~GRAVELV

A DIVISIO:'\ OF CLARKE-GRAVELY CORI'ORATIO:'\

To continue .ts program of qualltv and deSign Impro ement. the

manufacturer reserves the right to change specifications. design

or prices without nOtIce and without Incurring obligatiOn

OWNERS

MANUAL

34" ROTARY MOWER

. MODEL NUMBER 15459E1

~'.

"

..

.

.

l .GRAVELY.

]

408 LAWN TRACTOR WITH 34" ROTARY MOWER

GENERAL

1. The 34" mower is a center mounted unit

custom designed and built expressly for the

408 Lawn Tractor. The mower is recom-

mended for homeowners lawns and comes

from the factory fully assembled.

2. The Owners Manual includes attaching to the

tractor, safety, operation and maintenance

1

instructions. Use the illustrated parts list for

reference to individual part numbers. Contact

the Gravely Dealer for further information.

3. Height: 14"

Weight: 105 lbs.

Length: 27 1/2"

Width: 44"

Cutting Width: 34"

Deck: One piece stamped steel.

Drive: Right angl. bevel gears, ball bearings,

aluminum housing, self-adjusting spring

tensioned V-belt.

Blades: 2 steel, hi-strength, hi-lift

17" length, .204" thick

Features: Cutting height adjusts from opera-

tors position.

Purpose: Homeowners lawn care.

Tractor: 408 Lawn Tractor

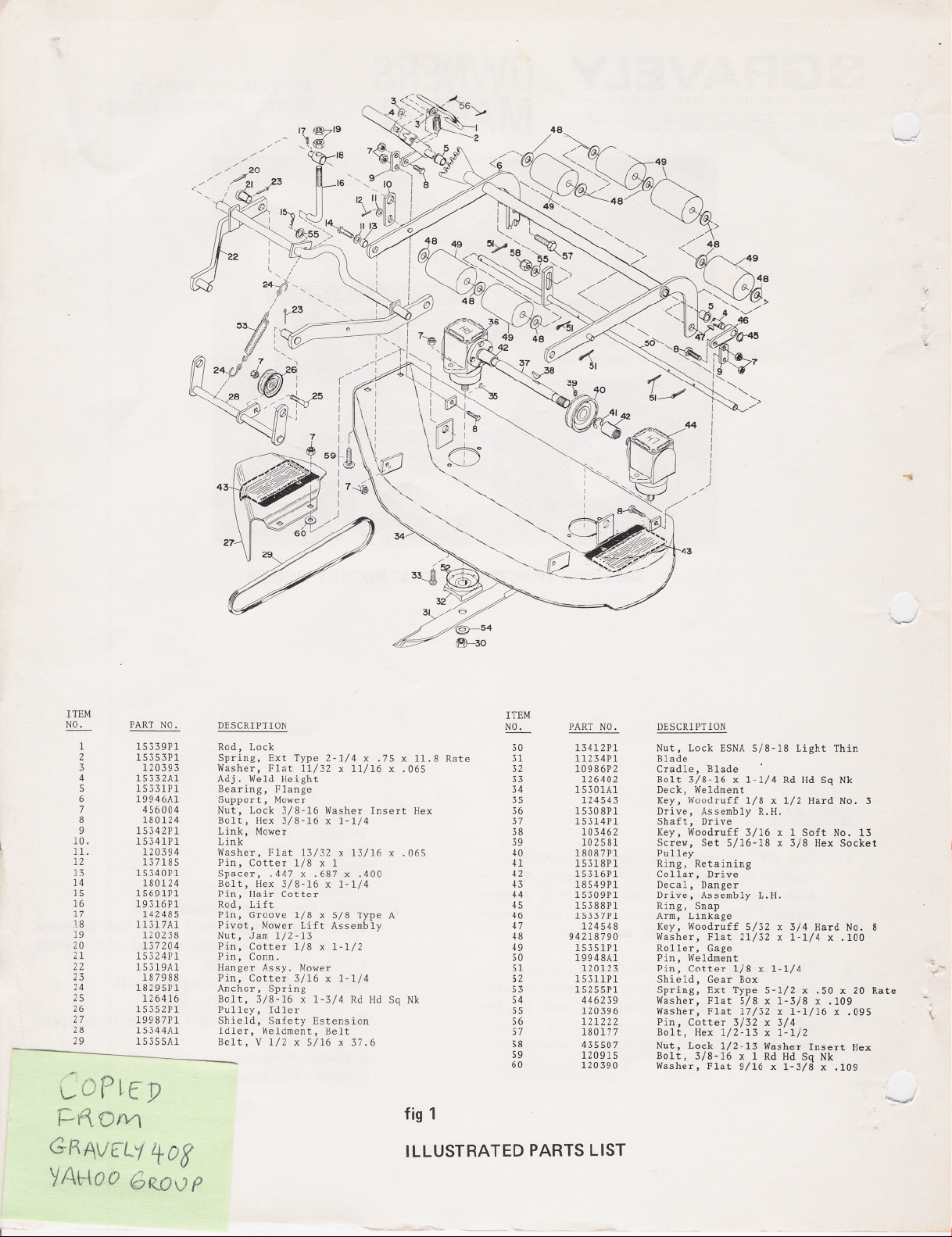

ITEM

NO.

1 15339P1

2

3 120393

4 15332A1

5

6

7

8

9

10. 15341P1

11. 120394

12

13 15340P1

14

15 15691P1

16

17

18

19

20

21

22 15319A1

23

24

25 126416

26

27

28

29 15355A1

PART NO.

15353P1

15331P1

19946A1

456004

180124

15342P1

137185

180124

19316P1

142485

ll317A1

120238

137204

15324P1

187988

18295P1

15352P1

19987P1

15344A1

DESCRIPTION

Rod, Lock

Spring, Ext Type 2-1/4 x .75 x 11.8 Rate

Washer, Flat 11/32 x 11/16 x .065

Adj. Weld Height

Bearing, Flange

Support, Mower

Nut, Lock 3/8-16 Washer Insert Hex

Bolt, Hex 3/8-16 x 1-1/4

Link, Mower

Link

Washer, Flat 13/32 x 13/16 x .065

Pin, Cotter 1/8 x 1

Spacer, .447 x .687 x .400

Bolt, Hex 3/8-16 x 1-1/4

Pin, Hair Cotter

Rod, Lift

Pin, Groove 1/8 x 5/8 Type A

Pivot, Mower Lift Assembly

Nut, Jam 1/2-13

Pin, Cotter 1/8 x 1-1/2

Pin, Conn.

Hanger Assy. Mower

Pin, Cotter 3/16 x 1-1/4

Anchor, Spring

Bolt, 3/8-16 x 1-3/4 Rd Hd Sq Nk

Pulley, Idler

Shield, Safety Estension

Idler, We1dment, Belt

Belt, V 1/2 x 5/16 x 37.6

ITEM

NO.

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

PART NO.

13412P1

ll234P1

10986P2

126402

15301A1

124543

15308P1

15314P1

103462

102581

18087P1

15318P1

15316P1

18549P1

15309P1

15388P1

15337P1

124548

94218790

15351P1

19948A1

120123

153llP1

15255P1

446239

120396

121222

180177

435507

120915

120390

DESCRIPTION

Nut, Lock ESNA 5/8-18 Light Thin

Blade

Cradle, "Blade

Bolt 3/8-16 x 1-1/4 Rd Hd Sq Nk

Deck, We1dment

Key, Woodruff 1/8 x 1/2 Hard No. 3

Drive, Assembly R.H.

Shaft, Drive

Key, Woodruff 3/16 x 1 Soft No. 13

Screw, Set 5/16-18 x 3/8 Hex Socket

Pulley

Ring, Retaining

Collar, Drive

Decal, Danger

Drive, Assembly L.H.

Ring, Snap

Arm, Linkage

Key, Woodruff 5/32 x 3/4 Hard No. 8

Washer, Flat 21/32 x 1-1/4 x .100

Roller, Gage

Pin, We1dment

Pin, Cotter 1/8 x 1-1/4

Shield, Gear Box

Spring, Ext Type 5-1/2 x .50 x 20 Rate

Washer, Flat 5/8 x 1-3/8 x .109

Washer, Flat 17/32 x 1-1/16 x .095

Pin, Cotter 3/32 x 3/4

Bolt, Hex 1/2-13 x 1-1/2

Nut, Lock 1/2-13 Washer Insert Hex

Bolt, 3/8-16 x 1 Rd Hd Sq Nk

Washer, Flat 9/16 x 1-3/8 x .109

~OPlfP

12-ftOfV\

GRAVf:L"/108'

YA~ooGROvP

-

fig1

ILLUSTRATED PARTS LIST

COPlfP

~"'OM

ATTACHING

1.

Slide the lift pivot on the lift rod with the

groove pin towards the bend in the lift rod,

fig 1, Items 16, 17, and 18.

2.

Run (me of the jam nuts 3/4 of the way on

the threaded portion of the lift rod. Keeping

it in position, jam the other nut against it,

fig 1, Items 16 and 19. .

3. Lower the attachment lift on the tractor all

the way down.

4.

Work from the right side of the tractor. Turn

the lift rod upside down (bent part up), and

put the lift pivot in the second hole from the

end of the tractor lift. Put it in from the right

side.

5. Rotate the lift rod to the right-side-up posi-

tion (bent part down) and raise the tractor

lift all the way up.

6. Slide the mower under the tractor, center the

hanger assembly and move it as forward as

possible.

7. Put the PTO in the IN position.

8. Slip the belt on the PTO pulley.

G-~AVf:L'1,+08

SAFETY

1.

READ THE TRACTOR OWNERS MANUAL.

Be familiar with all controls and follow safety

precautions outlined in the manual.

DO NOT ALLOW PASSENGERS to accom-

2.

pany the operator at any time.

3.

DO NOT ALLOW CHILDREN to operate the

equipment, nor allow adults to operate it

without proper instructions.

4.

INSPECT THE WORK AREA for rocks, glass,

metal, bones, and any other foreign objects.

Stay alert for holes and other hidden hazards.

5.

USE EXTREME CAUTION when operating

on slopes.

6. REDUCE SPEED on all side slopes and shart

turns.

7. DO NOT OPERATE equipment except from

operator position at the handles of the tractor.

8. KEEP SAFETY devices and shields in place

at all times.

9. DISENGAGE POWER to attachment and

stop the engine prior to making any adjust-

ment or clearing the unit.

,/1%\00 GWVp

9. Slide the mower as rearward as possible.

10. Lower the lift rod and connect it to the

hanger assembly with a flatwasher and a

hair pin cotter as in fig 1, Items 15 and 55.

10. DO NOT WEAR LOOSE fitting clothing.

11. KEEP HANDS, feet, hair, clothing, etc., away

from moving parts.

12. KEEP BYSTANDERS and pets removed from

11. Open the tractor attachment latches.

12. With the tractor lift lever, lift the mower and

guide the hanger into the attachment latches.

13. Close the attachment latches, lock them with

hair pin cotters and lower the mower.

"

the work area.

13. DIRECT DISCHARGE so as not to endanger

life or property; such as people, pets, struc-

tures, cars, etc.

OPERATION

14. Hook the spring anchors to the spring and

connect this assembly between the idler shaft

and the hanger assembly, fig 1, Items 22, 24,

28 and 53.

1. Refer to the tractor Owners Manual for

safety and operating instr~ctions to engage

and disengage the PTO (power take-off).

15. Set the flat side of the belt on the idler

pulley, fig 1, Item 26. The belt is now in the

tensioned running position. Put the PTO in

the OUT position.

2.

After the PTO is engaged run the engine at

full speed. In thick, lush growth reduce

ground speed (not engine speed) to allow che

mower enough time to cut and discharge.

r

~OPlfJ)

1=--f\OfV1

ADJUSTMENTS

GRAVtLY't0g

YAHOO GR.OvP

1. Cutting Height: The cutting height is con-

trolled by the lever on the right side of the

mower, fig 1, Items 1 and 4. It is most

easily adjusted when the mower is in the

raised (transport) position: adjusting the lever

forward for a low cut, rearward for a high

cut. The total range is 2 1/4 inches.

2. Leveling: If the mower appears to cut closer

to the ground on one side than the other,

adjust the mower support where it connects

to the roller assembly, fig 1, Items 6, 50,55,

57 and 58. To adjust, move the forked end of

the support away from the roller shaft to

make the right side cut higher. Move the

forked end of the support closer to the roller

shaft to make the right side cut lower.

3.

Belt Alignment: If the belt appears to be

wearing more on one side than the other, it is

possible that the mower pulley is not aligned

with the PTO pulley. To adjust, loosen the set

screw in the hub of the mower pulley, fig 1,

Items 37, 38, 39 and 40. Move the pulley in

the direction of the worn side of the belt

until the pulleys align. Raise the hood and

view from above. Retighten the set screw.

4.

Blade Timing: Correct timing is as follows:

one biade is in the cradle front to rear while

at the same time the other blade is in the

cradle side to side (900 out of phase), fig 1,

Items 31 and 32. To adjust, remove either one

of the collar retaining rings, fig 1, Items 41

and 42. Slide the collar towards the middle of

the shaft. Rotate the blades for correct

timing. Slide the collar back on the gear box

shaft and lock it in position with the retaining

ring.

5.

Lift Rod: If the mower does not come up

high enough when the lift lever is in the top

notch, move the jam nuts closer to the bend

in the lift rod. This adjustment should bring

the mower up closer to the tractor and still

allow the mower to "float" when all the way

down.

between the blades and the side of the

mower deck.

C. If the cradles are removed, be sure to

reinstall them with the woodruff keys,

fig 1, Item 35.

7. Blade Installation:

A. Set the blades in the cradles as in fig 1,

Items 31 and 32. The lift portion of the

blades points towards the mower deck.

B. Put on the washers and torque the nuts

to 25 ft. lbs., fig 1, Items 30 and 54.

Similar tightness can be reached with

any 8" length handle wrench when used

by an average man. A block of wood or

something similar can be used to keep

the blades from turning. Place the wedge

between the blade and the side of the

mower deck.

C. Check to be sure that the blades are

properly timed.

8. Belt Replacement:

A. Remove the mower from the tractor.

B. Remove the retaining rings from the

drive shaft, fig 1, Item 41.

C. Slide the collars toward the pulley, fig 1,

Item 42.

D. Remove the shaft and the old belt from

the shaft.

E. Set the new belt on the pulley and

reinstall the shaft. Note: Be sure that the

blades are properly timed when reas-

sembling the drive.

REMOVAL FROM TRACTOR

1. Lower the mower and disconnect the spring.

2. Raise the mower and open the attachment

latches.

3. Lower the mower and disconnect the lift rod

from the mower hanger and the tractor lift

lever.

4. Move the mower as forward as possible.

6. Blade Removal:

A. Remove the mower from the tractor and

turn the mower upside down.

B. Remove the nuts, washers and blades,

fig 1, Items 30, 31 and 54. It is not

ntcessary to remove the blade cradles,

fig 1, Item 35. A block of wood or

something similar can be used to keep

the blades from turning. Place the wedge

5. Put the PTO in the IN position and remove

the belt from the PTO pulley.

6. Slide the mower from under the tractor.

7. Reconnect the lift rod to the mower for

storage.

"

TROUBLE SHOOTING

ROUTINE MAINTENANCE

1. Blade timing is set at the factory and (with

normal use) cannot go out of time. The

obvious symptom of improper blade timing

is the sound of the blades hitting together.

2. Causes of improper blade timing:

A. The blades were not timed properly

..

3. Corrections for Items A, 'B and C:

when a new belt was installed.

B. A blade hit something hard enough to

shear its woodruff key allowing the

cradle to turn on the shaft, fig 1, Item

35. The key keeps the blade cradle from

turning on the shaft.

C. The same impact condition as "B" ex-

cept that the key did not shear but the

drive collar has turned (slipped) on the

shaft, fig 1, Item 42. This condition is

rare as the key should shear (to protect

the driveline) before the collar will slip.

A. Retime the blades; see ADJUSTMENTS.

B. Remove the blade and cradle and install

a new woodruff key. Check blade timing;

see ADJUSTMENTS.

C. Replace the drive collar with a new one;

check the drive shaft and gear box shaft

for damage. Retime the blades; see

ADJUSTMENTS.

1. Keep the mower blades sharp and balanced.

2. Keep the mower clear of cuttings and debris.

3. Periodically inspect the drive housings for

leakage of lubricant, fig 1, Items 36 and 44.

If the drive housings show signs of leakage,

contact the Gravely Dealer. Do not open the

drive housing as this voids warranty.

STORAG E

1. Clean the mower of all cuttings and debris.

2. Perform all routine maintenance.

3. Apply a light coat of oil to preserve the finish

and appearance.

FORM NUMBER: 20812L2

EFFECTIVE DATE: 6-15-74

PRINTED IN USA

COf~EP

~f\OfV\

G~AVf:Lvl ,+08

,/A800 GRfJ0P

-

..

I ----

--:;--~--

Loading...

Loading...