step Right Lower - Sheet 4

96. Rear Step Plate Left - Sheet 4

97. Rear Step Left Upper - Sheet 4

98. Rear Step Left Lower - Sheet 4

99. Rear Step Stabiliser - Sheet 4

100. Rear Step Plate Right - Sheet 4

101. Rear Step Right Upper - Sheet 4

102. Rear Step Right Lower - Sheet 4

103. Rear Step Stabiliser - Sheet 4

Cylinders

104. Cylinder Cover Left - Sheet 4

Page 12 GCR Class 8B

Page 12 GCR Class 8B

105. Cylinder Cover Right - Sheet 4

Springs

106. Axle Box Spring Mount - Sheet 4

107. Axle Box Spring Mount - Sheet 4

108. Axle Box Spring Mount - Sheet 4

109. Axle Box Spring Mount - Sheet 4

110. Rear Wheel Spring Mount - Sheet 5

111. Rear Wheel Spring Mount - Sheet 5

Wheels

112. Centre Wheel Weights - Sheet 5

113. Centre Wheel Weights - Sheet 5

114. Wheel Weights - Sheet 5

115. Wheel Weights - Sheet 5

116. Not Defined

117. Not Defined

Bits and Pieces

118. Lamp Bracket Top - Sheet 4

119. Smoke Box Handle - Sheet 4

120. Smoke Box Handle - Sheet 4

121. Regulator Lever - Sheet 4

122. Regulator Plate - Sheet 4

123. Regulator Plate - Sheet 4

124. Footplate Connection - Sheet 4

125. Smoke Box Door Hinge - Sheet 4

126. Cab Roof Blanking Plate - Sheet 5

127. Ramsbottom Actuators - Sheet 4

128. Ramsbottom Actuators - Sheet 4

129. Ramsbottom Side Cover - Sheet 5

130. Rear Wheel Spring Mount Locator - Sheet 5

131. Rear Wheel Spring Mount Locator - Sheet 5

Assembly Aids

132. Valence Spacing Aids +EM - Sheet 5

133. Valence Spacing Aids +EM - Sheet 5

134. Valence Spacing Aids +EM - Sheet 5

135. Valence Spacing Aids +EM - Sheet 5

136. Footplate Assembly Aid - Sheet 4

137. Cab Assembly Aid - Sheet 5

138. Cab Assembly Aid - Sheet 5

139. Fire Box Support Aid - Sheet 5

140. Fire Box Support Aid - Sheet 5

141. Belpaire Filing Aid - Sheet 5

GCR Class 8B

1. Drwg. 254 Dome Original (1 supplied)

2. Drwg. 251 Chimney Original (1 supplied)

3. Drwg. 239 Ramsbottom 4-column Safety Valve

4M778 Alan Gibson

LNER C4

4. Drwg. 252 Chimney Flowerpot (1 supplied) or

Drwg. 253 Chimney GCR Pseudo (1 supplied)

5. Drwg. 255 Dome Reduced (1 supplied)

6. Drwg. 228 Snifter (1 supplied)

7. Ross Pop Safety Valves Markits MASftyV7 £3.26

(2 supplied)

Additional Parts Required - not part of the kit

Wheels, motors and gears are a personal choice - these were

the ones used by the designer

1. Wheels Gibson G4880B 6’ 8” Dia. Alan Gibson

2. Crank Pins 4M42B Alan Gibson

3. Bogie Wheels G4842 3’ 6” Dia. Alan Gibson

4. Rear Wheel G4851 4’ 3”12 Spoke Alan Gibson

5. High Level Gear Box SlimLiner 40:1 2mm shaft

6. Mashima Motor 2mm shaft

7. Buffers AG 4M4901 £5.00 set of four or 4M4909

or Markits LNER Stepped

8. Markits Screw Couplings MCOUP/S

Recommended Tool

If 14 BA bolts are used to fix the cosmetic springs

CSTB141 Carbon Steel Taper Tap 14BA Eileen’s £14.40

If the eccentrics are fitted you will need a 16 BA tap

Carbon Steel Taper Tap 16BA CSTB161 £20.00

Page 13 GCR Class 8B

Page 13 GCR Class 8B

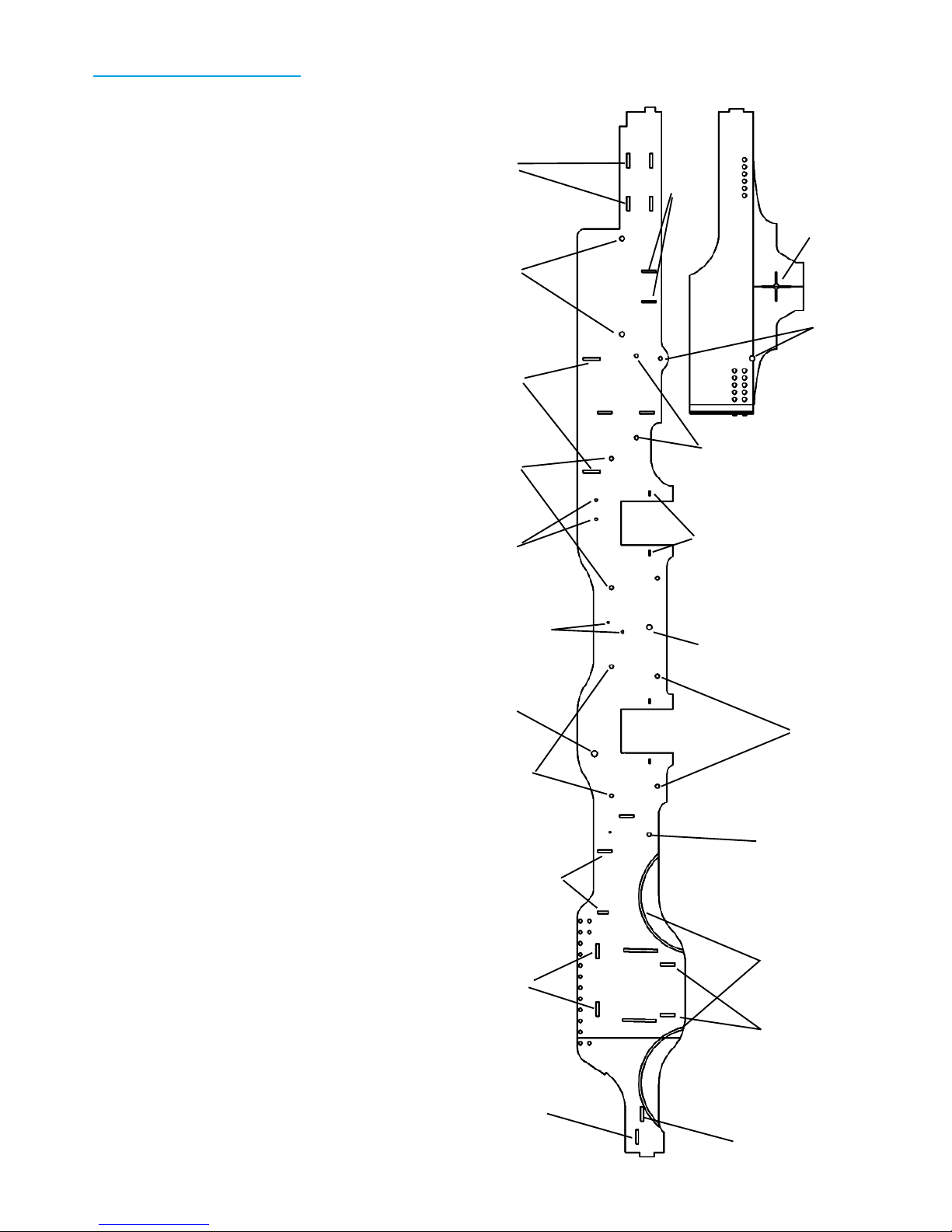

Main Frame Preparation

Note

You may wish to leave the main frames in the fret while

preparing them. I have found this a lot easier and only remove

the frames from the fret when I am ready to join the frames

together

Note

There seems to be a little photographic evidence that when first

built there were no visible, proud rivets on the frames under the

smoke box. Check photographs if this is of concern.

Before pushing out the rivets around the top of the frame under

the smoke box and those on the fire box sides you may wish to

test the pressure needed using the spare half etched holes which

are on Sheet 1.

Note that the frames on this locomotive have a distinct bend

inwards under the smoke box and this is modelled in P4 only.

Since the frames need to be closer together for EM gauge, they

must remain straight and therefore a short piece of 0.45 mm

wire should be soldered into the bend slot to strengthen the

frame at this point.

Note - small radius running

On the inside of the frames above the position of the bogie are

half etched lines. These indicate the cutting needed to allow the

bogie to move much more than would be prototype practice. If

your curves are less than 1200 mm radius then these must be cut

out. It is better to do this when the frames are assembled and

have some rigidity.

Push out the rivets under the smoke box, be careful with the top

row, they are close to the edge. Use the “Play Pen” area on Sheet

2 to practice.

Drill out the frame stiffener locating holes to 0.3 mm in Frame

Left (1) and Frame Right (2) - see picture right.

Measure the short handrail tails which will be used for the

springs (they will be about 0.7 mm diameter) and then drill out

the 6 spring mount positions shown (and marked as 0.65 mm in

the picture on the right) if you require active springing. Push the

handrails supplied into place on the inside of the frames, using a

length of 0.3 mm steel wire through the holes to align them and

solder them into place. Carefully file off the protruding tails on

the outside of the frames.

Drill out the holes for the cosmetic, removable springs, 6 each

side, which are located either side of the horn block spacing for

the front and rear axles only, to 0.80 mm to clear 16 BA c/s bolts

(not supplied) or 1.05 mm to clear 14 BA c/s bolts (supplied).

Carefully countersink the outer face very slightly for the fixing

bolts.

Drill out the brake shaft holes, 3 each side, to 0.7 mm - see

picture right.

Drill out the reversing arm holes to 0.8 mm - see picture right.

1. Frame Layout

9. Cab Base Support

Wheel Height Centres

Spring Mounts

Cosmetic Removable Springs

12,13,14,15. Rear Frame Spacer

16-18. Centre Frame Spacer

Reversing Arm

19-21. Valve Guide

Fire Box

Brake Shaft

Brake Shaft

Spring Mounts

38. Footplate Fixing Bracket

Cut Out Guides for

small radii running

0.33 mm

0.33 mm

0.33 mm

0.7 mm

0.5 mm

0.5 mm

0.5 mm

0.5 mm

0.7 mm

0.65 mm

0.65 mm

0.65 mm

0.65 mm

24,25. Buffer Supports

11. Smoke Box Base

48. Bogie Mount

26,27. Sand Boxes

0.65 mm

0.65 mm

Spring Mounts

10. Fire Box Base

0.8 mm

Rear Wheel Centre

Rear Wheel Brake Shaft

Rear Wheel Spring Mount

Locators (238,239)

Page 14 GCR Class 8B

Page 14 GCR Class 8B

Remove Rear Wheel Spring Mount Locators (238,239) from the

fret, fold with the etch on the outside and locate in place on the

insides of the frames.

Fire Box

Note

The firebox is inset from the sides of the frames as on the

prototype. This is located into the inside of the frame using

locating holes and brass wire.

Locate Fire Box Left (47), Fire Box Right (46) and Fire Box Brace

(42) on the fret, drill the 0.3 mm holes in the fixing tabs, press

out the rivets from the back and then remove from the fret. Bend

to shape and and solder into place inside the main frames using

0.3 mm wire to locate them. Fit Fire Box Brace (44) at the front of

the fire box at the correct angle to match the front slope.

Scale frame cross members

Locate parts Rear Frame Spacer Stiffener Left (14) and Rear

Frame Spacer Stiffener Right (15). Drill out the very small

locating holes to 0.3 mm. Remove these parts from the fret and

with the aid of some 0.3 mm brass wire locate and solder into

place on the inside of both frames.

Locate parts Centre Frame Spacer Stiffener Left (17) and Centre

Frame Spacer Stiffener Right (18). Drill out the very small

locating holes to 0.3 mm. Remove these parts from the fret and

with the aid of some 0.3 mm brass wire locate and solder into

place on the inside of both frames.

Locate parts Valve Guide Support Spacer Stiffener Left (20) and

Valve Guide Support Spacer Stiffener Right (21). Drill out the

very small locating holes to 0.3 mm and the larger holes to 0.7

mm. Remove these parts from the fret and with the aid of some

0.3 mm brass wire and some 0.7 mm brass wire for the larger,

lower holes locate and solder into place on the inside of both

frames.

Generic frame cross members

On Sheet 3 there are 2 generic cross members for either P4 or

EM. You may wish to use these in place of the scale cross

members. They are labelled as P4 or EM. Choose the locations

you prefer to use bearing in mind possible locations for pickup

wiring and make a light pencil mark. Note that you will probably

not need more than one of these and that it must not interfere

with the action of the Stephenson’s Valve Gear if that is fitted.

2.Fire Box

Left side shown with front

of chassis on the left of

picture

3. Main Frame Spacers

Half view - left side only shown

16-18. Centre Frame Spacer

12-15. Rear Frame Spacer

10. Fire Box Support

9. Cab Base Support

Half view - left side only shown

19-21. Valve Guide Spacer

11. Smoke Box Base

38. Footplate Fixing Bracket

48. Bogie Mount

Optional

Optional

Remove for EM and ‘00’

Page 15 GCR Class 8B

Page 15 GCR Class 8B

Connecting the frames together

Note P4 Only

The frames have a half etch bend close to the front. Now is the time to very carefully bend this inwards (it is only 2 degrees), Use

a pair of flat nosed pliers to hold the frames so that the elongated hole for the cylinder spacers is covered and will be held flat.

The smoke box base is etched to allow for this bend.

Note

The etching process is not always accurate so it may be wise to lightly file the cusp from the spacers where they meet the frames

before fitting, it is usually the tiniest bit that is needed. In an ideal world the width over the frames should be 16.10 mm for P4

and 14.70 for EM. Use +/- 0.1 mm as a general guide although it won’t hurt too much if a little more under sized.

Use the P4 Width Templates (231-235) to check if you do not have a micrometer.

Only solder the next parts solidly into place after they have all been fitted and checked. Even with very light tacking the frames

will be solid enough work on.

Remove parts Cab Base Support (9 or 9EM), Fire Box Base (10 or 10EM), Smoke Box Base (11 or 11EM) and Bogie Mount (48

or 48EM) from the fret, check the tabs are clean, bend to shape and one by one do a test fit into between the two frames.

Solder each of these parts into place very lightly starting with Cab Base Support (9 or 9EM). Ensure it is fitted the correct way,

the larger holes are on the underneath and are there to fit the cab and upper body to the chassis.

Fire Box Base (10 or 10EM) should be fitted in place and initially soldered on one side only.

Remove parts Valve Guide Support Spacer (19 or 19EM), Centre Frame Spacer (16 or 16EM), Rear Frame Spacer (12 or 12EM)

and Rear Frame Spacer Brace (13 or 13EM). Solder these in place checking the width of the frames carefully after each one

(16.20 mm for P4 and 14.80 for EM).

Once these are fitted and you are certain the frame is within the specified width then the Firebox Base (10 or 10EM) can be

soldered up on both sides.

Ensure that the large holes in Valve Guide Support Spacer (19 or 19EM) are clear so that the 2.4 mm tubing can fit in them. The

Smoke Box Base (11 or 11EM), Valve Guide Support Spacer (19 or 19EM) and Bogie Mount (51 or 51EM) can now be added to

the frames.

Check the chassis is still square after soldering each part lightly into place.

Slide Bar Stiffeners

Locate parts Slide Bar Support Left (22), Slide Bar Support Right (23). Drill out the very small locating holes to 0.3 mm and the

larger holes to 0.7 mm - the larger hole is also the brake pivot axle. Remove these parts from the fret and with the aid of the

locating wires solder to the outside of both frames noting that the stiffener part is to the rear of the frames.

Brake Frame Mounts

Remove parts Brake Frame Mounts (69-74) from the fret and

solder to the inside of the frames using 0.7 mm brass wire to

locate. When trimming this 0.7 mm wire do not use a pair of

cutters between the frames since this will seriously distort

them. Use a disc cutter or a triangular file to grind away a cut

in the centre.

Now add the brake spacers - these are used to ensure the

brake shoes are at the correct distance from the frames. They

are made from brass tubing which is 1/16” x 1/32” (1.6 mm x

0.8 mm ) and are 1 mm in length. Solder into place. Later, the

brake shoe assembly will simply clip over this.

Sand Boxes

Remove parts Sandbox Left (26) and Sandbox Right (27) from

the fret and fold to shape - locate the tabs just to the rear of

the smoke box and solder lightly to the main frames.

4. Slide Bar Supports and Sand Box

Slide Bar Support Left (22)

Sandbox Left (26)

Page 16 GCR Class 8B

Page 16 GCR Class 8B

Caveat

It will look nice if you fit the buffers next but it will be wrong

because it may inhibit the ease with which the parts of the

cylinders can be fitted such as when holes need to be reamed

out slightly etc

Cylinders

Note

The Cylinder Spacers (7,8) have a number of guide holes in

them. The inner pair are for the valve guide rod tubing. Just

outside of these are two 0.3 mm holes which can be used as

guides for locating the spacers accurately across the frames

(use the inner pair of these for EM and the outer for P4). There

are also two 0.45 mm holes each end which are used to locate

the Cylinder Heads (52-55). The two rectangular holes locate

the slide bars.

You may wish to consider using the Markits Double Slide bar

and Crosshead (M4CRHDSns) instead of the supplied cross head.

Drill out the 0.3 mm and 0.45 mm holes. Drill the larger, central, holes for the valve rod to 1.6 mm minimum, for an easier fit of

the working valve gear this should be 1.8 mm. Drill or ream the large outer holes to 2.4 mm if you intend to use a tube down the

centre of the cylinders or 2.1 mm for the Markits crosshead. You may choose to drill out the valve rod holes to 2.4 mm as well

and fit 2.4 mm tubing.

Remove Cylinder Spacers (7,8) from the fret and fix into the correct position using 0.3 mm brass wire as a guide, the outer holes

are for P4 and the inner holes are for EM. The cylinder tubes fit in the central end holes with the two rectangular holes used to

locate the slide bars.

Drilling Note

When drilling out the cylinder heads it may help to stabilise them if you solder temporarily a length of 0.9 mm brass wire across

one side since drilling them to 2.4 mm will put quite a strain on the tag holding them into the etch. An easier way to drill out

these 2.4 mm holes may be to temporarily solder the part to a bit of scrap and then drill, then un-soldering and fitting as normal.

Drill the two small holes in Cylinder Heads (49-52) to 0.45 mm. Drill the large centre hole to 2.4 mm or for the Markits crosshead

2.1 mm. Remove Cylinder Heads (49-52) from the fret and solder securely in place on the front of the front cylinder support

and the rear of the rear cylinder support using 0.45 mm brass wire to align them.

For the supplied crossheads, fit a length of 3/32” x 1/16” brass tube (2.4 mm x 1.6 mm) so that it is just proud at the front and is

2 mm proud at the rear, 14 mm in total. At the front this fits into the Drwg. 212 Cylinder Front. The front cylinder cover will have

a 1.6 mm tail rod (or the cut down version later) which will help to locate it into the cylinder block.

Slot short lengths of 1.6 mm rod through the inside holes of the Cylinder Spacers (7,8) so that it also runs through the Valve

Guide Spacer (19). Then slot a short length of 2.4 mm tube into the Valve Guide Spacer (19) so that at the rear there is 2 mm

showing and about 4 mm at the front. This will align the rods to the valve chest if fitted along with the Stephenson’s Valve Gear

and simulates the bearing and oiler on the full size locomotive. Solder this in place and remove the 1.6 mm rod.

Slide Bars

Note

Alternatively, the slide bars may be made up from 1 mm x 1 mm nickel silver bar, soldering one part on the top of the other and

filing to shape or using 2 mm x 1 mm bar and again filing to shape.

Parts 125-140 form Qty 4 identical slide bars. These are built up in four layers and soldered together with the aid of 0.3 mm brass

wires to locate and secure the individual layers. These are then filed to the correct shape.

Note that the short layer at the top is positioned the correct way around!

Remove Slide Bar Left Upper Main (125) (long), Slide Bar Overlay (127) (long with half etch section), Slide Bar Overlay (128)

(medium) and Slide Bar Overlay (129) (short) from the etch. Locate using 0.3 mm brass rod and solder up well using high

melting point solder with Nealetin as the flux - or similar.

5.Cylinders and Slide Bars

Cylinder Spacers (7,8)

Cylinder Heads (49-52)

Slide Bar Assembly

Page 17 GCR Class 8B

Page 17 GCR Class 8B

Complete the other slide bar parts as above and file to correct profile. They should be 1 mm wide and at the deepest point 1.2

mm.

Insert a pair of slide bars into each side of the frames and check they locate correctly and not too tightly into the cylinder head

rectangular slots with a small protrusion at the front. Ensure that they fit between the Slide Bar Supports (22,23).

Do not solder up at this stage, first the crossheads must be assembled and then tested for a smooth sliding fit! It is likely that a

small adjustment with a file will be needed to the slide bar supports to achieve the desired 4.66 mm spacing all along the slide

bars.

Crossheads

Note

An alternative to the crosshead assembly provided is the Markits Double Slide bar and Crosshead (M4CRHDSns). However, while

this looks very nice it is not deep enough between the slide bars, which means that the locating holes in the cylinder heads must

be adjusted very slightly inwards. The upper and lower slots of the cross heads must be slightly widened to suit the slide bars.

The Crossheads provided are built up in layers. There are two outer layers (one of them partly half etched to show the profile),

two inner layers one of which is half etched and two inside layers which are shaped to allow the Connecting Rods to partially

rotate. All of these should be used unless you are confident of great accuracy in which case the half etch layer may be left out.

Remove the two sets of Cross Head parts (171-184) from the fret and align each set locating them in place with a steel pin or

something else suitable through the centre into several layers of balsa or other hardwood. If using hardwood such as Ramin

then drill a hole as deep as possible to suit the steel pin. In preference use a higher melting point solder than normal and use

lots of heat. This will allow the parts to be re-aligned should they

move.

Solder these layers together. Do not pick this up too soon, it will

have got very hot!

Trim and file to finish, the top and bottom edges should be filed

down to less than the depth of the slide bars. Do a test fit to

make sure these slide easily.

In the end of the cross heads drill a small hole 1.6 mm to accept

the cross head rod which is 1/16” brass rod of length 25 mm.

Solder this in place ensuring that the cross head is securely

clamped. Do a test fit to ensure it slides easily into the cylinder

tubing.

Check the measurements for the sliding faces on the crossheads

- this should be 4.67 mm for the supplied version (equivalent to

1’ 2”). For the corresponding slide bars the distance between

them is 4.8 mm. Ensure this is the case, filing and trimming as

needed. This will make a nice close fit without being too tight - a

little oil helps here.

7. Cross Heads

Cross Head Rear (171)

Cross Head Overlay (173

Cross Head Top Overlay (183)

Cross Head Inner Layers A

Cross Head Inner Layers B

6. Slide Bar Measurements

Page 18 GCR Class 8B

Page 18 GCR Class 8B

File down the top and bottom carefully so that they do not hit

the Slide Bar Supports (22,23) and can move freely along the

length of the slide bars.

Coupling Rods

Note

The coupling rods are a mirror pair - so take care that all the oil

boxes end up at the top!

A range of extra parts are provided either full depth or half

etched to be attached to the bosses on the coupling rods either to

the front or the rear. These will allow you to choose how far to

off-set the wheels from the coupling rods. The boss at the rear of

the coupling rods is optional.

There is very little space behind the connecting rod in P4 so if

using the Alan Gibson crank pins and locknuts then the leading

hole in the Coupling Rods Left and Right Front (105,111) should

be opened up to 1.8 mm so that the locknut can fit into into it in

reverse. In Extremis is it just possible to open out the hole in

either top boss or the overlay to 2.5 mm so that the whole nut is

countersunk.

A better solution may be to use the crank pins designed by Tim

Venton (see Scalefour Society Forum). These are threaded and

the front one is countersunk into the coupling rods hole.

Drill 1.5 mm to 1.6 mm through all the other crank pin holes to

suit your crank pin bearings. The front crank pin is rather shorter

than on the other axles if the crank pin nut is reversed.

Drill out the coupling rods to suit your choice of crank pins.

Remove Coupling Rod Left (105), Coupling Rod Left Overlay

(106) from the fret.

Remove Coupling Rod Bosses (107-110) from the fret, select and

solder in place to inside and/or outside of main coupling rods.

Repeat for the right side coupling rods using parts (111-116).

Connecting Rods

Note

The Connecting Rods are a mirror pair.

Remove parts Connecting Rod Left (117), Connecting Rod Left

Overlay (118), Connecting Rod End Overlay (121) (square),

Connecting Rod End Overlay (122) (round) from the fret and

solder together.

The hole which fits over the centre axle crank pin should be

opened out to (1.5 mm to 1.6 mm) to suit your crank pin bearing.

The small end of the Connecting Rod should fit inside the

Crosshead Assembly and is secured with a 0.5 mm rivet (lightly

hammer in place or soldered on the rear according to

preference). A short piece of 0.45 mm brass wire will suit as well.

Leave the front slightly proud to represent the fixing bolt.

Repeat for the other connecting rod.

Buffers Beams - rear

Note

9. Connecting Rods

Connecting Rod Left Overlay (118)

Connecting Rod Left (117

Connecting Rod End Overlay (121)

Connecting Rod End

Overlay (122)

8. Coupling Rods

Coupling Rod Left Overlay (106)

Coupling Rod Bosses

Coupling Rod Left (105)

Page 19 GCR Class 8B

Page 19 GCR Class 8B

There is no reason why the buffer layers should not be made part

of the foot plate and soldered to the ends of the footplate using

the rear and front foot plates and the valences as a guide, which

may make fitting body and chassis together a little easier. If this

is done the tabs on the ends of the frames should be carefully

filed flat since they will no longer have a purpose.

The rear buffer has two layers. Drill holes 0.45 mm in Rear Buffer

Beam (5), Rear Buffer Beam Overlay (6) and Rear Buffer Housing

Plates (38,39). Drill large holes in Rear Buffer Beam Overlay (6)

and Rear Buffer Housing Plates (38,39) to 2.0 mm which will

locate the un-sprung rear buffers.

The Rear Buffer Beam (5) has four slots for the frames, the outer

pair of each pair is for P4 and the inner pair is for EM. The outer

pairs are for the secondary (external) frame.

Remove Rear Buffer Beam (5) from the fret and solder over the

end of the frames ensuring it is the right way up, the two slots

are nearer the bottom.

Remove Rear Buffer Beam Overlay (4) from the fret and solder

half etched Rear Buffer Beam Overlay (6) in place again ensuring

it is the right way up. The holes and slot are nearer the top.

Remove Rear Buffer Housing Plates (36,37) from the fret and

solder into place. Ream out the central holes and fit the Cast or

turned Rear Buffers.

Remove Rear Buffer Beam Draw Bar Plate (41) from the fret and

solder it in place to match the draw plate slot.

Fit Drwg. 216 Rear Buffers in place and solder.

Secondary Frame

Push out the rivets if required in Rear Frames (236,237) and

remove them from the fret.

Bend so that the half etch is on the inside and insert into the

sides of the frame and one of the outer pair of slots in the rear

buffer depending on whether you are modelling in P4 (outer) or

EM (inner).

Buffers Beams - front

Note

The Buffer Mounts (32,33) are optional. When first built they

were not fitted but were added later. The rear part of the Gibson

buffers (small circle with a hole in the centre) may be mounted

behind the buffer beam, in which case a small notch needs to be

filed to accommodate it. The four small holes in the corner may

be used to locate the buffer mounts and again optionally, the

Gibson buffers may be drilled out in each corner to 0.45 mm so

that the fixing bolts may be simulated.

The front buffer has two layers. To simulate the bolts that hold

the buffers to the buffer beam drill the locating holes in Front

Buffer Beam (3), Front Buffer Beam Overlay (4) and Buffer

Mounts (34,35) to 0.45 mm.

Remove Front Buffer Beam (3), Front Buffer Beam Overlay (4),

Buffer Support Left (24), Buffer Support Right (25) and Buffer

Mounts (32,33) from the etch.

11. Rear Buffer B (from front)

Slots for frame tabs (P4 outer)

Slots for frame tabs (EM inner)

Front Buffer Beam (3)

Front Buffer Beam Overlay (4)

Frames - shown in

P4 mode - curved

inwards

12. Front Buffer A

Front Buffer Beam

Draw Bar Plates

(39,40)

Buffer Mounts (32,33)

10. Rear Buffer A (from rear)

Rear Buffer Beam (5)

Rear Buffer Beam

Overlay (4)

Rear Buffer Housing Plates (36,37)

Rear Buffer Beam Draw Bar Plate (41)

Drwg. 216 Rear Buffers

Page 20 GCR Class 8B

Page 20 GCR Class 8B

Solder the buffers to Buffer Mounts (32,33) then drill through

0.45 mm from the rear for the corner fixing bolts.

Remove Foot Plate Fixing Bracket (38) from the fret and fit

between the frames. This part should have the TABS removed

and then it can sit either above or below the TABS from the

Buffer Supports (24,25). Fitting it below will allow a deeper 10 BA

fitting to be used under the footplate.

Note

Before fitting the buffer beams permanently it is worth checking

that the valve rod guides and cylinder guides are clear and

accurately set. It is difficult to check these with the buffer beams

in place.

Fix the Front Buffer Beam in place to the frames at the same

time as the Buffer Supports noting that the buffer beam slot is

closer to the top. Check the front buffer beam is square since for

P4 the frames have a distinct bend at 4’ from the front buffer

and if the bend if different at each side the buffer will not be

central. P4 and EM modellers use the same front slot for the

frames.

Ensure the Front Buffer Beam (3) is flat and then using 0.3 mm

brass wire and a couple of clamps locate the buffers, Front Buffer

Beam Overlay (4) and Buffer Mounts (34,35) and solder carefully

into place. Trim off the 0.3 mm wire to represent the bolt heads

on the buffers.

Remove Front Buffer Beam Draw Bar Plates (39,40) from the

fret, clean up where needed and solder into place.

Remove Couplers (34,35) from the fret and solder into the front

buffer beam.

Brake Cylinder Support

Remove parts Brake Cylinder Supports (28,29) from the fret, drill

the smaller hole to 0.45 mm (this takes the safety chain link to

the tender) and drill the larger hole to 1.0 mm for the actuating

axle for the brakes.

Solder into place under Cab Base Support (3) and check they are

square to this base.

Fit the cast/turned/printed Drwg. 218 Vacuum Cylinder after all

soldering is completed.

Stephenson’s Valve Gear

Note

The Stephenson’s Valve gear consists of mirror images of parts on

the centre axle. They can be configured to work by locking them

to the centre axle or may be left to rotate freely.

Make sure that the correct parts are on the outside or the

eccentrics may become twisted. Also note that parts for the

eccentric have a ‘tab’ on them and additional fixing holes to help

in getting them soldered up. After soldering these and before

fitting into the main motion these tabs are filed to the correct

shape. High melting point solder is recommended. Brass wire 0.3

mm is used to locate the parts accurately.

For parts 185-200 drill out all the locating holes to 0.3 mm.

14. Brake Cylinder Supports

Brake Cylinder Supports (28,29)

Left frame only shown, Cab

Base and Rear Buffer

15. Valve Gear Outer Rod

Valve Rod Right Outer (187)

Outer Rod End Strips (189,190)

Outer Rod Spacer (193)

16. Valve Gear Inner Rod

Valve Rod Right Inner (188)

Inner Rod Spacer (199)

Inner Rod End Strips (195,196)

Buffer Supports (24,25)

Foot Plate Fixing

Bracket (38)

13. Front Buffer B

Page 21 GCR Class 8B

Page 21 GCR Class 8B

Valve Rods

Start with the valve gear for the right hand side.

Remove Valve Rod Right Outer (187) and Valve Rod Right Inner

(188) from the fret. With a small piece of wet and dry paper ease

out the large holes to 5.7 mm so that they revolve easily round

the brass eccentric plates (Drwg. 215).

Remove Outer Rod End Strips (189,190) and Outer Rod Spacer

(193) from the fret and using a 0.3 mm piece of brass wire locate

these parts as shown and solder up.

Remove Inner Rod End Strips (195,196) and Inner Rod Spacer

(199) from the fret and using a 0.3 mm piece of brass wire locate

these parts as shown and solder up.

Eccentric

Note

Since these parts are the ones that tend to get either lost in the

carpet or are difficult to solder together a rear tag with an extra

locating hole is provided for them.

For the eccentric itself (201,204) drill out the holes at each end to

0.6 mm. These will fit on to the Lifting Arms.

Remove the eccentric parts 201-212 from the fret, complete with

their extensions and use 0.3 mm wire to locate them and solder

together as shown in the diagram.

Clean up as much as possible and cut and file the rear of the

eccentric assembly to shape.

Lifting Arms

For Lifting Arms (213-216), Rotation Arms (217-220), Rotation

Arm End Spacers (221,224) drill out the smaller holes to 0.5 mm

and the larger holes in the bottom end of Lifting Arms (213-216)

to 0.7 mm. This is the end that is locked through the centre of

the eccentric.

Steam Chest Rods

Remove Valve Rod Ends (226,227) from the fret and roll round a

piece of 1.6 mm brass rod on which the ends have been filed flat

over a length of 2 mm, drill through the locating holes and fix in

place by soldering. The flat should be such that the width of the

finished sub-assembly is no greater than 1.6 mm.

At this stage with a little judicious fettling it should be possible

(but only just) to slide this up and down the eccentric. It may be

easier to leave this in the fully up or fully down position since

they may never move when the engine is running.

Fit short lengths of 2.4 mm brass tubing (ideally this should be 4

mm long) into Valve Guide Support Spacer (19 or 19EM) and

using some 1.6 mm brass rod, align it through the Cylinder

Spacers (7,8) ensuring that the rod slides very easily.

Brass Plates

In Drwg. 215 Eccentric there are four plates which fit either side

of Valve Rod Outers (185,187) and Valve Rod Inners (186,188).

There is Eccentric Template (230) on the fret which can be used

17.Valve Gear Eccentric

18. Final Eccentric Shape

19. Lifting Gear

Main Eccentric (203,204)

Eccentric Bracket 205,206)

Eccentric Short Brackets (209,210)

Lifting Arms (213-214)

Rotation Arms (217-218)

Rotation Arm End Spacers (221,222)

20. Valve Rod

Valve Rod End

(226)

1.6 mm Brass Rod

21. Overview of eccentric and lifting gear

Page 22 GCR Class 8B

Page 22 GCR Class 8B

to mark the holes to be drilled. Check that the brass plates will sit

in the hole in the template, using a bit of wet & dry to ease as

needed. Remove this from the fret and fold over with the half

etch on the outside and solder up.

Lay the brass plates in the template ensuring the centre mark is

absolutely central and lightly mark the small holes by drilling with

a 0.45 mm drill.

At this stage it should be possible to do a trial fit with a 3 mm

drill, using a couple of lengths of 0.45 mm wire to fix in place.

Check the plates can rotate within Valve Rod Outers and Valve

Rod Inners without any friction.

There are two ways to fix these permanently, both of which have

proved satisfactory under test. Short lengths of 0.45 mm wire can

be soldered either side of the plates or the second plate can be

drilled out to 0.8 mm and the front counter sunk for a 16 BA bolt.

The first plate is then drilled to 0.6 mm and tapped to 16 BA and

a couple of 16 BA counter sunk screws fitted and trimmed off.

Once fixed and solid the centre hole should be carefully reamed

out to 1/8” to make an interference fit over the axle.

The connectors at the eccentric end of the rod may be trimmed

down to represent a curved connection.

Now do it all again for the left side mechanism.

Reversing Axle and Balance Weight

The Counterweight Weight Drwg. 211 will need a 1.2 mm hole

drilled in the side halfway along into which can be soldered

Balance Arm (225).

Note

For completeness of the reversing axle description the Reversing

Arm Chassis End (70), Reversing Arm Front Actuator (73) and

Reversing Arm Rear Actuators (72,73) are mentioned here. These

are in Brass and are on Sheet 4. Reversing Arm Front Actuator

(73) should be fitted just inside the right frame over the 0.8 mm

axle.

Fold Reversing Arm Front Actuator (72) to create a bend while