Gravely 260Z User Manual

Promaster 250Z, 260Z, 272Z

Service Manual

992018, 020, 023, 027, 029, 030

992032, 033, 034, 035

09254300A 8/04

Printed in USA

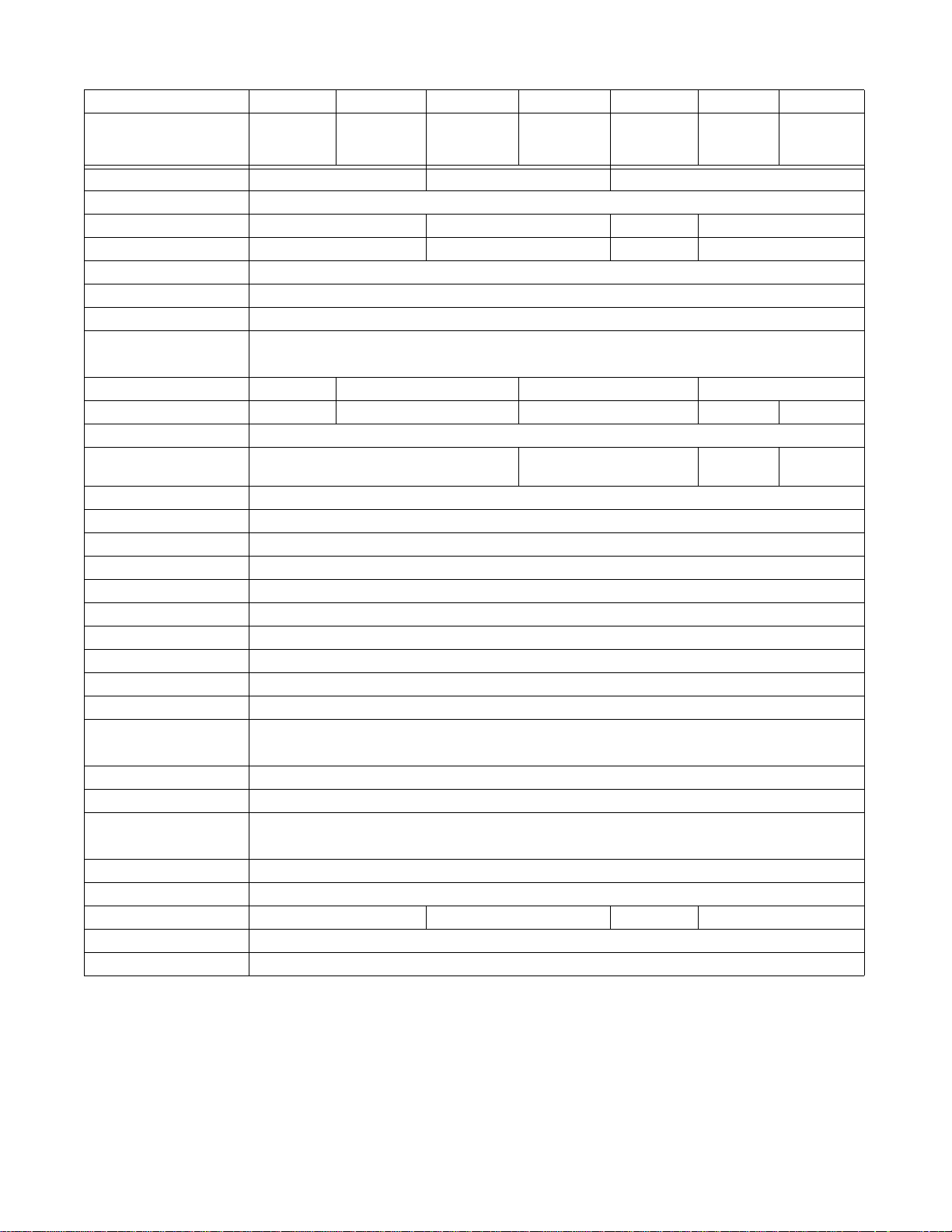

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

The Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Service and Replacement Parts . . . . . . . . . . . . .5

Product Registration . . . . . . . . . . . . . . . . . . . . . .5

Unauthorized Replacement Parts. . . . . . . . . . . .5

Disclaimer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Technical Service Communications . . . . . . . . . .5

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety Alert Symbol . . . . . . . . . . . . . . . . . . . . . .6

Signal Words. . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Notations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Practices and Laws. . . . . . . . . . . . . . . . . . . . . . .6

Required Operator Training . . . . . . . . . . . . . . . .6

Safety Decals And Locations . . . . . . . . . . . . . . .6

Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Controls and Features. . . . . . . . . . . . . . . . . . . . 14

General Maintenance & Adjustments. . . . . . . .15

Maintenance Schedule. . . . . . . . . . . . . . . . . . .15

Service and Adjustments . . . . . . . . . . . . . . . . .16

Service Positions . . . . . . . . . . . . . . . . . . . . . . .16

Moving Unit Manually . . . . . . . . . . . . . . . . . . . .16

Transporting Unit . . . . . . . . . . . . . . . . . . . . . . .17

Starting and Shutting Off the Engine. . . . . . . . .17

Cleaning and Storage . . . . . . . . . . . . . . . . . . . .17

Filling Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . .18

Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

General Lubrication . . . . . . . . . . . . . . . . . . . . .18

Servicing the Battery. . . . . . . . . . . . . . . . . . . . .18

Basic Engine Maintenance . . . . . . . . . . . . . . . .19

Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Mower Blades . . . . . . . . . . . . . . . . . . . . . . . . . .21

Adjusting Control Levers. . . . . . . . . . . . . . . . . .22

Adjusting the Parking Brake . . . . . . . . . . . . . . .22

Adjusting Unit To Track Straight . . . . . . . . . . . .22

Leveling the Mower Deck . . . . . . . . . . . . . . . . .23

Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Engine Troubleshooting . . . . . . . . . . . . . . . . . .24

Removing the Engine . . . . . . . . . . . . . . . . . . . .25

Installing the Engine . . . . . . . . . . . . . . . . . . . . .25

Electric Clutch. . . . . . . . . . . . . . . . . . . . . . . . . .25

Drive Train. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Checking the Hydraulic Fluid Level. . . . . . . . . .26

Changing Hydraulic Fluid and Filter . . . . . . . . .26

Hydraulic Drive Flow Test . . . . . . . . . . . . . . . . .26

Replacing the Hydraulic Pump . . . . . . . . . . . . .27

Replace Wheel Motor . . . . . . . . . . . . . . . . . . . .27

Hydraulic Deck Lift Pressure Test. . . . . . . . . . .28

Replace Lift Valve. . . . . . . . . . . . . . . . . . . . . . .28

Hydraulic Diagram . . . . . . . . . . . . . . . . . . . . . .29

Mower Deck . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Anti-Scalp Rollers . . . . . . . . . . . . . . . . . . . . . . .31

Front Suspension. . . . . . . . . . . . . . . . . . . . . . . . 32

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Electrical Measurements. . . . . . . . . . . . . . . . . .33

Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Solenoid and Relays. . . . . . . . . . . . . . . . . . . . .36

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Diodes and Rectifiers . . . . . . . . . . . . . . . . . . . .36

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . .38

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . .42

2

Ariens Company

655 West Ryan Street

P.O. Box 157

Brillion, Wisconsin 54110-0157

USA

Telephone (920) 756-2141

Facsimile (920) 756-2407

EC DECLARATION OF CONFORMITY ISSUED BY THE MANUFACTURER –

DÉCLARATION DE CONFORMITÉ CE ÉMISE PAR LE FABRICANT – EUÜBEREINSTIMMUNGSERKLÄRUNG DES HERSTELLERS – VERKLARING VAN

OVEREENSTEMMING VOOR DE EU, AFGEGEVEN DOOR DE FABRIKANT – EF

OVERENSSTEMMELSESERKLÆRING UDSTEDT AF FABRIKANTEN – DICHIARAZIONE

DI CONFORMITÀ CE RILASCIATA DAL PRODUTTORE – DECLARACIÓN DE

CONFORMIDAD CE EMITIDA POR EL FABRICANTE – EF-SAMSV ARSERKLÆRING FRA

PRODUSENTEN – EG-DEKLARATIONEN OM ÖVERENSSTÄMMELSE UTFÄRDAD AV

TILL VERKARE N – V ALMIS T AJAN ANTAMA EY-V AATIMUSTENMUKAI SUUSV AKUU TUS –

DEKLARACJA ZGODNO

DECLARAÇÃO DE CONFORMIDADE CE EMITIDA PELO FABRICANTE

We the undersigned, ARIENS COMPANY, certify that:

ARIENS COMPANY, bescheinigt, dass:

–

COMPANY, attesterer, at:

COMPANY, certificamos que:

La sottoscritta società ARIENS COMPANY certifica che:

–

Undertegnede, ARIENS COMPANY, bekrefter at: – Undertecknad, ARIENS COMPANY, intygar att:

–

Wij, de ondergetekenden, ARIENS COMPANY, verklaren dat: – Undertegnede, ARIENS

Allekirjoittanut, ARIENS COMPANY, vakuuttaa, että:

assinados, certificamos em nome da ARIENS COMPANY, que:

–

Nous, soussignés ARIENS COMPANY, certifions que :

–

My, niżej podpisani, ARIENS COMPANY, oświadczamy, że:

Ś

CI Z PRZEPISAMI EC WYDANA PRZEZ PRODUCENTA –

–

Der Unterzeichnete,

–

Nosotros, los abajo firmantes, ARIENS

–

Nós, abaixo

–

Type: – Type:

Type:

–

Type:

–

Tipo:

Tyyppi:

Type:

–

Typ: – Tipo:

Trade Name:

commerciale:

–

Typ:

–

Tipo:

–

Typ:

–

Appellation commerciale : – Handelsbezeichnung: – Handelsnaam: – Firmanavn: Nome

–

Nombre comercial: – Handelsnavn: – Handelsbeteckning: – Kauppanimi: Nazwa handlowa: –

Riding Rotary Lawn Mower – Tondeuse à gazon autoportée rotative – Aufsitz-Sichelmäher – Rijdende

–

roterende grasmaaier – Havetraktor med roterende knive – Trattorino con unità di taglio rotativa – Tractor

–

cortacésped giratorio – Plentraktor med rotorklipper – Rotoråkgräsklippare – Ajoleikkuri – Samobieżna

–

rotacyjna kosiarka trawnikowa – Tractor Cortador de Relva –

Gravely

Nome da Marca:

–

Model:

Cutting Widt h (cm): – Largeur de coupe (cm) : – Schnittbreite (cm): – Maaibreedte (cm): – Klippebredde (cm): –

Larghezza di taglio (cm):

Szerokość cięcia (cm):

Modèle : – Modell: – Model: – Model: – Modello: – Modelo: – Modell: – Modell: – Malli: – Model: – Modelo: 992318

152

–

Ancho de corte (cm): – Klippebredde (cm) –: Klippbredd (cm): – Leikkuuleveys (cm): –

–

Largura de corte (cm):

992319

152

Conforms to: – Est conforme à : – Mit den Anforderungen der folgenden Richtlinien übereinstimmt: – Voldoet aan: – Er i

–

overensstemmelse med:

–

Jest zgodny z: – De acordo com:

È conforme a: – Cumple con: – Er i samsvar med: – Överensstämmer med: – Täyttää seuraavat vaatimukset:

98/37/EC, 89/336/EEC;

2000/14/EC Conformity Assessment Annex VI.

–

Annexe VI de l'évaluation de conformité. – Konformitätsbewertung, Anhang VI. – Bijlage VI voor beoordeling van overeenstemming. –

Vurdering af ov eren ss tem mels e Ann ek s VI.

–

Samsvarsvurdering etter vedlegg VI. – Bedömning av överensstämmelse Bilaga VI. – Vaatimustenmukaisuuden arviointi, liite VI.

–

Annesso VI della valutazione di conformità. – Anexo VI de la evaluación de la conformidad.

–

Dodatek VI, Ocena zgodności. – Anexo VI da Avaliação de Conformidade.

Representative Measured Sound Power Level (L

puissance acoustiq ue représenta tif mesuré (L

gemessener Geräuschpegel (L

geluidsniveau (L

) – Repræsentativt, målt støjef fektnive au (Lwa) –

wa

) – Representatief gemeten

wa

wa

) – Repräsentativer

wa

Livello di potenza sonora rappresentativo rilevato (L

potencia acústica representativo medido (L

målt lydeffektnivå (L

Tyy pillinen mitat tu ääni tehota so (L

poziom mocy akustycznej (L

Medido Representativo (L

) – Representativ uppmätt ljudnivå (Lwa) –

wa

wa

wa

)

) – Zmierzony reprezentatywny

wa

) – Nível de Potência de Som

992318: 104 dB

992319: 104 dB

) – Representativt

wa

A

A

) – Niveau de

) – Nivel de

wa

Guaranteed Sound Power Level (Lwa) – Niveau de puissance

acoustique garanti ( L

Gegarandeerd geluidsn iveau (L

) – Livello di potenza sonora garan tito (Lwa) – Nivel de potencia

(L

wa

acústica garantizado (L

Garanterad uppmätt ljudnivå (L

) – Garantierter Geräuschpegel (Lwa) –

wa

) – Garantert lydeffektnivå (Lwa) –

wa

) – Garanteret støjeffektniveau

wa

) – Taattu äänitehotaso (Lwa) –

wa

Gwarantowany reprezentatywny poziom mocy akustycznej (L

Nível de Potência de Som Garantido (L

992318: 105 dB

992319: 105 dB

wa

) –

A

A

wa

) –

3

Notified Body – Organisme notifié – Zertifizierungsstelle –

Aangemelde inst antie – Bemyndi get organ – Organismo notificato –

Organismo notificado – Teknisk kontrollorgan – Anmält organ –

Ilmoitettu laitos – Organ zaświadczający – Organismo –

Certificador

SNCH

11, Route de Luxembourg

L-5230 Sandweiler

Philip J. Smucker:

Quality and Conformance Manager (Keeper of Technical File)

–

Responsable de la qualité et de la conformité des produits

(Dépositaire de la fiche tec hni que ) – Manager Qualitätssicherung

–

und Konformität (Archivar der technischen Akte)

normalisatiemanage r (Beheerder van technische bes tand)

kvalitet og overensstemmelse (Indehaver af tekniske data)

Kwaliteits- en

–

Chef for

–

Responsabile della qua lit à e della co nform ità del prodotto

(Depositariodel file tecnico) – Gerente de calidad y conformidad

–

(Depositariodel archivo técnico)

–

(innehaver av teknisk fil)

Chef för kvalitet och

produktöverensst ämmelse (I nnehavare av tekniska data)

Kvalitet- og samsvarsansvarlig

–

Laadusta

Ariens Company

Brillion, WI 54110-0157 USA

Signature

Handtekening

–

Signatur – Namnteckning All eki rjoitus –

Podpis

–

Signature – Unterschrift

–

Underskrift – Firma Firma

–

Assinatura

ja vaatimustenmukaisuudesta vastaava johtaja (Teknisen tiedoston

–

haltija)

(Przechowujący Dokumentację Techniczną)

Kierownik do spraw jakości i zgodności

–

Gestor de Qualidade

e Conformidade (Zelado rde Arquivos Técnicos)

CE Sound and Vibration – Bruits et vibrat ions

CE – CE Geräusch- und Vibrationswerte – CE

Geluid en trilling – CE støj og vibration –

Livello sonoro e vibrazioni CE – Sonido y

vibración CE – CE-lyd og -vibrasjon – CE

ljudnivå och vibrationer – CE, melu ja tärinä –

CE Dźwięku i Wibracji – Som e Vibração CE –

(Ref. EN836-2001)

Model: – Modèle : – Modell: – Model: – Model: – Modello: – Modelo: – Modell: Modell: – Malli: – Model: –

Modelo:

Oper. Ear Sound Pressure (L

Geräuschpegel am Ohr des Bedieners (L

Strøjtryk ved brugerens øre (L

de sonido en el oído (L

– Kuljettajan korvaan kohdistuva ä änenpaine (Lpa), dBA – Robocze ciśnienie akustyczne na uchu (Lpa) w

dB

A

decybelach

Vibration Measure (m/sec

2

) an des Bedieners – Gemeten trilling bi j (m/sec2) – Vibrationsmålinger (m/s2) ved brugerens – Vibrazioni

s

– Oper. Pressão do Som no Ouvido (Lpa) em dB

A

pa

percepite dall’operatore (m/sec

førerens

–

Vibrationsmå tt (m/s2) vid förarens – Tärinä (m/s2) kuljettajan – Pomiar wibracji (m/sec2) u operatora –

Medida de Vibração (m/seg.

) in dBA – Pression acoustique aux oreilles de l’opérateur (Lpa) en dBA –

pa

) målt i dBA – Pressione sonora a ll’ore cchio dell’ operat ore (Lpa) in dBA – Presión

pa

) in dBA – Geluidsdruk bij het oor van de gebruiker (Lpa) in dBA –

pa

) in dBA – Lydtrykk ved førerens øre (Lpa) inn dBA – Ljudeffekt vid förarens öron (Lpa) i

2

) at Operator – Mesure des vibrations (m/s2) au niveau de l’opérateur – Vibration (m/

2

) – Medida de vibración (m/seg2) en el operador – Vibrasjonsmåling (m/s2) ved

2

) no Operador

A

Hands – Mains – Hände – De hand en van de ge bruiker – Hæn der – Ma ni – Manos – Hender – Händer – Käsi ssä

– Ręce – Mãos X

Y

Z

Feet – Pieds – Füße – De voeten van de gebruiker – Fødder – Piedi – Pies – Føtter – Fötter – Jaloissa – Stopy

X

– Pés

Y

Z

Seat – Siège – Sitz – De bestuurdersp la at s – Sæde – Sedi le – Asien to – Sete – Säte – Istu im ell a – Siedze nie –

Assento X

Y

Z

11/24/2003

Date – Date – Datum

Datum

–

Dato – Data

–

Fecha

–

Dato Datum

Päiväys Data – Data

992318 992319

90 90

3.2

0.5

0.9

0.2

0.2

0.8

0.3

0.3

0.5

2.5

<

2.5

<

< 2.5

0.5

0.5

0.7

0.5

0.5

0.6

4

INTRODUCTION

THE MANUAL

The purpose of this manual is to provide complete

instructions for service, maintenance, disassembly,

repair, and installation of the mechanical components

for the Promaster 250Z, 260Z, and 272Z.

Dealer trained service personnel should use this

manual as a supplement to and reminder of the training

sessions conducted by the company.

Read all information for servicing a part or system

before repair work is started to avoid needless

disassembly.

Operation

Before operation of the unit, carefully and completely

read manuals supplied with the unit. The contents will

provide you with an understanding of safety

instructions and controls during normal operation and

maintenance.

Safety Messages

For your safety and the safety of others always read

understand, and follow all DANGER, WARNING, and

CAUTION messages found in manuals and on safety

decals.

Directional Reference

All reference to left, right, front, or rear are given from

operator seated in operation position and facing the

direction of forward travel.

SERVICE AND REPLACEMENT PARTS

When ordering publications, replacement parts, or

making service inquiries, know the Model and Serial

numbers of your unit and engine.

Numbers are located on the product registration form in

the unit literature package. They are printed on a serial

number label, located on the frame of your unit.

Serial Number

Label

OA0017

Figure 1

honored, whether or not the product registration card is

returned. Keep a proof of purchase if you do not

register your unit.

Customer Note: If the dealer does not register your

product, please fill out, sign, and return the product

registration card to Gravely.

UNAUTHORIZED REPLACEMENT PARTS

Use only Gravely replacement parts. The replacement

of any par t on this unit with anything other than a

Gravely authorized replacement part may adversely

affect the performance, durability, and safety of this unit

and may void the warranty. Gravely disclaims liability

for any claims or damages, whether warranty, property

damage, personal injury or death arising out of the use

of unauthorized replacement parts.

DISCLAIMER

Gravely reserves the right to discontinue, make

changes to, and add improvements upon its products

at any time without public notice or obligations. The

descriptions and specifications contained in this

manual were in effect at printing. Equipment described

within this manual may be optional. Some illustrations

may not be applicable to your unit.

TECHNICAL SERVICE COMMUNICATIONS

Gravely Technical Service communicates information

to the field using Service Letters, Service Bulletins,

Product Notices, and Campaigns. Each

communication signifies a type of information and

priority. The dealer is responsible to carry out the

directive provided in the communication. The types of

communication are:

Service Letter - General technical information for the

dealer. Technical information on how to service the

product and product improvements.

Service Bulletin - Notification to update products to

resolve certain issues or a notification of a policy

change.

Product Notices - Notification of limited product

located in a certain region. This is a limited distribution

to only those who received the product involved.

Campaigns - Notification of a safety related issue. All

products must be updated and are tracked by the

factory until all units are corrected.

PRODUCT REGISTRATION

The Gravely dealer must register the product at the

time of purchase. Registering the product will help the

company process warranty claims or contact you with

the latest service information. All claims meeting

requirements during the limited warranty period will be

PREPARATION

Before starting any removal of parts, proper

preparation is very important for efficient work. A clean

work area at the start of each job will allow you to

perform service repairs easily and quickly.

5

SAFETY

WARNING: This cutting machine is capable of

amputating hands and feet and throwing

objects. Failure to observe the safety

instructions in the manuals and on decals could

result in serious injury or deat h.

WARNING: Slopes are a major factor related to

loss-of-control and tip-over accidents. Operation

on all slopes requires extra caution.

WARNING: Tragic accidents can occur if the

operator is not alert to the presence of children.

Never assume that children will remain where

you last saw them.

WARNING: Gasoline is extremely flammable

and the vapors are explosive, handle with care.

WARNING: Disengage attachment, stop unit

and engine, remove key, engage parking brake,

and allow moving parts to stop before leaving

operator’s position.

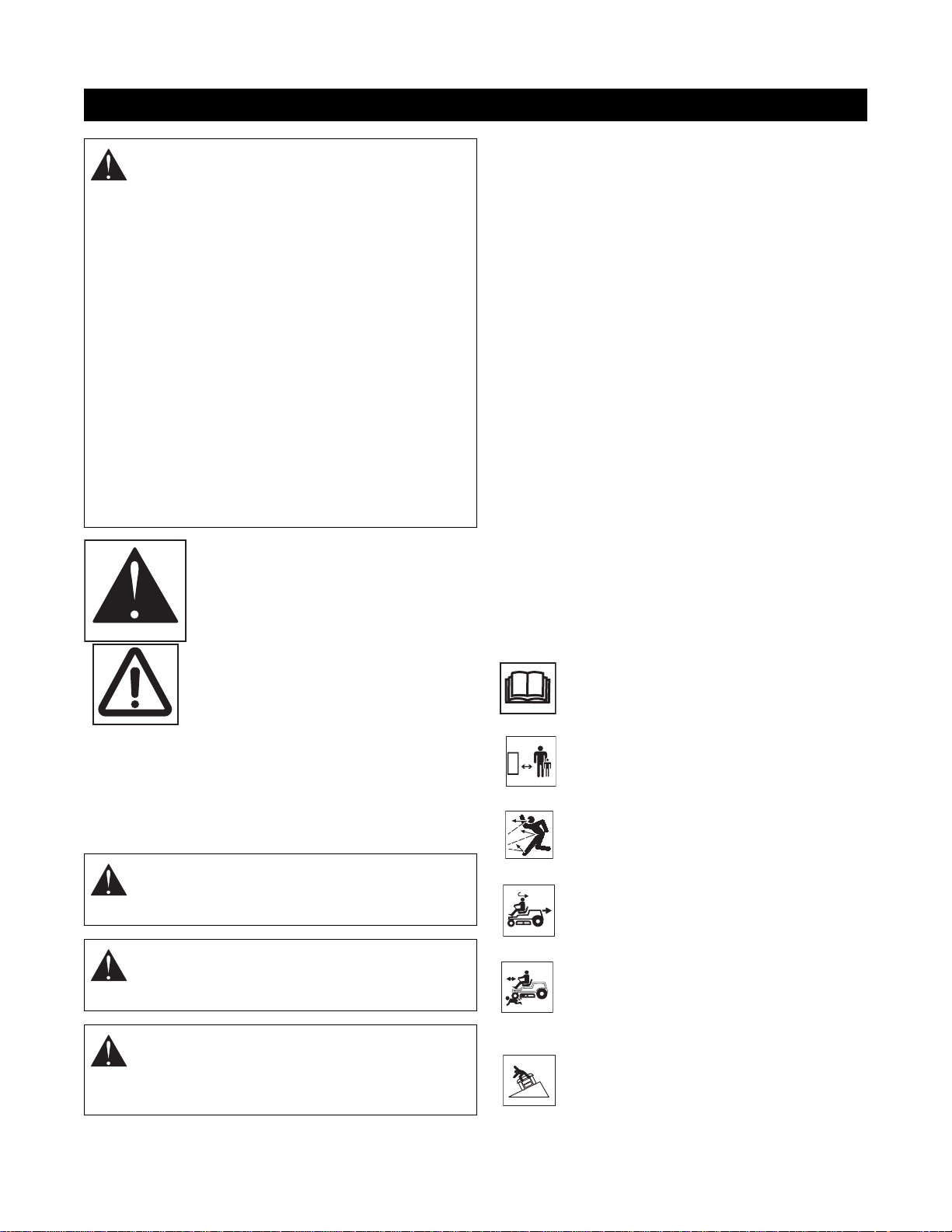

SAFETY ALERT SYMBOL

These are safety alert symbols. They

mean:

•ATTENTION!

OL1253

•YOUR SAFETY IS INVOLVED!

When you see this symbol:

•BECOME ALERT!

•OBEY THE MESSAGE!

OL3900

SIGNAL WORDS

The safety alert symbols above and signal words below

are used on decals and in this manual.

Read and understand all safety messages.

NOTATIONS

NOTE: General reference information for proper opera-

tion and maintenance practices.

IMPORTANT: Specific procedures or information

required to prevent damage to unit or attachment.

PRACTICES AND LAWS

Practice usual and customary safe working

precautions, for the benefit of yourself and others.

Understand and follow all safety messages. Be alert to

unsafe conditions and the possibility of minor,

moderate, or serious injury or death. Learn applicable

rules and laws in your area.

REQUIRED OPERATOR TRAINING

Original purchaser of this unit was instructed by the

seller on safe and proper operation. If unit is to be used

by someone other than original purchaser (loaned,

rented or sold), ALWAYS provide this manual and any

needed safety training before operation.

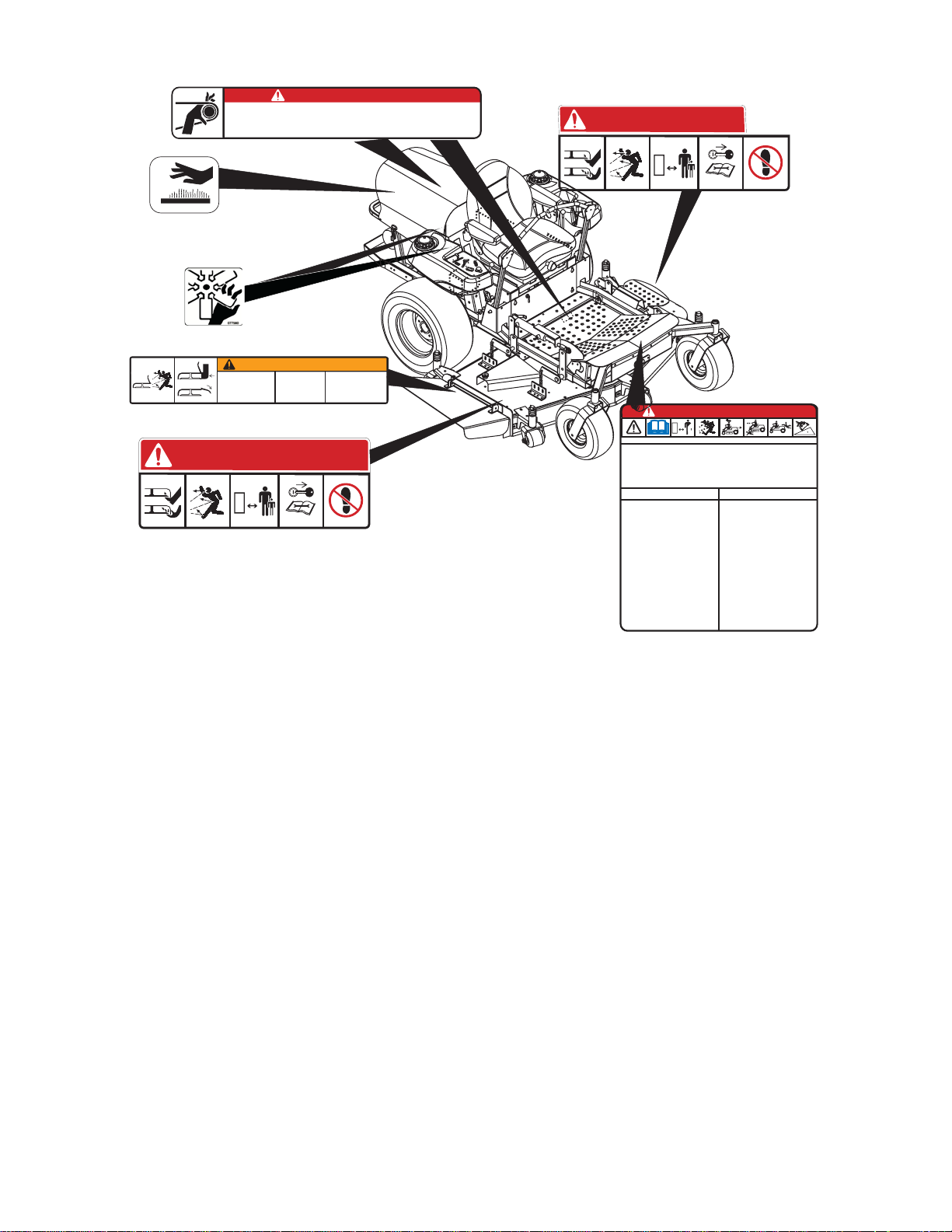

SAFETY DECALS AND LOCATIONS

ALWAYS replace missing or damaged safety decals.

See Figure 2 for safety decal locations.

1. DANGER! TO AVOID SERIOUS INJURY OR

DEATH

Read Operator’s Manual.

OL 1801

Keep children and others away from unit

while operating.

OL 4370

Never direct discharge toward other

people. Thrown objects can cause injury.

DANGER: IMMINENTLY HAZARDOUS

SITUATION! If not avoided, WILL RESULT in

death or serious injury.

WARNING: POTENTIALLY HAZARDOUS

SITUATION! If not avoided, COULD RESULT in

death or serious injury.

CAUTION: POTENTIALLY HAZARDOUS

SITUATION! If not avoided, MAY RESULT in

minor or moderate injury. It may also be used to

alert against unsafe practices.

6

OL 0910

OL 4460

OL 4470

MAX

17°

OL 4450

Look down and behind before and while

backing.

Never carry children.

Go up and down slopes, not across. DO

NOT operate on slopes over 17

o

.

• If machine stops going uphill, stop blade and back

down slowly.

• Avoid sudden turns.

• Keep safety devices (guards, shields, switches,

etc.) in place and working.

• Check interlock system per manual before use.

• Understand location and function of all controls.

• Never allow operation by untrained persons.

2. DANGER!

Always keep feet and hands away from

rotating parts.

OL 3030

Always stand clear of discharge area. Do

not direct discharge toward other people .

OL 0910

Keep people away from unit while

operating.

OL 4370

Shut off engine, remove key, and read

manual before you adjust or repair unit.

OL 4010

NO STEP! Always keep feet away from

rotating parts.

OL 4420

3. WARNING!

Always stand clear of discharge area.

OL 4430

Do not operate mower unless guards are in

operating position or bagger is attached.

OL 3320

4. HOT SURFACES!

DO NOT touch parts which ar e hot from

operation. ALWAYS allow parts to cool.

OD 0061

5. DANGER!

A VOID INJURY. Stay clear of rotating parts.

OL 4730

AVOID INJURY. Stay clear of rotating fan.

OL 4740

7

• Avoid injury - Stay clear of rotating parts.

• Risque de blessures - ne pas s’approcher des pièces en

mouvement.

• Evitar lesiones - Mantenerse alejado de las piezas giratorias.

DANGER / PELIGRO

07735200C

DANGER/ PELIGRO

07742300B

WARNING/AVERTISSEMENT/ADVERTENCIA

Do not operate mower

unless guards are in

operating position or

bagger is attached.

DANGER/ PELIGRO

Ne jamais utiliser

la tondeuse sans

protecteur sur le

canal d'ejection ou

sans le bac monte.

No operar segadora a

menos que las defensas

esten en posicion de

operacion o el

recogedor este fijo.

Figure 2 - Safety Decals

SAFETY RULES

Read, understand, and follow all safety practices in

Owner/Operator Manual before beginning assembly.

Failure to follow instructions could result in personal

injury and/or damage to unit.

ALWAYS remove key from ignition and wire from spark

plug before assembly. Unintentional engine start up

can cause death or serious injury.

Complete a walk around inspection of unit and work

area to understand:

• Work area

• Your unit

• All safety decals

Inspect unit before each use for: missing or damaged

decals and shields, correctly operating safety interlock

system, and deterioration of grass catchers. Replace

or repair as needed.

ALWAYS check overhead and side clearances

carefully before operation. ALWAYS be aware of traffic

when crossing or operating along streets or curbs.

Keep children and people away.

DANGER / PELIGRO

MAX

• Read the operator's manual.

• Keep children and others away from unit while

• Never direct discharge toward other people.

• Look down and behind before and while backing.

• Never carry children.

• Go up and down slopes, not across.

POUR EVITER LES BLESSURES GRAVES

OU LA MORT

• Lire le manuel d'utilisation.

• Éloigner les enfants et tout autre personne

• Ne jamais décharger directement en direction

• Regardez derrière et sur les côtés lorsque

• Ne transportez jamais d'enfant.

• Tondez toujours de haut en bas et

• Si la machine s

• Evitez les virages brusques.

• Maintenez toujours en place tous les

interrupteurs, etc.).

• Controler le bon fonctionnement du système

• Comprenez bien la fonction et la situation de

•

TO AVOID SERIOUS INJURY OR DEATH

operating.

Thrown objects can cause injury.

pendant le fonctionnement de la machine.

de quelqu’un. Des particules projetées

peuvent provoquer des blessures.

vous reculez.

inversement jamais le long des pentes.

'a

rrête en montee. Debrayez

la lame et redescendez doucement.

elements de sécurité (protecteurs,

de sécurité avant utilisation tel qu'indiqué

dans le manuel d'utilisation.

chacun des leviers et boutons de commande.

Ne jamais permettre l'utilisation par des

personnes n'ayant pas reçu la formation

nécessaire.

• If machine stops going uphill, stop blade and

back down slowly.

• Avoid sudden turns.

• Keep safety devices (guards, shields, switches,

etc.) in place and working.

• Check interlock system per manual before use.

• Understand location and function of all controls.

• Never allow operation by untrained persons.

PARA EVITAR DAÑOS SERIOS O LA

MUERTE

• Leer el manual del operador.

• Mantenga la unidad alejada de los niños y otras

personas cuando esté en funcionamiento.

• Nunca dirija la descarga hacia otras personas,

ya que los objetos lanzados pueden provocar

lesiones.

• Antes y durante retroceso mirar hacia abajo y

detras.

• Nunca monten niños.

• Suba y baje pendientes, no transversalmente.

• Si la maquina se detiene subiendo cuesta,

desactive la cuchilla y baje lentamente.

• Evite viradas subitas.

• Mantenga artefactos de seguridad (defensas,

protectores, interruptores, etc.) en su lugar y

trabajando.

• Verifique en el manual el sistema de engranar

antes de usar.

• Tenga conocimiento de funciones y

localizaciones de todos los controles.

• No permitir que personal sin la necesaria

formación use la máquina.

17

05359300

Keep children out of work area and under watchful care

of a responsible adult.

Keep area of operation clear of all toys, and debris.

Thrown objects can cause injury.

Check for weak spots on docks, ramps or floors, Avoid

uneven work areas and rough terrain. Stay alert for

hidden hazards or traffic.

DO NOT operate near drop-offs, ditches, or

embankments. Unit can suddenly turn over if a wheel is

over the edge of a cliff or ditch, or if an edge caves in.

Data indicates that operators, age 60 and above, are

involved in a larger percentage of riding mower related

injuries. These operators should evaluate their ability to

operate the riding mower safely enough to protect

themselves and others from serious injury.

Read the entire Owner/Operator manual and other

training material. If the operator or the mechanic

cannot read the manual, it is the owner’s responsibility

to explain it to them. Only the user can prevent and is

responsible for accidents or injuries occurring to

themselves, other people or property.

Only trained adults may operate unit. Training includes

actual operation.

8

Local regulations may restr ict the age of th e operato r.

NEVER allow children to operate or play on or near

unit. Be alert and shut off unit if children enter area.

NEVER operate unit after or during the use of

medication, drugs or alcohol. Safe operation requires

your complete and unimpaired attention at all times.

DO NOT wear loose clothing or jewelry and tie back

hair that may get caught in rotating parts.

Wear adequate outer garments.

NEVER wear open sandals or canvas shoes during

operation. Wear adequate safety gear, protective

gloves and footwear.

Wear proper footwear to improve footing on slippery

surfaces.

Always wear safety goggles or safety glasses with side

shields when operating mower.

Moving parts can cut or amputate fingers or a hand.

Wrap blade(s) or wear gloves to service. On multiblade

mowers, rotation of one blade will cause all blades to

rotate.

NEVER place your hands or any part of your body or

clothing inside or near any moving part while unit is

running.

ALWAYS keep hands and feet away from all rotating

parts during operation. Rotating parts can cut off body

parts.

ALWAYS keep body and hands away from pin holes or

nozzles which eject hydraulic fluid under pressure.

DO NOT touch parts which are hot. Allow parts to cool.

ALWAYS keep hands and feet away from all pinch

points.

Fumes from the engine exhaust can cause death or

serious injury. DO NOT run engine in an enclosed

area. Always provide good ventilation.

Read, understand, and follow all instructions in the

manual and on the machine before starting.

Understand:

• How to operate all controls

• The functions of all controls

• How to STOP in an Emergency

• Braking and steering characteristics

• Turning radius and clearances

Keep safety devices or guards in place and functioning

properly. NEVER modify or remove safety devices.

Do not operate without either entire grass catcher

or the discharge guard in place.

Stop engine before removing grass catcher or

unclogging chute.

Ensure Safety Interlock System is functioning properly.

DO NOT operate unit if safety interlock is damaged or

disabled.

Start and operate unit only when seated in operator’s

position. Steering control levers must be in neutral,

PTO disengaged and parking brake set when starting

engine.

Use care when approaching blind corners, shrubs,

trees or other objects that may obscure vision.

Dust, smoke, fog, etc. can reduce vision and cause an

accident. Mow only in daylight or good artificial light.

Avoid slippery surfaces. Always be sure of your footing.

DO NOT mow on wet grass. Reduced traction could

cause sliding and effect the machine’s stability.

Watch for traffic when operating near or crossing

roadways.

Never carry passengers.

DO NOT try to stabilize the machine by putting your

foot on the ground.

Never direct discharge towards persons or property

that may be injured or damaged by thrown objects. Use

extreme caution on gravel surfaces.

Always stand clear of the discharge area.

ALWAYS disengage PTO, stop unit and engine,

remove key, engage parking brake and allow moving

parts to stop before leaving operator’s position.

Never engage PTO while raising attachment or when

attachment is in raised position.

DO NOT operate at too fast a rate. DO NOT change

engine governor settings or over-speed engine. Slow

down before turning.

DO NOT operate in reverse unless absolutely

necessary.

ALWAYS look down and behind before and while

backing.

Stop and inspect equipment if you strike an object or if

there is an unusual vibration. Repair, if necessary,

before restarting. Never make adjustments or repairs

with the engine running.

Mower blades are sharp and can cut you. Wrap the

blade(s) or wear gloves, and use extra caution when

servicing them.

NEVER weld or straighten mower blades.

Rotation of one blade may cause rotation of the other

blades.

Take all possible precautions when leaving unit

unattended. Shut off engine. Remove wire from spark

plug and secure it away from spark plug.

ALWAYS remove key to prevent unauthorized use.

Know the weight of loads. Limit loads to those you can

safely control and the unit can safely handle.

Disengage PTO when attachment is not in use.

ALWAYS turn off power to attachment when traveling,

crossing dr iveways, etc.

Mow up and down slopes, not across them.

9

DO NOT operate on slopes of more than 17 degrees.

Use of a Rollover Protection System (ROPS) is

recommended for slope operation.

Always wear a seat belt when operating unit using a

Rollover Protection System (ROPS).

Keep all movements on the slope slow and gradual. Do

not make sudden changes in speed or direction.

Avoid starting or stopping on the slope. If tires lose

traction, disengage the blades and proceed slowly

straight down the slope.

If you cannot back up a slope or you feel uneasy on it,

do not mow it.

DO NOT park on slopes unless necessary. When

parking on slope always chock or block wheels. Always

set parking brake.

Use a slow speed. Tires may lose traction on slopes

even though the brakes are functioning properly .

DO NOT bypass transmission when on a slope.

Tow only with a machine that has a hitch designed for

towing. Do not attach towed equipment except at the

hitch point.

Follow the manufacturer’s recommendations for weight

limits for towed equipment and towing on slopes.

NEVER allow children or others in or on towed

equipment.

On slopes, the weight of the towed equipment may

cause loss of control.

Travel slowly and allow extra distance to stop.

Use extra care when loading or unloading unit onto

trailer or truck.

Secure unit chassis to transport vehicle. NEVER

secure from rods or linkages that could be damaged.

DO NOT transport machine while engine is running.

ALWAYS turn off power to attachment and shut off fuel

when transporting unit.

Keep unit free of debris. Clean up oil or fuel spills.

This product is equipped with an internal combustion

type engine. DO NOT use unit on or near any

unimproved, forest-covered or brush covered land

unless exhaust system is equipped with a spark

arrester meeting applicable local, state or federal laws.

A spark arrester, if it is used, must be maintained in

effective working order by operator.

Fuel is highly flammable and its vapors are explosive.

Handle with care. Use an approved fuel container.

NO smoking, NO sparks, NO flames. ALWAYS allow

engine to cool before servicing.

NEVER fill fuel tank when engine is running or hot from

operation.

NEVER fill or drain fuel tank indoors.

Replace fuel cap securely and clean up spilled fuel.

Never fill containers inside a vehicle or on a truck or

trailer bed with a plastic liner. Always place containers

on the ground away from your vehicle before filling.

When practical, remove gas-powered equipment from

the truck or trailer and refuel it on the ground. If this is

not possible, then refuel such equipment on a trailer

with a portable container, rather than from a gasoline

dispenser nozzle.

Keep the nozzle in contact with the rim of the fuel tank

or container opening at all times until fueling is

complete. Do not use a nozzle lock-open device.

If fuel is spilled on clothing, change clothing

immediately.

Avoid Electric Shock. Objects contacting both battery

terminals at the same time may result in injury and unit

damage. DO NOT reverse battery connections.

Reversed connections may result in sparks which can

cause serious injury. Always connect positive (+) cable

FIRST, and negative (-) cable SECOND.

Explosive Gases from battery can cause death or

serious injury. Poisonous battery fluid contains sulfuric

acid and its contact with skin, eyes or clothing can

cause severe chemical burns.

No flames, No sparks, No smoking near battery.

ALWAYS wear safety glasses and protective gear near

battery. Use insulated tools.

DO NOT TIP battery beyond a 45

direction.

ALWAYS keep batteries out of reach of children.

Battery posts, terminals and related accessories

contain lead and lead compounds, chemicals known to

the State of California to cause cancer and

reproductive harm. Wash hands after handling.

ALWAYS block wheels and know all jack stands are

strong and secure and will hold weight of unit during

maintenance.

Release pressure slowly from components with stored

energy.

NEVER attempt to make any adjustments to unit while

engine is running (except where specifically

recommended). Stop engine, remove key or spark plug

wire and wait for all moving parts to stop before

servicing or cleaning.

Check parking brake operation frequently. Adjust and

service as required.

ALWAYS maintain unit in safe operating condition.

Damaged or worn out muffler can cause fire or

explosion.

Maintain or replace safety and instruction labels, as

necessary.

NEVER store unit with fuel in fuel tank, inside a

building where any ignition sources are present.

o

angle in any

10

Shut off fuel and allow engine to cool completely before

storing in closed area or covering unit.

Clean grass and debris from unit, especially from

around muffler and engine, to help prevent fires.

For extended storage, shut off fuel and clean unit

thoroughly. See engine manual for proper storage.

Lower cutting deck unless a positive mechanical lock is

used.

Use only attachments or accessories designed for your

unit.

Check all hardware at regular intervals, especially

blade attachment bolts. Keep all hardware properly

tightened.

Check attachment components frequen tly. If worn or

damaged, replace with manufacturer’s recommended

parts.

Safety Interlock System

Test Steering

Levers

1 Neutral Off Engaged Start

2 Neutral On Engaged Doesn’t

3 Neutral Off Disengaged Doesn’t

OPERATING INTERLOCK (ENGINE ON)

4* Neutral On Engaged Shuts Off

5* Neutral Off Disengaged Shuts Off

6* Neutral Off Engaged On

*Operator lift s of f seat.

PTO Parking

Brake

STARTING INTERLOCK

Engine

Start

Start

WARNING: Safety interlock system failure

and improper operation of unit can result in

death or serious injury. Test this system each

time unit is operated. If this system does not

function as described, do not operate until

repairs are made.

Perform the following tests to ensure safety interlock

system is working properly. If unit does not perform as

stated contact your Gravely dealer for repairs.

NOTE: For all models, when parking brake is engaged,

steering levers are locked in neutral.

Parking Brake Interlock System

With parking brake engaged, steering levers must be

locked in neutral.

With parking brake disengaged, engine must not start

and engine must shut off if operator leaves seat.

11

SPECIFICATIONS

Model Number 992018 992023 992027

Model PM260Z 25 HP Kohler

Length - in (cm) 87 (221) 90 (229)

Height - in (cm) 50 (127)

Width - in (cm) 63 (160) 85 (216)

Weight Actual - lbs (kg) 1100 (499) 1080 (490) 1259 (572)

Battery 12 volt

Brakes Hydro/Dynamic Disk - Parking

Turning Radius 0

Tire Size Front 15 x 6 - 6 15 x 6 - 6 15 x 6 - 6

Rear 23 x 10.5 - 12 23 x 8.5 - 12 12 x 1.5 - 12

Engine - Manufacturer Kohler Briggs & Stratton Kohler

Model Number CV25S 351777 CV25S

Cycle 4

Engine Power- 25 HP 20 HP 25 HP

HP (KW/min

Starting System Electric

Fuel Tank Capacity 9 gals. US (34 liters)

Fuel See Engine Manual

Idle RPM 1800

Governed RPM 3600

Air Cleaner Large Capacity Dual ELement

Cooling Capacity Air Cooled

Engine Oil Type See Engine Manual

Spark Plug Gap See Engine Manual

Transmission Hydrostatic Drive

Speed - Forward Max. 9 MPH

Reverse Max. 4.5 MPH

Transmission Lube Mobil 1 15W - 50 Synthetic

Drive Clutch Hydrostatic

Tire Pressure Front 20-25 psi

Rear 12-15 psi

Lift system Hydraulic

Power Take Off Electric PTO Clutch/Brake

Cutting Width - in (cm) 50 (127) 72 (183)

Cutting Height - in (cm) 1 - 5 (2.5 - 12.7)

Cutting Increments - in (cm) Infinite between 1 - 5 (2.5 - 12.7)

-1

) (18.6 KW/min -1) (14.7 KW/min -1) 18.6 KW/min -1)

with 50 Inch Deck

PM250Z 20 HP Briggs &

Stratton with 50 Inch

Deck

PM260Z 25 HP Kohler with

72 Inch Deck

12

Model Number 992020 992029 992030 992032 992033 992034 992035

Model 260Z 25 HP

Kohler

w/60" deck

Length - in (cm) 80 (203) 84 (213.4) 80 (203)

Height - in (cm) 50 (127)

Width - in (cm) 73 (185) 85 (216) 73 (185) 63 (160)

Weight Actual - lbs (kg) 1125 (510) 1259 (572) 1125 (510) 1100 (499)

Battery 12 volt

Brakes Hydro/Dynamic Disk - Parking

Turning Radius 0

Tire Size Front 15 x 6 - 6

Rear 23 x 10.5 - 12

Engine - Manufacturer Kohler Kawasaki Kohler Kawasaki

Model Number CV25S FH721V CV26S FH601V FH680V

Cycle 4

Engine Power - HP (kw) @

Governed RPM

Governed RPM 3600

Idle RPM 1800

Starting System Electric

Fuel Tank Capacity 9 gals. US (34 liters)

Fuel See Engine Manual

Air Cleaner Large Capacity Dual ELement

Cooling Capacity Air Cooled

Engine Oil Type See Engine Manual

Spark Plug Gap See Engine Manual

Transmission Hydrostatic Drive

Speed - Forward Max. 9 MPH

Reverse Max. 4.5 MPH

Transmission Lube Mobil 1 15W - 50 Synthetic

Drive Clutch Hydrostatic

Tire Pressure Front 20-25 psi

Rear 12-15 psi

Lift system Hydraulic

Power Take Off Electric PTO Clutch/Brake

Cutting Width - in (cm) 60 (152) 72 (183) 60 (152) 50 (127)

Cutting Height - in (cm) 1 - 5 (2.5 - 12.7)

Cutting Increments - in (cm) In finite between 1 - 5 (2.5 - 12.7)

260Z 25 HP

Kawasaki

w/60" deck

25 (18.6) 26 (19.3) 19 (14.1) 23 (17.2)

272Z 25 HP

Kawasaki

w/72" deck

272Z 26 HP

EFI Kohler

w/72" deck

260Z 26 HP

Kawasaki

w/50" deck

250Z 23 HP

Kawasaki

w/50" deck

250Z 23 HP

Kawasaki

w/50" dek

13

20

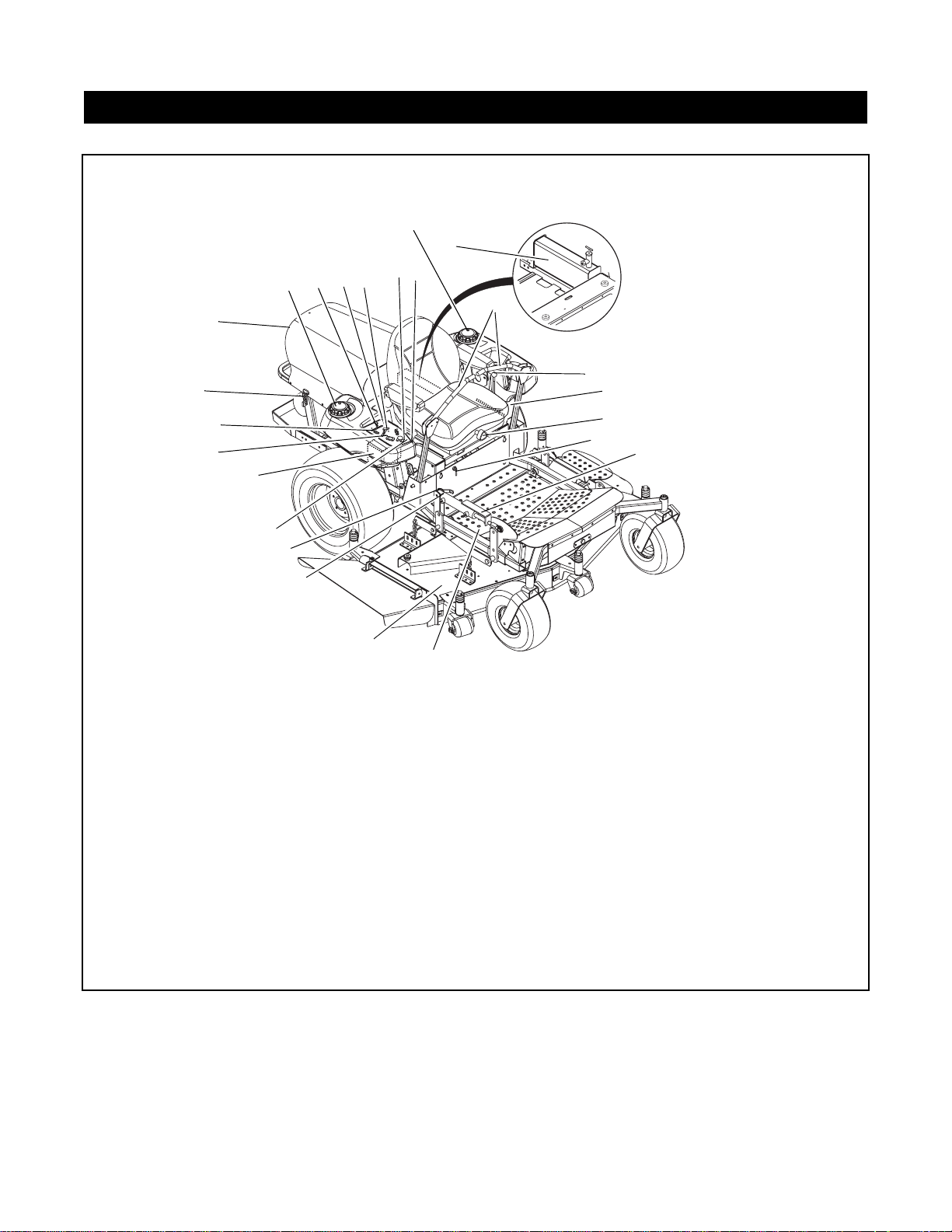

CONTROLS AND FEATURES

8

19

13

10

9

8

7

6

5

4

12

22

11

3

14

15

16

17

2

18

21

1

1. Mower Deck with Chute Deflector

2. Fuel Shut off Valve

3. Parking Brake

4. Battery

5. Hour Meter

6. Oil Pressure Indicator

7. Engine Frame and Hood

8. Fuel Tanks and Caps

9. C hoke Control (not on EFI* models)

10.Malfunction Indicator Light

11.Throttle Lever

OF 1722

23

12.Ignition Switch

13.Power Take Off (PTO) Switch

14.Steering Levers

15.Mower Lift Lever

16.Seat Adjustment Lever

17.Seat Suspension Adjustment Knob (not on

model 992034)

18.Height of Cut Indicator

19.Hydraulic Oil Reservoir

20.Engine Hood Latch

21.Cylinder Stop Storage Post

22.Cylinder Stops

*Electronic Fuel Injection

Figure 3

14

Loading...

Loading...