Page 1

ACCESSORIES

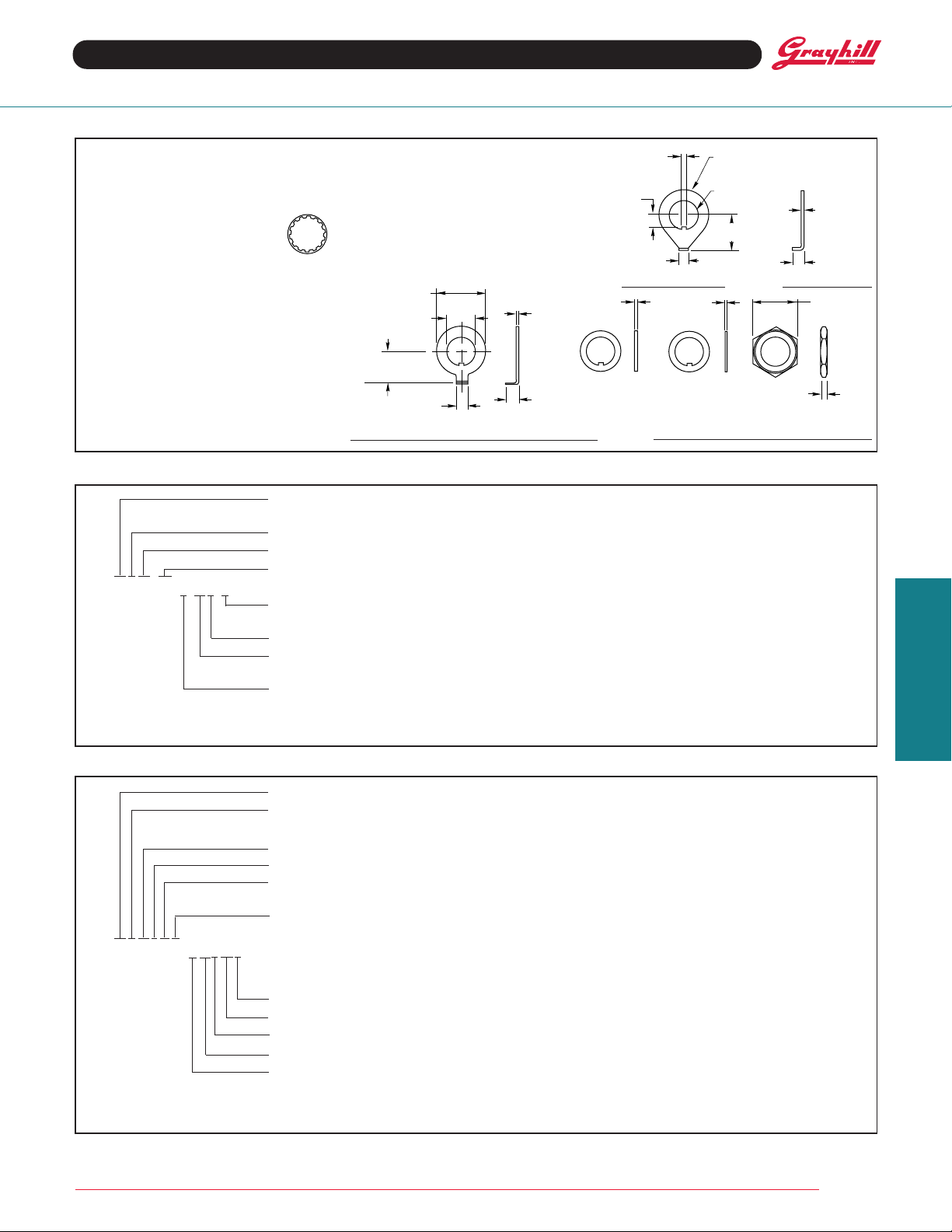

Non-Turn Washer Seal Keyed Washer Hex Nut

FIGURE C

.625 ± .010

(15,88 ± 0,25) DIA.

.375 + .004 – .000

(9,53 + 0,10) DIA.

.375 ± .005

(9,53 ± 0,13)

.125 ± .003

(3,18 ± 0,08)

C

L

.032

± .002

(0,81

± 0,05)

.187 ± .010

(4,75 ± 0,25)

.045 ± .003

(1,14 ± 0,08)

.010 ± .002

(0,25 ± 0,05)

.562 (14,27)

ACROSS

FLATS

.088 (2,24)/

.093 (2,36)

.120 ± .003

(3,18 ± 0,08)

.060 ± .002

(1,52 ± 0,05)

.154

+ .004

–.000

(3,91

+ 0,10

–0,00)

DIA.

.437 ± .010

(11,10 ± 0,25)

.625 ± .010

(15,88 ± 0,25)

DIA.

.376 + .003 –.000

(9,55 + 0,08 –0,00)

DIA.

.125 ± .010

(3,18 ± 0,25)

.032 ± .002

(0,81 ± 0,05)

FIGURE B

Multi-Deck Rotary Switches

Internal Tooth Lockwasher–Figure A

For a 3/8" bushing. Approximately 0.500" (12,7)

outside diameter, .022" (0,56) thickness. Material

is cadmium-plated steel. Part No. 12Q1272-1

For a 1/4" bushing. Approximately

0.400" (10,16) outside diameter, .018"

(0,46) thickness. Material is steel, tin/

zinc plated.

FIGURE A

bushing to the panel. The kit consists of four

items: a grooved hex nut, a keyed washer, a

keyed seal and a non-turn washer. Assembly is

described on Page J-53. Dimensions of panel

seal kit items are shown in Figure C. This kit

seals the bushing to the panel; it does not seal

the shaft to the bushing. Not usable with

adjustable stop switches. Part No. 42-24

Non-Turn Washer–Figure B

Can be ordered as extra hardware for the

Series 5000, 24, 42, 43, 44, 54, 71B, 53, 57 and

59 rotary switches. The internal key of the

washer slides into the bushing keyway. The

right angle tab locks into a predrilled hole on

the back side of the mounting panel. Material is

brass, tin/zinc plated. Part No. 12C1087-1

Panel Seal Kit–Figure C

Sold as a separate item to seal the switch

ORDERING INFORMATION: Single Shaft Switches, Add-A-Pot Switches

Series: Determined by the type of switch and

the angle of throw

Style*: Letter(s) from the Choices and Limitations chart

Angle of Throw: Must agree with Series Number

Number of Decks: As limited by the angle of throw, the poles per deck, switch style and type of contacts

44M30–02–1–12N–F

Stop Arrangement: Add letter F to a one pole per deck switch with the maximum number of positions for

a stop between position 1 and the last position. Leave blank for continuous rotation

Type of Contacts: N = Non-shorting; S = Shorting

Positions Per Pole: Requires 02 positions as a minimum to maximum allowable dependent on the angle

of throw and poles per deck. Use AJ for adjustable stops (Styles D and UD).

Poles Per Deck: As limited by angle of throw, switch series and style

Rotary Switches

ORDERING INFORMATION: Concentric Shaft Rotary Switches

Available from your local Grayhill Distributor

Grayhill, Inc. • 561 Hillgrove Avenue • LaGrange, Illinois 60525-5997 • USA • Phone: 708-354-1040 • Fax: 708-354-2820 • www.grayhill.com

* All rotary switches that are required to have military designated markings and testing adhering to MIL-3786 are to be ordered by specifying

the military part number identified on the appropriate slash sheet.

Series: Determined by the angle of throw, applicable to both sections

Style*: Letter(s) from the Choices and Limitations chart

Section A (front)

Number of Decks: As limited by the number of poles per deck

Poles Per Deck: As limited by the angle of throw

Positions Per Pole: Requires 02 positions as a minimum to the maximum allowable dependent on the angle

of throw and the poles per deck

Type of Contacts: N=Non-shorting, S=Shorting. All one pole per deck switches with the maximum number

of positions are continuous rotation

43M02110N–M03203S

Section B (rear)

The limitations listed for Section A apply to Section B

Type of Contacts

Positions Per Pole

Poles Per Deck

Number of Decks

Style

* All rotary switches that are required to have military designated markings and testing adhering to MIL-3786 are to be ordered by specifying

the military part number identified on the appropriate slash sheet.

For prices and discounts, contact a local Sales Office, an authorized local Distributor or Grayhill.

Rotary

31

Loading...

Loading...