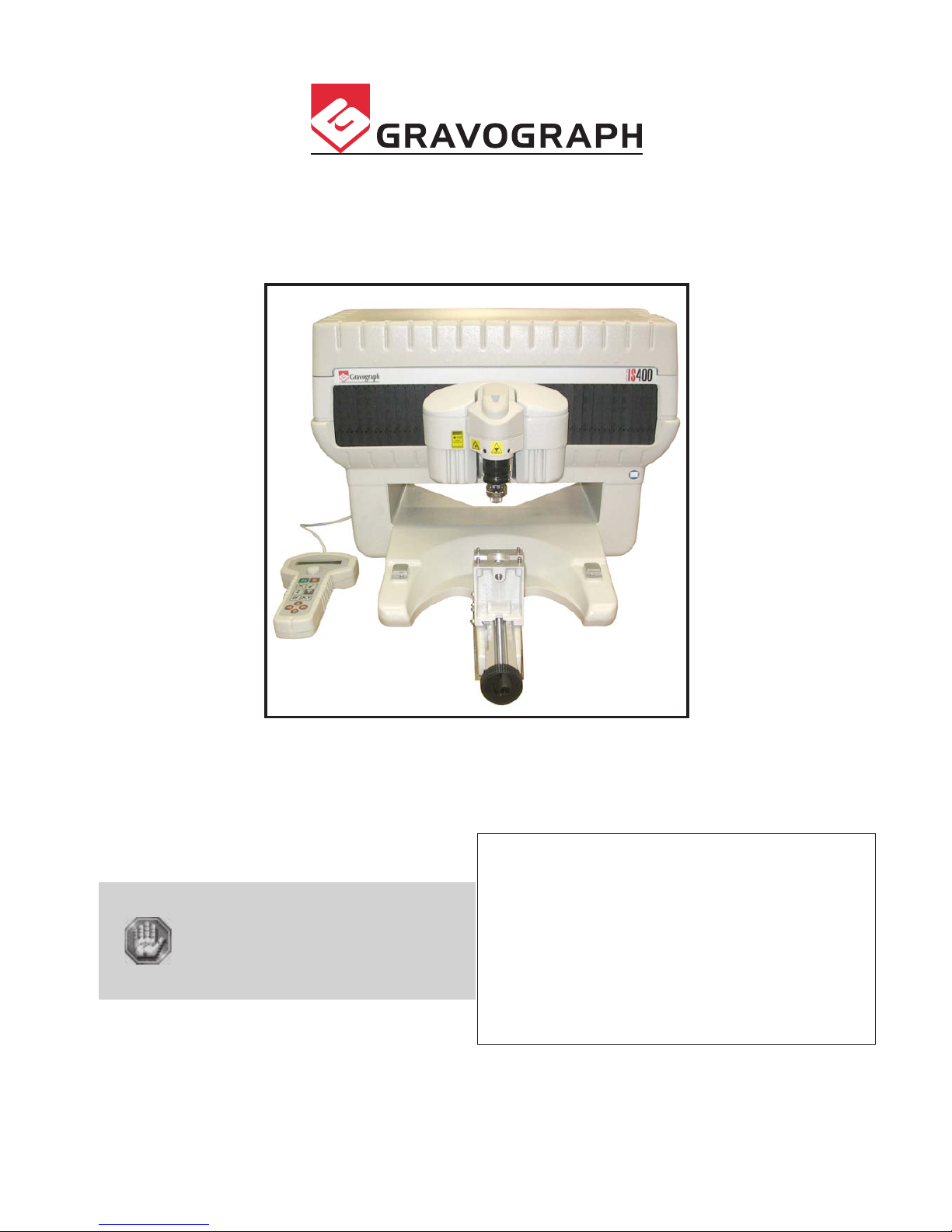

GRAVOGRAPH IS400 User Manual

Before installing and using this

machine, you must read this user

guide carefully. Keep it in a safe

place, in case you need to refer to

it later.

This manual should not be used

without the CN 97 program manual

- B2241 701.

D2083 701 - 02.2008 - ENG - (UPDATED EDITION NUMBER: 10)

(Please read carefully

before use)

User manual

IS400 machine

First contact

IS400 machine . 2

First contact

Gravograph reserves the right to modify the information contained in this document without notice.

TYPE OF MACHINE : IS400 Electronic Engraving Machine

MANUFACTURER : GRAVOGRAPH INDUSTRIE INTERNATIONAL

BP 15 - Z.I. - 10600 LA CHAPELLE SAINT LUC - FRANCE

(c) Gravograph Industrie International, 2008

All Rights Reserved.

Importer's address

This publication and its contents are proprietary to Gravograph Industrie International (Gravograph), and are intended

solely for the contractual use of Gravograph customers.

While reasonable efforts have been made to assure the accuracy of this manual, Gravograph shall not be liable for errors

contained herein or for incidental or consequential damage in connection with the furnishing, performance, or use of this

material.

Gravograph reserves the right to revise this manual and make changes from time to time without any obligation by

Gravograph to notify anybody of such revision or changes.

Gravograph can not be held liable for any problems arising out of the application or use of any products, circuits, or software

described herein. Neither does it convey a license under its patent rights nor the patent rights of third parties.

Gravograph provides no warranties whatsoever on any software used in connection with a Gravograph Engraving System,

express or implied. Neither does it guarantee software compatibility with any off-the-shelf software package or any software

program that has not been written by Gravograph.

Intended use of this system must be followed within the guidelines of this manual. In no event will Gravograph be liable

for any damages caused, in whole or in part, by customer, or for any economic loss, physical injury, lost revenue, lost profits,

lost savings or other indirect, incidental, special or consequential damages incurred by any person, even if Gravograph has

been advised of the possibility of such damages or claims.

Windows is a registered trademark of Microsoft Corporation.

PostScript is a registered trademark of Adobe Systems Inc.

First contact

IS400 machine . 3

Summary

Information about regulations ............................................................ 4

Conformity standards ...................................................................................................................... 4

Electrical security ........................................................................................................................... 4

Presentation ....................................................................................... 5

Contra-indications .......................................................................................................................... 5

Stages of unpacking ....................................................................................................................... 6

Unpacking - Contents of package ...................................................................................................... 7

Description ......................................................................................... 9

Front view of the machine ............................................................................................................... 9

Vice ............................................................................................................................................ 11

Long plate support kit ................................................................................................................... 12

Rear view of the machine .............................................................................................................. 13

Installing .......................................................................................... 14

Physical installation advice ............................................................................................................. 14

Electric installation advice .............................................................................................................. 15

Electrical connections of the machine .............................................................................................. 16

Connecting the IS400 machine to a PC ........................................................................................... 17

Switching the machine on .............................................................................................................. 20

Problems ..................................................................................................................................... 20

Switching the machine off ............................................................................................................. 20

Mechanical block .......................................................................................................................... 20

Switching on again ....................................................................................................................... 20

Machine configuration (language) ................................................................................................... 21

Installing the engraving software in Windows XP .............................................................................. 23

Engraving ......................................................................................... 24

Positioning the plate onto the vice .................................................................................................. 24

Point and Shoot ........................................................................................................................... 25

Transfer procedure ....................................................................................................................... 26

Adjusting the spindle .................................................................................................................... 27

Adjusting the rotation speed on the spindle ...................................................................................... 31

Starting to engrave ...................................................................................................................... 32

General maintenance ........................................................................ 33

Changing the belt ......................................................................................................................... 33

Adjusting the machine .................................................................................................................. 34

Technical Characteristics .................................................................. 36

Physical Characteristics ................................................................................................................. 36

Electrical Characteristics ................................................................................................................ 37

Engraving software characteristics .................................................................................................. 37

Optional accessories ..................................................................................................................... 38

IS400 machine . 4

First contact

Information about regulations

Conformity standards

This hardware was designed and built in conformity with the relevant EC marking and EEC directives :

• "Security" Directive 98/37/EEC (22/06/98).

• "Electromagnetic compatibility" Directive 2004/108/EC

• "Low voltage" Directive 2006/95/EC

The modification or transformation of this equipment, the adaptation and installation

of accessories not recommended by GRAVOGRAPH, the installation of this equipment

in a manufacturing process, the piloting by a robot, the connection to an external

automaton, modify the characteristics of this material and can make it not compliant

with the European Directives it is subjected.

These modifications voids the responsibility of the manufacturer.

In this case, the person who fits the machine and the equipment is responsible for the

EC compliance of the final work station.

Electrical security

This hardware is in conformity with the norms EN 60204-1 and EN 60950-1, which also refer to the LASER system safety

standard CEI 825-1 (08/2001).

The different fuses of the machine comply with the IEC 127-2 norm (International Electric Committee).

The different security levels the input/output answer are indicated for each connector in the chapter "Rear view of the

machine". Two security levels are possible :

- Dangerous voltage (power supply, accessories, plugs ...).

- Very low security voltage.

Machine security

This hardware is in conformity with the norm EN ISO12100-1 and EN ISO12100-2.

Electromagnetic compatibility

This hardware is in conformity with electromagnetic compatibility norms:

• EN 55022 - class B ; EN 61000-3-2 ; EN 61000-3-3 (emission in residential, commercial, and light industrial environment)

• EN 61000-6-2 (immunity in industrial environment)

All the cables used with this hardware must be in conformity with the electronic compatibility standards, norm

EN 55022 - class B.

Electrical security

This material is «class 1». The mains plug MUST always be connected to a neutral

socket and comply with the regulations in force in the country of installation. If you

do not have a plug of this type, have one installed by an approved electrician. Under

no circumstances should you depart from this instruction.

The manufacturer bears no responsibility towards any user where alterations have been carried out contrary to the

manufacturer's specifications, notably with respect to electrical/electronic elements.

Any operation, other than those mentioned here, must only be carried out by an

approved Gravograph technician.

Do not take the machine apart to repair or clean it : this will void your guarantee.

This symbol indicates that once this equipment has reached the end of its useful life,

it must not be disposed of with non-sorted municipal waste, in accordance with the

European Directive 2002/96/EC.

The equipment must be disposed of at an appropriate collection point for processing,

sorting, and recycling of Waste Electrical and Electronic Equipment (DEEE).

The elements which compose Electrical and Electronic Equipment may contain

substances which have harmful effects on the environment or on human health.

By following these instructions, you are helping the environment, contributing to the

preservation of our natural resources, and protecting human health.

First contact

IS400 machine . 5

Presentation

The machine must never be handled without an adult present. Keep the machine,

wires and cables out of children's reach.

Contra-indications

This machine is only designed for light engraving purposes and must never be used for

other applications.

To use this machine, you are advised to wear protectives glasses against the chip

ejections.

Never use this machine for sawing or drilling.

Do not use this machine for working with wood.

Do not use this machine in explosive environment.

This machine is only designed for one user. Do not let several people use the machine

simultaneously.

• If the machine is not to be used for a long period, unplug the electricity supply and cover the machine (packaging, cover,

lid...).

• Do not move the engraving head by hand unless mechanical block of the machine as described in the paragraph

"Mechanical block" of this manual's "Installing" chapter.

• Do not spill any liquids onto the machine (drinks, cleaning fluids…) unless when recommended by GRAVOGRAPH

(example: lubrication).

• Do not place any object on the machine other than that to be engraved.

• The machine should never be used with anything other than Gravograph accessories and tools.

• Never hold the material to be engraved in your hands. Only use the GRAVOGRAPH clamping systems designed for your

machine.

• Make sure that the material is well clamped before starting to engrave.

• During engraving, do not use this machine without a nose (depth regulating nose or vacuum nose) in order to avoid

projections of swarf.

• Do not take the engraving material out of the machine during engraving.

• If the engraving must be stopped, use the function key provided for this purpose on the keyboard of the machine.

To avoid any risks of being crushed by the machine during engraving, do not stand near

the tools (the travel area of the tool is 305x210mm).

Do not lean over the spindle holder.

Ensure that no one is in the travelling area of the moving parts of the machine and that

no object will obstruct the travelling of the moving parts.

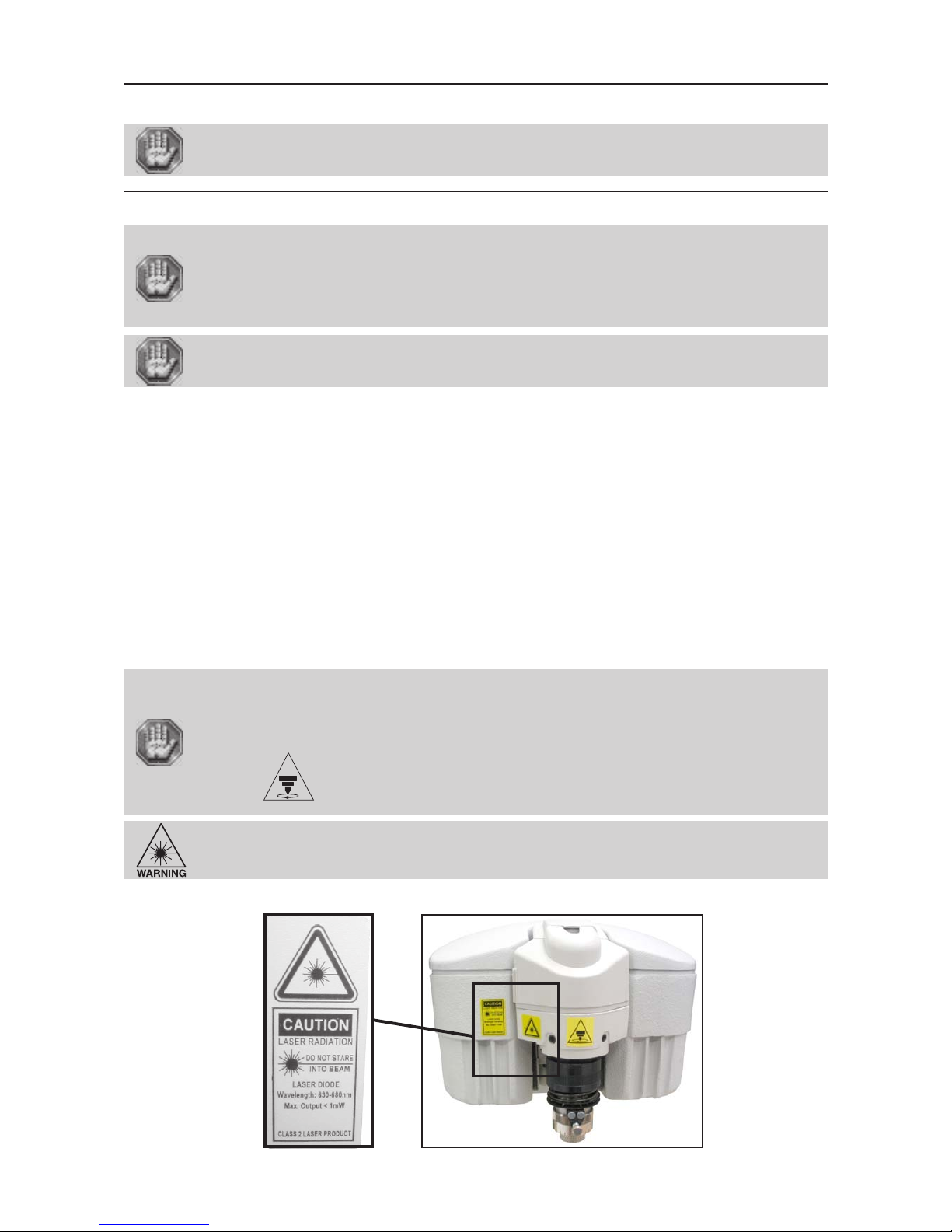

This sign shown on the tool-holder of the machine shows the danger

caused by the rotating spindle during engraving (risks of getting burnt

or cut).

To avoid any risks of getting burnt, the protective belt housing of the

tool-holder must be always closed, except when carrying out adjustments.

CAUTION - LASER RADIATION (pict. 2)

Do not stare into beam

Laser diode - Wavelength: 630-680nm - Max. Output < 1mW

CLASS 2 LASER PRODUCT

IS400 machine . 6

First contact

Stages of unpacking

Two people are necessary to unpack the IS400 machine.

Before opening the cardboard box, check that it is the right way up.

After opening the box (pict. 1):

1. Take out the documents.

2. Take off the protective packaging

3. Take out the tool box.

4. Take out the cables.

5. Take off any protective packing from the machine.

6. Take out the machine.

- There should be one person on each side of the machine.

- Both should lift the machine simultaneously, and place it on the working surface.

Make sure that no components are missing from the packaging. If any part has been

forgotten please get in touch with your GRAVOGRAPH dealer.

Keep all the packaging materials so that you can move your machine in total safety. This packing was conceived to guarantee

the protection of the machine during its transport (for a return in repair for example).

This packaging is in conformity with European recycling standards.

First contact

IS400 machine . 7

Unpacking - Contents of package

Check the condition of the packaging when you receive it. If there are any signs of

damage, inform the carrier and your GRAVOGRAPH dealer immediately by recorded

delivery, specifying the exact nature of the problem.

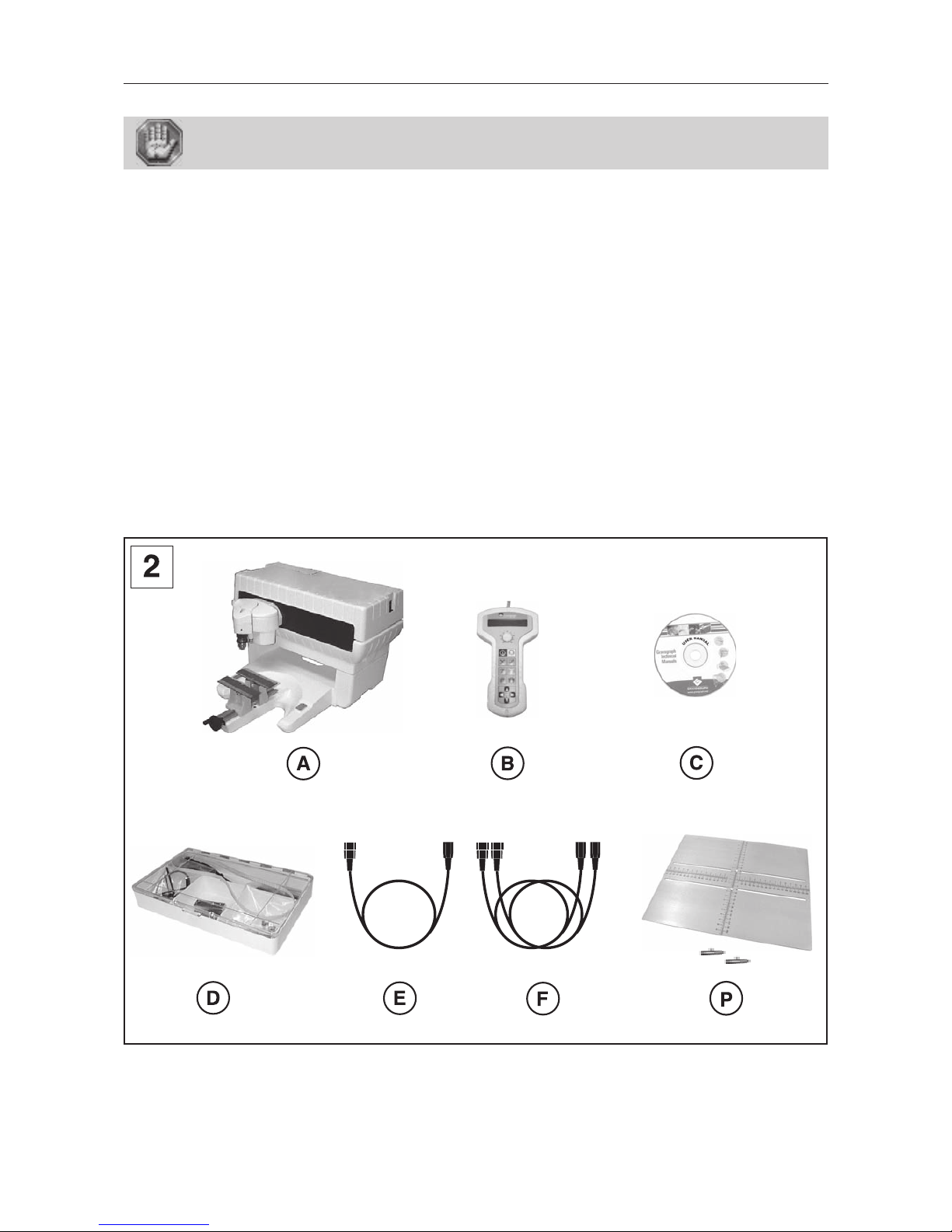

Contents of package

(pict 2)

A. An IS400 machine (IS400 electronics box + engraving table)

B. A control panel

C. A CD-Rom contains the user manual

D. A tool box

E. A power cable

F. 2 connection cables :

- an USB connection cable

- an engraving table - IS400 electronics box connection cable

P. One long plate support kit (installing page 12)

IS400 machine . 8

First contact

3,5

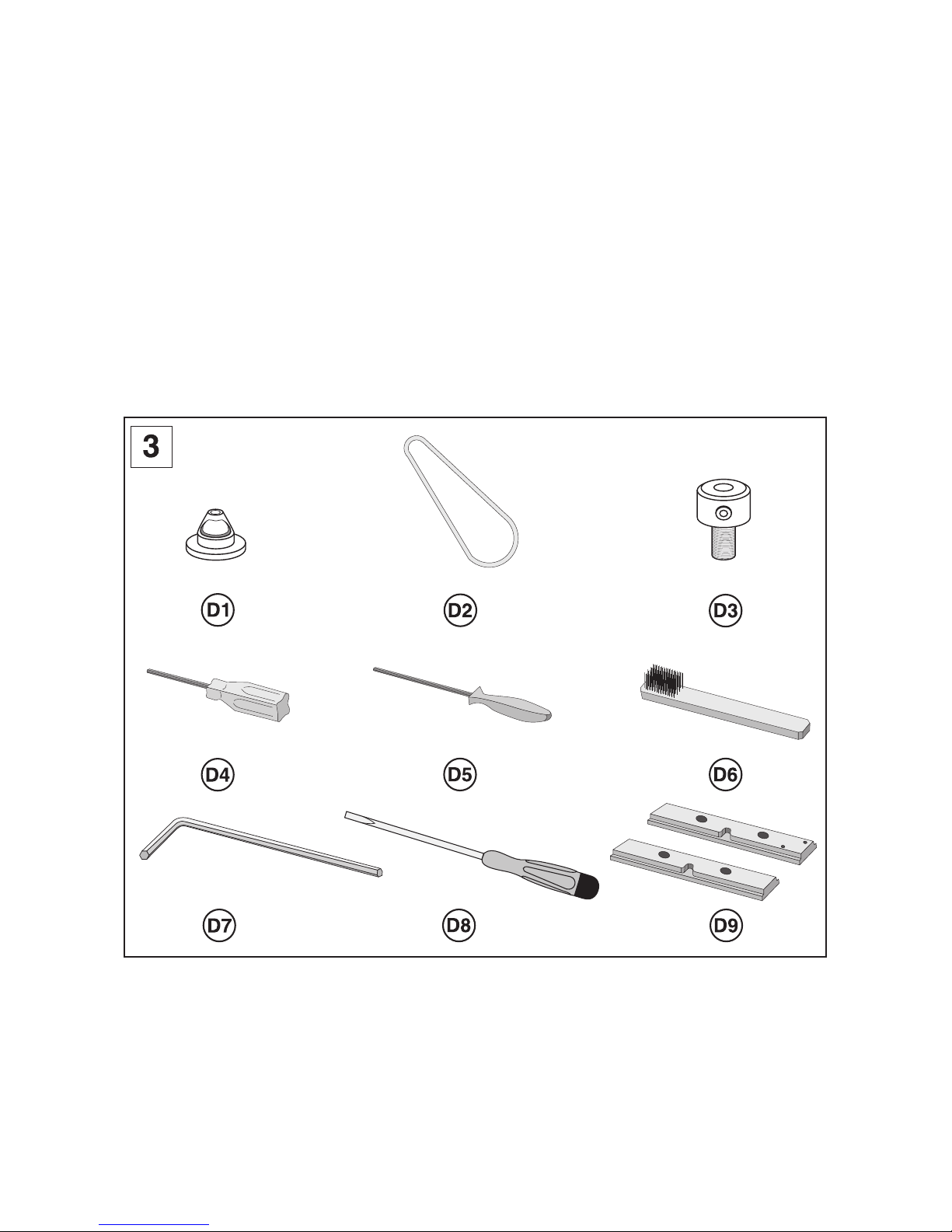

Contents of tool box

(pict 3)

D1. a depth-regulating nose

D2. a spindle belt

D3. a cutter knob

D4. a short allen key

D5. a round allen key

D6. a brush

D7. a key

D8. a screwdriver (3,5)

D9. a pair of standards jigs

First contact

IS400 machine . 9

Description

The IS400 machine is an electronic engraving machine.

It has a keyboard, and a control panel with a L.C.D. screen connecting the software which is in the machine.

Files to be engraved are transferred from the computer to the machine by the intermediary of a cable which is plugged into

one of the two ports on the IS400 machine.

The actual engraving process is controlled by the spindle.

The object to be engraved is held in the vice (as standard) or by any other system recommended by GRAVOGRAPH (consult

your GRAVOGRAPH dealer for more information on systems available).

The IS400 machine has a maximum engraving surface area of 305x210 mm.

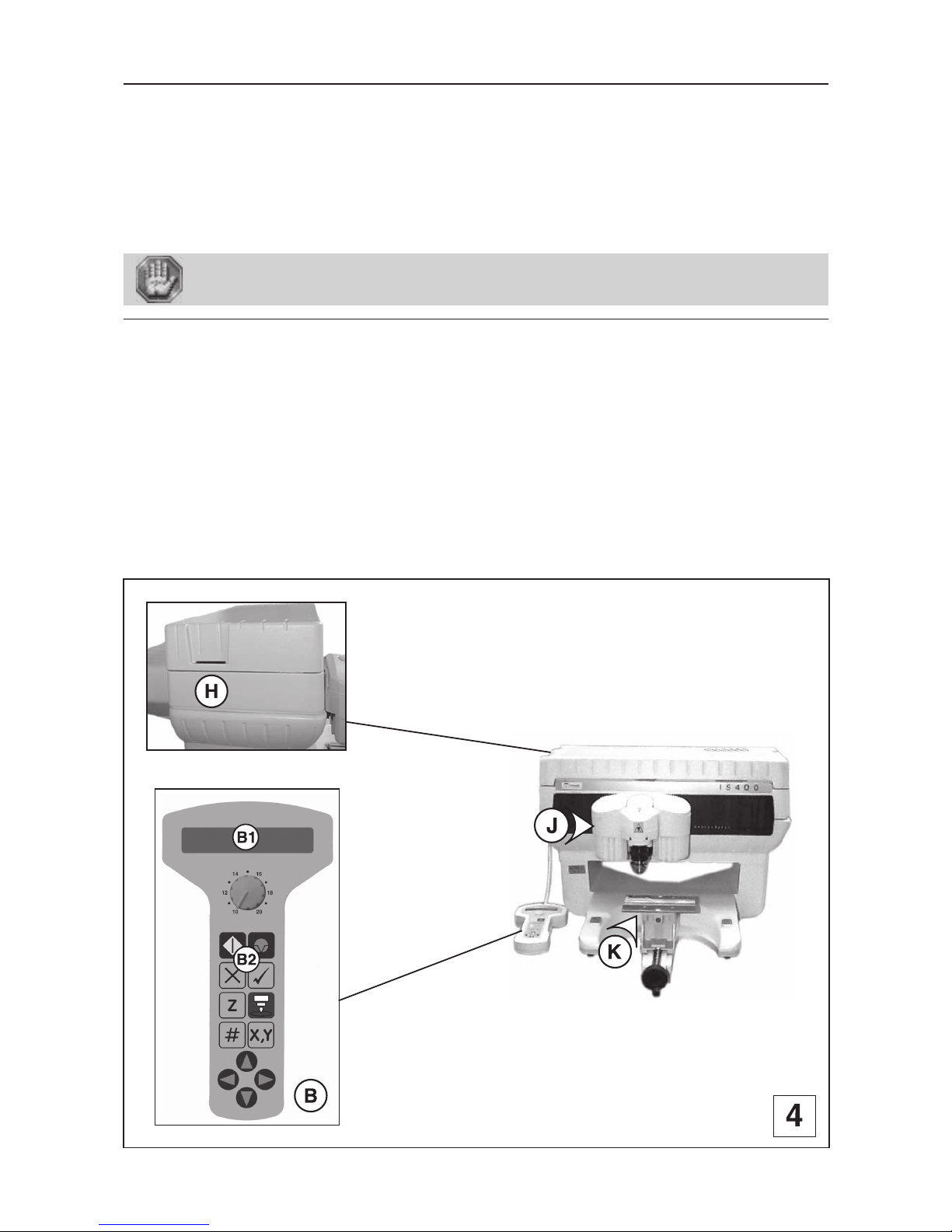

Front view of the machine

(pict 4)

B. Control panel

B1. L.C.D. screen

B2. 12-key control keyboard

H. Memory-card connector

J. Ensemble tool holder

K. Vice with pair of jaws

IS400 machine . 10

First contact

Tool holder

J1. Cutter

J2. Cutter button

J3. Pressure knurl on spindle

J4. Belt housing

J5. Belt

J6. Index finger

J7. Scaled knob

J8. Nose nut

J9. Auto ZRef switch

J10. LASER diode

CAUTION - LASER RADIATION

Do not stare into beam

LASER diode - Wavelength: 630-680nm - Max. Output < 1mW

CLASS 2 LASER PRODUCT

First contact

IS400 machine . 11

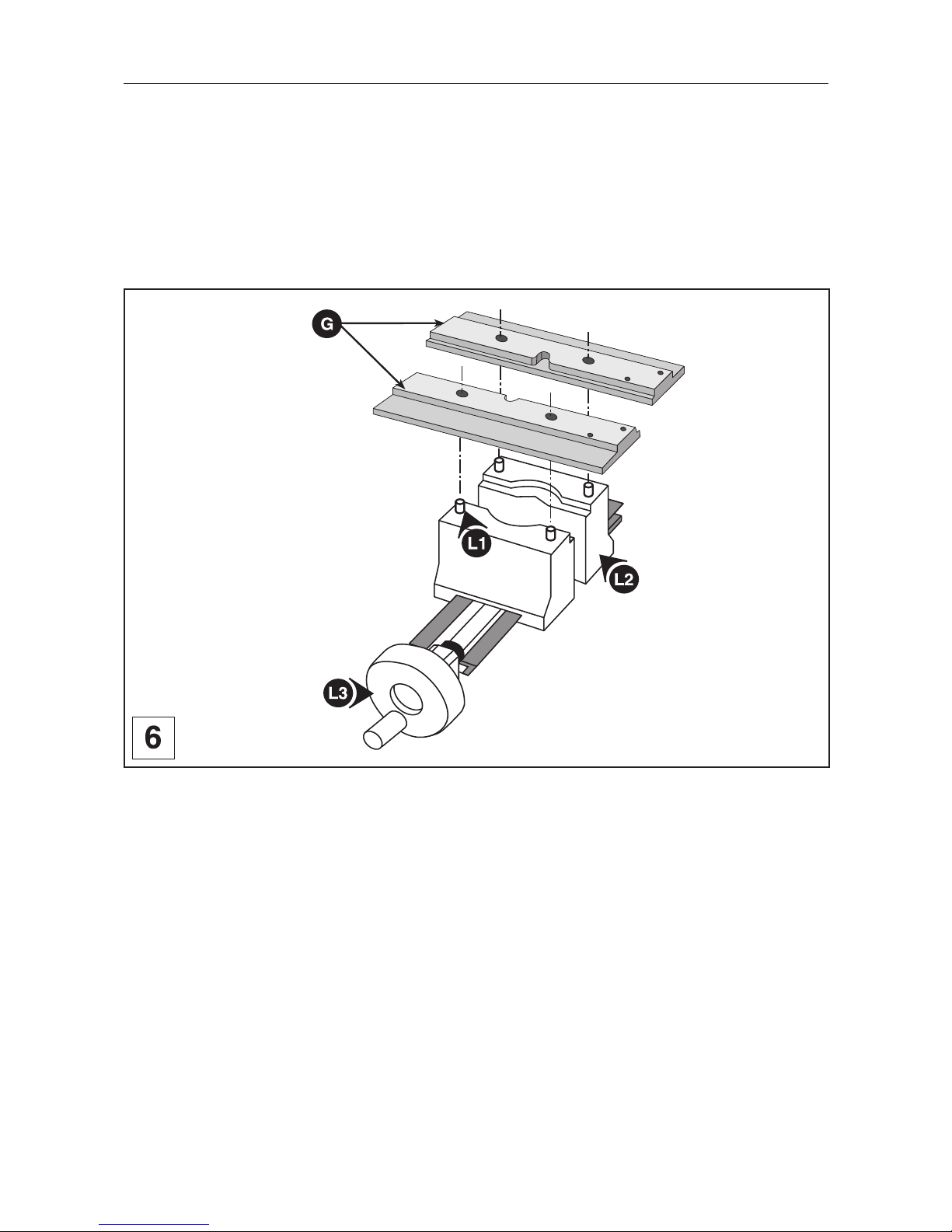

Vice

The vice holds the material to be engraved (pict 6).

The IS400 machine is supplied with a pair of jigs (G) which should be mounted onto the vice.

1. Open the jaws (L2) by turning the tightening knob (L3) anti-clockwise.

Open them far enough so as to mount the jaws easily.

2. Push the jigs (G) firmly onto the pins (L1) of the jaws (L2).

IS400 machine . 12

First contact

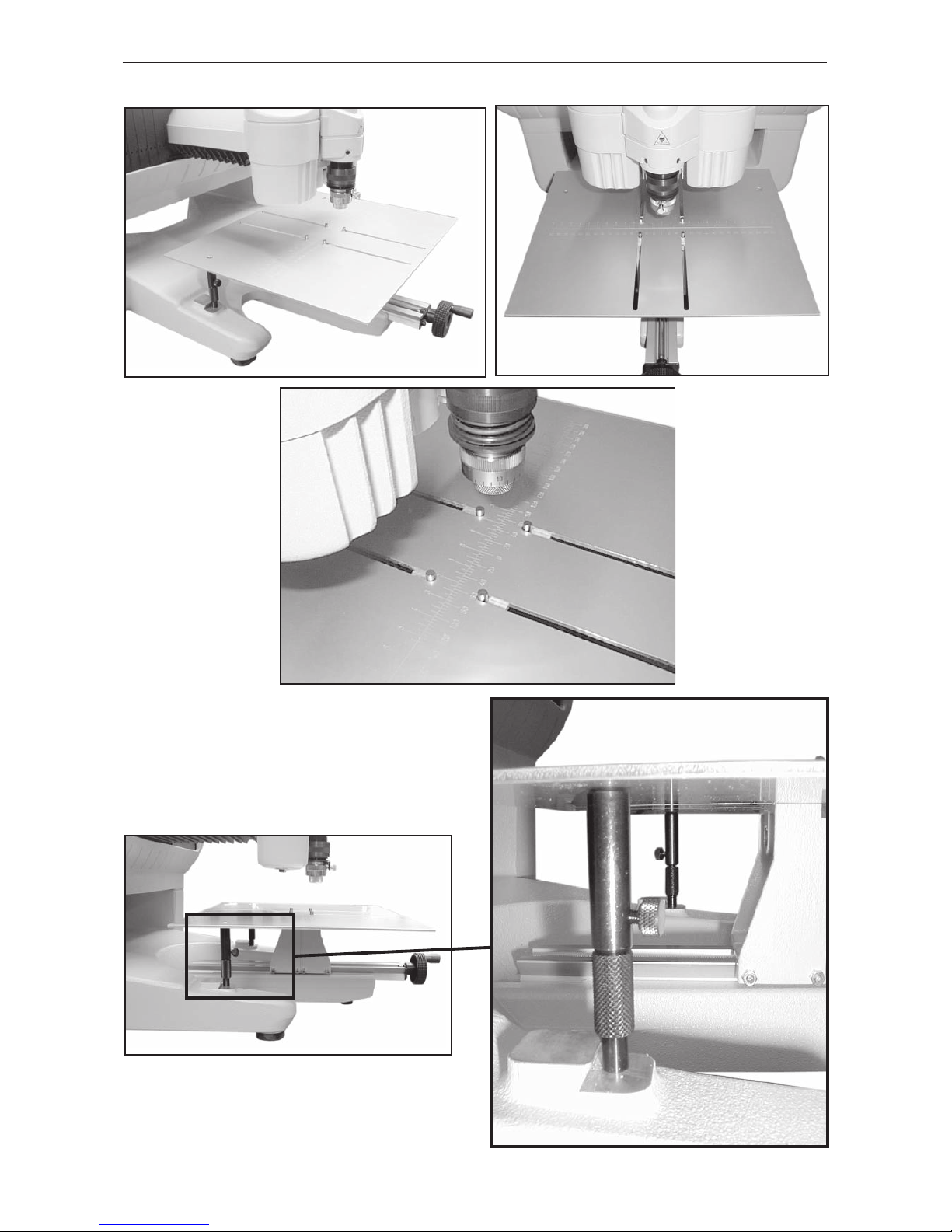

Long plate support kit

Loading...

Loading...