Gravely Pro 150, 988088, 988091, 988092, 988309 Owner's/operator's Manual

Pro 150

Owner/Operator Manual

Model

988088

988091

988092

988309

ENGLISH

FRANÇAIS

ESPAÑOL

08478400A 10/00

Supercedes 08478400

Printed in USA

Ariens Company

655 West Ryan Street

P.O. Box 157

Brillion, Wisconsin 54110-0157

U.S.A.

Telephone (920) 756-2141

Facsimile (920) 756-2407

MODEL CERTIFICATE OF CONFORMITY ISSUED BY THE MANUFACTURER

CERTIFICAT DE CONFORMITÉ DU MODÈLE DÉLIVRÉ PAR LE FABRICANT

MODELL-KONFORMITÄTSBESTÄTIGUNG AUSGESTELLT DURCH DEN HERSTELLER

MODELCERTIFICAAT VAN OVEREENSTEMMING AFGEGEVEN DOOR DE FABRIKANT

CERTIFICATO DI COMFORMITÀ DEL MODELLO RILASCIATO DAL PRODUTTORE

CERTIFICADO DE CONFORMIDAD DEL MODELO PROVISTO POR EL FABRICANTE

MODEL KONFORMITETS ERKLÆRING UDSTEDT AF FABRIKANTEN

MODELLSERTIFIKAT FOR OVERENSSTEMMELSE UTSTEDT AV FABRIKANT TILLVERKERENS

TILLVERKARENS MODELLCERTIFIKAT OM ÖVERENSSTÄMMELSE

VALMISTAJAN ANTAMA VAKUUTUS MALLIN MÄÄRÄYSTEN MUKAISUUDESTA

We the undersigned, - Je soussigné, - Mit meiner Unterschrift - De ondergetekende, - Il sottoscritto, - El abajo firmante,

Undertegnede, - Undertecknaren av detta dokument, - Me, allekirjoittaneet,

ARIENS COMPANY, certify that the riding rotary lawnmower - certifie que les tondeuse rotative autoportée - bestätige ich, daß der

Mäher - verklaart dat de Grasmaaimachine - certifica che le i trattorino con unità di taglio rotativa - certifica que el Cortacésped

giratorio para pasajeros - certificamos que o minitractor cortador de grama com lâminas giratórias - bevidner herved at Selvkørende

rotations græsslåmaskine - bevitner at gressklippertraktor - intygar att intygar att åkrotorklippare - vakuutamme, että lumilinko

Ajoleikkuri:

Category: WIDE-AREA COMMERCIAL

Make and Trade Name: GRA

Model:

988309 with 888301

VELY

WALK-BEHIND ROTARY MOWER

Serial # Range: From – To 000101 – 000999

conform to the specifications of directive 98/37/EC, and council directive 84/538/EEC as amended by 87/252/EEC, 83/180/EEC and 88/181/EEC,

and EC directive (EMC) 89/336/EEC as amended by EC directive 92/31/EEC.

sont conformes aux spécifications de la directive 98/37/EEC et la directive du conseil Européen numéro 84/538/EEC révisée par les directives 87/

252/EEC, 83/180/EEC et 88/181/EEC et de la directive EC (EMC) 89/336/EEC modifiée par la directive EC 92/31/EEC.

den Spezifikationen der Direktive 98/37/EEC, sowie der Ratsdirektive 84/538/EEC, modifiziert durch die Direktiven 87/252/EEC, 83/180/EEC und

88/181/EEC, sowie der EU-Direktive (EMC) 89/336/EEC, modifiziert durch die EU-Directive 92/31/EEC, entspricht.

in overeenstemming zijn met de specificaties van richtlijn 98/37/EEG, en richtlijn 84/538/EEG van de raad, zoals gewijzigd door 87/252/EEG, 83/

180/EEG en 88/181/EEG, en EC richtlijn (EMC) 89/336/EEC zoals gewijzigd door EC richtlijn 92/31/EEC.

sono conformi alla direttiva CEE 98/37 e alla direttiva del Consiglio Europeo CEE 84/538, emendata dalle direttive CEE 87/252, 83/180 e 88/181, e

la direttiva CE (EMC) CEE 89/336, emendata dalla direttiva CEE 92/31.

conforme a las especificaciones de la directiva 98/37/CEE, y la directiva del consejo europeo número 84/538/CEE modificada en las directivas 87/

252/CEE, 83/180/CEE y 88/181/CEE, y la directiva EC (EMC) 89/336/EEC reformada por la directiva EC 92/31/EEC.

opfylder specifikationerne i direktiv 98/37/EEC og rådets direktiv 84/538/EEC med ændringer i 87/252/EEC, 83/180/EEC og 88/181/EEC, og EC direktiv

(EMC) 89/336/EEC med ændringer i EC direktiv 92/31/EEC.

Enheten oppfyller spesifikasjonene i direktiv 98/37/EEC og rådets direktiv 84/538/EEC med endringer i 87/252/EEC, 83/180/EEC og 88/181/EEC, og

EC direktiv (EMC) 89/336/EEC med endringer i EC direktiv 92/31/EEC.

är i överensstämmelse med specifikationerna i direktiv 98/37/EEC, samt rådsdirektiv 84/538/EEC, med ändringar i 87/252/EEC, 83/180/EEC och 88/

181/EEC, och EC direktiv (EMC) 89/336/EEC med ändringar i EC direktiv 92/31/EEC.

On valmistettu 98/37/EEC, mukään. Ja neuvostori määräysten, 84/538/EEC tarkennettu 87/252/EEC, 83/180/EEC ja 88/181/EEC mukaan, ja EC

määräysten (EMC) 89/336/EEC tarkennettu määräysten EC 92/31/EEC mukaan.

Certifiying Laboratory to 84/538/EEC - TUV Rheinland.

F

ebruary 1, 1999

Date/Datum/Data/

Fecha/Dato/Päiväys

Manufacturers of Printed in U.S.A. 10-00

Outdoor Power Equipment

Manager of Product Conf

Position/Qualité/Stilling/Functie/Qualifica/

Puesto/Stilling/Funktie/Titel/Arvo

ormance

Signature/Unterschrift/Handtekening/Firma/

Underskrift/Underskrift Handlekening/

Underskrift/Allekirjoitus

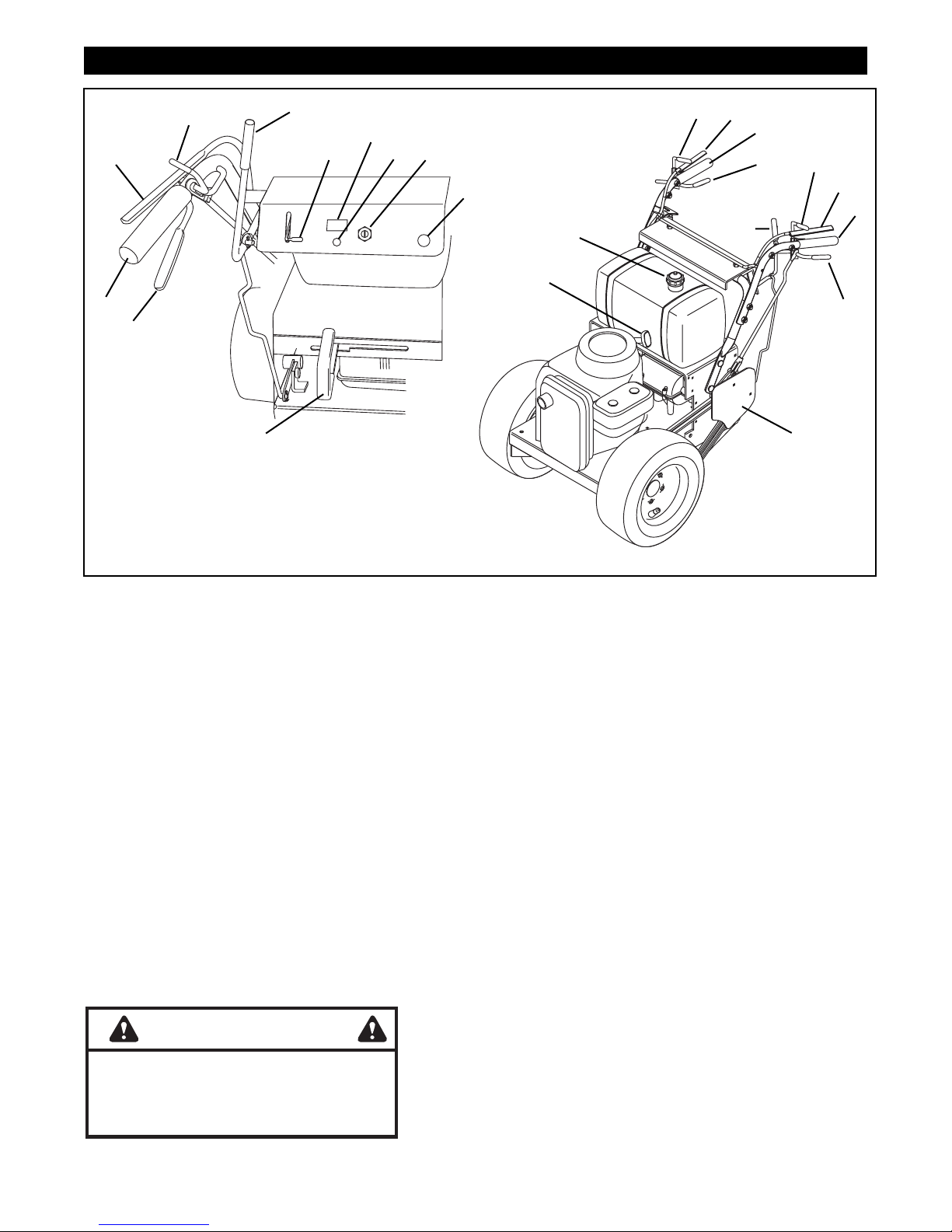

CONTROLS AND FEATURES

11

2

6

13

7

4

14

5

2

7

11

3

2

7

12

11

8

6

9

3

3

1

OG0741

Figure 1

10

OG1131

ENGLISH

1. Shift Lever

2. Steering Lever Latches

3. Steering Levers

4. Throttle-Choke Lever

5. Ignition Switch

6. PTO Lever

7. Operator Presence

Controls

8. Fuel Cap

9. Recoil Starter Handle

10. Traction Belt Guard

11. Handlebar

12. Choke Control (Electric

Start Models)

13. Hourmeter (Electric Start

Models)

14. Oil Light (Electric Start

Models)

WARNING

FRANÇAIS

1. Levier de vitesses

2. Verrouillage des poignées

de direction

3. Leviers de direction

4. Manette des gaz – Starter

5. Clé de contact

6. Commande de la PdF

7. Commandes de présence

de l’opérateur

8. Bouchon du réservoir

de carburant

9. Poignée du démarreur

à cordon

10. Garant de courroie

de transmission

11. Guidon

12. Commande du starter

(Modèles à démarreur

électrique)

13. Compteur horaire

(Modèles à démarreur

électrique)

14. Voyant de l’huile

(Modèles à démarreur

ESPAÑOL

1. Palanca de cambios

2. Trabas de las palancas

de la dirección

3. Palancas de dirección

4. Palanca del aceleradorestrangulador

5. Interruptor de encendido

6. Palanca de la TDF

7. Controles de presencia

del operador

8. Tapón del combustible

9. Manilla de arranque de

retroceso

10. Protección de la correa

de tracción

11. Manillar

12. Control de

estrangulamiento

(modelos con

arranque eléctrico)

13. Batería (modelos de

arranque eléctrico)

14. Luz del aceite (modelos

de arranque eléctrico)

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

OL4030

3

TABLE OF CONTENTS

Controls and Features. . . . . . . . . . . . . . . . . . . . . 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Service and Adjustments . . . . . . . . . . . . . . . . . 13

INTRODUCTION

THE MANUAL

Before operation of unit, carefully and completely read

your manuals. The contents will provide you with an

understanding of safety instructions and controls

during normal operation and maintenance.

All reference to left, right, front, or rear are given from

operator standing in operation position and facing the

direction of forward travel.

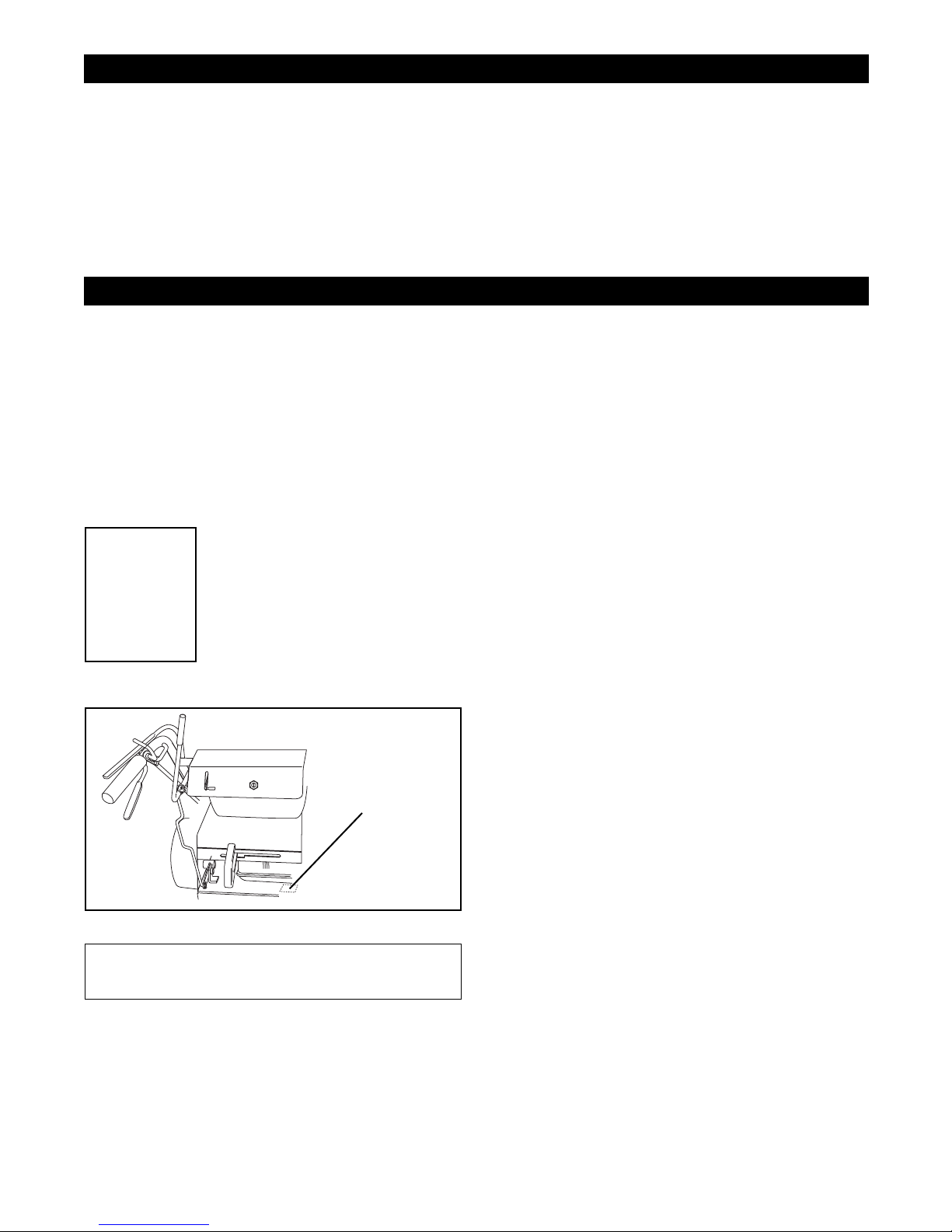

MODEL AND SERIAL NUMBERS

When ordering replacement parts

Transfer

model & serial

number label

from product

registration

here.

• Record Engine Model and Serial numbers here.

or making service inquiries, know

the Model and Serial numbers of

your unit and engine.

Numbers are located on the product

registration form in the unit literature

package. They are also printed on a

serial number label, located on the

frame of your unit.

Serial

Number

Label

OG1031

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 17

Accessories and Attachments . . . . . . . . . . . . . 18

Service Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

UNAUTHORIZED REPLACEMENT PARTS

Use only Gravely replacement parts. The replacement

of any part on this vehicle with anything other than a

Gravely authorized replacement part may adversely

affect the performance, durability, or safety of this unit

and may void the warranty. Gravely disclaims liability

for any claims or damages, whether warranty, property

damage, personal injury or death arising out of the use

of unauthorized replacement parts.

DISCLAIMER

Gravely reserves the right to discontinue, make

changes to, and add improvements upon its products

at any time without public notice or obligation.The

descriptions and specifications contained in this

manual were in effect at printing. Equipment described

within this manual may be optional. Some illustrations

may not be applicable to your unit.

DEALER DELIVERY

Dealer should:

1. Check all controls for proper function.

2. Check the safety interlock system to make sure

that it is functioning properly. (See Operation .)

3. Fill out Original Purchaser Registration Card and

return the card to Gravely.

4. Explain Limited Warranty Policy.

5. Explain recommended lubrication and

maintenance. Advise customer on adjustments.

6. Instruct customer on controls and operation of

unit. Discuss and emphasize the Safety

Precautions. Give customer Owner/Operator,

Parts, and Engine Manuals. Advise customer to

thoroughly read and understand them.

PRODUCT REGISTRATION

A warranty registration card must be filled out, signed,

and returned at time of purchase. This card activates

the warranty. Claims meeting requirements during

limited warranty period will be honored.

GB - 4

OL4370

SAFETY

SAFETY ALERTS

Look for these symbols to point out

important safety precautions. They mean:

Attention!

Personal Safety Is Involved!

Become Alert!

Obey The Message!

The safety alert symbols above and signal words below

are used on decals and in this manual.

Read and understand all safety messages.

DANGER: IMMINENTLY HAZARDOUS

SITUATION! If not avoided, WILL RESULT in

death or serious injury.

WARNING: POTENTIALLY HAZARDOUS

SITUATION! If not avoided, COULD

RESULT in death or serious injury.

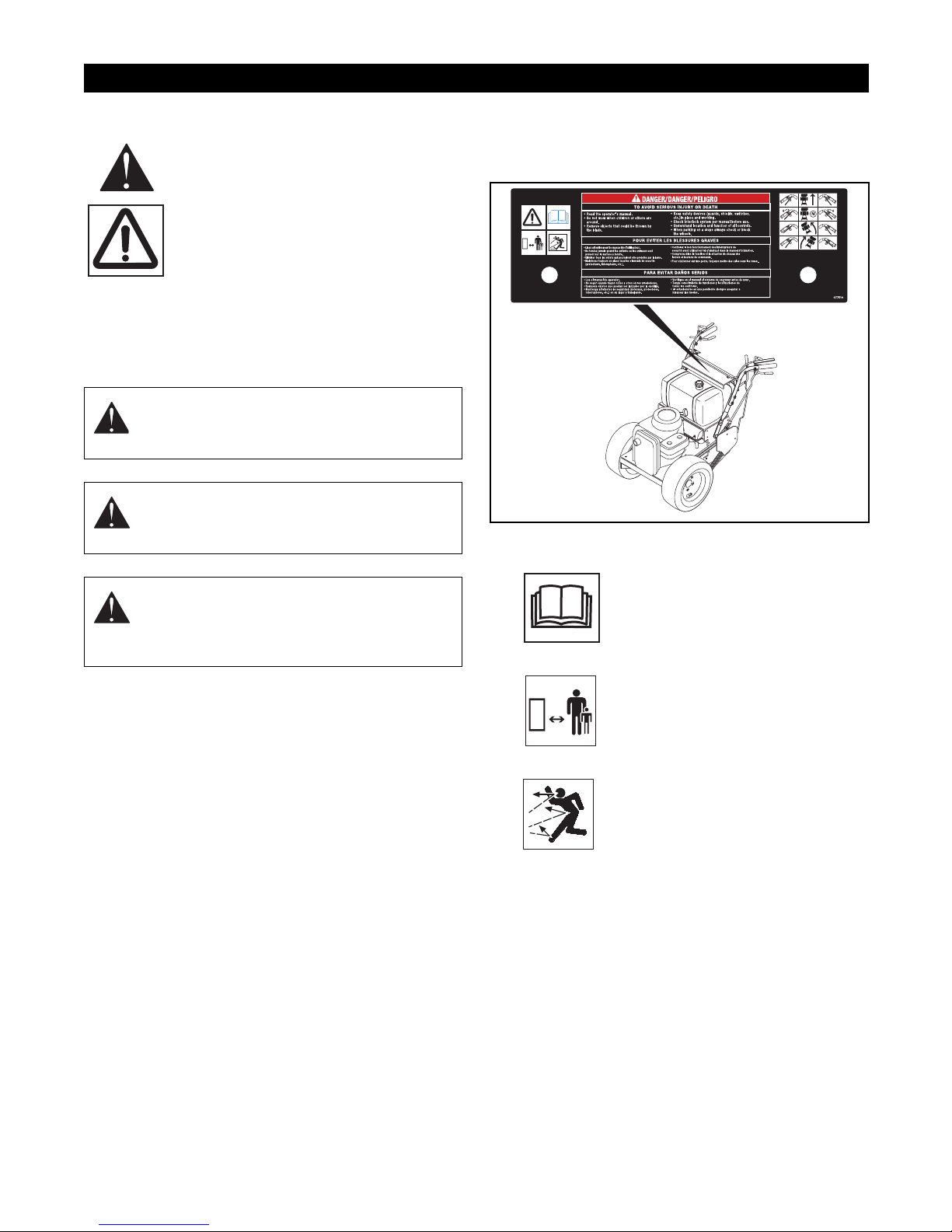

SAFETY DECALS AND LOCATIONS

ALWAYS replace missing or damaged Safety Decals.

Refer to figure below for Safety Decal locations.

1

OG1081

1. DANGER! To avoid serious injury or death

CAUTION: POTENTIALLY HAZARDOUS

SITUATION! If not avoided, MAY RESULT in

minor or moderate injury. It may also be

used to alert against unsafe practices.

NOTATIONS

NOTE: General reference information for proper

operation and maintenance practices.

IMPORTANT: Specific procedures or information

required to prevent damage to unit or attachment.

PRACTICES AND LAWS

Practice usual and customary safe working

precautions, for the benefit of yourself and others.

Understand and follow all safety messages. Be alert to

unsafe conditions and the possibility of minor,

moderate, or serious injury or death. Learn applicable

rules and laws in your area.

REQUIRED OPERATOR TRAINING

Original purchaser of this unit was instructed by the

seller on safe and proper operation. If unit is to be used

by someone other than original purchaser; loaned,

rented or sold, ALWAYS provide this manual and any

needed safety training before operation.

Read the operator’s manual.

OL1801

Keep children and others away from

unit while operating.

Never direct discharge toward other

people. Thrown objects can cause

injury.

OL0910

• Keep all controls, guards and safety

shields properly serviced and functional.

• Check interlock system per manual before

use.

• Understand location and function of all

controls.

• Never allow operation by untrained

persons.

• When parking on a slope always chock or

block the wheels.

GB - 5

OPERATIONAL SAFETY RULES

Walk Around Inspection

Complete a walk around inspection of unit and work

area to understand:

• Work area

• Your unit

• All safety decals

Work Area

ALWAYS check overhead and side clearances carefully

before operation.

ALWAYS be aware of traffic when operating along

streets or curbs.

Keep children and people away.

Keep children out of work area and under watchful care

of a responsible adult.

Keep area of operation clear of all toys, pets, and

debris. Thrown objects can cause injury.

Check for weak spots on dock, ramps or floors. Avoid

uneven work areas and rough terrain.

Avoid slippery surfaces. ALWAYS be sure of your

footing.

DO NOT operate on wet grass.

Dust, smoke, fog, etc. can reduce vision and cause an

accident. Operate unit only when there is good visibility

and light.

Personal Safety

• Only trained adults may operate unit

• Training includes actual operation

NEVER allow children to operate or play on or near

unit.

Be alert and shut off unit if children enter area.

Never carry passengers.

NEVER operate unit after or during the use of

medication, drugs or alcohol. Safe operation requires

your complete and unimpaired attention at all times.

NEVER allow anyone to operate this unit when their

alertness or coordination is impaired.

Wear adequate safety gear, protective gloves and

footwear.

NEVER wear open sandals or canvas shoes during

operation.

Protect eyes, face and head from objects that may be

thrown from unit. Wear appropriate hearing protection.

Sharp edges can cut. Moving parts can cut off fingers

or a hand. Wrap blade(s), wear gloves and use extreme

caution when servicing.

IMPORTANT: On multi-blade mowers, rotation of one

blade will cause all blades to rotate.

ALWAYS keep hands and feet away from all rotating

parts during operation. Rotating parts can cut off body

parts.

ALWAYS keep hands away from all pinch points.

DO NOT touch unit parts which might be hot from

operation. Allow parts to cool before attempting to

maintain, adjust or service.

NEVER place your hands or any part of your body or

clothing inside or near any moving part while unit is

running.

DO NOT wear loose clothing or jewelry. Tie back hair

that may get caught in rotating parts.

Keep children and people away from unit during

operation.

Fumes from engine exhaust can cause injury or death.

DO NOT run engine in an enclosed area. Always

provide good ventilation.

Thrown objects can cause injury and property damage.

DO NOT point discharge at anyone or discharge

directly onto paved or gravel surfaces.

Always stand clear of the discharge area when

operating this unit.

Operation

Understand:

• How to operate all controls

• The functions of all controls

• How to STOP in an Emergency

• Braking and steering characteristics

• Turning radius and clearance

ALWAYS keep protective structures, guards, and

panels in good repair, in place and securely fastened.

NEVER modify or remove safety devices.

ALWAYS keep discharge cover or complete grass

catcher in place and in proper working condition.

Check steering control operation frequently. Adjust and

service as required.

Safety Interlock System must function properly. DO

NOT operate unit if operator presence control is

damaged or disabled.

If equipment vibrates abnormally, stop engine at once,

disengage PTO, wait for all moving parts to stop, and

remove key. Check for any damage or loose parts.

Repair before restart.

Before starting engine: disengage PTO and place unit

in neutral.

DO NOT operate at too fast a rate. DO NOT change

engine governor settings or over-speed engine. Slow

down and turn corners slowly.

Disengage PTO when attachment is not in use.

ALWAYS turn off power to attachment when

transporting, crossing driveways, etc.

GB - 6

•

Avoid uneven and rough terrain. DO NOT operate near

drop offs, ditches, or embankments. Unit can suddenly

turn over if a wheel is over the edge of a cliff or ditch, or

if an edge caves in.

DO NOT try to stabilize unit by putting foot on ground

when operating with applicable riding attachments.

When engine is running and speed control lever is

forward, holding only one steering lever will cause unit

to circle around one drive wheel.

ALWAYS disengage PTO, stop unit and engine,

remove key and allow moving parts to stop before

leaving operator’s position.

Never leave a running unit unattended. ALWAYS shut

off engine before leaving unit.

ALWAYS remove key to prevent unauthorized use.

DO NOT operate in reverse unless absolutely

necessary. ALWAYS backup slowly. ALWAYS look

down and behind, before and while backing.

Hazardous Slopes

DO NOT operate on steep slopes. DO NOT operate on

slopes of more than 10°. Operate across the face of

slopes, not up and down.

Keep all movement on slopes slow and gradual. DO

NOT make sudden changes in speed or direction. Use

a slow speed to avoid stopping or shifting on slopes.

Avoid starting or stopping on a slope.

DO NOT park unit on a slope unless absolutely

necessary. When parking on a slope always chock or

block wheels.

Transport

Use extra care when loading or unloading unit onto

trailer or truck.

Secure unit chassis to transport vehicle. NEVER

secure from rods or linkages that could be damaged.

DO NOT transport machine while engine is running.

Cleaning

Keep unit free of grass, leaves, or other debris. Clean

up oil or fuel spills.

Spark Arrester

This product is equipped with an internal combustion

engine. DO NOT use on or near any unimproved, forest

covered or brush covered land unless the exhaust

system is equipped with a spark arrester meeting

applicable local, state or federal laws. A spark arrester,

if used, must be maintained in effective working order

by the operator.

FUEL SAFETY RULES

Fuel is highly flammable and its vapors are explosive.

Handle with care. Use an approved fuel container.

No smoking, No sparks, No flames. ALWAYS allow

engine to cool before servicing.

NEVER fill fuel tank when engine is running or hot from

operation.

NEVER fill or drain fuel tank indoors.

Replace fuel cap securely and clean up spilled fuel.

BATTERY SAFETY RULES

Battery posts, terminals and related accessories

contain lead and lead compounds, chemicals known to

the State of California to cause cancer and

reproductive harm. Wash hands after handling.

Reverse connections may cause sparks which may

result in injury. ALWAYS connect/disconnect cables in

proper order.

Poisonous battery fluid contains sulfuric acid and its

contact with skin, eyes, or clothing can cause severe

burns.

Explosive Gases! No flames, No sparks, No smoking

near battery.

ALWAYS wear safety glasses and protective gear near

battery.

DO NOT TIP battery beyond a 45° angle in any

direction.

ALWAYS keep batteries out of reach of children.

Battery Electrolyte First Aid

External Contact: Flush with water.

• Eyes: Flush with water for at least 15 minutes

and get medical attention immediately!

• Internal Contact: Drink large quantities of water.

Follow with Milk of Magnesia, beaten egg or

vegetable oil. Get medical attention immediately!

DO NOT induce vomiting!

MAINTENANCE AND SERVICE SAFETY

RULES

Before making any inspections, repairs, etc.:

disengage PTO, stop unit and engine, remove key,

allow moving parts to stop.

Allow hot parts to cool.

ALWAYS block wheels and know all jack stands are

strong, secure and will hold weight of unit during

maintenance.

ALWAYS maintain unit in safe operating condition.

Damaged or worn out muffler can cause fire or

explosion.

Keep hardware, especially blade attachment bolts,

tight.

STORAGE SAFETY RULES

For unit storage or extended storage:

• NEVER store with fuel in fuel tank, inside a

building where any ignition sources are present.

• Allow engine to cool completely.

GB - 7

Loading...

Loading...