Gravely 11362 User Manual

OPERATOR'S

MANUAL

NAME: 40" COMMERCIAL MOWER

40" COMMERCIAL MOWER ATTACHED TO C12 TRACTOR WITH DUAL WHEELS

GENERAL

1. The 40" Commercial Mower is a front mount unit

designed and built to give many years of excellent

service. The mower is recommended for rough

mowing conditions; has all gear drive from engine to

mower, heavy-duty steel deck, rugged skids and

casters, and 2 adjustable blades. The mower

attaches to both 2 and 4 wheel tractors (see

paragraph 3).

2. The Owners Manual includes the parts list, setting

up the mower, safety, operation, and maintenance

instructions. Use the parts list for reference to

individual part numbers. If further information is

necessary contact the local Gravely dealer.

3. Height: 15-1/2" Weight: 182 lbs.

Length: 34-3/4" Width: 42"

Cutting Width: 40"

Deck: Reinforced, welded steel.

Drive: Right angle bevel gear, tapered roller

bearings, cast iron housing, 2 self

adjusting spring tensioned V-belts.

PART NUMBER(S): 11362 - 40" Commercial Drive

11368 - 40" Commercial Deck

Blades: 2 steel, hi-strength, hi-lift,

20-1/2" length, 3/16" thick

Features: Adjustable casters, adjustable swivel

action.

Purpose: Heavy mowing conditions.

Recommended for the following tractors:

7.6 - C10A - C12

424 - 430 - 432

810 - 812 - 814 - 816S

Required attaching kits:

7.6 - C10A - C12: None

424 - 430 - 432:

15840E1 Front Drive Kit

11601E1 Front Adapter Kit

810-812-814-816S:

19075E1 Front Drive Kit

11601E1 Front Adapter Kit

Recommended optional equipment for special

applications:

7.6 - C10A - C12: None

Riding Tractors:

20181E1 Wheel Brake Kit, 800 Series

11924E1 Front Wheel Weights

Recommend option for riding tractors without

hydraulics:

11271E1 Lift Assist Kit

1

fig 1

ITEM N0. PART N0. DESCRIPTION

1 11369A1 Deck Weldment

2 180126 Bolt, Hex 3/8-16 x 1-1/2

3 9231P1 Idler

4 11379A1 Arm, Idler Pivot Weldment

5 11382A1 Idler, Pivot Arm

6 456004 Nut, Lock 3/8-16 Washer Insert

7 11263P1 Spring

8 9200A1 Housing, Spindle Bearing Weldment

9 9246P1 Bearing, Cones

10 9245P1 Bearing, Race

11 9206P1 Seal, Oil

12 9204P1 Ring, Seal

13 9207P1 Pulley, Rotor

14 131001 Washer, Flat 31/32 x 2-1/4 x .165

15 17313P1 Nut, Lock Esna 7/8-9 Heavy Thin

16 9203P1 Shaft, Rotor

17 9213P1 Key, Square 1/4 x 1

18 9205P1 Shield, Dust

19 9211P1 Collar, Blade Spacer 3/4"

20 9210P1 Collar, Blade Spacer 1/2"

21 9209P1 Collar, Blade Spacer 1/4"

22 9212P1 Blade, Mower

23 102581 Screw, Set 5/16-18 x 3/8 Hex Socket

24 94110270 Fitting, Lube 1/4-28

Complete 40" Rotary Mower Spindles R.H. #10398A1 and L.H.

#10399A1 Include Item Numbers 8 through 21 and Numbers 23 and 24

25 120915 Bolt, 3/8-16 x 1 Rd. Hd. Sq. Nk.

26 456004 Nut, Lock 3/8-16 Washer Insert

27 11384P1 Cover, Belt

28 94286380 Bolt, 3/8-16 x 5/8 Hex Hd.

29 120382 Washer, Lock 3/8 Sp.

30 120394 Washer, Flat 13/32 x 13/16 x .065

31 9240P1 Belt, Drive

32 9223P2 Skid

33 181596 Bolt, 5/16-24 x 7/8 Hex Hd.

34 120214 Washer, Lock 5/16 Sp.

35 120393 Washer, Flat 11/32 x 13/16 x .065

36 11376A1 Support, Deck Weldment

37 18549P1 Decal, Danger

38 11375P1 Bearing, Bronze

39 94110270 Fitting, Lube 1/4-28

40 180122 Bolt, Hex 3/8-16 x 1

41 120897 Bolt, 1/2-13 x 3 Rd. Hd. Sq. Nk

42 120384 Washer, Lock 1/2 Spring

43 120378 Nut, Hex 1/2-13

NS 9251A1 Guard, Weldment

45 137204 Pin, Cotter 1/8 x 1-1/2

46 131017 Washer, Flat

47 11385A1 Caster Fork Weldment

48 113871`1 Bushing

49 11386P1 Wheel, Caster

50 180193 Bolt, Hex 1/2-13 x 3-3/4

51 435507 Nut, Lock 1/2-13 Washer Insert

ILLUSTRATED PARTS LIST Continued on Page 4

2

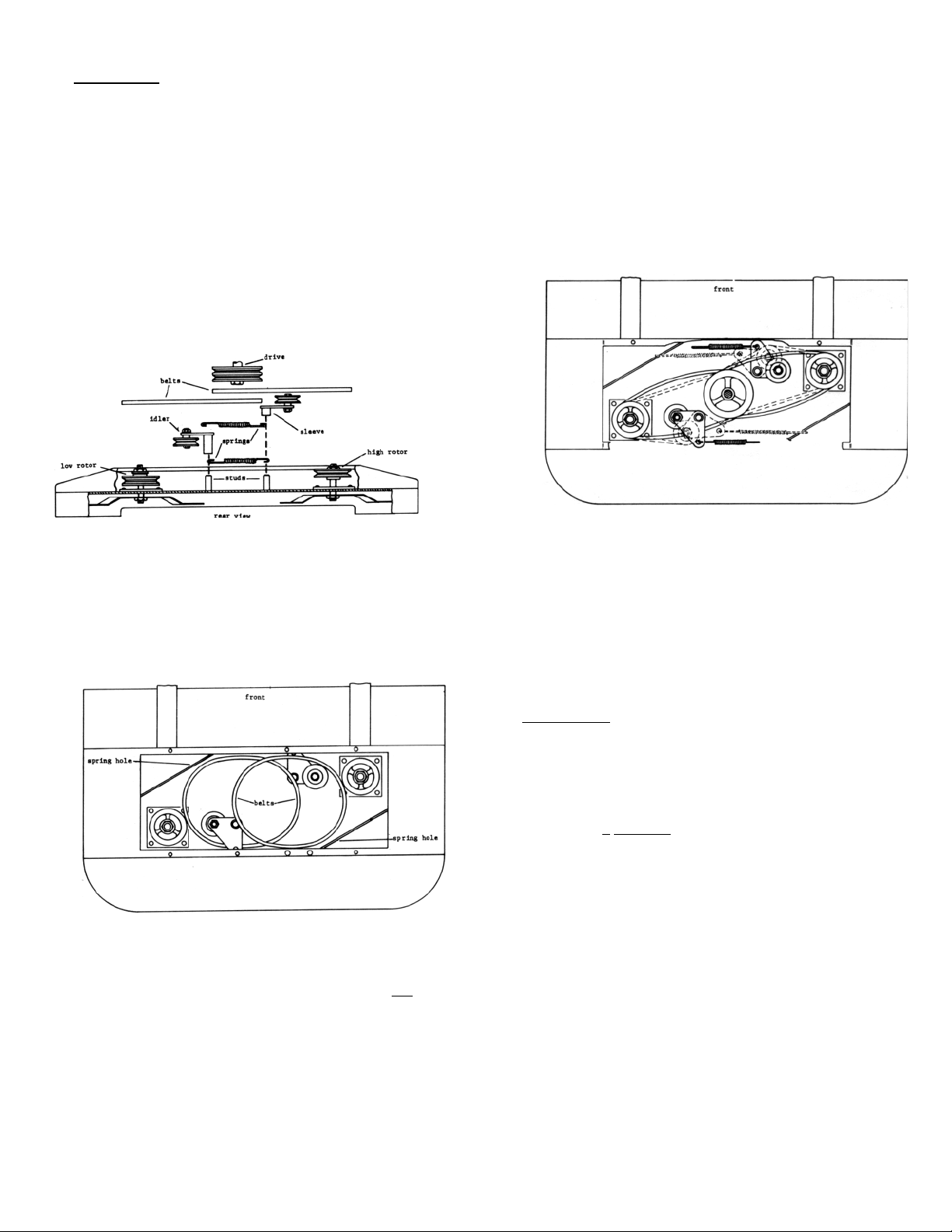

ASSEMBLY

g

g

1. Unpack the drive and deck.

2. Remove the belt covers, fig 1, Items 27.

3. Mount the idlers on the studs as in fig 2. Note the

different sleeve lengths of the idlers. The short

sleeve goes next to the high rotor and the tall

sleeve goes next to the low rotor. Set the idlers

on the studs with the extended sleeves down.

Work from the rear of the mower.

7. Bolt the drive to the deck. The 2 carriage bolts

are inserted from under the deck, fig 1, Items 41,

42 & 43. Be sure that the heads seat properly in

the deck. The 3 hex bolts fasten from the top, fig

1, Items 29 & 40. Start all bolts and nuts before

tightening.

fi

2

4. Set the belts as in fig 3; low belt first. This belt

positioning is important for ease of assembly.

3

fi

5. Hook the springs to the idler assembly from

underneath as in figs 2 & 4, solid lines.

6. Set the drive in position on the deck; do not

bolt

it down. Slip the belts on the drive pulley and

then on the rotor pulleys. Let the idlers float at

this time; solid lines, fig 4.

fig 4

8. Working from the sides, grip the springs with a spring

puller or clamp-lock pliers or equivalent. Extend the

spring hook up, over, and through the spring hole.

The belts are now in tensioned running position;

dotted lines fig 4.

9. Replace the belt covers.

10. Install the bushings in the caster wheels and

bolt the wheels in the caster forks.

LUBRICATION

1. Grease the spindle bearing weldment housing through

the grease fitting, with general purpose grease fig 1,

Item 8 & 24. Add grease until it comes out the vent

hole; opposite side of the grease fitting. Re-grease

every 8

HOURS of operation or more often when

operating in severe dust or sand.

2. Grease the bronze bearing and caster wheels through

the grease fittings with general purpose grease fig 1,

Items 38 & 49. Add grease until it comes out the

bearings. Re-grease periodically, especially when

operating in severe dust or sand.

3

Loading...

Loading...