Graupner and KG MX 12 User Manual

HOPPING.TELEMETRY.TRANSMISSION

33112.mx-12 HoTT.2.gb

HOPPING.TELEMETRY.TRANSMISSION

mx-12

GRAUPNER GMBH & CO. KG

POSTFACH 1242

D-73220 KIRCHHEIM/TECK

GERMANY

http://www.graupner.de

Modifi cations and availability reserved. Graupner products

are only available through model shops. We will gladly

inform you of your nearest stockist. We accept no liability

for printing errors.

Printed in Germany PN.PG-02

Although we have carefully checked the information contained in these instructions and

checked that it is correct, we can accept no liability of any kind for mistakes, incomplete

information and printing errors. Graupner reserves the right to alter the characteristics

and features of the software and hardware at any time and without prior notifi cation.

Programming Manual

33112_Um_mx12_HoTT_2_GB.indd 133112_Um_mx12_HoTT_2_GB.indd 1 06.06.2011 19:46:3606.06.2011 19:46:36

Contents

Guarantee certifi cate

Wir gewähren auf dieses Erzeugnis eine Garantie von

This product is warrantied for

Sur ce produit nous accordons une garantie de

24

Monaten

months

mois

General Information

Safety Notes .................................................................. 3

Saf

ety notes and handling instructions relating

to Nickel-Metal-Hydride rechargeable batteries ............8

Foreword ......................................................................10

Description of radio control set ....................................11

Recommended battery chargers ................................. 13

Transmitter power supply ............................................. 14

Receiver power supply ................................................ 16

Environmental protection notes ...................................16

Adjusting the stick length ............................................. 17

Opening the transmitter case ......................................17

Changing the stick mode ............................................. 18

Description of transmitter............................................. 20

Transmitter controls ...............................................20

Rear of transmitter .................................................21

Optional headphone socket ...................................21

PC socket .............................................................. 21

Data socket ...........................................................21

DSC (Direct Servo Control) ................................... 22

Data storage / card slot ......................................... 22

Screen and keypad ...............................................24

Operating the “Data Terminal” ...............................25

Short-cuts .............................................................. 25

Language selection, screen contrast .....................26

On-screen warnings .............................................. 28

On-screen function fi elds.......................................28

Position indicator, rotary controls CTRL 7 + 8 ....... 29

Input lock ............................................................... 29

Using the transmitter for the fi rst time ..........................30

Using the receiver for the fi rst time .............................. 32

Installation notes ..........................................................34

Receiving system power supply ............................ 35

Defi nition of terms .......................................................38

Switch and transmitter control assignment .................. 39

Contents

2

Digital trims .................................................................. 40

Fixed-wing model aircraft.............................................42

Receiver socket sequence .................................... 43

Model helicopters ........................................................46

Receiver socket sequence .................................... 47

Program descriptions

Setting up a new model memory .................................48

“Model memories”

...................................................... 52

“Base settings” (model)

Fixed-wing model aircraft ...................................... 56

Binding receivers .............................................61

Range-checking .............................................. 62

Model helicopter .................................................... 64

Binding receivers .............................................70

Range-checking .............................................. 71

“Servo settings” ..........................................................72

“Transmitter control settings”

Fixed-wing model aircraft ...................................... 74

Model helicopter .................................................... 76

Throttle limit function ....................................... 79

Basic idle setting ............................................. 79

“D/R Expo”

Fixed-wing model aircraft ...................................... 82

Model helicopter .................................................... 84

“Phase trim” (fi xed-wing) ............................................86

What is a mixer? .......................................................... 88

“Wing mixer” ..............................................................

88

“Heli mixer” ................................................................ 94

Setting up throttle and collective pitch curves ..... 100

Auto-rotation setting ............................................ 104

General notes re. freely programmable mixers .......... 106

“Free mixers” ........................................................... 107

Examples............................................................. 111

“Swashplate mixers” ...............................................112

“Servo display” .........................................................113

“Basic settings” ........................................................ 114

“Fail-Safe” .................................................................116

“Telemetry” ............................................................... 117

Setting & Data view ............................................. 118

Satellite operation with two receivers ............ 126

Simple data view ................................................. 128

RF status view ..................................................... 130

Voice trigger ........................................................ 131

“Trainer mode”

......................................................... 134

Wiring diagrams ..................................................137

Wireless HoTT system ........................................ 138

“Info display” ........................................................... 142

Programming examples

Introduction ................................................................ 144

Fixed-wing model aircraft

First steps ............................................................ 146

Including an electr

ic power system .....................150

E-motor and up-aileron using Ch1 stick .............. 152

Operating timers .................................................. 155

Use of fl ight phases .............................................156

Servos running in parallel .................................... 157

Deltas and fl ying wings .............................................. 158

F3A models ...............................................................162

Model helicopters ......................................................166

Appendix

Appendix .................................................................... 174

Conf

ormity declaration ............................................... 177

FCC Information ........................................................ 178

Guarantee certifi cate .................................................179

Servicestellen / Service / Service après-vente

Graupner-Zentralservice

Graupner GmbH & Co. KG

Henriettenstrasse 94 - 96

D-73230 Kirchheim

Belgie/Belgique/Nederland

Jan van Mouwerik

Slot de Houvelaan 30

NL 3155 Maasland VT

(+31) 10 59 13 59 4

Ceská Republika

Slovenská Republika

RC Service Z. Hnizdil

Letecka 666/22

CZ 16100 Praha 6 - Ruzyne

(+42) 2 33 31 30 95

Espana

Anguera

Hobbies

C/Terrassa 14

E 43206 Reus (Tarragona).

(+34) 97 77 55 32 0

info@anguera-hobbies.com

France

Graupner France

Gérard Altmayer

86, rue St. Antoine

F 57601 Forbach-Oeting

(+33) 3 87 85 62 12

Italia

GiMax

Via Manzoni, no. 8

I 25064 Gussago

(+39) 030 25 22 73 2

Servicehotline

(+49) 0 18 05 47 28 76*

Montag - Freitag

9:30-11:30 + 13:00-15:00 Uhr

Luxembourg

Kit Flammang

129, route d’Arlon

L 8009 Strassen

(+35) 23 12 23 2

Schweiz

Graupner Service

Wehntalerstrasse 37

CH 8181 Höri

(+41) 43 26 66 58 3

Sverige

Baltechno Electronics

Box 5307

S 40227 Göteborg

(+46) 31 70 73 00 0

United Kingdom

Graupner Service

Brunel Drive

GB, NEWARK, Nottingham-

shire

NG242EG

(+44) 16 36 61 05 39

* 0,14 Cent / Minute aus dem

Festnetz der deutschen

T-Com. Abweichende Preise

für Anrufe aus Mobilfunknetzen oder aus dem Festnetz

anderer Anbieter möglich.

Die Fa. Graupner GmbH & Co. KG, Henriettenstraße 94 - 96,

D-73230 Kirchheim/Teck gewährt ab dem Kaufdatum auf

dieses Produkt eine Garantie von 24 Monaten. Die Garantie

gilt nur für die bereits beim Kauf des Produktes vorhandenen

Material- oder Funktionsmängel. Schäden, die auf Abnützung,

Überlastung, falsches Zubehör oder unsachgemäße Behandlung zurückzuführen sind, sind von der Garantie ausgeschlossen. Die gesetzlichen Rechte und Gewährleistunsansprüche

des Verbrauchers werden durch diese Garantie nicht berührt.

Bitte überprüfen Sie vor einer Reklamation oder Rücksendung

das Produkt genau auf Mängel, da wir Ihnen bei Mängelfreiheit

die entstandenen Unkosten in Rechnung stellen müssen.

Graupner GmbH & Co. KG, Henriettenstraße 94 - 96. D-73230

Kirchheim/Teck, Germany guarantees this product for a period

of 24 months from date of purchase. The guarantee applies

only to such material or operational defects witch are present

at the time of purchase of the product. Damage due to wear,

overloading, incompetent handling or the use of incorrect

accessories is not covered by the guarantee. The user´s legal

rights and claims under guarantee are not affected by this

guarantee. Please check the product carefully for defects before you are make a claim or send the item to us, since we are

obliged to make a charge for our cost if the product is found to

be free of faults.

La société Graupner GmbH & Co. KG, Henriettenstraße 9496, D-73230 Kirchheim/Teck, accorde sur ce produit une

garantie de 24 mois à compter de la date d’achat. La garantie

ne s’applique qu’aux défauts de matériel et de fonctionnement

du produit acheté. Les dommages dus à une usure, à une

surcharge, à l’emploi d’accessoires non compatibles ou à

une manipulation non conforme sont exclus de la garantie.

Cette garantie ne remet pas en cause les droits légaux des

consommateurs. Avant toute réclamation ou retour de matériel,

vérifi ez précisément les défauts ou vices constatés, car si le

matériel est conforme et qu’aucun défaut n’a été constaté par

nos services, nous nous verrions contraints de facturer le coût

de cette intervention.

Garantie-Urkunde

Warranty certifi cate / Certifi cat de garantie

mx-12 HoTT Set

Order No. 33112

Übergabedatum:

Date of purchase/delivery:

Date d’achat :

Name des Käufers:

Owner´s name:

Nom de I`acheteur :

Straße, Wohnort:

Complete address:

Adresse complète :

Firmenstempel und Unterschrift des Einzelhändlers:

Stamp and signature of dealer:

Cachet et signature du détaillant :

Guarantee certifi cate

179

33112_Um_mx12_HoTT_2_GB.indd 233112_Um_mx12_HoTT_2_GB.indd 2 06.06.2011 19:46:5406.06.2011 19:46:54

Safety Notes

Please read carefully!

We all want you to have many hours of pleasure in our

utual hobby of modelling, and safety is an important

m

aspect of this. It is absolutely essential that you read

right through these instructions and take careful note

of all our safety recommendations. We also strongly

recommend that you register without delay at http://

www.graupner.de/en/service/product_registration, as

this ensures that you automatically receive the latest

information relating to your product by e-mail.

If you are a beginner to the world of radio-controlled

model aircraft, boats and cars, we strongly advise that

you seek out an experienced modeller in your fi eld, and

ask him or her for help and advice.

If you ever dispose of this transmitter, these instructions

must be passed on to the new owner.

Application

This radio control system may only be used for the

purpose for which the manufacturer intended it, i. e. for

operating radio-controlled models which do not carry hu-

mans. No other type of use is approved or permissible.

Safety notes

SAFETY IS NO ACCIDENT

and

RADIO-CONTROLLED MODELS

ARE NOT PLAYTHINGS

Even small models can cause serious personal injury

and damage to property if they are handled incompetently, or if an accident occurs due to the fault of others.

Technical problems in electrical and mechanical systems can cause motors to rev up or burst into life unexpectedly, with the result that parts may fl y off at great

speed, causing considerable injury.

Short-circuits of all kinds must be avoided at all times.

Short-circuits can easily destroy parts of the radio control system, but even more dangerous is the acute risk

of fi re and explosion, depending on the circumstances

and the energy content of the batteries.

Aircraft and boat propellers, helicopter rotors, open

gearboxes and all other rotating parts which are driven

by a motor or engine represent a constant injury hazard.

Do not touch these items with any object or part of your

body. Remember that a propeller spinning at high speed

can easily slice off a fi nger! Ensure that no other object

can make contact with the driven components.

Never stand in the primary danger zone, i. e. in the rotational plane of the propeller or other rotating parts, when

the motor is running or the drive battery is connected.

Please note that a glowplug engine or electric motor

could burst into life accidentally if the receiving system

is switched on when you are transmitting the transmitter.

To be on the safe side, disconnect the fueltank or the

fl ight battery.

Protect all electronic equipment from dust, dirt, damp,

and foreign bodies. Avoid subjecting the equipment

to vibration and excessive heat or cold. Radio control

equipment should only be used in “normal” ambient

temperatures, i. e. within the range -15°C to +55°C.

Avoid subjecting the equipment to shock and pressure.

Check the units at regular intervals for damage to cases

and leads. Do not re-use any item which is damaged or

has become wet, even after you have dried it out thoroughly.

Use only those components and accessories which

we expressly recommend. Be sure to use only genuine

matching Graupner connectors of the same design with

contacts of the same material.

When deploying cables ensure that they are not under

strain, are not tightly bent (kinked) or broken. Avoid

sharp edges, as they can chafe through insulating

materials.

Before you use the system, check that all connectors

are pushed home fi rmly. When disconnecting components, pull on the connectors themselves – not on the

wires.

It is not permissible to carry out any modifi cations to the

RC system components, as any such changes invalidate

both your operating licence and your insurance cover.

Installing the receiving system

In a model aircraft the receiver must be packed in soft

foam and stowed behind a stout bulkhead, and in a

model boat or car it should be protected effectively from

dust and spray.

The receiver must not make direct contact with the

fuselage, hull or chassis at any point, otherwise motor

vibration and landing shocks will be transmitted directly

to it. When installing the receiving system in a model

with a glowplug or petrol engine, be sure to install all

the components in well-protected positions, so that no

exhaust gas or oil residues can reach the units and

get inside them. This applies above all to the ON / OFF

switch, which is usually installed in the outer skin of the

model.

Secure the receiver in such a way that the aerial, servo

leads and switch harness are not under any strain. The

receiver aerial should be at least 5 cm away from all

large metal parts and any wiring which is not connected

directly to the receiver. This includes steel and carbon

fi bre components, servos, electric motors, fuel pumps,

cabling of all kinds, etc..

Ideally the receiver should be installed well away from

Safety Notes

3

33112_mx12_HoTT_2_GB.indd Abs2:333112_mx12_HoTT_2_GB.indd Abs2:3 06.06.2011 19:39:1306.06.2011 19:39:13

Safety Notes

any other installed equipment in the model, but in an

easily accessible position. Under no circumstances allow servo leads to run close to the aerial, far less coiled

round it!

Ensure that cables are fastened securely, so that they

cannot move close to the receiver aerial when the model

is fl ying.

Deploying the receiver aerial(s)

The receiver and its aerials should be installed as far

away as possible from all kinds of power system. If your

model has a carbon fi bre fuselage, the aerial tips must

always be deployed outside the fuselage. The orientation

of the aerial(s) is not critical, but we recommend installing them vertically (upright) in the model. If the receiver

features aerial diversity (two aerials), the second aerial

should be arranged at 90° to the fi rst.

Installing the servos

Always install servos using the vibration-damping

grommets supplied. The rubber grommets provide some

degree of protection from mechanical shock and severe

vibration.

Installing control linkages

The basic rule is that all linkages should be installed in

such a way that the pushrods move accurately, smoothly

and freely. It is particularly important that all servo output

arms can move to their full extent without fouling or rubbing on anything, or being obstructed mechanically at

any point in their travel.

It is essential that you should be able to stop your motor

at any time. With a glow motor this is achieved by adjusting the throttle so that the barrel closes completely when

you move the throttle stick and trim to their end-points.

Ensure that no metal parts are able to rub against each

other, e. g. when controls are operated, when parts

rotate, or when motor vibration affects the model. Metalto-metal contact causes electrical “noise” which can

interfere with the correct working of the receiver.

Directing the transmitter aerial

Transmitter fi eld strength is at a minimum in an imaginary line extending straight out from the transmitter

aerial. It is therefore fundamentally misguided to “point”

the transmitter aerial at the model with the intention of

obtaining good reception.

When several radio control systems are in use on adjacent channels, the pilots should always stand together in

a loose group. Pilots who insist on standing away from

the group endanger their own models as well as those

of the other pilots.

However, if two or more pilots operating 2.4 GHz radio

control systems stand closer together than 5 m, the

down-link channel may be swamped, triggering a very

premature range warning. If this should occur, walk

away from the other pilots until the range warning

ceases again.

Pre-fl ight checking

Before you switch on the receiver, ensure that the throt-

tle stick is at the stop / idle end-point.

Always switch on the transmitter fi rst,

and only then the receiver.

Always switch off the receiver fi rst,

and only then the transmitter.

If you do not keep to this sequence, i. e. if the receiver

is at any time switched on when “its” transmitter is

switched OFF, then the receiver is wide open to signals

from other transmitters and any interference, and may

respond. The model could then carry out uncontrolled

movements, which could easily result in personal injury

or damage to property.

Please take particular care if your model is fi tted with

a mechanical gyro: before you switch your receiver off,

disconnect the power supply to ensure that the motor

cannot run up to high speed accidentally.

As it runs down, the gyro can generate such a high

voltage that the receiver picks up apparently valid

throttle commands, and the motor could respond by

unexpectedly bursting into life.

Range checking

Before every session check that the system works properly

in all respects, and has adequate range.

adequately, and ensure that no persons are standing in

front of the model.

Carry out at least one complete function check on the

ground, followed by a complete simulated fl ight, in order

to show up any errors in the system and the model’s

programming. Be sure to read the notes on pages 62

and 71 in this regard.

When operating a model, i. e. when fl ying or driving,

do not operate the transmitter without the aerial fi tted.

Check that the transmitter aerial is fi rmly seated.

Operating your model aircraft, helicopter, boat or car

Never fl y directly over spectators or other pilots, and

take care at all times not to endanger people or animals.

Keep well clear of high-tension overhead cables. Never

operate your model boat close to locks and full-size vessels. Model cars should never be run on public streets or

motorways, footpaths, public squares etc..

Secure the model

Safety Notes

4

33112_mx12_HoTT_2_GB.indd Abs2:433112_mx12_HoTT_2_GB.indd Abs2:4 06.06.2011 19:39:2506.06.2011 19:39:25

Checking the transmitter and receiver batteries

It is essential to stop using the r

adio control system and

recharge the batteries well before they are completely

discharged. In the case of the transmitter this means –

at the very latest – when the message “battery needs

charging” appears on the screen, and you hear an

audible warning signal.

It is vital to check the state of the batteries at regular

intervals – especially the receiver pack. When the battery is almost fl at you may notice the servos running

more slowly, but it is by no means safe to keep fl ying or

running your model until this happens. Always replace or

recharge the batteries in good time.

Keep to the battery manufacturer’s instructions, and

don’t leave the batteries on charge for longer than

stated. Do not leave batteries on charge unsupervised.

Never attempt to recharge dry cells, as they may explode.

Rechargeable batteries should always be recharged before every session. When charging batteries it is important to avoid short-circuits. Do this by fi rst connecting the

banana plugs on the charge lead to the charger, taking

care to maintain correct polarity. Only then connect the

charge lead to the transmitter or receiver battery.

Disconnect all batteries and remove them from your

model if you know you will not be using it in the near

future.

Capacity and operating times

This rule applies to all battery types: capacity diminishes

with each charge. At low temperatures the battery’s

internal resistance rises, and capacity falls. This means

that its ability to deliver current and maintain voltage is

reduced.

Frequent charging, and / or the use of maintenance

programs, tends to cause a gradual reduction in battery

capacity. We recommend that you check the capacity of

all your rechargeable batteries at least every six months,

and replace them if their performance has fallen off

signifi cantly.

Use only genuine Graupner rechargeable batteries!

Suppressing electric motors

All conventional (brushed) electric motors generate

sparks between the commutator and the brushes, which

cause more or less serious interference to the radio

control system, depending on the type of motor. If an

RC system is to work correctly, it is therefore important

to suppress the electric motors, and in electric-powered

models it is essential that every motor should be effectively suppressed. Suppressor fi lters reliably eliminate

such interference, and should always be fi tted where

possible.

Please read the notes and recommendations supplied

by the motor manufacturer.

Refer to the main Graupner FS catalogue or the Internet

website at www.graupner.de for more information on

suppressor fi lters.

Servo suppressor fi lter for extension leads

Order No. 1040

Servo suppressor fi lters are required if you are obliged

to use long servo extension leads, as they eliminate the

danger of de-tuning the receiver. The fi lter is connected

directly to the receiver input. In very diffi cult cases a

second fi lter can be used, positioned close to the servo.

Using electronic speed controllers

The basic rule is that the electronic speed controller

must be chosen to suit the size of the electric motor it is

required to control.

There is always a danger of overloading and possibly

damaging the speed controller, but you can avoid this by

ensuring that the controller’s current-handling capacity is

at least half the motor’s maximum stall current.

Particular care is called for if you are using a “hot” (i. e.

upgrade) motor, as any low-turn motor (small number of

turns on the winding) can draw many times its nominal

current when stalled, and the high current will then burn

out the speed controller.

Electrical ignition systems

Ignition systems for internal combustion engines can

also produce interference, which has an adverse effect

on the working of the radio control system.

Electrical ignition systems should always be powered by

a separate battery – not the receiver battery.

Be sure to use effectively suppressed spark plugs and

plug caps, and shielded ignition leads.

Keep the receiving system an adequate distance away

from the ignition system.

Static charges

Lightning causes magnetic shock waves which can

interfere with the operation of a radio control transmitter

even if the thunderstorm actually occurs several kilometres away. For this reason …

… cease fl ying operations immediately if you notice

an electrical storm approaching. Static charges

through the transmitter aerial can be life-threatening!

Caution

In order to fulfi l the FCC RF radiation regulations •

Safety Notes

33112_mx12_HoTT_2_GB.indd Abs2:533112_mx12_HoTT_2_GB.indd Abs2:5 06.06.2011 19:39:2506.06.2011 19:39:25

5

Safety Notes

applicable to mobile transmitting apparatus, the

equipment’

person when the system is in use. We therefore do

not recommend using the equipment at a closer

range than 20 cm.

Ensure that no other transmitter is closer than 20 cm •

from your equipment, in order to avoid adverse

effects on the system’s electrical characteristics and

radiation pattern.

The radio control system should not be operated •

until the Country setting has been set correctly at

the transmitter. This is essential in order to fulfi l the

requirements of various directives - FCC, ETSI, CE

etc. Please refer to the instructions for your particular

transmitter and receiver for details of this procedure.

Check all working systems and carry out at least one •

full range check on the ground before every fl ight, in

order to show up any errors in the system and the

model’s programming.

Never make any changes to the programming of the •

transmitter or receiver whilst operating a model.

Care and maintenance

Don’t use cleaning agents, petrol, water or other solvents to clean your equipment. If the case, the aerial etc.

gets dirty, simply wipe the surfaces clean with a soft dry

cloth.

Components and accessories

As manufacturers, the company of Graupner GmbH &

Co. KG recommends the exclusive use of components

and accessories which have been tested by Graupner

and approved for their capability, function and safety. If

you observe this rule, Graupner accepts responsibility

for the product.

6

s aerial must be at least 20 cm from any

Safety Notes

Graupner cannot accept liability for non-approved

components or accessories made by other manufacturers. It is not possible for Graupner to assess

every individual item manufactured by other companies, so we are unable to state whether such parts

can be used without incurring a safety risk.

Liability exclusion / Compensation

It is not possible for Graupner to ensure that the user

observes the installation and operation instructions, and

the recommended conditions and methods when installing, operating, using and maintaining the radio control

components. For this reason Graupner denies all liability

for loss, damages or costs which arise through misuse

or mishandling of this equipment, or are connected with

such use in any way.

Unless obliged by law, Graupner’s obligation to pay compensation, regardless of the legal argument employed,

is limited to the invoice value of that quantity of Graup-

ner products which were immediately involved in the

event in which the damage occurred, unless the company is deemed to have unlimited liability on account of

deliberate or gross negligence.

The sole purpose of this manual is to provide information; it is subject to amendment without prior notifi cation.

Graupner accepts no responsibility or liability for errors

or inaccuracies which may occur in the information

section of this manual.

Environmental protection

This symbol on the product, in the operating instructions

or the packaging indicates that the product must not be

discarded via the normal household refuse at the end

of its useful life. Instead it must be taken to a collection

point for the recycling of electrical and electronic apparatus.

The materials can be re-used according to their identifi cation code. You can make an important contribution to

the protection of our shared environment by recycling

old equipment and making use of its

basic materials.

Dry and rechargeable batteries must

be removed from the device and taken

to the appropriate collection point.

Please ask your local authority for

the location of your nearest waste

disposal site.

33112_mx12_HoTT_2_GB.indd Abs2:633112_mx12_HoTT_2_GB.indd Abs2:6 06.06.2011 19:39:2506.06.2011 19:39:25

For your notes

33112_mx12_HoTT_2_GB.indd Abs56:733112_mx12_HoTT_2_GB.indd Abs56:7 06.06.2011 19:39:2506.06.2011 19:39:25

7

Safety notes and handling instructions relating to Nickel-Metal-Hydride rechargeable

batteries

As with all sophisticated technical products, it is vitally

important that you observe the following safety notes

and handling instructions if you wish the equipment to

operate safely and reliably for an extended period.

Safety notes

Rechargeable batteries are not playthings, and must •

be kept well away from children.

Store rechargeable batteries out of the reach of children.

Check that the batteries are in perfect, serviceable •

condition before every use. Do not re-use defective or

damaged batteries.

Rechargeable batteries must be used within the •

specifi ed limits stated for the corresponding cell type.

Do not heat, incinerate or short-circuit rechargea-•

ble batteries, and never charge them with excessive currents or reversed polarity.

Never use rechargeable batteries consisting of •

parallel-wired cells, combinations of old and new

cells, cells of different construction, size, capacity, make, brand or cell type.

Batteries installed inside equipment should always be •

removed from the device when it is not in use and not

about to be used. Always keep equipment switched

off in order to avoid deep-discharged cells. Batteries

must be recharged in good time.

The battery to be charged should be placed on a •

non-infl ammable, heat-resistant, non-conductive

surface for the whole of the charge period. Keep

infl ammable and volatile objects and materials well

clear of the charging area.

Batteries must always be supervised when on •

charge. Never exceed the maximum fast-charge cur-

Safety Notes

8

rent specifi ed for the cell type in use.

If the battery heats up to more than 60°C whilst on •

charge, halt the charge process immediately and

allow the pack to cool down to about 30°C.

Never recharge a battery which is already charged, •

hot, or not completely discharged.

Do not make any modifi cations to batteries. Never •

solder or weld directly to cells.

If incorrectly handled, rechargeable batteries are at •

risk of combustion, explosion, corrosive action and

burns. Suitable extinguishing materials include fi re

blankets, CO2 fi re extinguishers and sand.

Escaped electrolyte is corrosive - do not allow it to •

contact skin or eyes. In an emergency rinse the area

immediately with plenty of clean water before seeking

medical help.

The cells’ air vents must never be blocked or sealed, •

e. g. by solder. When soldering, the iron temperature

should not exceed 220°C, and each joint should be

completed in less than twenty seconds.

To avoid cell deformation, do not exert excessive •

mechanical pressure on battery cells.

If a battery should be accidentally overcharged, use •

the following procedure:

Simply disconnect the battery and leave it on a noninfl ammable surface (e. g. stone fl oor) until it has

cooled down. Never hold the battery in your hand, as

there is a risk that cells might explode.

Always observe the recommended rates for charging •

and discharging.

General information

The capacity of your rechargeable battery diminishes

with every charge / discharge process. Stored batteries

may eventually exhibit reduced capacity.

Storage

Batteries should not be stored in a completely discharged state. Store them in a dry enclosed space at an

ambient temperature of +5°C to +25°C. If you are storing

a battery for a period longer than four weeks, ensure

that the cell voltage does not fall below 1.2 V

Balancing individual battery cells

To balance new battery cells, i. e. to bring them all •

to the same state of charge, charge them at what

is known as the ‘normal’ rate until they are full. As a

general guideline a fully discharged battery needs to

be charged for a period of twelve hours at a current

corresponding to one tenth of the capacity printed on

the cell label (the “1/10C” method). After this treatment all the cells will be fully charged, and exhibit

the same voltage. This method of balancing battery

cells should be repeated after every ten fast-charge

processes, so that the cells are repeatedly balanced;

this helps to ensure an extended useful life for your

batteries.

If you have the facilities to discharge individual cells, •

we recommend that you make use of this before

every charge process. Otherwise the battery pack

should be run down to a discharge voltage of 0.9

V per cell. For example, this corresponds to a fi nal

discharge voltage of 3.6 V in the case of the four-cell

pack used in the transmitter.

Charging

Ni-MH batteries should only be charged using the specifi ed currents, charge times and temperature range, and

should be supervised constantly when on charge. If you

do not have access to a suitable fast charger, i. e. one

33112_mx12_HoTT_2_GB.indd Abs57:833112_mx12_HoTT_2_GB.indd Abs57:8 06.06.2011 19:39:2506.06.2011 19:39:25

which allows you to set the charge current accurately,

then the batter

y should always be recharged using the

“normal” charge rate of 1/10C; see the example stated

above.

Wherever possible, transmitter batteries should

always be recharged at the 1/10C rate, in order to

avoid differences in cell states. The charge current

must never exceed the maximum permissible value

stated in the transmitter instructions.

Fast charging

If your battery charger includes the facility to adjust •

the Delta Peak charge cut-off voltage, set this value

to 5 mV per cell. However, most chargers are set to

a fi xed cut-off value of 15 … 20 mV per cell, which

makes them suitable for use with both NiCd and

NiMH batteries. If you are not sure about this, please

refer to the operating instructions supplied with your

charger, or ask at your local model shop whether

your charger is also suitable for Ni-MH packs. If in

any doubt, charge your batteries at half the stated

maximum charge current.

Discharging

All rechargeable batteries sold by Graupner and GMRacing are suitable for a maximum continuous current

load of 6C … 13C, according to battery type (refer to the

manufacturer’s specifi cation!). The higher the continuous

current load, the shorter the batteries’ useful life.

Use your battery until its performance falls off, or until •

the low voltage warning is triggered.

Caution:

When stored for a long period, the cell voltage should

not be allowed to fall below 1.2 V. This means that

you may have to recharge the battery before stor-

ing it.

Refl ex charging and charge / discharge (cycle) •

programs shorten the effective life of batteries unnecessarily, and are only suitable for checking battery

quality or “reviving” relatively old cells. It also makes

no sense to charge / discharge a battery before using

it - unless you simply wish to check its quality.

Disposal of exhausted dry and rechargeable batteries

The German Battery Order places a legal requirement

on every consumer to return all used and exhausted

dry cells and rechargeable batteries. It is prohibited to

dispose of these items in the ordinary domestic waste.

At no charge to the user, old dry and rechargeable

batteries can be surrendered at local authority collection points, Graupner retail outlets, and any other shop

where dry and rechargeable batteries of the same type

are sold. You can also send batteries supplied by us to

the following address - with adequate pre-paid postage

- for disposal:

Graupner GmbH & Co. KG

Service: Gebrauchte Batterien (Used batteries)

Henriettenstr. 94 - 96

D-73230 Kirchheim unter Teck

You can make an important contribution to environmen-

tal protection in this way.

Caution:

Damaged batteries may require special packaging before despatch, as some contain highly toxic materials!!!!!

Safety Notes

33112_mx12_HoTT_2_GB.indd Abs57:933112_mx12_HoTT_2_GB.indd Abs57:9 06.06.2011 19:39:2506.06.2011 19:39:25

9

mx-12 the latest generation of radio control technology

HoTT (Hopping Telemetry Transmission) is the synthesis of expertise, engineering and world-wide testing by

professional pilots. The equipment operates on the 2.4

GHz band, and offers bi-directional communication between transmitter and receiver via a down-link channel

integrated into the receiver.

The mx-12 HoTT RC system is based on the Graup-

ner/JR mc-24 computer radio control system which

was introduced back in 1997. It has been developed

specifi cally for the beginner, but the mx-12 HoTT is

still capable of controlling all current model types without problem - whether fi xed-wing model or helicopter,

model boat or car.

In the area of fi xed-wing models and helicopters it is

often necessary to employ complex mixer functions

for the control surfaces or the swashplate actuation

system. Computer technology enables you to activate

a vast range of functions to cope with special model

requirements – just by pressing a button. With the mx-

12 HoTT all you do is select the appropriate model

type, and the software then presents you automatically

with the appropriate mixer and coupling functions. This

means that the transmitter requires no additional modules in order to implement complex coupled functions,

and you can forget all about old-fashioned mechanical

mixers in the model. The mx-12 HoTT provides an

extremely high level of safety and reliability in use.

The mx-12 HoTT offers ten model memories, each

of which can store model settings for different fl ight

phases. Individual phases can be called up in fl ight

simply by operating a switch, so that you can try out

various settings quickly and without risk. This can be

for test purposes or for varying parameters for different

phases of fl ight.

The large graphic screen makes operating the transmitter a simple, intuitive process. Mixers and other

functions can be displayed in graphic form, and this is

extraordinarily helpful.

The beginner quickly becomes familiar with the different

functions thanks to the clear, logically arranged program

structure. Four-way buttons to left and right of the highcontrast screen are used to enter settings, allowing the

user to exploit all the options he needs, in accordance

with his experience in handling radio-controlled models.

In theory the Graupner HoTT process allows more than

200 models to be operated simultaneously. Although in

practice the mixed operation of different technical systems in the 2.4 GHz ISM band – as required by the approval regulations – reduces this number considerably.

Generally, however, it will always be possible to operate

even more models simultaneously on the 2.4 GHz band

than on the 35 / 40 MHz frequency bands which we

have used to date. However, the actual limiting factor –

as it has always been – is likely to remain the size of the

(air-) space available. The simple fact that no frequency

control procedure is necessary equates to an enormous

gain in safety, especially at fl ying sites such as gliding

slopes where groups of pilots may be distributed over a

large area, with nobody in overall control.

The integral Telemetry menu provides a simple means

of accessing data and programming HoTT receivers.

For example, this method can be used to map receiver

outputs, distribute control functions to multiple servos,

and match servo travels and directions to each other.

This manual describes each menu in detail, and also

provides dozens of useful tips, notes and programming

examples to complement the basic information. More

general modelling terms, such as Transmitter controls,

Dual-Rates, Butterfl y (Crow) and many others, are all

explained in the manual.

Please refer to the Appendix for additional information

on the HoTT system. This manual concludes with the

transmitter’s conformity declaration and guarantee

certifi cate.

Please read the safety notes and the technical information. We recommend that you read right through the

instructions with great care, and check all the functions

as described in the text. This can be carried out simply

by connecting servos to the supplied receiver, and

watching their response as you program the transmitter. However, please read the notes on page 20 in this

regard. This is the quickest method of becoming familiar

with the essential procedures and functions of the mx-

12 HoTT.

Always handle your radio-controlled model with a

responsible attitude to avoid endangering yourself and

others.

The Graupner team wishes you great pleasure and success with your mx-12 HoTT - a radio control system of

the latest generation.

Kirchheim-Teck, June 2011

Introduction

10

33112_mx12_HoTT_2_GB.indd Abs3:1033112_mx12_HoTT_2_GB.indd Abs3:10 06.06.2011 19:39:2506.06.2011 19:39:25

mx-12 Computer System

Six-channel radio control set with Graupner HoTT 2.4 GHz technology (Hopping Telemetry Transmission)

Micro-computer radio control system exploiting the •

latest Graupner HoTT 2.4 GHz technology

Bi-directional communication between transmitter •

and receiver

Five different languages•

German and English; subsequent software updates

will offer French, Italian and Spanish.

Ultra-fast response times through direct, ultra-reliable •

data transmission from the main processor to the

2.4 GHz RF module. No additional delay caused by

detours through a module processor.

Telemetry menu for displaying telemetry data, and •

programming receiver outputs and optional sensors.

Telemetry display shows numerous programming and •

analysis functions directly on the transmitter screen.

Speech output possible using optional speech output •

module, Order No. 33001.71

User-selectable servo cycle times for digital servos, •

min. 10 ms

Short, folding aerial•

Methods of operation and programming based on the •

proven concepts of the mc-19 to mc-24

High-contrast graphic screen with blue backlighting •

ensures perfect monitoring of set-up parameters,

such as model type, model memory, timers and

Graupner HoTT technology offers excellent reliability in use, with bi-directional communication between transmitter and receiver, integrated telemetry

and ultra-fast response times.

Simplifi ed programming technology with four-way

push-buttons.

High-contrast eight-line graphic screen with blue

backlighting for ultra-clear display of all set-up

parameters and telemetry data. A micro-SD memory

card can be used to back-up model data and store

telemetry data.

12-bit / 4096-step channel signal resolution for

extremely fi ne control characteristics.

operating voltage.

Function encoder with two four-way buttons for sim-•

plifi ed programming and accurate settings

Key-Lock function to guard against accidental opera-•

tion.

Three programmable fl ight phases•

Ten model memories, with storage of all model-•

specifi c programming and set-up parameters

Description of radio control set

11

33112_mx12_HoTT_2_GB.indd Abs4:1133112_mx12_HoTT_2_GB.indd Abs4:11 06.06.2011 19:39:2506.06.2011 19:39:25

mx-12 Computer System

Six-channel radio control set with Graupner HoTT 2.4 GHz technology (Hopping Telemetry Transmission)

Four switches (two three-way switches, one two-way •

witch and one momentary switch), plus two digital

s

controls - already installed and extremely versatile

Unrestricted assignment of all switches to switched •

functions simply by operating the appropriate switch

Storage of model memories using the latest battery-•

free back-up system

Six control functions with simplifi ed, very convenient •

assignment of transmitter controls for auxiliary functions, such as switches and proportional controls

Convenient mode selector provides simple method •

of changing the stick mode (modes 1 - 4, e. g. throttle

right / throttle left).

When you change modes, all the affected settings

are switched at the same time.

Graphical servo display provides a straightforward •

overview of the servo set-up, and a swift method of

checking servo travels

Receiver output swap•

Comprehensive programs for fi xed-wing model •

aircraft and helicopters:

Fixed-wing menu for: 1 AIL, 2 AIL, 2 AIL + 2 FLAP, V-

tail, delta / fl ying wing, two elevator servos

Fixed-wing mixer: diff aile, diff.fl aps, ail ¼ rudd, ail

¼ fl aps, brake ¼ elev, brake ¼ fl ap, brake ¼ aile,

elev ¼ fl ap, elev ¼ aile, fl ap ¼ elev, fl ap ¼ aile

and diff. reduction

Heli menu: 1-point, 2-point, 3-point and 4-point •

linkages (1 servo, 2 servo, 3sv(2roll), 3sv(140°),

3sv(2nick (pitch-axis)), 4 SV (90°))

Swashplate limiter•

Servo travel adjustment +/- 150% for all servo out-•

puts, variable separately for each side (Single Side

Description of radio control set

12

Servo Throw)

Variable sub-trim, range +/- 125%, for adjusting the •

neutral position of all servos

Servo reverse, programmable for all servos•

EXPO / DUAL-RATE system, separately variable, can •

be switched in-fl ight, fl ight phase programmable

Stopwatch / count-down timer with alarm function•

Model memory copy function•

Integral DSC socket for use with fl ight simulators and •

Trainer systems

General features of the HoTT system

Simple, ultra-fast binding of transmitter and receiver•

Multiple receivers can be bound per model for paral-•

lel operation

Extremely fast re-binding, even at maximum range•

Two-receiver satellite operation using special cable •

connection

Range-check and warning function•

Receiver low-voltage warning on transmitter screen•

Ultra-wide receiver operating voltage range: 3.6 V to •

8.4 V (fully operational down to 2.5 V)

Fail-Safe•

Unrestricted channel assignment (channel-mapping), •

mixer functions and all servo settings programmable

in the Telemetry menu

Up to four servos can be actuated simultaneously •

as a block, with a servo cycle time of 10 ms (digital

servos only)

Optimised frequency hopping and broad channel •

spread for maximum interference rejection

Intelligent data transmission with corrective function•

Real-time telemetr

y analysis•

More than 200 systems can be operated simultane-•

ously

Future-proof update capability using data interface•

33112_mx12_HoTT_2_GB.indd Abs4:1233112_mx12_HoTT_2_GB.indd Abs4:12 06.06.2011 19:39:2606.06.2011 19:39:26

The set Order No. 33112 contains:

mx-12 HoTT micro-computer transmitter with integral

4NH-2000 RX RTU fl at-pack Ni-MH transmitter battery (specifi cation reserved), Graupner GR-12 HoTT

bi-directional receiver, switch harness and plug-type

battery charger

Recommended battery chargers (optional)

Suitable for

the following

battery types

Order

No. Description

220 V mains conn.

12 V DC connect.

NiCd

Ni-MH

LiPo

Lead-ac.

6407 Multilader 3 x x x x

6411 Ultramat 8 x x x x x

6425 Twin Charger x x

6427 Multilader 3 x x x x

6455 Multilader 7E x x x x

6463

Ultramat 12 plus

Pocket

xxxxx

6464 Ultramat 14 plus x x x x x x

6466 Ultra Trio plus 14 x x x x x x

6468 Ultramat 16S x x x x x x

6470 Ultramat 18 x x x x x x

Specifi cation,

mx-12 HoTT transmitter

Frequency band 2,4 … 2,4835 GHz

Modulation FHSS

Transmitter power see country setting, page 115

Control functions Six functions; four with trims

Temperature range -10 … +55 °C

Aerial folding

Operating voltage 3,4 … 6 V

Current drain approx. 180 mA

Dimensions approx. 190 x 195 x 90 mm

Weight approx. 770 g with transmitter

battery

Integral charge. lead

Accessories

Order No. Description

1121 Neckstrap, 20 mm wide

70 Neckstrap, 30 mm wide

3097 Wind-shield for hand-held transmitter

Trainer leads for mx-12 HoTT:

see page 137

Specifi cation, GR-12 HoTT receiver

Operating voltage 3,6 … 8,4 V

Current drain ca. 70 mA

Frequency band 2,4 … 2,4835 GHz

Modulation FHSS

Aerial approx. 145 mm long,

approx. 115 mm encapsulated and approx. 30 mm

active

Servo sockets 6

Sensor socket 1 (instead of servo 5)

Temperature range approx. -15° … +70 °C

Dimensions approx. 36 x 21 x 10 mm

Weight approx. 7 g

To recharge the mx-16iFS system you will also need the transmitter

charge lead, Order No. 3022, and the receiver battery charge lead,

Order No. 3021, unless stated otherwise in the table.

For details of additional battery chargers, and details of the chargers

listed here, please refer to the main Graupner FS catalogue, or our

Internet site at www.graupner.de.

33112_mx12_HoTT_2_GB.indd Abs4:1333112_mx12_HoTT_2_GB.indd Abs4:13 06.06.2011 19:39:2606.06.2011 19:39:26

Replacement parts

Order No. Description

2498.4FBEC

4NH-2000 RX RTU, fl at-pack

33800 HoTT transmitter aerial

Description of radio control set

13

Operating Notes

Transmitter power supply

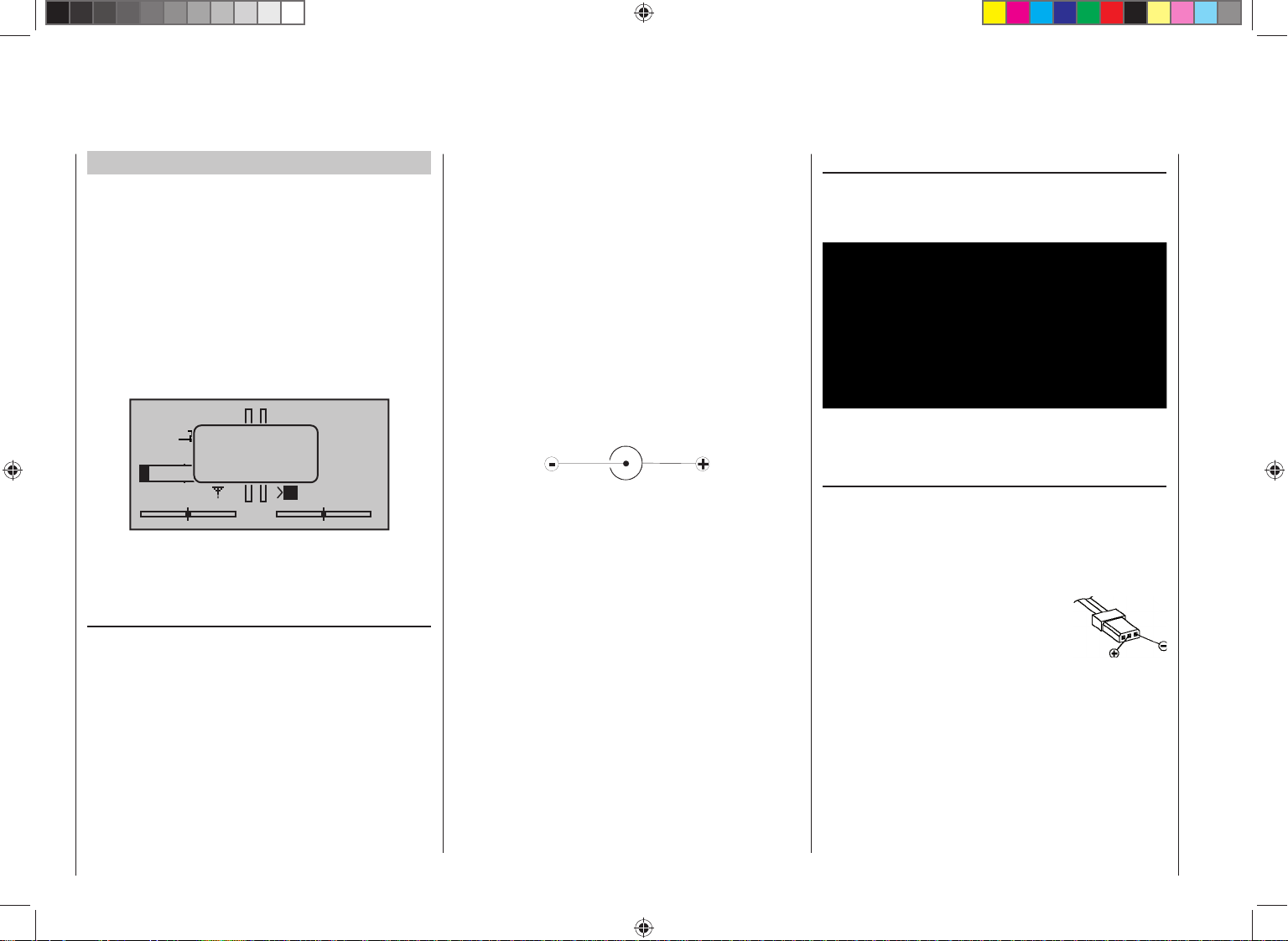

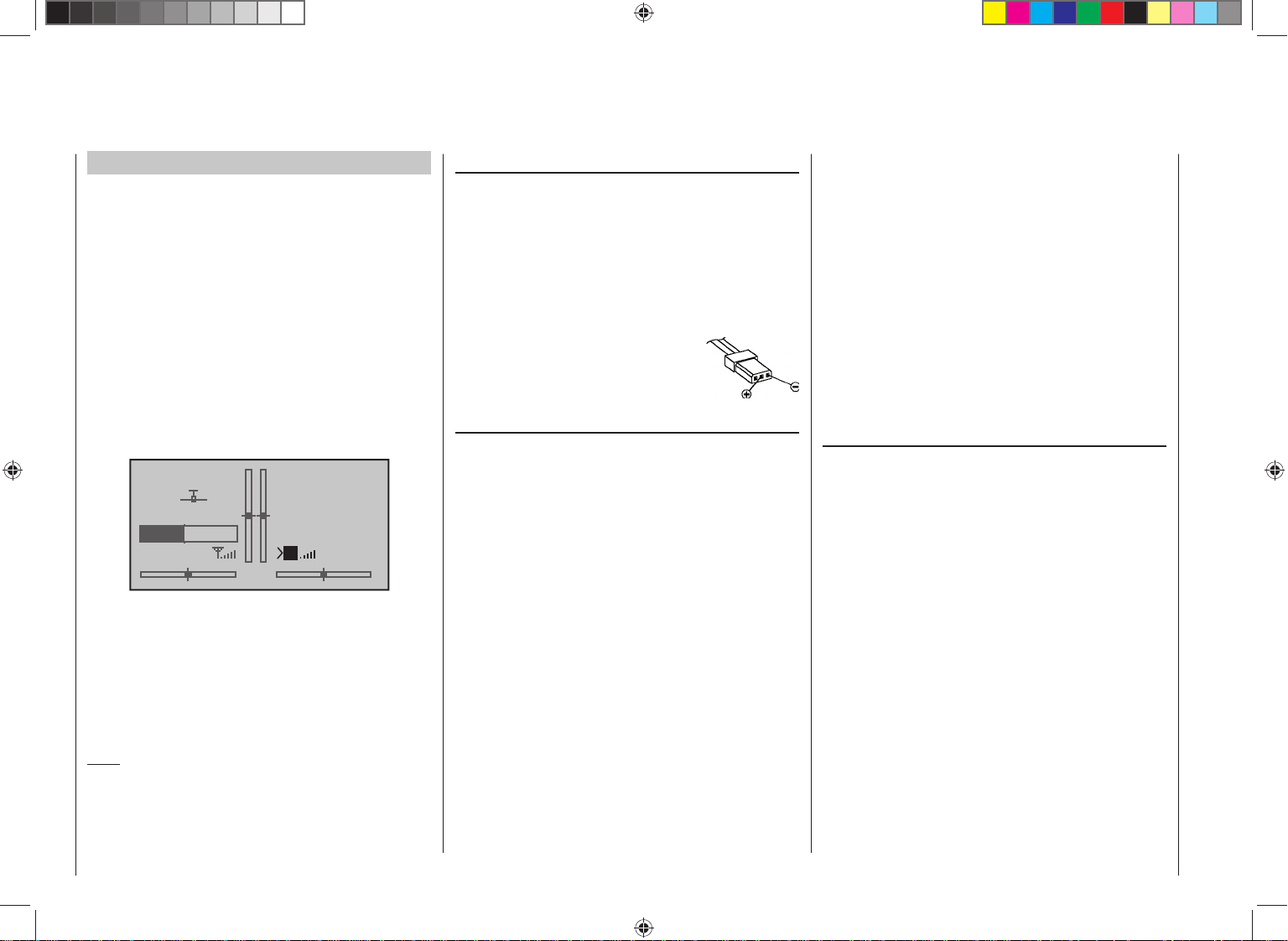

The mx-12 HoTT transmitter is fi tted as standard with

a high-capacity rechargeable 4NH-2000 RX RTU Ni-MH

battery (Order No. 2498.4FBEC) (specifi cation reserved). When delivered, the standard rechargeable

battery is not charged.

When you are using the transmitter you can monitor

the battery voltage on the LCD screen. If the voltage of

the transmitter battery falls below a certain point, you

will hear an audible warning signal. The screen then

displays a message reminding you that the transmitter

battery needs to be recharged.

GRAUBELE

#01

battery

needs

charging!!

10%

4.7V

0:22h

x

stop

Flug

«normal »

K78

Mx

0:00

0:00

HoTT

0.0V

Always recharge the transmitter battery in good time.

When you see this message, cease operations immediately and recharge the transmitter battery.

Charging the transmitter battery

The rechargeable Ni-MH transmitter battery can be

recharged with the battery charger (Order No. 33116.2)

supplied in the set, using the charge socket located on

the right-hand side of the transmitter. Leave the battery

inside the transmitter for charging, to avoid premature

damage to the internal battery socket.

As an approximate guideline a discharged battery

should be charged for twelve hours at a current corresponding to one tenth of the capacity printed on the

pack. If you are using the standard transmitter battery

and the charger supplied in the set, this current is

Operating Notes

14

200 mA.

The transmitter must be switched “OFF” for the whole

period of the charge process. Never switch on the

transmitter when it is still connected to the charger; even

a very brief interruption in the process can cause the

charge voltage to rise to the point where the transmitter

is immediately damaged. For this reason check carefully

that all connectors are secure, and are making really

good contact.

Polarity of the mx-12 HoTT charge socket

Commercially available battery charge leads produced

by other manufacturers are often made up with the opposite polarity. For this reason it is essential to use only

the genuine Graupner charge lead, Order No. 3022.

Using automatic battery chargers

Although the standard transmitter charge socket is protected against reversed polarity, it is still possible to use

suitable chargers to fast-charge the transmitter battery.

If possible, set the delta peak voltage difference of your

fast charger to a value in the range 10 mV … 20 mV or

equivalent, as described in the charger’s instructions;

this ensures that it is suitable for fast-charging Ni-MH

cells.

First connect the banana plugs on the charge lead

to the charger, and only then connect the other end

of the charge lead to the charge socket on the transmitter. When the charge lead is connected to the

transmitter, never allow the bare ends of the plugs to

touch! To avoid damage to the transmitter, the charge

current must never exceed 1 A. If necessary, limit the

current on the charger itself.

Removing the transmitter battery

To remove the transmitter battery, fi rst disengage the

cover over the battery compartment on the back of the

transmitter, then lift it off:

Remove the battery, then carefully pull on the power

lead to disconnect the transmitter battery connector.

Installing the transmitter battery

Hold the connector attached to the transmitter battery

in such a way that the black or brown wire faces the

aerial, and the unused socket of the battery connector

is on the side facing the bottom, then push the battery

connector onto the three pins projecting out of the inside

of the transmitter, in the direction of the

circuit board. (The battery connector is

protected against reversed polarity by

two chamfered edges; see illustration).

Finally place the battery in the compartment, and close the cover.

Polarity of

transmitter battery

connector

33112_mx12_HoTT_2_GB.indd Abs5:1433112_mx12_HoTT_2_GB.indd Abs5:14 06.06.2011 19:39:2606.06.2011 19:39:26

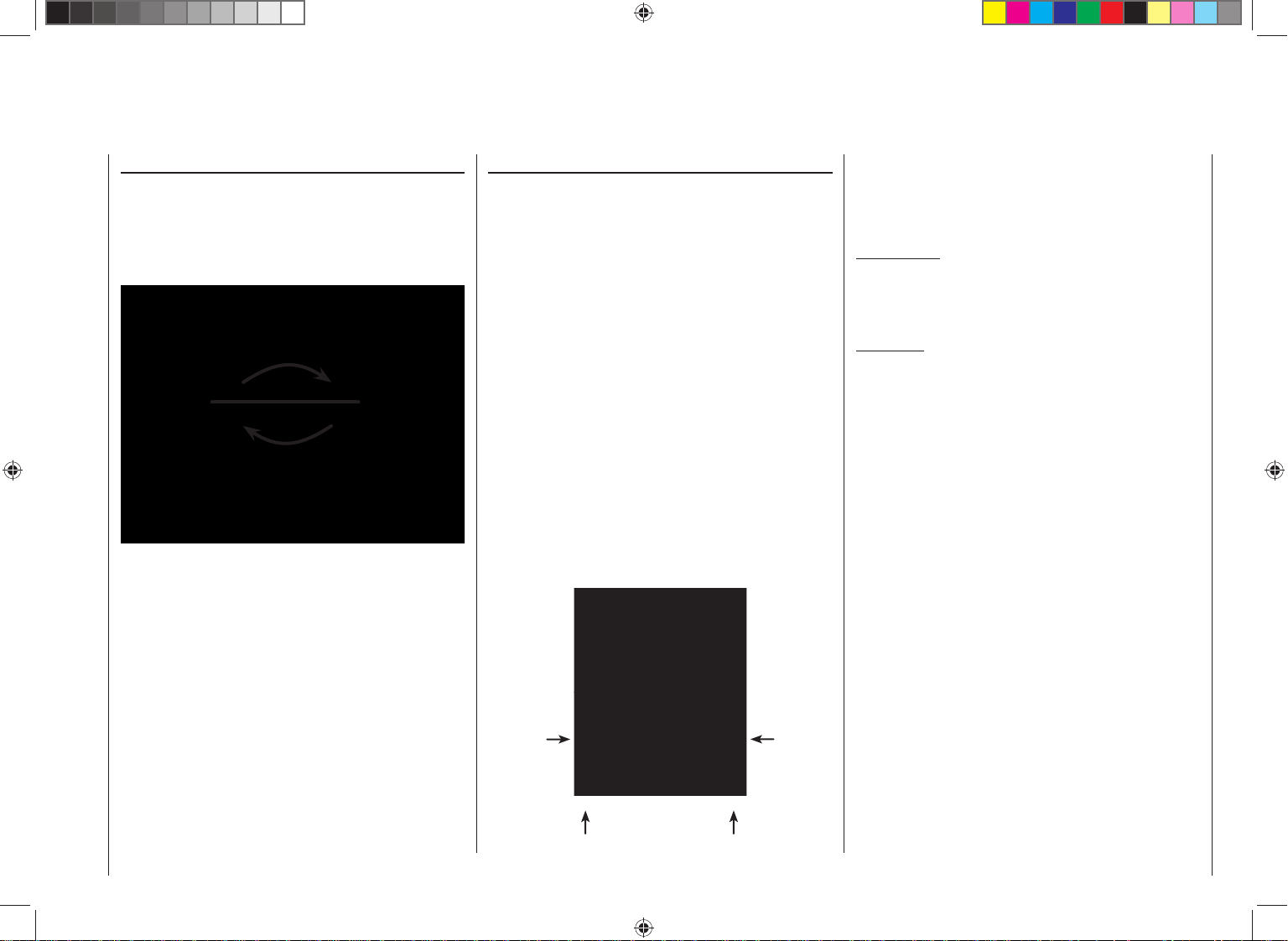

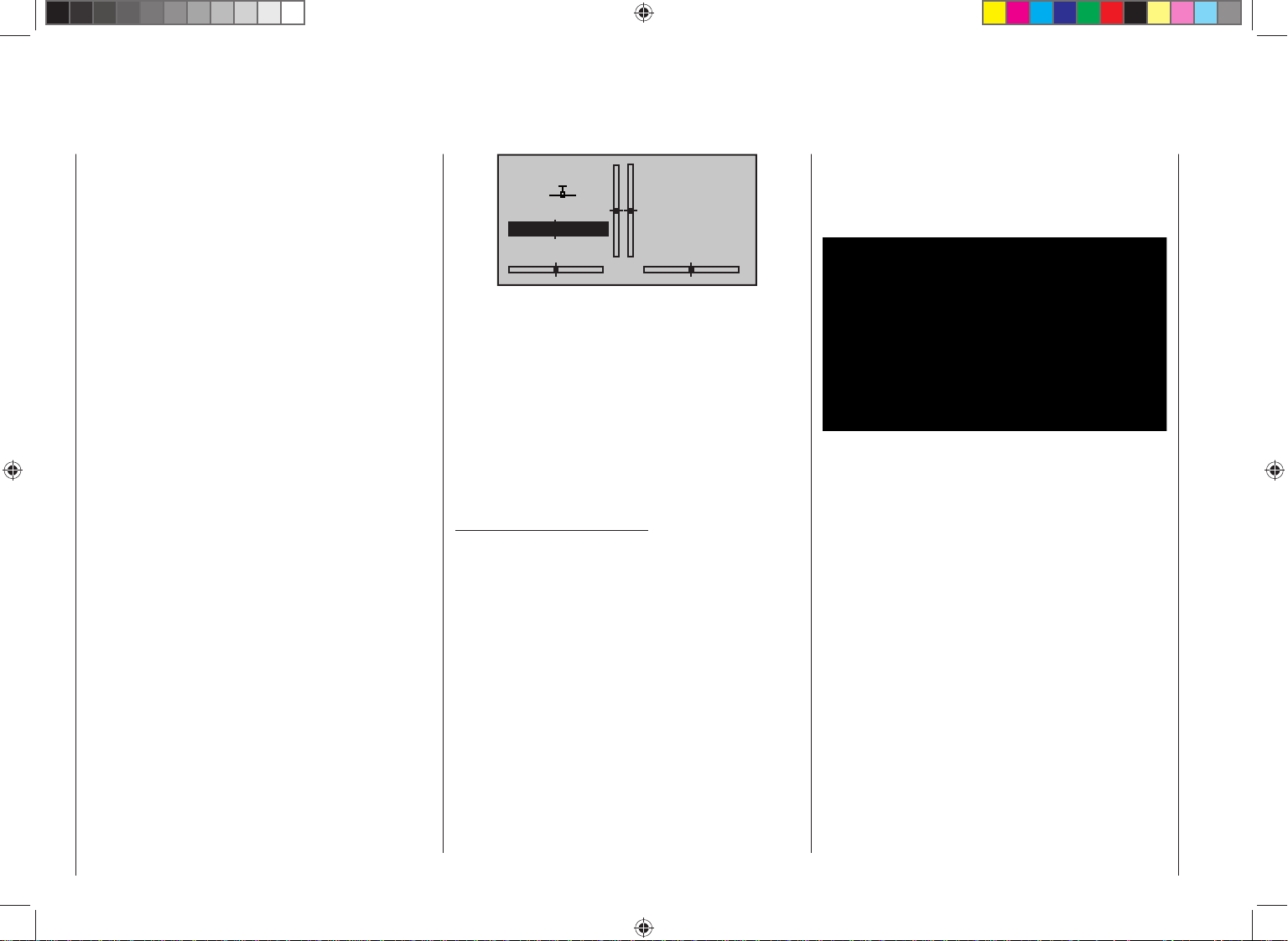

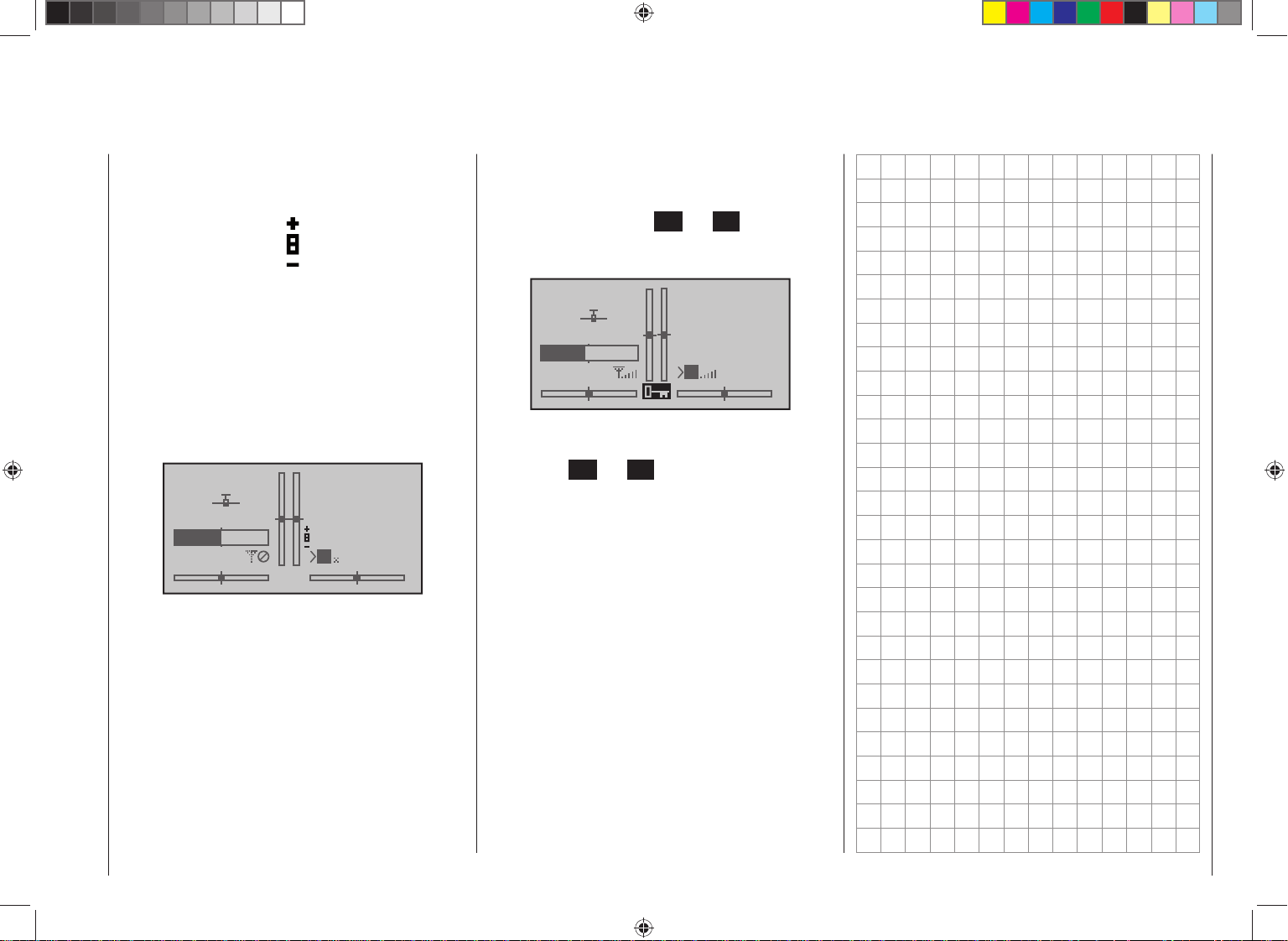

Battery timer, bottom left corner of the screen

This timer displays the cumulative operating time of the

transmitter since the last time the transmitter battery

was charged.

This timer is automatically reset to “0:00” when the

transmitter detects that the voltage of the transmitter

battery is signifi cantly higher than the last time it was

switched on, e. g. as a result of a charge process.

GRAUBELE

#01

6.1V

99%

0:00h

stop

flt

0:00

0:00

«normal »

HoTT

K78

Mx

0.0V

Operating Notes

33112_mx12_HoTT_2_GB.indd Abs5:1533112_mx12_HoTT_2_GB.indd Abs5:15 06.06.2011 19:39:2606.06.2011 19:39:26

15

Operating Notes

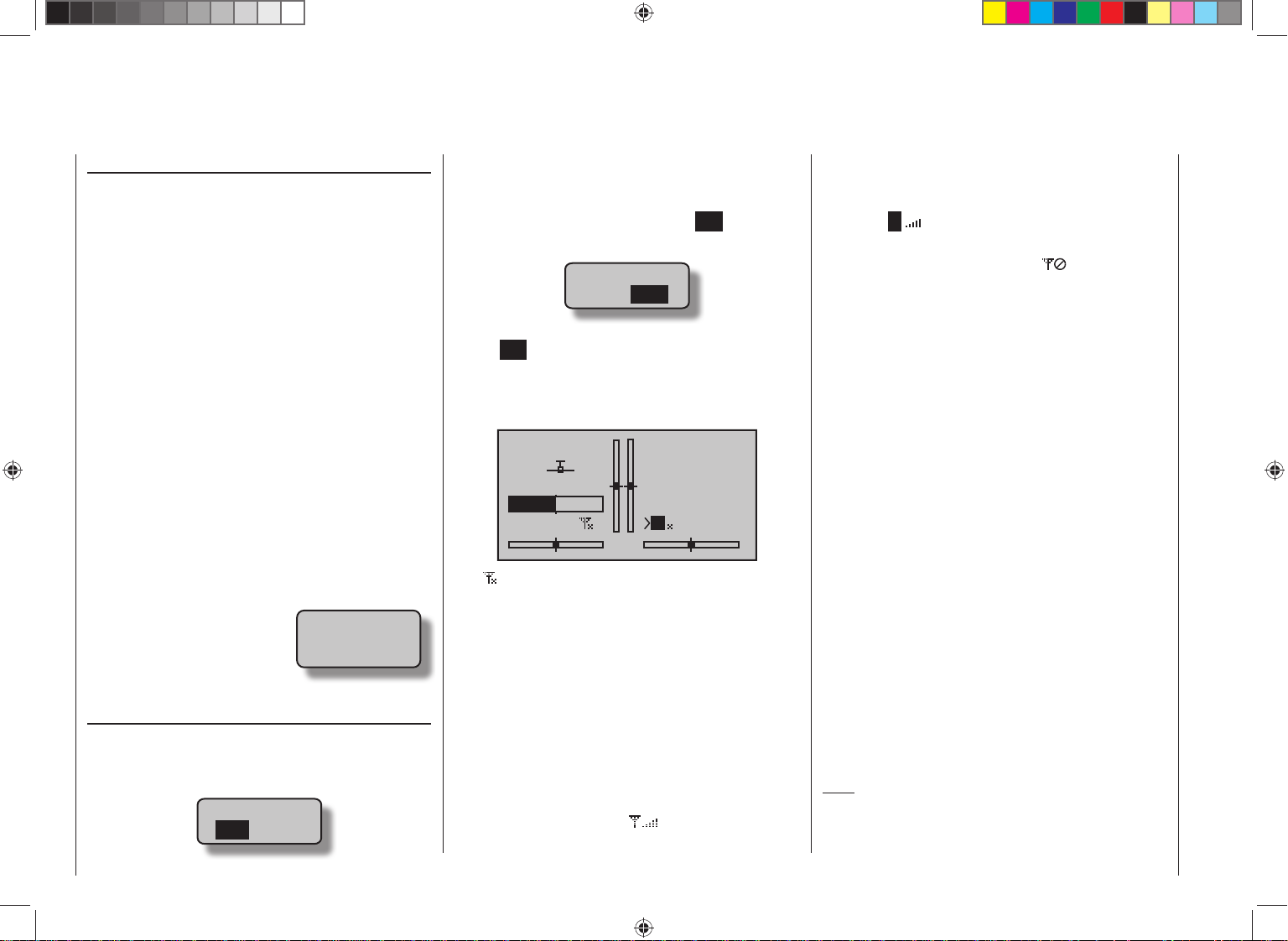

Receiver power supply

A wide range of rechargeable four-cell and fi ve-cell NiMH

batteries varying in capacity is available for use as the

receiver power supply. If you are using digital servos we

recommend that you use a fi ve-cell (6 V) pack of generous capacity. If your model is fi tted with a mixture of

digital and analogue servos, it is important to check the

maximum permissible operating voltage of all the types.

The PRX unit, Order No. 4136, provides a stabilised

receiver power supply with a user-variable voltage from

one or two receiver batteries; see Appendix.

For reasons of safety battery boxes or dry cells should

never be used.

The voltage of the airborne power supply is displayed on

the transmitter screen while the model is fl ying:

GRAUBELE

#01

5.2V

2:22h

If the voltage falls below the pre-set warning threshold -

3.8

Volt as standard, but variable in the Telemetry menu;

see page 126 - a visual and audible low-voltage warning

is triggered.

Nevertheless it is important to check the state of the

batteries at regular intervals. Don’t put off charging

the batteries until the warning signal is triggered.

Note:

Please refer to the main Graupner FS catalogue or visit

the Internet site at www.graupner.de for full details of

batteries, chargers, measuring equipment and battery

monitor units.

51%

stop

flt

«normal »

K78

M

0:00

0:00

HoTT

5.5V

Charging the receiver battery

The charge lead, Order No. 3021, can be connected

directly to the NC receiver battery for charging. If the

battery is installed in a model and you have installed one

of the following switch harnesses: Order No. 3046, 3934

or 3934.1 or 3934.3, the battery can be charged via the

separate charge socket, or the charge socket which is

built into the switch. The switch on the switch harness

must be left at the “OFF” position for charging.

Polarity of the receiver battery connector

General notes on battery charging

Observe the recommendations provided by the •

charger manufacturer and the battery manufacturer

at all times.

Keep to the maximum permissible charge current •

stated by the battery manufacturer.

The maximum charge current for the transmitter •

battery is 1.5 A. Limit the charge current to this value

on the charger.

If you wish to charge the transmitter battery at a •

current higher than 1.5 A, you must fi rst remove the

pack from the transmitter, otherwise you risk damaging the circuit board through overloading the conductor tracks, and / or overheating the battery.

Carry out a series of test charges to ensure that the •

automatic charge termination circuit works correctly

with your battery. This applies in particular if you

wish to charge the standard Ni-MH battery using an

automatic charger designed for Ni-Cd batteries.

You may need to adjust the Delta Peak trigger volt-•

age, if your charger provides this option.

Do not discharge the battery or carry out a battery •

maintenance program via the integral charge socket.

The charge socket is not suitable for this application.

Always connect the charge lead to the charger fi rst, •

and only then to the transmitter or receiver battery.

Observing this rule eliminates the danger of accidental short-circuits between the bare contacts of the

charge lead plugs.

If the battery becomes hot when on charge, it is time •

to check the pack’s condition. Replace it if necessary,

or reduce the charge current.

Never leave batteries unsupervised when on •

charge.

Environmental protection notes

Important information on the disposal of dry and

rechargeable batteries:

The German Battery Order places a legal requirement

on every consumer to return all used and exhausted

dry cells and rechargeable batteries. It is prohibited to

dispose of these items in the ordinary domestic waste.

At no charge to the user, old dry and rechargeable

batteries can be surrendered at local authority collection points, Graupner retail outlets, and any other shop

where dry and rechargeable batteries of the same type

are sold. You can also send batteries supplied by us to

the following address - with adequate pre-paid postage

- for disposal:

Graupner GmbH & Co. KG

Service: Gebrauchte Batterien (Used batteries)

Henriettenstr. 94 - 96

D-73230 Kirchheim unter Teck

You can make an important contribution to environmen-

tal protection in this way.

Operating Notes

16

33112_mx12_HoTT_2_GB.indd Abs5:1633112_mx12_HoTT_2_GB.indd Abs5:16 06.06.2011 19:39:2606.06.2011 19:39:26

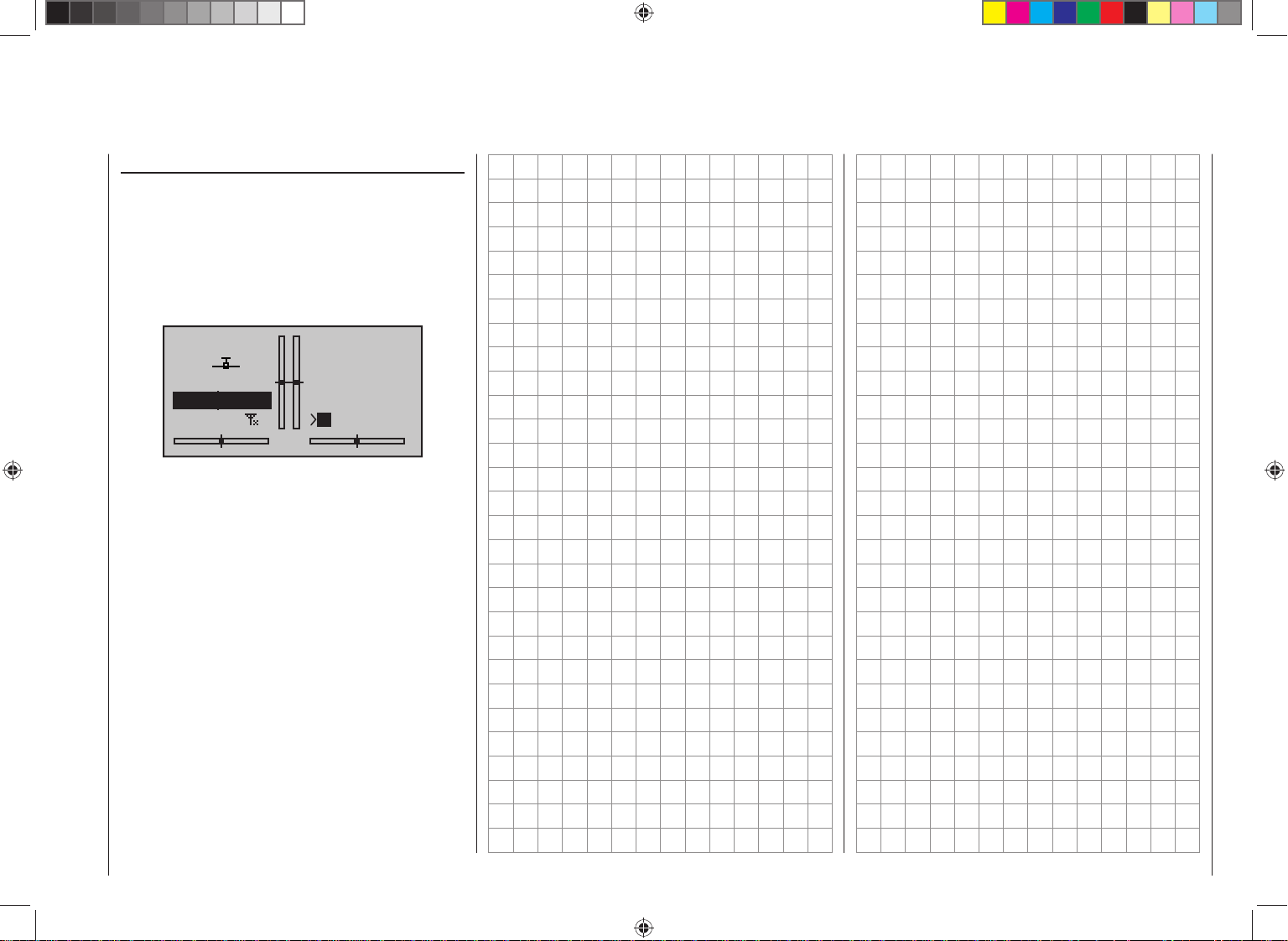

Adjusting stick length

Both sticks are infi nitely variable in length over a broad

range, enabling you to set them to suit your personal

preference.

Hold the bottom half of the knurled grip fi rmly, and

unscrew the top section:

Now screw the stick top in or out (shorter or longer) to

the length you prefer before tightening the top and bottom sections against each other to fi x the stick top.

Opening the transmitter case

Please read the following notes carefully before you

open the transmitter. If you have no experience in such

matters, we recommend that you ask your nearest

Graupner Service Centre to carry out the work for you.

The transmitter should only be opened in the following

cases:

When a self-neutralising stick needs to be converted •

to non-neutralising action, or a non-neutralising stick

to a self-neutralising action.

If you wish to adjust the stick centring spring tension.•

Before opening the transmitter check that it is switched

off (move Power switch to “OFF”).

Open the battery compartment and remove the transmitter battery as described on the previous double page,

together with any micro-SD card already installed.

After this, use a PH1-size cross-point screwdriver to

undo the six screws recessed into the back panel of the

transmitter, as shown in the illustration:

Arrangement of the case back screws

Hold the two case sections together with your hand, and

turn the unit over to allow these six screws to fall out

onto the table. Now carefully raise the case back and

fold it open to the right, as if you were opening a book.

C A U T I O N

Two multi-core cables connect the lower shell to the

transmitter electronics located in the top section.

Please take great care not to damage this cable!

Important:

Do not modify the transmitter circuit in any way, •

as this invalidates your guarantee and offi cial approval for the system.

Do not touch any part of the circuit boards with •

any metal object. Avoid touching the contacts

with your fi ngers.

Never switch the transmitter on while the case is •

open.

Please note the following points when closing the

transmitter:

Make sure that no cables are jammed between the •

transmitter case sections when you close the back.

Check that the two case sections fit together flush all •

round before fitting the retaining screws. Never force

the two case components together.

Fit the case screws in the existing threads, and tight-•

en them gently. Over-tightening them will strip the

threads in the plastic.

Remember to re-connect the battery.•

Operating Notes

33112_mx12_HoTT_2_GB.indd Abs5:1733112_mx12_HoTT_2_GB.indd Abs5:17 06.06.2011 19:39:2706.06.2011 19:39:27

17

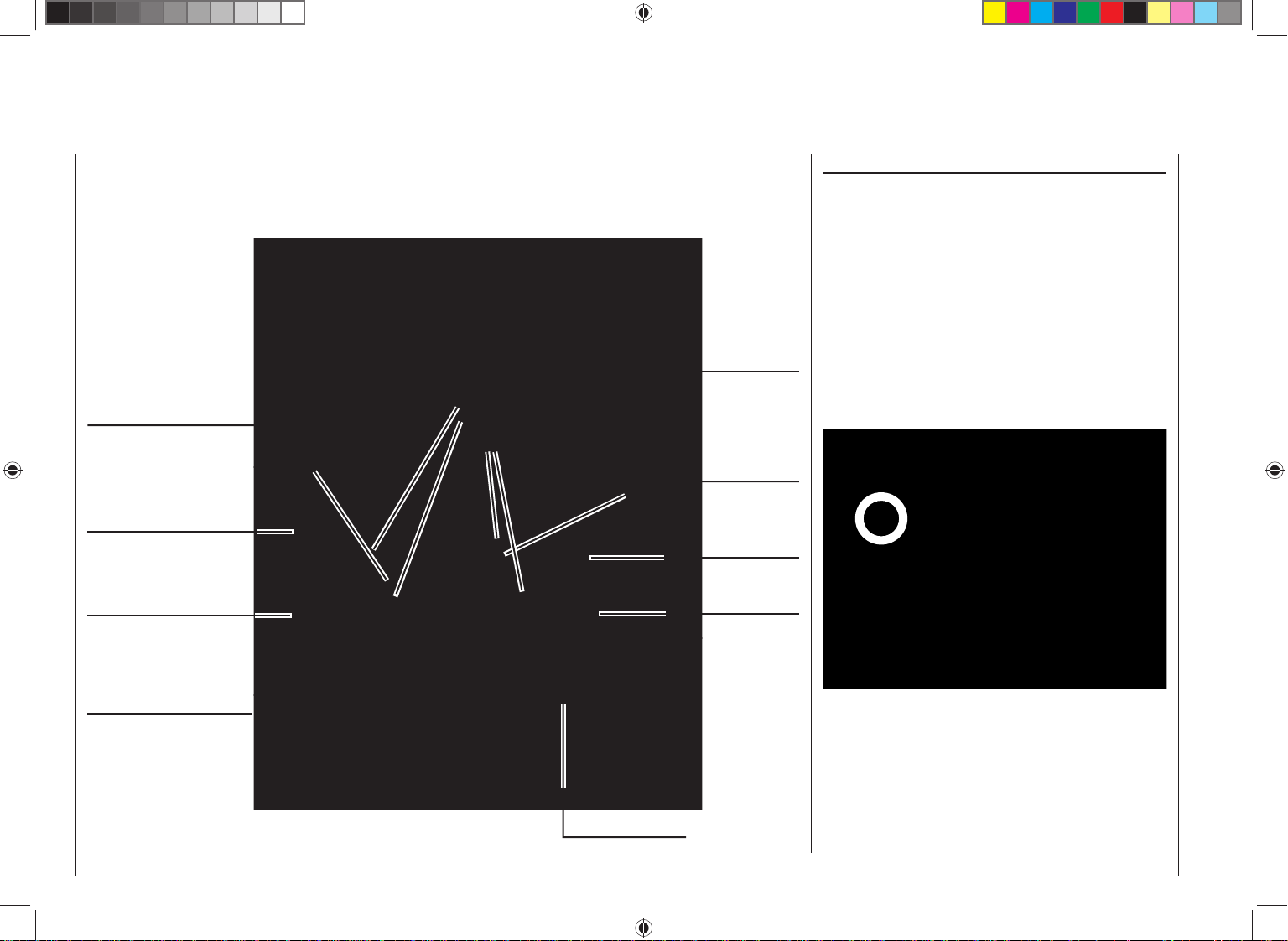

Operating Notes

Do not touch trans-

mitter circuit board

Do not touch trans-

mitter circuit board

Left-hand stick unit

Right-hand stick unit

Folding aerial

Converting the dual-axis stick units

Self-centring action

Either or both sticks can be converted from self-neutralising to non self-neutralising action: start by opening the

transmitter as described on the previous page.

If you wish to change the standard stick unit arrangement, start by locating the screw on the left-hand stick

unit shown circled in white in the photo below.

Self-centring screw

Brake springs

Adjuster screws

Charge socket

Right-hand stick unit

mitter circuit board

Do not touch trans-

Do not touch trans-

mitter circuit board

Adjuster screws for stick centring force

Left-hand stick unit

Memory card slot

Note:

The right-hand stick unit is of mirror-image construction,

i. e. the screw you require is located on the right, below

centre.

Self-centring screw

Brake springs

Adjuster screws

Turn this screw clockwise until the stick on that side

moves freely from one end-stop to the other; alternatively unscrew it until the stick is fully self-centring again.

Operating Notes

18

33112_mx12_HoTT_2_GB.indd Abs5:1833112_mx12_HoTT_2_GB.indd Abs5:18 06.06.2011 19:39:2806.06.2011 19:39:28

horizontal

vertical

Brake spring and ratchet

You can alter the braking force of the stick by adjusting

the outer of the two screws circled in white in the next

picture; adjusting the inner screw alters the strength of

the ratchet:

Note:

The right-hand stick unit is of mirror-image construction,

i. e. the screw you require is located on the right, below

centre.

Stick centring force

The centring force of the sticks is also variable to suit

your preference. The adjustment system is located

adjacent to the centring springs; see the white circles in

the following photo.

You can set the preferred centring spring force by rotating the corresponding adjuster screw using a cross-point

screwdriver:

Turn to the right = harder spring tension;•

Turn to the left = softer spring tension.•

vertical

horizontal

Note:

The right-hand stick unit is of mirror-image construction,

i. e. the screw you require is located on the right, below

centre.

Operating Notes

33112_mx12_HoTT_2_GB.indd Abs5:1933112_mx12_HoTT_2_GB.indd Abs5:19 06.06.2011 19:39:2906.06.2011 19:39:29

19

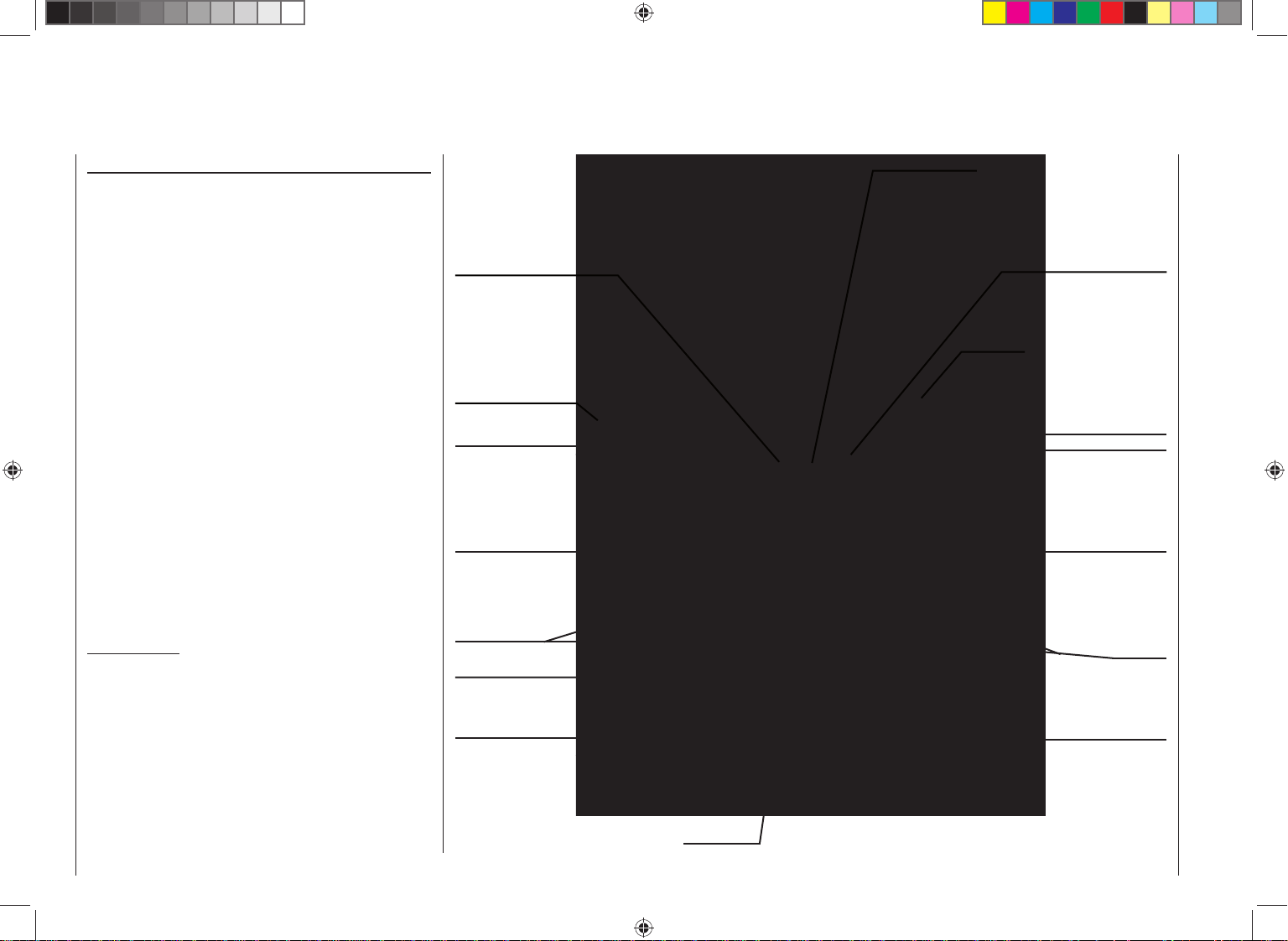

Description of transmitter

Transmitter controls

Attaching the transmitter neckstrap

You will fi nd a strap lug mounted in the centre of the

front face of the mx-12 HoTT transmitter, as shown in

the drawing on the right. This lug is positioned in such a

way that the transmitter is perfectly balanced even when

suspended from a neckstrap.

Order No. 1121 Neckstrap, 20 mm wide

Order No. 70 Neckstrap, 30 mm wide

Important note:

In the transmitter’s standard form any servos connected

to the receiver can initially only be operated using the

dual-axis sticks. For maximum fl exibility, all the other

transmitter controls (CTRL 7 … 8, SW 1, 3 … 7) are

“free” in software terms, and can be assigned to any

channels you like, enabling you to set up the system to

suit your personal preference or the requirements of a

particular model. This is carried out in the “contr set.”

menu, as described on pages 74 (fi xed-wing models)

and 76 (model helicopters).

Description of transmitter

20

Aerial with folding / rotating base

Rotary proportional control CTRL 7

3-position switch SW 4/5

2-position momentary

switch SW 1

Left-hand stick

Tr im

ON / OFF switch

Left-hand four-way button

Central Status LED

Neckstrap lug

Rotary proportional control CTRL 8

Carry handle

3-possition switch SW 6/7

2-position switch SW 3

Right-hand stick

Tr im

Right-hand four-way button

LCD screen

33112_mx12_HoTT_2_GB.indd Abs6:2033112_mx12_HoTT_2_GB.indd Abs6:20 06.06.2011 19:39:3106.06.2011 19:39:31

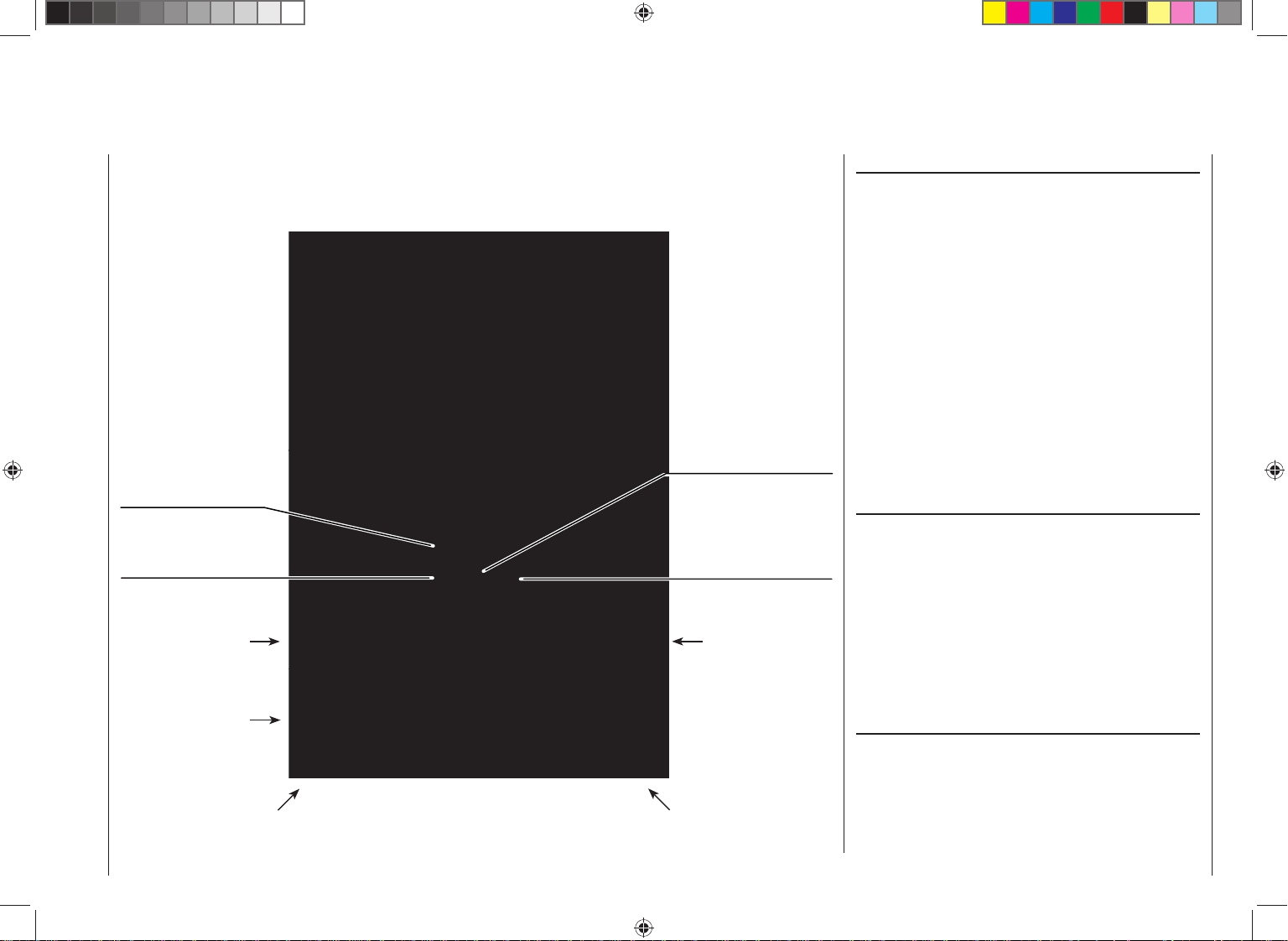

Data socket for connecting

Smart-Box, Order No. 33700

DSC socket for connecting

fl ight simulators and for Teacher

mode

Case screw

Transmitter battery

charge socket

Case screw

Case screw

Battery compartment cover

Case screw

Option well for speech output

module Order No. 33001.71

Three-pin socket for connecting transmitter to a PC

Case screw

Case screw

Optional headphone socket

If you install the optional speech output module, Order

No. 33001.71, and replace the name plate, it is possible

to connect a standard commercial earphone or headphones fi tted with a 3.5 mm barrel plug (not included in

the set) to the central socket.

Signals and voice messages associated with the Telemetry menu are generated via this optional socket, as

are the transmitter’s audible signals. As standard these

messages are spoken in the German language. For

more details please see the section entitled “Voice” in

the section “SECRET MODE” starting on page 26, and

“Telemetry” on page 131.

The volume of the headphone output can be adjusted

in the “Voice volume” line of the “Basic Settings” menu;

see page 115.

Three-pin “PC” socket

This socket can be used to connect the transmitter to a

PC running Windows XP, Vista or 7 using the optional

USB adapter, Order No. 7168.6 and the connecting

lead, Order No. 6466.S.

The software required at the PC, including a suitable

USB driver, can be found in the Download section for

the corresponding product at www.graupner.de.

Once you have installed the software required, you can

also update the transmitter via this connection.

Data socket

For connecting the optional Smart-Box, Order No. 33700.

For more details about the Smart-Box please refer to the

main Graupner FS catalogue, or refer to that product on

the Internet at www.graupner.de.

Description of transmitter

33112_mx12_HoTT_2_GB.indd Abs6:2133112_mx12_HoTT_2_GB.indd Abs6:21 06.06.2011 19:39:3106.06.2011 19:39:31

21

DSC

Direct Servo Control

The original function of this socket was for “Direct Servo

Control”, and that’s why the abbreviation is still in use.

However, for technical reasons “direct servo control” is

no longer possible with the HoTT system using a diagnosis lead.

The mx-12 HoTT transmitter’s standard two-pole DSC

socket is now used as a Trainer (buddy box) socket

(Teacher or Pupil), and as an interface for fl ight simulators.

For the DSC connection to work you must check the

following:

Carry out any adjustments required in the appropri-1.

ate menus:

See page 134 for information on setting up the mx-

12 HoTT transmitter to work as part of a Trainer system.

ALWAYS2. leave the transmitter’s On / Off switch in

the “OFF” position when using a fl ight simulator, and

when using the mx-12 HoTT transmitter as a Pu-

pil unit in a Trainer system, for only in this position is

the RF section of the transmitter module switched off

(no RF signal) even when the DSC lead is plugged

in. At the same time the transmitter’s current drain is

reduced slightly.

The central Status LED should now glow a constant red, and the abbreviation “DSC” appears in the

transmitter’s base display on the left, below the model number. At the same time the display of telemetry

symbols is suppressed:

PUPIL

#11

DSC

6.0V

0:01h

The transmitter is now ready for use.

ast, when the mx-12 HoTT is used in

In contr

Teacher mode, the transmitter must be switched on

before the appropriate cable is plugged in.

Connect the other end of the connecting lead to the 3.

appropriate apparatus, taking into account the operating instructions supplied with that device.

Important:

Ensure that all connectors are fi rmly seated in

their sockets.

Note regarding fl ight simulators:

The range of fl ight simulators available commercially

is now very wide, and you may fi nd that it is necessary

to swap over certain contacts at the barrel connector

or the DSC module. This work must be carried out by a

Graupner Service Centre.

99%

stop

flt

«normal »

0:00

0:00

HoTT

0.0V

Data storage

Card slot

micro-SD and micro-SDHC

When you switch off the mx-12 HoTT transmitter and

remove the battery compartment cover, you will see the

card slot for memory cards (of the micro-SD and microSDHC type) in the right-hand side of the compartment:

Any standard commercial micro-SD memory card with a

capacity of up to 2 GB can be used, and also any microSDHC card of up to 32 GB. However, the manufacturer

recommends the use of memory cards with capacities

up to only 4 GB, as these are completely adequate in all

normal circumstances.

The memory cards for which the transmitter is intended

are familiar from their use in digital cameras and mobile

telephones. Place the card in the slot with the contacts

facing up, towards the back panel, and push it in until it