Pro-Turn

400 Diesel

Operator’s Manual

Manuel du I’utilisateur

992236 – Pro-Turn 460 Diesel

992240 – Pro-Turn 472 Diesel

™

Models

(SN 050,000 +)

(SN 050,000 +)

ENGLISH

FRANÇAIS

04887100 • 9/15

Printed in USA

TABLE OF CONTENTS

Figure 1

1

1. Serial Number Label

SAFETY. . . . . . . . . . . . . . . . . . . . . . . . . . 4

ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . 13

CONTROLS AND FEATURES . . . . . . . 15

OPERATION . . . . . . . . . . . . . . . . . . . . . 16

MAINTENANCE SCHEDULE . . . . . . . . 24

SERVICE AND ADJUSTMENTS . . . . . 27

STORAGE. . . . . . . . . . . . . . . . . . . . . . . 44

TROUBLESHOOTING . . . . . . . . . . . . . 45

ACCESSORIES. . . . . . . . . . . . . . . . . . . 46

SERVICE PARTS . . . . . . . . . . . . . . . . . 46

SPECIFICATIONS. . . . . . . . . . . . . . . . . 47

WARRANTY . . . . . . . . . . . . . . . . . . . . . 48

INTRODUCTION

MANUALES EN IDIOMAS DIFERENTES DEL INGLES

Puede obtener manuales en

idiomas diferentes del inglés en su

distribuidor. Visite a su distribuidor

o vaya a www.ariens.com para

obtener una lista de idiomas

disponibles para su equipo.

T ambién puede imprimir manuales

en idiomas diferentes del inglés

descargándolos gratuitamente de

nuestra página Web:

http://www.gravely.com

THE MANUAL

Before operation of unit, carefully and

completely read your manuals. The contents

will provide you with an understanding of

safety instructions and controls during normal

operation and maintenance.

All reference to left, right, front, or rear are

given from operator sitting in the operation

position and facing the direction of forward

travel.

ENGINE MANUAL

The engine on this unit is covered by a

separate manual specific to the engine. This

manual is included in the literature package

that shipped with the unit. Refer to this

manual for engine service recommendations.

If the engine manual is not available, contact

the engine manufacturer for a replacement

manual.

SERVICE AND REPLACEMENT PARTS

When ordering publications, replacement

parts, or making service inquiries, know the

model and serial numbers of your unit and

engine.

Numbers are located on the product

registration form in the literature package.

They are printed on a serial number label,

located on the frame of your unit (Figure 1).

• Record Unit Model and Serial

numbers here.

• Record Engine Model and Serial

numbers here.

PRODUCT REGISTRATION

The Gravely dealer must register the product

at the time of purchase. Registering the

product will help the company process

warranty claims or contact you with the latest

service information. All claims meeting

requirements during the limited warranty

period will be honored, whether or not the

product registration card is returned. Keep a

proof of purchase if you do not register your

unit.

EN - 2

Customer Note: If the Dealer does not

register your product, please fill out, sign and

return the product registration card to Gravely

or go to www.gravely.com on the Internet.

UNAUTHORIZED REPLACEMENT PARTS

Use only Gravely replacement parts. The

replacement of any part on this equipment

with anything other than a Gravely authorized

replacement part may adversely affect the

performance, durability, and safety of this unit

and may void the warranty. Gravely disclaims

liability for any claims or damages, whether

regarding warranty, property damage,

personal injury or death arising out of the use

of unauthorized replacement parts.

NOTE: To locate your nearest Gravely

Dealer, go to www.gravely.com.

DISCLAIMER

Gravely reserves the right to discontinue,

change, and improve its products at any time

without public notice or obligation to the

purchaser. The descriptions and

specifications contained in this manual were

in effect at printing. Equipment described

within this manual may be optional. Some

illustrations may not be applicable to your

unit.

DEALER DELIVERY

Dealer should:

1. Test parking brake after unit is

assembled to be sure adjustment has

not been disturbed in shipment (See

Parking Brake Interlock System on

page 17). Wheel brakes are properly

adjusted at factory.

2. Check the safety inte rlock sys tem to

make sure that it is functioning properly.

With operator on seat, unit must not start

unless steering levers are in neutral and

power takeoff (PTO) is disengaged (Off).

Engine must stop if operator lifts from

seat when steering levers are in any

drive position or PTO is engaged (On).

See Safety Interlock System on

page 16.

3. Fill out Original Purchaser Registration

Card and return the card to Gravely.

4. Explain Limited Warranty Policy.

5. Explain recommended lubrication and

maintenance. Advise customer on

adjustments. Instruct customer on

controls and operation of unit. Discuss

and emphasize the Safety Precautions.

Give customer this Owner/Operator and

the engine manual. Advise customer to

thoroughly read and understand them.

Customer Note: Your Dealer has been

provided complete set-up and preparation

instructions which must be completed prior to

you taking delivery of this unit. The dealer is

required to review important information in

this manual with you before or upon delivery

of the unit or attachment.

PRACTICES AND LAWS

Practice usual and customary safe working

precautions, for the benefit of yourself and

others. Understand and follow all safety

messages. Be alert to unsafe conditions and

the possibility of minor, moderate, or serious

injury or death. Learn applicable rules and

laws in your area, including those that may

restrict the age of the operator.

REQUIRED OPERATOR TRAINING

Original purchaser of this unit was instructed

by the seller on safe and proper operation. If

unit is to be used by someone other than

original purchaser (loaned, rented or sold),

ALWAYS provide this manual and any

needed safety training before operation.

EMISSION CONTROL SYSTEM

This equipment and/or its engine may include

exhaust and evaporative emissions control

system components required to meet U.S.

Environmental Protection Agency (EPA)

and/or California Air Resources Board

(CARB) regulations. Tampering with emission

controls and components by unauthorized

personnel may result in severe fines or

penalties. Emission controls and components

can only be adjusted by an Ariens Company

dealer or an authorized engine

manufacturer's service center. Contact your

Ariens Company Equipment Retailer

concerning emission controls and

components.

EN - 3

SAFETY

WARNING: This cutting machine

is capable of amputating hands

and feet and throwing objects.

Failure to observe the safety

instructions in the manuals and on

decals could result in serious

injury or death.

Slopes are a major factor related

to loss-of-control and tip-over

accidents. Operation on all slopes

requires extra caution.

Tragic accidents can occur if the

operator is not alert to the

presence of children. Never

assume that children will remain

where you last saw them.

Fuel is extremely flammable and

the vapors are explosive, handle

with care.

Disengage attachment, stop unit

and engine, remove key, engage

parking brake, and allow moving

parts to stop before leaving

operator’s position.

Read these safety rules and follow them

closely. Failure to follow these rules could

lead to loss of control of unit, severe personal

injury or death to you or bystanders or result

in damage to property or the machine.

WARNING: This cutting machine is

capable of amputating hands and

feet and throwing objects. Failure to

observe the safety instructions in the

manuals and on decals could result

in serious injury or death.

Safety Alert Symbol

These are safety alert

symbols. They mean:

• ATTENTION!

• YOUR SAFETY IS

INVOLVED!

When you see this symbol:

• BECOME ALERT!

• OBEY THE

MESSAGE!

SIGNAL WORDS

The safety alert symbols above and signal

words below are used on decals and in this

manual.

Read and understand all safety messages.

1. Danger

DANGER: Indicates an

IMMINENTLY HAZARDOUS

SITUATION! If not avoided, WILL

RESULT in death or serious injury.

2. Warning

WARNING: Indicates a

POTENTIALLY HAZARDOUS

SITUATION! If not avoided, COULD

RESULT in death or serious injury.

3. Caution

CAUTION: Indicates a

POTENTIALLY HAZARDOUS

SITUATION! If not avoided, MAY

RESULT in minor or moderate injury .

It may also be used to alert against

unsafe practices.

4. Notice

NOTICE: Indicates information or procedures

that are considered important but not hazard

related. If not avoided property damage could

result.

5. Important

IMPORTANT: Indicates general reference

information worthy of special attention.

SAFETY DECALS

This cutting machine is capable of amputating

hands and feet and throwing objects. Failure

to observe the following safety instructions

could result in serious injury or death.

The safety decals on your machine are visual

reminders of the important safety information

found in this manual. All messages found on

your unit must be fully understood and

carefully followed. Safety decals found on the

machine are explained below.

Always replace missing or damaged safety

decals. Replacement decals can be found in

the parts manual for your machine and

ordered from your dealer.

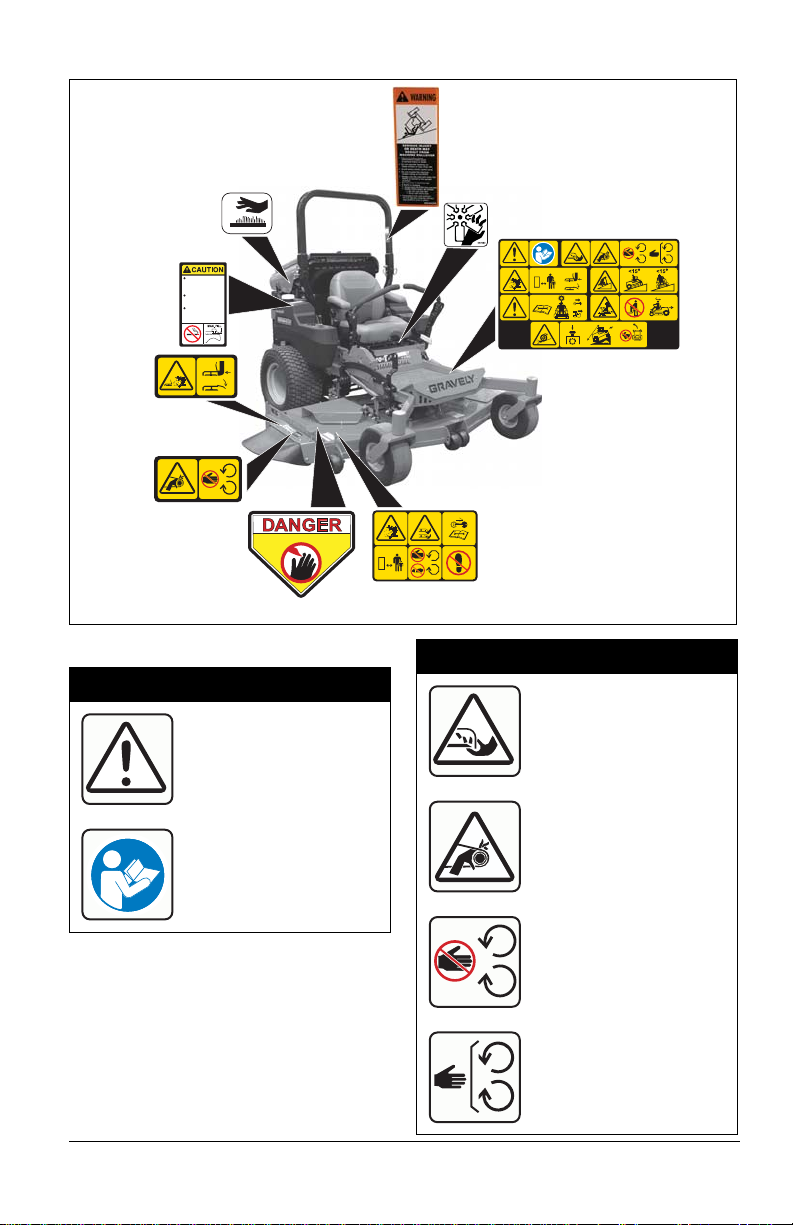

Refer to Figure 2 for safety decal locations.

EN - 4

1. Safety Decal Identification

Figure 2

1

2

5

3

6

7

4

8

9

Never fill tank when

engine is running,

hot or unit is indoors.

Never overfill fuel

tank.

Replace fuel cap

securely and clean

up spilled fuel.

08000611A

07800401

KEEP HANDS and FEET AWAY

P

07800403

02988100

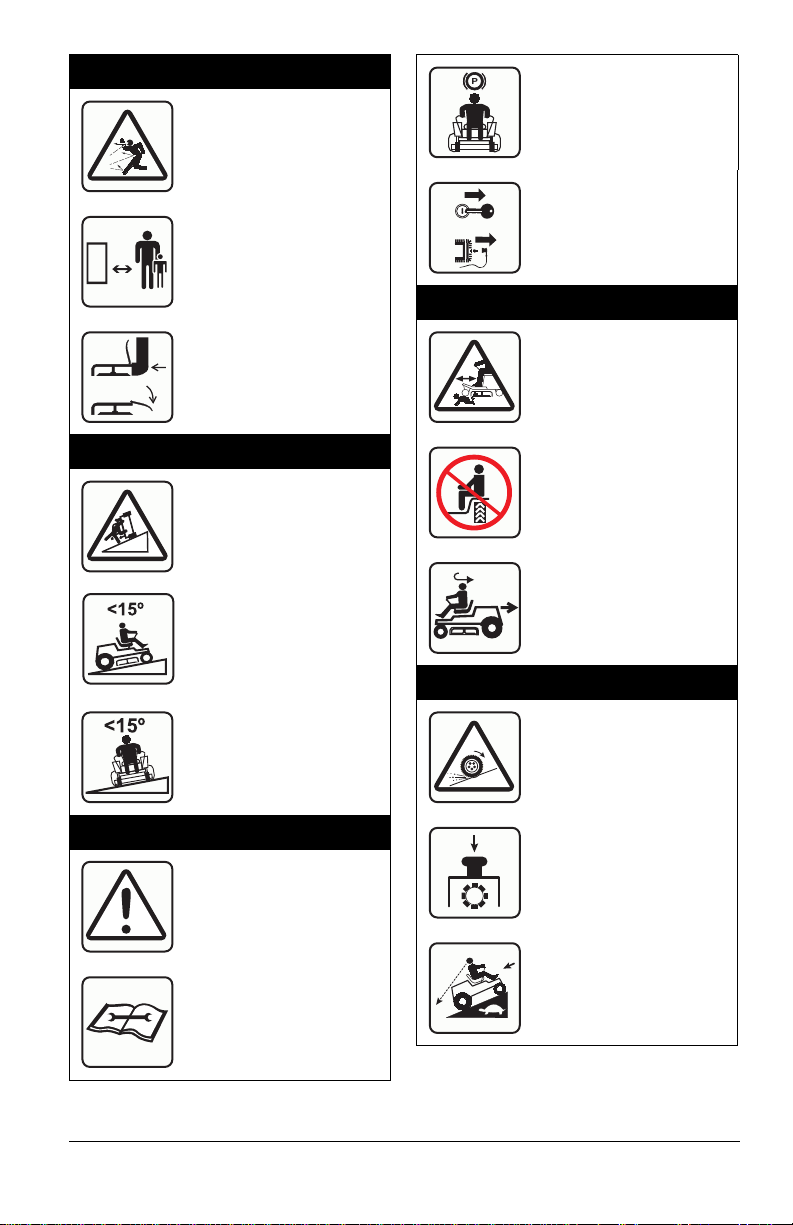

2. Safety Decal Description

1. DANGER!

DANGER!

Read and understand the

operator’s manual before

operating unit.

1.1 Amputation Hazard

EN - 5

To avoid amputation

hazard do not put hands

near rotating blades.

To avoid amputation

hazard do not put hands

near moving belts.

Keep hands away from all

rotating or moving parts.

Keep all guards and

shields in place.

1.2 Discharge Hazard

Discharge Hazard –

NEVER direct discharge

toward people, pets or

property. Thrown objects

can cause injury or

damage.

Keep children and others

away from unit while unit is

in operation.

P

Set parking brake.

Remove key and

disconnect spark plug

before servicing or making

adjustments to unit.

1.5 Bystander Hazard

Do not operate mower

unless all guards are in

operating position or

bagger is attached.

1.3 Tipping Hazard

Avoid tipping hazard.

DO NOT operate on slopes

over 15°.

DO NOT operate on slopes

over 15°.

1.4 Service Hazard

Before servicing unit do the

following:

DO NOT operate the unit in

the presence of

bystanders.

Do not carry passengers.

Look behind when

operating the unit in

reverse.

1.6 Loss of Traction Hazard

If loss of traction is

experienced do the

following:

Disengage PTO.

Read owners manual

before servicing or making

adjustments to unit.

Look before backing.

Proceed off slope slowly.

EN - 6

Do not try to turn or speed

up.

DO NOT step or stand in

this area.

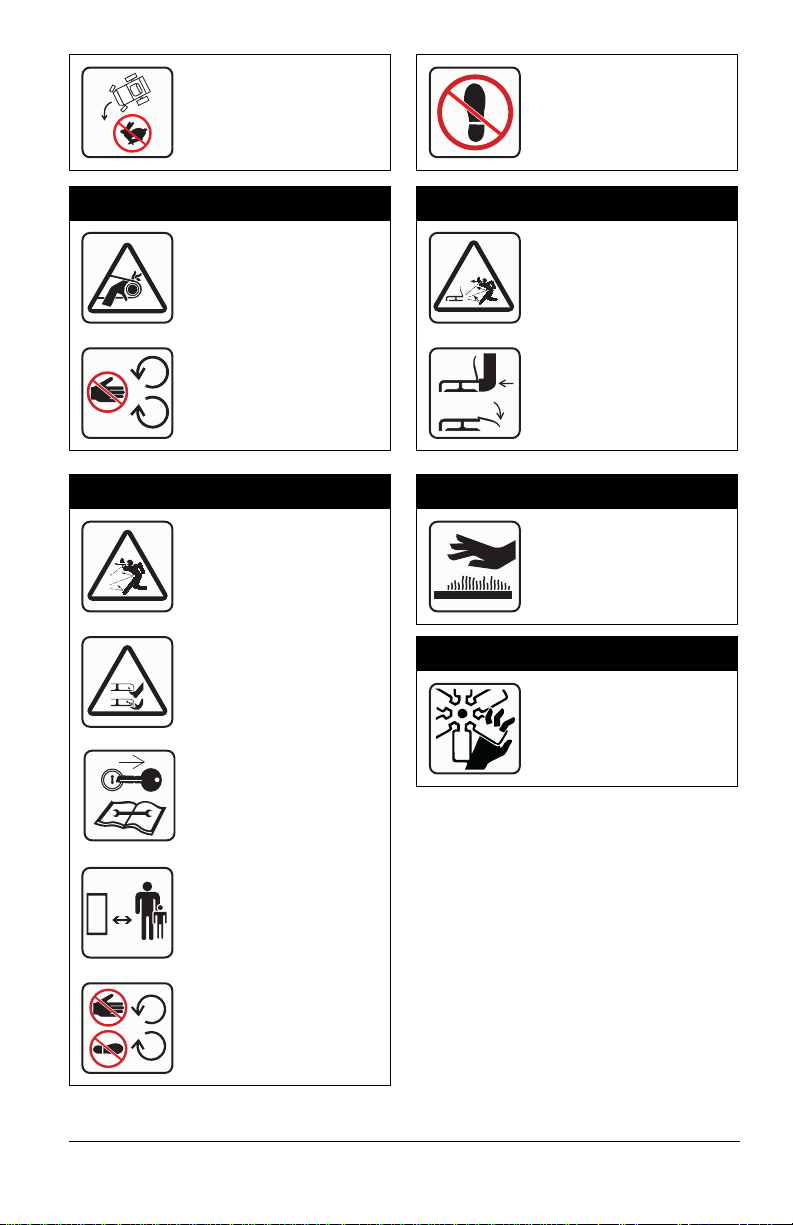

2. DANGER!

3. DANGER!

Discharge Hazard –

NEVER operate unit

without discharge chute

in operating position.

Thrown objects can

cause injury or damage.

Do not operate mower

unless all guards are in

operating position or

bagger is attached.

Discharge Hazard –

NEVER direct discharge

toward people, pets or

property. Thrown objects

can cause injury or

damage.

Amputation Hazard –

NEVER stick hands or feet

under deck or shielded

areas.

Shut off engine, remove

key, and read manual

before servicing or making

adjustments to unit.

4. DANGER!

Discharge Hazard –

NEVER operate unit

without discharge chute

in operating position.

Thrown objects can

cause injury or damage.

Do not operate mower

unless all guards are in

operating position or

bagger is attached.

5. HOT SURFACES!

DO NOT touch parts

which are hot from

operation. ALW A YS al low

parts to cool.

6. ROTATING PARTS!

AVOID INJURY. Stay

clear of rotating parts.

Keep children and others

away from unit while unit is

in operation.

Keep feet and hands away

from all rotating or moving

parts.

EN - 7

7. WARNING!

WARNING: Over Filling may cause

severe damage to evaporative

system!

SERIOUS INJURY OR

DEATH MAY RESULT

FROM MACHINE

ROLLOVER

• Failure to follow these instructions

could result in serious injury or

death

• Do not operate machine on steep

slopes or near drop offs

• Avoid sharp and/or quick turns

• Do not exceed the machine weight

rating of the ROPS

• Always use the seat belt when the

ROPS is locked in the upright

position

• Do not jump if machine tips

• If ROPS is foldable

– Always keep the ROPS fully

extended

– WHEN ROPS MUST BE

DOWN

• Do not use seat belt

• Drive with extra care

• If equipped with seat platform:

Do not operate machine without seat

platform pins in place or locks engaged.

ROLLOVER PROTECTIVE STRUCTURE

To maintain operator protection and roll

bar certification:

• Replace a damaged roll bar, do

NOT attempt to repair or modify.

• Any alteration of the roll bar must

be approved by the manufacturer.

• DO NOT exceed the machine

weight rating of the roll bar.

8. CAUTION!

No smoking.

MAX. FILL

Fill fuel tank to bottom of

neck – MAXIMUM.

• Never fill fuel tank when engine is

running, hot or unit is indoors. Never

overfill fuel tank.

• Replace fuel cap securely and clean up

spilled fuel.

9. DANGER!

ALW A YS keep hands and

feet away from discharge

chute.

SAFETY RULES

This cutting machine is capable of amputating

hands and feet and throwing objects. Failure

to observe the following safety instructions

could result in serious injury or death.

The following safety instructions are based

on the B71.4 specifications of the American

National Standards Institute in effect at the

time of production.

Training

Read, understand, and follow all instructions

on the machine and in the manuals before

starting.

Be sure the area is clear of bystanders and

pets before operating. Stop machine if

anyone enters the area.

Improper use of power equipment can cause

serous permanent injury or death to the

operator or a bystander.

Understand:

• How to operate all controls

• The functions of all controls

• How to STOP in an Emergency

• Braking and steering characteristics

• Turning radius and clearances

If the operator or the mechanic cannot read

the manual, it is the owner’s responsibility to

explain it to them.

Always train any inexperienced operators

and require them to read and understand all

manuals and decals.

EN - 8

Only allow responsible adults, who are

familiar with the instructions, to operate this

machine.

Only the user can prevent and is responsible

for accidents or injuries occurring to

themselves, other people or property.

Operator Age

Do not allow children under the age of 18 to

operate any outdoor power equipment.

Local regulations may restrict the age of the

operator.

Data indicates operators age 60 years and

above are involved in a large percentage of

riding mower-related injuries.

These operators should evaluate their ability

to operate the riding mower safely enough to

protect themselves and others from serious

injury.

Children

Tragic accidents can occur if the operator is

not alert to the presence of children.

Children are often attracted to the machine

and the mowing activity. Never assume that

children will remain where you last saw

them.

Be alert and turn machine off if a child enters

the area.

Before and while backing, look behind and

down for small children.

Never carry children, even with the blade(s)

shut off. They may fall off and be seriously

injured or interfere with safe machine

operation. Children who have been given

rides in the past may suddenly appear in the

mowing area for another ride and be run

over or backed over by the machine.

Never allow children to operate the machine.

Use extreme care when approaching blind

corners, shrubs, trees, or other objects that

may block your view of a child.

Keep children out of the mowing area and in

the watchful care of a responsible adult

other than the operator.

Personal Protection

DO NOT wear loose clothing or jewelry and

tie back hair that may get caught in rotating

parts.

Wear adequate outer garments.

NEVER wear open sandals or canvas shoes

during operation. Wear adequate safety

gear, protective gloves and footwear.

Wear proper footwear to improve footing on

slippery surfaces

Always wear eye and ear protection when

operating machine.

Before Operating

Keep all nuts and bolts tight to be sure the

equipment is in safe working condition.

Maintain the machine to be in compliance

with the maintenance schedule.

Clean grass and debris from unit, especially

from around muffler and engine, to help

prevent fires.

Check parking brake operation frequently.

Adjust and service as required.

Inspect unit before each use for missing or

damaged decals and shields, correctly

operating safety interlock system, and

deterioration of grass catchers. Replace or

repair as needed.

Ensure Safety Interlock System is

functioning properly. DO NOT operate unit if

safety interlock is damaged or disabled.

Start and operate unit only when seated in

operator’s position. Steering control levers

must be in neutral, PTO disengaged and

parking brake set when starting engine.

Never tamper with safety devices. Check

their proper operation regularly.

Keep machine free of grass, leaves, or other

debris build-up. Clean up oil or fuel spillage

and remove any fuel-soaked debris.

Operation

Be sure the area is clear of bystanders

before operating. Stop machine if anyone

enters the area.

Never operate machine in a closed or poorly

ventilated area.

ALWAYS maintain unit in safe operating

condition. Damaged or worn out muffler can

cause fire or explosion.

This product is equipped with an internal

combustion type engine. DO NOT use unit

on or near any unimproved, forest-covered

or brush covered land unless exhaust

system is equipped with a spark arrester

meeting applicable local, state or federal

laws. A spark arrester, if it is used, must be

maintained in effective working order by

operator.

Do not operate machine while under the

influence of alcohol or drugs.

EN - 9

Do not put hands or feet near rotating parts

or under the machine. Keep clear of the

discharge opening at all times.

DO NOT touch parts which are hot. Allow

parts to cool.

Do not operate machine without the entire

grass catcher, discharge guard, or other

safety devices in place and working.

Always keep hands and feet away from all

pinch points.

Avoid slippery surfaces. Always be sure of

your footing.

Never carry passengers.

Never direct discharged material toward

anyone. Avoid discharging material against

a wall or obstruction. Material may ricochet

back toward the operator. Stop the blade(s)

when crossing gravel surfaces.

Never engage PTO when attachment,

including mower blades, is not in use.

Always turn off power to attachment when

not in active use such as traveling or

crossing driveways.

Always disengage PTO, stop unit and

engine, remove key, engage parking brake

and allow moving parts to stop before

leaving operator’s position.

Never engage PTO while raising the

attachment, including mower blades, or

when attachment is in the raised position.

Keep safety devices or guards in place and

functioning properly. Never modify or

remove safety devices.

Do not mow in reverse unless absolutely

necessary. Always look down and behind

before and while backing.

Stop engine before removing grass catcher

or unclogging chute.

Slow down before turning.

If you strike a foreign object, stop and

inspect the machine. Repair, if necessary,

before restarting.

Never leave a running machine unattended.

Always turn off blade(s), set parking brake,

stop engine and remove key before

dismounting.

Disengage blade(s) when not mowing. Shut

off engine and wait for all parts to come to a

complete stop before cleaning the machine,

removing the grass catcher, or unclogging

the discharge guard.

Know the weight of loads. Limit loads to

those you can safely control and the unit can

safely handle.

Operating Conditions

Always check overhead and side clearances

carefully before operation.

Watch for traffic when operating near or

crossing roadways.

Clear the area of objects such as rocks,

wire, toys, etc., which could be thrown by the

blades.

Check for weak spots on docks, ramps or

floors. Avoid uneven work areas and rough

terrain. Stay alert for hidden hazards or

traffic.

Use care when approaching blind corners,

shrubs, trees or other objects that may

obscure vision.

Dust, smoke, fog, etc. can reduce vision and

cause an accident.

Operate machine only in daylight or good

artificial light.

Slope Operation

Slopes are a major factor related to loss of

control and tip-over accidents, which can

result in severe injury or death. Operation on

all slopes requires extra caution. If you

cannot back up the slope or if you feel

uneasy on it, do not mow it.

DO NOT operate on slopes of more than

15°.

Mow up and down slopes, not across.

Watch for holes, ruts, bumps, rocks, or other

hidden objects. Uneven terrain could

overturn the machine. Tall grass can hide

obstacles.

Do not mow on moist or wet grass. Tires

may lose traction causing a loss of control.

Use extra care while operating machine with

grass catchers or other attachments; they

can affect the stability of the machine. Do

not use on steep slopes.

Keep all movements on the slope slow and

gradual. Do not make sudden changes in

speed or direction, which could cause the

machine to roll over.

Avoid starting, stopping, or turning on a

slope. If the tires lose traction, disengage

the blade(s) and proceed slowly straight

down the slope.

EN - 10

Operation on slopes may lead to loss of

steering control. When operating on slopes

be prepared to react to an emergency

situation:

• Return steering levers to neutral

position.

• Immediately set parking brake.

• Turn off PTO and engine.

DO NOT try to stabilize the machine by

putting your foot on the ground.

DO NOT park on slopes unless necessary.

When parking on slope always chock or

block wheels. Always set parking brake.

Choose a low ground speed so you will not

have to stop or shift while on a slope.

DO NOT operate near drop-offs, ditches, or

embankments. Unit can suddenly turn over if

a wheel is over the edge of a cliff or ditch, or

if an edge caves in.

Do not bypass transmission or allow

transmission to free-wheel when on a slope.

Fuel

T o avoid personal injury or property damage,

use extreme care in handling fuel. Fuel is

extremely flammable and the vapors are

explosive.

Replace fuel cap securely and clean up

spilled fuel before starting engine.

Extinguish all cigarettes, cigars, pipes, and

other sources of ignition.

Use only an approved fuel container.

Never store the machine or fuel container

where there is an open flame, spark, or pilot

light such as on a water or space heater or

other appliances.

Never fill containers inside a vehicle or on a

truck or trailer bed with a plastic liner.

Always place containers on the ground away

from your vehicle before filling.

Never fuel the machine indoors.

Never remove gas cap or add fuel with the

engine running. Allow engine to cool before

fueling.

Fuel is highly flammable and its vapors are

explosive. Handle with care. Use only an

approved container with an appropriately

sized dispensing spout.

NO smoking, NO sparks, NO flames.

Remove equipment from the trailer and

refuel it on the ground. If this is not possible,

then refuel such equipment with a portable

container, rather than from a fuel dispenser

nozzle.

Keep the nozzle in contact with the rim of

the fuel tank or container opening at all

times until the fueling is complete. Do not

use a nozzle lock-open device.

Never overfill fuel tank. Replace gas cap

and tighten securely.

If fuel is spilled on clothing, change clothing

immediately.

Towing

Follow the manufacturer’s recommendations

for weight limits for towed equipment and

towing on slopes.

NEVER allow children or others in or on

towed equipment.

Tow only with a machine that has a hitch

designed for towing. Do not attach towed

equipment except at the hitch point.

On slopes, the weight of the towed

equipment may cause loss of control.

Travel slowly and allow extra distance to

stop.

Accessories

Follow the manufacturer’s recommendation

for wheel weights or counterweights

Check grass catcher components and the

discharge guard frequently nad replace with

the manufacturer’s recommended parts,

when necessary.

Use only Ariens Company-recommended

attachments that are appropriate to your use

and can be used safely in your application.

Batteries

Avoid Electric Shock. Objects contacting

both battery terminals at the same time may

result in injury and unit damage. DO NOT

reverse battery connections.

Reverse connections may result in sparks

which can cause serious injury. Always

connect positive (+) lead of charger to

positive (+) terminal, and negative (-) lead to

negative (-) terminal.

ALWAYS disconnect negative (-) cable

FIRST and positive (+) cable SECOND.

ALWAYS connect positive (+) cable FIRST,

and negative (-) cable SECOND.

EN - 11

Explosive Gases from battery can cause

death or serious injury. Poisonous battery

fluid contains sulfuric acid and its contact

with skin, eyes or clothing can cause severe

chemical burns.

No flames, No sparks, No smoking near

battery.

ALW AYS wear safety glasses and protective

gear near battery. Use insulated tools.

ALWAYS keep batteries out of reach of

children.

Battery posts, terminals and related

accessories contain lead and lead

compounds, chemicals known to the State of

California to cause cancer and reproductive

harm. Wash hands after handling.

Rollover Protection System (ROPS)

Frequently inspect ROPS and seat belt for

damage or loose hardware.

Use extreme care when working close to

fences, ditches, or on hills.

Check overhead clearance carefully before

driving under any objects.

Always wear seat belt while operating the

unit with the ROPS in the upright position.

Only lower ROPS for transport.

Do not wear a seat belt while operating the

unit with the center bar in the lowered

position.

Do not weld, cut, drill or modify ROPS in any

manner unless instructed by the

manufacturer.

Service

Maintain or replace safety and instruction

labels, as necessary.

Keep unit free of debris. Clean up oil or fuel

spills.

ALWAYS block wheels and know all jack

stands are strong and secure and will hold

weight of unit during maintenance.

Release any pneumatic or hydraulic

pressure from components slowly.

NEVER attempt to make any adjustments to

unit while engine is running (except where

specifically recommended). Stop engine,

remove key or spark plug wire and wait for

all moving parts to stop before servicing or

cleaning.

Lower cutting deck unless a positive

mechanical lock is used.

Allow engine to cool before servicing.

Moving parts can cut or amputate fingers or

a hand. On multiblade mowers, rotation of

one blade will cause all blades to rotate.

Never weld or straighten mower blades.

Never make adjustments or repairs with the

engine running.

Mower blades are sharp. Wrap the blade or

wear gloves, and use extra caution when

servicing them.

ALWAYS keep body and hands away from

pin holes or nozzles which eject hydraulic

fluid under pressure.

Transporting Unit

Use extra care when loading or unloading

the machine into a trailer.

Secure unit chassis to transport vehicle.

Never secure from rods or linkages that

could be damaged.

Do not transport machine while engine is

running.

ALWAYS turn off power to attachment and

shut off fuel when transporting unit.

Storage

NEVER store unit with fuel in fuel tank,

inside a building where any ignition sources

are present.

Keep machine free of grass, leaves, or other

debris build-up. Clean up oil or fuel spillage

and remove any fuel-soaked debris. Allow

machine to cool before storing.

For extended storage, shut off fuel and

clean unit thoroughly . See engine manual for

proper storage.

EN - 12

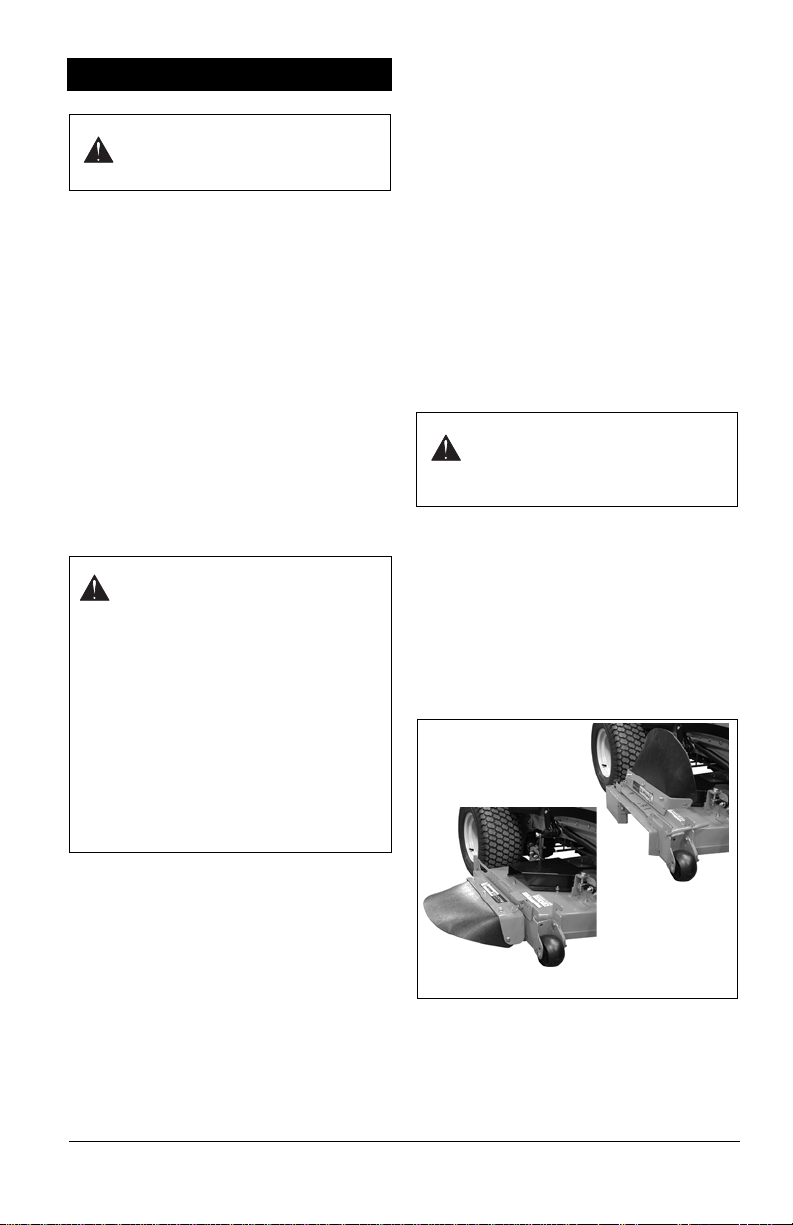

ASSEMBLY

Transport

Position

Operating

Position

Figure 3

WARNING: AVOID INJURY.

Read and understand entire

Safety section before proceeding.

UNIT ASSEMBLY

Package Contents

Unit, Mower Deck and Literature Pack

Preparation Checklist

Refer to the Owner/Operator manual as

required.

1. Unpack Unit – Remove wrap and

packaging materials.

2. Remove Unit From Container – Open

bypass valves (See To P ush The U nit on

page 23).

3. Push unit from container onto a level

surface.

4. Close the bypass valves.

5. Check Tire Pressures – See

Specifications on page 47.

CAUTION: Avoid injury! Explosive

separation of tire and rim parts is

possible when they are serviced

incorrectly:

• Do not attempt to mount a tire

without the proper equipment

and experience to perform the

job.

• Do not inflate the tires above the

recommended pressure.

• Do not stand in front or over the

tire assembly when inflating.

Use a clip-on chuck and

extension hose long enough to

allow you to stand to one side.

10. Check Engine Oil Level – Check and add

oil if needed. See engine manual for

specifications.

11. Check Hydraulic Fluid Level – Check and

add oil if needed. See Check Hydraulic

Fluid Level on page 28.

12. Check Coolant Level

13. F ill Engine Fuel Tank – Add clean fuel to

the fuel tank. See Filling Fuel Tank on

page 21.

IMPORTANT: Refer to engine manual for fuel

type.

14. Inspect Hardware – Check for loose

hardware.

15. Check Safety Interlock System – Check

to see that the interlock system operates

correctly (See Safety Interlock System on

page 16).

WARNING: FAILURE OF

INTERLOCK together with

improper operation can result in

severe personal injury.

16. Lubrication – Lubricate all fittings per

maintenance label under seat and check

hydraulic oil level (See Maintenance

Schedule on page 24).

17. Remove the knob retaining the discharge

chute from the transport position and

place the discharge chute in the

operating position. Return and tighten

knob in original position on deck for

storage.

6. Locate anti-rattle knobs in literature pack

and install in ROPS uprights on both

sides. Raise Rollover Protection Structure

(ROPS) center bar – See Rollover

Protection Structure (ROPS) on page 16.

7. Adjust Seat – See Seat Adjustments on

page 20 and Service Position on

page 27.

8. Check S teering Lever Positions – See

Adjusting the Parking Brake on page 37.

9. Charge Battery – Remove battery from

unit and charge (See Battery on

page 33).

Prepare Seat

1. Remove hairpin and clevis from shipping

position on left side of seat and reinstall

as shown below.

EN - 13

2. Secure adjustment dial to seat as shown

Figure 4

Reinstall

hairpin and

clevis here.

Shipping

position for

hairpin and

clevis.

Figure 5

1. Recliner Pin

2. Bearing

3. Seat Adjustment Dial

4. Washer

5. Bowed Washer

6. Flat Washer

7. 3/8-16 x 1 1/2" Hex Bolt

1

2

4

3

5

6

7

below. Use socket wrench to hand tighten

bolt until dial is difficult to rotate, then

loosen bolt slightly until dial rotates freely.

IMPORTANT: DO NOT loosen bolt more than

one full turn.

WARNING: FAILURE OF

CONTROLS could result in death

or serious injury.

3. Check Deck Level – Check unit to ensure

deck level set at factory has been

maintained (See Leveling the Mower

Deck on page 42).

4. Check Function of all Controls – Ensure

unit runs and performs properly.

EN - 14

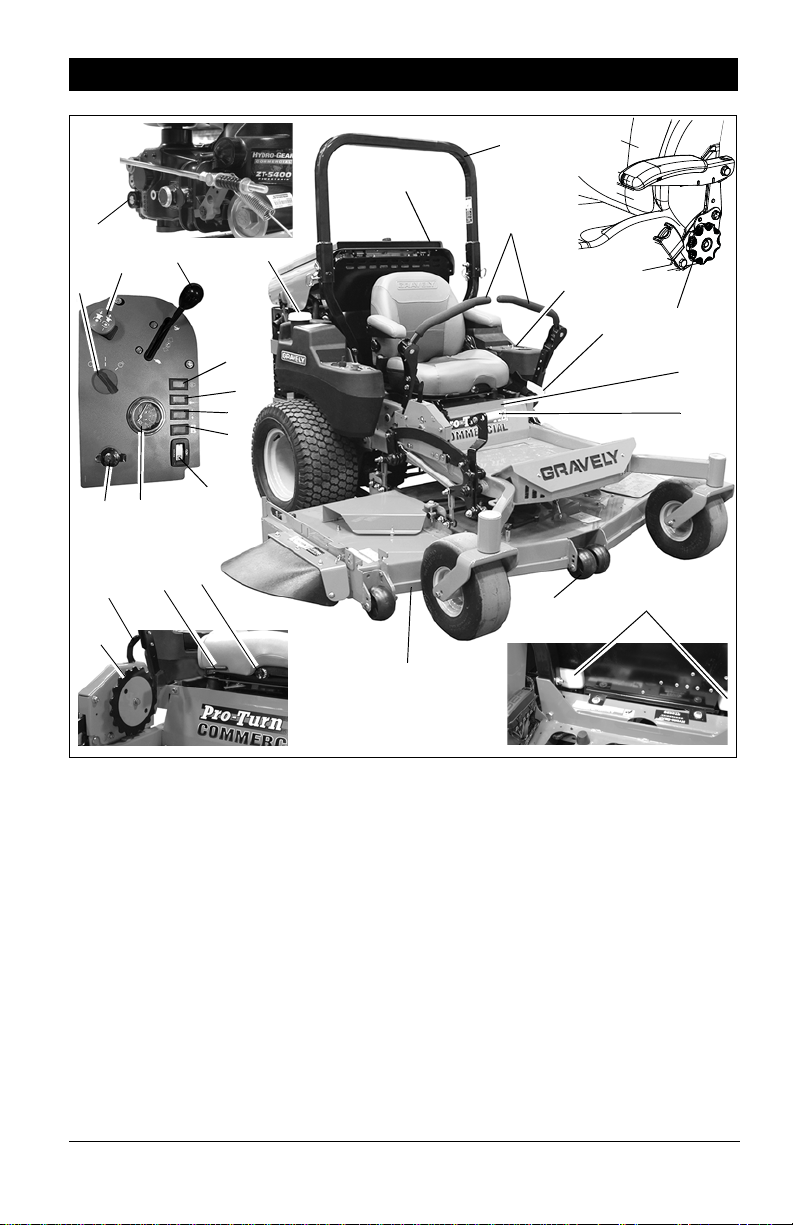

CONTROLS AND FEATURES

1

2

3

10

11

12

13

14

15

8

7

5

19

9

4

18

Figure 6

17

21

23

22

16

24

20

25

6

26

27

1. Fuel Tanks and Caps

2. Steering Levers

3. Hydraulic Oil Reservoirs

4. Ignition Switch

5. Hour Meter

6. Coolant Temperature Gauge

7.

Throttle Lever

8. Battery Charge Light

9. Power Take Off (PTO) Switch

10. Battery

11. Fuel Control Lever

12. Mower Lift Pedal

13. Mower Deck

14. Transport Lock Lever

EN - 15

15. Seat Adjustment Lever

16. Seat Height/Pressure Adjustment Knob

17. Parking Brake Lever

18. Transaxle Bypass Valve

19. Oil Pressure Light

20. Engine O verheat Light

21. Height- of-Cut (HOC) Index Wheel

22. Engine Preheat Indicator

23. Roll-Over Protection Structure (ROPS)

24. Radiator Filler and Cap

25. Anti-Scalp Wheels

26. 12V Auxiliary Power Port

27. Seatback Adjustment Dial

OPERATION

WARNING: AVOID INJURY.

Read and understand entire

Safety section before proceeding.

CONTROLS AND FEATURES

See Figure 6 for Controls and Features

locations.

Safety Interlock System

WARNING: Safety interlock

system failure and improper

operation of unit can result in

death or serious injury. Test this

system each time the unit is

operated. If this system does not

function as described, do not

operate until repairs are made.

Perform the following tests to ensure the

safety interlock system is working properly. If

the unit does not perform as stated, contact

your Gravely dealer for repairs.

NOTICE: When the parking brake is

engaged, the steering levers are locked in

neutral.

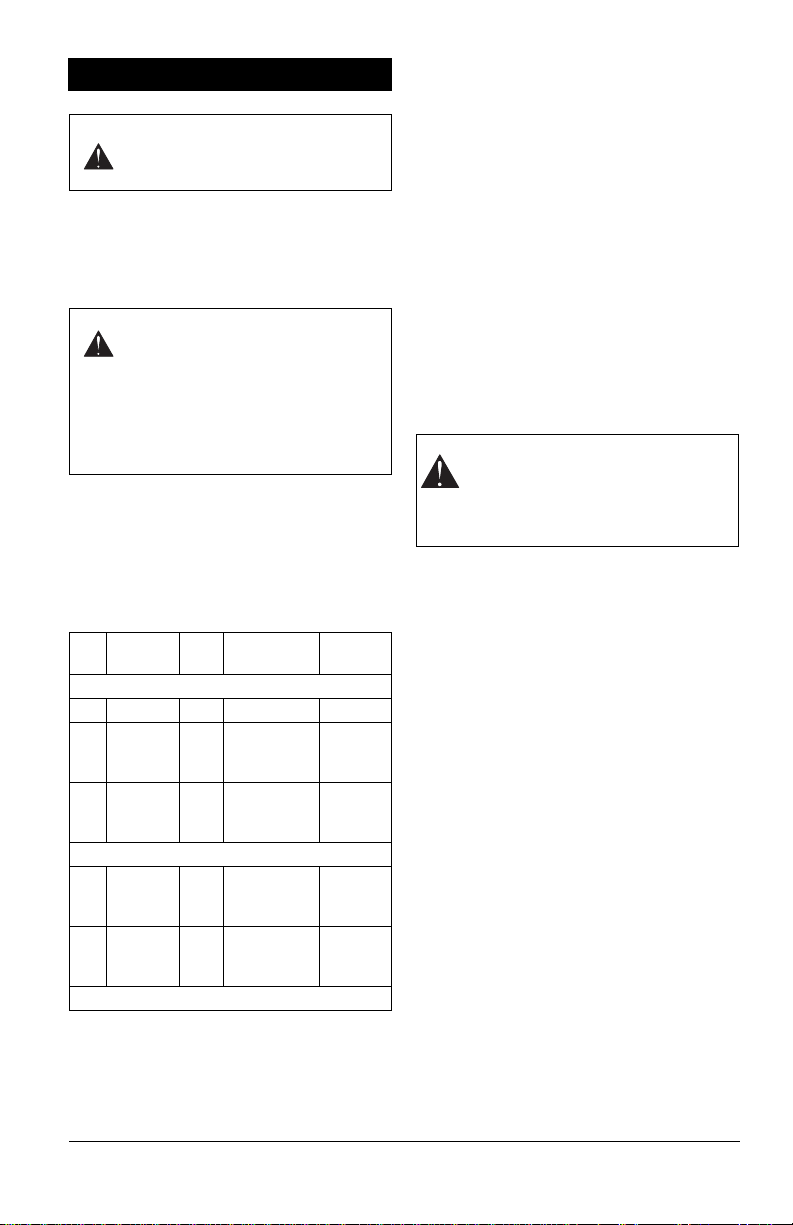

Test

Steering

Levers

STARTING INTERLOCK

1 Neutral Off Engaged Starts

2Forward,

Neutral,

Reverse

3Forward,

Neutral,

Reverse

OPERATING INTERLOCK (ENGINE ON)

4* Forward,

Neutral,

Reverse

5* Forward,

Neutral,

Reverse

* Operator lifts off seat.

PTO Parking

Brake

On Engaged or

Disengaged

On

Disengaged Does

or

Off

On Engaged or

Disengaged

On

Disengaged Shuts

or

Off

Engine

Does

Not Start

Not Start

Shuts

Off

Off

ROLLOVER PROTECTION STRUCTURE (ROPS)

Frequently inspect ROPS and seat belt for

damage or loose hardware.

Use extreme care when working close to

fences, ditches, or on hills.

Check overhead clearance carefully before

driving under any objects.

ALWAYS wear seat belt while operating the

unit with the ROPS in the upright position.

Do not wear a seat belt while operating the

unit with the center bar in the lowered

position.

IMPORTANT: Do not weld, cut, drill or modify

ROPS in any manner unless instructed by the

manufacturer.

Lower Center Bar

(Figure 7)

WARNING: Lower the center bar

only when necessary to drive under

an object. There is no rollover

protection with the center bar in the

down position.

1. Loosen but do not remove the two antirattle knobs on the front of the hinge

plate.

2. Remove the two hair pins and then

remove the ROPS lock pins from the

hinge plate.

3. Lower the center bar into down position.

4. Install the ROPS lock pins in the hinge

plate and secure with the hair pins.

Raise Center Bar

(Figure 7)

1. Remove the two hair pins and then

remove the ROPS lock pins from the

hinge plate.

2. Raise the center bar into up position.

3. Install the ROPS lock pins in the hinge

plate and secure with the hair pins.

4. Tighten anti-rattle knobs until threads

place tension on upper bar. Do not

overtighten.

NOTICE: Return the center bar to the raised

position when clear of obstacles.

EN - 16

Lowered

Position

Figure 7

Raised

Position

1. Lock Pin

1

Direction

1

2

3

of Travel

Left Turn Push right lever

Lever Position

farther forward

than the left lever.

Parking Brake Interlock System

With the parking brake engaged, the steering

levers must be locked in neutral.

With the parking brake disengaged, the

engine must not start and the engine must

shut off if the operator lifts from the seat.

Steering Levers

The steering levers control speed and

direction. In addition, they will stop the unit.

T o stop, return both steering levers to neutral.

Direction

of Travel

Forward Push both levers

Reverse Pull both levers

Right Turn Push left lever

Lever Position

forward from

neutral position.

backward from

neutral position.

farther forward

than the right

lever.

Stop Return both

levers to neutral

position.

NOTICE: The steering controls are

mechanically locked in neutral whenever the

parking brake is engaged.

NOTICE: Aggressive turning can scuff or

damage lawns. ALWAYS keep both wheels

rotating when making sharp turns. DO NOT

make turns with inside wheel completely

stopped. To obtain minimum turning radius,

slowly reverse inside wheel while moving

outside wheel slowly forward.

Ignition Switch

Operate the ignition

switch with the

removable key. The

switch has three

positions:

•Off (1)

•On (2)

•Start (3)

To start the engine, turn the key to Start, then

release to On. To stop the engine, turn the

key to Off.

Engine Preheat Light

Indicates when the engine

preheater is energized.

Preheater energizes for

approximately 5 seconds

when the key switch is

turned to the Run position.

Oil Pressure Light

Indicates when engine oil

pressure is low.

NOTICE: It does not

indicate engine oil level.

See Troubleshooting on page 45 or refer to

Engine Manual for details.

EN - 17

Coolant T e mpe rature Gauge

2

1

1

OFF

ON

Indicates

temperature of

engine coolant.

Engine

Overheat Light

Indicates when

coolant temperature

exceeds 93.3

F). See Troubleshooting

on page 45.

o

C (200o

Engine Overheating Wa rning Alarm

When the coolant

temperature exceeds

o

C (220o F) an

104.4

alarm located behind the

seat will sound to alert

the operator that the

engine coolant is

will continue to sound until the key switch is

turned to the Off position or the coolant

temperature drops below 104.4

overheating. The alarm

o

C (220o F).

Battery Charge Indicator

Lights when the key is in

the run position and the

charging system is not

charging the battery.

Transax l e By pass Valves

The unit can be

moved without the

engine running by

bypassing the

transaxles. The

bypass valves (1)

are located on the

transaxles near the

rear tires. See To

Push The Unit on

page 23.

NOTICE: Make sure

both transaxles are

set to neutral before

pushing the unit.

IMPORTANT: DO NOT tow the unit.

Transport the unit on an appropriate truck or

trailer.

Power Take Off (PTO) Switch

Power take off (PTO)

switch engages and

disengages the mower

blades.

Pull the power take off

(PTO) switch to On

position to engage

mower blades.

Push the power take off

(PTO) switch to Off

position to disengage

mower blades.

NOTICE: The engine will not start unless the

steering control levers are in the neutral

position, the PTO switch is in the Off position

and parking brake is set.

Throttle Lever

The throttle lever

changes the engine

speed.

Move the throttle lever

to Fast (1) to increase

engine speed.

Move the lever to Slow

(2) to decrease engine

speed.

MOWER LIFT PEDAL AND HEIGHT-OF-CUT (HOC) INDEX WHEEL

Mower lift pedal raises and lowers mower

deck for mowing or transport. Height-of-cut

(HOC) index wheel sets desired cutting

height or transport position. When in the lock

position, the transport lock lever allows the

deck to automatically lock in the highest (14

mm (5.5") HOC) position when the lift pedal is

pushed fully forward.

EN - 18

Transport Lock Lever

RELEASE OFF

TRANSPORT LOCK

CUT

HEIGHT

Figure 8

1. Mower Lift Pedal

2. Height of Cut (HOC) Index Wheel

3. Transport Lock Lever

4. HOC Setting Indicator

1

2

3

2

Off

Position

3

4

1

2

To m ove the mower deck into the

transport position:

1. Push mower lift pedal fully

forward. The lever will

automatically lock in the transport

position.

2. Release mower lift pedal.

To release the mower deck fr om

the transport position:

1. Push mower lift pedal to

relieve pressure from the

transport lock lever.

2. Pull back on the transport lock

lever.

3.Release the mower lift pedal.

NOTICE: With the lock lever in the lock

position (in) the deck will automatically lock at

transport height whenever the lift pedal is

pressed fully forward. To disable this feature

move the transport lock lever out and to the

rear to the Off position.

Height of Cut (HOC)

(Figure 8)

1. Push mower lift pedal to release deck

pressure from HOC index wheel.

2. If locked, move transport lock lever to

unlocked position.

3. Rotate HOC index wheel to the desired

HOC setting. Height setting is viewed in

the center the window on the top of the

HOC adjustment assembly.

4. Release mower lift pedal.

Fuel Control Lever

Controls fuel flow

from the left or

right fuel tank to

the engine.

Move the lever to

the Left Tank or

Right Tank

position to draw

fuel from that tank.

Parking Brake Lever

Engages and disengages

parking brake.

Push lever forward to

disengage (1) parking

brake.

Pull lever backward to

engage (2) parking brake.

EN - 19

SEAT ADJUSTMENTS

Figure 9

1. Height Adjustment Switch

1

Figure 10

Adjust to 3 – 6 mm (1/8 – 1/4")

gap between threaded washer

and seat isolator.

1. Threaded Washer

2. Seat Isolator

2

1

WARNING: Make all seat

adjustments with unit stationary,

parking brake engaged and

engine shut off.

Setting Seat Position

1. Pull seat adjustment lever outward and

slide seat forward or backward to desired

position.

2. Release lever and slide seat slightly

forward or backward to lock seat position.

Setting Seatback Angle

Turn adjustment knob counterclockwise to

move seatback forward. Turn knob clockwise

to move seatback rearward.

Setting Lumbar Support

Lift lever to increase lumbar support. Lower

lever to decrease support.

Setting Armrest Angle

Turn height adjustment knob

counterclockwise to raise the front of the

armrest or clockwise to lower the front of

armrest.

Setting Seat Height/Pressure

(Figure 9)

While seated in operator’s position, move

seat switch left to raise seat cushion or right

to lower seat cushion. Key must be in the

"On" position to raise seat.

Seat Retainer Adjustment

(Figure 10)

Damage to the seat isolators may occur if

units are operated for an extended period of

time with the seat retainer threaded washer

adjusted too far from the isolator.

The correct adjustment for the seat retainer threaded washer is 3 – 6 mm (1/8 – 1/4") below the bottom of the isolator mount.

HOUR / MAINTENANCE METER

Hour Meter-only Models

Hour meter measures engine runtime and

cannot be reset.

Maintenance Models

(Figure 11)

When the key is in the on position, the T imer

mode displays. Press the Mode button to

toggle between different models.

Timer: Measures engine runtime until reset.

To reset the timer, press the Mode button to

select TMR1 mode and then hold Mode

button for 3 seconds.

IMPORTANT: Turn ignition key to the off

position when unit is not in use. Some meters

may count hours when the key is in the on

position, even if the engine is off. This results

in inaccurate maintenance intervals.

Service Alerts: Counts down hours until

service is needed and displays "Now" when

service id due. Service time is measured for:

• Engine oil and filter changes (CHG OIL)

EN - 20

• Hydraulic oil and filter changes (CHG H

Mode Button

Figure 11

OIL)

• Air filter service (SVC AIRFILTER)

The service intervals preset into the hour

meter are:

• Hydraulic oil and filter: First 75 hours and

every 400 hours thereafter

• Engine oil and filter: First 25 hours and

every 100 hours thereafter

• Air filter: Every 100 hours

NOTICE: The preset engine oil services

intervals are normal recommended intervals.

Specific engine manufacturer’s

recommendations may vary.

To clear a service mes sage, press the Mode

button to select Service Alert mode and then

hold the Mode button for 3 seconds.

12-VOLT AUXILIARY POWER PORT

Use the auxiliary power port to run

compatible 12-volt accessories. The key must

be in the ON position to use.

T o reduce battery drain, only use accessories

when the engine is running. To avoid batteryand electrical-system damage, DO NOT use

high-draw accessories such as light kits, and

turn accessories off before plugging into port.

To help prevent damage, do not use port to

charge delicate accessories such as cell

phones.

NOTICE: The power port reaches 15 amps at

peak and 5 amps continuous.

If port does not have power, a fuse may be

blown. See Electrical Service on page 34.

Keep the protective cap on the port when not

in use.

IMPORTANT: Only use compatible

accessories. DO NOT use with a 110-volt

voltage inverter.

FILLING FUEL TANK

WARNING: AVOID INJURY . Read

and understand entire Safety

section before proceeding.

To add fuel to the fuel tank:

1. Move unit to an open, well-ventilated

area.

2. Stop engine and allow it to cool.

3. Clean fuel cap and surrounding area to

prevent dust, dirt, and debris from

entering fuel tanks.

4. Remove fuel caps.

IMPORTANT: See Specifications on page 47

for correct type and grade of fuel and fuel

tank capacity.

5. Fill fuel tanks to the bottom of filler neck.

IMPORTANT: DO NOT OVERFILL! Filling to

the recommended level ensures a vapor gap

required to allow for fuel expansion.

6. Replace fuel caps and tighten.

7. ALWAYS clean up spilled fuel.

PRE-START

CAUTION: Make sure all

hardware is tight, all safety

devices are in place and all

adjustments are made correctly.

1. Check Safety Interlock System

If this system does not function as described

do not operate until repairs are made.

2. Check Air Cleaner

Check air filter for dirt and overall condition.

Clean as required. Follow engine manual

maintenance schedule.

3. Check Engine Fuel and Crankcase

Oil

Check and add fuel if required. Check that

engine crankcase oil is full. Follow engine

manual maintenance schedule.

4. Check Tire Pressure

See Specifications on page 47 for correct tire

pressure.

5. Check Hydraulic Fluid Level

See Check Hydraulic Fluid Level on page 28.

6. Adjust Seat

Be sure all controls can be reached safely

from operator’s position. See Seat

Adjustments on page 20.

EN - 21

7. Set Cutting Height

Make sure the deck is set to the correct

cutting height. See Height of Cut (HOC) on

page 19.

8. Check Radiator Screen

Check radiator screen and remove any

debris. See Maintenance Schedule on

page 24.

STARTING AND SHUT OFF

CAUTION: Read entire

Owner/Operator and Engine

Manual first. DO NOT attempt to

start engine at this time.

NOTICE: If unit runs out of fuel the engine

must be primed prior to starting the engine.

Refer to engine manual for detailed

instructions.

IMPORTANT: Do not use ether or starting

fluid to attempt to start the engine. Severe

damage will occur.

Starting

To start engine:

1. Move the steering levers to the neutral

position.

2. Move the PTO switch to the Off position.

3. Engage parking brake.

4. Place the throttle control halfway between

the slow and fast positions.

5. Insert the ignition key in the switch and

turn the key switch to the On position.

The engine preheat indicator will glow.

Keep the switch in this position until the

engine preheat indicator stops glowing.

6. Turn the key switch to the Start position,

crank and start engine.

7. As soon as the engine starts, release the

key.

8. If the engine does not start after two

attempts see Troubleshooting on

page 45.

IMPORTANT: Do not crank the engine

continuously for more than 20 seconds at

a time. If the engine does not start, allow a

5 – 30 second cool down period between

starting attempts.

To stop the engine:

1. Bring the steering levers to neutral.

Disengage the PTO and engage the

parking brake.

2. Move the throttle lever to the Slow

position.

3. Allow engine to idle before shutting off

unless there is a safety problem that

requires immediate shut-down.

4. Turn the ignition key to the Off position.

STOPPING IN AN EMERGENCY

WARNING: Operating unit on

slopes may lead to loss of

steering control. When operating

on slopes be prepared to react to

an emergency situation.

1. Return steering levers to neutral position.

2. Immediately set parking brake.

3. Turn off PTO and engine.

TO MOW WITH UNIT

Operate the unit only when seated in the

operator’s position.

1. Start the engine. Let the engine warm

until it is running smoothly.

2. Release parking brake.

WARNING: Move the steering

control levers slowly and keep the

throttle control lever at slow

speed until you learn how to

operate the unit.

3. Move the steering levers to neutral.

4. Slow the engine down to about 3/4

speed.

5. Turn ON the PTO switch to engage the

mower.

IMPORTANT: Never engage the PTO if the

mower is plugged with grass or other

material. This may cause damage to the

electric clutch.

6. Move throttle control to the fast position.

7. Move the steering levers forward to

obtain a slow ground speed.

8. To disengage the mower, move the PTO

switch to the Off position.

9. When you know how to operate the unit,

select a speed appropriate to your

mowing conditions.

PARKING

To park the unit:

1. Bring the steering levers to neutral. Turn

off PTO.

2. Move the throttle lever to the Slow

position.

EN - 22

3. Engage the parking brake.

Figure 12

Bypass Position

Run Position

4. Lower the attachment.

5. Turn the ignition key to the Off position

and remove the key.

TO PUSH THE UNIT

Place the transaxles in bypass mode to move

the unit with the engine off.

NOTICE: Make sure both transaxles are set

to neutral before pushing the unit.

IMPORTANT: DO NOT tow the unit.

Transport the unit on an appropriate truck or

trailer.

1. Shut off engine.

2. Place seat in the service position (see

Service Position on page 27).

3. Turn the bypass valves a quarter-turn

clockwise to the bypass position.

WARNING: Do not bypass

transmission when on a slope.

4. Disengage parking brake.

5. Push unit to desired location.

6. Engage parking brake.

7. Turn the bypass valves a quarter-turn

counter-clockwise to the run position.

FOR BEST PERFORMANCE

• Cut grass when it is dry.

• Keep mower blades sharp.

• Keep mower deck properly leveled.

• Adjust anti-scalp rollers to prevent

scalping.

• Adjust the idler spring length as needed.

See Figure 34.

• Do not set height of cut too low. For very

tall grass, mow twice.

• Do not travel too fast.

• Mow with the engine set at full throttle.

• When mulching, only remove 1/3 of grass

length per cutting. Do not cut more than

2.5 cm (1") at any one time.

• Discharge clippings into areas already

cut.

• Vary cutting pattern with each mowing.

• Do not allow grass or debris to collect

inside of mower deck. Clean after each

use.

EN - 23

MAINTENANCE SCHEDULE

WARNING: AV OID INJURY.

Read and understand entire

Safety section before proceeding.

Period Service Task

Check Safety Interl o ck WARNING: Safety interlock system failure

Each Use

Each Use

Every 25

Hours

Check Parking Brake

Interlock System

Check Hydraulic Fluid Check hydraulic oil level mark on expansion tank. Add

Check Tires See Specifications on page 47 for correct tire

Clean Unit Clean engine, battery, seat, mower deck, etc. of dirt

Follow Engine Manual

Maintenance Schedule

Check Cooling System IMPORTANT: To avoid damaging the radiator, DO

Check Mower Blades Check mower blades for wear. Sharpen or replace as

See Parking Brake Interlock System on page 17.

15W-50 synthetic motor oil (Gravely p/n 00057100) or

equivalent as needed. Do not overfill. See Check

Hydraulic Fluid Level on page 28.

pressure.

• Do not attempt to mount a tire without the proper

• Do not inflate the tires above the recommended

• Do not stand in front or over the tire assembly

and debris. Do not use solvents, hard cleaners, or

abrasives.

NOTICE: Protect painted surfaces with automotive

type wax.

IMPORTANT: Do not spray the unit with water,

especially when the unit is warm from operation.

Water can seep into bearings and damage them.

Perform scheduled engine maintenance. Refer to

engine manual for detailed instructions.

NOT USE high-pressure water to clean the radiator.

Check cooling system for dirt and debris in radiator

screen, oil cooler, hoses, fan, etc. Refer to Engine

Manual for detailed instructions.

needed.

Proper maintenance can prolong the life of

unit. The following charts show the

recommended service schedule. More

frequent service may be required due to

extreme working conditions (heavy loads,

high ambient temperatures, dusty conditions,

or airborne debris).

See the maintenance instructions in the

Engine Manual for additional information.

and improper operation of unit can result in

death or serious injury. Test this system each

time the unit is operated. If this system does

not function as described, do not operate

until repairs are made. See Safety Interlock

System on page 16.

CAUTION: Avoid injury! Explosive

separation of tire and rim parts is possible

when they are serviced incorrectly:

equipment and experience to perform the job.

pressure.

when inflating. Use a clip-on chuck and extension

hose long enough to allow you to stand to one

side.

See COOLING SYSTEM on page 30.

EN - 24

Period Service Task

Every 50

Hours

Every 100

Hours

Every 400

Hours

Check Air Filter Check air filter for dirt. Clean as required. Follow

Lubricate Unit Oil all pivot points and pin connections.

Check Fan Belt Tension Correct fan belt tension is critical to proper water

Check Brake Gap Adjust gap if necessary. See Adjusting the Parking

Clean Battery Keep battery and its terminals clean. See Clean

Clean Engine Cooling

System

Check Fasteners Check mower blade mounting hardware and all other

Check Belts Replace worn or deteriorated belts. See Replacing

Change Gearbox Oil Completely drain and change gearbox oil after first

Change Hydraulic Fluid

and Filter

*

Engine Manual for maintenance schedule.

pump and alternator operation. Ensure fan belt has

proper tension.

Brake on page 37.

Battery on page 33

Check and clean cooling fins and inside the engine

shrouds to remove grass, chaff or dirt.

fasteners. Replace missing or damaged fasteners.

Tighten all nuts and bolts to their correct torque value.

Mower Belts on page 38 and Replacing the Hydro

Pump Belt on page 39.

75 – 100 hours of use and every 400 hours thereafter.

USE ONLY an AGMA EP 5 Full-Synthetic PAO

Industrial Gear Lube (16oz.) (Ariens Service Part

Number 00078300).

Drain hydraulic fluid tank, replace hydraulic oil filter,

refill system. See Hydraulic Fluid on page 28.

.

EN - 25

Period Service Task

Every 500

Hours

Service Front Caster

Assemblies

Lubricate Caster Fork

Bearings

Lubricate Caster Wheel

Bearings

Disassemble, clean, inspect and repack front caster

spindle assemblies.

1. Shut off unit, wait for all moving parts to stop,

2. Remove grease cap.

3. Apply grease to the fitting until new grease

4. Reinstall the grease cap.

1. Shut off unit, wait for all moving parts to stop,

2. Remove wheel from fork.

3. Remove end caps from wheel hub.

4. Apply grease through fitting until grease squeezes

5. Wipe off excess grease.

6. Reinstall end caps onto hub.

7. Reinstall wheel into fork. After tightening bolt, tire

*Change hydraulic fluid and filter after first 75 hours of operation.

remove key and engage parking brake.

appears at the top of the upper bearing.

remove key and engage parking brake.

through the seal in the wheel hub.

should not have any side-to-side play. T ighten bolt

until there is a slight amount of drag on the wheel

bearing. The wheel should not freewheel when

spun.

EN - 26

SERVICE AND

Figure 13

1. Seat Latch

2. Service Position

2

1

ADJUSTMENTS

Gravely Dealers will provide any servic e which

may b e required t o keep your unit operating at

peak efficiency. Should engine service be

required, it can be obtained from a Gravely

Dealer or the engine manufacturer’s

authorized service center.

WARNING: AV OID INJURY.

Read and understand entire

Safety section before proceeding.

CAUTION: HOT SURFACES may

result in injury. DO NOT touch

engine or drive parts which are

hot from operation. Allow parts to

cool before servicing.

SERVICE POSITION

(Figure 13)

1. Place unit on a flat level surface.

ALWAYS stop engine. Ensure unit is

secure and chock wheels. Strap and

clamp onto lift if used.

2. Place steering levers in neutral position

and engage parking brake.

3. Release the seat latch and tip seat

forward (Figure 13).

4. When service is complete, return seat to

operating position.

5. Ensure that seat latch if fully engaged

before operating unit.

CAUTION: Avoid I njury! S eat

assembly is heavy. Be sure

footing is secure to accomodate

weight shift of seat when rotating it

into service position.

Use care when returning seat to

operating position to avoid

pinching hands or fingers under

seat plate.

CHECK ENGINE OIL

(Figure 14)

The engine crankcase oil should be checked

every 5 hours of operation. Oil level MUST be

maintained in safe operating range on

dipstick at all times or engine damage will

result. See engine manual for correct oil level.

Park unit on a level surface. Refer to engine

manual for detailed instructions.

CHANGE ENGINE OIL

(Figure 14)

Change oil per engine manufacturer’s

recommendations. Refer to Engine Manual

for detailed instructions.

1. Run engine just prior to changing oil.

Warm oil will flow more freely and carry

away more contamination.

2. Remove the oil drain hose from the

storage clip and move it to the service

position.

3. Remove drain plug and drain engine oil.

NOTICE: Use the oil drain hose supplied with

unit, not the drain plug that is shown in the

engine manual.

IMPORTANT: Be sure to return oil drain hose

to its storage position to avoid contact with

moving parts or other damage.

EN - 27

HYDRAULIC FLUID

Figure 14

1. Oil Fill

2. Oil Dipstick

3. Oil Drain Hose – Storage Position

4. Oil Drain Hose – Service Position

2

3

1

4

Figure 15

1. Cold Fill Indicator Mark

1

WARNING: HYDRAULIC FLUID

can result in severe burns. Fluid in

hydraulic system can penetrate

skin and result in serious injury or

death.

Be sure to stop the engine before

doing any work on hydraulic parts.

Keep body and hands away from

pin holes or nozzles which expel

hydraulic fluid when under

pressure. Use paper or

cardboard, not hands, to search

for leaks.

Ensure all hydraulic fluid

connections are tight and all

hydraulic hoses and lines are in

good condition before applying

pressure to system.

FOREIGN FLUID INJECTED

INTO BODY can result in

gangrene. Fluid must be surgically

removed within a few hours by a

doctor familiar with this form of

injury.

Check Hydraulic Fluid Level

(Figure 15)

Check the system with the unit cold and

parked on a flat, level surface.

Then run the unit for about one minute and

recheck the levels.

Add Hydraulic Fluid

1. Remove the cap from the expansion tank.

2. Fill the expansion tank with 15W-50

synthetic motor oil (Gravely p/n

00057100) or equivalent until oil level

reaches the cold fill line on the tank.

3. Reinstall the expansion tank cap.

EN - 28

Change Hydraulic Fluid and Filter

2

1

3

Figure 16

1. Oil Filter

2. Filter Cover/Drain Plug

3. O-Ring

NOTICE: Change hydraulic fluid and filter

after the first 75 hours of operation and then

every 400 hours. Use 15W-50 synthetic

motor oil (Gravely p/n 00057100) or

equivalent.

1. Run the unit for a few minutes to warm

the hydraulic fluid, and then shut off the

engine, remove ignition key, and wait for

all moving parts to stop before servicing

unit.

2. Place container under oil filter to catch oil.

3. Remove the filter cover from the

transaxle. Remove and discard the o-ring

from the cover.

4. Remove the bottom oil fill vent port plug

from the transaxle to drain completely.

5. After the oil has drained from the unit,

replace the bottom oil fill vent port plug

and then remove the oil filter.

6. Clean the filter mounting surface and

then lubricate rubber gasket on new oil

filter with clean hydraulic oil.

7. Spin new oil filter onto filter housing until it

makes contact. Tighten oil filter another

3/4 turn.

8. Install the filter cover removed in step 3.

Tighten the mounting screws to 54 – 61

N•m (40 – 45 lb-ft).

9. Remove the top fill vent port plug and fill

with 15W-50 synthetic motor oil (Gravely

p/n 00057100) or equivalent until oil

reaches the bottom of the drain plug

(about 4475 mL (151 ounces) per

transaxle). Install the drain plug and

tighten to 22.5 N•m (16.7 lb-ft).

10. Remove the cap from the expansion tank.

11. Fill the expansion tank with 15W-50

synthetic motor oil (Gravely p/n

00057100) or equivalent until oil level

reaches the cold fill line on the tank.

12. Reinstall the expansion tank cap and then

purge the system. See Purging the

Hydraulic System on page 29.

13. Repeat steps 2 – 12 for the other

transaxle.

Purging the Hydraulic System

WARNING: This adjustment

requires operating the engine.

Use extreme care to avoid

contact with moving parts and hot

surfaces. Be sure rear of unit is

well supported and secure before

starting engine.

NOTICE: Purge the system of air any time

the transaxle has been opened for

maintenance or when oil has been added to

the system.

1. Make sure the transaxles are filled to the

proper oil level.

2. With the unit up to and facing a wall, jack

up the unit so that both drive wheels are

off the ground.

3. Disengage the parking brake and put the

transaxle bypass valves in the neutral

position. See To Push The Unit on

page 23.

4. Start the engine and slowly move the

steering levers in forward and reverse

five or six times. The oil level will drop.

5. Stop the engine and move the transaxle

bypass valves to the drive position. See

T o Push The Unit on page 23.

6. Start the engine and slowly move the

steering levers in forward and reverse

five or six times.

7. Stop the engine, check the hydraulic oil

level and add oil as needed.

EN - 29

8. Repeat steps 3 – 7 until the transaxles

Figure 17

2

1

1. Operating Range

2. Full

3. Low

3

Figure 18

2

1

1. Engine Block Drain Valve

2. Radiator Drain Valve

3. Radiator Fill Cap

3

operate smoothly in forward and reverse

at normal speeds without excessive

noise.

COOLING SYST E M

Checking Coolant Level

(Figure 17)

WARNING: To avoid personal

injury DO NOT remove radiator

cap when engine is hot. Check

coolant level at coolant reservoir,

not at radiator.

Check coolant level when engine is cold.

Check coolant level at overflow reservoir.

1. Check coolant reservoir. Coolant should

be between the low and full marks with

engine cold.

2. If coolant is below the low mark, remove

cap, and add coolant to the full mark.

Refer to Engine Manual for the correct

type of coolant.

CHANGING COOLANT

WARNING: To avoid personal

injury DO NOT drain radiator or

engine block when engine is hot.

Allow to cool before servicing.

Drain Coolant System

1. Stop engine and allow to cool.

2. Place suitable container under unit to

catch coolant.

3. Open engine block drain valve and allow

coolant to drain. See Figure 18.

4. Place suitable container under radiator

drain valve to catch coolant.

5. Remove radiator screen to gain access to

radiator.

6. Loosen radiator fill cap and open radiator

drain valve. See Figure 18.

EN - 30

7. Close engine block and radiator drain

Figure 19

1. Cartridge Fuel Filter

2. In-line Fuel Filter

1

2

valves.

IMPORTANT: If not reusing coolant be sure

to dispose of properly.

Fill and Purge Coolant System

NOTICE: Refer to engine manual for proper

type and mix ratio of coolant.

1. Ensure that engine block and radiator

drain valves are closed tightly.

2. Fill the radiator fully to the filler neck.

3. Install radiator cap.

4. Squeeze and gently shake radiator hoses

to remove air gaps and bubbles.

5. Remove cap and refill radiator. Replace

radiator cap.

6. Release hood locks and raise hood to a

o

angle and return to closed position.

45

7. Ensure that the coolant reservoir level is

within the operating range. See

Figure 17.

8. Replace radiator screen.

Fuel Filter

(Figure 19)

NOTICE: Unit has two fuel filters. One

cartridge style which is attached to the engine

and one in-line style which is installed in the

fuel line between the fuel valve and the fuel

pump.

1. Place suitable container under unit to

catch fuel.

2. Remove fuel filter and dispose of

properly.

3. Install replacement fuel filter.

MOWER BLADES

Remove

(Figure 20)

CAUTION: Use sturdy gloves or

padding to protect hands when

working with mower blades.

Rotation of one blade will rotate

the other blades.

1. Turn the engine off. Remove the ignition

key.

2. Remove the bolts, bevel washers and

blades from the spindle assemblies.

Replace

1. Install the blades, bevel washers and

bolts on the spindle assemblies.

2. Torque bolts to 156 – 217 N•m

(115 – 160 lb-ft).

EN - 31

Sharpen the Mower Blades

Figure 20

1

3

2

1. Blade

2. Cup Washer

3. Blade Bolt

4. Spindle Assembly

4

Figure 21

1. Cutting Edge

2. Square Corner

3. Air Lift Erosion

4. Air Lift

DO NOT sharpen to this pattern.

Sharpen to this pattern.

DISCARD if more than

1.27 cm (1/2”)

1

1

4

2

4

3

Figure 22

2

1

1. Mower Blade

2. Rod

CAUTION: DO NOT sharpen

mower blades while on unit. An

unbalanced mower blade will

cause excessive vibration and

eventual damage to unit. Check

mower blade balance before

reinstalling blades.

NEVER weld or straighten bent

• More than 1.3 cm (1/2”) of metal is

• Air lifts become eroded.

• Blade is bent or broken.

2. Sharpen mower blade by removing an

3. Check mower blade balance.

4. Install mower blade(s) on unit.

5. Torque bolts to 156 – 217 N•m

blades.

1. Remove mower blade from unit. Discard

mower blade if:

removed.

equal amount of material from each end

of mower blade. DO NOT change angle

of cutting edge or round the corner of the

mower blade.

Slide mower blade on an unthreaded

bolt. A balanced blade should remain in

a horizontal position. If either end of

mower blade moves downward, sharpen

the heavy end until blade is balanced.

See Figure 22.

(115 – 160 lb-ft).

IMPORTANT: When sharpening blades, be

sure to grind the same amount on each side.

Unbalanced blades will cause excessive

vibration and could cause the spindles to

wear prematurely.

EN - 32

BATTERY

Figure 23

1. Negative Terminal

2. Positive Terminal

3. Battery

4. Hold Down Bracket

2

3

1

4

(Figure 23)

WARNING: AV OID INJURY.

Read and understand entire

Safety section before proceeding.

WARNING: Battery posts,

terminals and related accessories

contain lead and lead

compounds, chemicals known to

the State of California to cause

cancer and reproductive harm.

Wash hands after handling.

Unit comes equipped with a battery that

requires no regular maintenance except

cleaning the terminals.

Remove Battery

1. Shut off engine. Engage parking brake.

Remove the ignition key.

2. Place seat in the service position (See

Service Position on page 27).

3. Disconnect cables from battery (negative,

then positive) (Figure 23).

4. Remove hold down bracket and remove