Gravely 988001-060, 988001-063, 988001-007, 988001-059, 988001-069 Service Manual

...

Pro 100/150/200

Service Manual

Models 988001-007, 059, 060, 062, 063, 069-072, 074, 075,

077-082, 085, 087, 088, 309

08484000 06/00

Printed in USA

TABLE OF CONTENTS

Section 1 - Introduction . . . . . . . . . . . . . . . . . . 1-3

1.1 The Manual. . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2 Service And Replacement Parts. . . . . . . . . 1-3

1.3 Product Registration. . . . . . . . . . . . . . . . . . 1-3

1.4 Unauthorized Replacement Parts. . . . . . . . 1-3

1.5 Disclaimer. . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.6 Technical Service Communications . . . . . . 1-3

Section 2 - Safety. . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.1 Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2 Signal Words. . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3 Notations. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4 Practices And Laws . . . . . . . . . . . . . . . . . . 2-4

2.5 Required Operator Training . . . . . . . . . . . . 2-4

2.6 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.7 Cleaning And Storage. . . . . . . . . . . . . . . . . 2-4

2.8 Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.9 Clean Unit. . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Section 3 - Specifications . . . . . . . . . . . . . . . . . 3-7

Section 4 - General Maintenance

& Adjustments . . . . . . . . . . . . . . . . . . . . . 4-12

4.1 Controls And Features . . . . . . . . . . . . . . . 4-12

4.2 Check Fuel Level . . . . . . . . . . . . . . . . . . . 4-12

4.3 General Lubrication . . . . . . . . . . . . . . . . . 4-14

4.4 Checking Fasteners . . . . . . . . . . . . . . . . . 4-14

4.5 Check Tires. . . . . . . . . . . . . . . . . . . . . . . . 4-14

4.6 The Steering Levers . . . . . . . . . . . . . . . . . 4-14

4.7 The Steering Lever Latches . . . . . . . . . . . 4-14

4.8 Adjusting The Levers . . . . . . . . . . . . . . . . 4-15

4.9 Adjusting The Shift Lever . . . . . . . . . . . . . 4-15

4.10 Adjusting The PTO Clutch . . . . . . . . . . . 4-16

4.11 Adjusting The Roller Chain . . . . . . . . . . . 4-17

Section 5 - Engine . . . . . . . . . . . . . . . . . . . . . . 5-18

5.1 Engine Troubleshooting . . . . . . . . . . . . . . 5-18

5.2 Checking Engine Oil. . . . . . . . . . . . . . . . . 5-19

5.3 Changing Oil Filter . . . . . . . . . . . . . . . . . . 5-19

5.4 Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5.5 Check Spark Plug. . . . . . . . . . . . . . . . . . . 5-19

5.6 Engine Removal . . . . . . . . . . . . . . . . . . . . 5-19

5.7 Engine Installation . . . . . . . . . . . . . . . . . . 5-19

Section 6 - Steering And Controls . . . . . . . . . .6-20

6.1 Steering Controls . . . . . . . . . . . . . . . . . . . 6-20

6.2 Operator Presence Control. . . . . . . . . . . . 6-20

Section 7 - Drive Train . . . . . . . . . . . . . . . . . . . 7-21

7.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . 7-21

7.2 transmission . . . . . . . . . . . . . . . . . . . . . . . 7-21

7.3 Transmission Removal . . . . . . . . . . . . . . . 7-21

7.4 Replacing The Transmission Belt . . . . . . . 7-21

7.5 Traction Clutch . . . . . . . . . . . . . . . . . . . . . 7-22

7.6 Replacing The Traction Belts . . . . . . . . . . 7-23

7.7 Replacing The Pto Clutch Belt . . . . . . . . . 7-24

7.8 Electric Clutch. . . . . . . . . . . . . . . . . . . . . . 7-25

7.9 Wheel Removal. . . . . . . . . . . . . . . . . . . . . 7-25

Section 8 - Fuel System. . . . . . . . . . . . . . . . . . .8-26

8.1 Fuel System Troubleshooting . . . . . . . . . . 8-26

8.2 Fuel Pump. . . . . . . . . . . . . . . . . . . . . . . . . 8-26

8.3 Fuel System Contamination . . . . . . . . . . . 8-26

8.4 Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

Section 9 - Electrical . . . . . . . . . . . . . . . . . . . . .9-27

9.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-27

9.2 Electrical Measurements. . . . . . . . . . . . . . 9-27

9.3 Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-28

9.4 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . 9-30

9.5 Solenoid And Relays. . . . . . . . . . . . . . . . . 9-31

9.6 Lighting Circuits . . . . . . . . . . . . . . . . . . . . 9-32

9.7 Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-32

9.8 Diodes And Rectifiers . . . . . . . . . . . . . . . . 9-32

9.9 Electric Clutch. . . . . . . . . . . . . . . . . . . . . . 9-32

9.10 Checking The PTO Clutch . . . . . . . . . . . 9-32

9.11 Interlock Switch. . . . . . . . . . . . . . . . . . . . 9-33

9.12 Fuse Holder . . . . . . . . . . . . . . . . . . . . . . 9-33

9.13 Pro 200 Check-out . . . . . . . . . . . . . . . . . 9-33

9.14 Continuity Diagrams . . . . . . . . . . . . . . . . 9-37

9.15 Wiring Diagram . . . . . . . . . . . . . . . . . . . . 9-41

9.16 Electrical System . . . . . . . . . . . . . . . . . . 9-44

2

SECTION 1 - INTRODUCTION

1.1 THE MANUAL

The purpose of this manual is to provide complete

instructions for service, maintenance, disassembly,

repair, and installation of the mechanical components

for the unit.

Dealer trained service personnel should use this

manual as a supplement to and reminder of the training

sessions conducted by the company.

Read all information for servicing a part or system

before repair work is started to avoid needless

disassembly.

Operation

Before operation of the unit, carefully and completely

read manuals supplied with the unit. The contents will

provide you with an understanding of safety

instructions and controls during normal operation and

maintenance.

Safety Messages

For your safety and the safety of others always read,

understand, and follow all DANGER, WARNING, and

CAUTION messages found in manuals and on safety

decals.

Directional Reference

All reference to left, right, front, or rear are given from

the operator in the operator position and facing the

direction of forward travel.

1.2 SERVICE AND REPLACEMENT PARTS

When ordering publications, replacement parts, or

making service inquiries, know the Model and Serial

numbers of your unit and engine.

Numbers are located on the product registration form in

the unit literature package. They are printed on a serial

number label, located on the frame of your unit.

Serial Number

1.3 PRODUCT REGISTRATION

A warranty registration card must be filled out, signed,

and returned at time of purchase. This card activates

the warranty. Claims meeting requirements during

limited warranty period will be honored.

1.4 UNAUTHORIZED REPLACEMENT

PARTS

Use only Gravely replacement parts. The replacement

of any part on this vehicle with anything other than a

Gravely authorized replacement part may adversely

affect the performance, durability, or safety of this unit

and may void the warranty. Gravely disclaims liability

for any claims or damages, whether warranty, property

damage, personal injury , or death arising out of the use

of unauthorized replacement parts.

1.5 DISCLAIMER

Gravely reserves the right to discontinue, make

changes to, and add improvements upon its products

at any time without public notice or obligation. The

descriptions and specifications contained in this

manual were in effect at printing. Equipment described

within this manual may be optional. Some illustrations

may not be applicable to your unit.

1.6 TECHNICAL SERVICE

COMMUNICATIONS

Gravely Technical Service communicates information

to the field using Service Letters, Service Bulletins,

Product Notices, and Campaigns. Each

communication signifies a type of information and

priority. The dealer is responsible to carry out the

directive provided in the communication. The types of

communication are:

Service Letter

dealer. Technical information on how to service the

product and product improvements.

Service Bulletin

resolve certain issues or a notification of a policy

change.

Product Notices

located in a certain region. This is a limited distribution

to only those who received the product involved.

Campaigns

products must be updated and are tracked by the

factory until all units are corrected.

- General technical information for the

- Notification to update products to

- Notification of limited product

- Notification of a safety related issue. All

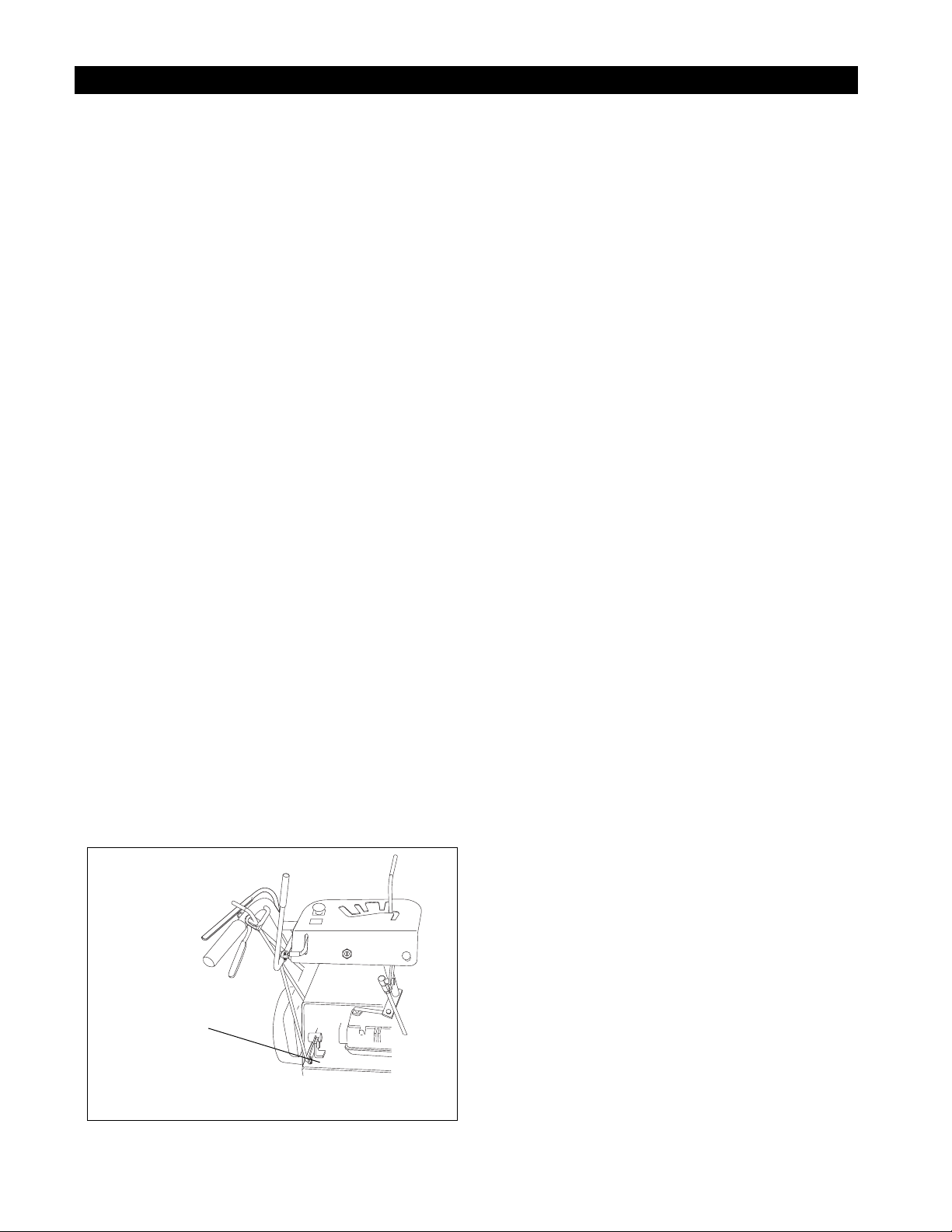

Figure 1

1 - 3

SECTION 2 - SAFETY

2.1 SAFETY ALERTS

Look for these symbols to point out

important safety precautions. They

mean:

Attention!

Personal Safety Is Involved!

Become Alert!

Obey The Message!

2.2 SIGNAL WORDS

The safety alert symbol is used in decals on the unit

and with proper operation procedures in this manual.

They alert you to the existence and relative degree of

hazards.

Understand the safety message. It contains important

information about personal safety on or near the unit.

DANGER:

SITUATION! If not avoided, WILL RESULT in

death or serious injury.

WARNING:

SITUATION! If not avoided, COULD RESULT

in death or serious injury .

CAUTION:

SITUATION! If not avoided, MAY RESULT in

minor or moderate injury. It may also be used

to alert against unsafe practices.

IMMINENTLY HAZARDOUS

POTENTIALLY HAZARDOUS

POTENTIALLY HAZARDOUS

2.3 NOTATIONS

NOTE:

ation and maintenance practices.

IMPORTANT:

required to prevent damage to unit or attachment.

General reference information for proper oper-

Specific procedures o r infor mati on

2.4 PRACTICES AND LAWS

Practice usual and custo mar y safe worki ng

precautions, for the benefit of yourself and others.

Understand and follow all safety messages. Be alert to

unsafe conditions and the possibility of minor,

moderate, or serious injury or death. Learn applicable

rules and laws in your area.

2.5 REQUIRED OPERATOR TRAINING

Original purchaser of this unit was instructed by the

seller on safe and proper operation. If unit is to be used

by someone other than original purchaser; loaned,

rented or sold, AL WAYS provide the Operator’s Manual

and any needed safety training before operation.

2.6 PREPARATION

Before starting any removal of parts, proper

preparation is very important for efficient work. A clean

work area at the start of each job will allow you to

perform service repairs easily and quickly.

To reduce the incidence of misplaced tools or parts,

place removed components with all attaching hardware

in the disassembly order on a clean work surface.

Organization is a key part of proper reassembly.

T ools, instruments, and parts needed for the job should

be gathered before work is started. Interrupting a job to

locate tools or parts is a needless delay. A list of

required special tools has been included in this

manual.

CAUTION:

spillage will occur. Remove battery to prevent

spillage of electrolyte.

Remove enough fuel so that no

2.7 CLEANING AND STORAGE

IMPORTANT:

outdoors.

A unit that is excessively dirty should be cleaned

before work starts. Cleaning will occasionally uncover

trouble sources. Dirt and abrasive dust reduce the

efficient work life of parts and can lead to costly

replacement.

When taking unit out of extended storage:

1. Check for any damage or loose parts. Repair

replace, or tighten hardware before operation.

2. If a preservative fluid was used in fuel tank, drain

and discard. Fill fuel tank with fresh new fuel.

Never spray unit with water or store unit

2.8 SAFETY RULES

Walk Around Inspection

Complete a walk around inspection of unit and work

area to understand:

• Work area.

• Your unit.

• All safety decals.

Work Are a

ALWAYS check overhead and side clearances

carefully before operation. ALWAYS be aware of traffic

when operating along streets or curbs.

ALWAYS keep hands and feet within the limits of the

unit.

Keep children, people, and animals away. Keep

children out of work area and under watchful care of a

responsible adult.

2 - 4

Keep area of operation clear of all toys, pets, and

debris. Objects can cause vehicle instability and injury.

Check for weak spots on dock, ramps or floors. Avoid

uneven work areas and rough terrain. Stay alert for

hidden hazards.

DO NOT run engine in an enclosed area. Always

provide good ventilation.

Unit

ALWAYS keep protective structures, guards, and

panels in good condition, in place and securely

fastened. NEVER modify or remove safety devices.

Check Safety Interlock System for proper operation

daily (see Operation section). Do not operate unless

system operates properly.

Operation

Understand:

• How to operate all controls

• The functions of all controls

• How to STOP in an Emergency

• Speed ranges

Do not operate any of the control levers or power takeoff unless both feet are resting on the platform.

DO NOT travel at too fast a rate. DO NOT change

engine governor settings or over-speed engine.

Always back up slowly. Always look down and behind

before and while backing.

Never leave a running unit unattended. ALWAYS shut

off power take off, lower throttle setting, and stop

engine before leaving unit. ALWAYS remove key to

prevent unauthorized use.

Never carry passengers on any part of unit.

Avoid uneven and rough terrain. DO NOT operate near

drop offs, ditches, or embankments. Unit can suddenly

turn over if a wheel is over the edge of a cliff or ditch, or

if an edge caves in.

If tires lose traction, turn off power take off and proceed

slowly straight down slope. Avoid wet surfaces.

Avoid parking on a slope. If necessary, use wheel

chocks.

DO NOT leave unit unattended on a slope. ALWAYS

use wheel chocks when leaving unit.

ALWAYS operate unit in good visibility and light.

Fuel is highly flammable and its vapors can explode.

Use ONLY approved fuel containers.

NO Smoking!

NO Sparks!

NO Flames!

Allow engine to cool before servicing.

NEVER fill fuel tank when engine is running, hot, or unit

is indoors.

Abnormal Vibrations are a warning of trouble. Striking a

foreign object can damage unit. Immediately stop unit

and engine. Remove key and wait for all moving parts

to stop. Remove wire from spark plug. Inspect unit and

make any necessary repairs before restart.

Hazardous Slopes

DO NOT operate on steep slopes. Avoid operating on

slopes. When you must operate on a slope, travel up

and down the slope. Never operate across a slope.

Never operate on a slope greater than 10 degrees.

Child Safety

NEVER allow children to operate or play on or near

unit. Be alert and shut off unit if children enter area.

Personal Safety

Read and obey all warning, caution, and instructions

on the unit and in provided manuals.

• Only trained adults may operate unit.

• Training includes actual operation.

• Clearly understand instructions.

• Be alert! Conditions can change.

NEVER operate unit after or during the use of

medication, drugs or alcohol. Safe operation requires

your complete and unimpaired attention at all times.

NEVER allow anyone to operate the unit when their

alertness or coordination is impaired.

DO NOT operate unit without wearing adequate outer

garments. Wear adequate safety gear and protective

gloves. Wear proper footwear to improve footing on

slippery surfaces.

Protect eyes, face, and head from objects that may be

thrown from unit. Wear appropriate hearing protection.

Avoid Sharp Edges. Sharp edges can cut. Moving

parts can cut or amputate fingers or a hand. Wear

gloves to service unit when handling sharp edges.

ALWAYS keep hands away from any pinch points.

ALWAYS keep hands and feet away from all moving

parts during operation. Moving parts can cut off body

parts.

DO NOT touch unit parts which might be hot from

operation. Allow parts to cool before attempting to

maintain, adjust, or service.

Controls

Come to a complete stop before reversing.

Never jerk the control levers. Always use a steady

even action to achieve smooth control.

Always be aware of obstructions that may cause injury

to operator or damage to the unit.

2 - 5

Service Position

WARNING:

that jack stands or blocks used are stable,

strong, or secure and will hold the weight of

the unit during maintenance.

WARNING:

body parts. Keep hands and feet away. Loose

clothing, long hair or scarves can get caught

in rotating parts and cause death or serious

injury.

Place unit on flat, level surface. ALW AYS stop engine

and disengage clutches. Assure unit is secure and will

not tip over. Strap and clamp onto lift, if used.

To ensure the unit is positioned in the proper service

position:

1. Place jack stands under rear transaxles only.

2. If jacks are not available, place support blocks

under both transaxles at the rear of unit.

CAUTION:

spills will occur.

ALWAYS block wheels and know

ROTATING PARTS can amputate

Remove enough fuel so that no

meeting applicable local, state or federal laws. A spark

arrester, if used, must be maintained in effective

working order by the operator.

Battery

Avoid Electric Shock. DO NOT reverse battery

connections.

Explosive Gases! Poisonous battery fluid contains

sulfuric acid and its contact with skin, eyes, or clothing

can cause severe burns.

No flames. No sparks. No smoking near battery.

Always wear safety glasses and protective gear near

battery.

DO NOT TIP battery beyond a 45

direction.

ALWAYS KEEP BATTERIES OUT OF REACH of

children.

o

angle in any

Transport

Use extra care when loading or unloading unit onto

trailer or truck. Secure unit chassis to transport vehicle.

NEVER secure from rods or linkages that could be

damaged.

DO NOT transport with attachment in raised position.

Lower attachment when unit is parked or stored unless

a positive mechanical lock is used.

Maintenance

ALWAYS maintain unit in safe operating condition.

Damaged or worn out muffler can cause fire or

explosion.

Check the conditions of the unit at the end of each day

and repair any damage or defects.

ALWAYS block wheels and know all jack stands are

strong and secure and will hold weight of unit during

maintenance.

Keep nuts and bolts tight and keep equipment in safe

operating conditions.

Before maintenance, adjustments, or service (except

where specifically recommended), shut off engine.

Allow hot parts to cool.

Keep unit free of dirt, stones, and other debris. Clean

up oil or fuel spills.

Storage

DO NOT store unit inside a building with fuel in the fuel

tank where any ignition sources are present. Allow unit

to cool completely.

ALWAYS clean unit before extended storage. See

Engine Manual for proper storage.

Attachments and Accessories

Use only attachments or accessories designed for your

unit.

2.9 CLEAN UNIT

Brush grass, dirt and debris off of unit with a soft brush.

Clean packed grass out from under mower deck. Apply

paint or oil to exposed, bare metal surfaces to prevent

rust.

Inspect unit for visible signs of wear, breakage, or

damage. Order any parts required and make

necessary repairs to avoid delays when beginning use

again.

Clean seat regularly, using a non-solvent cleaner.

Extreme temperatures can damage seat when left

unprotected against weather. If seat should tear, apply

vinyl repair tape to protect damaged area.

Transaxle cooling fins must be kept clean to prevent

damage from overheating. Use a cloth or brush to

remove grass, chaff and debris.

Unless there are indications of leakage, transaxle does

not have to be checked for proper oil level. If leak

occurs, have it repaired by your Gravely Dealer.

Spark Arrester

This product is equipped with an internal combustion

engine. DO NOT use on or near any unimproved,

forest covered or brush covered land unless the

exhaust system is equipped with a spark arrester

2 - 6

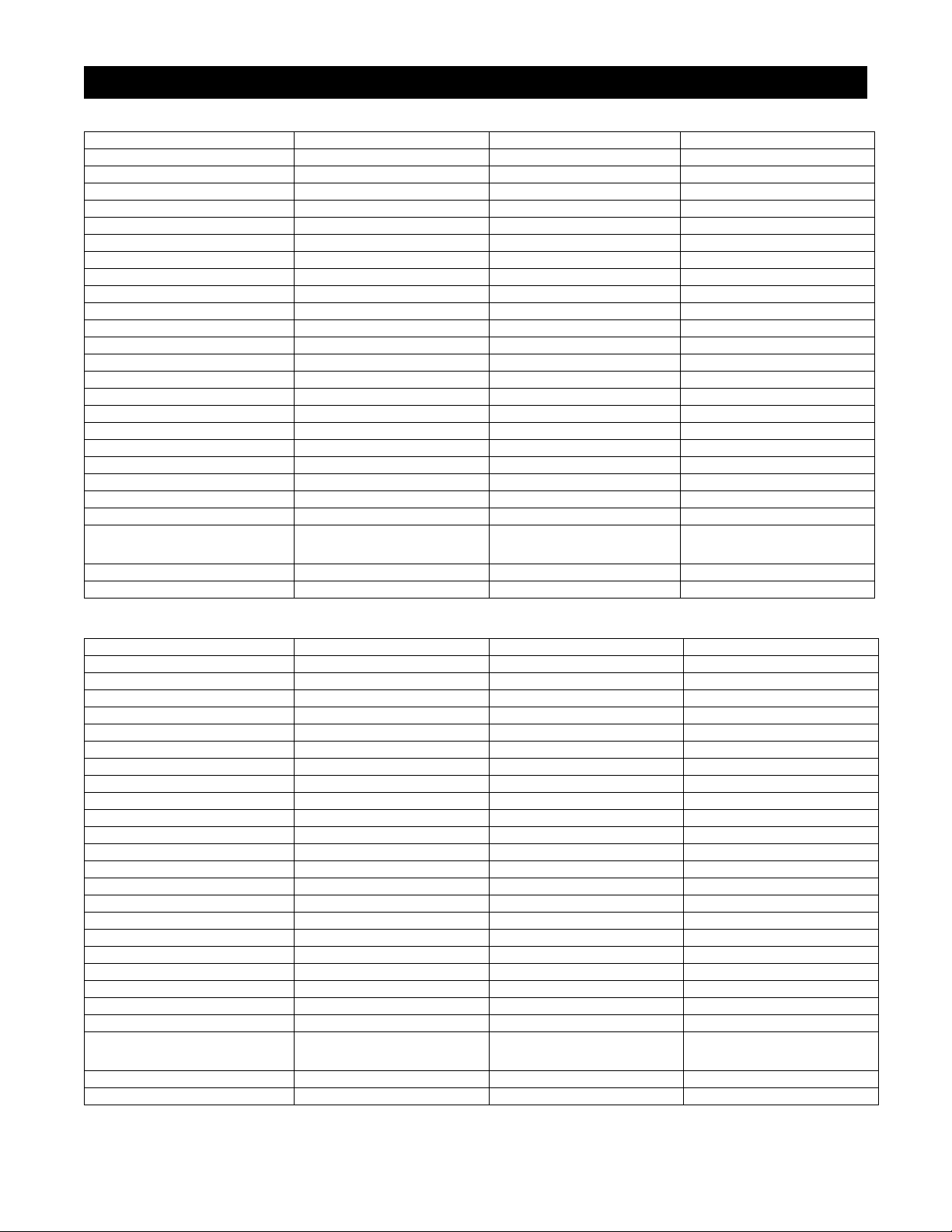

SECTION 3 - SPECIFICATIONS

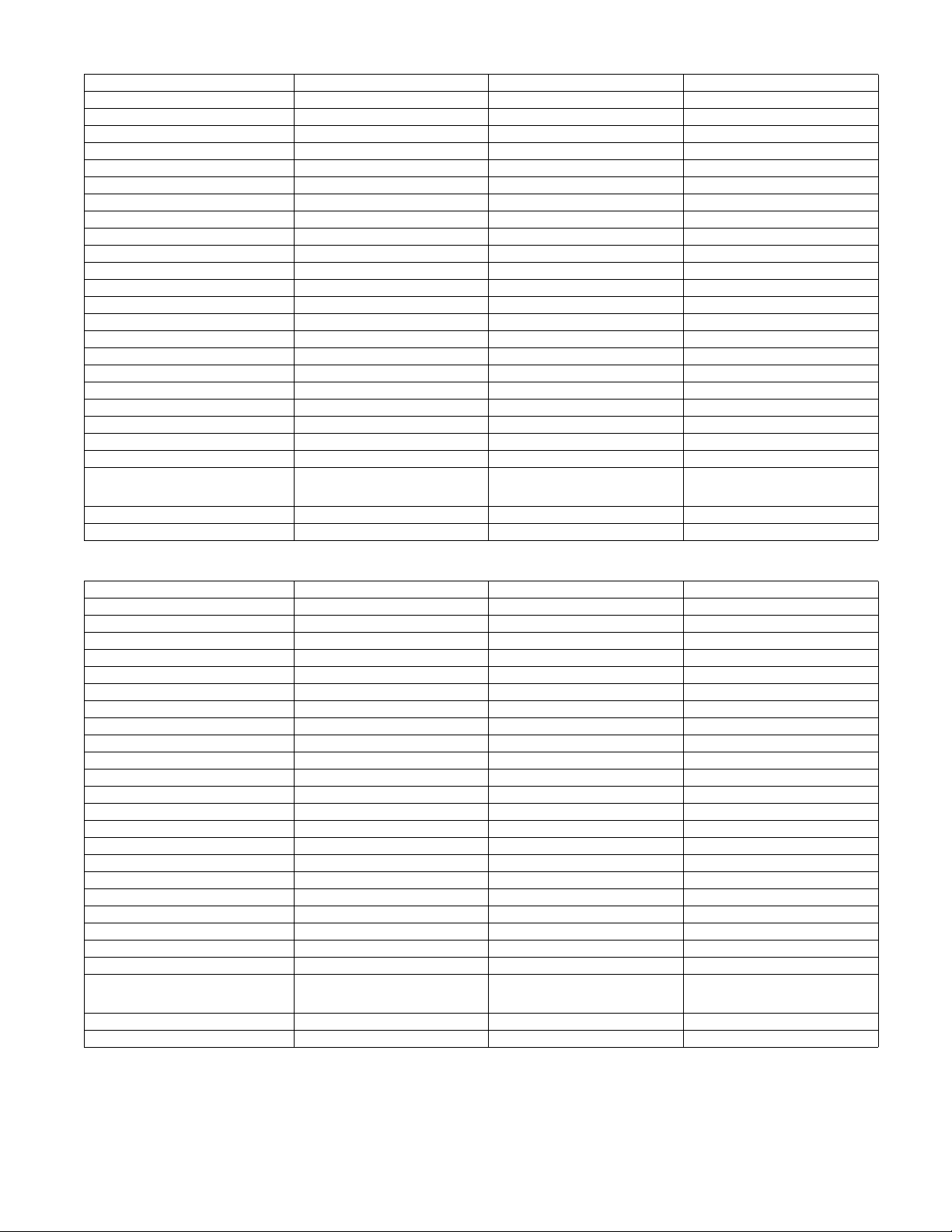

Model Type Pro 100 Pro 100 Pro 150

Model Number 988001 988002 988059

Manufacture Briggs & Stratton Kawasaki Kawasaki

Horsepower 12 HP 12.5 HP 14 HP

Engine Spec. No. 281702-902512 FB 460V AS20 FC 420V-ES 15

Fuel Unleaded Unleaded Unleaded

Fuel Tank Cap. 3 gal. (11.4L) 3 gal. (11.4L) 4.5 gal. ( 17L)

Fuel Filter P/N 040742 040742 040742

Engine Oil SAE 30 10W 30 SAE 30

Crankcase Cap. 4 pts. (1.9L) 3 pts. (1.4L) 3 pts. (1.4L)

Engine Oil Filter N/A 20777000 20777000

Governed RPM 3300 RPM 3300 RPM 3600 RPM

Air Cleaner w/Foam Precleaner N/A 042926 Paper Element

Brakes & Steering 6 " Band/Drum 6 " Band/Drum 6 " Band/Drum

Tire Size Front 13 x 5.00-6 (4 Ply) 13 x 5.00-6 (4 Ply) 13 x 6-6 (2 Ply)

Tire Pressure 12 to 15 psi 12 to 15 psi 12 tp 15 psi

Transmission Tecumseh Pro Line 700-032 Tecumseh Pro Line 700-032 Peerless 700-032

Speed-Forw. Max 5.4 mph (8.7 kph) 5.4 mph (8.7 kph) 5.2 mph (8.4 kph)

Reverse Max. Assist Assist 3 mph (4.8 kph)

Transmission Lube Sealed Sealed Sealed

Spark Plug Champion Champion Champion

Type RC19 LM RCJ-8 RN 11 YC

Spark Plug Gap 0.03 0.024-0.028 0.028-0.031

Wheel Drive Belt

(Matched Set)

Traction Drive Belt 049270 049270 04927

PTO Belt 041963 041963 N/A

07225800 07225800 07225800

Model Type Pro 150 Pro150 Pro 150

Model Number 988060 988069 988070

Manufacture Kawasaki Kohler Kohler

Horsepower 12.5 HP 14 HP 15 HP

Engine Spec. No. FB 460V-DS20 PS-1411 PS-41532

Fuel Unleaded Unleaded Unleaded

Fuel Tank Cap. 4.5 gal. (17L) 4.5 gal. (17L) 4.5 gal. (17L)

Fuel Filter P/N 040742 040742 040742

Engine Oil SAE 30 SAE 30/10W30 10W 30

Crankcase Cap. 3 pts. (1.4L) 3 pts. (1.4L) 3 pts. (1.4L)

Engine Oil Filter 20777000 N/A 042366

Governed RPM 3300 RPM 3600 RPM 3600 RPM

Air Cleaner w/Foam Precleaner Paper Element Paper Element Paper Element

Brakes & Steering 6 " Band/Drum 6 " Band/Drum 6 " Band/Drum

Tire Size Front 13 x 6-6 (2 Ply) 13 x 6-6 (4 Ply) 13 x 6-6 (4 Ply)

Tire Pressure 12 to 15 psi 12 to 15 psi 12 to 15 psi

Transmission Tecumseh Pro Line 700-032 Tecumseh Pro Line 700-032 Peerless 700-032

Speed-Forw. Max 5.2 mph (8.4 kph) 5.2 mph (8.4 kph) 5.2 mph (8.4 kph)

Reverse Max. 3 mph (4.8 kph) 3 mph (4.8 kph) 3 mph (4.8 kph)

Transmission Lube Sealed Sealed Sealed

Spark Plug Champion Cham pi on Champion

Type RN J-8 RC 12 YC RC 12 YC

Spark Plug Gap 0.024-0.028 0.04 0.04

Wheel Drive Belt

(Matched Set)

Traction Drive Belt 049270 049270 049270

PTO Belt N/A N/A N/A

07225800 07225800 07225800

3 - 7

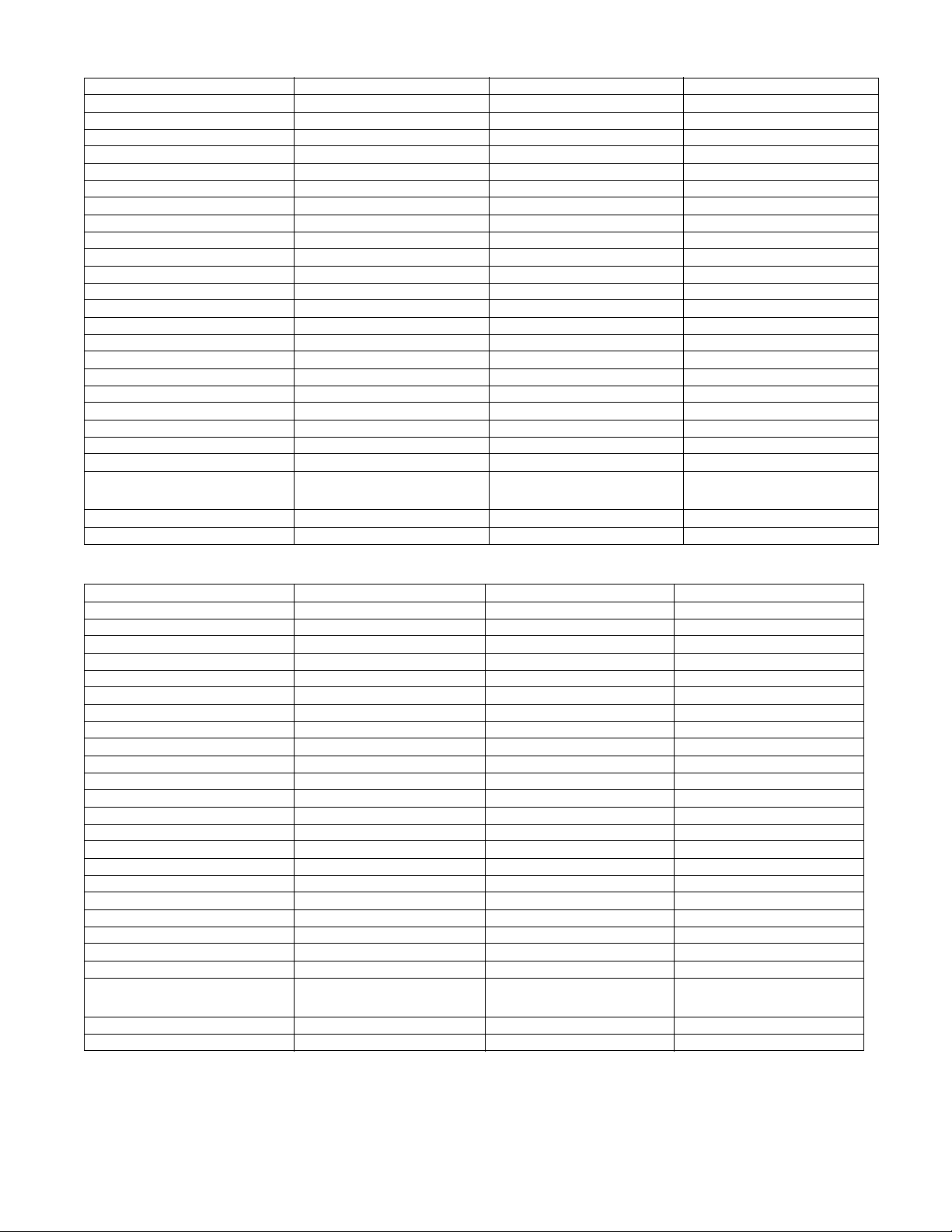

Model Type Pro 150 Pro 150 Pro 150

Model Number 988074 988075 988077

Manufacture Kohler Kawasaki Kawasaki

Horsepower 12.5 HP 12.5 HP 14 HP

Engine Spec. No. PS-1283 FB 460V-DS20 GS01 FC 420V-ES 15

Fuel Unleaded Unleaded Unleaded

Fuel Tank Cap. 4.5 gal. (17L) 4.5 gal. (17L) 4.5 gal. (17L)

Fuel Filter P/N 040742 040742 040742

Engine Oil 10W30 SAE 30 SAE 30

Crankcase Cap. 3 pts. (1.4L) 3 pts. (1.4L) 3 pts. (1.4L)

Engine Oil Filter 042366 20777000 20777000

Governed RPM 3600 RPM 3300 RPM 3300 RPM

Air Cleaner w/Foam Precleaner Paper Element Paper Element Paper Element

Brakes & Steering 6 " Band/Drum 6 " Band/Drum 6 " Band/Drum

Tire Size Front 13 x 6.-6 (4 Ply) 13 x 6-6 (4 Ply) 13 x 6-6 (4 Ply)

Tire Pressure 12 to 15 psi 12 to 15 psi 12 to 15 psi

Transmission Peerless 700-032 Peerless 700-032 Peerless 700-032

Speed-Forw. Max 5.2 mph (8.4 kph) 5.2 mph (8.4 kph) 5.2 mph (8.4 kph)

Reverse Max. 3 mph (4.8 kph) 3 mph (4.8 kph) 3 mph (4.8 kph)

Transmis si on Lub e Sealed Sealed Sealed

Spark Plug Champion Champion Champion

Type RC 12 YC RCJ-8 RN 11 YC

Spark Plug Gap 0.040 0.024-0.028 0.028-0.031

Wheel Drive Belt

(Matched Set)

Traction Drive Belt 049270 049270 049270

PTO Belt N/A N/A N/A

07225800 07225800 07225800

Model Type Pro 150 Pro 150 Pro 150

Model Number 988078 988079 988088

Manufacture Kohler Kohler Kawasaki

Horsepower 12.5 HP 15 HP 14 HP

Engine Spec. No. PS-1283 PS-41532 FC 420V-ES 15

Fuel Unleaded Unleaded Unleaded

Fuel Tank Cap. 4.5 gal. (17L) 4.5 gal. (17L) 4.5 gal. (17L)

Fuel Filter P/N 040742 040742 040742

Engine Oil 10W 30 10W 30 SAE 30

Crankcase Cap. 3 pts. (1.4L) 3 pts. (1.4L) 3 pts. (1.4L)

Engine Oil Filter 042366 042366 20777000

Governed RPM 3300 RPM 3300 RPM 3300 RPM

Air Cleaner w/Foam Precleaner Paper Element Paper Element Paper Element

Brakes & Steering 6 " Band/Drum 6 " Band/Drum Foam Precleaner

Tire Size Front 13 x 6.00-6 (4 Ply) 13 x 6.00-6 (4 Ply) 6 " Band/Drum

Tire Pressure 12 to 15 psi 12 to 15 psi 13 x 6.00-6 (2 Ply)

Transmission Peerless 700-032 Peerless 700-032 12 to 15 psi

Speed-Forw. Max 5.2 mph (8.4 kph) 5.2 mph (8.4 kph) Peerless 700-079

Reverse Max. 3 mph (4.8 kph) 3 mph (4.8 kph) 5.2 mph (84 kph)

Transmission Lube Sealed Sealed 3 mph (4.8 kph)

Spark Plug Champion Champion Sealed

Type RC 12 YC RC 12 YC Champion

Spark Plug Gap 0.04 0.04 RN 11 YC

Wheel Drive Belt

(Matched Set)

Traction Drive Belt 049270 049270 07225800

PTO Belt N/A N/A N/A

07225800 07225800 0.028-0.031

3 - 8

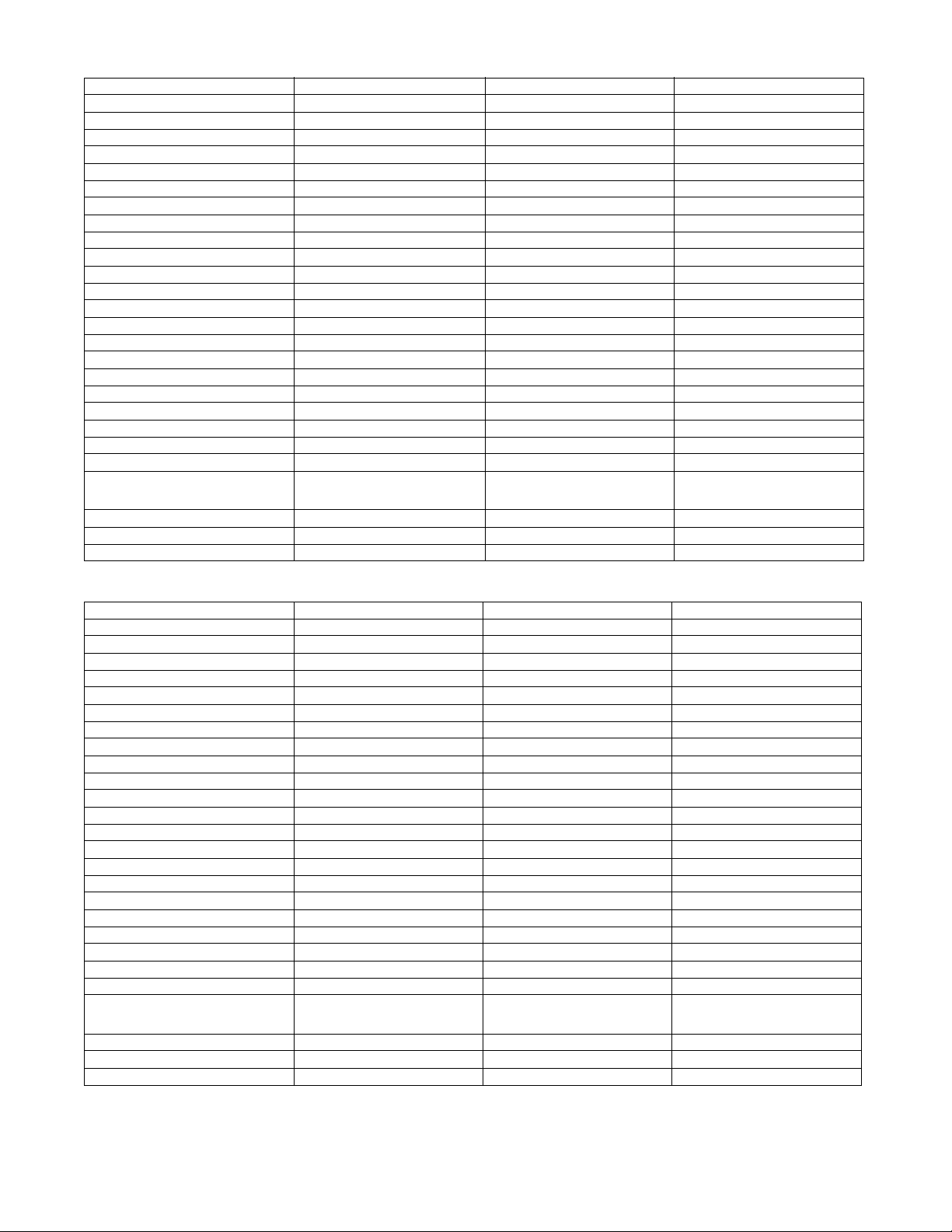

Model Type Pro 150 Pro 150 Pro 200

Model Number 988091 988309 988003

Manufacture Kawasaki Kawasaki Kawasaki

Horsepower 12.5 HP 10.9 HP 12.5 HP

Engine Spec. No. FB 460V DS20 GS01 FC 420V ES15 FB 460V AS20

Fuel Unleaded Unleaded Unleaded

Fuel Tank Cap. 4.5 gal. (17L) 4.5 gal. (17L) 3 gal. (11.4L)

Fuel Filter P/N 040742 040742 040742

Engine Oil SAE 30 SAE 30 SAE 30

Crankcase Cap. 3 pts. (1.4L) 3 pts. (1.4L) 3 pts. (1.4L)

Engine Oil Filter 20777000 20777000 20777000

Governed RPM 3300 RPM 2950 RPM 3300 RPM

Air Cleaner w/Foam Precleaner Paper Element Paper Element Paper Element

Brakes & Steering Foam Precleaner 6 " Band/Drum 6 " Band/Drum

Tire Size Front 6 " Band/Drum 13 x 6.50-6 (4 Ply) 13 x 6.50-6 (4 Ply)

Tire Pressure 13 x 6.00-6 (4 Ply) 12 to 15 psi 12 to 15 psi

Transmission 12 to 15 psi Tecumseh Pro Line 700-079 Tecumseh Pro Line 700-052

Speed-Forw. Max Peerless 700-079 5.2 mph (8.4 kph) 5.4 mph (8.7 kph)

Reverse Max. 5.2 mph (8.4 kph) 3 mph (4.8 kph) 1.8 mph (2.9 kph)

Transmission Lube 3 mph (4.8 kph) Sealed Sealed

Spark Plug Sealed Champion Champion

Type Champion RN 11 YC RCJ-8

Spark Plug Gap RCJ - 8 0.028-0.031 0.024 - 0.028

Wheel Drive Belt

(Matched Set)

Traction Drive Belt 07225800 049270 052776

PTO Belt N/A N/A 07225000

0.024-0.028 07225800 049029

Model Type Pro 200 Pro 200 Pro 200

Model Number 988004 988005 988006

Manufacture Kohler Kohler Kawasaki

Horsepower 14 HP 16 HP 17 HP

Engine Spec. No. PS - 1411 PS - 56518 FC 540V AS04

Fuel Unleaded Unleaded Unleaded

Fuel Tank Cap. 3 gal. (11.4L) 3 gal. (11.4L) 3 gal. (11.4L)

Fuel Filter P/N 040742 040742 040742

Engine Oil 10W 30 10W 30 SAE 30

Crankcase Cap. 4 pts. (1.9L) 4 pts. (1.9L) 3 pts. (1.4L)

Engine Oil Filter 042366 042366 20777000

Governed RPM 3300 RPM 3300 RPM 3300 RPM

Air Cleaner w/Foam Precleaner Paper Element Paper Element Paper Element

Brakes & Steering 6 " Band/Drum 6 " Band/Drum 6 " Band/Drum

Tire Size Front 13 x 6.50-6 (4 Ply) 13 x 6.50-6 (4 Ply) 13 x 6.50-6 (4 Ply)

Tire Pressure 12 to 15 psi 12 to 15 psi 12 to 15 psi

Transmission Tecumseh Pro Line 700-052 Tecumseh Pro Line 700-052 Tecumseh Pro Line 700-052

Speed-Forw. Max 5.4 mph (8.7 kph) 5.4 mph (8.7 kph) 5.4 mph (8.7 kph)

Reverse Max. 1.8 mph (2.9 kph) 1.8 mph (2.9 kph) 1.8 mph (2.9 kph)

Transmission Lube Sealed Sealed Sealed

Spark Plug Champion Champion Champion

Type RC 12 YC RC 12 YC RN 11 YC

Spark Plug Gap 0.04 0.035 0.028-0.031

Wheel Drive Belt

(Matched Set)

Traction Drive Belt 052776 052776 052776

PTO Belt 07225000 07225000 07225000

049029 049029 049029

3 - 9

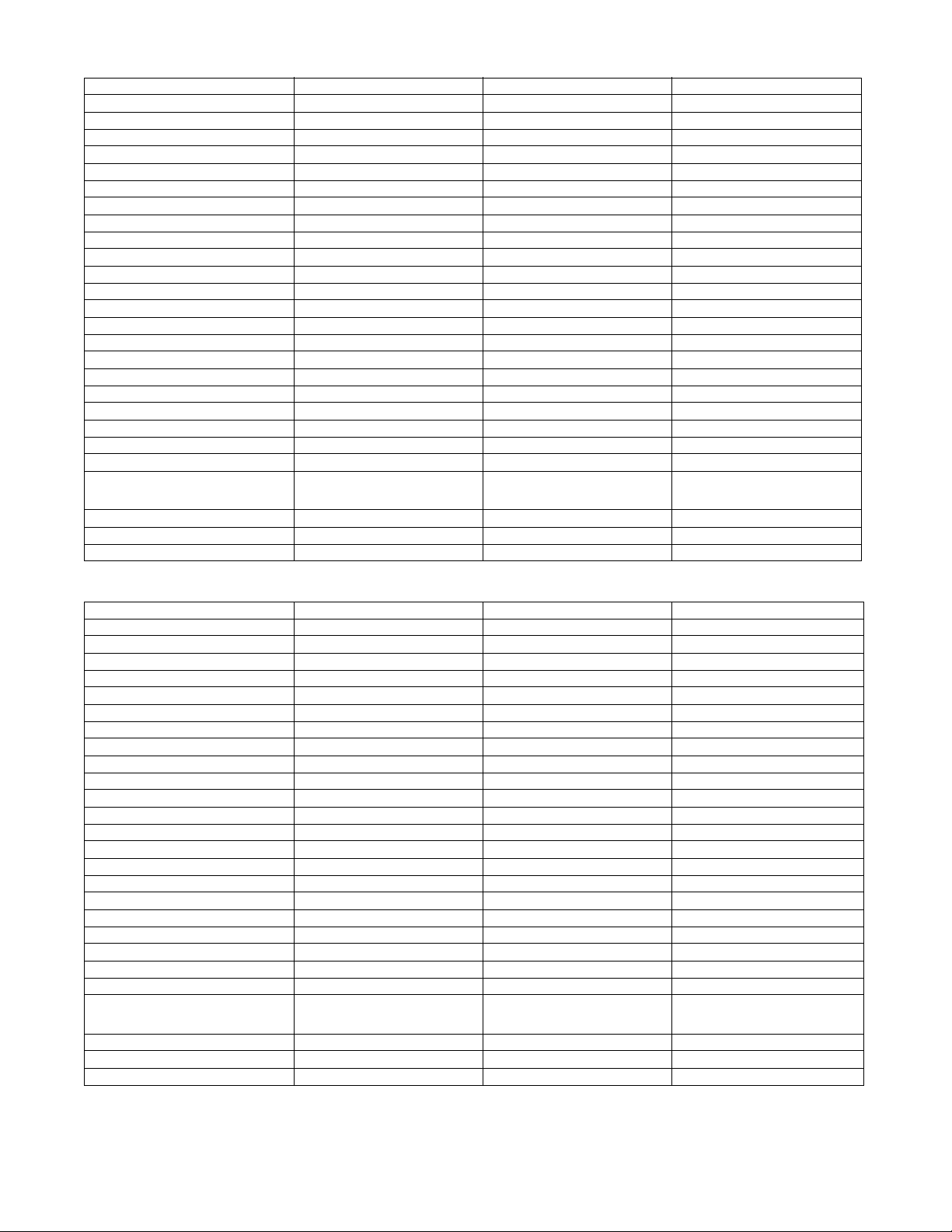

Model Type Pro 200 Pro 200 Pro 200

Model Number 988007 988062 988063

Manufacture Kohler Kawasaki Briggs & Stratton

Horsepower 18 HP 14 HP 16 HP

Engine Spec. No. PS - 58516 FC 420V AS15 303777 - 0138

Fuel Unleaded Unleaded Unleaded

Fuel Tank Cap. 3 gal. (11.4L) 3.5 gal. (13.3L) 3.5 gal. (13.3L)

Fuel Filter P/N 040742 040742 040742

Engine Oil 10W 30 SAE 30 SAE 30/10W30

Crankcase Cap. 4 pts. (1.9L) 3.4 pts. (1.4L) 4 pts. (1.9L)

Engine Oil Filter 042366 20777000 N/A

Governed RPM 3300 RPM 3300 RPM 3600 RPM

Air Cleaner w/Foam Precleaner Paper Element Paper Element Paper Element

Brakes & Steering 6 " Band/Drum 6 " Band/Drum 6 " Band/Drum

Tire Size Front 13 x 6.50-6 (4 Ply) 13 x 6.50-6 (4 Ply) 13 x 6.50-6 (4 Ply)

Tire Pressure 12 to 15 psi 12 to 15 psi 12 to 15 psi

Transmission Tecumseh Pro Line 700-052 Tecumseh Pro Line 700-052 Tecumseh Pro Line 700-052

Speed-Forw. Max 5.4 mph (8.7 kph) 5.4 mph (8.7 kph) 5.4 mph (8.7 kph)

Reverse Max. 1.8 mph (2.9 kph) 1.8 mph (2.9 kph) 1.8 mph (2.9 kph)

Transmission Lube Sealed Sealed Sealed

Spark Plug Champion Champion Champion

Type RC 12 YC RN 11 YC RC 14 YC

Spark Plug Gap 0.035 0.028-0.031 0.03

Wheel Drive Belt

(Matched Set)

Traction Drive Belt 052776 052776 052776

PTO Belt 07225000 07225000 07225000

Battery 041358 041358 041358

049029 049029 049029

Model Type Pro 200 Pro 200 Pro 200

Model Number 988071 988072 988080

Manufacture Kohler Kohler Kohler

Horsepower 15 HP 18 HP 15 HP

Engine Spec. No. PS-41532 PS61527 CV 15T PS-41532

Fuel Unleaded Unleaded Unleaded

Fuel Tank Cap. 3.5 gal. (13.3L) 3.5 gal. (13.3L) 3.5 gal. (13.3L)

Fuel Filter P/N 040742 040742 040742

Engine Oil 10W 30 10W 30 10W 30

Crankcase Cap. 4 pts. (1.9L) 2.1 pts. (2L) 4 pts. (1.9L)

Engine Oil Filter 042366 042366 042366

Governed RPM 3300 RPM 3300 RPM 3300 RPM

Air Cleaner w/Foam Precleaner Paper Element Paper Element Paper Element

Brakes & Steering 6 " Band/Drum 6 " Band/Drum 6 " Band/Drum

Tire Size Front 13 x 6.50-6 (4 Ply) 13 x 6.50-6 (4 Ply) 13 x 6.50-6 (4 Ply)

Tire Pressure 12 to 15 psi 12 to 15 psi 12 to 15 psi

Transmission Tecumseh Pro Line 700-052 Tecumseh Pro Line 700-052 Tecumseh Pro Line 700-052

Speed-Forw. Max 5.4 mph (8.7 kph) 5.4 mph (8.7 kph) 5.4 mph (8.7 kph)

Reverse Max. 1.8 mph (2.9 kph) 1.8 mph (2.9 kph) 1.8 mph (2.9 kph)

Transmission Lube Sealed Sealed Sealed

Spark Plug Champion Champion Champion

Type RC 12 YC RC 12 YC RC 12 YC

Spark Plug Gap 0.04 0.03 0.04

Wheel Drive Belt

(Matched Set)

Traction Drive Belt 052776 052776 052776

PTO Belt 07225000 07225000 07225000

Battery 041358 041358 041358

049029 049029 049029

3 - 10

Model Type Pro 200 Pro 200 Pro 200

Model Number 988081 988082 988085

Manufacture Briggs & Stratton Kohler Robin

Horsepower 16 HP 18 HP 18 HP

Engine Spec. No. 303777-0138 CV 18S PS-61527 EH 63 V

Fuel Unleaded Unleaded Unleaded

Fuel Tank Cap. 3.5 gal. (13.3L) 3.5 gal. (13.3L) 3.5 gal. (13.3L)

Fuel Filter P/N 040742 040742 040742

Engine Oil SAE/10W 30 10W 30 10W 30

Crankcase Cap. 4 pts. (1.9L) 2.1 pts. (2L) 4 pts. (1.9L)

Engine Oil Filter N/A 042366 21527000

Governed RPM 3600 RPM 3300 RPM 3300 RPM

Air Cleaner w/Foam Precleaner Paper Element Paper Element Paper Element

Brakes & Steering 6 " Band/Drum 6 " Band/Drum 6 " Band/Drum

Tire Size Front 13 x 6.50-6 (4 Ply) 13 x 6.50-6 (4 Ply) 13 x 6.00-6 (2 Ply)

Tire Pressure 12 to 15 psi 12 to 15 psi 12 to 15 psi

Transmission Tecumseh Pro Line 700-052 Tecumseh Pro Line 700-052 Tecumseh Pro Line 700-052

Speed-Forw. Max 5.4 mph (8.7 kph) 5.4 mph (8.7 kph) 5.4 mph (8.7 kph)

Reverse Max. 1.8 mph (2.9 kph) 1.8 mph (2.9 kph) 1.8 mph (2.9 kph)

Transmission Lube Sealed Sealed Sealed

Spark Plug Champion Champion NGK

Type RC 14 YC RC 12 YC Part # 21526900

Spark Plug Gap 0.03 0.03 0.03

Wheel Drive Belt

(Matched Set)

Traction Drive Belt 052776 052776 052776

PTO Belt 07225000 07225000 07225000

Battery 041358 041358 041358

049029 049029 049029

Model Type Pro 200

Model Number 988087

Manufacture Kawasaki

Horsepower 14 HP

Engine Spec. No. FC 420V-ES 15

Fuel Unleaded

Fuel Tank Cap. 3.5 gal. (13.3L)

Fuel Filter P/N 040742

Engine Oil SAE 30

Crankcase Cap. 4 pts. (1.9L)

Engine Oil Filter 20777000

Governed RPM 3300 RPM

Air Cleaner w/Foam Precleaner Paper Element

Brakes & Steering 6 " Band/Drum

Tire Size Front 13 x 6.00-6 (2 Ply)

Tire Pressure 12 to 15 psi

Transmission Tecumseh Pro Line 700-052

Speed-Forw. Max 5.4 mph (8.7 kph)

Reverse Max. 1.8 mph (2.9 kph)

Transmission Lube Sealed

Spark Plug Champion

Type RN 11 YC

Spark Plug Gap 0.028-0.031

Wheel Drive Belt

(Matched Set)

Traction Drive Belt 052776

PTO Belt 7225000

Battery 041358

049029

3 - 11

SECTION 4 - GENERAL MAINTENANCE & ADJUSTMENTS

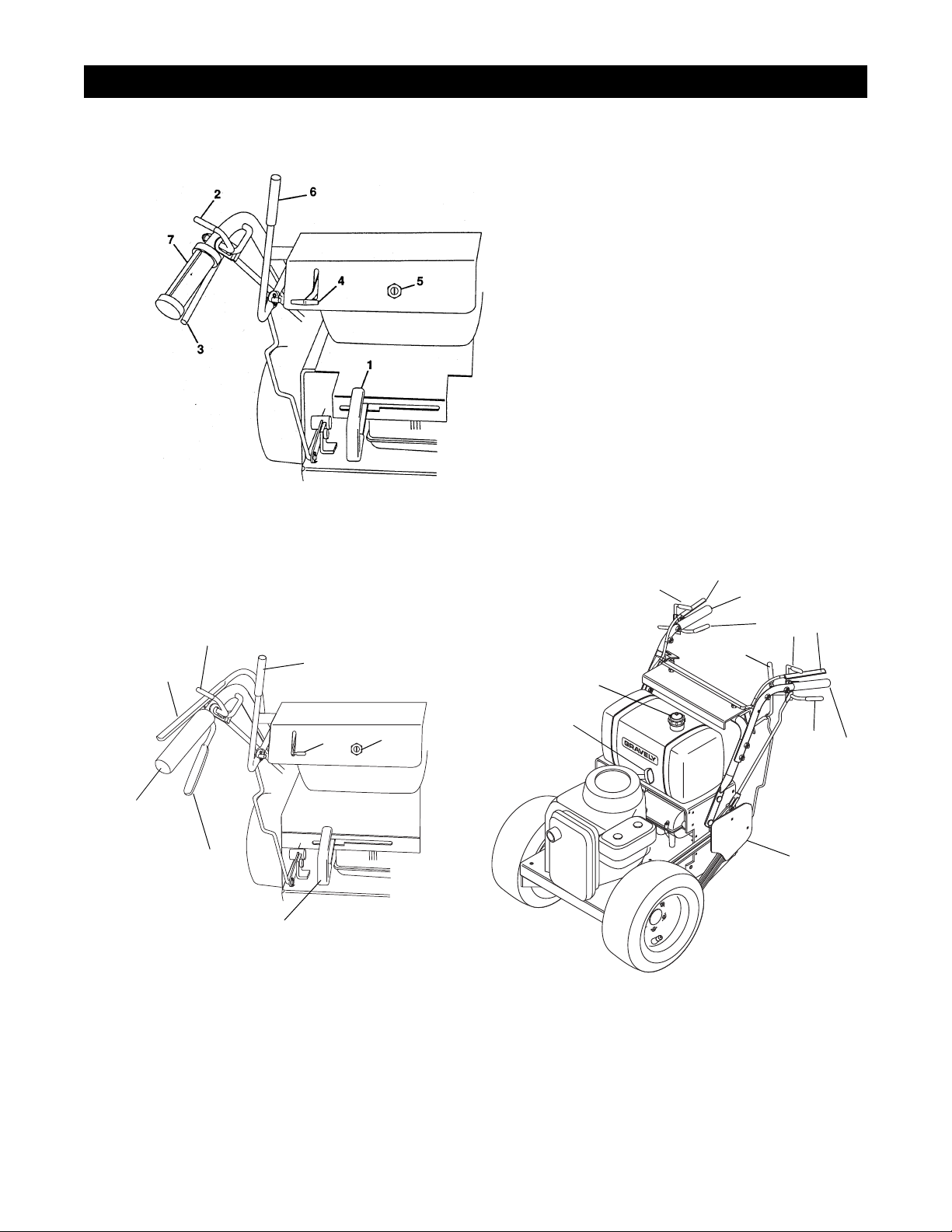

4.1 CONTROLS AND FEATURES

Pro 100

1. Shift Lever

2. Steering Lever Latch

3. Steering Lever

4. Throttle-Choke Lever

5. Ignit ion Switch

6. PTO Lever

7. Operator Presence Controls

Figure 2 - Pro 100

11

2

2

7

3

6

4

1

5

Pro 150

8

9

OG0741

7

11

3

6

7

2

3

11

10

OG1131

1. Shift Lever

2. Steering Lever Latches

3. Steering Levers

4. Throttle-Choke Lever

5. Ignition Switch

6. PTO Lever

7. Operator Presence Controls

8. Fuel Cap

9. Recoil Starter Handle

10.Traction Belt Guard

Figure 3 - Pro 150

4 - 12

Pro 200

6

2

7

9

10

1

3

1. Shift Lever

2. Steering Lever Latch

3. Steering Lever

4. Throttle-Choke Lever

5. Ignition Switch

6. PTO Lever (recoil start models)

7. Operator Presence Control

4

8. Transmission Shifter Rod

9. PTO Switch (electric start models)

10. Hour Meter (electric start models)

11. Choke Control (electric start models)

Figure 4 - Pro 200

5

11

8

4 - 13

4.2 FILLING THE FUEL TA NK

WARNING:

flammable. Keep fuel in a clean and tight

container. Keep fuel away from fire and heat.

Never put fuel in the fuel tank while the engine

is running or hot. Clean up any spilled fuel

before starting the engine.

Add fuel to the fuel tank as needed. See your engine

manual for the correct type and grade of fuel to be

used.

1. Put the unit in an open and well ventilated area

prior to refueling.

2. Stop the engine.

3. Allow the engine to cool.

4. Clean the fuel cap and in the area around the fuel

cap. Remove the cap from the fuel tank.

5. Fill the fuel tank with the proper grade of fuel

recommended by the engine manufacturer. Be

careful not to spill any fuel.

6. Install fuel cap on the fuel tank and tighten.

7. Clean up any spilled fuel before starting engine.

Use caution with fuel. Fuel is very

4.3 GENERAL LUBRICATION

Apply a small amount of oil to the pivot points as

required for smooth and proper operation.

Every 8 hours of operation, add Sten Mix Hi-Temp

Grease or equivalent to the lube fittings, in each of the

wheel hubs. After every 8 hours of operation, apply a

small amount of oil to the drive chain.

4.4 CHECKING FASTENERS

Each day before operating, check all nuts, bolts, and

other fasteners. Replace fasteners that are missing or

damaged.

4.5 CHECK TIRES

Keep tires properly inflated at all times. The correct air

pressure is 12 to 15 psi 83 to 103 kN/m

2

. After

checking and/or inflating, replace and tighten valve

caps to prevent air loss.

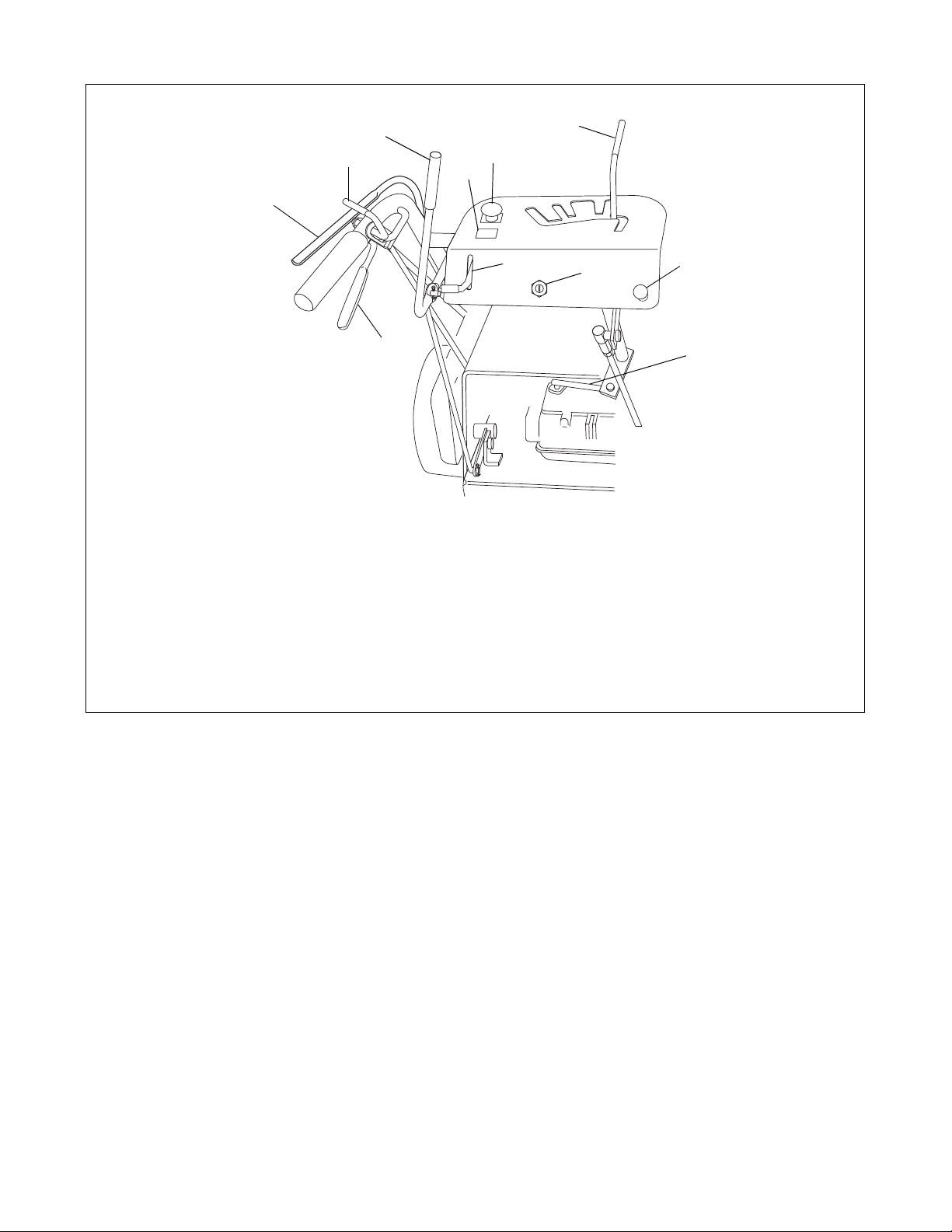

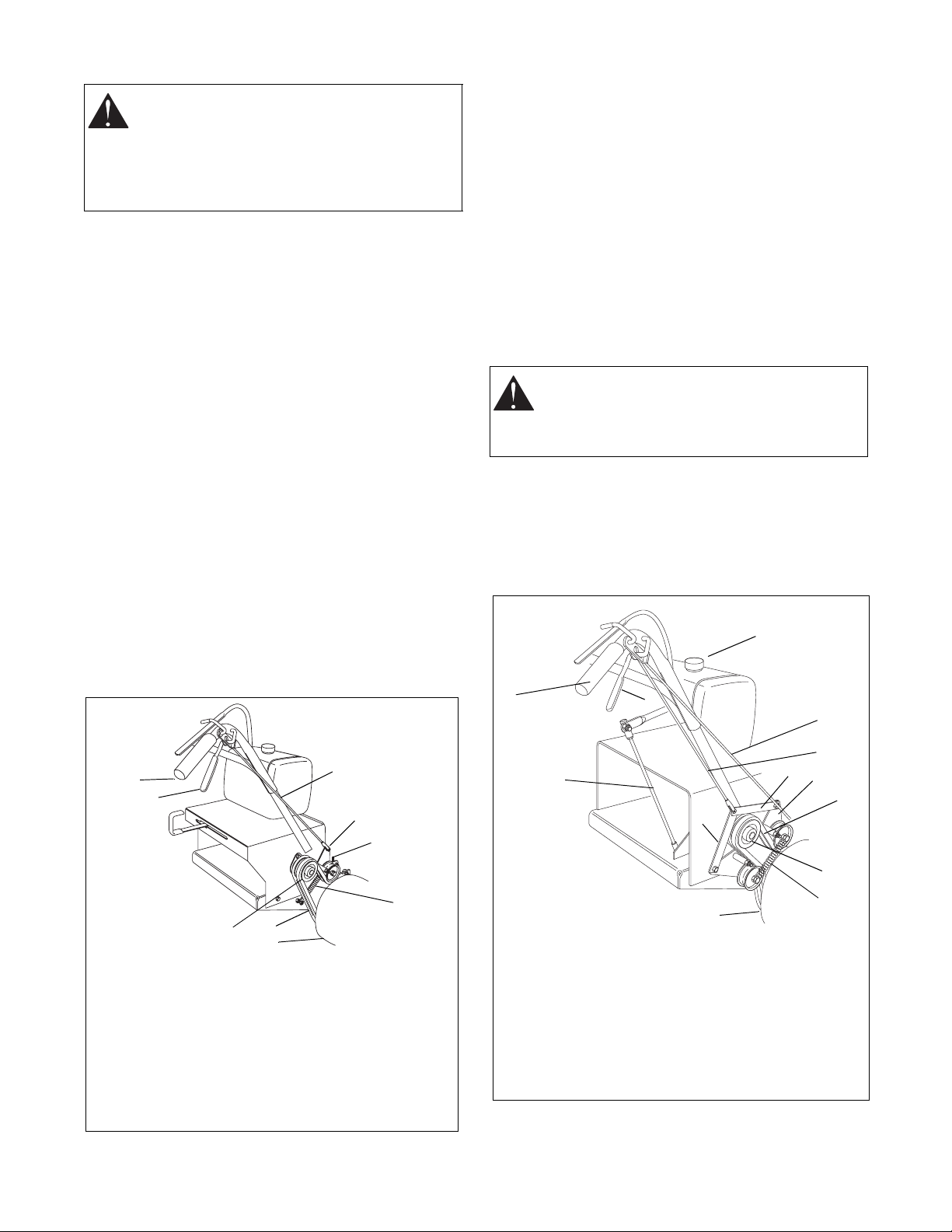

4.6 THE STEERING LEVERS

The steering levers are used to steer the unit. Pull up

on the left hand lever to turn to the left. Pull up on the

right lever to turn to the right. Holding both levers up

stops the unit. See Figures 5 and 6.

WARNING:

When the engine is running and

transmission is in gear, holding only one

steering lever up will cause the unit to circle

around one drive wheel.

4.7 THE STEERING LEVER LATCHES

The steering lever latches are used to hold the steering

levers in the up position. Engaging both steering lever

latches will free one of the operator’s hands for a

throttle adjustment, etc. (see Figures 2 and 3).

10

1

2

6

1. Handlebar

2. Steering Lever

3. Wheel Clutch

Actuating Rod

4. Wheel Clutch Arm

Weldment

5. Brake Rod

8

9

Figure 5

3

4

5

7

6. Transmission Shaft

Pulley

7. Clutch Idler Pulley

Spring

8. Traction Belt (Pro 200

shown - Pro 100 has

one belt)

9. Drive Wheel

OG0751

1

11

1. Handlebar

2. Steering Lever

3. Brake Rod

4. Clutch Rod

5. Jack-Shaft Pulley

6. Clutch Actuating Strap

7. Traction Belt

Figure 6 - Pro 200

2

3

4

6

12

7

6

8

9

8. Clutch Idler Pulley

Spring

9. Drive Wheel

10. Fuel Cap

11. Clutch Actuating Rod

12. Wheel Clutch Arm

Weldment

5

4 - 14

Loading...

Loading...