Zoom & ZT

Bagger

Owner/Operator Manual

Model

815040 34” Bagger

815041 42” Bagger

815042 50” Bagger

04444100B 4/12

Printed in USA

TABLE OF CONTENTS

Transfer

model & serial

number label

from product

registration

here.

Serial

Number

Label

Figure 1

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

INTRODUCTION

THE MANUAL

Before operation of unit, carefully and completely read

this Manual and the unit’s Owner/Operator Manual. The

contents will provide you with an understanding of safety

instructions and controls during normal operation and

maintenance.

All reference to left, right, front, or rear are given from

operator sitting in operation position and facing the

direction of forward travel.

MODEL AND SERIAL NUMBERS

When ordering replacement par ts or

making service inquiries, know the

Model and Serial numbers of your

unit.

Numbers are located on the product

registration form in the unit literatur e

package. They are printed on a serial

number label, located on the frame of

your unit.

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

PRODUCT REGISTRATION

The Ariens/Gravely dealer must register the product at

the time of purchase. Registering the product will help the

company process warranty claims or contact you with the

latest service information. All claims meeting

requirements during the limited warranty period will be

honored, whether or not the product registration card is

returned. Keep a proof of purchase if you do not register

your unit.

Customer Note: If the dealer does not register your

product, please fill out, sign, and return the product

registration card to Ariens or go to www.ariens.com or

www.gravely.com.

UNAUTHORIZED REPLACEMENT PARTS

Use only Ariens/Gravely replacement parts. The

replacement of any part on this vehicle with anything

other than an Ariens/Gravely authorized replacement

part may adversely affect the performance, durability, or

safety of this unit and may void the warranty.

Ariens/Gravely disclaims liability for any claims or

damages, whether warranty, property damage, personal

injury or death arising out of the use of unauthorized

replacement parts.

• Record Unit Model and Serial numbers here.

DISCLAIMER

Ariens/Gravely reserves the right to discontinue, make

changes to, and add improvements upon its products at

any time without public notice or obligation. The

descriptions and specifications contained in this manual

were in effect at printing. Equipment described within this

manual may be optional. Some illustrations may not be

applicable to your unit.

DELIVERY

Customer Note: If you have purchased this product

without complete assembly and instruction by your

retailer, it is your responsibility to:

1. Read and understand all assembly instructions in

this manual. If you do not understand or have

difficulty following the instructions, contact your

nearest Ariens/Gravely Dealer for assistance.

sure all assembly has been properly completed and

safety interlock system works properly.

© Copyright 2012 Ariens Company

2

Make

NOTE: To locate your nearest Ariens Dealer, go to

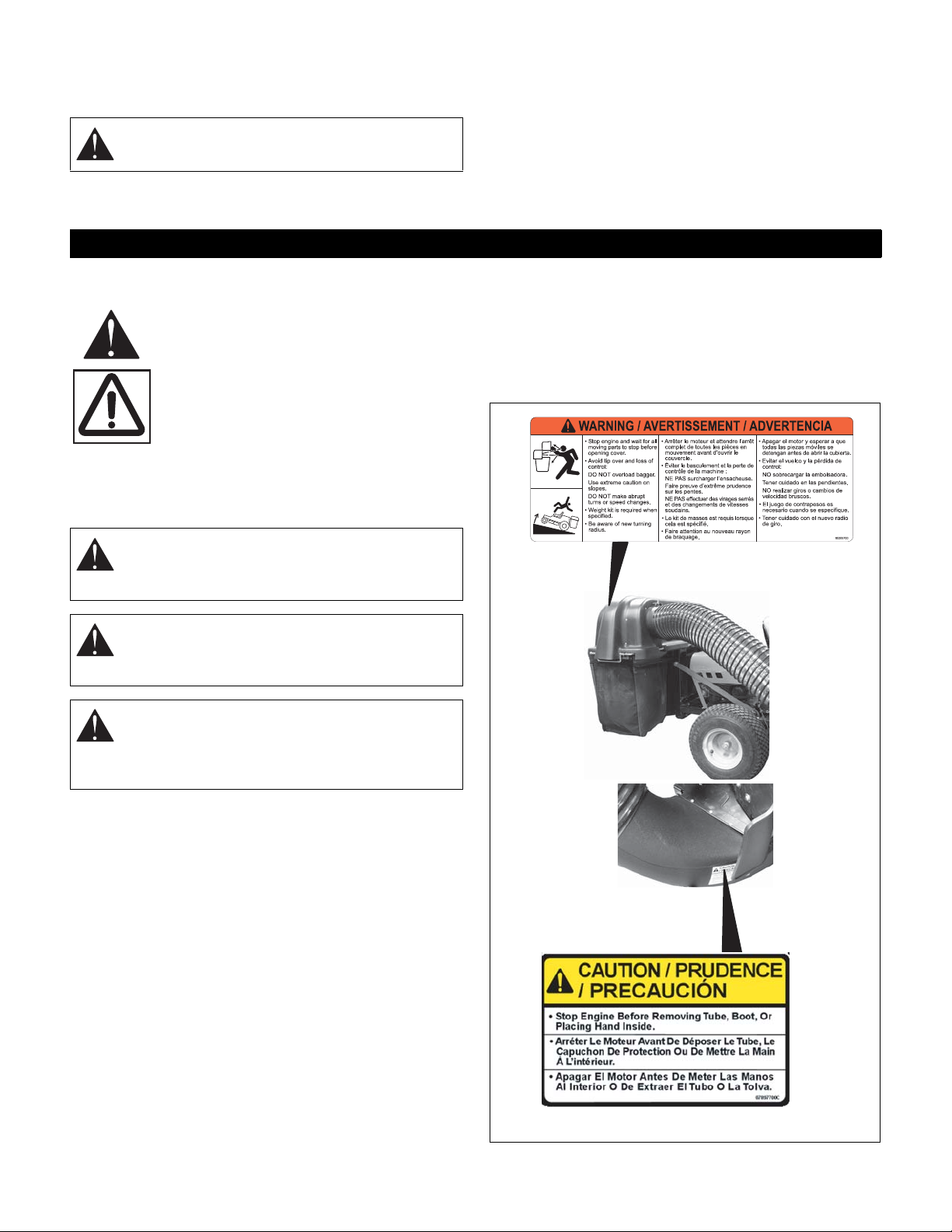

Figure 2

OEe001

1

2

www.ariens.com on the internet. To locate your nearest

Gravely Dealer, go to www.gravely.com on the internet.

WARNING: Improper assembly or adjustments

can cause serious injury.

2. Understand all Safety Precautions provided in the

manuals.

SAFETY

3. Review control functions and operation of the unit.

Do not operate unit unless all controls function as

described in this manual.

4. Review recommended lubrication, maintenance

and adjustments.

5. Fill out a Product Registration Card and return the

card to the Ariens Company or go to

www.ariens. com or www.gravely.com.

SAFETY ALERTS

Look for these symbols to point out

important safety precautions. They mean:

Attention!

Personal Safe t y Is In v o lve d !

Become Alert!

Obey The Message!

The safety alert symbols above and signal words below

are used on decals and in this manual.

Read and understand all safety messages.

DANGER: IMMINENTLY HAZARDOUS

SITUATION! If not avoided, WILL RESULT in

death or serious injury.

WARNING: POTENTIALLY HAZARDOUS

SITUATION! If not avoided, COULD RESULT in

death or serious injury.

CAUTION: POTENTIALLY HAZARDOUS

SITUATION! If not avoided, MAY RESULT in

minor or moderate injury. It may also be used to

alert against unsafe practices.

REQUIRED OPERATOR TRAINING

Original purchaser of this unit was instructed by the seller

on safe and proper operation. If unit is to be used by

someone other than original purchaser; loaned, rented or

sold, ALWAYS provide this manual and any needed

safety training before operation.

NOTATIONS

NOTE: General reference information for proper

operation and maintenance practices.

IMPORTANT: Specific procedures or information

required to prevent damage to unit or attachment.

PRACTICES AND LAWS

Practice usual and customary safe working precautions,

for the benefit of yourself and others. Understand and

follow all safety messages. Be alert to unsafe conditions

and the possibility of minor, moderate, or serious injury or

death. Learn applicable rules and laws in your area.

Always follow the practices set forth in this manual.

3

1. WARNING!

OTt2080

OTt2070

Stop engine and wait for all moving parts to

stop before opening cover.

Avoid tip over and loss of control:

DO NOT overload bagger.

Use extreme caution on slopes.

DO NOT make abrupt turns or speed

changes.

• Weight kit is required when using bagger.

• Be aware of new turning radius.

2. CAUTION!

• Stop Engine Before Removing Tube, Boot, Or

Placing Hand Inside.

SAFETY RULES

Do not operate on slopes over 10°.

DO NOT operate mower unless guards are in place or

boot assembly and entire bagger are attached.

NEVER operate bagger if the unit’s safety interlock

system is not working properly.

Always be aware of maximum sweep of bagger when

turning. Always allow adequate clearance between

bagger, personnel and other objects when turning.

As grass catcher fills, be alert to changing unit stability

and control.

Always install front weight before operating u nit with

bagger attached.

Read, understand, and follow all safety practices in

Owner/Operator Manual before beginning assembly.

Failure to follow instructions could result in personal

injury and/or damage to unit.

ALWAYS remove key and/or wire from spark plug before

assembly. Unintentional engine start up can cause death

or serious injury.

Complete a walk around inspection of unit and work area

to understand:

• Work area • Your unit • All safety decals

Determine which attachments are needed and can be

used safely.

Inspect unit before each use for: missing or damaged

decals and shields, correctly operating safety interlock

system, and deterioration of grass bagger. Replace or

repair as needed.

ALWAYS check overhead and side clearances carefully

before operation. ALWAYS be aware of traffic when

operating along streets or curbs.

Keep children and people away.

Keep children out of work area and under watchful care

of a responsible adult.

Keep area of operation clear of all toys, pets, and debris.

Thrown objects can cause injury.

Check for weak spots on docks, ramps or floors. Avoid

uneven work areas and rough terrain. Stay alert for

hidden hazards or traffic.

DO NOT operate near drop-offs, ditches, or

embankments. Unit can suddenly turn over if a wheel is

over the edge of a cliff or ditch, or if an edge caves in.

Data indicates that operators, age 60 and above, are

involved in a larger percentage of riding mower related

injuries. These operators should evaluate their ability to

operate the riding mower safely enough to protect

themselves and others from serious injury.

Read the entire Owner/Operator manual and other

training material. If the operator or the mechanic cannot

read the manual, it is the owner’s responsibility to explain

it to them. Only the user can prevent and is responsible

for accidents or injuries occurring to themselves, other

people or property.

Only trained adults may operate or service unit. Training

includes actual oper ation.

Local regulations may restrict the age of the operator.

NEVER allow children to operate or play on or near unit.

Be alert and shut off unit if children enter area.

NEVER operate unit after or during the use of

medication, drugs or alcohol. Safe operation requires

your complete and unimpaired attention at all times.

DO NOT wear loose clothing or jewelry and tie back hair

that may get caught in rotating parts.

Wear adequate outer garments.

NEVER wear open sandals or canvas shoes during

operation. Wear adequate safety gear, protective gloves

and footw ear.

Wear proper footwear to improve footing on slippery

surfaces.

Always wear safety goggles or safety glasses with side

shields when operating mower.

Moving parts can cut or amputate fingers or a hand.

Wrap blade(s) or wear gloves to service. On multiblade

mowers, rotation of one blade will cause all blades to

rotate.

NEVER place your hands or any part of your body or

clothing inside or near any moving part while unit is

running.

ALWAYS keep hands and feet away from all rotating

parts during operation. Rotating parts can cut off body

parts.

ALWAYS keep body and hands away from pin holes or

nozzles which eject hydraulic fluid under pressure.

DO NOT touch parts which are hot. Allow parts to cool.

ALWAYS keep hands and feet away from all pinch

points.

Fumes from the engine exhaust can cause death or

serious injury. DO NOT run engine in an enclosed area.

Always provide good ventilation.

Read, understand, and follow all instructions in the

manual and on the machine before starting.

4

Understand:

• How to operate all controls

• The functions of all controls

• How to STOP in an emergency

• Braking and steering characteristics

• Turning radius and clearances

Keep safety devices or guards in place and functioning

properly. NEVER modify or remove safety devices.

Do not operate without either entire bagger or the

discharge chute in place.

Stop engine before removing grass catcher or unclogging

chute.

Ensure Safety Interlock System is functioning properly.

DO NOT operate unit if safety interlock is damaged or

disabled.

Start and operate unit only when seated in operator’s

position. Steering control levers must be in neutral, PTO

disengaged and parking brake set when starting engine.

Use care when approaching blind corners, shrubs, trees

or other objects that may obscure vision.

Dust, smoke, fog, etc. can reduce vision and cause an

accident. Mow only in daylight or good artificial light.

Avoid slippery surfaces. Always be sure of your footing.

DO NOT mow on wet grass. Reduced traction could

cause sliding and effect the machine’s stability.

Watch for traffic when operating near or crossing

roadways.

Never carry passengers.

DO NOT try to stabilize the machine by putting your foot

on the ground.

Never direct discharge towards persons or property that

may be injured or damaged by thrown objects. Use

extreme caution on gravel surfaces.

Always stand clear of the discharge area.

ALWAYS disengage PTO, stop unit and engine, remove

key, engage parking brake and allow moving parts to

stop before leaving operator ’s posi ti on.

Never engage PTO while raising attachment or when

attachment is in raised position.

DO NOT operate at too fast a rate. DO NOT change

engine governor settings or over-speed engine. Slow

down before turning.

DO NOT operate in reverse unless absolutely necessary.

ALWAYS look down and behind before and while

backing.

Stop and inspect equipment if you strike an object or if

there is an unusual vibration. Repair, if necessary, before

restarting. Never make adjustments or repairs with the

engine running.

Mower blades are sharp and can cut you. Wrap the

blade(s) or wear gloves, and use extra caution when

servicing them. NEVER weld or straighten mower blades.

Rotation of one blade may cause rotation of the other

blades.

Take all possible precautions when leaving unit

unattended. Shut off engine. Remove wire from spark

plug and secure it away from spark plug.

ALWAYS remove key to prevent unauthorized use.

Know the weight of loads. Limit loads to those you can

safely control and the unit can safely handle.

Disengage PTO when attachment is not in use. ALWAYS

turn off power to attachment when travelling, crossing

driveways, etc.

Mow up and down slopes, not across them.

Keep all movements on the slope slow and gradual. Do

not make sudden changes in speed or direction.

Avoid starting or stopping on the slope. If tires lose

traction, disengage the blades and proceed slowly

straight down the slope.

If you cannot back up a slope or you feel uneasy on it, do

not mow it.

DO NOT park on slopes unless necessary. When parking

on slope always chock or block wheels. Always set

parking brake.

Use a slow speed. Tires may lose traction on slopes

even though the brakes are functioning properly.

Do not bypass transmission when on a slope.

Tow only with a machine that has a hitch designed for

towing. Do not attach towed equipment except at the

hitch point.

Follow the manufacturer’s reco mme nda tion s for weigh t

limits for towed equipment and towing on slopes.

NEVER allow children or others in or on towed

equipment.

On slopes, the weight of the towed equipment may cause

loss of control.

Travel slowly and allow extra distance to stop.

Use extra care when loading or unloading unit onto trailer

or truck.

Secure unit chassis to transpor t vehicle. NEVER secure

from rods or linkages that could be damaged.

DO NOT transport machine while engine is running.

ALWAYS turn off power to attachment and shut off fuel

when transporting unit.

Keep unit free of debris. Clean up oil or fuel spills.

This product is equipped with an internal combustion

type engine. DO NOT use unit on or near any

unimproved, forest-covered or brush covered land unless

exhaust system is equipped with a spark arrester

meeting applicable local, state or federal laws. A spark

arrester, if it is used, must be maintained in effective

working order by operator.

Fuel is highly flammable and its vapors are explosive.

Handle with care. Use an approved fuel container.

NO smoking, NO sparks, NO flames. ALWAYS allow

engine to cool before servicing.

NEVER fill fuel tank when engine is running or hot from

operation.

5

NEVER fill or drain fuel tank indoors.

Replace fuel cap securely and clean up spilled fuel.

Never fill containers inside a vehicle or on a truck or

trailer bed with a plastic liner. Always place containers on

the ground away from your vehicle before filling.

When practical, remove gas-powered equipment from

the truck or trailer and refuel it on the ground. If this is not

possible, then refuel such equipment on a trailer with a

portable container, rather than from a gasoline dispenser

nozzle.

Keep the nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete.

Do not use a nozzle lock-open device.

If fuel is spilled on clothing, change clothing immediately.

Avoid Electric Shock. Objects contacting both battery

terminals at the same time may result in injury and unit

damage. DO NOT reverse battery connections.

Reverse connections may result in sparks which can

cause serious injury. Always connect positive (+) lead of

charger to positive (+) terminal, and negative (-) lead to

negative (-) terminal.

ALWAYS disconnect negative (-) cable FIRST and

positive (+) cable SECOND. ALWAYS connect positive

(+) cable FIRST, and negative (-) cable SECOND.

Explosive Gases from battery can cause death or serious

injury. Poisonous battery fluid contains sulfuric acid and

its contact with skin, eyes or clothing can cause severe

chemical burns.

No flames, No sparks, No smoking near battery.

ALWAYS wear safety glasses and protective gear near

battery. Use insulated tools.

DO NOT TIP battery beyond a 45° angle in any direction.

ALWAYS keep batteries out of reach of children.

Battery posts, terminals and related accessories contain

lead and lead compounds, chemicals known to the State

of California to cause cancer and reproductive harm.

Wash hands after handling.

ALWAYS block wheels and know all jack stands are

strong and secure and will hold weight of unit during

maintenance.

Release pressure slowly from components with stored

energy.

NEVER attempt to make any adjustments to unit while

engine is running (except where specifically

recommended). Stop engine, remove key or spark plug

wire and wait for all moving parts to stop before servicing

or cleaning.

Check parking brake operation frequently. Adjust and

service as required.

ALWAYS maintain unit in safe operating condition.

Damaged or worn out muffler can cause fire or explosion.

Maintain or replace safety and instruction labels, as

necessary.

NEVER store unit with fuel in fuel tank, inside a building

where any ignition sources are present.

Shut off fuel and allow engine to cool completely before

storing in closed area or covering unit.

Clean grass and debris from unit, especially from around

muffler and engine, to help prevent fires.

For extended storage, shut off fuel and clean unit

thoroughly. See engine manual for proper storage.

Lower cutting deck unless a positive mechanical lock is

used.

Use only attachments or accessories designed for your

unit.

Check all hardware at regular intervals, especially blade

attachment bolts. Keep all hardware properly tightened.

Check attachment components frequently. If worn or

damaged, replace with manufacturer’s recommended

parts.

6

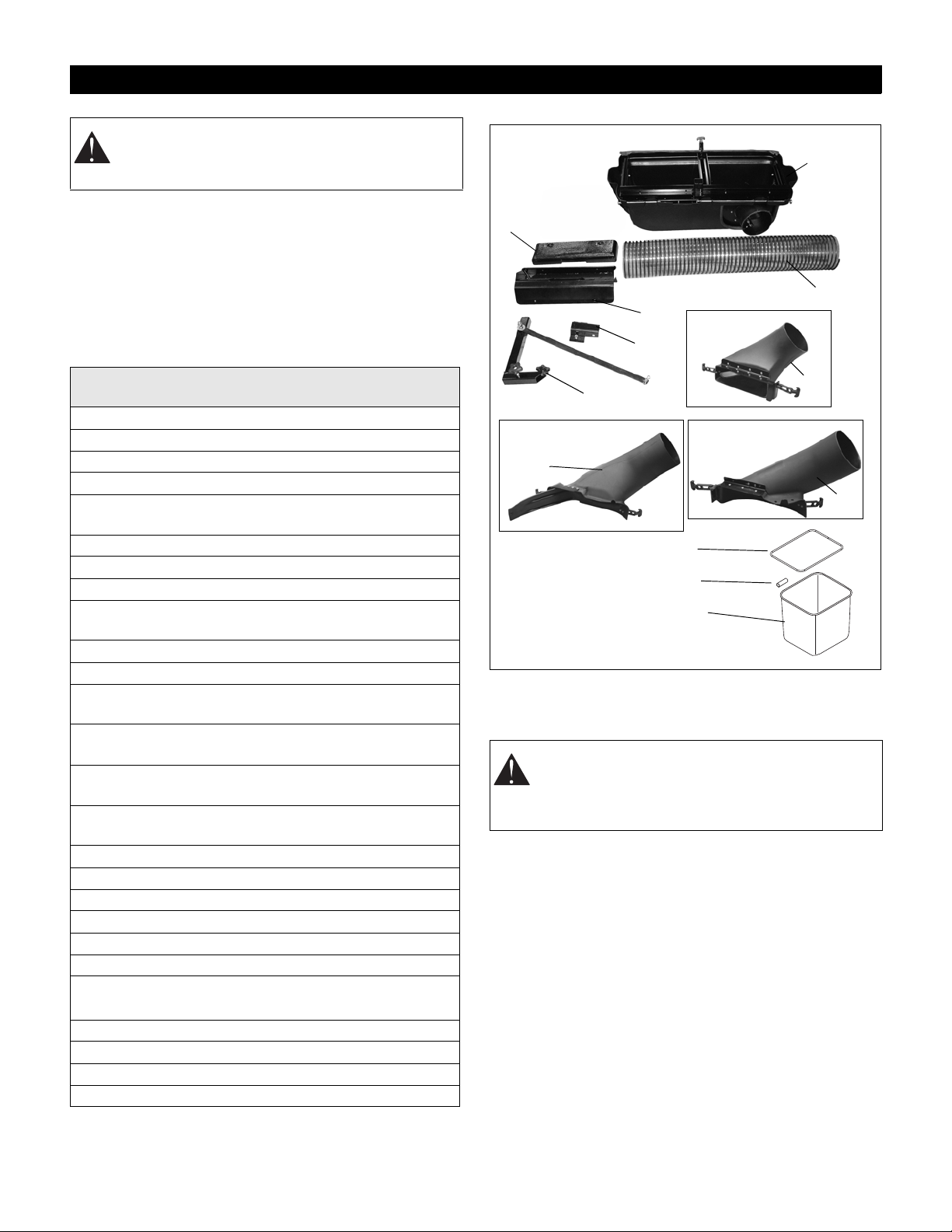

ASSEMBLY

Figure 3

22

18

19

20

21

4

1

18

18

815040

815041

815042

2

23

24

WARNING: AVOID INJURY. Read and

understand the entire Safety section before

proceeding.

UNPACKING UNIT

IMPORTANT: Remove contents from carton carefully.

Place cover assembly on a flat piece of cardboard to

avoid scratching it.

Package Contents:

Check the contents of your kit for the parts listed below

and shown in Figures 3 – 6.

Item Description

1 Weldment Bagger Weight Tray 1 04215451

2 Mesh Bag 2 03862900

3 Grip, Adhesive 1 03833800

4 Cast Iron Weight 1 00172000

5 5/16 x 1" Round Head Square

Neck Bolt

6 5/16-18 Nyloc Nut 2 06545400

7 3/8-16 x 3" Hex Bolt 2 05957800

8 3/8" Lock Washer 4 06308800

9 1/2 x 2" Round Head Square

Neck Bolt

10 1/2" Nyloc Flange Nut 4 06500010

11 1/2" Push Nut 2 06500705

12 .515 x 1.625 x .250 Flat Steel

Washer

13 .438 x 1.00 x .083 Flat Steel

Washer

14 .390 x 1.5 x .125 Flat Steel

Washer

15 Locking Bow Tie Cotter Pin

.091 x 7.875

16 Wing Knob 1 07500225

17 Studded Wing Kn ob 1 07500226

18 34" Boot Assembly (815040) 1 51577500

42" Boot Assembly (815041) 1 51577600

50" Boot Assembly (815042) 1 51577700

19 L Bracket, Brace & Hardware 1 N/A

20 Bagger Hose (815040)

Bagger Hose (815041, 042)

21 Hood Assembly 1 51577800

22 Receiver & Hardware 1 N/A

23 Bag Frame 2 00663200

24 Plastic Tube, 3/8 x 1/2 x 3" 2 00677000

Qty Part

Number

2 06216100

2 06200205

6 06445000

4 06435900

2 06441700

4 06700201

1 04445600

04222900

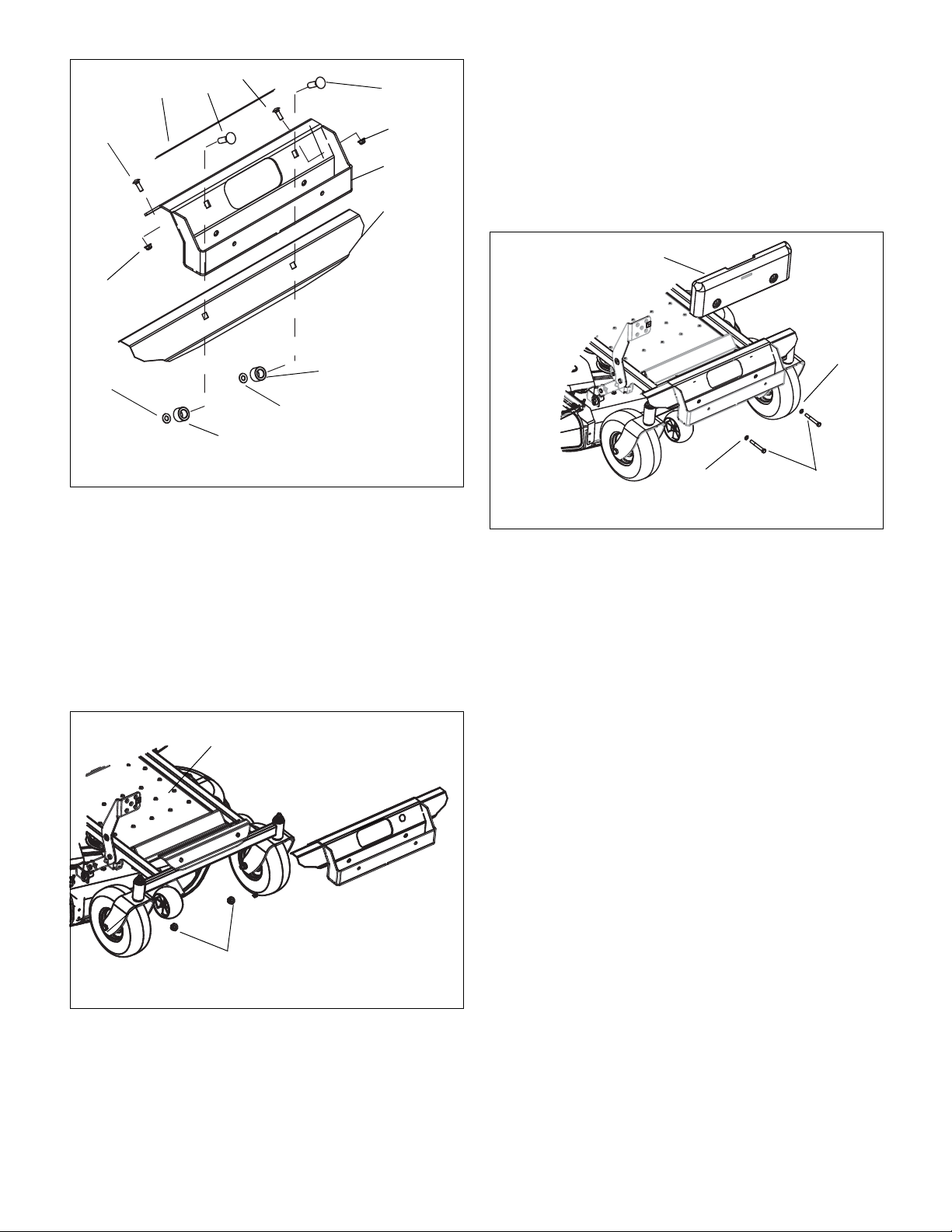

INSTALL FRONT WEIGHT TRAY &

COUNTERWEIGHT

WARNING: ALWAYS install counterweight

before operating unit with bagger attached.

ALWAYS remove counterweight when bagger is

removed from unit.

1. Remove the front footrest. There are two 1/2 x 2"

(item 9) and 5/16 x 1" (item 5) round head square

neck bolts that secure the footrest to the chassis.

The 1/2 x 2" bolts (item 9) and metal spacers are

held on the footrest by two 1/2" push nuts (item 11).

Twist or cut off the push nuts to remove. Save the

spacers and discard all other hardware. See

Figure 4.

2. Lay the footrest onto the back of the weight tray

(similar profile). It may be helpful to have the weight

tray laying upside down on the ground when mating

it to the footrest. Install two 1/2 x 2" bolts (item 9)

thru the front of the weight tray and footrest. Slide

the two spacers (from step 1) over the bolts and

secure with push nuts (item 11). Secure the push

nuts as tight as possible. See Figure 4.

7

3. Place the footrest/weight tray assembly over the

Figure 4

Front Footrest

11

6

Spacer

1

6

9

5

3

5

9

Spacer

11

Figure 5

10

6

3

Figure 6

8

7

8

4

chassis. The two 1/2 x 2" bolts (item 9) will drop

through the two holes in the chassis. It may be

necessary to tilt the assembly back slightly to align

the bolts with the holes. Secure with two 1/2" nyloc

flange nuts (item 10). See Figure 5.

4. Install two 5/16 x 1" bolts (item 5) through the two

holes on the footrest portion of the assembly.

Secure with two 5/16 nyloc flange nuts. Adhere the

grip adhesive (item 3) just above the two bolts

(item 5) on the footrest. See Figure 4.

5. Place the cast iron weight (item 4) into the weight

tray. Install two 3/8 x 3" hex bolts (item 7) and two

3/8" lock washers (item 8) through the front of the

weight. There are two weld nuts on the back of the

weight tray. Thread the bolts into the weld nuts and

tighten until the lock washers engage. Do not

overtighten the bolts or the tray will flex. The bolts

are only inst a lle d to prev ent the weig ht s fr om f alli ng

out of the tray. See Figure 6.

8

INSTALLING BAGGER BOOT

Figure 7

Front

Deck

Post

Front Boot Strap

Boot Bracket

Slide boot

bracket under

discharge

chute.

Secure boot by

hooking boot

straps to front and

rear deck posts.

Boot

Figure 8

Bagger Boot

Connect rear

boot strap to

deck post.

Connect front

boot strap to

deck post.

(815040 ONLY)

NOTE: Discharge chute can remain attached to deck.

WARNING: On multi-blade mowers, rotation of

one mower blade will cause all blades to rotate.

WARNING: Mower blades are sharp and can

cut you. Wrap the blades or wear gloves, and

use extra caution when servicing them.

INSTALL BAGGER BOOT

(815041 ONLY)

1. Lift discharge chute and insert discharge bagger

boot into deck discharge opening. See Figure 8.

NOTE: Discharge chute can remain attached to deck.

1. Slide boot bracket under discharge chute bracket.

See Figure7.

2. Using front and rear boot straps, secure the boot by

attaching boot straps to deck posts. See Fi gure 7.

2. Insert bagger boot fully into opening making sure

that the front of the boot is positioned inside of the

deck shell and the top edge of the boot is

positioned on top of the deck shell and below the

discharge chute. See Figure 8.

3. Push the bagger boot fully into the discharge

opening and attach the rear boot strap to the rear

attaching post. See Figure 8.

4. Attach the boot front strap to the front attaching

post. See Figure 8.

9

INSTALL BAGGER BOOT

Figure 9

Boot

Bracket

Front Deck Bolt

Connect rear

boot strap to

deck post.

Discharge

Chute

Rear Deck Bolt

Front Boot Hole

Boot Notch

Connect front

boot strap to

deck post.

(815042 ONLY)

1. Lift discharge chute and slide bagger boot bracket

under discharge chute. See Figure 9.

NOTE: Discharge chute can remain attached to deck.

2. Insert bagger boot fully onto discharge opening

making sure that the hole and notch in the top of the

boot line up over exposed deck bolts. See Figure 9.

3. Attach rear boot strap to the rear attaching post.

See Figure 9.

4. Attach front boot strap to the front attaching post.

See Figure 9.

10

INSTALL FRAME AND HOOD ASSEMBLY

Figure 10

Receiver

3/8 x 1" Hex Bolt &

3/8" Locking Nut

Figure 11

1/2" Studded Wing Knob

L Bracket

1/2 x 2 3/4" Hex Bolt &

1/2" Wing Knob

Figure 12

L Bracket

Hood

Assembly

Figure 13

Support Bar

Engine Control Cables

1/2 x 2 3/4" Hex

Bolt,

1/2" Flat

Washer &

1/2" Flange Nut

1. Install receiver to the right rear frame using two 3/8

x 1" hex bolts and two 3/8" locking nuts. Tighten

hardware. See Figure 10.

2. Insert L bracket into the receiver and fasten using

1/2 x 2 3/4" round head square neck bolt and wing

knob. Do not fully tighten. See Figure 11.

3. Install front studded wing knob into front of receiver.

Tighten studded wing knob and hardware installed

in step 2.

NOTE: It may require two people to position hood

assembly onto bracket.

5. Position bagger support bar inside of engine control

cables and attach support bar to L bracket using 1/2

x 2 3/4" hex bolt, 1/2" flat washer and 1/2" flange

nut. Flat washer is positioned between bar and L

bracket. Do not fully tighten hardware. See

Figure 13.

4. Position hood assembly over L bracket and install

onto bracket. See Figure 12.

6. Mount front of support bar to the mower frame

using 3/8 x 3/4" clevis pin, 3/8" washer and bow-tie

locking cotter pin. Tighten hardware installed in step

5. See Figure 14.

11

Figure 14

Clevis

Pin

3/8" Washer & Bow-Tie

Locking cotter Pin (Not Shown)

Figure 15

Thread bag frame (23) through sleeve

in mesh bag (2).

Install 3/8 x 1/2 x 3" plastic tube (24)

on each end of frame and push the

ends together.

CAUTION: MAKE SURE the heat resistant

(smooth side) side of the mesh bags are facing

the unit.

INSTALL BAG ON FRAME (FIGURE 15)

1. Thread the bag frames (23) through the sleeve on

the open end of the mesh bag (2).

2. Install the 3/8 x 1/2 x 3" plastic tubes (24) on the

ends of the bag frames and push then ends

together. on the ends of the bag frame and push

the ends together.

NOTE: The rope handle on the bottom of the bag will

point to the outside when the bag is assembled correctly.

12

3. Install mesh bags to bagger frame. Make sure that

Figure 16

MAKE SURE the heat resistant side

(smooth side) faces the unit.

Mesh Bags

Figure 17

Latch

Strap

Figure 18

Thumb Latch

Bagger Hose

the heat-resistant side of the mesh bags face the

unit.

4. Close hood assembly and connect latch strap.

Install Hose

1. Install bagger hose on bagger boot assembly and

2. F lip up thumb latc h and pus h b agg er hose int o the

bagger cover assembly.

latch. Flip down the latch, making sure the latch is

attached to a rib on the hose. See Figure 18.

13

REMOVAL

Figure 19

Airflow

Restricted

Airflow

Unrestricted

Airflow

Indicator

WARNING: AVOID INJURY. Read and

understand the entire Safety section before

proceeding.

1. F lip up thumb latc h and re move bagg er hose from

bagger cover assembly and bagger boot assembly

(see figure 18 on page 13).

2. Remove bagger boot assembly.

WARNING: AVOID INJURY. Read and

understand the entire Safety section before

proceeding.

CAUTION: Do not tow anything with the hitch

when the bagger is installed.

BEFORE EACH USE

1. Check bagger parts for wear, deterioration, or

damage. Replace ONLY with Ariens/Gravely

original service parts before operating.

2. Make sure the cast iron weight is installed.

3. Ensure all hardware is tight.

4. Remove any grass buildup from bagger parts.

5. Ensure hose is fastened securely on boot

assembly.

6. Ensure grass bagger baskets are installed, and the

bagger cover is closed and securely latched.

3. Remove mesh bags (see figure 16 on page 13).

4. Remove bagger frame and cover assembly, bagger

strap and all mounting hardware. The receiver and

the front weight tray can remain on the unit for

further use.

5. Remove the cast iron weight from the front weight

tray.

OPERATION

AIRFLOW INDICATOR (FIGURE 19)

When the airflow indicator is pointed straight up, the air is

restricted which indicates one or more possible

problems:

• The grass bagger baskets are full and need to be

emptied. See Emptying Mesh Bags on page 14.

• There is a clog in the bagger. See Unclogging

Bagger on page 15.

When the airflow indicator is facing forward, the air is

unrestricted indicating that the grass bagger baskets are

not full and there are no clogs in the bagger.

OPERATING THE BAGGER

Starting

1. Start engine and engage PTO (see unit’s

Operator’s Manual).

2. Set throttle to full.

3. Set mower deck height.

4. Choose a slow ground speed.

Shutting Off

WARNING: Lower attachment, stop engine, and

remove key to prevent unauthorized use. DO

NOT park on slopes.

1. Allow the mower blades to run for at least 30

seconds to clear boot assembly and hose of debris.

2. Disengage PTO.

3. Shut off unit (see unit’s Operator’s Manual).

EMPTYING MESH BAGS

If bagger stops picking up grass clippings, the mesh bags

may be full.

14

WARNING: NEVER open cover asse mbly wh ile

Figure 20

the engine is running and the PTO is engaged.

ALW AYS shut off engine prior to emptying mesh

bags.

To empty grass bags:

1. Disengage PTO, stop engine, and remove ignition

key. W ait for all moving parts to stop before leaving

operator’s position.

2. Disconnect latch strap and open cover and remove

each mesh bag from bagger frame.

1. Stop engine and remove ignition key. Wait for all

moving parts to stop.

2. Flip thumb latch and remove hose.

3. Remove grass from hose and boot assembly.

4. Install hose and secure with thumb latch.

OPERATING TIPS

IMPORTANT: DO NOT remove more than 1 1/4” (3.2 cm)

of grass when bagging.

• Cut grass when it is dry.

• Cut grass in two passes when cutting thick, long, or

wet grass. Make the first cut higher than desired.

Make the second cut at desired height.

• Always use full throttle when bagging.

• Adjust ground speed as needed to allow the bagger

to pick up debris.

MAINTENANCE

WARNING: AVOID INJURY. Read and

understand the entire Safety section before

proceeding.

3. Empty the grass from each mesh bag.

4. Install mesh bags back on bagger frame. Make

sure that the heat-resistant side of the mesh bags

face the unit.

5. Close and latch cover.

UNCLOGGING BAGGER

WARNING: MOVING PARTS can cut or

amputate body parts.

NEVER attempt to clear boot assembly while

engine is running.

ALWAYS stop engine, remove key, and wait for

moving parts to stop.

Sharp edges can cut. Movement of parts can

cut off fingers or a hand. Wrap blade(s), wear

sturdy gloves and use extreme caution when

working near blades.

Ariens/Gravely Dealers will provide any service or

adjustments which may be required to keep your unit

operating at peak efficiency.

Interval Task Action

Each

Use

Check

counter

weight

Check

Hose

Check

mesh

bags

Check

Fasteners

Inspect

Bagger

Parts

Clean Unit Clear away debris in boot

Ensure the cast iron weight

is installed and securely

fastened.

Ensure hose is securely

fastened to cover assembly and

boot assembly.

Ensure mesh bags are installed,

and bagger cover is closed and

securely latched.

Ensure all hardware is tight. Pay

special attention to the guards

and safety shields.

Inspect bagger parts for holes,

abrasions, or structural damage.

Replace any worn or damaged

parts with Ariens/Gravely service

parts.

assembly, in tube, and in cover

assembly.

If hose or boot assembly become clogged, stop forward

motion and allow unit to clear itself. If unit will not clear

itself, unclog the hose and/or boot assembly manually as

instructed below.

15

STORAGE

WARNING: AVOID INJURY. Read and

understand the entire Safety section before

proceeding.

IMPORTANT: NEVER spray unit with high-pressure

water. DO NOT store unit outdoors.

Clean plastic surfaces with sponge and mild detergent.

Dry with a soft cloth.

Clear away debris under belt cover, in boot assembly, in

tube, and in cover assembly before storing.

Remove all dirt, grease, leaves, etc. from unit.

Store in a clean, dry area.

Ensure all fasteners are properly tightened. Inspect

moving parts for damage and wear.

Touch up all rusted or chipped painted surfaces.

TROUBLESHOOTING

Problem Probable Cause Correction

Airflow

indicator

points

straight

up.

Bagger

fails to

pick up

grass or

leaves.

1.Air flow is

restricted.

1.The grass bagger

baskets are full.

2.Bagger is

clogged.

1.The grass bagger

baskets are full

(see Emptying

Mesh Bags on

page 14).

2. The bagger is

clogged (see

Unclogging

Bagger

page 15).

on

1.Empty g ra ss

bagger baskets

(see Emptying

Mesh Bags on

page 14).

2.Unclog bagger

(see Unclogging

Bagger on

page 15).

SPECIFICATIONS

Model Number 815040

Description Non-Powered Bagger

Serial Number 000101 and up

Added Length to Unit 19 5/8 in. (49.8 cm)

Added Width to Unit 10 in. (25.4 cm)

Added Weight to Unit 129 lb. (58.5 kg)

For Use on Models 915146, 157, 168, 169

(S/N 10,000 & up)

Model Number 815041

Description Non-Powered Bagger

Serial Number 000101 and up

Added Length to Unit 19 5/8 in. (49.8 cm)

Added Width to Unit 13 in. (33 cm)

Added Weight to Unit 129 lb. (58.5 kg)

For Use on Models 915148, 159, 170, 171

(S/N 10,000 & up)

Model Number 815042

Description Non-Powered Bagger

Serial Number 000101 and up

Added Length to Unit 19 5/8 in. (49.8 cm)

Added Width to Unit 8 in. (20.3 cm)

Added Weight to Unit 129 lb. (58.5 kg)

For Use on Models 915150, 161

(S/N 10,000 & up)

16

SAFETY DECALS

OEe002

1

2

PARTS LIST

Item Part No. Qty. Description

1 05359700 1 Decal, Bagger Cover

2 07897700 1 Decal, Boot Caution

17

BAGGER HOOD

PREASSEMBLED IN KIT 51577800

15

13

19

18

14

12

11

8

1

11

2

9

9

10

9

16

6

5

7

3

10

9

10

9

10

17

BOM ID Number Qty Description

1 04409600 1 COVER, 2-BUCKET BAGGER

2 04409900 1 SEAL, UPPER BOOT

3 04410051 1 WLDMT, BAGGER HOOD VENT, LH

4 04410700 1 SEAL, BULB - BAGGER HOOD

5 04431051 1 WLDMT, BAGGER HOOD VENT, RH

6 04439500 1 SEAL, BULB

7 04439751 1 WLDMT, TUBE SUPPORT

8 04446800 1 BOOT, UPPER

9 06116700 5 SCR-MCH 10-24X.50 HWH YWZC

10 06116900 5 SCR-MCH 10-24X.75 HWH YWZC

11 06442700 25 WSHR-FL-STL

4

20

BOM ID Number Qty Description

12 06536000 8 NUT-LK-NYL #10-24 YWZC

13 06714800 1 PIN-HAIR, ENDRIES #25 YWZC

14 06800108 17 RVT-POP .187x.375

15 06815300 1 PIN, CLEV .309X1.62 YWZC

16 07411500 2 SCR-TAP .31-18X.50 HWH TR YWZ

17 09079500 1 LATCH, RUBBER

18 07000026 1 LATCH, THUMB

19 00168300 1 INDICATOR, FLOW

20 04445600 1 BAGGER TUBE (815040)

04222900 1 BAGGER TUBE (815041, 042)

18

BAGGER LOWER BOOT

MODEL 815040

PREASSEMBLED IN KIT 51577500

5

2

4

6

1

3

BOM ID Number Qty Description

1 04433200 1 BAGGER, BOOT MOLDED

2 04449751 1 BRKT, BOOT 34" ZOOM/ZT

3 06116900 4 SCR-MCH 10-24 x .75 HWH YWZC

4 06442700 8 WSHR-FL-STL .219 x .500 x .049 YWZC

5 06803800 8 RVT-POP .187 x .375

6 09079500 2 LATCH, RUBBER

MODEL 815041

PREASSEMBLED IN KIT 51577600

8

7

2

1

5

4

9

6

5

3

4

BOM ID Number Qty Description

1 04392000 1 BOOT, BAGGER ,42" TUNNEL DECK

2 04449651 1 WLDMT, BOOT 42" ZOOM/ZT

3 04513051 1 BRKT, BOOT REINFORCEMENT

4 06116900 4 SCR-MCH 10-24X.75 HWH YWZC

5 06442700 5 WSHR-FL-STL.219X.500X.049YWZC

6 06536000 1 NUT-LK-NYL #10-24 YWZC

7 06803800 4 RVT-POP .187x.375

8 09079500 2 LATCH, RUBBER

9 05960800 1 BLT-HEX 10-24X 1.0 YWZC

8

3

BOM ID Number

1 04432300

2 04449551

3 06442700

4 06803800

5 09079500

6 06116900

MODEL 815042

PREASSEMBLED IN KIT 51577700

4

2

1

6

Qty Description

1 BAGGER, BOOT MOLDED

1 BRKT, BOOT 50" ZOOM/ZT

5 WSHR-FL-STL .219 x .500 x .049 YWZC

5 RVT-POP .187 x .375

2 LATCH, RUBBER

4 SCR-MCH 10-.75 HWH YWCZ

5

19

BAGGER FRAME

8

6

19

9

21

2

1

16

15

13

11

3

24

7

22

23

10

5

20

14

18

BOM ID Number Qty Description

1 03844151 1 OVERLAP PLATE, BAGGER FRAME

2 04409551 1 ASM, BAGGER FRAME UPPER

3 04409751 1 BRKT, RECEIVER SLEEVE INSERT

4 04409851 1 BRKT, RECEIVER LOWER

5 04410551 1 BRKT, BAG FRAME SUPPORT BAR

6 04439500 2 SEAL, BULB

7 04443400 1 PIN, BAGGER HINGE (L)

8 04443500 1 PIN, BAGGER HINGE (R)

9 04446700 1 SEAL, HINGE

10 05948700 2 BOLT-HEX-Gr5-UNC-YWZC

11 05965500 1 BOLT-HEX-Gr5-UNC-YWZC

12 06225700 1 BLT-RDHDSQNK .50-13X2.75 G5 Y

13 06430200 1 WSHR-FL-STL .531X1.250X.100 YWZC

12

4

17

BOM ID Number Qty Description

14 06436200 1 WSHR-FL-STL.406X.812X.065 YWZ

15 06442700 3 WSHR-FL-STL.219X.500X.049YWZC

16 06500010 1 NUT-LK-NYL-FLG .50-13 YWZC

17 06545500 2 NUT-LK-NYL-FLG .38-16 YWZC

18 06700201 1 PIN, BOWTIE LOCKING .091X1.875

19 06803800 3 RVT-POP .187x.375

20 06814800 1 PIN-CLEV .38X.75 YWZC

21 07411500 2 SCR-TAP .31-18X.50 HWH TR YWZ

22 07500225 1 KNOB, WING

23 07500226 1 KNOB, WING STUDDED

24 06714800 2 PIN-HAIR, ENDRIES #25 YWZC

* Frame Kit #51577900 Includes items 2 and 6.

20

COUNTERWEIGHT ASSEMBLY

1

2

5

8

6

3

4

10

9

7

Item Part No. Qty. Description

1 04215451 1 Weldment, Bagger Weight Tray

2 00172000 1 Cast Iron Weight

3 06200205 2 Bolt, Round Head Square Neck 1/2-13 x 2.00

4 06216100 2 Bolt, Round Head Square Neck 1/2-13 x 1.00

5 03833800 1 Grip, Adhesive

6 05957800 2 Bolt, Hex 3/8-16 x 3.00

7 06308800 2 Washer, Lock 3/8

8 06545400 2 Nut, Nyloc 5/16-18

9 06500705 2 Nut, Push

10 06500010 2 Nut, Flange Nyloc 1/2-13

21

Consumer Mowing Equipment

Limited Warranty

Ariens Company (Ariens) warrants to the original purchaser that Ariens, Gravely and Countax brand lawn and garden

consumer products purchased on or after 1/1/2012 will be free from defects in material and workmanship for the time period

noted in the chart below. Equipment put to personal use around a single household or residence is considered “Consumer

Use”; equipment put to any business use (agricultural, commercial, or industrial) or used at multiple locations is considered

“Commerc ial Use.” If any product is rented or leased, then the duration of these warranties shall be 90 days af ter the da te of

purchase.

An authorized Ariens dealer (Ariens brand products), Gravely dealer (Gravely brand products), or Countax dealer (Countax

brand products) will repair any defect in material or workmanship, and repair or replace any defective part, subject to the

conditions, limitations and exclusions set forth herein. Such repair or replacement will be free of charge (labor and parts) to

the original purchaser except as noted below.

Warranty

Code

HA Zoom & ZT Zero-Turn Riders; AMP™ Rider 3 Years 90 Days

HB Max Zoom & ZT HD Zero-Turn Riders 3 Years 1 Year

HC Tractors, "961" Series Walk-Behind Mowers 2 Years 90 Days

HD Classic LM Series Mowers; Wide Area Walk Mowers 3 Years 90 Days

N/A Service (replacement) Parts 90 Days (no labor) 90 Days (no labor)

Special Extensions

The chart below details special extensions to this warranty:

Warranty

Code

HA, HB

HA, HB

HA Batteries for AMP™ Rider 2 Years Consumer 100% first year; prorated second year

Exceptions and Limitations

The chart below details special exceptions to this warranty:

Warranty

Code

All Batteries 1 Year Consumer Prorated

All Belts, Muffler, Tires None Commercial

All

All Engines

Warranty Exception

Mower Deck Shell on

Zero-Turn Riders

Main Frame on

Zero-Turn Riders

Warranty Exception

Cloth, Plastic, and Rubber

Components (Including

Belts and Cables)

Product Group

Warranty

Period

5 Years Consumer

5 Years Consumer

Warranty

Period

Maximum

2 Years

See Engine

Manufacturer’s

Warranty

Use Detail

Use Detail

All

All

Warranty Period

Consumer Use

3 years parts and labor

Additional 2 years parts only

3 years parts and labor

Additional 2 years parts only

These components are not covered when used

commercially.

Warranty is limited to 2 years for consumer use.

Except as noted above, these components are

covered for defect, not for wear.

Engines are covered by engine manufacturer’s

warranty. Refer to engine manufacturer’s warranty

statement.

Warranty Period

Commercial Use

Customer Responsibilities

Register the product immediately at the time of sale. If the dealer does not register the product, the customer must

complete the product registration card in the literature package and return it to the Ariens Company, or register the unit online

at www.ariens.com, www.gravely.com, www.countax.com.

To obtain warranty service, the original purchaser must:

• Perform the maintenance and adjustments explained in the owner's manual.

• Promptly notify Ariens or an authorized Ariens, Gravely or Countax service representative of the need for warranty service.

• Transport the product to and from the place of warranty service at owner's expense.

• Have the warranty service performed by an authorized Ariens, Gravely or Countax service representative.

Consumer_2012_Rev.A

22

To Find an Authorized Service Representative:

In the U.S. and Canada:

Use the dealer locator on our websites: www.ariens.com • www.gravely.com

Or contact us by mail or by phone:

In the U.S., Canada, Mexico, Caribbean,

Central and South America:

Ariens Company

655 W. Ryan Street

Brillion, WI 54110

Phone: (920) 756 - 4688

www.ariens.com

Exclusions – Items Not Covered by This Warranty

• Parts that are not genuine Ariens, Gravely or Countax service parts are not covered by this warranty and may void the warranty.

• Damages resulting from the installation or use of any part, accessory, or attachment which is not approved by the Ariens

Company for use with product(s) identified herein are not covered by this warranty.

• The following maintenance, service and replacement items are not covered by this warranty unless they are noted in the

Limitations section above: lubricants, spark plugs, oil, oil filters, air filters, fuel filters, brake linings, brake arms, brake

shoes, skid shoes, scraper blades, shear bolts, mower blades, mower vanes, brushes, headlights, light bulbs, knives, cutters.

• Any misuse, alteration, improper assembly, improper adjustment, neglect, or accident which requires repair is not covered

by this warranty.

• Use of gasoline blends exceeding 10% ethanol voids any and all warranties.

• Products are designed to the specifications in the area that the product was originally distributed. Different areas may

have significantly different legal and design requirements. This warranty is limited to the requirements in the area in which

the unit was originally distributed. Ariens Company does not warrant this product to the requirements of any other area.

Warranty service is limited to service within the area originally distributed.

• In countries other than the United States and Canada, contact the Ariens Company dealer for warranty policies that govern

within your country. Rights may vary from country to country and within any one country.

Disclaimer

Ariens Company may from time to time change the design of its products. Nothing contained in this warranty shall be

construed as obligating the Ariens Company to incorporate such design changes into previously manufactured products, nor

shall such changes be construed as an admission that previous designs were defective.

LIMITATION OF REMEDY AND DAMAGES

Ariens Company's liability under this warranty, and under any implied warranty that may exist, is limited to repair of any defect

in workmanship, and repair or replacement of any defective part. Ariens Company shall not be liable for incidental, special, or

consequential damages (including lost profits). Some states do not allow the exclusion of incidental or consequential

damages, so the above limitation or exclusion may not apply to you.

In Europe, Asia, Africa or the

Middle East:

Countax Ltd, Countax House

Great Haseley, Oxfordshire,

OX44 7PF

Phone: 0800 597 7777

www.countax.com

In Australia or New Zealand:

Ariens Company

Building 2

6 Wedgewood Rd.

Hallam, Victoria 3803 Australia

Phone: (03) 9796 4244

1800 335 489

www.ariens.com.au

AUSTRALIAN CONSUMER LAW

The following applies solely to warranties subject to Subsection 102(1) of the Australian Consumer Law: Our goods come

with guarantees that cannot be excluded by the Australian Consumer Law. You are entitled to a replacement or refund for a

major failure and for compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the

goods repaired or replaced if the goods fail to be of acceptable quality and failure does not amount to a major failure.

DISCLAIMER OF FURTHER WARRANTY

Ariens Company makes no warranty, express or implied, other than what is expressly made in this warranty. If the

law of your state provides that a n implied warranty of merchant ability, or an implied warranty of fitness for particular

purpose, or any other implied warranty, applies to Ariens Company, then any such implied warranty is limited to the

duration of this warranty. Some states do not allow limitations on how long an implied warranty lasts, so the above

limitation may not apply to you.

This warranty gives you specific legal rig hts, and you may also have ot her right s which var y from region to region.

Consumer_2012_Rev.A

23

Ariens

Gravely

655 West Ryan Street

Brillion, WI 54110-1072

920-756-4688

Fax 920-756-2407

www.ariens.com

www.gravely.com

Loading...

Loading...