Gravely Pro-Master 252, Pro-Master 260, 992213, Pro-Master 272, 992215 Owner's/operator's Manual

...

Pro-Master 252 / 260 / 272

Owner/Operat or Ma nu al

Manuel Du Propriétaire/Utilisateur

Models

992210 – 260M

992212 – 252M

992213 – 272H

992215 – 260H

992216 – 272H

992217 – 260H

US Patent 6,301,864

Gasoline containing up to 10% ethanol (E10) or up to 10% MTBE (methyl tertiary butyl

ether) is acceptable for use in this machine.

The use of any gasoline exceeding 10% ethanol (E10) or 10% MTBE will void the product

warranty.

Il est possible d’utiliser de l’essence contenant jusqu’à 10% d’éthanol (E10) ou 10% de

MTBE (éther méthyl-tertiobutylique) sur cette machine.

L’utilisation d’une essence contenant plus de 10% d’éthanol (E10) ou de 10% de MTBE

annulent la garantie

ENGLISH

FRANÇAIS

04273700A 1/11

Printed in USA

TABLE OF CONTENTS

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Assembly . . . . . . . . . . . . . . . . . . . . . . . 10

Controls and Features. . . . . . . . . . . . . 12

Operation . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance Schedul e . . . . . . . . . . . . 20

Service and Adjustments . . . . . . . . . . 22

INTRODUCTION

Storage . . . . . . . . . . . . . . . . . . . . . . . . . 34

Trouble s hooting. . . . . . . . . . . . . . . . . . 35

Accessories . . . . . . . . . . . . . . . . . . . . . 37

Service Parts . . . . . . . . . . . . . . . . . . . . 37

Specifications . . . . . . . . . . . . . . . . . . . 39

Warranty. . . . . . . . . . . . . . . . . . . . . . . . 42

NON-ENGLISH MANUALS

Manuals in languages other than

English may be obtained from your

Dealer. Visit your dealer or

www.gravely.com for a list of

languages available for your

equipment.

Manuals printed in languages other

than English are also available as a

free download on our website:

http://www.gravely.com

MANUALES EN IDIOMAS

DIFERENTES DEL INGLES

Puede obtener manuales en

idiomas diferentes del inglés en su

distribuidor. Visite a su distribuidor

o vaya a www.gravely.com para

obtener una lista de idiomas

disponibles para su equipo.

También puede imprimir manuales

en idiomas diferentes del inglés

descargándolos gratuitamente de

nuestra página Web:

http://www.gravely.com

MANUELS NON ANGLAIS

Des manuels dans différentes

langues sont disponibles chez

votre revendeur. Rendez-vous

chez votre revendeur ou allez sur

le site www.gravely.com pour

consulter la liste des langues

disponibles pour votre équipement.

Les manuels imprimés dans des

langues différentes de l’anglais

sont également disponibles en

téléchargement gratuit sur notre

site Web:

http://www.gravely.com

THE MANUAL

Before operation of unit, carefully and

completely read your manuals. The contents

will provide you with an understanding of

safety instructions and controls during normal

operation and maintenance.

All reference to left, right, front, or rear are

given from operator sitting in operation

position and facing the direction of forward

travel.

ENGINE MANUAL

The engine on this unit is covered by a

separate manual specific to the engine. This

manual is included in the literature package

that shipped with the unit. Refer to this

manual for engine service recommendations.

If the engine manual is not available, contact

the engine manufacturer for a replacement

manual.

MODEL AND SERIAL NUMBERS

When ordering replacement parts or making

service inquiries, know the Model and Serial

numbers of your unit and engine.

Numbers are located on the product

registration form in the unit literature

package. They are printed on a serial number

label, located on the frame of your unit.

(Figure 1)

• Record Unit Model and Serial numbers

here.

• Record Engine Model and Serial numbers

here.

GB - 2

DELIVERY

Figure 1

Serial Number Label

OF3310

Customer Note: If you have purchased this

product without complete assembly and

instruction by your retailer, it is your

responsibility to:

1. Read and understand all assembly

instructions in this manual. If you do not

understand or have difficulty following

the instructions, contact your nearest

Gravely Dealer for assistance. Make

sure all assembly has been properly

completed and safety interlock system

works properly.

NOTE: To locate your nearest Gravely dealer ,

go to www.gravely.com on the internet

UNAUTHORIZED REPLACEMENT

PARTS

Use only Gravely replacement parts. The

replacement of any part on this vehicle with

anything other than a Gravely authorized

replacement part may adversely affect

performance, durability, or safety of this unit.

Gravely disclaims liability for any claims or

damages, whether warranty, property

damage, personal injury or death arising out

of the use of unauthorized replacement parts.

DISCLAIMER

Gravely reserves the right to discontinue,

make changes to, and add improvements

upon its products at any time without public

notice or obligation. The descriptions and

specifications contained in this manual were

in effect at printing. Equipment described

within this manual may be optional. Some

illustrations may not be applicable to your

unit.

PRODUCT REGISTRATION

The Gravely dealer must register the product

at the time of purchase. Registering the

product will help the company process

warranty claims or contact you with the latest

service information. All claims meeting

requirements during the limited warranty

period will be honored, whether or not the

product registration card is returned. Keep a

proof of purchase if you do not register your

unit.

Customer Note: If the dealer does not

register your product, please fill out, sign, and

return the product registration card to

Gravely.

WARNING: Improper assembly

or adjustments can cause serious

injury.

2. Understand all Safety Precautions

provided in the manuals.

3. Review control functions and operation

of the unit. Do not operate unit unless all

controls function as described in this

manual.

4. Review recommended lubrication,

maintenance, and adjustments.

5. Fill out Product Registration Card and

return the card to Ariens Company or go

to www.gravely.com.

GB - 3

SAFETY

OL1253

OL3900

WARNING: This cutting machine

is capable of amputating hands

and feet and throwing objects.

Failure to observe the safety

instructions in the manuals and

on decals could result in serious

injury or death.

Slopes are a major factor related

to loss-of-control and tip-over

accidents. Operation on all slopes

requires extra caution.

Tragic accidents can occur if the

operator is not alert to the

presence of children. Never

assume that children will remain

where you last saw them.

Gasoline is extremely flammable

and the vapors are explosive,

handle with care.

Disengage attachment, stop unit

and engine, remove key, engage

parking brake, and allow moving

parts to stop before leaving

operator’s position.

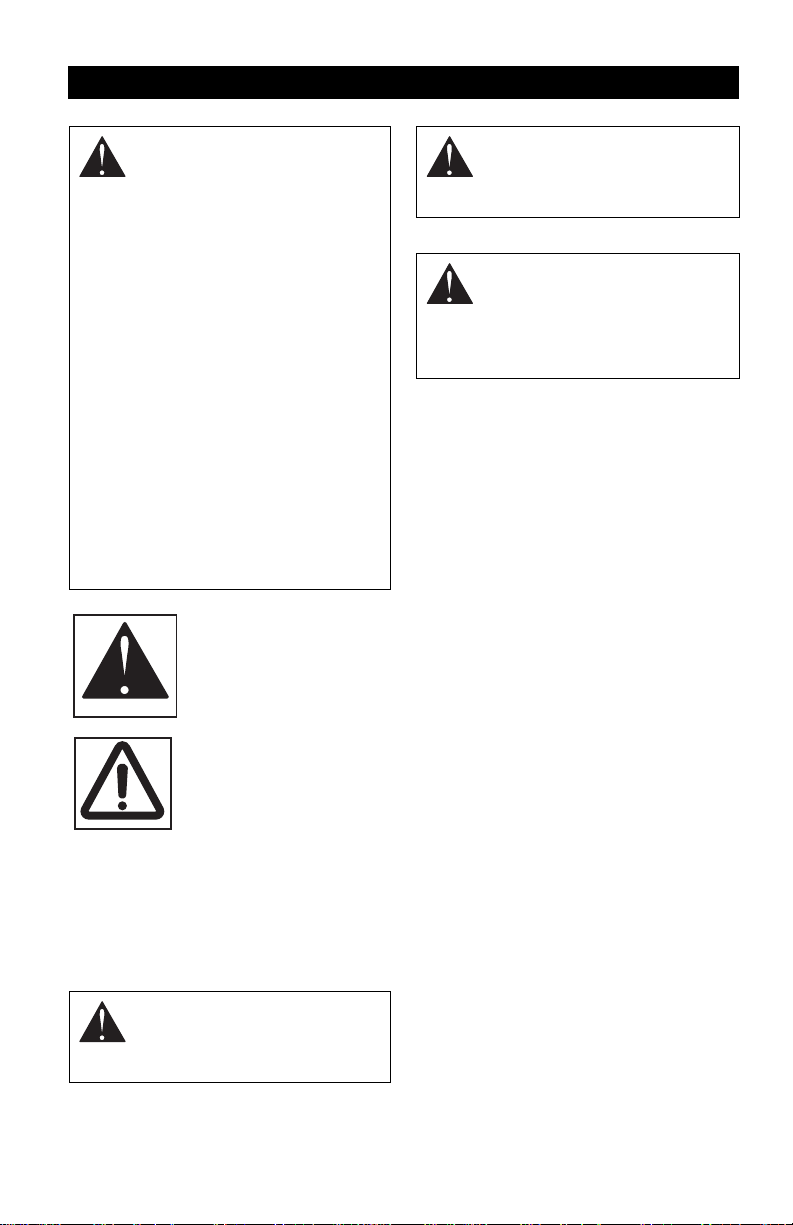

SAFETY ALERT

SYSTEM

These are safety alert

symbols. They mean:

•ATTENTION!

•YOUR SAFE TY IS

INVOLVED!

When you see this symbol:

•BECOME ALERT!

•OBEY THE MESSA GE!

SIGNAL WORDS

The safety alert symbols above and signal

words below are used on decals and in this

manual.

Read and understand all safety messages.

WARNING: POTENTIALLY

HAZARDOUS SITUATION! If not

avoided, COULD RESULT in

death or serious injury.

CAUTION: POTENTIALLY

HAZARDOUS SITUATION! If not

avoided, MAY RESULT in minor

or moderate injury. It may also be

used to alert against unsafe

practices.

NOTATIONS

NOTE: General reference information for

proper operation and maintenance practices.

IMPORTANT: Specific procedures or

information required to prevent damage to

unit or attachment.

PRACTICES AND LAWS

Practice usual and customary safe working

precautions, for the benefit of yourself and

others. Understand and follow all safety

messages. Be alert to unsafe conditions and

the possibility of minor, moderate, or serious

injury or death. Learn applicable rules and

laws in your area, including those that may

restrict the age of the operator.

REQUIRED OPERATOR

TRAINING

Original purchaser of this unit was instructed

by the seller on safe and proper operation. If

unit is to be used by someone other than

original purchaser (loaned, rented or sold),

ALWAYS provide this manual and any

needed safety training before operation.

DANGER: IMMINENTLY

HAZARDOUS SITUATION! If not

avoided, WILL RESULT in death

or serious injury.

GB - 4

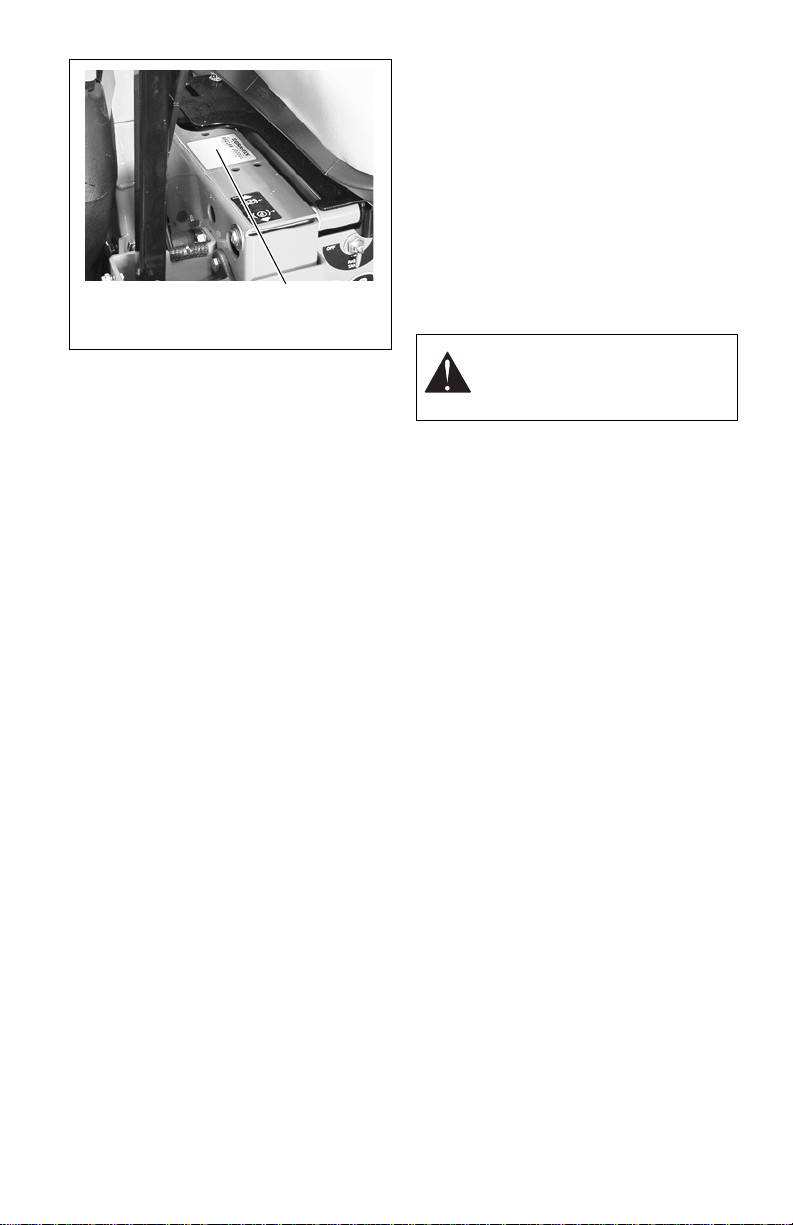

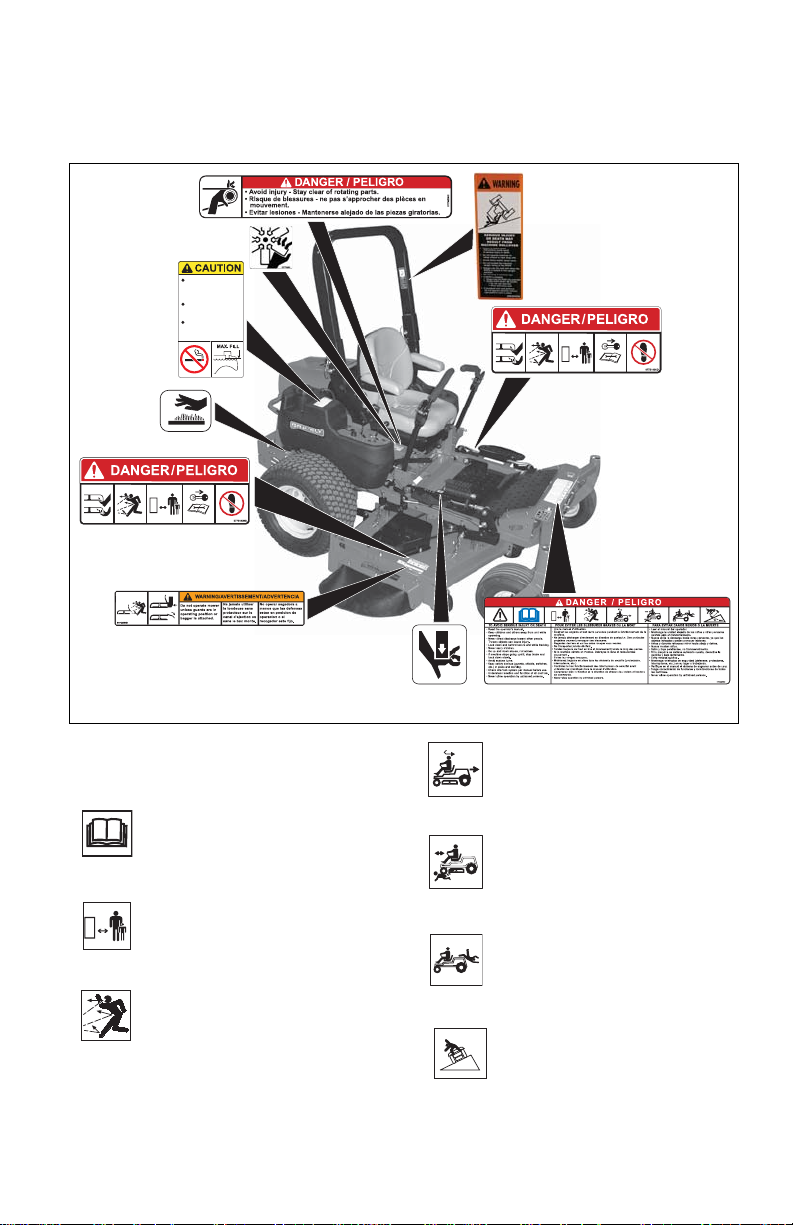

SAFETY DECALS AND

Figure 2

1

2

4

3

7

5

8

4

9

6

OL1801

OL4370

OL0910

OL4460

OL4470

OL4480

17°

MAX

OL4450

LOCATIONS

ALWAYS replace missing or damaged safety

decals. Refer to figure 2 for Safety Decal

locations.

Never fill tank when

engine is running,

hot or unit is indoors.

Never overfill fuel

tank.

Replace fuel cap

securely and clean

up spilled fuel.

08000611

1. DANGER! TO AVOID SERIOUS

INJURY OR DEATH

Read Operator’s Manual.

Keep children and others away

from unit while operating.

Never direct discharge toward

other people. Thrown objects

can cause injury.

GB - 5

Look down and behind before

and while backing.

Keep children out of work area

and under watchful care of a

responsible adult.

NEVER CARRY CHILDREN.

Go up and down slopes, not

across.

DO NOT operate on slopes

over 17°.

• If machine stops going uphill, stop

OL4900

OL4430

OL3320

OL3030

OL0910

OL3292

OL4010

OL4420

OD0061

OL4740

OL4730

blade and back down slowly.

• Avoid sudden turns.

Shut off engine, remove key,

and read manual before you

adjust or repair unit.

• Keep safety devices (guards,

shields, switches, etc.) in place and

working.

• Check interlock system per manual

before use.

• Understand location and function of

all controls.

• Never allow operation by untrained

persons.

2. PINCH POINT!

Avoid pinch points.

WARNING!

3.

Always stand clear of discharge

area.

Do not operate mower unless

guards are in operating position

or bagger is attached.

NO STEP! Always keep feet

away from rotating parts.

5.HOT SURFACES!

DO NOT touch parts which are

hot from operation. ALWAYS

allow parts to cool.

6.CAUTION!

No smoking.

MAX. FILL

Fill fuel tank to bottom of neck MAXIMUM.

• Never fill fuel tank when engine is

running, hot or unit is indoors. Never

overfill fuel tank.

• Replace fuel cap securely and clean up

spilled fuel.

4. DANGER!

Always keep feet and hands

away from rotating parts.

Always stand clear of discharge

area. Do not direct discharge

toward other people.

Keep people away from unit

while operating.

7. DANGER!

DANGER!

8.

GB - 6

AVOID INJURY. Stay clear of

rotating fan.

AVOID INJURY. Stay clear of

rotating parts.

9. WARNING!

OL3521

SERIOUS INJURY OR

DEATH MAY RESULT FROM

MACHINE ROLLOVER

• Failure to follow these

instructions could result in

serious injury or death

• Do not operate machine on

steep slopes or near drop

offs

• Avoid sharp and/or quick

turns

• Do not exceed the machine

weight rating of the ROPS

• Always use the seat belt

when the ROPS is locked in

the upright position

• Do not jump if machine tips

• If ROPS is foldable:

– Always keep the ROPS

fully exteneded

– WHEN ROPS MUST BE

DOWN -

• Do not use seat belt

• Drive with extra care

• If equipped with seat

platform,

Do not operate machine

without seat platform pins in

place

EMISSION CONTROL SYSTEM

This equipment and/or its engine may include

exhaust and evaporative emissions control

system components required to meet U.S.

Environmental Protection Agency (EPA)

and/or California Air Resources Board

(CARB) regulations. Tampering with

emission controls and components by

unauthorized personnel may result in severe

fines or penalties. Emission controls and

components can only be adjusted by an

Ariens Company dealer or an authorized

engine manufacturer's service center.

Contact your Ariens Company Equipment

Retailer concerning emission controls and

component questions.

SAFETY RULES

Read, understand, and follow all safety

practices in Owner/Operator Manual before

beginning assembly. Failure to follow

instructions could result in personal injury

and/or damage to unit.

ALWAYS remove key and/or wire from spark

plug before assembly. Unintentional engine

start up can cause death or serious injury.

Complete a walk around inspection of unit

and work area to understand:

• Work area • Your unit • All safety decals

Determine which attachments are needed

and can be used safely.

Inspect unit before each use for: missing or

damaged decals and shields, correctly

operating safety interlock system, and

deterioration of grass catchers. Replace or

repair as needed.

ALWAYS check overhead and side

clearances carefully before operation.

ALWAYS be aware of traffic when operating

along streets or curbs.

Keep children and people away.

Keep children out of work area and under

watchful care of a responsible adult.

Keep area of operation clear of all toys, pets,

and debris. Thrown objects can cause injury.

Check for weak spots on docks, ramps or

floors. Avoid uneven work areas and rough

terrain. Stay alert for hidden hazards or traffic.

DO NOT operate near drop-offs, ditches, or

embankments. Unit can suddenly turn over if

a wheel is over the edge of a cliff or ditch, or if

an edge caves in.

Data indicates that operators, age 60 and

above, are involved in a larger percentage of

riding mower related injuries. These

operators should evaluate their ability to

operate the riding mower safely enough to

protect themselves and others from serious

injury.

Read the entire Owner/Operator manual and

other training material. If the operator or the

mechanic cannot read the manual, it is the

owner’s responsibility to explain it to them.

Only the user can prevent and is responsible

for accidents or injuries occurring to

themselves, other people or property.

Only trained adults may operate or service

unit. Training includes actual operation.

Local regulations may restrict the age of the

operator.

NEVER allow children to operate or play on

or near unit. Be alert and shut off unit if

children enter area.

NEVER operate unit after or during the use of

medication, drugs or alcohol. Safe operation

requires your complete and unimpaired

attention at all times.

GB - 7

DO NOT wear loose clothing or jewelry and

tie back hair that may get caught in rotating

parts.

Wear adequate outer garments.

NEVER wear open sandals or canvas shoes

during operation. Wear adequate safety gear,

protective gloves and footwear.

Wear proper footwear to improve footing on

slippery surfaces.

Always wear safety goggles or safety glasses

with side shields when operating mower.

Moving parts can cut or amputate fingers or a

hand. Wrap blade(s) or wear gloves to

service. On multiblade mowers, rotation of

one blade will cause all blades to rotate.

NEVER place your hands or any part of your

body or clothing inside or near any moving

part while unit is running.

ALWAYS keep hands and feet away from all

rotating parts during operation. Rotating parts

can cut off body parts.

ALWAYS keep body and hands away from

pin holes or nozzles which eject hydraulic

fluid under pressure.

DO NOT touch parts which are hot. Allow

parts to cool.

ALWAYS keep hands and feet away from all

pinch points.

Fumes from the engine exhaust can cause

death or serious injury. DO NOT run engine in

an enclosed area. Always provide good

ventilation.

Read, understand, and follow all instructions

in the manual and on the machine before

starting.

Understand:

How to operate all controls

The functions of all controls

How to STOP in an Emergency

Braking and steering characteristics

Turning radius and clearances

Keep safety devices or guards in place and

functioning properly. NEVER modify or

remove safety devices.

Do not operate without either entire grass

catcher or the discharge guard in place.

Stop engine before removing grass catcher or

unclogging chute.

Ensure Safety Interlock System is functioning

properly. DO NOT operate unit if safety

interlock is damaged or disabled.

Start and operate unit only when seated in

operator’s position. Steering control levers

must be in neutral, PTO disengaged and

parking brake set when starting engine.

Use care when approaching blind corners,

shrubs, trees or other objects that may

obscure vision.

Dust, smoke, fog, etc. can reduce vision and

cause an accident. Mow only in daylight or

good artificial light.

Avoid slippery surfaces. Always be sure of

your footing.

DO NOT mow on wet grass. Reduced

traction could cause sliding and effect the

machine’s stability.

Watch for traffic when operating near or

crossing roadways.

Never carry passengers.

DO NOT try to stabilize the machine by

putting your foot on the ground.

Never direct discharge towards persons or

property that may be injured or damaged by

thrown objects. Use extreme caution on

gravel surfaces.

Always stand clear of the discharge area.

ALWAYS disengage PTO, stop unit and

engine, remove key, engage parking brake

and allow moving parts to stop before leaving

operator’s position.

Never engage PTO while raising attachment

or when attachment is in raised position.

DO NOT operate at too fast a rate. DO NOT

change engine governor settings or overspeed engine. Slow down before turning.

DO NOT operate in reverse unless absolutely

necessary. ALWAYS look down and behind

before and while backing.

Stop and inspect equipment if you strike an

object or if there is an unusual vibration.

Repair, if necessary, before restarting. Never

make adjustments or repairs with the engine

running.

Mower blades are sharp and can cut you.

Wrap the blade(s) or wear gloves, and use

extra caution when servicing them. NEVER

weld or straighten mower blades.

Rotation of one blade may cause rotation of

the other blades.

Take all possible precautions when leaving

unit unattended. Shut off engine. Remove

wire from spark plug and secure it away from

spark plug.

ALW A YS remove key to prevent unauthorized

use.

Know the weight of loads. Limit loads to those

you can safely control and the unit can safely

handle.

GB - 8

Disengage PTO when attachment is not in

use. ALWAYS turn off power to attachment

when travelling, crossing driveways, etc.

Operation on slopes may lead to loss of

steering control. When operating on slopes

be prepared to react to an emergency

situation:

• Return steering levers to neutral

position.

• Immediately set parking brake.

• Turn off PTO and engine.

Mow up and down slopes, not across them.

DO NOT operate on slopes of more than 17

degrees.

Keep all movements on the slope slow and

gradual. Do not make sudden changes in

speed or direction.

Avoid starting or stopping on the slope. If tires

lose traction, disengage the blades and

proceed slowly straight down the slope.

If you cannot back up a slope or you feel

uneasy on it, do not mow it.

DO NOT park on slopes unless necessary.

When parking on slope always chock or block

wheels. Always set parking brake.

Use a slow speed. Tires may lose traction on

slopes even though the brakes are

functioning properly.

Do not bypass transmission when on a slope.

Tow only with a machine that has a hitch

designed for towing. Do not attach towed

equipment except at the hitch point.

Follow the manufacturer’s recommendations

for weight limits for towed equipment and

towing on slopes.

On slopes, the weight of the towed equipment

may cause loss of control.

NEVER allow children or others in or on

towed equipment.

Travel slowly and allow extra distance to stop.

Rollover Protection Structure (ROPS) safety

precautions:

• Frequently inspect ROPS and seat

belt for damage or loose hardware.

• Use extreme care when working close

to fences, ditches, or on hills.

• Check overhead clearance carefully

before driving under any objects.

• ALWAYS wear seat belt while

operating the unit with the ROPS in

the upright position.

• Do not wear a seat belt while

operating the unit with the center bar

in the lowered position.

• Do not weld, cut, drill or modify ROPS

in any manner unless instructed by the

manufacturer.

Use extra care when loading or unloading

unit onto trailer or truck.

Secure unit chassis to transport vehicle.

NEVER secure from rods or linkages that

could be damaged.

DO NOT transport machine while engine is

running.

ALWAYS turn off power to attachment and

shut off fuel when transporting unit.

Keep unit free of debris. Clean up oil or fuel

spills.

This product is equipped with an internal

combustion type engine. DO NOT use unit on

or near any unimproved, forest-covered or

brush covered land unless exhaust system is

equipped with a spark arrester meeting

applicable local, state or federal laws. A spark

arrester, if it is used, must be maintained in

effective working order by operator.

Fuel is highly flammable and its vapors are

explosive. Handle with care. Use only an

approved gasoline container with an

appropriately sized dispensing spout.

NO smoking, NO sparks, NO flames.

ALWAYS allow engine to cool before

servicing.

NEVER fill fuel tank when engine is running

or hot from operation.

NEVER fill or drain fuel tank indoors.

Replace fuel cap securely and clean up

spilled fuel.

Properly remove fuel before tipping unit.

Never fill containers inside a vehicle or on a

truck or trailer bed with a plastic liner. Always

place containers on the ground away from

your vehicle before filling.

When practical, remove gas-powered

equipment from the truck or trailer and refuel

it on the ground. If this is not possible, then

refuel such equipment on a trailer with a

portable container, rather than from a

gasoline dispenser nozzle.

Keep the nozzle in contact with the rim of the

fuel tank or container opening at all times until

fueling is complete. Do not use a nozzle lockopen device.

If fuel is spilled on clothing, change clothing

immediately.

Avoid Electric Shock. Objects contacting both

battery terminals at the same time may result

in injury and unit damage. DO NOT reverse

battery connections.

GB - 9

Reverse connections may result in sparks

which can cause serious injury. Always

connect positive (+) lead of charger to

positive (+) terminal, and negative (-) lead to

negative (-) terminal.

ALW A YS disconnect negative (-) cable FIRST

and positive (+) cable SECOND. ALWAYS

connect positive (+) cable FIRST, and

negative (-) cable SECOND.

Explosive Gases from battery can cause

death or serious injury. Poisonous battery

fluid contains sulfuric acid and its contact with

skin, eyes or clothing can cause severe

chemical burns.

No flames, No sparks, No smoking near

battery.

ALWAYS wear safety glasses and protective

gear near battery. Use insulated tools.

DO NOT TIP battery beyond a 45° angle in

any direction.

ALWAYS keep batteries out of reach of

children.

Battery posts, terminals and related

accessories contain lead and lead

compounds, chemicals known to the State of

California to cause cancer and reproductive

harm. Wash hands after handling.

ALWAYS block wheels and know all jack

stands are strong and secure and will hold

weight of unit during maintenance.

Release pressure slowly from components

with stored energy.

ASSEMBLY

WARNING: AVOID INJURY . Read

and understand entire Safety

section before proceeding.

Unpack Unit

Remove unit and all other components from

shipping container. Open bypass valves (see

Moving Unit Manually on page 19). Push unit

from container onto a level surface. Close

bypass va lves.

Raise Rollover Pro tection Str ucture

(ROPS) Center Bar

See Rollover Protection Structure (ROPS) on

page 16.

NEVER attempt to make any adjustments to

unit while engine is running (except where

specifically recommended). Stop engine,

remove key or spark plug wire and wait for all

moving parts to stop before servicing or

cleaning.

Check parking brake operation frequently.

Adjust and service as required.

ALWAYS maintain unit in safe operating

condition. Damaged or worn out muffler can

cause fire or explosion.

Maintain or replace safety and instruction

labels, as necessary.

NEVER store unit with fuel in fuel tank, inside

a building where any ignition sources are

present.

Shut off fuel and allow engine to cool

completely before storing in closed area or

covering unit.

Clean grass and debris from unit, especially

from around muffler and engine, to help

prevent fires.

For extended storage, shut off fuel and clean

unit thoroughly. See engine manual for proper

storage.

Lower cutting deck unless a positive

mechanical lock is used.

Use only attachments or accessories

designed for your unit.

Check all hardware at regular intervals,

especially blade attachment bolts. Keep all

hardware properly tightened.

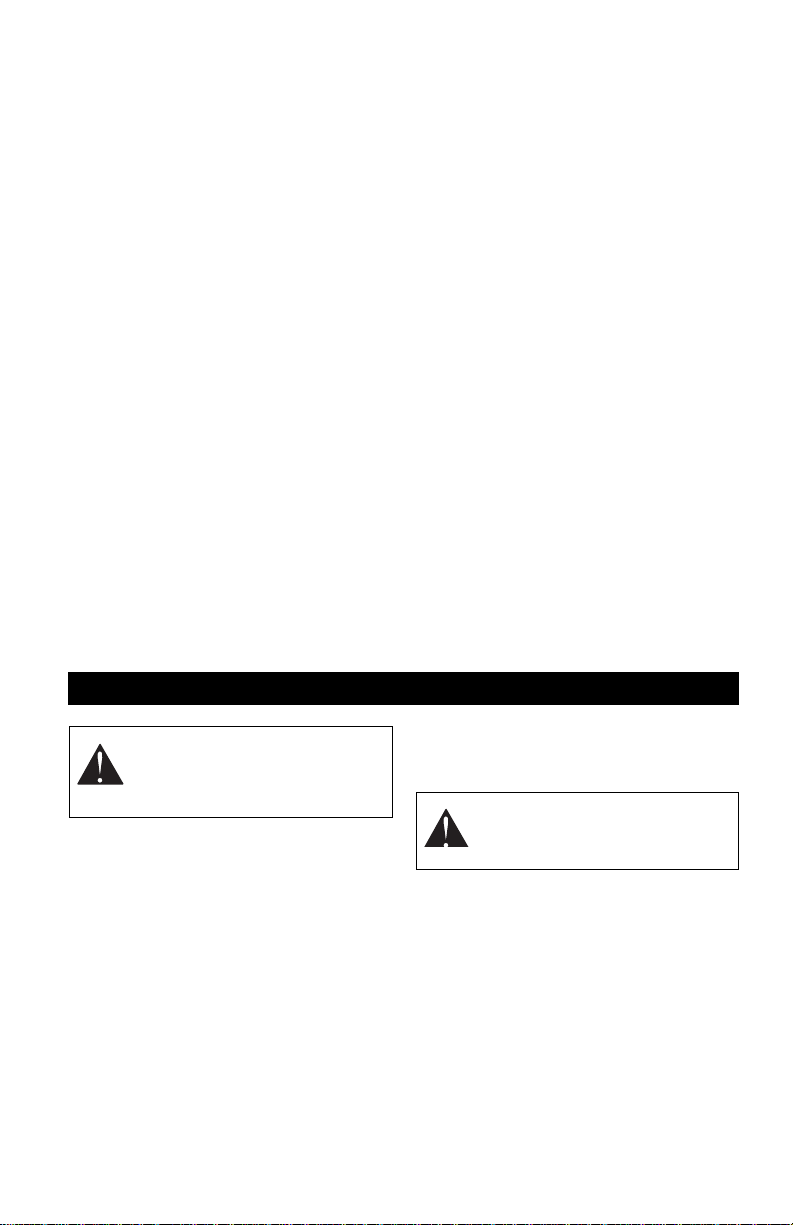

Place Discharge Chute

in Operating Position

(Figure 3)

WARNING: Do not operate

mower unless the discharge chute

is in the operating position.

Prior to operating the unit, remove the

discharge chute from the transport position

and place the discharge chute in the

operating position .

GB - 10

Check Tire Pressure

Figure 3

Discharge Chute in Transport Position

Discharge Chute in Operating Position

CAUTION: Avoid injury! Explosive

separation of tire and rim parts is

possible when they are serviced

incorrectly:

• Do not attempt to mount a tire

without the proper equipment

and experience to perform the

job.

• Do not inflate the tires above

the recommended pressure.

• Do not weld or heat a wheel

and tire assembly. Heat can

cause an increase in air

pressure resulting in an

explosion. Welding can

structurally weaken or deform

the wheel.

• Do not stand in front or over the

tire assembly when inflating.

Use a clip-on chuck and

extension hose long enough to

allow you to stand to one side.

Check Engine Oil

Refer to Engine Manual.

Check Hydraulic Oil

See Checking Hydraulic Oil Level on

page 33.

Check Coolant Level (992215, 216)

Refer to Engine Manual.

Fill Fuel T ank

Fill fuel tank. DO NOT OVERFILL! See Filling

Fuel Tank on page 16.

Connect Battery

Place unit in the service position (see Service

Position on page 22). Connect negative (–)

battery cable to battery (see Battery

Installation (Figure 10) on page 23 and

perform steps 2 through 4 in the installation

section).

Check Blade Level and Blade Pitch

See Leveling the Mower Deck on page 26.

Check Safety Interlock System

WARNING: Safety in terlock

system failure and improper

operation of unit can result in

death or serious injury. Test this

system each time unit is operated.

If this system does not function as

described, do not operate until

repairs are made.

See Safety Interlock System on page 13.

Check Function of All Controls

Ensure unit runs and performs properly.

See Specifications on page 39.

GB - 11

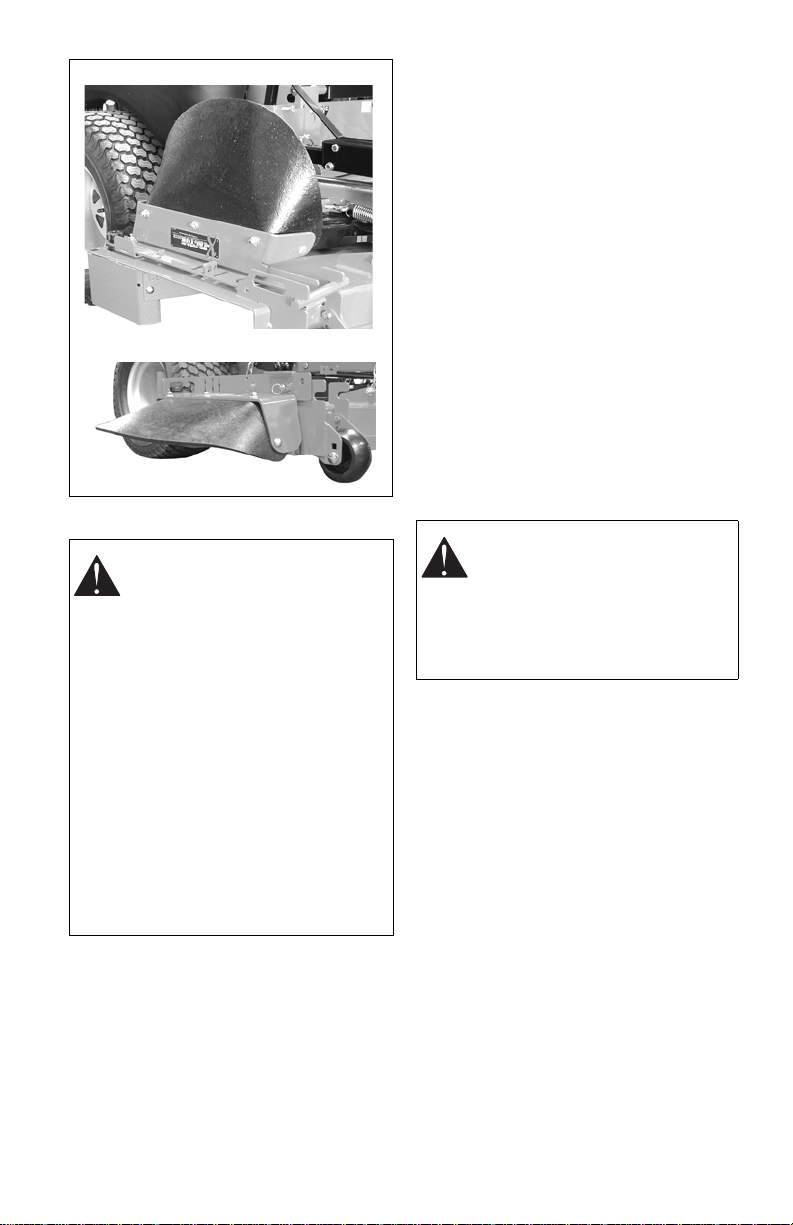

CONTROLS AND FEATURES

Figure 4

1

18

3

4, 5

7

2

8

9

13

16

17

15

19

21

27

22

25

Control Panel for Models 992215, 216

Control Panel for Models

922210, 212, 213, 217

19

21

25

20

26

28

11

23

23

27

12, 14

24

29

10

11

992210, 212

6

15

1. Hood

2. Parking Brake Lever

3. Steering Levers

4. Mower Lift Lever (992213, 215, 216,

217)

5. Seat Adjustment Lever (Front/Back)

6. Seat Suspension Adjustment Knob

7. Fuel Shut-Off Valve

8. Axle Locks

9. Tie-Down Lugs

10. Mower Lift Pedal (992210, 212)

11. Height of Cut Indicator

12. Cylinder Stops (992213, 215, 216, 217)

13. Anti-Scalp Rollers

14. Cylinder Stop Storage Post

(992213, 215, 216, 217)

15. Foot Board Latch

16. Mower Deck with Chute Deflector

17. Belt Cover

18. Fuel Tanks

19. PTO (Power Take-Off) Switch

20. Glow Plug Light (992215, 216)

21. Ignition Switch

22. Coolant Temperature Gauge

(992215, 216)

23. Hour Meter

24. Charging System Light (992215, 216)

25. Throttle Lever

26. Fuel/Water Separator Light

(992215, 216)

27. Oil Pressure Light

28. Choke Control

(922210, 212, 213, 217)

29. Seat Release Knob (Tilt)

GB - 12

WARNING: AVOID INJURY . Read

1

2

3

2

1

1

2

and understand entire Safety

section before proceeding.

CONTROLS AND FEATURES

See figure 4 for Controls and Features

locations.

Safety Interlock System

WARNING: Safety interlock

system failure and improper

operation of unit can result in

death or serious injury. Test this

system each time the unit is

operated. If this system does not

function as described, do not

operate until repairs are made.

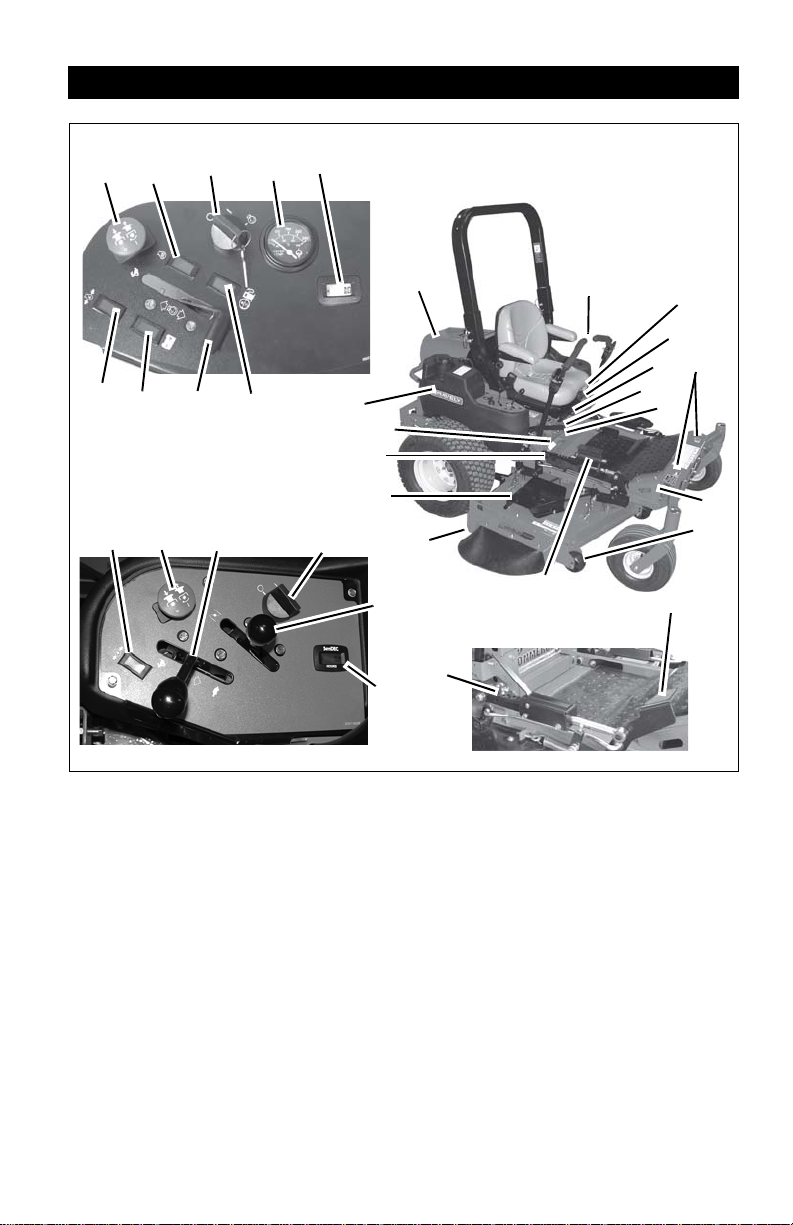

OPERATION

Ignition Switch

Operate the ignition

switch with the

removable key. The

switch has three

positions: Off ( 1 ) , Ru n

(2) and Start (3). See

Starting And Shutting Off

Engine on page 18 for

detailed instructions on how to start engine.

Choke Con trol (922210, 212, 213, 217)

Use to start a cold engine.

Push choke lever forward

to start a cold engine. Pull

the choke lever to the rear

when the engine is warm.

Throttle Lever

Changes the speed of engine.

Perform the following tests to ensure the

safety interlock system is working properly. If

the unit does not perform as stated, contact

your Gravely dealer for repairs.

IMPORTANT: With the parking brake

engaged, the steering levers must be locked

in neutral.

IMPORTANT: With the parking brake

disengaged, the engine must not start and

the engine must shut off if the operator leaves

the seat.

Test Steering

Levers

STARTING INTERLOCK

1 Neutral Off Engaged Starts

2 Neutral On Engaged Doesn’t

3 Neutral Off

OPERATING INTERLOCK (ENGINE ON)

4* Neutral On Engaged Shuts Off

5* Neutral Off

6* Neutral Off Engaged On

* Operator lifts off seat.

PTO Parking

Brake

Disengaged

Disengaged

Engine

Start

Doesn’t

Start

Shuts Off

Fast (1) – Increases

engine speed.

Slow (2) – Decreases

engine speed.

Power Take Off (PTO) Switch

Engages (1) and

disengages (2) mower

blades.

GB - 13

°F

170

195

220

280

100

40

80 100

140

WATER

TEMP

°C

Display

Toggle Button

RIGHT

TANK

LEFT

TANK

OFF

1

2

3

1

3

2

4

Oil Pressure Light

Indicates when engine oil

pressure is low.

NOTE: It does not

indicate engine oil level.

See Troubleshooting on

page 35 or refer to Engine

Manual for details.

Charging System Light (992215, 216)

Indicates when the charging system is not

charging the battery.

Glow Plug Light (992215, 216)

Indicates when the engine glow plugs are

energized. Glow plugs energize for

approximately 5 seconds when the key

switch is turned to the Run position.

Fuel / Water Separator Light

(992215, 216)

Indicates when the fuel/water separator filter

needs to be replaced (refer to Engine

Manual).

Coolant T e mpe rature Gauge

(992215, 216)

Indicates temperature

of coolant. See

Troubleshooting on

page 35 or refer to

Engine Manual for

details.

Hour Meter

Press and release the toggle button to shift

between different functions.

Press and hold the toggle button to reset the

timer or clear a service message.

The hour meter has three functions:

Hour Meter: measures the amount of time

the engine has been run. This time cannot be

cleared.

Timer (TMR1): measures the time spent on

individual jobs.

Press and hold the toggle button to reset the

timer to zero. TMR1 will then start measuring

engine run time until it is reset to zero again.

Service Alert (Chg Oil, Chg H Oil & Filter,

SVC Airfilter): reminds operators of the

maintenance interval for changing the engine

oil, changing the hydraulic oil and filter and

servicing the air filter.

The alert starts counting down two hours

before the maintenance is due. The meter

flashes the word, "Now," when it reaches the

maintenance time.

Press and hold the toggle button to reset the

maintenance clock to zero after perfoming

the service.

NOTE: The hour meter is preprogrammed for

the initial oil change at 25 hours and for 100

hours thereafter. The hour meter is

programmed for the initial hydraulic oil and

filter change at 75 hours and for 400 hours

thereafter.

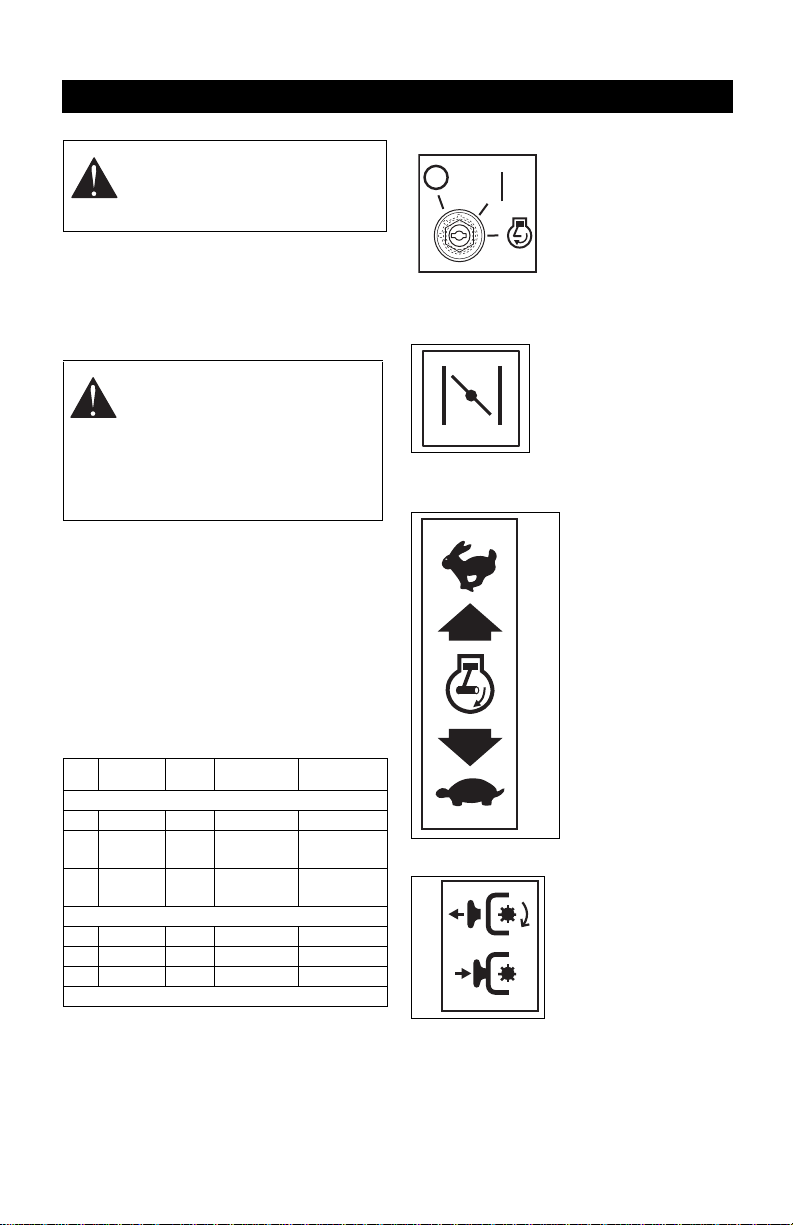

Fuel Shut-Off Valve

Controls fuel flow from

left fuel tank (1) or right

fuel tank (2).

Open valve to operate

the engine. Turn the

valve to off (3) when

storing or transporting

the unit.

NOTE: There is no off (3) position on models

992215, 216.

Steering Levers

Control

speed,

directional

control, and

stopping unit.

•Reverse (1)

– Pull both

steering

levers

backward.

GB - 14

• Forward (2) – Push both steering

levers forward.

• Left (3) – Pull left steering lever back

or push right steering lever forward or

a combination of both.

• Right (4) – Pull right steering lever

back or push left steering lever

forward or a combination of both.

T o stop, return both steering levers to neutral.

1

2

1

2

NOTE: Steering levers are mechanically

locked in neutral whenever parking brake is

engaged.

NOTE: Aggressive turning can scuff or

damage lawns. ALWAYS keep both wheels

rotating when making sharp turns. DO NOT

make turns with inside wheel completely

stopped. To obtain minimum turning radius,

slowly reverse inside wheel while moving

outside wheel slowly forward.

Parking Brake Lever

Engages (2) and

disengages (1)

parking brake.

Mower Lift Lever (992213, 215, 216,

217)

Raises and lowers

mower deck.

To lower (1) – Move

mower lift lever

forward.

To raise (2) – Move

mower lift lever

rearward.

Cylinder Stops (992213, 215, 21 6, 217 )

CAUTION: AV OID PI NCH

POINTS. Always use the T-portion

of the cylinder stop when

removing or installing the cylinder

stops.

Ensure the same cutting height after raising

mower deck to clear an obstacle. Cylinder

stops are stored on a post behind hydraulic

lift cylinder and come in two sizes: 11/32 in.

and 11/16 in. (8.73 mm and 17.5 mm).

1. Remove cylinder stops from post and

snap onto lift cylinder rod.

2. Push lift lever forward until cylinder rests

against cylinder stops.

Mower Lift Pedal (992210, 212)

Mower lift pedal raises and lowers the mower

deck for transporting the unit and for setting

the cutting height.

To Transport: Push mower lift pedal (1) all

the way forward until lift lock (2) engages.

To Set Cutting Height: Put cutting height

adjustment pin in desired hole. Push mower

lift pedal (1) forward and hold while pushing

down on the lift lock (2). Slowly lower mower

lift pedal (1) until deck lift contacts cutting

height adjustment pin.

NOTE: See Mower Lift Force Adjustment

(992210, 212) on page 25 to adjust the force

required to lift the mower deck.

SEAT ADJUSTMENTS

WARNING: Make all seat

adjustments with unit stationary,

parking brake on and engine shut

off.

To adjust seat forward or backward:

1. While seated, pull seat adjustment lever

outward and slide seat into desired

position.

2. Release lever and slide seat forward or

back to lock seat into position.

Seat Suspension Adjustment Knob

To make seat more firm turn knob clockwise.

To make seat less firm turn knob counter

clockwise.

Tipping Se at Forward

1.Pull seat release

knob out.

2.Tip seat forward.

07800221

returning seat to upright position seat will

automatically lock in place.

NOTE: Seat release

knob is spring

activated. When

GB - 15

AXLE LOCKS

1

2

3

Figure 5

1. Axle Lock Storage

2. Axle Locks Installed

3. Front Axle

Lowered Position

Figure 6

Raised Position

Lock Pin

Hair Pin

For a solid front axle, install axle locks on

front axle. For a pivoting front axle, remove

axle locks from front axle and store on unit

(Figure 5).

2. Raise the center bar into up position.

3. Install the ROPS lock pins in the hinge

plate and secure with the hair pins.

NOTE: Return the center bar to the raised

position when clear of obstacles.

ROLLOVER PROTECTION

STRUCTURE (ROPS)

Frequently inspect ROPS and seat belt for

damage or loose hardware.

Use extreme care when working close to

fences, ditches, or on hills.

Check overhead clearance carefully before

driving under any objects.

ALWAYS wear seat belt while operating the

unit with the ROPS in the upright position.

Do not wear a seat belt while operating the

unit with the center bar in the lowered

position.

IMPORTANT: Do not weld, cut, drill or modify

ROPS in any manner unless instructed by the

manufacturer.

Lower Center Bar (Figure 6)

WARNING: Lower the center bar

only when necessary to drive under

an object. There is no rollover

protection with the center bar in the

down position.

1. Remove the two hair pins and then

remove the ROPS lock pins from the

hinge plate.

2. Lower the center bar into down position.

3. Install the ROPS lock pins in the hinge

plate and secure with the hair pins.

Raise Center Bar (Figure 6)

1. Remove the two hair pins and then

remove the ROPS lock pins from the

hinge plate.

FILLING FUEL TANK

WARNING: AVOID INJURY . Read

and understand entire Safety

section before proceeding.

To add fuel to fuel tank:

1. Place unit in an open or well-ventilated

area.

2. Shut off engine and allow to cool.

3. Clean fuel caps and surrounding area to

prevent dirt from entering fuel tank.

4. Remove fuel caps.

NOTE: If unit runs out of fuel on diesel

models (992215, 216), the engine must be

primed prior to starting the engine. Refer to

Engine Manual for detailed instructions.

5. Fill fuel tank to the bottom of filler neck.

See Specifications on page 39 for fuel

tank capacity.

GB - 16

IMPORTANT: DO NOT OVERFILL! This

equipment and/or its engine may include

evaporative emissions control system

components, required to meet EPA and/or

CARB regulations, that will only function

properly when the fuel tank has been filled to

the recommended level. Overfilling may

cause permanent damage to evaporative

emissions control system components. Filling

to the recommended level ensures a vapor

gap required to allow for fuel expansion. Pay

close attention while filling the fuel tank to

ensure that the recommended fuel level

inside the tank is not exceeded. Use a

portable gasoline container with an

appropriately sized dispensing spout when

filling the tank. Do not use a funnel or other

device that obstructs the view of the tank

filling process.

6. Replace fuel cap and tighten.

7. ALWAYS clean up spilled fuel.

GASOLINE

IMPORTANT: ALW AYS use gasoline that

meets the following guidelines:

• Clean, fresh gasoline.

• A minimum of 87 octane/87 AKI (91

RON). High altitude use may require a

different octane. Consult your engine

manual.

• Gasoline with up to 10% ethanol

(gasohol) or up to 15% MTBE (methyl

tertiary butyl ether) is acceptable.

• Use of any gasoline other than those

approved above may void the engine

warranty. If the pumps are not marked

for the content of alcohol or ethers,

check ethanol and MTBE levels with

the fuel supplier.

• Do not modify the fuel system to use

different fuels.

• Never mix oil and gasoline.

NOTE: All gasoline is not the same. If the

engine experiences starting or performance

problems after using a new gasoline, switch

to a different fuel provider or fuel brand.

IMPORTANT: Excessively oxygenated or

reformulated fuels (fuels blended with

alcohols or ethers) can damage the fuel

system or cause performance problems. If

any undesirable operating problems occur,

use a gasoline with a lower percentage of

alcohol or ether.

Fuel Stabilizer

Gasoline left in the fuel system for extended

periods without a stabilizer will deteriorate,

resulting in gum deposits in the system.

These deposits can damage the carburetor

and the fuel hoses, filter and tank. Prevent

deposits from forming in the fuel system

during storage by adding a quality fuel

stabilizer to the fuel. Follow the

recommended mix ratio found on the fuel

stabilizer container.

PRIOR TO STARTING THE UNIT

CAUTION: Make sure al l

hardware is tight, all safety

devices are in place and all

adjustments are made correctly.

1. Check Safety Interlock System

If this system does not function as described

do not operate until repairs are made.

2. Check Air Cleaner

Check air filter for dirt. Clean as required.

Follow Engine Manual for maintenance

schedule.

3. Check Engine Fuel and Engine Oil

Check and add fuel if required. Check that

engine oil level is within operating range.

Follow Engine Manual for maintenance

schedule.

NOTE: If unit runs out of fuel on diesel

models (992215, 216), the engine must be

primed prior to starting the engine. Refer to

Engine Manual for detailed instructions.

4. Check Tire Pressure

See Specifications on page 39 for correct tire

pressure.

5. Check Hydraulic Fluid Level

See Checking Hydraulic Oil Level on

page 33.

6. Adjust Seat

Be sure all controls can be reached safely

from operator’s position (see Seat

Adjustments on page 15).

7. Set Cutting Height

Make sure the deck is set to the correct

cutting height.

GB - 17

8. Check Radiator Screen (992215,

1

2

3

1

2

3

216)

Check radiator screen for debris see

Maintenance Schedule on page 20 and refer

to Engine Manual for detailed instructions.

STOPPING IN AN EMERGENCY

WARNING: Operating unit on

slopes may lead to loss of steering

control. When operating on slopes

be prepared to react to an

emergency situation.

1. Return steering levers to neutral position

2. Immediately set parking brake

3. Turn off PTO and engine

STARTING AND

SHUTTING OFF ENGINE

NOTE: DO NOT operate starter more than 15

seconds per minute, as overheating and

damage can occur. If engine will not start, see

Troubleshooting on page 35 or refer to

Engine Manual.

NOTE: The engine will not start unless the

steering control levers are in the neutral

position, the PTO switch is in the off position,

and parking brake is engaged.

NOTE: If unit runs out of fuel on diesel

models (992215, 216), the engine must be

primed prior to starting the engine. Refer to

Engine Manual for detailed instructions.

To Start Gas Units (922210, 212, 213,

217):

1. Insert ignition key.

2. Move choke

control to the on

position.

3. Move the throttle to

3/4 fast position.

4. Turn ignition key to

Start (3) position.

NOTE: If engine does not start in five

seconds, release ignition key, wait, and then

repeat. Once engine has started, ignition key

will return to the Run (2) position.

5. Move the choke control to the off

position when engine has warmed up.

To Start Diesel Units (992215, 216):

1. Insert ignition key.

2. M o ve the throttle to

3/4 fast position.

3. Turn ignition key to

Run (2) position.

The glow plug light

will come on for

approximately 5

seconds.

4. When glow plug light goes out, turn

ignition key Start (3) position.

NOTE: If engine does not start in five

seconds, release ignition key, wait, and then

repeat. Once engine has started, release

ignition key and ignition key will return to the

Run (2) position.

To shut off:

1. Disengage PTO.

2. Set parking brake.

3. Turn ignition key to Off (1) position.

OPERATING MOWER

1. Start engine.

2. Move throttle lever to 3/4 to full speed.

IMPORTANT: Never engage the PTO if the

mower is plugged with grass or other

material.

3. Engage PTO to engage mower blades.

4. Mo v e th ro ttle lever to fa st.

5. Release parking brake.

WARNING: Move the steering

control levers slowly and keep the

throttle control lever at slow speed

until you learn how to operate the

unit.

6. Use steering levers to move the unit.

7. Disengage PTO to stop mower blades.

PARKING THE UNIT

1. Move steering levers to the neutral

position. Shut off PTO.

2. Move throttle lever to the slow position.

3. Engage parking brake.

GB - 18

MOVING UNIT MANUALLY

Figure 7

1. Right Bypass Valve

2. Left Bypass Valve

2

1

OD5115

IMPORTANT: Never tow unit.

1. Place unit in the service position (see

Service Pos i tion on page 22).

2. Turn right and left bypass valves

counterclockwise half turn (Figure 7).

WARNING: Do not bypass

transmission when on a slope.

3. Disengage parking brake.

4. Push unit to desired location.

5. Engage parking brake.

6. Turn right and left bypass valves

clockwise half turn.

TRANSPORTING UNIT

ALWAYS shut off engine, set parking brake,

and remove key when transporting unit on a

truck or trailer. Tie unit down securely. Do not

tie down by linkages, guards, cables or other

parts that may be damaged.

FOR BEST PERFORMANCE

Cut grass when it is dry.

Keep mower blades sharp.

Keep mower deck properly leveled.

Adjust anti-scalp rollers to prevent scalping.

Do not set height of cut too low. For very tall

grass, mow twice.

Do not travel too fast.

Mow with the engine set at full throttle.

When mulching, only remove 1/3 of grass

length per cutting.

Discharge clippings into areas already cut.

Vary cutting pattern with each mowing.

Do not allow grass or debris to collect inside

of mower deck. Clean after each use.

GB - 19

MAINTENANCE SCHEDULE

WARNING: AVOID INJURY . Read

and understand entire Safety

section before proceeding.

Interval Task Action

Proper maintenance can prolong the life of

unit. The following chart shows the

recommended service schedule. More

frequent service may be required due to

working conditions (heavy loads, high

ambient temperatures, dusty conditions, or

airborne debris).

See the maintenance instructions in the

Engine Manual for additional information.

Each

Use

Check Safety

Interlock

System

described, do not operate until repairs are made. See Safety

Interlock System on page 13.

Check

Parking Brake

Check Hydraulic

Oil Level

Check Tires CAUTION: Avoid injury! Explosive separation of tire

Clean Unit Clean engine, battery, seat, mower deck, etc. of dirt and

Engage parking brake. Push unit. If unit rolls adjust parking

brake (see Parking Brake Adjustment on page 32).

See Checking Hydraulic Oil Level on page 33.

See Specifications on page 39 for correct tire pressure.

debris. Do not use solvents, hard cleaners, or abrasives.

IMPORTANT: Do not spray the unit with water, especially

when the unit is warm from operation. Water can seep into

bearings and damage them.

NOTE: Protect painted surfaces with automotive type wax.

WARNING: Safety inte r l ock system failure and

improper operation of unit can result in death or

serious injury. Test this system each time the unit is

operated. If this system does not function as

and rim parts is possible when they are serviced

incorrectly:

• Do not attempt to mount a tire without the proper

equipment and experience to perform the job.

• Do not inflate the tires above the recommended

pressure.

• Do not weld or heat a wheel and tire assembly. Heat

can cause an increase in air pressure resulting in an

explosion. Welding can structurally weaken or deform

the wheel.

• Do not stand in front or over the tire assembly when

inflating. Use a clip-on chuck and extension hose long

enough to allow you to stand to one side.

Follow Engine

Maintenance

Schedule

Perform scheduled engine maintenance. Refer to Engine

Manual for detailed instructions.

GB - 20

Interval Task Action

Each

Use

Every

25

Hours

Every

50

Hours

Every

100

Hours

Check

Cooling

System

(992215, 216)

Check Mower

Blades

Lubricate

Front Axle

and Pivot

Points

Clean Battery Keep battery and battery terminals clean (see Cleaning the

Check

Fasteners

Check All

Belts

IMPORTANT: To avoid damaging the radiator, DO NOT USE

high-pressure water to clean the radiator.

Check cooling system for dirt and debris in radiator screen,

oil cooler, hoses, fan, etc. Refer to Engine Manual for

detailed instructions.

Ensure mower blade hardware is tightened to 115 – 160 lbf-ft.

(156 – 217 N•m). Check mower blades for wear. Sharpen or

replace mower blades as needed (see Sharpening Mower

Blade on page 24).

Oil all pivot points, pin connections, and apply grease to front

axle grease zerk (see Lubricating Unit on page 22).

Battery (Figure 10) on page 23).

Check mower blade mounting hardware and all other

fasteners. Replace missing or damaged fasteners. Tighten all

nuts and bolts to their correct torque value.

Replace worn or deteriorated belts.

• Check mower drive belt. See Mower Drive Belt on

page 29 for belt location.

• Check PTO belt. See PTO Belt on page 28 for belt

location.

• Check transmission belt. See Transmission Belt on

page 29 for belt location.

• Check radiator fan belt. Refer to Engine Manual

(992215, 216).

Grease Front

Every

400

Hours

*Change hydraulic fluid and filter after the first 75 hours of operation and then every 400

hours.

Axle Caster

Pivots

Change

Hydraulic Oil

and Filter*

Repack front axle caster pivots (see Lubricating Unit on

page 22).

See Changing Hydraulic Oil and Filter on page 33.

GB - 21

SERVICE AND ADJUSTMENTS

1. Hood

2. Hood Cable

3. Hood Frame

Handle

4. Hood Latches

5. Steering Levers

Figure 8

2

1

3

4

5

Service Position

1

2

1

Gravely Dealers will provid e any ser vice wh ich

may b e required t o keep your unit operating at

peak efficiency. Should engine service be

required, it can be obtained from a Gravely

Dealer or the engine manufacturer’s

authorized service center.

WARNING: AVOID INJURY . Read

and understand entire Safety

section before proceeding.

CAUTION: HOT SURF ACES may

result in injury. DO NOT touch

engine or drive parts which are

hot from operation. Allow parts to

cool before servicing.

SERVICE POSITION

(Figure 8)

IMPORTANT: Place unit on a flat level

surface. ALWAYS shut off engine, set parking

brake, and remove ignition key. Ensure unit is

secure and will not tip over. When a lift is

used, strap and clamp unit to the lift.

1. Place steering levers in neutral position

and engage parking brake.

2. Tip seat forward (see Seat Adjustments

on page 15).

3. Unlatch the hood latches.

4. Using the hood frame handle, slowly lift

the hood up until the hood cable is taunt

and is supporting the weight of the hood.

LUBRICATING UNIT

Item Lubrication Location Interval

1 Repack Front Axle Caster

2 Grease Front Axle Grease

Oil All Pivot Points and

IMPORTANT: Wipe front axle grease zerk

and two front axle castor pivots clean before

and after lubrication.

NOTE: Use Ariens Hi-Temp Grease or

equivalent (part number 00036700).

Pivot

Zerk

Pin Connections

Figure 9

400

hours

50

hours

50

hours

SERVICING THE BATTERY

WARNING: AVOID INJURY . Read

and understand the entire Safety

section before proceeding.

WARNING: Battery posts,

terminals and related accessories

NOTE: Unit comes equipped with a

maintenance-free battery that requires no

regular maintenance except cleaning the

terminals.

GB - 22

contain lead and lead compounds,

chemicals known to the State of

California to cause cancer and

reproductive harm. Wash hands

after handling.

Battery Removal (Figure 10)

1. Battery

2. Negative (–)

Terminal

3. Negative (–)

Cable

4. Positive (+)

Terminal

5. Positive (+)

Cable

Figure 10

2

4

1

3

5

Battery for models

922210, 212, 213, 217

Battery for models 992215, 216

2

4

1

3

5

1. Place unit in the service position (see

Service Pos i tion on page 22).

2. Disconnect negative (–) cable first, then

positive (+) cable.

3. Remove battery hold-down bracket and

battery from unit.

(

Battery Installation (Figure 10)

1. Install battery on unit with battery holddown bracket.

2. Connect positive (+) cable first, then

negative (–) cable.

3. Coat terminals with dielectric grease or

petroleum jelly.

4. Close hood (see Service Position on

page 22).

Cleaning the Battery (Figure 10)

1. Disconnect negative (–) cable first, then

positive (+) cable.

2. Clean battery cable ends and terminals

with wire brush. Rinse with a weak

baking soda solution.

3. Connect positive (+) cable first, then

negative (–) cable.

4. Coat terminals with dielectric grease or

petroleum jelly.

Charging the Battery (Figure 10)

WARNING: FROZEN

BATTERIES CAN EXPLODE and

result in death or serious injury.

DO NOT charge a frozen battery.

Let battery thaw before charging.

Follow First Aid directions for contact with

battery fluid.

• External Contact: Flush with water.

• Eyes: Flush with water for at least 15

minutes and get medical attention

immediately!

• Internal Contact: Drink large

quantities of water. Follow with Milk of

Magnesia, beaten egg or vegetable

oil. Get medical attention immediately!

• In case of internal contact, DO NOT

induce vomiting!

IMPORTANT: DO NOT fast charge. Charging

at a higher rate will damage or destroy

battery. ALWAYS follow information provided

on battery and battery charger. Contact

battery manufacturer and battery charger

manufacturer for detailed instructions.

1. Remove battery from unit (see Battery

Removal (Figure 10) on page 23).

2. Place battery on bench or other wellventilated area.

3. Connect positive (+) lead of charger to

positive (+) terminal, and negative (–)

lead to negative (–) terminal.

4. Charge battery according to the

instructions from battery charger

manufacturer and battery manufacturer.

5. Install battery on unit (see Battery

Installation (Figure 10) on page 23).

Jump-Starting

Gravely does not recommend jump-starting

your unit. Jump-starting can damage engine

and electrical system components. See your

Engine Manual for more detailed information.

GB - 23

MOWER BLADE

Figure 11

1

1. Mower Blade

2. Spindle Shaft

3. Washer

4. Bolt

2

3

4

3

Figure 12

OF3310

1

2

DO NOT Sharpen To This Pattern

Sharpen To This Pattern

DISCARD if more

than 1/2 in. (1.27 cm)

1. Air Lift Erosion Area

2. Cutting Edge

NOTE: If mower is used under sandy soil

conditions, replace mower blades when air

lifts become eroded through at ends

(Figure 12).

Removal (Figure 11)

CAUTION: Mower blades are

sharp and can cut you. Wrap

mower blades or wear gloves, and

use extra caution when servicing.

1. Block mower blades to prevent rotation.

1. Remove mower blade from unit.

Discard mower blade if (Figure 12):

• More than 1/2 in. (1.27 cm) of metal is

removed.

• Air lifts become eroded.

• Blade is bent or broken.

2. Remove bolts, washers, and mower

blades from spindle shafts.

Installation (Figure 11)

1. Install mower blades, washers, and bolts

on spindle shafts.

2. Tighten bolts to 115-160lbf-ft

(156-217 N•m).

SHARPENING MOWER BLADE

(Figure 12)

NOTE: If mower is used under sandy soil

conditions, replace mower blades when air

lifts become eroded through at ends.

CAUTION: DO NOT sharpen

mower blades while on unit. An

unbalanced mower blade will

cause excessive vibration and

eventual damage to unit. Check

mower blade balance before

reinstalling blades.

NEVER weld or straighten bent

blades.

2. Sharpen mower blade by removing an

equal amount of material from each end

of mower blade. DO NOT change angle

of cutting edge or round the corner of

mower blade.

3. Check mower blade balance. Slide

mower blade on an unthreaded bolt. A

balanced blade should remain in a

horizontal position. If either end of

mower blade moves downward, sharpen

the heavy end until blade is balanced.

4. Install mower blade on unit.

ANTI-SCALP ROLLER

ADJUSTMENT

(Figure 13)

The anti-scalp rollers are set at the factory for

typical mowing height, but can be adjusted for

high or low cutting conditions.

Anti-Scalp rollers are intended to prevent

lawn scalping, not to control cutting height.

For a very high cutting height, set the antiscalp rollers in the lowest position on the

bracket.

GB - 24

For a very low cutting height, set the anti-

Figure 13

Lowest

Cutting

Height

Highest

Cutting

Height

Figure 14

Increased Spring Length =

Decreased Force required

to Lift Mower Deck

Decreased Spring Length =

Increased Force required to

Lift Mower Deck

3

1

1. Eye-Bolt

2. Jam Nuts

3. Mechanical Lift Spring

2

Figure 15

1. Nut

2. Bolt

3. Foot Pedal

2

3

1

scalp rollers in the highest position on the

bracket.

NOTE: There are four anti-scalp rollers on

the outside of the mower deck and two antiscalp rollers on the inside of the mower deck.

Make sure all anti-scalp rollers are set at the

same height.

MOWER LIFT FORCE

ADJUSTMENT (992210, 212)

(Figure 14)

The mower lift pedal can be adjusted to

decrease or increase the amount of force

required to lift the mower deck.

NOTE: Decreasing the amount of force

required to lift the mower deck will increase

the mower deck’s bouncing. Increasing the

amount of force required to lift the mower

deck will decrease the mower deck’s

bouncing.

• Adjust the eye-bolt to increase the

length of the mechanical lift spring

which will decrease the amount of

force required to lift the mower deck.

• Adjust the eye-bolt to decrease the

length of the mechanical lift spring

which will increase the amount of force

required to lift the mower deck.

1. Raise mower deck to transport position

to reduce spring tension (see Mower Lift

Pedal (992210, 212) on page 15).

2. Loosen the jam nuts on the eyebolt

away from the mounting tab. (Figure 14)

3. Turn appropriate jam nut to adjust

position of eyebolt in mounting tab,

changing spring tension.

4. Tighten both jam nuts up against the

mounting tab to lock the eyebolt in

position.

5. Verify the mechanical lift springs on

each side of the unit are the same

length.

6. Lower mower deck to cutting position

(see Mower Lift Pedal (992210, 212) on

page 15).

7. Check effort of mower lift pedal and

adjust as necessary by repeating steps

1 through 6.

MOWER LIFT PEDAL

ADJUSTMENT (992210, 212)

1. To adjust the foot pedal, partially loosen

the nuts securing bolts to foot pedal.

2. Move foot pedal to desired location.

3. Tighten nuts and torque to 52-70 lb-ft

(Figure 15).

IMPORTANT: Adjust the mechanical lift

spring on each side of the unit to the same

length.

GB - 25

MOWER DECK

Figure 16

1. Eye-Bolt

2. Mechanical Lift Spring

OF4040

21

Figure 17

1. Link Chain

2. Mower Mounting Arm

3. Mower lift Arm

2

1

3

Figure 18

DO NOT place blocks

under reinforcement bar.

DANGER: MOVING PARTS can

cut or amputate body parts.

ALWAYS wait for moving parts to

stop before performing

maintenance or service.

Removal (Figure 16)

NOTE: Only remove PTO belt from electric

clutch.

1. Remove PTO belt from electric clutch

(see PTO Belt on page 28).

NOTE: Perform steps 2 and 3 for mechanical

lift mower decks only (992210, 212).

CAUTION: Use care when

releasing mechanical lift spring

tension. Keep body parts well

away from springs when

performing this operation.

5. Install mechanical lift spring on each

side of unit (Figure 16).

6. Install PTO belt on electric clutch (see

PTO Belt on page 28).

7. Level mower deck (see Leveling the

Mower Deck on page 26).

2. Raise mower deck to transport position

to reduce spring tension(see Mower Lift

Pedal (992210, 212) on page 15).

3. Remove mechanical lift spring from each

side of unit.

4. Lower mower deck all the way down.

5. Remove link chains from mower lift arms

(Figure 17).

6. Remove mower mounting arms from

frame.

7. Slide mower deck out from under unit.

Installation (Figure 17)

NOTE: Perform steps 4 and 5 for mechanical

lift mower decks only (992210, 212).

1. Slide mower deck under unit.

2. Install mower mounting arms on frame.

3. Install link chains on the mower lift arms.

4. Raise mower deck to transport position

(see Mower Lift Pedal (992210, 212) on

page 15).

LEVELING THE MOWER DECK

These adjustments should be made on a

level surface with the tires inflated to the

correct air pressure.

Check Blade Level and Pitch

1. Raise mower deck to a 3 in. (7.62 cm)

cutting height.

2. Shut off engine. Engage parking brake.

Remove the ignition key.

NOTE: Place blocks under the bottom edge

of the deck, not under the reinforcement bar

welded along deck face (Figure 18).

3. Place blocks at each corner of the deck

to support the weight of the deck.

4. Turn the blades so the blade ends point

left to right across the width of the deck.

GB - 26

5. Measure the distance between the

Figure 19

Blade Side-to-Side Level

Blade Front-to-Back Pitch

Left

Right

Front

Rear

Rear

Figure 20

Height Adjusters

NOTE: On diesel units, height

adjusters are on the opposite

side of the rear arms.

ground and cutting edge of the blade on

the left blade (Left position in figure 19)

and on the right blade (Right position in

figure 19). Distances should be within

3/16 in. (4.7 mm). If they are not, raise

the low side of the deck using the height

adjusters on the deck lift brackets

(Figure 20).

6. After deck is level side to side, check the

deck front to back pitch.

7. Turn the blades so the blade ends point

front to back as shown in figure 19.

8. Measure the distance between the

ground and the cutting edge of the

middle blade at the front of the deck

(Front position in figure 19) and between

the ground the cutting edge of the left

and right blades at the rear of the deck

(Rear position in figure 19).

9. The cutting edge at the front of the deck

(Front position in figure 19) should be

1/8 in. (3.18 mm) lower than the cutting

edges at the rear of the deck (Rear

position in figure 19).

10. If measurements are out of range, raise

the low side of the deck using the height

adjusters on the deck lift brackets

(Figure 20). Be sure to raise the deck

evenly to keep the deck level side to

side.

NOTE: Pitching the front of the blades lower

than the rear provides a balance between cut

quality and the power needed to cut grass.

Certain cutting conditions require the deck to

be pitched with the rear of the blades lower

than the front. Heeling the deck this way

requires more engine power but can provide

better cut quality.

11.Remove the blocks from under the deck.

Adjust Blade Height

Level and pitch the mower with the height

adjusters on each deck lift bracket. (see

Check Blade Level and Pitch on page 26)

Loosen the jam nut on the deck lift

bracket bolt about quarter turn to reduce

clamp load on the height adjusters.

(Figure 20)

Loosen the jam nut on the deck adjuster

bolt and then turn the bolt clockwise to

raise the deck or counterclockwise to

lower the deck. Tighten both jam nuts.

MOWER DRIVE BELT AND PTO

BELT ACCESS

1. Lower the mower deck.

2. Place seat in most rearward position.

3. Place foot board in open position

(Figure 21).

4. Secure raised footboard with latch.

GB - 27

PTO BELT

Figure 21

1. Footboard in

open position

2. Frame

3. Latch

1

2

3

OF3229

Figure 22

1. PTO Belt

2. Square Hole

3. Springs

4. Drive Belt Idler Pivot Bolt

5. Drive Belt Idler

6. Mower Drive Belt

7. Blade Spindle Pulleys

8. PTO Belt Idler

9. Electric Clutch

10.Idler Pulleys

1

2

3

4

5

7

6

8

9

10

WARNING: MOVING PARTS can

cut or amputate body parts.

ALWAYS wait for moving parts to

stop before performing

maintenance or service.

CAUTION: DAMAGED OR

WORN BELTS may result in injury

and/or damage to unit. Check

belts for excessive wear or cracks

often.

NOTE: The Ogura electric clutch can be

adjusted if the clutch starts to slip (see Clutch

Adjustment on page 34).

Removal (Figure 22)

1. Open footboard (see Mower Drive Belt

And Pto Belt Access on page 27).

2. Remove left hand belt cover from mower

deck.

CAUTION: Use care when

releasing idler spring tension.

Keep body parts well away from

idlers when performing this

operation.

3. Place 1/2-inch driver and ratchet

extension into square hole in PTO belt

idler.

4. While pulling PTO belt idler towards rear

of unit, remove PTO mower belt from

PTO belt idler.

5. Slowly release tension on PTO belt idler

until all tension is removed from springs.

6. Remove PTO mower belt from blade

spindle pulleys, idler pulleys, and

electric clutch.

Installation (Figure 23)

1. Install the new PTO belt on electric

clutch, idler pulleys, and blade spindle

pulleys.

2. Place 1/2-inch driver and ratchet

extension into square hole in PTO belt

idler.

3. While pulling PTO belt idler towards the

rear of unit, install PTO mower belt on

PTO belt idler.

4. Slowly release the tension until PTO belt

idler is firmly against PTO belt.

NOTE: The PTO idler spring length range is

12.25 to 12.50 in. (31 to 31.8 cm) measured

at a 3 in. (7.6 cm) cutting height. Adjust the

idler spring length as needed (Figure 23).

5. Install belt guard on rear of unit.

6. Install left hand belt cover on mower

deck.

7. Close footboard (see Mower Drive Belt

And Pto Belt Access on page 27).

GB - 28

MOWER DRIVE BELT

Figure 23

The PTO idler spring length range is

12.25 to 12.50 in. (31 to 31.8 cm)

measured at a 3 in. (7.6 cm) cutting

height. Adjust as necessary.

Measure

PTO idler

spring

length here.

PTO Idler Spring Length

1. Right Hand

Hydrostat

2. Hydro Belt

3. Left Hand

Hydrostat

4. Spring

5. Clutch

6. Clutch Anchor

7. Engine Sheave

8. Idler

Figure 24

1

2

3

4

5

6

7

8

Removal (Figure 22)

NOTE: The PTO belt must be removed from

blade spindle pulleys prior to removing

mower drive belt. The PTO belt does not

need to be removed from electric clutch.

1. Remove PTO belt from blade spindle

pulleys (see PTO Belt on page 28).

2. Remove mower drive belt from right

blade spindle pulley and then from

center blade spindle pulley.

3. Loosen drive belt idler pivot bolt just

4. Remove mower drive belt from unit.

Installation (Figure 22)

1. Install the new mower drive belt on

2. Tighten drive belt idler pivot bolt.

3. Install PTO belt on blade spindle pulleys

enough to gain clearance to remove

mower drive belt from under drive belt

idler.

center blade spindle pulley, right blade

spindle pulley, and drive belt idler.

(see PTO Belt on page 28).

TRANSMISSION BELT

(922210, 212, 213, 217)

Removal (Figure 24)

1. Remove PTO belt from electric clutch

(see PTO Belt on page 28).

CAUTION: Use care when

releasing idler spring tension.

Keep body parts well away from

idlers when performing this

operation.

2. Remove clutch anchor.

3. Slowly release the tension on the hydro

pump belt idler until all the tension is

removed from the springs.

4. Remove old hydro pump belt from right

hand hydrostat sheave first.

Installation (Figure 24)

1. Install new hydro pump belt by

positioning belt on sheaves. Put belt

onto right hand hydrostat sheave last.

2. Replace clutch anchor.

3. Install PTO belt on electric clutch (see

PTO Belt on page 28).

GB - 29

TRANSMISSION BELT

Figure 25

1

6

2

4

5

3

1. Square Hole

2. Idler Pulley

3. Crankshaft Pulley

4. Transmission Belt

5. Hydrostatic Pump Pulleys

6. Spring

Figure 26

1

2

3

4

3

5

6

7

1. Damper Lock

2. Damper

3. Tie-Rod Jam

Nut

4. Tie-Rod

5. Steering Level

6. Brake Interlock

7. Hydrostatic

Transmission

(992215, 216)

Removal (Figure 25)

1. Place unit in the service position (see

Service Pos i tion on page 22).

CAUTION: Use care when

releasing idler spring tension.

Keep body parts well away from

idler when performing this

operation.