Graymark 808 User Manual

PARTS IDENTIFICATION AND INVENTORY EXPERIENCE

This experience is provided to acquaint you with the

vari-

ous electronic components and fittings included in this

To assist you in proper identification of the major parts and

project. Unpack the project carefully and check

(V)

each

fittings, pictorial and schematic illustrations are given in

part and fitting against the PARTS LIST In case of incor-

Figure

1,

rect, missing, or damaged parts, please refer to How to

Or-

der Replacement Parts and Graymark’s Warranty.

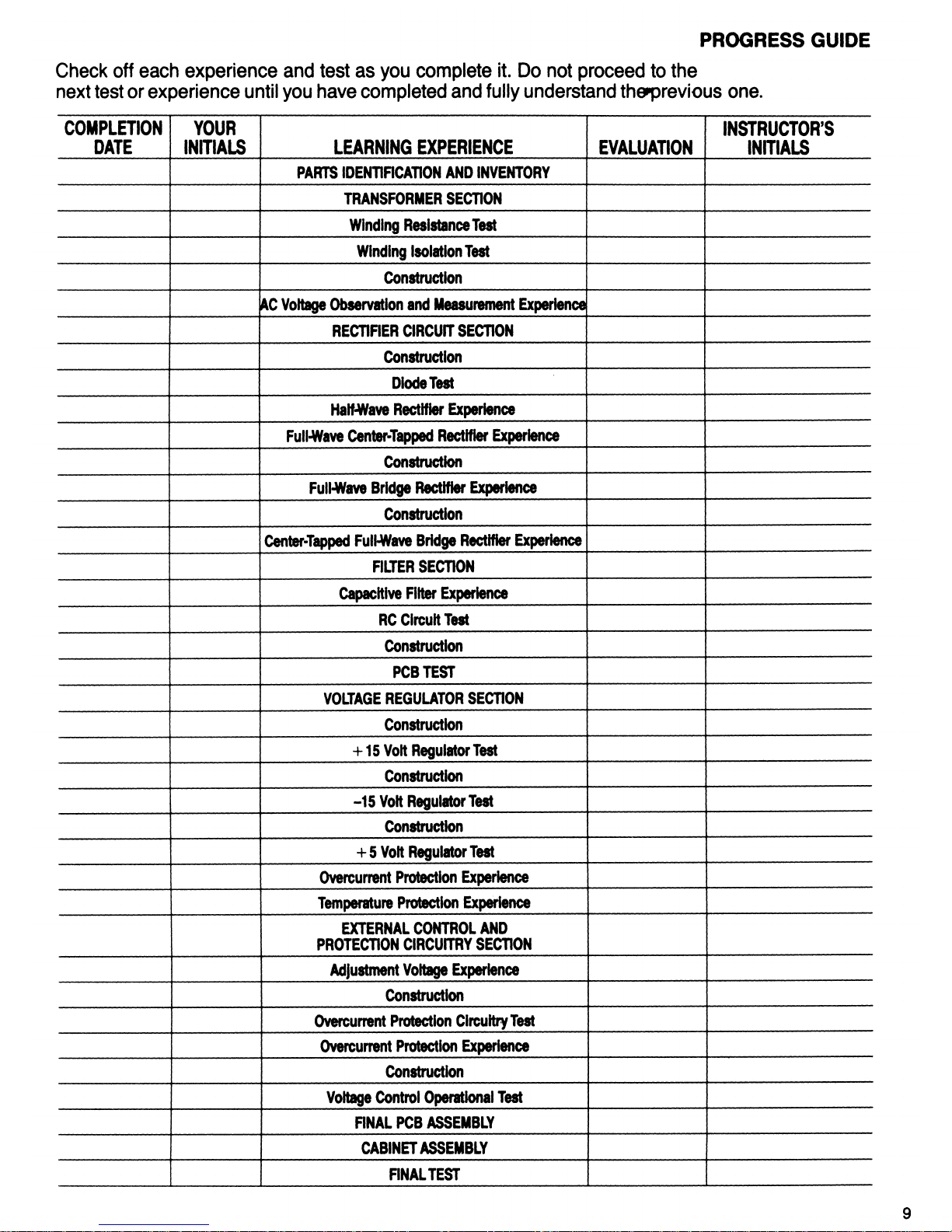

Upon completion of the parts identification and inventory,

have your instructor initial your Progress Guide.

-;

DIODE, SIGNAL

i

i

u

IA@09

INTEGRATED CIRCUIT

FUSE HOLDER

DIODE, POWER

1

,

TRANSFORMER

POWER RESISTOR

HEAT SINK

LM317-LM337

POST, RED,

BlACK

POTENTIOMETER

RUBBER FOOT

+-_-_-.-

SOLDER LUG

.- . . _.-

._

. _d

_._~_~__

--I

MACHINE SCREW

SELF-TAPPING SCREWS

f3 x Qmtn

AND 2.6 x

5mm

i

SPACER

1Omm

AND

4Omm

~-_---..-

ELECTROLYTIC

CAPACITOR

PCB

---j----

LM317-LM337

BREADBOARD

--

__.

-..---_

,

LOCK WASHER SPLIT

STRAIN RELIEF

AND INTERNAL STAR

TRANSISTOR

FIG.

1

5

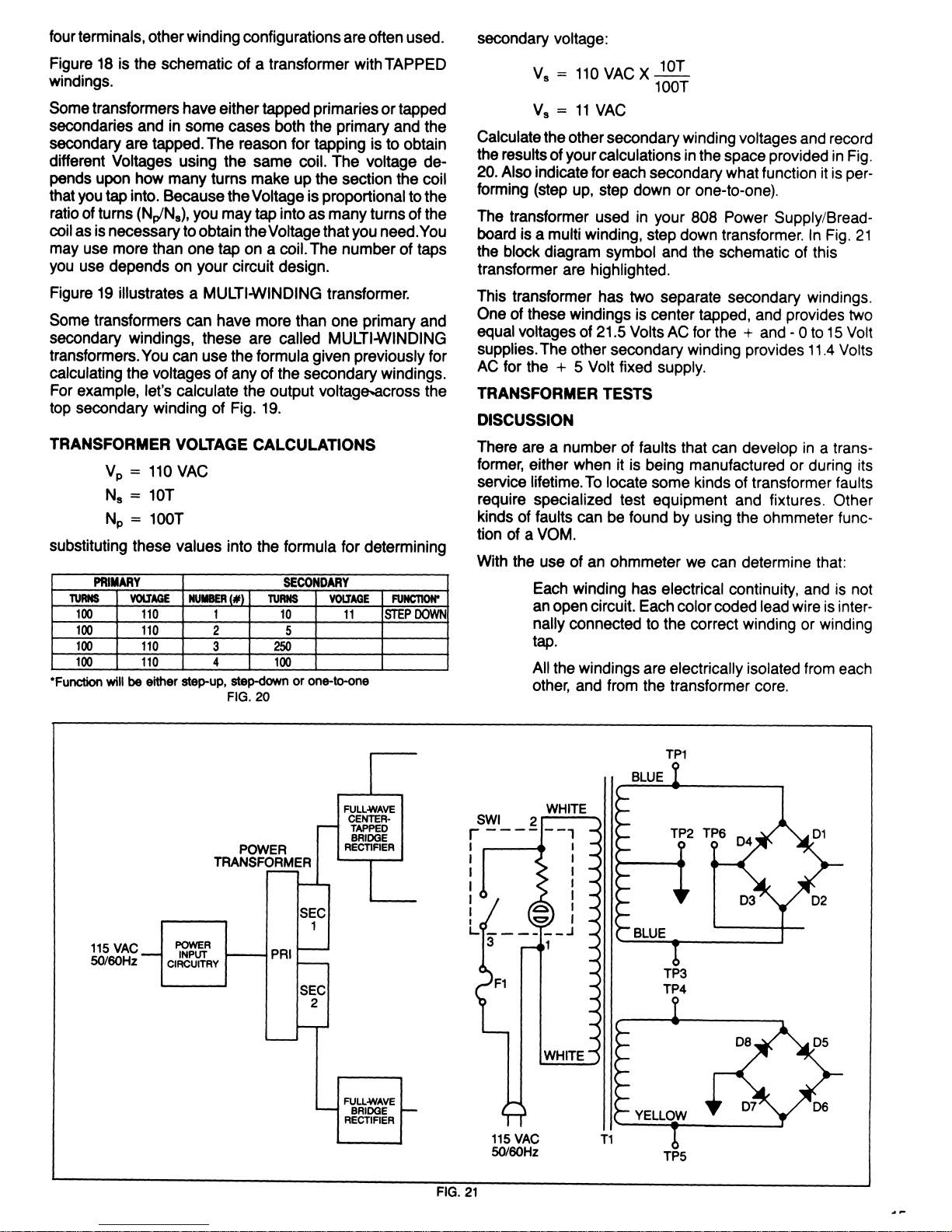

FIG. 29A

_FlG.

29B

l

I

TPl8

0

T:-I

5”

TP17

I

I

OT:+W

1 .

I

.

, RlO

0

Dll

T&

’ f

r----------

i

l

, .

I

I

I

1

R6

l-/N

OJOJI

fTP9

l Tm

.b.

. . . .

TPlA

YELLOW fl

FYELLOW

FIG.

30

BUCK+

MBL”E

connect the meter test leads from the power

Plug

.

-

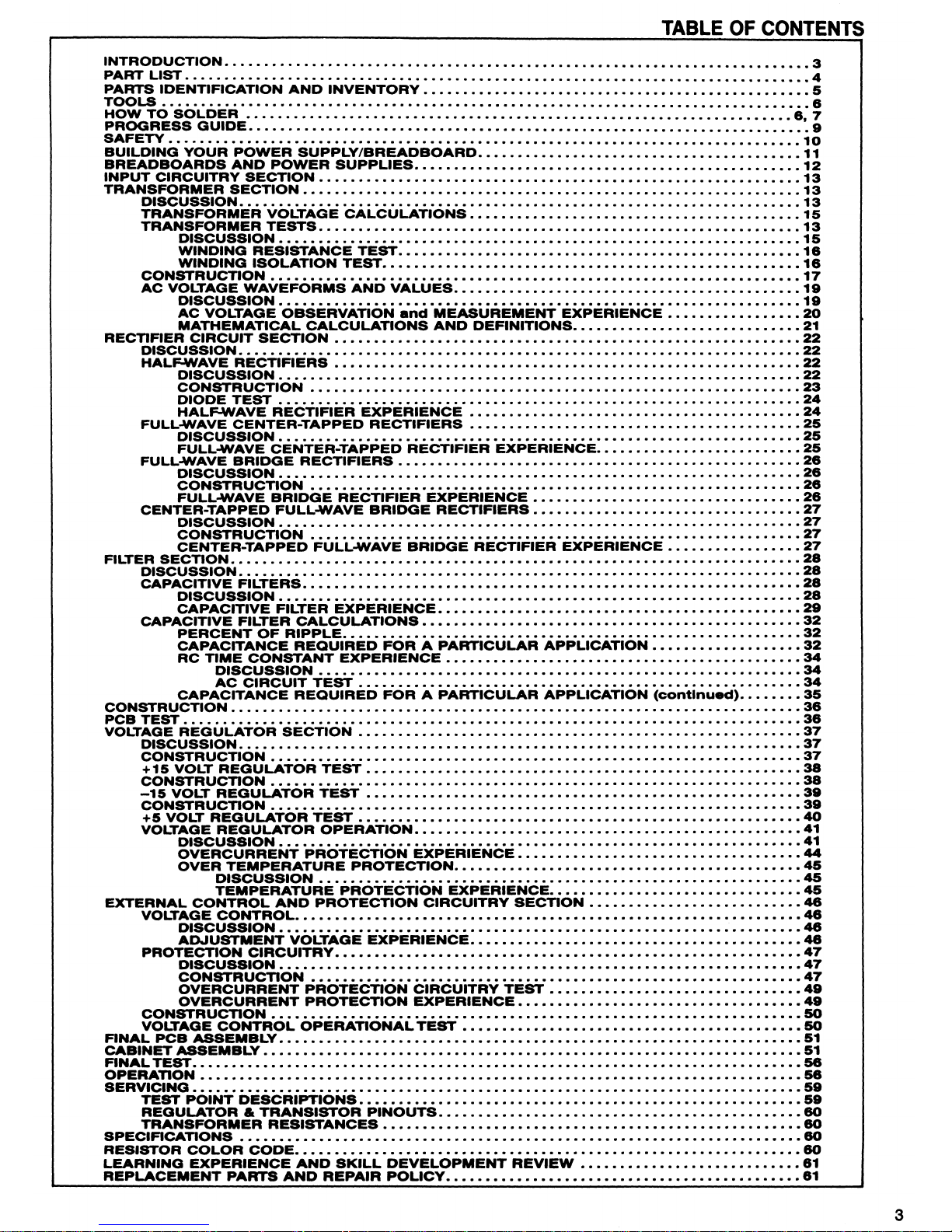

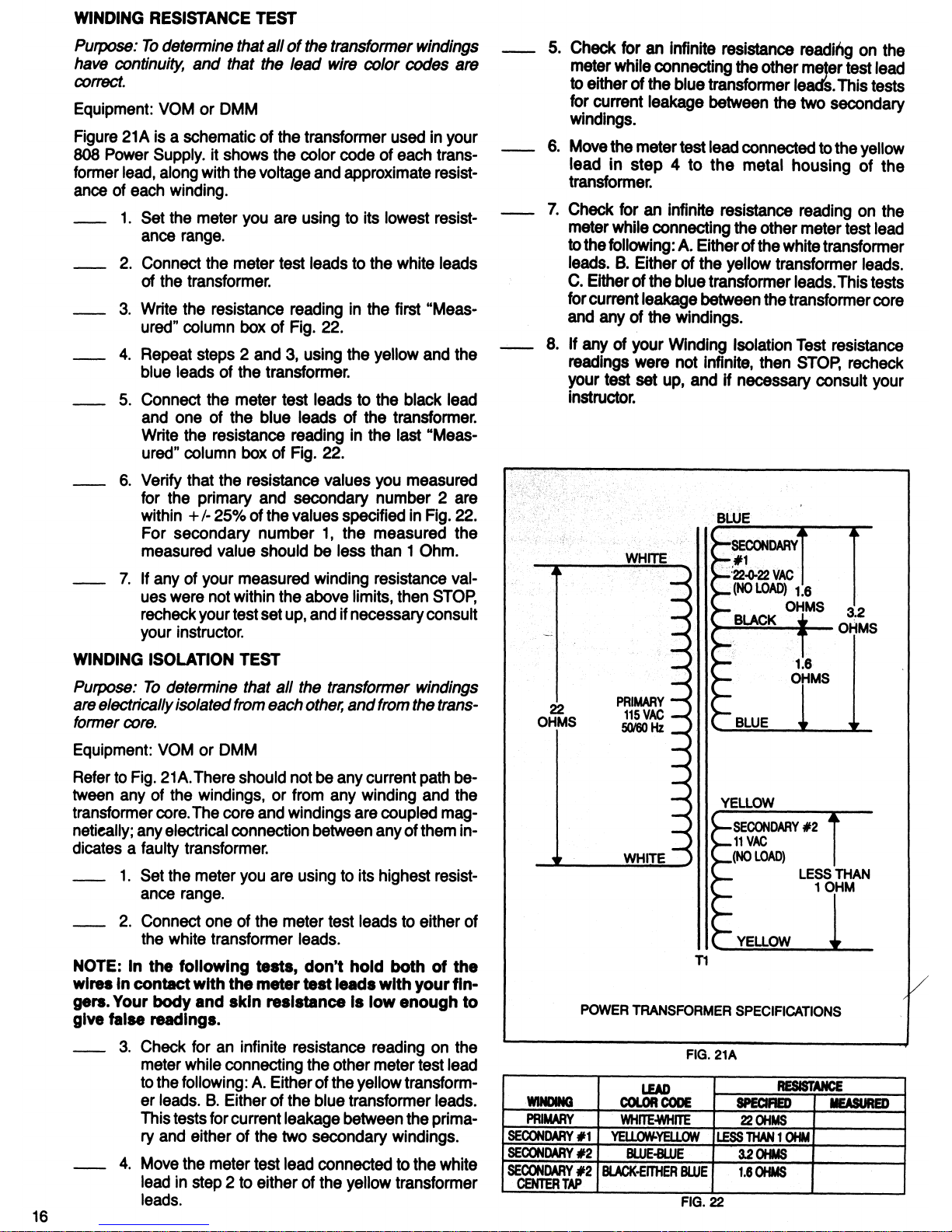

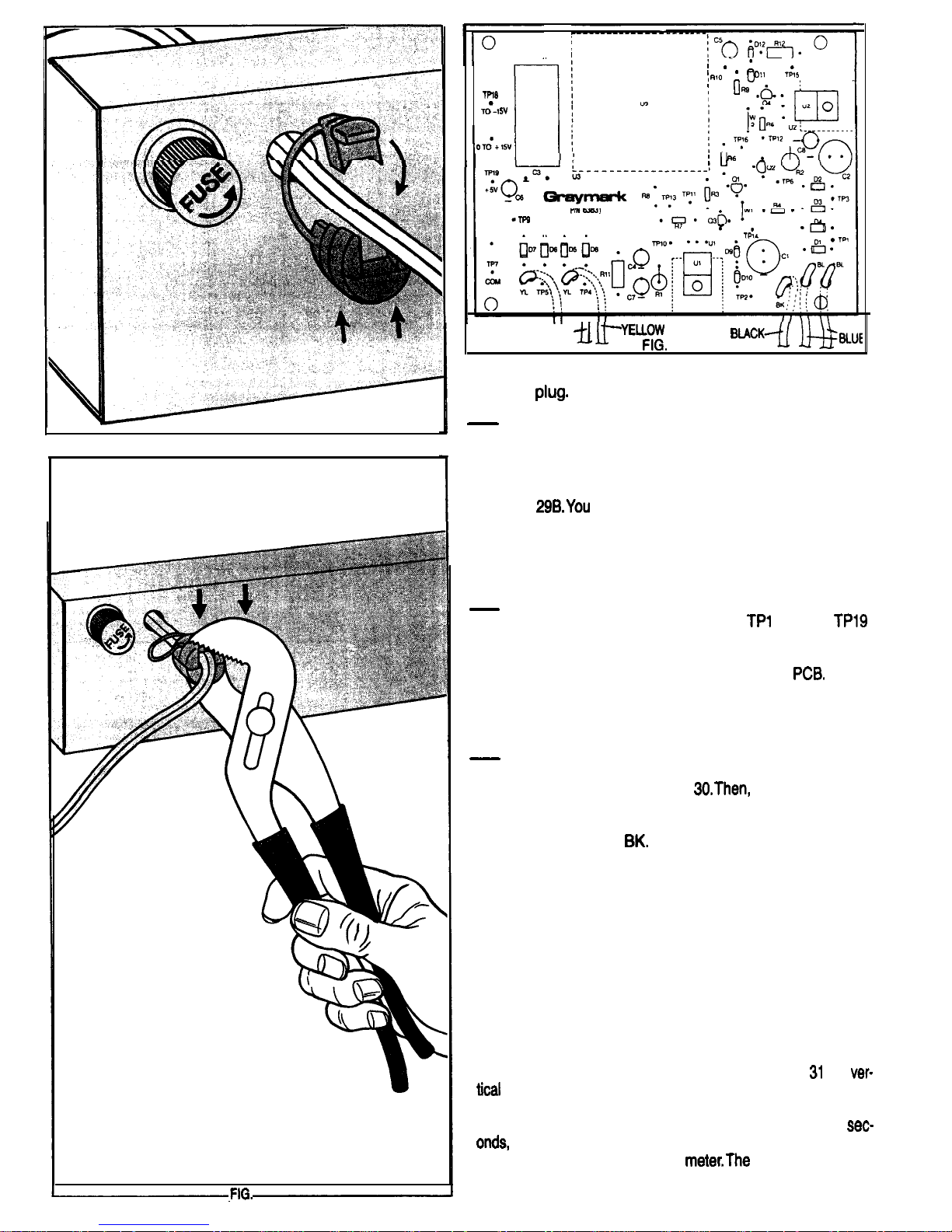

24. Position the two portions of the AC power cord

grommet around the cord where it extends out of

rear of the cabinet top, as shown in Fig. 29A. Using slip-joint pliers, insert the grommet into the

hole in the rear of the cabinet top as shown in Fig.

29BYou

will have to squeeze the grommet quite

hard with the pliers so that the power cord is

formed into a “U” inside the grommet, and the

grommet is compressed enough to fit into the

hole.

-

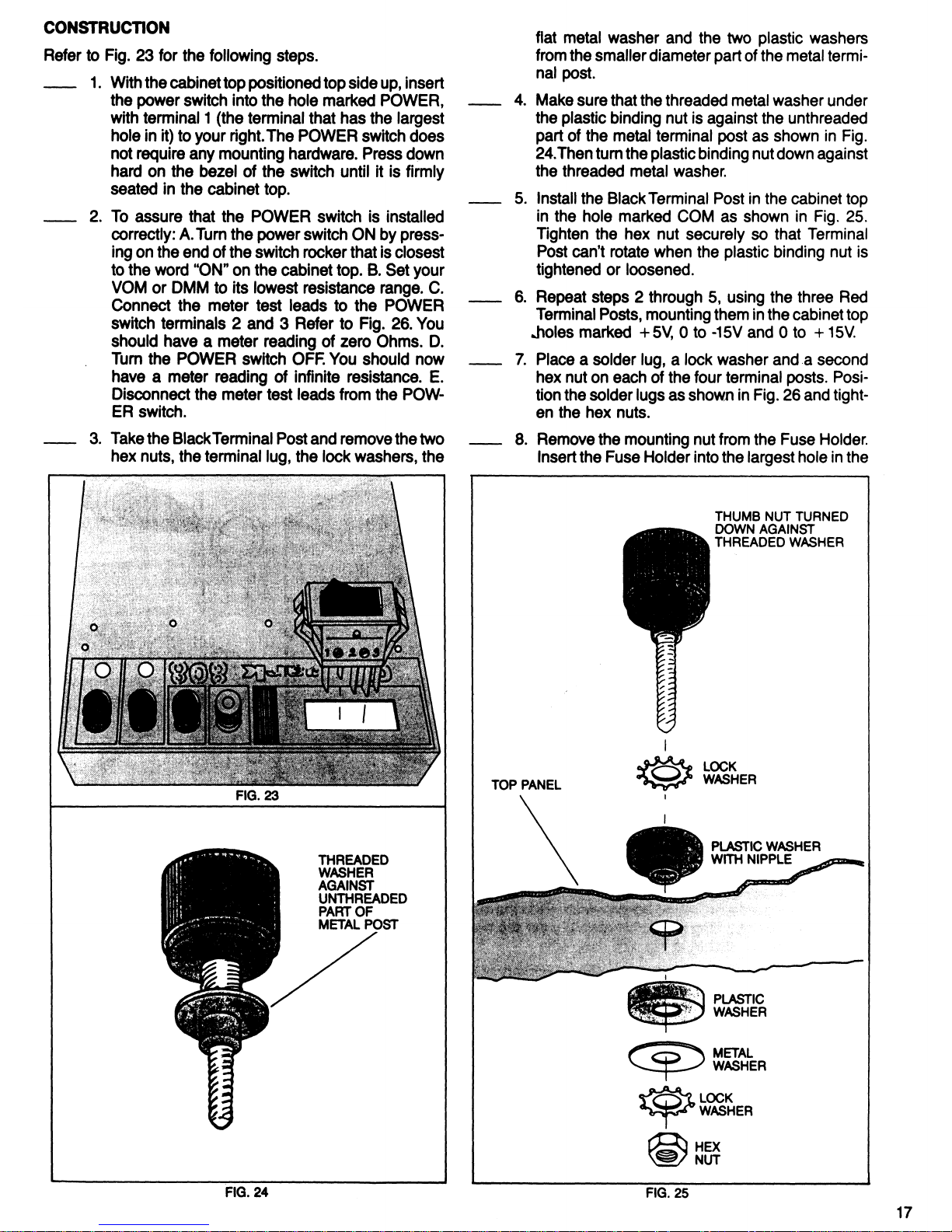

25. Locate the Printed Circuit Board (PCB) and the

test points. Insert and solder

TPl

through

TPl9

into the PCB. The test points are inserted from

the component side of the PCB and soldered to

the copper on the solder side of the

PCB.

Refer

to Fig. 30 and the the silkscreened legend on the

component side of the PCB for the test point

locations.

-

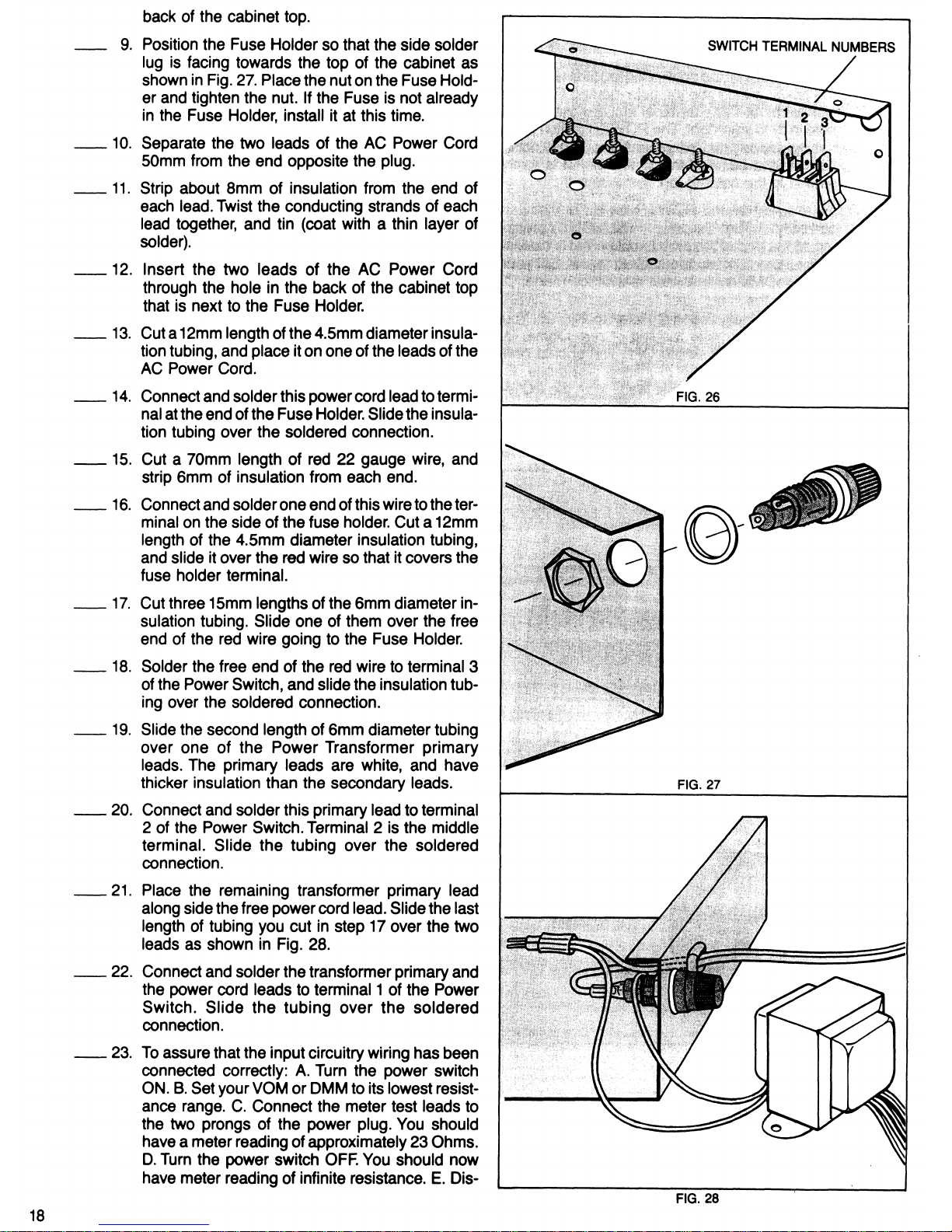

26.

From the solder side (bottom) of the PCB thread

the transformer leads through the holes in the

PCB as shown in Fig.

3O.Then,

from the component side (top) of the PCB, thread the stripped

and tinned wire ends through the holes marked

YL, BL and

BK.

Solder these five wires to the

PCB, and cut off any excess lead length. Note:

This is done so when the board is handled during

component installation and testing, the wires

won’t bend and break at the weak points where

the wire insulation stops and the tinned copper

wire goes through the PCB.

AC VOLTAGE WAVEFORMS AND VALUES

DISCUSSION

Measuring a DC voltage is simple and straight forward.

Shown on a graph, the voltage of an automobile battery

would appear as a straight horizontal line. In Fig.

31

the

ver-

tical

axis shows the magnitude of the voltage being meas-

ured, and the horizontal axis represents time. The time

shown on the graph would be in the order of several

sec.

ends,

the time it takes for the meter pointer to stabilize and

for you to accurately read the

meter.The

graph shows that

the meter test probes were connected to the the battery at

19

Loading...

Loading...