Page 1

2 Channels DC Charger

OPERATING INSTRUCTION

Please read this manual thoroughly.

Keep this manual in a convenient place

for quick and easy reference.

No. S2003

Page 2

- CONTENTS -

BEFORE USE

SUPPORT AND SERVICE

CUSTOMER SUPPORT

INTERNET SALES SITE / FIRMWARE UPGRADE

A/S SUPPORT

WARRANTY INFORMATION

OPENHOBBY A/S SUPPORT AND SERVICE CENTER

BOX CONTENTS

SAFETY PRECAUTIONS

SPECIFICATIONS

CHARGER CONTROL IDENTIFICATION

MENU CONFIGURATION

ACTION BUTTONS

MENU DESCRIPTION

BATTERY CONNECTION

INPUT POWER SETUP

MAIN PAGE

PROFILE PAGE

DISPLAY

BATTERY NAME EDITING

CHARGE PAGE

LiPo, LiIon, LiFe BATTERY CHARGE SETUP

NiCd/ NiMH BATTERY CHARGE SETUP

Pb BATTERY CHARGE SETUP

LiPo, Lilon, LiFe, NiCd, NiMH, Pb BATTERY CHARGE PROCESSES

CHARGE MODE PER BATTERY TYPE

DISCHARGE PAGE

LiPo, LiIon, LiFe, NiCd, NiMH, Pb BATTERY DISCHARGE MODES

LiPo, Lilon, LiFe, NiCd, NiMH, BATTERIES DISCHARGE PROCESSES

DISCHARGE MODE PER BATTERY TYPE

CYCLE PAGE

LiPo, Lilon, LiFe, NiCd, NiMH, Pb BATTERY CYCLE PAGES

LiPo, Lilon, LiFe, NiCd, NiMH, Pb BATTERY CYCLE PROCESSES

CYCLE OPERATION MODE PER BATTERY TYPE

BALANCE PAGE

DATA VIEW PAGE

USER SETUP PAGE

MISC PAGE (ADDITION FUNCTION)

SERVO AND BRUSHLESS MOTOR TESTING SETUP

BRUSHED MOTOR SETUP

WARMER SETUP

SPEED CONTROLLER

SETUP

FACTORY SETUP AND SCREEN CALIBRATION

DATA INITIALIZATION

TOUCH CALIBRATION

RESOURCE UPGRADE

BLC PORT TEST

3 4

4

4

4

4

4

4

4

5

5-7

8

9-10

11

11

11

11-12

12

12

12-13

13

13

14-19

14

15

15

16

16-19

20-23

20

21

21-23

23-27

24

24-25

25-27

27-28

28-29

29-30

31-38

31-33

34-35

35-37

37-38

39-41

40

40

41

41

SLAVE BOARD UPGRADE (PRODUCT UPDATE)

ERROR MESSAGES

COMMON PROBLEMS AND PRECAUTIONS FOR THE POLARON PRO DC CHARGER

NiCd/MH BATTERY SAFETY

Pb BATTERY SAFETY

Lilon, LiPo, LiFe BATTERY SAFETY

THE GUIDE FOR THE RELATED COUNTRIES’CERTIFICATIONS

ENVIRONMENTAL

PROTECTION NOTES

◎ BEFORE USE

Thank you for purchasing the POLARON PRO 2CH DC Charger. Designed for both novices and pro

fessionals, this system is extremely versatile. To make the best use of your system, please read this

manual carefully.

For any difficulties with your system, we offer multiple resources to assist you, including this referenece

manual, an online Frequently Asked Questions webpage (www.openhobbby.com), your hobby dealer, or

the Graupner/SJ Service Center (contact information below).

Due to unforeseen changes in production procedures, the information contained in this manual is

subject to change without notice.

◎ SUPPORT AND SERVICE

Customer support

We are happy to assist you with any question by e-mail or phone. Customer service

hours are from 9 am to 5 pm PST (Pacific Standard Time) during the workweek, Monday

through Friday. E-mailed questions will be answered as soon as possible

Online Support

Please visit us at www.openhobbby.com, to stay up to date with the latest software,

firmware and product information.

A/S support

During the warranty period, we can repair this product at no cost in the event that it has

become faulty under normal operating conditions.

For non-functional products that are past the expiration date of the warranty or have

been improperly used, we would be happy to repair this product for an appropriate

amount of cost to the consumer.

Warranty information

Refer to the WARRANTY CARD in the Package

◎ OPENHOBBY A/S SUPPORT AND SERVICE CENTER

3245 University Ave, Suite 1520, San Diego, CA 92104, United States of America

Phone: +1 855-5-RCisHoTT ( +1 855-572-4746) Fax: +1 855-546-0350

E-mail: service@openhobby.com

©2014 Graupner/SJ USA – OPENHOBBY LLC. The HoTT trademark is used with permission of SJ Inc. 4386066

41

42-44

45

46

46

46-47

48

48

-

Page 3

◎ BOX CONTENTS

- If possible, place the battery in a safety bag during the charging or discharging process.

- Pay attention to the charger during use. Do not leave the charger unattended.

1. Charger

2. 7 Cells Balance board/Cable (EH to XH)

3. Temperature sensor (2pcs)

4. USB cable

5. Output cable with alligator clip (2 pairs)

6. Charger rack (optional)

7. User manual

8. Warranty card

9. DC Input Cable

◎ SAFETY PRECAUTIONS

- Do not attach the charger to both the AC and DC power sources at the same time.

- If the charger becomes hot, disconnect the battery and remove the input power immediately.

Allow the charger and the battery to completely cool down before reconnecting.

- Do not attempt to charge dead or damaged batteries.

- Use identical batteries in the charger.

- Do not attempt to charge a battery pack containing different types of batteries.

- Do not use a too short or damaged cables.

- Ensure that each channel has a completely charged pack.

- Do not use near a flammable object. Use only in well-ventilated areas. Explosive gases may

be generated during the operation of this product.

- Do not reverse the positive and negative terminals. An incorrect connection will damage the

batteries and may cause damage to the charger.

- Use only rechargeable batteries that meet the product specifications of this charger.

- Do not allow water, moisture or foreign objects into the charger.

- Do not use in humid locations. Do not operate with wet hands.

- Do not attempt to dismantle the charger.

- Do not use on fleecy materials, such as carpets, blankets, beds and cushions.

- Never connect the input jack (DC input) to the AC power.

- Disconnect the docking power supplier while connecting the DC power source to the rear

terminal of the charger.

- Program the input power setup correctly during the USER SETUP.

- During the USER SETUP, program the correct settings for the docking power supplier.

- CAUTION: Using an automobile battery as a power source can result in a complete discharge/

draining of the automotive battery.

- Supply sufficient power to the charger. The max output power for CH1 is 500W and for CH2 is 30W.

5 6

Use on hard flat surfaces.

- Do not use in the extreme cold or heat, as the charger may not operate using the expected

values, causing failures in the operation.

- Use in a well-ventilated location. Do not block the cooling fan (rear) and the air inlet (front).

- Ensure that the TFT panel is visible during the operation of this product.

The TFT panel might not be visible under direct sunlight.

- We strongly recommend balancing Lithium packs. An unbalanced pack can cause damage

and, in extreme cases, can cause a fire.

Page 4

- Connect the battery pack to a balance board. Without this connection, either the batteries

or the charger may be damaged.

◎ SPECIFICATIONS

- Do not charge a battery with a voltage below 2.8V per cell. If this type of battery is forced

to charge, the pack can be damaged and, in extreme cases, can result in a fire.

- The default charging current is 1C. Monitor the voltage and the temperature of batteries

during charging operations that may exceed 1C.

- Do not charge Lithium Polymer battery packs to values that exceed 4.2V per cell.

- Always disconnect the battery after charging. Allow the charger to cool between the charges.

- Do not charge the batteries inside a car. Never use a cigarette socket as a power source.

- Do not charge the batteries using a digital camera, a camcorder, or a cell phone, as the power

source.

- Please use insulating gloves during the handling of the batteries, the charger or the wires.

Failure to do so may cause personal injury, as the voltage differential between the input and the

output can result in the formation of sparks.

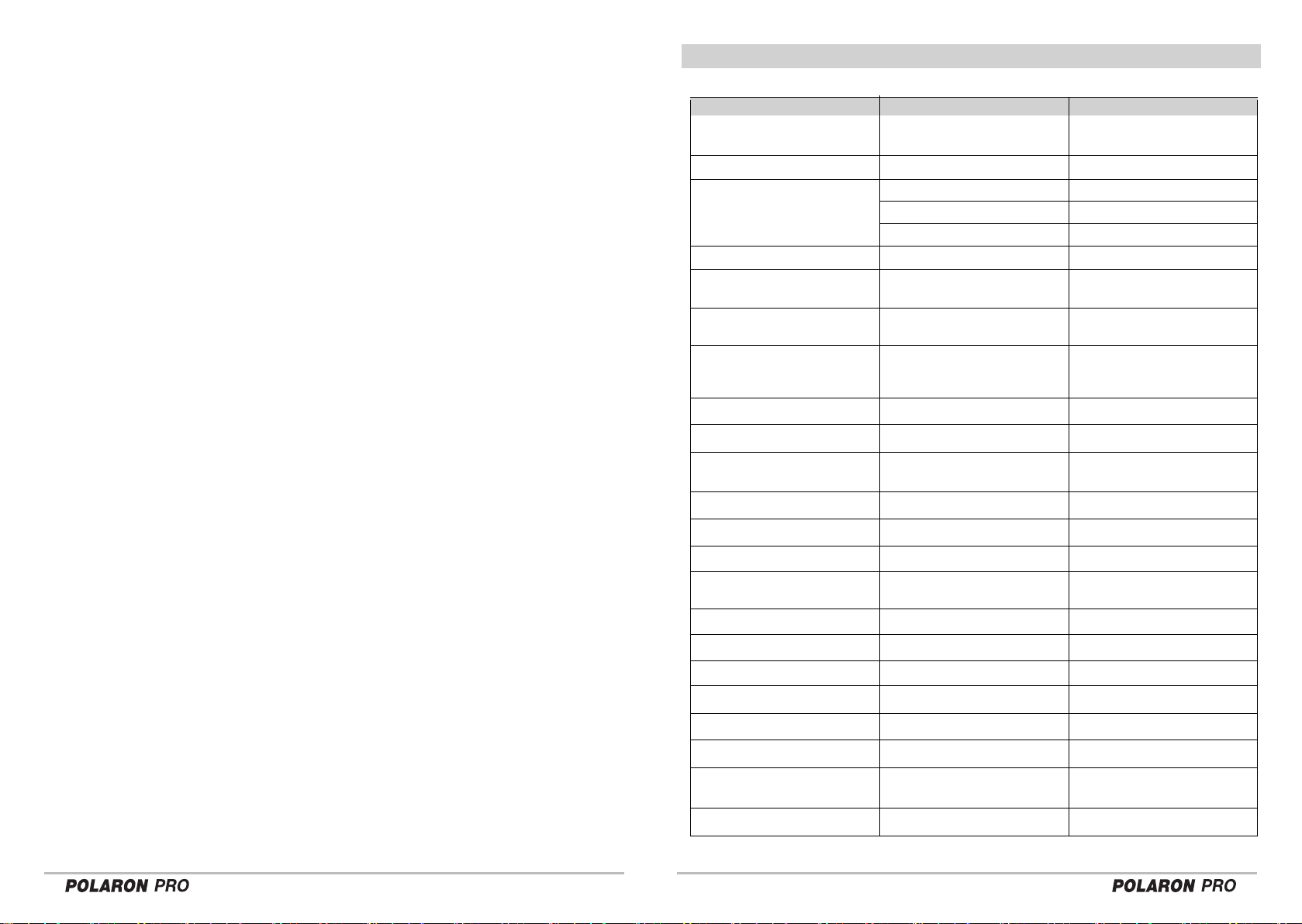

MODE SPECIFICATION (CH1) (CH2)

Power source

Display

Battery Type & Cells

Output

Charge Current

Discharge Current

Cycling

Balancing current

USB

Sub Function

Firmware upgrade

PC communication

Languages

Cooling system

Ext. Module socket

Motor Test socket

Servo Test socket

Speed Controller Setting

11-28V PROternal DC Power Supply

(Docking system)

3.0” TFT LCD W/ Touch screen

NiCd, NiMH / 1~32 cells

LiPo, LiFe, LiIo / 1~14 cells

Pb / 1~12 cells (2V/cell)

2 Channels (1CH : Max.500W)

0.1~20.0A (100mA steps)

Max.500W-24V, Max.260W-12V

0.1~10.0A (100mA steps)

Max.60W

Discharge, Charge to Discharge /

Discharge to Charge /

Charge to Discharge

Max. 350mA

USB 5V output (5.0V 2.5A)

Servo Test, Motor Test, Warmer,

ESC setting

External Mini USB device

Data Logging

Optional (Basically English)

50x50x10mm x 2ea

Dynamic Cooling Fan

Futaba 3P socket

ZHR

Futaba 3P socket

Ext. Module socket

-

-

NiCd, NiMH / 1~8 cells

-

-

(2CH : Max.30W)

0.1~3.0A (100mA steps)

Max.30W

0.1~1.0A (100mA steps)

Max.5W

-

-

USB B-Type

-

-

-

-

-

-

-

-

-

Memory

SMPS Docking Terminal

Dimension

Weight

7 8

30 Memories

Yes

88.2x203.4x196.3mm /

3.47x8.00x7.73 inch

1160g / 40.92 oz

10 Memories

-

-

-

Page 5

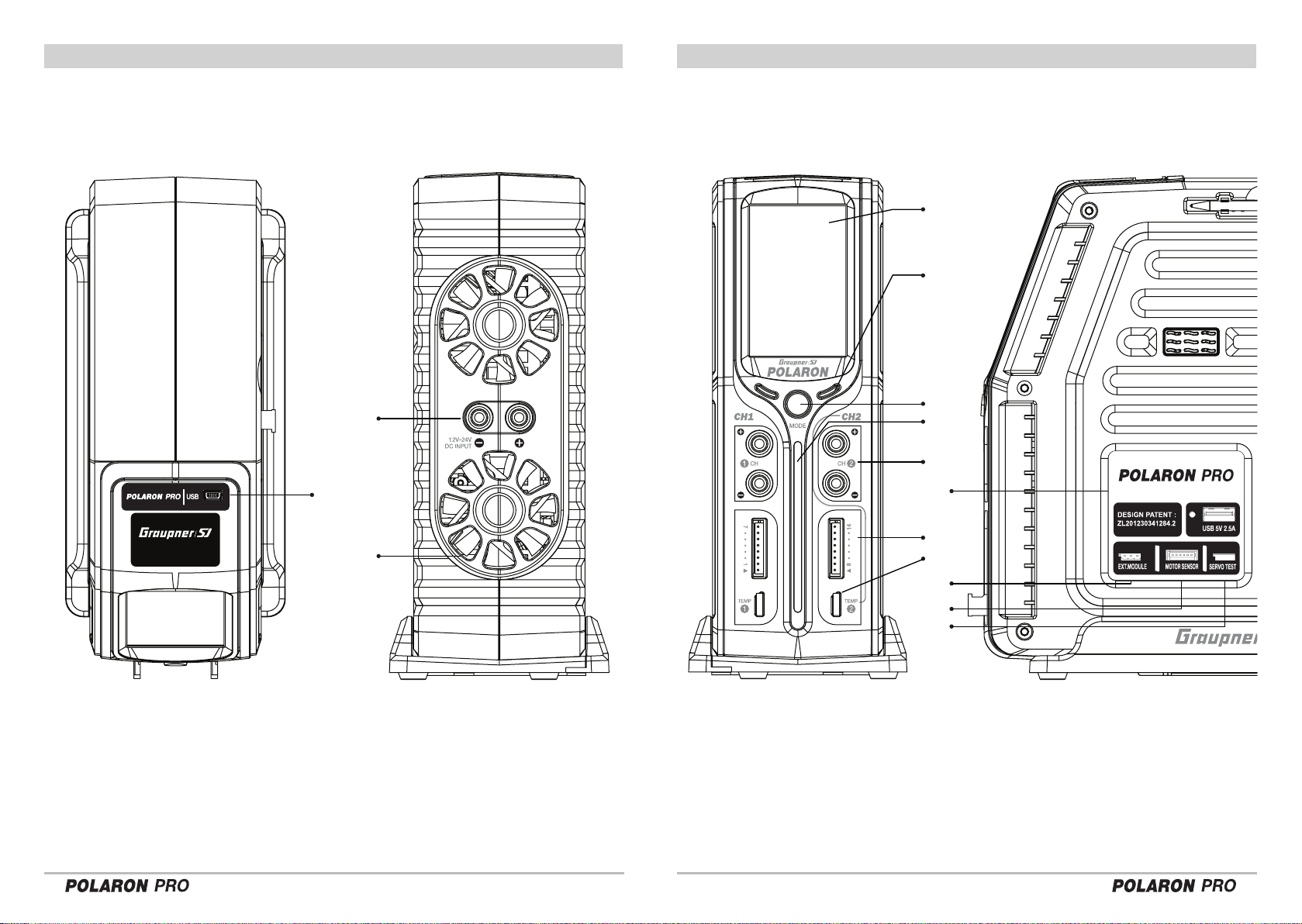

◎ CHARGER CONTROL IDENTIFICATION

TOP FRONTBACK RIGHT

④

⑤

②

①

③

① Mini USB ④

② DC Input

③ Cooling Fan ⑥

⑦

⑩

⑬

3.0”TFT LCD with Touch Screen

Charge / discharge status LED bar

Temperature sensor port

Motor sensor

⑤

⑧

⑪

⑭ Servo test

⑥

⑦

⑧

⑪

⑨

⑩

⑫

⑬

⑭

LED Indicator for charge / discharge

Battery socket

USB +5V 2.5A

Channel selection button

⑨ Balance port

⑫

Ext. Module / Speed Controller

Setting

9 10

Page 6

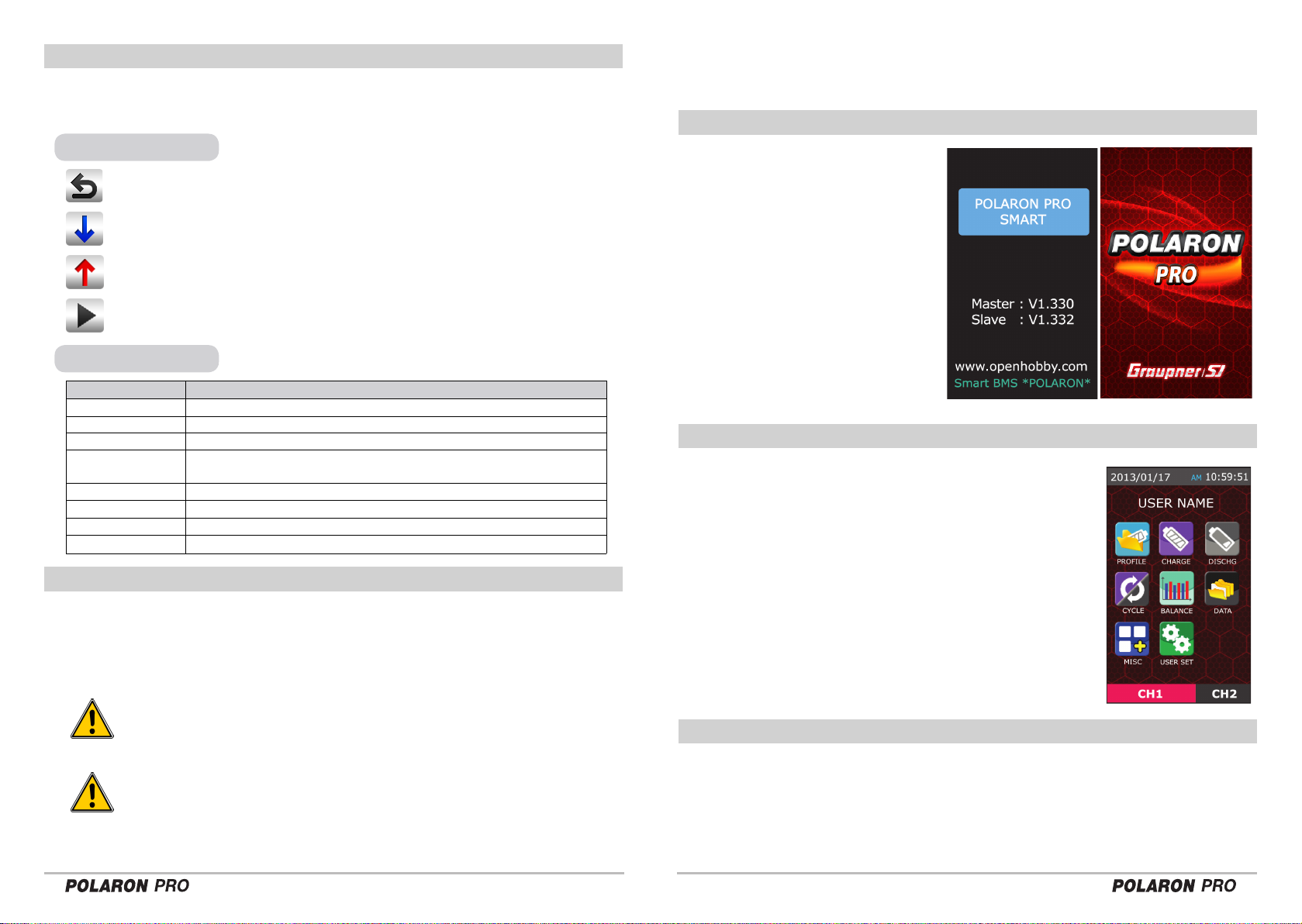

◎ MENU CONFIGURATION

Graupner/SJ POLARON Series chargers are equipped with a highly sensitive touch screen.

Touch the icons to access every mode and set up your device.

ACTION BUTTONS

-

ESC button: Return to the previous page, store the setup data, etc.

- DEC button: Page transition, data setup, etc.

- INC button: Page transition, data setup, etc.

- ENTER button:

Start / complete the operation, store the setup data, etc.

Go to the next page, Complete the data setup,

MENU DESCRIPTION

Main page Function

PROFILE

CHARGE

DISCHG

CYCLE

BALANCE

DATA

MISC

USER SET

Battery name, type, capacity, number of cells, memory number, memory copy

Setup the battery charge data

Setup the battery discharge data

Setup cycle type and delay the time of charge / discharge

( using the charge / discharge setup data )

Display the cell voltage and related data. Setup the balance data

Display the completed data and battery status

Setup servo, motor and warmer data, E.S.C setting

Setup input data, warning, date, time, user name and etc.

capacity than other cells, over time, the pack can become unbalanced. For an unbalanced pack, some

of the cells can exceed the maximum voltage during the charging process, with other cells falling below

the minimum voltage during discharge processes. Both circumstances can cause damage to the cells. For

an overcharged Lithium cell, damage can occur, with extreme conditions resulting in a fire.

◎ INPUT POWER SETUP

This charger has a capacity of 40 memories

(CH1 20 /CH2 20). Each battery can be configured with the basic programming setup to

manage the batteries efficiently. The charger

should be connected to the docking SMPS

or a suitable 11-28V DC power source, with

the black lead connecting to the negative (-)

and the red lead connecting with the positive

(+) input voltage. The CH1 could be configured by max 260W for 12V and max 500W for

24V. The current can be programmed during

the USER SET (ref. page 30) process.This

charger will control the output automatically,

depending on the power input source.

▲

Power on

◎ MAIN PAGE

- The channel numbers (accessed using the bottom boxes)

can be used to select the channel. The main page of the

selected channel in shown in red. Tapping the link to the

other channel box will select for the other channel.

◎ BATTERY CONNECTION

POLARON PRO 2CH DC chargers have two sets of outputs on the front of the charger. Channel 1 is on

the left. Channel 2 is on the right. Each channel has two 4mm banana sockets with a 7 cell balance port

and a temperature sensor input port. An appropriate charge lead must be selected to match the specific

connector on your battery. The charge leads must be connected to the 4mm output sockets on the spe

cific charger channel, with the positive (+) lead connected to the red socket and the negative (-) lead

connected to the black socket.

Only connect the battery to the charge lead AFTER the charge lead has been connected

to the charger, as the connectors on the charge lead could touch together and cause the

battery to short circuit.

During the charging of a Lithium pack, the balance lead MUST be connected to the charger. The

charger has a ‘JST-EH’ type balance port, but also comes with other balance adaptor boards.

To use an adaptor board, connect the supplied balance adaptor board lead to the charger. Then,

connect the board using the appropriate battery balance connector. This balancing connector is

essential.

main battery power

or discharge the connected Lithium

recommended. As some cells may retain more

11 12

Without connecting the balancing connector to the balancing port on the charger (i.e.,

leads ONLY are connected to the output banana sockets)

pack without balancing it. Balancing a Lithium pack is highly

, the charger will charge

-

the

- The date and time are displayed on the top of the main

page. This data can be programmed during the USER SET

process.

- The links displayed on the main page can be accessed

by tapping the images. Activated icons turn to a dark gray

and the charger emits a beeping tone.

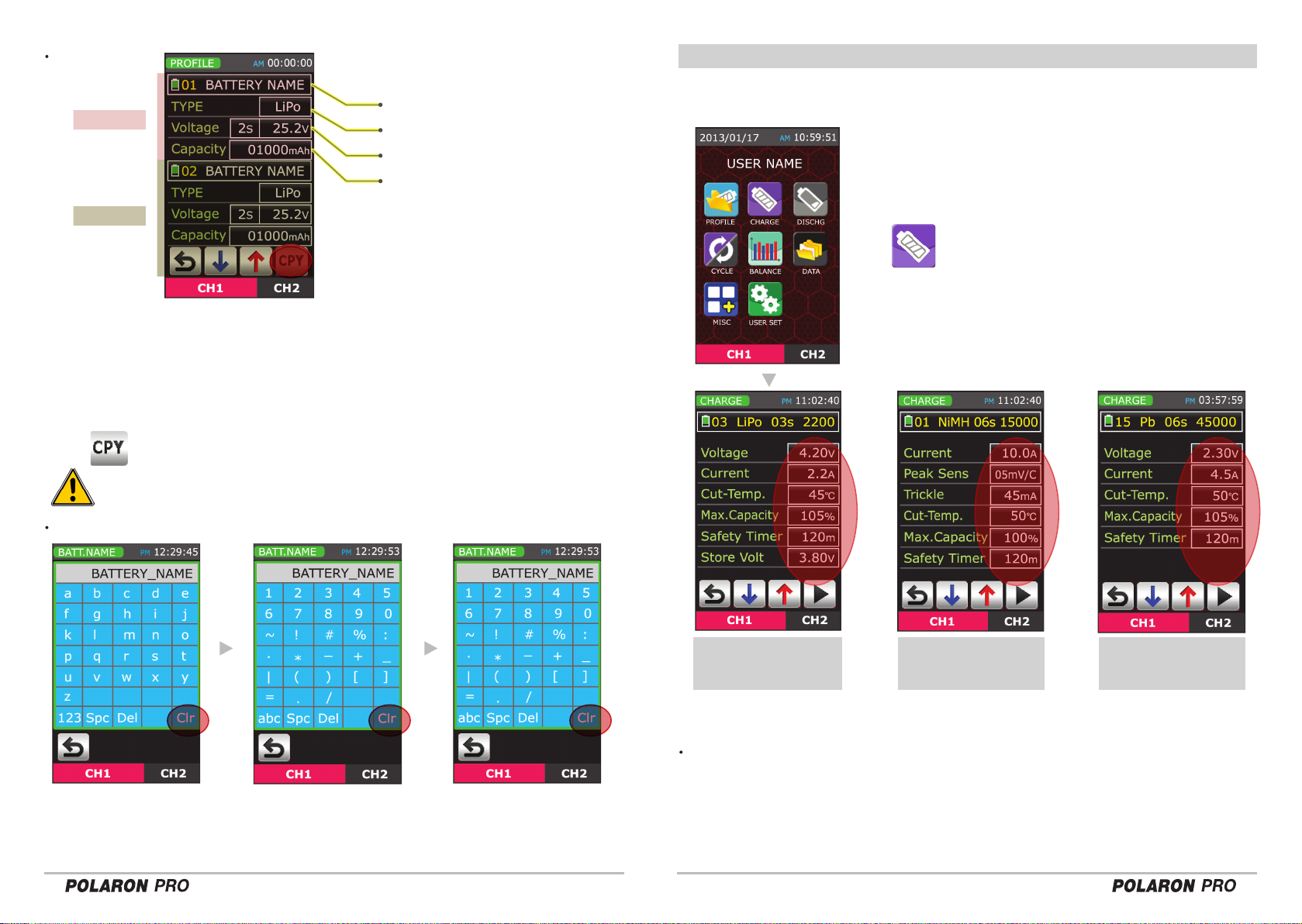

◎ PROFILE PAGE

The profile page is the main functional page for this charger. This page can be used to set

up the battery name, battery type, capacity, number of cells and the memory number, as well

as being used to initiate the charging, discharging, cycling and balancing mode functions.

The related functions for the charge and discharge processes are operated according to the

stored data of the charging, discharging, cycling and balancing modes.

Page 7

Display

◎ CHARGE PAGE

Section 1

Memory number & Battery name

Battery type

Battery voltage

Battery capacity

Section 2

1)

Tap the memory number box in section 1 to activate. Tap the INC/DNC buttons to set the memory number.

The numbers 0~19

name page.

2)

Tap the battery type, the number of cells and the capacity to activate these functions. Tapping the INC/DEC buttons

can be used to edit the battery parameters.

3) Memory copy

Tap the number box in Section 2 to activate. Tap the INC/DNC buttons to set the memory number. Tap

the Enter button to copy the battery parameters from Section 1 to the battery parameters for Section 2.

4)

Tap button to store the battery parameters and tap ESC button to get back to the previous page

are available and changeable. Press and hold the memory number box to access the battery

IMPORTANT: The battery parameters must be entered correctly, as incorrect values may

cause the charger to damage your battery, which can result in a fire!

Battery name editing

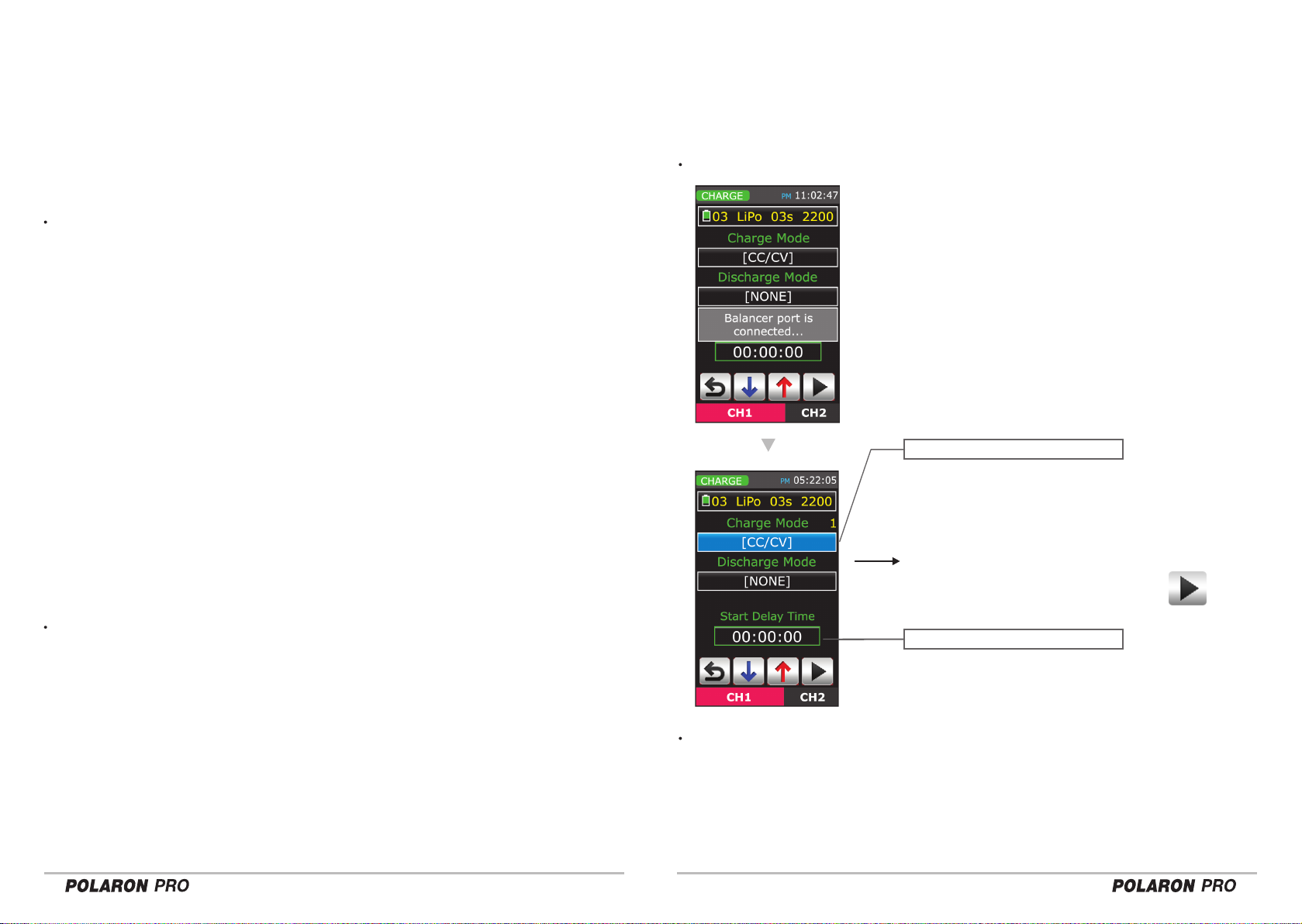

To access the charge mode, tap the CHARGE icon on the main page. The parameters in this mode

are dependant on the selected battery type that was set on the profile page.

Tap the CHARGE icon on the main

page to initiate the charging process.

The battery parameters

on the charge page for

the LiPo, Lilon, LiFe

batteries

The battery parameters

on the charge page for the

NiCd, NiMH batteries

The battery parameters

on the charge page for the

Pb batteries

To program the battery parameters, tap each data box, activating to a blue color. To edit the

battery parameters, tap the INC/DEC buttons.

LiPo, LiIon, LiFe battery charge setup

- Voltage

Battery names can be written with 12 characters. Tapping the Clr button (shown in the red circles, above) erases the

default name, allowing the new name to be entered. To enter the battery names “ABC”, “abc”, or “123”, each

page with the upper case letters, the lower case letters and the numbers with special characters should be separately

accessed by tapping the respective icons. Tapping the ESC button will return the screen to the previous page.

13 14

- Current

: Maximum cell voltage - CV (Constant Voltage)

:

Charge current. - Tapping the INC/DEC buttons can activate and edit the

parameters The default charge current is set to 1C (1 x capacity).

This value can be adjusted from

0.1 to 20 Amps, operating within the 500W limitation

Page 8

:

- Cut-Temp

Cut-off temperature. Detected using an optional temperature sensor, a safety cut-off

temperature can be set to automatically terminate charging or discharging processes. This

termination can occur for battery temperatures exceeding a preset value.

:

- Max Capacity

The maximum capacity setting is used to terminate a charge. The maximum capacity is

used to prevent the battery capacity from exceeding a preset percentage. Damaged, poorly

balanced, or improperly programmed batteries can be overcharged without this limitation.

:

- Safety Timer

The safety timer can be used to terminate a charge for charging times that exceed

this preset time period. This timer can be used to protect the battery from damage.

:

- Store Volt

The battery voltage in the store mode. This parameter is used to terminate a charge

for voltages that reach a preset voltage value.

NiCd/ NiMH battery charge setup (Applied to CH1 and CH2)

- Current

:

Charge current. - Tapping the INC/DEC buttons can activate and edit this parameter. The default charge current is set to 1C (1 x capacity). The CH1 could be configured from 0.1A to 20A (to be operated within 500W) and CH2 could be configured

from 0.1A to 3.0A (to be operated within 30W).

- Peak Sens

:

Delta-peak cut-off voltage. - This parameter is used to charge the NiCd/ NiMH

batteries. As the pack voltage peaks, the pack becomes hot and the pack voltage

drops off. This charger terminates the charging process using a Delta-peak cut-off.

The default parameter is 3mV/cell for the NiMH batteries and 7mV/cell for the NiCd

batteries.

- Tricke

:

Trickle charge current. - With NiCd and NiMH type batteries, a trickle charge process is recommended after the main charge has completed, allowing the battery

become fully charged and ready to be used. The recommended trickle

is approximately 10% of the pack capacity (possible to set to a max of 500mA).

- Cut-Temp

:

Cut-off temperature. - Used with an optional temperature sensor, a safety

temperature value can be specified, allowing the charging or discharging processes to

automatically terminate for battery temperatures exceeding a preset value.

- Max Capacity:

The maximum capacity setting is used to terminate charging processes for battery

capacities exceeding the selected percentage values. Damaged or improperly programmed batteries can be overcharged without a proper setting of this parameter.

- Safety Timer

:

The safety timer can be used to terminate the charging process for charging times

that exceed a preset time period. This timer is used to protect the batteries.

Pb battery charge setup (applied to CH1)

- Voltage

- Current

: Maximum cell voltage. - CV (Constant Voltage)

:

Charge current. - Tapping the INC/DEC buttons can activate and edit the parameters. The default charge current is set to 1C (1 x capacity). This value can be

adjusted from 0.1 to 20 Amps, operating within the 500W limitation.

- Cut-Temp

:

Cut-off temperature. - Used with an optional temperature sensor, a safety cut-off

temperature can be set, allowing the charging or discharging processes to automatically

terminate at battery temperatures exceeding the preset temperature value.

- Max Capacity

: The maximum capacity setting is used to terminate charging processes that result in

battery capacities exceeding a preset percentage value. Damaged, poorly balanced,

or improperly programmed batteries can be overcharged without this limitation.

- Safety Timer

: The safety timer can be used to terminate the charging process for charging times

that exceed a preset time period. This timer is used to protect the batteries.

to

charge current

cut-off

The programmed data are stored in the memory and used to charge the batteries. Tapping the Enter

button initiates the charging process. The balance connector verification, the charge mode verification,

the number of cells to be charged, and the delay time setup should be finished prior to the charging

process. For an improperly programmed setup, the charger will initiate a 5-second countdown without

any external controls.

Below picture shows the sequence of charging

LiPo, Lilon, LiFe, NiCd, NiMH, Pb battery charge process

The charger verifies the connection with

the balance board. This step is an auto-

matic process.

Charge mode selection

Both the charge mode and the delay time are programmed

parameters.

To activate, tap the box to become blue. Tap the DEC/INC

button to select the desired mode.

Charge modes are explained below

After a 5-second countdown, the charger initiates the

charging process. Tapping the Enter button initiates the charging process immediately.

Delay time setup

The Start Delay Time can be set at values ranging from

1-150 minutes.

The charger initiates the battery charging process after

the preset time has expired.

Charge mode per battery type

[ AUTOMATIC ]

NiCd/NiMH : This step is an automatic charging process, first determining the number of cells and then mon

itoing the charge current. The charger calculates the internal resistance and charge current for every period

of time, automatically adjusting the charge current to ensure the delivery of the optimal charge current to your

pack. The

PEAK SENS values (NiCd=7mV/cell, NiMH=4mV/cell) are applied automatically. The CUT-TEMP values

can be programmed.

15 16

Page 9

[ NORMAL ]

NiCd/NiMH :

The charger will charge the pack with a preset charge current, stopping the charging

process every minute to calculate the voltage and detect the Delta peak. This process allows for im-

proved peak detection, determining the amount of battery wear and instabilties in the charge cable.

[ LINEAR ]

NiCd/NiMH :

The charger will charge the pack with the preset charge current, detecting the Delta

peak every second without stopping the charging process. As changing the charge cable contact

point might terminate the charging process, do not touch the charge cable during the charging

process. After 10 minutes, the charger will stop charging for a few seconds to calculate the internal

resistance. This method can detect the ZEROpk (0mV/cell) and terminate without an increase in the

temperature.

Charge modes for the POLARON PRO CHARGER

LiPo, LiIon, LiFe

CC-CV : Normal charge.

FAST : Fast charge.

N-STORE : Normal store charge.

Q-STORE : Quick store charge.

NiCd, NiMH

CV-LINK :

AUTO :

The packs that have the same number of cells and capacity

can be charged simultaneously

The charge will automatically adjust the charging conditions.

NORMAL : Normal charge conditions.

LINEAR :

Pb

In the CV-LINK mode, the packs should have the same voltage, capacity and number

of cells. With variances in the charging parameters, damage to the batteries can occur.

Please install a balance cable to CH1, CH2

CC-CV : Normal charge.

The preset current is maintained throughout the charge.

(If the cells are different, errors can occur.)

[ CC/CV ]

LiIon/LiPo/LiFe/Pb :

After charging with a constant current, the charger will then charge the pack

with a constant voltage. The calculated voltage from the balance cable is used to control the pro-

cess, allowing the pack to be charged safely (Only a battery equipped with a balance cable should

be charged, excluding the Pb batteries).

[ FAST ]

LiIon/LiPo/LiFe :

After charging with a constant voltage, the charger will charge the pack with

a constant current. The calculated voltage from the balance cable is used to control the process,

allowing the pack to be charged safely (Only a battery equipped with a balance cable should be

charged, excluding the Pb batteries).

[ STORE ]

LiIon/LiPo/LiFe :

After charging / discharging under constant current conditions, the charger will

charge/discharge to store the pack with a constant voltage. CC/CV is applied to N-STORE. FAST

is applied to Q-STORE.

This page (left) demonstrates the battery check process

after the balancer is connected. The next page is accessed

automatically. Tapping the Enter button will

immediately cause the charger to initiate the

charge process.

Battery Cell Check

Number of cells check

After connecting the balance board, the charger can check the

number of cells. If the reported number of cells is not correct,

tap the ESC button to return to the previous page and re-run the

parameters check again. Repeat this process until the number of

cells is correct. With the correct parameters, the next page will be

accessed automatically.

Without the balance board connection, the number of cells should be

entered manually. Tapping the Enter button will cause

the charger to immediately initiate the charging process.

(This page does not appear for connections with NiCd, NiMH batteries.)

17 18

Page 10

This page (left) shows the charging process with the parameters

and graph. Both the voltage and current will increase to the preset

parameters. The preset current may be limited by the charge/discharge capacity and the input voltage setup. The maximum charging

process can operate with 500W by CH 1 and 30W by CH 2.

Tapping the graph will access the data view page.

The operating data can be displayed.

Please refer to pages 27-29 for further information.

Tapping the part in the red circle (image to the left), the set current window will appear. The operating charge current can then

be set. Tapping the X button will cause the set current window to

disappear.

This setup is applied to the charger during the charging process

and the parameters are not stored in the memory.

◎ DISCHARGE PAGE

Tapping the DISCHARGE icon on the main page will access the discharge mode. The pro-

gramming setup and the page transition are the same as described for the CHARGE mode.

USER NAME

On the main page, tap the DISCHARGE

icon to start the discharge process.

This page shows discharge setup for selecting

LiPo, Lilon, LiFe, NiCd, NiMH, Pb batteries

To program the battery parameters, tap each data box,

activating to a blue color.

To edit the battery parameters,

tap the INC/DEC buttons

Pressing the STOP button will cause a pop-up window to ap

pear, asking whether to stop operating. Tapping the STOP or

ESC buttons will cause the charger to either stop or continue

with the charging process, respectively.

-

LiPo, LiIon, LiFe, NiCd, NiMH, Pb battery discharge modes

- Voltage

- Current

:

Final discharge voltage for each cell can be programmed

:

Discharge current. - The CH1 could be configured from 0.1A to 10A (to be operated within

60W) and CH2 could be configured from 0.1A to 1.0A (to be operated within 5W).

- Cut-Temp

:

Cut-off temperature. - With an optional temperature sensor, a safety cut-off temperature

can be set, allowing the charging or discharging process to terminate automatically for

battery temperatures exceeding the preset temperature.

- Max Capacity

: The maximum capacity setting is used to terminate a discharge at battery capacities exceeding a preset percentage value. Damaged, poorly balanced or improperly

programmed battery parameters can result in an overdischarge.

19 20

Page 11

The programmed data are stored to memory to be used in the battery discharge process.

Tapping the Enter button causes the charger to initiate the preliminary steps, including

a check of the balance connector, discharge mode, number of cells, and the delay time

setup. The discharge process starts immediately after these preliminary steps. With proper

programming, the charger will display a 5-second countdown. The discharging sequence

is shown below.

LiPo, Lilon, LiFe, NiCd, NiMH battery discharge processes

[ NORMAL ]

-

The charger will stop the discharging process every minute to calculate the average resistance.

[ LINEAR ]

- The charger will discharge the pack, stopping once after 3 minutes to calculate the internal resistance.

Discharge mode for the POLARON EX CHARGER

LiPo, LiIon, LiFe

NORMAL : Normal discharge.

LINEAR : The preset current is maintained throughout the discharge process.

LINK : The packs with the same number of cells and capacity can be

discharged simultaneously.

The charger checks for a connection with the balance

board.

This process is automatic.

Discharge mode selection

The charge mode is programmed.

Tap the box to activate (blue). Tap the DEC/INC button to

select the desired mode. The discharge modes are explained

below.

After counting down, the charger initiates the discharge

process. Tapping the Enter button will cause

the charger to immediately initiate the discharge

process.

Delay time setup

The delay time can be programmed to values between

1-150 minutes. After this preset time, the charger will then

initiate the battery discharge process.

Discharge mode per battery type

[ AUTOMATIC ]

- In this discharge mode, the discharge process proceeds automatically.

The first two steps in

clude checking the number of cells and determining the discharge current. The charger then calculates the

internal resistance and discharge current for every period of time. The programming automatically adjusts the

discharge current to ensure that the optimal discharge current is delivered to your pack.

-

Cutoff voltages (NiCd=0.9V/cell, NiMH=0.8V/cell, LiIon/Po=3.0V/cell, LiFe=2.5V/cell, Pb=1.8V/cell) are

applied (Charging the Lithium and Pb batteries after discharging does not affect the battery performances.)

- The preset CUT-TEMP is used in this discharge mode.

NiCd, NiMH, Pb

In the LINK mode, the packs should have the same voltage, capacity and number of

cells. Differences in these charging parameters can cause damage to the batteries.

* Please install the balance cable to CH1, CH2.

AUTO : The charger will automatically adjust the discharging conditions.

NORMAL : Normal discharge process.

LINEAR : The preset current is maintained throughout the discharge process.

This page (left) shows the battery check process with the

balancer connected to the charger.

Tapping the Enter button will access the next page

and cause the charger to automatically initiate

the charge process.

Number of cells checking

After connecting the balance board, the charger can then

check the number of cells. If the number of cells is

incorrect, tap the ESC button to return to the previous page

and re-check the parameters. With the correct number of

cells, the next page will automatically be accessed.

To initiate without a balance board, the number of cells

should be determined and manually entered. After tapping

the Enter button, the charger will then immediately initiate

the discharge process.

21 22

Page 12

This page (left) shows a display of the discharging process with the parameters and graph. Both the voltage and

current will increase to the preset parameters. The preset current value may be limited by the charge/discharge

capacity and the input voltage setup. The max discharge

operates at 60W by CH1 and 5W by CH2.

Tapping the graph will access the data view page, allowing

the operating data to be displayed.

Please refer to pages 27-29 for more information.

USER NAME

Tap the CYCLE icon on the main

page to

access the cycle mode.

Tapping the part in the red circle (left) will change the

screen to the Set current window. The discharge current

parameter used during the operation can then be entered.

Tapping the X button will return to the operating window.

These setup parameters are immediately used by the

charger in the discharging process and the parameters are

not stored in the memory.

Pressing the STOP button will cause a pop-up window to

appear, asking if you want to stop operating. Tapping the

STOP or ESC buttons will cause the charger to either stop

or continue the discharge process, respectively.

LiPo, Lilon, LiFe, NiCd, NiMH, Pb battery cycle pages

Tapping the part in the red circle will activate (blue) this parameter, allowing this value to be programmed. The parameters entered

into the Charge and the Discharge mode are used to set the

charge/discharge current during the operations. Tapping the Enter

button will access the next page.

1) Operating sequence of the cycle mode

C > D - Discharge after the charge

D > C - Charge after the discharge

D:C > D - 1 time discharge: Discharge after the

charge

2) Cycle -

The number of operating cycles ( 1-10 times)

3) C->D Delay - Time interval after the charge (1-30min)

4) D->C Delay - Time interval after the discharge (1-30min)

The parameters entered into the Charge and Dis

charge modes are used in the charge/discharge pro

cesses. These values can be changed.

LiPo, Lilon, LiFe, NiCd, NiMH, Pb battery cycle processes

The charger determines if there is a connection to the balance board.

This determination is an automatic process.

-

-

◎ CYCLE PAGE

Tapping the CYCLE icon on the main page will access the cycle mode. Tapping the data

box will activate this parameter (blue). Tapping the DEC/INC buttons will access the program for the parameters.

23 24

Page 13

Charge mode selection in cycle mode

Discharge mode selection in cycle mode

The charge mode and the start delay time parameters are programmed.

Tap the box to activate (blue). Tap the DEC/INC button to select the

desired mode. Discharge modes are explained below

After counting down, the charger initiates the discharge process.

Tapping the Enter button will cause the charger to

immediately initiate the charging process.

Start delay time

The start delay time can be set at values betwee 1-150

minutes.

After the preset delay time has completed, the charger initi-

ates the cycle charge/discharge.

Cycle operation mode per battery type

Cycle charge discharge mode of the POLARON PRO Charger

LiPo, LiIon, LiFe, Pb

CC-CV : Normal charge mode

NORMAL : Normal discharge mode

LINEAR :

The preset current is maintained throughout the

discharge process.

NiCd, NiMH

AUTO :

The charge will automatically adjust the

charge/discharge conditions

NORMAL : Normal charge/discharge

LINEAR : The preset current is maintained throughout the

charge/discharge process.

Number of cells checking

After connecting the balance board, the charger can check

the number of cells. If the confirmed number of cells is not

correct, tap the ESC button to return to the previous page.

Re-check the parameters. With the correct number of cells,

the next page will be accessed automatically.

To initiate the process without a balance board, the cell can

be activated and the number of cells programmed into the

cell. Tapping the Enter button will cause the charger to immediately initiate the charging process.

This page (left) shows the cycle process with the parameters and graph.

Both the voltage and current values will increase to the preset parameters.

The preset current may be limited by the charge/discharge capacity and

ithe nput voltage setup. The max charging process operates at 500W with a

max discharging process at 60W by CH 1. And the max charging process

operates at 30W with a max discharging process at 5W by CH 2.

Cycle operating screen

The operating indicator blinks at the top

The number of operating cycles is shown

Tap the graph to display the operating data

This page (left) shows the battery check process after a con

nection to the balancer has been established. The next page

is accessed

automatically. Tapping the Enter button will cause

the charger to immediately initiate the charging

process.

-

Tap the part in the red circle (left) to display the set current

window. The charge/discharge current parameters used during the operations can then be entered. Tap the X button to

close the set current window. These parameters are used by

the charger during the operation and are not stored in the

memory.

Battery Cell Checking

25 26

Page 14

Center voltage

Pressing the STOP button will cause the pop-up window

to appear, asking for a confimation that you want to stop

the operation. Tapping either the STOP or ESC button will

cause the charger to either stop or continue the cycle,

respectively.

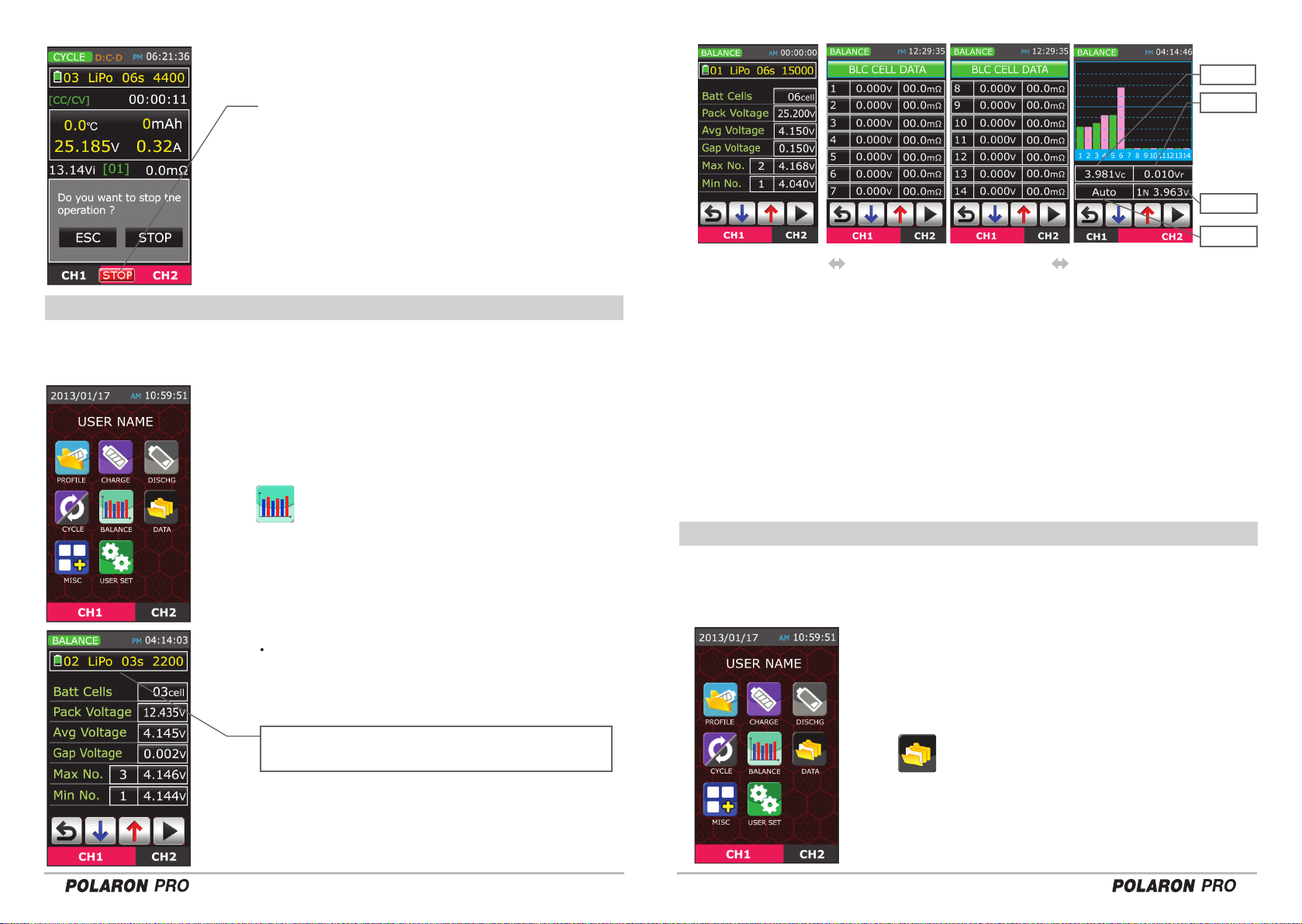

◎ BALANCE PAGE (Applied to CH 1)

Tapping the BALANCE icon on the main page will access the balance mode. Tap the DEC/INC Buttons to

toggle between the 3 modes. Tap the Enter button to initiate the balancing process. The selected mode

is used with the batteries that are equipped with a cell balance connector (LiPo, LiIon, LiFe batteries).

Tap the BALANCE icon to access the balance

mode.

(The balance connector should be installed.)

Range voltage

Cell Voltage

Manual / Auto

▲ ▲ ▲

BALANCE MODE 1 BALANCE MODE 2

BALANCE MODE 3

1) BALANCE MODE 1 : This page (above, left) shows the basic date of the battery.

2) BALANCE MODE 2 : This page (above, center) shows the cell voltage and internal

impedance values.

3) BALANCE MODE 3 : This page (above, right) displays multiple parameters.

- Center Voltage(Vc): The voltage of the center in the Y axis.

- Range Voltage(Vr) : The voltage range of every section in the Y axis

- Manual / Auto

Manual:

The graph can be manually operated. Tap the data box to activate. Tap the DEC/INC

buttons to program the parameters. The Center Voltage and Range Voltage can

be activated and programmed using the manual setup.

Auto:

This mode performs an automatic setup of the graph for the operation.

Each cell voltage is activated and checked.

- Cell Voltage :

Displays the cell voltage. Tapping activates this paramter, allowing the cell data to

be checked.

◎ DATA VIEW PAGE

Tap the DATA icon on the main page to access the data view mode. There are 3 view modes. After

activating the buttons, the data can be programmed by tapping the DEC/INC buttons. In the Cycle data

and Graph data modes, the data can be accessed. In the Normal data mode, the parameters can not

be programmed.

LiPo, Lilon, LiFe battery balance page

This page (left) displays the connected battery parameters.

Tapping will activate the box (blue). The battery memory

can then be selected.

27 28

Tap the DATA icon to check the charge/discharge

data on the main page.

Page 15

Charge time

Peak voltage

Charge capacity

Internal impedance

of charge battery

Cycle number

Discharge time

Average voltage

Discharge capacity

Internal impedance

of discharge battery

Finish Sound : 10 types of sounds are available.

Sound Time :

The times available for the charger are

ON, OFF, 5sec, 15sec, and 1min.

Beep :

This parameter can be turned on/off to select

either an internal or an external button.

LCD Bright

: Backlight brightness can be adjusted

(1-20 steps).

Temp. Scale : The temperature unit can be changed.

Sound Vol. :

The sound level can be adjusted. (1-5 steps)

NORMAL DATA CYCLE DATA GRAPH DATA CONFIG MODE 1

1) NORMAL DATA :

Real time display of the input/output voltage, temperature, resistance of

battery.

2) CYCLE DATA :

Display of the data according to the cycle number.

- Charge/discharge time : Displays the total time of the charge/discharge process.

- Peak voltage : Display of the max voltage during the charging process.

- Average voltage : Display of the average voltage during the discharging process.

-

Charge/discharge capacity : Display of the charge/discharge capacity at completion.

- Internal impedance of the battery : Display of the internal impedance during charging/dis

▲▲ ▲ ▲

Input from the rear side and docking side.

The Wattage Setting of the User’s SMPS

from the rear side

The Voltage & Current Setting of the User’s

SMPS from the rear side

charging.

3) GRAPH DATA :

The graph reflects the programmed data, entered either automatically or

Display of the graph with the operating voltage, current, and temperature.

Output Sharing of Ch.1 and Ch.2

(Wattage with percentage)

manually.

◎ USER SETUP PAGE

Tap the USER SET icon on the main page to access to user setup modes (4 modes). The

data can be programmed. The page can be navigated by tapping the DEC/INC buttons.

Tap the USER SET icon to program

the user setup on the main page.

▲ ▲

CONFIG MODE 3 CONFIG MODE 4

Not yet Applicable.

Low Voltage Error Setting

▲

CONFIG MODE 2

CH1 user setup of can be set at CONFIG

MODE 1-4.

Only the Finish sound of CONFIG MODE 1

in CH2 user setup can be set

Date & Time : Date, month, year, time setup

Alarm 1 : The first alarm time setup.

When not in use, set to OFF

User Name : Enter user name

Language : Not yet applicable

Option : Not yet applicable

Alarm 2 : The second alarm time setup.

When not in use, set to OFF

29 30

Page 16

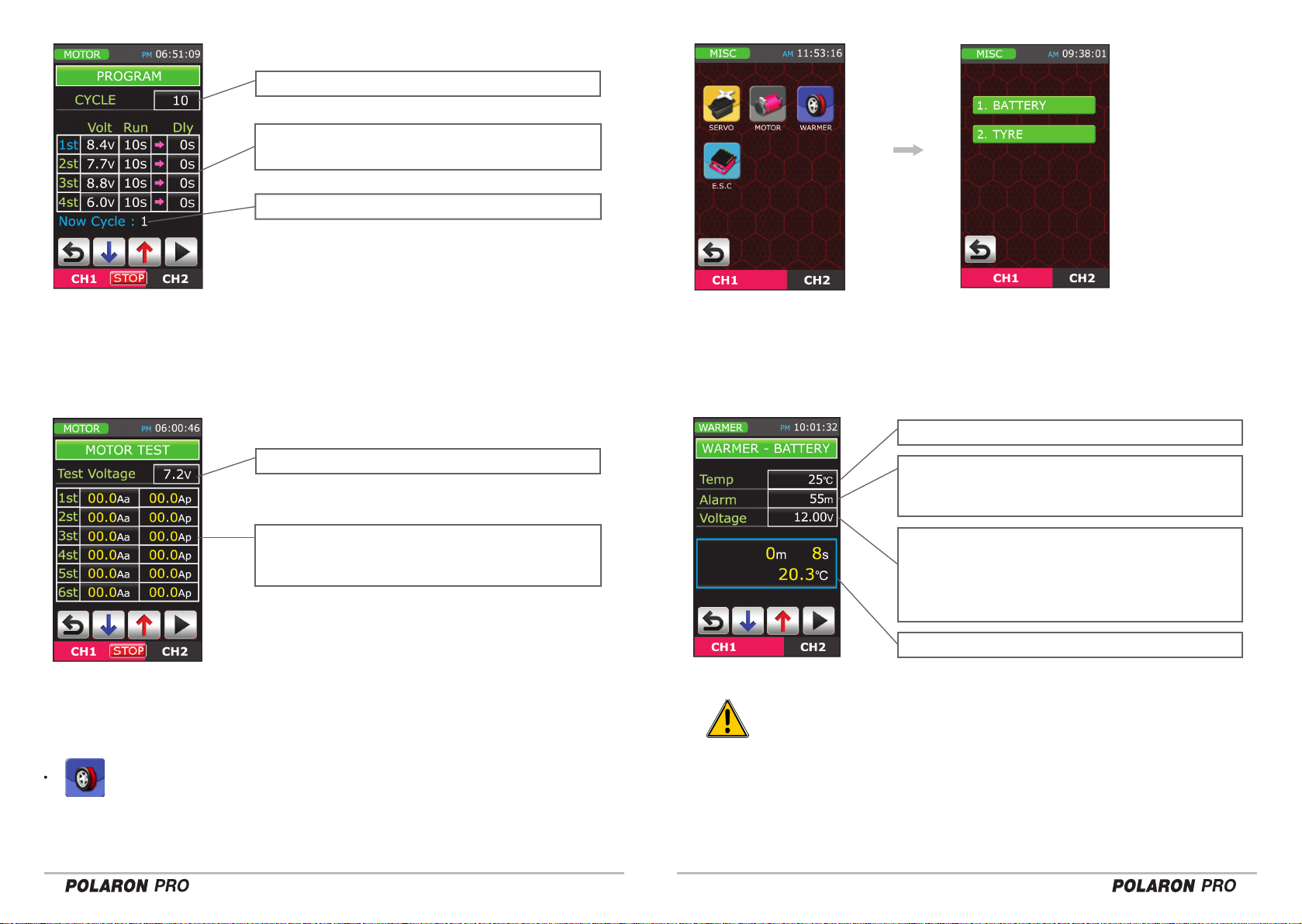

◎ MISC PAGE (Addition function)

Tap the MISC icon on the main page to access the MISC mode and to program the

Servo, Brushless/Brushed power motor, Warmer and ESC functions.

Tap the MISC icon to program the MISC

setup on the main page

The additional functions of Polaron Pro

CH 1 : Motor Test, Servo Test, ESC Configuration and Warmer

CH 2 : Servo Test and ESC Configuration

This is the MISC setup page.

Tap the 3 icons to access each mode. Tap the ESC button to

return to the previous page.

- Used to test the Servo and Brushless Motor.

- Used to test and condition the Brushed Motor.

- Used to warm up the batteries and tires.

- Used for the

speed controller

setup and settings.

Servo and Brushless motor testing setup

1) Servo test division (Screen top)

- Connect the Servo to the connecter on the right side of the charger

(see picture, below).

Check the servo connector

polarity S,+,-

Min, Mid, Max signal

:

Tap the relevant buttons. The servo is operated in accordance with the preset

signal. The parameters of each article can be changed by tapping the DEC/INC buttons.

Output signal

Auto loop time

: Displays the current signal output parameters.

: After entering the Auto loop time (0.1 - 5.0sec),

tap the Enter button.

High power servos may not function well using only short operatinng times, as

these servos often require a high peak current demand. For these servos,

extend the operating time to accomodate the increased peak current

requirements.

2) Motor test division (Screen Top and bottom)

- Motor sensor connector and servo test connector are both used.

The 3 sensors at the top indicate if the motor is OK or not.

RPM and Kv are shown at the bottom.

Continuously rotate the motor shaft for approximately 5 seconds.

Mid Signal

Min Signal

Output Signal

Motor RPM

Output voltage

Sensor check

Max Signal

Auto loop time

Output current

KV data

The charger will then indicate if the sensor is OK or not.

The motor should be connected to the motor sensor connector.

An (optional) splitter is required to check the motor RPM

and Kv. (Please refer to the picture on the next page.)

Auto Loop Start

31 32

Page 17

The optional accessory

Wire splitter for testing the motor

sensor (S8002)

Connection configuration for the ESC, Motor, Battery, and Wire splitter

Brushed motor setup

Connect the motor to a 4mm banana charge socket. Tap the MOTOR icon to access the motor

setup mode. This page has 3 menus.

1) Break-In

- The motor is operated and limited by the preset voltage for the preset time.

The operating time is set by minutes and seconds

The operating voltage is set.

Tap the Enter button to check the operating time, voltage, and consumption current.

For the connections on the charger side terminal, the connector marked “sensor in the wire

splitter” is connected to the motor and the left 2 connectors are connected to the charge

and the ESC, respectively. The ESC signal connector is connected to the charge servo test

socket.

2) Program

- Programming requires 4 inputs: the voltage, the operating time, the delay time and the

number of cycles. After entering each data value, tap the Enter button. The charger will

repeat to load the motor using the preset number of cycles. The blue character shows the

current process.

33 34

Page 18

Setting the number of cycles (1-10 cycles)

Setting the operating voltage, the operating time, and the

delay time, for each of the 4 steps.

The operating cycle number.

3) Motor test

- For the motor operations (6 steps), the average current (Aa) and the peak current (Ap) can be selected, using either 4.8V or 7.2V.

1) Battery Warmer

-

At low temperatures, lithium type batteries tend not to perform well. This function is used

to warm up the batteries to ensure proper function for batteries stored outdoors. Connect the

exclusive battery warmer bag to the charger output terminal and the temperature sensor connector.

Then, program the required parameters.

Temperature setup

Test voltage setup. (4.8V or 7.2V)

Alarm setup

Alarm rings at the preset time. The charger continue operating. Tap the STOP button to stop the alarm.

Displays the average current and the peak current for

6 steps.

Each step is operated using 5sec on/ 3sec off.

Output voltage setup

With an installed temperature sensor, this function is controlled automatically. The preset voltage can be outputted

for operations without a temperature sensor.

The temperature setup range is 5-15V

Processing time and temperature

With bags that can not accommodate a temperature sensor, the temperature can not

be controlled automatically. To ensure a proper temperature, control the voltage to

maintain the desired temperature inside the bag. Caution is warrented as an over

voltage setup can cause fires.

Warmer setup

Connect the warmer to the 4mm banana charge socket. Tap the WARMER icon to access

the warmer setup mode. This page has 2 menus.

35 36

2) Tire Warmer

-

This feature can be used to warm rubber tires, providing an important competitive edge on the

track. Connect the tire cup to the charger output terminal and to the temperature connector.

Then, program the required parameters.

Page 19

Temperature setup

Alarm setup

Alarm rings at the preset time. The charger continues operating. Tap the STOP button to stop the alarm.

Output voltage setup

With an installed temperature sensor, this feature is controlled automatically. The preset voltage can be outputted for setups without a temperature sensor. The temperature setup range is 5-15V.

Processing time and temperature

Connection configuration for the ESC setup (Charger, ESC, Motor, Battery, Receiver included)

For warmers not equipped with a temperature sensor, the temperature can not be con

trolled. To warm without a temperature sensor, control the voltage to maintain the desired

temperature of the tires. Please notice that an over voltage setup can cause fires.

Speed Controller Setting

Both the Car ESC and the Air ESC with a telemetry function

can be programmed without an extra programmer. Select the

ESC setup icon. Turn on the model’s power. Then, connect

the telemetry terminal to the EXT. MODULE, allowing the data

to be displayed and programmed. (pages 38-39)

The data can be programmed with 6 buttons.

1. The 3 modes can be accessed by the DEC/INC buttons.

2. The UP/DW buttons are used for the setup only after

the SET button has been touched. Without this toggle,

the UP/DW buttons are used to change the page.

3. The ESC setup page can be exited by touching the ESC

button.

-

Connect the telemetry terminal to the EXT MODULE.

Please note that some ESCs are required to connect the transmitter. Please check the

version of your ESC and throttle position. After connecting a battery to the ESC, the ESC

setup will become available.

To check the data, connect the telemetry terminal to the EXT MODULE without removing

the batteries.

- CAUTION -

· Depending on the version of the Air ESC, the throttle stick should be in the low-position.

· Depending on the version of the Car ESC, the throttle stick should be at neutral position.

· The ESC setup is not available while other functions are in operation.

37 38

Page 20

◎ FACTORY SETUP AND SCREEN CALIBRATION

Button for Channel changing and initializing

Data Initialization

*** Factory Data ***

Initializing Data...

Tap No1 to access the factory data mode.

The blinking characters alternate between red and blue,

indicating that the program is operational. After the Data

Initialization has completed, the return to the Start up page

will proceed automatically.

< Factory Setting >

1. Data Initialization

2. Touch Calibration

3. Resource Upgrade

4. BLC Port Test

Smart BMS *POLARON*

Press and hold the button. Turn on the charger’s power.

1. Return to the factory setup.

2. Touch screen calibration.

3. Image and sound update.

4. Checking the balance port.

The user can adjust No. 1,2,3. The manufacturer

can adjust No. 4 (The user can not adjust).

Smart BMS *POLARON*

Touch calibration (Touch screen calibration)

Tap the “+” icon 3 times on the screen to arrange the screen.

After completing the arranging process, the system will be rebooted for the charging

mode.

Tap anywhere on the screen to complete the Touch calibration. Then, return to the Start up page.

39 40

Page 21

Resource Upgrade (Image and sound download)

RESOURCE UPGRADE

<Image & Sound>

◎ ERROR MESSAGES

Press the button.

‘Download Start’

< WARNING !!! >

DO NOT TURN OFF

THW POWER.

Smart BMS *POLARON*

1. This screen is used to downlowed image and sound files from a PC to the flash memory in the

charger.

2. Program updates are found at www.openhobby.com and www.graupner-sj.com

BLC Port Test (Checking balance port)

*** BLC Port Test ***

This screen (left) is used to check the balance port. Please note

that the user cannot access this mode. (Only available to the

Testing BLC Port...

Smart BMS *POLARON*

manufacturer)

No Battery

Battery is not connected

to the output.

Pls connect the battery to

the output then restart!

Reverse Polarity

A Battery is connected

to the output in reverse!

Pls correctly connect the

battery to the output.

POLARON PRO DC chargers have a number of error and

warning messages that are designed to advise the user

of any problems. Tapping the error message can clear the

message and return to the previous page.

▶ Input voltages of less than 11V or exceeding 28V.

◆ A No Battery error message indicates that there is

no battery connected to the charger.

◆ A Reverse Polarity error message indicates that

the battery is plugged in “backwards”, inverting

the positive to negative connections.

◎ SLAVE BOARD UPGRADE (Product Update)

Open Circuit

A Battery is disconnec-

1. This screen (left) is for product updates from a PC

ted during an operation.

Pls reconnect the battery

and restart!

◆ An Open Circuit error message indicates that the

charging/discharging battery has been disconnected.

during an operation.

(personal computer).

2. Updates are available at www.openhobby.com and

www.graupner-sj.com

Short-Circuited

Output short-circuited.

Pls check the output.

◆ A Short-Circuited error message may indicate

multiple errors, including faults at the charger output

leads, at the battery leads, within the battery and locations on the cables, causing the short circuit.

41 42

Page 22

Low Output-Volt BLC Volt Low

Output voltage is lower

than the selected cells

or voltages.

Pls select proper cells

or voltages.

◆ A Low Output-Volt error message indicates that

either the voltage setup is below the requirements for

the charging/discharging battery or the number of cells

has been improperly selected.

Balancer cell voltage is

too low !

Low cell is [0]

◆ A BLC Volt Low error message indicates that

the balancer cell voltage is below the recommended operating conditions.

High Output-Volt

Output voltage is higher

than the selected cells

or voltages.

Pls select proper cells

or voltages.

◆ A High Output-Volt error message indicates that

either the out voltage setup exceeds the requirements

for the charging/discharging battery or the number of

cells has been improperly selected.

Calibration

Either calibration data or

internal circuit might

have been damaged.

Temp. Sensor No Sensor

A temperature sensor is

connected in reverse or

is defective.

◆ A Temp. Sensor error message indicates that the

temperature sensor either is plugged in “backwards”

with the positive to negative connections inverted or

A temp-sensor is not

connected to the port.

Pls connect the sensor

to the port then restart!

has a fault inside the sensor.

Bat.Temp Too Low Connection

Battery temp is too low

to be operated !

Bat.Temp Too High

Battery temp is too high

to be operated !

◆ A Bat. Temp Too Low error message indicates that

the battery temperature is too low to operate using the

charging process.

◆ A Bat. Temp Too High error message indicates

Selected cells and

cells connected to the

balancing port are

different !

Pls recheck and restart!

Motor Current

Pls reconnect the moto

rand restart !

that the he battery temperature exceeds the preset

temperature values.

◆ A Calibration error message indicates that threre

is a fault in either the default calibration data or the

internal circuits of the charger.

◆ A No Sensor error message indicates that

the temperature sensor has been disconnected.

◆ A Connection error message indicates that the

preset number of cells and the detected number of

cells are different.

◆ A Motor Current error message indicates that

the operating current exceeds the value in the

MISC MOTOR function.

Internal Temp.

Internal temp is too hot!

Contact Hobby Services

if this message appears

often.

◆ An Internal Temp. error message indicates that

the internal temperature within the charger exceeds the recommended operating conditions.

BLC Volt High

Balancer cell voltage is

too high !

Over cell is [0]

◆ A BLC Volt High error message indicates that

the balancer cell voltage exceeds the recommended operating conditions.

43 44

Balancer Port

BLC Port is opened.

Pls check the BLC port.

Sync. Command

Sync order failed.

Error occured in the

counterpart channel !

◆ A Balancer Port error message indicates that

the balance connector has been disconnected.

◆ A Sync. Command error message indicates that

the preset number of cells and the number of cells

of CH1, CH2 are not matched to the values entered

into the Charge/discharge and Sync modes,

Page 23

◎

COMMON PROBLEMS AND PRECAUTIONS FOR THE POLARON PRO DC CHARGER

◎ NiCd, NiMH BATTERY SAFETY

- The charger has been turned on, but the LCD Screen is off.

. Check that the external power source is an appropriate source.

. This charger should be operated only with the types of power sources that are indicated

on the specifications.

. Please contact the A/S center for additional information.

- The charger does not recognize the batteries.

.

Check that the battery connections and the polarity are correct.

.

Worn or excessively used cables should be replaced.

.

Replace damaged or defective cells in the battery pack.

- Battery voltage is low after the charging process has been completed.

(Cell voltages: NiCd, NiMH less than 1.2V or LiPo, LiIon less than 3.6V or 3.7V)

.

Increase the max charge capacity if the final results are too low.

.

Control Peak sense of NiCd, NiMH, if the values are too low or high

.

Replace worn or damaged charge cables.

- Discharging mode cannot be accessed.

.

Check to see if the the preset battery voltage and the cell voltage match.

.

Change damaged or defective cells in the battery pack.

- The mAh/time is too low after the charging process has completed.

. The battery may not be fully charged.

. Fully charge the battery and repeat the discharge process. Perform a cycle process to

improve the battery capacity for worn out or infrequently used batteries.

.

Reduce the discharge cut-off voltage values that have been programmed too high.

Control the discharge ratio.

. Check that the preset battery voltage and the cell voltage values match.

. For discharging with over current, repeat the discharge process to discharge the

remaining current. For example: for discharging processes exceeding 5A, cool down

the battery and repeat the discharge with 1A.

- Charging Lithium type batteries.

. Use a balance board with an EH to XH cable (MUST).

. Do not charge Lithium battery packs above the maximum charge rate. Using excessive

charge rates can damage the pack and be dangerous. Generally, Lithium Polymer

packs should not

be charged above 3C. However, some newer packs do allow charging at up to 5C, but

charging at these higher rates will reduce the life of the pack.

- With charging new NiCd/ NiMH batteries for the first time, the process may terminate

within minutes. This stoppage does not indicate a problem. This stoppage results from an

unstabilized battery. To stabilize the batteries, charge the batteries either after increasing

the delta peak value or after performing a discharging process followed by a cooling down

period.

Do not use the batteries, if the charged capacity of the battery exceeds the specifications

for the battery capacity. If you experience repeated terminations upon charging, repeat the

charge and discharge process by at least 5 times and then repeat the charging process.

Premature terminations may occur up to the third time that the battery has been charged.

◎ Pb BATTERY SAFETY

- Pb batteries need to be charged every day. If the charged capacity of the battery falls

below 50%, this battery may not be recharged. The average charge time of a Pb battery

is 4-5 hours. Do not charge with an automobile battery, as the charger may be seriously

damaged.

◎ LiIon, LiPo, LiFe BATTERY SAFETY

-

Only charge batteries that have a Lithium ion or Lithium polymer mark.

-

Do not charge batteries that have a Lithium mark. Charging Lithium mark batteries will damage

the batteries and may cause fires or personal injuries.

-

Only charge batteries labelled with these cell voltages ( 3.3V / 3.6V / 3.7V ).

- Place the charger and battery on a non-flammable surface during the charging process.

- NEVER charge Lithium ion/Polymer/Fe batteries inside a vehicle.

- Always ensure that the charger is correctly programmed for the battery being charged,

checking both the voltage and the capacity. Be particularly careful with series/parallel battery

packs or using packs of different specifications with the same charger.

- Never charge at a rate exceeding the recommended specifications by the cell manufacturer.

(VERY DANGEROUS).

- Do not leave Lithium ion/Polymer/Fe batteries unattended during the charging process.

Continual monitoring of the batteries is very important.

- Every few minutes, check the temperature of the battery being charged. If the battery

becomes hot to the touch, disconnect it from the charger immediately and allow to cool. Do not

restart the charging process until both the battery and the charger have been checked for

compatibility

and the

charger settings have been confirmed as being correct.

- In the unlikely event of the Lithium ion/Polymer/Fe battery catching fire, DO NOT use water to

attempt to put the fire out! Instead, use sand or a fire extinguisher designed for electrical fires.

45 46

Page 24

- When used correctly, Lithium ion/Polymer/Fe battery packs are as safe as any other type of

rechargeable battery pack. However, these batteries do require different charge regimes than the more

established Nickel Cadmium and Nickel Metal Hydride technologies and have the potential for catching

fire, if severely mistreated.

- If Lithium Polymer battery packs are short-circuited or severely over-charged, elemental Lithium may be

deposited internally. If the battery pouch is damaged, elemental Lithium can escape from inside the

battery. If this occurs, a fire may result. Elemental Lithium is highly reactive with exposure to water or

moisture,

producing flammable hydrogen gas and corrosive fumes. Elemental Lithium is only produced

with severly mistreated battery packs. During normal usage, explosions or fires are extremely rare.

- Lithium Ion/Polymer battery packs must NEVER be discharged below 3 volts per cell (Li-Fe 2.0V), as

this will result in damage to the cells. If the voltage is allowed to drop below 3 volts per cell, the

battery voltage may seem to recover following a charge, but the battery may not have full

nominal capacity and a reduction in performance is likely. Allowing the voltage to fall below 3 volts per

cell will invalidate all warranty claims.

- Never charge Lithium Polymer battery packs to values exceeding 4.2V per cell, Lithium Ion batteries

exceeding 4.1V volts per cell or LiFe batteries exceeding 3.7V per cell. Exceeding these recommended

values can cause irreversible damage to the cells and will invalidate all warranty claims.

- Never charge Lithium battery packs at rates exceeding the maximum charge rate, as damage to the

pack can occur and this process may be very dangerous. Generally, Lithium Polymer packs should

not be charged above 2C (2 x Capacity).

However, some newer packs do allow charging at rates up to 5C. Charging at these excessily high rates

will

reduce the life of the pack. (e.g Pack of 2500mAh capacity : 2C = 5000mAh = 5A max)

- Do not use discharge rates in excess of those specified with the battery pack, as a significant

drop in voltage under load will occur that can dramatically reduce the number of

charge/discharge cycles that the battery pack will hold.

- Disposal of the Lithium battery packs requires that the pack be completely discharged.

Use a light bulb, electric motor or similar to completely discharge the pack.

◎ The Guide for the related Countries’ Certifications

Conformite Europeenne

NO. BCT13KC-2189E

Model: POLARON PRO CHARGER

Item Number(s): S2003

The object of declaration described above is in conformity with the requirements of the

specifications listed below, and accordance with the following applicable

directives: 2004/108/EC Electromagnetic Compatibility

EMC : EN 55014-1:2006+A2:2011

EN 55014-2:1997+A2:2008

◎ ENVIRONMENTAL PROTECTION NOTES

This product must not be disposed of with other waste. Instead,

Do not allow a Lithium battery pack to short-circuit! A short-circult may result in a

minor explosion with a consequential fire.

- Before charging Lithium battery packs, inspect closely for any damage, such as punctures in

the sleeving or swelling (expanding) of the battery. Do not charge if any damage has been

detected, even if the battery otherwise appears to be new and unused.

- Before starting the charging process, double-check the settings on the charger to ensure that

the correct parameters have been entered for the specific battery pack that is to be charged.

Using the wrong settings is likely to result in damage to the battery pack being charged and

could result in the battery catching fire.

47 48

it is the user’s responsibility to their waste equipment by handing it over to

a designated collection point for the recycling of waste electrical and

electronic equipment. The separate collection and recycling of

your waste equipment at the time of disposal will help to conserve natural resources and

ensure that it is recycled in a manner that protects human health and the environment. For more

information about where you can drop off your waste equipment for recycling, please contact your

local city office, your household waste disposal service or where you purchased the produce

Loading...

Loading...