Page 1

GREAT-150iM-II

For Milling Machine

& Machining Center

User Manual

Page 2

GREAT-150IM-II MANUALS

INDEX

CHAPTER I PREFACE................................................................................................................................................ 1

CHAPTER II TECHNICAL FEATURE............................................................................................................................2

2.1 SYSTEM CONSTRUCTIONS ...................................................................................................................................... 2

2.2 SYSTEM TECHNICAL PARAMETER....................................................................................................................... 2

2.3 SYSTEM FUNCTION.................................................................................................................................................... 2

2.3.1 AUTO-DIAGNOSIS FUNCTION:...................................................................................................................................... 2

2.3.2 COMPENSATION FUNCTION: ........................................................................................................................................2

2.3.3 ABUNDANT INSTRUCTION SYSTEM:............................................................................................................................. 3

2.3.4 CHINESE/ENGLISH MENU, FULL SCREEN EDITION:....................................................................................................... 3

2.3.5 ABUNDANT DEBUGGING FUNCTIONS:.......................................................................................................................... 3

2.3.6 PROGRAM EXCHANGE BETWEEN CNC SYSTEM AND IBM/PC SERIES COMPATIBLE COMPUTER................................... 3

2.4 SYSTEM OPERATION CONDITION......................................................................................................................... 3

2.4.1 POWER SUPPLY:........................................................................................................................................................... 3

2.4.2 CLIMATE CONDITION................................................................................................................................................... 3

2.4.3 OPERATION ENVIRONMENT:........................................................................................................................................ 3

CHAPTER III OPERATION...............................................................................................................................................4

3.1 PANEL L AYOUT AND SWITCH................................................................................................................................. 4

3.2 OPERATION INTERFACE .......................................................................................................................................... 6

3.3 PARAMETER................................................................................................................................................................. 9

3.4 PARAMETER EXPLANATION................................................................................................................................. 10

3.4.1 USER PARAMETER..................................................................................................................................................... 10

3.4.2 SPEED ....................................................................................................................................................................... 14

3.4.3 COORDINATE SYSTEM ............................................................................................................................................... 19

3.4.4 MACRO VARIABLE PARAMETER ................................................................................................................................ 20

3.4.5 AXIS PARAMETER...................................................................................................................................................... 20

3.4.6 COMPREHENSIVE PARAMETER .................................................................................................................................. 31

3.4.7 PASSWORD ................................................................................................................................................................ 39

3.4.7.1 Access authority setting .................................................................................................................................... 40

3.5 DIAGNOSE................................................................................................................................................................... 43

3.5.1 I/O REAL-TIME MONITOR ..........................................................................................................................................43

3.5.2 LADDER REAL-TIME MONITOR .................................................................................................................................. 44

3.5.3 CONFIGURATION OF INPUT/OUTPUT AND SELF-DEFINED ALARM................................................................................ 44

3.5.4 CLEAR ALARM ACCIDENT OF FEED SERVO DRIVER..................................................................................................... 45

3.5.5 EDIT LADDER DIAGRAM............................................................................................................................................ 45

3.5.6 ALARM DISPLAY........................................................................................................................................................ 46

3.6 PITCH ERROR COMPENSATION........................................................................................................................... 46

3.7 TOOL............................................................................................................................................................................. 49

3.8 PROGRAM................................................................................................................................................................... 52

1

Page 3

GREAT-150IM-II MANUALS

3.8.1 NEW/SEK.................................................................................................................................................................. 52

3.8.2 COPY ........................................................................................................................................................................ 53

3.8.3 RENAME ...................................................................................................................................................................53

3.8.4 DELETE..................................................................................................................................................................... 54

3.8.5 INFORMATION ........................................................................................................................................................... 54

3.8.6 COPY PROGRAM APPLY USB-DISK ............................................................................................................................ 54

3.8.7 PROGRAM TRANSMITTED BY SERIAL PORT ................................................................................................................ 57

3.8.8 EDIT.......................................................................................................................................................................... 59

3.8.9 SELECT PROCESSING PROGRAM ................................................................................................................................ 63

3.8.10 SHIFT PROGRAM FILES PATH.................................................................................................................................... 63

3.9 MANUAL ......................................................................................................................................................................63

3.9.1 CONTINUOUS MODE.................................................................................................................................................. 63

3.9.2 INCREMENT............................................................................................................................................................... 64

3.9.3 MPG MODE............................................................................................................................................................... 64

3.9.4 REFERENCE RETURNING............................................................................................................................................ 64

3.9.5 AUTOMATIC MIDPOINT IDENTIFICATION FUNCTION ................................................................................................... 65

3.9.6 RETURN TO THE ZERO POINT OF G17 PLANE OF WORK COORDINATE SYSTEM ............................................................ 67

3.9.7 OTHER OPERATION IN MANUAL MODE:...................................................................................................................... 68

3.10 AUTO........................................................................................................................................................................... 70

3.10.1 COORDINATES......................................................................................................................................................... 70

3.10.2 GRAPHIC................................................................................................................................................................. 70

3.10.3 CONTINUAL ............................................................................................................................................................ 71

3.10.4 STEP...................................................................................................................................................................... 71

3.10.5 SIMULATION............................................................................................................................................................ 71

3.10.6 FEEDING HOLD........................................................................................................................................................ 71

3.10.7 MPG WHEEL TRIGGER IN AUTO RUNNING............................................................................................................... 71

3.10.8 DNC FUNCTION ...................................................................................................................................................... 72

3.11 MDI MODE................................................................................................................................................................. 73

3.12 RUN PROGRAM FROM A REAL LINE................................................................................................................. 73

3.13 RUN PROGRAM FROM A CERTAIN MARKED LINE....................................................................................... 73

3.14 RUN PROGRAM FROM A CERTAIN TOOL NUMBER...................................................................................... 74

3.15 SET COORDINATES/CHOOSE COORDINATES................................................................................................ 74

3.16 MASS PROGRAM FOR MOULD PROCESSING................................................................................................. 75

3.17 TOOL EXCHANGE AND T OOL SETTING ........................................................................................................... 75

3.17.1 TOOL MAGAZINE OPERATION...................................................................................................................................75

3.17.2 TOOL EXCHANGE .................................................................................................................................................... 76

3.17.3 TOOL SETTING......................................................................................................................................................... 76

3.18 EXIT SYSTEM........................................................................................................................................................... 77

CHAPTER IV PROGRAMING........................................................................................................................................ 78

4.1 BASIC CONCEPTS......................................................................................................................................................78

4.2 GENERAL DESCRIPTION OF PROGRAM............................................................................................................ 79

2

Page 4

GREAT-150IM-II MANUALS

4.3 PROGRAM INSTRUCTION...................................................................................................................................... 79

4.3.1 FUNCTION AND MEANING OF ADDRESS SYMBOL, DATA RANGE LIST........................................................................... 79

4.3.2 G, M FUNCTION INSTRUCTION DATA LIST .................................................................................................................. 80

4.3.3 F FUNCTION:............................................................................................................................................................. 83

4.3.4 T/H/D FUNCTION ...................................................................................................................................................... 84

4.3.5 S FUNCTION .............................................................................................................................................................. 84

4.4 PREPARATION FUNCTIONS ................................................................................................................................... 85

4.4.1 COORDINATE SYSTEM SETTING (G92)....................................................................................................................... 85

4.4.2 CHOOSE COORDINATE SYSTE M (G53/G54/G55/G56/G57/G58/G59)........................................................................ 85

4.4.3 LOCAL COORDINATE SYSTEM (G52).......................................................................................................................... 86

4.4.4 PROGRAMMING METHODS (G90/G91) ......................................................................................................................87

4.4.5 SELECT PLANE (G17/G18/G19)................................................................................................................................ 87

4.4.6 RAPID POSITIONING (G00)........................................................................................................................................ 88

4.4.7 LINEAR INTERPOLATION (G01) ................................................................................................................................. 88

4.4.8 CIRCULAR/ARC INTERPOLATION (G02/G03) ............................................................................................................. 88

4.4.9 HELICAL INTERPOLATION (G02/G03) ....................................................................................................................... 90

4.4.10 DWELL (G04)..........................................................................................................................................................90

4.4.11 MIRROR INSTRUCTION (G11/G12).......................................................................................................................... 91

4.4.12 SCALING (G36/G37)............................................................................................................................................... 92

4.4.13 COORDINATE SYSTEM ROTATE (G68/G69) .............................................................................................................. 93

4.4.14 REFERENCE POINT (G28/G281/ G282/ G283/ G30/ G301/ G302/ G303)................................................................ 95

4.4.15 TOOL LENGTH COMPENSATION (G43/G44/G49)...................................................................................................... 96

4.4.16 TOOL RADIUS INCREASING OR DECREASING (G45/G46/G47/G48).......................................................................... 97

4.4.17 TOOL RADIUS COMPENSATION (G40/G41/G42)....................................................................................................... 98

4.4.18 PROGRAM RECYCLE INSTRUCTION (G22--G800)..................................................................................................... 99

4.4.19 ACCURATE POSITIONING/CONTINUAL PATH WORKING (G60/G64) ......................................................................... 100

4.4.20 CANNED CYCLE OF MACRO DEFINITION (G73,G74,G76,G80~G89).................................................................... 101

4.4.20.1 High speed deep hole drilling (G73) ............................................................................................................ 102

4.4.20.2 CCW peck deep hole tapping cycle (G74) .................................................................................................... 103

4.4.20.3 Finished boring cycle (G76)......................................................................................................................... 105

4.4.20. 4 Drilling cycle, point drilling cycle (G81) .................................................................................................... 106

4.4.20.5 Drilling cycle, countersink boring cycle (G82) ............................................................................................ 106

4.4.20.6 Chip removal drilling cycle (G83)................................................................................................................ 107

4.4.20.7 CW peck deep hole tapping cycle (G84)....................................................................................................... 108

4.4.20.8 Boring cycle (G85) ........................................................................................................................................110

4.4.20.9 Boring cycle (G86) ........................................................................................................................................110

4.4.20.10 Boring cycle, counter boring cycle (G87)....................................................................................................111

4.4.20.11Boring cycle (G89)........................................................................................................................................112

4.4.20.12 Cancel cycle instruction (G80)....................................................................................................................11 3

4.4.21 POLAR COORDINATE (G15/G16)........................................................................................................................... 114

4.4.22 METRIC AND INCH SYSTEM (G20/G21)................................................................................................................. 115

4.4.23 THREADING(G33)................................................................................................................................................. 116

4.4.24 RETURN TO PROGRAM ORIGINAL POINT (G26/ G261/G262/G263)........................................................................ 117

4.4.25 SPINDLE POSITIONING (SP)................................................................................................................................... 117

4.4.26 WAITING FOR AUX-RELAY M1XXX IS VALID, WAITING FOR AUX-RELAY M2XXX INVALID...................................... 117

4.4.27 MAKE AUX-RELAY M3XXX VALID, MAKE AUX-RELAY M4XXX INVALID................................................................ 117

3

Page 5

GREAT-150IM-II MANUALS

4.4.28 EDIT THE OUTPUT FUNCTION OF OUTPUT POINT AND AUX-RELAY IN CNC PROGRAM DIRECTLY ............................ 118

4.4.29 CONDITIONAL SKIP FUNCTION ............................................................................................................................... 118

4.4.30 AUXILIARY FUNCTION........................................................................................................................................... 118

4.5 PROGRAM CONVENTION................................................................................................................................ 120

4.5.1 MULTI-COMMANDS CAN BE ONE BLOCK TOGETHER ................................................................................................120

4.5.2 THE COMMANDS AND PARAMETER CAN BE LOCATED ARBITRARILY IN PROGRAM BLOCK......................................... 120

4.5.3 REPEATABLE COMMANDS ISN’T ALLOWED IN THE PROGRAM BLOCK ....................................................................... 121

4.5.4 THE OPERATION THAT IRRELA TIVE T O THE COMMANDS ISN’T ALLOWED IN PROGRAM BLOCK.................................. 121

4.5.5 SEMICOLON CAN BE APPLIED AT THE END OF PROGRAM BLOCK, REMARK FOLLOWED SEMICOLON .......................... 121

4.5.6 THE FIRST CHARACTER OF PROGRAM BLOCK IS “%”,“O”,“(”,MEANS THIS BLOCK IS REMARK LINE......................... 121

4.5.7 SPACE IS AVAILABLE BETWEEN COMMANDS IN PROGRAM BLOCK ............................................................................ 121

4.5.8 THE CODES G00, G01, G02, G03, M02 CAN BE WRITTEN TO BE G0, G1, G2, G3, M2............................................. 121

4.5.9 GLOBAL VARIABLE AND SYSTEM VARIABLE CAN BE ADOPTED INTO PROGRAM........................................................ 121

4.5.10 ARITHMETIC EXPRESSION CAN BE ADOPTED INTO PROGRAM ................................................................................. 121

4.5.11 MDI FUNCTION EXPLANATION .............................................................................................................................. 122

4.6 THE INTRODUCTION FOR TOOL RADIUS COMPENSATION C.................................................................. 122

4.6.1 INSIDE AND OUTSIDE .............................................................................................................................................. 122

4.6.2 ESTABLISH TOOL RADIUS COMPENSATION ...............................................................................................................122

4.6.2.1 The tool moving along inside of the corner (

4.6.2.2 The tool moving along outside of the corner for obtuse angle (90

4.6.2.3 The tool moving along outside of the corner for acute angle (α<90)............................................................. 123

4.6.3 THE TOOL MOVING OF TOOL OFFSET MODE.............................................................................................................. 123

4.6.3.1The tool moving along inside of the corner (180

4.6.3.2 The tool moving along outside of the corner for obtuse angle (90

4.6.3.3 The tool moving along outside of the corner for acute angle (α<90)............................................................. 124

4.6.4 THE TOOL MOVING IN THE MODE OF TOOL OFFSET CANCELING ............................................................................... 125

4.6.4.1 The tool moving along inside of the corner (

4.6.4.2 The tool moving along outside of the corner for obtuse angle (90

4.6.4.3 The tool moving along outside of the corner for acute angle (α<90)............................................................. 126

4.7 PROGRAM EXAMPLE.............................................................................................................................................126

4.8 USER MACRO PROGRAM..................................................................................................................................... 128

CHAPTER V PLC FUNCTION...................................................................................................................................... 143

5.1 GENERAL................................................................................................................................................................... 143

α≥

180)................................................................................... 122

≤α

<180) ............................................... 122

≤α

).................................................................................... 123

≤α

<180) ............................................... 124

α≤

180)................................................................................... 125

≤α

<180) ............................................... 125

5.2 CELLS INTRODUCTION......................................................................................................................................... 143

5.2.1 CELL AND CELL NUMBER......................................................................................................................................... 143

5.2.2 CELL TABLE ............................................................................................................................................................ 143

5.2.3 CELL INTRODUCTION .............................................................................................................................................. 143

5.2.3.1 Input relay ( X )............................................................................................................................................... 143

5.2.3.2 Output relay (Y) .............................................................................................................................................. 144

5.2.3.3 Interior relay (M)............................................................................................................................................ 144

5.2.3.4 Timer (T) ......................................................................................................................................................... 144

5.2.3.5 Counter (C)..................................................................................................................................................... 145

5.3 BASIC CELL SIGN IN LADDER DIAGRAM........................................................................................................ 146

4

Page 6

GREAT-150IM-II MANUALS

5.4 BASIC LOGIC COMMANDS IN INSTRUCTION LIST...................................................................................... 146

5.4.1 LD, LDI, OUT COMMANDS .................................................................................................................................... 146

5.4.2 AND, ANI COMMANDS........................................................................................................................................... 147

5.4.3 OR, ORI COMMANDS.............................................................................................................................................. 147

5.4.4 ORB COMMAND ..................................................................................................................................................... 147

5.4.5 ANB COMMAND ..................................................................................................................................................... 147

5.4.6 MPS, MRD, MPP MEMORIZER AND MULTIPLE OUTPUT COMMANDS....................................................................... 147

5.4.7 SET AND RST COMMANDS ..................................................................................................................................... 147

5.4.8 NOP AND END COMMANDS.................................................................................................................................... 147

5.5 PLC PROGRAM EDITING...................................................................................................................................... 147

5.5.1 EDIT PLC PROGRAM ON PC.................................................................................................................................... 147

5.5.1.1 Edit software installation and running environment....................................................................................... 147

5.5.1.2 Basic operation of software editing................................................................................................................ 148

5.5.1.3 Edit PLC Ladder............................................................................................................................................. 149

5.5.1.4 Generate instruction list file ........................................................................................................................... 151

5.5.1.5 Logic testing ................................................................................................................................................... 152

5.5.2 EDIT PLC PROGRAM ON THE PANEL OF THE CONTROLLER....................................................................................... 153

5.5.2.1 Basic operation in editing interface................................................................................................................ 153

5.5.2.2 Edit PLC ladder.............................................................................................................................................. 154

5.6 PLC FILE TRANSMISSION..................................................................................................................................... 156

5.6.1 TRANSMIT PLC FILE BY RS232 .............................................................................................................................. 156

5.6.1.1 Transmit PLC file (PLC.lad, PLC.plc) to controller....................................................................................... 156

5.6.1.2 Transmit PLC file (PLC.plc, PLC.plc) to PC from controller......................................................................... 158

5.6.2 TRANSMIT PLC FILE BY USB PORT ......................................................................................................................... 159

5.6.2.1 Restore PLC file to controller from U disk ..................................................................................................... 159

5.6.2.2 Backup PLC file into U disk ........................................................................................................................... 160

5.7 THE DEFINITION OF INTERI OR AUXILIARY RELAY....................................................................................161

5.8 PROGRAMMABLE I/O DIAGRAM IN SYSTEM.................................................................................................165

5.8.1 GENERAL I/O BOARD..............................................................................................................................................165

5.8.1.1 General I/O board (GREAT-GEN-IO) ............................................................................................................ 165

5.8.1.2 General I/O board (GREAT-GEN-IO-A) ........................................................................................................ 166

5.8.2 MOVEMENT CONTROL BOARD................................................................................................................................. 167

5.8.3 SUBPANEL............................................................................................................................................................... 167

5.8.4 MANUAL PULSE GENERATOR................................................................................................................................... 169

5.9 EXAMPLE AND EXPLANATION OF PLC PROGRAMMING...........................................................................169

5.10 EDIT REPLY NAME................................................................................................................................................ 172

5.10.1 EDIT RELAY NAME ON PANEL................................................................................................................................. 172

5.10.2 EDIT RELAY NAME ON PC...................................................................................................................................... 173

5.10.3 EXAMPLES TO SELF-DEFINED ALARM USAGE OF INTERIOR RELAYS M80---M95.................................................... 174

5.11 PROGRAMMABLE I/O PRESET FUNCTION DEFINITION........................................................................... 176

5.11.1 MOVEMENT CONTROL BOARD............................................................................................................................... 176

5.11.2 SUBPANEL ............................................................................................................................................................. 177

5

Page 7

GREAT-150IM-II MANUALS

5.11.3 MANUAL PULSE GENERATOR................................................................................................................................. 178

5.11.4 GENERAL I/O BOARD ............................................................................................................................................ 178

5.12 THE DEFINITION OF PLC, INSTRUCTION AND PARAMETER FOR MACHINE MATCH WITH

TOOL MAGAZINE..........................................................................................................................................................

181

5.12.1 SPECIFICATION OF MACHINING CENTRE WITH UMBRELLA TOOL MAGAZINE........................................................... 181

5.12.2 SPECIFICATION OF MACHINING CENTRE WITH ATC TOOL MAGAZINE..................................................................... 183

CHAPTER VI. CONNECTION& INSTALLATION.................................................................................................... 186

6.1 GENERAL................................................................................................................................................................... 186

6.2 SYSTERM CONFIGURATION................................................................................................................................ 186

6.2.1 SYSTEM ASSEMBLIES AND FUNCTION ...................................................................................................................... 186

6.3 SYSTEM CONNECTION DIAGRAM..................................................................................................................... 189

6.3.1 THE CONNECTION DIAGRAM MATCH WITH A TYPE SUBP ANEL..................................................................................189

6.3.2 CONNECTION DIAGRAM MATCH WITH B TYPE SUBPANEL ........................................................................................190

6.4 DIMENSION............................................................................................................................................................... 190

6.4.1 MAIN PANEL DIMENSION......................................................................................................................................... 190

6.4.2 SUBPANEL DIMENSION (A TYPE AND B TYPE IS SAME)............................................................................................. 191

6.4.3 GENERAL I/O BOARD DIMENSION ........................................................................................................................... 192

6.4.4 DIMENSION OF MOVEMENT CONTROL BOARD ......................................................................................................... 193

6.4.5 THE INSTALLATION DIMENSION OF I/O POWER MODULE (DC24V/ 3A)................................................................... 193

6.5 SYSTEM INSTALLATION ENVIRONMENT........................................................................................................ 193

6.5.1 POWER CAPACITY ................................................................................................................................................... 194

6.5.2 POWER SUPPLY CONNECTION AND CONFIGURATION ................................................................................................194

6.5.2.1 Power supply connection diagram ................................................................................................................. 194

6.5.2.2 I/O power supply setting................................................................................................................................. 194

6.5.3 CNC POWER TURN ON/ OFF SEQUENCE ................................................................................................................... 195

6.6 SYSTEM CONNECTED WITH SURROUNDING EQUIPMENT....................................................................... 195

6.6.1 CONNECTION WITH COMMUNICATION BOARD ......................................................................................................... 196

6.6.1.1 connection with communication board ........................................................................................................... 196

6.6.1.2 Interface connection ....................................................................................................................................... 196

6.6.2 CONNECTED WITH SPINDLE ENCODER ..................................................................................................................... 197

6.6.2.1 Connected with spindle encoder..................................................................................................................... 197

6.6.2.2 Interface with spindle encoder........................................................................................................................ 197

6.6.3 CONNECTED WITH MPG (MANUAL PULSE GENERATOR).......................................................................................... 197

6.6.3.1 Connected with MPG...................................................................................................................................... 197

6.6.3.2 The interface connected with MPG................................................................................................................. 198

6.6.3.3 MPG internal connection diagram................................................................................................................. 198

6.6.4 CONNECTED WITH SUBPANEL.................................................................................................................................. 199

6.6.4.1 Connected with subpanel................................................................................................................................ 199

6.6.4.2 Connected with subpanel................................................................................................................................ 200

6.6.5 CONNECTED WITH GENERAL I/O BOARD ................................................................................................................. 202

6.6.5.1 Connected with general I/O board.................................................................................................................. 202

6.6.5.2 Interface connected with general I/O board ................................................................................................... 202

6

Page 8

GREAT-150IM-II MANUALS

6.6.6 CONNECTED WITH MOVEMENT CONTROL BOARD.................................................................................................... 204

6.6.6.1 Connection with movement control board ...................................................................................................... 204

6.6.6.2 Interface connected with movement control board ......................................................................................... 204

6.7 CNC CONTROLS CONNECTED WITH SPINDLE DRIVER............................................................................. 207

6.7.1 CNC CONTROLS CONNECTED WITH FREQUENCY INVERTER..................................................................................... 207

6.7.2 CNC CONTROLS CONNECTED WITH SPINDLE SERVO DRIVE ..................................................................................... 207

6.7.2.1 Connection diagram of CNC controls connected with GTB-GA spindle servo drive ..................................... 207

6.7.2.2 Connection diagram of CNC controls connected with MODROL spindle servo drive................................... 208

6.8 CNC CONTROL CONNECTED WITH FEED SERVO DRIVE...........................................................................209

6.9 MACHINE ELECTRIC INSTALLATION PRINCIPLE....................................................................................... 210

6.9.1 DIRECT-CURRENT POWER SUPPLY............................................................................................................................ 210

6.9.2 I/O PORTS................................................................................................................................................................ 211

6.9.2.1 I/O port classification and distribution............................................................................................................211

6.9.2.2 General I/O input port principle which is available by "IPE".........................................................................211

6.9.2.3 General I/O input port principle which is available by "+24V ".....................................................................211

6.9.2.4 Sub-panel input port principle which is available by " GND "....................................................................... 212

6.9.2.5 Sub-panel output port principle which is availability by "+5V ".................................................................... 212

6.9.2.6 General, movement control I/O output port principle which is availability by "IPE".................................... 212

6.9.2.7 Reference points connection principle............................................................................................................ 213

6.9.2.8 Limit signal connection principle ................................................................................................................... 214

7

Page 9

GREAT-150IM-II MANUALS

CHAPTER I PREFACE

GTCNC-150IM-II is one middle grade flush type CNC control system that has been designed by

Chengdu Great Industrial Co., Ltd, aiming specially at milling machine & machining center.

Based on modern computer technology, system move control core & PLC program running technology,

and stable unique real time control engine subsystem RTAI, this system ensures the stabilization of

operation. The use of high performance, low power consumption industrial grade ARM microprocessor

as core of hardware, large scale FPGA integrate circuit, multiple layer (4,6) printed circuit, 32MB flash

memory, 8.4 inch real color LCD which provides friendly human-machine dialogue interface makes this

system work to its best.

DEFINITION OF CAUTION, WARNING, AND NOTE

1. WARNING

Applied when there is a danger of user being injured or user being injured and equipment is damaged.

2. CAUTION

Reminds operator must be caution

damage the equipment.

3. NOTE

in the relative operation, otherwise lead this operation failure or

APPLIED TO INDICATE SUPPLEMENTARY INFORMATION AND EXPLANATION.

NOTE

This system has function to backup parameters. After debugging machine, it can backup all parameters

of machine & system and PLC documents to computer. It is convenient not only for mass debugging, but

also for machine recovery to normal after changing system. (refer to Chapter 3.6)

NOTE

WHEN USE THIS SYSTEM AT THE FIRST TIME, PLEASE READ CAREFULLY ALL

THE DETAILS OF EACH CHAPTER SO AS TO MAKE IT WORK MORE EFFICIENTLY.

1

Page 10

GREAT-150IM-II MANUALS

CHAPTER II TECHNICAL FEATURE

2.1 System constructions

● 32 bits high performance, low power consumption industrial grade ARM microprocessor

● 64MB memory

● 32MB user store room

● 640x480 8.4 inch real color LCD displayer

● Touch screen main and sub panel

● High anti-jamming switch power

● USB-disk interface

● RS232 interface

● Programmable I/O 118X46

● Spindle servo speed control/spindle frequency conversion speed control

● Manual pulse generator

2.2 System technical parameter

● controllable axes: X, Y, Z, A, B five axes

● simultaneous axes: Arc 2-3 axes, liner 2-5 axes.

● pulse equivalent: X, Y, Z, A, B axes: 0.001mm

● max speed: X, Y, Z, A, B: 60000mm/min

● cutting speed: 1-20000mm/min

● min input unit: 0.001mm

● program size range: ± 99999.999

● 99 tools management

● umbrella type and turn-plate type tool magazines are available

● program code: ISO-840 international standard

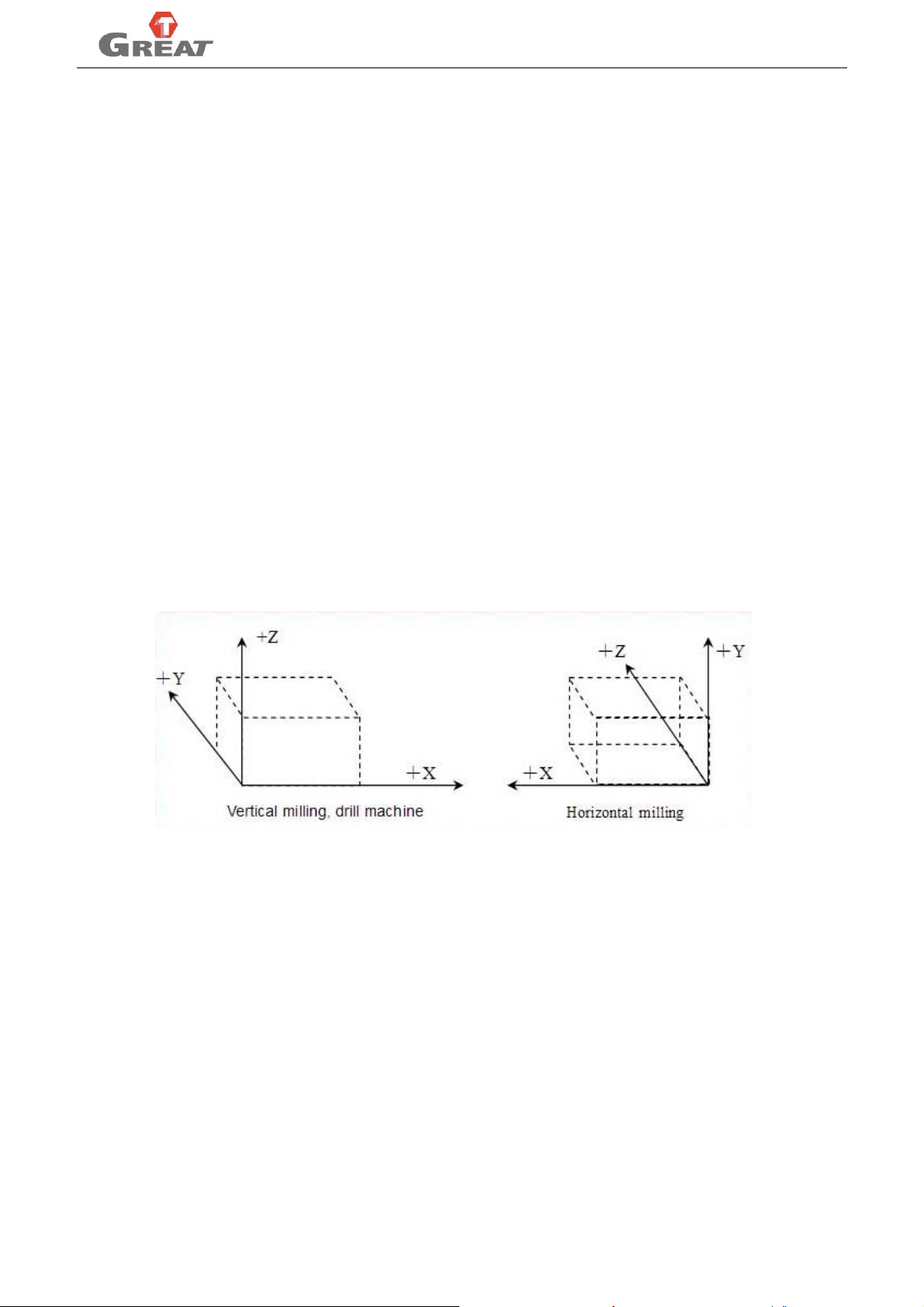

● program coordinate system definition: ISO-841

● mean time between failure(MTBF): more than 5000 hours

● cabinet protection complies with regulation of IP54

2.3 System function

2.3.1 Auto-diagnosis function:

All around diagnosis of CPU, memory, LCD, I/O interface, parameter status, coordinates, machining

program etc. shall execute when the system starts or resets. In operation, it makes real time diagnosis

for power supply, spindle, limit and all I/O interface.

2.3.2 Compensation function:

● automatic backlash compensation

● tool length automatic compensation

● tool radius automatic compensation

● tool radius automatic offset and sharp angle transition

● leading screw pitch error automatic compensation

2

Page 11

GREAT-150IM-II MANUALS

2.3.3 Abundant instruction system:

● scaling up/down instruction

● mirror machining instruction

● multiple tool offset instruction

● program cycle, jump, call and different program ending

● multiple positioning instruction: starting point, setting fixed point, etc.

● linear, circular, spiral line interpolation instruction

● program management instructions: program cycle, call, transfer and different

program ending method, etc.

● 6 work coordinate system and 4 reference points

2.3.4 Chinese/English menu, full screen edition:

Easy operation, convenient viewing

2.3.5 Abundant debugging functions:

it can point out clearly what errors of operation are and guide to correct them.

2.3.6 Program exchange between CNC system and IBM/PC series compatible computer

Apply CAD/CAM/CAPP auxiliary programming by using PC series compatible computer's abundant

software resources, then transfer the CNC program into CNC system through (USB-disc port, RS232

port. Likewise it also can transfer the program from system to PC through communication port.

2.4 System operation condition

2.4.1 Power supply:

AC 220V(+10% /-15%), Frequency 50Hz±2%. Power: ≤ 200W.

NOTE: It must apply isolation transformer to supply power, primary input: 380V

2.4.2 Climate condition

z operation condition: temperature 0~45 ,relative moisture ℃ 30-95%

z storage & transportation condition temperature: -40~55 ,relative moisture<93℃ %(40 )℃

z atmosphere pressure: 86-106kpa

2.4.3 Operation environment:

No excessive dust, acid, alkali corrosive gas and explosive gas, no strong electromagnetic interference

3

Page 12

GREAT-150IM-II MANUALS

CHAPTER III OPERATION

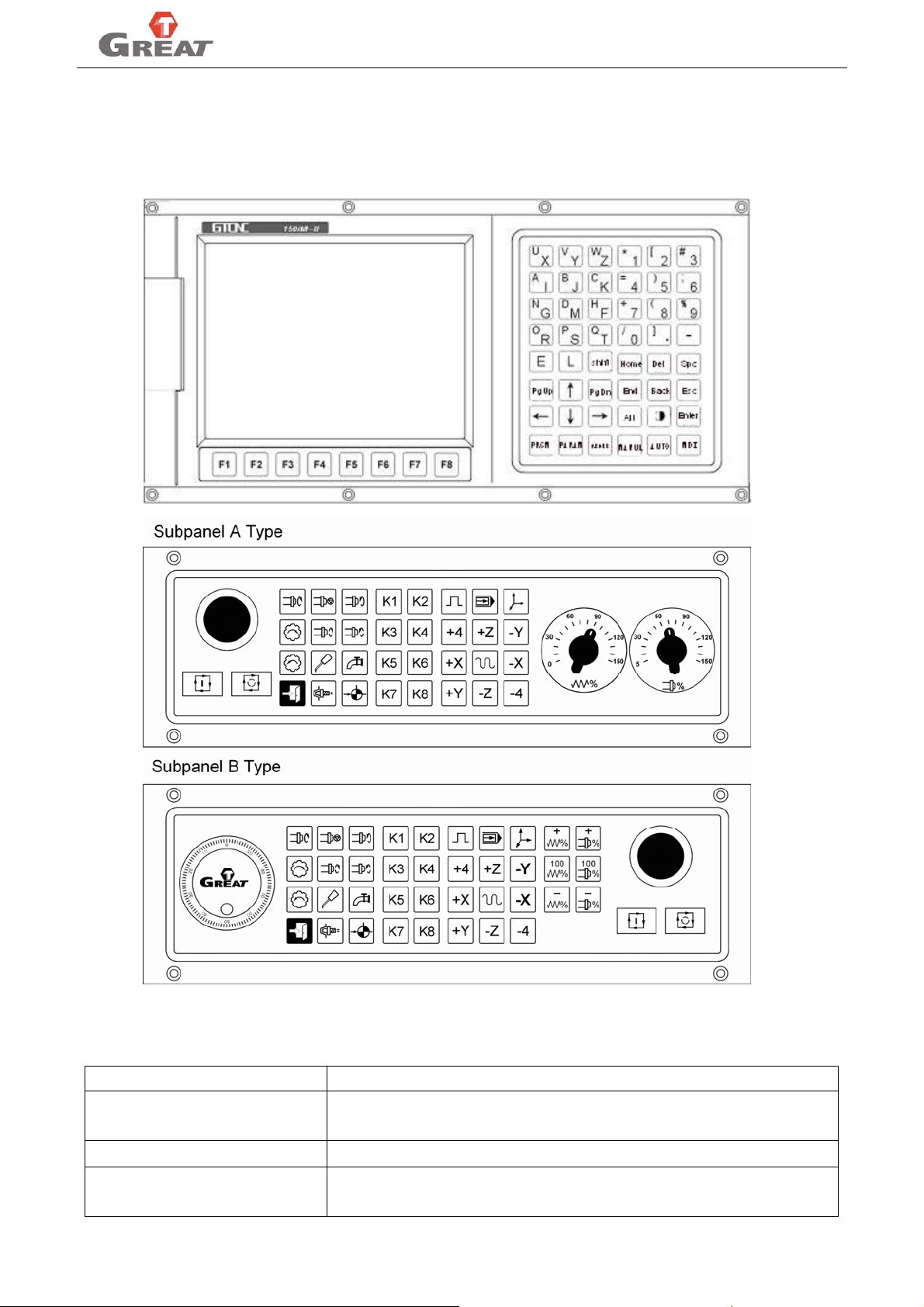

3.1 Panel layout and switch

Switch introduction:

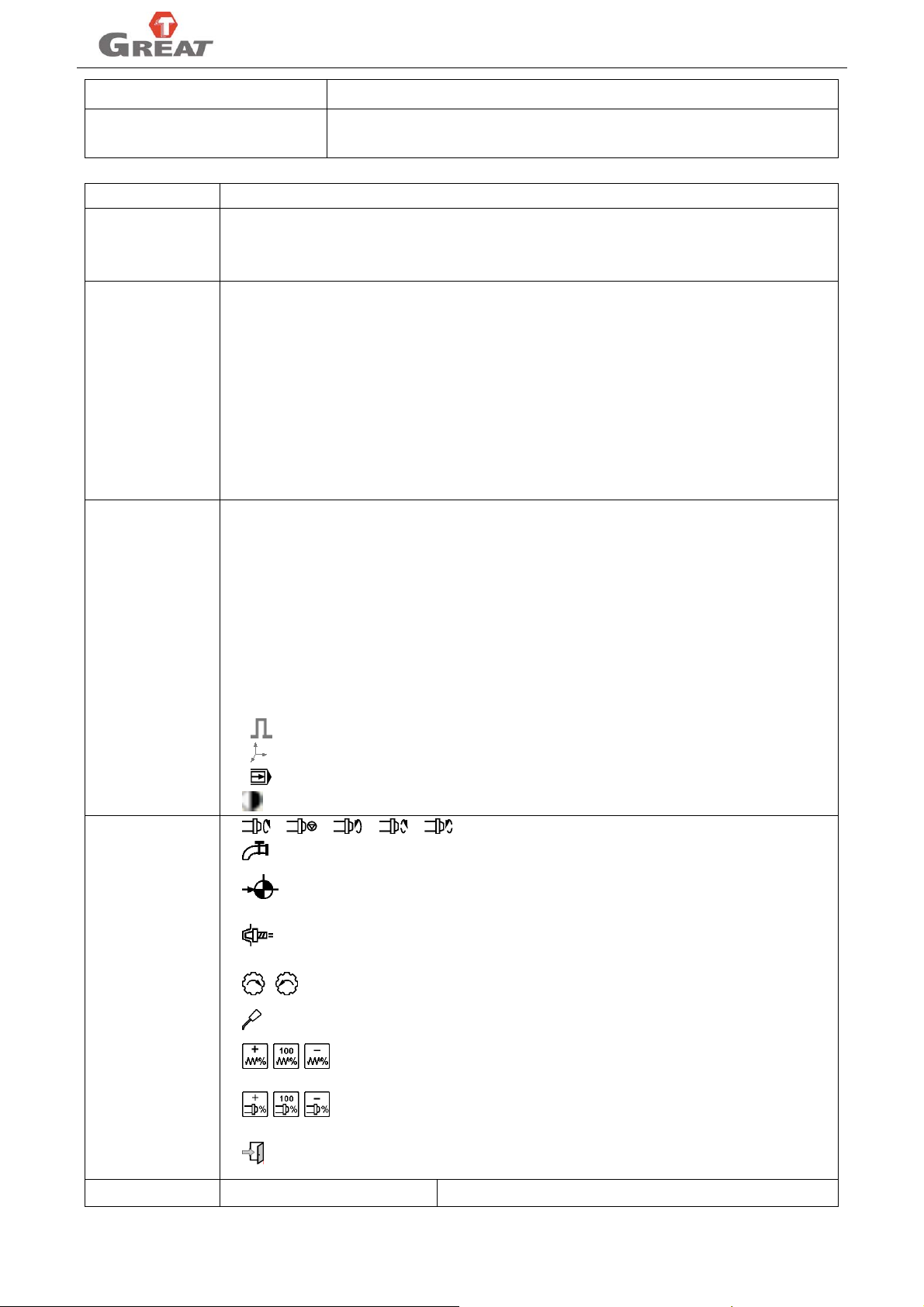

Chart 1: Switch introduction

Emergency stop (yellow/red)

Program run (green) Execute the auto-machining program, meanwhile light turns on

Program end (red)

4

Fig 3.1 panel layout

Switch Functions

Driver and motor stop immediately, turns off the spindle, coolant,

waits for the release E-stop button, and initializes values

In automatic continual run, press once to pause, twice to end

immediately; in manual mode run, press once to end.

Page 13

GREAT-150IM-II MANUALS

Spindle override switch In the process of spindle running, adjusts the speed accordingly.

Feed axes override switch

Chart 2: buttons introduction:

Keyboards Functions

Letter key

Number key

CHRTAXYZLIJKSFMGDPN0123456789.-: used for editing program

instructions, parameters; number keys are used for inputting data and selecting

sub-menu.

↑, ↓, →, ←: move cursor, input data or select menu. etc

Del: delete one character behind the cursor

PgUp, PgDn: page up, page down

Alt: shift key , shift coordinate system in manual or auto mode

Edit key

Back: delete one character before the cursor

Home: move the cursor to the beginning of line in programming editing status; move

cursor to the first parameter place in parameter menu

End: move the cursor to the end of line in programming editing status; move cursor

to the last parameter place in parameter menu

“Esc” returning to upper level or stop a operation

“Enter” selecting sub-menu and changing a new line

“Shift” top key input

“program” shift to program edition interface

“para” shift to parameter setting interface

“dgnos” shift to diagnosis function interface

Function key

“manual” shift to manual status interface

“auto” shift to automatic status interface

“ M D I ” shift to MDI function interface

” adjust manual increment or handwheel override

“

“

” shift auto-coordinates/graphic machining mode

“

” shift between single block/continuous mode

“

“ work with “PgUp” or ”PgDn”: set the brightness of the screen.

“

“

” coolant on/off

When program runs or in manual state, it can make a real-time

adjustment of feed speed

” spindle cw, stop, ccw, jog cw, jog ccw

” axis reference returning

“

“ ” spindle tool tighten / release

Control key

“

“

“

“

“

” tool magazine rotate CW, CCW

” lubrication on/off

” adjust federate

” adjust spindle rotating speed

” exit system safely

Feed key +X +Y +Z +4 –X –Y –Z -4 For X, Y, Z, A axes feed

5

Page 14

GREAT-150IM-II MANUALS

Rapid key

Used for rapid moving axis in manual mode

Self-definition key K1, K2, . . . K8 Self definition control

Soft key F1, F2, ……F8 Menu shift, function selection

3.2 Operation interface

Whole system adopts multi-leveled menu full screen operation, user-friendly interface, providing

comprehensive information. It enters into the main interface as followed as booting.

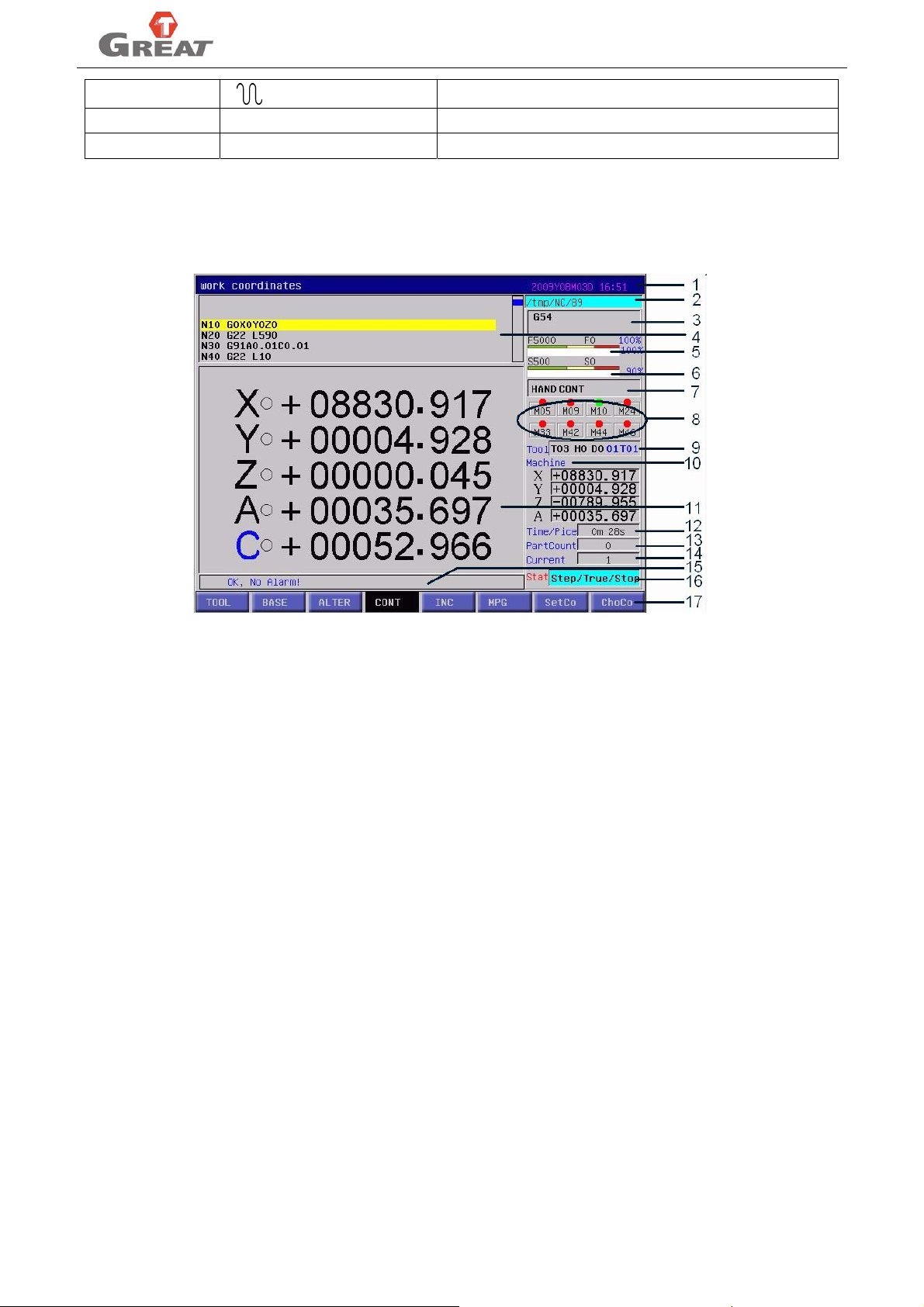

Fig3.2 operation panel

Definition of each display area (fig 3.2) in the system main screen as below:

1. title bar: the top column shows company’s logo and current time

2. program display area: show the program which will execute or being running “/tmp/NC/”is default path

or program and “89” is program name.

3. G code display area: show the G status of current executing program or the coordinate system in

non-auto mode. For example: G53 means machine coordinate system.

4. program display area: show the program content which being executed or running and the progress

(show through scroll bar)

5. feed speed display area: show the speed, rate, real speed and speed ratio of feed axis. “F5000” in the

column means the speed is 5000mm/min; “F0” means real running speed is 0mm/min; percentage

means the rate switch gear level is 100%.proportional band shows the proportion between real running

speed and the max speed setting in the parameter. The green part means the real running speed is less

than 60% of the max running speed, it is safety area; yellow part means the real running speed is

60%-100% of the max speed, it is warning area; red part means the real running speed is more than

100% of the max running speed. It is dangerous area.

6. spindle revolution display area: show speed, rate, real running speed and speed ratio of spindle under

present code. “S2000” in the column means the speed is 2000r/min; “S0” followed means the real

running speed is 0r/min; percentage means the rate switch gear level is 100%. proportional band shows

the proportion between real running speed and the max speed setting in the parameter. the green part

means the real running speed is less than 60% of the max running speed, it is safe area; yellow part

means the real running speed is 60%-100% of the max speed, it is warning area; red part means the real

running speed is higher than 100% of the max running speed. It is dangerous area.

7. manual or auto mode display area: show the display mode in manual or auto and continuous,

increment, MPG status etc and relevant information in the manual mode.

6

Page 15

GREAT-150IM-II MANUALS

8. M code display area: show the validity of M code. Green light means valid and red-light means invalid.

9. tool status display area: show relevant information, as show in fig3.2 from left to right, the first T01

means the current tool number on the spindle; H0 means the current tool edge H (length compensation

number); D0 means the current tool edge D (radius compensation number) 01 means current cutter seat

number, cutter seat number at tool exchange position; T00 means tool number on the current cutter seat.

10. machine coordinates display area: show the coordinates value of machine coordinates (G53)

11. coordinates display area: dynamic coordinates display, showing present coordinates (machine

coordinate system or work coordinate system).the circle behind coordinates sign (X, Y, Z, A)means

indicator light, which shows the status of reference returning for each coordinate, green light means the

coordinates has returned machine refer zero, otherwise not. Make sure all zero returning indicator are

green during running or before auto running.

NOTE: If servo driver alarm or other phenomenon after zero returning, the green light will go off.

12. machining time display area: show the executed time for present program.

13. workpiece number display area: show the cycle times for present program, quantity of machined

workpieces

14. program block display area: show the exact program block for present program.

15. information display area: show the relevant information of system and machine. such as alarm, soft

limit and so on.

16. program running status display area: show the auto running status of the program .such as step,

continual, real machining, simulation, stop, run etc.

17. menu display area: used for display function menu. Press corresponding softkey (F) to shift.

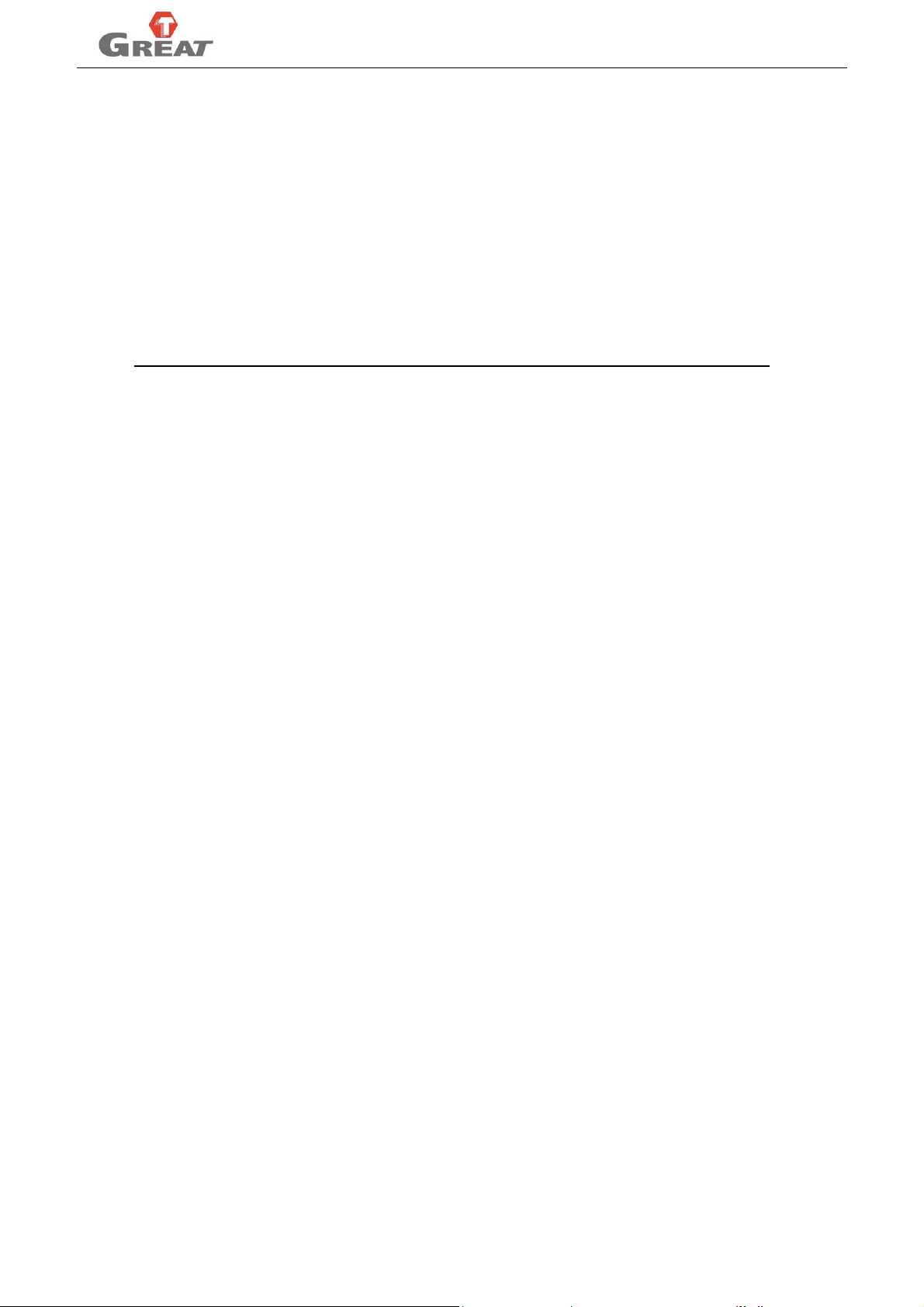

System menu structure:

Whole system adopts multi-leveled menu as followed:

7

Page 16

GREAT-150IM-II MANUALS

Above menus in fig3.3 can be viewed by press the function softkeys of “PRGRM”, “PARAM”, “REDEEM”,

“MANUAL”, “AUTO” on the panel, press “ESC” will return to main menu.

Input data into the dialogue box:

The whole system adopts dialogue data input. Replace the data directly when input data in the dialogue

box and confirm by pressing “Enter” key or cancel by pressing “Esc” key.

NOTE: There are words like“<-Clear:F1> <-Zero:F8>” on the top of dialogue box, means you can clear

8

Fig 3.3 menu array

Fig3.4 dialogue box for data input

Page 17

GREAT-150IM-II MANUALS

the data in the dialogue box by pressing “F1”, set the data as 0 by pressing “F8”.

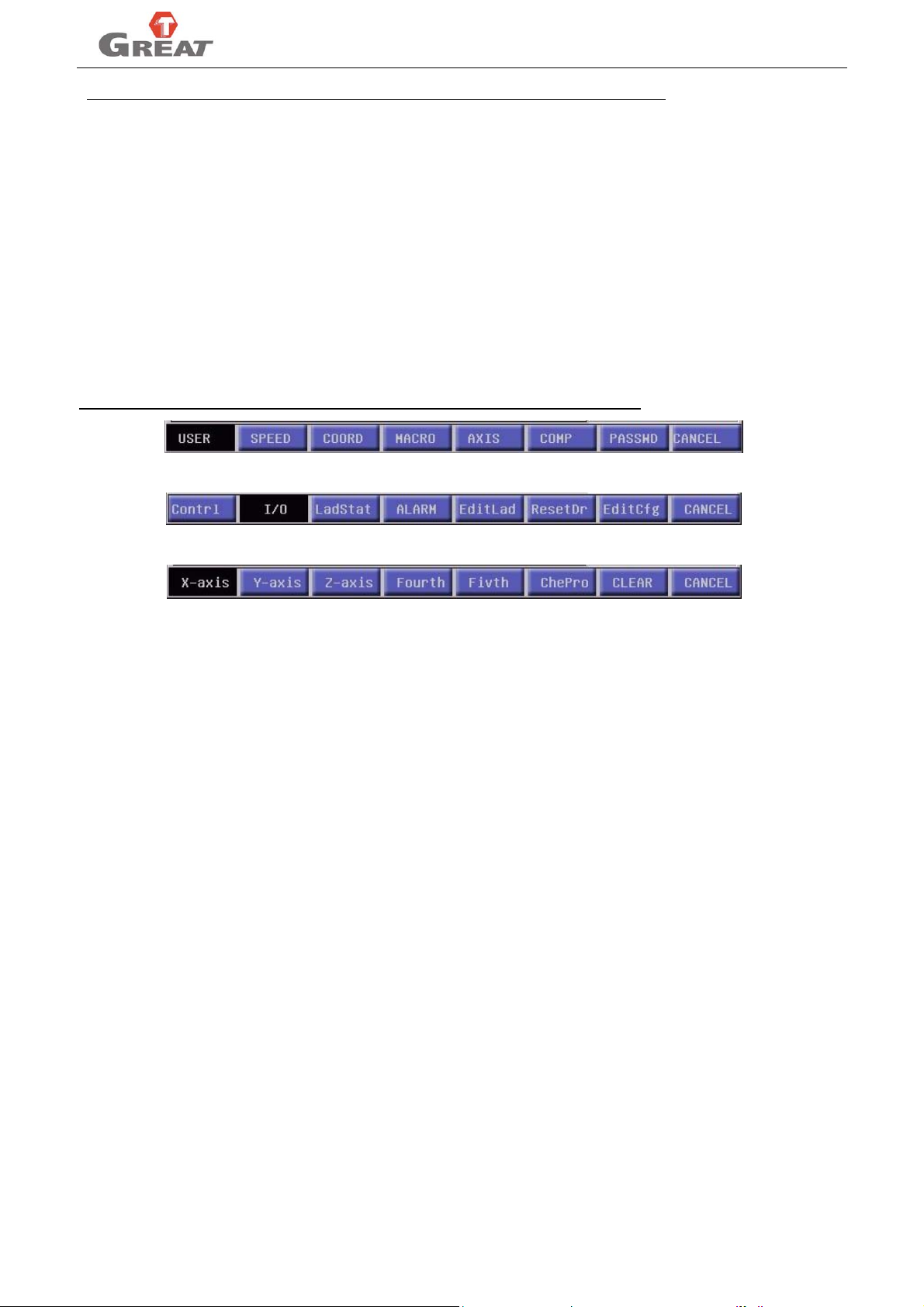

3.3 Parameter

Shift to parameter setting menu by pressing “PARAM” on the main panel, press “PARAM” once will shift

to parameter interface, including “USER”, “SPEED”, “COORD”, “MACRO”, “AXIS”, “COMP”, “PASSWD”,

“CANCEL”; press twice will shift to diagnosis interface, including “Contrl”, “I/O”, “LadStat”, “ALARM”,

“EditLad”, “ResetDr”, “Editcfg”, “CANCEL”; press three times will shift to pitch error compensation

interface, including “X-axis”, “Y-axis”, “Z-axis”, “Fourth”, “Fifth”, “CLEAR”, “CANCEL”; shift to the

parameter setting interface by pressing corresponding key, press “CANCEL” or “Esc” will return to main

interface.

NOTE

Repeat press “PARAM” will shift among “PARAM”, “Diagnosis”, and “PITCH”.

The 1st screen parameter

The 2nd screen diagnosis

rd

The 3

screen pitch compensation

Fig3.5 parameter interface

First interface: Parameter

“USER” system basic function parameter, user maybe set these parameters as machining.

“SPEED” the parameters related to speed of each axis.

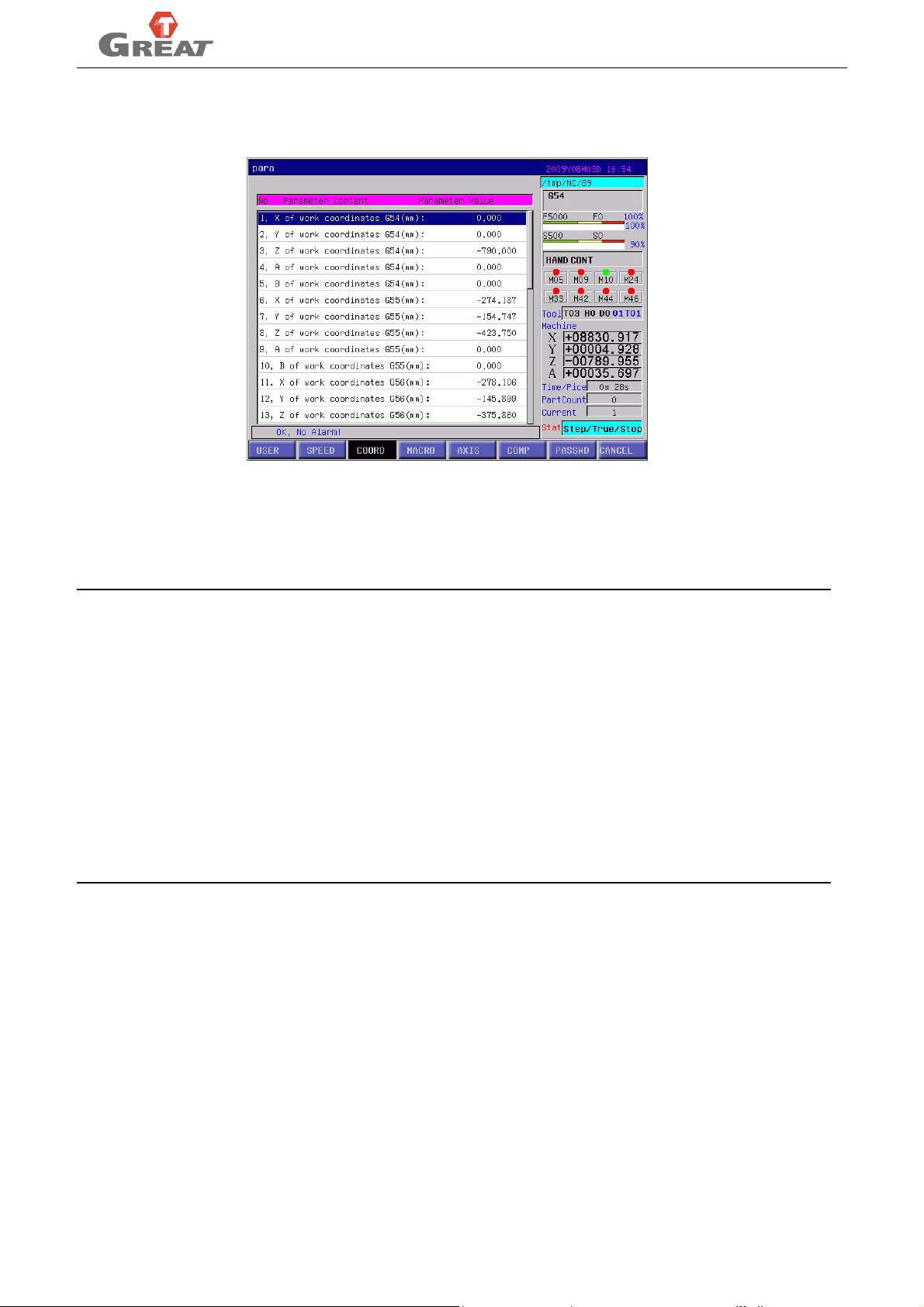

“COORD” set the coordinates value of work coordinate systems from G54 to G59 in the machine

coordinate system.

“MACRO” set macro variable value from No.30 to No.190.

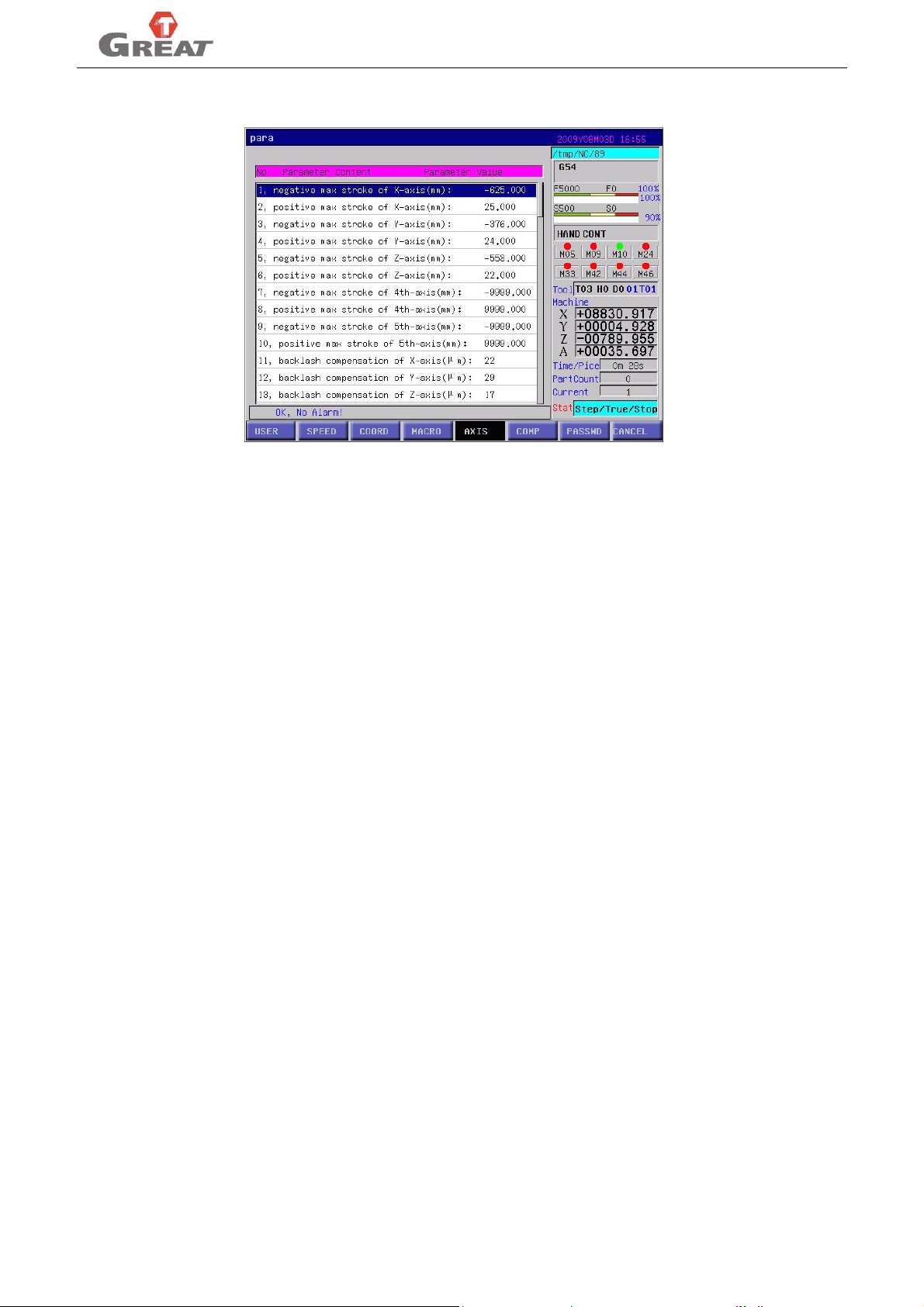

“AXIS” set parameters related to each axis such as compensation, limit, function parameters.

“COMP” set the parameters except for above menus.

“PASSWD” set the parameters related to system operation limit.

Second interface: diagnosis

“Contrl” set the program type of tool exchanging.

“I/O” display of input and output.

“LadStat” status display of PLC ladder.

“ALARM” display the current alarm and history records of 10 alarms.

“EditLad” set embedded PLC ladder online.

“ResetDr” reset servo driver.

“Editcfg” edit the current configuration.

Third interface: pitch error compensation

“X-axis”, “Y-axis”, “Z-axis”, “Fourth”, “Fifth” used for setting the parameter related to pitch error

compensation of X-axis, Y-axis, Z-axis, fourth axis and fifth axis.

“CLEAR” clear the current pitch error compensation.

9

Page 18

GREAT-150IM-II MANUALS

3.4 Parameter Explanation

For convenient search for parameters, parameters are classified to be “user parameter”, ”speed

parameter”, “coordinate system”, “macro variable parameter”, “axis parameter” and “comprehensive

parameter”.

3.4.1 User parameter

User parameter composed by basic function parameter, which are frequent applied in the system.

Under the main interface, press ”USER”(F1) softkey, will shift to user parameter setting interface, refer to

fig 3.6

Fig 3.6 User parameter

User parameter list:

1. workpiece machining number setting

2. program automatic running times with M20

3. retraction value "d" of canned cycle G73(mm)

4. retraction value "d" of canned cycle G83(mm)

5. direction of offset Q of canned cycle G76

6. direction of offset Q of canned cycle G87

7. spindle orienting stop degree of boring canned cycle(0.1degree)

8. chip removal tapping G84G74(0:high speed, 8:normal)

9. retraction value “d” of chip removal tapping G84G74 (mm)

28. whether need spindle rotate as program running(0: yes, 90: no)

30. whether need individual adjustment to G00 override(88:yes, 0: no)

31. whether manual soft limit is valid without zero returning (88:yes, 0: no)

32. is there any hint for spindle top/low gear(88:yes, 0: no)

33. whether apply intervention switch(88:yes, 0: no)

34. make soft limit invalid(X4,Z16,Y8,A32,B64)

35. system default coordinate system(54-59 corresponding G54-G59,other G53)

36. can G92 modify G54-G59 (800:yes, 0: no)

37. are lubrication and cooling keys valid in auto mode(1:yes, 0: no)

38. does spindle rotation and tool unclamp interlock (1:yes, 0: no)

39. request for zero return as booting and program running(1: no need, 0: hint, 8:force, 9:super force )

10

Page 19

GREAT-150IM-II MANUALS

40. checking input point of G31 (valid+300, invalid+400)

41. G31_X

42, G31_Y

43. G31_Z

44, G31_A

45. G31_B

51. edit increment value of program sequence number

100. set LCD brightness

101. set system time(Y-M-D-H-M)

102. restore factory para setting

User parameter explanation:

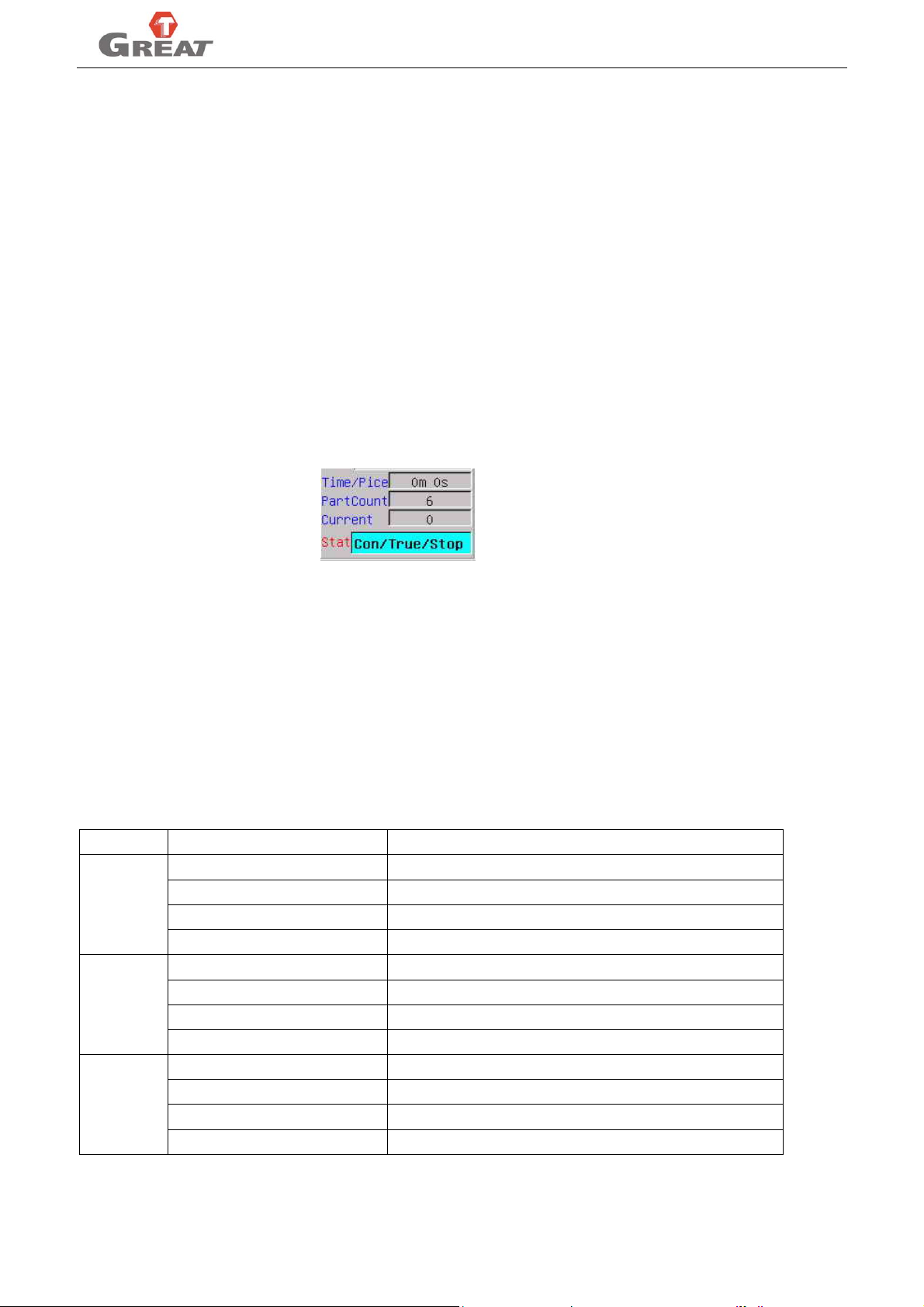

No.1 workpiece machining number setting

To set the work count showing on the screen for current machining, after set this parameter, the

“PartCount” will display the refreshed number, and the this value will be increased according to the

machined parts increasing.

Fig3.7

NO.2 program automatic running times with M20

Set times of cycle programming using M20 command. if the value is set to be minus, means limitless

recycle.

NO.3 retraction value "d" of canned cycle G73 (mm)

Set the dimension of retraction value “d” of high speed deep hole drill cycle G73. unit:mm.

NO.4 retraction value "d" of canned cycle G83 (mm)

Set the dimension of retraction value “d” of chip removal drill cycle G83. unit: mm.

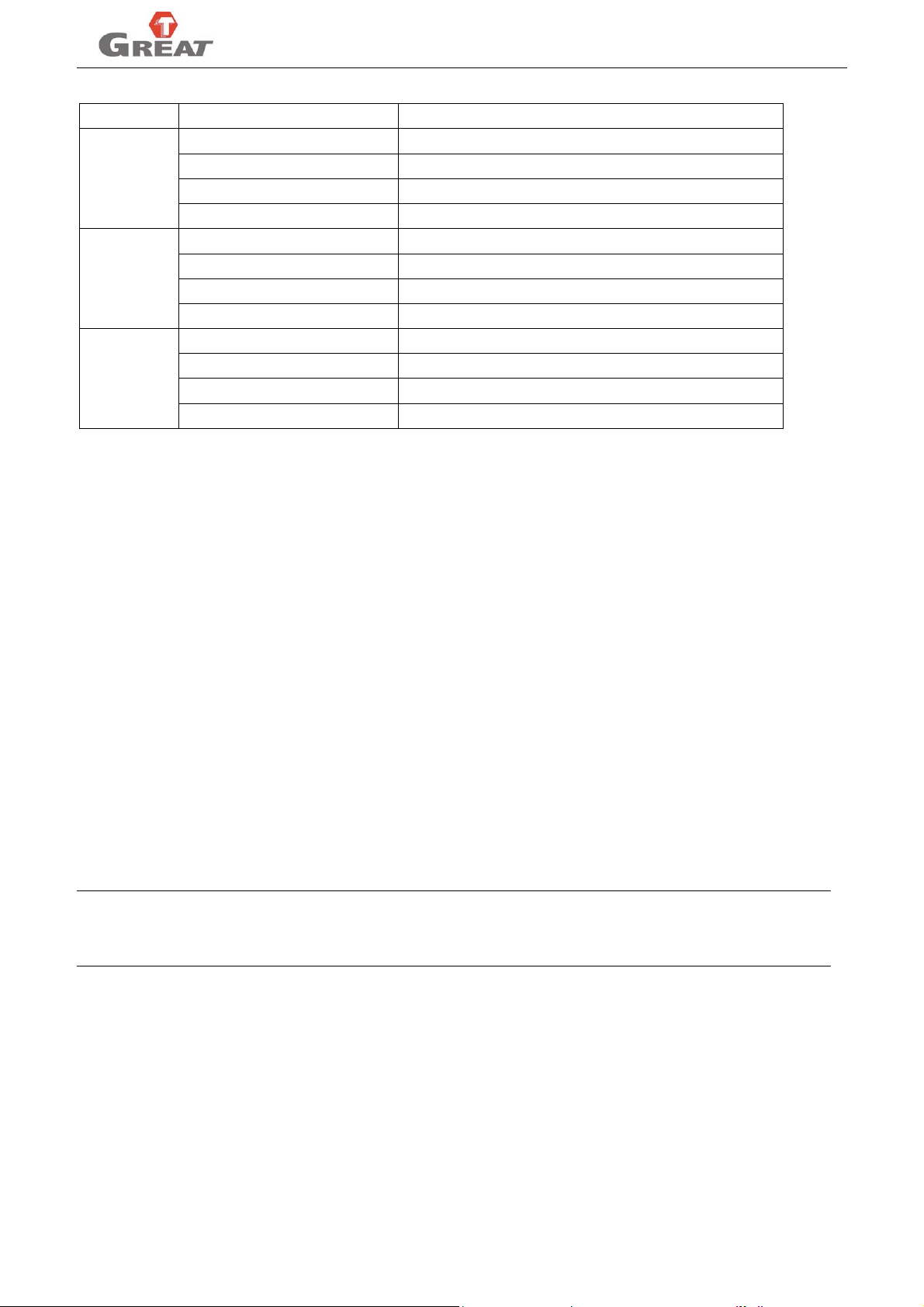

NO. 5 direction of offset Q of canned cycle G76

To set G76 Circle code’s offset (Q) direction of precision boring cycle. The coordinates and directions are

some differences to same value in different plane, refer to following tables:

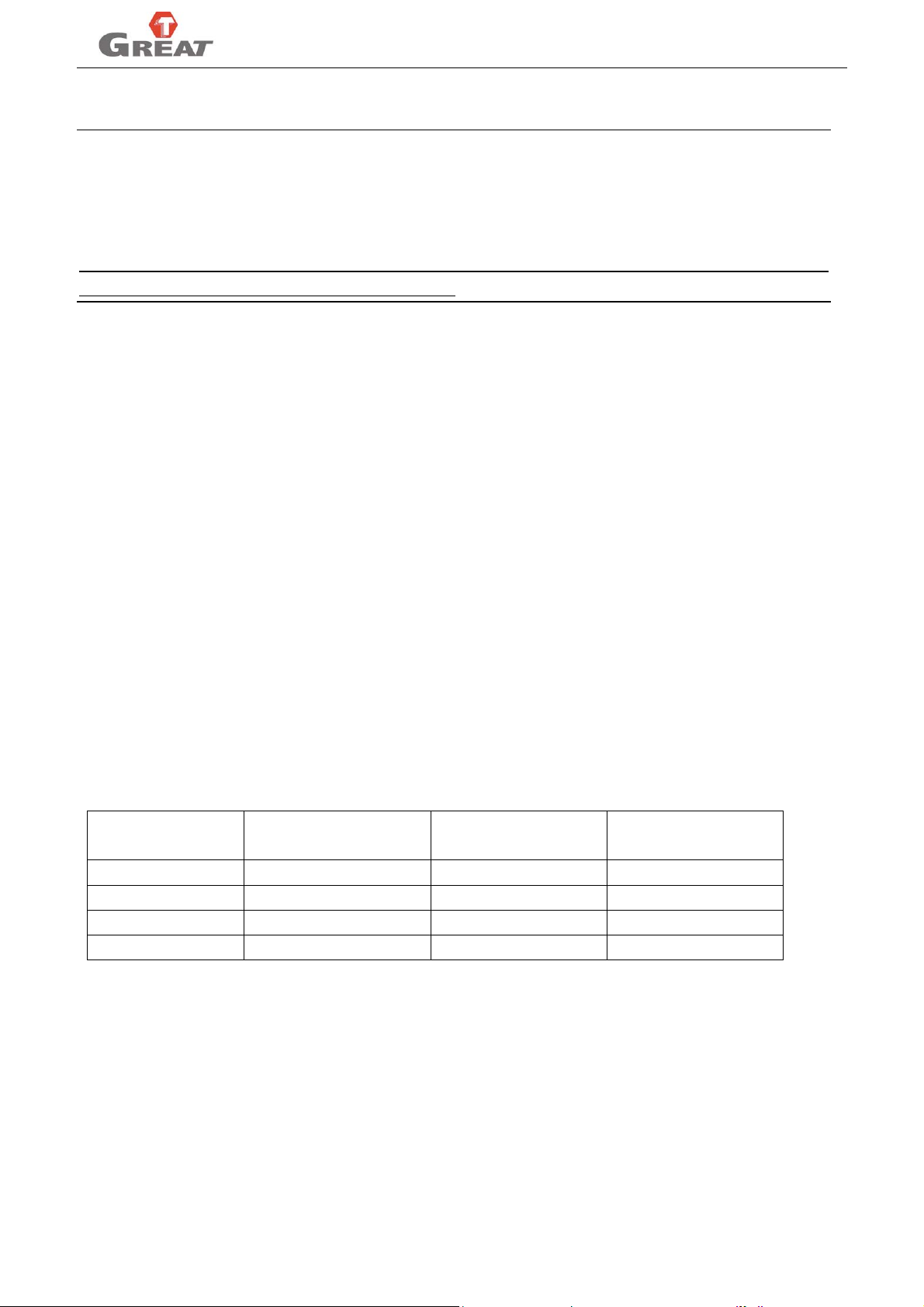

Plane NO.5 parameter setting NO. 5 direction of offset Q of canned cycle G76

1 +X

G17

2 -X

3 +Y

4 -Y

1 +Z

G18

2 -Z

3 +X

4 -X

1 +Y

G19

2 -Y

3 +Z

4 -Z

NO.6 direction of offset Q of canned cycle G87

To set G87 Circle code’s offset (Q) direction of back boring cycle. The coordinates and direction are

11

Page 20

GREAT-150IM-II MANUALS

different to same value in different plane, please refer to following tables:

Plane NO.6 parameter setting NO.6 direction of offset Q of canned cycle G87

1 +X

G17

2 -X

3 +Y

4 -Y

1 +Z

G18

2 -Z

3 +X

4 -X

1 +Y

G19

2 -Y

3 +Z

4 -Z

NO.7 spindle orienting stop degree of boring canned cycle (0.1degree)

Used for set the spindle stop angel degree after boring job when execute boring canned cycle, ensure the

workpiece not be scratched by tools. Unit: 0.1 degree, set range: 0-3600.

NO.8 chip removal tapping G84G74 (0: high speed, 8: normal)

As chip removal tapping G84G74; this value is set to be 0 means removal chip high speed, set to be 8

means normal removal chip.

NO.9 retraction value “d” of chip removal tapping G84G74 (mm)

Set the retraction value “d” of chip removal tapping G84G74. unit: mm

NO.28 whether need spindle rotate as program running (0: yes, 90: no)

Set the spindle rotate interlock with program running, set to be 0, program running need spindle rotating;

set to be 90 means no need detect spindle rotate as program running.

NO.30 whether need individual adjustment to G00 override (88: yes, 0: no)

Set the G00 override. Set to be 88 means individual adjustment, means G00 override is set by PgUp and

PgDn; set to be 0 means machining speed override is adjusted by feed override.

NO.31 whether manual soft limit is valid without zero returning (88: yes, 0: no)

Set the relationship between reference returning status and soft limit. Set to be 88 means the soft limit

function is valid although without reference returning; set to be 0 means the soft limit function is invalid

before reference returning.

CAUTION

This parameter’s setting depends on using situation, but may lead to accident because of improper

setting or operation, please pay attention!

NO.32 is there any hint for spindle top/low gear (88: yes, 0: no)

Set whether automatic hint when shift spindle gear. Set to be 88 means there is hint automatically if the

speed is not suitable for the gear as automatic gear shifting; set to be 0 means system does not check

whether speed is suitable for the gear.

NO.33 whether apply intervention switch (88: yes, 0: no)

This value set to be 88 means apply intervention switch, set to be 0 means not apply intervention switch.

NO.34 make soft limit invalid (X4, Z16, Y8, A32, B64)

This parameter is used for setting whether soft limit function valid. When set this value is 0 means soft

limit is valid; set to be 4 means X-axis soft limit function is invalid; set to be 16 means Z-axis soft limit

12

Page 21

GREAT-150IM-II MANUALS

function is invalid; set to be 8 means Y-axis soft limit function is invalid; set to be 32 means A-axis soft

limit function is invalid; set to be 64 means B-axis soft limit function is invalid;

NOTE

1. Set two or more axes soft limit function is invalid, just add the corresponding axes parameter value. i.e.

set X and Z axes soft limit function is invalid, the parameter is set to be 20(4+16).

2. This parameter setting depends on user’s need, normally we suggest this value set to be valid, to

prevent equipment is damaged from excess of stroke. Please attention, to realize soft limit function,

besides set this parameter, you have to set the each axis’ limit stroke in the “USER” parameter.

CAUTION

This parameter’s setting depends on using situation, but may lead to accident because of improper

setting or operation, please pay attention!

NO.35 system default coordinate system (54-59 corresponding G54-G59, other G53)

Applied to set the system default coordinate system, value 54-59 corresponding to G54-G59, other value

is G53.

i.e.: this parameter is set to be 54 means system default coordinate system is G54.

NO.36 can G92 modify G54-G59 (800: yes, 0: no)

As this parameter set to be 800, G92 will modify the current work coordinate system as program running,

set to be 0 will not modify the current work coordinate system.

37. are lubrication and cooling keys valid in auto mode(1:yes, 0: no)

Set whether the lubrication and cooling keys valid in the “AUTO” mode. As this parameter set to be 0

means invalid; set to be 1 means valid.

This parameter setting related to operation mode, as this parameter set to be valid, operator can control

the valid status of lubrication and cooling to satisfy the condition of manufacturing process.

NO.38 does spindle rotation and tool unclamp interlock (1:yes, 0: no)

Set whether spindle rotation and tool unclamp interlock, as this parameter set to be 0 means spindle

tighten/release tool is not related to spindle rotation; as this parameter set to be 1 means that spindle

tighten/release tool is interlocked with spindle rotation, that means spindle can be rotated only in the

status of tool tightened.

This parameter setting is related to machine tools configuration and user applied request, for the sake of

safety, strongly recommend set this parameter to be 1 and make it interlock.

NO.39 request for zero return as booting and program running (1: no need, 0: hint, 8:force,

9:super force)

To set the treatment mode of reference returning as system booting, there are 4 kinds of treatment mode

as below:

Set to be 1: there is no remind or limit to reference returning after system booting.

Set to be 0 is remind mode: there is a dialogue box remind operator to execute reference returning

after system booting every time, there is no limit after then.

Set to be 8 is force mode: there is a dialogue box reminds operator to execute reference returning

every time after system booting and run system, system will reminds “feed axes have not returned to

reference” and won’t execute program if not execute reference returning before running in the “AUTO”

mode.

Set to be 9 is super forcing mode: there is a dialogue box reminds operator to execute reference

returning every time after system booting and feed axes moving, system will reminds “feed axes have

not returned to reference” and won’t execute moving if not execute reference returning.

CAUTION

13

Page 22

GREAT-150IM-II MANUALS

This parameter setting is related to machine tools configuration, set to be other value if no reference

point switch on the machine, if there is reference point switch on the machine, suggest set this parameter

to be 8 or 9, to prevent equipment failure from without reference returning.

NO.40 checking input point of G31 (valid+300, invalid+400)

As this parameter set to be 300, will check the input signal of skip function; as this value set to be 400,

won’t check the input signal of skip function.

NO.41 G31_X

NO.42 G31_Y

NO.43 G31_Z

NO.44 G31_A

NO.45 G31_B

NO.41~NO.45 parameters are skip block function.

NO.51 edit increment value of program sequence number

This parameter is applied to set increment value of program sequence number.

NO.100 set LCD brightness

Set the brightness of LCD display. In the parameter dialogue box: PgUp means increasing brightness,

PgDn means decrease brightness, Home means back to default.

NO.101 set system time(Y-M-D-H-M)

Applied to modify system date and rime, system will base on this time after setting, will time according to

inner clock, and display on the top right corner.

Set methods as below:

Select NO.101 under the interface of “USER”, press “enter” and pop up dialogue as Fig3.8, input year,

month, day, hour, minute to set, press “Enter” after setting: for example: August, 04, 2008. 09:50, will input

2008-8-4-09-50 and then press “Enter”.

Fig3.8

NO.102 restore factory para setting

Set factory parameter to be current parameter. If there is parameter confused in the process of

debugging, apply this parameter to set the factory parameter to be current parameter.

NOTE

After executing restore factory parameter, the existing parameter will be covered.

3.4.2 Speed

in order to make sure feed axis motor(machine work table) run in the safe scope and guaranty operation

characteristic, this system supply some parameter setting related to speed and acceleration.

In the parameter interface, press “SPEED” soft key will shift to speed parameter setting menu. Select the

parameter needs to be modified, then press “Enter” will pop up a dialogue box, then input value. Refer to

fig3.9.

14

Page 23

GREAT-150IM-II MANUALS

fig3.9 speed parameter setting

Speed parameter list:

1. G00 speed of X-axis(mm/min)

2. G00 speed of Y-axis(mm/min)

3. G00 speed of Z-axis(mm/min)

4. G00 speed of 4th-axis(mm/min)

5. G00 speed of 5th-axis(mm/min)

6. default speed of G01/G02/G03(mm/min)

7. simulation speed (mm/min)

8. acceleration of X-axis ((mm/min)/s)

9. acceleration of Y-axis ((mm/min)/s)

10. acceleration of Z-axis ((mm/min)/s)

11. acceleration of 4th-axis ((mm/min)/s)

12. acceleration of 5th-axis ((mm/min)/s)

15. MPG acceleration(12--5000)

16. speed up/down in auto running mode(500-32000)

17. positive speed of X-axis as reference returning (mm/min)

18. positive speed of Y-axis as reference returning (mm/min)

19. positive speed of Z-axis as reference returning (mm/min)

20. positive speed of 4th-axis as reference returning (mm/min)

21. positive speed of 5th-axis as reference returning (mm/min)

22. reverse speed of X-axis as reference returning (mm/min)

23. reverse speed of Y-axis as reference returning (mm/min)

24. reverse speed of Z-axis as reference returning

25. reverse speed of 4th-axis as reference returning

26. reverse speed when 5th-axis as reference returning (mm/min)

27. max speed as rapidly stop feed axis (mm/min)

28. max feed speed in manual mode (mm/min)

29. max feed speed in auto mode (mm/min)

30. max MPG speed of Z-axis (mm/min)

31. max MPG speed of X,Y(C), 4th-axis (mm/min)

32. initial speed as feed axis running(mm/min)

33. speed skip variable of continuous track(mm/min)

15

Page 24

GREAT-150IM-II MANUALS

34. end speed of reverse deceleration in program running(mm/min)

35. whether enable speed treating function (76: yes, 0: no)

36. manual feed axis speed (mm/min)

100. spindle manual revolution (rpm)

101. max spindle revolution at top gear(rpm)

102. max spindle revolution at low gear (2nd gear) (rpm)

103. max spindle revolution at 3rd gear (rpm)

104. max spindle speed at 4th gear (rpm)

105. max revolution of 2nd spindle (rpm)

106. acceleration of spindle pulse control((mm/min)/s)

120. serial communication speed of RS232

Speed parameter explanation:

NO.1 G00 speed of X-axis, unit: mm/min

X axis running at the rapid traverse rate in auto mode (G00 called speed). initial value: 10000, Max

value:30000.

NO.2 G00 speed of Y-axis, unit: mm/min

Y axis running at the rapid traverse rate in auto mode (G00 called speed). initial value: 10000, Max

value:30000.

NO.3 G00 speed of Z-axis, unit: mm/min

Z axis running at the rapid traverse rate in auto mode (G00 called speed). initial value: 10000, Max

value:30000.

NO.4 G00 speed of 4th-axis, unit: mm/min or deg/min

th

The 4

axis running at the rapid traverse rate in auto mode (G00 called speed). initial value: 10000, Max

value:30000.

NO.5 G00 speed of 5th-axis, unit: mm/min or deg/min

th

The 5

axis running at the rapid traverse rate in auto mode (G00 called speed). initial value: 10000, Max

value:30000.

NO.6 default speed of G01/G02/G03, unit: mm/min

As no given speed for the first interpolation command (G01/G02/G03) in the program, the command

called default speed in the auto mode. Initial value: 2000, max value: 5000.

NO.7 simulation speed, unit: mm/min

Running speed in simulation mode. initial value: 20000, Max:30000

NO.8 acceleration of X-axis, unit: (mm/min)/s

The acceleration time constant for X-axis, the more the value the faster the speed. initial value: 50000,

value range: 1-99999

NO.9 acceleration of Y-axis, unit: (mm/min)/s

The acceleration time constant for Y-axis, the more the value the faster the speed. initial value: 50000,

value range: 1-99999

NO.10 acceleration of Z-axis, unit: (mm/min)/s

The acceleration time constant for Z-axis, the more the value the faster the speed. initial value: 50000,

value range: 1-99999

th

NO.11 acceleration of 4

The acceleration time constant for 4

-axis, unit: (mm/min)/s

th

-axis, the more the value the faster the speed. initial value: 50000,

value range: 1-99999

th

NO.12 acceleration of 5

The acceleration time constant for 5

-axis, unit: (mm/min)/s

th

-axis, the more the value the faster the speed. initial value: 50000,

16

Page 25

GREAT-150IM-II MANUALS

value range: 1-99999

NOTE: The value of acceleration is related to equipment configuration. usually, the heavier the load the

smaller the value.

NO.15 MPG acceleration(12--5000)

To set the acceleration time constant as apply MPG, setting range is 12-5000, the bigger the value, the

bigger the acceleration.

NO.16 speed up/down in auto running mode (500-32000)

To set acceleration constant in the auto mode, value range: 500-32000. as this parameter value set

within the range of 500-32000, speed will depends on this parameter in auto mode, otherwise, will

depends on each axis’ acceleration value in user parameter.

This parameter is mainly used to distinguish acceleration in manual mode and auto mode; Set this

parameter only there is much difference of acceleration in the two modes; otherwise, usually set as

invalid.

NO.17 positive speed of X-axis as reference returning, unit: mm/min

The running speed of X-axis meets reference switch moving towards positive direction as returning

reference point. Initial speed: 5000, value range: less than G00 speed of X-axis.

NO.18 positive speed of Y-axis as reference returning, unit: mm/min

The running speed of Y-axis meets reference switch moving towards positive direction as returning

reference point. Initial speed: 5000, value range: less than G00 speed of Y-axis.

NO.19 positive speed of Z-axis as reference returning, unit: mm/min

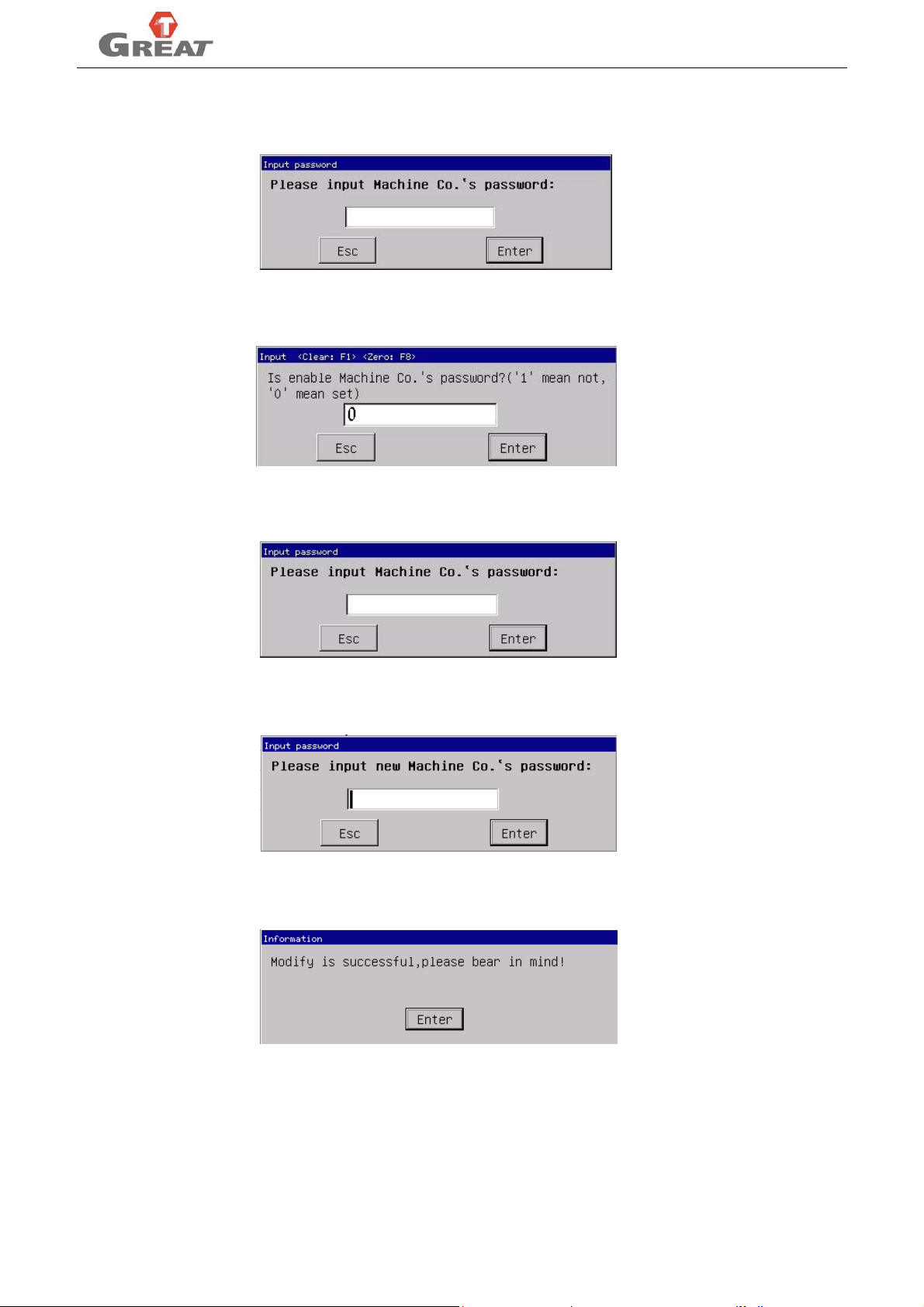

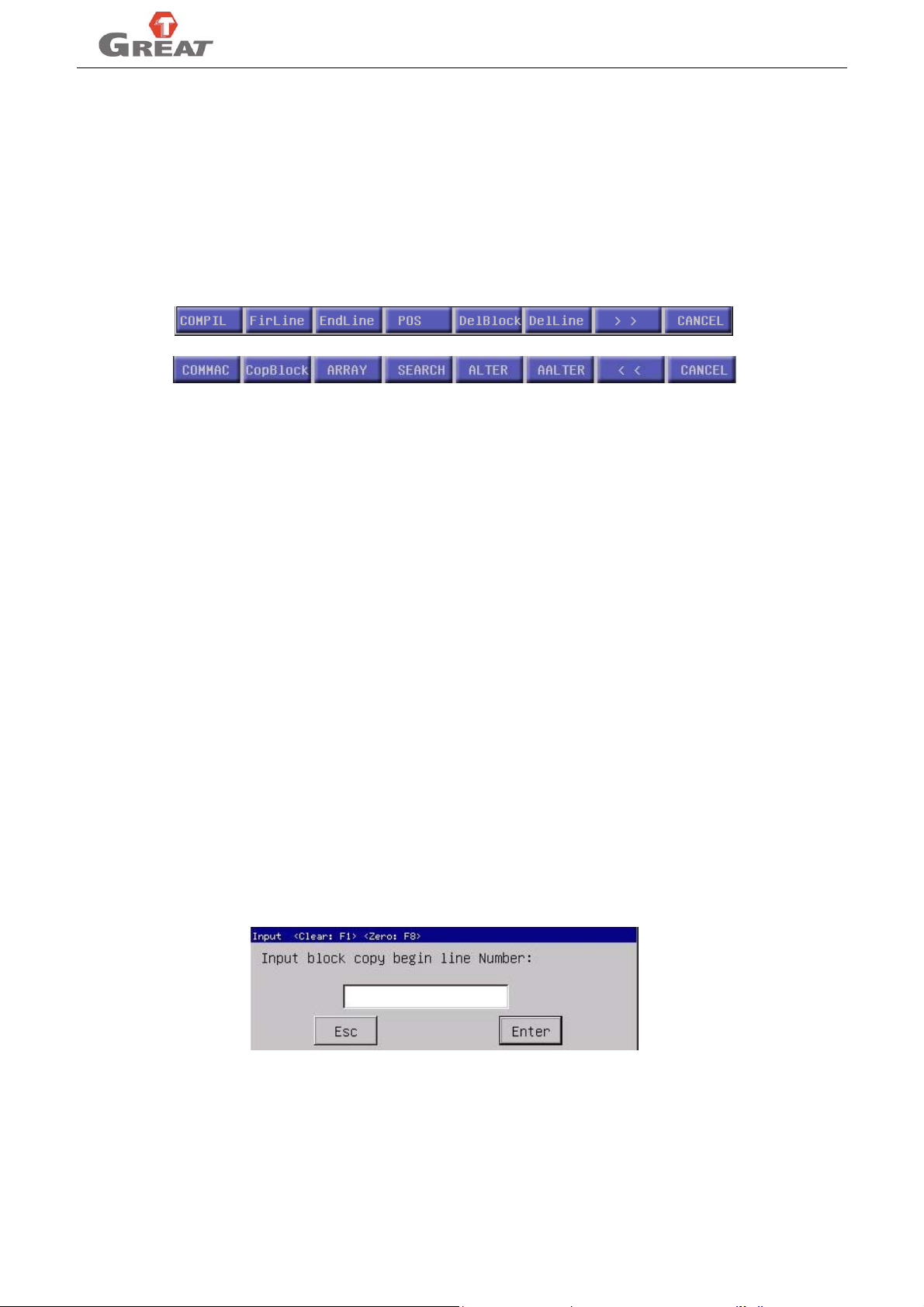

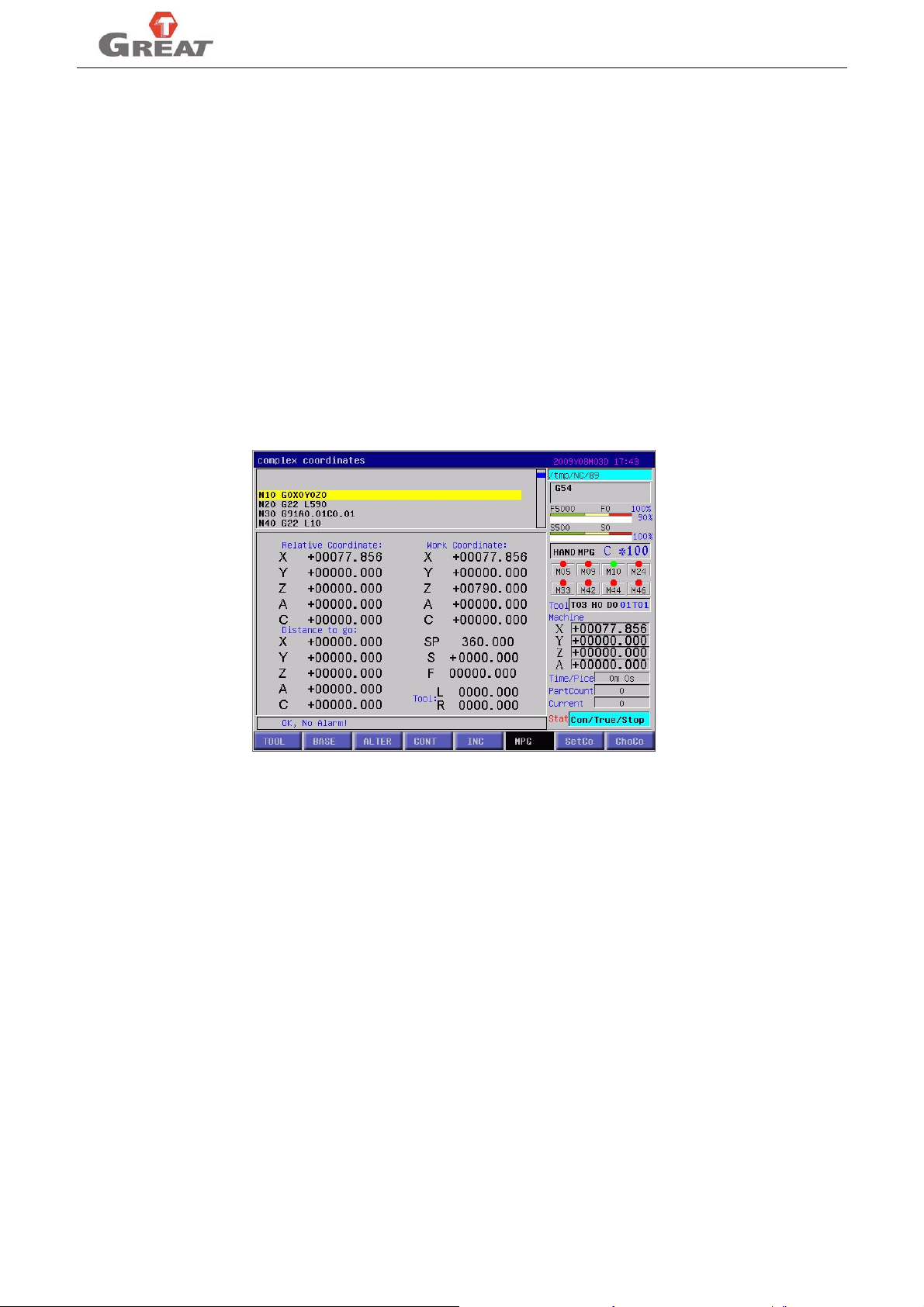

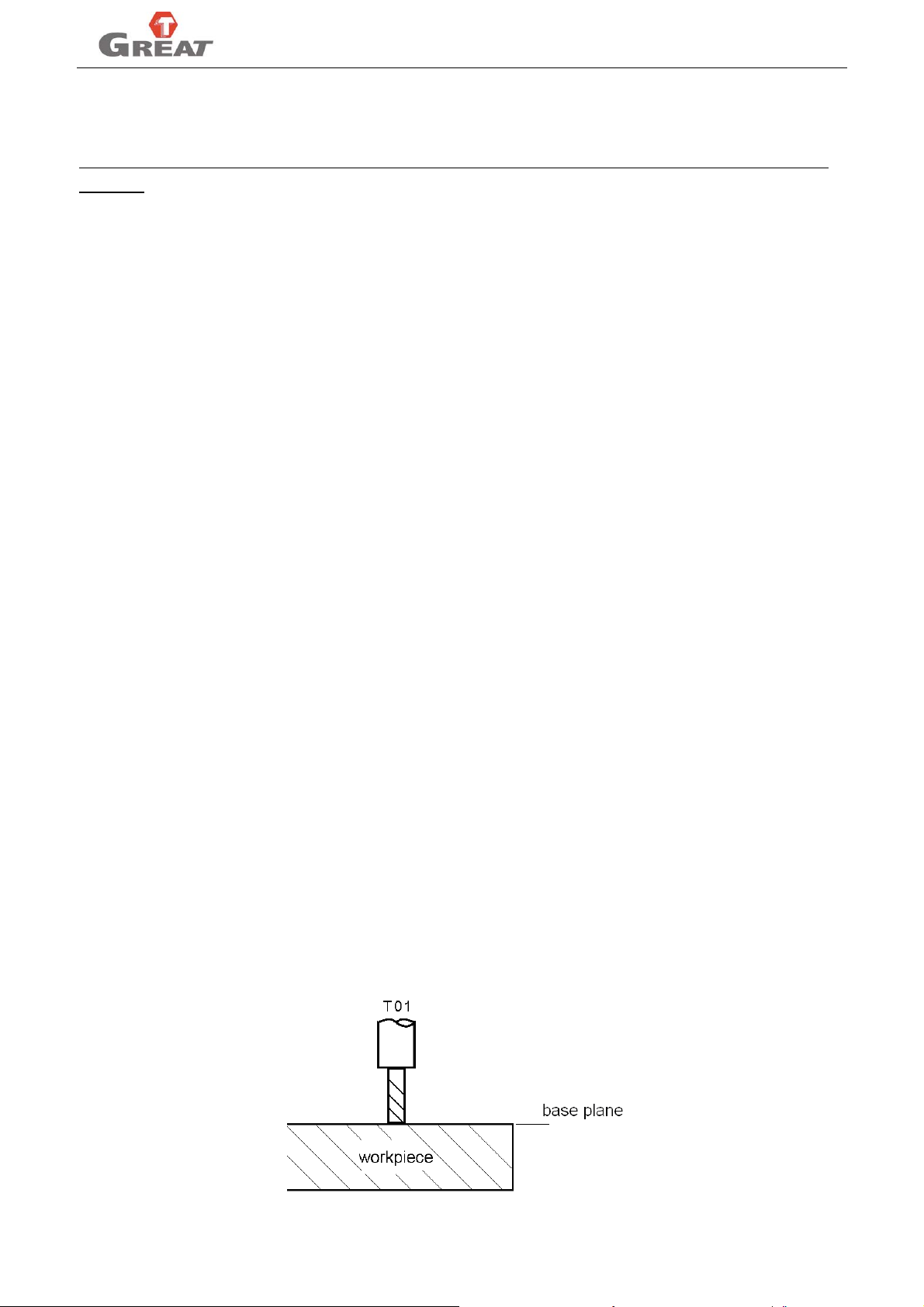

The running speed of Z-axis meets reference switch moving towards positive direction as returning