Page 1

Before installing and using this

machine, you must read this user

guide carefully.

Keep it in a safe place, in case you

need to refer to it later.

E8147 703 - 09.2007 - ENG - (UPDATED EDITION NUMBER : 3)

(

Please read carefully before use

User manual

L-SOLUTION

700 / 800 / 900

Machines

LASER engraving machines

First contact

)

Page 2

TYPE OF MACHINE : L-SOLUTION 700 / 800 / 900 LASER ENGRAVING MACHINES

MANUFACTURER : GRAVOGRAPH INDUSTRIE INTERNATIONAL

This publication and its contents are proprietary to Gravograph Industrie International (Gravograph), and are intended

solely for the contractual use of Gravograph customers.

While reasonable efforts have been made to assure the accuracy of this manual, Gravograph shall not be liable for errors

contained herein or for incidental or consequential damage in connection with the furnishing, performance, or use of this

material.

Gravograph reserves the right to revise this manual and make changes from time to time without any obligation by

Gravograph to notify anybody of such revision or changes.

Gravograph can not be held liable for any problems arising out of the application or use of any products, circuits, or software

described herein. Neither does it convey a license under its patent rights nor the patent rights of third parties.

BP 15 - Z.I. - 10600 LA CHAPELLE SAINT LUC - FRANCE

Importer's address

Gravograph provides no warranties whatsoever on any software used in connection with a Gravograph Laser Engraving

System, express or implied. Neither does it guarantee software compatibility with any off-the-shelf software package or

any software program that has not been written by Gravograph.

Intended use of this system must be followed within the guidelines of this manual. In no event will Gravograph be liable

for any damages caused, in whole or in part, by customer, or for any economic loss, physical injury, lost revenue, lost profits,

lost savings or other indirect, incidental, special or consequential damages incurred by any person, even if Gravograph has

been advised of the possibility of such damages or claims.

Windows is a registered trademark of Microsoft Corporation.

PostScript is a registered trademark of Adobe Systems Inc.

(c) Gravograph Industrie International, 2005

All Rights Reserved.

L-SOLUTION 700 / 800 / 900 machines . 2

First contact

Page 3

Summary

Regulatory information ....................................................................... 5

Compliance standards ...................................................................................................................... 5

Electrical security ............................................................................................................................ 5

Overview ............................................................................................ 6

Introduction ................................................................................................................................... 6

Contra-indications ........................................................................................................................... 6

Unpacking stages ............................................................................................................................ 8

Unpacking - Package contents ........................................................................................................... 9

LASER safety ................................................................................................................................ 10

Description ....................................................................................... 13

Front view of the machine .............................................................................................................. 13

Rear view of the machine ............................................................................................................... 14

Installation ....................................................................................... 15

Physical installation recommendations .............................................................................................. 15

Exhaust system installation recommendations ................................................................................... 17

Air-assist requirements (compressor optional) ...................................................................................17

Computer requirements ................................................................................................................. 18

Software suggestions ..................................................................................................................... 18

Font requirements ......................................................................................................................... 18

Electric installation recommendations ............................................................................................... 19

Electrical connections of the machine ............................................................................................... 21

Powering the machine on ............................................................................................................... 22

Problems ...................................................................................................................................... 22

Powering the machine off ............................................................................................................... 22

Mechanical jamming ...................................................................................................................... 22

Powering on again ......................................................................................................................... 22

Setting up transmission between the L-SOLUTION (700 / 800 / 900)

machine and a PC type computer ...................................................... 23

Connection cables ......................................................................................................................... 23

Connecting L-SOLUTION to your PC using the USB port ...................................................................... 24

Connecting L-SOLUTION to your PC using the parallel port .................................................................. 25

Connecting L-SOLUTION to your PC using the serial port (only with the old machines) ............................ 26

Machine setup (language)............................................................................................................... 27

The printer driver of the LASER machine........................................... 29

How the computer controls the LASER machine ................................................................................. 29

Installing the Windows® (Windows 2000®, XP® or 98®) driver ......................................................... 30

Driver controls .............................................................................................................................. 43

Graphics software ............................................................................. 64

Software setup .............................................................................................................................. 64

Speed optimization ........................................................................................................................ 65

Bitmapped / scanned images .......................................................................................................... 65

First contact

L-SOLUTION 700 / 800 / 900 machines . 3

Page 4

System operation .............................................................................. 66

How it works ................................................................................................................................ 66

The control panel ......................................................................................................................... 69

The engraving menu ..................................................................................................................... 72

Engraving menu description ........................................................................................................... 75

Automaton function (user standard Inputs/Outputs) .......................................................................... 82

Running the machine step by step .................................................... 83

Powering on ................................................................................................................................ 83

Creating the graphic ..................................................................................................................... 83

Setting the drivers' properties ........................................................................................................ 83

Downloading the file ..................................................................................................................... 83

Positioning the plate ..................................................................................................................... 84

Focusing the LASER beam ............................................................................................................. 84

Starting the engraving process ....................................................................................................... 85

Removing and reloading the material .............................................................................................. 86

Problems and solutions ................................................................................................................. 87

Options and accessories.................................................................... 88

Cylinder attachment ..................................................................................................................... 88

Stand of slant for cylinder attachment ............................................................................................. 88

Cutting kit ................................................................................................................................... 88

Compressor kit (air assist) ............................................................................................................. 89

Honeycomb cutting table ............................................................................................................... 89

Materials for LASER engraving .......................................................... 90

Safety ......................................................................................................................................... 90

Printer driver setting tips ............................................................................................................... 91

List of materials for LASER engraving .............................................................................................. 91

General maintenance ........................................................................ 92

Suggested cleaning and maintenance supplies .................................................................................. 92

System cleaning ........................................................................................................................... 93

Optics cleaning ............................................................................................................................ 95

Maintenance schedule ................................................................................................................... 95

Autofocus adjustment ................................................................................................................... 96

"Tickle" adjustment ...................................................................................................................... 99

Technical characteristics ................................................................. 102

Physical characteristics ................................................................................................................. 102

Electrical characteristics ............................................................................................................... 103

Firmware and driver characteristics ................................................................................................ 103

Optional accessories .................................................................................................................... 103

L-SOLUTION 700 / 800 / 900 machines . 4

First contact

Page 5

Regulatory

Regulatory information

Compliance standards

This hardware was designed and built in compliance with the relevant EC marking and EEC directives :

• "Security" Directive 98/37/EEC (22/06/98).

• "Electromagnetic compatibility" Directive 89/336/EEC (03/05/89) (modified)

• "Low voltage" Directive 73/23/EEC (modified)

Any change or transformation made to this equipment, any adaptation or installation

of accessories not recommended by GRAVOGRAPH, any installation of this equipment

in a manufacturing process, any piloting by a robot, any connection to an external

automaton, any change to the characteristics of this material, can make it become noncompliant with the European Directives it is subjected to.

Such changes void the manufacturer's responsibility.

In this case, the person who fits the machine and the equipment is responsible for the

EC compliance of the final work station.

Electrical security

This hardware complies with standards EN 60204-1 and EN 60950, which also refer to the LASER system safety standard

CEI 825-1 (08/2001).

Machine security

This hardware complies with standards EN 292-1, EN 292-2 and EN 12626.

Electromagnetic compatibility

This hardware complies with the following electromagnetic compatibility standards:

• EN 55022 - class A

• EN 61000-3-2

• EN 61000-3-3

• EN 61000-6-2 (immunity in an industrial environment)

This is a class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

Electrical security

This material is «class 1». The mains plug MUST always be connected to a neutral

socket and comply with the regulations in force in the country of installation. If you

do not have a plug of this type, have one installed by an approved electrician. Under

no circumstances should you depart from this instruction.

The manufacturer bears no responsibility towards any user where alterations have been carried out contrary to the

manufacturer's specifications, notably with respect to electrical/electronic elements.

Any operation, other than those mentioned here, must only be carried out by an

approved Gravograph technician.

Do not take the machine apart to repair or clean it : this will void your guarantee.

First contact

This symbol indicates that once this equipment has reached the end of its useful life,

it must not be disposed of with non-sorted municipal waste, in accordance with the

European Directive 2002/96/EC.

The equipment must be disposed of at an appropriate collection point for processing,

sorting, and recycling of Waste Electrical and Electronic Equipment (DEEE).

The elements which compose Electrical and Electronic Equipment may contain

substances which have harmful effects on the environment or on human health.

By following these instructions, you are helping the environment, contributing to the

preservation of our natural resources, and protecting human health.

L-SOLUTION 700 / 800 / 900 machines . 5

Page 6

Overview

Overview

Introduction

Thank you for purchasing the L-SOLUTION machine. Years of testing and refinements have made this unit the ultimate

LASER engraving and cutting system.

Thanks to its innovative design with :

- the "F-load" Front loading concept developed to allow for the front loading of the plates and items to engrave,

- the "A-sens" Auto sensor concept, which adjusts the focal length automatically for you according to the surface

to be worked on (even when engraving a hollow item),

- the "D-fit" Depth fitting concept which calculates and adjusts the position of the LASER head automatically when

cutting thick materials in several passes,

- the beam concentration with the "X-beam" eXpanding beam concept designed to produce perfect quality

engraving over the entire surface of the table,

and with its performance results (speed, power and engraving areas), the L-SOLUTION combines flexibility and full featured

performance without sacrificing simplicity, ease of use, or ease of maintenance.

Using advanced engineering and design features, the L-SOLUTION is truly one-of-a-kind.

Actually, the L-SOLUTION is such a breakthrough in technology that it is more than just a LASER system, it is a precision

engraving and cutting device used as a tool for the imagination.

To begin with, we highly recommend that this entire manual be read before attempting to use the LASER system. The

manual includes important information about safety, assembly, use, and maintenance.

Contra-indications

Do not use the controls or settings and do not carry out procedures other than those

specified in the use manual, to avoid risking exposure to dangerous radiation.

The machine must never be handled without an adult present. Keep the machine,

wires and cables out of children's reach.

This machine is only designed for one user. Do not let several people use the machine

simultaneously.

The LASER engraving machine is a high performance machine : All safety instructions

must be complied with.

Exposure to the LASER beam may cause physical burns or severe eye damage. Proper

use and care of this system are essential to safe operation.

This machine is only designed for engraving and cutting purposes of the materials

listed in this user manual and must never be used for other applications.

The LASER machine must be properly installed and connected to an appropriate

discharge system in accordance with the specifications defined in this manual.

Do not use this machine in an explosive environment.

The processing materials must be introduced entirely into the machine.

Never expose yourself to the LASER beam. It could cause severe physical burns and

irreparable eye damage.

L-SOLUTION 700 / 800 / 900 machines . 6

First contact

Page 7

Overview

Never operate the LASER system without the machine protective casing.

Never operate the LASER system if the doors are in bad condition or can not be closed

properly.

Never operate the LASER system without constant supervision of the cutting and

engraving process.

Exposure to the LASER beam may cause ignition of combustible materials and start a

fire. A properly maintained fire extinguisher should be kept on hand at all times.

Never operate the LASER machine without a properly configured, installed, maintained,

and operating fume/smoke exhaust system.

Fumes and smoke from the engraving process must be extracted from the LASER

system and exhausted outside.

Never engrave or cut with LASER materials which may produce toxic and corrosive

fumes. DISCONTINUE processing any material that shows signs of chemical

deterioration of the LASER system (Systems damaged from this abuse will NOT be

covered under warranty).

We suggest that you obtain the Material Safety Data Sheet (MSDS) from the materials

manufacturer. The MSDS discloses all of the hazards that may arise from handling or

processing that material. The law requires all manufacturers to provide this information to anyone who requests it.

DO NOT ENGRAVE OR CUT PVC (Polyvinylchloride) BASED MATERIALS. The fumes are

extremely toxic if you inhale them. The fumes are so corrosive that they can chemically

destroy the metallic parts of the LASER system. Damage to the LASER system from this

type of abuse WILL NOT be covered under warranty.

Never work on the electronics and LASER parts of the machine without having

unplugged the machine, as hazardous voltages are present.

Although access to these areas is not necessary during normal use, should you need

to open one of these enclosures for service reasons, please remember to unplug the

machine first.

Never move or lift the LASER machine without the assistance of one (or three) person.

(176.4 to 375 lb - 80 to 170 kg). Severe bodily injury may occur if improper lifting

techniques are applied.

Be careful not to drop the LASER system. Not only can it cause bodily harm, but it can

also severely damage the equipment and render it inoperable.

Do not move, push, press on, or shake the LASER machine while the engraving is in

progress. This might shove the engraving part aside and make the engraving

unsuccessful.

Do not connect this equipment to an IT power supply card.

• If the machine is to remain unused for a long period, unplug the power supply and cover the machine (packaging, cover,

lid, etc.)

• Do not move the focus carriage holder manually except in case of a mechanical jamming of the machine, as described

in the paragraph entitled "Mechanical jamming" in this manual's "Installing" chapter.

• Do not spill any liquids onto the machine (drinks, cleaning fluids, etc.) unless recommended by GRAVOGRAPH (e.g. for

lubrication).

• If the engraving process must be stopped, use the function key provided for this purpose on the keyboard of the machine.

First contact

L-SOLUTION 700 / 800 / 900 machines . 7

Page 8

Unpacking stages

This machine should only be transported in its packaging and using a lifting apparatus

able to carry loads of least 661 lb (300 Kg).

After opening the box:

1. Loosening and removing the strap.

2. Remove the guards.

Unpacking of the L-SOLUTION 700 machine must be done by two people.

It weighs 176.4 lb (80 kg).

Unpacking of the L-SOLUTION 800 machine must be done by four people.

It weighs 331 lb (150 kg).

Unpacking of the L-SOLUTION 900 machine must be done by four people.

It weighs 375 lb (170 kg).

3. One (or two) person(s) on each side, lower the machine.

Make sure that no components are missing from the packaging. If any part has been

forgotten please get in touch with your GRAVOGRAPH dealer.

Unpacking

Keep all the packaging materials so that you can move your machine in total safety.

This packaging complies with European recycling standards.

L-SOLUTION 700 / 800 / 900 machines . 8

First contact

Page 9

Unpacking - Package contents

Check the condition of the packaging when you receive it. If there are any signs of

damage, inform the carrier and your GRAVOGRAPH dealer immediately by recorded

delivery, specifying the exact nature of the problem.

Unpacking

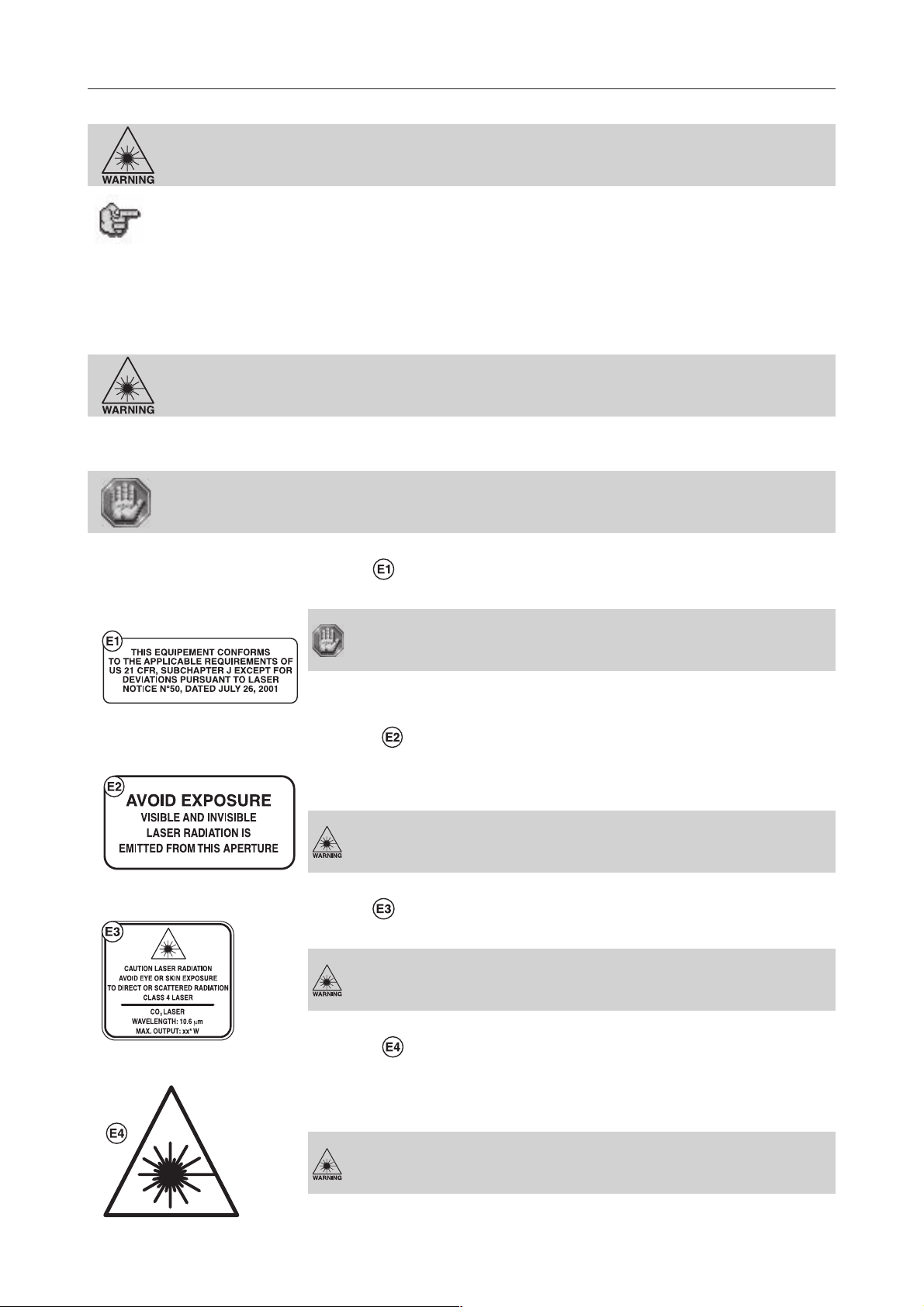

Package contents

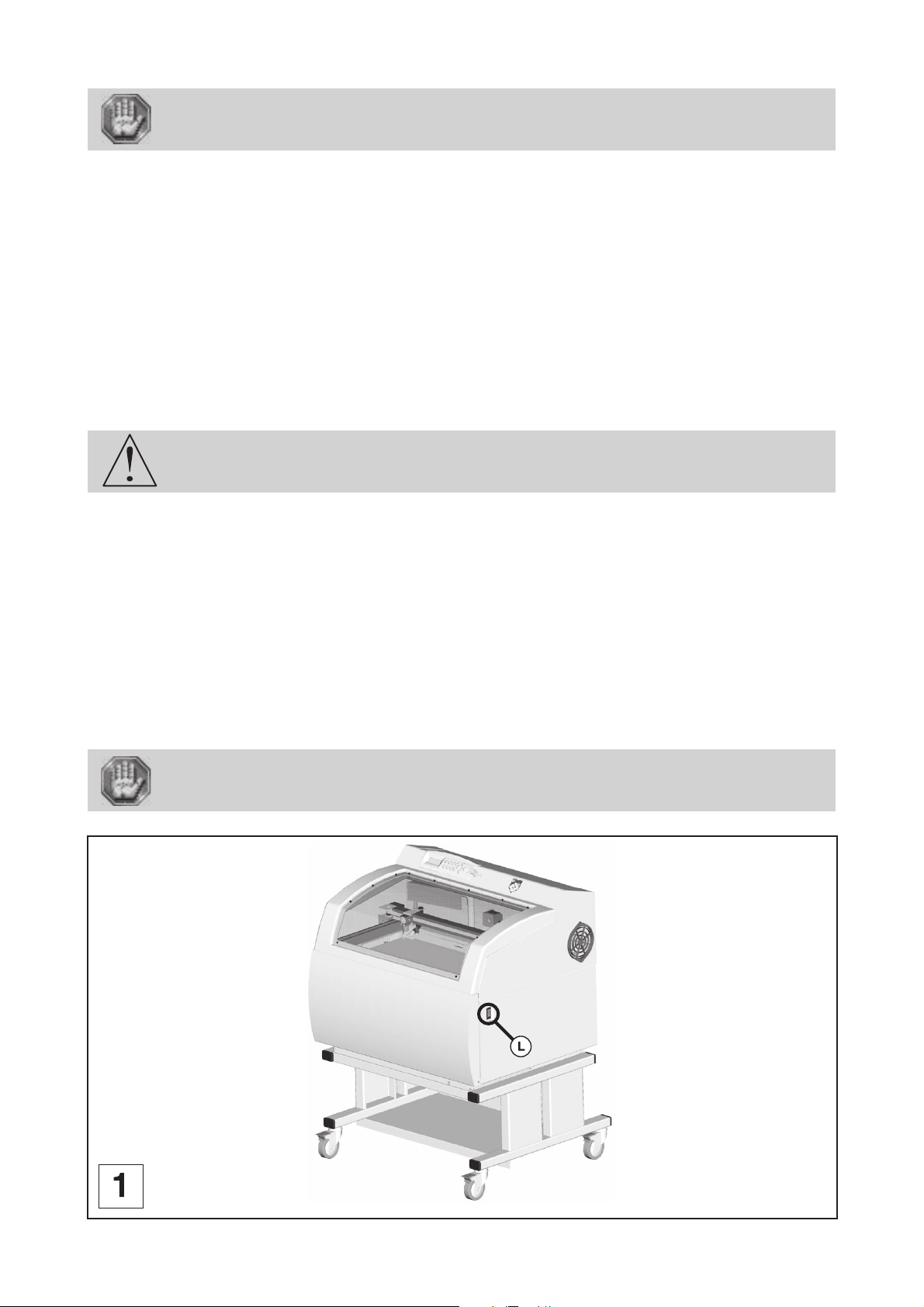

(pict. 1)

A. An L-SOLUTION machine (700, 800 or 900)

((A1) support is optional for the

L-SOLUTION 800 and 900)

B. A CD-Rom contains the driver of the LASER

machine

C. A CD-Rom contains the user manual

(PDF file - Acrobat Reader)

D. A tool box

E. A power cable

F. An USB connection cable

L-SOLUTION 800

Tool box contents

(pict. 2)

D1. a lens/mirror cleaning solution

D2. a lens cleaning paper

D3. cotton swabs

D4. a short allen key

D5. a round allen key

D6. a brush

D7. four keys ...

D8. a wedge for Autofocus adjustment

First contact

L-SOLUTION 700 / 800 / 900 machines . 9

Page 10

LASER safety

LASER safety

This LASER machine contains a sealed carbon dioxide (CO2) LASER that produces

intense and invisible LASER radiation at a wavelength of 10.6 microns (µm)

(0.417 10-6 inch) in the infrared spectrum.

This LASER system contains a CO2 LASER in a Class I enclosure. However, due to the

presence of a visible red LASER diode (power < 1mW), the entire LASER system is

classified as Class 2.

- The entire system is completely enclosed with a protective housing. This will completely contain the invisible C02 LASER

beam under normal use. However, the red diode LASER is a visible LASER beam. DO NOT STARE INTO THE BEAM

OR VIEW DIRECTLY WITH OPTICAL INSTRUMENTS.

- The user door(s) are safety interlocked and will disable the CO2 LASER beam from firing when the user door(s) are opened.

The red diode LASER beam is NOT safety interlocked and can be activated with the door(s) either open or closed.

Do not modify or disable any safety feature of this system. Do not operate any system

that has had its safety features modified, disabled, or removed.

Improprer use of controls and adjustments, or performance of procedures other than

those specified in this manual, may invalidate the safety of this system.

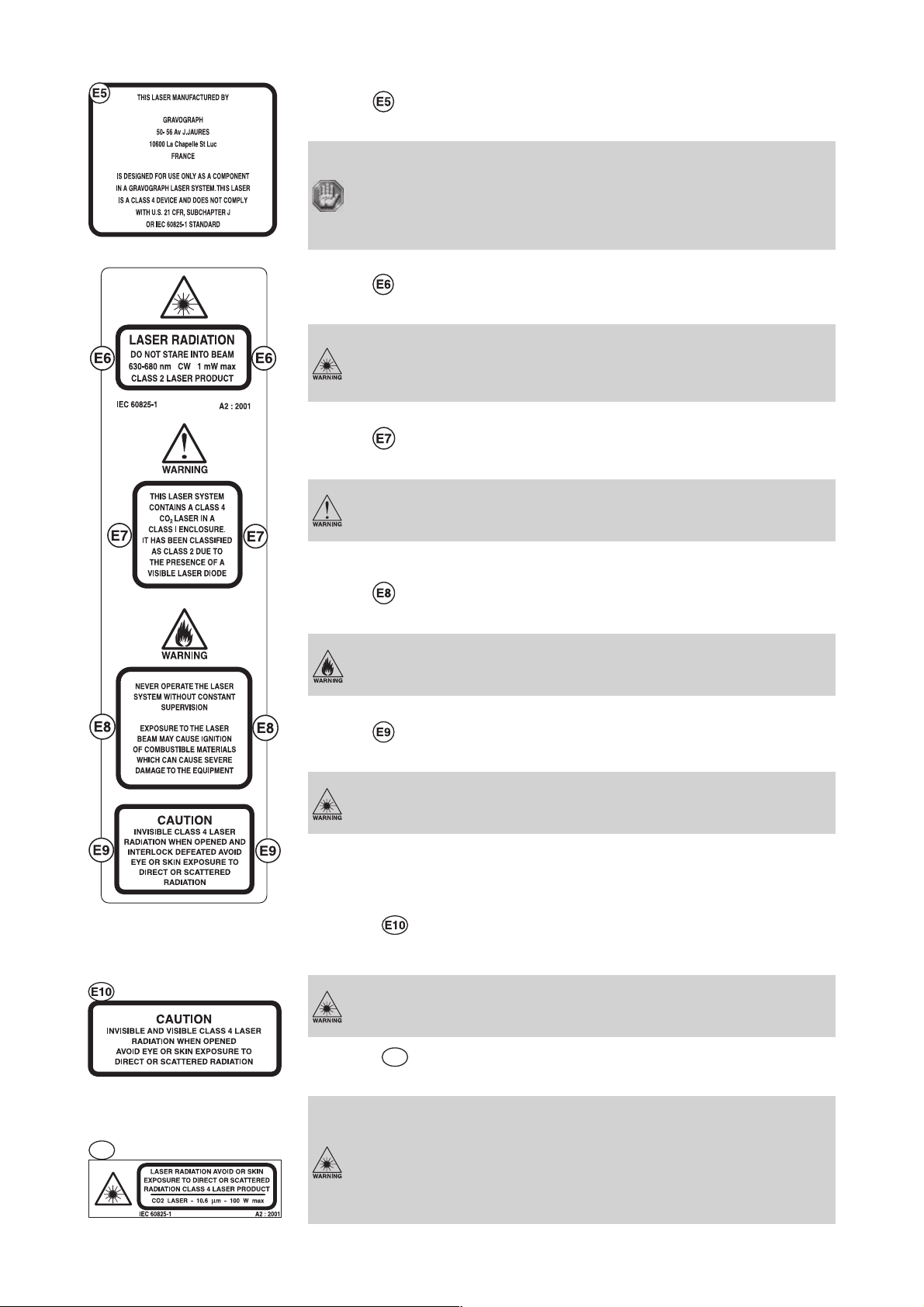

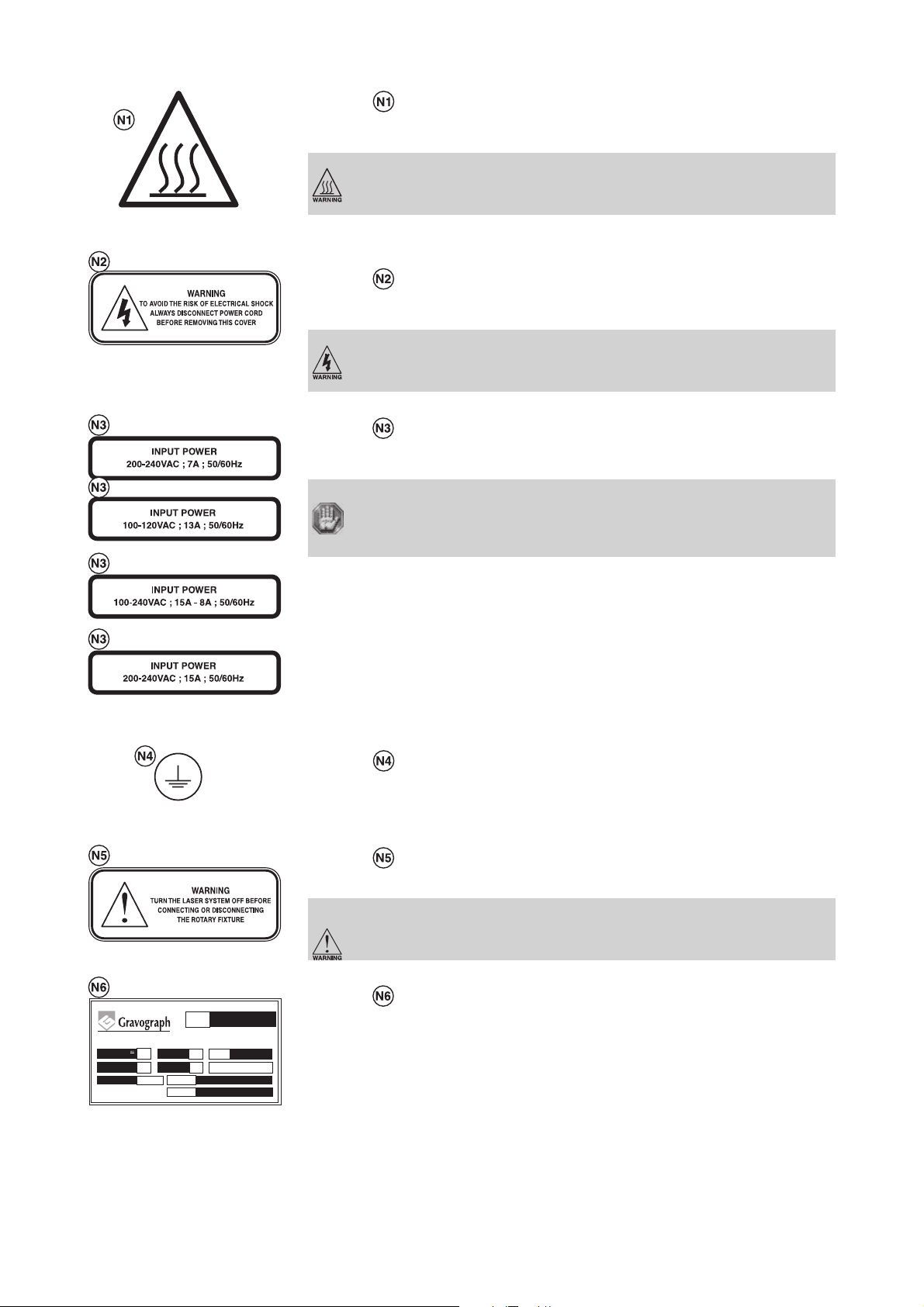

CDRH and EC regulations require all LASER manufacturers to affix warning labels in specific locations throughout the

equipment.

The following warning labels are placed on the LASER system for your safety. DO NOT

remove them for any reason. If the labels become damaged or have been removed for

any reason, DO NOT OPERATE the LASER system and immediately contact Gravograph

for a free replacement.

1 label :

On the back of the system next to the serial number tag. Visible when viewing the LASER system from the backside.

This machine is in compliance with American 21 CFR standards,

subchapter J except for deviations pursuant to LASER notice N° 50,

dated July 26, 2001.

2 labels :

One is next to the beam window where the LASER beam enters the engraving area inside the LASER system and

is visible when the front door is opened.

The second one is located on the LASER source where the LASER beam comes out. It is not visible under normal

operating conditions.

AVOID EXPOSURE - Visible and invisible LASER radiation is emitted

from this aperture.

1 label :

On the LASER tube assembly. Not visible under normal operating conditions.

CAUTION LASER RADIATION.

Avoid eye or skin exposure to direct or scattered radiation.

Class 4 LASER - CO2 LASER - Wavelength : 10,6µm (0.417 10-6 inch)

- Max. output : 100W.

4 labels :

One is next to the beam window where the LASER beam enters the engraving area inside the LASER system and

is visible when the front door is opened.

The second one is on the right, on the #1 mirror cover.

The third one is located on the LASER head next to the access hole of the #2 mirror.

The fourth one is located on the buse of the head.

L-SOLUTION 700 / 800 / 900 machines . 10

DANGER - Invisible and visible LASER radiation is present at that

place. Avoid eye or skin exposure to direct or scattered radiation.

First contact

Page 11

LASER safety

1 label :

On the LASER tube assembly. Not visible under normal operating conditions.

This LASER is manufactured by

GRAVOGRAPH

50-56 avenue J. JAURES - 10600 La Chapelle St Luc - FRANCE.

It is designed for use only as a component in a GRAVOGRAPH LASER

system.

This LASER is a class 4 device and does not comply with U.S. code 21

CF subchapter J, or European standard EN 60825-1.

1 label :

On the outside of the front door. Visible from the outside under normal operating conditions with the door closed.

CAUTION LASER RADIATION.

Do not stare into beam.

Wavelength : 630-680 nm (25 10-9 - 27 10-9 inch) - Max. output :

1mW.

Class 2 LASER product.

1 label :

On the outside of the front door. Visible from the outside under normal operating conditions with the door closed.

WARNING.

This LASER system contains a CO2 class4 LASER in a class I enclosure. It has been classified as class 2 due to the presence of a visible

LASER diode.

1 label :

On the outside of the front door. Visible from the outside under normal operating conditions with the door closed.

WARNING.

Never operate the LASER system without constant supervision.

Exposure to the LASER beam may cause ignition of combustible

materials which can cause severe damage to the equipment.

1 label :

One is on the front door and visible under normal operating conditions.

CAUTION - Invisible class 4 LASER radiation if open and the lock is

disabled. Avoid exposing the skin or eyes to direct or diffuse

radiation.

2 labels :

Inside the LASER system, on the machine protective casing on the left and on the right of the Y-Rails. Visible from

the outside under normal operating conditions with the door opened.

CAUTION.

Invisible and visible class 4 LASER radiation when opened. Avoid

eye or skin exposure to direct or scattered radiation.

E11

First contact

2 labels

Inside the LASER system, on the machine frame on the left and on the right of the Y-Rails.

E11

:

This label must not be visible under normal operating conditions

(machine with casing).

CAUTION.

LASER radiation. Avoid all skin exposure to direct or scattered

radiation. Class 4 LASER product.

CO2 LASER - Wavelength : 10,6µm (0.417 10-6 inch) - Max.

output : 100W

L-SOLUTION 700 / 800 / 900 machines . 11

Page 12

LASER safety

1 label :

On motor Y guard ( on bridge X on the right). Visible from the outside in normal operating conditions when in front

of the machine.

To avoid all risk of being burned do not touch the guard.

1 label :

One is on the back of the LASER machine next to the plug receptacle. Visible from the outside under normal operating

conditions when viewed from the backside of the system.

WARNING.

To avoid any risk of electrical shock, always disconnect the power

cord before removing this cover.

LASER 10W/20W

or

LASER 25W/30W/40W

LASER 60W/80W

1 label :

On the left back side of the LASER machine and next to the plug receptacle. Visible from the outside under normal

operating conditions.

Electrical power supply :

LASER 10/20W :200-240 V (VAC) ; 7A ; 50-60 Hz

or 100-120 V (VAC) ; 13A ; 50-60 Hz

LASER 25/30/40W :100-240 V (VAC) ; 15A-8A ; 50-60 Hz

LASER 60/80W :200-240 V (VAC) ; 15A ; 50-60 Hz

1 label :

Inside the LASER system's power supply cover next to the chassis ground green wire. Not visible under normal

operating conditions. Visible only when cover is removed for maintenance only.

1 label :

Next to the cylinder attachment connector. Visible under normal operating conditions.

WARNING.

Turn the LASER system off before connecting or disconnecting the

cylinder attachment (rotary fixture).

1 label :

CE

06/01

10600 La Chapelle Saint Luc FRANCE

V

200-240

W

1300

20W

/mn

50/60

7

Service

N° Ser.

Hz

TYPE

A

CLASSE 1

S1

000000/0601

LS 800

On the rear side of the LASER system on the right when viewing the machine from the rear. Visible under normal

operating conditions.

L-SOLUTION 700 / 800 / 900 machines . 12

First contact

Page 13

Description

Description

The L-SOLUTION machine is a LASER engraving machine.

It has a control panel with a L.C.D. screen connected to the software in the machine.

Files to be engraved are transferred from the computer to the machine via a cable which is plugged into one of the two ports

on the L-SOLUTION machine.

The actual engraving process is controlled by a LASER.

The object to be engraved is placed on a table (as standard) or held by any other system recommended by GRAVOGRAPH

(consult your GRAVOGRAPH dealer for more information on systems available).

The L-SOLUTION machine has a maximum engraving surface area of:

- 12" x 12" (305 x 305 mm) (L-SOLUTION 700).

- 24" x 12" (610 x 305 mm) (L-SOLUTION 800).

- 24" x 24" (610 x 610 mm) (L-SOLUTION 900).

The L-SOLUTION LASER engraving machine is a high performance machine: All safety

instructions must be complied with.

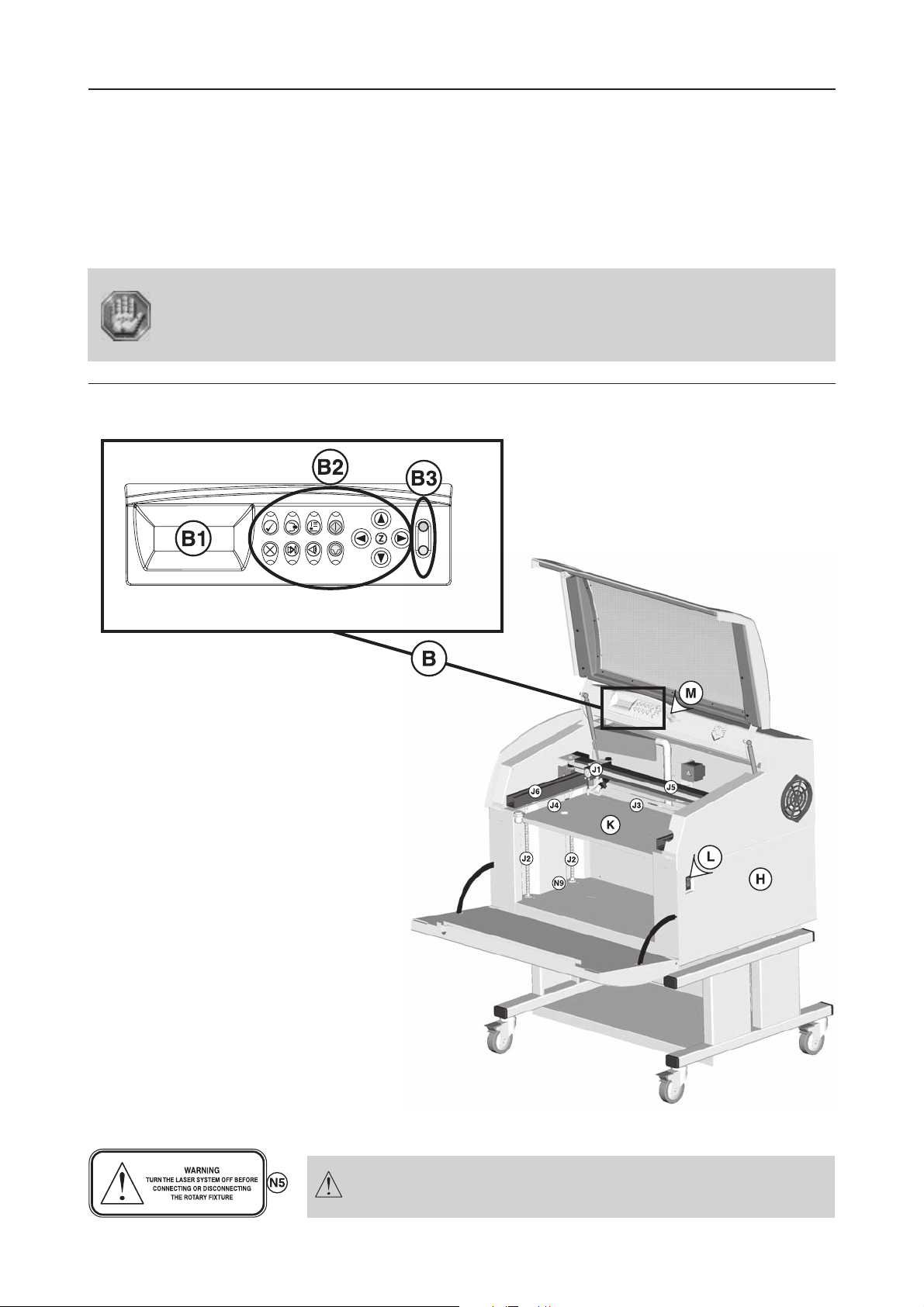

Front view of the machine

LASER engraving machine

(diagram 1)

H. Base

K. Engraving table

L. Main stop button

B. Control panel

B1. L.C.D. screen

B2. 12-key control keyboard

B3. 2 indicator lights (red and green)

M. Air-assist adjustment button

J1. Head

J2. Thread columns for the rise-lower moving

J3. Graduated X-ruler

J4. Graduated Y-ruler

J5. X-Rail

J6. Y-Rails

N9. Cylinder attachment connection (optional accessory)

L-SOLUTION 800

First contact

The machine must always be switched off before connecting or

disconnecting a cable or the cylinder attachment (optional

accessory), as indicated on label(N5).

L-SOLUTION 800 machine . 13

Page 14

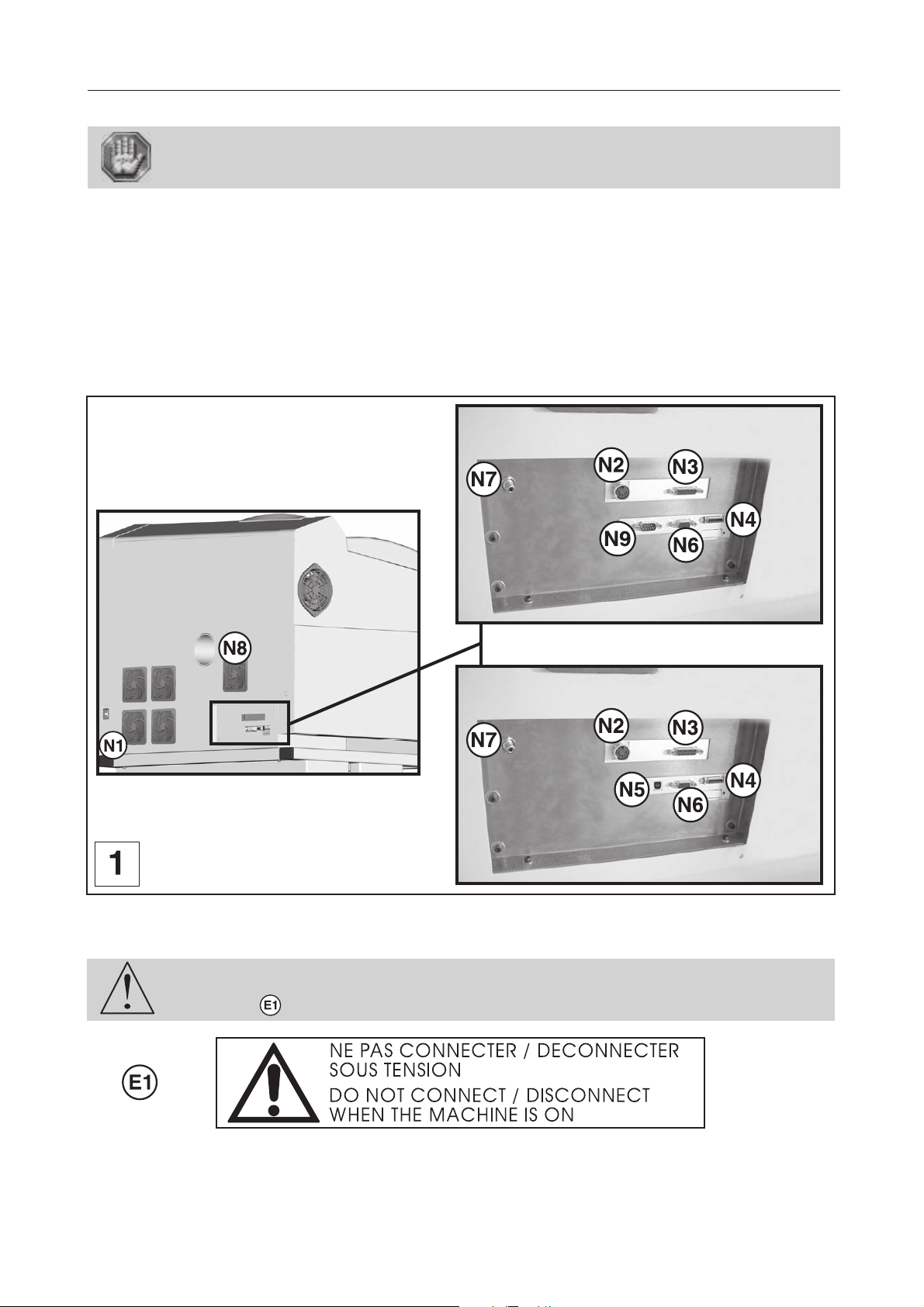

Rear view of the machine

Each connection responds to one of the following security levels :

- Dangerous voltage.

- Very low security level.

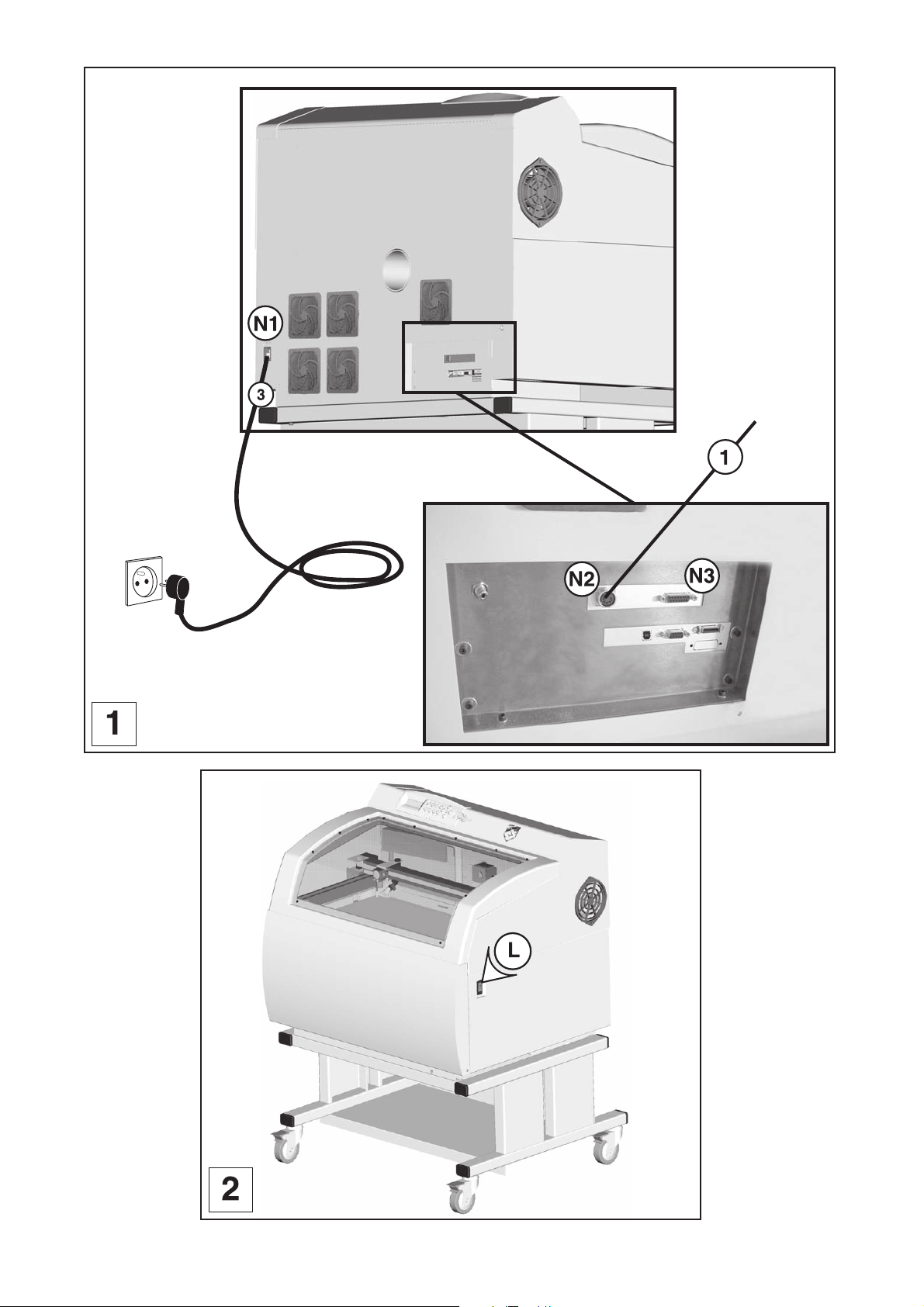

N. Connection socket (diagram 1)

N1 - Mains supply plug - Dangerous voltage

N2 - Exhaust system Inputs /Outputs - Very low security level

N3 - Standard Inputs /Outputs - Very low security level

N4 - Parallel port - Very low security level

N5 - USB port - Very low security level

N6 - Do not use (the protection cap is not to be removed for any reason)

N7 - Pneumatic supply for the air assist

N8 - Hole for the air evacuation pneumatic tube to the exhaust system.

N9 - Serial port (old machines) - Very low security level

Description

Old machines

L-SOLUTION 800

OR

New machines

The machine must always be switched off before connecting or disconnecting a cable

or the cylinder attachment (optional accessory), as indicated on

label :

L-SOLUTION 800 machine . 14

First contact

Page 15

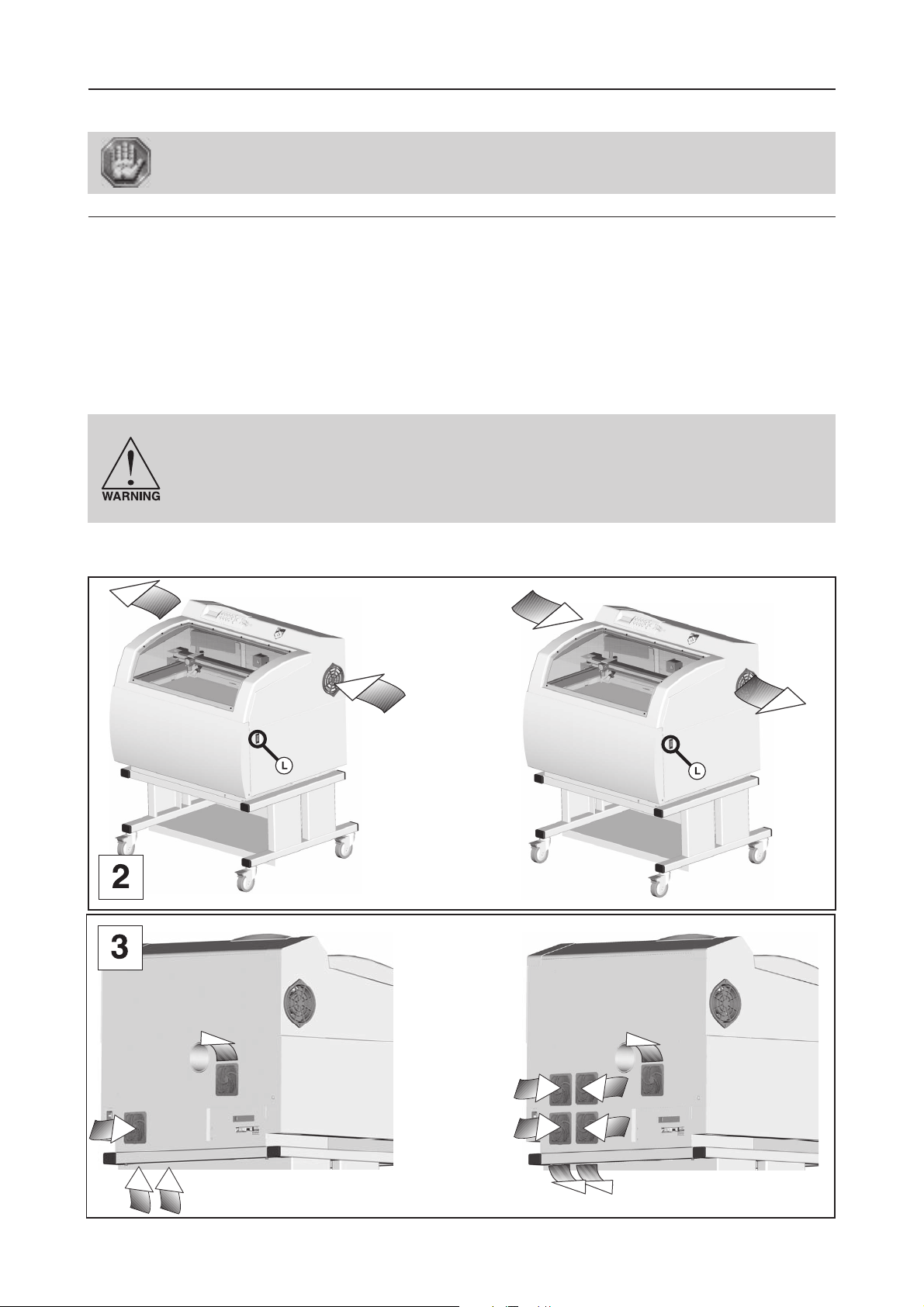

Installation

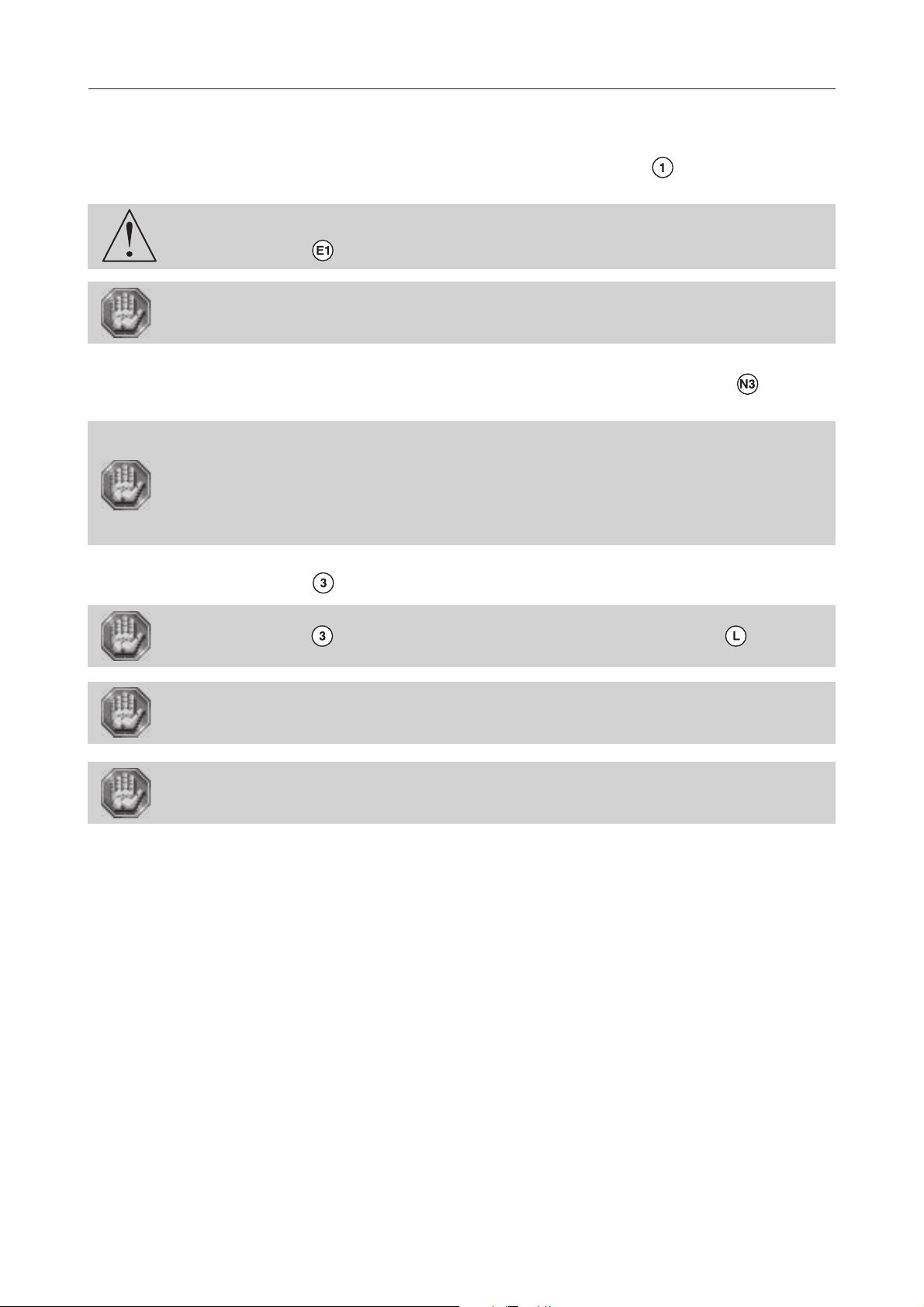

Installation

Physical installation and electrical installation (connections) must only be carried out

by an approved GRAVOGRAPH technician.

Before carrying out the following operations, make sure the machine is switched off

and unplugged, switch (L) to position 0 (pict. 1).

Physical installation recommendations

• Put the Gravograph machine onto a stable flat, clean surface able to carry loads:

- of least 176.4 lb (80 Kg) (L-SOLUTION 700).

- of least 331 lb (150 Kg) (L-SOLUTION 800).

- of least 375 lb (170 Kg) (L-SOLUTION 900).

• Place the Gravograph LASER engraving machine in a clean and ventilated environment such as an office environment

and make sure the machine is well-ventilated (pict. 1 and 2). Choose a place providing the shortest and most direct

path to the exhaust ductwork (not provided). Refer to exhaust requirements later on in this section.

Avoid small, enclosed, non-ventilated areas. After LASER engraving or cutting, certain materials keep on emitting fumes

for several minutes after the processing has been completed. Having these materials present in a confined, unventilated

room can contaminate the room.

To ensure a good ventilation, it is necessary to leave a 8" (=20 cm) clearance all

around the machine:

Do not confine the back of the machine by surrounding it with furniture, shelving,

backing it into a corner, etc. The rear side of the LASER system must be allowed to

"breathe". Otherwise, it can overheat the LASER tube, the power supply, and/or the

CPU module.

Overheating may cause serious and very costly damage to the LASER system.

LASER systems of this class use fans to keep the LASER tube and electronics cooled during operation. Maintain the room

temperature at the recommended ambient temperature range outlined previously in the following page.

L-SOLUTION 800

LASER 10, 25, 40W

L-SOLUTION 800

LASER 25W

L-SOLUTION 800

LASER 60, 80W

L-SOLUTION 800

LASER 10, 40, 60, 80W

First contact

L-SOLUTION 800 machine . 15

Page 16

Installation

Ambient room temperature MUST be between 50 and 95 degrees F(10 and

35 degrees C).

• If transporting the LASER system from a very cold or very hot environment to the proper operating environment, the

LASER system must be allowed time to adjust to the ambient temperature. To do this, turn on the LASER system (and

chiller if applicable), and let the system idle for 15 minutes before processing materials. This will allow the ambient

temperature to circulate through the LASER system to either warm it up or cool it off.

Ambient room dewpoint temperatures MUST be less than 50 degrees F (10 degrees C).

• Normal lighting is sufficient to use the machine (Inside the work area of the L-SOLUTION 900 machine, there is an electric

lighting device with ON/OFF switch).

• Clear the work surface so that you can

- easily and quickly access all external parts of the machine,

- quickly access, in case of necessity, the main stop button (L) on the engraving table (pict. 1),

- make sure that all moving parts of the machine have enough room to move freely,

- place the computer within 10 feet (3m) of the machine, if planning to connect the LASER engraving system

to a computer through the parallel port (the maximum recommended parallel cable length is 10 feet (3m)).

- avoid any accidental unplugging of the cables.

The connectors screws must be very tight to avoid accidental disconnection of the

cables while the machine is turned on as this could permanently damage the electronic

cards.

• If connecting an additional LASER system or other printer to the same computer, we recommend the installation of an

additional parallel port into the computer. DO NOT use a manual A/B type switch box. This creates electrical noise which

can cause an engraving problem or damage the LASER system and/or the computer’s electronics.

• Protect your Gravograph equipment against:

- Moisture (rain, snow, condensation, etc.),

- Heat (direct sunlight, heating, etc.),

- Sudden changes in temperature,

- Dust (exhaust pipe, sand-blasting or sandpapering systems),

- Liquid splashes, spillages on the electronic rack, cables and connections, and any other part of the machine; unless

recommended by GRAVOGRAPH (e.g. lubrication),

- Vibrations,

- Electric or electronic radiation.

The electrical plug acts as a sectioning device. it is therefore important that you set

up the machine in order to always have easy access to the power cable.

L-SOLUTION 800

L-SOLUTION 800 machine . 16

First contact

Page 17

Installation

Exhaust system installation recommendations

To properly exhaust fumes and smoke from the LASER engraving system during operation, you must have a proper exhaust

system.

A slide gives the possibility to select two distinct air exhaust system modes :

- Head mode (Exhaust to the level of the head):

the more effective but a high-performance vacuum

exhaust system is required.

- General mode (general Exhaust ) :

gives the possibility to adapte with an air exhaust system

which have a good air draught but with a small vacuum.

An air inlet is provided in the double door.

Avoid to combine the two exhaust system modes.

For the cutting works, it is also possible to have an exhaust to the level of the table (in

general mode).

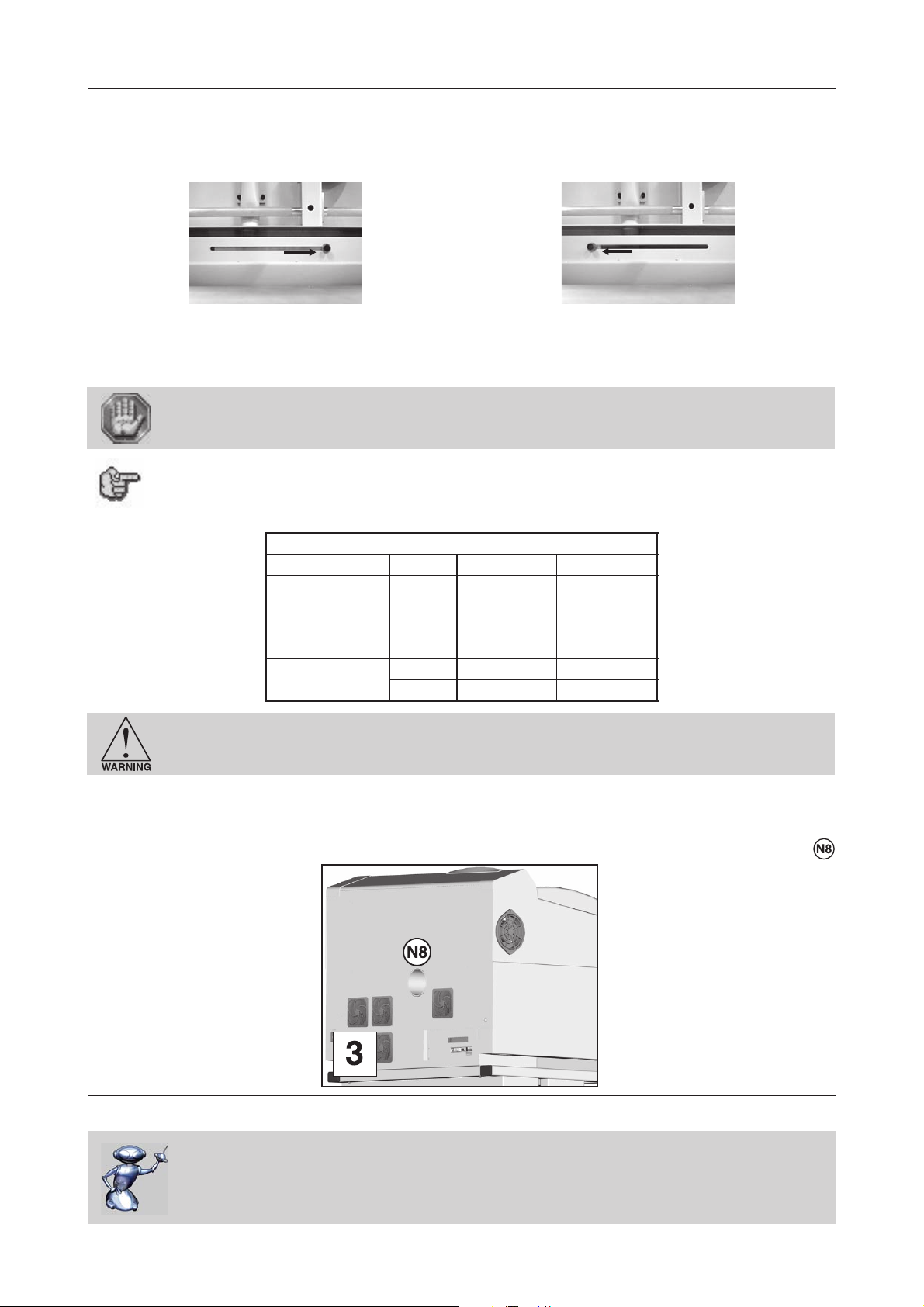

The air exhaust system MUST comply with the following minimum requirements (according to the mode):

SCITSIRETCARAHCROTCARTXEDEDNEMMOCER.NIM

edomdaeHedomlareneG

3

h/051≥003≥

m

tuphguorhtria.xaM

3

nim/72.3≥45.6≥

dray

muucav.xaM

retemaidteltuO

aPk02≥5.0≥

ISP9.2≥70.0≥

mm05001

ni"1

23/13

61/51

"3

Never operate the LASER engraving system without a properly installed and operating

exhaust system. When cut or engraved, some materials can produce fumes that are

hazardous in concentrated amounts.

To install the exhaust system properly, we recommend having the exhaust system installed by a licensed contractor

compliant with safety and local code requirements as well as being able to calculate the correct size blower required for

your particular installation.

The fume exhaust to the air exhaust system goes through the tube connected on the rear side of the LASER machine

(pict. 3).

L-SOLUTION 800

Air-assist requirements (compressor optional)

In order to use the Air-assist system (air seal), you should use an air compressor

(optional accessory, not delivered) that has the following characteristics :

- Power = 30 W

- Air draught = 0.0196 yard3/mn or 3.87 US gallon/mn

(15 l/mn)

First contact

L-SOLUTION 800 machine . 17

Page 18

Installation

Computer requirements

The following is our minimum recommended computer configuration. Using a faster computer with more capacity will

increase efficiency and throughput. Although using a computer that does not meet our minimum recommendation might

be acceptable to you, a faster computer will definitely pay for itself in a short amount of time.

- Pentium 500 MHz or equivalent

- 128 MB of RAM (256 MB recommended)

- 4 Gigabyte hard drive or bigger (10 gigabyte recommended)

- 15 inch color VGA monitor (17 inch recommended)

- 3.5" floppy disk drive

- CD-ROM Drive

- USB Port 1.1 or 2.0

- Mouse or other pointing device

- Microsoft Windows 2000® (XP, NT)

- 300 DPI Optical Resolution Scanner

Remember that the LASER system is an output device just like a printer is. The faster you can create graphics and

manipulate your software, the faster you can download to the LASER system to keep it producing.

Software suggestions

Gravograph Engraving software

- LaserStyle (Windows 2000®, XP, NT)

Font requirements

True Type

We recommend using True Type fonts only. TrueType fonts are the most versatile and should be used whenever possible.

They provide the best print quality and will print well at any size.

PostScript

We do not recommend using PostScript fonts. The LASER system is NOT a PostScript printer and therefore has no capability

of printing PostScript fonts. Sometimes a PostScript font will print if you are running Adobe Type Manager (ATM). Adobe

Type Manager converts PostScript fonts to bitmapped fonts before sending the information to our printer driver. Using ATM

does not guarantee that the PostScript font will print properly. Therefore it is NOT recommended.

Bitmap

Bitmapped fonts only print well when used at the specific point size they were designed for. This point size is usually

indicated in the font name such as Times Roman 12. If a font is only available in bitmap form, you must print it at the size

it was created for. Scaling the font larger will result in a more jagged looking character although scaling it smaller produces

good results.

Tip

If you are having any problems printing a font and you cannot figure out what is going on, select the font and «convert

to curves» or «convert to paths» in your graphics software. This will convert the font into a bitmapped image and will print

correctly to the LASER system. Refer to your graphics software on how to convert fonts.

As you can see, we strongly recommend the use of True Type fonts only.

L-SOLUTION 800 machine . 18

First contact

Page 19

Installation

Electric installation recommendations

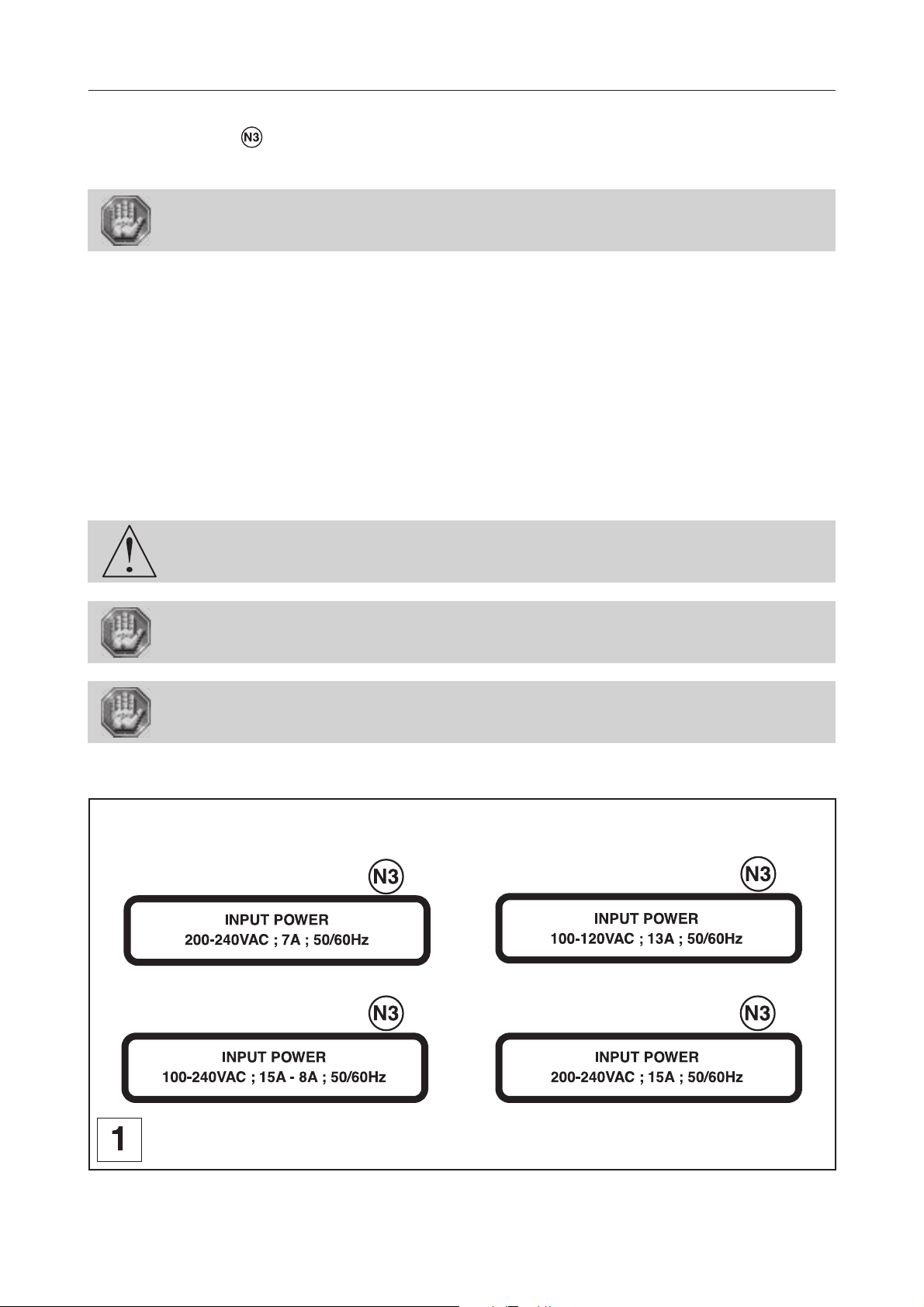

Please refer to the label (diagram 1) « INPUT POWER » near the system’s ON/OFF switch and power inlet for your

system’s electrical requirements. Make sure that your electrical outlet is capable of providing the proper voltage, frequency

and amperage that your LASER system needs.

This material is «class 1». The mains plug MUST always be connected to a neutral

socket and comply with the regulations in force in the country of installation. If you

do not have a plug of this type, have one installed by an approved electrician. Under

no circumstances should you depart from this instruction.

In order to avoid any interference with the outside, the user is advised to follow the instructions below.

• Plug the Gravograph machine into a mains line, avoiding having several machines on the same line (several plugs on the

same line or using a multi-plug).

Exception : If other items are connected to the machine (e.g. a computer or an ISIS console linked

• Avoid using the same line to supply inductive or capacitive machines as well as the Gravograph machine (motors,

electrosluices, chargers, etc.).

• Avoid using a manual or automatic switch on the same mains line as the Gravograph machine (relay, temporizer,

programmer, automatic circuit breaker, automatic switch, etc.).

• Check that machines surrounding your Gravograph machine comply with the standards relative to radioelectric

interference (please refer to the technical leaflet shipped with each machine). If they are not compliant, place them as

far away as possible from the Gravograph machine.

• Only use Gravograph accessories (Gravograph relay box, etc ...).

to an IS table), all your machines should be connected to the same mains line.

10/20 W :

The machine must always be switched off before connecting or disconnecting a cable

or the cylinder attachment (optional accessory).

The electrical plug acts as a sectioning device. It is therefore important that you set

up the machine in order to always have easy access to the power cable.

Do not connect this equipment to an IT power supply card..

OR

25/30/40 W : 60/80 W :

First contact

L-SOLUTION 800 machine . 19

Page 20

L-SOLUTION 800

Installation

Exhaust

system

L-SOLUTION 800

L-SOLUTION 800 machine . 20

First contact

Page 21

Installation

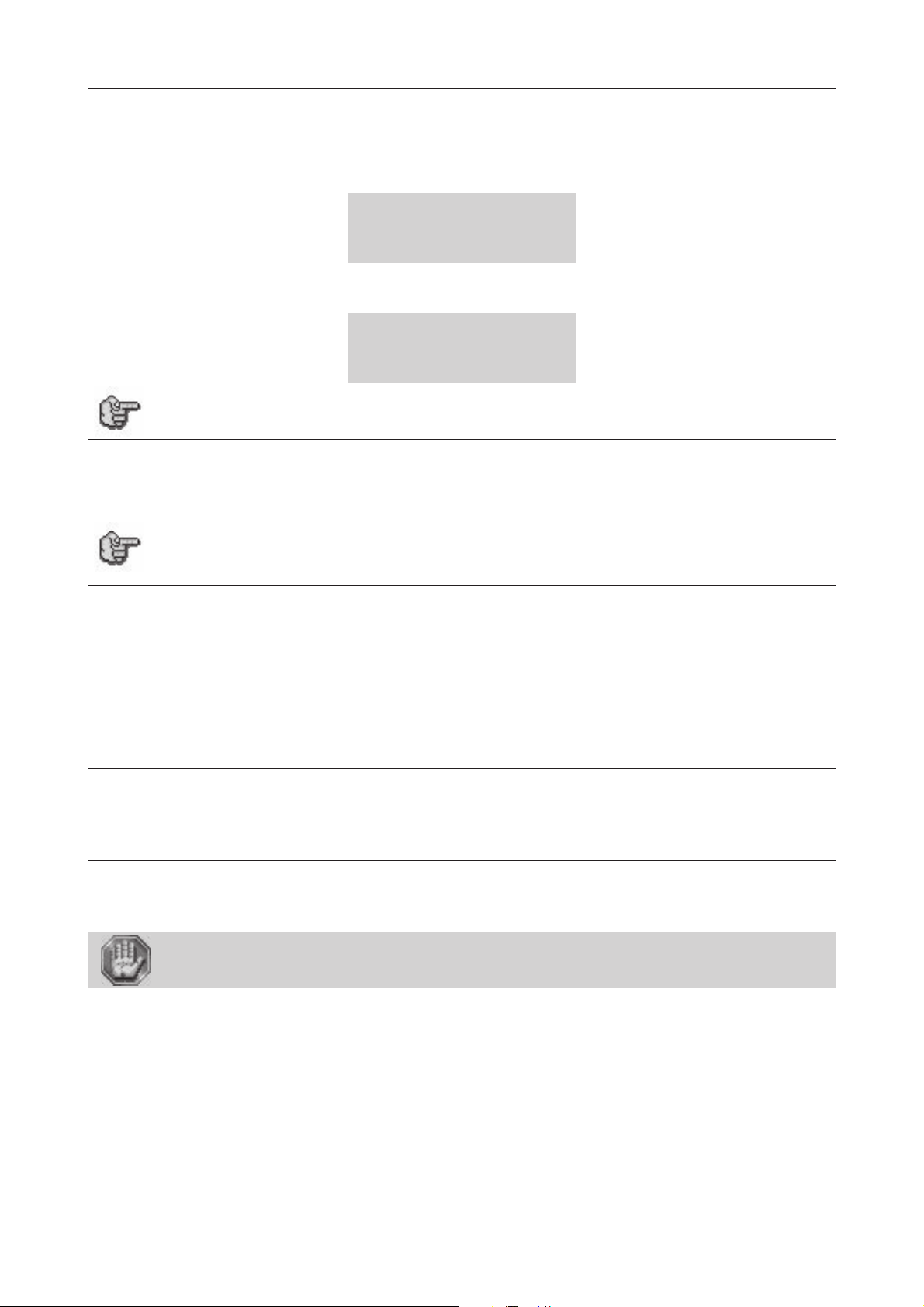

Electrical connections of the machine

Stand behind the machine (diagram 1).

1. Plug in the input/output machine-exhaust system connection cable , first to the exhaust

system, then to the LASER machine. Tighten the connectors screws using the screwdriver (3.5).

The connectors screws must be very tight to avoid accidental disconnection of the

cables while the machine is turned on as this could permanently damage the electronic

cards (label ).

Before making any user standard inputs/outputs connections you must check taht the

electric and electronic features of the different inputs and outputs are respected (see

"the Automaton function" described in the chapter "System operation" page 74).

A bad connection can irreparably damage the electronics of your machine.

2. Plug in the user standard inputs/outputs connection cable to the LASER machine if you use

the Automaton function described in the chapter "System operation" (see page 74).

The use of the function Automaton means that the engraving machine cannot be

considered individually to ensure the safety of the operator.

The engraving machine is actually integrated into a global process (the automated

production line).

Consequently, it is the final work station (engraving machine + automaton + loading

robot) that must comply with the regulations in terms of safety.

The person who fits the engraving machine within the manufacturing process is

therefore responsible for the EC compliance of the final work station.

3. Plug in the electric cable , first to the engraving table, then to the mains supply..

To cut off the mains supply to your machine in case of severe problems, unplug the

mains cable or switch off the machine with the main stop button at the front

of the LASER engraving machine (pict. 2). Make sure that you can reach them easily.

The electrical plug acts as a sectioning device. It is therefore important that you set

up the machine in order to always have easy access to the power cable.

Do not connect this equipment to an IT power supply card.

First contact

L-SOLUTION 800 machine . 21

Page 22

Powering the machine on

Switch on the machine (main stop button (L) to I position).

When switched on the ventilator of the machine will start.

The following message will be displayed on the L.C.D. screen of the machine :

SET UP

FPGA X.XX

LCD SOFT X.XX

16 Mo BOOT X.X

The machine will then issue a "beep" and a new message will be displayed :

<< GRAVOGRAPH >>

LASER VERSION X.XX

LCD SOFT X.XX

16 Mo BOOT X.X

Leave the machine plugged in even if it is not in constant use.

Problems

If one of the operational signs is missing, check the following points :

• Are both ends of the mains cable connected correctly ?

• Is the mains plug connected ? Is it live ?

If the machine does not come on, before calling a technician, please check power

connections to the mains socket.

Installation

Powering the machine off

Switch the main stop button (L) to the 0 position.

Switch the machine off in the following cases :

- if you are leaving the workstation (e.g. at the end of the day),

- physical damage (fall, fire, liquids coming into machine, etc.),

- mechanical/electrical/electronic faults, leading to a possible breakdown,

- in case of a major problem or a mechanical jamming of the machine,

- to reboot,

- for external cleaning.

Mechanical jamming

In the following cases :

- the medium to be engraved is jammed,

- an object placed in the work area is causing a jam,

Powering on again

If the machine or the programme which runs it crashes you may have to reboot the machine.

If this happens, switch the machine off. Wait 30 seconds and switch it on again.

You must wait 30 seconds. This delay helps avoid any electric shock to the machine

likely to damage the power supply.

L-SOLUTION 700 / 800 / 900 machines . 22

First contact

Page 23

Installation

Setting up transmission between the L-SOLUTION and a PC type

computer

The computer and the L-SOLUTION machine must be switched OFF.

PC computers and the WINDOWS® graphic environment being very widespread

throughout the world, we have based ourselves on these products to define the

installation and use procedures of the L-SOLUTION.

If your equipment is not compatible and you encounter problems when installing or using the product, contact your

Gravograph agent.

Connection cables

• Use Gravograph connection cables (please refer to your Gravograph vendor for a list of products available).

These cables are suited for the machines that are to be connected to.

They comply with the CEM radio waves standards and protect from external electric "attacks" (compliant with CEM

immunity and sensitivity standards).

• Do not use cables which are too long. Keep the machines as close as possible and use as short a cable as possible.

• Separate the mains cable and the transmission cable (avoid connecting the transmission and mains cables to the same

socket, etc ...).

Follow the connection procedure depending on the transmission cable supplied with the

L-SOLUTION.

The new model of machine is delivered with the following cable :

• USB cable

First contact

L-SOLUTION 700 / 800 / 900 machines . 23

Page 24

Installation

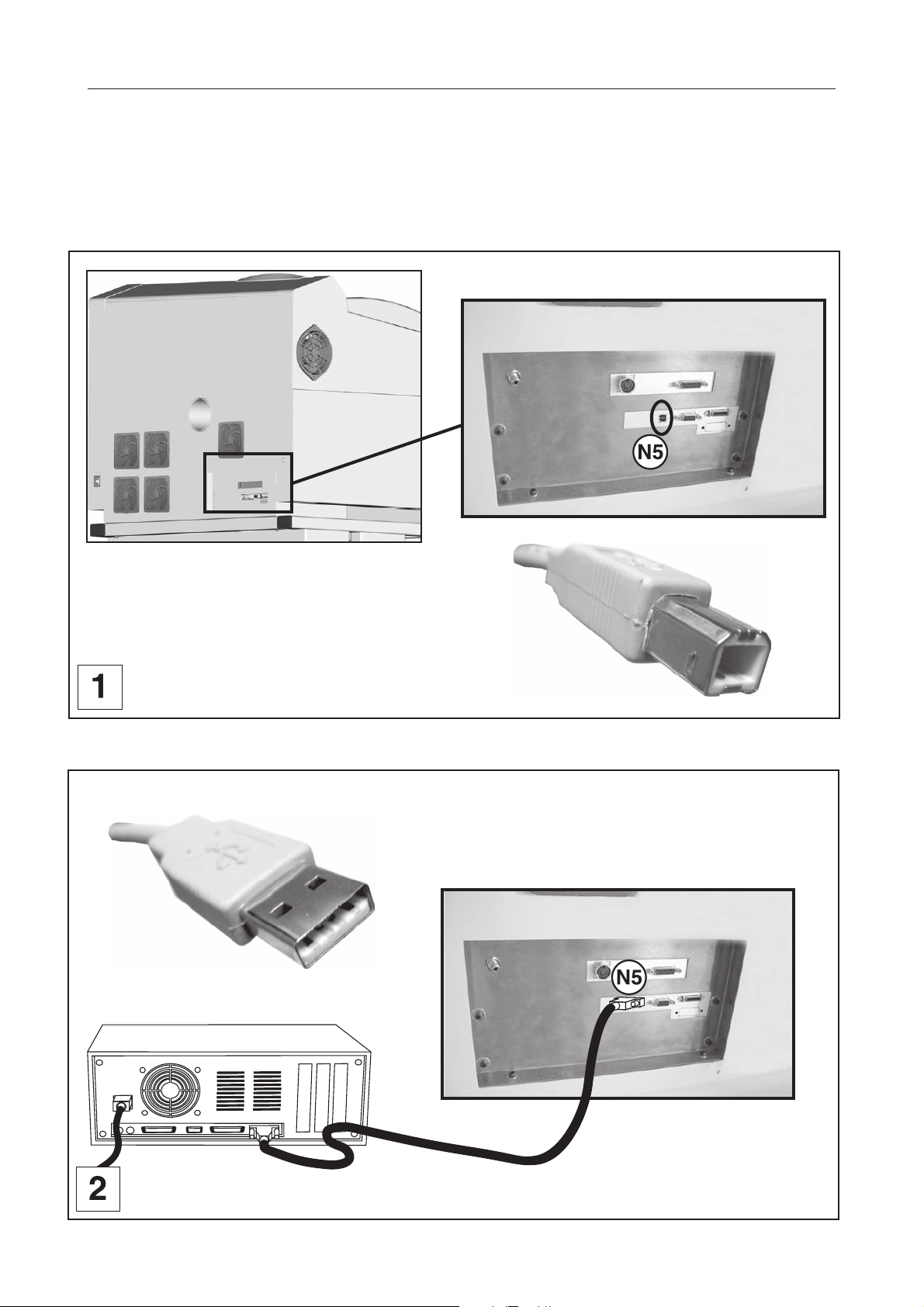

Connecting L-SOLUTION to your PC using the USB port

1. Plug the USB cable into the USB port (N5) of the L-SOLUTION 800 machine (diagram 1).

2. Plug the USB cable into the USB port of the PC.

Refer to the installation manual of the computer for the USB port (1.1 or 2.0).

L-SOLUTION 800

L-SOLUTION 700 / 800 / 900 machines . 24

First contact

Page 25

Installation

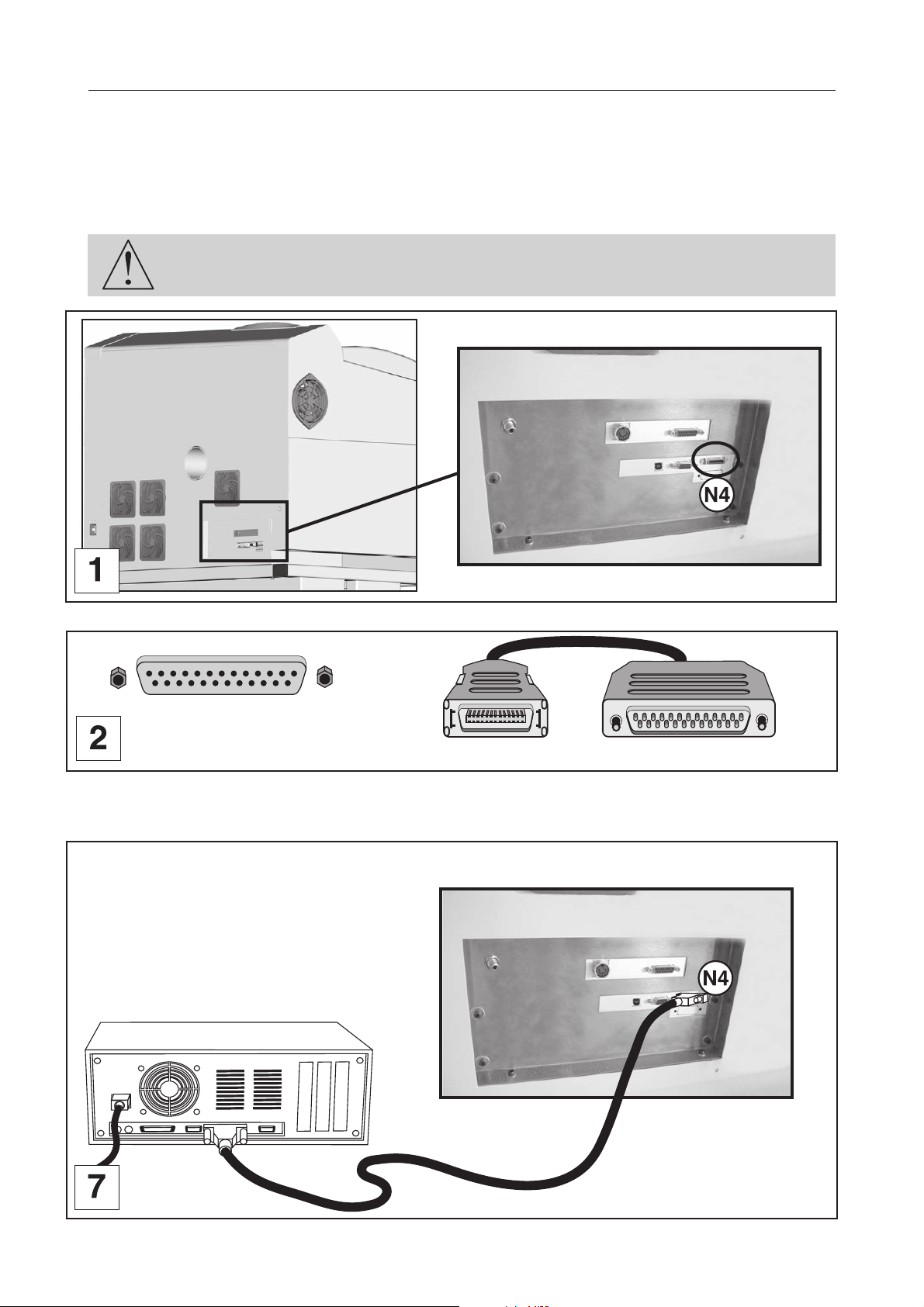

Connecting L-SOLUTION to your PC using the parallel port

1. Plug the parallel cable into the parallel port (N4) of the L-SOLUTION machine (diagram 1).

This is a 26-pin Mini-Delta Ribbon connector.

2. Plug the parallel cable into the parallel port of the PC (diagrams 2 and 7).

Refer to the installation manual of the computer for the parallel port.

The connector screws must be very tight to avoid any accidental disconnection of the

cables while the machine is turned on, as this could damage the electronic boards

permanently.

L-SOLUTION 800

1

25

L-SOLUTION

1

PC

25

First contact

L-SOLUTION 700 / 800 / 900 machines . 25

Page 26

Installation

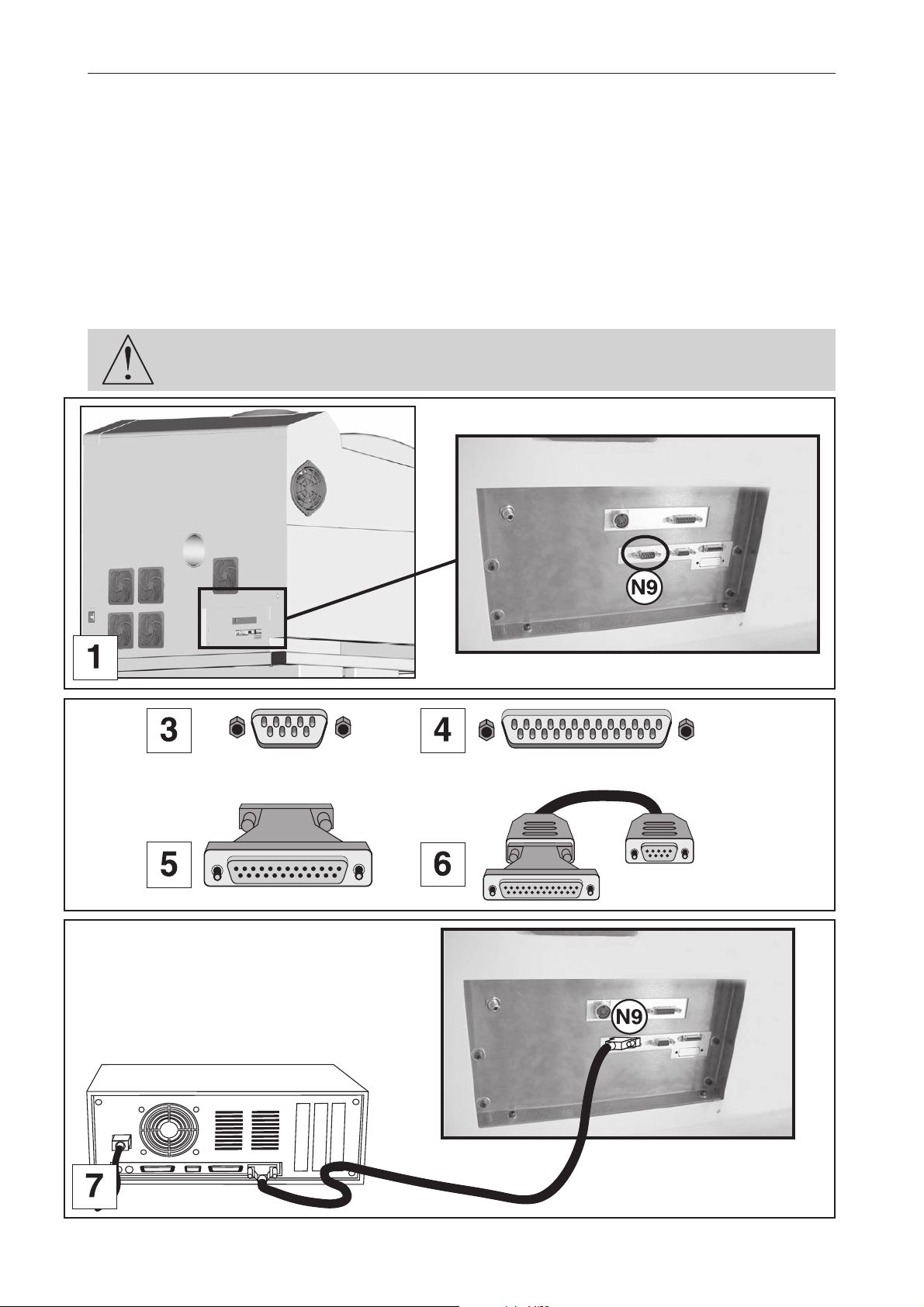

Connecting L-SOLUTION to your PC using the serial port (only with the old machines)

1. Plug the serial cable into the serial port (N9) of the L-SOLUTION 800 machine (diagram 1).

This is a 9-pin connector.

2. Plug the serial cable into the serial port of the PC.

Refer to the installation manual of the computer for the serial port.

PC computers can have two types of serial ports :

• 9-point serial port (diagram 3, transmission example diagram 7)

• 25-point serial port (diagram 4)

If you use a 25-point serial port, connect the 25-9 point adaptor (diagram 5) onto the serial cable

(diagram 6) before plugging it into the computer.

The connector screws must be very tight to avoid any accidental disconnection of the

cables while the machine is turned on, as this could damage the electronic boards

permanently.

Old machines

L-SOLUTION 800

1

9

1

25

1

1

9

25

1

25

1

9

Old machines

L-SOLUTION 700 / 800 / 900 machines . 26

First contact

Page 27

Machine setup (language)

1. Switch on the L-SOLUTION machine (main stop button (L) in I position).

A first message will be displayed on the screen :

SET UP

FPGA X.XX

LCD SOFT X.XX

16 Mo BOOT X.X

A new message will be displayed on the L.C.D. screen of the machine :

<< GRAVOGRAPH >>

LASER VERSION X.XX

LCD SOFT X.XX

16 Mo BOOT X.X

Wait a few seconds.

The following message is displayed on the screen :

<READY TO RECEIVE>

001 FILENAME1

PUI 40 VIT 10

DPIX 400 DPIY 400

Installation

2. Press

PARAMETERS

FILE

INFO

CONFIGURATION

3. Select the CONFIGURATION menu.

To choose the CONFIGURATION menu, press as many times as necessary

To validate your choice press

L-SOLUTION 800

LANGUAGE ENGLISH

SERIAL PORT

DISPLAY UNIT MM

4. Select the LANGUAGE menu.

To choose the LANGUAGE menu, press as many times as necessary

To validate your choice press

First contact

ENGLISH

FRENCH

DEUTSCH

L-SOLUTION 700 / 800 / 900 machines . 27

Page 28

Installation

5. Select the language you want ("ENGLISH").

When you receive your L-SOLUTION machine, it is set up to display the messages in English.

To choose the language you want, press as many times as necessary.

To validate your choice press

The following message is displayed on the L.C.D. screen :

L-SOLUTION 800

LANGUAGE ENGLISH

SERIAL PORT

DISPLAY UNIT MM

6. Select the machine menu (L-SOLUTION 800)

The programme used by the L-SOLUTION 800 machine is also used by other GRAVOGRAPH machines.

To choose the machine menu press as many times as necessary.

To validate your choice press

L-SOLUTION 700

L-SOLUTION 800

L-SOLUTION 900

L-SOLUTION 500 XL

7. Select the L-SOLUTION machine you want

To choose the machine you want, press as many times as necessary.

To validate your choice press

L-SOLUTION 800

LANGUAGE ENGLISH

SERIAL PORT

DISPLAY UNIT MM

8. Press

The following message is displayed on the L.C.D. screen :

<READY TO RECEIVE>

001 FILENAME1

PUI 40 VIT 10

DPIX 400 DPIY 400

L-SOLUTION 700 / 800 / 900 machines . 28

First contact

Page 29

Printer driver

The printer driver of the LASER machine

This section describes how the computer controls the LASER system through the printer driver.

It defines some very important terms that you need to know in order to operate the system correctly.

How the computer controls the LASER machine

The LASER system is a unique type of output device. Let’s call it a very sophisticated printer/plotter.

A regular LASER printer is a "raster"-based output device. So is a bubble jet, ink jet, or dot matrix printer.

A plotter is a «vector» based output device.

The difference lies in the way the characters and other graphics are formed. To explain what «raster» and «vector» are,

let us use the example of trying to print the letter «T» (diagram 1). A raster printer will make a back-and-forth motion

to create the character whereas a vector plotter will follow the path of the outline of the character.

The LASER system can actually raster the image, vector the image, or do both raster and vector motions. The LASER

systems printer driver works directly with your software program to send the correct image to the LASER system.

The LASER system is an output device just like a printer or plotter is.

Once the graphic is created on your computer system, you print the graphic the same way you would print to a LASER printer

or plot to a plotter. This information is then sent down to the LASER system through the parallel cable and is stored in the

LASER systems RAM memory.

Once the file is in the memory, press the «Start» button on the control panel to begin processing.

The only real difference between how a LASER printer or a plotter works compared to the LASER system is that the LASER

printer driver also has control on how much LASER power as well as motion system speed is applied.

First contact

L-SOLUTION 700 / 800 / 900 machines . 29

Page 30

Printer driver

Installing the Windows® (Windows 2000®, XP® or Windows 98®) printer driver.

The printing driver of the LASER machine is delivered on a CD-ROM. It should therefore be installed and selected in

Windows® (Windows 2000®/Windows XP®/Windows 98®).

It enables your software to transfer the information necessary for engraving to a LASER machine.

The following paragraphs describe the procedure for setting up Windows® so that the C.A.D. software can use the LASER

machine as a printer connected to the computer's serial or parallel port.

Complete understanding of how Windows® works is essential to the operation of the LASER system. Before continuing,

please refer to the Windows® owner’s manual regarding installation, use, and operation.

For a connection L-SOLUTION/PC using the USB port, plug the USB cable into the USB

port of the L-SOLUTION machine and into the USB port of your computer. Then switch

on the L-SOLUTION machine before installing the L-SOLUTION machine driver.

1. Power ON your PC.

2. Insert the CD-Rom which contains the driver of the L-SOLUTION machine (provided with the

machine)

3. Wait for the opening of the "L-SOLUTION Set Up 2000":

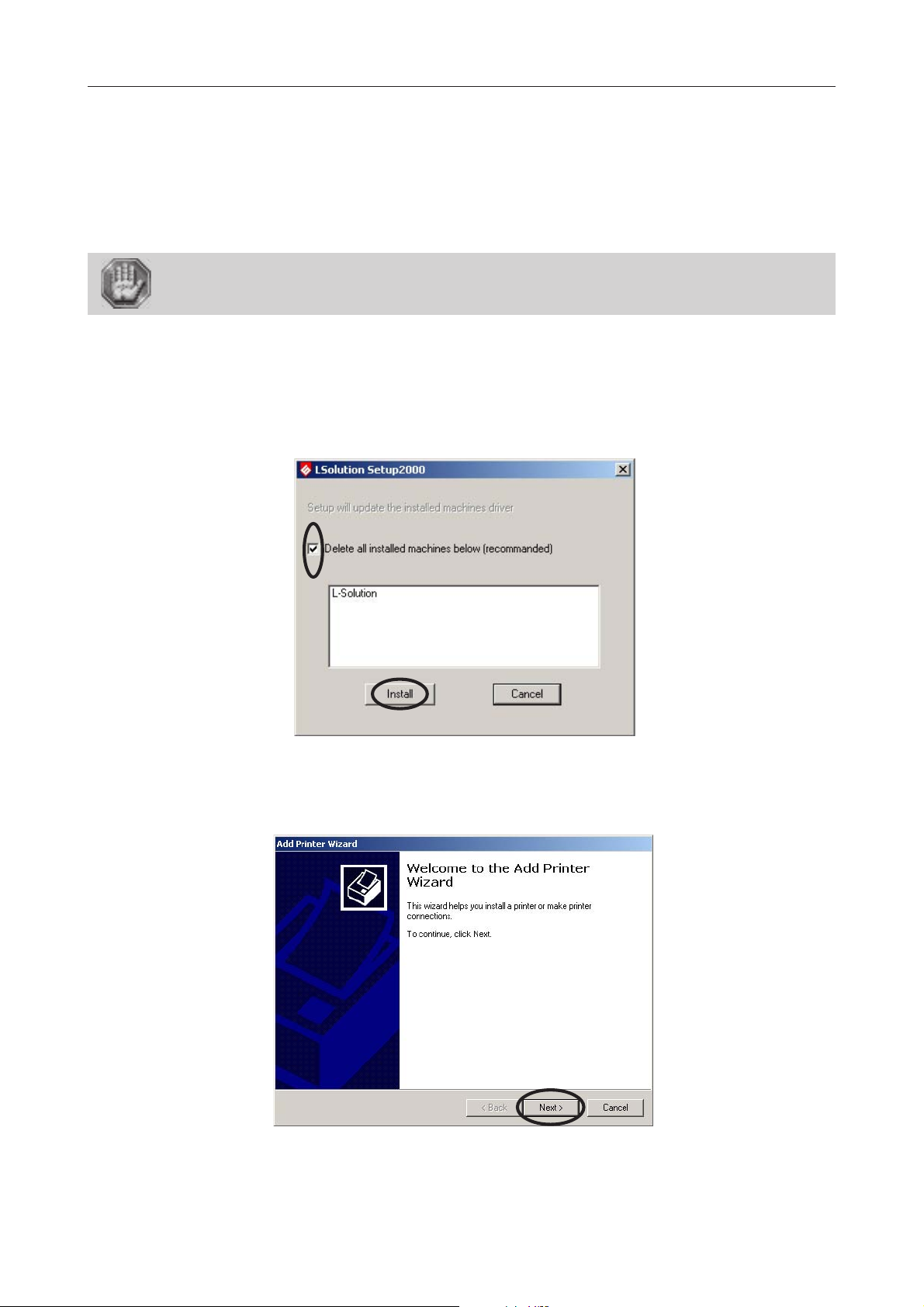

4. Select "Delete all installed machines below (recommanded)" and click "Install".

5. When the «Add Printer Wizard» appears click «Next».

L-SOLUTION 700 / 800 / 900 machines . 30

First contact

Page 31

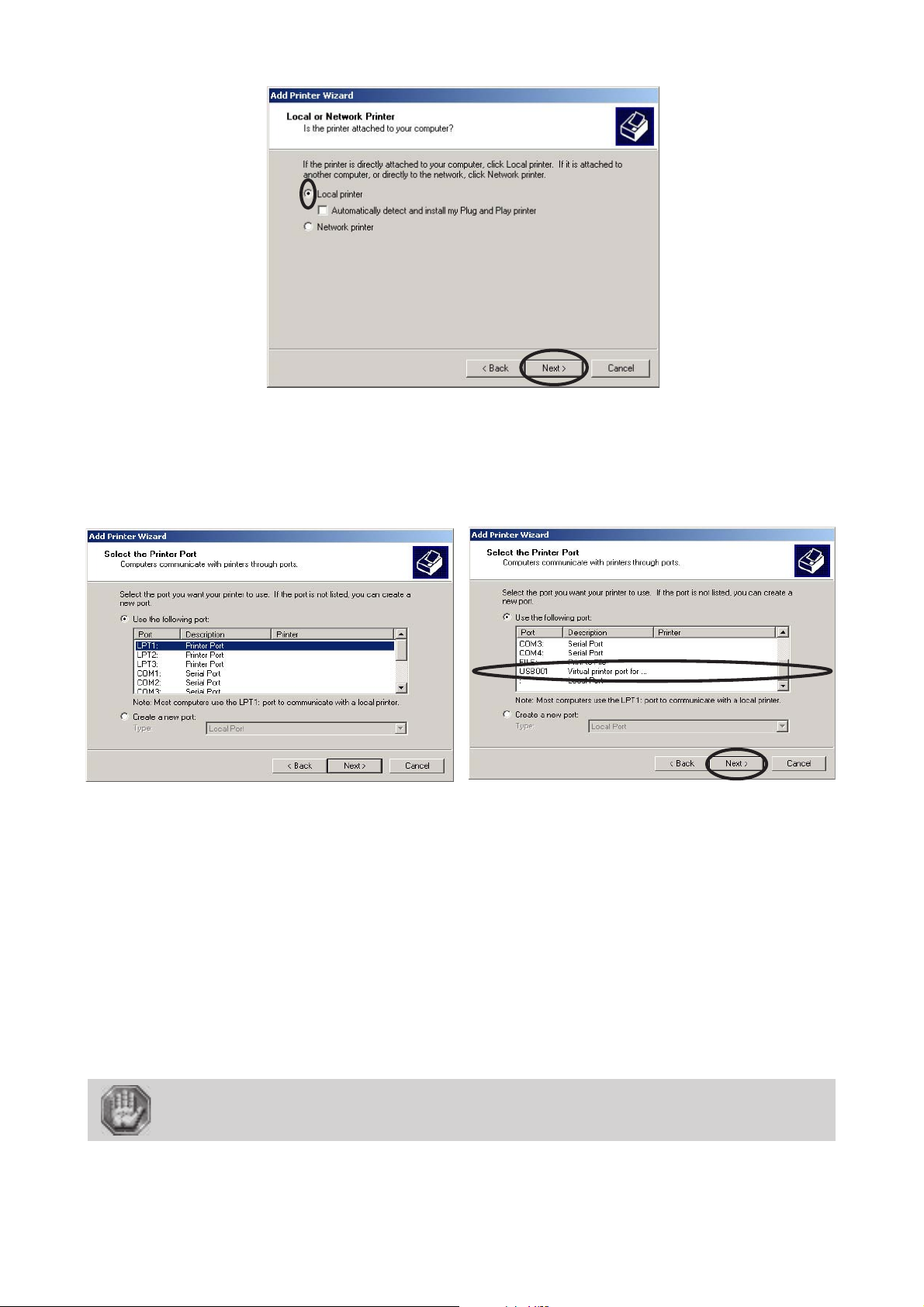

6. Click «Local Printer» and click «Next».

Printer driver

7. Click the port your LASER system is connected to and click «Next».

LPT port if you have set up the transfer with a suitable Gravograph parallel cable, connected

to the parallel port of the engraving machine and an LPT port of the computer.

COM port if you have set up the transfer with a suitable Gravograph series cable, connected to the series

port of the engraving machine and a COM port of the computer.

USB port if you have set up the transfer with a suitable Gravograph USB cable, connected to the USB port

of the engraving machine and an USB port of the computer. As soon as the machine and the PC computer

are connected and switched on, a virtual USB port is created automatically (ex: "USB001 (Virtual printer

port for USB)").

Please refer to the installation guide shipped with your computer to identify the port the

transmission cable should be connected to.

Most computers have at least one parallel port called LPT1 and 2 series ports, called COM1 and

COM2. COM1 is generally used to connect the mouse. Ports LPT1 and COM2 can be used

to connect your engraving machine.

If you select a COM port, set up the serial link or your computer ! (see the following

paragraph).

First contact

L-SOLUTION 700 / 800 / 900 machines . 31

Page 32

Printer driver

8. When the «Manufacturer» and «Printers» menu list appears click «Have Disk»

(Do not look for the printer in the menu).

9. Indicate where is the driver (on the CD-Rom already inserted). The driver for Windows 2000 and

Windows XP is in the folder "LSolution2000" and the driver for Windows 98 is in the folder

"LSolution98" :

9a. Select the drive where is the

CD-Rom which contains the driver of the machine.

L-SOLUTION 700 / 800 / 900 machines . 32

First contact

Page 33

9b. Select the folder where is the driver

for your Windows version (in

LSOLUTION98 for Windows 98 or in

LSOLUTION2000 for Windows 2000

or XP) :

9c. Click "Open".

Printer driver

9d. Click "Open".

10. Click «OK».

First contact

L-SOLUTION 700 / 800 / 900 machines . 33

Page 34

11. DO NOT click «Have Disk» again, click «Next».

Printer driver

12. Choose if you would like to set it as your default printer and click «Next».

13. Choose if you would like to share your printer with someone else and click «Next».

L-SOLUTION 700 / 800 / 900 machines . 34

First contact

Page 35

14. Select «No» when it offers to print a test page, and then click «Next».

Printer driver

15. An “Completing the Add Printer Wizard” window appears with a reminder of the information

about the parameters chosen for the printer driver. Click «Finish».

16. Click "OK" and restart your computer to activate the new driver :

17. Your driver installation is now complete. Store your driver disk in a safe place.

Now, to transfer the engraving to your L-SOLUTION machine, just like with a printer, all you need to select in the "Print..."

option.

First contact

L-SOLUTION 700 / 800 / 900 machines . 35

Page 36

Printer driver

Setting up the serial transmission

Synchronize the serial link settings between the computer and the engraving machine, each time you

- set up a printer using a COM port,

- select this printer to transfer the composition.

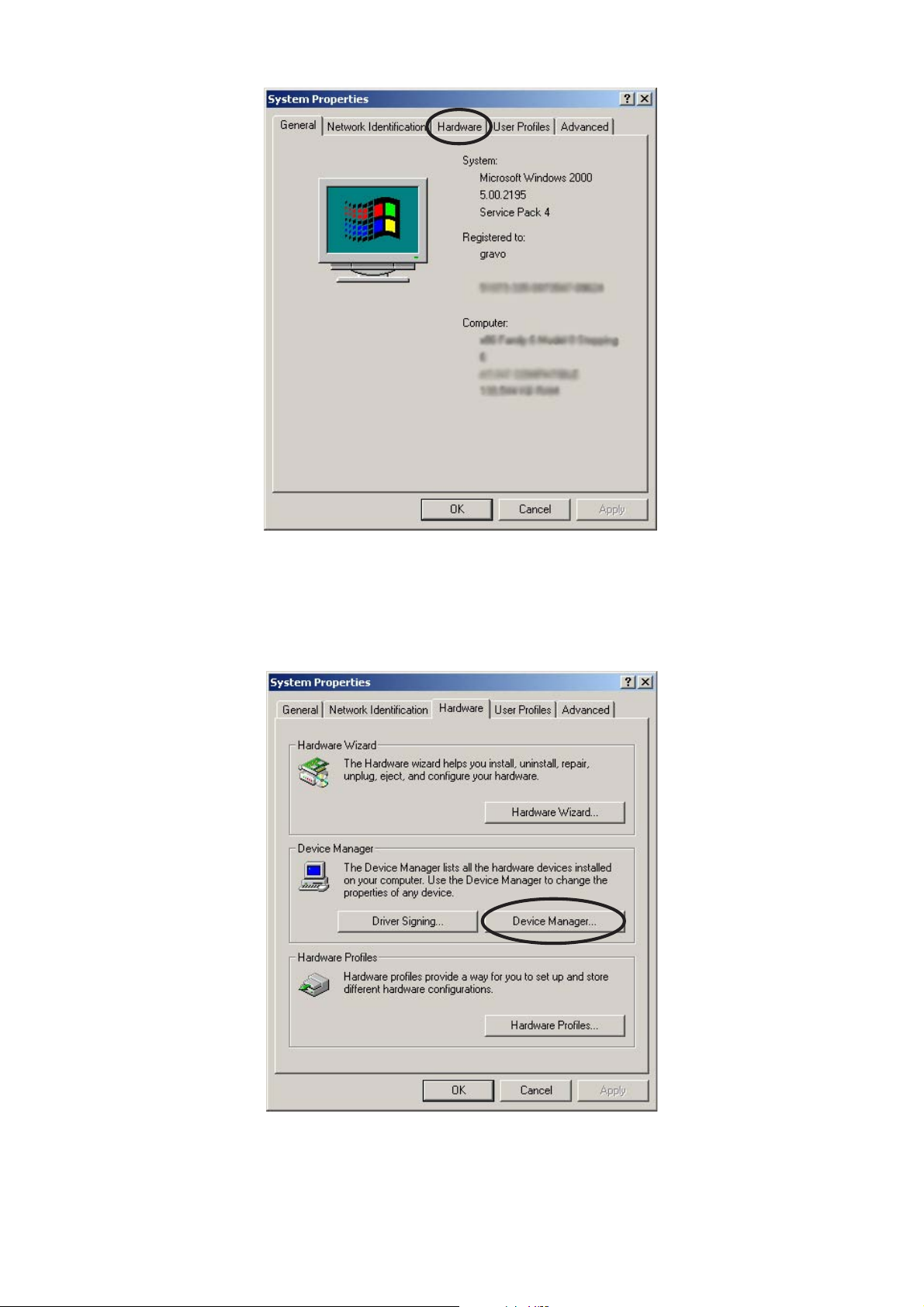

1. In the Windows 2000® Taskbar , click "Start".

2. Click the Settings option of the Start menu.

3. Click the Control Panel option of the Settings menu.

4. Click the System icon of the Control Panel.

L-SOLUTION 700 / 800 / 900 machines . 36

First contact

Page 37

Printer driver

5. Click the Hardware tab, and then Device manager In the System Properties dialog.

First contact

L-SOLUTION 700 / 800 / 900 machines . 37

Page 38

Printer driver

6. Click the "+" in front of the Ports option (COM and LPT) of the Device Manager list.

7. Double-click the COM Port used by the link.

L-SOLUTION 700 / 800 / 900 machines . 38

First contact

Page 39

Printer driver

8. Click the Port settings tab of the Communication Port Properties dialog.

9. Enter the serial settings of the machine (please refer to the manufacturer's guide).

The serial link of your L-SOLUTION machine is set up as follows:

• Transfer rate : 9600 Bauds

• Number of data bits : 8

• Parity : none

• Number of stop bits : 1

• Transfer protocol : RTS/CTS (equipment)

10. Click "Advanced...".

First contact

L-SOLUTION 700 / 800 / 900 machines . 39

Page 40

Printer driver

11. In the "Advanced Settings for COM" dialog , remove the "Use FIFO buffers" function which is activated

by default.

12. Click OK to validate.

If the serial settings between the machine and the computer are different, the

composition will not be transferred in the best conditions (risk of transfer errors,

altering the final engraving result)!

Now, to transfer the engraving to your L-SOLUTION machine, just like with a printer, all you need to select in the "Print..."

option.

L-SOLUTION 700 / 800 / 900 machines . 40

First contact

Page 41

Printer driver

First contact

L-SOLUTION 700 / 800 / 900 machines . 41

Page 42

Printer driver

L-SOLUTION 700 / 800 / 900 machines . 42

First contact

Page 43

Printer driver

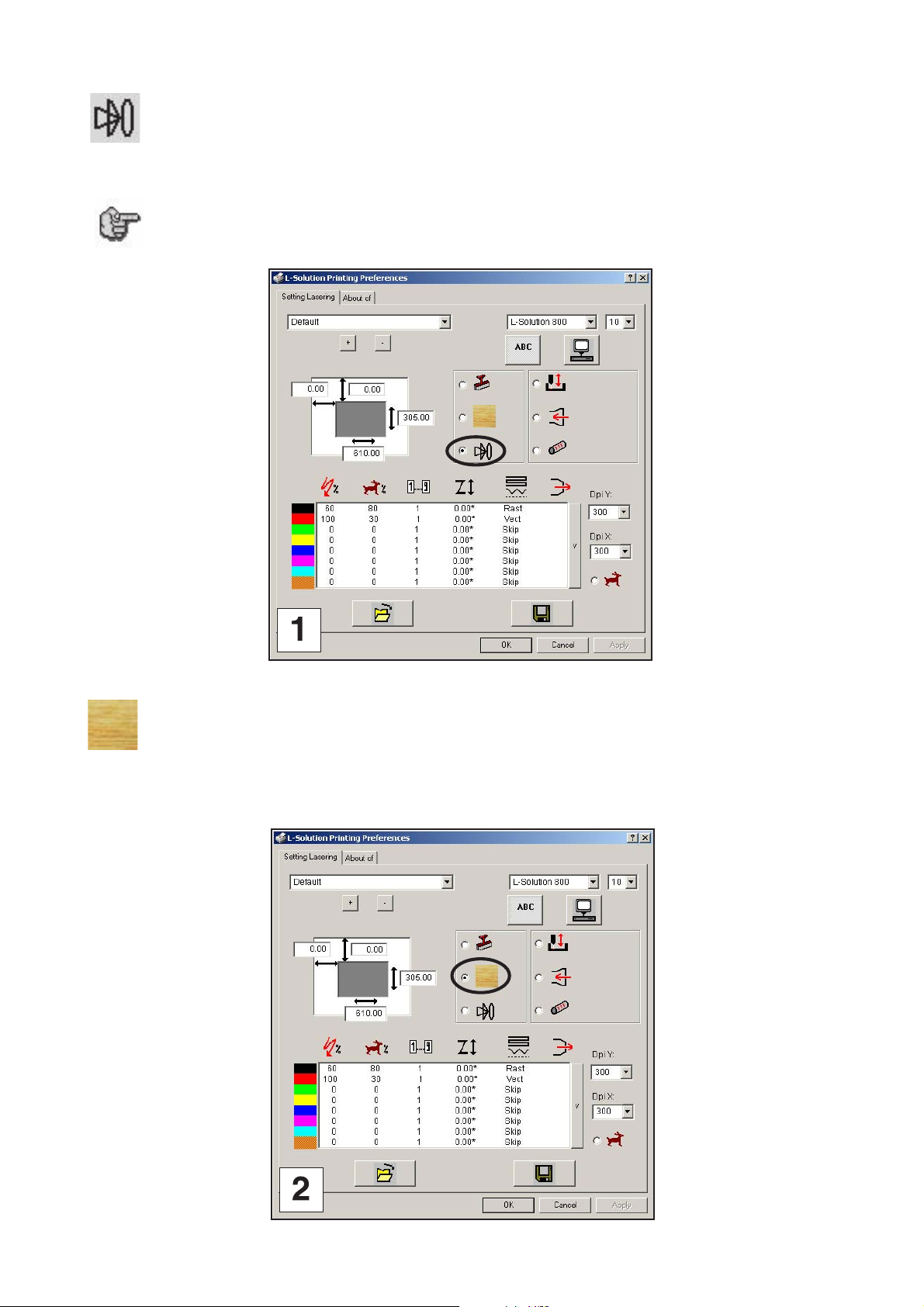

Driver controls

The Printer Driver for Windows 2000® (driver for short) has the appearance of other Windows 2000® printer drivers

(pict. 1). A thorough understanding of how Windows 2000® operates is essential to operating the driver’s controls. Please

refer to your Windows 2000® manual or online help screen on how to install, operate, and troubleshoot Windows 2000®.

About of tab

This «About of» tab (pict. 1) is controlled by Windows 2000® and is present in all Windows 2000® Drivers. For information

on how to use the controls located in this tab, please refer to your Windows 2000® manual or online help screens.

The “?” in the top right corner of every tab takes you to the driver's online help screens.

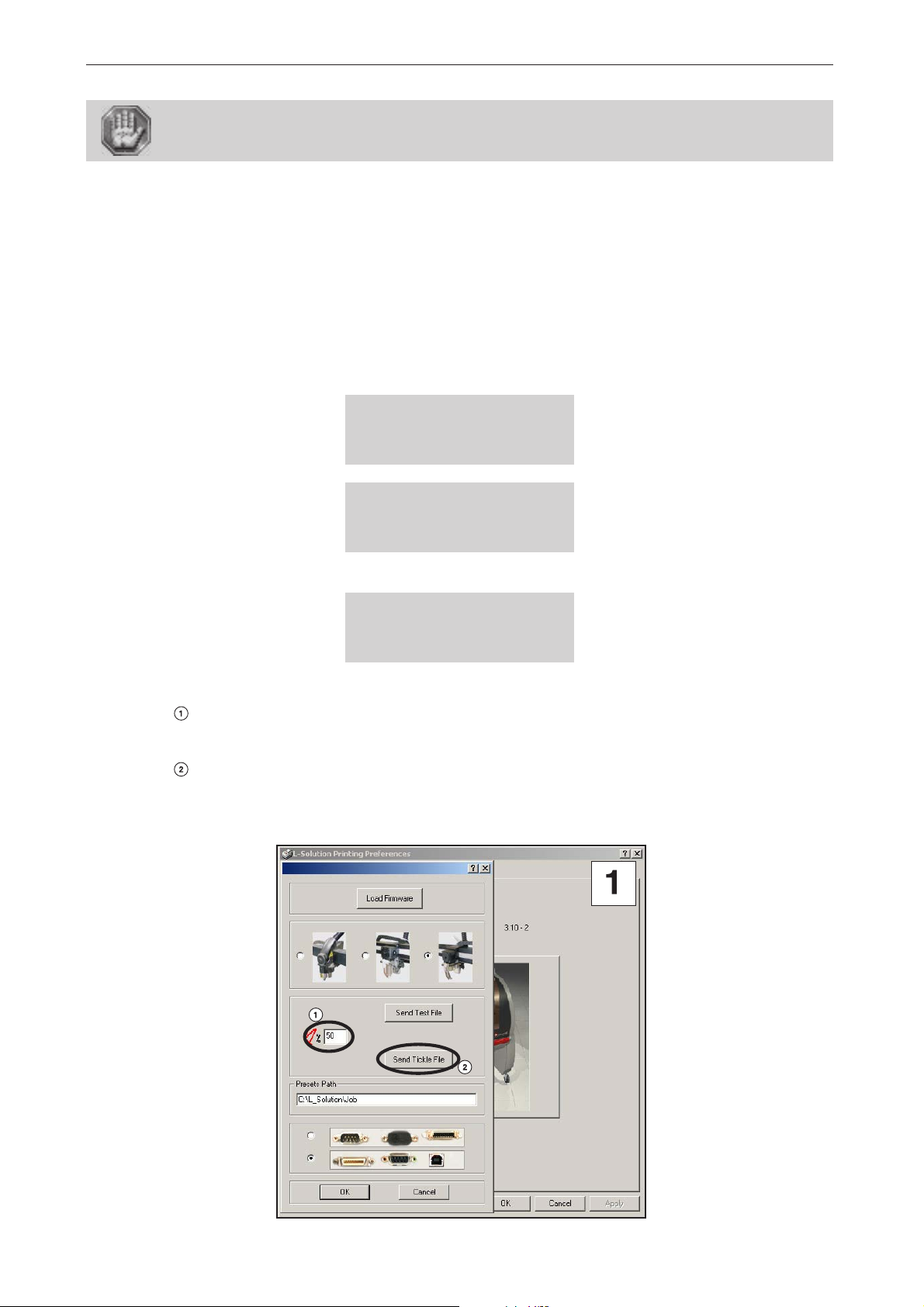

By clicking on the photo of the machine it is possible to (pict. 1) :

- to load a new version of the machine program

- select bridge X installed on the machine :

first bridgeX second bridge X third bridge X

- select the connections installed on your machine :

Serial RS232 / Parallel connections (Old machines)

USB / Parallel connections (New machines)

- choose a storage folder for your engraving job files (JOB):

Storage folder example ("Presets Path" ) : C:\L_SOLUTION\Job

- to send an engraving test file to adjust your LASER alignment :

1 - Adjust the power of your laser based on the material used for engraving the test file.

2 - Start the test file on the machine

13 lines (numbered from 0 to 12) of vertical lines are then engraved :

6

- to send an engraving test file to adjust your "Tickle" parameter (pict. 6):

First contact

3 - Select the number of the best engraved line (for example line no. 6 - pict. 3 and 4)

4 - Apply (pict. 5)

5 - Confirm (pict. 5)

The "Tickle" adjustment is described in the "General maintenance" chapter.

L-SOLUTION 700 / 800 / 900 machines . 43

Page 44

Printer driver

LASER Settings tab

(pict. 1)

This LASER settings tab is used to adjust the various settings required for the LASER engraving.

L-SOLUTION 700 / 800 / 900 machines . 44

First contact

Page 45

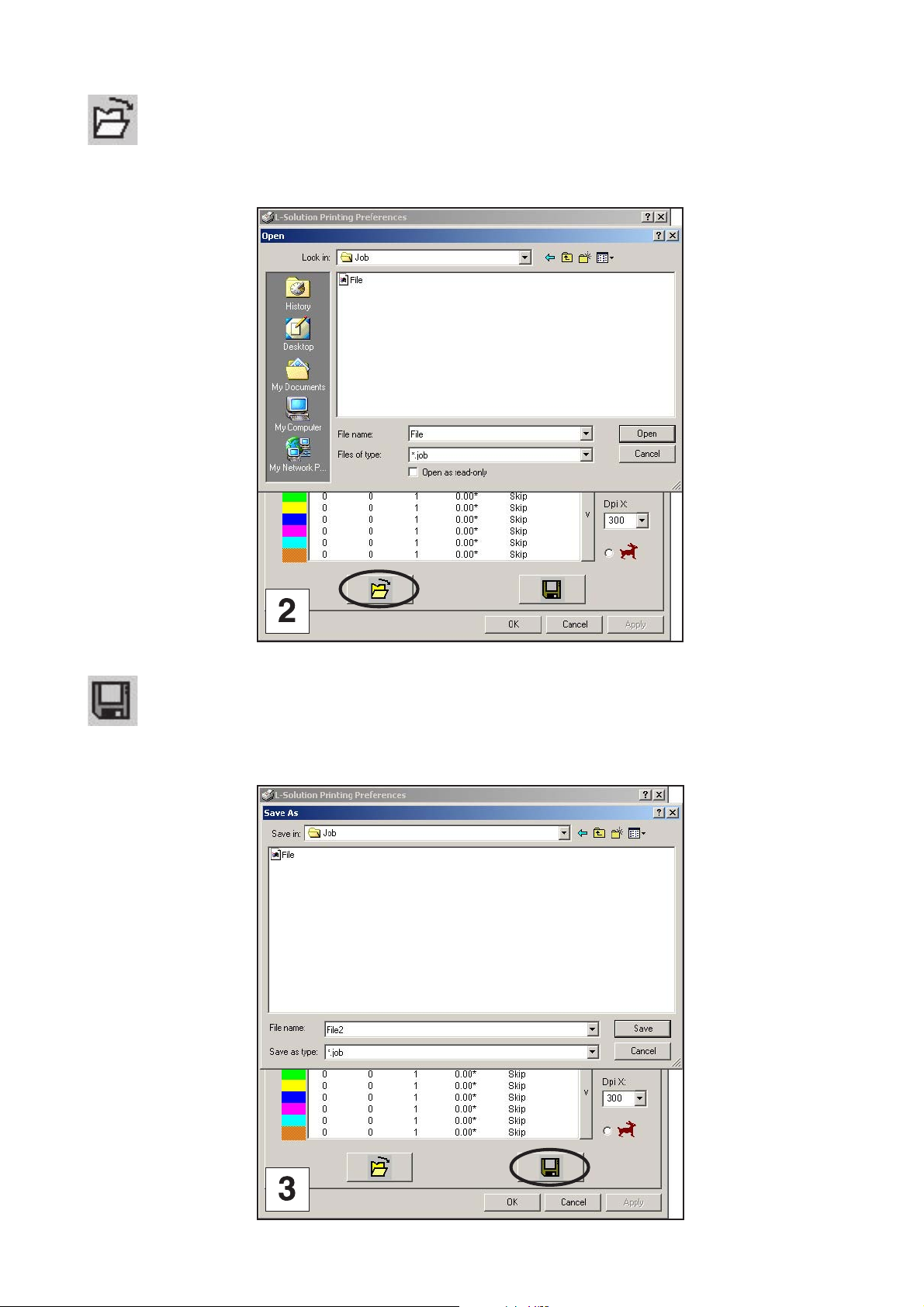

Open

(image 2)

used to open a job file corresponding to a saved engraving job.

Printer driver

Save

(image 3)

used to save an engraving job in the form of a job file.

First contact

L-SOLUTION 700 / 800 / 900 machines . 45

Page 46

Printer driver

Definition of the machine used

(pict. 1)

A list of the machines available appears by clicking the “machine” drop down menu . Select the name of the machine

you want to use.

Definition of the plate

(pict. 1)

A list of 3 available pre-defined plates is displayed by clicking the “plate” drop down menu ("Default","Default rubber

stamp", "Untitled") . Select the name of the plate you want to use.

From these 3 pre-defined plates, you can define another plate by entering its dimensions:

Values correspond to the plate dimensions you have to enter for them to be EXACTLY the same as those defined in

your software; otherwise there might no output, a partial output or a poor alignment of the graphics. The operator has to

enter the suitable setting values (the maximum dimensions allowed are those of the machine maximum engraving area).

Values correspond to the original engraving which is the default value of the machine (point (0.0) in the top left corner

of the engraving table).

Once your new parameters defined, save them with a new name of plate. Change the name and click (+) in order to add

it in the list of your plates. Click (-) in order to delete the selected plate. The 3 pre-defined plates "Default","Default rubber

stamp" and "Untitled" can not be modified or deleted.

L-SOLUTION 700 / 800 / 900 machines . 46

First contact

Page 47

Printer driver

Selecting the power available on the LASER machine

(pict. 2)

By clicking on the "power"" , pull-down menu the list of available powers is displayed. Select the power for your machine.

Plate orientation

(pict. 3)

Determines the orientation of the graphic and of the text to be engraved on the plate.

First contact

L-SOLUTION 700 / 800 / 900 machines . 47

Page 48

Printer driver

L-SOLUTION 700 / 800 / 900 machines . 48

First contact

Page 49

Printer driver

Graphics

The LASER machine acts like a black and white printer (black is engraved and white is not), so the photographs (bitmaps)

in a scale of grey or colours as well as multicoloured clipart images are transformed into smooth images. This is done when

the LASER machine reproduces the image. This process is very similar to the way magazine photos are printed, as well as

photos obtained from LASER printers

A conversion must be made by your software or by the printing drive of your LASER machine. The following paragraphs

describe the various conversion possibilities with the printing drive of the LASER machine in the normal mode (image 1)

and rubber mode (image 2)

« Automatic » (only normal mode - image 1)

is used to run the printing to convert the colours in the cliparts and texts (everything that is generated starting from graphic

forms and texts) to levels of grey so that it can automatically assign the adequate power to each pixel based on the level

of grey and proportional to the power assigned to the colour black.

The colours in the photos (bitmap format) are processed in the same way.

Engraving of the entire job is done in one scan. The engraving parameters (max power, speed etc.) are set by the colour

black.

« Filling » (normal and rubber mode - images 1 and 2)

is used to process the colours in the same way as the automatic mode with a power range divided into 64 levels. For each

of these levels a specific filling is applied.

The engraving parameters (max power, speed etc.) are set by the colour black.

All the points are engraved with the same power (set by the colour black).

Engraving of the entire job is done in one scan.

« Black and white mode » (only rubber mode - image 2)

is used to process the colours in the same way as the automatic mode for the cliparts and texts (everything generated

starting from the graphic forms and texts) and sets the limit of the image to 50% of black (power set by the user) for the

photos. Each pixel over 50% of black is converted to white (engraved) and each pixel less than or equal to 50% of black

is converted into black (not engraved). This operation is similar to a photo duplication process with a photocopier.

« User colours » (only normal mode - image 1)

is used to run the printing to convert the colours in cliparts and texts (everything generated starting from graphic

forms and texts) from 8 basic colours set in the print drive interface. The other colours are converted to the closest

colour of these 8.

Engraving of each colour block is done separately with its associated engraving parameters.

The colours in the photos (bitmap format) are processed like in automatic mode. Engraving of the photo block is

effected after the last colour block with engraving parameters of the colour black.

« Negative image » (normal and rubber mode - images 1 and 2)

used to run printing to convert an image into its negative image. All the objects which were filled with black and thus

engraved become images filled with white and no longer engraved.

« Photo mode » (normal and rubber mode - images 1 and 2)

"Photo mode" scatters the pixels in a random pattern to represent shading. Each obtained dot will be engraved with the

same power (the power of the black color). The optical illusion of shades of grays appears due to the density of these dots.

Therefore the result will be the same whatever the material you use.

First contact

L-SOLUTION 700 / 800 / 900 machines . 49

Page 50

Printer driver

L-SOLUTION 700 / 800 / 900 machines . 50

First contact

Page 51

Printer driver

Settings

(pict. 1 and 2)

Color

The colors in the driver allow you to assign different LASER settings and modes to your multi-colored drawn artwork. This

enables you to control the depth of the burn as well as different visual effects to your material. You can assign settings

for up to eight (8) DRAWN colors.

Power Setting

LASER power is controlled by assigning the percentage of power from 0 - 100% to each color used in the graphic drawing.

Since the LASER is pulsed proportionally, this percentage represents how long the LASER remains on for each LASER pulse

fired.

Basically, the power setting is directly related to how deep the engraving will be.

The Power setting is linear meaning that 100% power will engrave or cut twice as deep as 50% power.

Speed Setting

This setting controls how fast the motion system moves in a percentage of the maximum speed of the LASER engraver.

The actual time that an object takes to engrave or cut is entirely dependent on the size of the graphic. Power and speed

work together in determining how deep the engraving will be. Higher power settings and slower speeds will produce deeper

engraving or cutting. You might notice that on small objects, engraving or cutting at a faster speed as opposed to a slower

speed might not produce a faster engraving time. The time it takes to engrave or cut can be related to the size of the graphic

and the mechanical ability of the engraver to achieve the speed that you have selected. If the LASER system determines

that it cannot achieve the speed that you have selected, for a graphic of that size, it will automatically adjust its speed

internally, to the maximum speed it can achieve. This is evident visually when cutting curves or circles as opposed to straight

lines, and you see the motion system slow down automatically.

Proportional pulsing of the LASER will ensure that there is no difference in the depth of cut from straight lines to curves.

Refocussing

A refocussing can be defined by the user (depth) at each pass.

The value indicated is the distance to be sent between two passes for making the engraving material rise or cutting it so

as to be within the LASER focus during the next pass (negative values are possible).

A refocussing of 0.10 mm will be carried out after each pass (0,10*).

A refocussing of 0.10 mm will be carried out before the first pass and then after each pass (*0,10).

Passes

The number of passes can vary from 1 to 9.

First contact

L-SOLUTION 700 / 800 / 900 machines . 51

Page 52

Printer driver

Rast/Vect (raster/vector)

(pict. 1)

The LASER machine can actually raster the image, vector the image, or do both raster and vector motions

(see page 29).

RAST :