Document No. 5002866 Rev. C (DRAFT)

28 April 2003

SYSTEM OPERATIONS MANUAL

FOR

LOCOTROL

®

REMOTE CONTROL LOCOMOTIVE

(RCL)

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

SYSTEM OPERATIONS MANUAL

FOR

LOCOTROL

®

REMOTE CONTROL LOCOMOTIVE

(RCL)

P.O. Box 8900

Melbourne, Florida 32902-8900

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

SYSTEM OPERATIONS MANUAL

FOR

LOCOTROL

®

REMOTE CONTROL LOCOMOTIVE

(RCL)

Prepared by: Approved by:

G. Peltonen Date S. Kellner Date

G. Smith Date Date

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

Notice/Copyright

These instructions are not intended to cover all details or variations in equipment nor are

they intended to provide for every possible contingency to be met in connection with

installation, operation, or maintenance. Should further information be desired or should

particular problems arise which are not covered sufficiently for the user’s purposes, the

matter should be referred to GE Transportation Systems Global Signaling, LLC. Any

applicable Federal, State or local regulations or company safety or operating rules must take

precedence over any instructions given in this material. GE Transportation Systems Global

Signaling, LLC has no obligation to keep the material up to date after the original

publication. There are no warranties of accuracy, merchantability or fitness for particular

service.

This document contains confidential and proprietary information of GE Transportation

Systems Global Signaling, LLC, and is protected as an unpublished, copyrighted work.

©

Copyright 2002 GE Transportation Systems Global Signaling, LLC. All rights reserved.

Reproduction and Use Restrictions Agreement

The information contained in this Technical Manual (the “Document”) is the property of

GE Transportation Systems Global Signaling, LLC (“GETSGS”) and is protected by

copyright and other intellectual property laws. Any unauthorized use or reproduction of this

Document without the prior written consent of GETSGS, whether in hard copy or in an

electronic form, is strictly prohibited (except as otherwise set forth below).

GETSGS hereby grants to the purchaser of the GETSGS equipment, or licensee of the

GETSGS software (such purchaser or licensee, including, but not limited to all employees

and/or representatives, referred to herein as “You”), to which the Document pertains, the

following limited reproduction rights. This Document will remain the property of GETSGS,

will be used solely for its intended purpose and will not be used in any way directly or

indirectly that is detrimental to GETSGS or its affiliates, and such Document will be kept

strictly confidential by You and will not be disclosed to any person in any manner

whatsoever, except that You may disclose the Document or portions thereof to those of its

directors, officers, employees who need to know such information (it being agreed that

those individuals will be informed of the confidential nature of the Document and will

agree to be bound by this agreement and not to disclose the information to any other

person). You agree to be responsible for any breach of this agreement by its

Representatives. You may make additional copies of the Document solely for Your internal

use in connection with the GETSGS equipment or GETSGS software to which it pertains,

provided that each copy is a complete copy, is not placed into the public domain and does

not alter the content or meaning of the Document in any way, and provided further that

each such copy preserves unaltered all trademark, copyright, patent designations and

proprietary or confidentiality notices contained therein, including this Reproduction and

Use Restrictions Agreement. By reproducing the Document and/or any portion thereof, You

expressly agree to these terms and conditions. Any other use, distribution or reproduction of

any portion of the Document without the prior written authorization of GETSGS is

expressly prohibited. Without limiting any other rights or remedies of GETSGS, in the

event that You or any of Your employees, agents or contractors violate any terms or

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

conditions of this Agreement, You agree to indemnify, defend and hold harmless GETSGS

from and against any and all claims, damages, losses, liabilities and expenses (including

reasonable attorney’s fees) that can be incurred or awarded by reason thereof. You also

agree that GETSGS shall be entitled to equitable relief, including, without limitation,

injunction and specific performance, without proof of actual damages or exhausting other

remedies, in addition to all other remedies available to GETSGS at law or in equity.

DataTrain

®

is a registered trademark of General Railway Signal Corporation. Trademarks,

marked and not marked, are the property of their respective owners.

®

LOCOTROL

is a registered trademark for GE Transportation Systems Global Signaling,

L.L.C.

FCC Compliance

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at their own expense.

Compliance Statement (Part 15.19)

This device complies with Part 15 of the FCC Rules and with RSS-210 of Industry Canada.

Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may

cause undesired operation

Warning (Part 15.21)

Changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment.

RF Exposure (OET Bulleting 65)

To comply with FCC RF exposure requirements for mobile transmitting devices, this

transmitter should only be used or installed at locations where there is at least 2m

separation distance between the antenna and all persons.

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

Safety Conventions

GE Transportation Systems Global Signaling, LLC, Technical Information Department

under the direction of the designated equipment Product Manager, issues this document.

The manual provides equipment setup instructions. Please read carefully and thoroughly

understand the instructions and processes before making any adjustments or modifications

to the equipment. Carelessness may result in loss of life or property damage.

The following table illustrates and describes the primary safety and static sensitive symbols

used throughout this document.

Through our Technical Support Hotline, 1-800-645-6245, you can directly reach a Product

Support Leader Monday through Friday, 8 a.m. to 5 p.m. or visit the GE Transportation

Systems Global Signaling website.

For after hours Locomotive Products technical support pertaining to RCL, call 1-800-8257090 and press 3.

Revision History

This document supersedes all previously issued versions, providing new or revised

information. The most recent publication can be determined by comparing the last three

characters at the end of the part number and the date issued.

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

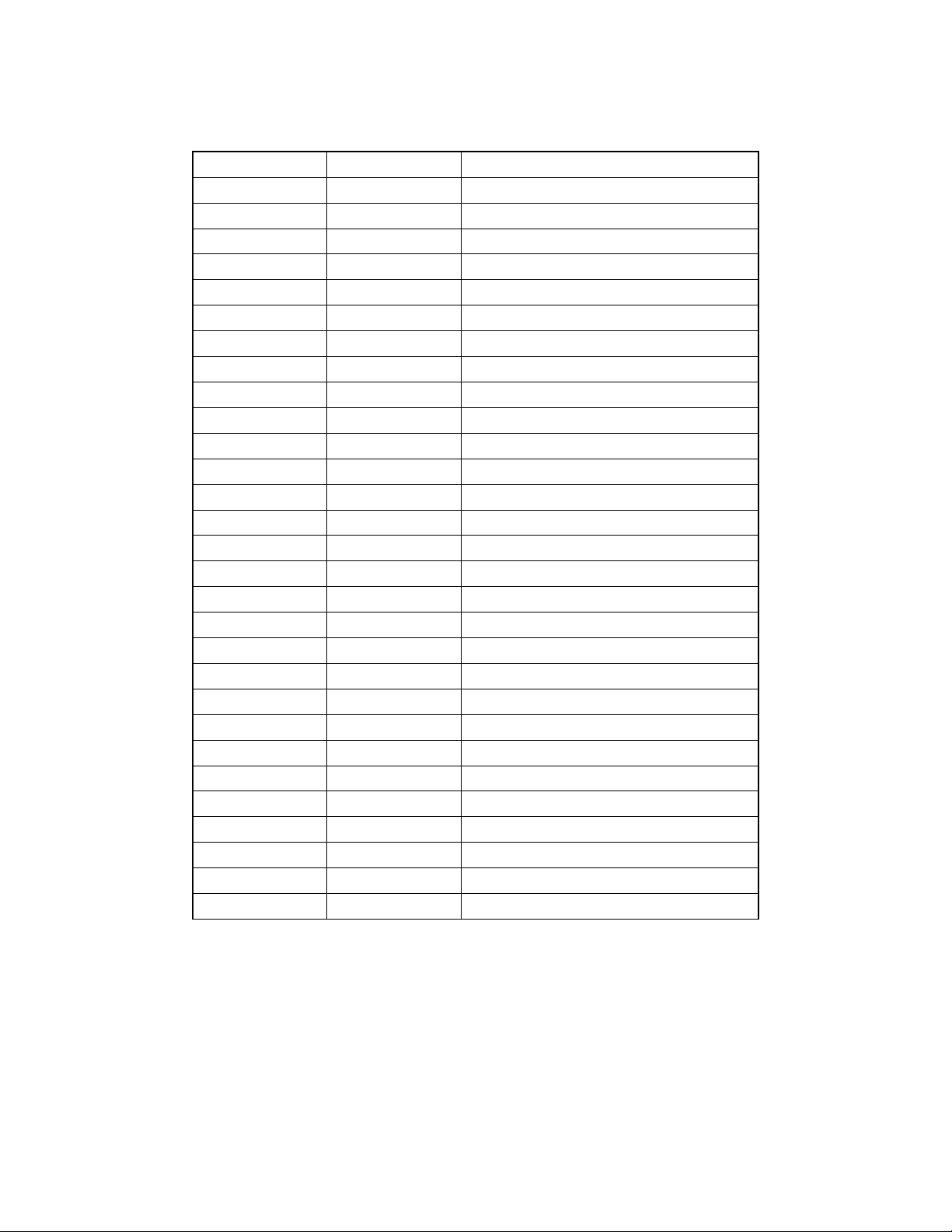

REVISION RECORD

Revision Date Description

A 11/21/02 Initial Document/Revision

B 03/06/03 Incorporate Product Updates

C 04/28/03 Incorporate Product Updates

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

i

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

TABLE OF CONTENTS

Section Title Page

1. INTRODUCTION .........................................................................................1-1

1.1 Document Overview.....................................................................................................1-1

1.2 Purpose of Equipment..................................................................................................1-1

1.3 Physical Description of Equipment.............................................................................1-1

1.4 Operational Overview..................................................................................................1-8

1.5 OCU Commanded Functions ......................................................................................1-8

1.6 LCU Control and Status Functions ............................................................................1-9

2. CONTROLS AND INDICATORS ..............................................................2-1

2.1 Operator Control Unit (OCU).....................................................................................2-1

2.2 Setup Control Unit (SCU)............................................................................................2-8

3. INTRODUCTION .........................................................................................3-1

3.1 Operator Interface Overview ......................................................................................3-1

3.2 Initial Conditions..........................................................................................................3-1

3.3 Preparing RCL Equipment for Service......................................................................3-1

3.3.1 Locomotive Set Up for RCL Operation....................................................................3-1

3.3.2 Operator Control Unit Setup.....................................................................................3-3

3.3.3 RCL Equipment Shutdown Procedure......................................................................3-3

3.4 System Linking and Testing........................................................................................3-3

3.4.1 Linking RCL Operation............................................................................................3-4

3.4.2 Emergency Valve Test..............................................................................................3-5

3.4.3 System Status Functions...........................................................................................3-6

3.4.4 System Operating States...........................................................................................3-7

3.4.4.1 Initialization (Power Up) State............................................................................3-7

3.4.4.2 Setup State...........................................................................................................3-7

3.4.4.3 Standby Mode .....................................................................................................3-7

3.4.4.4 Ready State..........................................................................................................3-7

3.4.4.5 Park State.............................................................................................................3-8

3.4.4.6 Safe State.............................................................................................................3-8

3.5 Control Functions.........................................................................................................3-9

3.5.1 Air Brake Functions..................................................................................................3-9

3.5.1.1 Automatic Brake .................................................................................................3-9

3.5.1.2 Charge .................................................................................................................3-9

3.5.1.3 Independent Brakes.............................................................................................3-10

3.5.1.4 Emergency Brakes...............................................................................................3-10

3.5.2 Air Brake Function Interlocks ..................................................................................3-11

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

ii

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

3.5.3 Electrical Functions ..................................................................................................3-12

3.5.3.1 Direction Control.................................................................................................3-12

3.5.3.2 Throttle Control...................................................................................................3-12

3.5.3.3 Speed Control......................................................................................................3-13

3.5.3.3.1 Throttle vs Excitation Speed Mode ...............................................................3-13

3.5.3.4 Headlight Control................................................................................................3-14

3.5.3.5 Horn / Bell Control..............................................................................................3-15

3.5.3.6 Sand Control........................................................................................................3-15

3.5.3.7 Electrical Function Interlocks .............................................................................3-15

3.6 Special Operating Features..........................................................................................3-16

3.6.1 Pitch and Catch.........................................................................................................3-16

3.6.2 Sleep Mode...............................................................................................................3-16

3.6.3 Yard Containment.....................................................................................................3-17

3.6.4 AEI Tag Reader........................................................................................................3-17

3.6.4.1 Yard Containment ...............................................................................................3-17

3.6.4.2 Speed Restrictions...............................................................................................3-18

3.6.4.3 Pullback Control..................................................................................................3-18

3.6.4.4 Bell and Horn ......................................................................................................3-19

3.6.5 GPS...........................................................................................................................3-19

3.6.6 Vigilance...................................................................................................................3-20

3.6.7 Fault Reporting.........................................................................................................3-20

3.6.8 Operator Down .........................................................................................................3-20

3.6.9 Communication Loss................................................................................................3-21

3.6.10 Battery Monitor.......................................................................................................3-21

3.7 Event Recorder.............................................................................................................3-22

LIST OF APPENDICES

Appendix Title Page

Appendix A System Faults ......................................................................................................A-1

LIST OF FIGURES

Figure Title Page

Figure 1.3-1 RCL Top Level Block Diagram............................................................................1-3

Figure 1.3-2 Operator Control Unit (OCU)...............................................................................1-4

Figure 1.3-3 Operator Vest ........................................................................................................1-4

Figure 1.3-4 Setup Control Unit (SCU).....................................................................................1-4

Figure 1.3-5 Headlight Control Module ....................................................................................1-5

Figure 1.3-6 Locomotive Control Unit (LCU) ..........................................................................1-5

Figure 1.3-7 Brake Control Unit................................................................................................1-5

Figure 1.3-8 AEI Tag Reader.....................................................................................................1-6

Figure 1.3-9 Radio Module/Router............................................................................................1-6

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

iii

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

Figure 1.3-10 Axle Generator....................................................................................................1-6

Figure 1.3-11 Traction Current Module.....................................................................................1-7

Figure 1.3-12 Air Sensor Module..............................................................................................1-7

Figure 1.3-13 Emergency Stop Button ......................................................................................1-7

Figure 2.1-1 Operator Control Unit – Actuators........................................................................2-1

Table 2.1-1 Operator Inputs.......................................................................................................2-2

Figure 2.1-2 Operator Control Unit - Indicators........................................................................2-6

Figure 2.2-1 Setup Control Unit (SCU).....................................................................................2-8

Figure 3.6.3-1 Yard Containment............................................................................................3-17

Figure 3.6.4.3-1 Pullback Control............................................................................................3-19

LIST OF TABLES

Table Title Page

Table 1.3-1 Remote Control Locomotive Components.............................................................1-2

Table 1.5-1 OCU Command Functions.....................................................................................1-8

Table 1.6-1 LCU Controlled Functions.....................................................................................1-9

Table 1.6-2 LCU Monitored Functions .....................................................................................1-9

Table 2.1-2 OCU Outputs/Indicators.........................................................................................2-6

Table 2.2-1 SCU Inputs .............................................................................................................2-9

Table 2.2-2 SCU Outputs...........................................................................................................2-9

Table 3.3.1-1 Locomotive Setup................................................................................................3-2

Table 3.3.2-1 OCU Switch Setup ..............................................................................................3-3

Table 3.4.3-1 Status Functions...................................................................................................3-6

Table 3.5.1.3-1 LBA Brake Cylinder Pressure........................................................................3-10

Table 3.5.3.3.1-1 MMA Actuator (Flat Yard) .........................................................................3-13

Table 3.5.3.3-2 MMA Actuator (Hump Yard) ........................................................................3-13

Table 3.5.3.4-1 Headlight Control...........................................................................................3-14

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

iv

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

1. INTRODUCTION

1.1 Document Overview

The following outlines the content of Remote Control Locomotive (RCL) Operations

Manual:

• Introduction – Describes the purpose and physical description (Chapter 1).

• Controls and Indicators – Lists and describes the controls and indicators (Chapter 2).

• Operation – Provides guidelines for operation as well as information on the various

modes used (Chapter 3).

• System Faults – Lists the system faults and actions (Appendix A)

This manual refers to the operator as the user of the RCL system; however, the term

operator and you are used interchangeably when outlining procedures or instructions.

1.2 Purpose of Equipment

The Remote Control Locomotive (RCL) system provides railroad yard crews the ability to

control one locomotive at a time through an Operator Control Unit (OCU) for switching

and general yard operations. The locomotive under control can be used in Multiple Unit

(MU) locomotive consists. The system provides control of the locomotive by command

signals transmitted over a radio link from the OCU. Operationally, several trains equipped

with the RCL system can operate on the same radio frequency and within radio range of

one another. Additionally, the RCL system allows two OCUs to operate the train in a pitch

and catch method where only one OCU is in control of the train. The RCL system consists

of the portable OCU and a Locomotive Control Unit (LCU) located on the locomotive and

other support components. The support components are such items as an operator vest for

the OCU, an electronic fence for hump yard operations, and various safety and operational

attachments to the locomotive.

1.3 Physical Description of Equipment

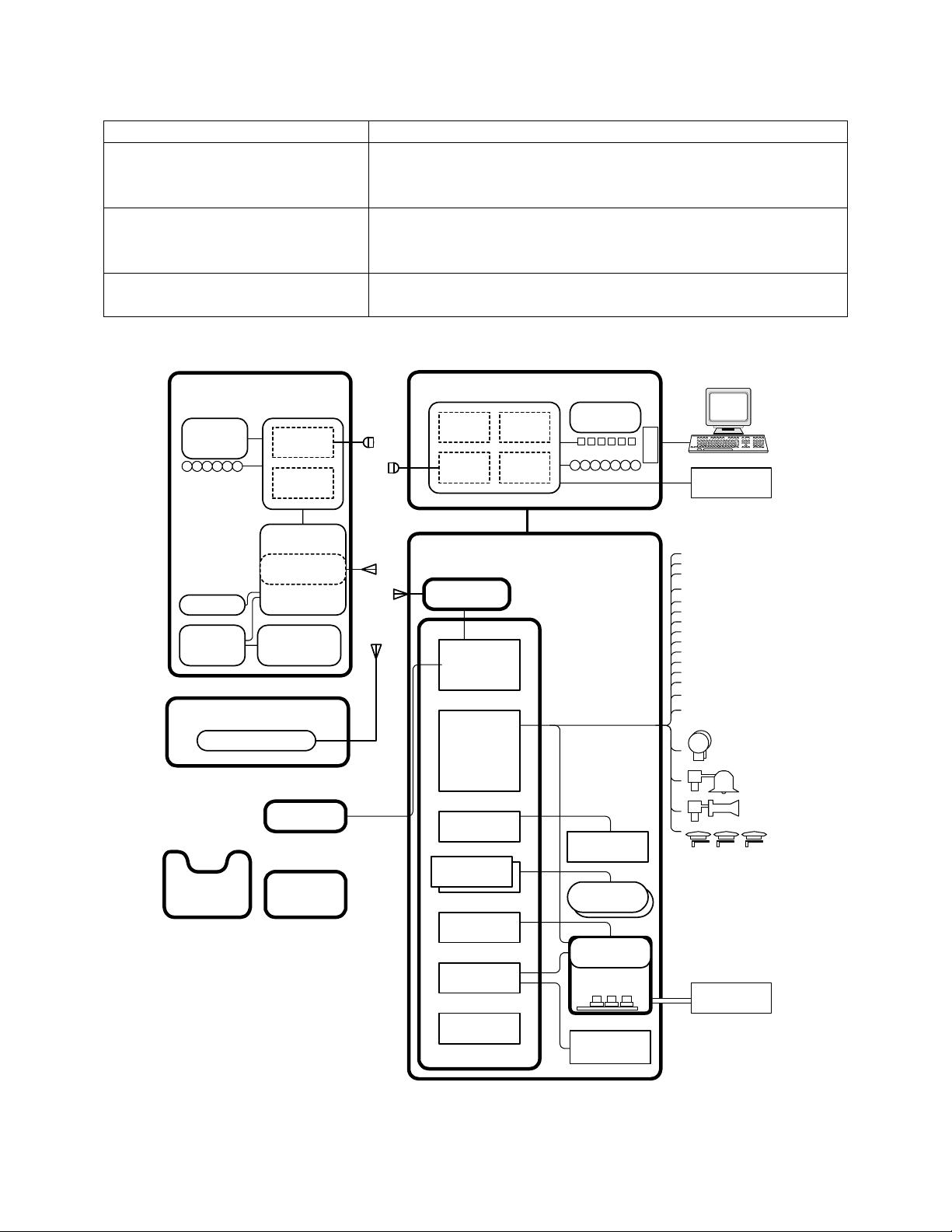

The RCL system consists of On-board locomotive equipment and Off-board Operator

equipment. The Off-board equipment functions as the commanding unit and the On-board

equipment functions as the locomotive controlling unit (Figure 1.3-1).

The locomotive equipment is mechanically designed to withstand, the shock and vibration

encountered in locomotive operation. The system is sealed against dust, locomotive gasses

and oily fumes; however, it is not weatherproofed and must be sheltered from the elements.

The Operator Control Unit (OCU) is designed to meet NEMA 4 standards and to withstand

the rigors encountered in the railroad environment, however, the OCU is not waterproof

and must be sheltered from the elements.

Copyright 2002, 2003 GE Transportation Systems

Global Signaling, LLC

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

- All rights reserved

1-1

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

The major components of the RCL system are briefly described in the following table.

Table 1.3-1 Remote Control Locomotive Components

Component Description

Component Description

Operator Control Unit (OCU) Contains the switches and controls necessary to control the

RCL locomotive as well as the alarms and fault reporting

messages (see Figure 1.3-2).

Operator Vest Contains the D ring clips for attaching and securing the OCU

during RCL operation (see Figure 1.3-3).

Setup Control Unit (SCU) Contains the equipment on the RCL to allow for operator set-

up, system status display, and provides RCL system

interfaces to on and off train equipment (see Figure 1.3-4).

Voice Radio Contains a standard 35-watt Spectra locomotive radio. This

radio provides the capability for the SCU to send alerts and

status over the railroad voice radio network (customer

provided).

Headlight Control Module Contains the electronics used for controlling the Long and

short hood headlights. These control both Bright and Dim

operation (see Figure 1.3-5)

Locomotive Control Unit (LCU) Contains the electronics, which perform the functions

necessary to control the overall system operations. In

addition, it provides electrical isolation between the system’s

module circuitry and the locomotive’s train line signals (see

Figure 1.3-6).

Brake Control Unit (BCU) Contains the electronic and pneumatic devices to control the

locomotive Automatic, Emergency, and Independent brakes

(see Figure 1.3-7).

AEI Tag Reader Contains the necessary tag reader electronics for detecting

track bed mounted AAR/ISO AEI tags. These tags will be

placed at the defined boundaries of operation such as yard

containment or pullback, as well as at high traffic areas, such

as grade crossings within the boundaries (see Figure 1.3-8).

Radio Module Contains the low power radios. This radio provides the closed

loop radio based communications between the OCU and the

LCU (see Figure 1.3-9).

Axle Generator Contains the electronics to detect locomotive wheel rotation

rate and convert it to speed and direction signals (see Figure

1.3-10).

Traction Motor Current Module Contains the electronics necessary to interface to the

Locomotive traction motor shunt (see Figure 1.3-11).

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

1-2

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

Component Description

Air Sensor Module (ASM) Contains the electronic and pneumatic devices used to detect

Brake Pipe airflow, Truck Brake Cylinder cut in, and Horn

activation (see Figure 1.3-12).

GPS Contains necessary equipment for Global Positioning

Satellite (GPS) location determination to supplement AEI

Tag Reader System.

Emergency Stop Buttons Two exterior and one interior mounted red mushroom

emergency stop buttons for RCL. (see Figure 1.3-13)

O

p

r

a

e

Display

LEDS

Speed

Speed Enable

Loco Brake

Loco Brake Enable

Direction

Train Brake

Pitch/Catch

Tilt Ovr-ride

Headlight

On/Off/Mode

Tilt

Power

Mngmt

RF Router (if needed)

ISM Band Radio

R

O

P

E

A

O

T

E

V

T

S

t

o

r

R

o

C

n

t

o

r

Interface

Actuator

Conditioning

Processor

ISM Band

Radio

Battery

AEI Tag

Reader

A

B

C

H

l

IRDA

T

A

RCL PTU

P

T

U

Event Downloader

Voice

n

U

t

i

Voice

Synth

IRDA

Interface

S

t

e

-

u

p

o

n

C

t

r

o

l

U

n

t

i

GPS

Receiver

Status

Control

Display

Buttons

LEDS

Radio

L

o

c

o

m

o

t

v

i

o

C

e

ISM Band

Radio

Processor

I/O

+

Drivers

I/O

Speed (2)

R

E

T

Y

R

E

G

R

Speed

Air Brake

I/O

n

t

r

o

U

l

n

t

i

Excitation

Amp

Axle

Generators

Brake

Control

Pneu.

Headlight F Brt

Headlight Dim

Headl i g h t R Brt

Alarm

A Valve

B Valve

C Valve

D Valve

Forward

Reverse

Gen Field

Manual Sand

Slow Speed Enable

Wheel Slip

PCS

Light

Pneu

Bell

Horn

Emr Stop

26-L

Power

Traction

Current

Figure 1.3-1 RCL Top Level Block Diagram

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

1-3

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

Figure 1.3-2 Operator Control Unit (OCU)

Figure 1.3-3 Operator Vest

Figure 1.3-4 Setup Control Unit (SCU)

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

1-4

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

Figure 1.3-5 Headlight Control Module

Figure 1.3-6 Locomotive Control Unit (LCU)

Figure 1.3-7 Brake Control Unit (BCU)

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

1-5

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

Figure 1.3-8 AEI Tag Reader

Figure 1.3-9 Radio Module/Router

Figure 1.3-10 Axle Generator

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

1-6

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

Figure 1.3-11 Traction Current Module

Figure 1.3-12 Air Sensor Module

Figure 1.3-13 Emergency Stop Button

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

1-7

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

1.4 Operational Overview

In conventional railroad yard switching operations without an RCL system, all car and

locomotive movements require an operator on board the locomotive as well as personnel on

the ground to direct movements and set switches.

The RCL system provides the yard crews with the ability to control the locomotive from a

portable/handheld unit, thereby eliminating the need for an operator on board the

locomotive. The yard crew can then set switches and directly control the locomotive/train

movements from the ground. Additionally, the RCL system allows one operator to transfer

control to another operator in a pitch and catch method when control of the train is needed

from another position in the yard.

The yard crew uses the portable OCU to command locomotive movement. The OCU also

provides the operator the ability to control the direction, speed, and braking of the

locomotive/train. Additionally, the OCU provides the capability to control the headlights,

manual sand, bell, and horn. The OCU provides fault and alarm status data from the

locomotive.

The LCU on board the locomotive receives the commands from the OCU and activates the

appropriate control functions. Control relays or solenoid valves control each function on the

locomotive. Sensor circuits monitor the status of the controlled functions to ensure that the

control function has been properly activated. If the status does not match the commanded

function, a miscompare alarm is generated and appropriate action is taken to ensure the

locomotive is in a safe and appropriate state.

If communications are lost between the OCU and LCU for greater than 5 seconds the LCU

will go to the Park state where the locomotive is idled and a full service automatic and

independent brake application is made. The system remains linked and if communications

are restored the Park State can be recovered and normal operations resumed. If

communications is lost for longer than the comm. loss unlink time as set in the

Configuration File, the LCU will go to the Safe State where the emergency brakes are

applied, the locomotive is set to idle, and the system is unlinked.

1.5 OCU Commanded Functions

The OCU detects the operator inputs and transmits these commands to the LCU. The LCU

then activates the appropriate control signals to carry out the commanded control function.

Table 1.5-1 lists the normal command functions transmitted to the LCU.

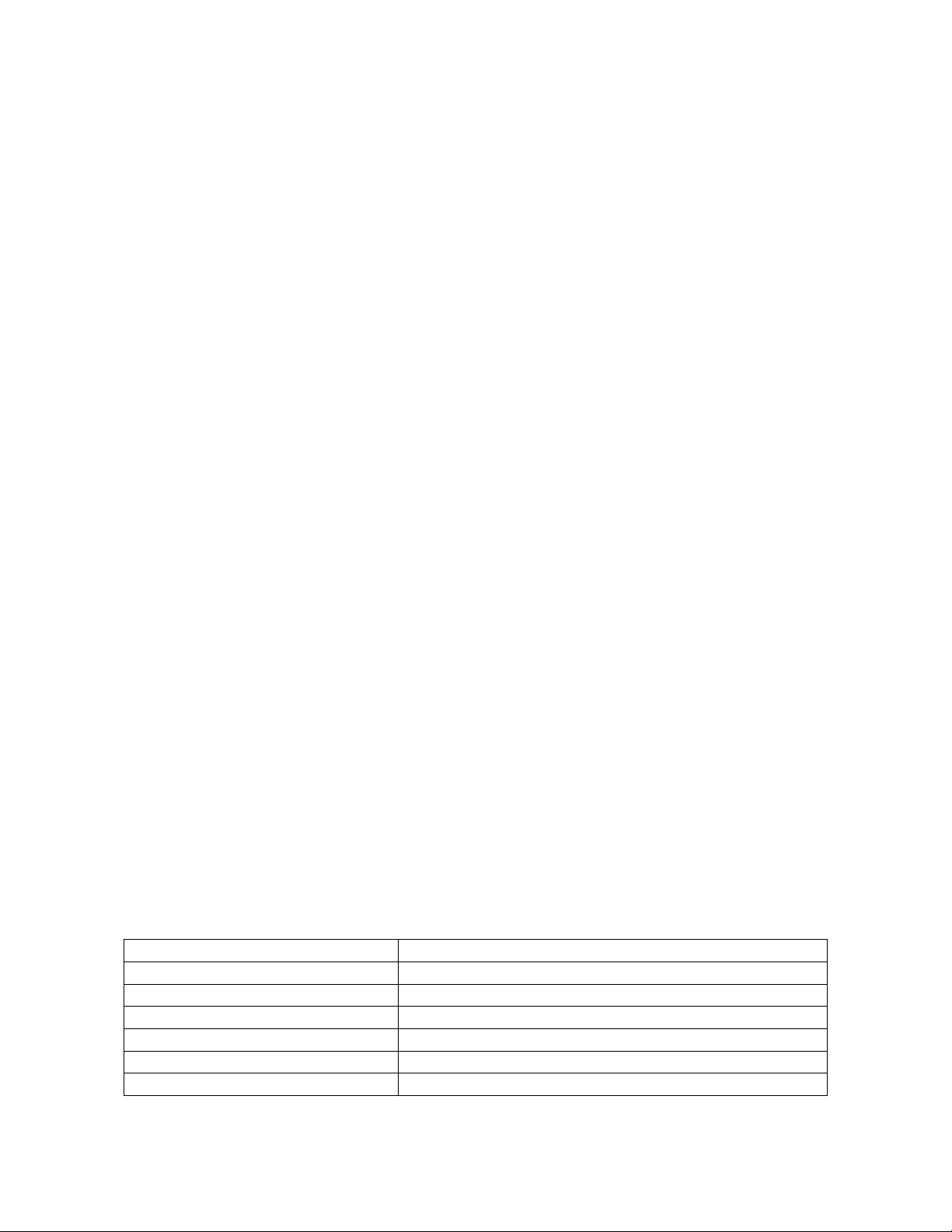

Table 1.5-1 OCU Command Functions

Electrical Functions Pneumatic Functions

Electrical Functions Pneumatic Functions

Direction Automatic Brake Applications and Releases

Set Speed Independent Brake Applications and Releases

Bell Emergency Brake Applications and Releases

Horn

Sand

Headlight

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

1-8

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

1.6 LCU Control and Status Functions

When the LCU receives commands from the OCU, it activates the appropriate locomotive

control lines needed to perform the commanded control function. Locomotive status lines

are monitored to ensure that the proper functions have been activated and to provide

feedback for function control loops. Table 1.6-1 and Table 1.6-2 lists the normal LCU

controlled and monitored functions.

Table 1.6-1 LCU Controlled Functions

Electrical Functions Pneumatic Functions

Electrical Functions Pneumatic Functions

Direction: (FO, RE) Equalizing Reservoir (DEC, FST, SLO)

Throttles: (AV, BV, CV, DV) Independent Brake: (IBA, IBR)

Generator Field: (GF) Bail (ABL)

Manual Sand Emergency: (EBA)

Slow Speed Enable Backup Emergency: (BUEMV)

GF Excitation Control (Analog Control) Emergency Reset: (EBR)

Head Light Control Horn

Strobe Lights (if equipped) Bell

Vigilance Disable (if equipped)

Table 1.6-2 LCU Monitored Functions

Electrical Functions Pneumatic Functions

Electrical Functions Pneumatic Functions

Emergency Stop Buttons ER Pressure, BC Pressure, MR Pressure

Rear Headlight Switch Position BP Pressure

Wheel Slip Front and Rear Truck BC Pressure > 25 psi

PC Switch Bell

Traction Motor Current Horn

Axle Generator #1 Speed Feed (Brake)Valve (FV)

Axle Generator #1 Direction Penalty Pipe

Axle Generator #1 Speed Switch Pipe

Axle Generator #1 Direction BP Flow

Locomotive Alarm

Manual Sand

Governor Shutdown

Hot Engine

Ground Fault

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

1-9

Document No. 5002866 Rev. C (DRAFT)

LR

SS RS RR

RI

28 April 2003

2. CONTROLS AND INDICATORS

This Chapter provides the operator with a comprehensive background for operation of all

controls and an understanding of the monitoring indications. Each control and indicator

located anywhere on the system is listed and described in one of the tables provided.

Refer to Figure 2.1-1 and 2.1-2, OCU layout, when reading Table 2.1-1 and Table 2.1-2;

Figure 2.2-1, SCU Assembly, when reading Table 2.2-1 and 2.2-2; and Figure 2.3-1 and

2.3-2, LCU Assembly, when reading Table 2.3-2.

No attempt is made to describe any circuitry in detail. Only functional descriptions are

provided. For detailed circuit descriptions, see the Service Manual.

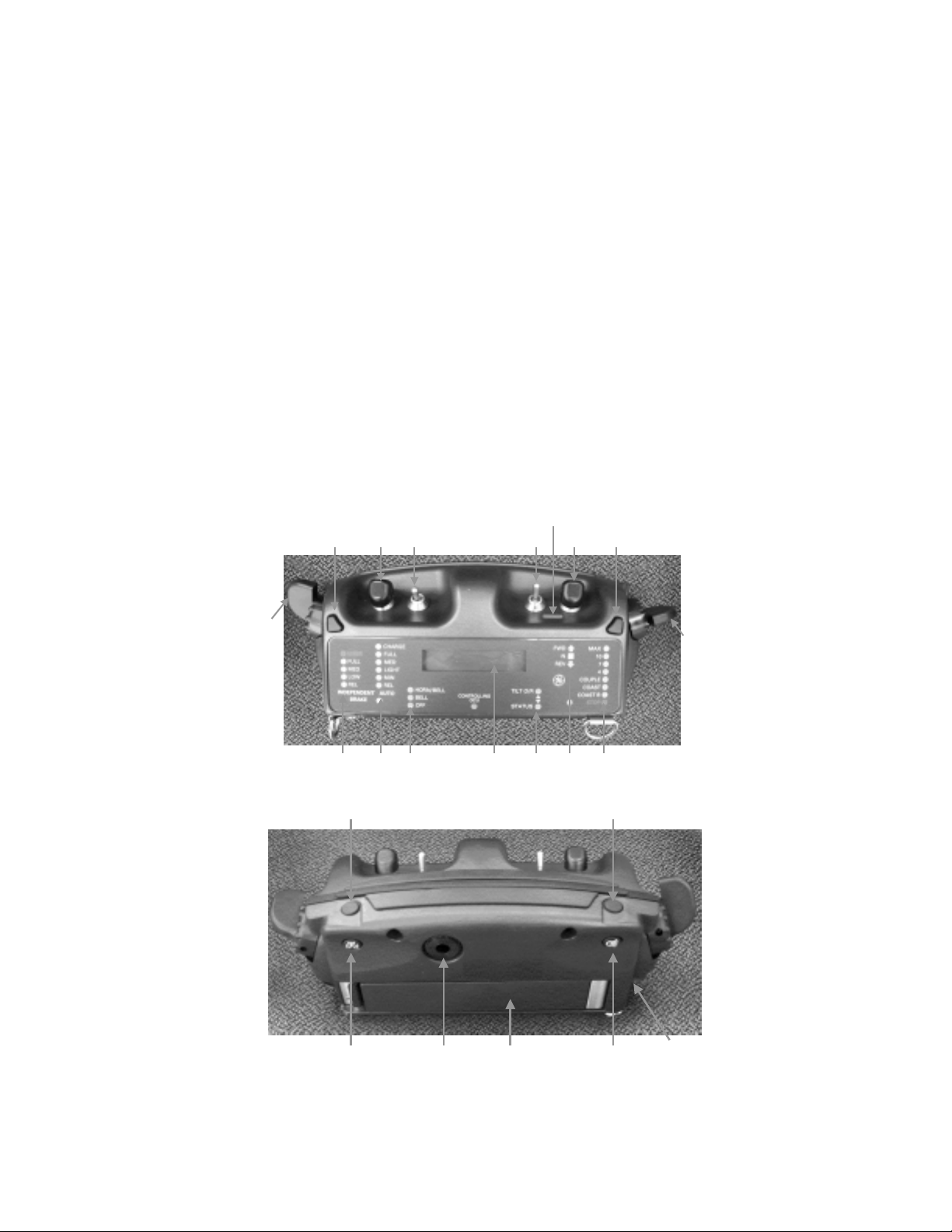

2.1 Operator Control Unit (OCU)

The OCU contains controls, a display, a speaker and an Infra-Red Port (see Figure 2.1-1).

Table 2.1-1 lists and describes the Operator controls. Table 2.1-2 lists and describes the

OCU outputs. Commanded functions are indicated on the OCU display by a flashing LEDs

and the actual locomotive status is indicated by a solid LEDs. When the actual locomotive

status matches the commanded value the status LED is solid.

ABS

BHS

IR Port

TOR

IBS

ABI

IBI

BHI

Display

SI/TOI

SSI

Future use

(spare)

Future use

(spare)

PCC/LNK

BatterySonalert MHL

PWR

Figure 2.1-1 Operator Control Unit – Actuators

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

2-1

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

Table 2.1-1 Operator Inputs

Function Description

Function Description

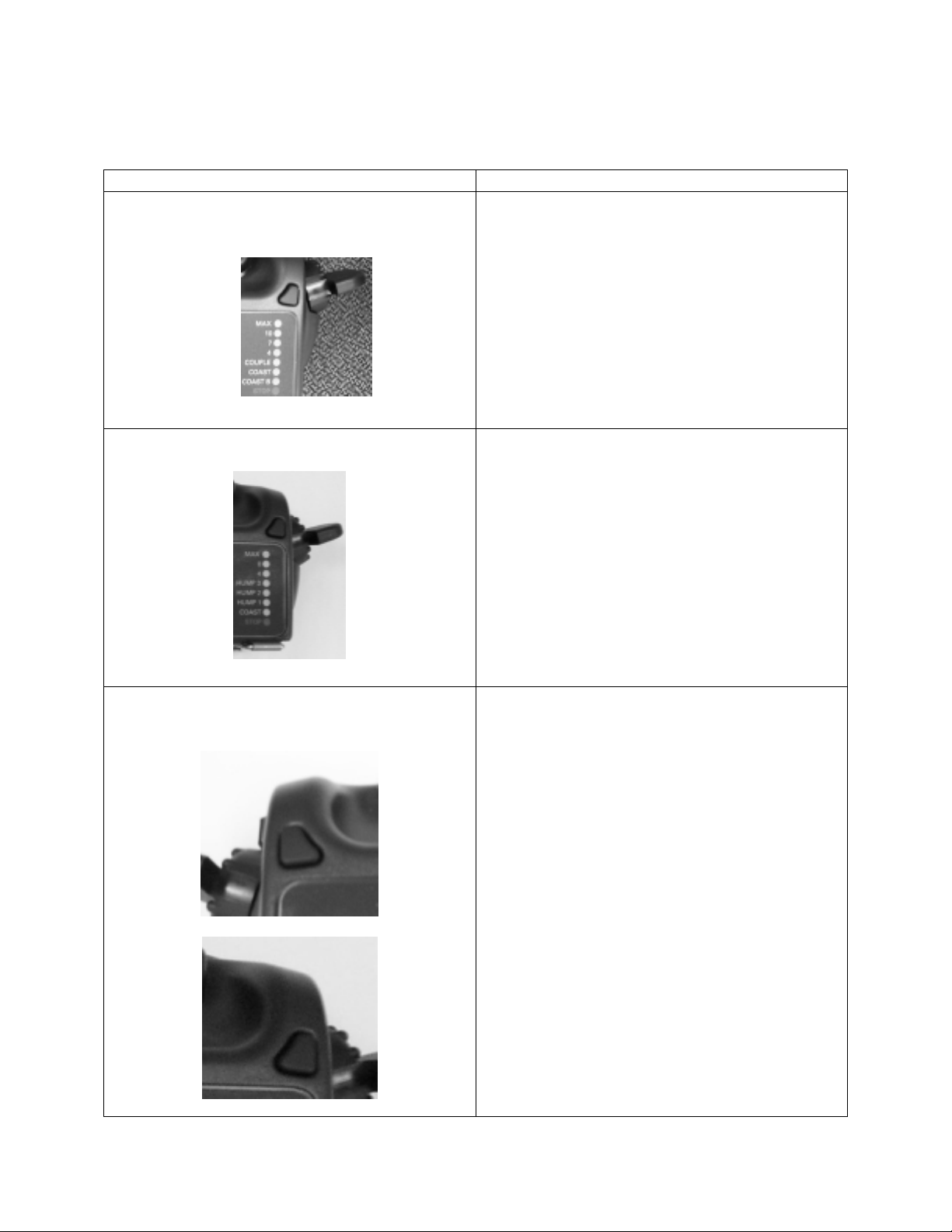

Speed Selector (SS) (Flat Yard OCU) The Speed Selector provides eight positions

that result in the OCU transmitting speed and

stop commands. Movement of the Speed

Selector also provides a signal to reset the

vigilance timer.

Speed Selector (SS) (Hump Yard OCU)

The Speed Selector provides eight positions

that result in the OCU transmitting speed and

stop commands. Movement of the Speed

Selector also provides a signal to reset the

vigilance timer.

Left Reset (LR)

Right Reset (RR)

These switches need to be pressed first to

allow the following OCU actions within 3

seconds:

• SS out of stop

• ABS from full to charge

Also these buttons:

• Command Manual sanding if pressed for

more than 5 seconds:

• Resets OCU vigilance.

• Approves linking of secondary OCU

• Commands sleep mode option

• LR:

i) unfreezes locomotive status screen

ii) lowers OCU LED brightness

• RR:

i) freezes locomotive status screen

ii) increases OCU LED brightness

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

2-2

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

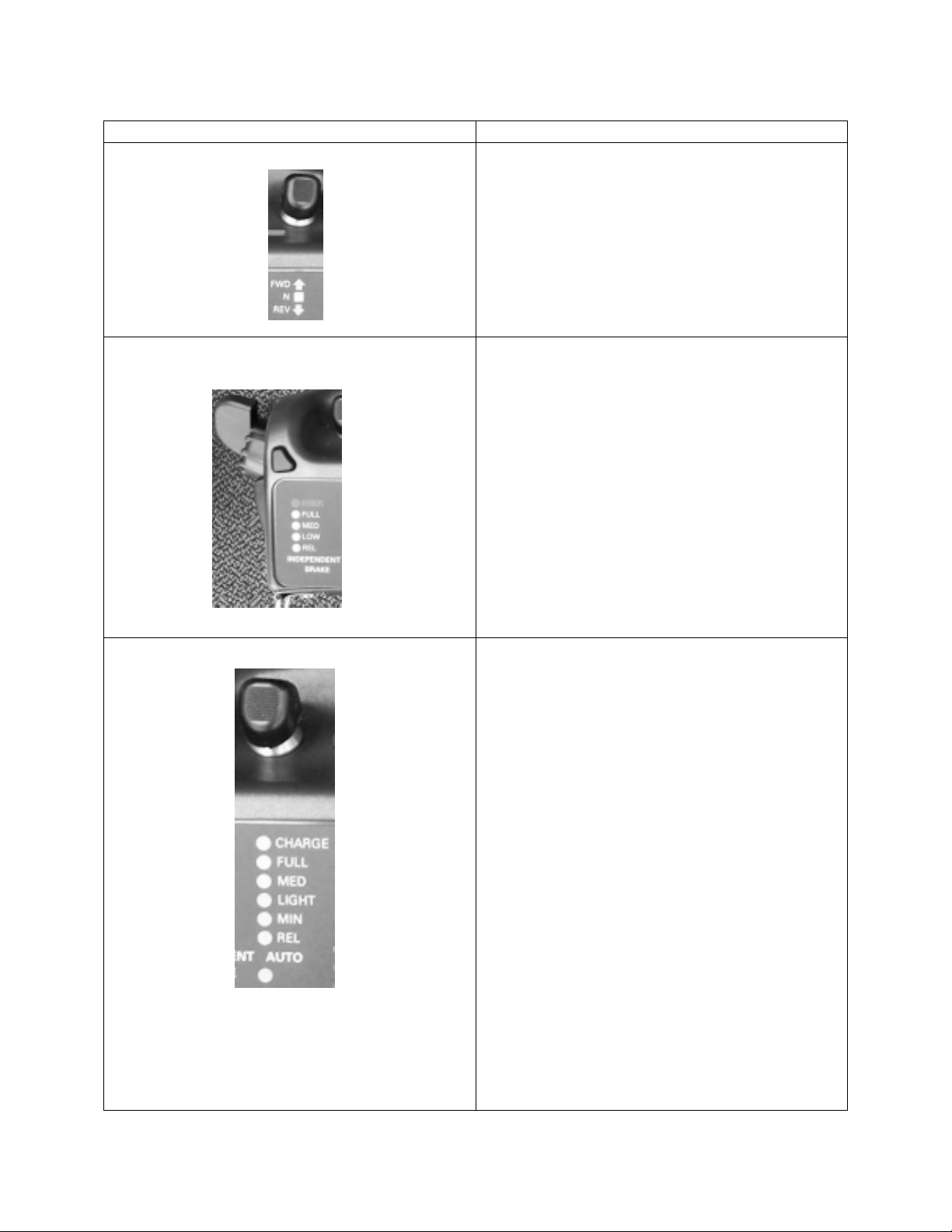

Function Description

Reverser Selector (RS)

The RS is a three-position toggle switch:

(a) FWD Position: Activates Locomotive

Forward trainline (TL8)

(b) N Position: Neutral, no direction

commanded

(c) Rev Position: Activates Locomotive

Reverse trainline (TL9)

Independent Brake Selector (IBS)

The IBS provides five positions that result in

the OCU transmitting the following

independent brake commands:

(a) emergency

(b) full

(c) medium

(d) low

(e) released

Actuation of the IBS also provides a signal to

reset the vigilance timer.

Automatic Brake Selector (ABS)

The ABS is a three-position toggle switch. The

Center position is a no change position. The

ABS toggle position away from operator’s

body is a momentary position that results in the

OCU transmitting a command to the next

sequential brake application in the following

sequence:

(a) Release

(b) Minimum (7 psi reduction)

(c) Light (15 psi reduction)

(d) Medium (20 psi reduction)

(e) Full (26 psi reduction)

(f) Charge

The ABS toggle position toward operator’s

body for at least 2 seconds results in the OCU

transmitting a direct release command.

ABS also resets OCU vigilance.

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

2-3

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

Function Description

Bell and Horn Selector (BHS)

The BHS is a three-position toggle switch. The

BHS toggle position toward the operator is bell

and horn off. The BHS switch center position

results in locomotive bell on with horn off. The

BHS toggle position away from the operator is

a momentary position and results in a bell and

horn on.

BHS also resets the vigilance timer.

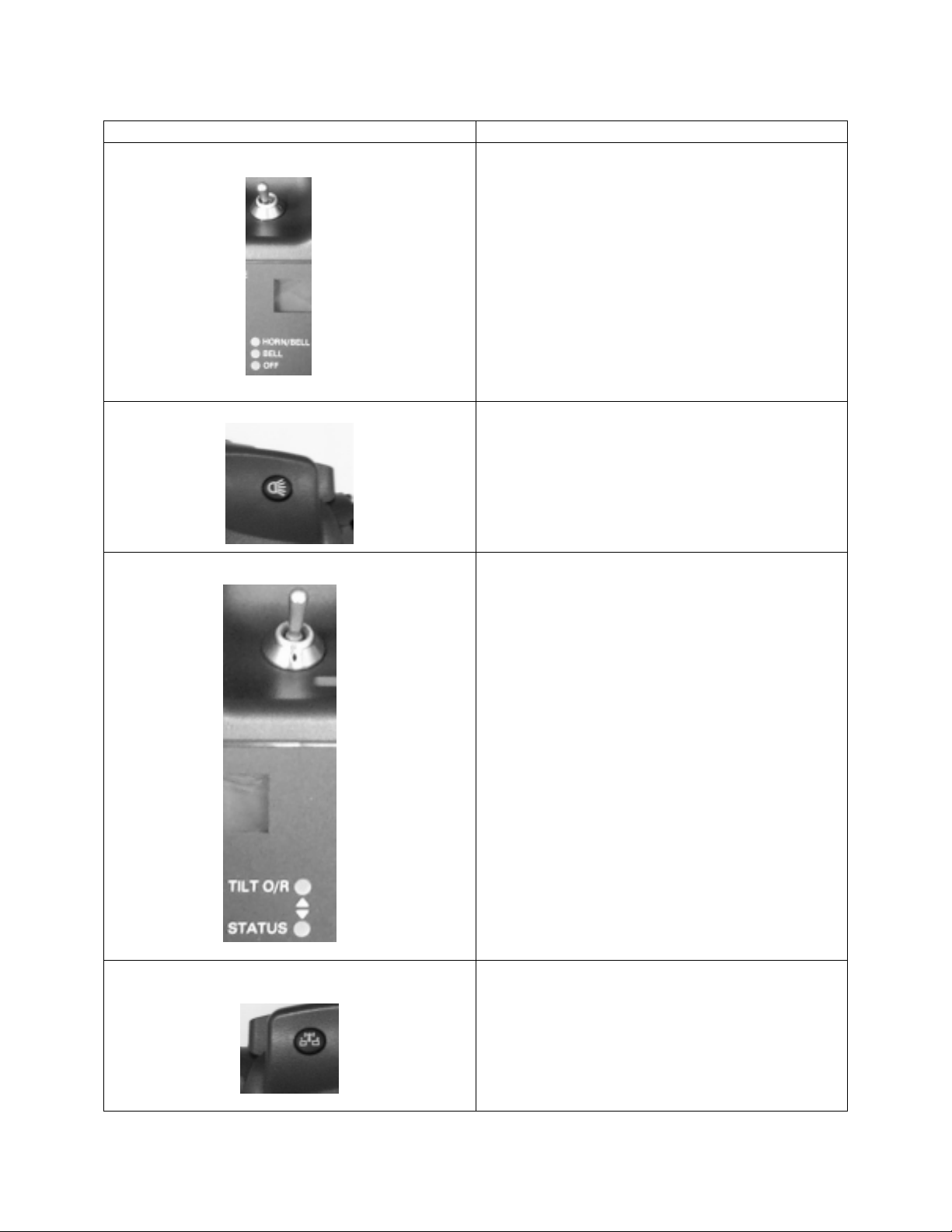

Manual Headlight (MHL)

The MHL is a push button that results in the

OCU transmitting a headlight command to

control the brightness level (Off, Dim, or

Bright) of the Locomotive consist’s front and

rear headlights. MHL resets the vigilance

timer.

Tilt Over-ride / Tilt Test Over-ride / Status

(TOR)

The TOR is a three-position toggle switch.

TOR toggle in the center position shall be in

the neutral position.

TOR toggle position toward the operator is a

momentary position and adjusts the OCU

display for status. Toggling the switch Multiple

times steps the Status display through the

following status displays:

• Loco Status

• OCU Status

• Link Status

TOR toggle position away from operator is a

momentary position for tilt timer extend and

tilt test. The Tilt Override feature will be

activated for up to 60 seconds when the switch

is toggled to this position. Changing any OCU

control will cancel the tilt override timer.

TOR also resets the vigilance timer.

Pitch Catch Control / Link (PCC/LNK)

The PCC/LNK is a momentary switch that:

• Starts OCU linking via infrared port to SCU

• Pitch and catch operation to move locomotive

control to a secondary OCU

• Resets OCU vigilance.

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

2-4

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

Function Description

Power (PWR)

The PWR is a push button switch that performs

a soft power on/off of the OCU and must be

held for 5 seconds to power off the OCU.

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

2-5

Document No. 5002866 Rev. C (DRAFT)

LR

SS RS RR

RI

28 April 2003

ABS

BHS

IR Port

TOR

IBS

ABI

IBI

BHI

Display

SI/TOI

SSI

Figure 2.1-2 Operator Control Unit - Indicators

Table 2.1-2 OCU Outputs/Indicators

Function Description

Display The display is used to report system events and

status and fault and alarm data. Toggling the

TOR actuator to the Status position selects the

following system status:

1. Loco Status

2. OCU Status

3. Link Status

Independent Brake Indicator (IBI)

The IBI is the status indicator for the

Independent Brake Selector (IBS). It indicates

the actual independent brake level (illuminated

indicator) and the commanded independent

brake level (flashing indicator) for the LCU.

The following braking levels are indicated:

(a) EMER

(b) FULL

(c) MED

(d) LOW

(e) REL

Automatic Brake Indicator (ABI)

The ABI is the status indicator for the

Automatic Brake Selector (ABS). It indicates

the actual automatic brake level (illuminated

indicator) and the commanded automatic brake

level (flashing indicator) for the LCU. The

following braking levels are indicated:

(a) CHARGE

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

2-6

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

Function Description

(b) FULL

(c) MED

(d) LIGHT

(e) MIN

(f) REL

Bell and Horn Indicator (BHI) The BHI is the status indicator for the Bell and

Horn Selector (BHS). It indicates the

commanded Bell and Horn settings for the

LCU. The following settings are indicated:

(a) HORN-BELL

(b) BELL

(c) OFF

Controlling OCU (CO) The CO is the status indicator for the

Controlling OCU. When this LED is

illuminated, this OCU is in control of the RCL

locomotive (primary).

Status Indicator (SI) The SI is the status indicator for the Display

status. When this indicator is illuminated, the

OCU Display is displaying status information.

Reverser Indicator (RI)

The RI is the status indicator for the Reverser

Selector (RS). It indicates the actuator position

and the commanded direction for the LCU. The

following settings are indicated:

(a) FWD

(b) N

(c) REV

Speed Selector Indicator (SSI)

The SSI is the status indicator for the Speed

Selector (SS). It indicates the actual LCU

speed (illuminated indicator) and the

commanded locomotive Speed level (flashing

indicator) for the LCU. The following braking

levels are:

(a) MAX

(b) 10

(c) 7

(d) 4

(e) COUPLE

(f) COAST

(g) COAST (B)

(h) STOP

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

2-7

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

Function Description

Tilt Over-ride / Tilt Test Indicator (TOI) The TOI is the status indicator for the Tilt

Over-ride/Tilt Test Switch (TOR). The

indicator is illuminated when TOR is pressed

and flashes to indicates that the tilt by-pass or

tilt test functions are enabled.

Ambient Light Detector (ALD) The OCU provides a photo detector to

determine ambient lighting conditions and, if

selected, automatically adjust the OCU display

illumination for day/night operation.

Audible Output The audible device is a dual tone output used

for normal annunciations (low level, chirping

tone) and emergency warnings (high level,

continuous tone).

Infra-Red Port The IR port is an Infra-red interface transceiver

used for OCU to SCU linking. The IR port is

also used for upgrading the OCU software.

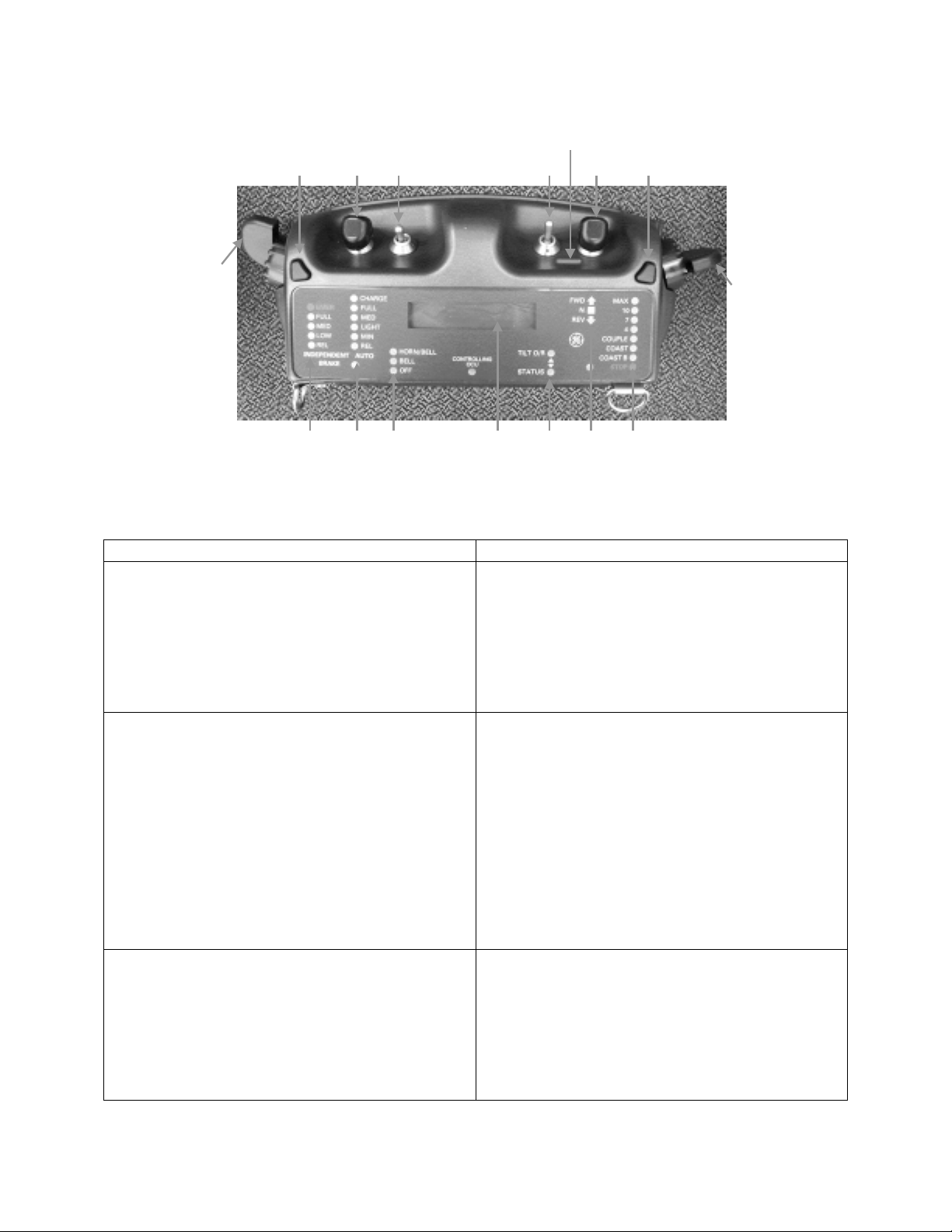

2.2 Setup Control Unit (SCU)

The SCU is part of the RCL On board equipment and provides the human interfaces

required on the locomotive. It contains a keypad, circuit breaker, status LEDs, Synthesizer,

PTU interface port, Infra-Red Port and other electronic devices to allow for operator set-up,

system status display, (see Figure 2.2-1). Table 2.2-1 lists and describes the Operator input

switches and actuators. Table 2.2-2 lists and describes the SCU outputs and Indicators.

Figure 2.2-1 Setup Control Unit (SCU)

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

2-8

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

Table 2.2-1 SCU Inputs

Function Description

Relay Circuit Breaker The Relay Circuit Breaker provides power to

the LCU locomotive control relays

Keypad The Keypad is a sixteen (16) button keypad for

control of the status display and entry of

information. The keypad is disabled when the

LCU is linked to the OCU.

GPS Input The GPS input provides a connection for the

GPS antenna.

Table 2.2-2 SCU Outputs

Function Description

Display The display is a 2 line, 16 character display. It

is used to report system status and diagnostic

data.

Infra-Red Port The IR port is used for OCU to LCU linking,

and data transfer.

Status LEDs Status LEDs are provided for the following

items

(a) SCU power (green)

(b) Trainline relay Power (green)

(c) Event Recorder Continuous Self-Test

(green)

(d) OCU #1 linked (green)

(e) OCU #2 linked (green)

(f) Primary OCU Comm Loss (red)

(g) System Failure (red)

(h) Spare

PTU Port The PTU port provides the serial channel

interface to a Laptop computer and is used for

downloading Event Recorder data.

Voice Radio The radio connection provides an interface to

the voice radio.

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

2-9

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

3. INTRODUCTION

This chapter provides recommended guidelines for operating the RCL system and includes

additional information to assist the operator in understanding the various modes of

operation.

The procedures are written to assist the railroad in establishing safe operating procedures

for the RCL System; however, they are not intended to replace standard locomotive

operating procedures or approved railroad practices. Standard railroad operating procedures

should take precedence.

A periodic checkout of the RCL system is recommended. This checkout should include a

complete test of all system functions as well as checks of the radios. For detailed circuit

descriptions, see the Service Manual.

3.1 Operator Interface Overview

The Operator Control Unit (OCU) is the primary operator interface. The OCU operation

begins at RCL system linking and progresses through the required tests until the operator

has complete control of the RCL locomotive.

3.2 Initial Conditions

The following conditions are required prior to RCL start-up and operation:

1. The RCL System is installed and operating properly.

2. The operator is completely familiar with locomotive operating procedures and

established railroad practices and is duly authorized by the railroad to operate an RCL

equipped train.

3. All RCL power switches and circuit breakers in the RCL locomotive are in the OFF

position.

Note – If the locomotive is in Manual Mode all the RCL switches and circuit breakers will

be on.

4. The operator puts fresh batteries in the OCU and verifies battery charge.

5. The operator puts on the operator vest and adjusts for comfort.

3.3 Preparing RCL Equipment for Service

Preparation of the RCL equipment is done in steps as indicated in the following sections.

Note – Locomotive Independent brakes (cabstand) should not be released until after the

RCL system is setup.

3.3.1 Locomotive Set Up for RCL Operation

Set the following switches on the RCL locomotive to the positions indicated.

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

3-1

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

Table 3.3.1-1 Locomotive Setup

Switch Position

Control and Fuel Pump Switch ON

Dynamic Brake Circuit Breaker (if equipped) OFF

Reverser NEUTRAL (Handle Removed)

Unit Isolation Switch RUN

Automatic Brake Valve RELEASE

Brake Valve Cut-out FREIGHT or IN

MU2A LEAD

Independent Brake Handle RELEASE

Engine Run Switch ON

Generator Field Switch OFF

Cab Stand Headlight Switch OFF

Remote Headlight Select Switch Set for Normal MU Operation

Note – All units which form the part of the RCL consist must be coupled to the RCL

equipped unit in the conventional trailing unit mode.

Set the RCL System switches to the position indicated:

1. RCL Manual/RemoteValve –Remote position

Note –When RCL Manual/Remote valve is placed in the Remote position, the locomotive

will go to emergency.

2. RCL main Circuit Breaker -ON

3. SCU Relay Circuit Breaker -ON

After system initialization the RCL SCU unit turns on the following LED status indicators:

LCU/SCU Power (green), Train line Relay Power (green), and Event Recorder Continuous

Self-Test (green). The SCU displays “Low MR” until the Main Reservoir pressure is

greater than 80 psi. The SCU then displays the “Setup Emergency” message.

After system initialization the RCL LCU unit enters the Setup State where it will wait for

link commands from the OCU. While in the Setup State the LCU will be in the Safe mode

in which the emergency brakes are applied, the Independent Brakes are set to full, and the

Throttle is set to Idle.

If the LCU is not linked to an OCU within 90 seconds then the LCU enters the Standby

Mode. In this mode, the LCU remains powered up but relinquishes control of the

locomotive air brakes and allows the locomotive to be operated conventionally. When the

LCU enters the Manual mode (after 90 seconds) the emergency valves are closed which

allows manual recovery of the train brake pipe using the automatic brake handle. When the

brake pipe is recovered and the brake pipe pressure rises above 65 psi, then the LCU

releases the Independent brakes and turns control over to the locomotive operator. When

the LCU receives a link command from an OCU it will then re-enter the Setup State.

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

3-2

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

3.3.2 Operator Control Unit Setup

Set the following switches on the OCU to the positions indicated:

Table 3.3.2-1 OCU Switch Setup

Switch Position

Speed Selector (SS) STOP

Reverser Selector (RS N

Independent Brake Selector (IBS) EMERGENCY

Bell / Horn Selector (BHS) OFF

Power (PWR) ON

3.3.3 RCL Equipment Shutdown Procedure

The following procedure should be followed to shutdown the RCL system:

1. With the train stopped; set the Speed Selector to STOP, the Reverser to the Neutral

(N) position, The Bell and Horn Selector (BHS) to OFF, and the independent brake

to FULL or Emergency.

2. Unlink the system by setting the PWR switch on the Primary OCU to the OFF

position (press and hold pwr for 5 seconds). Follow the directions on the OCU

display to power down OCU. The OCU transmits the Unlink command to the LCU

and after receiving an acknowledge command from the LCU that it is the Safe mode,

and then powers off.

3. When the RCL system on the locomotive receives the unlink command from the

Primary OCU, it enters the Setup State and initiates an Emergency Brake Application,

sets a Full Independent Brake Application, sets the Throttle to idle and enters the Safe

mode. The LCU then transmits an acknowledge command to the OCU indicating that

it is in the Safe mode.

4. After 90 seconds the LCU enters the Manual Mode, closes the emergency valves, and

allows the locomotive operator to operate the locomotive conventionally.

The locomotive can now be operated conventionally without having to power off the LCU,

cutout any pneumatic valves, or re-configure any switch settings. Alternatively, the LCU

can be powered off and cutout as follows:

1. Place the RCL Main Circuit Breaker to OFF.

2. Move the RCL Manual/Remote Valve to the Manual position.

3. Configure the locomotive for conventional lead operation.

3.4 System Linking and Testing

When the train has been made up properly and the RCL system has been prepared per the

previous instructions, system linking and safety checks can be performed. On initial power

up, the OCU performs a display and audible alarm test. All display indicators light in

sequence, each line of the display is exercised, and the audible alarm sounds. When all

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

3-3

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

indicators and the audible alarm have been verified, the display shows GETS GS

LOCOTROL RCL, and the OCU is now ready for linking to the Setup Control Unit

(SCU). If the locomotive is not set up properly for RCL operation (i.e., Air brake cutout

cock not cut in, Locomotive trucks cutout, automatic brake handle not in release, etc.) or an

alarm condition exists on the locomotive, the SCU display will indicate which device that is

improperly setup or the RCL fault that is active. If properly set up, the SCU will indicate

Setup Emergency when the LCU is in the Setup State or Manual Mode when it is in the

Manual mode and is ready for linking with the OCU.

3.4.1 Linking RCL Operation

To begin the RCL linking process, follow the guidelines outlined below:

1. Hold the OCU so that its Infrared Port is pointed at the SCU Infrared port and press

and release the PCC/Link button on the OCU. (see Figure 3.4.1-1) The OCU will

give a Linking LCU and Radio Testing message.

2. Verify that the OCU and the SCU are linked together by observing that the OCU

displays Linked to Locomotive, Loco ID: XXXX and that the Green OCU # 1

Linked status LED is lit. The first OCU that links to the SCU is defined as the

Primary OCU and the Controlling OCU LED illuminates on the OCU to indicate that

it is the controlling OCU for the RCL system.

3. Once linked, the SCU will display Primary Tilt Test Not Complete. Press and hold

the tilt override switch forward. Rotate the OCU greater than 45 degrees from

horizontal until the SCU message disappears. The locomotive voice Radio will send a

voice message that the tilt test is completed and the locomotive number. The RCL

system remains in the Setup State (or transitions to the Setup State if it was in the

Manual mode) with the emergency brakes applied, the Independent Brakes set to Full,

and the Throttle in Idle. Release independent brakes on cabstand.

4. Leave the locomotive and proceed to the area of intended operation.

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

3-4

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

Figure 3.4.1-1 Linking

A secondary OCU can be linked to the LCU for use during Pitch and Catch operations.

Linking the secondary OCU is accomplished in the same manner as the Primary OCU

except the Primary OCU must acknowledge and authorize the secondary OCU linking.

The process for linking the secondary OCU is outlined below:

1. Hold the second OCU so that its Infrared Port is pointed at the SCU Infrared port and

press and release the PCC/Link button on the OCU. The Primary OCU operator will

get a Secondary OCU Link message on their display and within 5 seconds the

operator must press the LR or RR button on the OCU to authorize the second OCU to

Link.

2. Verify that the second OCU and the SCU are linked by observing the Locomotive

road number on the second OCU display and that the Green OCU # 2 Linked status

LED is lit. The Controlling OCU LED on the secondary OCU remains off.

3. If the Setup Emergency has been recovered by the Primary OCU, the locomotive will

be put into Park State. Once the secondary OCU is linked a secondary OCU Tilt test

must be performed using the same method as the primary Tilt test. If the Setup

Emergency has not been recovered prior to linking a secondary OCU, the RCL

system will remain in the Setup State.

3.4.2 Emergency Valve Test

The Emergency Valve Test verifies the proper operation of the RCL locomotive

emergency. The test runs automatically when the automatic brakes are released for the first

time after linking.

The operator moves the Independent Brake Selector (IBS) from the EMERGENCY

position to the RELEASE position. The SCU will display EMV Test in Progress. The

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

3-5

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

OCU will display Consist Recovering and if the test passes, BP will recover and the OCU

will display Consist Ready.

Upon successful completion of the Link operation, recovery of the Set Up Emergency, and

verifying the emergency valves, the Locomotive Control Unit (LCU) transitions into the

Ready State. The Ry State allows an OCU operator to control the locomotive’s speed and

brakes. The SCU display Remote Mode on the display.

3.4.3 System Status Functions

The RCL system status is displayed on the OCU display. Select the status functions using

the TOR actuator. By toggling the TOR actuator toward the Status position, the OCU

display toggles through the each status function. As the operator selects each status

function, the OCU scrolls through the information related to the selected item. The selected

status functions and information provided is as follows:

Table 3.4.3-1 Status Functions

Status Function Information Provided

Status Menu Status List

Pitch to Proyard (If a Hump Yard OCU is

being used)

1. Pitch to Proyard…

Press PCC to Pitch

Loco Status 1. Brake Pipe: XX psi

BP Flow: YY scfm

2. Main Res: XX psi

Brake Cyl: YY psi

3. Loco speed: XX mph

Loco Thr o t : Z

4. Headlight Command:

Dim (Bright) (Off)

OCU Status 1. LED Intensity: AUTO (XX %)

Adjust with LE/RE

2. Ver: 8000451-6XX

SW Date: MM/DD/YY

3. Battery Life

XX hrs YY mins

4.

Link Status 1. Radio Link Status

Unlinked (Linked to Loco XXXX)

2. IR Linked Status

Unlinked (Linked)

Note: The Loco Status Screen can be frozen with the RR button and unfrozen with the LR

button while the loco status is being displayed.

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

3-6

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

3.4.4 System Operating States

The following sections identify and describe the main operating States of the RCL system

and the criteria used to transition between states.

3.4.4.1 Initialization (Power Up) State

Upon power up the LCU performs a power up self-test and checks the status of the

locomotive, brake, and yard containment.

If the self-test passes, the LCU system transitions to the Setup State. Failure of the self-test

holds the system in the Initialization State and an alarm message is displayed on the SCU

display.

3.4.4.2 Setup State

In the Setup State, the LCU commands the air brake system to emergency, the independent

brakes to maximum, and the locomotive to Idles with direction Neutral. The SCU display

shows Setup Emergency. The LCU also checks for system faults, improper system setup,

and invalid configuration parameters.

If the LCU system checks pass then the LCU can be linked to the OCU. Failure of the

system checks holds the system in the Setup State, displays an alarm message on the SCU

display, and prevents the LCU from Linking with the OCU.

3.4.4.3 Manual Mode

If the LCU remains in the Setup State for 90 seconds without linking to an OCU, then the

LCU transitions to the Manual Mode. When the LCU transitions to the Standby Mode, the

SCU display shows Manual Mode. The locomotive is still in emergency with the LCU

maintaining a Maximum (Full) independent brake application. The brake pipe may now be

recovered manually using the automatic brake handle on the cabstand. When the brake pipe

pressure rises above 65 psi, the LCU releases the independent brakes and the locomotive is

now suspended from RCL operation and can be operated conventionally.

The LCU remains in the Manual Mode until a Link command is received from an OCU via

the Infra – Red port. When a Link command is received, the LCU re-enters the Setup State,

applies the emergency brakes, sets the independent brakes to maximum (Full). The LCU

then processes the linking commands from the Setup State as outlined above.

3.4.4.4 Ready State

Upon successful completion of the Linking sequence with the OCU, recovery of the Setup

emergency, and verification of the emergency valves, the LCU transitions to the Ready

State. The Ready State is the system operational State and allows the operator to control the

following:

• Locomotive Speed

• Independent Brakes

• Automatic Brakes

• Bell

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

3-7

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

• Headlights

• Horn

• Sand

The system monitors the yard containment to ensure that the system is operating safely

within the proper boundaries.

The system also monitors all critical parameters and subsystems to ensure no fault

conditions are present. If fault conditions are detected, the system transitions to either the

Park State or the Safe State, depending on the severity of the fault.

The System returns to the Setup State if it receives an Unlink command from the

controlling OCU or if it unlinks automatically due to an extended loss of OCU

communications.

3.4.4.5 Park State

When a minor fault is detected, the system enters the Park State. Minor faults result from

situations where the locomotive should be stopped until the fault is resolved, but does not

warrant an emergency brake application.

Minor faults result in the following:

• Full Service Automatic Brake Application

• Full Independent Brake application

• Direction Neutral

• Throttle Idle

The system will remain in the Park State until:

• The Fault is Cleared

• The locomotive has stopped

• Primary operator acknowledges the fault by moving the Speed Selector to the STOP

position and the IBS to the FULL position as prompted by the OCU.

3.4.4.6 Safe State

The system enters the Safe State when a Major Fault is detected. Major Faults result from a

situation where the locomotive needs to be stopped using an emergency brake application.

For Major Faults, the system commands the locomotive to a Safe State which consists of:

• Emergency Brake Application

• Full Independent Brake Application

• Direction Neutral

• Throttle Idle

The system will hold the locomotive in the Safe State until:

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

3-8

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

• The Fault has been cleared

• A 60 second Emergency Brake timer has elapsed. (The OCU display shows a 60

seconds count down timer when the IBS is placed in the Emergency position to

indicate the time remaining).

• The operator acknowledges the fault by moving the SS actuator to the STOP position

and the IBS actuator to the EMERGENCY position as prompted by the OCU.

• The Operator moves the IBS actuator from the EMERGENCY position to the

RELEASE position.

3.5 Control Functions

3.5.1 Air Brake Functions

The LCU provides all air brake control of the locomotive and train brake functions

including Multiple Unit (MU) capability and emergency brake control. The brake system is

operated with the Brake Valve always cut in to ensure operation is allowed only when

automatic braking capability is available.

3.5.1.1 Automatic Brake

Automatic brake applications can be initiated by the operator using the OCU ABS switch as

follows:

1. Push the ABS switch away from operator and then release to increase brake

application one level

2. REL is 0 psi reduction

• MIN is 7psi reduction

• LIGHT is 15 psi reduction

• MED is 20 psi reduction

• FULL is full service reduction

3. The solid LED on the indicator shows switch position and the flashing LED shows

current brake level on the locomotive.

4. Operator releases brake application by pulling back on the ABS for 2 seconds.

Note: Automatic brakes are bailed for an automatic brake applications except full and

emergency.

3.5.1.2 Charge

Charge will recharge locomotive brake pipe and release automatic brakes. To initiate

charge:

1. Press LR or RR on the OCU and move ABS immediately from FULL to CHARGE

position.

2. From REL pull back for 5 seconds on TBA to wrap it back to CHARGE.

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

3-9

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

To release from charge pull back of ABS momentarily.

Note: i) Locomotive is not allowed to move while in charge.

ii)If MR is less than 110 psi the RCL system will “dry charge” the locomotive by

setting throttle to Notch 4 (Direction is Neutral).

3.5.1.3 Independent Brakes

The locomotive independent brake functions are controlled manually by the operator via the

Operator control Unit (OCU) or automatically (during speed control operation) by the LCU.

The operator initiates independent brake applications by rotating the independent brake

control on the left side of the OCU. The operator can select the following independent

brake setting as shown in Table 3.5.1.3-1 by moving the independent brake controller to the

appropriate position.

Table 3.5.1.3-1 IBS Brake Cylinder Pressure

IBS Setting Brake Cylinder Pressure

REL 0 psi

LOW 25 psi

MED 45 psi

FULL > 65 psi

Note: The locomotive brake cylinder pressure is determined by the J type relay valve

installed on the locomotive and the actual brake cylinder pressure may vary from those

noted above in Table 3.5.1.3-1. See Table 3.5.1.3-2 below.

Table 3.5.1.3-2 Various J Type Relay Valve Brake Cylinder Pressures

J Type Valve Brake Cylinder Pressure

J8.6 38 psi

J1 45 psi

J1.6 72 psi

The LCU will automatically apply independent brakes as needed to control the train speed.

An automatic Bail feature is provided in the RCL system to release the locomotive brakes

after any automatic brake application. When the LCU commands an automatic brake

application less than Full Service, the BAIL function will be activated for 20 seconds. The

locomotive brakes are not bailed during Full Service Applications. During emergency brake

applications and locomotive penalty applications the locomotive brakes will not be bailed.

3.5.1.4 Emergency Brakes

An emergency brake application can be initiated by the operator in any of 3 methods:

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

3-10

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

a) Rotate the IBS actuator to the EMER position on either the Primary or Secondary

OCU. This causes an emergency brake command to be sent to the LCU on the

locomotive which puts the train in to emergency.

b) Cause a brake pipe emergency at the locomotive cabstand by moving the automatic

brake handle to emergency or opening the conductor’s emergency valve.

c) Press one of the RCL Emergency STOP switches located in the locomotive cab or

on the left or right side of the locomotive.

When an emergency brake application is in effect, the locomotive is placed in the Safe State

where the emergency brakes are applied, Independent brakes are set to full, Bail is

deactivated, and the throttle is idled.

When an Emergency Application is commanded the OCU will display

Emerg.Countdown:XX. This is a 60 second count down timer, which indicates when the

Emergency application can be reset.

An operator initiated emergency brake application is released by disengaging the

locomotive emergency stop switches or brake valves (if previously activated), setting the

OCU speed selector to the STOP position, the independent brake selector to the EMER

position, waiting for the emergency timer to expire (1 minute), then rotating the IBS

actuator to the REL position. The OCU will prompt the operator throughout this recovery

process.

3.5.2 Air Brake Function Interlocks

To ensure the RCL system operates in a Safe State, interlocks are provided in the air brake

control system to protect against improper operation.

1. Brake Valve CUT IN – The locomotive Brake Valve must always remain in the Cut

IN position (except Emergency). Detection of the Brake Valve out will put the train

in the Safe State.

2. Automatic Brake Handle in Release – The locomotive brake handle must always be

placed in the RELEASE position. Movement of the Automatic Brake handle out of

the RELEASE position will result in the locomotive being commanded to the Park

State. The OCU will display BV Handle not in Release.

3. Low Main Reservoir – If the Main Reservoir pressure drops below 105 psi for

greater than 5 Seconds, a Low Main Reservoir Warning alarm will be generated. If

the Main Reservoir pressure drops below 90 psi for greater than 5 Seconds, a Low

Main Reservoir Fault will be declared and the locomotive will be commanded to the

Safe State. While the RCL system is in the Charge mode, the Low Main Reservoir

feature is disabled.

4. Brake Pipe not Charged – If the train brake pipe is not properly charged, the

locomotive will be prohibited from releasing the independent brakes. The brake pipe

is considered charged if the rate of change of airflow into the brake pipe is less than 5

cfm per second.

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

3-11

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

5. Low Brake Pipe – If the brake pipe pressure drops below 45 psi, the locomotive will

be commanded to a Safe State. If the direction is neutral and the brake cylinder

pressure is greater than 25 psi this interlock will be disabled.

6. Brake Pipe Rise – The LCU system continually monitors the brake pipe pressure

during all automatic brake applications. If brake pipe pressure increases significantly

(2 psi sustained for 2 seconds) when not expected, an emergency brake application is

applied and the system commanded to the Safe State.

7. Train Separation Detection – A train separation causes a charged brake pipe to fall

at an emergency rate. If the brake valve cuts out with an un-commanded drop in brake

pipe pressure, the LCU will declare a train separation and command the locomotive to

the Safe State.

8. Brake Cylinder Pressure Monitoring – The brake cylinder pressure is monitored at

each truck to ensure that each truck has been properly cut in and that the cylinder

pressure is rises to at least 25 psi when the commanded independent brake control

pressure is greater than or equal to 25 psi. If the monitored brake cylinder pressure

does not rise greater than 25 psi the locomotive will be commanded to the Park State.

3.5.3 Electrical Functions

The LCU provides all electrical control of the locomotive including MU capability. Control

relays provide the required signals for proper locomotive operation and safety equipment

operation. In addition monitoring circuits are provided to ensure safe and effective

operations.

3.5.3.1 Direction Control

The LCU controls the locomotive direction as defined by the operator using the Reverser

Selector on the OCU. The Speed Selector (SS) must be in the STOP position with actual

speed at 0 m.p.h. in order to select a direction with the Reverser.

Once a direction is selected and the speed selector is set for speed control operation,

movement of the Reverser Selector back to the neutral (N) position returns the locomotive

throttle back to the idle and sets the direction to neutral. No brake application is applied.

The locomotive remains in this state until:

1. The operator moves the OCU Reverser Selector (RS) to the previously commanded

direction. The locomotive then resumes speed control operation at the OCU

commanded speed setting.

2. The operator moves the SS actuator to the STOP position. The LCU commands the

locomotive to stop.

3.5.3.2 Throttle Control

The RCL system does not provide the operator direct throttle step control; rather, the

operator uses the OCU to select the desired operating speed. The LCU also provides MU

capability for controlling the tractive effort on all locomotives within the consist.

GE Transportation Systems Global Signaling, LLC

Proprietary and Confidential

3-12

Document No. 5002866 Rev. C (DRAFT)

28 April 2003

3.5.3.3 Speed Control

The RCL system provides a speed control system for controlling traction and moving the

locomotive and train. Provisions are made within the speed control algorithms for operation

at Hump yards and Flat yards.

3.5.3.3.1 Throttle vs Excitation Speed Mode

Before linking the OCU, the SCU inside the locomotive can be set to excitation or throttle

mode. On the SCU press MENU, scroll down to the Speed Control option. Press enter and

use arrow key to pick Exciationt or Throttle and press ENTER again.

Throttle mode must be used if another locomotive is MU’d that does not have slow speed

control. Excitation uses the excitation Trainline and will provide a smoother speed control.

To enter the Speed mode and move the train, the operator uses the OCU to perform the

following steps:

1. Set the SS actuator to the STOP position.

2. Select the desired movement direction using the Reverser Selector.

Press the LR or RR button and, within 3 seconds, move the speed selector to the desired